the Hellmann Pre-enriched eu 24-241

• offers a transitional system that is not Colony housing awaiting enrichment. Cage measures 60 x 75 cm.

• is specially made to enhance Producer Profitabilty

• minimizes under grades in both its Pre-enriched and Enriched configurations.

the Hellmann Pre-enriched eu 24-241 offers

• pre-enriched compartments that hold 8 birds and meet feed, water and square inch recommendations.

• pre-enriched compartments that will minimize bird densities and undergrades

• removable side partitions that allow full cage enrichment to a compartment measuring 241 x 75 cm. when regulations are mandated

the Hellmann Fully enriched eu 24-241 offers

• nests located at the front of the compartment to reduce egg roll out distances, dirty eggs and toe cracks.

• segregated nesting and feeding areas to eliminate egg roll out interference from hens

• more nesting areas per running foot and egg belt advance to keep under grades to a minimum

Contact: Jim Currie Cell: ( 519 ) 868 - 1882

Contact: Calvin Hiebert Cell: ( 204 ) 346 - 3584

OntariO & QuebeC Contact: stephane Chouinard Cell: ( 450 ) 266 - 9604

INDUSTRY: Seeking Supply Management

The Pullet Growers of Canada are one step closer By Jim

Knisley

TECHNOLOGY: Farming by the Inch Does precision agriculture have a place in manure management?

By Karen Dallimore

Sustainable Funding By Tim

Nelson,

Executive Director

BARN MANAGEMENT: Cold-weather Ventilation

It’s a matter of timer By

Shawn Conley

NUTRITION: Feeding Hens in Alternative Housing by Paul Patterson, Professor, Poultry Extension Specialist, Department of Poultry Science, University Park, Pennsylvania

RESEARCH: Cracking Down on Disease

Using egg yolk to combat major diseases in poultry By Sandra Avant, United States Department of Agriculture –Agricultural Research Service

BY KRISTY NUDDS

The argument that supply management costs Canadians more at the grocery store once again has become news fodder, and, as usual, the focus on cost differences is flawed and detracts from the bigger issue at hand.

The Canadian Broadcasting Corp. (CBC) has released details of an investigation it conducted into cheese smuggling across the U.S./Canada border in Niagara Falls, Ont. It reported that the Niagara Regional Police service is investigating several officers who are accused of using their police vehicles to bring mozzarella cheese from the U.S. into Canada, and offering it at reduced cost to Canadian pizzeria owners.

The cost of cheese in Canada has long been a contentious issue for the pizza and restaurant industry, and has in part led the Canadian Restaurant and Foodservices Association to appeal to the Standing Committee on Agriculture and Agri-Food that supply management in the poultry and dairy industries increases prices for its members, stifles innovation and creates unfair competition among buyers.

Coincidentally, several days prior to the CBC report, the British Columbia Egg Marketing Board (BCEMB) released a new consumer campaign called “Eggonomics” to try to address the issue of price differences between U.S. and Canadian eggs at the grocery store. The BCEMB says that cross-border egg shopping costs its industry upwards of $3 million a year. The organization has launched a website – www.eggonomics.ca – where it gives “six reasons to take U.S. eggs off your shopping list.” These include the negative impact on B.C.’s GDP, the loss of economic support in B.C. communities, quality and freshness concerns, and the impact on infrastructure (for example, the concern that spending outside of Canada will leave less money available for social programs such as health care).

The Eggonomics campaign speaks to

Canadian consumers’ values, a strategy that Charlie Arnot, CEO of the U.S.-based Center for Food Integrity, has been championing, most recently at the North American forum on Sustainable Animal Agriculture held in Mississauga, Ont. Rather than relying on explanations of economics and science, he feels, animal agriculture needs to gain consumer confidence and trust by communicating values that farmers and consumers share, such as producing and eating highquality products that sustain farming and rural communities – essentially, the benefits agricultural production provides to society as a whole, not just to farmers’ bottom lines.

Of course, immediately after the CBC report and the release of the BCEMB Eggonomics campaign, national newspapers such as the Vancouver Sun and the National Post ran columns criticizing supply management, saying it costs consumers too much money and that if tariffs were eliminated and U.S. product was allowed in, everybody would win: costs would go down, and Canadian farmers could suddenly become more competitive and innovative.

What’s missing from their collective argument is not only the loss of revenue to the Canadian agricultural industry, but also its sustainability. As an example, take what is happening in the beef and pork industries in Canada right now. Both are at a tipping point and predictions are that they will continue to shrink. This has a spill-over economic effect on communities, and although we will see more U.S. beef and pork products in the grocery store, it’s doubtful consumers will reap any price benefit. They certainly didn’t during the BSE crisis nine years ago.

Without control over or support of domestic supply, livestock industries have two other choices: shrink and be eliminated altogether by foreign competition, or continue in chaos and hope for the best. Where is the value in that? n

NOVEMBER 2012

Vol. 99, No. 11

Editor

Kristy Nudds – knudds@annexweb.com 888-599-2228 ext. 266

Associate Editor

David Manly – dmanly@annexweb.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-429-5193 888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Emily Sun

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation e-mail: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Got Lubing? Contact your local Lubing Distributor for more detailed information about our innovative products or vist our website at www.lubingusa.com.

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Our innovative products are produced with the most modern manufacturing capabilities giving our customers a profitable advantage in productivity.

Curve Conveyors

Handle up to 60° angles

Belt Conveyors

Lengths up to 2,000 ft.

Transfer Tables

Rugged Construction - Built to last

Dirty Egg Returns

Superior design - Reliable performance

Nipple Drinking

Ideal water flow from pullets to layers

ederal, provincial and territorial (FPT) Ministers of Agriculture reached agreement on the content of the Growing Forward 2 policy framework for the agriculture, agri-food and agri-products sector in mid-September. The new five-year agreement includes investments in strategic initiatives of over $3 billion for innovation, competitiveness and market development, including a 50 per cent increase in governments’ cost-shared initiatives.

Key highlights of Growing Forward 2 include: a suite of Business Risk Management programs to protect against market volatility and disasters, as well as greater flexibility for provinces and territories to invest in environmental initiatives and on-farm water infrastructure.

Modifications to AgriStability and AgriInvest will ensure that Canadian producers continue to have access to a suite of BRM programs. AgriInsurance (crop insurance), AgriRecovery, and the Advanced Payment Program will continue to help farmers manage production risks and provide cash flow assistance. Governments will boost coverage for those with negative margins as well as substantially increase farmers’ ability to contribute greater funds into their AgriInvest account. BRM program reform is in line with government and industry agreement that programs should not mask market signals and should create space for the development of private risk management tools.

In collaboration with the sector, governments will also encourage the development of private sector risk management tools and will continue to monitor and review BRM programming over the term of the framework.

Following consultations with industry, governments have committed to increase their focus on innovation, competitiveness and market development. Innovation will lead to more efficient, sustainable farming and processing operations and help position Canada as a world leader in agriculture.

Governments will continue to work closely with the sector as Growing Forward 2 programs are developed and implemented. Consultations with stakeholders will be ongoing and focus on the longer-term direction for BRM programs, explore new insurance-based tools, and seek input and partnership on strategic investments.

The agreement sets the stage for FPT governments to complete bilateral agreements so programs will be in place by April 1, 2013, when the current framework expires.

More information about Growing Forward 2, is available at www.agr.gc.ca/ GrowingForward.

Soaring commodity values and limited supply continue to push Canadian farmland values to new heights, with price per acre now commanding top dollar in most markets across the country, says a new RE/MAX report.

The RE/MAX Market Trends Report, Farm Edition 2012, highlighting trends and developments in 16 markets throughout Canada, found that prices have increased almost across the board this year, with only the Annapolis Valley, parts of Windsor/Essex, and the Fraser Valley reporting levels on par with 2011. Tight inventory has been an issue in all markets, restricting year-over-year sales activity to a large extent. While low interest rates, high commod-

The World’s Poultry Congress was held in Salvador, Brazil, from Aug, 6-9, 2012. A large Canadian contingent was present, including representatives from industry, government and academia. Among the Canadian presenters were winners of the World’s Poultry Science Association – Canada Branch student competition. Each of the following students was awarded $500 in support of travel costs to attend the meeting:

• Aman Deep, University of Saskatchewan. “Feeding

ity prices, and nutrient/supply management requirements have been the primary factors fuelling the trend toward expansion, increased advancement in farm equipment has

peas (Pisum sativum) to modulate post-prandial physiological responses in broiler breeders.” A Deep, TA Scott and HL Classen (oral presentation).

• Jocelyn Fournier, University of Saskatchewan. “Impact of toe trimming on productivity, carcass grading and welfare of turkey hens raised to 15 weeks of age.”

J Fournier, K SchweanLardner, TD Knezacek, S Gomis, HL Classen (oral presentation).

• Thania Moraes, University of Alberta. “Effect of maternal diet composition on broiler BW and carcass yield,” whose authors are: TGV Moraes, A Pishnamazi, II Wenger, ET Mba, RA

JANUARY 2013

January 28-31, 2013

International Poultry Exposition (IPE), International Feed Exposition (IFE) and American Meat Institute (AMI) tradeshow

Georgia World Congress Center, Atlanta, Ga. visit: www.ipe11.org

February 5-7, 2013

Canadian International Farm Show

International Centre, Mississauga, Ont. visit: www.masterpromotions.ca

February 25-27, 2013

also been behind the push for additional acreage.

View the full RE/MAX Market Trends Report, Farm Edition 2012, at http://goo.gl/ DsMKb.

Renema, MJ Zuidhof (poster presentation).

• Kim Ton, University of Alberta. “Effect of early nutrition, 25-OH vitamin D3, and Bacitracin Methylene Disalicylate on broiler innate immunity and ileal morphology.” K Ton*, JL Saunders-Blades, DR Korver, MJ Zuidhof (poster presentation).

• Cibele Torres, University of Alberta. “Effect of incubator temperature and parent flock age on chick bone characteristics at hatch.”

CA Torres, DR Korver, JA Hamidu (oral presentation).

The Canadian Hatching Egg Producers and the Turkey Farmers of Canada generously provided funding for the awards.

Pacific Egg & Poultry Association annual convention InterContinental Hotel, Monterey, Calif. contact Debbie Murdock, e-mail: dmurdock@cgfa.org tel: (916) 441-0801

March 6-8, 2013

London Farm Show

Western Fair District, London, Ont. visit: http://www.westernfairdistrict.com

APRIL

April 10-11, 2013

London Poultry Show

Progress Building, Western Fair District, London, Ont. visit: www.westernfairdistrict.com

June 19-21, 2013

Canada’s Farm Progress Show

The Co-Operators Centre, Regina, Sask. www.myfarmshow.com

The federal goverment has appointed a new chief food safety officer and a new chief veterinary officer, Agriculture Minister Gerry Ritz announced recently.

Dr. Martine Dubuc is Canada’s new chief food safety officer and Dr. Ian Alexander has been appointed as the new chief veterinary officer.

Dr. Dubuc has been with the CFIA since November 2008 and previously worked

at senior levels in the Quebec government with responsibility for animal health and the food safety system. She will continue her work as the CFIA’s vice-president of science.

As chief veterinary officer, Dr. Alexander will provide national leadership to ensure that Canada’s animal and veterinary public health infrastructure is positioned to effectively manage current and emerging disease threats.

TScott Gillingham (L) and Jacob Middelkamp

he Canadian Poultry Research Council (CPRC) held an event at the University of Alberta’s Poultry Research Centre (PRC), on Sept. 13, 2012, to unveil its new Research Sponsorship Program. A cheque was presented to Jacob Middelkamp, CPRC’s Chair, by Scott Gillingham, Canadian Regional Business Manager for Aviagen Inc.. Aviagen is the inaugural sponsor of the program.

The event was held at a PRC banquet attended by many poultry industry stakeholders including: producers, researchers, educators and government representatives. The Research Sponsorship Program is designed to

June 16-18, 2013

CPEPC/CMC Convention

Fairmont Banff Springs Hotel, Banff, Alta. visit: www.cpepc.ca

July 21-25, 2013 Poultry Science Association (PSA) annual meeting

Town & Country Resort & Conference Center, San Diego, Calif. For more information, visit: www.poultryscience. org

September 10-12, 2013

Canada’s Outdoor Farm Show

Canad’a Outdoor Park, Woodstock, Ont. visit: www.outdoorfarmshow.com

September 30-October 2, 2013

enhance the industry research funding received from CPRC Member Organizations, which is becoming more important as governments of different levels realign their funding as a result of budget pressures.

CPRC representatives provided banquet attendees with information on the recently released National Research Strategy for Canada’s Poultry Sector and preliminary results from the Poultry Research Cluster Program that will end in March 2013. They also discussed plans for a new Poultry Research Cluster under Growing Forward 2 that is projected to take effect in April 2013.

- Chicken Farmers of Canada

National Meeting on Poultry Health and Processing Ocean City, Maryland. For more information, visit: www.dpichicken.org

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont. N3Y 4N5; e-mail knudds@annexweb.com; or fax 519-429-3094.

Sullair recently introduced its line of 230 Volt VSD S-energy Lubricated Rotary Screw Air Compressors. Designed to meet the growing demand for variable speed drive energy efficiency in a 230V package, this expanded line of compressors now includes Models 1100e, 1500e, 1800e, 1800, 2200, 3000P, 3700 and 4500, all of which are now available with variable speed drive. These models range from 15 to 60 horse-

power, with capacities from 46.4 to 222 cfm and pressures ranging from 100 to 175 psig.

Having the same footprint and performance character-

The new BigFoot radiant tube brooder series by Space-Ray is designed to yield an extra-wide, rectangular heat pattern for poultry houses. It provides one of the largest rectangular-shaped heating footprints available for modern poultry applications. Available in natural or propane gas models, the new PBF Series saves on fuel costs, reduces maintenance and permits higher mounting in

the poultry house for broader coverage and added efficiency.

The reflector angle of the Big Foot radiant tube brooder is engineered to an optimum angle of 19 degrees, which improves the radiant footprint and minimizes convective wash. The result is a more uniform heat distribution, better brooding conditions and more comfort for the birds.

Each of the heaters comes with a choice of one-stage or two-stage input controls for added flexibility and a totally enclosed burner box that places all the power, thermostat and gas connections in one central location for easier installation and maintenance.

The CSA-Certified Big Foot radiant tube brooder series is available in four sizes from 60,000 BTU/hr (18 kW/hr) to

The new 440 front-wheel drive tractor from Steiner is bolder and more powerful yet retains the compact, highly manoeuvrable and easily versatile attributes of its predecessor, the 430. Most attachments for Steiner 430

istics as the 460V, the Sullair 230V VSD S-energy compressors are designed to help users significantly reduce operating and energy costs over the entire compressor life cycle.

The Sullair S-energy compressor package also includes a variety of design features that simplify maintenance, improve reliability and extend service life.

For more information, visit your local Sullair dealer or visit www.sullair.com.

and 235 front-wheel drive tractors are interchangeable with the new 440.

The 440 has a higher power-to-weight ratio than its nearest competitor and offers more power in a smaller, more versatile machine.

90,000 BTU/hr (26 kW/hr). The Big Foot is alsoavailable in either U-shaped tube or straight tube versions. The standard emitter tube length is 20 ft. (6.1 m), while the overall length for the U-tube version is 11.5 ft. (3.5 m) and the straight version is 21.5 ft. (6.6 m).

Each unit is pre-assembled for easy installation and comes with fresh air intake kit, exhaust hood, stainless steel flexible gas connector and a pre-wired electrical connection.

The radiant brooder series also features Space-Ray’s unique TISS systemthat automatically turns off the heater in the unlikely event of a tube failure.

For more information, contact your local Space-Ray dealer at info@spaceray.com, or visit www.spaceray.com.

For more information, contact your local Steiner dealer or visit www.steinerturf.com.

PrimoWeigher combination scales provides an extensive range of time-saving software features that reduce startup time, increases productivity and gives the manager control from the convenience of the office.

For operators, the control panel includes an easy-to-read 15-inch colour touch screen and the choice of several languages, including English, Spanish, and French – other languages can be added easily. If an operator ever forgets how to enter a new recipe, a Wizard function walks the operator through the step-bystep on-screen procedure. An unlimited number of recipes

Vencomatic’s Grando Nest for broiler breeders or layers is an automatic nest featuring a moveable floor that pushes the birds out after a period of lay, preventing broodiness. The moveable floor means the nest pad is self cleaning, resulting in clean eggs.

It’s welfare-friendly design and the materials used create an optimum environment for a hen to lay her eggs. It’s easily accessible for the birds and the large nest surface allows for a high density per nest.

The egg belt is perforated

can be entered in the system and are quickly located using flip-through photographs of the product that can be attached to each recipe.

The Primo Pocket Control gives operators complete control of the PrimoWeigher in the palms of their hands eliminating the need to go back and forth between the scale and control panel or to obtain the assistance of a second person.

Should an operator or maintenance person ever need support from CombiScale, PrimoWeigher 360 Online Support allows the service technicians to connect to the PrimoWeigher and provide immediate support. With a

digital camera connected to the PrimoWeigher, the technicians can see what the operator sees in real time and with the customers’ authorization, CombiScale technicians can even operate the scale from anywhere in the world.

Managers benefit from software features that save time and give feedback on how the scale is performing. Planning and scheduling can be done remotely from the manager’s computer. When operators log in each morning, the production schedule is already there to be run.

Managers can access realtime data remotely, see all the screens of the control panel, and even see actual product flowing into the scale from the digital camera mounted above. Triggers and alerts can be set up to send e-mails automatically to managers for a broad range of performance indicators as well as report any delays in production. Protection of sensitive data is assured with a multi-level security system that gives managers control of what different users of the scale can access.

with square holes for minimum contact, ensuring gentle egg transfer.

The nest is easily operated and all vital parts are easy to reach for easy maintenance.

Foodmate’s Opti Thigh Deboner produces a quality meat and yield that provides a hand-cut appearance but requires minimal manual trimming.

The Opti Thigh Deboner’s state-of-theart thigh holding unit allows for easy loading and increased output. The innovative scraper design and tendon cutting system eliminates bone shattering or fragmenting, which reduces trimming and inspection time.

The deboner was developed to bring solutions to familiar problems found in both manual and automated thigh deboning operations, such as shattering or fragmenting bones.

Cleaning is fast and easy. For more information, contact Vencomatic Canada at 800-224-9833, by e-mail at info@vencomatic.ca, or visit www.vencomatic.ca.

In addition, the Opti Thigh Deboner eliminates the need for rubber discs to clean the bone, significantly reducing operating costs and manual production interaction for producing a quality product. Available options include an automatic kneecap remover that reduces manual trimming labour, resulting in higher yield; product conveyors that can be customized to suit specific needs; and thigh skinners that are built into the machine, minimizing additional labour needs.

For more information, visit: www.foodmate.nl.

The poultry industry in Canada has made tremendous strides in virtually every respect. Improved production efficiencies, enhanced management practices, and superior disease detection, treatment and prevention can all be traced back to research. Clearly, past investments in research have paid enormous dividends. Therefore, continued investment in research is key to the future success of the poultry industry.

In order to maximize the return on an investment in research, many would argue, one should only support research that has obvious industry applications. However, it may not always be obvious how a particular research project will translate into results a farmer will see in the barn. Often, it is the amalgamation of seemingly unrelated research discoveries that eventually leads to these improvements.

Take, for example, a study at the University of Manitoba that is looking at enzyme supplements for broiler feed. The enzymes are being used to break down otherwise indigestible components of corn, soybean and wheat in common broiler diets because it was discovered that the presence of these indigestibles in the gut could promote the growth of several deleterious organisms. The study found that birds supplemented with the enzymes performed better when challenged with necrotic enteritis compared to the control birds. The mix of enzymes developed during this research is now commercially available to the poultry industry through Canadian Bio-Systems Inc. (which was an active supporter of the research program) and is being used in some low-dose antibiotic feeding programs.

The success of this study is rooted in a range of research efforts that came before it; fundamental knowledge of immunology, botany and nutrition were applied

to enzyme chemistry, gut microbiology and etiology to achieve results that could ultimately be used in industry. In other words, this research could not have been put into practice were it not for the range of discoveries that preceded it.

Research can be described as occurring along an “Innovation Continuum,” which begins with primary research – that which pushes back the frontiers of knowledge and provides us with conceptual understanding of the world around us. Further along, applied research directs this fundamental knowledge towards more tangible end results and the next stage, innovation, leads to products and processes that may be of use to the end user. Finally, application is the point at which the research actually impacts the end user, which would be considered the most interesting from an industry standpoint. But, as illustrated in the example above, a successful research program requires support at all points along the Innovation Continuum.

The recently released “National Research Strategy for Canada’s Poultry Sector” (for details, visit www.cp-rc.ca/news. php#Strategic_Planning) outlines an approach that helps push research towards the application stage while maintaining a healthy balance of all types of research along the Continuum. The approach is based on articulating target outcomes for each research priority area. For example, one of CPRC’s research priorities areas is “Food Safety.”

In the Strategy document, the industry has listed a number of outcomes

it would like to see from food safety research. Proposals submitted to CPRC therefore will be reviewed in light of their potential to help move the program towards one or more of these target outcomes. Research anywhere along the Innovation Continuum is eligible for support, provided it can demonstrate that potential. This approach will focus CPRC research programs on the work required to reach industry’s target outcomes and at the same time provide support for discovery research.

CPRC has, along with various government and industry partners, supported a number of research projects. In some cases, research that yielded promising results was not continued after the original studies were completed. The CPRC is therefore considering what steps are required to move these projects along the Innovation Continuum towards industry application with consultation from project leaders. If it sees value in doing so, the CPRC will facilitate that next step, whether it is more research, field trials, extension or other activities.

The future success of the poultry industry depends on innovations from research and the CPRC continues to work towards a strong poultry research program that balances industry’s desire for quick application of innovations with the need to foster discoveries that will fuel the innovations of tomorrow.

For more details on these or any other CPRC activities, please contact the Canadian Poultry Research Council, 350 Sparks St., Ste. 1007, Ottawa, Ontario, K1R 7S8, phone: 613-566-5916, fax: 613241-5999, e-mail: info@cp-rc.ca, or visit us at www.cp-rc.ca. n

BY JIM KNISLEY

The Pullet Growers of Canada have come a long way in their quest to become the first commodity in more than two and a half decades to come under supply management. But, it is a long road and there are a few more miles to go.

In mid-July, the Pullet Growers of Canada (PGC) made their formal submission to the Farm Products Council of Canada (FPCC) to seek Part 2 status under the Farm Products Agencies Act. The FPCC formed a committee and the submission is expected to come before the full council at a meeting at the end of September.

“This has been a long time coming,” said Andy DeWeerd, the PGC Chair. “There hasn’t been a new commodity to come under supply management since 1986, so it’s new for everyone involved.”

In preparing their submission, the pullet growers spent two years consulting with pullet and egg producers across the country as well as provincial supervisory agencies to gather ideas, address all questions and concerns, and ensure all details were attended to.

DeWeerd added that he is confident the pullet growers have done their due diligence and is hopeful of a positive result at the council meeting.

Pullets were one of the components of the poultry industry that were not under supply management. DeWeerd said he understands that an attempt was made in the 1980s to get pullets under supply

management, but it fell apart and he’s not sure why.

But once approval is received for pullet producers to form their own agency, “we will have the industry voice and price parity shared by the rest of the poultry industries,” he said.

“Being an autonomous agency will give PGC the required legal powers to make decisions on such issues as cost of production, disease control programs and housing standards, among many others,” said DeWeerd. “The time has come for the Canadian pullet industry to come into its own.”

At present, different provinces have different rules for such things as housing, HACCP and disease control.

The formal drive for a new federal agency began in 2010 when pullet growers from several provinces got together and decided they wanted supply management. At this point in time, it looks as if five

provinces – Ontario, Quebec, Manitoba, Nova Scotia and New Brunswick, which represent about 80 per cent of national production – will be members from the start. But the agency is open to the other provinces and others may want to sign on once it is established, he said.

However, there are strict requirements for establishing a new supply-managed marketing agency.

The federal Farm Products Agencies Act says: “The Governor in Council (federal cabinet) may, by order, establish an agency with powers relating to any farm product or farm products the marketing of which in interprovincial and export trade is not regulated under the Canadian Dairy Commission Act if the Governor in Council is satisfied that a majority of the producers of the farm product or of each of the farm products in Canada is in favour of the establishment of an agency.”

In the legislation, a Part 2 agency is defined as a “marketing agency and it relates to “eggs and poultry, and any part of any such product.”

The agency will develop a marketing plan, which, under the legislation, means “a plan relating to the promotion, regulation and control of the marketing of any regulated product in interprovincial or export trade that includes provision for all or any of the following:

“The marketing of the regulated product on a basis that enables the agency that is implementing the plan to fix and determine the quantity, if any, in which the regulated product or any variety, class or grade thereof may be marketed in interprovincial or export trade by each person engaged in the marketing thereof and by all persons so engaged, and the price, time and place at which the regulated product or any variety, class or grade thereof may be so marketed.”

It continues, saying “a system for the licensing of persons engaged in the growing or production of the regulated product for, or the marketing thereof in, interprovincial or export trade, including provision for fees, other than fees related to the right to grow the regulated product, payable to the appropriate agency by any such person in respect of any licence issued to such person and for the cancellation or suspension of any such licence where a term or condition there of is not complied with, and the imposition and collection by the appropriate agency of levies or charges from persons engaged in the growing or production of the regulated product or the marketing thereof and for such purposes classifying those persons into groups and specifying the levies or charges, if any, payable by the members of each group.”

The pullet growers have also developed a draft Federal-Provincial Agreement. This describes the basis of the federal-

provincial relationship on pullets, proposals of how the agreement might work and a quota methodology. A new agency would also be able to establish housing and disease control standards and more.

Once the Pullet Growers are under supply management, Canada’s 550 pullet growers will have the ability to recover their costs of production. DeWeerd said the growers are falling behind.

The organization has the support of the Egg Farmers of Canada and provincial egg organizations. And like other supply managed groups, the pullet growers will have provincial representation, as well as a national organization. To date provincial organizations have been formed in Ontario, Quebec, Manitoba and Nova Scotia.

At present Manitoba, Ontario and Nova Scotia pullet growers operate under their provincial egg marketing boards. Quebec growers recently became a stand-alone organization outside the province’s egg board. n

Don’tforgettopick-up aftermy$25giftcardbuying$500worth ofanyofVetoquinol’s Cleaners&Disinfectants products.

If you could protect your farm this way, you wouldn’t need any detergents or disinfectants.

Vétoquinol would like to remind you of the importance of a good biosecurity protocol and its implementation on a daily basis. Need more information? Consult your farm Biosecurity specialist: Vetoquinol!

Does precision agriculture have a place in manure management?

BY KAREN DALLIMORE

With a show of hands, about half of those listening to the presentation in Jake Kraayenbrink’s back 40 near Moorefield, Ont., confessed to having a smartphone of some sort.

That means that half of the crowd at that manure management demonstration would instantly be able to pinpoint their location at that particular moment, in that particular field, using the global positioning system (GPS) feature on their smartphone. It also means that they may be only a step away from utilizing precision agriculture to manage their manure.

But what exactly is precision agriculture?

Simply put, it is farming by the inch instead of the acre. It is achieved by using satellite and sensor data in conjunction with computer software to map and manage field data and to generate distinct records for every field of the farm. The goal is to better manage resources.

The most common tool to achieve this is GPS technology, used on field equipment to accurately steer and control applications based on the position of the equipment in the field. Every operation done by the equipment can be mapped and managed as a business management tool.

“It’s pretty cool technology,” Larry Prong, GPS specialist with Premier Equipment in Elmira, Ont., told farmers. “It’s starting to become the norm to sell GPS equipment with new tractors.”

Precision agriculture components typically include aGPS receiver, an in-cab computer display, machine controls for

PRECISION APPLICATION

Satellite and sensor data in conjunction with computer software map and manage field data to help manage resources.

guidance (commonly known as autosteer systems), spray controllers, rate controllers for dry box spreaders and flow meters for manure tankers. Other components may include field scouting devices anddesktop geographic information systems (GIS) for data management.

But does precision agriculture technology have an application in manure management?

“Yes,” said Prong. “That’s the purpose of precision agriculture: getting more exact with our field operations and gaining the efficiencies through that.”

Using precision agriculture technology and tools can increase manure placement accuracy and application rates, but then the data can be sent back to the office to map your fields and help to keep good records as well.

When it comes to manure application, the placement accuracy you are looking for is probably six to eight inches, explained Prong. That’s good enough to make sure you don’t have any big skips as you move up and down the field, but make sure that at the same time you are not getting a lot of overlap.

One good example of where GPS accuracy would come into play in nutrient management would be side-dressing liquid manure into standing corn: it’s tricky and there is not a lot of room for error. Corn planted with high accuracy will have bullet-straight rows but, more importantly, you can go back exactly into same wheel track within one inch six or eight weeks later.

Some people may say, “But it is just manure, why do we have to record all that data?

As your commercial fertilizer costs go up manure becomes liquid gold, said Prong, and there is tremendous value to what you’re putting on the land. If you’re going to take the time to work with an agronomist, you are expecting a certain yield from your ground and precision agriculture is just another piece of the puzzle.

Another side of the coin is that, unfor-

tunately, manure is regarded as hazardous material. After the Walkerton incident, we need to know where it’s going down as well as setbacks from wellheads and waterways, said Prong. Every time you use a GPS system it provides an audit trail: this is how much I put down and this is where I put it down.

One of the key pieces of information is the amount of manure you’re putting down, which involves measuring not only amounts but also application rates. This is where a rate controller can be useful.

For solid manure, a rate controller gives you the ability to measure load size under a dry spreader box, measuring change in weight to calculate the application rate. A hydraulic gate valve can then help regulate the amounts going on the field.

Prong said liquid manure measurement requires the use of a flow meter, a

common feature nowadays that will measure liquid manure application in gallons per minute from the tanker.

“That’s important in injected manure where you can’t see what’s going in the ground,” he said. “It’s amazing how a change in ground speed can spike your application rates.”

For example, at four miles per hour with a 2,500-gallon-per-acre target flow, 300 gallons per minute will be applied. Keeping the same flow but dropping to three miles per hour, that application rate will now be 3,300 gallons per acre. That’s a 30 per cent increase in application rate just by slowing down, and that decrease in speed can be caused by something as simple as going up a hill.

Premier Equipment has developed a creative solution that integrates an application rate control system with the IVT transmission of many John Deere tractors. As Prong explained, their rate controller actively adjusts the transmission of the tractor to maintain a consistent

Efficient feed conversion and excellent growth rate assist in the customer’s goal of achieving a targeted weight with competitive advantage of lowest cost. Cobb achieves the lowest cost of producing a kilogram or pound of meat in markets around the world.

The has the best uniformity in the market. Higher uniformity gives the processor more birds within a target weight specified by the customer. The Cobb500 is a competitive breeder providing excellent egg and chick numbers.

World’s Most Efficient Broiler

cobb-vantress.com

ground speed, which is highly critical in a dragline scenario for maintaining a consistent application rate.

In precision agriculture, as the technology is used, maps of your fields are created, allowing you to define and record not only where you’re putting down manure but how much you’re putting down. When you need to calculate how much commercial fertilizer to use above and beyond just manure, you’ll have accurate data. “That’s a plus for nutrient management,” said Prong.

Whether you have a GPS in your tractor, carry it in the phone on your belt or take it out on the four-wheeler to chart your fields, you’ll still need software to process and organize the data. The records from the field will also need to be stored and accessible, as you will need

to go back and analyze that information over time, both in the short term and over several years.

A number of software products are available, and even more are still in

development. Farm Works software has released the Connected Farm app, which runs on iPhones and Android smartphones and allows field scouting with a GPS-enabled smartphone.

Data can be transferred from the tractor using a memory stick, but when you use wireless technology, that transfer can be done while out in the field. As soon as the manure is put down, the data can be sent wirelessly to the office desktop computer and the software will automatically recognize and file it, including the geographical locations in the field.

“Quite a few people haven’t gotten there yet – they’re physically moving their data from the tractor to the desktop, but I think this is the next step in precision agriculture,” said Prong.

Looking to the future, he predicts that the next advancements will be in wireless transmission and software improvements. n

BY TIM NELSON, EXECUTIVE DIRECTOR

Acouple of months ago I commented on the federal government’s reduction in funding for research in agriculture and the paramount importance of working together to ensure that we in the poultry industry get our fair share of federal and provincial research dollars and retain, as far as is possible, our research infrastructure.

In September, the Provost at the University of Guelph (U of G) released a statement that talked of the University undertaking “a Program Prioritization Process (PPP),” which “is part of the assessment component of the University’s Integrated Plan. Its purpose is to help the university ensure its limited resources are directed toward services and programs that are “missioncritical,” said Maureen Mancuso, provost and vice-president (academic).

“We are living and working in an era of scarce resources and significant financial difficulties,” said Mancuso. “We face the challenge of continuing to maintain and enhance quality with limited revenues, so we must make decisions that are evidencebased.”

What this suggests is that the university is taking a hard look at where it makes money and where it does not. Does anyone think that the provost’s gaze will not rest on the cost of maintaining agricultural programs, faculty positions and researchers, costs that include expensive research facilities and equipment? Indeed not.

infrastructure and equipment purchases.

The last time the knife came out at the University of Guelph, the Ontario Agricultural College (OAC) copped more than its fair share of the cuts. Despite all of that, and mainly thanks to the efforts of the then-new Dean Gordon, the OAC managed to haul itself up by its bootstraps and survive.

We sincerely hope that, combined, our livestock and poultry industries create agricultural careers for those educated at Guelph, and the funds that flow from our sectors into research and faculty positions – coupled with the cash flow from the province through the OMAFRA U of G agreement – will be enough to encourage the provost to look beyond short-term edu-dollar revenue to the very sustainable long-term funding (albeit not as lucrative) that agriculture undergraduate education provides.

We need people, and good ones at that, but educating them does not come cheap

Our message to the provost is to remind her that agrifood is the number 1 economic driver and employer in this province and is likely to remain so for some time. People will always need to eat; thus, farming and the revenue it creates for the province are permanent fixtures. Agriculture is “mission critical” to the economy of the province and agriculture needs well-educated employees.

We need highly skilled workers moving out of high-quality agricultural educational institutions, but our industry cannot compete with the huge volume of students being churned through the cash-cow “edu-dollar rich” degree offerings that are taught online to hundreds of students at a time. We need people, and good ones at that, but educating them does not come cheap and neither does the research that is vital to the future of our agricultural industries.

Collaboration is key, and the advent of the Livestock Research Innovation Corporation (LRIC) could not have come at a more critical time. Designed to bring the combined weight of all of Ontario’s livestock and poultry research dollars and organizations in behind one entity, the LRIC has a mandate to negotiate with the province and university on key issues relating to research priorities, faculty appointments, research

According to the mission of the university, it feels the same way: “it recognizes agriculture and veterinary medicine as areas of special responsibility.” Our message to the provost when considering the options is to honour the university’s special responsibility to agriculture and keep the delivery of agriculture to undergraduates in the “mission-critical” envelope. And secondly, we ask that the provost never to lose sight of the fact that the significant provincial tax revenues from agrifood support the funds the university receives for the delivery of the more lucrative undergraduate online education delivery, ironically making agrifood an invisible benefactor of those courses.

Finally, we would like to offer one last thing for the provost to consider: Think sustainable funding. Think of, and believe in, agriculture. n

Keep your flock clean, healthy, and happy with Patz Model 2405, 8916, 1608 Trough Slider-Bed Belt Conveyors & 400 Stable Cleaner!

Transport litter away from your birds to where you really need it: up inclines into storage areas, stockpiled into windrows, or loaded into trucks. Efficient, high-volume conveying gets your litter windrowed, composted, and off to the fields faster!

Agri Automation Systems Dunnville (905) 774-7737

Byers Farm Equipment Chesterville (613) 448-2185

CNK AG-TECH Chesterville (613) 447-3447

Conestogo Agri Systems, Inc. Alma (519) 638-3022

Patz Corporation

Lloyd Cross Sales & Service L’Orignal (613) 675-4697

Embro Farm Systems, Inc. Embro (519) 423-9595

McCann Farm Automation, Ltd. Seeley’s Bay (613) 382-7411

Milestone Equipment, Inc. Wellesley (519) 656-9157 NEIL BOBIER - PATZ DISTRICT REP (519) 521-1946

Pound, WI · (920) 897-2251 · (800) 236-7280

www.patzcorp.com · info@patzcorp.com

Keith Siemon Farm Systems, Ltd. Walton (519) 345-2734

Systematic Construction Ltd. Mildmay (519) 367-2266

Verne Leonard Company (1987) Ltd. Oro Station (705) 487-3382

Woods Farm Automation S & S Ltd. Keene (705) 295-4752

BY SHAWN CONLEY

”Even those who fancy themselves the most progressive will fight against other kinds of progress, for each of us is convinced that our way is the best way.” – Louis L’Amour

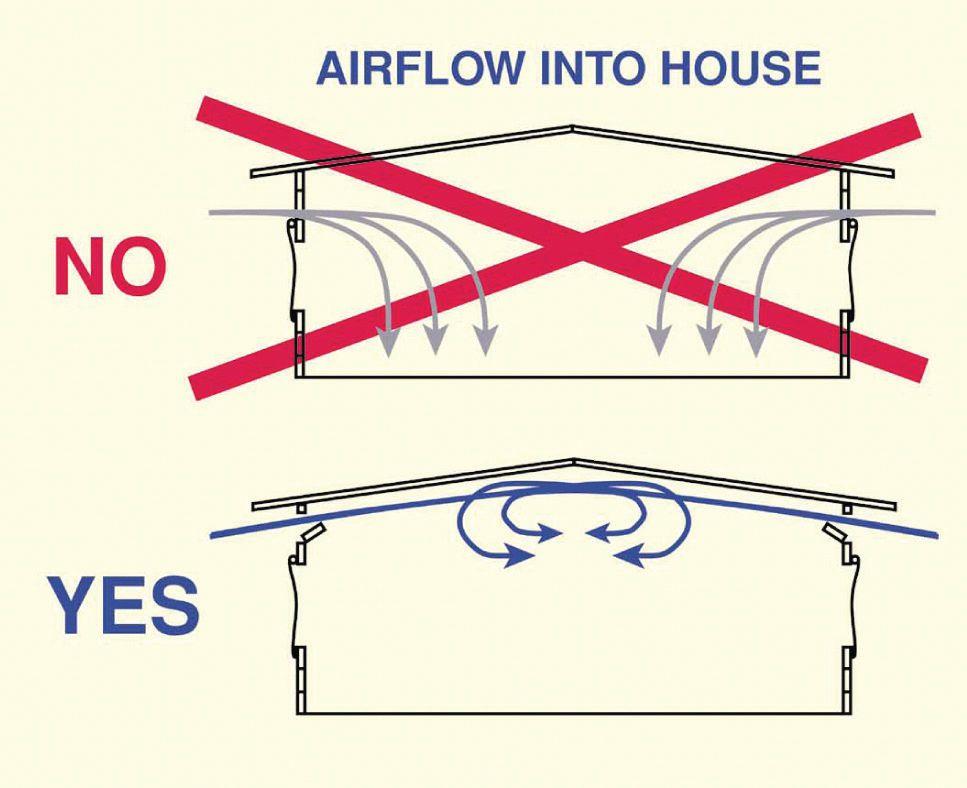

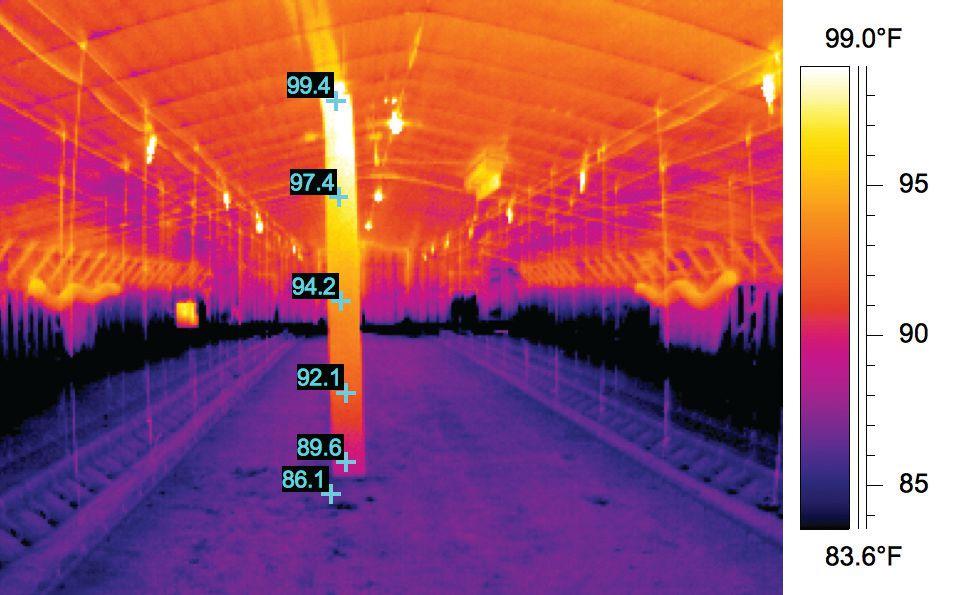

This quote by L’Amour applies to all forms of progress, even in our poultry industry. A great example is ventilation, and, specifically at this time of the year, cold-weather ventilation. There have been many significant innovations in cold weather ventilation in the last decade – some you may have heard of but not understood; others you may not have thought worthwhile but they deserve another look.

Timer fans instead of variables for exhaust, sidewall and ceiling inlets, circulation fans, humidity and CO2 sensors, static pressure levels and controller options are just some of the keys to succeeding in cold weather. Heaters are also an important factor, but could easily fill a whole article themselves. For now, it suffices to say that if you are producing a commercial bird today and still using forced-air heating instead of radiant, you aren’t just burning gas, you are burning cash.

If you’ve ever experienced uneven bird distribution, water condensation on walls or wet litter near the walls, the issues stem from variable speed fans and continuous inlet systems.

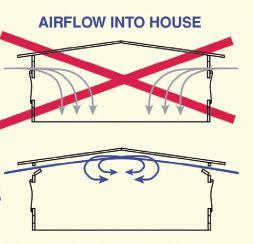

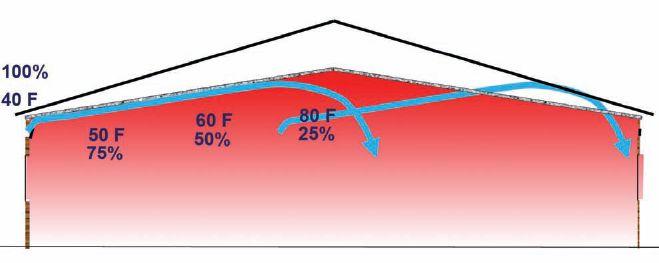

Essentially, when using variable speed exhaust fans, you are trying to ventilate with a constant flow of air. Think

Air shouldn’t fall on to heaters, but travel further into the barn before dropping to prevent heaters from running too often.

of it as a freight train that has to build speed, and you want to stop it as little as possible to make sure it doesn’t lose momentum, but the exact opposite is happening! Your air has no momentum, and falls straight to the floor, chilling your birds and condensing water in your litter. Ideally, the goal is to bring air into the barn at a high velocity along the ceiling, allowing it to preheat and mix with hotter air as it begins to drop.

But, how do we accomplish this?

There are two parts to this: modular

inlets and timer fans. Variable speed fans and continuous inlets are a problem, not a solution, in cold weather, and with a continuous inlet system is practically impossible to open a precise amount along its entire length. Looking along the edge of your baffle, it is easy to see how inconsistent the opening is.

Adding modular inlets to the ventilation system allows for precise control of air intake, consolidating the air into a tighter column, giving it the momentum required to shoot over the birds and heaters toward

the middle of the barn before descending toward the floor. This is a problem that can be avoided by creating an air column along the ceiling. Imagine how many more

heaters are running when cold outside air is hitting the sensors as the air drops just a few feet inside the barn.

The second part is timer fans because

you simply cannot create the required static pressure by running air continuously. By running your fans at 100 per cent for 60 seconds out of every 180 to 300 seconds, you enable enough air to be sucked in at high velocity to reach the centre or far side of the barn without reducing the temperature of the barn at bird level. This strategy keeps the air fresh. The static pressure levels in this system need to approach 0.10 inches H2O, unlike your warm weather levels of about 0.05-0.07. As a rule of thumb, without obstructions, you should get about two feet of air travel for each hundredth unit of pressure.

As well, ceiling inlets offer another level of incoming air control. Not only do they provide precise air volume control, but also they pull air from the attic, which acts as a giant heat exchanger. The air comes into the barn exactly where you want it – in the centre.

Along with ammonia and carbon monoxide, humidity and carbon dioxide are the main reasons that we have minimum ventilation requirements. Most climate controllers available have the capability to accept sensors for both of these measurements. Ammonia, CO, and CO2 levels seem to follow humidity, so ventilating for it will keep these gases in check. Everyone is familiar with the effects of high ammonia levels, such as blindness and air sac damage, but high levels of CO are associated with aortic rupture, as well as uniformity and weight gain issues.

Some controllers include programs that will automatically ramp up ventilation as humidity and CO2 increase, while others can be manipulated to run your first-stage fans when levels get too high. By wiring the same fans into two sets of relays, the first set can run your preset fan program and the second can activate the fans whenever humidity and carbon dioxide set points are reached. This is an excellent way to manage ventilation during brooding when little air is needed, and can allow you to keep humidity levels high enough to prevent dehydrating young birds.

Stratification of air in poultry barns can cause thousands of BTUs to be wasted. Whether you are using radiant or box heaters, a large amount of heat will immediately rise from the heaters to the ceiling, and not return to floor level. Fortunately, returning this heat to the birds is a simple process.

You can estimate the number of fans required to de-stratify the air by calculating 10 per cent of the total air volume of the barn and dividing by the CFM of the circulation fan you intend to use. For example: A 250 x 40 foot floor of a barn with a 10-foot ceiling would have a volume of 100,000 cubic feet3 of air. Ten per cent of this is 10,000 CFM. Therefore, with 2500 CFM fans, only four would be necessary. Box fans and basket fans will do the job, whereas tube fans will create

We see a flock of numbers that connect us. We see the millions of pounds of feed that together, we have worked to save every year with our birds. We see more secure operations, thanks to our industry leading health status. We see the many lasting relationships we have forged in this dynamic industry.

Together, by understanding the numbers, we understand the industry. Strength in Numbers.

more of an “air cannon” effect and not mix the air properly. Ceiling fans can also work well, especially when run in reverse to suck up air and push it out along the ceiling. In open-truss or cathedral-type barns, a fan referred to as a turbulator does a great job of moving air. You can view a video of it on Mike Czarick’s website, www.poultryventilation.com or at http://www.youtube.com/watch?v=MX

9nZSONeBc&feature=player_embedded. In the video, you can clearly see the smoke stays in the peak until the fan is activated, proving the value of circulation fans in moving this heat throughout the barn.

All of these ideas truly are the tip of the iceberg, but hopefully they provide a place to start in your quest to perfect your cold-weather ventilation. I would encour-

age you to do your own research about the options that are available, but utilizing timer fans, modular inlets, humidity monitoring and circulation fans will make a huge difference. n

Shawn Conley is with Weeden Environments in sales and technical service, in Canada amd internationally. He manages projects with many U.S. poultry companies and works frequently with researchers in the industry. Management in pharmaceuticals, a degree in cell and molecular biology and some NCAA and professional basketball preceded his six years working in the poultry equipment and feed-additive industry. Being a former Ontario farm kid, his motivation is to help producers build a strong Canadian poultry industry. He can be reached by e-mail at shawnc@weedenenvironments.com or shawn.d.conley@gmail.com.

The power of O2 and acidification combined.

• removes biofilm

• removes scale

• is equipment friendly

• “the greatest reduction in microbial presence”*

Bird performance and welfare could likely benefit from greater diet nutrient density

BY PAUL PATTERSON, PROFESSOR, POULTRY EXTENSION SPECIALIST, DEPARTMENT OF POULTRY SCIENCE, UNIVERSITY PARK, PENNSYLVANIA

Alternative production systems for hens compared with caged housing present both egg marketing opportunities and challenges to management.1 And while many studies have addressed the equipment, behavior, welfare and stressors on birds in alternative production settings vs. cages, little has been reported about the impact of these systems on the nutritional requirements of the hen.

Aviary – Although there were no nutritional treatments applied, a study comparing aviary vs. battery cage housing indicated alternative nutritional parameters might be warranted.2,3 Aviary hens were significantly lighter than those in cages (2021 vs. 2241g), despite having consumed more feed (121 vs. 116g/bird/ day) and having a higher feed conversion ratio (FCR). Caged hens also had poorer feather cover (39 per cent of caged hens had denuded areas (5cm2)] vs. 32 per cent among aviary hens. No difference in tibia breaking strength was measured between the two housing systems in these studies.

Production and egg parameters were also evaluated among aviary hens fed either mash or crumbled diets with the same nutrient composition.4 Birds fed the mash diet had a higher FCR and energy

SYSTEM IMPACT

Existing research into feeding birds in alternative systems shows that greater diet nutrient density would appear to benefit bird performance and welfare.

consumption than those fed crumbs. Hens fed the crumbs had greater body weight, egg weight and egg mass than those fed mash. These parameters indicated better performance on the higher density crumble diet compared to mash. The same dietary strategies with greater nutrient density may be advantageous for commercial birds housed in aviary settings.

Floor – Because of the greater initial investment required for aviaries and furnished cage systems, most non-cage eggs are produced in floor systems in the United States.5

In a field study comparing three types of layer housing including high-rise (HR), manure-belt (MB), and cage-free floorraised (FR), air temperature, RH, CO2, and atmospheric NH3 under winter and summer conditions in Iowa were monitored.6 Under winter conditions, the HR and MB houses had more comfortable temperatures (mean 24.6 and 20.6 C, or 76.3 and 69.1 F) and NH3 levels (9 to 24 ppm of NH3,

respectively) than the FR houses (mean 15.5 C, or 59.9 F and maximum 85 to 89 ppm of NH3, respectively). The FR house temperature varied more with outside winter conditions. In summer the FR house showed the least increase above ambient conditions (mean 0.3 C) compared to a 4.7 and 1.2 C increase for the MB and HR houses, respectively. Ammonia levels were similar for all housing types during summer conditions (mean 3 to 9 ppm).

Birds housed in alternative floor systems and birds with access to pasture demonstrate significantly greater activity including running and flying. Most often these birds are placed at lower densities per cubic foot or meter than birds in cage systems that are stacked in multiple decks. This results in lower heat production (HP) per unit area and presents the potential for lower house temperatures in cooler climates. To maintain hen body temperature this will require either greater feed consumption or fuel to heat the building

so the hen can maintain thermal balance. Taken independently or together both activity and lower housing density can require greater calories per hen per day than hens houses in battery cages.

Colder environmental temperatures are a reality in floor systems without supplemental heat in the winter and when bird density does not maintain house temperatures. In studies evaluating dietary wheat middling for floor layers, the low energy levels of some diets could not maintain production despite great feed consumption in December and January when temperatures averaged only 11 and 15 F.7 Hens fed diets with 89 per cent middlings, had an average feed intake of 136g/hen/day and feed conversion of 4.03 kg/doz eggs over twelve 28-day periods. Today, many floor layers are housed in heated barns, but often additional dietary measures are required to optimize hen performance.8 Elliot (2012) indicated higher density diets including protein, amino acids and energy are necessary for brown layers to get equivalent performance as hens housed in cages.9 Energy density is typically increased by 20kcal/lb in winter for floor layers, and can increase to 30, 40 or even 50kcal/lb if house temperatures cannot be maintained.10

Layers on litter floors fed wheat based diets with access to course wood shavings showed up to 60 per cent greater weight of the gizzard and its contents than caged layers fed the same diets without access to wood shavings.11 No such affect was observed when feeding oat based diets. This indicated the appetite for wood shavings may be dependent on fiber level in the diet. In a second experiment the hens’ appetite for wood shavings and paper was examined for birds fed wheat or oat based diets. Neither the paper or wood affected hen performance. However, the intake of wood shavings or paper by birds fed the wheat-based diet was twice as high as birds fed oat-based diets, and neutral detergent fiber in the gizzard was also elevated compared to birds fed only wheat. Furthermore, birds fed the wheat diet consumed almost twice the amount of wood shavings than those fed the oat diet. In their final study,

birds fed a high-fiber diet and a diet containing coarsely ground oat hulls had a negligible amount of feathers in their gizzards compared to hens fed a lowfiber diet and one with finely ground oat hulls. The authors indicated that featherpecking behavior may be partly related to the feed structure and consistency.

Pasture – In the U.S. pastured hens eggs often sell at a premium price with the claim of enhanced nutritional and health benefits from the eggs. The effect of alfalfa, clover and grass pastures on egg production and composition was examined and compared to sister hens housed in cages.12 In a cross over design three groups of 75 (Hy-Line brown) hens rotated to one of three pastures treatments for 2-week periods and were provided 70g/hen/day commercial hen mash (16.9 per cent CP, 2863 kcal/kg) and were expected to forage for the remainder of their nutritional requirements. Fifty sister hens housed in cages (60in2/bird) were offered the same mash ad libitum (averaging 113g/hen/day intake). At the end of the study body weight was not significantly different between the pasture treatments, but significantly less than hens in the cages (1571 vs. 1821g). Similarly egg production was not maintained by hens on the pasture averaging 72 per cent vs. 85 per cent for hens housed in the cages. It was estimated the pastured hens derived approximately 13.2 per cent of their energy requirement (36 kcal ME) and 21.5 per cent of their CP needs (3.9g) from pasture foraging. However, pastured hens were still lacking dietary protein and energy (2.3g and 35 kcal) on a daily basis to match the caged hens. The authors of the study believe an additional 13g of mash per hen per day would be required to sustain egg production and body weight equal to that of the caged hens. Despite greater linolenic acid in the pasture clover and alfalfa compared to the grass, there were no significant differences in egg linolenic acid levels. When compared to the eggs from caged hens, eggs from pastured hens had greater egg yolk omega-3 fatty acids, vitamin A and E. However, these nutrients can readily be supplemented in the hens diet to derive the same egg levels as pasture treatments for less money.13-16 The authors

concluded that if additional mash was provided to pastured hens to maintain hen welfare, body weight and egg production, this would undoubtedly mute the changes in egg composition observed herein.

The nutritional composition of eggs from hens housed in cages vs. sister hens in range paddocks established with bermudagrass, fescue and clover was similarly compared in another study.17 Supplemental feeds for all hens were provided ad libitum in a phase program from 17-82 weeks of age. Eggs from the cage environment had significantly more total fat, monounsaturated fat, and polyunsaturated fat than eggs produced by caged hens. Levels of omega-3 fatty acids were also significantly higher (0.17 per cent vs. 0.14 per cent) in range eggs vs. cage eggs. There was no difference in egg cholesterol, vitamin A or E levels between eggs from the different management systems. Hen body weight was similar at the

conclusion of the study (1970g range vs. 2000g caged), egg weight, mass and production were all lower for the range birds and while feed consumption was greater in cages (103 vs. 101g) this indicated little reliance on pasture for the hens’ nutritional requirements.18 Finally egg income minus feed costs was lower for the range treatment ($18.07 vs. 23.70/ hen) and labor to care for them was more than 15 times greater than hens housed in cages. The author concluded that no significant nutritional advantage of eggs produced by range hens over hens maintained in cages could be established.

Enriched Cage – In a study to examine the effects of dietary energy on egg production and quality of hens kept in conventional (3/cage) or furnished cages (8/cage), it was determined that higher energy levels improved egg production, reduced feed consumption and improve feed conversion, but there were no inter-

actions with housing type.19 Housing type had no impact on production parameters, and the authors concluded that like previous studies cage type had no impact on egg production or feed conversion ratios. Several studies have shown a greater incidence of cracked eggs in furnished than in conventional cages. Because hens kept in furnished cages often have greater bone strength, they may lay eggs with weaker shells because the calcium is utilized for bone mineralization. In a similar trial, the effects of added dietary calcium for hens in 3/cage conventional and 8/ cage enriched cages.20 Normal calcium was 37-40g/kg diet, and 44-50g/kg diet in the supplemented diets. Dietary calcium had similar effects in both cage systems. Greater limestone increased the laying rate, with no effects on egg quality, specific gravity, or tibia-breaking strength. Based on this study the weakening of eggshells in furnished cages is not caused

by a possible calcium shortage resulting from high bone mineralization.

Two studies looking at the influence of conventional (CC) and enriched cages on nitrogen, calcium and phosphorus balance recorded greater feed intake in the CC (95.0 vs. 92.5g/hen/day).21,22 However, this did not result in any greater body weight, egg production, egg weight or mass. In the end manure and egg nitrogen output was not significantly different between hen housing treatments. With greater feed intake, CC hens did have both greater manure calcium and phosphorus excretion compared to hens from enriched cages. Deposition of egg shell calcium (g/hen/day) was also greater in CC vs. enriched cages, but there was no impact on eggshell P deposition or absolute P balance (average -48.3mg/hen/day).

Bird Health – Decreased egg production, egg drop syndrome and cannibalism in free-range flocks in the UK was reported

as early as 1986 by Swarbrick.23 A more recent survey of birds raised in alternative systems reported the greatest mortality in the litter and free-range systems compared to conventional cages. Bacterial infections caused the greatest mortality in birds raised on litter and included erysipelas, colibacillosis and pasteurellosis.24 Greater mortality with viral diseases (lymphoid leukosis, Marek’s disease and Newcastle) coccidiosis and red mites was also associated with litter and free-range hens. Many of these diseases and ectoparasites are a result of contact with wild birds and animals that can bring them to domestic poultry with outdoor access. Furthermore, these birds are at risk of predation. Other infections of layers result from direct contact with soil, litter and fomotes (rodents, beetles and equipment) known to carry disease.25

Another study evaluated the effectiveness of diatomaceous earth (DE) as a feed additive to treat for parasites and to

increase feed efficiency and egg production in brown organic free-range layers.26 Bovan brown hens fed the DE had significantly lower Capillaria, slightly lower Eimeria and fewer birds with Heterakis Hens fed the DE were significantly heavier, laid more eggs and consumed more feed that the control hens. Furthermore, dusting with DE reduced mite numbers. Two additional studies both indicated hens in aviary, and enriched cage systems can be plagued by Red mites that might benefit from diatomaceous earth added to the feed.27,28 And finally, according to Sossidou et al. (2011) a high incidence of bone breakage in free range flocks represents a serious issue which compromises welfare benefits one might anticipate.29 n

This article was presented at the 2012 Midwest Poultry Federation Convention. References are available by request and online at www.canadianpoultrymag.com

BY SANDRA AVANT, UNITED STATES DEPARTMENT OF AGRICULTURE – AGRICULTURAL RESEARCH SERVICE

It’s not mother’s milk, but egg yolk may be the closest remedy for boosting the immune system of newly hatched chickens against infectious diseases such as coccidiosis.

A major disease of chickens, coccidiosis is caused by intestinal parasites – single-celled protozoans in the genus Eimeria. Disease-affected birds are unable to absorb feed or gain weight, costing the poultry industry more than $600 million annually in the United States and $3 billion worldwide.

Scientists at the Agricultural Research Service (ARS) Henry A. Wallace Beltsville [Maryland] Agricultural Research Center (BARC) and collaborators from different universities and the Mexican company IASA (Investigacíon Aplicada, S.A.) have developed a novel, antibiotic-free method that uses hyperimmune egg yolk antibodies to control intestinal poultry diseases.

“Coccidiosis is associated with other pathogens, such as the one that causes necrotic enteritis – a prevalent gut disease of poultry,” says avian immunologist Hyun Lillehoj, who works in BARC’s Animal Parasitic Diseases Laboratory. “By controlling one, you’re also reducing the impact of the other.”

Good management practices and live vaccinations reduce the spread of coccid-

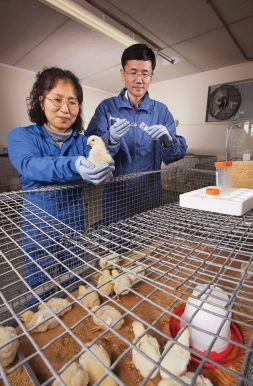

Research by Sung Hyen Lee (left) feeds hyperimmune egg yolk antibodies from immune chickens to chicks with the hope of passing the immunity on. MODIFIED EGGS

iosis, but alternative strategies are needed to help control drug-resistant strains and to enhance organic farming for the poultry industry.

Generally, a host can develop two types of immunity – active and passive

– to resist infection. Passive immunity allows immune molecules that are already formed to be transferred from the hen, via the yolk, to the chick. Active immunity relies on vaccines to build immunity in the birds.

“When chicks hatch, they have no immunity to this pathogen. But if we give preformed immune proteins to one-dayold progeny, they are ready to fight infection,” she says. “It’s similar to how immunity is passed to newborns through milk.”

The method involves extracting antibodies from yolks of eggs from pathogen-free birds that have been hyperimmunized, meaning they possess greaterthan-normal immunity due to an abundance of antibodies against the disease. Egg yolk is spray dried, mixed with feed, and given to chicks that have no immune protection right after hatching.

Lillehoj teamed up with ARS visiting scientist Sung Hyen Lee from the Rural Development Administration in South Korea, IASA scientist Eduardo Lucio and other researchers to conduct different experiments to demonstrate the efficacy of inducing passive immunity against coccidiosis.

One-day-old broiler chickens were continuously fed a standard diet containing a commercially available egg yolk powder prepared from hens hyperimmunized with multiple species of Eimeria. They were then given a challenge infection with live coccidia. Body weight gain between days zero and 10 and fecal shedding between days five and 10 postinfection were analyzed. Chickens given 0.5 per cent or less of the hyperimmune egg yolk antibodies had a significant increase in body weight gain, reduced fecal Eimeria shedding and fewer gut lesions compared to control birds fed a non-supplemented diet.

“It’s very simple technology, and it works,” Lillehoj says.

Based on these results, one company has developed a commercial product that can be fed to chickens to control coccidiosis. Similar technology may be used in the future to guard against other devastating poultry diseases. n

This article was originally published in the July 2012 issue of Agricultural Research magazine.

BY JIM KNISLEY

You no doubt know the old line about the way to get out of a hole; the first thing you do is stop digging. But that is just the first thing. The next item on your escape plan should be to assess just how deep a hole you’re in and what the hole looks like. Common sense dictates that it is going to take longer and be harder to get out of a 100-foot-deep hole than a five- or 10-foot one.

The shape of the hole also matters. In St. Andrews, Scotland, among the ruins of the old castle there is something called the bottle dungeon. As the name implies, it is shaped like a bottle and is as bleak a place as can be imagined. Prisoners were lowered into the cell and escape was impossible. The only way out was to yell for help and hope it arrived.

Today, much of the world economy – think of southern Europe – is in a 100-foot hole. Other areas, such as much of the United States, are in a decent sized hole. Some regions, such as North Dakota and Montana, are standing on little hills because of newly developed oil and gas reserves. But in California and Nevada, the hole is deep and getting deeper. And in the rust belt of Michigan, Indiana and Ohio, the hole is deep, but thanks to the saving and recovery of the auto industry, they have at least stopped digging.

In Canada, the picture is similar.

The Prairies – thanks to natural resources – are doing fine. In Quebec and the Maritimes, the picture is mixed, with some areas and large cities doing OK and some rural areas not. In Ontario, Ottawa is fine and even Windsor is coming back because of the auto industry recovery. But, and I’m going to get parochial here, the region in which I live is sinking. This area has the highest unemployment rate in Ontario at 10.9 per cent (EI Program Characteristics for the period of September 09, 2012 to October 06, 2012, Human Resources and Skills Development Canada, http://srv129.services.gc.ca/rbin/eng/rates_cur.aspx). This region is called Niagara by Statistics Canada, which is a misnomer. The region consists of the counties of Haldimand, Norfolk and Brant, one township from the Niagara Region and one from Elgin County.

down. Only a steel plant and an oil refinery remain.

Sadly, people and politicians living in this area thought they were in a 10-foot hole, had stopped digging and were looking for some ways out. But little did they know that others living in Toronto and the United States were, for business reasons, tunnelling underneath them and proceeding to drop them into a 100-foot bottle dungeon. The only saving grace is that retirees from Toronto and area have discovered the low housing prices.

Farmers know what can happen when you’re hit by forces beyond your control. Floods, droughts, political machinations and other events can wreak havoc, but sometimes you can recover on your own. Other times, you may need someone to give you a ladder, provide a rope or simply throw down some climbing gear. Once you’re out, you then set about filling the hole.

You do all this not out of a sense of charity, though that isn’t a bad reason; you do it because no one can know when they might fall or be pushed into a hole and need help getting out.

Farmers know what can happen when you’re hit by forces beyond your control.

Senator Herb Sparrow knew about holes and about helping guide people out of them. Back in the 1980s, the farmer-rancher from North Battleford, Sask., saw the economic and agronomic hole farmers were digging for themselves with summerfallow and constant tillage and what was happening to the prairie soil. He saw that localized dust storms were returning and that nutrients were being sucked from the ground at an alarming rate. In response, he used his Senate office to put together a seminal report titled “Soil At Risk.”

It was and remains a classic.

The report played a huge role in changing what farmers thought and did, and influenced government actions for decades. It is, in my mind, the most significant thing to come out of the Senate in the last 30 years. It also showed what one dedicated and determined senator could accomplish.