Rethinking training

COMINGSOON Contactustodayformoreinformation.

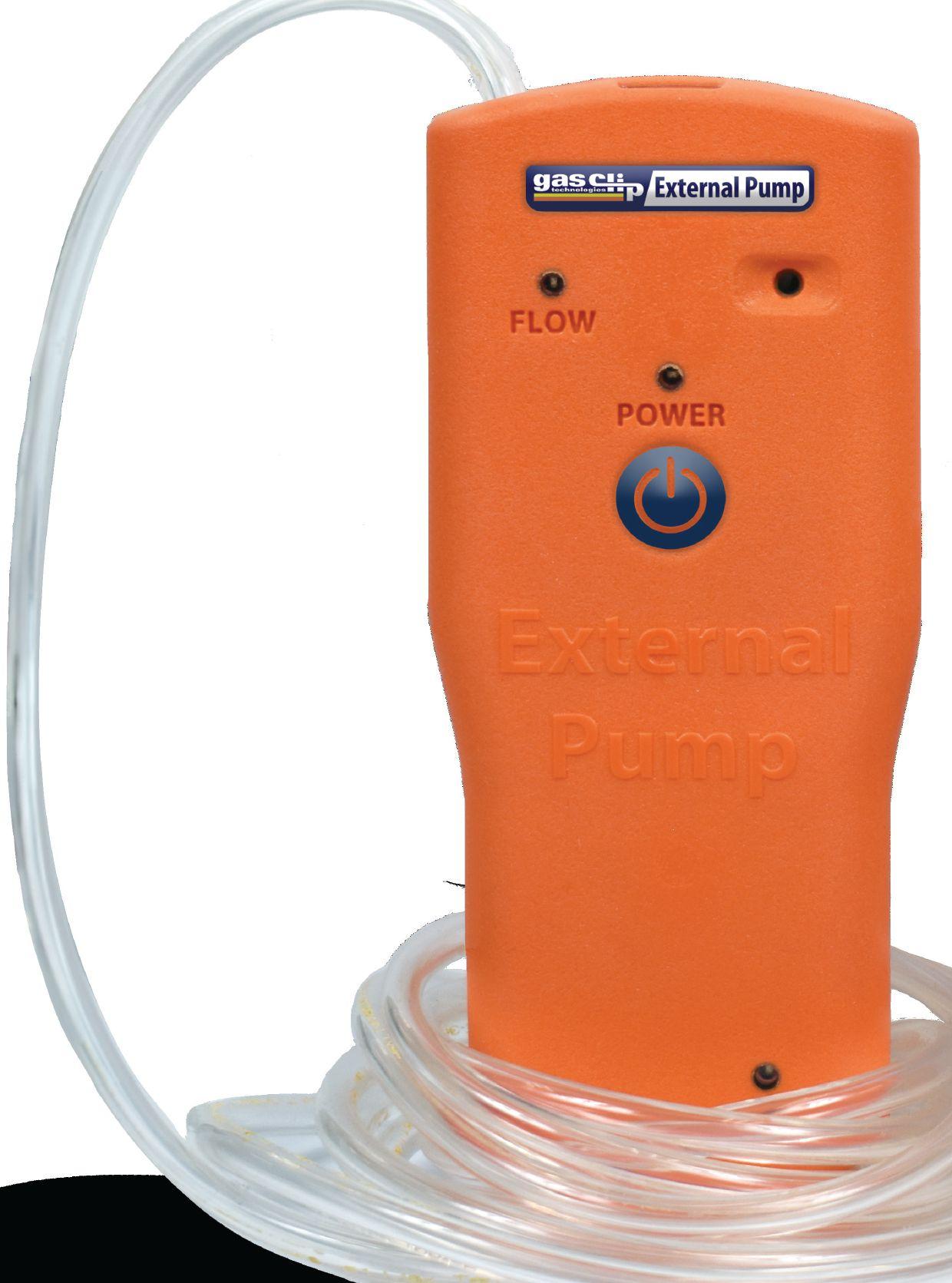

The External Pump

Give any Gas Clip diffusion detector the ability to take remote samples from up to 75 feet away.

DEPARTMENTS

04 | From the Editor

Honouring our safety heroes

05 | In the News

24 | Safety Gear

Strapping in for fall protection

26 | CCOHS Corner

A collective approach to COVID-19 prevention

29 | Hot Items

30 | Time Out

COLUMNS

10 | Safety Culture

COVID-19 or not, these are your safety tenets

12 | Person of Interest

Sandro Perruzza discusses HVAC’s increased importance through the pandemic

14 | Neurosafety

Understanding the training dilemma

Rethinking training

COVID-19’s effects mean employers are facing unique challenges ahead of summer hiring

BY MEAGAN GILLMORE

Farm safety protocols beginning to mature

Updating

BY JACK BURTON

By Marcel Vander Wier

Honouring our safety heroes

National Safety Council president and CEO Lorraine Martin said it best.

In the opening keynote of the Global NSC Safety Congress and Expo, she proclaimed 2021 as the “Year of the safety hero.”

As the world continues to operate in the twilight zone of the COVID-19 pandemic, “safety pros are the nation’s secret weapon in the fight to save lives,” said Martin.

Health and safety professionals have been the “unsung heroes” of the now-year-long pandemic, she said.

“They’re shouldering great responsibility as the entire world focuses on human safety, particularly at work.”

It is in this spirit that OHS Canada unveils an expanded awards program, highlighting excellence in the Canadian occupational health and safety profession.

Alongside our Top 10 Under 40 competition, our media brand has launched OHS Canada Honours for 2021 — where we aim to recognize the achievements of Canadian

EDITORIAL ADVISORY BOARD

OH&S professionals with three individual awards.

“ There is no doubt that the past 12 months have been difficult for all Canadians, due to the COVID-19 pandemic,” said OHS Canada group publisher Paul Grossinger.

The importance of OH&S professionals has been on full display through the COVID-19 pandemic, and the team at OHS Canada want to acknowledge the best and brightest in the field.

March/April 2021 Vol. 37, No. 2 ohscanada.com

READER SERVICE

Print and digital subscription inquires or changes, please contact Jay Doshi, Audience Development Manager Tel: (416) 510-5124

Fax: (416) 510-6875

Email: jdoshi@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Marcel Vander Wier 416-510-5115 mvanderwier@ohscanada.com

MEDIA DESIGNER

Lisa Zambri

OHS Canada has launched an expanded awards program, honouring excellence in the profession.

“ But when I think of what occupational health and safety professionals in Canada have had to endure, it makes me believe anything is really possible.”

Recognizing excellence in the OH&S profession is something OHS Canada is proud to do on an ongoing basis, he said.

“Our annual Top 10 Under 40 and OHS Canada Honours recognition programs really put a deserving spotlight on people who have made a difference at their workplace and in their communities — in the face of newfound realities, uncertainties, responsibilities and, sometimes, fears.”

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Cindy Moser: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

OHS Canada Honours recognizes the achievements of Canadian OH&S workers in three categories:

• OH&S Professional of the Year

• Lifetime Achievement Award

• Community Leader Award

Anyone in an occupational health and safety position with a Canadian company who fits the criteria for the individual awards can be nominated.

And back for another year, OHS Canada’s Top 10 Under 40 recognizes the achievements of the newest generation of Canadian OH&S workers.

Anyone in an OH&S position with a Canadian company who is under the age of 40 as of Dec. 31, 2021 is eligible for this award.

To nominate your health and safety hero, visit our website. Nominations will be accepted until May 28

ACCOUNT CO-ORDINATOR Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

NATIONAL SALES MANAGER Ross Anderson 289-925-7565 randerson@annexbusinessmedia.com

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital) PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec Canada $100/yr plus tax USA $130/yr (100 USD) Foreign $214/yr ($164.50 USD)

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

Nova Scotia work fatalities increased in 2020

Acute workplace fatalities in Nova Scotia hit a tragic high in 2020, according to information released in March by WCB Nova Scotia and the province’s Department of Labour and Advanced Education.

Eighteen Nova Scotians died from acute traumatic injuries on the job — the highest the province has seen since 2008.

“This is an important time for us to come together and renew our commitment to improving workplace health and safety across our province.”

There were also 14 fatalities classified as chronic — seven related to occupational dis -

eases and seven caused by health-related issues, such as heart attacks.

“My heart goes out to all of the families who have lost someone on the job. One workplace fatality is too many,” said Labour and Advanced Education Minister Lena Metlege Diab.

“We do not take this increase lightly,” she said.

“This is an important time for us to come together and renew our commitment to improving workplace health and safety across our province.”

The year ended in tragedy at sea with the sinking of the Chief William Saulis, and the loss of its six-member crew.

“Over the last five years, the fishing industry has worked vigorously to improve condi tions for the men and women who earn their living at sea,” said WCB Nova Scotia CEO Stuart MacLean.

“This is a profound reminder that fishing remains a danger ous and demanding job.”

In the News

Regina steelmaker fined $935K for breaking safety rules

(CP) A Regina steelmaker has been fined $935,000 for two serious workplace injuries that resulted from the company breaking Saskatchewan health and safety rules.

Evraz Inc. pleaded guilty on Feb. 9 in Regina provincial court.

The Ministry of Labour Relations and Workplace Safety says in one case, a worker was pinned between a steel pipe and a steel plate on Jan. 24, 2019. The worker was rolling a pipe and slipped on ice and snow, before becoming pinned.

In the second case, a little more than a week later, a worker was hurt when a machine moved during a grease fire. The worker was attempting to extinguish the blaze.

The initial fine was for $360,000, while the secondary penalty cost Evraz an additional $575,000.

The ministry would not disclose the medical condition of the injured employees or whether they have returned to work, though both injuries were described as serious.

Both incidents took place at the Evraz plant in Regina. Evraz Regina says it is the largest steel company in Western Canada and makes steel plate, coil, pipe, and oil- and gas-well tubing for the energy sector.

Stay-at-home order ends in Toronto

The Ontario government lifted its stay-at-home order in Toronto, Peel Region and North Bay-Parry Sound on March 8.

The three regions were the last ones still under the order.

Ontario hires more inspectors to assist in COVID-19 blitz

Ontario has hired more than 100 new occupational health and safety inspectors to support business inspection campaigns.

The new inspectors have begun a condensed training program, and will begin making field visits with a mentor within five weeks of their start date, according to a news release. They are scheduled to be fully trained and deployed by July 1.

WEB POLL: What OH&S issue is top of mind for you in 2021?

responses 174

“As the province continues to reopen, we need businesses of all sizes to do better as there are no shortcuts to safety,” said Monte McNaughton, Minister of Labour, Training and Skills Development.

“With a new total of more than 500 inspectors, our government is building the largest team of inspectors in Ontario’s history to educate business owners, enforce public health measures and keep workplaces safe now, and for many years to come.”

As of March 4, Ontario’s provincial offences officers had conducted

more than 13,374 COVID-related workplace inspections and investigations across the province since the beginning of 2021, issuing 9,480 orders and 373 tickets, and stopping unsafe work 15 times. These inspections have demonstrated that the majority of businesses are learning how to operate safely during COVID-19 and appreciate the support and guidance from the province, according to the government.

“As the province continues to reopen, we need businesses of all sizes to do better, as there are no shortcuts to safety.”

Workplace inspections continue to focus on educating small businesses across the province to help them reopen from lockdowns safely.

PHOTO:

Death of supervisor results in $200K fine for Hamilton construction firm

A construction company in Hamilton, Ont., was fined $200,000 on Feb. 11 following a 2018 mini-excavator incident that resulted in the death of a crew supervisor.

The penalty against McNally Construction also warranted a standard 25-per-cent victim fine surcharge under the Provincial Offences Act.

The incident occurred in June 2018, when a miniexcavator being operated in an underground pipe tipped over.

According to a court bulletin, the incident occurred on June 21, 2018, when a mini-excavator being operated in an underground pipe tipped over. The machine did not have the required cab or screen, which may have protected the worker.

The diameter of the pipe measured 1.8 meters at that location.

The tip-over protection system (TOPS) of the mini-excavator had been removed prior to it being lowered down and into the pipe. It is not known when the TOPS was removed or by whom.

A TOPS protects a miniexcavator from tipping over and can protect an operator of a miniexcavator from overhead hazards.

The supervisor decided to operate the mini-excavator.

While operating it, the supervisor was fatally injured when the front tracks of the machine lifted, causing the worker to be pinned between the top of the inside of the pipe and parts of the mini-excavator.

Section 99 of the Construction Projects Regulation (Ontario Regulation 213/91) requires that a cab or screen be

provided to protect a worker who is exposed to an overhead hazard while operating a vehicle.

The company was previously convicted in 2013 following the death of a young worker.

P.E.I. chief health officer hopes Atlantic bubble reopens by April 1

(CP) The chief medical health officer in Prince Edward Island says she hopes the Atlantic travel bubble could reopen as early as April 1.

A final decision, however, rests with the region’s premiers, Dr. Heather Morrison said in February, adding that a jump in COVID-19 cases could halt plans to reopen provincial boundaries.

“It is hoped that could take place by the first of April, knowing that things within a day could change, or a phone call could change that,” Morrison told reporters in Charlottetown.

Low case numbers last summer led to the travel bubble, permitting Atlantic residents to travel within the region’s four provinces without having to isolate for two weeks.

“That will be a decision with the premiers, based on our epidemiology in Atlantic Canada,” Morrison said.

Two men dead, one rescued after B.C. tugboat incident

(CP) Two men are dead and one man has been rescued after a tugboat incident on British Columbia’s north coast.

The RCMP say at 12:40 a.m. Feb. 11, the Joint Rescue Co-ordination Centre received an emergency beacon from a tugboat in the Gardner Canal near Kemano, about 75 kilometres southeast of Kitimat.

An RCMP West Coast Marine vessel and the Canadian Coast Guard responded.

B.C. Emergency Health Services took one patient to hospital in serious but stable condition.

Police say the tugboat involved was towing a barge that was en route from Kitimat to Kemano.

Ontario warns health-care providers of counterfeit N95 masks sent from stockpile

(CP) — Ontario unknowingly obtained and distributed counterfeit N95 masks to health-care providers, the government said Feb. 26, before urging them to check their supply for the fake personal protective equipment.

Seventy-six per cent of people who responded to an online poll conducted by Angus Reid in February said the COVID-19 pandemic had caused stress, anxiety or depression. More than 1,500 people responded.

The province could not immediately say how many of the counterfeit 3M masks it had acquired for its stockpile, or how many were given to health-care workers.

The Ministry of Health sent a memo to health-care providers notifying them of the problem and asked them to seek out and “isolate” the faulty gear by product number.

“We have launched a thorough investigation as we work with our health system partners to ensure that these masks are no longer used by anyone and are removed from the system,” the ministry said in a statement.

The government said it is reviewing its entire stockpile to check for the counterfeit product and has also alerted Health Canada of the situation. The province also said it has put safeguards in place to ensure it buys quality PPE.

The ministry said it has mandated that all of its 3M N95 masks undergo inspection from an independent third party.

“Wherever possible, PPE is procured from known, reliable vendors that the ministry has relationships with,” the statement said.

The president of 3M Canada said the company has been receiving increasing reports from across the country of fraud related to its product.

Penny Wise said the company recently helped Ontario and other provincial authorities confirm that N95 masks purchased from a distributor with no relation to the company are fake.

“Counterfeit products may not meet the rigorous quality standards that our authentic 3M respirators are subject to, and put the lives of those battling this pandemic at risk,” she said in a statement.

Wise said the company distributes its products through a network of authorized vendors, and recommends that customers make their purchases from that verified database.

‘It wasn’t called COVID at the time’: One year since Canada’s first case of novel coronavirus

(CP) — The patient, when he came into the hospital ER with what seemed to be mild pneumonia, wasn’t that sick and might otherwise have been sent home.

Except the man had just returned from China, where a new viral disease was spreading like a brush fire. His chest X-rays were also unusual.

“We’d never seen a case like this before,” says Dr. Jerome Leis. “I’d never seen an X-ray quite like that one.”

It was the evening of Jan. 23, 2020, when the team at Toronto’s Sunnybrook Health Sciences Centre decided to admit the 56-year-old patient. That same day, Canada’s chief public health officer, Dr. Theresa Tam, told the country: “The risk of an outbreak in Canada remains low.”

It was a refrain she and other officials would repeat for weeks.

Less than two days after admission to Sunnybrook, the man would become “Patient Zero” — the first COVID-19 case in Canada.

For several weeks, Leis, the hospital’s medical director of infection prevention and control, had been anticipating just such a moment.

He had known since the end of December about the outbreak in Wuhan, China, and he’d been following Chinese authorities as they published information about the new pathogen and its effects.

Drawing on lessons learned from the SARS epidemic years earlier, Sunnybrook’s screening staff were already asking new specific questions of incoming patients. Protocols were sharpened.

“We were extremely suspicious that this was the novel coronavirus that had been described,” Leis said recently.

“It does feel like a lifetime ago and yet it does just seem like yesterday.”

800,000

Canada crossed a disheartening threshold in the COVID-19 pandemic on Feb. 6. Federal government data showed Canada had logged 801,057 total infections and 20,702 deaths over the course of the pandemic.

PM suspends flights to sunny destinations until April 30

(CP) Canada’s main airlines are suspending service to popular sun destinations while travellers returning from abroad will quarantine in a designated hotel as they await results of a COVID-19 test administered at the airport, Prime Minister Justin Trudeau announced Jan. 29.

As part of the new restrictions aimed at discouraging travel and reducing the spread of more infectious variants, Trudeau said all returning Canadians will quarantine in an approved hotel for three days at their own expense while they await results of a COVID-19 test taken at the airport.

Trudeau says that requirement could cost each traveller more than $2,000.

Those with negative test results will be able to quarantine for the rest of the mandatory two weeks at home, while those with positive tests will isolate in designated government facilities.

Brakes compromised by ice in runaway train that killed worker

(CP) A report into the 2018 death of a New Brunswick CN worker says the brakes of two runaway railcars were compromised by ice before the cars collided.

The Transportation Safety Board of Canada says two cargo cars running uncontrolled in opposite directions along tracks at a CN yard in Edmundston, N.B., collided on the morning of Dec. 4.

The crash killed a conductor trainee who was trapped on the footboard of the locomotive.

Investigators concluded in the report released Jan. 27 that the two cargo cars, which rolled down a slight grade, had been temporarily left with only their emergency brakes engaged.

Safety Culture

By Christopher Hurley

COVID or not, these are your safety tenets

To say COVID-19 has been overwhelming may be the understatement of the year.

The world has changed so much since March 2020.

Back then, no one was assigned to check temperatures; pre-screening forms didn’t have a slot in the filing cabinet; and anyone wearing a mask would have looked like a germophobe. Oh, how things have changed.

One thing hasn’t changed, though — health and safety professionals need to ensure all hazards are being managed as aggressively and effectively as COVID-19 in your workplace.

Many safety pros have heard concerns regarding workforces losing sight of other hazards amongst the COVID storm. This cannot be allowed to happen.

Manage your hazards from top to bottom — much like you have the novel coronavirus.

Is your program current?

Although many think that program documentation is simply a home for the dust collection in the office, it serves a much higher purpose!

Programs become your operational safety playbook and allow you to set standards for the different layers of your organizations, as well as clarifying roles and responsibilities.

If we don’t know what to do or who is supposed to be doing it, how can we accomplish anything or measure our success?

Further, if there isn’t a written plan to refer back to from time to time during audits, reassessments and changes to the environment, over time the potential for confusion and eventual deviation from the required process will occur.

On the flip side, a good quality program will become second nature to the operation. Expectations that are worked into orientation, training, performance

management, day-to-day floor activities, the management of corrective actions and each level of the organization, will result in a clear understanding as to what responsibilities individuals have and where they land in the process.

A functional program is the backbone of everything you do from a safety perspective.

Are your communications documented?

“If it’s not written down, it doesn’t exist!” It’s the rally cry of safety pros everywhere and it rings true in every case.

A visit from your local regulator, regardless of the topic, will almost always result in a check-in on your documentation.

Training records, program documentation, standard operating procedures, email communication, toolbox talks, field-level hazard assessments, JHSC minutes — the list goes on and on.

If your due diligence folder is empty and you plan on defending yourself under criticisms with “I told them the right way to do it,” consider yourself a target for further evaluation.

Compile and audit your documentation on a regular basis to spot gaps. Escalate concerns to your team to ensure issues are addressed in a timely manner.

Do you remain nimble?

Few of our operations are stagnant or repetitive in nature.

Employee turnover, new chemicals, modern equipment, or even something as simple as a recommendation from a JHSC, may result in changes to your operation.

In my experience, the vast majority of incidents have a “new” component to them.

Be it people, place or thing, a change should always be a pause for the cause to ensure safety-related concerns have been considered.

Christopher Hurley, CRSP, is the founder of Safety Services Canada in Caledonia, Ont.

• Is the recent hire adequately trained for the task they’ve been assigned?

• Have staff been made aware of changes to a procedure?

• Has a specific procedure been changed to address an identified concern?

All of these situations should be red flags to operation managers, supervisors

and safety people alike. Be ready to address issues on the fly and be certain to take the time and do it right.

Even minor changes to the work environment can significantly throw off the routine within your workforce.

Are you relentless?

At the end of the day, be relentless with your safety program and encourage others

to do the same at every turn.

If you are in a position where your hazards aren’t being managed at a level considered “reasonable,” start somewhere, and start today.

If you’re a senior manager, get engaged with incident summaries, trends and incoming changes. Check and double check to ensure steps are being taken to manage your hazards.

A supervisor? Widen the scope of your staff meetings to refresh people’s memory on non-COVID-related hazards.

Safety pro? Set up a meeting to discuss that big hazard that needs attention, but no one wants to deal with.

COVID came as an unexpected pile of extra work for many — it’s been time consuming, difficult and hard to predict.

Don’t make the mistake of allowing COVID-19 to let you lose sight of all of the other health and safety-related “to-dos” on your list.

Person of Interest

featuring Sandro Perruzza

COVID-19 has increased HVAC’s importance in workplace safety

As the COVID-19 pandemic continues, more focus is being put on heating, ventilation and air conditioning (HVAC) systems. Through the winter months, many HVAC systems in public and commercial spaces re-circulate air instead of funnelling fresh air in, according to the Ontario Society of Professional Engineers (OSPE) in Toronto.

As a result, HVAC systems recycle the same air, potentially infected with COVID-19.

Sandro Perruzza, CEO of the OSPE, recently joined OHS Canada editor Marcel Vander Wier on the Safe Zone podcast to discuss best practice in air ventilation systems amid the pandemic. Responses have been edited for length and clarity.

OHS Canada: Why are HVAC systems so important right now when it comes to keeping workers safe?

Sandro Perruzza: When we first learned about COVID-19 early in 2020, we really didn’t know that much about the virus. At first, when it was communicated by public health that it was being spread predominantly through surface contact, the focus back then was around cleaning high-contact surfaces like doors, handles, table tops, hand railings, etcetera. Masks were not even mandatory or strongly recommended.

When they were first being introduced, it was to act as a barrier to prevent your hand from coming into contact with your nose or your mouth. It wasn’t until many months later, (when) the pandemic had grabbed hold worldwide, that the medical community and public health started suspecting that airborne transmission is viable.

On April 7, the prime minister used that now-famous term of trying to tell people to avoid “speaking moistly.” Canada’s first reported case was on Jan. 25 — so three and a half months later.

There was more and more mounting evidence that the transmission was actually happening airborne as well.

And there’s been a tremendous amount of work worldwide but also here in Canada by University of Alberta engineering professor Dr. Brian Fleck. He’s been working to show just how poor ventilation systems impact the transmission of COVID.

His comment is that the quality of ventilation systems in buildings affects not only COVID, but how many sick days we take off, how happy we are, and how long we live. The impact of the focus on ventilation is going to have benefits beyond the COVID days.

Also, let me emphasize that improved ventilation is not a replacement for masks. Masks are still the most effective measure to protect ourselves. And a mask is a control at the source of risk, which as safety professionals, we always want to focus on.

Every workplace now has a strict masking policy and workers need to keep the masks on at all times to limit exposure. But if you’re in a lunchroom or a washroom and the worker takes off their mask to eat or wash their face, and they’re breathing heavily or coughing or sneezing, they’ve released that aerosol into the workplace.

The ventilation system passes that aerosol and that COVID-19 particle through the building. There’s mounting evidence that even though the risk is low, it is happening.

OHS: As governments prepare for re-opening economies and schools, do you believe there has been enough focus on ventilation and air flow in indoor work environments?

SP: There’s certainly been a lot discussed about it, but whether there’s been enough done on it? I don’t think enough has.

You have 5,000 schools in Ontario. Of those 5,000, the average age of a school is about 39.5 years old. Those ventilation systems usually aren’t upgraded, so your ventilation systems are over 30 years old. They’re not maintained well and aren’t looked at. And it’s not just in schools — it’s in long-term care homes and processing plants.

Businesses need to look at ventilation systems as a way to control that spread. It’s great to reopen, but then if transmission goes up again because people are indoors and we have to close again, it doesn’t help anybody.

I really want to focus on ventilation systems as an additional control, as opposed to a replacement of the existing controls that we have there.

OHS: Is there a gold standard when it comes to various equipment choices in this area?

SP: Not when it comes to equipment, and I’ll tell you why.

There’s certainly a number of different products out there, and more are coming onto the market every day it seems. Some are very complicated, very intricate, and very expensive. But more costly isn’t necessarily better.

CBC Marketplace recently ran a story looking at your household indoor air quality systems. It was done by U of T engineering researchers. What they found is that mid-price units actually significantly outperformed the more costly units. When you look at equipment, you need to do your research.

HVAC system. How well maintained is it? When’s the last time it had an inspection? When’s the last time it was checked to make sure it was working properly? When’s the last time the filters were changed?

Let me emphasize that improved ventilation is not a replacement for masks. Masks are still the most effective measure to protect ourselves.

HVAC systems are often neglected. The units are usually on a roof. Because they’re up there, no one goes and looks at them until something goes wrong. You may not even know your HVAC system isn’t working properly until you actually inspect it.

Then the ASHRAE standards actually give you five different recommendations:

• Verify that your HVAC systems are functioning as designed.

their people are safe and the air that they’re breathing is clean.

OHS: What does the future hold in this area of air quality and workplace safety?

SP: That’s a really good question. I think air quality’s going to be a bigger and bigger issue in the next decade or more.

COVID has really shone a light on the importance of indoor air quality. But just looking at the environmental movement right now — green buildings, net-zero buildings — these are all closed systems now. So people are going to be re-breathing and re-circulating the air.

The more clean air, or recycled air, you have, the less

you have to condition it, and it’s more cost effective to do so. But as a byproduct to that, you also have to make sure that air is clean, not just for chemical contaminants, but for biological contaminants.

I think a lot of technology is going to be developed to make sure that we’re constantly cleaning that air — especially recycled air. Looking at longterm care homes, I’m willing to wager that the majority of cases they’re having is not patient-to-patient exposure, it’s through the ventilation systems. So, moving forward, as the building codes get reviewed, ventilation systems and upgrading them will be part of those new building codes.

21_0522_CN_OHnS_MAR_APR_CN Mod: February 17, 2021 10:19 AM Print: 03/11/21 2:28:26 PM page 1 v7

But there is a gold standard for ventilation systems as they relate to infectious aerosols... As a health and safety professional, your first step is to go to the American Society of Heating, Refrigerating and Air-Conditioning Engineers website (ashrae.org). They actually have a COVID subsite that (has some key) documents listed on it.

OHS: What tips would you give health and safety professionals for investigating equipment in their own buildings?

SP: The first thing I would do is actually go and look at your air conditioning unit or your

• What are the public health guidelines?

• Look at ventilation, filtration and sanitation or air cleaning.

• Look at air distribution, such as directional air flow. You don’t want air flowing from a high concentration of people to a low concentration.

• And then this is where the technical stuff comes in around HVAC system operations. This is where you may need to bring in an HVAC specialist.

These are, at a very high level, some of the things your health and safety professional needs to be doing to ensure that

Neurosafety

By Theo Heineman

Understanding the training dilemma

As a safety professional, have you ever faced resistance from management when you’ve proposed employee safety training initiatives?

Chances are you’ve heard responses like: “We don’t have the time;” “We don’t have the budget;” or “I need you to condense that eight-hour training class into three hours.”

The fact is training is costly. Let’s take for example a business paying their employees $35 in wage and benefit costs, and billing out $100 per hour for the services provided by those employees.

For a business that has 50 employees to train — factoring only the cost of wages and the opportunity cost of not being able to bill out for services rendered — the cost to the employer is $54,000 per day of training. Five days of training per year and that’s $270,000.

Consider the ‘forgetting curve’

On top of the cost objection, according to research, up to 90 per cent of training is forgotten within seven days.

The “forgetting curve” was hypothesized and tested by German psychologist Hermann Ebbinghaus. His research showed that when people first learn something, it disappears at an exponential rate.

In fact, most learning is lost in the first couple of days.

However, if we understand how learning occurs, then we can do something about the forgetting curve and demon -

strate to management with confidence how they can deliver safety training that produces a return on investment.

A key reason for the forgetting curve is that three parts of the brain are involved in learning retention and competency, and most training only engages one part of the brain — and at best two.

Knowledge, application and competency reside in different parts of the brain.

Knowledge: Lets take forklift training, for example. When workers sit through the lecture, watch the videos, or read the safe work procedure on how to operate a forklift, neurons fire in the neocortex of the brain to log the new information by making new synaptic connections.

The neocortex is the seat of our conscious awareness and

where we store information.

In 2000, Nobel Prize winner Eric Kandel found that if information is not reviewed or applied, the new circuits formed in the neocortex prune apart within hours or days. As the saying goes: “If you don’t use it, you lose it!”

Application: As they review their workbooks and watch the videos about how to operate the forklift, workers might be thinking “Hey, I’ve got this… This looks easy!”

However, out in the parking lot when its time to apply what they have just intellectually learned, they find out that it’s actually not that easy. The forklift jerks forward, hydraulics go up when they were meant to go down, and the pallet gets dropped.

The reason for difficulty is because “doing” or application

resides in a different part of the brain — the limbic brain. The application of the new knowledge (or experience) causes jungles of neurons to organize into networks and the brain makes a chemical that activates the limbic brain to releases neuropeptides.

Now the workers are beginning to chemically instruct and emotionally teach their body what the mind has intellectually understood. So, knowledge is for the mind (neocortex), but application or experience is for the body (limbic brain).

Competency: After a few weeks or months, the workers are so skilled at operating the forklift that they don’t have to consciously think about what they are doing.

They can even be talking to another worker in the area all

Theo Heineman, CRSP, CHSC, is a certified NeuroChangeSolutions consultant

while scooping and setting a pallet perfectly. They have applied the knowledge enough times, so that now they no longer have to consciously think about it.

When workers have repeated something over and over, it causes neural networks in the cerebellum, the storehouse of implicit (non-declarative) memory, to become highly enriched. Now, their body as the unconscious mind is operating the forklift, and neurochemically, mind and body have become as one.

So, if learning is making new synaptic connections in the brain, then remembering is maintaining and sustaining those connections.

Competency, then, is neuroconnections fired and wired through repeated application so that the worker can perform the task skillfully with their body as the unconscious mind — just like tying our shoelace.

When we understand how the brain and body learn, we have a better understanding why the learning pyramid estimates retention at five to 10 per cent with lecture or reading alone.

Tips for better training outcomes

1. Make it meaningful: People are more likely to pay attention and retain information when they are interested in the content, and they understand how it practically applies to them.

2. Make it interactive: The more participants interact with the content, the more the brain has to fire and wire, and the better the learning and retention. For example, if people can turn to the person next to them end explain what they just learned, they are building a model of understanding.

3. Promote critical thinking: Build case studies and scenarios into your training program. As people apply what they have just learned immediately, the brain starts firing in new patterns, sequences, and combinations and the new neurosynaptic connections being formed are more likely to stick. Moreover, questions hook the brain, making people think. This then causes more neurons to fire and wire to promote learning and retention.

4. Deliver content in micro-courses: Instead of a full-day training program, consider breaking it down into three sessions of two hours each. Learning drops off significantly and even stops when people feel overloaded or overwhelmed.

5. Include application right away: Make sure people apply what they are learning. Remember that “experience” resides in a completely different part of the brain. For example, have students create the WHMIS workplace label, physically set up the ladder, practise running to get the AED and calling for help.

6. Test for understanding: Whether it’s a written test or a competency checklist — or both — it’s another way for the knowledge to be applied. It also measures the level of learning and provides a record for your company’s due diligence.

7. Revisit the material often: Send an email, hold a safety talk, and host short refresher courses often, so that the brain fires and wires into a long-lasting connection.

In summary, every year, organizations invest billions in performance-based training that fails to produce the desired results.

Why? A primary reason is the inability to produce the sustained change required to have a lasting impact on human behaviour.

True and lasting change requires becoming aware of how the brain works and creating deep-seeded habits and beliefs that rest mostly in the unconscious mind.

Next time management pushes back on allocating safety training time or dollars, share your understanding of how learning occurs to help assure them why and how they’re going to get a return on their investment.

And when you’re asked to cram eight hours of training into three, explain to management why it’s time and money down the drain.

Simply put, workers are not even going to have a chance to learn.

Canadian Registered Safety Technician (CRST)

A CRST supports a safe working environment by maintaining OHS administrative processes, conducting training, and applying a range of state-of-the-art tools, processes and common practice solutions to mitigate risk. They oversee and drive monitoring and compliance in relation to technical and behavioural risk controls.

Canadian Registered Safety Professional (CRSP)®

A CRSP® applies broad based safety knowledge to analyze and develop systems that will achieve optimum control over hazards and exposures detrimental to people, equipment, material and the environment. A CRSP® is dedicated to the principles of loss control, incident prevention and environmental protection as demonstrated by their daily activities.

Leadership critical to young workers’ success

By Meagan Gillmore

While the COVID-19 pandemic presents specific workplace safety challenges for young workers, consistent and clear leadership and training from supervisors remains key for them to stay safe and successful at work.

Young workers are often classified as those between the ages of 15 and 24, which means many of them are students.

The 2020-2021 school year, like the one before it, was significantly altered because of pandemic restrictions. It’s important to realize that students may not have had the opportunity for hands-on learning like they had in previous years, said Jan Chappel, a senior technical specialist at the Canadian Centre for Occupational Health and Safety in Hamilton, Ont.

“For employers who are used to hiring out of a particular program, they should probably confirm and be aware that students may have not had the same hands-on training,”

she said. “They may not have been able to receive it in the past little while.”

The pandemic has impacted specific fields of study differently, but it’s important for employers to realize that education has changed.

Depending on the length of a program and a student’s particular year of study, the educational disruptions may just be a temporary “blip,” said Brad Seward, an assistant professor at the Centre for Industrial Relations and Human Resources at the University of Toronto.

“We’re training a whole host of students through pretty uncharted territory,” he explained.

“Distance education has been around for a while, but this mass adoption where every curriculum has had to bolt on this new form of delivery means that there will be some areas that might be a little more unpolished than a traditional trajectory.”

Proper training processes

Employers need to look out for potential gaps in knowledge and ensure each worker is properly trained before starting a new task, said Chappel.

While studies suggest that the rate of injury is higher during the first months on a job, Chappel notes that injuries are often more closely related to a worker’s inexperience, rather than their age.

“(Employers) need to verify that they’re able to do the job training.

Whether that’s formally going through all the training steps or taking a refresher course, that’s up to the employer to decide,” she said, noting that physical distancing and other safety protocols can still be followed during on-the-job training.

Standard aspects of workplace orientation and training, like information about hazardous materials and spills, procedures for operating equipment, or protocols for reporting harassment, should not be

Overcoming inexperience

Injuries are often more closely related to a workers inexperience, rather than their age.

neglected just because COVID-19 protocols need to be explained, said Chris Serratone, prevention services director at Workplace Safety North in North Bay, Ont.

“There’s a certain element of COVID fatigue, where that’s all the focus seems to be on right now, no matter what you do, where you turn,” he said. “It’s the same in the workplace and it just creates other distractions…so they’re not as focused on the job-task hazards as they might normally be.”

Equipping managers and supervisors with the right tools to address the mental health needs of young workers is also important, he said, noting that it can be a big concern for some.

Listening to young workers is crucial

Regardless of the challenges of the pandemic, young workers are often more at-risk for experiencing a workplace injury because, in general, they can struggle to voice their

concerns about potential workplace hazards.

“It’s important that people feel psychologically safe to speak up,” said Nick Turner, a professor at the Haskayne School of Business at the University of Calgary.

Employers need to show their young employees that they are a valuable part of the organization.

“Many young workers aren’t considered ‘real’ or ‘full’ employees

by their organizations or employers,” he explained.

Often, this can result in these workers being asked to do jobs that are of a lesser quality than those that are assigned to more experienced workers, said Turner.

For example, younger workers may be assigned tasks that have less personal autonomy or include a greater amount of physical risk.

The economic challenges of the pandemic have heightened the chances that young workers have of working in more physically dangerous situations.

The economic challenges of the pandemic have heightened the chances that young workers have of working in more physically dangerous situations, he said.

“COVID restricted the work opportunities,” Turner observed. “Young workers may be more willing to go after riskier work.”

These heightened risk factors increase the need for employers and frontline supervisors to be good leaders.

“Young workers may be more susceptible to the peer pressure which may lead to unnecessary risks,” explained Andrew Widdop, an account manager in Kingston, Ont., with Workplace Safety and Prevention Services (WSPS).

That’s why workplace leaders need to take training seriously and model good behaviour.

“As a new worker, just knowing that you’re going to have someone there asking you questions and guiding you as a mentor” makes a big difference.

“Young workers model their behaviour on those that are in their sphere of influence.”

If workers see their employers not following the proper procedures, it will make it easier for them to do the same, he explained.

Great supervisors “take away a lot of your worry,” said Widdop, reflecting on the jobs he worked at while attending university.

“As a new worker, just knowing that you’re going to have someone there just asking you questions and guiding you as a mentor” makes a big difference, he said.

“Providing positive feedback is good,” according to Widdop.

“It shows that workers are valued.”

Engagement brings benefits

Due to the pandemic, a lot of training material for young workers and those who work with them are being offered online. This may be particularly helpful when training a generation of workers that was raised in the technological era. Training needs to be delivered in a way that encourages younger workers to participate.

“It really helps if it’s conversational so that the new workers have an opportunity to ask questions. They’re empowered with the ability to ask questions,” said Serratone.

As much as possible, workplace trainers should avoid an “oldschool” mentality where the instructor lectures and the workers

Don’t generalize Older workers need to avoid making untrue statements about their younger colleagues.

listen. That can seem adversarial, he said.

“You’re trying to level that playing field so people do feel comfortable to ask the question. It’s a position of vulnerability when you say, ‘I really don’t know how to do that yet.’”

Part of Serratone’s job is to make sure supervisors and managers who lead training sessions are equipped to do their jobs well. Many of them may be young workers themselves.

“It’s not easy” to create an environment where conversations can occur naturally, he said.

“That’s why young worker education can’t solely be focused on the workers themselves. It also has to be focused on the supervisors and managers that are at that worksite.”

Older workers need to avoid making untrue generalizations about their younger colleagues, added Turner.

“They’re not necessarily more reckless,” he said. “They’re eager to be able to work and will benefit from the work design from leadership and supervision that any of us would benefit from.”

While Serratone acknowledged that supervisors may have to interact with parents who take too active a role in their child’s employment, he said younger workers bring many advantages to an organization.

“They haven’t yet been jaded by all of the other experiences. They’re coming into it fresh,” he said. “A lot of innovation comes from going into things with an unbiased perception so that you don’t have these pre-conceived notions that this is the only way to do it.”

“Younger workers are a really strong asset to your organization so you should be doing everything in your power to make that initial experience for them a good one.”

Meagan Gillmore is a freelance writer in Toronto.

Farm safety protocols beginning to mature

Pandemic a catalyst for improvements in agricultural sector

By Jack Burton

In occupational safety, the agricultural sector stands as one of the more complex industries due to its position at the intersection of a number of intricate safety factors including livestock, labour, mechanical operation and mental health.

While the emphasis brought by the pandemic onto the whole of workplace safety has done little to curb this complexity, it has provided a necessary catalyst in growing and maturing the attitudes and protocols around safety on the farm.

It is this array of safety factors that make up the focus of this year’s Canadian Agricultural Safety Week, March 14 to 20, which sees safety organizations across the sector educating the wider industry

The unique relationship that farmers have to their work “can make it difficult to identify and manage stress and accommodate the necessary self-care.”

about the various safety issues across agriculture.

This year, the Canadian Agricultural Safety Association (CASA) in Winnipeg has chosen to focus on resilience and wellness as it relates to worker safety.

Communications co-ordinator Robin Anderson believes the focus on well-being to be “important in maintaining a safe and strong farmer, and therefore a safe and strong farm.”

Tractor trouble Machine safety is responsible for 70 per cent of on-site farming fatalities each year.

The Canadian Safety Council (CSC) in Ottawa is taking a more fundamental approach to the agriculture sector, making this year about machine safety — an issue that continues to be responsible for 70 per cent of on-site farming fatalities each year, according to national projects manager Lewis Smith.

Unique workplace, hazards

Another significant reason for the complexity of agricultural safety is the unique context of the work, which finds farmers and workers existing not only in rural — often insular — communities, but ones where the lines between home and work life are blurred.

Farm workers tend to be “very hard-working and independent,” said Smith.

Because of this blurring, there exists a tendency — especially where daily tasks

are concerned — “to feel more comfortable cutting some corners because they’ve done the same many times before without incident.”

These circumstances makes the act of developing robust and actionable safety education plans an essential duty of safety professionals for both cultivating mind-

fulness of these issues and protecting workers in this sector, according to Smith.

“We can’t and shouldn’t treat safety as something to be rushed through, taught once, then forgotten,” he said. “Safety education needs to be reinforced, and that’s the biggest challenge facing workplace safety on the farm.”

Tough and Flexible

Reflex Polymer Safety Barriers

Protect people and equipment from accidental impact of moving vehicles.

Industry leading polymer safety barriers flex upon impact and return to their original state. This energy absorbing ability significantly reduces maintenance costs and help prevent expensive floor repairs.

Our patented, proprietary, REFLEX polymer is scratch resistant, safe in food processing environments and is fire resistant.

The modular design can accommodate virtually any application.

Used in over 85 countries REFLEX polymer safety barriers are the most cost effective logical choice for modern day facility and asset protection.

Ontario Bollards, 53 Armstrong Ave., Unit 1, Georgetown ON L7G 4S1 844-891-8559 info@ontariobollards.com www.ontariobollards.com

Case Study

Changing attitudes around safety

The task that agricultural safety professionals have of growing safety into something comprehensive and commonplace on the farm isn’t achieved simply through updating procedures, but also addressing longstanding attitudes across the industry.

It’s a much-needed conversation; buy-in begins with understanding why safety is a priority on the farm, said Robert Gobeil, agricultural health and safety specialist at CASA.

“To be point-blank honest, safety in agriculture — the way that safety professionals look at health and safety — it’s in its infancy; it’s at least one generation behind other sectors like construction.”

Like Smith, Gobeil believes these attitudes come from the informal “mom and pop” nature of the work. Though overall intentions of workers and employers may not be directly negligent, a culture resistant to safety protocols can emerge from these ideals.

“With safety being such a new thing in the sector, it’s a tough conversation to have still, to some degree,” he said.

This resistance isn’t specific to one level of the industry, either.

“The employer often does not want to adopt a safety management system because of the cost and how it takes away from their perceived productivity,” Gobeil explained, noting that at “the worker level, it’s extra duties put on the worker — in their opinion — a lot of the time.”

COVID uncovers gaps

These critical gaps in agricultural safety were showcased this summer, following a series of high-profile COVID-19 outbreaks across the sector, with many of the cases concentrated amongst the migrant farmworker populations in southwestern Ontario.

“The worst-case scenario was somewhere around 1,800 cases that occurred in agriculture, so that’s probably close to 10 per cent of the cases WSIB (Workplace Safety and Insurance Board) would recognize (despite the fact that) farming generally makes up two per cent of the employment,” said Dean Anderson, strategic advisor of agricultural initiatives at Workplace Safety and Prevention Services (WSPS) in Mississauga, Ont.

Approaching another farming season amid the pandemic, a number of policies have been developed by federal and provincial governments in response to these gaps. Among them is the Prevention, Control and Outbreak Support Strategy for COVID-19 in Ontario’s Farm Workers, developed by the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA).

The strategy is comprised of 35 new protocols, along with a number of additions to existing government strategies, which aim to “address the unique impacts of

These outbreaks, according to Anderson, came from a mixture of lax policies in keeping potentially infected third-party personnel, such as delivery drivers, from being exposed to working environments, and the shared living spaces of the workers that allowed this exposure to spread.

COVID-19 to our sector,” according to OMAFRA media relations strategist Christa Roettele in Guelph, Ont.

Since the project’s November launch, Roettele confirms steady progress has been made.

One area of progress pursued by the strategy is safer housing, achieved through the formation of the Housing Working Group — a new initiative made up of government and industry groups — that aims to reassess the housing and safety issues that exacerbated the spread in the summer.

Another need is accessible safety education, which OMAFRA has responded to by collaborating with

Migrant issues

The safety of migrant workers has come into focus as a result of the COVID-19 pandemic.

the Ontario Vegetable Growers’ Association to develop a comprehensive health and safety toolkit that aims to maximize access for foreign workers by being free, online, and available in a number of different languages.

Self-care for farmers

While those initiatives target safety gaps that are visible to those outside of agriculture, the Prevention, Control and Outbreak Support Strategy also offers a digital first-aid kit for an issue in the industry that’s a little less obvious: mental health.

The unique relationship that farmers have to their work “can

make it difficult to identify and manage stress and accommodate the necessary self-care for managing stress,” said Roettele.

Meanwhile, in line with their theme of resilience and well-being for Canadian Agricultural Safety Week, CASA’s Gobeil admitted “there’s a big stigma and stereotype in the agricultural sector, where a lot of the older generations just do not want to talk about mental health; they bottle things up.”

A work culture discouraging openness around one’s feelings does not mix well with the physical isolation of the lockdowns that many across the country are experiencing, often leaving agricultural workers without their primary outlet for social and emotional relief.

“Just on a personal mental health note for the farm operator or the worker, it’s that isolation — where you can’t visit your family or friends,” Gobeil said.

“A lot of farmers already live in relatively isolated communities, but having these provincial restrictions in place of tent visits outside of your household, or really restricted group sizing, things like that, it puts extra stress on the way the work is done.”

Despite the backseat that mental health has taken in the agricultural industry, Gobeil believes that “society has definitely come a long way in the last generation or so, and people are starting to open up more.”

This increased openness, he said, is the key solution to normalizing the mental health discourse.

“It’s a matter of reaching out more, to be honest. It’s just that promotion and realization that everybody has problems occasionally, we all do, and it’s just a matter of saying ‘Hey, I have an issue, I could use some help.’”

Jack Burton is a freelance writer in Toronto.

Safety Gear

By Meagan Gillmore

Strapping in for fall protection

Falls continue to be a leading cause of workplace accidents. For workers to be protected, their equipment needs to be easy to use, while also meeting — and at times, exceeding — current safety standards, according to leading subject experts.

A key component of fall protection is having harnesses and connectors — such as self-retracting lifelines (SRLs) or energy-absorbing lanyards — that work well together. Workers must be aware of changing preferences in SRLs and standards for energy-absorbing lanyards.

Leading-edge SRLs have become more popular in recent years, said Tim Accursi, an Ancaster, Ont.based fall protection specialist for SureWerx.

“The lag in the industry is in training and knowledge about leading-edge SRLs. It’s important for us to get that knowledge out there,” he said.

“As soon as people hear ‘leading edge,’ they think that everything is a leading edge, and that’s not the case. One of our big pushes is training and understanding so individuals know what products are.”

Balancing padding, comfort

While leading-edge SRLs are popular, they can be quite heavy. This can cause discomfort for workers because they’re heavier than lanyards.

This has caused manufacturers to design harnesses that accommodate these SRLs without putting extra weight and burden on workers.

“One of the constant objectives

of evolving good harness design is finding that balance between heavy, bulky padding and optimal comfort,” said Judd Perner, brand and product marketing director for Texas-based Pure Safety Group (PSG).

PSG has adapters that allow workers to connect to leading-edge SRLs from the back of their harness, instead of using the dorsal D-ring. This leaves the D-ring available for connecting to an overhead SRL when climbing a ladder, or for rescue applications, said Perner.

Both Series 3 and Series 5 harnesses have adapters to accommodate personal SRLs and leading-edge SRLs.

“It comes down to comfort and how easy it is to connect,” added Alex Tsen, director of fall protection at Laval, Que.-based PIP Canada Ltd.

More padding isn’t always best, he said. Padding can make equipment heavier for workers, resulting in fatigue and discomfort from heat. PIP Canada puts padding on the strategic areas — the shoulders and the back of the legs.

Increasing wearability

Some manufacturers use different designs to increase wearability. Three years ago, MSA launched its V-Series harness line. It uses a racing style design across three models: the V-FLEX, V-FIT and V-FORM+.

“It dons like a vest and connects similar to a cross-style,” said Brandon Griffin, director of Canadian sales at MSA in Kingston, Ont.

The buckle goes across the middle, and the leg connection goes across the thighs in a boxer-type style. Users are able to put it on and adjust it easily, according to the proper instructions, he said.

“They’re able to do that very competently, very confidently. I’ve seen some very good quick fits when people are picking up the harness. It does seem very intuitive for the end user.”

At 3M Canada, STRATA harnesses have a metal spine that transfers weight from a worker’s shoulder to the base of the hips, said John Fuke, technical services manager for Canada, based in Mississauga, Ont.

A key component of fall protection is having harnesses and connectors.

These harnesses also have a purpose-built connector that is easy-to-use and a polar vest to reduce heat, he said.

Proper knowledge is also key when using shock-absorbing lanyards, said Accursi. In the past, these lanyards had an E4 and E6 classification. However, that CSA standard has been removed.

“Now we can make and market any capacity rating we want on a shock-absorbing lanyard, as long as it meets the testing requirements,” he said.

Each manufacturer’s energy-absorbing lanyards will be different.

Customers need to “read the labels and make sure they’ve got the proper range for what they’re required to do,” according to Accursi.

Some lanyards are created to fit a range of workers.

PIP Canada Ltd. sells the DynaONE, an energy-absorbing lanyard that can be used for workers who are between 100 and 350 pounds. The idea, said Tsen, was to create “one class that fits them all.”

If workers aren’t rescued in the first 15 minutes after they fall, they could have a heart attack while waiting to be rescued.

When adding the weight of equipment, most workers will come in between 100 and 350 pounds, he said.

Manufacturers are also making it easier for users to maintain their equipment; proper, daily inspection is crucial.

SureWerx’s PeakProPlus harness has webbing that turns red to show when it needs to be repaired.

“It’s a higher-end model of ours, but it’s a great tool to aid in the inspection,” said Accursi.

Many manufacturers also offer radio-frequency identification (RFID) tags that can be added to equipment. These ID tags can indicate who the equipment belongs to, and can also be used to track when equipment has been inspected.

Rescue retrieval, confined entry

Another crucial part of fall protection is ensuring there’s a way to rescue workers.

In 2020, PSG released the 3-Way Rescue & Retrieval SRL. It can be used as part of an overhead application or connected to a tripod to help retrieve workers or lower them into confined spaces. It connects to one leg of the tripod and to the worker’s dorsal D-ring.

If a worker falls, “the lifeline will lock up and act like a normal SRL,” said Perner. The device can switch into a rescue-retrieval mode and the worker can be brought up or lowered to safety through a hand winch.

“Customers like that capability because it helps them develop a rescue plan that they can write into their operating procedures so they know what to do if they have a worker in a confined space,” according to Perner.

MSA offers the XTIRPA line of products for confined entry. Instead of using a tripod, these products are modular. It includes gating that attaches to the anchor and goes around the point of entry, which allows it to be used in more situations, said Griffin.

This design “allows the user to adapt to the varying confined spaces and ways of entry,” he said.

Trauma straps save lives

Trauma straps are also becoming a more common accessory with harnesses, and some manufacturers are including them in certain

designs. When a worker falls, their harness straps can cut off the circulation in their legs.

If workers aren’t rescued in the first 15 minutes after they fall, they could have a heart attack while waiting to be rescued, said Tsen.

Trauma straps give them more time. The straps have loops that workers can step into and support them to stand up. This keeps the circulation flowing in their legs.

PIP Canada Ltd. includes trauma straps with their harnesses.

“It’s a matter of life and death,” said Tsen. “Every harness should have them, in my opinion.”

“It’s a low-cost item that could save their lives,” added Accursi.

The straps are not mandated by safety standards, he said, and SureWerx includes them on a highend harness model and also sells them as accessories that can be added to other harnesses. Trauma straps are also available in all of 3M’s DBI-SALA brand harnesses.

Finally, no matter what products are purchased, workers still need to properly and daily inspect their

equipment. They also need to have a plan for how they will rescue someone if a fall happens on the worksite.

“You need to write a rescue plan around the rescue product, so you ensure that the worker is rescued in a timely manner,” said Tsen, noting it’s the only way to ensure the equipment works properly.

Meagan Gillmore is a freelance writer in Toronto.

Trauma straps are becoming a more common accessory with harnesses.

CCOHS Corner

The Canadian Centre for Occupational Health and Safety

A collective approach to COVID-19 prevention

“There is strength in numbers.”

We often hear or say this phrase to describe the power and influence that a group of people can have over a situation.

As the COVID-19 pandemic evolves, this phrase can take on a whole new meaning.

Workplaces and workers have the opportunity to bring this phrase into their planning and actions, helping to answer: What would it look like if we all did our part to keep ourselves and our teams safe?

Everyone has a role in controlling the spread When it comes to controlling the spread of COVID-19, we each have a role to play.

To help reduce the risk of exposure, it’s important for employers to remember that risks aren’t just contained to the work environment. Every person who walks through the door — customers, staff, volunteers, etcetera — all contribute to the safety of the workplace.

While it may seem like a lot of variables to address, there are measures that employers can take or encourage to help facilitate a healthy environment.

Here are a few to get started.

Understand the variables in home environments

Every worker has a different living situation. Let’s look at a couple of staff members at a grocery store, for example.

Elena, a cashier, lives at home with her partner and two dogs. One might assume that because Elena’s household is so limited in number of people, the exposure risk is low.

However, Elena’s partner is a registered nurse who works at a retirement home in the city, caring for more than 20 seniors each day.

In the same store, we also have Peter who works at the deli counter. Peter works part-time at the grocery store and picks up shifts at the local butcher shop on weekends.

He lives with two roommates — one is a resident at a major city hospital, and the other is a full-time university student who makes extra cash driving for a ride share app.

Through each scenario, we can begin to see that the risk of exposure to COVID-19 is not just limited to workplace interactions.

In Elena’s case, the household isn’t limited to two individuals — it’s actually two essential workers who are exposed to hundreds of people a day.

In Peter’s living situation, there are multiple points of community exposure.

Each of these workers, and their respective roommates and partners, increase workplace risk — and not just for the grocery store. Each environment is now brought into the mix — the retirement home, the hospital, the university, and the general community. These living conditions are not unique to grocery store employees. Workers in Canada live in all types of home environments.

This fact helps to illustrate how crucial it is for employees and workplaces to protect themselves, their workers, and the community through workplace policies and supports for workers.

Prevent the spread

There are many ways individuals can protect themselves, and in turn protect others, but all steps begin

with knowing the facts about the virus and how it spreads.

COVID-19 commonly spreads from an infected person through respiratory droplets when you cough or sneeze, close personal contact like shaking hands, or touching something with the virus on it, then touching your eyes, nose or mouth before washing your hands.

These methods mean that the virus spreads more when people are in closed spaces, crowded places, and when there are close interactions.

Symptoms can take up to 14 days to appear after exposure to the virus, which is why the following tips are so helpful to follow to prevent spread.

• Daily check-ins: Prevention

14 days

COVID-19 symptoms can take up to two weeks to appear after exposure to the virus.

Every contact with a person outside your household increases your risk.

and care starts with checking yourself daily for symptoms of COVID-19. Common symptoms include a new cough or one that becomes worse, shortness of breath, difficulty breathing, fever, chills, and others. If you have any of these symptoms, even if mild, stay home.

• Limiting contact outside of your immediate household: Every contact with a person outside your household in -

creases your risk, so it’s important to be aware of possible exposures. You can download the free COVID-19 Alert app to help notify you of any exposures so you know if you should get tested. You can also confidentially report your case, which helps to track the pandemic and reduce the spread by identifying infected regions.

• Physical distancing: When you’re out, keep a physical

COVID-19 ‘infodemic’

From the start of the COVID-19 pandemic, an enormous amount of information has been communicated about the virus and how to keep ourselves and our workplaces safe. Unfortunately, not all of this information is reliable. It might not be applicable to your specific workplace situation, or it could change as the pandemic continues to evolve. Here are three questions to ask before using COVID-19 guidance information in your workplace:

1. Can the information source be trusted?

2. Does the information apply to my workplace?

3. Is the information current?

More information about COVID-19 fact checking: www.ccohs.ca/ products/ publications/ covid19-factchecking/

CCOHS Corner

The Canadian Centre for Occupational Health and Safety

distance of at least two metres from others. Wear a non-medical mask especially when you cannot consistently keep two metres away from others, such as in crowded settings.

• Wash your hands: Practising good hygiene remains vital to reducing the spread. Wash your hands often with soap and water for at least 20 seconds or use an alcohol-based hand sanitizer containing at least 60 per cent alcohol. Avoid touching your face with unwashed hands, and cough or sneeze into the bend of your arm or a tissue. Clean and disinfect frequently touched or shared surfaces and objects often.

Support a healthy workplace

Just as employees have a role to play in reducing the spread, so do employers.

Workplaces are responsible for ensuring their workers are safe at work, and this duty can start with developing a COVID-19 safety plan that can include a flexible attendance policy allowing employees to work from home, or stay home if they are sick, or need to care for a sick family member.

Workplaces can continue to support their workers by:

• Communicating protocols and policies to workers: Ensuring workers know that their job is not at risk if they need to stay home is an important part of a flexible attendance policy. Supporting a healthy workplace through such a policy means actively encouraging sick workers to

stay home if they have symptoms of COVID-19, even if they’re mild.

Updated your sick policy or introduced a new one? Let your employees know about the changes and how it impacts them. You can communicate the updates in a number of ways, including but not limited to: sending out an email, holding a meeting (virtual included), or posting a notice on a bulletin board. Whatever method you choose, make sure your employees will receive the information. For example, if you manage a grocery store, you can layer your approach by e-mailing, but also by putting a reminder notice on a bulletin board in the staff room and holding (physically distanced) team meetings before each shift.

TIP: Providing a designated contact, like a member of the health and safety committee, who can assist with any questions or concerns will also help workers understand what to do if they are sick or have had contact with a symptomatic person known or suspected to have COVID-19.

• Implementing a screening protocol: Employers can use a screening questionnaire to help determine the presence of symptoms and ask workers to report if they have had a risk of exposure to COVID-19. A screening checklist includes questions about the presence of symptoms and asks whether a worker or

anyone in their household has travelled outside of Canada within the past 14 days. If so, they are asked to remain at home, which means they may not be able to report physically to work. The checklist can be used in person, online, or over the phone to determine if a worker is fit for work or should stay at home.

• Encouraging a clean and healthy workplace: Develop a plan to clean and disinfect touched or shared surfaces and objects often. Encourage workers to also clean and disinfect their personal work environments and provide them with disinfecting wipes. Post signs to remind workers and clients to follow safe practices. In areas where physical distancing is not possible, set up physical barriers such as Plexiglas windows. Workplaces should also provide increased access to hand hygiene facilities and make sure that persons with disabilities or other accommodation needs can access them.

By developing and participating in safe practices, and following advice from credible and reliable resources, such as the Public Health Agency of Canada or your local public health authority, we can all reduce the risk of COVID-19 for everyone in our workplaces and in our community.

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial and mental health — of workers in Canada by providing information, advice, education, management systems and solutions that support the prevention of injury and illness.

Showcasing the latest OH&S products available in Canada. Email mvanderwier@ohscanada.com to have your product listed.

Honeywell introduces reusable, dual-layer face cover

Honeywell has announced a reusable, three-dimensional knitted face cover with replaceable filters for everyday use.

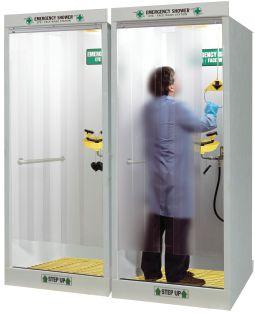

HEMCO emergency showers assist workers exposed to hazardous chemicals

When time is of the essence after an exposure to a hazardous chemical substance, any delay even for a few seconds can result in serious injury.

HEMCO Decontamination

Booths are fully assembled and ready for installation to water supply and waste systems.

The shower is built of chemicalresistant fibreglass and is equipped with a pull-rod activated shower and push handle eye/face wash for immediate drenching of personnel.

KEEN Utility introduces next generation of safety sneakers

The CSA-certified Vista Energy is a work shoe built to perform in the rigorous and fast-paced indoor manufacturing environments where speed, agility and comfort are key.

It mimics the athletic style and comfort of a sneaker, without sacrificing the critical safety features KEEN Utility is known for.

For men and women who work long hours standing and walking on hard surfaces, safety footwear offering the best in cushioning support is a top priority.

The Honeywell Dual-Layer Face Cover features an innovative 3D knit design that contours to the wearer’s face and is made with a washable material, making it easy to clean.

The face cover also has a hidden pocket that securely holds a Honeywell protective filter made

with melt-blown polypropylene, which is similar to the material used in the construction of N95s masks, according to a news release.

The face covering’s base layer features a seamless, 3D knit construction using polyester, nylon and cotton and provides four-way stretch, minimizing gaps and enhancing comfort.

It has a contoured design with adjustable ear straps, a flexible nose clip and ventilation holes for enhanced comfort, function and breathability for most adult face shapes and sizes.

Comfortable, lightweight N95 masks by Jackson Safety

SureWerx has unveiled its all-new premium N95 Pouch-Style Respirators by Jackson Safety.