SUBSC RIBE to our e-newsletter for news and updates. Egg Farmers of Canada provides fresh egg industry news to help you stay informed about topics that affect our industry Visit eggfarmers.ca to subscribe and learn more.

by Brett Ruffell

SUBSC RIBE to our e-newsletter for news and updates. Egg Farmers of Canada provides fresh egg industry news to help you stay informed about topics that affect our industry Visit eggfarmers.ca to subscribe and learn more.

by Brett Ruffell

Ihad the privilege of visiting numerous barns this summer, and lugged my video equipment with me to document my travels. I met many passionate farmers doing innovative things. People like Ryan Kuntze, a Stratford, Ont.-based broiler producer and self-described peat moss guinea pig.

Disappointed with how other bedding options were performing, he started using peat moss about a year ago. The idea of using it for broilers was so novel he had to travel to the Netherlands just to get a firsthand look at another poultry farmer using it. As you’ll read on page 38 and see on our website, Kuntze says his experiment has improved barn conditions and delivered bird health and welfare benefits.

Then there’s Cindy “Egg Farmerette” Huitema. If you frequent our website you’re likely familiar with her fascinating blog where she chronicled her family’s conversion from conventional layer housing to an enriched system. A year later the new barn is up and running and her blog has, unfortunately, concluded.

I got a sneak peak at the state-of-the-art facility, a tour you can watch on our website, and was blown away. Now, in our alternating housing supplement Phasing Out Conventional, a special guide for egg producers included with this issue, she looks back on the experience and shares her key

takeaways for others planning a similar barn conversion.

Yet another farm I visited this summer was Egg Farmers of Canada (EFC) chairman Roger Pelissero’s layer operation in West Lincoln, Ont. I was there for an important announcement of global significance.

Since 2007, Canadian Poultry has been documenting the development of Hypereye, a made-in-Canada egg scanning technology that identifies fertility and gender in-ovo. The first-of-its-kind tool, which Egg Farmers of Ontario (EFO) and Livestock Research Innovation Corporation are partner-

“We’ve

constantly demonstrated our strong defense of supply management”

ing on, promises to drastically improve animal welfare and hatchery efficiency.

And it’s getting closer to market every day, as researchers fine-tune the device. “We’re running at about 90 per cent accuracy on the gender side and probably 98 per cent on the fertile side,” Pelissero reveals. “The gender side we want to get up to the 98-99 per cent area.”

A financial commitment the feds pronounced at the EFC exec’s barn this summer should help them get there. Minister

of Agriculture Lawrence MacAulay was on hand to announce the government was providing $844,000 to EFO for the initiative. “This tool has the potential to transform the industry,” MacAulay said in announcing the funding. “It would save millions of dollars in energy costs by cutting waste.”

There was an underlying theme to the event. With supply management under prolonged attack during NAFTA renegotiations (The Donald is not a fan), the minister said the investment was partly to show the government’s commitment to the system. “We have consistently demonstrated our strong support and defense of supply management,” said the former dairy farmer. “As I’ve said many times and I’ll say again, it’s a model for the world.”

Will the Liberals stay true to their word? We’ll soon find out. I’m writing this column shortly after talks surpassed the Trump-imposed NAFTA deadline.

And the president is still targeting supply management, threatening to impose tariffs on other sectors if he doesn’t get concessions.

Pelissero says home-grown innovations like Hypereye provide strong cases for Canada standing firm. “I think it’s a powerful story about how supply management contributes to better animal welfare,” the producer says of the scanning technology.

“[The system] allows us to look at innovation and research. We’re not afraid to spend dollars because we’re able to make a fair return.”

canadianpoultrymag.com

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Associate Editor Jennifer Paige jpaige@annexbusinessmedia.com 416-305-4840

National Account Manager

Catherine Connolly cconnolly@annexbusinessmedia.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Emily Sun

Circulation Manager

Anita Madden amadden@annexbusinessmedia.com 416-442-5600 ext 3596

VP Production/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

President/CEO

Mike Fredericks

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Circulation email: rthava@annexbusinessmedia.com Tel: 416-442-5600 ext 3555 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates Canada – 1 Year $32.00 (plus applicable taxes) USA – 1 Year $69.00 USD Foreign – 1 Year $78.00 USD GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

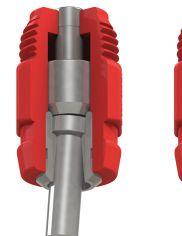

With LUBING’s drinkers you can say goodbye to Chicken Little and hello to Bigger Settlement Checks! Customers using broiler drinkers are experiencing faster weight gains, better conversions and lower mortality rates.

p

Large bottom pin that holds a drop of water to attract day old birds to nipple / great starts / average first week mortality below 1%.

o verage

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Greater side flow with minimal triggering force allows all birds to easily trigger the nipple and get off to a great start. Great Starts = Greater Finishes!

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Fax: (403) 337-3590 Les Equipments

Tel: (780) 963.4795

Fax: (780) 963.5034

Greater side orce allows all bi nd to av fo an

Both, vertical and side action, deliver the Opti-mum flow rates and ability to grow a 4 lb small bird up to a 10 lb Jumbo bird with the same nipple. After hundreds of house updates, customers are consistently seeing improved weight gains of up to 1/2 lbs/bird with dry litter conditions!

For the first time, HatchCare chicks have been born in the United Kingdom. These chicks were hatched in mid-July in Boston, Lincolnshire, U.K., and were directly provided with feed, water and light post-hatch. HatchTech commissioned the HatchCare hatchery together with Annyalla Chicks, a family business that runs independent hatcheries in Ireland and the U.K.

The World Organisation for Animal Health has found Canada to be a top performing country and a leading example for meeting international veterinary service standards, with no major weaknesses. The evaluation, conducted at Canada’s request, was co-ordinated by the Canadian Food Inspection Agency and involved federal, provincial and territorial governments and representatives from the private veterinary sector, academia and veterinary regulators.

The University of Guelph recently honoured Tim Lambert at the UGAA Awards of Excellence Gala. Lambert holds an honours degree in animal and poultry science and is the longest-serving CEO of Egg Farmers of Canada. Well known for his pursuit of excellence in management, evidence-based decision-making and organizational culture, Lambert has spurred tremendous growth in production and sales for egg farmers in Canada.

of Canadian chicken farmers are enrolled in their provincial Environmental Farm Plan.

The vast majority of the Canadian chicken sector’s total energy use comes from renewable sources.

Considering the average carbon footprint of chicken around the world, Canadian chicken has one of the lowest carbon footprints of all. This is a key result coming from a recent Life Cycle Assessment (LCA) conducted by Groupe AGÉCO, a consultation firm specializing in corporate social responsibility and economic studies. The study was designed to measure the environmental and social performance of Canada’s chicken sector, from hatching egg to processor.

Since 1976, environmental performance significantly improved because of major productivity gains and significant improvements in feed conversion ratio. Per kilogram of protein, the carbon footprint of Canadian chicken is lower than that of other livestock commodities produced in North America based on FAO’s

assessment of global livestock emissions.

In the last 40 years, the carbon footprint of the sector was reduced by 37 per cent. Water consumption has been reduced by 45 per cent in the same timeframe. And 62 per cent of the entire sector’s total energy use comes from renewable sources, with chicken feed accounting for the bulk of renewable energy consumption.

Canadian chicken farmers are certified on the mandatory Raised by a Canadian Farmer On-Farm Food Safety Program and Animal Care Program, both of which are third-party audited. They’re also committed to phasing out the preventitive use of categories II and III antibiotics, are heavily involved in their communities and provide competitive working conditions.

Dr. David Fraser is a professor in the animal welfare program and the director of the applied biology program at University of British Columbia. Fraser chaired the expert consultation on animal welfare of the Food and Agriculture Organization of the United Nations (UNFAO) and was elected one of the original members of Canada’s National Farm Animal Health and Welfare Council. He was appointed a Member of the Order of Canada in 2005 for his work as a pioneer in the field of animal welfare science.

What sparked your lifelong interest in animal welfare?

I have always been fascinated by animals. My childhood activities ranged from hunting frogs to exploring forests with dogs. Eventually, I studied the science of animal behaviour. Just as I was graduating, the growing social concern about farm animal welfare led to a research position opening up. It involved studying the behaviour of farm animals in the then-new housing systems such as gestation stalls for sows.

How did the concept of ‘one welfare’ (the recognition of the many interconnections between the welfare of humans, animals and the environment) come about?

For some years we have used the term ‘one health’ to recognize that human health and animal health are closely linked, and that both are influenced by the environment. However, the focus of ‘one health’ was mostly infectious diseases. For example, when forest cutting pushed fruit bats closer to human settlements where they

transmitted Nipah virus to farm animals and to people.

How is ‘one welfare’ applied?

We have started to use it to capture the many other links between human welfare and animal welfare, often with the environment involved. An important example is that good mental health of animal producers is an important determinant of the welfare of the animals in their care.

How is it taking hold globally?

The concept applies in different ways in different countries. In a country like India, for example, drivers of horse-drawn carts are encouraged to use non-injurious harnesses both to improve horse welfare and the amount of work the horse can do. Elsewhere, good animal loading practices are encouraged to reduce losses from bruising. I think the concept has wide applicability because it focuses on win-win situations.

What do you see as current poultry welfare trends?

In many sectors of animal production, we are seeing a move toward a more professional mentality among producers. This involves setting standards for performance and having a collective means to ensure that all producers comply. I also see increasing recognition that genetics plays a key role in animal welfare. A challenge for poultry is to think how breeding for production traits may contribute to problems of bird health and welfare, and how to modify genetic selection to have favourable production and good bird health and welfare as well.

OCTOBER 2018

OCTOBER 10-11

Alberta Livestock Expo

Lethbridge, Alberta

OCTOBER 12

World Egg Day thinkegg.com

OCTOBER 15-16

Advancing Women in Agriculture Conference

Niagara Falls, Ontario

OCTOBER 16-18

Poultry Service Industry Workshop Banff, Alberta

OCTOBER 25

PIC Annual General Meeting Guelph, Ontario

NOVEMBER 2018

NOVEMBER 5-7

Poultry Tech Summit Atlanta, Georgia

DISEASE WATCH

Stay informed on infectious disease outbreaks with the latest alerts from Canadian Poultry magazine. For more, visit: canadianpoultrymag. com/health/disease-watch

AUGUST 20

Avian Influenza

Kostromskaya, Russia

AUGUST 16

Infectious laryngotracheitis

Brock Township, Durham Region, Ontario, Canada

AUGUST 10

Newcastle disease

Los Angeles, Riverside and San Bernardino counties, California United States

Maple Leaf Foods recently announced it is investing approximately $28 million to transition its Edmonton poultry processing facility to world-class controlled atmosphere stunning (CAS) technology, reflecting its commitment to building on its leadership in animal care, the poultry sector and value-added branded fresh chicken.

Maple Leaf will convert its transportation, lairage and receiving area and handling systems to optimize rest-time and create a climate-controlled environment as it implements this technology.

The new lairage system will enhance lighting, air quality and temperature control, allowing chickens to rest comfortably and significantly reducing stress.

The CAS technology selected is a very humane system that will ensure birds are fully insensible prior to processing. The conversion will result in a 26,000-square foot expansion at the Edmonton facility, which is expected to be completed by the end of 2019.

“We are on a journey to become the most sustainable protein company on earth and being a leader in animal care is a cornerstone of this vision,” said Michael McCain, president and CEO, Maple Leaf Foods. “We are deploying world-class technologies and best practices that support our goal to eliminate stress and pain and provide humane treatment of animals in our care, while enhancing employee health and safety and food quality. With Canada’s leading poultry brands, we are advancing many dimensions of sustainability, from eliminating

antibiotics, to best practices in animal care and dramatic reductions in our environmental footprint.”

“CAS provides many advantages to animal welfare, ensuring chickens are fully unconscious and humanely euthanized, while greatly reducing stress,” according to Dr. Greg Douglas, vice-president, animal care. “This technology, which we have also installed at our pork processing facility in Manitoba, is acknowledged as a best practice around the world,” Douglas added.

Maple Leaf Foods is also installing Remote Video Auditing at this facility, a training and auditing tool that supports rigorous monitoring and compliance to best animal care practices. This will be the ninth implementation as part of Maple Leaf’s commitment to incorporate Remote Video Auditing across its network.

To support its leadership, Maple Leaf has added a second shift at this facility to keep pace with demand and recently invested approximately $16 million to expand capacity at its hatchery operations in Wetaskiwin, Alta.

Maple Leaf has additionally reached an agreement to acquire two poultry processing facilities and related supply, with significant value-added capabilities, from Cericola Farms.

The company isn’t the only processor to recently go the CAS route. In April, Cargill Protein installed a state-of-the-art system at its London, Ont., poultry facility. The $22 million technology, which is now operational, replaced electric stunning at the processing site.

Accomplished poultry industry veteran Dr. Greg Rosales has been honored with the Lasher-Bottorff Award by the American Association of Avian Pathologists. The award is granted to those who have made significant contributions to poultry health programs in North America in the past decade. A retired vice president of veterinary services for Aviagen, Rosales continues to serve the industry as a consultant for Aviagen, as well as poultry production and pharmaceutical companies throughout the world. He is also a renowned author and editor.

Researchers from the University of Saskatchewan are heading a chicken farming pilot project in Mozambique to improve public health by bolstering the economy. Project FranGO is designed to be a “self-sustaining Mozambican incubator project” that will train local residents to start and manage a chicken farm. The goal of the project is for 16 families per year to learn about raising chickens and running a farm business.

Cristiano Bortoluzzi has received an award for his paper on improved performance and regulating the expression of intestinal immune-related genes of broiler chickens. Bortoluzzi’s winning paper evaluated the effect of sodium butyrate on performance, expression of immune-related genes in the cecal tonsils, and cecal microbiota of broiler chickens when dietary energy and amino acids concentrations were reduced.

By Lilian Schaer

are studying ways to reduce the

There’s a new poultry ration ingredient available on the Canadian market. Insect meal from defatted black soldier fly larvae is high in protein and low in fat, making it a potentially attractive alternative to soy in poultry diets.

For it to be used on commercial egg farms, though, more needs to be known about its impacts on both production and costs. That’s where Elijah Kiarie, assistant professor in poultry nutrition at the University of Guelph, comes in.

His master’s student Zipporah Mwaniki recently completed a project that replaced about 60 per cent of soy protein in layer rations with black soldier fly larvae meal, and is now working on new research where soy protein is entirely substituted with insect meal.

“Feed accounts for more

than 65 per cent of the variable costs of poultry production, and energy and amino acids make up more than 90 per cent of this cost,” Kiarie explains. “Right now the cost of insect protein is still high but we are looking to see what we can do to reduce these costs to make this a good alternative to soy and animal proteins such as meat and bone meal.”

Insect protein is also a great fit for organic poultry producers who have limited ingredient pools for their rations, he adds.

Defatting the meal and using the extracted fat in biodiesel production is one way to create additional value from insect production. As well, Kiarie says black soldier flies consume organic waste, which would help turn some of the 1.3 billion tons of food that is wasted every year around the world into a useful product with value.

Perhaps most interesting for

“We are seeing a stronger shell with insect protein, so maybe it can have an impact on bones too.”

producers, though, are the results of the first trials feeding insect protein to layers alongside soy.

There was no difference in egg production volume, but there was some noted variation in egg size as well as differences in yolk colour – the insect-fed birds produced eggs with darker yolks.

“Egg size is very important so it’s not good that there is variability, but consumers like stronger colours in the yolk, so that’s a positive development,” he says.

Most surprising to Kiarie, however, was that eggs from hens fed the insect protein had better shell quality with higher thickness and strength. This suggests the new protein

might have other benefits beyond just nutrition – one of the issues challenging North American and European egg producers is a decrease in egg shell quality and skeletal system strength as birds age.

“We are seeing a stronger shell with insect protein, so maybe it can have an impact on bones too. This is an exciting possibility because we need birds with strong skeletal systems as we move hens out of the cage system so maybe there is potential to rear stronger pullets,” he says, adding that this is an area in need of further exploration.

It’s also interesting to note that insects are almost 10 per cent fibre, called “chitin”, and preliminary data suggests there may be gut health benefit for the birds as well. What’s more, fibre’s ammonia-reducing properties could make for a better barn environment that would benefit both farmers and their flocks.

“Poultry will never digest everything we feed them but with what they do excrete, we want to have minimal impact on the environment and on bird and farmer health,” Kiarie says.

This research is supported by a discovery grant from the Natural Sciences and Engineering Research Council and the Ontario Ministry of Agriculture, Food and Rural Affairs – University of Guelph partnership. Kiarie’s position is supported by the McIntosh Professorship in Poultry Nutrition.

This article is provided by Livestock Research Innovation Corporation as part of LRIC’s ongoing efforts to report on Canadian livestock research developments and outcomes.

By Nathan Pelletier

Growing interest in the concept and practice of sustainable sourcing is redefining relationships and expectations in the agri-food landscape. Sustainable sourcing, simply put, refers to procurement of goods or services subject to their meeting a specified set of socio-economic, animal welfare and environmental sustainability criteria.

Examples of well-established sustainable sourcing initiatives include: third-party certified ethical sourcing programs like Fairtrade (designed to ensure that small-holder farmers get a fair price for their products); multi-stakeholder platforms such as the Round Table on Sustainable Palm Oil; and inhouse private sector activities like Unilever’s Sustainable Agriculture Program.

The phenomenon of sustainable sourcing reflects a broader trend in society towards accountability and transparency, as well as the rising expectation that businesses take a more active role in promoting positive outcomes that span people, planet and profit. This includes committing to measure, report and demonstrate progress with respect to clear sustainability goals.

For businesses, sustainable sourcing can serve multiple objectives. It can improve profitability by making better use of resources or capitalizing on sustainability marketing opportunities. It can aid them in managing brand reputation. And it can enhance public trust.

In a globally interconnected marketplace, sustainable sourcing presents obvious challenges. Material, energy and labour inputs to the production, processing and distribution of agri-food products along their value chains often span multiple countries and potentially impact on numerous stakeholders and ecosystems. For this reason, co-operation among value chain partners in producing and sharing information is essential to supporting effective and efficient sustainable sourcing. So, too, is the use of life cycle-based sustainability indicators that consider the potential benefits and impacts of products along the whole value chain.

Life cycle inventory databases can play a critical enabling role in data sharing and the calculation of life cycle-based indicators (e.g., carbon, land or water footprints) by providing value chain stakeholders with a common, quality-controlled repository for the information

that they or their value chain partners may need in order to meet sustainable sourcing program requirements. When publicly available, such databases are also suitable for hosting data used for in-house sustainability initiatives in order to promote transparency, credibility and reproducibility.

A variety of public and commercial life cycle inventory databases have become available in recent years. These may be national or global in scope, and either general or focused on specific sectors. To date, only two limited Canadian life cycle inventory data resources have been developed. The first is the Canadian Raw Materials Database, which was created in 1998 to house inventory data for the aluminum, glass container, plastics, steel and wood products industries. The second is the Quebec Life Cycle Inventory Database. In general, however, life cycle inventory data to support sustainable sourcing activities in the Can-

adian agri-food sector are limited, and no common repository has been established.

In order to resolve this bottleneck, I’m working with a team of researchers at the UBC Food Systems PRISM Lab to develop the Canadian Agrifood Life Cycle Data Centre (CALDC). This will be a publicly available database to support sustainability measurement and reporting activities in the agri-food sector. We’re currently creating the architecture for this database, backed by an expert stakeholder advisory panel comprised of representatives from industry, government, academia and others.

Following construction and testing, we intend to begin populating the database in late 2018 with data sets that are currently available in the public domain. We’ll also simultaneously invite private companies, industry associations, consultants and other research groups to begin to use the database to host their data sets. This will allow participants to retain ownership and control over their data, periodically update data sets as required and ensure that the information that they make publicly available is maximally interoperable with data from similar platforms elsewhere.

This is database will represent a huge step forward in terms of making sustainable sourcing and sustainability marketing/ communication more cost and time efficient, as well as more transparent and credible. I’m very excited to engage with food space leaders in moving this initiative forward.

The Canadian Poultry Research Council, its board of directors and member organizations support and enhance Canada’s poultry sector through research and related activities. For more details, call 613-566-5916, email info@cp-rc.ca or visit www.cp-rc.ca.

Research shows that under natural conditions, domestic fowl spend 70 per cent of their active time foraging by walking on the ground because their flight abilities are limited. When threatened or roosting, domestic hens seek elevated refuges. For roosting, birds fly up to the lowest branch of a tree and seek higher elevation by flying branchto-branch, whereas they descend by flying directly to the ground. Hens use their wings only for brief escape flights.

The conventional cage system is being phased out in Canada and will be replaced by single-tier or multi-tier systems; commonly known as aviary systems. These complex housing systems enhance opportunities for hens to express natural locomotion. However, research shows that complex housing systems increase the risk of bone breakages, foot disease and behaviour that may be detrimental to hen welfare.

Several designs of non-caged systems are commercially available but outcome-based animal welfare indicators are more prevalent in non-caged systems. These system designs have not been determined from a biological point of view to prevent injuries and it is unknown whether birds raised in alternative housing systems may be overtaxed in their locomotion skills.

Dr. Alexandra Harlander from the University of Guelph and her research team aim to investigate the locomotive development and skills of pullets and laying hens and to assess differences in them across strains. The intention of the research is to provide scientifically-based recommendations with respect to freedom of locomotion to improve the design of multi-tier systems to ensure that converting to non-caged systems in Canada results in the desired improvement of hen welfare.

Layer chicks prefer horizontal to inclined surfaces and to remain on ground surfaces but use elevated horizontal surfaces as early as two weeks of age. Strain differences in use of space were observed, with a white-feathered strain of layer

“System designs providing less than 40-degree inclines… minimize bird stress in aviaries and are recommended.”

chicks utilizing the space above the ground more frequently. Young pullets expressed the greatest level of high-intensity physical activity and brown-feathered strains allocated less time towards low-intensity physical activity compared to white-feathered strains. Chicks and adult laying hens performed walking behaviour in order to climb 40-degree inclines, and performed wing assisted incline running or aerial ascent on steeper inclines. White-feathered strains performed more wing associated locomotor behaviour compared to brown-feathered strains. Additionally, when birds are

experienced at climbing inclines, the time they require for sensory processing or decision making varies directly with the degree of the challenge before them. Whether a bird utilizes a direct or indirect pathway when ascending to perch varies by strain, but does not vary if there is footpad dermatitis.

The research provided descriptions of the development of leg and wing locomotion in the use of ramps and perches by laying hens. These results indicate that improving space use in rearing aviaries can be accomplished by introducing lower perches, platforms and ramps/ladders to accommodate age-dependent locomotor abilities. Additionally, system designs providing less than 40-degree inclines, which are easily navigated by chicks and adult hens, minimize bird stress in aviaries and are recommended.

Finally, the results highlight that overcrowding, visual constraints and poor physical health all reduce perching performance. The results of this research should help the laying industry adapt the environments of aviary systems to maximize the welfare of laying hens.

This research was funded by the Canadian Poultry Research Council (CPRC) and was part of the Poultry Science Cluster 2, which was supported by AAFC as part of Growing Forward 2, a federal-provincial-territorial initiative. The research additionally received funding from Egg Farmers of Canada.

Celebrate tradition with Canadian turkey. Families know they can trust Canadian turkey to be of the highest quality.

mitment to Producing Safe, High Quality Turkey Turkey Farmers of Canada (TFC) is one of only 4 ganizations to receive full government recognition under the Canadian Food Inspection Agency’s Food Safety Recognition Program. Com or

By Crystal Mackay

Undercover video. Two words that will send shivers up the spine of anyone who works in agriculture and food. There have been well over 200 undercover videos in the U.S. and 16 in Canada since 2012 targeting agriculture from farms through to processing. While it’s human nature to hope one never focuses on you, your company, suppliers or customers – it’s always better to be prepared.

Following and continually improving solid animal care practices in all aspects of farming, transport, handling and processing is, and always will be, the fundamental base of doing the right thing. However, with animals, people, equipment and mother nature all working for and against each other some days, even the best situation and people can be framed in a negative light by someone hired for that purpose or anyone with a cellphone camera.

The best time to plan for a crisis is when you aren’t in one. With that in mind, here is some information on the Canadian Centre for Food Integrity (CCFI)’s Animal Care Review Panel and how it works.

The panel process was developed several years ago by the U.S. Center for Food Integrity as a valuable tool to assist leaders within the food system to make more informed decisions with views from thirdparty experts in these often-difficult situations, which can lead to lost markets and customers. The CCFI Farm Animal Care Review Panel engages recognized third-

party animal care specialists, such as veterinarians, animal behaviour and (ACRP) experts to examine videos and provide their expert perspectives.

The experts review the videos independently and their comments are not edited or approved by others, to be truly representative of that expert’s opinion. CCFI puts together a report based on the experts’ opinions in a very timely manner, to be most useful in crisis communications timelines. This report provides a credible assessment of what the experts saw in the video, to be of service for food retailers, foodservice, agri-food industry partners and the media who may be covering or considering covering the story.

CCFI is a service provider in business to help the food system earn public trust. The Animal Care Review Panel is a service that can be requested by any provincial or national not-for-profit organization member of CCFI, with the goal to be helpful to the whole sector. When an undercover video response is handled poorly, it reflects badly and erodes trust in the entire agri-food sector, not just the company or sector being profiled. An individual for-profit company may not request an ACRP. This is to avoid potential conflicts of interest and to maintain the credibility of the process, as CCFI does not advocate for any positions or companies. So, if a company is in a video situation, they can ask their respective provincial or national association to launch and pay for an expert panel as a tool to help the entire

sector with credible content, context and a reference that can be shared widely.

“When an undercover video response is handled poorly, it reflects badly and erodes trust in the entire agri-food sector.”

Once a panel is underway, there is no contact with any industry partners to maintain the highest level of credibility. The release of the report and the findings of the panel are released to CCFI members, the media and other key food industry associations at the same time to strengthen the report’s integrity and influence. In an age of continually increasing scrutiny, the value of third-party processes like this will continue to grow.

Hidden camera investigations have heightened public attention on animal care issues, with CCFI research showing almost half of Canadians are unsure if these videos are reflective of normal farm practices. The ACRP provides a mechanism that agri-food sector stakeholders can rely on to objectively evaluate video investigations, regardless of species or subject matter.

There have been well over 200 undercover videos in the U.S. and 16 in Canada since 2012 targeting agriculture from farms through to processing.

The Farm Animal Care Review Panel process tests the veracity of the allegations and demonstrates the food system commitment to quality care and continuous improvement. This might include determining appropriate corrective actions when necessary. The panel is another tool in Canada’s farmer and processor associations’ comprehensive and evolving strategies to help maintain customer and consumer confidence and markets.

You can see the previous Farm Animal Care Review Panel reports at foodintegrity.ca.

Interested in learning more about public trust and consumer confidence in Canadian food and the poultry sector? Register and help shape the conversations about the future of public trust at the Canadian CFI Public Trust Summit in Gatineau, Que., November 13-14.

By Treena Hein

Whole bird turkey sales in Canada have declined quite a bit over the last few years, especially during the last two. Still, the turkey sector in Canada and in the U.S. continues to find success building consumption of other products.

There are many reasons why more families just aren’t having traditional holiday turkey dinners as often as they used to – or at all – including changing demographics and a desire to try new holiday meal options. There is also the fact, as recognized by Turkey Farmers of Canada (TFC), that turkey is simply not a part of diets in some corners of the world and, therefore, some immigrants to Canada just don’t tend to feed a turkey to the family crowd at holiday gatherings. “Household sizes tend to be reducing,” adds Alan Sakach, TFC manager of corporate communications, “so the size of the bird is an issue for many consumers…[but] farmers and processors are responding with smaller-size birds.”

In rural areas of Canada, whole turkeys are also quite expensive. In

urban areas, they’ve historically been quite cheap (retail chains have offered them at low prices to get customers in the door for their holiday meal shopping), but that’s changed, according to Sean Maguire.

Nowadays, says Maguire, sales and operations manager at Hayter’s (Hayter’s Farms and Hayter’s Turkey Products) in Dashwood, Ont., big chains seem to have lost interest in offering whole turkeys as a loss leader, and this is yet another factor contributing to the whole bird sales decline. “The big stores have reduced the length of time turkeys are on sale,” he asserts, “and have also increased the price compared to years past.”

However, Sakach notes that, on a per-serving basis, turkey is an excellent value compared to other meats, whether in whole form, cut piece tray packs or deli meats. He also points out that whole turkeys usually provide multiple meals.

In an effort to break through the traditional consumer mindset that turkey is only a special occasion menu choice and to promote Canadian-grown product, TFC has launched the Canadian Turkey brand. TFC’s research on consumption trends and consumer needs shows that 90 per cent of Canadians want their turkey produced in Canada, and that they view turkey as nutritious, tasty and healthy. TFC is, therefore, focused on engaging consumers throughout the year and not just at holidays, and is enhancing awareness of turkey

among three important groups: the main purchasers of groceries (women); health influencers such as dieticians; and ethnic consumers who may not be very familiar with turkey. These efforts involve ongoing relationships with Walmart, Canada Bread, Sopexa Avocados, Weight Watchers and Chef’s Plate, with more firms to come, and involve the promotion of the full range of turkey products.

TFC is also directly promoting turkey through an increased social media presence, including monthly contests, recipe postings, videos, nutrition resources and blogs with easy and affordable meal planning solutions. “Followers on our Twitter, Pinterest, Instagram and YouTube accounts,” Sakach says, “have increased by 18 per cent over the last year…One of our most recent social media campaigns launched in the spring (#timeforturkey) is focused on creating new ‘whole bird occasions’ such as Mother’s Day, graduations and Father’s Day and has generated nearly 29 million impressions.”

TFC also holds regular meetings, as others in the industry do, with producers and processors to more closely understand the emerging market dynamics and increase consumption of turkey. It also works with the provincial turkey boards when possible, which conduct their own outreach.

This year, TFC and some boards like the Turkey Farmers of Ontario (TFO) are promoting turkey as a great option on the BBQ. TFO’s Summer Sizzlin contest encourages independent restaurants to

include turkey sausages, burgers, tacos and more on their menus, and consumers who order a menu item with turkey in it are entered to win summer-focused prize packs, including a grand Ontario getaway prize. TFO marketing and communications lead Emily Haramule says close to 80 restaurants are involved across the province.

She adds that Ontario Turkey Foodservice Ambassadors also meet regularly with turkey processors, suppliers and foodservice distributors to ensure they stay current with the turkey products available. In addition, these ambassadors attend tradeshows such as the Restaurants Canada Show to engage with attendees about the benefits of turkey, ways of including it on the menu and more.

The National Turkey Federation

(NTF) in the U.S. is also actively promoting turkey for the BBQ.

Every June (proclaimed Turkey Lovers’ Month), and especially on National Turkey Lovers’ Day (which coincides with Father’s Day), NTF suggests grilling kabobs, sausages, tenderloins, cuts and burgers, and provides help with a Turkey Grilling Tip Sheet.

Back here in Canada, Hayter’s turkey burgers are selling really well. Maguire reports that three years ago, Hayter’s sold 500 kg of burgers every week and now it’s 10 times that, due to both the addition of new retail customers as well as increased demand from existing customers. Maguire adds that ground turkey is selling well, and is now being seen as interchangeable for ground beef. To increase the popularity of cut pieces, Hayter’s is

working to produce them from smaller toms so that the pieces are similar in size to chicken pieces.

“There is definitely a desire to try turkey,” Maguire says. “It’s something different but not too different. We are trying to keep prices close to chicken, so portion sizing is important.”

To achieve exact consistency in breast meat portions for food service, Hayter’s bought a processing machine for that purpose about a year ago. It now sells significant amounts of these exact portions to meal kit provider firms like HelloFresh and Chef’s Plate.

“The meal kit market is growing quickly,” Maguire says. “The meals are easy to prepare, with ingredients and steps and instructions provided, and they use a lot of ethnic recipes, which helps consumers

Turkey production, consumption and export in 2017

$384 million is the value of turkey products produced in Canada

542 is the number of regulated turkey producers in Canada

170.8M kg is the amount of turkey (eviscerated weight) produced in Canada, 65.3 per cent of which was produced in Quebec and Ontario

4.2 kg is the per capita turkey consumption

315,242 kg is the amount of turkey meat (eviscerated weight) the average turkey farm produced

7.8M-plus is the number of poults (young turkey) Canada exported, worth $32.7 million, to 10 countries

About 23M kg of turkey meat and edible bi-products (fresh, chilled, frozen), worth more than $38.5 million, was exported to 36 countries

Source: Agriculture and Agri-Food Canada

see the flexibility of turkey. Each company serves thousands of meals a week in Canada, and if turkey is one of five meal options provided, we can have up to 20 per cent of that market.” In total, Hayter’s processes six million kg of turkey a year (from its own farm and its contract producers) to foodservice and retail customers such as Longo’s, Sobey’s and Farm Boy. Hayter’s also supplies major Canadian foodservice companies that supply institutional markets. These products are

Cage-Free Solutions from Volito

When Chore-Time acquired Volito in 2016, we combined our decades of global leadership in egg production systems with Volito’s decades of expertise in cage-free. That means our lineup of rearing, aviary and nest systems may be new to this market, but they are not designed from scratch. These are proven solutions developed and refined by a company that helped pioneer cage-free in Europe nearly 30 years ago – now backed by one of the biggest names in the poultry industry to create a total package solution for today’s leading egg producers.

Learn more at choretime.com/volito

Domestic Disappearance refers to the amount that has been taken out of the available food supply in Canada: domestic consumption and exports.

(Source: Turkey Farmers of Canada)

mainly turkey breast and convenience items like breakfast sausages and bacon. But Maguire says there is room to be more innovative with packaging and portions.

Canadian Poultry and Egg Processors Council (CPEPC) president Robin Horel adds that fully-cooked products have been a favourite for a while among institutional cooking staff, as these items are easy to prepare and offer advantages in terms of both food safety and inventory management.

Generally, Horel notes that processors are marketing turkey as a lean, high protein, nutritious and versatile meat that is reasonable in cost. “We have lots of supply,” he says. “Our members are marketing whole-muscle turkey bacon, fully-cooked products (tenders, pulled, boneless and bone-in breasts, low-sodium boneless breasts), and uncooked turkey tenderloin, drums and wings and more.”

Sakach says Canadian turkey farmers want consumers to know that turkey is very versatile and adaptable to any cuisine. “We have more than 600 recipes posted to our website, with more added every day,” he says. Visit canadianturkey. ca for recipes, cooking tips and videos.

By Karen Dallimore

The laying hen industry in Canada is at the beginning of a 20-year transition. Following the lead of worldwide efforts to improve laying hen welfare, in February 2016 the Egg Farmers of Canada (EFC) announced that a move away from conventional egg production to alternative production methods would begin.

At the time this directive was unveiled, EFC estimated that 90 per cent of eggs were produced in conventional housing. The goal is to achieve a 50:50 split of conventional and ‘alternative production’ - enriched, free-run, aviary or freerange - within eight years, increasing to 85 per cent alternative production in 15 years and ultimately all production by 2036, if indicated by the market forecast.

With this transition still in its early phases, a new study recently completed by researchers at the University of Guelph has provided a snapshot of current laying hen husbandry practices in Canada.

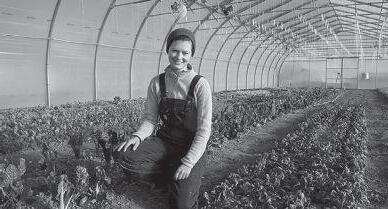

In October 2017, 122 Canadian commercial laying hen farmers with furnished or cage-free systems were invited through their provincial egg boards to participate in a questionnaire. In this voluntary study farmers were asked to describe their housing, management and flock characteristics. Sixty-four ques -

Egg farmers described their housing, management and flock characteristics for a University of Guelph study.

tionnaires were returned, providing data on 65 flocks, representing 26 furnished cage, 17 single-tier and 22 multi-tier systems with representatives from all major egg production provinces.

At the time of this study, approximately 11 per cent of Canadian layer farms had furnished cages and 17 per cent supplied non-cage housing systems on their

farms, sometimes in conjunction with conventional systems. The data, therefore, represents approximately 22 per cent of the furnished and non-cage farms in Canada at that time, housing approximately 935,000 laying hens.

Most furnished cage farms had 10,000 to

15,000 hens, housed in two-tier (36 per cent), three-tier (50 per cent) or more than three tiers (14 per cent), while farms with non-cage systems were typically larger with more than 25,000 hens. Seven of the farms were organic certified with multi-tier housing; two farms were furnished or single-tier operations with less than 1,000 hens.

As a reflection of the fast changes happening in the egg production sector, 10 farmers had only been working with their system for less than a year, while 26 systems were one to four years old, 17 were between five and ten years old and six were more than 10 years old.

Space allowance in furnished cages was 764.8 cm2 per hen; in single-tier and multi-tier systems, the average space allowance was 1,285.9 cm2 and 925.4 cm2 per hen, respectively, but there was a wide range of space allowance between flocks. The same can be said for group size, which averaged 40 hens in the furnished cages, 5,500 birds in single-tier, and 15,000 birds in multi-tier systems.

Outdoor access was provided for one single-tier flock and seven multi-tier flocks, with the majority of farmers providing artificial or natural shelters in the outdoor area. Birds were given access to the outdoors at an average age of 28 weeks, ranging from 24-to-30 weeks of age. Farmers reported a wide variation on the amount of outdoor range actually used and the percentage of the birds using the range.

Perches were provided in the majority of flocks. In most cases (82 per cent), farmers reported that all birds were able to perch at the same time, although actual perch space allowance was not recorded in this study.

Providing some sort of enrichment seemed to be part of standard farming practice in non-cage systems, with exposure at an average age of 25 weeks. Hanging objects such as bottles, ropes or string were used in eight percent of noncage systems, as well as bales of hay or straw (18 per cent) or mineral blocks and pecking stones (16 per cent).

Scratch areas that simulate foraging

and dust bathing opportunities were reported in 54 per cent of flocks with furnished cages, typically as textured plastic mats. Where scratch areas were in a cage, substrate was provided on the scratch pad in 57 per cent of the flocks. Scratch areas were typically cleaned one time per production cycle.

All multi-tier systems provided a litter substrate such as wood shavings (43 per cent) or sawdust (21 per cent). In 25 per cent of barns, manure was considered a litter substrate and in two-thirds of the flocks, litter was not replaced or raked to break up the surface.

Not all facilities complied with the requirements for space allowance and scratch areas as set out in the 2017 National Farm Animal Care Council Code of Practice for the Care and Handling of Pul-

According to lead researcher Dr. Alexandra Harlander, this description of non-conventional housing systems in Canada is part of a larger project funded by the Egg Farmers of Canada to develop a Canadian Feather-pecking Management Plan (CFMP) based on Canadian-tailored risk factors to prevent, reduce or stop feather pecking and poor plumage condition in hen flocks.

Through further analysis, Harlander and her research team will be identifying risk factors for feather pecking in Canadian laying hen flocks where hens were housed in enriched and non-cage housing systems. “With the feedback and information from the farmers combined with results from on-farm feather damage assessments for which we developed an illustrated guide, we will be able to develop the CFMP. This will help them choose between several courses of action to prevent, reduce or delay poor feather cover in laying hens.”

lets and Laying Hens , having been installed prior to the new code coming into effect. Similarly, over 20 per cent of non-cage systems provided a fully slatted barn and no litter, a practice no longer allowed under the code of practice.

A dusk to dawn period was typically created on 83 per cent of farms by the gradual dimming of lights in different areas in multi-tier systems or by automatic dimming in furnished and single-tier systems. Birds received 15 hours of light per day, on average.

Commonly used breeds were represented through the 65 flocks in this study. In furnished cages, the majority of birds were white-feathered while brown-feathered birds were more common in non-cage systems.

Consumers generally perceive that brown-shelled eggs have a higher nutritional value and are more ‘natural’, says primary researcher Dr. Nienke van Staaveren, which may explain their prevalence in non-cage systems.

Flocks were 45 weeks old, on average, but ages ranged from 19 to 69 weeks. Birds were generally placed to lay between 14 and 20 weeks of age. In singleor multi-tiered systems they were usually home-reared; for furnished cages, the birds typically came from conventional cage pullet systems. Rearing systems simulated eventual housing conditions for 52 flocks in terms of housing, perches, feed and environment.

Most farmers (55 per cent) inspected their flocks one to two times per day, checking bird health (100 per cent), behaviour (83 per cent), equipment (97 per cent) and litter quality (65 per cent).

At an average of 2.1 per cent, cumulative mortality appeared highest in multi-tier systems, while single-tier and furnished cages compared at 1.6 and 1.1 per cent, respectively.

Farmers reported that the most frequent cause of mortality was birds getting trapped in housing equipment (19 per cent), followed by disease (17 per cent), leg injuries (15 per cent) and cannibalism (14 per cent).

While disease issues were not commonly reported, less than one-third of farmers (29 per cent) had a flock health program in place with their veterinarian.

Additional information was gathered regarding egg production, flock performance, litter management and ventilation.

This voluntary study sample data represents a wide range of farm sizes and locations across Canada. “This information can be used to better understand practices in these housing systems to increase farmer awareness of expected changes during the transition phase of the Canadian egg production sector,” van Staaveren says.

For more information on alternative housing systems and management, visit canadianpoultrymag.com/tag/alternative-poultryhousing.

By Melanie Epp

Last year, Canadian Poultry outlined how some North American retailers were starting to source slow-growth broiler meat due to pressure over welfare concerns with conventionally grown chickens. Now, we look at economic, environmental and animal welfare factors attached to slow-growth broilers and also at Europe’s experience.

About a year-and-a-half ago, Whole Foods announced that it would be making the switch from conventionally raised broilers to slow-growth broilers. The move is expected to be complete by 2024 and will mean repopulating broiler farms that supply the store with breeds like Red Ranger and Naked Neck. Many believe that the move is activist not consumer driven, which begs the question: Is slow-growth production better? And, what are the economic, environmental and welfare implications of making the switch?

According to the Global Animal Partnership, slow-growing broilers grow 23 per cent slower than conventional breeds. While they deem slow-growing breeds as better, they do not take into consideration the environmental impact of 23 per cent longer production cycles. Tatijana Fisher, a PhD from the University of Kentucky, presented slow-growth broiler data at a Poultry Industry Council conference earlier this year. The data she presented came from self-selection feeding trials that compared the growth performance of Red Ranger (slowgrowth) and Cornish Cross (conventional).

For the trials, birds were housed on the floor in groups of 25 in a standard system, Fisher says. The birds were offered four choices of feed: A protein concentrate that contained all of the necessary vitamins and minerals, cracked corn, pearl millet and rolled naked oats. Birds were monitored to see what

While a relatively new trend in North America, slow-growth production is much more established in Europe. But research raises questions about its sustainability.

they ate and, over the course of 20 weeks, average energy intake was calculated.

Slow-growing broilers grow 23% slower than conventional breeds.

The findings show that while Red Ranger was cheaper to feed day-to-day, the cost to feed it out in the long run was much higher. In terms of growth performance, the Cornish Cross has a higher average daily gain than the Red Ranger. “We have about a 1.9 feed conversion on the Cornish Cross, which is not the best you can get off them,” she says. “The Red Ranger had about a 2.2, which is downright awful on some level.”

“Still it was better than some heritage breeds, which have a feed conversion rate of about five,” she adds.

Fisher looked at other factors, too, including carcass weight without giblets as a percentage of live weight. The Cornish Cross was around 74 per cent, she says, while the Red Ranger was about 68 per cent. Most of that weight is lost from the breast. The Cornish Cross,

in fact, has almost double the Red Ranger in terms of breast weight.

“If you’re selling this as a whole bird it’s kind of okay,” Fisher says. “It’s smaller and it’s different, but it’s not that bad. Cut up parts and you’re going to have a lot of trouble getting enough breast meat off of these birds to meet the breast meat demand on the market.”

Fisher said more research is needed to look at nutrient requirements, meat quality, behaviour and welfare parameters. She says they have not officially looked at welfare parameters, however she says she didn’t notice a difference between the two breeds when it came to mortality or other welfare-related issues.

While slow-growth production is new to North America, it’s not new in Europe and has been particularly successful in the Netherlands where many retailers have made the switch. Researchers have conducted similar studies in Belgium to see if fast-growing broil-

ers are more efficient when fed the same daily feed quantity as a slower growing strain. Evelyne Delezie, a researcher at the Institute for Agriculture and Fisheries Research in Belgium, concluded that feed efficiency was significantly better in the fast-growing strain than in the slow-growing breed.

“My opinion is that those animals have better welfare [slow-growth breed], but it’s not sustainable if you look at the efficiency of those animals,” she says.

Research has also been conducted in the Netherlands where adoption of slow-growth production is almost certainly the highest in the world. Retailers have vowed to source 100 per cent slow-growth breeds by 2020.

Today, about 90 per cent of the fresh market in the Netherlands is slow-growth. But has the move been a good one? Peter van Horne, economic researcher at Wageningen University in the Netherlands, crunched the numbers to find out. He presented his findings at a recent poultry conference in Portugal.

Van Horne’s calculations considered production parameters, including growing period, the number of cycles per year, flock density, mortality, live weight, growth and feed conversion, comparing conventional breeds with slow-growth breeds. Revenue earned for both types of production were compared, and it was concluded that slow-growth producers earned more at €1.17 ($1.83 CAD) per kg versus €0.90 ($1.41 CAD) per kg for conventional breeds.

Van Horne’s calculations didn’t stop there. He wanted to know if the amount compensated was worth the extra cost. After crunching the numbers, he found that Dutch farmers made essentially the same amount of money for doing the extra work. The gross margin per square meter, he found, was 15.2 for conventional versus 15.7 for slow-growth production.

“My opinion is that those animals have better welfare [slow-growth breed], but it’s not sustainable if you look at the efficiency of those animals.”

He did admit that most factors cost more in slowgrowth production – heating, catching, litter and manure disposal – but pointed out that animal health came at a lower cost in slow-growth production. This, he said, is because 29 per cent of regular flocks are treated versus four per cent for slower-growing breeds.

“Farmers are happy with slow-growing birds because the margin is the same,” Van Horne says. “To be honest, with the slow growing birds it’s less work. You don’t have to do the same amount of work because you have fewer birds and mortality is lower. You even get a better price because you have less work with the slower-growing breeds. Farmers seem to like it.”

Despite its success, Van Horne recognizes that slowgrowth production has a larger carbon footprint – 20 per cent worse, in fact.

“That’s the dilemma,” the researcher says. “Some

people say the slow-growing bird is a welfare-friendly bird, but the fast-growing is an environmental bird. Then you have to make a choice.”

For those who are considering making the switch, Van Boekholt advises them to

come up with a strong branding and marketing plan. When it comes to pricing, he prefers to look at slow-growth chicken as an “added value” product, rather than from the price-cost perspective.

He also suggested that farmers know

what they’re getting into before making the switch. “If you don’t believe in it, please don’t start,” he adds. “You really have to believe in it to produce slower-growing chickens because it is different. If you don’t believe in it, it will fail.”

Dutch farmer saw a significant decrease in mortality after switching to slow-growth broilers.

Ruurd Abma, 55, is a first-generation broiler farmer. His farm is based in Groningen, in northern Netherlands, where they raise 150,000 broilers and own a hatchery. Although Abma started out in conventional production, he switched to slow-growing broilers two years ago.

Abma says he had a lot of problems, particularly leg problems, with the conventional breed, which had an average daily gain of 68 to 69 grams. The local slaughterhouse frequently rejected the meat he produced.

Taking notice of his frustration, the local slaughterhouse asked Abma if he would like to switch to a slower-growing breed. They were willing to compensate him financially for the increased cost in production. He agreed.

With traditional breeds, Abma could produce eight flocks each year. “Now we only have six flocks per year,” he says. Immediately, Abma noticed a difference in the health of the new breed. Mortality is lower: 1.7 per cent versus four to four-and-a-half per cent with the traditional breed. “The chicken are much stronger,” he says.

Switching to a slower-growing breed meant a change in management practices. For instance, the barn now lets in more daylight.

Abma said he would have liked to make the change earlier, but four years ago consumers were not willing to pay the extra costs. Two years ago, they agreed to pay more, he says. “If the slaughterhouse doesn’t pay more, I cannot do it,” he notes. “We are happy that, in Holland, the time has come.”

The latest research examining welfare concerns and more. By Treena Hein

Feeding young broiler breeders around the world generally involves restriction starting when the chicks are one week or a few weeks of age. This is done so that they grow at a rate that supports their health and welfare – one that prevents obesity, lameness and reproductive problems.

In North America, feed restriction is managed either through daily feed restriction or skip-day feeding schedules, where chicks receive no feed on one or more non-consecutive days per week and receive a greater quantity of feed on the remaining days.

“Methods of skip-day feeding vary from farm-to-farm across Canada, but it is a practice many of our producers are familiar with or have employed,” notes Jack Greydanus, chair of Canadian Hatching Egg Producers (CHEP). “In general, skipday feeding typically begins at about three weeks, and the days skipped are reduced

as birds approach the laying period. By 22 weeks, every-day feeding is more typical.”

There are some welfare concerns with both types of feed restriction. Limiting feed on a daily basis means that while birds still get enough food for their growth, they can exhibit signs of chronic hunger. Not being fed to satiety can also cause stress and injury due to the competition for food (pecking) it promotes.

That some chicks outcompete others for food also can mean weights in the flock are not uniform.

Skip-day feeding can cause stress as well, from hunger on off-feed days and also from the birds not knowing when their next meal is coming. As far as CHEP members’ use of skip-feeding, Greydanus notes that, as an organization, CHEP works closely with animal welfare experts, and that skip-day feeding is a practice that is acceptable under Canada’s voluntary National Farm Animal Care Code of Practice.

“That said, as an industry we are always looking for ways to improve and update our practices,” he notes. “Welfare is a main research priority for CHEP. We are funding research by Dr. Stephanie Torrey at the University of Guelph on alternative feeding strategies for broiler breeders.”

Torrey suggested consulting Aitor Arrazola, a PhD candidate in the university’s Department of Animal Behaviour & Welfare under her supervision. Arrazola led a recent two-year study to assess the effect of alternative feeding strategies on broiler breeder pullets and he also analyzed some long-term effects of these strategies after the pullets had grown into laying hens.

Arrazola notes that while some positive effects of alternative diets have been reported under lab trials in the past, there has been no conclusive findings by the scientific community relating to advantages in commercial production settings.

In Arrazola’s study, broiler breeder

chicks donated by Aviagen (via Horizon Poultry of Hanover, Ont.) were reared for two years at the Ontario Ministry of Agriculture, Food and Rural Affairs’ Arkell Poultry Research Station in Guelph. Throughout this period, Arrazola and his team gathered data about pullet performance, behaviour, health, feeding motivation, stress indicators, physiology, anatomy and gastrointestinal functioning and development.

Arrazola found that pullets given skip-day feeding showed reduced feeding motivation compared to pullets given daily feeding during early rearing. However, compared to pullets on a graduated feeding schedule (which involved daily feeding at the end of rearing), pullets on a 4/3 schedule (Three days fasting within four days feeding) were highly motivated to forage and to eat feathers after feeding time. Arrazola says his measurements of physiological indicators suggest that broiler breeders can habituate to their feeding frequency, especially if the schedule is more predictable (e.g., a 4/3 schedule compared to the 5/2 schedule – two days fasting within five days feeding).

Later on, hens that had received the 4/3 schedule and the graduated feeding schedule were found to have a greater laying persistency compared to hens that had received daily feed.

“Methods of skip-day feeding vary from farm-to-farm across Canada.”

Graduated schedule hens also had the highest cumulative egg production, which Arrazola says may be the result of compensatory growth when the feeding schedule switched from skipday to daily.

However, hens that received skip-day feeding lay settable eggs with a relative heavier yolk than hens reared on daily fed treatments, and hens reared on the 4/3 schedule had the fastest feed intake and the highest compensatory feeding at the end of lay, combined with a better body weight uniformity. Furthermore, Arrazola says “there were fewer males hatched from eggs laid by older broiler breeder hens reared on [skip-day] schedules.”

A recent study by Dr. Caroline Lindholm and colleagues at Linköping University in Sweden was recently published in the journal, Poultry Science. The team compared birds raised on a 5/2 skip-day schedule to birds raised on daily feed restriction. They found signs of increased physiological stress levels in the skipday birds, and that the birds showed no signs of learning the feeding schedule. The researchers believe this unpredictability is a stress factor.

At the same time, 5/2 skip-day birds showed signs of lower anxiety before feeding times, which may be a result of the lower feed competition associated with larger portion sizes. (That is, the birds seem to understand that they will each be getting a large meal and are not stressed about having to compete for it.)

The 5/2 skip-day birds also generally showed more interest in a novel object in the home pen, which indicated increased risk taking and reduced fear while fasting.

“Taken together, the effects of 5/2 feeding versus daily feed restriction on the welfare of broiler breeder pullets remain inconclusive,” states Lindholm, “and differ between feeding and fasting days. In addition to reducing stress by minimizing the number of fasting days, we suggest that a shift to more predictable schedules may help improve the welfare of broiler breeder pullets.” Based on this study, which did not include 4/3 skip-day feeding schedules, they conclude, “Restricted feeding of broiler breeders is required for improved long-term health and welfare.”

In terms of what recommendations Arrazola would like to communicate from his research, he notes that, in terms of improving body weight uniformity, rearing practices such as grading, increasing feeder space and using a pellet or crumble diet rather than mash seem more promising than pursuing skipday feeding schedules.

From a welfare perspective, Arrazola notes that unlike the European study, his results do not support that daily feed restriction is better than skip-day feed restriction for broiler breeders. However, he describes skip-day feeding as “an ethical concern” because the birds are hungry on off-feed days.

The researcher advises that if producers use skip-day feeding, they might “consider providing non-nutritive ingredients during off-feed days – for example, rolled wheat in an alternative feeder.” Arrazola adds that because broiler breeders are highly motivated to forage independently of what feeding day they are in during a skip-day schedule (especially those raised on the 4/3 schedule), providing bedding material and scratching areas could reduce further behavioural problems such as feather pecking, aggressive (severe or injurious) pecking and drinker pecking.

“Environmental enrichment can help to redirect oral behaviours toward objects instead of feather pecking,” he adds. “I recommend producers check for feather coverage, prevalence of skin lesions and litter

1. Provide non-nutrient ingredients on off-days.

2. Add enrichments to help redirect oral behaviours.

3. Regularly check feather coverage, skin health and litter quality.

quality on a regular basis.”

Greydanus says producers in Canada use a variety of skip-day feeding schedules. Indeed, some will use (throughout each pullet cycle) daily feeding for the first week or weeks, then 4/3, then 5/2, then 6/1, finishing with every-day feeding.

Greydanus does not provide non-nutritive ingredients during off-feed days to his poults, nor provide them with enrichment objects in order to reduce pecking. To his knowledge, no other CHEP members use them, but he and others use dimmed lights and other methods to reduce pecking.

However, Greydanus believes that non-nutritive ingredients during off-feed days and permanent enrichment objects may be employed by CHEP members to their poults in the future, as feather pecking is getting more prevalent. “It didn’t happen in years past, but has only started in the last two to three years,” he notes, “which makes me and others believe it’s related to new genetics. We are always responding to genetics changes.”

atLanta, ga USa | FEB. 12 - 14, 2019

Join us for the 2019 IPPE and experience the most current technology and solutions used in the production and processing of poultry and eggs. See it at IPPE first and connect with more than 30,000 industry professionals in feed, meat, poultry and more at one powerhouse of a show in February! R E g IS t ER now at www.ippexpo.org

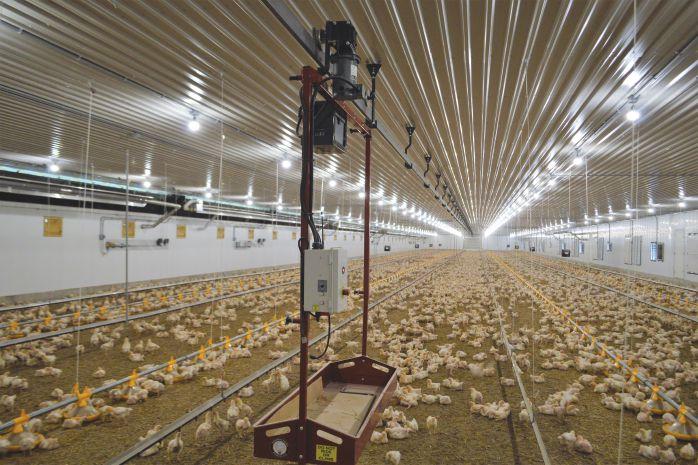

By Andrew Bourne

The broiler housing and equipment industry continues to develop, introducing new technologies in line with trends in modern management, communication and ventilation systems. As you might expect, early adoption in markets such as Europe and North America, which have high labour and utility costs, easily justifies investment in these modern technologies. Due to market volatility, poultry growers in developing countries can have financial constraints that limit access to modern technology.

In the past couple years there has been considerable consolidation within the equipment industry. The current focus is on combined heating and recirculation systems and renewable energy resources. There is increased scrutiny from government and environmentalists on CO 2

emission levels, which is driving the change away from direct gas burners to indirect gas burners (heat exchanges), or water-based heating systems.

Water-based heating systems have been used for years, but renewed interest is sparked by the system’s numerous advantages. They do not contribute to house CO2 and humidity levels and also offers flexibility with regards to fuel choice. Hot water circulation systems with finned tube designs have higher surface areas for more efficient heat release and the ability to maintain excellent temperature uniformity in a low noise environment.

The suppliers of livestock housings controllers for both the swine and poultry sectors are integrating biometric sensor technology. They integrate the use of various sensors to monitor and measure water and feed intake, behaviour and hourly weights. All this data along with animal behaviour in terms of distribution and activity monitored by cameras is input in an

early warning system for proactive and predictive flock management.

An exciting, innovative technology advancement is the introduction of on-farm hatching in Europe. The eggs are transferred directly to the farm at day 18, where they are hatched and have direct access to feed and water. Trials have shown improved early weights and feed conversion when compared with traditional hatching. However, the investment cost and technology involved is still a limiting factor for most growers.

Ensuring maximum early feed intake and daily gains requires optimal water consumption. The benefits of fresh cool water during brooding and early production have seen renewed interest and research. Many of the suppliers of nipple drinkers are also supplying automatic flushing and pressure regulating systems, which are fully integrated with the controller. The monitoring of water temperature in the nipple lines, which has already

been adopted by certain suppliers, will be the industry standard in the near future.

In the housing sector, there’s been a dramatic increase in the construction of modern, environmentally controlled houses across regions where open sided housing was the norm, especially in the tropical regions of the world. With the steady increase in further processing in what were exclusively live bird markets, a need for reliable volumes of high quality birds has stimulated the growth in closed environment systems.

Traditionally, most houses have been constructed with curtain sides due to unreliable electricity supplies and the fear of backup generator failure. The relatively small difference in cost between good curtain installations versus solid side walls are very easily offset by the advantages that are seen in their increased adoption. One of the keys is the tightness or ability to maintain static pressure of a solid sidewall when compared with the maintenance and poor lifespan of a traditional curtain.

In most markets outside Western Europe, tunnel houses have moved away from the traditional 12 m by 120 m design. Longer and wider houses are being constructed to better optimise capital investment and floor space. The 15 m by 150 m tunnel house has become the design of choice, with some integrations in North America opting for even larger houses, such as 18 m by 180 m. All new broiler houses are being equipped with tunnel airspeed capabilities more than 2.8 metres per second or 600 feet per mintue, depending on bird size.

In China and Southeast Asia, land cost and availability have resulted in many fully integrated companies adopting broiler colony systems, allowing integrations to place up to three times the number of birds per square metre as opposed to a traditional floor system.

In markets that are fully integrated and have increasing demand for further processed birds, they are certainly feasible. The high capital cost per bird of such systems will limit adoption in many countries where live bird market prices are extremely volatile and very sensitive to local changes in supply. A very large single age production facility can potentially disrupt local live bird prices.

As in many parts of the world, bedding materials such as rice husks and wood shavings are becoming more scarce and expensive. This has driven the industry to look at different options. The adoption of plastic slat systems is widespread across Southeast Asia. The most popular format is the short slat, about 15 to 20 cm in height.

The adoption of the low slat system has some major challenges. The labour-intensive process of washing the slats is one hurdle. Probably the biggest obstacle is difficulty keeping the manure dry during the production period. Careful management of the nipple drinking systems to reduce dripping and unnecessary waste of water is a must.

The low air exchange rates across the manure will result in poor moisture removal. Almost 70 per cent of water consumed is deposited in the manure. Elevated levels of wet manure attract huge fly control issues, which could result in bird health and local environmental concerns. In regions where farms are located near villages, fly infestations will be a public concern.

An alternative to the low slat system is the adaption of the broiler pit style slat houses. They include a 1.5 to 1.8 m enclosed ventilated area below the slats. The advantages include easier access and cleaning of the manure, and the ability to manage moisture levels, reducing the fly issues.

The developers of environmental controllers are designing systems to manage ever-larger poultry farms, offering the producer an ever-expanded array of options for monitoring and controlling farms, irrespective of their geographical distribution.