Premium motors engineered to be direct replacements for your existing equipment. Every GrowerSELECT motor comes with the industry’s best 2-YEAR WARRANTY and is backed by our network of local stores.

by Brett Ruffell

Premium motors engineered to be direct replacements for your existing equipment. Every GrowerSELECT motor comes with the industry’s best 2-YEAR WARRANTY and is backed by our network of local stores.

by Brett Ruffell

Experts’ predictions of a second COVID-19 wave have, unfortunately, come true – at least in certain parts of the country.

As I write this column, Ontario just announced it is bringing back several restrictions in a handful of hotspots, including Toronto, Peel Region and Ottawa. Importantly for producers, this once again includes closing indoor dining in those areas.

R estaurants Canada estimates that those closures will result in sales losses of up to 80 per cent for full-service restaurants and more than 40 per cent for quick service eateries. “Our sector was one of the first to suffer the impacts of this crisis and continues to be among the hardest hit,” says Restaurants Canada president and CEO Todd Barclay. “Going back to this level of shutdown will be a huge blow.”

This will, of course, have a trickle-down effect on poultry farmers. The closures will also result in tens of thousands of jobs lost across Ontario, Restaurants Canada forecasts. This means food banks will continue to see unprecedented demand. It also means, I’d bet, that poultry producers will once again step up to help fill that demand.

Previously, I highlighted some of the outstanding things national poultry organizations have done to combat hunger.

Now I’d like to underscore a few regional initiatives that caught my attention.

M anitoba Egg Farmers (MEF) spearheaded one such effort. When the pandemic first hit, it caused both demand at food banks to soar and, after a brief shortage, an oversupply of eggs.

Producers contacted MEF asking how they could help since they had plenty of product. In response, MEF reached out to Winnipeg Harvest, a food bank it had worked with previously.

I n collaboration with Burnbrae, which is one of MEP’s graders, the board agreed to donate a pallet of

“We recognized the long-term need, even after the pandemic. We plan to continue this on.”

eggs (900 dozen) weekly for six weeks starting in April.

“The eggs were extremely well received because they’re such a high source of protein,” says MEF chair Harold Froese, noting that Winnipeg Harvest’s large refrigerated area means it can store perishable items that many other food banks can’t.

That spring donation turned out to be a catalyst for an ongoing initiative. “We recognized the long-term need, even after the pandemic,”

Froese says. “We plan to continue this on a long-term basis.” For the foreseeable future, MEF will donate a pallet of eggs per month to Winnipeg Harvest, with the not-forprofit buying an additional monthly pallet.

Food bank usage in Ontario has surged as well. Feed Ontario estimates that around 225,000 people per month have turned to them this year. But the province’s broiler producers are doing what they can to provide protein to those in need during the COVID-19 pandemic.

One way they’re doing so is by taking part in the Chicken Farmers of Canada (CFO): Farmers to Food Banks program. Through this initiative, chicken producers can donate up to 300 birds. They receive a tax credit from the provincial government for their contribution.

Farmers simply register with the program and CFO takes it from there. The board gets the birds to and from processors and out to a network of 128 food banks through Feed Ontario. As of late-September, about 550 chicken farms have donated 950,000 meals to Ontario food banks this year.

“Our critical focus right now is making sure individuals who rely on food banks continue to have access to the food they need during this pandemic,” says Carolyn Stewart, executive director of Feed Ontario.

“We’re extremely grateful to Chicken Farmers of Ontario for their ongoing support.”

canadianpoultrymag.com

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Associate Publisher Catherine McDonald cmcdonald@annexbusinessmedia.com Cell: 289-921-6520

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Curtis Martin

Circulation Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

VP Production/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Circulation email: rthava@annexbusinessmedia.com Tel: 416-442-5600 ext 3555 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates

Canada – 1 Year $32.50 (plus applicable taxes)

USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

2.0

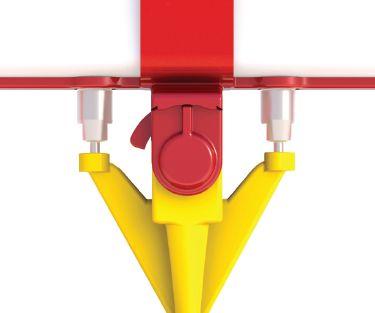

The New Patented Pendulum

At the heart of the system is the patented pendulum and new, twin-nipple technology. As the birds drink from the cup, their heads move the pendulum from side to side, thus triggering the nipples in a vertical action.

Twin,Vertical Action, Stainless Nipples

Pivot Pin Solid Pendulum

www.lubingusa.com info@lubingusa.com (423) 709-1000

The next breakthrough in Turkey Drinking is finally here! EasyLine2.0 with innovative Twin-Nipple technology.

•

•

Vertical triggering Twin-Nipples eliminate sliding friction for minimal component wear and a long product life

• Large diameter Pivot Pin increases surface area for reduced wear and requires no tools for assembly

Solid Pendulum with outer surface water flow allows for easy inspection and cleaning

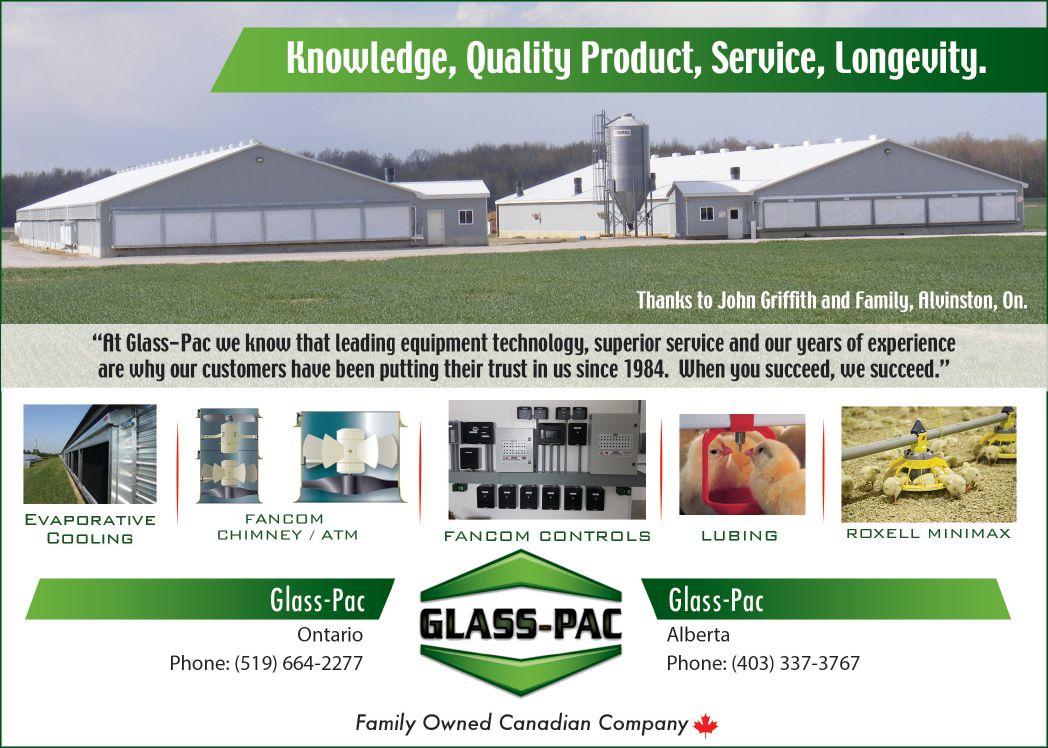

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

In September’s Throne Speech, the federal government reaffirmed its commitment to assisting producers that have been negatively impacted by recent trade deals. In a joint statement, Canada’s poultry and egg farmers welcomed the news. Signed by Egg Farmers of Canada, Chicken Farmers of Canada, Turkey Farmers of Canada and the Canadian Hatching Egg Producers, the statement continued that they look forward to seeing “concrete plans and clear timelines” on implementing support measures.

A poultry plant in B.C.’s Okanagan has been fined nearly $39,000 after an employee was seriously injured in a workplace accident. The worker’s arm was caught in machinery during a routine end-of-day cleaning at Colonial Farms Ltd.’s processing plant in Armstrong, according to a WorkSafeBC penalty report. “WorkSafeBC determined that the machine lacked adequate safeguards to prevent worker access to hazardous points of operation,” it reads.

Olymel is investing more than $31.5 million to expand its poultry slaughtering and cutting plant in St-Damase, Montérégie, Que., in order to diversify operations and add new activities. This project will result in the creation of more than 80 new jobs and bring the total number of employees at this facility to nearly 500, spread over two shifts. The company is using the investment to equip the plant with additional cutting, deboning and tray packing lines and more.

participated in the tournament,

raised $17,000 for programs and events

The highlight of the 2020 Poultry Industry Council (PIC) charity golf tournament was certainly not the weather. Yet, despite intermittent showers, a contingent of 117 devoted golfers had a great time at the September 2nd event.

Foxwood Golf Club in Baden, Ont., created a safe and fun space where everyone benefitted from a day out to reconnect with colleagues in the poultry sector.

The annual fundraising tournament nearly didn’t get off the ground this year, as ongoing restrictions of outdoor gatherings related to the pandemic made logistics challenging. Despite a tenuous few months of stop and start planning, the day was made possible by volunteers from the sector, the golf course and PIC staff.

The annual event usually draws around 160 golfers. However, due to gathering restrictions, this year’s attendance was scaled back. Still, it brought in important funds that directly support PIC’s delivery of programs and training.

A highpoint for the day was celebrating contest winners showing off the results of a season of golf practice. Ken Wrightson won the Longest drive with a 302-yard shot, followed closely by female counterpart Cali MacPherson. Greg Leis won straightest drive with a drive that landed spot on the center white line.

“The Annual PIC Golf Tournament is a highlight each year and PIC looks forward to hosting the industry in the coming year,” says says Ashley Honsberger, PIC’s executive director.

Did you know that feed accounts for over 50 per cent of the cost to raise a flock of turkeys? Therefore, it is no surprise that growers look to this area to reduce operating costs. Hybrid Turkeys consulting nutritionist, Dave Laurin, suggests although the action may save money in the short term, it can have unfavourable and lasting effects on the health and performance of a flock. We asked him five questions.

Tell us about yourself.

I am the owner and founder of RAC Nutrition, a consulting service that provides nutrition advice for all poultry species (turkeys, chickens, gamebirds) and swine. I graduated from the University of California –Davis (U.S.) with a Ph.D. in Nutrition. Since 2005 I have been working with Hybrid Turkeys as consulting nutritionist.

Why is nutrition so important to raising turkeys?

Feed is the largest economic input in turkey production and is responsible for supplying the required nutrients for growth and development. Any feed given to a turkey flock should be professionally and scientifically formulated to ensure all needs are met and to help growers achieve the results they expect. Any feed-related decisions should be done in consultation with a trained expert who uses their expertise and specialized computer software to formulate diets.

When is the role of nutrition the most important for the development of turkeys?

Feed plays a key role at all ages but if I had to pick an age, particularly when speaking about development, the earliest feeds are most

important. From placement through to six weeks of age is critically important because there are certain physiological developments that happen during that time that if missed, you are unable to correct for later in life.

What types of issues can arise from extreme deviations to diet recommendations?

Nutrition-based issues become apparent early in life, around two to four weeks of age. Symptoms such as poor development of the growth plate in the leg bones can be seen manifesting itself as twisted legs or ‘cowboys’. Bone mineralization issues are generally classified as ‘rickets’ or ‘soft bones’. Both issues can build up stress and cause mobility issues, which may lead to poor performance and ultimately increased mortality. Leg development tends to be the number one issue I see in the field related to poor nutrition. Issues can also arise from improper formulation of diets, specifically regarding calcium and phosphorus levels. Also common is a lack of required vitamins in the feed such as vitamin D and the B complex vitamins that are essential for strong bones. Additionally, deviations can affect the digestive system and cause a variety of health concerns.

What can be done to get turkey’s health back on track?

The earlier you address these issues the better, because course-correction becomes more difficult the longer the issue persists. If you fear limitations in your diet composition are causing problems, you can consider adding things to your water, such as vitamins.

NOVEMBER

NOV. 12

Eastern Ontario Poultry Conference Part 1, Webinar poultryindustrycouncil.ca

NOV. 19

Eastern Ontario Poultry Conference Part 2, Webinar poultryindustrycouncil.ca

NOV. 30

Science in the Pub, Webinar poultryindustrycouncil.ca

DECEMBER

DEC. 9

Producer Update, Webinar poultryindustrycouncil.ca

JANUARY 2021

JAN. 24

Science in the Pub, Webinar poultryindustrycouncil.ca

JAN. 26-28

IPPE, Atlanta, Ga. ippexpo.org

FEBRUARY

FEB. 10

Producer Update, Webinar poultryindustrycouncil.ca

FEB. 24

Producer Update, Webinar poultryindustrycouncil.ca

ADP Direct Poultry has acquired Cami International Poultry Ltd, effective October 1, 2020. Cami is a poultry slaughter and processing company located in Welland, Ont., and employs 55 people. It’s one of the few primary poultry processors in Ontario with both CFIA and USDA certification. Cami’s facility produces a premium ‘air chilled’ poultry product, and has significant capacity for growth. ADP Direct Poultry is a food processing company that serves the grocery retail, food service, industrial, and co-manufacturing markets.

The governments of Canada and Manitoba will be providing support to Agriculture in the Classroom to adjust their educational and outreach resources in response to the COVID-19 pandemic, Federal Agriculture and Agri-Food Minister Marie-Claude Bibeau and Manitoba Agriculture and Resource Development Minister Blaine Pedersen announced in September. Agriculture in the Classroom brings together industry, government and educators in an effort to increase the public’s understanding of agriculture.

An animal rights activist has been charged under a new Ontario law for allegedly interfering with a truck carrying pigs to slaughter. But Diane Smele vowed to fight the charges, which were laid Monday when she and about 20 other activists protested outside Fearman’s Pork in Burlington, Ont. Halton police said it’s the first time it has laid a charge under Bill 156..

The money will subsidize farms’ purchases of PPE and sanitary stations and it will help to cover extra costs in cases of COVID-19 outbreaks.

Some Canadian farmers can now apply for emergency funding to protect their workers during the COVID-19 pandemic, Agriculture Minister Marie-Claude Bibeau said in early October.

A $35-million program first announced at the end of July will subsidize farms’ purchases of personal protective equipment and sanitary stations and it will help to cover extra costs in cases of COVID-19 outbreaks.

The government will cover 50 per cent of the costs under the program and 60 per cent if a farm is owned by women or youths.

“Our government will continue to support farmers and (food) processors,” Bibeau said. “They are key partners in Canada sustainable economy recovery.”

Farmers in Saskatchewan, Alberta, New Brunswick, Newfoundland and Labrador, Yukon and the Northwest Territories can apply. Bibeau said the government will announce programs that will be managed by the other provinces in the coming weeks.

Wearing N95 masks has been standard at grain farms since before COVID-19, because farmers deal with dust and rodents around some of the bins, said Keith Degenhardt, the vice-president of Alberta Federation of Agriculture. So the pandemic brought a shock.

“We saw the price on personal protection equipment increased,” said Degenhardt, who runs a crop and cow-calf farm with his family close to Wainwright, Alta.

The program will be applied retroactively to cover any COVID-19-related costs between March 15 and the end of next February, Bibeau said.

She said the program can apply equally to Canadian or migrant farm workers and it will prioritize farms at the highest risk of COVID-19 outbreaks.

The number of workers and the amount of space they have in their workplaces and housing facilities will be key elements in identifying farms at high risk of COVID-19 outbreaks, Bibeau said.

Elanco welcomes Bayer Animal Health.

Making life better means creating a healthier life for your animals.

That’s why we’re coming together with Bayer Animal Health to make an even better Elanco. Together, we’re committed to providing a more comprehensive portfolio of products along with unparalleled service and support for the health of animals, and for the good of people and the planet.

Observations and outlook on the postponement of the Category III deadline, from various industry stakeholders.

By Treena Hein

As Canadian broiler producers well know, their sector has eliminated the use of Category I and II human medically important antibiotics (MIA) for health and growth promotion and disease prevention. While the ban of preventative use of Category III MIAs was set for the end of 2020 – there’s actually just one of them at present, Bacitracin – Chicken Farmers of Canada (CFC) decided in September to reassess the timeframe.

“The realities of the COVID-19 pandemic have resulted in the postponement of key meetings between important partners at a provincial level,” CFC states. “The success of the strategy has been based on taking a responsible approach to ensure animal welfare and sustainability, and these currently remain unresolved…It is important to note that this remains a key priority for the Canadian chicken sector. The reassessment requires further consultation with industry.”

Steve Leech, CFC director of food safety and animal health, notes that there were a number of issues that needed to be examined further, including vaccines,

alternative products and industry readiness. “We are continuing with a reassessment of the timeframe and deciding right now on next steps, within CFC and across the stakeholder chain,” he says. “Having the entire industry involved in decisions, the elimination strategy and implementation of the strategy has been important from the start.”

Bacitracin transitional period?

In the view of Babak Sanei, national business and technical manager for poultry and medicated feed additives at Zoetis, postponing the ban is a very wise decision. He feels that way because he doubts the Canadian broiler industry is prepared to cope with technical and economic consequences.

He notes that there are several alternative products such as prebiotics, probiotics, acidifiers and essential oils. However, he states that the effects of many of these products have been inconsistent across different times of year and geographical regions.

Sanei adds that all pertinent members of the broiler industry need more time to focus on applied research of these products. He says that in order for the industry to further reduce its reliance on infeed antibiotics, experts need to closely examine bird welfare, flock performance level, costs and prevention of necrotic enteritis (NE).

“The risk of NE outbreaks and gut flora imbalance is to a large extent linked to the control of subclinical coccidiosis in broilers,” he explains, “and can vary in various geographical locations, seasons

with high precipitation and onfarm management practices.”

He believes it’s possible to effectively control subclinical coccidiosis by using alternative products, changing flock management practices and properly rotating available coccidiostats. Still, be believes there are better approaches when all factors are considered.

Sanei suggests that instead of a Category III ban for preventive use, strategic and judicious preventative use should be allowed on a case-bycase basis as determined by a poultry veterinarian, in phases of the lifespan when such use generally has the strongest potential to prevent NE (e.g., when broilers are 15 to 30 days of age).

Says Leech, “We will continue to work with industry to make final decisions with the overall objective of making sure implementation [of the Category III preventative use ban] is successful.”

As mentioned, various feed and water additives are a promising way to mitigate the absence of preventative antibiotic use in broilers. There was some exciting related news on that front in July, when scientists based in the U.S. published results showing 14 commercial feed additives are able to mitigate the effects of viruses that can be present in pig feed (Senecavirus A, Porcine Epidemic Diarrhea virus, and Porcine Reproductive and Respiratory Syndrome virus).

These additives include essential oils, organic acids, fatty acid blends and formaldehyde-based products.

The researchers concluded that “pigs on supplemented diets had significantly-greater average daily gain, significantly lower clinical signs and infection levels, and numerically lower mortality rates compared to non-supplemented controls.” CFC is funding research on feed additives and more.

There is also much activity here in Canada to deal with a long-standing backlog of submissions for the approval of new feed additives, including alternatives to MIAs. The Canadian Animal Health Institute (CAHI), which represents animal pharmaceuticals, feed additives and more, continues to work with the Canadian Food Inspection Agency (CFIA) on this backlog. It’s also collaborating with the CFIA, the Animal Nutrition Association of Canada, CFC and other groups on

new regulatory consultations and policy initiatives related to feed.

In addition, CAHI has been advocating for regulatory harmonization with trusted regulators such as the European Union, Australia and the U.S. to streamline and accelerate the Canadian approvals processes – and CAHI programs director Colleen McElwain says, “We are pleased to share that these efforts appear to be gaining momentum.”

In addition, CFIA and Health Canada have established a classification process for “viable microbial products,” laying out the appropriate review pathway that should be followed based on a product’s intended claim. Claims could be related, for example, to general health and wellness, nutrition and digestion or gut modification and performance. This new classifica-

tion process should allow more new products to come to market.

However, McElwain echoes Sanei’s view that there are no products at this time that are as effective as the Category II or even III MIAs in reducing enteric pathogens such as those that cause NE. These products are, therefore, only one of many tools and strategies that broiler producers must employ.

Leech adds that using best management practices in every barn is important and that lessons learned from the Category I and II bans have been shared throughout the industry. “There is no silver bullet or one size fits all solution,” he explains, “and evaluating management practices at each farm and along the supply chain is part

Here are some keys points to remember from this update on the antimicrobial use strategy.

• The timeframe for eliminating the preventative use of Category III medically important antibiotics (MIAs) in broilers has been postponed.

• Elimination was set for the end of 2020.

• Right now, there is only one Category III MIA, Bacitracin.

• Research continues into vaccines and into alternative products that can help control diseases.

• Federal regulatory updates currently underway should enable a faster approval process for alternative products.

• Broiler farmers must use many tools in order to keep their flocks as healthy as possible.

• Poultry nutritionists continue to use a multifactorial approach in creating feed formulations that best support broiler gut health.

• Some believe Canadian veterinarians will need to increase prescriptions of both Category II and III products to treat outbreaks of disease in broiler flocks, should a full Category III ban for preventative use proceeds.

of the work that’s going on.”

Lisa Hodgins, monogastric nutrition manager at New Life Mills, agrees that feed and feed additives are only one of many factors that influence the chicken microbiome; besides barn aspects like type of housing, temperature and litter quality, age, sex and more can factor in.

However, over the past two years, she and many of her poultry nutritionist peers across Canada have incorporated a multifactorial approach to their feed programs in order to support gut health. She says quality ingredients, enzymes, prebiotics, probiotics, essential oils and acidifiers are all used to help maximize gut integrity in the absence of antibiotics for prevention of enteric diseases. Looking back, McElwain believes

Having the entire industry involved in decisions, the elimination strategy and implementation of the strategy has been important from the start.

the removal of Category II MIAs from Canadian broiler production has underscored the importance of the veterinary client-patient relationship to ensure that enteric pathogens are managed and animal welfare is maintained. This importance will remain.

“It is our understanding that in some cases,” she notes, “the removal of preventive Category II MIAs has resulted in more prescriptions

of Category III products for preventive use and more Category II prescriptions at treatment doses for enteric pathogen control.”

She believes that going forward, the Category III preventative use ban will likely mean that Canadian veterinarians will need to consider increased prescriptions of both Category II and III products to treat flock diseases, consistent with what has been seen in Europe.

Tavistock, Ontario 1-888-218-7829 sales@ruby360.ca ruby360.ca

Columbia, Alberta & Saskatchewan Quebec, New Brunswick & Eastern Ontario Lance Fluckiger Leduc, Alberta 587-926-0090 lancen@fluckigercarpentry.com

Jacques Plante Saint-Hyacinthe, Quebec 514-232-2539 jacques@ruby360.ca

By Melanie Epp

Raising poultry without the use of antibiotics is not for everyone, but it’s a challenge Lisa Jones and her husband Dan are happy they took on. While it’s more time consuming and requires serious attention to detail, it’s very rewarding once you get it right. Four experts, including Jones, offer these eight tips for success.

1. Success starts at breeding

Raising poultry without the use of antibiotics is challenging, but not impossible. Success starts at breeding, says Paul McCartan, director of live procurement and field service at Sofina Foods Company. McCartan runs the raised without antibiotic (RWA) program at Sofina, and has also raised RWA broilers as a farmer. Sofina’s 17 RWA growers are part of a program designed by McCartan and Poultry Health Services’ veterinarians, the foundation of which is their breeder program.

The immune system of the chick starts with hen nutrition, disease status and maternal antibody status.

“We have got an autogenous vaccine in our breeders. We have built what I hope to be one of the most robust breeder program vaccine programs in Canada,” he says. “Our progeny, they have very high internal antibody titers. The immunity that those chicks come into the barn with is quality number-one.”

The program, in fact, starts with the

selection of eggs from prime breeders. From there, Sofina hand selects broiler farmers based on their ability to work with the company.

2. Hatchery hygiene is key

But not all producers will have the opportunity to work so closely with a program director, nor will they know what’s going on in the hatchery. Hygiene

is king in the hatchery, says retired hatchery specialist Donna Hill of Donna Hill Consulting. Hill offers technical consulting to hatchery managers with emphasis on incubation quality.

Sanitation and hygiene inside the hatchery are crucial, Hill says, pointing to egg sanitation and hatchery disinfection. Eggs should be nest clean, as should all egg-handling equipment, she says.

3. Know the signs of incubation problems

In addition to sanitation, good incubation itself is crucial to the success of RWA production, Hill says. Chicks that were developed under good incubation quality have a better chance of maturing their immune system after hatch.

Unless producers switch to on-farm hatching, this is next to impossible to control, but the signs of poor incubation quality are hard to miss. Signs of incubation problems include, but are not limited to: large unabsorbed yolk; yellow down around the navel; strings; red hocks, diffuse and bilateral; clubbed down; brown wiry feathers; small-sized chicks with pale, short down; bloody egg debris; leg problems; and areas with no feathers. Hill recommends that farmers work closely with their hatcher. She also ad -

vises RWA producers to switch to a system that provides chicks with early access to feed and water like HatchTech or an on-farm hatching solution like Nestborn or X-Treck by Vencomatic.

4. Take your time in the barn, especially in the first weeks

The first week in the barn sets the stage for the rest of the production cycle. First-generation farmers Lisa and Dan Jones run a 15,000-unit broiler operation north of Fergus in Ontario. Lisa is in charge of dayto-day operations in the barn.

“In the first week, you need to pay extremely particular attention to the environment in the barn,” she says. “If you don’t take that time to do that, the rest of your crop generally isn’t going to go very well.”

Most importantly, Jones says, you need to know your birds. “I find it’s really import-

PulsFOG® disinfecting and pest control

ant that you have one main person who’s doing chores so that they know those birds,” she says. “They know their mannerisms, their little quirks, and if anything’s changing, they’re going to be picking that up.”

Key management factors include ensuring timely feed and water intake, stress reduction, moisture management and maintaining barn and chick temperature.

Help chicks develop balance

Probably the most important factor for ensuring strong development is promoting good intestinal development, technical manager for Alltech Canada Kayla Price explains.

When chicks first arrive from the hatchery, it’s important to start with a strong brooding period, making the first 10 to 14 days especially important. Early access to quality feed and clean water is also incredibly important, as it aids in intestinal development and later maintenance, Price says. When a bird is first hatched, she says, it has very immature microflora. It takes time and management to develop a mature microflora.

“When we talk about microflora, it’s not just the total number of bacteria that is there, it’s also who is there and what are they doing,” Price says. “We’re looking to balance our good guys, our potentially bad guys – those opportunists – as well as those bad guys.”

“That diversity is going to help protect them from other challenges that come through,” she adds.

Developing strong microflora means managing environment conditions that create stress and potentially support opportunistic bacteria in the gut.

It’s important that RWA producers monitor temperature and litter moisture closely in the first weeks of life so that the coccidiosis vaccine can properly cycle through the birds. Chicks are sprayed at the hatchery with the vaccine, which is spread through pecking and walking on feces on the barn floor. Doing

so lowers the risk of losses to necrotic enteritis later. This mean checking the barn several times a day to ensure humidity levels are high enough for sporulation to occur, Jones says. Ventilation also needs to be just right to improve air quality without removing moisture.

Later, keep litter dry and feed and water accessible

Litter need only stay moist for the first week or so, though, Jones explains. “When we think the cycle is through, that’s when we increase our ventilation and reduce that moisture and dry up the litter as much as we can,” Jones says.

This helps to reduce the risk of developing footpad issues later in the bird’s life.

Food and water should be accessible at all times throughout the bird’s life. If feed runs out, even for a relatively short

period of time, broilers will go looking for food. When they can’t find it they’ll start pecking litter, which can create problems in the gut.

A water outage can be equally as damaging, Price says.

Ensuring flock health sometimes means knowing when to call it quits. This means culling sick birds and birds that are not going to do well, and picking up dead birds as soon as possible, Price says.

“When we’re talking about birds we’re really talking about flock health over individual health,” she says.

McCartan agrees, which is why Sofina offers a prorated program where the price farmers get paid increases as they get closer to finishing a flock. “We do not want

management to be making decisions purely on the financial implications associated with that type of decision,” he says. “That’s a welfare decision that we encourage our veterinary oversight to be part of.”

“But at the end of the day, we will pull the flock if necessary,” he says.

RWA production can best be described as ‘finicky’. It is hard production that requires great attention to details, but it is doable. All four experts offered one last tip for success: Build a strong network of experienced individuals.

“It’s important to have those resources to speak with to help with the things that come up because it’s a completely different way of raising birds,” Jones says. “Having those resources was very helpful and probably key to our succeeding.”

Research

This research was funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster 2 which was supported by AAFC as part of Growing Forward 2, a federal-provincial-territorial initiative. Additional funding was provided by the Ontario Ministry of Agriculture, Food and Rural Affairs, and Canada’s First Research Excellence Funds.

By Jane Robinson

The parallels between the current COVID-19 pandemic and past avian influenza (AI) outbreaks are not lost on Shayan Sharif. “In any pandemic, swift and measured actions are needed to contain and control the imminent spread. When a vaccine is available, the options change. And when a vaccine can be made more effective, progress is made,” says Sharif, associate dean of research and graduate studies at the Ontario Veterinary College at the University of Guelph.

Sharif led a multi-year research project looking at novel ways to prevent future AI outbreaks by boosting the immune response of the bird. The premise was that if the bird’s own immune system can rally to work in concert with a vaccine, then the level of disease protection provided will be stronger and more effective.

With no commercial AI vaccine currently available in Canada – and culling the only “treatment” option – the push for effective ways to protect birds is desperately needed. That’s where some of Sharif’s latest research comes in. He looked at immune-enhancing activities to protect birds against AI.

His research holds promise for a solution for Canadian poultry producers to prevent the disease. It also offers vital insights into technology that can boost a bird’s own immune system to be better

equipped to fight off AI and other diseases.

Sharif’s research looked at two avenues for helping birds build a stronger defence against disease, particularly AI. The first part of the study looked at how PAMPs – pathogen associated molecular patterns – could be used to boost immune response.

PAMPs are naturally occurring microbes that have been extensively studied for more than 20 years. They act as an adjuvant (or immune booster) and can be used with a vaccine or on their own to trigger a stronger response in birds.

When PAMPs are used with a vaccine, the vaccine must be a killed form, and that poses some challenges for the route of administration. Killed vaccines don’t always induce enough immune response on their own, and are most effective when injected – an impractical proposition in poultry production.

The search for a better solution led Sharif to nanoparticles as an effective carrier to administer killed vaccines with or without PAMPs.

“Nanoparticles are like tiny cages that can carry vaccine and PAMP molecules directly to target cells in the bird – respiratory or intestinal in the case of AI,”

Sharif says. “They have been shown to boost the efficacy of vaccines and PAMPs, and are an effective vehicle for penetrating and integrating into target cells faster and more directly, delivering a better immune response for the bird.”

Sharif’s team searched for a PAMP that could deliver the best immunity. “We identified PAMPs with varying degrees of potency and efficacy and found one called CpG – which is microbial DNA – was the best for efficacy and immune response.”

Sharif’s work confirmed that nanoparticles work well to boost immune response and reduce virus shedding in birds. “There is a lot of promise for nanoparticles and vaccines in poultry and in people,” says Sharif. “In fact, it’s a technology that is being investigated in the current work on a coronavirus vaccine.”

The second technology investigated for boosting immune response was the use of adenovirus as a biological carrier for AI vaccine. Sharif’s colleague Eva Nagy, avian virologist at OVC, led the team that discovered the efficacy of two particular adenoviruses as potential vehicles for delivering the vaccine antigen for AI and a variety of other vaccines.

Adenovirus works as a vector or delivery vehicle for vaccine. “A vector is like a car that can carry different passengers,” Sharif says. “In this case, an adenovirus vector may carry the key genes of avian influenza virus that when given to a chicken could confer immunity against the virus.”

Through the course of this research project, adenovirus 4 and 9 were licensed

and commercialized with a Mexican vaccine company. While there has yet to be a commercial application for Canadian poultry producers, the opportunity is there.

“My hope is that in the near future we will be able to use vectors like adenovirus to carry bits and pieces of AI virus to be used as a vaccine,” Sharif says. The technology also has potential as a carrier for Newcastle and infectious bronchitis vaccines.

Sharif knows nanotechnology holds tremendous promise for the Canadian poultry industry as a way to package killed vaccines. “If many of the poultry vaccines we use could be packaged in nanoparticles, we could deliver better efficacy,” says Sharif.

“And if we can commercialize adjuvants like PAMPs we can further enhance the immunity caused by vaccines.” And the routine use of nasal vaccines in Canada gives Sharif confidence that the nanotechnology would be an effective means to administer AI protection.

Sharif hopes to get the technology to market. Commercialization wasn’t part of this research project but his goal is to get it to market because of the tremendous potential it shows as an effective option for dealing with AI.

An exciting part of Sharif’s work on nanoparticles is that it doesn’t start and stop with protecting birds against another AI pandemic. It has potential for Newcastle, infectious bronchitis, Marek’s disease, Campylobacter and Clostridium perfringens – the latter microbe being the causal agent for necrotic enteritis.

For Sharif, the big question is how to move this work forward. “This is an open avenue for commercialization opportunities and I wish there were more options already available for Canadian poultry producers because we know that pandemics are a certainty. We can’t let our guard down. Influenza could have a comeback and we have to be ready.”

By Ron Wardrop

As we move quickly towards alternative style housing, it’s important to understand how it differs from conventional housing and how to handle those differences. It is also crucial to know how alternative systems are managed, and how to properly deal with the flock within these alternative housing environments. In this article, we look at some best practices for aviary systems.

1. Start the chicks right

It’s best to raise your chicks in an environment that mirrors the laying system that they will be housed in during the lay period. It is a proven fact that birds have a very difficult time learning new behaviours, such as jumping, moving up into the system to drink, feed, perch and lay their eggs in the nest, just to name a few.

The health and performance of your layer flock begins with a good foundation.

Starting them in a system that enables your birds to learn the necessary behaviours to thrive as a layer is the key to maximizing your flock’s performance, all the while minimizing management effort. In short, birds that are going into an aviary laying system need to be reared in an aviary rearing system – no exceptions.

2. Train the birds

Chickens are very trainable, and one crucial part of training is during the sunset phase of each day. As the lights dim in the house, it’s important that you train the young chicks to move back into the system for the evening.

After the lights are completely out, you will need to go throughout the barn (with a headlamp) and move any chicks that remain on the floor into the system. After a couple times of doing this, your chicks will start moving back into the system on their own as the lights dim.

With the birds in the system at night, the air movement is able to dry the litter thoroughly and the birds will be encouraged to move and jump throughout the system. Well-trained birds lay almost no floor or system eggs and have superior performance in the layer house.

Flock movement is another important part of maximizing flock health and performance. One way to promote bird movement is by walking the flock. Walking the flock is as simple as slowly walking up and down each litter aisle so your birds move around. You can also take this time to inspect the birds and the system, ensuring they’re healthy and the system itself is working properly.

We recommend to start walking at random times so the birds do not get used to being moved the same way each day, and start walking your flock as soon as the lights begin to come on. This also offers an opportunity

to see floor and system eggs that you must collect immediately. We suggest that you walk the flock five to six times per day.

In addition to walking the flock, we recommend that you spend time every day sitting among the flock. You’d do this to observe the behaviour and temperament of the birds and then adjust as needed. For example, change the light intensity to curb aggression.

Any egg that is laid outside of the nest is considered a mislaid egg and collecting these eggs is critical. If a mislaid egg is left, other birds will be attracted to them, resulting in more mislaid eggs. This will further increase the amount of management time and effort. By walking your flock and picking up mislaid eggs, your hens will develop what’s called nest acceptance. It’s common to see very high nest acceptance in the range of 98 per cent or higher when the flock is comfortable and walking the litter aisles at least three times per day.

Birds that are going into an aviary laying system need to

5.

Lighting is one of the best management tools offered in an aviary barn. The way the lights are turned on and off will help train and prompt the birds to begin laying and to rest at night.

Using sunrise lighting in the morning and a sunset in the evening encourages natural behaviours and birds will require less management overall. During the sunset phase when your lights begin to dim, you should begin with the lights under the system first. Next, move to the ceiling lights.

Finally, move to the in-system lighting working from the bottom of the system with the top lights being the last to shut off with the end of the sunset. Birds will naturally follow the light and will be encouraged to move off the floor and into the system.

6. Control the egg after it’s laid

Once the egg is laid, it becomes important to make sure it remains high quality. The systems exist on the aviaries to accomplish this if managed correctly. You can program the moving of the belt and the length of the nest box frequently during peak lay periods (this becomes a matter of experimentation that depends on the breeds and barn conditions). This will ensure the eggs are spread out evenly on the egg belt and the eggs do not build up and cause damage to each other due to overcrowded areas along the way.

As well, most aviaries include a programmable egg saver system that stops the egg just before the egg belt,

slows the eggs entrance to the egg belt and provides a tool to help control the even distribution of the eggs on the egg belt. Again, this will require some experimentation to work in tandem with the moving of the egg belt. Together when programmed properly these two devices can increase the salable eggs dramatically.

Although not a management practice, it is crucial to the long-term success of the facility that some simple barn layout fundamentals are followed. Make sure the aisles are wide enough so that litter remains dry and loose. If the aisles are too narrow, the litter will remain wet and will clump and stick to the floor. This will discourage birds from dust bathing and require a great deal of effort to control litter throughout the

flock. I recommend at least 50 inches of space between sections.

This also becomes important when installing combi systems (systems that can convert from enriched housing to aviary at a later time). If you plan your system with this in mind, your combi system will be a much more effective aviary in the future.

Having a planned feeding program helps establish a routine for the birds and encourages nest acceptance. There are many ideas out there on how many hours you should wait between each feeding, but I think the most important principles to follow are wake the birds up with a feeding and then do not feed them again until after the peak laying period.

Birds are attracted to the sound of the

feed system. Thus, they are encouraged to go to the trough when they hear it run and will disturb the use of the nest and cause more mislaid eggs. Once the peak laying period is over, feed the birds at regular intervals throughout the day so that it best suits your situation

If you adopt these simple ideas, your aviary experience will be successful. I know there are many more things that make a successful layer farm, but these I feel are the things that will have the largest impact on a successful aviary operation.

Some equipment manufacturers have bird behavioral specialist on staff to help with the startup and operation of aviary equipment for the novice user. I encourage you to use them to ease the transition and make the aviary experience a success from the very first flock.

By Lilian Schaer

Results from a wide-ranging University of Guelph study into slow-growing broiler chickens may help poultry breeders and producers breed for better welfare.

The world’s largest, most comprehensive study of broiler chicken welfare offers fascinating insights into the relationships between bird welfare and the realities of modern productivity.

Over the last several decades, improvements in genetics and nutrition have led to modern broiler chicken strains that grow larger than in the past, and at a much faster pace with higher breast yields – the most in-demand part of the bird.

The trade-off, many welfare advocates have argued, is poorer health and overall decreased welfare for the birds.

There’s a growing body scientific evidence to back it up, including this study led by animal biosciences professor Tina Widowski that included a team of poultry welfare, nutrition, physiology and meat science experts at University of Guelph.

“Overall, we found that many indicators of welfare are directly related to the rate of growth,” says Widowski, who is also the Egg Farmers of Canada Chair in Poultry Welfare.

Faster-growing birds, for example, were found to be less mobile with lower activity levels. They also had more breast muscle damage such as woody breast or

white striping, poorer foot health and potentially inadequate organ development as well.

For example, at 26 days of age, the fastest-growing strains spent 73.6 per cent of their time sitting, 4.2 per cent of their time standing and 2.3 per cent of their time walking.

By comparison, all other strains spent an average of 63 per cent of their time sitting, 7.8 per cent of their time standing and 4.3 per cent of their time walking at that same age level.

The two-year study included more than 7,500 chickens from 16 genetic strains0 bred for four different growth rates (conventional, fastest slow strains, moderate slow strains and slowest slow strains) as well as other traits and raised over eight trials.

Members of the research team used wearable devices – think Fitbit-style – on the birds to track and compare activity levels and mobility, and an obstacle test to look at leg strength in the different

strains of birds. They also evaluated meat quality and tracked the presence of foot lesions.

The Global Animal Partnership (G.A.P), an animal welfare-friendly labelling program that certifies farms and ranches who adhere to certain production protocols, initiated the project and provided a substantial portion of the funding.

A criterion for G.A.P labelling includes the use of enrichment items in broiler housing, so this was a component of the poultry housing during the trial and researchers monitored birds’ interaction with those items.

“Because we wanted to raise the study birds to meet the requirements for G.A.P, we also used a vegetarian, antibiotic-free diet,” notes Stephanie Torrey, the lead scientist on the study. “We were comparing the welfare of the different strains, so all were housed in the same type of environment.”

Each identical pen housed 44 birds at a density of 30 kilograms per square metre.

The combination of high breast yield and rapid growth resulted in the poorest welfare outcomes among the birds, she notes. The researchers recorded a range of growth rates among the different strains, with some only taking an extra three to four days to reach the same weight as conventional strains whereas others took up to a couple of weeks.

“The birds that took longer needed more feed and water, but there’s not much difference in the management of those birds compared to more rapidly growing conventional strains,” Torrey adds.

Fewer birds to market per year combined with higher input costs represents a barrier that could be keeping many producers from moving to slower, more welfare-friendly production. Both Widowski and Torrey stress, however, that this project did not focus on any economic aspects of slow-growth production, whether producer costs to make the switch in production systems or longer-term economic viability.

According to Widowski, a decrease in the occurrence of the breast muscle conditions that cause meat quality issues at processing, like white striping or woody breast, could result in fewer losses to producers. However, whether that reduction compensates for higher production costs has not been determined.

“Those diseases are one of the consequences of high breast yield and accelerated growth rate, but we did not do an economic assessment on the impacts on producer profitability,” Widowski says.

This study also did not look at the potential willingness of the marketplace to compensate producers

for their increased costs by paying more for chicken raised in this way or Canadian market demand for slow-growth birds. Some estimates suggest slowgrowth chicken represents about five per cent of the market in the United Kingdom, and it’s more widely prevalent in Europe too than here in North America.

For Torrey, a surprising yet positive finding from the research was a lack of difference in mortality rates across the different strains. Overall, the mortality rates among all birds in the study was very low, averaging only 2.5 per cent across eight different flocks.

Another good news story stemming from the study lies in what the researchers actually didn’t find. And those are health and welfare issues like leg bone deformities, sudden death and poor bone strength that were prevalent among conventional broiler strains 15 to 20 years ago.

“We didn’t see any of that, which shows that selection for welfare traits has been successful at alleviating those problems,” Widowski says. “So, issues we see now could possibly also be mitigated by putting traits into selection programs that will reduce current welfare problems.”

Research results were recently made public by G.A.P and the research team is now preparing a series of research papers for publication. In the meantime, the outcomes have been shared with the breeding companies who participated in the project. “They can potentially make changes or look further into welfare traits in their particular lines,” Torrey says.

By Kayla Price

Antimicrobial resistance is a broad term that is used for any organism, such as parasites, bacteria, insects, etc., that have developed resistance to something that is used to kill them or decrease their numbers. Over the past several years, the conversation about antibiotic resistance, specifically related to bacteria resistance, on the farm, in pets and in humans has received most of the attention. Antibiotic resistance can transfer between bacteria and these bacteria can move between people, animals and the environment.

There are two major debates in the scientific community: 1) antibiotic resistance bacteria and genes can pass between people, pets, farm animals and the environment, but which is more responsible; and 2) which is more likely to generate resistance, small doses of antibiotics over a long period or high doses over a short period.

Regardless of the opinions on different debates, antibiotic resistance is widespread globally. What follows is the first installment of a two-part series on this important topic.

Antibiotics have an important role to play in farm animals, pets and humans when there is a bacterial infection that cannot be controlled by other means. The harnessing of specific compounds from moulds, soils and eventually synthetic means was the start and the continuation of the antimicrobial, including antibiotic, revolution.

In 1928, Sir Alexander Fleming accidentally discovered that “mould juice” could stop bacteria growth and this resulted in the discovery of one of the first mass produced antibiotics, penicillin. Fleming may have discovered the source of penicillin, but many others played a role in developing a simple, quality-controlled way to purify and mass produce the drug by 1941. Interestingly, Fleming was

amongst the first to caution against antibacterial resistance and the first resistant bacteria to penicillin was found in 1942.

The “golden age” of new antibiotic discoveries were from the 1950s to the 1970s. Recently, new antibiotics brought to the market are synthetic re-structuring of other known antibiotics and the majority of these are for human use.

New antibiotic compounds are being discovered but still need to go through the quality control, regulatory and mass production hurdles before they can be widely used and would, most likely, be used in human multiple resistant bacterial challenges.

Modern poultry production started around the 1940s with the access to relatively inexpensive anticoccidial drugs. By 1946, research demonstrated that the inclusion of antibiotics in poultry feed increased weight gain and more studies followed showing similar effects in poultry and swine. From this research, antibiotics were used as growth promoters in the industry and by the 1950s this

strategy was used without a veterinary prescription in the USA. By 1951 concerns were expressed about antibiotic resistance in agriculture.

Concerns continued to grow by various country governing groups and lobbying consumer groups demanded that countries started to ban antibiotic growth promoters. Reducing the use of antibiotics in animal production became an important objective for the European Union (EU) in the late 1990s. Since promoting growth involves the continuous consumption of antibiotics, this practice was completely banned in the EU on January 1, 2006. Several countries had made the choice before a formal ban, including Sweden in the mid-1980s and Denmark in1996. Since then, New Zealand (1999), Chile (2006), Bangladesh (2010) and Korea (2011) have followed suit.

Antibiotic resistant genes can be found in bacteria that have never “seen” an antibiotic as well as those bacteria which are under constant pressure because of antibiotic use. Antibiotic resistance genes have been found in some bacteria which are millions of years old. These ancestral antibiotic resistance genes may have originally been intended to protect the bacteria from general damage and encourage successful replication and function. These genes may move to other bacteria but at a slow and random rate because there was no major selection pressure. When antibiotics were introduced, they only killed susceptible bacteria, ones that could be killed, and did not harm resistance bacteria.

With continued use of the same anti-

biotic there was a pressure placed on the bacteria and only resistance bacteria could survive, replicate, and spread.

There are different resistance strategies that are coded by various resistance genes. The different strategies include: 1) avoid an antibiotic target; 2) change or destroy an antibiotic with enzymes or proteins; 3) change the entry paths or limit the number of entry paths for the antibiotic; 4) change the antibiotic target; 5) pump out the antibiotic; and 6) at the population level, work together to create a biofilm.

The resistance genes stay in bacterial populations because they can increase the survival of the bacteria (fitness) and/or they can increase the virulence of that bacteria. For those genes that increase overall fitness or virulence then the resistance can be long-term and hard to get rid of, whereas genes that only do this when

the bacteria is under pressure may only last as long as the pressure is there.

You can think of this like your favourite challenge reality tv show. The contestants that can perform well regardless of the situation are the long-term, hard to get rid of “all-stars”.

In contrast, the contestants that perform well under certain pressures usually only last for the one season that there is that pressure.

Antibiotics are categorized into different classes and within a class there can be further variation. To put it simply, you can think of these classes like the general classes in school – science, English and geography. Within each of these classes there is further distinction such as chemistry and biology within science and this would represent the distinctions between antibiotics within the same class. Antibiotic resistance genes can have mechanisms that act against one class or multiple classes of antibiotics.

Antibiotic resistance genes can move from bacteria to bacteria regardless of whether the bacteria are good, opportunistic or bad. Depending on how these genes move between bacteria is one way to determine how the bacteria may gain multiple resistance.

To make this easier to understand, imagine a barbeque where hot dogs with all the condiments are being served. The hot dog is the bacteria genes and the condiments are the resistance genes. If you expected one hot dog and were to receive one hot dog with ketchup, this would represent a single resistance strategy that acts against one antibiotic class.

If you expected to receive one hot dog but you received one with ketchup and mustard, this would represent co-resistance where two

genetically linked genes are close together and are transferred at the same time. If you expected one hot dog with ketchup but received one hot dog with “mayochup”, a mayonnaise and ketchup blend (yes, it’s out there), this would represent cross-resistance where a single gene may act against multiple antibiotic classes. This transfer of resistance genes can help explain resistance to multiple antibiotics.

Additionally, resistance can develop from other substances used to kill bacteria such as high levels

and elsewhere. When we talk of the intestinal bacteria microbiota specifically, these bacteria contain many genes. These groupings of genes can include resistance genes.

On a flock level, there is a “core resistome” that includes the resistance genes that every bird in the flock will have.

This core resistome may come from all the bacteria interacting with each other, transferring genes and birds picking up bacteria from their environment. On the individual level, there is an “accessory resistome” that represents the vari-

Regardless of the opinions on different debates, antibiotic resistance is widespread globally.

of trace mineral salts (e.g., zinc and copper sulphate) and low acid levels used over a long time (e.g., pH 3 tolerance). Once resistance is developed to these other substances the resistance genes may be common or beneficial for antibiotic resistance and can pass between bacteria.

Conversely, other alternative products used in animal nutrition to modulate microbial populations may act differently in ways such as to selectively remove certain bacteria, feed beneficial bacteria or allow beneficial bacteria to grow. These different modes of action have a knock-on impact on the environment in which resistant bacteria thrive which is not beneficial to their survival.

How does antibiotic resistance impact the flock?

Each bird has their own unique microbiota, which includes bacteria, that can be found in the intestine, respiratory tract, on the skin

able group of resistance genes that are bird specific.

In terms of poultry health and performance, this is discussed on a flock level rather than by the individual bird. As a result, the core resistome, or the resistance genes the flock shares, is important when determining what antibiotics may work well for a challenge.

Due to the risk of resistance, veterinarians complete a sensitivity analysis on the diagnosed bacteria to ensure the correct drug is used to combat the challenge. For example, if a bacterium were to show up as resistance to certain antibiotics on the test then those specific antibiotics would not be helpful against that bacteria.

Look for second part of my two-part series in an upcoming issue of Canadian Poultry, in which I’ll outline where Canada stands in terms of antibiotic resistance and what else can be done. References available online at candianpoultrymag.com.

• All Stainless Steel with 12 AP80 diamond packers.

• Machine has leak, dirt and blood detection and the computer, cameras and scales all have been updated in the last 4 years.

• The grader has been updated to the new windows 7 computer with all new wiring going to the packers.

• The accumulator has been upgraded to a Sanovo OptiAccumulator 12.

Cornerstone Group provides barn washing and disinfecting as well as end of flock services. Excellent service and industry approved. We strive for efficient and effective solutions. Give us a call today: 519-402-2316. Visit: www.cornerstonepressurewashing.ca

• There is a pre washer, full washer with brushes and a final rinse and 6 blowers

For more info or pictures contact Samuel King at samkingj@gmail.com or call at (717) 253-4043.

Barn

Magalas Produce is mainly a broiler farming operation based in Waterford, a small community in Norfolk County, Ont. They also grow over 1,000 acres of cash crops. The family business includes Martin and Cheryl Magalas and their son Chase.

LOCATION

Ont.

SECTOR

The Magalas family ran a large vegetable operation for many years. But as Chase got closer to taking the reins from his parents, he sought to diversify. “I saw that down the line it was going to be too much for me to be able to run on my own,” Chase says of the vegetable business, which at one point employed over 150 people. After weighing some options, they chose to get into broilers.

Working with Clark Ag Systems, they built their first broiler barn in 2016 and a second a year later. Both were 65 ft. by 300 ft. cross-ventilated facilities. Then in 2018, tragedy struck. In February, Martin suffered a stroke. With Cheryl and Martin now semi retired, everything fell on Chase’s shoulders. One of the first big decisions he made was to get out of the vegetable business. Then this spring the family opened their third broiler barn. It’s identical to their others except it also includes sensors on all four feed lines. Looking back, Chase is glad to have gotten into broiler production. “It’s such a stable industry,” he says.

for 20 minutes.