Colin Breukelman reflected on his decision, saying,

‘The

New welfare assessment tools International Poultry Welfare Alliance unveils guide series.

New understanding of yeastbased additives for gut health.

makes sense Five reasons poultry barns should go solar.

by Brett Ruffell

Leading up to this past spring, many in the industry were bracing for another wave of highly pathogenic avian influenza (HPAI) infections.

Experts expected this because the H5N1 strain that spread across the country has been so persistent globally.

But aside from in Quebec, things were relatively quiet compared to last year. And now in its latest report released mid-summer, the World Organisation for Animal Health (WOAH) said that the HPAI situation in Canada’s poultry flocks was resolved.

A commercial pigeon farm in Chilliwack, B.C., was released from its primary control zone (PCZ) mid-July. Prior to that, the last PCZ to be released was at a turkey farm in Rouville, Que., earlier that month.

Still, one expert says we must remain watchful. “What WOAH is basically saying is that all of the outbreaks in Canada have been resolved,” says Dr. Shayan Shariff, an avian immunologist with the Ontario Veterinary College.

“That doesn’t provide any assurances that it would not return,” he continues.

In fact, he says globally HPAI is still quite active. What’s more, he adds that looking back to last year, Canada saw a major reduction of the virus in the summer only for it to return in the fall. Could it re-emerge this year, too? “That remains to be seen

but I don’t think you’re completely out of the woods,” Sharif says, adding that producers should remain cautious and continue to follow biosecurity best practices.

Another reason to be careful is the deadly disease is infecting mammals.

In fact, the National Microbiology Lab worked with the Canadian Food Inspection Agency (CFIA) on first of its kind research around this topic, the results of which were published this summer.

for business and maintaining their flocks, but it is also good for themselves,” Sharif points out.

According to WOAH, about 7.7 million birds have been affected by HPAI since the latest outbreak began on an exhibition farm in Newfoundland in late-December 2021. Since then, it has spread to every province and territory.

Looking back on Canada’s efforts to stop the virus, Sharif commends the job CFIA has done cooperating with producers and international colleagues.

“The virus is a smart virus, but we’ve been able to, by and large, contain it to the best of our capacity,” he says.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

“If mammal-to-mammal happens and the virus can sustain that chain of transmission then that would be disconcerting.”

Researchers found that one of the strains of H5N1 spread easily by direct contact from mammal to mammal and caused severe disease in ferrets. This was the first research study showing strong mammal-to-mammal transmission in a lab setting. “If mammal-to-mammal happens and the virus can sustain that chain of transmission then that would be disconcerting,” the immunologist says.

And since producers work closely with poultry, they have their own personal health to think about when it comes to avian influenza.

“So, that’s why keeping our guards up and implementing good biosecurity is not only good

On another note, I want to remind you of an exciting new opportunity from the agriculture brands at Annex Business Media as we continue to expand our Influential Women in Canadian Agriculture (IWCA) program.

Held virtually since 2020, the IWCA Summit provides valuable discussions on balance, communication, and leadership. Now, for the first time we’re bringing people together in person to celebrate the achievements of women in Canada’s agricultural industry.

Join our six IWCA honourees in Hamilton, Ont., on November 7th. Featuring our hand-selected group of honourees as well as other prominent ag trailblazers, this event will provide a platform for invaluable mentorship and networking as our guests share their experience, life lessons and much more.

Visit agwomen.ca for more information and to register. I hope to see you there!

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes) USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Glass-Pac Canada St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

Ontario chicken farmers made a donation of 600 kilograms of chicken, which will contribute to over 5,000 meals for families and individuals in need, through The Mississauga Food Bank. In response to a public request for donations due to the soaring number of families needing to utilize The Mississauga Food Bank, chicken farmers worked swiftly to ensure The Mississauga Food Bank had chicken in their possession to distribute to families and individuals in need.

Cobb-Vantress recently announced the appointment of Bernardo Gallo to lead its newly formed Latin American Canada business unit, joining the Cobb leadership team effective immediately. Gallo, a Brazilian native and poultry veterinarian, has broad experience spanning across multiple leadership roles within Cobb as well as previous company experience across sales, technical leadership, nutrition, and veterinarian services with Tyson Foods, BRF, Cargill and Globoaves.

This summer, a meeting of Australian agriculture ministers agreed to phase out the production of battery eggs by 2036, in accordance with the new national animal welfare standards and guidelines for poultry. The industry and its supporters were in uproar, saying that they needed more time to adjust to avoid financial penalties for farmers and consumers. Animal welfare activists, meanwhile, said the timeline is too long.

Canada and Ontario committed up to $7.5 million to support biosecurity measures to enhance food safety.

The governments of Canada and Ontario are investing up to $7.5 million through the Sustainable Canadian Agricultural Partnership (Sustainable CAP) to help eligible agri-food businesses and contributors enhance their biosecurity measures to support animal and plant health, and food safety.

or the Biosecurity Enhancement Initiative is a new cost-share offering that will help agri-food businesses protect their operations against disease.

The Biosecurity Enhancement Initiative (BEI) is a new, cost-share offering that will help farmers, food processors, and other essential farm-supporting agri-food businesses protect their operations against disease, enhance operational resilience and heighten public trust in the food supply system.

A safe and stable supply chain requires strong biosecurity.

To support Ontario in this goal, as outlined in the Grow Ontario Strategy, this initiative will be available to entities such as veterinary clinics, livestock auction barns and commingling facilities, grain elevators, seed treatment facilities, and transportation providers.

Examples of eligible projects include establishing or improving

cleaning practices, creating isolation facilities, constructing wash bays for disinfecting and training to support the mitigation of biosecurity risks in food production.

Under the BEI, the maximum amount of funding available and the proportion of cost-share funding for projects depends on the activity supported.

This initiative was developed following discussions with agri-food sector businesses and organizations. It also follows investments of approximately $3 million to enhance biosecurity and emergency preparedness in Ontario’s pork sector.

“In our Grow Ontario Strategy, we identified that new technologies, best practices and biosecurity measures will strengthen Ontario’s agriculture and food industry,” says Lisa Thompson, Ontario Minister of Agriculture, Food and Rural Affairs. “By ensuring the industry can embrace these protocols, consumers can trust that the highest safety standards are employed as Ontario produces some of the best sources of food available around the globe.”

The VALLI BABY AREA is ideal housing for the intensive rearing of pullets, with all main components built right in, while the VALLI COLONY SPACE allows you to customize your multi-tiered configuration from 3 - 12 floors.

Valli-Italy operates on the premise of passion and quality to ensure each producer receives the ideal system for their operation.

By Lilian Schaer

Livestock Research Innovation Corporation (LRIC) fosters research collaboration and drives innovation in the livestock and poultry industry. Visit www.livestockresearch.ca or follow @LivestockInnov.

Improving how the livestock sector can get research into practice brought approximately 60 people together for a daylong event earlier this year hosted by Livestock Research Innovation Corporation (LRIC) in Elora, Ont.

The mixed format featured presentations from various speakers including LRIC CEO Mike McMorris, Dr. Steven Roche of Acer Consulting, and noted U.S. extension specialist Dr. Alison Van Eenennaam from the University of California Davis.

“Most Ontario livestock and poultry producers, through their service fees or checkoffs, support research in their respective sectors – but we recognize that more needs to be done to get those research outcomes into use on-farm,” says LRIC CEO Mike McMorris. “Working on how to do that collaboratively has been a priority over the last two years for LRIC and the industry.” Extension – also known as

technology transfer, getting research into practice (GRIP), knowledge mobilization or knowledge translation and transfer (KTT) – has evolved in Ontario since the 1990s, when the provincial government, in a situation not unique to Ontario, dramatically reduced its funding for these types of activities.

In the livestock and poultry industry, gaps were filled by a variety of businesses and organizations, including veterinarians, nutrition companies and producer groups, leading to discrepancy of service levels between sectors. Overall, although a lot of people are involved in GRIP, there is a lack of coordinated planning and execution, and there is consensus that industry, government and academia need to collaborate on both research priorities and sharing research outcomes.

Dr. Steven Roche of Acer Consulting has done considerable research into what motivates change and how researchers can do a better job at engaging with farmers and making re-

“More needs to be done to get those research outcomes into use on-farm.”

search outcomes applicable on farms. Ultimately, he notes, it comes down to people, relationships, and understanding the needs and mindsets of livestock farmers and their supply chain. There needs to be more direct interaction between producers and researchers to build understanding of one another’s worlds.

Alison Van Eenennaam is a professor of cooperative extension at University California Davis and has become an expert at melding her research program with extension work over her more than 20-year career. Knowing her audience and what resonates with them has been key to her success, as has recognizing that her research needed to be applicable to farmers.

“Sometimes, the incentives we have as researchers don’t reflect the translational impact on industry of what we are

doing,” she said in highlighting a genomics project she worked on with a large U.S. beef producer that has had a dramatic impact on the livestock industry, but very little scientific outcome in terms of published papers for the research team.

“For me as a scientist, the best project has industry relevance but is also intellectually intriguing. I have to get a (publishable) paper out of it, but it needs to have a business interest to the company involved,” she added.

Together with Jennifer Ellis from the University of Guelph and Poultry Industry Council, LRIC has developed a new library of resources to help the livestock and poultry industry get research and innovation information directly to the farm.

More than 20 producer perspective videos showcase farmers from a variety of livestock sectors and their challenges and how they think researchers can best support driving adoption of innovation on the farm.

A 10 podcast series features interviews with researchers and industry leaders on their work with innovation, their experiences with which approaches work and which do not.

These resources, as well as LRIC’s Horizon Series of webinars and white papers focused on the big issues affecting livestock agriculture, are available on the LRIC website, livestockresearch.ca.

This article is provided by Livestock Research Innovation Corporation as part of its ongoing efforts to report on research developments and outcomes, and issues affecting the Canadian livestock industry.

By Mary K. Foy

Acommon question I am often asked is “What’s new in water?” I started working in the poultry industry in 1994 and in those 29 years there has been a lot of “new in water”. Research and practice have taught us all how vital water is to feed conversion and the health of our birds.

As growth and performance efficiency have improved, the demand for quality water has increased significantly. No longer can we fill an open trough with water and leave it for a few days. The advancement of the water systems on our farms has some of us operating what feels like miniaturized city water treatment systems!

With all the new companies and products that have entered the market in the last few decades, what innovations should you be focused on when it comes to providing water for your birds?

Water storage is an ancient tool. However, with the increased performance of our animals, we are finding an increased need for a consistent water supply. The drought in the plains of Canada in the early 2000s empha-

“As growth and performance efficiency have improved, the demand for quality water has increased significantly.”

sized the increased agricultural dependance on water. As a result, water storage has become a much more common occurrence than it used to be.

It can be as basic as a dugout that collects rainwater, all the way to 10,000-gallon tanks with their own heated buildings. This increase in the demand for storage has prompted an entire new industry that caters to a farmer’s requirements. It has also prompted the revamping of the laws and needed licensing for water storage in each province or territory.

If you are considering water storage for your farm, be sure to research what is allowed and the legal requirements for the type of water storage you plan to use.

Water treatment innovation is mostly focused on the safety and automation of the system being used. The basics of water treatment is choosing an oxidizer (hydrogen peroxide or chlorine) to treat the water

and, if needed, an acid to activate the chlorine by lowering pH or an acid to simply lower the pH in the water for various other reasons.

Beyond this, one needs to consider the safety, ease of use and required attention of a chosen system. There are several systems that use an electric water meter on the incoming water line to trigger the injection of a product into the water line through a pump. The goal here is to choose a system that can treat the entire farm, including underground water lines, and pull directly from the product container so you are not mixing stock solutions.

Choosing a treatment system that does not require the mixing of a stock solution or the excessive handling of products is considered a safer and more consistent alternative to the use of a medicator and stock solutions.

Digital communication is another advancement in water treatment. Several systems are able to communicate with an app on your phone letting you know product levels and allowing you to adjust injection rates remotely.

While many growers have been able to keep up with the amount of water their birds are drinking on a daily basis thanks to the controllers in the anterooms, most of us are still learning how that data is best utilized. Real time monitoring allows us to, again, use an app connected to a monitoring device to watch the water flow and volume in our barns. We are now able to quickly detect (or have an alarm for) a leak or no water flow at all right from our phone.

The graphing capabilities of some of these apps allows us to see trends in the water consumption that may help us head off an illness in the birds or a sneaking malfunction in the equipment. Depending on your needs, you can have volume, flow and/or pressure all reported to an app.

A look at how it’s made, new products, regulatory updates and more. By Treena Hein

Whatever consumers think of cell-cultivated chicken at this point – in terms of food safety, eating experience, cost, animal welfare, environmental impact and many other factors – it’s already available at two U.S. restaurants, with rollout to expand across the country in restaurants and then grocery stores.

Two California-based firms, GOOD Meat and UPSIDE Foods, received approval from the U.S. Department of Agriculture to sell their cell-cultivated chicken, which is the approved label term.

Before we look at the process and more, let’s review some other developments. As far back as 2020, U.S.-based cultivated meat developer Mission Barns offered the public stateside the chance to try bacon grown from pig cells. In July this year, the Netherlands government announced that it will allow cultivated meat and seafood to be taste tested.

Also this summer, global beef producer JBS SA announced it’s building the world’s biggest cultured meat plant in Spain. It will be owned by cell-cultivated meat firm BioTech Foods, which is majority owned by JBS SA. The facility will cost $41 million USD and is expected to be finished next year. JBS SA is also planning to build a $60 million USD-research institute in southern Brazil to develop cellular agriculture technology. BioTech did not respond to inquiries about what types of cell-cultivated meat will be produced at the plant in Spain or other matters, but media reports indicate 1,000 metric tons of product will be produced per year, with capacity to expand to about four times that.

GOOD Meat is the world’s first-to-market cell-cultivated meat company, and has been selling its products in Singapore for about three years. UPSIDE is owned by egg substitute company Eat Just.

To celebrate and launch their cell-cultivated chicken products, both firms recently hosted splashy dinners for the media and select paying customers in renowned restaurants with famous chefs. At a restaurant in San Francisco, tempura-fried UPSIDE cell-cultivated chicken was served with a burnt chili aioli. In Washington, D.C., diners sat down to enjoy charcoal-grilled GOOD Meat cell-cultivated chicken marinated with anticucho sauce.

GOOD Meat’s products are pre-cooked and come in shapes such as cutlets. “When we process our chicken into a finished product, we use heat and pressure to do so, which cooks the meat,” says Carrie Kabat, the company’s consumer communications director. “The [product] is then frozen to extend its shelf life.”

UPSIDE’s current filet product is not pre-cooked. “In the future, it’s possible we will have products that are both precooked and not pre-cooked,” explains a spokesperson.

The overall process involves selecting cells from a live bird or a cell bank and placing them in vats to grow and divide in a solution of amino acids, sugars, carbohydrates, vitamins and other nutrients.

UPSIDE uses cells from fertilized chicken eggs, and harvest takes place in two or three weeks. GOOD Meat uses fibroblasts (a type of cell that contributes to the formation of connective tissue) and cell banks as the starting point, with product ready in four to five weeks.

At this point, production at both firms is small, but scale up is coming. GOOD Meat can currently produce tens of thousands of pounds per year, but Kabat says “by the end of this decade, we aim to produce tens of millions of pounds…per year.”

She adds that at this point, GOOD Meat is not making a profit on products sold to restaurants, but “that will change as we tackle some the remaining technical and engineering hurdles inherent in large-scale commercial production.” They are working to decrease the cost of the growth solution and increase cell density, among other tasks.

UPSIDE can currently produce over 50,000 pounds of meat per year, with a future capacity at the present facility of over 400,000 pounds. The spokesperson reports “we’re currently in the site selection and design process of a larger-scale commercial facility that will be capable of producing millions of pounds per year.”

Right now, UPSIDE’s products are offered at a premium price, but its ultimate goal is to offer products that are more affordable than conventionally produced meat. Similarly to GOOD Meat, there is a focus on reducing the cost of the nutrient solution and finding other efficiencies in scaling up.

“We’ve already made tremendous progress on both of these fronts,” says the spokesperson, “and continue to invest in developing and testing new production processes to help achieve these goals.”

UPSIDE plans to partner with additional chefs and restaurants in the short term, while GOOD Meat plans to do the same things it’s already done to successfully develop its market in Singapore.

“There, our chicken has been featured on

menus at fine dining establishments, popular hawker stalls, via the ‘foodpanda’ delivery platform and most recently by reservation at Huber’s Butchery, one of Singapore’s premier producers and suppliers of high-quality meats,” Kabat reports. “Thousands of dishes, ranging from crispy strips

Ziggity makes upgrading your watering system fast, easy and affordable with its lineup of drinkers and saddle adapter products, designed to easily replace the nipples of most watering system brands with our own advanced technology drinkers. So if your watering system nipples show signs of wear, leaking and poor performance, just upgrade to Ziggity drinkers to start enjoying improved results! See how easy it is and request a quote at www.ziggity.com/upgrade.

“We recognize it will take time for people to come around to this new way of making meat.”

and curries to skewers and salads, have been sold in Singapore, and have received universally high marks from diners.”

Making the product available to try is a critical aspect to the GOOD Meat marketing plan. “Based on what we’ve seen in Singapore and in private tastings at our headquarters in the San Francisco Bay Area,” Kabat says, “we know that tasting is believing, so we want to allow as many people as possible to try our [product].

“As more people try it and enjoy it, the more accepted it will become. We believe there will be high demand for [cell-cultivated] meat in the years to come. We envision a world where

consumers will have a choice between conventionally produced meat, [cell-cultivated] meat and plant-based meat.”

Similarly, UPSIDE wants its products to be available everywhere normal meat is sold, with the public viewing it as equally suitable for enjoying at a Michelin Star restaurant or a backyard barbeque.

“Education is a top priority,” says the UPSIDE spokesperson. “We recognize it will take time for people to come around to this new way of making meat. That means our job, from a communications perspective, is to have conversations like the one we are having now, and to make sure consumers have access to the facts.

“At that point, we trust people to make the purchasing decisions that make the most sense for them – and we think many of them will choose cell-cultivated meat because of the value add. Ultimately, the real magical moment happens when someone sees the [cell-cultivated] meat, hears it sizzling and tastes it. The more these moments happen, the greater consumer enthusiasm will be.”

Interestingly, the cells used to produce UPSIDE chicken come from a heritage chicken breed. This is not surprising, as many people view heritage chicken meat as much more flavourful than that of conventional commercial chickens.

When asked about his views on consumer appetite for cultivated chicken, JJ Hochrein, director of brand marketing at Chicken Farmers of Canada, says that while it’s captured a lot of media attention, “other than the curiosity factor, it is unclear if consumers will really want to consume it on a regular basis.”

He adds that “the environmental impact of cell-cultivated chicken is still unknown and can make cell-cultivated meat not acceptable to consumers, especially for chicken, which has the lowest carbon footprint of all livestock.”

There’s a growing body of research assessing the use of pecking blocks for broilers to reduce feather pecking. Now, scientists have started testing them in enriched layer housing.

By Ronda Payne

Laying hens naturally forage. Without options to participate in this behaviour, they often resort to flock-harming activities like pecking each other, which can increase injury and mortality in fellow birds. Pecking blocks are proving to be a better solution than the code-required scratch mats.

While European and Canadian farmers have already begun using enrichment devices like pecking blocks in non-cage housing systems to enhance foraging, the research in this area is sorely lacking. That’s where Tina Widowski, a professor in animal biosciences and core faculty member at the Campbell Centre for the Study of Animal Welfare for the University of Guelph, comes in.

She is involved in a study assessing the ways packing blocks can be best used in enriched housing colonies to improve animal welfare.

The job of a laying hen

“The code of practice for laying hens requires supporting of foraging behaviour. In enriched colonies, hens are only given scratch mats at this time. Scratch mats can become soiled with feces and they do

not provide much variety,” Widowski says.

“Under natural conditions, hens spend 60 to 70 per cent of the day foraging. This is their ‘job’ – looking for food. When they are provided all of their food in a concentrated form, they have no job, so they redirect foraging behaviour at each other’s feathers, leading to feather pecking and poor feather coverage.”

When the code of practice was being researched, finding ways to optimize enriched housing to better support natural behaviours like foraging was identified as a need. While scratch mats were the first solution implemented, Widowski and others think pecking blocks are a better option.

Leanne Cooley, poultry scientist and Poultry Animal Auditor Certification Organization auditor with L.H. Gray & Son Limited, sees tools like pecking

blocks in enriched environments as a beneficial solution.

“L.H. Gray & Son Limited Farms have always provided a variety of pecking enrichments in our cage-free barns,” she says. “Historically, these ranged from items like hanging bales of forage (hay), to insoluble grit, to hanging colourful plastic bottes and shiny CDs.

“In 2017, we began routinely using Vilofoss PECKStones. In 2021, we began evaluating Alltech ChikPek blocks, and in 2023, we were introduced to Probiotech’s Happy Block. Presently, we only offer supplemental pecking enrichments in our cage-free barns.”

The problem of feather pecking

Widowski says a previous study, done before the Code of Practice for Egg-laying

Hens was updated to include scratch mats, showed that feather conditions in hens in enriched housing were worse when there was no scratch mat. But, as previously noted, scratch mats aren’t the best option.

No scratch mat or better option to meet the hens’ foraging need means hens will resort to feather pecking. Canadian farmers need to consider solutions like pecking blocks to ensure that natural job is fulfilled and, thereby, reduce feather damage as they make the switch away from battery cages.

While other variables have been associated with feather damage in large groups of birds, incorporating foraging options into enriched housing can make a difference with minimal flock disruption.

Mild feather pecking is natural in colonies for the establishment of pecking order (this is where the cliché originates), but when the behaviour grows beyond normal hierarchy establishment, it can turn severe to a state of cannibalism. This harmful behaviour can be learned and spread through the flock quickly because of hens’ tendency to imitate each other.

Once it starts, severe hen pecking (yes, another cliché) is extremely hard to stop and results in reduced egg production, reduced hen welfare overall and increased mortality.

Although the study is not yet complete, it is promising to see hens mimicking each other’s behaviours in using the stones while also showing greater consumption of pecking stones at night.

“The birds appear to learn the behaviour over time as pecking behaviour and block disappearance increases the longer the birds have the blocks,” Widowski says. “Pecking at the blocks increases near the end of the day; at least with the mineral (calcium)- based blocks. This might be related to the hens’ physiological needs for calcium for eggshell formation at night.”

The blocks being used in the study are already commercially available and Widowski promises to provide details on im-

plementing blocks into flocks including: frequency, duration, placement, quantity and replacement rates. She asks producers to stay tuned for more details as the study concludes.

Pecking stones in broilers have been positively received by birds who peck and use it as a perch, but feather pecking is less of an issue in broilers than in laying hens.

Although not part of the study, Cooley’s observations are positive and support the need for interactive forage above the litter floor. Food reward, colour and motion have all shown positive results.

“We observe highly visible and colourful enrichments are very well utilized. Any items that are hanging/suspended at bird head height or a little higher are regularly in use,” she says.

“Edible pecking blocks need to offer enough of a food reward during pecking to continue to be utilized by the birds or

they will lose interest. Inedible pecking objects need to be colourful and generate some type of movement or interesting sound when pecked.”

Any edible blocks placed on the litter floor are less used as they blend in to the environment and are covered with dust and feces quickly. These should be suspended or mounted over the floor areas to generate ongoing use. But overall, she has found anything on the ground needs to be large, colourful and raised to ensure continual interest.

“We observe the birds spend as much time pecking at the coloured plastic base as they do the mineral stone itself and we often continue to use the plastic bases in various ways as enrichments in the barn after the stone has been consumed,” she says.

“Overall, we observe our best results by offering combinations and variety of pecking-foraging enrichments. We ob -

serve even greater utilization in the lay barns when we also introduce them during pullet rearing.”

She has seen an improvement in foraging behaviour and a reduction in aggression between birds as a result of pecking stone introduction. This has led to improved maintenance of feather cover, which she sees corelated to improvements in livability and feed efficiency.

“We also find that placing enrichments in a uniform pattern across the barns assists us with keeping birds evenly distributed across the litter areas and can be used to attract birds to spend time in underutilized spaces,” she says.

While not conclusive, it seems that pecking stones make a strong enrichment option for laying hens. If introduced in ways that avoid excess dust and feces, the blocks can create continuous benefits for hens in enriched housing.

The National Environmental Sustainability and Technology Tool is a first-of-its-kind system that egg farmers can use to track, assess and benchmark the environmental impact of their farm.

How the tool can help you

You can use the tool to:

Understand the environmental impact of your farm

Compare your results to other egg farms

Improve your operations with tailored recommendations

Access the latest on-farm sustainability resources for egg farmers

How to access the tool

By using the tool, you’re supporting the broader movement of egg farmers who are collaborating and innovating for a more sustainable future.

All you need to get started is your Farm Registration ID!

Series of guides from the International Poultry Welfare Alliance supplement existing Canadian codes.

By Ronda Payne

No one is resting on their laurels in Canada when it comes to poultry welfare. With an already enviable mandatory program for farmers, it would be possible, even easy, to say “good enough,” but, the International Poultry Welfare Alliance (IPWA) has published its Key Welfare Indicator (KWI) Guide this spring and this tool can serve as another layer (no pun intended) of support for farmers advancing the wellbeing of their poultry.

Elyna Myhre, director of marketing and communications for IPWA, says Canadian producers should be proud of what they have already accomplished and the new guides can help get to the next step.

The Code of Practice for the Care and Handling of Pullets and Laying Hens and the Code of Practice for the Care and Handling of Hatching Eggs, Breeders, Chickens and Turkeys were both created by teams of experts to provide a standard of care. These codes are the basis for the nationally enforced animal care audit.

“Nowhere else in the world has a mandatory minimum animal care program that all farmers must pass regardless of their size, except for Canada and our five supply

managed commodities,” she says. “Because of our mandatory standards, we are also in a very unique position to ensure that all our birds’ needs are met.”

While the new KWI guides are intended for a global poultry-producing audience that may not have the regulatory information and support Canadian producers do, there is still much benefit to be gained from the new documents. They can be seen as a resource for individual pieces of information or a collection of practices.

The choice in use is the farmers.

Farmers joined a number of people in creation of the new guides and it was far from an academic exercise. Nearly 60 individuals served as primary authors as well as being members of the IPWA Poultry Health and Welfare Committee.

Myhre explains that the team members included production managers, farmers, welfare program supervisors, business owners, veterinarians and “other professionals actively involved in the creations, implementation or verification of welfare protocols for poultry.”

As she outlines, many of the audit requirements outlined in the codes are prescriptive in specifying minimum standards of resources to ensure good welfare.

“In contrast, the KWIs look at how resources are used and, in the case of the Layer KWIs that I helped to create, focus on animal-based measures as indicators of welfare,” she says. “The codes and KWI guides are not in competition, but rather, the KWI guides can be used as an additional resource by farmers.”

The guide is broken into the unique needs of broilers, layers and turkeys. It is then, in the case of a laying hen’s life, further split into the four phases of on-farm, processing, transportation and hatchery. Some of the KWIs are repeated in the different sections because they are relevant to those life stages but with different welfare implications and factors.

To make navigation easier, the KWI’s include call-out boxes of key points, “start here” boxes to deliver initial information and QR codes to offer further information.

“For example, injury tracking is relevant at the hatchery as an indicator of hatchery design, handling protocols and equipment use; injury tracking at processing may indicate handling issues at the layer farm, or equipment issues at the processor,” she explains.

Having tools like the codes and new guides that are focused on animal care and wellbeing provide a service not only to the farmer and producer, but also to the processor, wholesaler, retailer and consumer involved in the accessing and handling of poultry at all stages. Kathleen E Long, vice president of animal care with Maple Leaf Foods, says having the benchmarks (and science behind them) most important to animal welfare in the KWI guides is important for farmers.

“Producers can use the information in the guide to implement farm-level KWIs in their own operations and monitor performance over time, with the goal of continually improving welfare outcomes,” she says.

She states that the agriculture industry inherently has an ethical responsibility to care for animals to the highest standards. It’s the spoken (and sometimes unspoken) promise that ensures trust between farmers, consumers and others in between.

“Tools like this help us to gather more data about animal welfare performance,” she says. “Enabling timely and effective corrective actions to improve the care we provide to our animals.”

There is flexibility built into the guides that appreciates the variety of management practices that are region specific, farm specific and even flock specific. This allows for continued growth and development both for the farmer, but also for scientists looking to further improve poultry welfare, according to Myhre.

“While there is already a recommended practice within the Canadian layer code for farmers to routinely conduct feather scoring to monitor their flock, the KWI Guide goes one step further, providing detailed background information and making some methodological recommendations based on the

MELLER POULTRY EQUIPMENT

AUTHORIZED DEALER VDL JANSEN AND VDL AGROTECH

The RearMaxx is a multi-tier system designed to train cage-free pullets effectively and use the house area optimally. Apart from rearing quality, this system stands out in managementand cleaning ease. Opening and closing the RearMaxx takes limited effort, which makes working with this system a true pleasure!

Call us on: 519-587-2667

Or visit our website: www.meller.ca

“Nowhere else in the world has a mandatory minimum animal care program that all farmers must pass.”

rigorous academic research that has already been conducted in this area,” she says. “However, the KWI Guide does not include an optimal level that a farmer should strive for with their flock since that depends on too many different factors.”

Instead, the information with each KWI tends to be it’s own consideration with access to research and data that outlines the importance and details of various factors. In the KWI on litter quality, litter moisture is reviewed in a “hands-on” observation method as well as in a testing device method with several reference links to provide further details.

Long says KWIs are important to measure and validate an animal welfare program.

“Although certain outcomes-based measures have been part of welfare audit standards for years, there has been a large increase in the use of KWIs more recently – both a greater breadth of KWIs and a demand for greater monitoring frequency,” she says.

Access to science-based information about the various factors that contribute to animal welfare outcomes and functional guides for implementation and measurement support Maple Leaf Foods. It offers a more complete picture of the realities of animal care when the prescriptive approach is integrated with the science around welfare outcomes.

“Maple Leaf Foods is highly supportive of the Chicken Farmers of Canada Animal Care Program, which is based on the National Farm Animal Care Council Code of Practice, to which all Canadian chicken farmers are audited for animal welfare

practices,” she says.

Maple Leaf also conducts internal and third-party audits throughout the supply chain. She sees the new KWI guide as a benchmark to hold next to both the Canadian programs and that of Maple Leaf.

Because the guides are a global aid, Myhre says there were discussions about the goal to “meet farmers where they are” and provide tools for measurement that could help improve poultry welfare regardless of

what stage in farming they are at.

“For example, flock mortality is one key animal-based metric that can point towards the overall health of the flock,” she says. “The ‘start here’ form of this metric is to count the number of birds that have died, ideally on a daily basis. This alone is very helpful to see trends over time when compared to what is normal for that strain, housing type and age.”

Taking it a step further would be to divide mortalities into causes to help elevate issues that need attention.

While Canadian poultry farmers have access to a number of great tools to work to improve poultry health, the KWI guides fill a gap of knowledge without making the information mandatory in implementation. The shared science discoveries of poultry welfare will be a significant benefit to all farmers domestically and internationally.

This research is funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster which is supported by Agriculture and Agri-Food Canada as part of the Canadian Agricultural Partnership, a federal-provincial-territorial initiative. Additional funding was received from CBS Bio-Platforms and Manitoba Egg Farmers.

By Lisa McLean

In the ongoing quest for alternatives to antibiotics, many poultry producers have adopted yeast-based feed ingredients because of the impact on growth and gut health. Now, at the conclusion of a five-year research study that dug deep into the novel bioactives of yeast, researchers are better equipped to understand how and why yeast-based feed ingredients improve gut function in poultry.

Dr. Bogdan Slominski, leader of the novel feed technology research program at the University of Manitoba, has been working with feed additives derived from yeast for more than two decades. His work has contributed to the development of different multi-carbohydrases and enzyme-pretreated yeast products for poultry from Canadian Bio-Systems, an industry partner.

“Foodborne diseases continue to be an important health and economic issue in Canada and abroad, and there is considerable work being done to replace antibiotics as growth promoters with antibiotic alternatives,” Slominski says. “We believe we have found an alternative in yeast-based bioactives, which have a prebiotic effect in poultry.”

Prebiotics are nondigestible compounds that, as they are metabolized by microorganisms in the gut, have a beneficial physiological effect.

“Prebiotic components have a profound

effect on the proliferation and function of the growth of beneficial bacteria to control pathogens and to ensure food safety,” Slominski says.

Yeast-based prebiotics improve bird health in two ways. First, they provide important nutrients that encourage “good bacteria” to grow in the gut, serving to lower gut pH and fight pathogens such as Salmonella, E. coli or C. perfringens.

Also, in saturating the binding sites in the bird’s gut, the enzymes stop the pathogens from attaching and growing.

But Slominski says the microbiota of the gastrointestinal tract of poultry is a complex community with around one million bacterial genes. His team has been working to find the right combination of enzymes

to provide the most beneficial prebiotic components from yeast cell walls. To accomplish that, they had to break down the yeast cell wall polysaccharides first to access other specific and beneficial components, including nucleotides.

Slominski has worked to combine yeast products and their fractions to refine the products currently on offer. And, thanks to new sequencing technology, they are now able to gain a better understanding of the processes that happen in a bird’s gut.

“A newer tool called new generation sequencing (NGS) allows the genome structure of entire microbial communities to be studied, and to understand the structure

The Chicken Farmers of Canada’s Young Farmer Program is a professional development program that teaches young leaders in the chicken sector about governance, succession planning and personal branding, while also networking with key agriculture and government stakeholders. It also helps young farmers better understand the sector and gives them the tools to succeed. Every year, five young Canadian farmers will be selected to participate in the 18-month program.

DEADLINE IS NOVEMBER 3, 2023

and function of microbiota,” Slominski says. “In the case of chickens, it has been estimated that about 20 per cent of bacterial genes in the ceca control carbohydrate metabolism, and much less are involved in metabolism of amino acids and lipids. However, only a few studies have sought to

understand the turkey microbiome.”

In the first part of the most recent study, Slominski’s team used a yeast-based growth promoter alone, and with other enzymes to measure how the additive modulates gut

physiology of young turkeys to have an anti-inflammatory effect and generally improve essential functions and fight disease.

“We determined a diet with the multi-carbohydrase enzyme in combination with an enzymatically modified yeast cell wall can modulate the gut physiology and function of turkeys and could have anti-inflammatory effects due to an increased concentration of butyric acid in the ileal digesta,” Slominski says.

In another study using laying hens, researchers examined how different components used in a yeast-based growth promoter affected laying hens when they were challenged with Salmonella enteritidis (SE) zero, three and eight days post-infection.

Of the three types of yeast-based feed additives used in the study, each had different functions to support gut health. One reduced SE cecal counts and fecal shedding, and a second type of particle structure mitigated SE proliferation. The third type had little effect on SE, but it did support the growth of beneficial bacteria providing energy for gut development, function, and health.

“Each component plays an important role in supporting antibiotic-free feeding programs in poultry,” Slominski says.

“As we conclude this project on yeastbased feed additives, we have a better understanding of how to develop products for prebiotic feed supplements,” Slominski says. He suggests further fine-tuning of yeast components would be best completed by industry partners.

Slominski sees opportunities for further research looking at the release of bioactive components from different natural fibre components. He expects his research associate and colleague Dr. Anna Rogiewicz to continue work with fibres from such feedstuffs as canola meal, soybean, and other grains and oilseeds. “With this research, we have better information about the microbiota of the gut and intestinal tract in poultry, and that gives us something to continue to build on,” he says.

7, 2023 LIVE EVENT I 1:00PM ET

INSPIRE | LEARN | LEAD | CONNECT

Register today for this unique live event coming to Hamilton.

Join us to hear from today’s most influential female leaders in Canadian agriculture.

This year, six IWCA honourees were chosen by our team. On November 7, 2023 at 1:00pm ET, they come together with other prominent trailblazers in agriculture to share their experiences, life lessons and more for the live 2023 IWCA Summit.

Join us for an afternoon of interactive discussions as they share their experience, offer guidance and discuss their journey in agriculture.

Shaun Mayhew

Agricultural businesses have been faced with some of the greatest challenges in recent years. From extreme weather events and constantly increasing costs of doing business to keeping up with changing environmental standards for air quality and even disease management.

Every part of our industry is increasing efforts to eliminate greenhouse gas emissions. Not only do solar panels help reduce greenhouse gas emissions but they can also save your business thousands of dollars. Knowing the federal incentives available for businesses is extremely important, as these incentives can cover a significant portion of solar installation costs.

Here are five key reasons for farms to adopt renewable energy by going solar!

Federal incentives can help offset the initial cost of installation and make solar

more affordable for agricultural operations. These incentives provide savings up to 49 per cent when installing solar panels!

On March 28, 2023, the federal government announced the Clean Technology Investment Tax Credit, which provides businesses a refundable tax credit of 30 per cent and covers the capital costs of installing solar panels, as well as stationary storage systems such as battery backup power.

The Canadian government offers tax incentives allowing businesses to write down 100 per cent of the solar costs in the first year. Under Class 43.1 and 43.2 in Schedule II of the Income Tax Regulations is where you can locate the appropriate information to review with an accountant to see how this applies to your business.

Both the income tax regulation incentives and the Clean Technology ITC can be combined, allowing businesses to have up to 49 per cent of costs covered in the first year of operation.

The cost of electricity is continuing to increase as electricity providers across the country plan to increase rates annually. Additionally, providers are moving towards ‘time of use’ billing structures, which charge higher rates during peak hours of energy consumption. For businesses operating during daylight hours, specifically in the afternoon, it’s expected to result in significant cost increases.

As businesses become more electrified, solar power provides an opportunity for businesses to protect themselves against these increasing costs by producing their own energy and reducing the amount of electricity consumed from the grid.

By installing solar panels, businesses can insulate themselves against these billing structure changes and protect themselves against future energy cost increases. The more electricity a business generates, the better protected a business will be from cost increases.

Solar panels can help save money on your electricity bills by generating your own renewable energy from the sun. Depending on location and the solar panel system size, businesses can offset or even eliminate electricity bills entirely.

Solar panels can help businesses save money on their electricity bills, which can be a significant expense for many agricultural operations. By generating their own electricity from the sun, businesses can reduce their dependence on the grid and lower their operating costs.

By generating electricity with solar panels, businesses can become more energy independent and less reliant on utility companies. This can be particularly advantageous during power outages or when there

are disruptions to the energy grid.

Power outages and other energy disruptions can be costly and disruptive to businesses. By generating electricity with solar panels, businesses can ensure they have a reliable source of energy during outages and other emergencies.

Solar panels are a clean and sustainable energy source that produces no greenhouse gas emissions or air pollutants. By installing solar panels, businesses can reduce their carbon footprint and contribute to a more sustainable future for our planet.

Installing solar panels can help businesses demonstrate their commitment to sustainability and environmental responsibility, which can enhance their reputation and appeal to customers and investors who prioritize ethical and environmentally

conscious practices.

As farmers, we take pride in our land and creating a business that is sustainable for future generations. Taking advantage of these government incentives significantly reduces the initial investment of putting your rooftop to work when going solar. Many agricultural businesses are capitalizing on these incentives to harness the power of the sun and to help future-proof their business from increasing electricity costs.

Shaun Mayhew is the president of Penfolds Roofing & Solar in B.C. The family owned and operated company has been in business for over 86 years and has installed over 15,000 solar panels during the past eight years. Penfolds has quickly grown to be one of the largest solar panel installers in the Lower Mainland and has helped numerous farmers streamline their businesses.

Breeder Signals contains practical information about broiler breeders to ensure a maximum production of first grade hatching eggs. With practical tools and modern insights to optimize egg production, fertility, sexual behaviour and hatchability, based on the look-think-act approach. It shows the best start of day-old chicks in a hygienic and healthy surrounding, rearing and the transition to productive broiler breeders. Both data and practical information provide opportunity for Breeder Signals is a necessity for all people working in the poultry meat chain as breeder farm managers and staff, advisors, veterinaries, students, etc. $93.20 | Item# 9087403324 Scan code to buy this book

Location

Tavistock, Ont.

Sector Broilers

The business

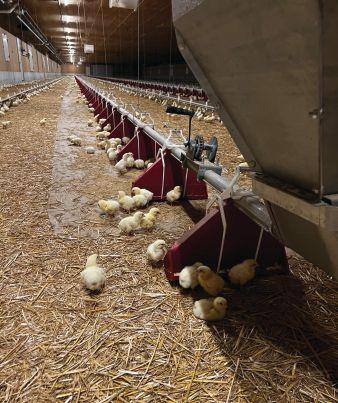

Larwen Poultry Ltd. is a 100-acre operation that includes broiler chickens and cash crops. They have quota for just over 35,000 units and grow heavy 3.85 kg birds. Jesse McCauley started working on the farm alongside his father-in-law Larry Wagler in 2015 and took over the operation two years ago when Wagler passed away.

The need

McCauley and Wagler had talked about either expanding their existing barns or building a new one for several years to create more space for their birds. “We just kept getting fuller and fuller,” McCauley says. However, they put those talks on hold when Wagler was diagnosed with cancer. A few months after his father-in-law passed away in 2021, McCauley reset his sights on expanding to ease the stocking density in his barns. He built a new barn last year while retaining his two older barns.

The barn

McCauley worked with Clark Ag Systems on the new barn. It’s the first time the farm has used cross ventilation with fans and vents on both sides of the barn. “It seems to really get the air across these birds, and it just makes the air so much nicer,” McCauley says. The barn also includes butterfly feeders, which the producer likes because they’re easy to clean. He just cranks them open to drop out any excess feed then cranks them back closed to refill them. Barn

S T R EN G T H EN Y OU R

B R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use