Colin Breukelman reflected on his decision, saying,

‘The

by Brett Ruffell

Avian influenza is back. After a mostly mild spring and a disease-free summer, a handful of outbreaks were detected in Western Canada in September. That’s why, during the recent lull in cases, industries still made important investments to safeguard their sectors from the disease.

In the most recent development, the federal government announced it was investing $1.81 million over three years to help the B.C. Poultry Association prepare for future outbreaks in the province. The organization represents all four supply managed poultry sectors on common issues.

This investment will assist the association in accomplishing several priorities. Specifically, it will help it create and implement standard operating procedures (SOPs) for comprehensive training, personal protection equipment (PPE) inventories and rotation, secondary destruction methods and hiring contractors.

It will also support the association in creating and tendering a contract for a primary supplier for destruction, biocontainment, and training as well as secondary destruction capacity to assist if there is a surge in infected premises.

What’s more, the money will aid the organization in developing a partnership with B.C. AgSafe to assist with worker safety during training and annual fit

tests for workers requiring PPE.

Lastly, the investment will help the association develop and build strategic partnerships with B.C. Ministry of Agriculture and Food, processors and allied trades for an effective HPAI response.

A few weeks before the B.C. announcement, Alberta’s poultry industry revealed a similar commitment. To support Alberta’s poultry industry, Results Driven Agriculture Research (RDAR), Alberta Chicken Producers (ACP), and Egg Farmers of Alberta (EFA) awarded $733,801 to avian virologist Dr. Faizal Careem, University of Calgary, Faculty of Veterinary Medicine, to lead an avian influenza research project.

“During the recent lull in cases, industries still made important investments to safeguard their sectors.”

The investment, including $633,801 from RDAR, will help define effective, science-driven biosecurity procedures, and outbreak control measures.

Careem’s research will target several areas for understanding the magnitude of the current avian influenza outbreak in Alberta, including: identifying the route HPAI is introduced to poultry flocks; defining HPAI transmission risk in primary control zones in the period between diagnosis and depopula-

tion; and determining the role that non-migratory birds might have in HPAI outbreaks.

An Ontario-based project announced this summer takes a different approach. To support and mitigate further impacts, specifically to small flock and non-supply managed flocks, the governments of Canada and Ontario established a “Small Flock Future State” project with Poultry Industry Council (PIC) in the amount of $300,000 over two years. The intent is to create proactive outreach and information sharing resources as well as to train a roster of case workers to support active infected premises.

This venture will take two years to complete and begins with the development of novel online and paper-based informational resources for farmers.

The original Small Flock Kits, which OMAFRA developed, will be updated and revived into kits that will be handed out at key dissemination locations such as feed supply shops, or by ordering online. A separate component of the project is to train available industry people to act as case workers in the instance there is an overabundance of small flocks affected by HPAI and needing a coach or liaison to assist them through the response process, so that business can return to normal.

Are you aware of any other initiatives aimed at protecting the industry against future outbreaks? Email me at bruffell@ annexbusinessmedia.com.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson

randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada – 1 Year $32.50 (plus applicable taxes)

USA – 1 Year $91.50 CDN

Foreign – 1 Year $103.50 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

From the first day your chicks and poults are placed, water is one of the first things they look for, and for decades farmers and poultry have relied on our drinkers for a consistent flow of fresh water.

Our drinkers provide poultry the single most important ingredient for the BEST POSSIBLE START, AND HEALTHIEST LIFE DURING LAY PERIOD AND GROW-OUT.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc. Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

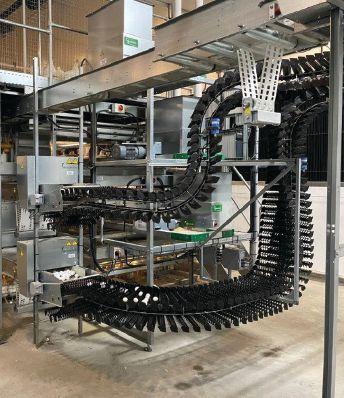

Recently, the federal government announced an investment of up to $2,932,500 for Eden Valley Poultry under the Supply Management Processing Investment Fund. This investment will help Eden Valley Poultry modernize its processing and wastewater systems, purchase and install new packaging equipment, and adopt an enterprise resource planning system. Through these improvements, the company will be able to increase processing capacity and efficiency through automation.

The Meuneries Mondou Inc., and Groupe Hubert have announced that they have recently reached an agreement regarding the ownership at Wilfrid Major Ltd.’s production site in North Lancaster, Ont. Since September 1st, the Meuneries Mondou Inc. has been producing all standard poultry feeds from North Lancaster under their brand name, Meuneries Mondou. Meanwhile, Groupe Hubert has been providing organic poultry feed under the name Wilfrid Major Ltd. from their facilities in Nicolet, Que.

After nearly four years as executive director of the Poultry Industry Council, Ashley Honsberger left the organization in late September for a role with the Ontario Soil and Crop Improvement Association. She led PIC through the stormy times of the pandemic and avian influenza. The PIC board will soon commence a search for a replacement.

Egg Farmers of Canada recently announced the appointment of Drew Black as its new chief executive officer, effective November 6, 2023.

“We are excited to welcome Mr. Black as our CEO. He brings a wealth of knowledge and in-depth experience from working within the agriculture sector for many years. His incredible passion for nurturing collaborative teams, which is something we prioritized throughout our CEO search, makes him particularly well suited to lead Egg Farmers of Canada,” says Roger Pelissero, chair of Egg Farmers of Canada.

“He is a proven leader who will be working closely with our board of directors and our talented staff to continue to strengthen Canada’s egg farming sector.”

Advertisement Black takes over for Tim

Lambert, who recently moved on after serving in the role for over 20 years.

Black has extensive knowledge of governance, advocacy, and policy and program development.

He takes on the role of CEO after serving as executive director at the Canadian Hatching Egg Producers, where he was the principal liaison between the board of directors, board committees, and the organization’s operations.

Prior to this, he served as the director of environment and science policy at the Canadian Federation of Agriculture.

He has sat on a range of federal and global advisory committees and roundtables, advancing policy and regulations in the areas of animal health, biosecurity, and climate change.

“I am honoured to join Egg Farmers of Canada and for the opportunity to work with the board of directors, the staff team, provincial and territorial egg boards, and the organization’s many stakeholders,” Black says.

“Egg Farmers of Canada is a well-known leader, and I have significant respect for what the organization has achieved throughout its long history. I look forward to supporting the growth of key areas such as on-farm standards, innovation, and sustainability within Canada’s egg farming sector.”

OPTIMAL AND COST-EFFECTIVE SOLUTIONS BASED ON LIFELONG EXPERIENCE

Increased turnover and efficiency are key factors for the success of the SKIOLD LANDMECO customers in the broiler farming industry all over the world.

The patented pan feeding solution for broilers increases growth rate and makes it more homogeneous and more efficient. With the unique design of the pan the chicks will learn correct feeding behaviour from day one and the chicks will grow faster, hitting their target weight in less time, which makes the whole operation more profitable for you. The patented solutions from Landmeco also secures an optimization of the performance and operational reliability through simple robust designs that always make a difference.

An optimal production in broiler farming requires that the equipment is modern, efficient and easy to use — and ours is. At the end of the day you can trust us to install a barn for you which is much more profitable, and which makes your daily operation much easier.

The system stimulates the chicks’ curiosity and collectively activates them to seek fresh feed. Experiments have thus shown that chick bodyweight is up to 30 g higher than normal after the first week when the kick-off system is used.

County Line Equipment Ltd. sales@county-line.ca | www.county-line.ca

Listowel 8582 Hwy 23 N., Listowel ON N4W 3G6 (800) 463-7622

Hickson 596202 Highway 59, Woodstock, ON N4S 7W1 (800) 463-7622 ext 4

By Dr. Gigi Lin

Dr. Gigi Lin is a board-certified poultry veterinarian. She provides diagnostic, research, consultation, continuing education, and field services to all levels of the poultry industry in Western Canada. In this column, she will share case-based reviews of brooding best practices.

On a cold Christmas Day, a conventional turkey grower called to consult about a flock of seven-day-old poults. Over the past 48 hours, the flock experienced an increase in mortality, signs of lethargy and a decrease in feed intake.

A field visit was arranged, and the necropsy findings indicated gross lesions consistent with starvation: dehydrated birds; off-feed; empty crops with gizzards filled with litter; and distended gall bladders.

Upon entering the barn, the poults were quiet and inactive. Many birds were found huddled in groups throughout the barn. A comprehensive assessment was conducted, systematically evaluating temperature, feed, litter, air quality, water availability, and sanitation (TFLAWS).

The poults were provided with adequate feed and water supply. The air and litter temperatures were within the expected range, with no discernible drafty or cool spots detected under the infrared camera. However, the most significant finding was the elevated carbon dioxide (CO2) levels, with readings ranging from 3,500 to 4,500ppm throughout the barn.

Carbon dioxide in poultry barns is often generated by normal combustion processes and bird respiration. The build-up of CO2 levels are particularly prevalent in under-ventilated barns, especially during the winter season.

When the concentration of CO 2 exceeds 2,500 to 3,000 ppm, the adverse effects on bird behaviour becomes obvious. Poults may display signs of lethargy, drowsiness, and huddling behaviour, as their metabolism slows down – this behaviour can also be observed in flocks exposed to cold temperatures.

Subsequently, these birds reduce their feed and water intake, leading to an increase in mortality due to starvation in chronic cases. Long-term exposure to high CO2 levels can negatively impact gut health,

“This case shows that birds exposed to environmental challenges usually recover well if the underlying cause are corrected promptly.”

flock uniformity, and overall flock performance, ultimately impeding growth rates. Turkey, in particular, is more susceptible to high CO2 level. Studies have shown that carbon dioxide levels above 2,500ppm of were linked to significant spontaneous cardiomyopathy, also known as round heart disease.(1)

Therefore, during colder months, it is important to strike a balance between energy costs and ensuring sufficient fresh air flow.

Following the consultation, the ventilation and heat systems were adjusted. Additional creep feed was placed on chick paper to facilitate easier access to feed.

The next day’s follow-up phone call showed that the birds had returned to normal behaviour. The flock was bright and alert, and evenly distributed throughout the barn. The feed and water consumption levels also returned to normal. The grower expressed his intention to install a CO 2 meter for continuous monitoring.

This case shows that birds exposed to environmental challenges usually recover well if the underlying cause are corrected promptly.

Looking for more from Dr. Gigi Lin? A webinar she delivered for our Broiler School series outlining case-based reviews of brooding best practices is now available on-demand at canadianpoultrymag.com. The series also includes experts speaking about emerging diseases, gut health in a post-antibiotic world and biosecurity best practices.

Reference: 1. Frame, D. D., Buckner, B. E, and Anderson, G. L. Causes and Control of Spontaneous Cardiomyopathy or Roundheart Disease in Utah Turkeys. Utah State University Extension. 1999

Although the number of onfarm feed mills on poultry farms in Canada isn’t easy to determine, it’s currently a substantial number and could be growing. The reasons for taking the plunge are similar among all farms –more control over feed to have more control over production (bird health, performance and profits).

Alberta broiler breeder producer Jeff Notenbomer, former chair of the Alberta Hatching Egg Producers and current director at the Canadian Poultry Research Council, has had an on-farm feed mill for over 25 years and it’s been a very positive experience overall.

Around 1996, Notenbomer decided he’d had enough of fighting feed consistency, both in volume and protein level. At his operation, Willow Creek Poultry in Lethbridge, he installed a mill for his 30,000 birds. He explains that “here in Alberta, it’s a wheat-based diet and differences in

wheat protein level each year can be extreme. So, in addition to putting in our own feed mill around 1996, I started buying all our wheat for the year from one source and stored it. I made fresh feed for the layers every day and had excellent bird performance.”

But in 2019, difficulties emerged in sourcing micro-ingredients such as vitamins and amino acids. At times, Notenbomer was only able to buy lower-quality products, which represented a strong potential risk to flock health and more.

“I was getting nervous,” he remembers. “There was another issue as well. My feed is obviously mash, and I noticed there were more fines at the end of the row compared to the start of the row. It’s obviously really important with breeders, because they’re feed-restricted, that each bite for each bird has full nutrition. I wanted to solve that too.”

Notenbomer then decided to try feeding a blend of ground wheat with a purchased

pellet. This strategy means that each bird gets a consistent bite and that Notenbomer still has control over protein level. He’s also still getting all or mostly all the savings an on-farm feed mill provides, compared to buying the total ration.

“We are getting consistent results, and I think it’s actually better results but it’s hard to compare exactly right now,” he explains.

“Since the avian influenza outbreaks last year, we are doing longer production runs to ensure there are enough chicks due to a few breeder farms in the province having been wiped out.

“By the end of this year, those barns should be back to full production. Overall, I think I’m spending only a bit more, but I’m very happy with the results of this new blended feed.”

Since he put this strategy in place, Notenbomer has also been trying different levels of wheat, each of them over an entire year, and adjusting protein in the pellet accordingly. “I’m trying 20 per cent right now and

I’m going to try 30 per cent for a year in November,” he says.

The on-farm feed mill at Triaro Farms near Arthur, Ont., started up in November 2021. The farm is owned by Clarence Pronk and his sons Jason and Steve. There, they crop over 1,800 acres and produce almost a million broilers per year.

A commercial-sized feed mill was always part of the farm business plan for several reasons. “We’d always thought about it, and we knew we could do better with bird performance with our own feed,” says Jason, “and we were done with zero control over price and sub-par feed quality. It’s been the best investment we’ve ever made in terms of profitability.”

Having an on-farm feed mill (in this case a roller mill to ensure a consistent grind size for the corn, and a Hayes & Stoltz mixer) would also provide an income stream through sales to other producers.

The push to finally order and install the mill came after a flock health disaster in early 2017 (bronchitis). “We were told it was all our fault, but turned out it was a hatchery problem,” Jason explains. “So, when we switched hatcheries, it was a great opportunity to try a new feed mill and compare that flock with another flock fed with feed we bought from a farmer who makes his own.

“We found bird performance was significantly better with the feed produced on farm, and so we went ahead with our own mill. Our feed conversion, mortalities and condemns are so much better and the barn conditions are too. The ammonia levels are lower, and litter is dryer, making the birds

so much more comfortable.”

In Jason’s view, this is because the feed they make is closer to what chickens are created to eat, and because it’s better quality. He explains that their mash requires the birds’ gizzard to work, whereas commercial feed pellets do not, circumventing this

natural digestive system component.

“The closer you get to nature, the better for the bird,” he says. “You do have to manage the birds differently, but it’s not a big deal. And in terms of quality, we don’t put in fillers or cheaper by-products, and we use high-quality vitamin and minerals as opposed to lower quality. So of course, the birds are healthier.

“We have ground corn, expeller soybean meal, hi-pro corn distillers and a high-quality premix that make up the bulk of our feed rations. Right now, we use all our corn to make feed for ourselves and a few customers, so if we expand, we’ll need to buy corn. We sell all our soybeans and buy meal, but we’re dreaming of our own on-farm

“It’s been the best investment we’ve ever made in terms of profitability.”

8soybean processing system.”

ROI was expected to be 10 years but Jason and his family think that with their feed sales, it will likely be reached in seven or eight years. They sell their feed at a price that’s at least that of commercial feed, usually, but that makes sense as the quality is so high. “We are not least-cost formulated and we are now selling almost as much feed to other farmers as we use,” he says. “We can make ten times as much feed as we are now, so we will expand. We tell other farmers who want to buy from us, you will not save money buying our feed, and if they made their own feed like we do they would save on that, but we tell them the money is made in the barn.

“The bird health, feed conversion and mortalities are all much better. It’s a no-brainer. And we also tell other farmers, size doesn’t matter. If you produce this many birds, put in a feed mill that fits your farm. It’s still worth time and money. I’ve heard that out west, it’s common to produce feed on the farm, but Ontario broiler producers are being told there is no money in it. That’s just not true.”

Continued to page 24

Vencomatic Group offers a full range of innovative equipment for poultry farms accross North America. We are proud to be a global leader in cage-free solutions that are flexible, practical and high-performing.

Our poultry experts provide expert advice on barn layout, bird management, climate management and egg handling.

More information: www.vencomaticgroup.com or please contact your local dealer.

BLR Solutions

QC - T: +1 450 772 2929 jfbourbeau@blrsolutions.ca

Jonkman Equipment Ltd.

BC - T: +1 604 857 2000 info@jonkmanequipment.com

Penner Farm Services

AB - T: +1 403 782 0675

MB - T: +1 204 326 3781 info@pennerfarmservices.com

Pols Enterprises Ltd. ON - T: +1 905 708 5568 sales@polsltd.ca

Ruby360 Ltd. ON - T: +1 888 218 7829 sales@ruby360.ca

Western Ag Systems

SK - T: +1 306 222 4881 wayne@westernagsystems.com

A round up of new Canadian poultry feed ingredients and broad trends.

By Treena Hein

Anthony Dick, who runs his family’s third-generation broiler operation, Tandem Grove Farms in Chilliwack, B.C., is one of many producers across Canada currently trying out a phytogenic feed additive (PFA) on their flocks.

PFAs represent the biggest current trend in feed, but they are far from new. Over the last few decades these substances have undoubtedly been the main focus of feed research, says Dr. Bertrand Medina, technical manager at Probiotech International in Saint-Hyacinthe, QC.

PFAs are described as plant-derived bioactive compounds, including extracts like saponins and essential oils, capable of improving many aspects of livestock health and productivity. Through boosting nutrient digestibility and energy availability of feed, and through their other unique properties, PFAs can boost immune system function and disease resistance, improve the gut microbiome, decrease pathogen prevalence and much more.

Dick has trialed a PFA called Selko Synerco from Trouw Nutrition with two consecutive flocks. These trials have taken place in one of the farm’s barns that’s served as a research barn since the 1990s.

Conditions are monitored closely, and the broilers are pen-housed but otherwise live under commercial conditions. All the farm’s broilers are fed from the Chilliwack feed mill (with Trouw Nutrition products since they’ve been available in Chilliwack).

Synerco is a blend of oregano, cinnamon,

and essential oils. Trouw Senior Researcher Dr. Stephanie Torrey explains that it helps in the maintenance of normal gut mucosa and contributes to healthy digestive functions and metabolism in poultry.

“It helps increase body weight gain while improving feed conversion,” she says. “Synerco can be combined with other products, including high copper and/or organic acids, and it can be used in antibiotic-free production systems as well as organic production systems.”

Dick has seen several positive performance benefits from feeding Synerco, including increased growth and improved feed efficiency. “As the industry continues to move away from using antibiotics in a preventative manner, we need to continue to look for alternatives to antibiotics,” he says. “Synerco seems like a good alternative. I haven’t used it anywhere else yet, but I would love to try it in the other barn to see if it improves performance there as well.”

Michael Foti, director at Phibro Animal Health in Guelph, Ont. agrees that PFAs have gained traction in the animal nutrition sector due to numerous natural benefits. Phibro offers a unique combination of quillaja, a bark extract of the soapbark tree, and yucca, a hardy desert plant.

These ingredients have individual benefits but their combination results in a synergistic, enhanced effect, says Foti. Over the past five years, Phibro Animal Health has conducted more than 40 studies on the combination, several of which have been published in peer-reviewed publications.

“Their combination can aid in better digestion and nutrient absorption,” Foti explains. “Research has also shown that when quillaja and yucca combination is fed at recommended inclusion rates, poultry are better able to defend themselves against important intestinal pathogens.”

These exceptional students are the winners of the 2023 CABEF Scholarships. We are proud to support each of them with $2,500 for their ag-related post-secondary education.

Help us empower more students to pursue diverse careers in agri-food. Strengthen the future of Canadian agriculture and food by investing in the cream of the crop.

Become a Champion of CABEF and directly support a scholarship for a Canadian student.

Sarah MacDonald Vanderhoof, BC Erin Hughes Longview, AB Wyatt Pavloff Perdue, SK

Milan Lukes Winnipeg, MB

Kyla Lewis Dorchester, ON Matthew Bishop Round Hill, NS

Congratulations to this year’s CABEF scholarship recipients.

Contact CABEF today to learn how you can become a “Champion of CABEF” at info@cabef.org

CABEF is a registered charity (#828593731RR0001). For more information on all registered charities in Canada under the IncomeTaxAct, please visit Canada Revenue Agency www.cra-arc.gc.ca/charities.

In addition, he says both Quillaja saponaria and Yucca shidigera contain polyphenols which have shown potential anti-inflammatory effects that “can be beneficial in reducing stress and promoting overall animal wellbeing.”

Meanwhile, the Probiotech R&D team has designed specific PFA formulas for supporting raised-without-antibiotics or raised-without-medically-important-antimicrobials broiler programs.

Medina explains that in 2022, Dr. Carl Julien, a research scientist at Deschambault Animal Sciences Research Center (CRSAD) in QC, developed a set of in-vitro methods for finely evaluating anticoccidial capacities of drugs and their alternatives.

He demonstrated the potential of a formulation of essential oils, Yucca Schidigera pulp and polyphenols to alter Eimeria pathogenicity in-vitro and reduce coccidiosis impact in both Eimeria-vaccinated or

non-vaccinated broilers.

Medina also reports that “recently, Candice Blue, a PhD student at University of Georgia in the U.S., assessed a commercial blend of etheric (rich in terpenes) and functional vegetable oils (rich in medium chain fatty acids) on performance and tight junction proteins in broiler chickens during a necrotic enteritis challenge and concluded that this tested PFA might be considered as a potential alternative to alleviate disease effects.”

Solid state fermentation is being used by Alltech to produce unprecedented complexes of synergistic enzymes made by fungi. One complex has been formulated to achieve “improved nutrient release through the breakdown of indigestible portions of the diet, such as non-starch polysaccharides and

phytic acid,” explains Dr. Kayla Price, poultry technical manager for Alltech Canada.

“The second-generation enzyme complex developed through solid state fermentation improves the energy, phosphorous and calcium release of previous versions. This complex can be used in both corn and wheat-based diets for all poultry and supports greater flexibility in feed reformulation and enhances the use of alternative raw materials, resulting in improved cost savings, more efficient feed utilization and maintaining performance.

“Since the development and release of this technology, research trials have been completed in pullets, broilers, and layers, with upcoming work in turkeys.”

Dr. Tanka Khanal, poultry nutritionist at Grand Valley Fortifiers in Ontario, notes a trend of using higher-quality premixes.

“Premix companies and poultry nutritionists are investing more and more in technologies and knowledge on better mineral stability and relatively higher bioavailability,” Khanal says. “Hence, the way of manufacturing a quality premix is being redefined. The possibility for negative interaction of components in premix is more focused and will continue in the days to come.”

Khanal also points to research into by-products from processed chicken meat that can be used in poultry feed. This may lead to substantial use in future. “Plasma, feather meal is heavily researched to see if can be used as a sustainable source of feed ingredients,” he says. “Researchers are also working on several fibre fractions of co-products to potentially utilize as nutraceuticals,” which are components with health-promoting or disease protection properties.

Water products

Just this summer, Trouw Nutrition also introduced Selko ProHydro+, a blend of organic acids that effectively reduces and stabilizes drinking water pH, promoting intestinal health and digestion.

Holistic view

Khanal also observes that nowadays in Canada, the poultry production system has embraced a holistic nutritional program approach. This includes a greater integration of nutrition, health, performance and economics.

“This integrated nutrition, health and welfare (both producer and poultry) approach is trending to switch feed from least cost to best cost,” he explains. “With this, the road map of the poultry industry will strive for less protein in feed and better digestibility of nutrients.

“This will move forward to a more environment-friendly and sustainable production system with less use of antibiotics or alternatives. The feed efficiency and profit per kilo of meat, per dozens of eggs, or per chick hatched will matter more than just total profit.”

The fog generated by PulsFOG will cover all hard to reach areas. Assortment of PulsFOG models to choose from.

Evaluating gut health in layers fed black soldier fly meal. By Jane

Robinson

When Stephanie Collins thinks about insects as a poultry feed ingredient, she’s really thinking about the future. Collins and her research team at Dalhousie University have recently completed a feeding trial with black soldier fly larvae meal in laying hen diets.

“We aren’t the first to use insects but we are thinking about how to feed future generations and also looking to adopt more efficient environmental practices,” says Collins, an associate professor and animal nutritionist in the faculty of agriculture.

Black soldier fly meal is showing signs of being a bit of a wonder feed, as an economical alternative protein in poultry diets to

replace some of the corn or soybean content, and one that’s generated in a carbon negative environment. Already an approved feed ingredient in Canada, and in other countries around the world, widespread commercial production and adoption of the insect meal is a little way off.

In the meantime, Collins and her team, including PhD student Jing Lu, are gathering valuable experience and information about the impact and opportunities of including black soldier fly meal in laying hen diets.

They recently completed a four-month feeding trial with 180 laying hens to compare levels of black solider fly meal in layer diets – 0 per cent, 6.5 per cent or 13 per cent of the diet – in brown- and white-feathered

birds. They measured hen performance, egg production, egg quality, diversity of microbes in the gut, production of short chain fatty acids in the gut, as well as the fatty acid composition of eggs.

“Our goal was to learn more about this up-and-coming feed ingredient to support gut health, food security and environmental sustainability,” says Collins.

She credits her full team on this research – in addition to Lu – including Hannah Facey, Sarah MacPherson, Krista Budgell, Janice MacIsaac, Sasha Di Stefano-Pitre and Jamie Fraser.

More meal is better

Sometimes the most important finding in research is that the idea worked. That’s

what Collins and Lu found with black soldier fly meal.

“You don’t always get what you wish for in research,” says Lu. “But we did this time in terms of a more diverse gut microbiome with birds fed black soldier fly meal.”

In fact, they found that more is better. When birds were fed black solider fly meal in the diet, there was increased diversity in the gut microbiome. And the diversity increased with the percent of black soldier fly meal in the diet.

“At the 13 per cent inclusion level, both strains of birds had a more diverse microbiome community in the gut,” says Lu. “What was interesting was the white strain had a more naturally diverse gut microbiome at the beginning of the trial, but the brown strain hens basically caught up by the end of the trial.”

Lu says this could be beneficial if you feed black soldier fly meal to birds that have a less diverse gut at the start of the feeding period, as opposed to indicating the insect meal is more beneficial to brown-feathered birds.

They also looked at short chain fatty acids in the gut, comparing them between the different levels of black soldier fly meal in the diet. Again, they found encouraging, positive results.

Short chain fatty acids are formed when bacteria in the gut are metabolized. They saw a similar response to the gut microbiomes and more signs of improved gut health. “When we fed increased levels of black soldier fly meal, we saw a corresponding increase in acetic acid and decrease in butyric acid,” says Lu.

When they analyzed the impact on egg quality and production, Collins and Lu found that including black soldier fly meal in the diet – at any level – had no negative effect. But again, they also found more encouraging news.

“We saw an increase in lauric acid levels in eggs yolks as a result of feeding black soldier fly meal,” says Lu. “Birds

fed 13 per cent black soldier fly meal were really good at assimilating the fatty acid from the meal and in turn making a big impact on the fatty acid profile of the egg yolk.”

That’s important because lauric acid is associated with antimicrobial effects – eggs with more lauric acid could have the potential for improved food safety with better shelf life and less spoilage. “That was a fun finding to realize the positive impact on the fatty acid profile in the egg yolk was the result of feeding black soldier fly meal,” says Collins.

With all the positive findings from this trial with laying hens, Collins and Lu will be taking a closer look at what the bacteria are doing in the gut. “We’ll be looking at resilience and immune response in hens fed black soldier fly meal,” says Collins.

The bigger implications are that better gut health –that includes a more diverse microbiome – potentially contributes to a stronger immune response and better bird health. “We are really excited about this research

per cent is the inclusion level at which point both brown- and white-feathered birds had a more diverse microbiome community in the gut.

and believe additional work is warranted to be sure that what we are finding is true to theory,” says Collins. While there isn’t a consistent supply of black soldier fly meal available in Canada, Collins wants the industry to be ready. “We saw an improvement in many parameters we measured with black soldier fly meal,” says Collins. “Feeding insects is a tool that I’d like to be ready for producers if and when they want to use it.”

• Approved feed ingredient in Canada by CFIA

• Excellent source of protein and calcium

• Requires low levels of water and feed

• Efficient converters of low-value nutrients into high-value protein

• Rearing considered net negative for greenhouse gas emissions

• Can be farmed vertically

• Need for larger scale operations in Canada to provide more readily available, cost-effective product

Physical barriers at the barn entry are your best defence.

New industry platform designed to create collaborative solutions.

By Jane Robinson

Jeff Wilson believes most of the big and little issues in Canada’s poultry industry can be tackled by picking up the phone. It’s a problem-solving strategy and collaborative approach that’s behind the new National Poultry Network.

Wilson is an Ontario veterinarian with a particular penchant and passion for bringing people together. He has doctorates in avian pathology and dairy cattle epidemiology, many years teaching at the University of Guelph and a general fascination for human behaviour. He’s also president of Novometrix Research Inc., a Guelph-based business that helps various sectors set up a new collaborative style of network – from animal health to human health and the environment.

“About eight years ago, Novometrix began creating a platform that could address any issue an industry has – economic, social, environmental, health – by bringing people together to collaborate,” says Wilson, who is a facilitator to the new poultry network.

Wilson has spent his entire, diverse career building networks. He’s naturally talkative, upbeat and inquisitive and loves the role of connector. He’s also amassed a broad understanding of global issues and that’s what led him to develop the concept of Community Network Integration (CNI) – the idea behind the National Poultry Network and others he’s helped get off the ground.

CNI is half business process and half social psychology. The network-forming plan requires some organic growth, as well as a bit of business structure, to bring people together and work through perceived roadblocks.

“I’ve done a lot of work in the poultry industry and I knew there was a need to bring the sector together in a new way to tackle issues like antimicrobial resistance, avian influenza and the overall profitability of the sector,” says Wilson.

To get the National Poultry Network started, Wilson began by making a list of contacts in the poultry industry. It’s just the way he works. He picks up the phone and has a conversation that inevitably uncovers

another contact and more connections. And he keeps going.

It’s a process that works. Novometrix has helped facilitate networks like the National Poultry Network in other sectors, bringing people and organizations together. He’s quick to clarify that the National Poultry Network isn’t designed or intended to replace organizations and initiatives already in place. “We want to connect with existing efforts and knit them together in a way that encourages greater collaboration to effectively solve issues that the Canadian poultry industry is facing,” he says.

The idea behind the new network is to act as a clearing house of sorts, bringing together all the players in the industry to address issues that the industry has identified. Wilson knows that when we build a

structure for something big, in the future like a network, it’s important to have smaller pilot projects that show people how it works and how it solves problems that will save time or money for producers.

“National issues like avian influenza need to be addressed at the farm level,” he says. “And while the network is big picture, it starts small by working on individual projects.”

The network has already started some smaller pilot projects to work with individ ual producers on issues impacting their productivity and profitability, often by just connecting people to resources or informa tion. One of those projects is with a local producer looking at ways to reduce bird losses and improve bird health.

The National Poultry Network is just in its infancy. “We were just getting started when COVID happened, but that coincidentally made people more aware of the need for collaboration, especially at a time with so many disparate opinions.”

A 12-member leadership team has been established with broad representation from the University of Guelph, Animal Health Laboratory, OMAFRA, Feather Board Com mand Centre, CFIA, BC Agriculture, a broiler producer, duck breeder and veterin arian, as well as representatives from com panies that specialize in water purification systems and control systems (ventilation, water, feed). There is also a wider growing group of advisors and observers involved in the network.

when dealing with complex issues that may have conflicting approaches.”

website and creating a regular newsletter. Novometrix is also looking for producers,

Everyday stressors from environmental or feed changes to handling and socialization can impact poultry health and productivity. This stress can lead to reduced feed intake, fertility and productivity — just to name a few of its effects. But it doesn’t have to be this way.

Novometrix is currently working with the National Poultry Network leadership team to develop values, determine project priorities and define how the network will best provide value to the industry.

The most important part of any network, from Wilsons’ experience, is that everyone involved is asked and expected to bring cre ative problem solving to the table, along with a state of respect and appreciation of others. “As you do the work, it helps to bring a mind ful, calm approach,” he says. “It really helps with collaboration, and you can accomplish much more with this mindset, especially

KemTRACE® Chromium from Kemin helps alleviate the negative impacts of stress for improved maintenance, reproduction, growth and immunity. In fact, supplementing with KemTRACE Chromium can lead to a 2-point improvement in feed conversion ratio.

MORE AT kemin.com/ktchromium

Continued from page 12

Costs, research and pivoting

It was 2018 when the Steeles took the plunge into on-farm feed milling. Ron and Debbie Steele established Steele Hall Farm in southern Ontario in 1976, where the family produces turkey, chicken, grain and processing vegetables. Their sons Matt and John Steele are the next generation leading and growing the business, supported by their sister Julie Lyzenga, who is the farm’s health and nutrition specialist.

Similarly to others, Matt explains that “we decided to build an on farm mash mill in order to allow us to achieve complete control over our poultry diets and control more aspects of our production. Milling feed has reduced our total feed input expense by lowering our freight costs, utilizing grain from our elevator system, and continuously working to optimize ingredient

value, as well as researching and utilizing innovative feed additives.”

Having their own feed and monitoring bird performance also means the Steeles “have the ability to make changes to our diets very quickly if a challenge related to nutrition is discovered,” says Matt. “It also allows us to react to our processing customers market demands such as Halal, grainfed, raised without antibiotics, etc.”

At the beginning of feed mill operation

five years ago, their flocks took a few days longer to reach market weight compared to commercial pellet feed, but they quickly narrowed that gap through collaborating with a nutritionist. In addition, Matt says “we recently added a pre-grind corn system along with an additional minor and major ingredient scale which has increased our production speed to 18MT per hour which works well for our operation, with growth in mind.”

Middlesex Centre, ON: 400 acres with almost 350 workable available as one block or 4 separate +/-100 acre parcels. Bungalow home, shop & machine shed. 20mins to London, 5 mins to hwy 401. Offers Nov 27th, 2023 before 4pm.

Location

Bassano, Alta.

Sector

Layers

The business

Newell Colony is a Hutterite Colony near Bassano, Alta. They own 12,000 acres, where they have hog, dairy, and layer operations. They have quota for 23,000 birds and produce their product for Spark Eggs.

The need

The colony couldn’t raise enough pullets for their layer quota. So, they shook things up. First, they built a new organic freerange barn, which they recently opened. Next, they’re converting their old layer barn into a pullet facility. They went the cage-free route because they believe the industry will eventually phase out enriched cages like it’s doing with conventional housing due to activist pressure. “We more or less want something where we can have peace of mind so we don’t have to redo it for another 40 to 50 years,” egg barn manager Ken Hofer says.

The barn

Working with Vencomatic, the colony built a new barn with a free-run capacity for 48,000 birds and an organic capacity for 30,000. They installed Vencomatic’s Bolegg Gallery aviary system. The barn features cutting-edge automation. For example, Pegasus safely and efficiently transports the eggs to the Meggsius Count, which uses a camera to count the eggs. The technology can automatically detect problems and pinpoint where the issues are coming from using a colour-coded system.

Barn Spotlight highlights new and renovated barns and

Do you know of a good candidate to be featured? Let us know at poultry@annexweb.com.

S T R EN G T H EN Y OU R

B R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use