Happy Thanksgiving

Celebrate your Thanksgiving tradition with Canadian turkey.

Turkey farmers across Canada are committed to raising turkey with the highest safety and animal welfare standards.

by Brett Ruffell

Celebrate your Thanksgiving tradition with Canadian turkey.

Turkey farmers across Canada are committed to raising turkey with the highest safety and animal welfare standards.

by Brett Ruffell

This past summer, I was fortunate to talk to poultry leaders once again for both the Top 4 Under 40 and Influential Women in Canadian Agriculture (IWCA) programs. In these interviews, one of my favourite questions to ask is, “What is it you love most about the poultry industry?” It’s such a simple question and yet it elicits a range of interesting responses.

For Conrad Vanessen, a freerun egg farmer and Egg Farmers of Alberta (EFA) director, the answer is threefold. “There are a whole bunch of things that make this industry fun to work in,” says the Top 4 Under 40 winner.

For one, he likes the good, stable living that supply management provides. “For sure, that inspires me,” he admits. But he also loves knowing that the food he’s producing is going to people’s plates. Knowing that the eggs that leave his cool room every Thursday are going to be on a grocery store shelf or in somebody’s kitchen in seven to 10 days fills him with pride.

“To know I’m that intrinsically involved in the production business – I think that’s inspiring,” he says.

What’s more, as an EFA director who advocates for the industry on several fronts, he likes that he has a voice as a farmer and that he gets to use it help the industry conquer

challenges.

For David Arand, a turkey farmer from Atwood, Ont., it’s the animals that make it worthwhile. When he first converted his family’s hog farm to turkeys, a veteran farmer gave him a heads up about what to expect. He said the wonderful thing about turkeys was that every time you open the barn door you have thousands of new friends.

Curious by nature, turkeys want to know who you are and why you’re there when you enter their space.

A few years later, the Top 4 Under 40 honouree found this to be true, likening them to pet dogs. “If you’re having a bad

“So, all of that – the people, the animals, the connectedness of the industry – is all very exciting.”

day, your day just instantly gets better,” says Arand of when you enter the turkey barn.

Broiler farmer Emma Rutherford also finds barn chores to be relaxing compared to her fast-paced off-farm job as a dental hygienist. “It’s a nice change,” she notes.

The Top 4 Under 40 winner also values the flexibility that chicken farming offers, especially considering she has a dairy farm to oversee and her non-farming job as well. “The flexibility has allowed us to keep our off-farm jobs and

manage other areas of the farm, too,” she says.

Dr. Teryn Girard, a poultry veterinarian from Red Deer, Alta., who works with both Prairie Livestock Veterinarians and Cargill Animal Nutrition, says she’s “obsessed” with her job. She frequently works directly with farmers, both when providing veterinary services and also when helping to educate producers. It’s a part of the job she loves. “It’s incredible, getting to work with producers and learn from them – I’m so fortunate.”

Likewise, IWCA honouree Valerie Varney, the Poultry Innovation Partnership lead, says, “I love this industry.” Firstly, she likes that even though poultry is comprised of four different sectors, they’re all connected by supply management.

Also, as a geneticist by training, she admires the rate of progress that the poultry industry has achieved through genetic selection. Lastly, it’s the birds themselves. She says poultry are much easier and safer to work with than other farm animals she’s had experience with.

“So, all of that – the people, the animals, the connectedness of the industry – is all very exciting.”

If you still haven’t listened to these podcasts, you can hear my conversations with our Top 4 Under 40 winners at canadianpoultrymag.com and my discussion with Carney at agwomen.ca.

What is it you love most about the poultry industry? Let me know at bruffell@ annexbusinessmedia.com.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer

Brooke Shaw

Group Publisher

Michelle Allison mallison@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes) USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

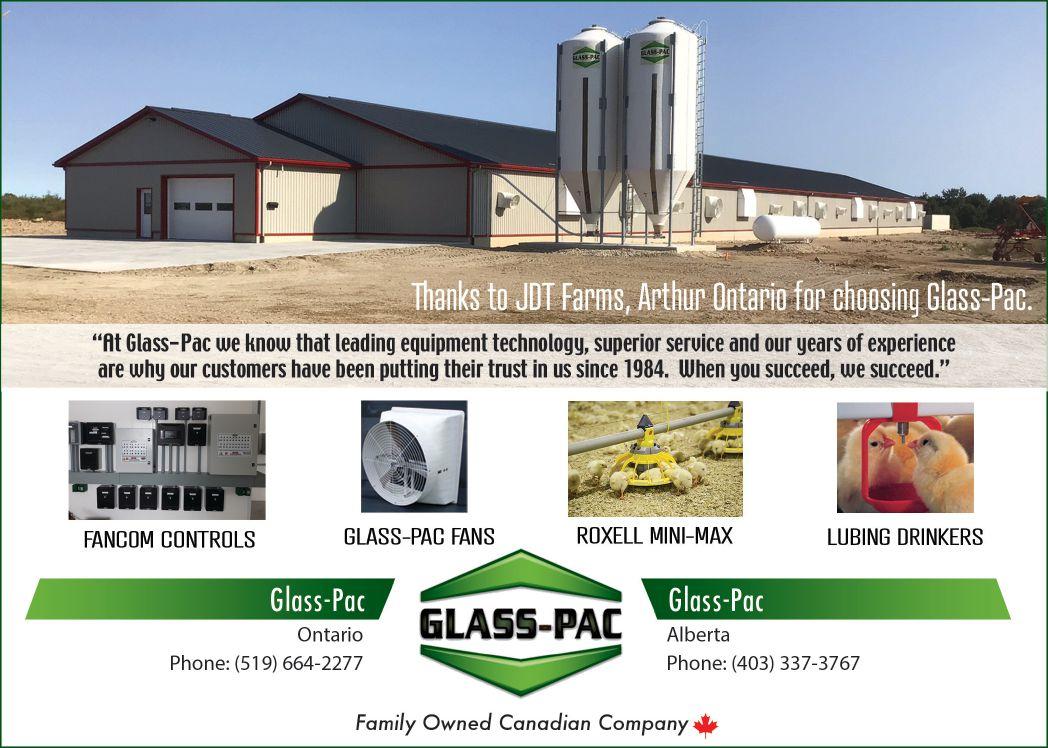

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

In August, the federal government announced an investment of up to nearly $3 million to three national organizations to enhance animal welfare and tracking in the country. With funding under the AgriAssurance Program, the organizations will draw on new research to update industry standards for the care and handling of animals, and will evaluate technology to more efficiently trace farm animals in the production system in the event of a disease outbreak. The recipients include the Canadian Poultry and Egg Processors Council (CPEPC), Animal Health Canada (AHC) and the Canadian Cattle Identification Agency (CCIA).

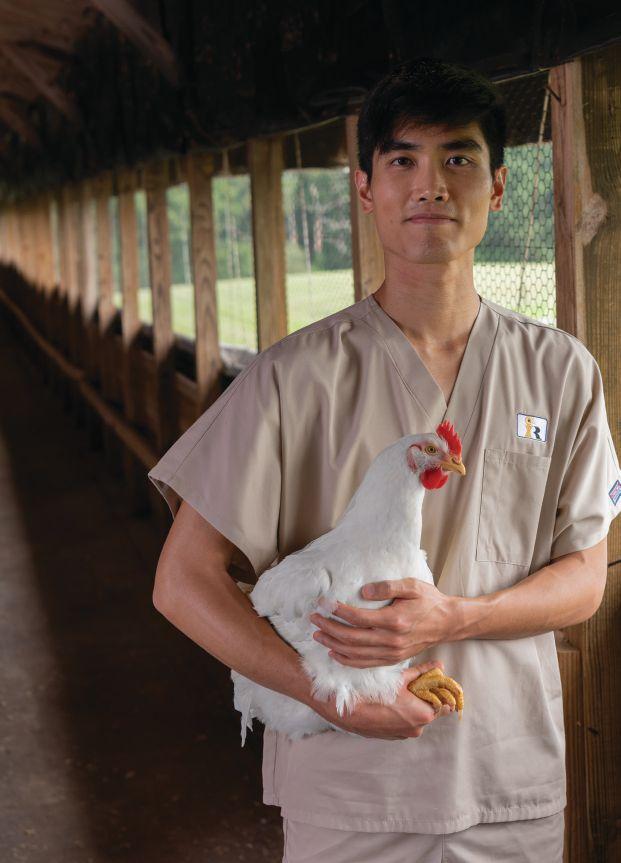

Hybrid Turkeys has expanded its Canadian veterinarian team. Dr. Elana Huong joins the company as staff veterinarian focused on flock health programs throughout Hybrid’s Ontario-based operations. Huong is a Doctor of Veterinary Medicine and completed her studies at the Ontario Veterinary College at the University of Guelph. She is based out of the Canadian office in Kitchener, Ont.

Poultry genetics company Cobb-Vantress has announced four new members of its leadership team, including executives who will be servicing the company’s clients in Canada. William Herring is Cobb’s new vice president, research and development. Ben Church is the company’s new vice president, engagement. Ray Ables joins Cobb as vice president, live production. And Robin Jarquin is promoted to vice president, commercial.

A ground-breaking ceremony was held this summer at the site with representation from the provincial government, Manitoba Egg Farmers and the University of Manitoba.

A new, state-of-the-art egg-laying research centre is coming to the University of Manitoba’s Glenlea Research Station.

This past summer, representatives from the provincial government, Manitoba Egg Farmers (MEF) and UM broke ground on the 4,500 laying-hen barn, which is expected to open early next year.

$4M is the approximate total cost of the facility, which is expected to open early next year.

Named the Egg Layer Research and Public Engagement Facility, its total cost is around $4 million.

The governments of Canada and Manitoba provided $1.5 million for MEF to establish the facility, with the board picking up the rest.

“I am pleased to support the ongoing research at the UM that also supports our great Manitoba egg farmers,” says Manitoba’s Agriculture and Resource Development Minister Ralph Eichler.

“Our province’s egg farmers account for 10 per cent of the country’s egg production and generate about $120 million in farm cash receipts. We look forward

to the continuation of research that helps drive interest in eggs and advances the egg industry.”

The UM currently operates the only egg research facility in Manitoba, but this facility needs significant upgrades. The new facility will advance and enhance research on modern egg production techniques and technologies. This new facility will help ensure Manitoba is home to world-class research on egg production and development in support of the Manitoba Protein Advantage Strategy, Eichler notes.

“This new, state-of-the-art facility will showcase what we do as modern egg farmers for the benefit of the general public. It’s important to us that we open the barn doors and show consumers how eggs are produced and how hens are housed,” says Catherine Kroeker-Klassen, MEF board chair.

“It will be the most modern egg and layer research, education and training facility in all of Canada.”

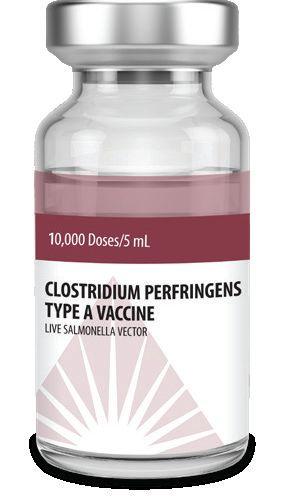

The only mass-administered vaccine available for controlling necrotic enteritis in chickens that has been demonstrated to meet CFIA and USDA standards for purity, efficacy, potency, and safety.

Only vaccine for necrotic enteritis that stimulates an immune response against a-toxin and Netb toxin of C. perfringens Type A. Clostridium perfringens Type A vaccine has been shown to be effective for the vaccination of healthy chickens day of age or older against necrotic enteritis due to Clostridium perfringens Type A.

Talk to your Huvepharma sales representative or contact customer service at customerservice@huvepharma.ca

New hatchery concept for turkeys a collaborative effort. By

Melanie Epp

When Dutch equipment supplier HatchTech’s new hatchery concept first came to market in 2014, it was well received, but only available for broilers. Now Next Nest Hatching, a company born out of a three-year collaboration between HatchTech Incubation and Life-Science Innovations in Minnesota, has released a similar hatchery system, this time intended for turkeys.

Preliminary studies show turkey poults hatched using the Next Nest system are larger and healthier. Peter Gruhl, a 30-year veteran in the Canadian turkey sector and director of sales at Life-Science Innovations, and Jonathan Huisinga, general manager at Next Nest Hatching, explain how the system works.

The HatchTech concept ‘HatchCare’ has already been proven in broilers. Because chicks hatch under optimum and uniform conditions and are provided with fresh water, feed and light as soon as they hatch,

overall chick quality is improved. The system has been adopted by two major hatcheries in Canada, Trillium and Synergy Agri Group. Globally, the HatchCare system has hatched over 3.2 billion chicks.

Similar to HatchCare for broilers, HatchCare for turkeys incubates eggs and provides access to food and water immediately after poults hatch. Under conventional systems, the farm is the first-time poults have something to eat and drink. This can cause great challenges for farm managers, says Jonathan Huisinga, as farm managers have to teach weakened, dehydrated birds to find feed and water. For early-hatching birds, the wait from egg to food can be up to four full days.

“Their egg yolk sac will help them survive but using those critical nutrients up to stay alive limits the potential for more robust early development of critical systems,” Huisinga says.

Using the HatchCare system for broilers in

turkey hatcheries wasn’t possible. A whole new system needed to be developed to account for the size of their head and feeding height. The Huisinga family, with their 75 years of experience in turkey production, were the right people to take on this task.

“The details make all the difference,” Huisinga says. “Millimeters of width or height of many different aspects of the HatchCare basket mean the difference between an ideal environment and failure.”

During its development, temperature and humidity profiles had to be completely re-evaluated, too, Huisinga explains. “Birds on feed and water kick off far more heat and need to be treated differently,” he says. “Manure is tricky, too. Birds poop a lot more once they start eating.”

“With turkey eggs, the early production eggs are 70 to 72 grams,” Gruhl explains. “End of production eggs can be 105 to 108 grams, so you definitely have different amounts of heat being produced.”

To address this issue, HatchTech included a laminar airflow system in the Hatch-

Advantage Welfare

We are a champion of bird welfare. Through balanced breeding, the health, livability and robustness, combined with performance and feed efficiency, provide a sustainable bird with strong welfare and viability. Learn more at Aviagen.com.

Care system. While a typical hatchery would use just one main heat source, HatchCare for turkeys passes air through 14 radiators to provide ideal temperature control.

“Every section has a thermostat on it so you can add temperature or take temperature away as you need,” he adds. “And because of how the machines are set up, we run a lower CO 2 level, which is good for the poult. We know at higher CO2 levels, birds do not eat and grow optimally.”

What research shows

HatchCare for turkeys was first tested on the Huisinga family farm, Willmar Poultry

Farms. But as they only raise about four flocks of toms each year, they decided to partner with third parties.

“We wanted to focus our initial tests on tom’s because that’s where most of the value comes out of the turkey industry,” Huisinga says.

Next Nest completed three multi-pen tom trials in a regional research facility with a third party. The trial followed turkeys from hatching to maturation. Posted birds on day of servicing or delivery day show feed in the digestive system of every bird, Huisinga says.

“The body weights at the end of one week are actually 20 to 40 per cent bigger,”

Gruhl adds.

The studies also show that growth continues throughout maturation. Turkeys under the new system are 400 grams heavier once they reach 140 days of growth and five points feed conversion better than control birds.

“That’s a big deal at historical-average feed costs, but right now it’s an even bigger deal,” Gruhl says. “This growth advantage was accomplished with the same amount of feed as standard-hatched birds, providing a significant cost savings.”

Come processing, toms grown under the turkey HatchCare system were two per cent larger than those grown under conventional systems, as well.

But the benefits aren’t just for the birds. “Farmers have already recognized the advantages of brooding on a more convenient schedule for their farm team,” Huisinga reveals.

“On service day, you can feel the difference between Next Nest and control birds,” he continues. “Our gender identification techs have said they could tell which birds are on feed/water if they were blindfolded, there’s that much difference. In fact, identifying gender is easier because of improved organ development, lending speed and accuracy to a challenging role.”

Under the turkey HatchCare system, the intestine, the largest immune organ in the bird, is also better developed. That improved organ development could confer improved immune status as well in the long term.

Both Gruhl and Huisinga are excited about the introduction of HatchCare’s new system for turkeys. Gruhl says it’s the first real value-add for turkey hatcheries in over four decades.

“As our industry becomes more under the microscope, this is a big step in a direction that nobody else has gone before,” he said. “It will help with the challenges of the economics of turkeys today because it’ll be getting better final performance.”

Globally, it’s estimated that the layer sector culls 6.5 billion male chicks each year. In Europe, the culling of day-old chicks has become a politically contentious issue that has promoted policy change in various countries.

While some solutions show promise, others have little environmental, economic or ethical basis. In Germany, for instance, policymakers have been accused of putting the proverbial cart before the horse. A panel of experts gathered at VIV Europe in June to discuss the options: sex determination technology; the raising of male layers; or switching to dual-purpose breeds.

This year, chick culling has or will become illegal in several European countries. Under German legislation, it was banned in January 2022, and it will be banned in France by the end of 2022. Discussions are ongoing in other European countries, including Austria, Switzerland and the Netherlands.

Three solutions have been proposed to end the practice: raise dual-purpose birds; raise male hens; or adopt technology that determines sex in-ovo. For the latter, several

solutions are either on the market already or on the horizon.

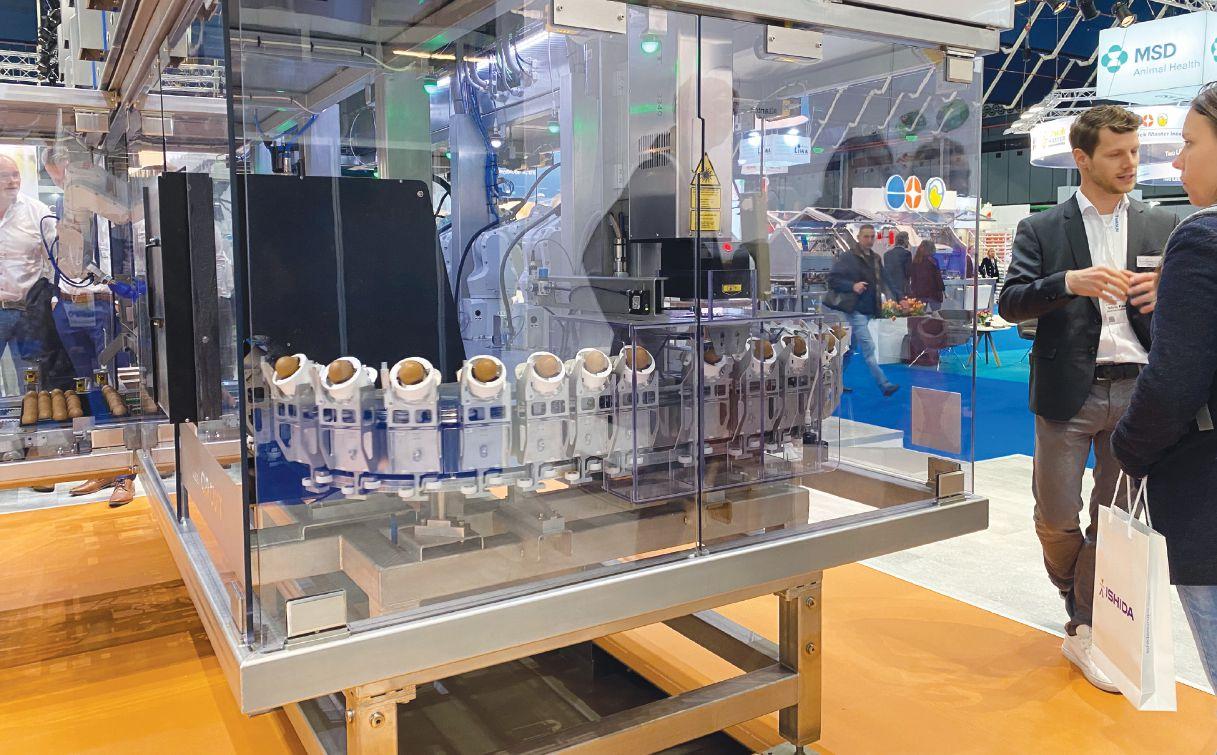

Dutch hatchery equipment company HatchTech is co-owner of two technologies: Seleggt and PLANTegg. Carla van der Pol, head of research and development at HatchTech, explains how they work.

Developed in Germany, Seleggt sexes eggs using hormone-based gender identification. Lasers create a 0.3 millimetre hole in the shell of the egg and extract a small amount of allantoic fluid. The allantoic fluid of a female hatching egg contains estrone sulphate, a female hormone. That fluid is placed into a patented marker where it changes colour if estrone sulphate is present. The eggs are sealed after extraction and sorted according to results. Seleggt can sample one hatching egg per second or 3,000 eggs per hour.

It’s designed for 24-hour use and has been on the market since 2018.

Also developed in Germany, PLANTegg uses a small needle to remove allantoic fluid, which is analyzed using PCR technology for

gender chromosomes. Once sampled, they are sealed and sorted, and the female eggs are returned to the setters to continue the hatching process. Sex determination is completed in 1.5 hours. PLANTegg says it is 98 to 99 per cent accurate.

Both Seleggt and PLANTegg are in operation in Europe. At the time of her talk in June, Van der Pol said seven million hens had been hatched using the two technologies. Table eggs from these hens are available at 10 different retailers.

“The demand for these eggs at the moment is in Germany, but also in the Netherlands and France,” Van der Pol said. “But there’s upcoming awareness all over Western Europe.”

In the short-term, HatchTech would like to further improve and industrialize the systems to increase the number of hatcheries using them.

“If we can move to an earlier day of incubation that would be preferable for us, both from an ethical perspective, but also from a capacity perspective,” she said. “If you could already analyze your eggs at day zero, you don’t have to incubate any male eggs, and

you only have to use half your incubators.”

Currently, German law requires eggs to be sexed by day seven, but there is talk of pushing that to day six. Currently, there is no technology that can determine sex by day six, though.

As HatchTech moves towards day six detection, Van der Pol said they’re facing technical challenges. Eliza and mass spectronomy technology could test allantoic samples at day six, but some improvements are needed to detect hormone levels, as they can be much smaller at this stage of development. PCR tests also work at day six, Van der Pol added, but some compromises will need to be made in terms of cost-price effectiveness and accuracy.

Overall, the researcher sees a bright future for in-ovo sexing technology. “As these technologies become even more streamlined and cheaper, you will see a big advantage in pro-

duction capacity in the hatchery,” she said. “There will also be economical benefits to using these technologies but we do have to go through these periods of development to get there.”

Another option is Dutch company In Ovo. Co-founded by Wouter Bruins, it has developed a high-throughput screening machine called Ella that samples at very high speed. Using a tiny needle, Ella obtains a fluid sample, and screens the sample for a specific bio marker using Echo mass spectrommetry technology. In less than a second, the gender of the egg is determined. The eggs are stamped and male eggs removed from incubation. This machine currently operates in-line in a commercial hatchery in the Netherlands.

In May of this year, Orbem and Vencomatic Group announced they’re working in partnership to market “Genus Focus”, a fully

automated, end-to-end system for sex determination. Using non-invasive magnetic resonance imaging (MRI), Genus Focus determines sex between day 12 and 13 and has a throughput of 24,000 eggs per hour. Two installations with the capacity of 6,000 and 12,000 eggs per hour will be fully operational in France by January 2023.

Pedro Gomez, co-founder and CEO of Orbem, said the technology offers four key advantages: it is safe for eggs and operators; it works with all breeds and egg colours; it’s fast; and, lastly, it’s 96 per cent accurate.

“The big advantage of this setup is that it can be scaled modularly,” said Gomez, adding that their aim is to sex earlier than 12 days. “We believe the earlier, the better, as long as it doesn’t hinder performance.”

Other solutions have been to grow out the male layers or adopt dual-purpose breeds. Peter van Horne, poultry economist from Wageningen University & Research, evaluated both the environmental footprint and economic cost of adopting these solutions in the Netherlands.

There are some 33 million layers in the Netherlands. Sixty per cent of eggs produced are exported, 80 per cent of which goes to Germany. The culled male chicks are not disposed of as waste. Instead, hatcheries receive a small revenue by selling them to zoos, falconers and pet shops as feed.

“It’s a useful destination at the moment, and there are no welfare issues [with culling],” Van Horne said.

If Dutch farmers were forced to switch to dual-purpose production, by Van Horne’s calculations, the industry would require 39 million hens to produce the same number of eggs as the highly productive commercial breeds they would be replacing. The transition would cost the industry an additional €286 million, he said, especially as male layers require 10 per cent more feed.

“My conclusion is the lowest cost to produce eggs is with modern layer breeds,” Van Horne said.

Field data from the Netherlands reveals further inefficiencies in male layer production. It takes 98 days for a male layer to reach 1.5 kilograms. Once mature, they have approximately 17 per cent breast meat and a feed conversion rate of 3.5.

Conversely, broilers take just 42 days to reach a live weight of 2.4 kilograms. They have 25 per cent breast meat and a feed conversion rate of 1.6. At current feed prices, Van Horne estimates an additional cost of €4 per male layer.

Then there’s the question of how to market the end product.

“What do you do with this bird?” asked Van Horne. “Nobody wants it.”

Dutch slaughterhouses have offered four cents per kilogram for layer males, which is even lower than what is paid for spent hens. To meet rising costs, egg prices would need to be lifted one to 1.5 cents per egg, he said.

Some companies have further processed male layers into sausage and chicken burgers, but there is no real market demand for these products.

“Consumers will have to pay for this,” Van Horne said.

Sex determination comes with additional costs as well. In-ovo testing requires equipment to sample and separate, plus the additional cost for disposal of male eggs. Including some margin for error, Van Horne estimates it will cost an additional €3.30 per bird, which is similar to the cost of growing out male layers.

But given current feed prices, the cost of growing out male layers would actually be much higher than adopting technology for sex determination, he said.

Van Horne also looked at the environmental cost of switching to male layer production, calculating for regular feed use,

land use and energy consumption. He found the carbon footprint of layer males to be three times that of broilers.

“It’s very clear there is a negative carbon footprint,” he said. “It’s also very clear, looking at the environment, that this is not the way to go.”

There has been much discussion around the ethics of culling embryos based on whether or not they feel pain. Eddy Decuypere, professor emeritus at the Catholic University of Leuven in Belgium and Wageningen University & Research in the Netherlands, is a neurophysiologist who works with chickens. He discussed the ethical questions around pain reception in embryos at the different stages of development.

The brains of chick embryos develop slowly, Decuypere said. At day 15.5 to 16.5, he

www.poultryinmotion.ca

said, embryos show high rates of movement, but no higher brain activity. By day 16.5 to 17.5, the first signs of higher-brain activation appear with decreasing movement rates as development progresses. By day 17.5 to 18, all embryos have higher brain activation, and by day 18 to 21, different brain patterns (waking, REM and NREM) begin to emerge.

Pain and suffering from pain can only be present when consciousness is developed, and in chicks, brain function is active at 80 to 90 per cent of embryonic development,

Decuypere explained. On the question of moving to earlier and earlier detection, he laughed.

“Forget it. In my view, it’s marketing,” he said. “It’s marketing for companies, it’s marketing for politicians, but it has no scientific basis.”

While discussions continue across Europe, most agree that France has come up with what is currently the best solution. Chick culling in France will come to an end at the end of 2022. Hatcheries will be pro-

vided with subsidies to adopt technology that determines sex by day 15. In the case of error, which occurs approximately three per cent of the time, regulars will permit dayone culling. Detection is easier in brown eggs, so because the French prefer brown layers, in-ovo sexing solutions will be cheaper. Dutch poultry economist Van Horne quoted an additional price of €1.20 per bird.

“The French, I think, have found a nice solution and a very pragmatic way to solve the problem,” Van Horne concluded.

Test your barn alarm

Check water lines for signs of leaks

Maintain uniform barn temps

Ensure generators are running properly

Check ventilation system for performance issues

Monitor any equipment with the BarnTalk Wireless Dry Contact Sensor, including generators, controllers, feed motors, and more.

BarnTalk automatically completes a self–test every two minutes.

BarnTalk detects no water flow, large leaks, and sudden changes in use.

With BarnTalk, get notified if barn temps fall out of your safety zone.

If your generator fails, BarnTalk sends an alarm.

If your ventilation system fails, BarnTalk sends an alarm.

the QR Code to learn more.

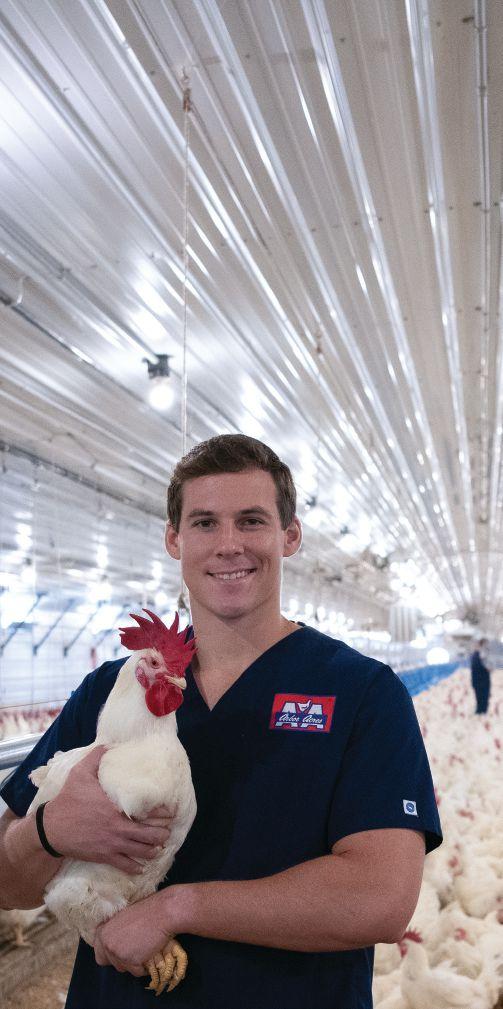

Maple Leaf Foods expert shares insights into how broiler welfare has changed and where we need to go.

By Treena Hein

Lighting, stocking density, enrichments, genetics –these are the main welfare concerns the Canadian broiler industry is discussing these days. What does the science show us and what standards are experts deliberating across the chicken industry?

We caught up with poultry veterinarian Dr. Kathleen Long, vice president of animal care at Maple Leaf Foods, to discuss. Long recently presented on broiler welfare at the Canadian Poultry Research Forum.

She explains that interest in animal welfare is still strong and various sets of standards, both created by industry and from external sources, are garnering a lot of attention.

She and her colleagues at Maple Leaf are among the many who believe industry must engage in standards discussions from a position of science-backed credibility, comprehensive understanding of what standards entail, transparency, continuous improvement and a big picture perspective.

For example, over 200 companies have signed a set of standards called the Better Chicken Commitment. But Long notes that leaders at some of these firms don’t fully understand what they have agreed to.

“There is a set of requirements to be met by 2024 and another for 2026, which includes the use of slow-growing broiler

breeds,” she explains. “At this point, we at Maple Leaf Foods have committed that some of our supply will meet the 2024 requirements. There are quite a few food service, retail and restaurant firms that have signed onto the 2026 requirements but production firms have largely not done this. I believe that there is a lot of learning that will occur in terms of what slow-growth production entails.”

Long notes that the rate of updates over the last few years to standards from sources external to the broiler industry have been rapid and challenging for industry to address. “There are perhaps perceptions that

industry-led national farm animal care programs aren’t keeping up, but there is also great opportunity here for transparency, to share what we are doing and the science behind the standards we follow,” she says.

“We believe strongly at Maple Leaf that if you didn’t report it, you didn’t do it. We get frequent survey inquiries from retailers, food service and restaurants asking how we are meeting, or will meet, various welfare standards that have been created. We put a huge amount of time into answering each one thoroughly. A lot of that relates to farmlevel practices. These surveys are a great way to build trust and provide transparency.”

When they learn about our Animal Care Program, almost 80% of Canadians have an improved opinion about Canadian chicken. Your participation and support of the program absolutely give credibility to both our sector and the Raised by a Canadian Farmer brand.

Canadians know that Canadian chicken stands for excellence –and that’s thanks to you.

Maple Leaf Foods has also taken steps to gather and publicly release a large amount of detailed information about welfare practices, which includes an annual Sustainability Report and its Animal Care Performance Report. Also, this year, following its review of 150 companies in 25 countries, the Business Benchmark on Farm Animal Welfare, the leading global measure of policy commitment, performance and disclosure, ranked Maple Leaf Foods in Tier 2 among 11 other firms, with only four in Tier 1. Maple Leaf believes private companies and industry associations should share detailed information with the public.

Long notes that Canada has a great history of progress with animal care and welfare.

“The National Farm Animal Care Council (NFACC) Codes of Practice are something to be proud of,” she says. “They are very robust and are backed by a large amount of scientific data. There is some discussion going forward that there should be tiered standards, and the NFACC Codes have requirements and also recommendations, so they are already tiered in a sense. Globally, we also have organic industry standards and special industry standards like raised without antibiotics. And another example is the Red Tractor program in the U.K., which has conventional farming standards, indoor higher welfare standards and free-range standards.”

Long notes that in Canada, some believe tiered standards are a way to avoid overburdening industry and move forward effectively with animal welfare. That said, some have concerns about the economic and environmental impacts of trying to meet the potential upper tier of any new standards and feel Canada has strong, unified standards already. “And we must remember that the NFACC Codes are reviewed every five years (which can trigger an update) and fully updated every 10 years,” she says, “and it is a very detailed process that examines all new research findings.”

Indeed, continuous improvement of national codes and updated on-farm practices are critical to maintain industry credibility, says

Long. “We need research findings behind the creation of standards and validation that practices related to standards actually address welfare outcomes in commercial settings,” she says. “There is a lot of opportunity to improve industry understanding of what are the most important outcomes for broilers and other types of poultry and how to implement them in practical ways.”

Long believes that this approach provides industry a position of strength to defend against ill-advised standards that risk bird health, standards that do not actually improve bird welfare and those that are environmentally and financially unsustainable.

Long says there are four aspects of broiler farm level welfare that are of high interest to stakeholders, some of which require more study, consensus or broader implementation. One of these is stocking density. Broilers in Canada are kept at 31 kilograms per m2 or up to 38 if additional requirements are met. “Density is a very important focus for customers and animal welfare groups,” Long says. “We get inquiries on this all the time. In 2021, 69 per cent of birds supplying our primary processing operations were kept at 31 kilograms per m2 or less.”

Use of enrichments is the second major aspect. “The broiler NFACC Code is behind layer and pig codes in terms of enrichments and we are trying to advance that with our farmers,” Long says. “With our enrichments, we are seeing a lot of benefits for the birds and our farmers are noticing also and love seeing the birds interact with the enrichments.”

There is also inconsistency with the findings on lighting in broiler barns. “There is a great range of conclusions about light intensity, newer technologies like gradient lighting and varying colour spectra, and a lot of focus on natural light in different countries, which also has worker benefit,” Long says. “The topic is not understood well enough yet for changes to be implemented by industry. We are tentatively planning a research trial in 2023 in collaboration with researchers at University of Saskatchewan.”

Slow-growing breeds is the fourth and the most impactful broiler welfare aspect, Long says, one that is not yet well understood with regards to welfare. “There are findings that some aspects of welfare are improved with these breeds, and we cannot ignore those findings, but slower growth rates have an enormous negative environmental impact because much more feed, barn space and water is required,” Long says.

“We’ve done a number of trials using different breeds and learned a lot through a very in-depth analysis of welfare, sustainability and production efficiency. We must remember that the genetics of conventional birds in terms of certain historical welfare problems, such as leg strength, have undergone so much progress. I would say those issues have been largely addressed and were a main reason why slower-growing breeds were promoted in the first place.”

Long notes that there is a lot of focus on behaviour in the research as slow-growing breeds behave differently than conventional. “We also must remember that welfare outcomes depend on many factors besides breed, such as production practices and barn environment.”

she says, “and that we are making steady progress on those fronts with conventional birds.”

Barn environment monitoring has never been better due to new technologies, and control has never been more precise, which provides many opportunities to optimize bird welfare.

Long says that “as a vet, it makes me very excited that if we can detect that a flock is dealing with a disease before we see signs of it in other ways, we can take proactive measures. We can also use historical data and also do predictive modelling for health and welfare outcomes. It’s a huge shift that is starting and there is no one consolidated way of doing things in the industry yet, but those will be developed. We will find ways to use all the measurements we can now obtain.”

In terms of other technologies, Maple Leaf is gathering data from automated scoring of foot pads (a welfare indicator) at processing to determine if there are differences in flocks and barns and why.

Long notes that Canada’s poultry welfare research programs at various universities are known worldwide but the challenge remains to translate research results into commercial practice standards.

She also notes that there is still debate on which welfare outcomes are most important. But the industry is moving from prescriptive outcomes such as cage size to things like foot pad scores that expose differences in bird health that are, in turn, affected by feeding program, barn conditions, management practices, genetics and more.

“The International Poultry Welfare Alliance has been doing a lot of work to come up with new welfare outcome measures recently and they are going for public consultation soon,” Long says. “I have been involved in these working groups and I hope the outcomes will be adopted globally. For broilers, they include gait mobility scoring, catching and transportation-related injuries and mortality.”

• Use less straw (also works for shavings)

• Create a base that is nice and flat for waterers & feeders

• Save on fuel vs. blown in bedding

Save on fuel vs. blown in bedding

• Fast and easy process, can be done by 1 person

• Barn setup according to your own schedule, not dependent on weather

• 9’ Fork (9’ 8” Overall Width)

• • Fork Available in Skid Steer, ALO & Manitou

• Available in Skid Steer, ALO & Manitou mounting configurations

• 5’ Fork (70.5” Overall Width)

• Fits standard Ventrac / Steiner implement mounting brackets

• Hydraulically Driven using aux. machine hydraulics

• Hydraulically Driven using aux. machine hydraulics Fork Fits standard Ventrac / Steiner implement

• Levelling jacks to set bedding depth

Another innovation available from:

• Belt Driven using machine drive pulley

• Levelling jacks to set bedding depth

• Belt Driven using machine drive pulley Levelling jacks to set bedding depth

Visit our website for links to videos of the Rotary Fork in action

Another great product from: County Line Equipment Ltd.

8582 Hwy 23 N., Listowel ON N4W 3G6

County Line Equipment Ltd.

Another great product from: County Line Equipment Ltd.

8582 Hwy 23 N., Listowel ON N4W 3G6

PH. (800) 463-7622

8582 Hwy 23 N., Listowel ON N4W 3G6

PH. (800) 463-7622

www.county-line.ca

www.county-line.ca

PH. (800) 463-7622

info@county-line.ca

info@county-line.ca

PH. (800) 463www.county-line.ca -line.ca

www.county-line.ca info@county-line.ca

By Treena Hein

Over the last year or so, highly pathogenic avian influenza (HPAI) has again taken centre stage on the global poultry disease front, and discussion of vaccination is heating up. This is especially because the current strain of HPAI is persistent and seems to be endemic in wild bird populations.

The International Egg Commission (IEC) conference in Europe in September has two sessions on AI vaccination: ‘The Future of Avian Influenza Prevention’ by Dr. Ben Dellaert of Avined in The Netherlands and ‘Opportunities and challenges of AI Vaccination’ by Dr. Arjan Stegeman, professor at Utrecht University, The Netherlands. However, these experts cannot comment until after the conference has ended.

IEC also has an AI Global Expert Group,

which was established in 2015 and brings together top scientists and experts from around the world to propose practical solutions to combat avian influenza in the short, medium and long term. In the U.K., a consortium of eight groups headed by the Animal and Plant Health Agency have formed a new project called ‘FluMap,’ looking at AI viral evolution, entry onto farms and control methods, including vaccination.

However, there are many questions in Canada and elsewhere about whether vaccination is an effective and feasible control option for some groups of poultry or in any of them.

Indeed, AI vaccination is impossible for broilers because of the 21-day withdrawal time and because only killed vaccines can be used. “It’s the same issue for turkeys” says Dr. Jean-Pierre Vaillancourt, a profes-

sor at University of Montreal and a member of CRIP Swine and Poultry Infectious Diseases Research Centre. “They live longer but using a killed vaccine would be an issue.”

As Dr. Mart de Jong, a professor of Quantitative Veterinary Epidemiology at Wageningen University in the Netherlands, noted in a recent story in the University’s research magazine, one major question about new vaccines against AI is “whether they are effective enough – whether they provide sufficient protection against transmission.”

De Jong added that “many of the existing vaccines work well in the lab, but their effectiveness in the field is very disappointing. This is especially true of the traditional vaccines, which consist of an inactivated

BroilerMeatSignals contains practical information about broilers and all further steps in processing. With practical tools and modern insights to guarantee an efficient produced, safe, healthy and tasty product.

On a global scale, poultry will soon be one of the most important protein source in the human diet. The quality of this meat is essential. The modern consumer is critical and has high standards of expectation. It is a challenge to meet up to these expectations.

‘To meet modern consumers standards in broiler meat, all partners in the chain should focus on quality, from the fertilized egg through broiler production and processing to consumption!’

$73.75 | Item# 1883052607

While vaccinating broilers and turkeys isn’t an option due, in part, to trade issues, there have been discussions around administrating it to layers.

virus. With them, we see much lower quantities of antibodies in the field. The question now is whether this is also the case with newer types of vaccine.”

Dr. Mike Petrik, veterinarian director of technical services at McKinley Hatchery in St. Mary’s, Ont., explains, “We currently have vaccines that seem to reduce clinical signs, but don’t get rid of viral spread.” This generally means that the level of antibodies created in the bird’s body in response to the vaccine is too low to provide adequate protection against virus transmission and vaccinated birds can still pass on the virus.

Says Petrik’s, “If we vaccinate, it is likely that the virus will continue to circulate in the Canadian flock. It will

be very important to have a vaccine that can be differentiated from a field virus, so that if a flock tests positive, we will know for certain whether it was from the vaccine, or whether they have influenza virus exposure.”

This is called the ‘DIVA’ (Differentiating Infected from Vaccinated Animals) strategy.

This aspect of potential AI vaccination ties strongly into serious trade concerns. Importing countries obviously only want healthy animals to enter. In addition, existing trade agreements prohibit vaccination.

Petrik notes that Canadian firms export significant numbers of genetic poultry stock to a great number of countries around the world. He explains that if we

OCT. 18, 2022

10:00AM MT / 12:00PM ET

INSPIRE | LEARN | LEAD | CONNECT

Register for this free, virtual mentorship-style event with some of the most influential female leaders in Canadian agriculture.

Hear from the 2022 Influential Women in Canadian Agriculture program and other industry trailblazers on important topics such as leadership, balance, and communication.

Join Lana Shaw, Megz Reynolds, Valerie Carney, Heather Watson, Lisa Mumm and more for an afternoon of interactive discussions as they share their experience, offer guidance and discuss their journey in agriculture.

vaccinate for AI in Canada, we will need trade agreements that address this, and it may be difficult to get agreements with all the countries involved.

When contacted for comment, United Egg Producers (UEP) in the U.S. also revealed concerns about trade. The organization states, “While our farmer-members have not taken a position on AI vaccinations, UEP appreciates the U.S. Department of Agriculture’s continuing consideration of an AI vaccine. We strongly encourage continued discussion in close collaboration with national and international poultry industry leaders and regulatory authorities, especially as it relates to the complexities around both the science and the potential trade implications of HPAI vaccines.”

Another issue with AI vaccination is how it could be accomplished affordably. The vaccine must be injected, which involves a huge amount of manual labour. A vaccine that could be administered by water is a possibility.

However, no matter the type of delivery, any AI vaccine must address the current strain or strains. That is, as the global poultry industry well knows, new AI variants are constantly emerging

“We currently have vaccines that seem to reduce clinical signs, but don’t get rid of viral spread.”

through genetic mixing, the same thing that happens with human flu viruses.

Overall, Vaillancourt does not foresee widespread AI vaccination occurring in Canada, nor even in France, where the current AI outbreaks in Europe – the worst in history – have mostly been concentrated. “The strategy will be to target certain regions and types of birds: breeders, layers, ducks,” he says. “We need to look at backyard flocks as well.”

The broiler breeder and turkey producers in the U.S. are against the use of a vaccine due to trade issues, says Dr. John Clifford, who was Chief Veterinarian at the U.S. Department of Agriculture and now works for the U.S. Poultry and Egg Export Council.

“With layers, you can still get infection with vaccinated birds,” he adds, “and the cost is prohibitive. There is the cost of the vaccine, and there are also the costs associated with a DIVA strategy or sentinel strategy, where unvaccinated birds are placed with vaccinated birds in the same facility and tested for infection.

“Vaccine companies would need a big market in order to develop an AI vaccine, and I don’t see this market existing in the U.S. and other countries that do a lot of poultry trade. It could be an effective tool in eradication efforts and for those countries that do not export.”

For his part, Petrik believes the Canadian poultry industry needs to take more time with the topic of AI vaccination.

“My feeling is that we will need to wait and see what this fall and next year bring with respect to the impact of the wild virus, to determine whether it makes sense to start a vaccine program,” he says. “But there is a great deal of interest in Europe and the U.S. in investigating vaccination, so it’s a discussion that is definitely getting more traction now than ever before.”

The Canadian Food Inspection Agency has studied vaccination as a strategy against the spread of AI and has created guidelines around its effective use. The agency states that these guidelines “are part of an internal document, which is not available to the public. The option to vaccinate may be considered depending on the circumstances of the outbreak. Various outbreak conditions and physical and resource limitations will have an impact on which control measures will be the most effective.”

Location

Tourond, Man.

Sector

Broiler breeders

The farm

Suncrest is a Hutterite colony with a diverse agricultural operation. They’ve been raising broiler breeders since 2010 under the guidance of barn manager Ryan Kleinsasser.

The need

To get started in the broiler breeder sector, the colony bought an older farm. Fast-forward 10 years and the aged facility was approaching its best before date. What’s more, the producers needed room to expand. Thus, when they had the opportunity to move into a new location, they seized it. First, they started building a new pullet barn in the summer of 2020. Second, they got started on a layer barn. Both facilities were completed by November 2021.

The barn

The structures are made of concrete walls with a plastic finish, both on the inside and outside, making them easier to wash. Both facilities also include Roxell oval pan feeders. For their nest system, they went with a Jansen community nest – a centre nest with a side scratch. “It’s better all around,” says Kleinsasser of the nests, noting lower floor eggs. They also went with a Jansen egg packer and conveyer system that brings the eggs to a central location. For ventilation, they installed the Better Air inlet system and Better Air fans. While they’re currently running two flocks of 10,000, they built the facilities to accommodate future growth. For more, see the photos and descriptions to the right.

YOU HAVE AN INSTINCT TO PROTECT. WE HAVE AN INSTINCT TO PROTECT FAST.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic and important variant IBD strains.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative.