Reduction of heating costs by up to 65%

Improvement of animal welfare

Fast payback (ROI of 2 to 3 years)

Reduction of CO2, humidity and ammonia levels

Better returns, more income

Justin Montreuil, agr. (Sollio & Avantis)

« I was amazed to find that ESA-3000 heat exchangers are very quiet. In the first few weeks of use, we managed to recover 72% of the heat from the buildings thanks to the ESA-3000 heat exchangers. »

Contact IEL Technologie Agricole for the full testimony!

Summit Technologies Inc. 26 Millwork Dr, Steinbach, MB, R5G 1V8 Phone: (204) 320-3276 www.summittechnologies.ca

596202 Hwy 59, Woodstock, ON, N4S 7W1 Phone: (519) 291-5012

www.county-line.ca Agritech Farm Equipment

2 Tantramar Ct, Amherst, NS B4H 4H8 Phone: (902) 667-5550 warehouse@lbjfarm.ca

43 Minas Warehouse Rd, New Minas, NS, B4N 5A5 Phone: (902) 678-2430 newminasparts@lbjfarm.ca Jonkman Equipment Ltd. 28355 Fraser Highway, Abbotsford, BC, V4X 1K9 Phone: (604) 857-2000 www.jonkmanequipment.com

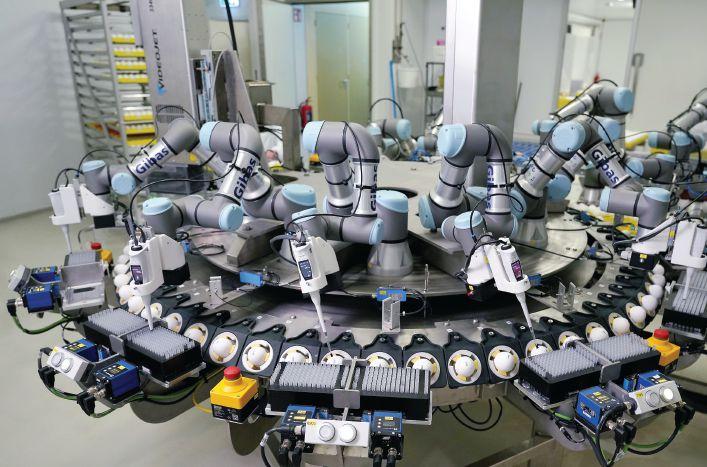

20 In-ovo sexing surge

The technology is gaining global momentum, offering a groundbreaking solution to end male chick culling while boosting hatchery efficiency.

Understanding the historical development, current challenges, and future of welfare standards in poultry production.

by Brett Ruffell

The Canadian poultry sector has long been a beacon of resilience, and recent developments in broiler, egg, and turkey production demonstrate that steadfastness in the face of unpredictable market forces.

The industry’s ability to adapt to avian influenza outbreaks, shifting consumer preferences, and global economic pressures is evidence of the strength and foresight of its producers. However, these challenges have also laid bare the growing need for innovative strategies and long-term planning as we look to the future of poultry production in Canada.

In a recently published report, Graeme Crosbie, a senior economist at Farm Credit Canada (FCC), provided a detailed assessment of the sector’s current state, particularly in light of declining broiler prices.

According to Crosbie, “Broiler prices peaked in 2023 and have slowly retreated since. We are forecasting this decline to continue in the second half of 2024 before stabilizing in spring 2025.”

This reflects broader trends in feed costs, which have seen some relief after the volatility of recent years. As Crosbie notes, “Feed prices are down -22 per cent relative to their peak in the A-180 quota period (December 2022 - February 2023).”

This reduction in feed costs is a welcome respite for producers. However, there is a balance that must be struck. As feed prices decline, chick costs continue to rise, a direct consequence of avian influenza’s lingering effects on supply. This balancing act has resulted in steady pressure on broiler producers, who must remain vigilant in managing their input costs while navigating an uncertain market.

“Canada’s poultry industry has proven itself resilient in the face of disease outbreaks and market volatility.”

The industry’s efforts to recover from the avian influenza outbreaks have been nothing short of commendable. Broiler production grew by 3.3 per cent in 2023 despite these challenges, although Crosbie points out that this growth is expected to slow to 1.7 per cent in 2024 – the lowest rate of growth since 2014, barring the pandemic year of 2020. Even so, the resilience demonstrated by the industry underscores a larger truth: Canadian poultry producers have built an infrastructure capable of weathering storms.

Egg production, meanwhile, has reached record highs. Crosbie reports that “between June 2023 and May 2024, 903 million dozen eggs were produced,

the biggest 12-month tally on record.” This level of output comes on the heels of avian flu-induced disruptions, showing that the sector is quickly recovering from its lows. Egg production is increasingly a point of pride for Canadian producers, who continue to innovate in the face of mounting global competition and rising consumer expectations.

Turkey production, which has seen declining demand in recent years, is also showing signs of a turnaround. As Crosbie explains, “2023 was the first time in nearly a decade that per capita consumption of turkey increased.”

This renewed interest in turkey products, coupled with stable production levels, signals a potential revival for the sector. However, this is not a time for complacency. Producers must seize this moment to reinvigorate their marketing strategies and tap into changing consumer habits that favor leaner, healthier meat options.

While the sector has made significant strides, there are still challenges ahead. Crosbie points to the uncertainties surrounding international trade agreements, particularly with regards to chicken imports under the Comprehensive and Progressive Trans-Pacific Partnership.

The bottom line? This is no time for complacency. Canada’s poultry industry has proven itself resilient in the face of disease outbreaks and market volatility. But now, more than ever, it must lean into innovation, embrace change, and set the pace for the global poultry industry. The future is bright for those who are willing to forge ahead.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer/Team Lead

Graham Jeffrey

Group Publisher

Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

I have looked at many brands of drinkers and LUBING’s EasyLine 2.0 turkey drinker was our choice, and they have helped our turkeys to perform to their highest potential.

Holly Coffman - Summit View Farms

As the birds drink from the cup, their heads move the patented pendulum from side-to-side, which triggers the nipples in a vertical action which eliminates wear on the nipple.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

A commercial that aired during the 2024 Olympics on CBC, created by Chicken Farmers of Canada (CFC) and Swimming Canada, highlights the similarities between Olympian Sophie Angus and Nova Scotia broiler farmer Rachel Sheffield. Both share a passion for hard work and dedication to their craft. The inspiring ad, which resonated with viewers beyond Canada, is available on YouTube and Instagram.

Cobb-Vantress has announced the recipients of its 2024 Cobb Research Initiative (CRI) grants, aimed at advancing poultry genetics through international collaborations. Now in its second year, the CRI funds projects focused on animal health, sustainability, and efficiency. Notable projects include AI-powered precision health and digital twins for broilers. Cobb’s leadership emphasizes the company’s dedication to leveraging science and technology to meet the global demand for sustainable protein.

Agricon Buildings has appointed Jeremy Houdek as its new global sales director, aiming to expand the company’s footprint beyond the U.S. Houdek brings extensive poultry industry experience and a commitment to innovation. He began his career in 2009 with Big Dutchman, supporting sales and overseeing the service department in the LATAM division before moving to cage-free sales in Western North America.

Chicken farmers joined by elected officials to donate over 1,000 kilograms of locally grown chicken to food banks in Oshawa and Peterborough. is how many kilograms of chicken producers donated to food banks in Oshawa and Peterborough. Visit

Over 1,000 kilograms of locally grown chicken were donated by Chicken Farmers of Ontario (CFO) to food banks in Oshawa and Peterborough in August as part of the CFO Cares: Farmers to Food Banks program.

The donations, totaling 1,050 kilograms, will provide over 9,000 meals for families and individuals in need throughout Durham Region and Peterborough.

At the Oshawa event, 700 kilograms of chicken were donated to Feed The Need Durham (FTND). The celebration was attended by MPP Jennifer French, Mayor Dan Carter, and local chicken farmers.

In Peterborough, a separate donation of 350 kilograms of chicken was made to Kawartha

Food Share, where MP Michelle Ferreri, MP Philip Lawrence, MPP Dave Smith, and Mayor Jeff Leal joined farmers for the event.

“Food insecurity continues to be an issue for many Ontario families, and Ontario chicken farmers are continuing to step up to help take a bite out of hunger,” says Tim Klompmaker, CFO Board Director for District 9.

“Thanks to the continued dedication of the Ontario chicken farming community, since 2015, the CFO Cares: Farmers to Food Banks program has donated over nine million chicken meals.”

CFO’s donation program, run in partnership with Feed Ontario, contributes over one million meals annually to food banks across the province.

For

A look at the major bird welfare advances in Canada’s poultry industry. By Treena

Hein

The Canadian poultry sector has been dedicated over many years to putting bird welfare at the forefront, along with sustainability, ensuring the various consumer market needs are met and more. As all aspects of welfare continue to advance, here is an update on genetics, research, codes of practice, transport, processing and consumer awareness.

Many areas of welfare continue to be researched in relation to poultry. A study published in 2023 by several researchers, including Dr. Tina Widowski, Egg Farmers of Canada Chair in Poultry Welfare at University of Guelph, examined laying hens housed in large groups where reactive fear

responses increase the risk of injury through collisions and injurious behaviours.

The team noted that understanding strain (brown hens versus white) differences in fear, fear response and fearfulness of different types of stimuli is important for designing and managing housing systems to reduce situations that cause fear, and to better match strains of birds with housing systems.

In a recent paper, Widowski, Dr. Alexandra Harlander (also at University of Guelph, and current holding the Burnbrae Farms Professorship in Poultry Welfare) and colleagues found that overall, pullets from low or intermediately complex early-life environments had a more active fear response than those from barren environments or those from complex environments.

White-feathered pullets had a more active

fear response than brown pullets. Widowski reports that standards are currently in development for pullet housing so that it matches the housing where pullets are destined for the egg lay stage of their lives.

She notes that feather pecking is a longterm poultry welfare problem, one that’s part of fear response. Harlander is currently doing ground-breaking experiments to examine how changes in gut microbiome affect feather pecking behaviour.

In terms of other poultry welfare priorities, Widowski notes that production is always changing and welfare research should therefore always be ongoing. “A good example is the extension of the lay period,” she explains. “This is an emerging area of research in terms of how we can sustain hen health and wellbeing over a longer time.

Among other aspects, osteoporosis and keel bone fracture risk need to be examined, as well as feather cover, particularly in aviary systems as birds need good feather cover to fly up and down.”

In enriched cage housing, Widowski notes a particular need to investigate how to maximize opportunities for foraging. In free-run systems, research into piling and smothering is needed to understand why birds crowd into a corner or against a wall and how to mitigate this.

While research is on this is scarce, a large project is underway in Switzerland to track individual birds and see if a tendency to not pile and smother can be selected for in breeding programs. In broilers, welfare issues related to fast growth remains an area where more research is needed.

The first Code of Practice for the Care and Handling of Pullets and Laying Hens was released in 2017, a document that combined input from welfare specialists and industry. The five-year review of this code was completed in 2022 and amendments are now being reviewed in three areas. They are: round feeder space for laying hens

1. Genetics and Welfare: Innovations in genetics aim to enhance cardiovascular health and leg strength, using technologies like X-rays to address welfare issues.

2. Fear Response in Housing: Research emphasizes designing housing systems to reduce fear and injuries by understanding strain-specific fear responses in hens and pullets.

3. Pullet Housing Standards: New standards for pullet housing are being developed to match future egg-laying environments, improving overall welfare.

4. Processing Plant Innovations: Maple Leaf Foods’ new plant features technologies like controlled atmosphere stunning to minimize stress during processing.

5 Public Trust and Education: Transparent communication and shared values are essential for building public trust and addressing concerns about poultry welfare.

and pullets; minimum space allowance for pullets in multi-tier systems; and maximum number of tiers allowed in laying and rearing facilities. The public comment period goes to January 2025. The amendments should be completed by April 2025.

Updates are also underway also to the 2016 Code of Practice for the care and handling of Hatching Eggs, Breeders, Chickens and Turkeys. With the release of the updated Code, Chicken Farmers of Canada (CFC) will review its Raised by a Canadian Farmer Animal Care Program, which is code-based and must be implemented by all commercial chicken farmers to ensure that any new or revised animal welfare requirements are incorporated. The program was first developed in 2009. CFC notes that “the priority welfare issues, which will be reviewed as part of the Code development process, are still being determined.”

Improvements in genetics are critical to bird welfare, covering factors such as leg strength and overall robustness. For example, take Aviagen. Like other poultry genetics companies, it has focused on a balanced breeding strategy that combines biological efficiency, reproductive fitness, environmental adaptability and welfare.

“Key welfare-related outcomes, such as cardiovascular function, leg and foot health and gait are crucial to a bird’s overall performance,” explains Dr. Eduardo Souza, Aviagen’s VP of R&D. “We have used technologies like pulse oximeter function and X-ray techniques to identify and mitigate the risks of cardiovascular issues and skeletal defects. By improving leg health and cardiovascular function, we have enhanced the overall livability of our birds.”

Currently, Aviagen is focusing on computed tomography to conduct comprehensive whole- body assessments, enabling greater accuracy in the measurement of welfare-related traits. Aviagen is also looking at novel approaches like computerized video systems coupled with machine learning applications, which offer opportunities to study the genetic basis of a wide range of bird behaviors.

“Breeding for welfare is a dynamic process, and we are dedicated to making continuous gains,” says Souza. “Future improvements will focus on studying various body systems of birds (cardiovascular, musculo-skeletal, integuments and immune) to identify novel indicators of biological functions related to welfare outcomes.”

Welfare is also crucial at end of life, and new approaches are being used to reduce bird stress. Maple Leaf Foods completed the transition of all its Ontario fresh poultry processing volume to a new state-of-the-art poultry facility in London, Ont. in late 2023.

“The new facility boasts an environmentally controlled indoor lairage area with heating, misters and blue lighting to promote bird comfort and reduce stress,” explains Kathleen Long, VP animal care. “The process is designed so that birds are never handled until after they have been rendered insensible through humane controlled atmosphere stunning, which greatly reduces stress to the birds.”

Long adds that most large processors in Canada, including Maple

Leaf, are now using modular loading to enable easier catching, loading and to facilitate plant automation. “This has required the cooperation of farmers, catching crews and live transporters to facilitate a coordinated transition to new equipment,” says Long.

“Other advancements in transportation include improvements to trailer ventilation capabilities, environmental monitoring, and pilot testing of new approaches such as climate-controlled trailers. When building London Poultry, we optimized the location of the facility relative to the chicken farms supplying it, which has reduced overall transportation times for the birds we process in Ontario.”

According to Crystal Mackay, Founder & CEO, Loft32 (an Ontario-based firm offering speaking, training, project management and subject matter expertise), connecting and engaging with the public about poultry welfare has come a long way.

“This work falls under the larger umbrella of earning public trust in our food system,” she explains. “The framework for earning public trust has three pillars – doing the right thing, trusted assurance and verification systems, and communications. Each pillar needs a foundation of research, with coordination and collaboration to fuel the efforts and make it work.”

Mackay explains that groups like Farm & Food Care are excellent collaborators who focus on the communications aspect of earning public trust. She notes, however, that awareness and education are not the goal for people other than students. “Canadians want to know more, not learn more and they want honest, transparent information from people they can trust,” she says.

“Canadian Centre for Food Integrity research shows levels of trust and overall impressions of poultry farming and farmers has stayed relatively steady over the past decade. When it comes to welfare specifically, the biggest concern is that roughly half of Canadians are unsure what to think. That’s a huge risk or opportunity that could swing either way depending on how well we do at connecting with those people.” She adds that trust can only be earned if someone is sharing those stories in an authentic way.

For the past 10 years, Egg Farmers of Canada has proudly supported the next generation of agricultural leaders through our national young farmer program This initiative helps young farmers develop leadership skills, connect with peers and share best practices. Contact your egg board to learn how to get involved.

Learn more at eggfarmers.ca Facebook.com/eggsoeufs

As Canada’s Muslim population grows, demand for halal chicken expands, pushing it into mainstream outlets and creating opportunities for poultry producers.

By Ronda Payne

Observing Muslims gain greater choices as halal chicken demand and production increases, making its way into mainstream outlets.

Twenty-five years ago, options for alternative diets were limited. Terms like gluten-free, vegan and halal were mostly unheard of in mainstream retailers, let alone restaurants. Imagine asking for a gluten-free, halal chicken sandwich in 1999.

The tides turned. Populations shifted, dietary needs and preferences generated new demands.

By about a decade ago, it was obvious that consumer demand for alternative food options was not the short-term fad it once was seen to be. It became big business. Just as gluten-free and vegan have grown in acceptance and become commonplace, so too has the integration of halal foods like chicken. These dietary decisions are not trends, but rapidly growing choices expected by Canadian consumers.

An unverified letter from KFC to some of its franchisees in July 2024 prompted an

increase in awareness of halal chicken in Canada. Some applauded the decision, while others pushed for a boycott. Among the standpoints is a general lack of knowledge in non-Muslim communities about what halal means and how it is implemented in food systems in Canada.

The halal market

Salima Jivraj, account director and multicultural lead at Nourish Food Marketing, a self-described “full-service marketing agency specializing in the food sector from field to fork”, says Canada’s Muslim population has grown to 1.8 million in 2021 according to Canada’s Census. The halal customer base is expected to hit 2.6 million by 2030. While the current Muslim population represents just shy of five per cent of the overall

Canadian population, immigration will add to an exponential increase in Muslim residents in Canada going forward.

Unlike gluten-free or vegan choices, halal foods don’t change the appearance, taste or use of familiar foods like poultry. Therefore, in a restaurant or grocery setting, customers wouldn’t know there is a difference between conventional and halal chicken unless it is labelled or they ask. In fact, halal chicken has been offered in many restaurants like KFC for a number of years.

Because of the growing Canadian Muslim population, producing halal options has a beneficial financial aspect for chicken farmers. The global halal market was $2,447 billion in 2023 according to the Globe and Mail.* In Canada, that translates to an expectation of $300 million in the meat market alone by 2031** and that market is growing at about 10 to 15 per cent annually***.

An Arabic term meaning permissible, ha-

SAVE YOUR BACK

lal is more than just a dietary standard, or method of producing food. It also applies to everything from clothing and body care to financial products. Observing Muslims require halal products in every aspect of their lives. But, this has led to criticisms and concerns from non-Muslims about minorities driving food systems and other products in the marketplace. The KFC announcement sparked a range of comments even though some non-Muslims also seek out halal choices.

Among these comments were those who feel halal slaughter is less humane than conventional slaughter. It requires, among further elements, the use of a sharp knife that is re-sharpened between animals and must be done quickly, out of the sight of the animal being butchered as well as other animals.

Sylvain Charlebois, senior director, Agri-

Food Analytics Lab at Dalhousie University, says there have been changes within the industry to enhance animal welfare in halal

The EggLifter has established itself as the most cost-effective and user friendly solution for egg palletization. With a design focused on simplicity and efficiency, this innovative set up allows poultry farmers to stack and palletize eggs in an effortless manner. It minimizes the complexity and costs associated with other palletizing systems, making it a favourite choice in the poultry industry.

Contact

sales@county-line.ca 519-291-5012

meat production. For example, although stunning is not required in halal practices prior to slaughter, this is being employed more often.

“Many halal producers now adhere to stricter guidelines that emphasize the use of pre-slaughter stunning techniques, which aim to render animals unconscious before the actual slaughter,” he says. “These changes reflect a growing commitment within the halal community to align religious practices with improved animal welfare standards, addressing concerns and ensuring that ethical considerations are integrated into the process.”

Jivraj believes that concerns about halal slaughter methods being less humane are “fear-based and purely speculative,” she says.

“Hala processing prioritizes animal welfare,” says Jivraj. “The Halal Monitoring Authority (HMA), a major halal certifier in Canada, monitors how livestock is transported and flags issues like rough handling or poor environments on the spot.”

She adds that animals exposed to acute stress are not processed.

But, just as there are less-honourable companies that don’t follow practices as required in the organic certification sector, the same

sometimes crops up in halal producers. The HMA started enforcing halal labelling in 2016 and because meat is unlikely to have any taste or appearance differences from conventional meat, inspection is the only way to be sure practices are followed.

“Organizations like the HMA have been advocating for humane practices for years,” says Jivraj. “However, similar to the broader meat industry, misinformation often spreads from practices outside Canada, leading to negative perceptions.”

Maple Leaf Foods launched its Mina halal brand in 2014 to continue to serve the preferences and lifestyle choices of diverse customer segments.

“ We pride ourselves in industry-leading food safety, people safety and animal welfare practices at Maple Leaf Foods,” says the company’s media hotline in an email response to Canadian Poultry Magazine. “Mina offers a wide range of halal certified products prepared according to Islamic dietary laws and audited by thirdparty agencies. Mina strictly adheres to Islamic law and our products are certified by the HMA.”

The hotline response further states that the same animal welfare standards are used with all animals in the organization’s care.

“As part of our Mina brand, we are creating a destination for ethnic flavours to meet the evolving needs of Canadians,” the email response continues. “This year, we launched core seasoned items such as Tandoori, Tikka Masala and Shawarma and are building out a pipeline for further flavours. We see tremendous opportunities for Maple Leaf Foods in the Halal market.”

Poultry farms wishing to grow for the halal market would not experience any changes in their practices if they are already producing for Maple Leaf Foods according to the hotline’s response. Halal is about animal care from beginning to end and those producing for the company already follow rigid guidelines.

Other farmers may need to make small modifications to produce halal poultry.

“For farmers, the changes would be minimal, if any,” says Jivraj. “But, at the processing level, there may be adjustments depending on the size of the operation and whether they are provincially or federally licensed. However, once a processing facility partners with a halal certifier, they will find that the benefits outweigh the initial changes. Most certifying bodies work closely with processing facilities to customize solutions that fit their parameters.”

Most Canadian poultry farmers already produce their meat poultry in ways that would be designated halal.

According to Wehalal, an online halal marketplace, to be considered halal, animals must be cared for humanely with no history of abuse. They must be fed “a natural, vegetarian diet.” And raised on clean, low-stress farms. Plus, there must be a traceable record of the meat’s history up to and following the animal’s slaughter.

Given these practices, and the addition of stunning before slaughter, certified halal meat is just as humanely raised and processed as conventional meat. Plus, because blood is drained from the meat

“This is very much a response not only to population growth but also to the increasing interest among the general population.”

immediately after slaughter, there is a lower risk of blood-borne contamination as well as prevention of bacterial growth.

Because pork is not permitted in a halal diet, chicken is a natural choice. “Demographic shifts are reshaping the landscape of consumer preferences and restaurants must adapt accordingly,” says Charlebois. “One of the most compelling opportunities lies in embracing chicken, which stands out as one of the most versatile and universally appealing meats available.”

Plus, he says that because chicken is adaptable to many different cuisines, it is well suited to meet the shifts in consumer demands.

“ The impact on poultry production in Canada will be significant,” Charlebois adds. “With the rising demand for halal poultry, it’s clear that more producers will need to adapt to this growing market.”

He says that likely, more producers will enter the halal poultry space due to the increasing demands.

“It’s a sign of a continuing trend,” says Jivraj of the KFC move. “This is very much a response not only to population growth but also to the increasing interest among the general population who view halal meat as a ‘healthier’ or ‘cleaner’ option.”

She says that despite some of the negativity that followed the release of the KFC statement, opportunities both domestically and internationally abound and good business decisions should trump any fears over what she describes as “a smaller group with louder voices who now have social media as a tool to amplify their Islamophobia.”

Poultry is a major driver of the halal market in Canada, which Jivraj notes has a value of $1.5 billion.

“More and more restaurants, QSRs, grocers and manufacturers are exploring ways to tap into this market,” she says. “The growth is driven by the increasing Muslim population in Canada and internationally, as well as the growing interest among non-Muslims who see halal as a value-added benefit.”

Costs between halal and conventional meat are “very competitive” she says and adds that people tend to appreciate the differences in processing such as draining the animal’s blood.

“ The challenge lies in finding the right partners and aligning

with organizations that have the knowledge and experience to offer proper guidance, as each business is unique and requires specialized planning to implement halal practices effectively,” she says. “Canada is a diverse country and in major urban centres, visible minorities are the majority.”

She advises poultry producers interested in making the switch to producing halal meat to research the markets and the opportunities for poultry within it.

And, as for that negativity around KFC’s statement, Jivraj provides a few closing thoughts.

“ The KFC news was based on an internal memo directed at a small group, which went viral,” she says. “The memo wasn’t meant for the general public and used language that could understandably be seen as non-inclusive to other groups. Again, since this memo hasn’t been verified by KFC, I can only speculate.”

What she can speculate on is the potential for growth in poultry in the halal marketplace.

The numbers and demand tell the greater story that halal poultry is commanding a place in Canada’s food market with both Muslim and non-Muslim consumers and that means that options for Canadian poultry growers to occupy a place in that market are significant.

Europe’s ambitious chicken welfare initiative may significantly increase production costs and environmental impact, raising sector concerns.

By Melanie Epp

Across Europe, over 300 major companies have signed up for the European Chicken Commitment (ECC). The framework of standards, which was developed by animal welfare NGOs, requires signatories to commit to a list of requirements, including maximum stocking density, the adoption of slower-growing breeds, and proof of compliance through third-party audits.

To date, the list of signees includes retailers and catering businesses, as well as major fast-food restaurants like KFC. ECC transition must be completed by 2026.

The European poultry sector is concerned that the environmental and economic impacts of the transition have not been fully assessed. AVEC, the voice of Europe’s chicken producers, commissioned RSK ADAS Ltd (ADAS) to conduct an in-depth study into the possible repercussions of adopting such a system. Its findings were highlighted in a recent webinar, hosted by AVEC.

Since its inception in September 2017, the group of European NGOs that joined forces to get the food industry to commit to new welfare standards for broilers has seen great success. The movement, however, superseded the research on its potential impact, as it often does.

The framework lays out guidelines on stocking density, lighting requirements, perch space, and air quality. However, Europe already has high standards when it comes to broiler welfare. Council Directive 2007/43/CE lays down minimum rules for the protection of chickens kept for meat production that aim to reduce overcrowding by setting a maximum stocking density.

It ensures better animal welfare by specifying requirements such as lighting, litter, feeding, and ventilation. Furthermore, AVEC believed moving to the ECC system would likely lower productivity and increase the cost of production.

AVEC published the commissioned study, Costs and Implications of the European Chicken Commitment in the EU, in May. On the day of its release, the group hosted a webinar to share the results of the study. Moderated by AVEC Secretary General Birthe Steenberg, the webinar brought together industry experts and key stakeholders.

Toby Townsend, principal sustainable food and agriculture Consultant, ADAS, explained to attendees that the study compared standard poultry production in Europe to the ECC recommendations. Transitioning to ECC standards would result in a 37.5 per cent increase in production

costs per kilogram of meat. This calculation, he said, considers the cost of additional building space needed to maintain current EU output, as well as additional requirements for feed and water

Broilers in standard EU systems reach the thinning stage (1.8 kg live weight) in 31 days, and cull weight in 40 days. ECC broilers, however, take 37 days to reach the thinning stage, and 51 days to reach cull weight. During that time, they consume more feed and water, produce more manure and emissions, and require more energy to get there.

“ Taken together that means that we have just under six production cycles per year for the ECC system, whereas we can achieve 7.3 for the standard system,” Townsend said. “The ECC system does give us a slightly lower mortality rate.”

One of the key differences between the two systems is feed and water use. The standard system has a feed conversion ratio of 1.55, whereas the ECC system has a feed conversion ratio of 1.85. Overall feed intake

increases by 7.3 million tonnes, and water use would increase by 12.44 million m² under the ECC system.

“Because of that, we’re looking at a higher amount of feed required per bird, so 3.84 kg per bird for a standard system and 4.58 for the ECC system – so quite a bit high,” Townsend said. “And that’s also associated with a higher water use of 6.5 litres per bird in the standard system and 7.8 for the ECC system.”

The study found carcass yield to be 6 per cent higher in the standard versus the ECC system. While feed is slightly more expensive in the standard system, they are offset by the slightly higher capital costs that are assumed in the ECC system.

“ We’re looking at about a 22 per cent increase in costs for the ECC system relative to the standard production system,” Townsend said.

The ECC system also uses more space per bird, while producing 44 per cent less per square meter. Moving towards the ECC system would also require 48 per cent more space, and because meat output is lower, in order to meet current production levels, 66 per cent more space would be needed to maintain current EU production.

According to the study, switching to ECC production would require 25.55 million square meters of

growing space, equivalent to 9,692 new buildings. At the current new build price of €420/m>, the move would cost the EU poultry sector over €8.24 billion.

ADAS compared the environmental footprint of the two systems by adding up energy, feed and water consumption, as well as total production of manure and emissions. Greenhouse gas emissions, it found, are 24.4 per cent higher per kilogram of produced meat in the ECC system. Under both systems, feed is the primary source of greenhouse gas emissions. In fact, it accounts for about 90 per cent of total emissions.

Wolfgang Schleicher, Managing Director of the Central Association of the German Poultry Industry (ZDG), expressed additional concerns. He does not expect producers will even be able to get permission to build the additional barns needed to match current production. By German calculations, the per-bird cost of production will increase 36.7 per cent, and as a result, he expects the cost of breast meat to climb to €9.70/kg.

“ We expect as consequences, if we change to the ECC, we will lose self-sufficiency in the European Union,” Schleicher said.

The European Chicken Commitment requires signatories to commit to a list of requirements like maximum stocking density and adopting slower-growing breeds.

During her talk, Claire Bury, Deputy Director-General, DG Sante, criticized the study, saying that it does not weigh the costs against the overall benefits, nor does it include figures on the lower mortality rate associated with the ECC system.

Emma Calvert, senior food policy officer, The European Consumer Organisation (BEUC), agreed, adding that consumers want more welfare-friendly options. According to BEUC surveys, seven in 10 are willing to pay more for animal welfare products, she said, but to varying degrees.

“ We really want to see the European Commission come forward, finally, with the legislation – which they have promised to do – that will make higher animal welfare standards the case across the board,” Calvert said.

In a closing address, Paul Lopez, poultry expert and former AVEC president, echoed Schleicher’s concerns about not getting permission to build the 10,000 new poultry houses needed to compensate for lower stocking densities.

In his final comments, Lopez expressed concern about having to rely on imports from countries with unfair practices.

“ The rules are not the same, and it has a huge impact on the cost, on the way we want to have our agriculture, but also on the food on our table,” he said.

OCT 22, 2024

12:00PM ET

The Influential Women in Canadian Agriculture program honours women who have created lasting impacts on Canadian agriculture. Since 2020, the program has recognized 33 women who have positively contributed to the industry, whether actively farming, providing agronomy or animal health services, completing research, leading marketing or sales teams, and more.

The program receives dozens of incredible nominations every year, highlighting just how many influential women are working within Canada’s agriculture industry.

Join us in our annual virtual summit on October 22 at 12 p.m. ET. Featuring our hand-selected group of honourees and other prominent ag trailblazers, this free event will provide a platform for the exchange of knowledge and ideas as our guests share their thoughts through interactive sessions.

The technology is gaining global momentum, offering a groundbreaking solution to end male chick culling while boosting hatchery efficiency. By

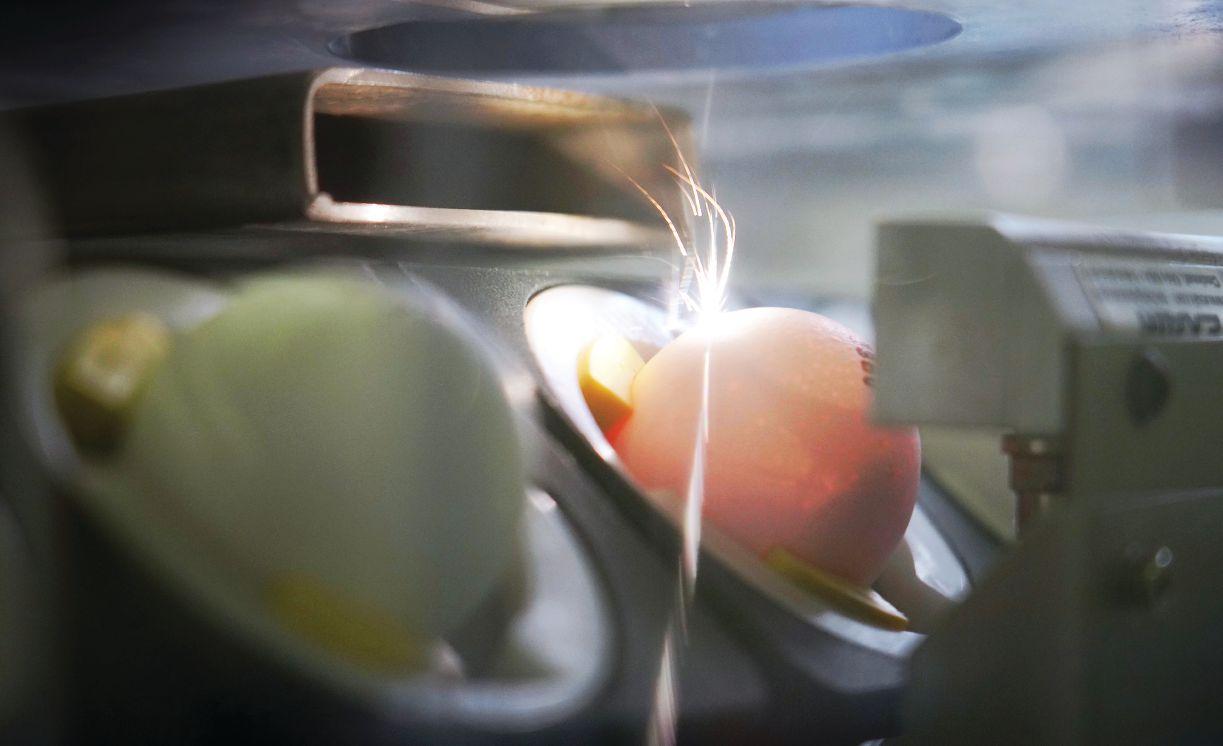

Over the last few years, in-ovo sexing technology has gained traction globally, particularly in Europe where the practice of male chick culling has been banned in Germany, France and Italy. In recent months, however, several US-based companies announced their plan to source in-ovo sexed chicks, following in Europe’s footsteps more quickly than expected. While there are multiple technological egg-sexing solutions in development, only five have seen widespread adoption. Each offers benefits, and presents challenges. Regardless, their adoption could be a gamechanger, especially as in-ovo sexing makes on-farm hatching and in-ovo vaccination more accessible since post-hatch sex sorting is no longer necessary.

Europe leads the way, the US follows According to non-profit think tank Innovate Animal Ag, as of September 2023, at

least 56.4 million of the then 389-million layer hen population was sexed in-ovo, a number that represents 15 per cent of the EU market. That number has continued to climb as hatcheries adopt available technology. At last count, 20 per cent of EU chicks had been sexed in-ovo.

In the United States, several major organisations and companies have expressed interest in adopting in-ovo sexing technology, but only when the technology is convenient and cost effective. In a 2021 statement from United Egg Producers (UEP), an organisation that represents 90 per cent of US egg production, president and CEO Chad Gregory said their search for an ethical, economically feasible alternative to male chick culling will continue. In a follow-up conversation at the 2024 International Egg Commission conference, held in Edinburgh, Scotland in April, he said UEP still hadn’t found the right solution.

“We remain hopeful a breakthrough is

on the horizon,” he said. “We will continue our engagement with stakeholders and active support of this goal.”

Two companies announced they’d be

adopting in-ovo sexing technology in the very near future though. In April of this year, John Brunnquell, founder and CEO of Egg Innovations, announced his intention to source in-ovo sexed chicks by Q1 of 2025. In a follow-up interview, he explained that no hatcheries have adopted in-ovo sexing technology as of yet. He believes that the US will have a bias towards the non-invasive solutions. While he believes the commercial hatcheries will get on board, he’s working on a Plan B in case they don’t in time for his self-imposed deadline.

“One way or another we’re going to do this,” Brunnquell said in an interview. “We’re waiting to see who would like to join us in this journey.”

One month later, Kipster, a Dutch climate-neutral egg producing that moved into the US in December 2022, announced its intention to adopt in-ovo sexing tech-

In a keynote address at the International Egg Commission conference, Wageningen UR poultry economist Peter Van Horne adoption has picked up because the economics have improved dramatically. In the early stages of adoption, hatcheries charged €4.00+ per male bird,” he said. Two years ago, that price dropped to €3.50 per male bird. Currently, hatcheries charge approximately €3.10 per male bird.

“That’s the cost for sex determination per male bird,” Van Horne explained in a follow-up interview. “I added on the cost of the pullet – the farmer has to pay €3.20 more for the pullet – so the pullet goes from €4.00 to €7.20.”

nology this fall, although it did not mention which solution it has chosen.

Cost of adoption has also improved because there’s more competition as well. The industry’s five biggest players – Ella by In Ovo, Genus Focus by Orbem, Respeggt by Respeggt Group, Cheggy by Agri Ad-

Guide to the Feeding of Organic Farm Animals aims to translate the science of feeding organic livestock and distil it into practical guidance for farmers and producers.

Sections of the book cover poultry, pigs, attle, sheep, and goats, reviewing the utritional requirements of the species, entifying suitable ingredients and feeds, overviewing husbandry techniques and ystem approaches, providing advice on electing suitable breeds, and advising on utrition and its relationship to health with a preventative approach.

vanced Technologies, and PLANTegg by Hatchtech Group – have made significant improvements in terms of speed and scale, as well as a reduction in sexing errors.

“We have more companies and we have competition now between those companies, so that’s also reducing the price,” Van Horne said.

Introduced to the market in 2020, Ella is currently in use in hatcheries in Belgium and The Netherlands. The company has identified a unique biomarker that distinguishes male from female embryos inside the egg at an early stage of development. This is done at stage of development where embryos cannot perceive pain, explained Martin Enderink, Global Sales Director at In Ovo.

“From an ethical of view, if you look at the development of an embryo in an egg, I think the earlier, the better,” Enderink said.

Ella is suitable for both brown and white layer breeds.

Respeggt Group developed the first inovo sexing technology on the market. At around day-nine of incubation, hatching eggs are removed from the incubator. Laser technology that Respeggt calls “the Circuit,” is used to create a 0.3 mm hole in the shell of each fertilized egg. From there, a small amount of allantoic fluid is then extracted from the egg and placed in an external marker. The hole is then sealed with beeswax. The extracted liquid is assessed using PCR analysis to determine whether the hatching egg is male or female. The information is sent automatically to the sorter. Male hatching eggs are pro -

cessed into feed, and female eggs are returned to the incubator.

“Our accuracy rate currently is about 99%,” said Silvin Faulstich, business development manager at Respeggt. “But there’s still ways to get closer to the 100% mark.”

Other solutions include Cheggy, a fully automated machine that uses hyperspectral imaging technology to identify the gender of brown layer lines by analysing embryonic plumage colours. Similar to Respeggt, PLANTegg collects and tests allantoic fluid and PCR tests it to determine genetic differences. Genus Focus by Orbem uses a non-invasive magnetic resonance imaging (MRI) solution that determines gender between day 12 and 23 at a throughput of 24,000 eggs per hour.

Research and development continues. The University of Minnesota researchers are using an artificial intelligence platform combined with a 3D scanner that analyses the geometric shape of eggs. It also uses proton transfer reaction mass spectrometry to analyse volatile organic compounds and other molecules.

KU Leuven in Belgium is looking into a gender specific volatile detection technique to determine sex in-ovo. Similarly, the USDA-ARS is using fibreoptics and machine learning for the analysis of volatiles that assist in gender determination.

SensIT Ventures Inc. is working to develop a microchip-based sensor for early-stage gender determination. Researchers are capturing and characterising gases released from individual eggs during

storage and incubation. They are hoping to develop a chemical sensor chip to detect volatile organic compounds and use machine learning to classify the eggs by gender.

Here in Canada, Egg Farmers of Ontario and Egg Farmers of Canada partnered with MatrixSpec Solutions to bring to market a revolutionary technology that aims to offer a solution to the complex issue of ending male chick culling.

The research and development of the technology, HyperEye, has taken 10 years and is now in the final stages of development, according to Donna Lange, director of public affairs, Egg Farmers of Ontario. The made-in-Canada innovation is close to the commercialization stage, she said, and is expected to be available to hatcheries worldwide.

HyperEye offers a non-invasive method to detect egg fertility and gender pre-incubation. Since the scanning is undertaken pre-incubation, eggs identified as non-fertile or in the case of male eggs, can be used as table eggs. This, of course, depends on the country’s legislation. It could also be used as an industrial product or as highgrade animal feed.

The technology is stand-alone and can therefore be built into the processes of normal hatchery operations or any other position within the entire lay to hatch process, Lange explained. It can also be used in both egg and broiler hatcheries.

“This method of sexing eggs is done without any form of gene modification or editing, and without affecting the integrity of the egg,” Lange said. “Not only does this technology mean hatcheries will be able to address animal welfare concerns and respond to new government legislation, it will also help accelerate the industry’s sustainability efforts by reducing waste and increasing the food supply.”

While MatrixSpec has met all of its development milestones of the last year, Lange was unable to provide an estimated timeline for HyperEye’s release.

Sharing of employees, equipment, and/or service providers is likely responsible for the majority of HPAI spread that occurs from one premise to another.

Fall migration is a great time to evaluate your biosecurity practices and review compliance across your team of workers and service providers.

Understanding the past, present and future of welfare standards in poultry production.

By Treena Hein

Poultry producers in Canada must care for their birds according to their respective Animal Care Programs (ACP), which are aligned with the Codes of Practice created by the National Farm Animal Care Council.

There are also various external audits required by restaurant and retailers for their contracted producers, generally arranged through the processing plant and involving catch and transport, explains Alberta-based certified welfare auditor and trainer Jennifer Woods. Farmers undergoing these external audits typically work with a company veterinarian before and throughout the audit process.

Woods is the owner of J. Woods Livestock Services in Foothills, Alberta, and one of only two people in the world to have five accreditations (meat plant, beef feed lot, dairy, poultry, swine on farm, air transport of animals) from the Professional

Animal Auditor Certification Organization. She has been in the field for 26 years and is also head welfare auditor for the Calgary Stampede.

Looking at the future of external audits, Woods also reports that a standard version is being developed for Canada, similar to what is has been developed by the National Certification Corporation in the U.S.

Examining the history of welfare programs, Dr. Kate Barger-Weathers of KB Welfare Consulting in South Carolina explains that they originated from three sources.

These sources are industry groups that desired to set national standards, companies that wanted to achieve specific expectations for all the animals under their care, and government agencies that believed in the necessity of legislated standards for improving outcomes across the board.

Barger-Weathers explains, how-

ever, that in recent years, others have influenced welfare standards criteria. “These groups include non-governmental organizations (NGOs), supply chain partners, consumers and civil society organizations,” she observes.

Each of these may have different perspectives and goals with regards to the entire spectrum, from defining the main welfare challenges and how to address them, which standards should be used, the practicality of change – to the projected improvements in welfare if changes are made, and the implication (cost, sustainability etc.) of making changes, for both producers and the food production system.

“In addition to the diversity of thought that’s influencing the evolution of welfare standards,” she adds, “the reasons for proposing these changes are also variable. For example, companies within the poultry industry regularly advocate for continuous improvement via

“Companies within the poultry industry regularly advocate for continuous improvement via their own policies, national welfare standards and supply chain welfare expectations.”

their own policies, national welfare standards and supply chain welfare expectations. The basis for this change is grounded in practical experience, scientific knowledge, implementation of innovative technology and evidence-based trials.”

At the same time, she notes the existence of independent pressures to change welfare standards that often originate from those who’ve never stepped foot on a farm or have limited experience in the daily decisions of poultry production.

“For example, in recent years, NGO advocacy campaigns have focused on changing inputs for poultry production (breed used, stocking density, type of stunning methods, housing type, lighting intensity, etc.) as a means of advocating for their agendas and creating major change for national and multi-national food companies,” explains Barger-Weathers. “While these bold

changes have resulted in major commitments from food companies, the change does not guarantee improved welfare outcomes.”

She also notes that proposed changes may not be possible to implement within proposed timelines – and furthermore, often produce unintended consequences that are in direct conflict with sustainability goals and the business strategy of the producer and the supply chain.

In terms of best advice for farmers to meet welfare program criteria, Woods urges the achievement of a full understanding of each of them and how they are measured. She adds that Egg Farmers of Canada, Chicken Farmers of Canada and the provincial boards have ACP educational initiatives available but advises to also work with your veterinarian and the verification auditors.

Overall, farmers should always be audit ready. “That means knowing the standards well and staying on top of things like stocking density, euthanizing lame animals and so on,” Woods says. “Do some practice audits, especially before your first actual audit.”

Dr. Hayley Bowling with Prairie Livestock Veterinarians in Red Deer and Lethbridge Alberta, also strongly advices producers to be familiar with the Codes of Practice. “I would pay special attention to the orange text boxes throughout the documents,” she says. “These indicate baseline requirements for all poultry in Canada. There is also a list of these requirements at the end of the appendices.”

Barger-Weathers considers the 3M approach to be effective, with its focus on welfare metrics that can be monitored, measured and managed. Monitoring can involve a myriad

Welfare criteria at a glance

According to Barger-Weathers, examples of key poultry welfare indicators include:

• Footpad condition for broilers;

• Stunning efficiency/ effectiveness in the processing plant;

• Feather condition of laying hens;

She adds that the best welfare criteria are:

• Based on outcomes;

• Can be objectively measured;

• Utilize a known scoring guide (or scientifically based reference for benchmarking) to determine if the outcome is acceptable; and

• Allow the outcome to be reliably and repeatably evaluated.

While key welfare indicators have long been assessed by trained observers (using a sample size, with results extrapolated), future assessments using automated software, camera and sensor technology will allow more accuracy and efficiency.

of people who work at the production site. For example, air quality and litter quality can be monitored daily as a farmer walks the flock. In the processing plant, monitoring bird activity (wing flapping) and thermal stress (panting) during lairage and at unloading can be monitored during each shift to assess bird comfort.

Measuring involves using a tool to objectively verify what is being monitored. In the case of air quality, a farm manager or internal auditor can use various devices to verify they are within the expected range.

In processing plants, a thermal camera can be used to objectively evaluate conditions of birds and the lairage area.

Managing results involves analytics of the data to determine what changes are needed (if any) based on what has been monitored and measured. To continuously improve welfare outcomes, the data management process may result in corrective actions, adjusting protocols and guidance documents, or continued benchmarking of the outcomes.

Barger-Weathers adds that “from a practical perspective, managing welfare metrics also means ‘connecting the dots’ to help all understand how they can help improve outcomes. That is, if air quality and litter quality are improved on the farm, the resulting footpad condition metric will also improve.”

Drawing on her extensive auditing experience, Woods encourages producers to ensure training records and Standard Operating

Procedures are all recorded properly. “That’s probably where there is the biggest gap in audits,” she explains, “so make sure you know what is required and that is all ready and organized before the audit.”

For her part, Bowling says she sometimes sees confusion or room for improvement among producers around humane euthanasia. Producers understanding approved methods, training, decision making regarding when to euthanize, and how to confirm that euthanasia is successful.

Likewise, she sees room to improve in the areas of transportation (which birds should be shipped vs. euthanized on site, etc.) and lighting (duration of darkness required for broilers, intensity required for laying hens, etc.).

Bowling adds that “it’s always recommended to have an ongoing relationship with a veterinarian experienced with poultry, so that if a producer has questions related to health or welfare specific to their site, they have someone familiar with their operation who can provide guidance.”

In the end, in Barger-Weathers’ view, there will be stumbling blocks to success in achieving welfare standards when they’re perceived to be a marketing ploy, are intended to provide a specific perception about a product, or don’t align with what production managers know to be necessary aspects of animal care. Conversely, “when animal welfare is a holistic part of farm animal production and supply chain relationships,” she says, “positive and incremental changes can occur.”

Location

Grey County, Ont.

Sector

Pullets

Swan Creek Pullet Farm, located in Elora, Ont., is a new venture run by Dave and Bob Ottens. The farm supplies pullets for their own cage-free layer operations and other producers. “It’s a new pullet operation to provide pullets for our layer operation,” says Dave Ottens. The family has been in poultry farming for over 20 years, primarily in pullets and eggs. Dave’s daughter, Kourtney, and Jim Swanston will manage the state-of-the-art barn.

The expansion of their cage-free production led to the decision to build this new barn. “We’re expanding in the cage-free industry, and we need cage-free pullets,” says Dave. They previously sourced pullets from other producers but decided to internalize this part of production to better meet growing consumer demand for cage-free eggs.

The new pullet barn features a cutting-edge system from FK Poultry specifically designed to prepare pullets for aviary layer housing. The facility boasts unique, flexible, three-piece door designs, which ensure producers have easy access to the pullets for management purposes. It also features novel epoxy-coated floors for a more comfortable surface. In addition, a custom remote-winching system reduces labour demand. They placed their first birds in early September. Barn

By Frank Luttels

Floor systems are used by many organic and specialty egg producers looking to distinguish themselves from bigger producers who utilize more large-scale systems that maximize bird density. As a result, these floor systems are often marketed as a more natural and bird-friendly environment, due to lower house density.

This marketing approach has prevented many smaller producers from considering aviary systems, despite some of the proven bird welfare benefits they offer, such as manure belts, different levels and perches that promote natural bird behaviour and good hygiene. The thinking is that these aviaries may appear too cage-like and overcrowded for consumers in their target market. In some cases, the integrators may specifically prohibit the use of aviaries in floor systems to help avoid these perceptions.

However, more organic and specialty operations are discovering benefits through all the experience farmers have with less-intense systems in Europe — especially in Switzerland — that have been on the market since the 1980s. These systems can aid natural bird behaviours, create a more hygienic environment and generate more revenue without sacrificing any of the unique marketing advantages of floor setups.

The early style of system that was introduced in Switzerland has a multi-tier design. The lower level offers space for nat-

ural bird activities, such as scratching and dust bathing, and the top includes perches for sleeping. More tiers can be stacked as desired.

Unlike the complex multi-tier aviaries used by many of the larger cage-free egg producers, the modified floor systems do not have integrated nests. The configuration preferred by many specialty producers is two rows of multi-tiered systems along the walls of a house with nests located down the centre, providing a separate area for laying.

One example of this setup is ChoreTime’s Vike Tradition aviary system in conjunction with Valego Pagoda nests. Although a system like this may sometimes be referred to as an aviary, producers who

wish to avoid aviaries should not let semantics get in the way of decisions. After doing the research they’ll likely find that the upgraded systems continue to meet all the requirements of floor systems.

Those who have upgraded their floor systems with the multi-tiered system have found an improvement in bird welfare. Much of this is credited to the upper perches. Birds naturally seek higher spots to sleep, so they prefer the tree-style design, in which they can easily access the upper level from the bottom tier.

Not only do birds like to use the upper perches for sleeping, but birds that are being bullied will also use the perches to

This Thanksgiving, join us in celebrating the 50 th Anniversary of Turkey Farmers of Canada. We extend our thanks to the dedicated farmers who make our Thanksgiving meals special. Here’s to the tradition, quality, and joy of Canadian turkey!

seek safety. Offering this space may help reduce mortality from pecking.

Having these systems installed does not take away from floor activities either. The floor level still allows ample room for ground sourced pecking, scratching and dust bathing. By performing these types of natural behaviours, the birds are less prone to peck at each other.

Additionally, easy access to food and water is maintained in the multi-tier design. Integrated feeders and drinkers are included on multiple levels, offering plenty of options, no matter where birds are located in the system.

Another benefit of upgrading floor systems is the improved climate, thanks to manure belts that remove litter daily. This feature greatly reduces ammonia levels within the house compared with traditional floor systems, which may generate over 16 months’ worth of manure before it can

be cleared out when the house is empty. Not only is a hygienic environment a great benefit for bird performance, but producers will also appreciate the reduced labour per bird. Multi-tier systems eliminate the need to raise equipment and remove slats to take out the litter. And, as a whole, all other cleaning and preparation in between flocks is simpler. Many of today’s multi-tier systems and nests are designed to wipe down easily with great access to all components.

The separate nests offer many of the advantages of those found in larger aviary systems. Many of today’s nests are made of high-quality materials, such as film-faced plywood and stainless-steel legs, for long-lasting corrosion resistance. Many other features are built in for easy inspection, maintenance and cleaning.

Multiple nest configurations are available, including the choice of different egg belts, expellers and more. Producers have plenty of options to meet their house requirements with a nest that provides a safe and quiet environment for birds, adding to house comfort.

By upgrading their floor systems, some specialty egg producers are able to increase the number of birds in their houses by 40 to 50 percent without increasing the overall density. That’s because the multiple levels of a tiered system add to the total square footage of living area within the house, allowing more birds to be added while maintaining the same amount of square footage per bird.

Adding more birds to existing houses generally offers the greatest economic advantage for those looking to expand their flocks and generate more income. Building costs have soared in recent years, making a difficult return on investment scenario for putting up new houses. This is especially true in Canada, where construction costs are even greater than in other markets due to higher snow load requirements.

When it comes to labour, the upgraded systems typically require the same amount of management as floor systems, despite supporting a larger number of birds. As a result, producers don’t need to hire additional workers, and profitability can be improved.

Although today’s organic and specialty egg producers prefer floor systems, the bird welfare benefits of the multi-tiered systems are hard to ignore. Not only do birds perform better when perches are available, but the integrated manure belts and separate nest systems provide a superior environment to help them thrive. The added bonus, of course, is the higher profit potential, which can help sustain the business model of smaller producers. Considering all the advantages of these hybrid systems, it may be time to start exploring upgrade options with integrators.

Frank Luttels is layer product manager for Chore-Time.

Eastern Canada: sales@county-line.ca 519-291-5012 www.omnivorecomposter.com

Western Canada: info@agprowest.ca 604-746-5376 www.agprowest.ca

Central Canada: info@caldorapoultryequip.ca 431-205-3365 www.caldorapoultryequipment.ca

By Eduardo Souza

Poultry welfare and sustainability go hand in hand to ensure a reliable supply of robust broiler breeding stock for producers worldwide. This synergy supports food security by enabling them to consistently provide local communities with healthy and affordable chicken meat. Over the years, innovations in poultry breeding have championed animal welfare while also boosting the economic success of producers.

B alanced poultry breeding means that desirable genetic traits are all promoted simultaneously, and it is crucial to ensure the development of healthy, efficient chickens that meet the highest standards of animal welfare.

By focusing on these principles, we can produce birds that are sustainable, using fewer resources, and generating less pollution and a lower carbon output. This approach also supports economic sustainability by lowering the cost of poultry production.

Maintaining a diverse gene pool is crucial for empowering poultry producers to meet both current and future market demands. This genetic diversity allows primary breeders to offer the right bird for the right market at the right time.

Close collaboration between

poultry breeders and their customers keeps breeders attuned to market trends, enabling them to address present needs while preparing for future challenges.

By adopting the latest technologies, modern breeding programs have seen significant improvements. Tools like computed tomography (CT), x-ray and ultrasound – many adapted from human medicine – have greatly enhanced our ability to select healthier birds. These advancements have also led to greater performance in areas such as meat yield and a healthier growth rate. Genomic selection further sharpens the accuracy of trait selection, making breeding

more efficient. Over the years, a focus on research and development and innovative technologies has continually advanced bird health, performance, and efficiency.

A significant achievement in broiler breeding has been steady improvement in feed efficiency. The Lifetime Feed Conversion Ratio (FCR) innovation, which uses transponders and electronically monitored feed stations, has significantly enhanced feed efficiency. By focusing on FCR, we’ve achieved an annual improvement of 1.5 to two points, leading to a one per cent yearly reduction in the carbon footprint of global poultry production. This advancement not only

contributes to environmental sustainability but also supports the economic sustainability of poultry businesses, as feed represents their greatest cost.

Animal welfare and performance heavily depend on cardiovascular, leg, and foot health. Since the 1990s, technologies like the lixiscope and oximeter have been used to identify birds at risk for leg defects and cardiovascular issues. Strengthening leg health and cardiovascular function improves livability. Additionally, since the early 2000s, genetic selection has been employed to alleviate footpad dermatitis.

Real-world trials and field tests under various conditions help poultry breeders identify which birds perform best in different commercial environments. These trials generate valuable data that improve selection accuracy and drive ongoing genetic progress.

B alanced breeding has consistently strengthened poultry health, welfare, and performance, ensuring a safe and sustainable supply of a nutritious food source. These developments support producers and families in their global communities now and for decades to come.

A unique coccidiosis vaccine that balances the safety and efficacy needed for poultry that are raised without antibiotics, or in management programs to reduce resistance against anticoccidials.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic IBD and AL-2.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative or visit PoulvacProcerta.com.