MOVE OVER CEMA...

Egg Farmers of Canada has arrived!

We’ve chosen a new name that we believe better reflects who we are.

Egg Farmers of Canada didn’t make this change alone. We did research with Canadians to find out what they think about the national organization representing egg farmers. In so doing, we found that people wanted us to highlight the fact that we’re farmers, we’re Canadian, and we’re dedicated to quality.

So, we listened and got cracking. The result: a new name, new logo and new tagline—all of which are showcased here. We’ve also changed our Web address to www.eggs.ca, so be sure to drop by for a visit and see what’s new!

It’s with great enthusiasm that we begin this next chapter in our history.

Laurent Souligny

Chairman, Egg Farmers of Canada

Egg Farmers of Canada

Tel: (613) 238-2514

Fax: (613) 238-1967

info@eggs.ca

L’OCCO

FAIT PLACE AUX PRODUCTEURS D’ŒUFS DU CANADA!

Nous avons choisi un nouveau nom qui, nous le croyons, reflète davantage qui nous sommes.

Les Producteurs d’œufs du Canada n’ont pas été les seuls à contribuer à ce changement. Nous avons mené des recherches auprès de tous les Canadiens afin de savoir ce qu’ils pensaient de l’organisation nationale qui représente les producteurs d’œufs. Ce faisant, nous avons découvert que les gens veulent que l’on fasse davantage ressortir le fait que nous sommes des producteurs, que nous sommes des Canadiens et que nous sommes dédiés à la qualité.

Nous avons écouté nos consommateurs et nous avons craqué. Le résultat : un nouveau nom, un nouveau logo et une nouvelle signature qui sont affichés au haut de cette page. Nous avons aussi modifié notre adresse Web à www.lesoeufs.ca. Veuillez la consulter pour voir ce qu’il y a de neuf!

C’est donc avec enthousiasme que j’entrevois le prochain chapitre de notre histoire.

Laurent Souligny Président, Les Producteurs d’œufs du Canada

Les Producteurs d’œufs du Canada

Tél. : (613) 238-2514

Téléc. : (613) 238-1967

info@lesoeufs.ca

FROM THE EDITOR

BY KRISTY NUDDS

Entrants Needed

Our cover story (see page 10) this month demonstrates something that the poultry industry in Canada is lacking: new entrants into the quota system.

Without doubt there are “new” producers each year, but they are few and far between, and likely have an economic advantage that allows them to purchase quota, land and barns. Often, such fortunate new producers are those that have left the other supply-managed sector –dairy – and thus have the capital required. Or, they are a family member of someone who already has quota.

I realize there are many who acquired large debts and didn’t see a cash flow for many years in order to enter the business, but I fear those days are gone, or they will be for several years to come. Given the recent bank crisis in the United States and leaders around the world putting in motion measures to protect banking industries outside of the U.S. in a desperate attempt to stave off a deep recession (dare I say a depression), banks will not be so eager to extend, or even offer, credit.

Such economic turmoil will undoubtedly make it even more difficult for new entrants into the industry. It will also impact existing producers wishing to purchase additional quota, expand barn space, and purchase and/or upgrade equipment.

This will only add to what I see as an existing problem. As an industry, we must be careful not to dwindle in numbers.

The primary reason for this is maintaining the supply management system. In a democracy numbers count. The more people who are involved, the more clout you carry.

The Conservative government has pledged support for supply management; however, its behaviour, which could be considered harassment, towards the Canadian Wheat Board (CWB) in the last two years makes me wonder how strong this support is, or how long it will last.

The CWB does not operate in the same manner as poultry marketing boards; however, they have two things in common: they get a fair price for commodities grown by Canadian farmers, and are strongly supported by the farmers they represent.

The CWB is seen by Stephen Harper as a monopoly, and his two federal agriculture ministers have worked ever so hard to see it crumble. Fortunately, his government has not been successful, but with a majority government in place, the tables could turn.

The CWB is fortunate with respect to farmer numbers, which reach the tens of thousands. It’s easier to plead a case for many than it is for few.

If supply-managed industries continue to consolidate, both with respect to quota holders and the businesses that serve them, they can be left vulnerable. Lobbying to protect what is viewed by critics of supply management as a decreasing group of large (with respect to quota) farmers could very well lose its lustre in years to come. ■

November 2008 Vol. 95, No. 11

Editor

Kristy Nudds – knudds@annexweb.com

888-599-2228 ext. 266

Contributing Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com

888-599-2228 ext 234

Production Artist

Brooke Shaw

Editorial Director

Drew McCarthy – dmccarthy@annexweb.com

VP/Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: cnowe@annexweb.com.

Periodicals postage paid at Buffalo NY. USPS 009-324, ISSN 1703-2911. Published monthly by Annex Publishing and Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St. Buffalo NY 14240. US Postmaster send address change to PO Box 611 Niagara Falls NY 14304.

Printed in Canada ISSN 1703-2911

Circulation e-mail: cnowe@annexweb.com Tel: 866-790-6070 ext 207 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 25.44

(includes GST – #867172652RT0001)

USA – 1 Year $ 60.00

From time to time, we at Canadian Poultry make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. We acknowledge the financial support of the Government of Canada, through the Publication Assistance Program and the Canada Magazine Fund, toward our mailing and editorial cost. Nous reconnaissons l’aide financière accordée par le gouvernement du Canada pour nos coûts d’envoi postal et nos coûts rédactionnels par l’entremise du Programme d’aide aux publications et du Fonds du Canada pour les magazines. www.canadianpoultrymag.com

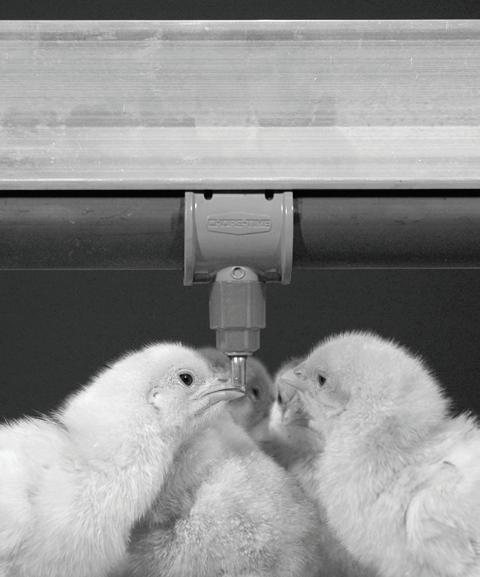

Great productssell.

More than 142 miles of chain sold worldwide in 2006/2007.

More than 29 million nipples sold worldwide in 2007.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd. London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

WHAT’S HATCHING HATCHING

Faster Genetic Test for Flu Virus

The U.S. government approved a new genetic test for the flu virus that will allow labs across the country to identify flu strains within four hours instead of four days.

The timesaving test could be crucial if a deadly new strain emerges, federal health officials said. The new test also could help doctors make better treatment decisions during a conventional flu season.

The new test was developed by the Centers for Disease Control and Prevention and Applied Biosystems Inc. of Foster City, Calif. The Food and Drug Administration approved the test kit Tuesday, and state health labs are expected to start using it this fall.

CDC officials celebrated it as a potential lifesaver,

especially if the nation is hit by a pandemic of bird flu or some other mutant influenza.

“We’ll now be able to detect influenza in the community faster, which allows us to take steps more quickly to protect and save lives,” CDC director Dr. Julie Gerberding said in a prepared statement.

The CDC is requiring labs to buy Applied Biosystems equipment to run the test, and the CDC will provide the necessary chemicals. About 20 to 30 state labs should be up and running by the end of the year, CDC officials said.

Until now, the tests used by different states varied.

“Now we have all the states able to do this rapid method,” said Pete Shult, who oversees infectious disease testing at Wisconsin’s state laboratory.

“It’s good to use the same method so the results will translate from state to state, and CDC can better understand what’s happening,” he added.

Six state labs evaluated the new test and found it to be as good as the “gold standard” traditional viral culture method, said Shult, who was involved in that review.

The test correctly detected the most common flu viruses about 99 per cent of the time. It also picked up some viruses that the older test missed.

Shult and others said the new method’s main selling point is its potential against a dangerous new pandemic.

“The bottom line, for us, is that it will allow us to more rapidly detect introduction of a new strain,” said Rosemary Humes, senior adviser for scientific affairs at the Association of Public Health Laboratories.

But the test could be handy for conventional flu, too, said Dr. Doug LoweryNorth, an Emory University emergency physician who does flu research.

Canola Proteins

BRITISH COLUMBIA

AVancouver-based company with Winnipeg roots has made a breakthrough in the American market by isolating proteins in canola that could potentially replace eggs in mayonnaise and find their way into countless other foods and beverages.

Burcon NutraScience Corporation, which has a research and development arm in Fort Garry, Man., says the proteins have received the seal of approval from a panel of

international experts, allowing them to be considered generally regarded as safe for human consumption in the United States.

Burcon president Johann Tergesen says the nod from the U.S. Food and Drug Administration is a major advancement in the commercialization of the world’s first food-grade canola proteins, which the company has named Puratein and Supertein.

The proteins have yet to

2008 Poultry Service Worker

ALBERTA

John Deshoux was named the Poultry Service Worker of the year at the recent Poultry Service Industry Workshop (PSIW) held in Banff, Alta.

Deshoux began his career in poultry with his late wife June, when they took over her family’s hatchery in Westlock after her father’s death in 1972. They also later

became broiler producers and in 2002, Clark Hyline (now Pinnacle Nutrition and Genetics) purchased the business goodwill and retained John as an employee, and he has worked as a serviceman for them since then.

He was nominated by former CTMA chairman Richard Ruchkall, who said “John is a person of truly unending

ACA Receives Loan

The Nova Scotia government has loaned $3.5 million to the province’s sole remaining poultry processor, ACA Co-operative, headquartered in Kentville in the Annapolis Valley.

The provincial government statement says the loan will help ACA maintain its 650 jobs with an annual payroll of over $25 million. ACA also accounts for a further 650 spin-off jobs.

Founded in 1943, ACA is now the fourth largest farmer’s co-op in Atlantic Canada with a poultry processing plant, breeder barns and hatchery, egg processing unit, retail fuel and farm equipment divisions, and an outlet store.

It is Nova Scotia’s only surviving chicken processor since the closing of the Maple Leaf plant last year in nearby Canard; ACA also slaughters

receive regulatory approval in Canada.

A unique feature of one of the Burcon canola proteins is that it can be dissolved into highly acidic beverages, such as fruit juices, sport energy drinks or soda pop.

The other protein can be used as an emulsifier, ingredient binder or thickening agent suitable for use in mayonnaise, salad dressings, baked goods, protein bars and meat substitutes.

honesty, integrity and service” and someone who is always working on bettering the industry and educating producers. John does “what he said he would do, just plain old serviceman 101,” said Ruchkall.

JANUARY 2009

January 28-30, 2009

International Poultry Expo/International Feed Expo, Georgia World Congress Center, Atlanta, Ga. Registration now open. For more information, e-mail expogeneralinfo@poultryegg. org; visit www.internationalpoultryexposition.com or telephone 770-493-9401.

FEBRUARY 2009

February 3-5, 2009

Canadian International Farm Show, International Centre, Toronto, Ont. For more information, visit www. masterpromotions.ca/canadian-farm-show.asp, telephone 1-888-454-7469 or e-mail info@masterpromotions.ca.

February 19-20, 2009

Atlantic Poultry Conference, Old Orchard Inn, Greenwich, N.S. The conference will feature speaker Dr. Temple Grandin and ventilation and alternative energy workshops; additional speakers and topics will be available soon. For more information, contact conference chair Dr. Bruce Rathgeber, e-mail brathgeber@nsac.ca, visit www.nsac.ns.ca/apri; or write Atlantic Poultry Conference, 25 River Road, P.O. Box 550, Truro, N.S. B2N 5E3.

most of the turkeys produced in the province and processes about 25 per cent of its eggs.

ACA CEO Sue Payne says the provincial loan will provide her co-operative with a new line of working capital at a time when credit is tight due to the current economic downturn.

The new loan will enable ACA to undertake, she says, “new marketing initiatives.”

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Publishing, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont. N3Y 4N5; e-mail knudds@annexweb.com; or fax 519-429-3094.

NOVA SCOTIA

HATCHING HATCHING

IPE Expo Education Program

The program committee met recently to develop the agenda for the Poultry Education Program at the 2009 International Poultry Expo and International Feed Expo sponsored by U.S. Poultry & Egg Association and the American Feed Industry Association.

IPE/IFE 2009 is scheduled Jan. 28-30 at the Georgia World Congress Center in Atlanta. The poultry education sessions will be held Thursday, Jan. 29, from 8 to 10 a.m.

“The committee has recommended an agenda that will address vital issues facing

today’s poultry and egg operations,” said program chairman Donnie King, Tyson Foods, Springdale, Ariz.

The program includes Social Responsibility in the Poultry Industry; Food Safety; Animal Welfare; Employee Relations Environment; Community Relations; Affordable Food; Industry Economic Outlook; A CEO’s Perspective; Overall State of the Market Exports; and Input Cost.

For more information about the 2009 International Poultry Expo and International Feed Expo, go to www.ipe09.org.

DNA Technology Breeding Project

The recently formed alliance between multi-species breeding company Hendrix Genetics and the broiler breeding company CobbVantress, Inc., is to become the first in the world to implement genomic selection in poultry breeding.

The USDA has agreed to provide $US2.5 million towards a $US10 million large-scale field evaluation of DNA selection technology in chicken breeding.

The use of this new technology is a breakthrough in animal breeding. The selec-

tion of pedigree stock through analysis of DNA from the whole genome will provide accurate and rapid results, enabling significant genetic improvement. Such progress – hard to realize using traditional breeding methods – will now be feasible for disease resistance, animal health and welfare traits.

The field evaluation began on Oct.1, 2008 and will run for a period of four years. A consortium of leading universities and institutes in a number of countries will also be involved.

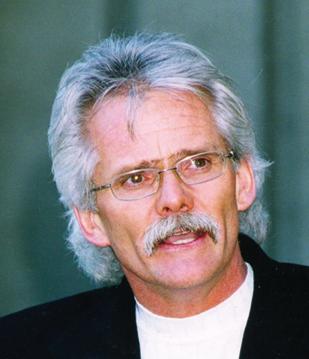

PEOPLE IN THE NEWS

Diamond is pleased to announce that Stan Drouen has joined its team as director of sales and marketing for the Americas. Stan will oversee the outside sales team throughout North and South America, while working a part of the U.S. territory himself. He will also be overseeing the inside sales team. Stan brings with him to Diamond more than 20 years of experience in sales management in capital equipment markets serving food processing and packaging industries.

Bob Friesen resigned from his position as president of the Canadian Federation of Agriculture (CFA) to pursue a career in federal politics. He ran as a Liberal candidate for Charleswood-St. JamesAssiniboia (Manitoba) riding in the recent federal election.

The directors of Maple Lodge Farms Ltd. are pleased to announce the appointment of Michael Burrows as the company’s new chief executive officer. Burrows brings more than 25 years of business experience, mostly in consumer packaged goods, to his new role. Most recently, he was the president and chief executive officer of E.D. Smith Income Trust and E.D. Smith & Sons Ltd.

BOB FRIESEN

MICHAEL BURROWS STAN DROUEN

Production

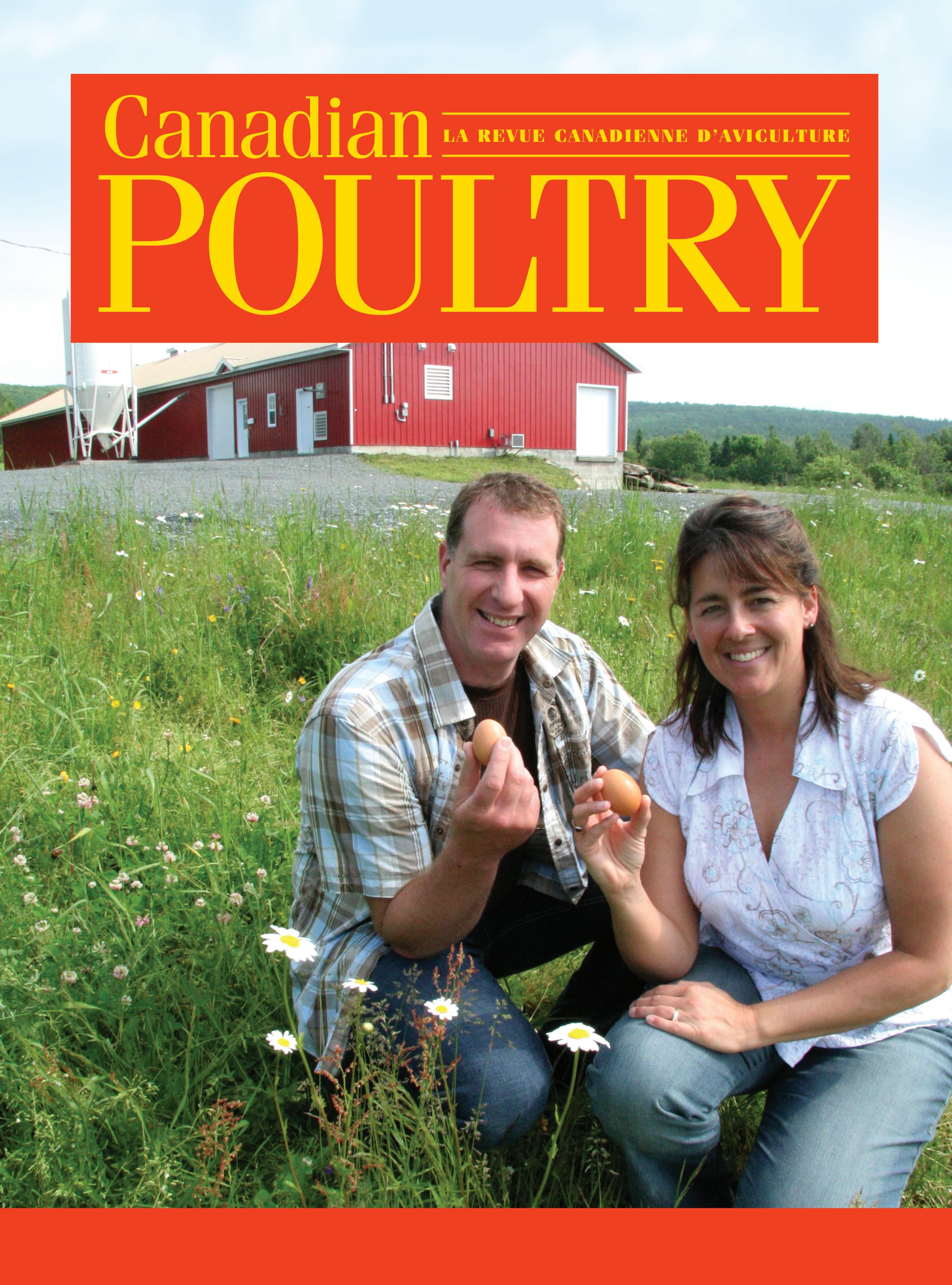

No Quota, No Problem

Joanne LaBranche and Patrick Côté have realized their dream

BY ANDRÉ DUMONT

Joanne LaBranche and Patrick Côté just couldn’t believe their eyes. The weekly agriculture newspaper La Terre de chez nous was announcing a new program offering a free lifetime quota loan for 5,000 layers. “We looked at each other and said: ‘This is for us. We have to apply, ’ ” Joanne says.

That was in 2006. Twelve years earlier, Joanne and Patrick had abandoned the idea of going into egg production because of high start-up costs. They now decided to direct all their efforts into preparing for the contest put forward by the Fédération des producteurs d’œufs de consommation du Québec (FPOCQ –Quebec Egg Farmers).

It was a summer with very few outings for Justin, 10, Anthony, 12, and Philippe, 14, as their parents were often busy visiting poultry farms and crunching numbers in front of a computer screen.

The business plan was finished a few days before the deadline. After putting so much effort into their application, Joanne and Patrick were convinced they’d be among finalists. “Our application was clear and concise. Everything was there, exactly as requested,” Joanne says.

The good news came on Oct. 27, 2006. The couple became the first beneficiaries of the FPOCQ’s Start-up Assistance Program for new producers. They were to become egg producers, without having to invest in quota.

“We felt very, very privileged,” says Patrick, who was a poultry representa-

EGGCITING OPPORTUNITY

Joanne LaBranche and Patrick Côté took advantage of FPOCQ’s start-up program that allowed them to get into egg farming without buying quota.

tive for the Coopérative fédérée de Québec before buying a hog farm with his wife in Kinnear’s Mills, near Thetford Mines, in 1994.

Joanne and Patrick decided to build an 8,640 layerhouse with new equipment only. The building currently houses 5,550 (some rented quota was added). Egg revenues complement those from their

5,000-hog-per-year swine operation.

If their application stood out from the lot, they say, it’s because they have complementary experience. Joanne holds a degree in business administration and is also a Certified Management Accountant (CMA). She handled the financial side. Patrick used his experience and contacts in the poultry industry to gather

up-to-date technical data. The couple also relied on its past experience bringing a hog operation to high performance levels.

Joanne and Patrick refuse to see themselves as the happy winners of a lottery jackpot, even though the egg quota they use is worth several hundred thousands of dollars. “People don’t see all the work

Start-up programs in Quebec

Eggs

The Fédération des producteurs d’œufs de consommation du Québec (Quebec Egg Producers) offers one free lifetime quota loan for 5,000 layers every year. This quota is only transferable to one’s children. Regions with lower egg production density are advantaged.

Chicken

Les Éleveurs de volailles du Québec (Quebec Poultry Producers) give 50 m2 or 100 m2 of broiler quota to any new producer aged 18 to 40 who has never owned more than 150 m2 of quota over more than five years.

To get 50 m2, the applicant must purchase 150 m2 or own 20 per cent of the farm. To get 100 m3, the applicant must purchase 300 m2.

The free quota comes from a reserve in which les Éleveurs de volailles du Québec put five per cent of the fiveyear average of annual new quota allocations to Quebec by Chicken Farmers of Canada each year.

Milk

The Fédération des producteurs de lait du Québec (FPLQ – Quebec Milk Farmers) offers a five-kilogram quota loan to young producers joining an existing farm. After five years, the quota must be reimbursed at a rate of one kilogram per year. The FPLQ also offers a limited number of 10-kilogram quota loans towards new milk farms.

Production

we put into this,” Patrick says. “There were 32 other candidates and I’m sure they worked just as hard as we did.”

Even with the free quota, starting up was no joyride. Investing more than $400,000 at the same time the Quebec hog industry was entering a crisis was a nerve-wracking experience. From Day

1 of construction to the first egg pay, finances were stretched to the limit.

This was no risk-free investment, Patrick says. If for any personal reason, the egg production must stop, the quota goes back to the FPOCQ. An empty 8,640-layer henhouse with no quota to sell along with it isn’t worth much, he

• Exceptional Performance

• Exceptional Performance

• Reduced Feed Costs

• Reduced Feed Costs

• Utilize Home Grown Grains

• Utilize Home Grown Grains

• Ensure Long Term Viability

• Ensure Long Term Viability

says. However, the loaned quota is transferable to the next generation. Patrick and his wife hope at least one of their three sons will take over one day.

The FPOCQ’s start-up program was founded to address a concern for the accessibility of egg farming to newcomers. Even though many of the current 103 egg farmers in Quebec have children willing to take over, one hard fact remains: the availability and price of egg quota makes it nearly impossible to start a new production.

Producing eggs had long been excluded in Joanne and Patrick’s plans to diversify their farm. “For anyone with financial means similar to ours, it’s simply impossible to start,” Patrick says.

In 2006, FPOCQ members decided to use part of the federation’s quota reserve to help start up one new layer farm every year. The decision was not unanimous, because the program excludes existing farmers’ immediate family members, while others didn’t see the point in starting a new farm with so few hens.

“Quebec egg producers have always been visionaries,” says FPOCQ president Serge Lefebvre. “If we want to keep our number of producers stable, we have to make space for new ones.”

The program addresses both the problems of egg farm concentration in specific regions and the slow but steady erosion of the number of egg farmers throughout the province. In 2007, the free quota loan was awarded to Nicholas Tremblay, who will build his henhouse in Saguenay-Lac-Saint-Jean, a region where there are only four other egg producers.

The FPOCQ is also in the process of setting up a centralized quota exchange system. This will make quota more accessible to those who received help to start and now want to expand, Lefebvre says.

For now, quota prices remain very high. But will that be the case in the future, when new quota allocations to Quebec will allow the FPOCQ to help more than one new producer get started every year?

The deadline for application in 2008 was June 30. The name of this year’s winner was announced in October. ■

Production

LaBranche and Patrick Côté spent months preparing their application to acquire quota.

How the Program Works

Applicants to FPOCQ Start-up Assistance Program for new egg producers must comply with the following criteria: be between 18 and 40 years of age

• intend to start a new egg production in which they will be fully involved

• live in Quebec and be permanent residents of Canada

• have a college-level education in agriculture or management

• have at least one year of work experience on a farm

• complete a business plan approved by a financial institution, covering financial,

• technical and environmental aspects demonstrate that the project meets environmental regulations

• have never owned quota in any agriculture production under supply management

• or been a shareholder of a farm using quota be an immediate family member of someone holding egg quota or owning a

• layer farm

“We felt very, very privileged,” says Patrick.

Joanne

Biosecurity without compromise What if you could

disease-causing pathogens …without exposing your animals, your employees or your family to disinfecting solutions containing harsh chemicals,** …or placing an added burden on our already-fragile environment?

Production Catching Machines Fill Gap in B.C.

Klaas Korthius has imported Ciemme Apollo 60 catching machines

from Italy

BY DAVID SCHMIDT

Catching remains the most labour-intensive aspect of broiler production. It is also considered among the least desirable of jobs in the poultry industry. Given that, it is no surprise finding enough good help is becoming more and more difficult.

That is one reason veteran poultryman Klaas Korthius imported several Ciemme Apollo 60 catching machines from Italy.

“I brought the first machine into Canada, Aug 24, 2007, and put it into use two days later,” Korthius says, noting he now has two machines operating in B.C. and one in Saskatchewan.

While three Alberta producers have purchased the Ciemme for use on their own farms, Korthius notes his machines are the first in Canada to be used on multiple farms. “We try to do one farm/night with each machine.

We have now operated the first machine for 950 hours without any difficulty.”

The Ciemme Apollo is not the first automated catching machine in Canada. That honour belongs to the EZ Load system from England, which B.C.’s Sunrise Poultry has been using for over a decade.

While the EZ Load system uses a long “arm” with a sweeping motion to go through the barn and sweep in the chickens, the Ciemme Apollo looks and acts more like a forage harvester or combine.

The Apollo 60 catching machines from Italy and the rest of the system can be operated by as few as three people.

Because the machine is track-mounted, it easily traverses both sawdust and straw-based litter. The track mounting also allows it to move straight down a barn without a full-time driver. Designed to be towed on a trailer, once unloaded the harvest head is unfolded to open up to a 20-foot width. Korthius has ordered a second 10-foot-wide head to allow the

machine to be used in barns with narrower entries and/or narrower spaces between the posts.

A tiny light bar is located just under the head, which itself rides only centimetres above the surface. The bar provides just enough light to cause the chickens immediately in front of it to stand up. They are then whisked up the belt and

LABOUR SAVER

Defer principal payments for up to 12 months with our new

We understand that you may need new farming equipment at any time. That’s why we’re ready to help. With the new TD Canada Trust Interest Only Term Loan, you can finance up to $500,000¹ for equipment purchases today and pay the principal later. You make

Visit

interest-only payments for up to 12 months, which means lower monthly payments, helping to improve your overall cash flow.

We offer competitive rates, and no set-up fee is required.² Plus, loans can be amortized up to 10 years based on the useful life of the equipment.

Production

onto a cross conveyor. The conveyor deposits the birds into a chute that then fills the catching trays, which are mounted on a trailer. The chute moves up and down and from side to side so each of the individual trays can be filled. The whole system is fully computerized so the system stops momentarily as each tray is filled and the operator moves the chute to the next tray. The trailer holds three modules and the modules are rotated so one is in the fillable position, a second in the empty position and the third loaded tray ready to be removed. By the time the machine gets to the far end of a 200-foot barn, the forklift operator is moving pretty quickly to keep up with removing the filled modules and bringing in the empty trays.

The entire system can be operated with as few as three people: one to walk alongside the machine to supervise the system, a second to operate the chute and a third to move the modules in and out.

“The machine can do up to 7,000 birds/hour,” Korthius notes. While that is similar to the output of a crew of 10 top manual catchers, he notes the machine doesn’t tire. “Unlike a catching crew which often sees its production drop in half by the end of a shift, the machine is still doing 7,000 birds/hour at the end of the night.”

Even though over 100 birds/minute are almost literally flying through the machine, Korthius says the machine is

actually better for the birds than manual catching.

“A European study showed 38 per cent better leg grading and 11 per cent better wing grading with the Apollo than with manual catching.”

While the 6,250 kg weight of the machine prohibits its use on upper floors and the width of the catching head precludes its use in small barns, Korthius worked with Ciemme to create a lighter eight-foot-wide, ATV-style catcher to be used in concert with the Apollo. When used in barns with smaller openings the ATV drives into the barn, scoops up the chickens (the catching head works very similarly to the head on the main machine), then delivers them to the main machine, which is still used to fill the trays.

The portable catcher is also light enough to be raised by a forklift and used on an upper floor (if the opening is wide enough). Korthius has also developed a special conveyor that collects the birds from the catcher, in turn feeding them to the main machine. If the main machine can fit into the lower floor of the barn and the upper floor is equipped with drop slots, the conveyor can be inserted into the drop slots, reducing the travel required by the portable catcher.

Chilliwack, B.C., chicken grower Gerry Mammel says the machine has been used at his farm several times and he continues to be impressed with how well it works. ■

Transferring chicken from the portable catcher to the Apollo 60.

The catcher operates like a forage harvester and can catch and load up to 7,000 birds an hour.

Commodities

Financial Turmoil Affects Commodities

Grain and oilseed prices are well off their recent highs and more volatility is expected

BY JIM KNISLEY

It’s not just about supply and demand anymore when it comes to grain and oilseed prices. The turmoil in world financial markets is also affecting prices and demand.

In its September Pool Return Outlook for 2008-09 the Canadian Wheat Board said forecast prices for wheat and feed barley have fallen as the financial volatility spreads from banks and mortgages to commodities.

“The global grain trade is closely linked to international financial markets for currency, credit, and other commodities. Recent extraordinary events are creating high levels of volatility and uncertainty in all markets. These events are also having a negative impact on global economic growth and are changing the buying behaviour of grain customers. These conditions are expected to take some time to stabilize and have the potential to significantly impact overall pool returns,” the CWB said.

“The recent sharp decline in commodity prices, as well as the extreme day-to-day volatility, reflects as much the impact of U.S. and global financial market developments as it does actual world supply/demand fundamentals for commodities,” Patricia Mohr, Vice-President, Economics, and Commodity Market Specialist at Scotiabank, said.

Darrel Good, extension economist at the University of Illinois writes: “On a daily basis, prices have been influenced by changes in the value of the U.S.

dollar, changes in crude oil prices, export news, weather and production expectations, and developments in the financial markets.”

The economic conditions are also reflected in the Baltic Dry Index, which measures demand for ocean-going bulk carriers. In recent weeks the index has plunged. The BDI hit a record high of 11,793 in May, and is now below 4,000.

Tighter credit, rising interest rates and volatile currency markets are also having an impact. Add to this shifts in supply and demand and the result is rapidly falling grain prices.

Leading the way is wheat. The International Grains Council (IGC) is predicting a record world wheat crop of 676 million tonnes. But much of the

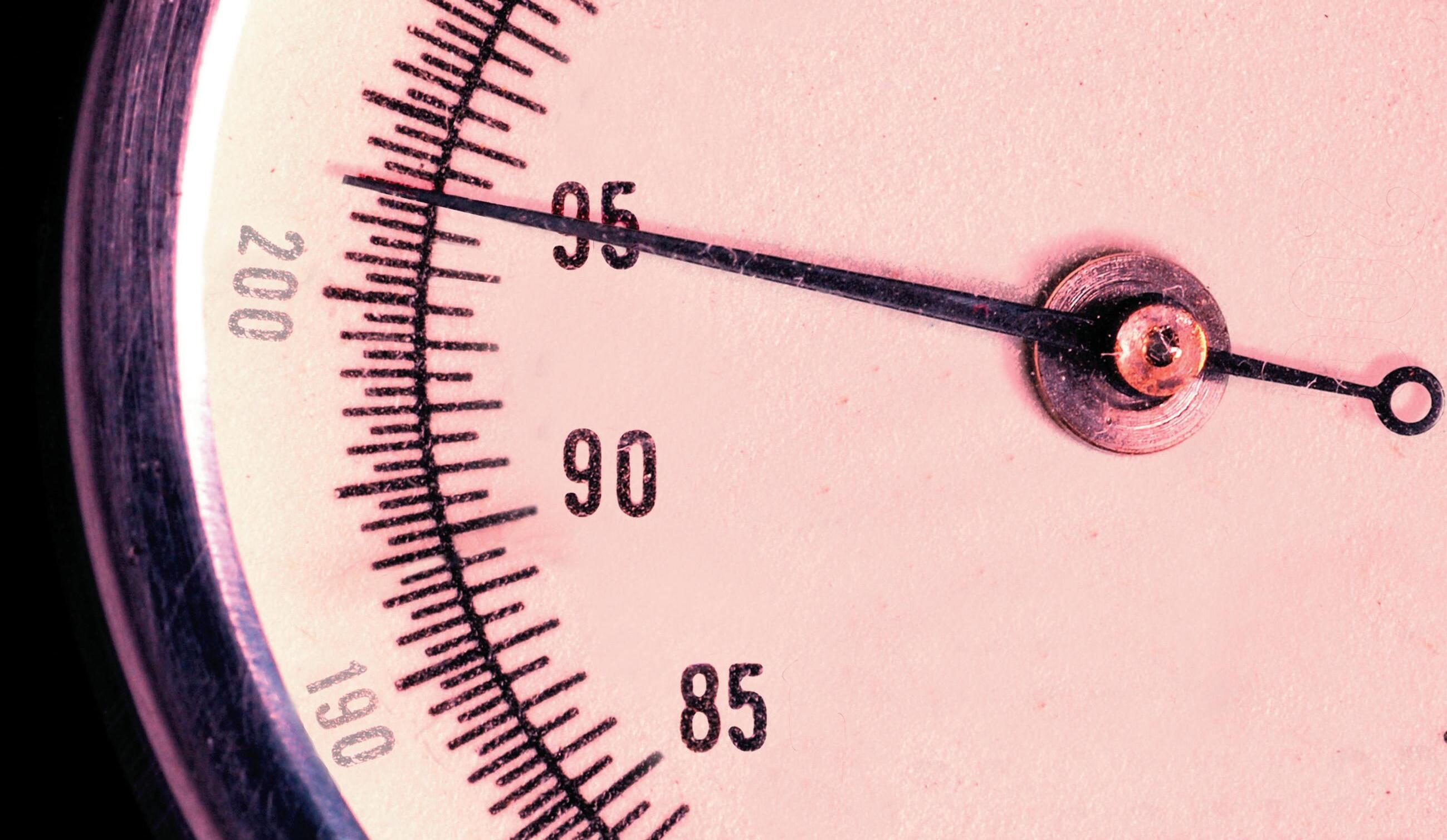

Feed prices have been taking more twists and turns than a roller coaster.

European and Ukrainian production is lower quality and is pressuring corn and other feed grains.

The IGC projects total world corn production will come in at 771 million tonnes this year down from 787 million tonnes last year. It expects trade to drop to 87 million tonnes from 100 million tonnes, but closing stocks to fall to 109 million tonnes from 127 million tons at the end of the 2007/08 crop year. However, the IGC forecasts wheat supplies at the end of the 2008/09 crop year will rise almost 25 per cent to 153 million tonnes. ■

WILD RIDE

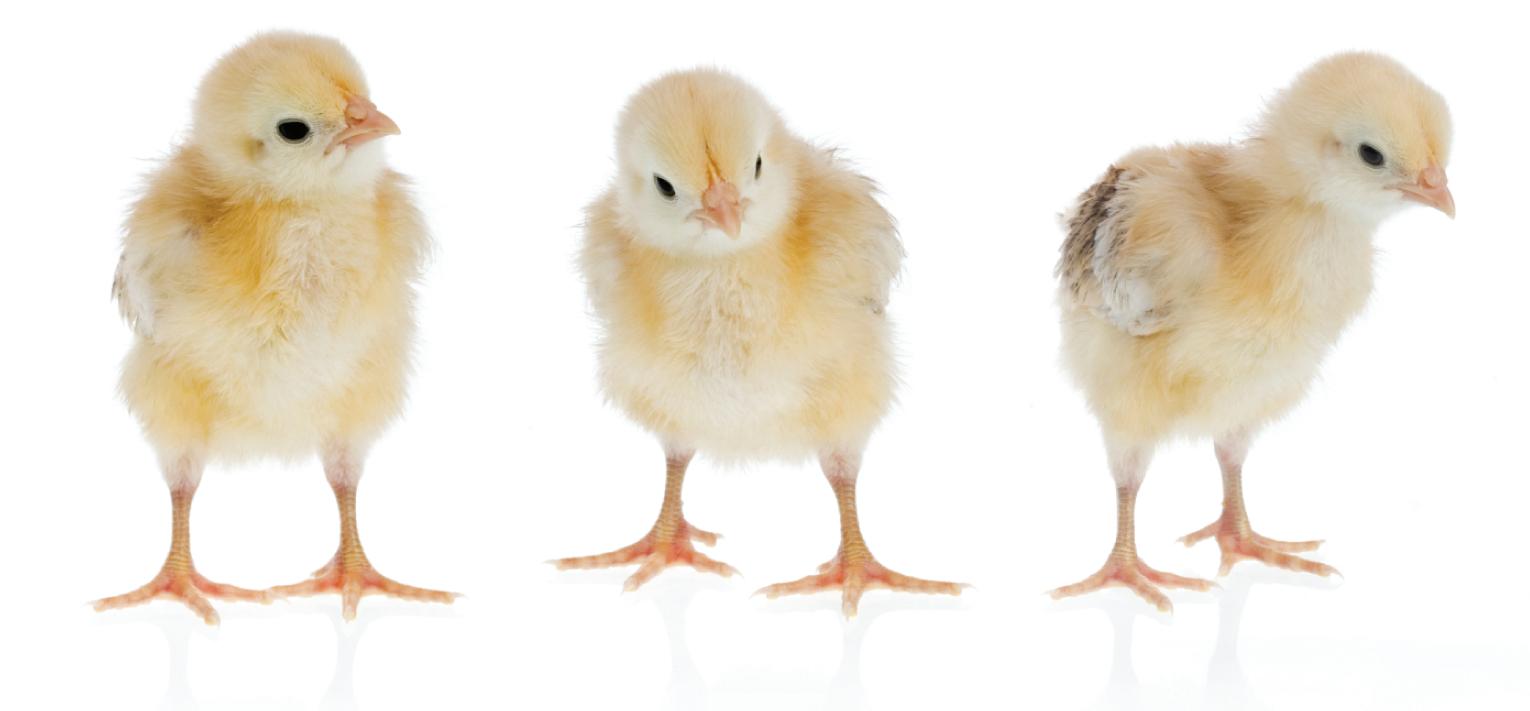

Layers Robustness of Laying Hens

Is it all about genes, environment or early-life experiences?

BY L. STAR, H.K. PARMENTIER, J.J. VAN DER POEL, AND B. KEMP, WAGENINGEN UNIVERSITY, THE NETHERLANDS

SUMMARY

Immune competence and physiological parameters (production and endocrine) during various environmental stress conditions were studied in purebred layer lines at various ages.

Our purpose was to establish the contribution of genetic background, environment and early-life experiences to the so-called “robustness.” Next to egg production, levels of innate and specific immune competence depended on genotype. Within breeds, however, innate immune competence was related with survival. Comparable response patterns to climatic and immune stress were found within breeds, but breeds differed in response levels towards these stressors. The response levels could not be influenced by early-life experiences. Our data suggest that robustness mainly depends on the capacity to respond to stressors within a genetic background, and that the maintenance of different fitness strategies within a selected purebred may favour coping with different environments on the long term.

INTRODUCTION

There are a limited number of internationally operating poultry breeding

Genetic background plays a role in how hens cope with stress. TOUGH ENOUGH?

companies that provide laying hens worldwide. For these companies, it is favourable to have animals that can function under a wide variety of environmental conditions. In addition, robustness is a term that is rapidly becoming a main interest in animal production. 1

Robustness can be defined as an animal under a normal physical condition

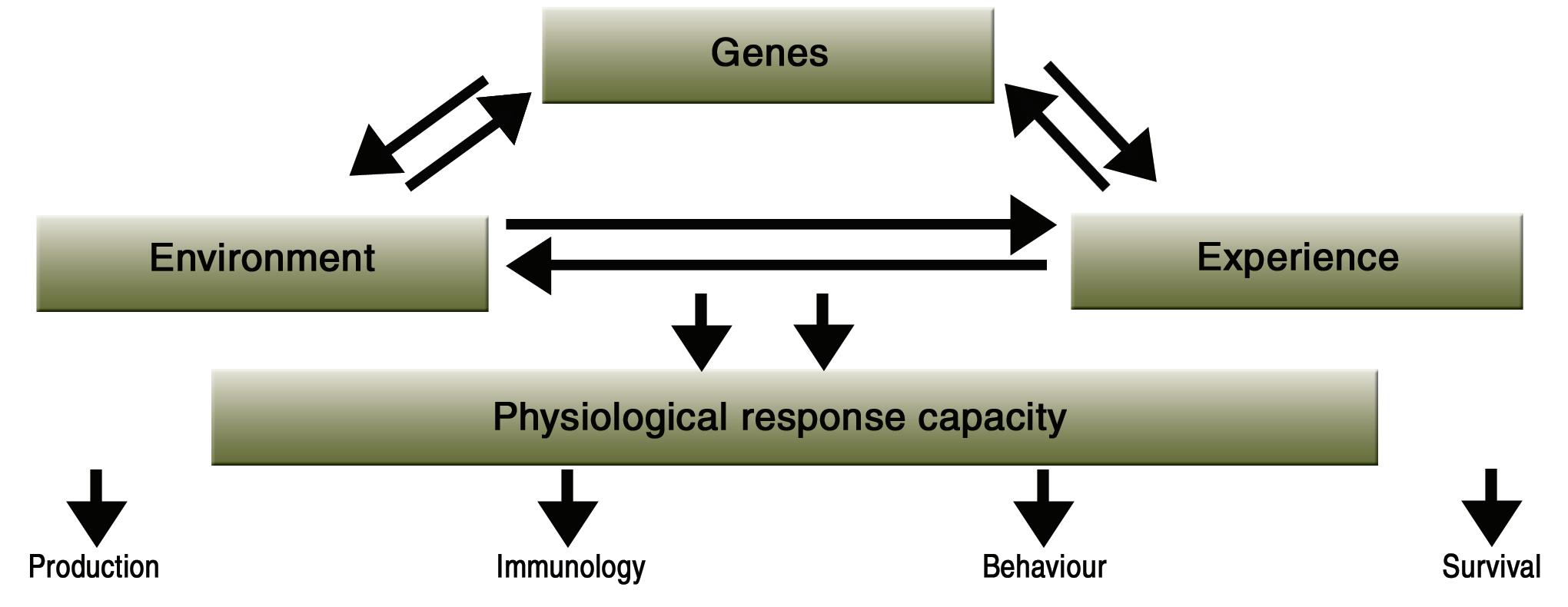

that has the potential to keep functioning and take short periods to recover under varying environmental conditions. Robustness of an animal probably depends on genetic potential, environmental influences, and early-life experiences, and robustness can be evaluated in terms of physiological, behavioural, and immunological traits (Figure 1).

Egg Farmers of Ontario A Legacy of Research

Egg Farmers of Ontario (EFO) has a long-standing commitment to hen health and egg research. Since 1964, EFO has contributed more than $3 million to research leading to improvements in farm management, biosecurity and egg production.

Changing with the Times

Research in the egg industry has evolved from addressing immediate industry needs to a variety of proactive studies that enhance the industry’s future.

• Feeding and nutrition have become more ef cient.

• Research into the hen’s reproductive system, while still not complete, has led to discoveries that have enhanced the well-being and production of laying hens.

• Support from EFO and other industry groups is vital in order to continue research in the egg industry.

Health and Disease

EFO has supported research projects at the University of Guelph for many years in the eld of virology. Projects include:

• Control management of viruses causing inclusion body hepatitis (IBH) and improved diagnosis for infectious bronchitis (IB); and

• Identi cation of virus types that exist on Ontario farms and investigating responses to conventional vaccines.

EFO has also supported various research into Marek’s disease.

• Marek’s disease causes high mortality, mostly in young hens.

• Researchers at McGill University and the University of Guelph are investigating speci c DNA sequences that may be used to improve resistance to Marek’s disease.

Moving Forward

By working with industry partners, such as the Poultry Industry Council, EFO’s contributions continue to lead to better disease management and improved poultry health. Through advances in egg and hen research, farmers reap the bene ts of improved farming practices and consumers bene t from a better quality egg.

Egg Farmers of Ontario (EFO) is dedicated to continuing innovation in egg production and improving farm practices, hen health and egg quality.

Every year, EFO sponsors several research projects that are designed to increase the ef ciency of egg production.

Egg Farmers of Ontario 7195 Millcreek Drive Mississauga, Ontario L5N 4H1

Phone: (905) 858-9790 Fax: (905) 858-1589

Website: www.getcracking.ca

Layers

Figure 1. Robustness of an animal is influenced by genetic background, environment and early-life experiences, where production, survival, behaviour, immune and physiological parameters can be used as read-out for robustness.

Three experiments were performed to establish the importance of genetic potential, environmental influences, and early-life experiences on the robustness of laying hens. Results of these experiments will be described briefly. Thereafter, a discussion will follow on robustness in relation to genetic potential, environmental influences, and early-life experience. The discussion will end with a suggestion of which parameter or trait is of interest for implementation into a breeding goal for robustness.

RESULTS

2a. Genetic potential

A population of 1,063 laying hens was used to establish natural antibody (NAb) levels and haemolytic complement activity. Within this population 12 purebred layer lines (Hendrix Genetics, Boxmeer, the Netherlands) could be distinguished: six White Leghorn lines (W1, WA, WB, WC, WD, and WF) and six Rhode Island Red lines (B1, B2, B3, BA, BB and BE).

Differences between layer lines in levels of natural humoral immune competence were established, but most importantly, the data suggests, regardless of line, levels of Nab were related to the probability of surviving the laying period.2

2b. Environmental influence

From the former experiment (2a), four of the 12 lines (WA, WB, WF, and B1) were selected, based on a profile of high or low natural immune competence and a high or low survival rate. These lines were exposed to the following environmental stressors: heat (climatic stress), lipopolysaccharide (LPS, hygienic stress), or combined exposure to heat and LPS.3-5 Hens were able to cope with single or combined heat stress and LPS challenge. The lines had similar response patterns, but differed in response levels, suggesting that some lines were better able to adapt to stressors than others.

Lipopolysaccharide and heat stress initiated sequential responses over time, with an earlier effect of short-term LPS exposure (within the first and second week) and a later effect of long-term heat exposure (within the second and third week), indicating that heat stress and LPS challenge acted like two independent stressors.

2c.

Early-life experience

From the former experiment (2b), one line (B1) was selected. Hens of this line were not able to maintain a high hen-day egg production during heat stress. Effects of early-life experience with heat stress on adaptability to the same stressor in

later-life were studied (Star et al., submitted). The data suggest that early-life heat stress exposure did not affect adaptability of laying hens to heat stress in later-life.

DISCUSSION

Comparable response patterns to climatic and immune stress were found within breeds, but breeds differed in response levels towards these stressors. Line B1 had, for instance, a strong reduction in feed intake, body weight, and henday egg production during heat stress compared to lines WA, WB, and WF. The response levels of line B1 could not be influenced by early-life experiences. Hester et al. concluded from their studies that, from criteria used to evaluate stress (e.g., physiological and immuno-logical parameters), egg production and mortality provided the best evidence for adaptability to stress.6-8 Our data also suggest that some lines are better able to cope with environmental stressors than other lines based on egg production and mortality. Line B1 had a high mortality rate under commercial circumstances and showed a decline in hen-day egg production by exposure to high temperatures.2 Line WA had a decline in hen-day egg production at the end of the laying period (60 to 69 wk of age) under commercial

circumstances (unpublished data) and had more problems with keeping up production under heat stress than the other White Leghorn lines. Line WB and WF were able to maintain a high hen-day egg production under heat stress. However, line WF was a better survivor under commercial circumstances than line WB (Star et al., 2007a), which makes line WF a more “robust” line. Our data suggest that robustness mainly depends on the capacity to respond to stressors within a genetic background, and that the maintenance of different fitness strategies within a selected purebred may favour coping with different environments on the long term.

The conclusion about robustness as discussed above is, however, based on line difference. For the final goal of these experiments it was important to find traits on individual level that could be implemented into a breeding goal. In future livestock systems it is necessary that breeding goals should not only be defined in terms of production, but that

Layers

they should also include traits related to animal health and welfare. Therefore, the findings described in the first experiment (2a) are of interest and probably most important for robustness. Regardless of line, low levels of NAb binding to keyhole limpet haemocyanin (KLH) were detected in chickens that did not survive the laying period (Figure 2a).

Recently, we have established a similar relation between NAb binding to KLH in a crossbred line (Figure 2b). In the same crossbred population we have estimated a heritability of NAb binding to KLH of 0.23, indicating that selection for NAb levels is possible. In practical – commercial – context, however, selection for this “robustness” trait must be in balance with selection for production traits.

ACKNOWLEDGMENTS

This research is part of a joint project of Institut de Selection Animale, a Hendrix Genetics Company, and Wageningen University on “The genetics of robust-

Scott’s Nutrition of the Chicken, 4th Edition

ness in laying hens” which is financially supported by SenterNovem. ■

REFERENCES

1. Knap, P.W. (2005). Australian Journal of Experimental Agriculture, 45 :763 -773.

2. Star, L., Frankena, K., Kemp, B., Nieuwland, M.G.B. and Parmentier, H.K. (2007a). Poultry Science, 86:1090 -1099.

3. Star, L., Nieuwland, M.G.B., Kemp, B. and Parmentier, H.K. (2007b). Poultry Science, 86:1894 -1903.

4. Star, L., Van den Anker, I., Kemp, B. and Parmentier, H.K. (in press). Poultry Science.

5. Star, L., Decuypere, E., Parmentier, H.K. and Kemp, B. (in press). Poultry Science.

6. Hester, P.Y., Muir, W.M. and Craig, J.V. (1996a). Poultry Science, 75 :1315 -1320.

7. Hester, P.Y., Muir, W.M., Craig, J.V. and Albright, J.L. (1996b). Poultry Science, 75 :1295 -1307.

8. Hester, P.Y., Muir, W.M., Craig, J.V. and Albright, J.L. (1996c). Poultry Science, 75 :1308 -1314.

Nutrition of the Chicken is the classic text covering all aspects of nutrition and metabolism of meat and egg-laying birds.

This new edition represents a total update and revision of all the important aspects of nutrition and metabolism covered previously, together with new chapters on Digestion, and Natural Toxins. The reference material reflects the most recent research conducted in all areas of poultry nutrition and metabolism of the major nutrients. The Chapters on Energy, and Proteins and Amino Acids cover in detail the most recent methods of quantitation and partitioning for maintenance and production. The classical sections on Vitamins and Minerals have been extensively modified to cover all aspects of potential interactions and antagonisms together with consequences of simple or induced deficiencies.

#0969560044

The Health of Poultry

The Health of Poultry, by Mark Pattison, is a unique book describing the overall concepts of poultry health with the emphasis on creating the right conditions and environment to minimize the occurance of disease. By demonstrating the interrelationships between husbandry, medicine and nutrition the author shows how to prevent diseases and to maximize the genetic potential made possible with modern breeds of poultry. Each of the main poultry species - chicken including breeder and broiler, turkey and duckis dealt with in separate chapters that explain the principle of disease control with the emphasis on preventive medicine. All aspects of care are drawn together to provide guidance on devising a rigorous health regime that is controlled by proper management. Chapters on hatchery, nutrition, environment, and housing examine topics such as planning, ventilation, hygiene, quality control and medication.

Item #0582065798

Energy

Energy Audits

Helping farmers save energy

BY DAN WOOLLEY

Anew program initiated by the Nova Scotia Federation of Agriculture to help its farmers save energy has just hired its first two energy auditors.

Julie Bailey, a graduate chemical engineer with a master’s degree in agriculture, is one of the two new energy auditors. She says the objective of the farm energy audit program is to provide expertise and support for farmers who want to conserve energy.

As energy auditors, Bailey and her colleague, Rick Hoeg, will inventory onfarm energy use, principally electrical uses, but they will also look at fuel oil and propane use on the farm. She is also looking at adding a component to the inventory to look at on-farm diesel and gasoline use.

As for poultry producers, Bailey, as part of her master’s thesis, surveyed 700 Nova Scotia farms. “I found that the average Nova Scotia farmer spent $11,000 annually on their energy bill. The average dairy farm, however, was twice that and the average poultry and hog operation was three times that (approximately $32,000).”

Based on her research, she estimates poultry and hog producers can save at least 15-percent on their yearly electrical bills. Bailey recommends: “Poultry producers pay attention to your control systems and lighting as they can provide a significant payback.”

The Nova Scotia EcoTrust for Clean Air and Climate Change is helping the NSFA sustain the energy auditing

An average Nova Scotia poultry producer could cut energy costs by about 15 per cent often by doing something as simple as switching to energy-efficient lighting.

system for farmers with funding. Bailey found through research for her thesis, published in 2007, that the average Nova Scotia farm emits about 48 tonnes of GHG (greenhouse gases) annually and she also discovered that 78 per cent of Nova Scotia farmers are interested in adopting energy-saving measures, but she adds, “I also found that 90 per cent of

Nova Scotia Farms weren’t using renewable energy technology. Surprisingly, I even found that 42 per cent of Nova Scotia farms were still not using energyefficient lighting.”

The energy audit program, Bailey notes, is voluntary for farmers. “I have 13 farms participating right now. I have

Continued on page 38

ENERGY ABUSE

CPRC Update

The Canadian Poultry Research Council (CPRC) provides funding for research projects under a number of themes.

Below are summaries of the final reports for two of these projects:

MANAGING BROILER BREEDERS

The laying performance of commercial broiler breeder chickens can vary widely. Careful management decisions are required, especially during sexual maturation, to maximize egg production. Drs. Frank Robinson and Robert Renema, and their team at the University of Alberta have undertaken a large research program on broiler breeder physiology and are working towards a better understanding of the impact of various management decisions on breeder performance.

Protein intake

One aspect being examined within this program is the interaction between protein intake and reproductive efficiency. An experiment was set up during which pullets were fed either a standard breeder ration during their growth phase, or one that was either 20 per cent higher or lower in crude protein. The HIGH or LOW protein rations were fed over different time periods and various measures of body and reproductive development were taken throughout the experiment. The different diets had only minor effects on the developing birds and resulted in no change in the number of eggs laid. These results suggest that feeding a high protein diet during the growth phase may not be necessary for proper reproductive development. This is a significant conclusion and suggests that other management decisions are likely to have greater impact on breeder flocks.

Timing of feed restriction and photostimulation

In a related trial, chicks were full fed for either one or three weeks. Growth curves thereafter were designed to merge the two groups by 10 weeks of age. As expected, the 3WK group initially gained much more weight, but upon being feed restricted virtually matched the other group in all respects, including apparent reproductive development, by the end of the 16-week trial. Flock uniformity was better for the 1WK group, presumably due to a smoother transition into feed restriction and less competition for feed from aggressive birds. The pullets were photostimulated at 17, 19, 21 or 23 weeks. As expected, stimulating birds later resulted in delayed onset of sexual maturity, but these birds matured more quickly. Flocks stimulated later came into lay most consistently and had larger early eggs. These results suggest that more mature birds can better respond to photostimulation cues.

The importance of body size

Data were also collected on two commercial breeder flocks from hatch to end of lay. Chick size had little correlation to production traits, while measurements at nine weeks were more predictive of the birds’ performance later on. On average, lighter

hens were less productive, while hens that were too heavy tended towards more double-yolked eggs and other reproductive problems.

Next steps

The many data produced during this project are being analyzed in the context of the overall breeder physiology program. In light of the relatively small impact of changing protein levels, future work will concentrate on the effects of varying energy intake and age of photostimulation.

Funding for this project was provided by CPRC, Alberta Agricultural Research Institute and Aviagen.

WORKPLACE EXPOSURES OF POULTRY BARN WORKERS

There are relatively few data available on the exposure of poultry workers to environmental contaminants. The purpose of this study was to log the amount of time poultry workers spend on various activities on farm and to measure their exposure to environmental contaminants such as ammonia, respirable dust and CO2. Exposures were compared between layer and broiler operations throughout production cycles at different times of the year.

During an earlier study, the tasks of poultry barn workers were recorded during their workshifts and personal exposures were monitored with Personal Environmental Sampling Backpacks to measure contaminant exposure during the work tasks they conducted.

Ammonia, CO2 and dust

These studies suggest that ammonia exposures for poultry workers do not exceed the 25ppm Time Weighted Average Threshold Limit Value (TLV) set by the American Conference of Governmental Industrial Hygienists (the TLV of a chemical substance is the level to which it is believed a worker can be exposed day after day for a working lifetime without adverse health effects). Similarly, measured CO2 levels did not exceed the 5,000ppm TWA-TLV. Because of the high dust levels, the authors do recommend that poultry workers use N95 or comparable respirators while working in their barns to reduce their exposure to and mitigate adverse effects from respirable dust in the layer barn and broiler barn environment.

Funding for this project was provided by CPRC, the Natural Sciences and Engineering Research Council and Agriculture and Agri-Food Canada.

For more details on any CPRC activities, please contact Gord Speksnijder at The Canadian Poultry Research Council, 483 Arkell Road, R.R. #2, Guelph, Ont., N1H 6H8, phone 289-251-2990, fax 519-837-3584, e-mail info@cp-rc.ca, or visit us at www.cp-rc.ca.

The membership of the CPRC consists of the Chicken Farmers of Canada, Canadian Hatching Egg Producers, Canadian Turkey Marketing Agency, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns. ■

Non-invasive Tests of Stress in Laying Hens

BY TIM NELSON, EXECUTIVE DIRECTOR AND KIMBERLY SHEPPARD, RESEARCH CO-ORDINATOR

Issues of animal welfare and assurance of care are areas of growing public interest. Assessment of laying hen welfare is often based on behavioural observations or physical indications of abnormal behaviour such as feather loss due to feather pecking. It is well recognized that the assessment of animal welfare should involve, as far as possible, a comprehensive approach that includes physiological measures of biomarkers indicative of stress. Having such comprehensive assessment strategies in place can aid the industry in making objective decisions about the welfare of poultry in any given system.

A commonly used biomarker of stress in all species is the measurement of corticosteroid hormones. In avian species, the hormone measured is usually corticosterone. This is difficult to measure via blood sampling, however, since the sampling itself requires handling the birds, which stresses them. It is difficult to validate corticosterone levels in alternative sample media such as feces or eggs for the same reason, since these must be compared to circulating levels in the blood to determine if they accurately reflect circulating corticosterone levels. To date, the appropriateness of eggs and excreta to assess stress levels in birds has not been fully validated.

To overcome this problem and validate these measures, Dr. Nigel Cook at Alberta Agriculture and Rural Development, and his research team, utilized a method to collect blood without handling the birds.

They inserted a catheter, which allowed for blood collection from birds that are able to move freely within their cages, undisturbed.

The first step was to determine if corticosterone levels could be captured in eggs and excreta over time. Compared to the amount of hormone in the excreta (99 per cent), very low amounts of administered corticosterone were found in the eggs (less than one per cent), suggesting measurement of stress hormones in eggs might pose technically challenging. The corticosterone was present in the feces up to at least 48 hours postinjection of corticosterone.

A second experiment was designed to compare corticosterone levels in blood, albumin, yolk and excreta. Birds were

MEASURING STRESS

Dr. Nigel Cook and his team are trying to determine effective non-invasive methods to test stress in laying hens.

stressed by either holding them or by injecting them with a small amount of hormone that stimulates the adrenal cortex. Overall, measurements of corticosterone in the eggs and feces did not reflect the blood levels stimulated by the hormone, suggesting that these are not appropriate for use in measuring acute stress. However, the levels in the eggs and excreta closely matched overall daily adrenocortical activity, and may be

While producers such as yourself, and our competition, are trying to understand the challenges involved in designing, building and converting houses into Alternative Layers, we’ve been doing it. In fact, there are MILLIONS of Big Dutchman Alternative Layers globally. Let our Production Specialists, full-time personnel that understand production management requirements, show you how using our extensive product line can help you to get off the fence.

Making a world of difference one client at a time. +1 616 392 5981 • e-mail bigd@bigdutchmanusa.com www.bigdutchman.com

POULTRY DISEASES AND MEAT HYGIENE

Item#: 081382463X

Price: $152.60

Offers an easy-to-understand baseline pathology reference that presents all information needed in North American slaughterhouses and poultry production operations to identify and diagnose pathological problems and evaluate the suitability of poultry carcasses (chicken, turkeys, ducks, and geese). Included are 405 full-colour photographs of lesions, supported by descriptive findings, 31 additional illustrations, and additional data.

1938 - 2008

POULTRY HEALTH AND MANAGEMENT: CHICKENS, DUCKS, TURKEYS, GEESE, QUAIL

Item#: 0632051728

Price: $79.49

This fourth edition discusses systems that are environmentally and welfare friendly; and there is more emphasis placed on hygiene and vaccines in disease control and the role of molecular biology and cloning. New material also includes the advances in management, with special reference to feeding, drinking, lighting, and egg collection; and advances in genetics, developments in housing, and nutrition. A comprehensive section regarding the increasingly restrictive legislation concerning the safety of poultry products and public welfare is included.

PIC Update

appropriate for measures of long-term, chronic stress. To read more, please visit www.poultryindustrycouncil.ca.

FEATURED RESEARCHERS

protein and polypeptide mass profiles that may be indicative of disease, stress and pain.

Dr. Nigel Cook did his undergraduate studies at Portsmouth University, U.K., where he majored in biology. Upon graduating in 1980, he took the position of Biomedical Scientist at the Tenovus Institute for Cancer Research, Cardiff, U.K. There he completed a PhD in 1992 entitled: “The Stressor: Response Paradigm: An Assessment by Salivary Steroid Analysis.” This was a study of the stress responses of humans and the relationship of stress to disease states.

He then moved to Canada and took the position of Research Scientist with Agriculture and Agri-food Canada studying stress responses of livestock, and in 2002 became Research Scientist in livestock welfare with Alberta Agriculture, where he remains.

Dr. Cook’s research interests are in the discovery, development and application of biomarkers of stress, pain and disease in livestock species. The research program focuses on minimally invasive sampling methods and the analysis of stress-related hormones, e.g., cortisol and corticosterone. Also, the proteomic profiling of blood and saliva samples for the identification of

Carlton Gyles is Professor emeritus in the Department of Pathobiology, University of Guelph. He is a 1964 graduate of the Ontario veterinary College who has conducted research on E. coli in poultry, pigs, cattle and humans over the past 40 years.

PIC PICKS

Golf Day

Did you make it to the golf tournament? It was a great event with more than 200 players, a beautiful day and fabulous prizes. If you’re thinking about playing with us next year, don’t wait too long to book because next year we don’t clash with Poultry Day at the Outdoor Farm Show so we expect to be sold out (and we can’t book a bigger course). The tournament will be held on Wednesday, Sept. 9, 2009, so book now.

Annual Meeting

Our annual meeting took place on Oct. 7 and went well. The meeting was preceded by an update of our research endeavours for the year. About 40 people turned up and gave some terrific feedback on how we can improve what we’re doing at PIC to

A new approach to immunization against E. coli infections in broilers

Avian pathogenic E. coli (APEC) are common in barn dust. Following inhalation by chickens, the bacteria are often eliminated by the clearance mechanisms of the respiratory system. However, in the presence of other immune challenges caused by viruses, Mycoplasma, ammonia, or dust, APEC can establish in the respiratory system and disseminate throughout the body. This results in respiratory/septicemic disease. This diseaae occurs commonly in two- to four-weekold broilers and is a leading cause of economic loss. A vaccine against APEC would provide industry with a tool to manage this problem, improving both animal health and profitability.

Dr. Carlton Gyles and graduate student Haitham Ghunaim at the University of Guelph have been investigating four different antigens for their ability to induce protection in broilers against E. coli respiratory/septicemic disease. The researchers injected the antigens into broilers and collected serum contain-

ing the antibodies produced in response. When the antibodies were injected into broiler chickens it was found that antibodies against three of the four antigens tested protected the birds from APEC respiratory challenge. They then tested the three successful antigens further by two methods: i) vaccinating broiler breeders and assessing their chicks for protection after challenge with APEC, and ii) vaccinating broiler chicks and later challenging them with APEC.

Their findings? Vaccinating the broilers breeders did not lead to a protective effect for their chicks in this study. For the directly vaccinated chicks, one antigen (PapG) was effective in eliciting protective antibodies against E. coli. This finding indicates that PapG is a promising vaccine candidate for a vaccine against respiratory/septicemic disease due to E. coli in broilers.

To read more on this study, please visit www.poultryindustrycouncil.ca.

CARLTON GYLES, UNIVERSITY OF GUELPH

PIC Update

make it more relevant to you and more powerful in terms of tackling some pressing industry issues.

Funding

This year the PIC has more than $2 million worth of new projects under management. More than half of that money is coming from external (to industry) investors: the Agricultural Adaptation Council and the Ontario Ministry of Agriculture, Food, and Rural Affairs (OMAFRA). Between them, these investors are contributing over $1 million – many thanks to them. This external funding is a major bonus to industry and when we calculate the income from other provinces and institutions we are now receiving $6.40 for every $1 invested by Ontario producers and industry.

Board Members

Canadian Poultry Magazine and Intervet Canada present the Great Canadian

Great Canadian FLY THE COOPGetAway

Congratulations, you have found Brewster!

Record the page number and issue date where this ad is located on the contest ballot located at the Intervet insert in the centre fold of this magazine. Complete the remainder of the information on the ballot, attach a first class stamp and mail to: Great Canadian “Fly the Coop” Get Away Contest, c/o Canadian Poultry Magazine, Annex Printing and Publishing Inc., P.O. Box 530, 105 Donly Drive South, Simcoe, Ontario, Canada N3Y 4N5. Good Luck!

JUNE 2008

Amy Bouwmeester – Rockton, Ontario

JULY 2008

Barb Cowan – Auburn, Ontario

AUGUST 2008

Danny Gilbert – Burtts Corner, New Brunswick

SEPTEMBER 2008

Mike B. Hofer – Hodgeville, Saskatchewan

Prizes sponsored by Intervet Canada, 250 Water St., Whitby, ON, L1N 9T5

At the annual meeting retiring members were re-elected. We welcome back Stephen Halley (Intervet – ScheringPlough), Mike Terpstra (RBC), Charlie Elliott (Masterfeeds) and Brian Baynton (Alltech) as board members. These guys do a great job of keeping the PIC working on delivering research and education for industry – for absolutely no reward. Many thanks to all of them and the other members Rick Bennet (KL Products), Helen Anne Hudson (Burnbrae Farms), Ed McKinlay (McKinlay Farm) and Kevin Weeden (Weeden Environments) and to the feather board representatives for the coming year: George Campbell (TFO), Bob Guy (OBHECC), Vic Slobodian (EFO) and Murray Opsteen (CFO).

Thompson Steps Down

We said goodbye to Kevin Thompson, who has served on the PIC board for a number of years and helped steer PIC through some turbulent times – thanks for your valuable input, Kevin.

Research Facilities

This month, discussions about the new research facilities at Elora (the Guelph 2050 initiative), get underway between Industry, OMAFRA and U of G –watch this column for updates. ■

The PIC Board of Directors (left to right): Mike Terpstra, George Campbell, Helen Anne Hudson, Charlie Elliott, Rick Bennett, Stephen Halley, Ed McKinlay, Brian Baynton, Bob Guy, Murray Opsteen, and Tim Nelson. Missing from the photo are Kevin Weeden and Vic Slobodian.

CUSTOMER SATISFACTION ACROSS CANADA

...“The strength and durability of the system told me that this was going to last more years than I had left in the business. ... As we got into the reality of using the system, I knew we had made the right decision.”

Al Dyck, Harman Poultry Farm, Prince Albert SK

...“My Hellmann Cage System is awesome. An excellent system to work with on a daily basis.”

Doug Pauls, Highplain Farms, Niverville MB

...“With the Hellmann Cages I am getting results I cannot believe. Uniformity in the mid 90’s...Feed conversion also improved dramatically (5.9 kilos/bird). The Hellmann troughs keep the feed in the troughs and not on the floor.”

Gerard Hoftyzer, Londesboro, ON

... “With 94% uniformity, excellent feed conversion, very good air quality; all accomplished with minimal labour inputs; I am extremely pleased with my decision to purchase Hellmann Pullet Cages.”

Paul Overmars, St. Andrews, Nova Scotia

Maritimes

Contact: Herb Jansen

Phone: (902) 680-1267

Fax: (530) 430-2020

e-mail: janse17@attglobal.net

Manitoba, Saskatchewan & British Columbia

Contact: Greg Olson

Phone: (306) 260-8081 or (306) 492-2266

Fax: (306) 492-2265

e-mail: gaolson@sasktel.net

Eastern Ontario & Quebec

Contact: Stephane Chouinard

Phone: (450) 266-9604

Fax: (450) 263-2638

e-mail: stef@greenfarmline.com

Alberta

Contact: Len Mandel

Phone: (403) 308-7288

Fax: (403) 320-5866

e-mail: doubledd@shaw.ca

Western & Central Ontario

Contact: Jack Lepelaars

Phone: 1-866-767-2986 or (519) 348-8483

Fax: (519) 348-9271

e-mail: jack@newtechag.com

U.S.A.

Contact: Jim Currie

Phone: (519) 868-1882 or (519) 453-3913

Fax: (519) 453-3996

e-mail: hellmannpoultry@bellnet.ca

Production Le poulet biologique, une affaire de valeurs

Patience et persévérance

portent enfin leurs fruits à la Ferme Bio-Rard, où la production de poulet biologique a pris son envol grâce à un nouveau partenariat

PAR ANDRÉ DUMONT

Après cinq ans de hauts et de bas, d’essais et d’erreurs et des milliers d’heures et de dollars investis par conviction, l’avenir sourit enfin à la production biologique de la Ferme Bio-Rard. Depuis février dernier, 1200 poulets certifiés quittent la ferme à chaque semaine.

« Ça commence à valoir la peine, affirme Mario Bérard. Pendant les premières années, on ne faisait pas nos frais. » L’entreprise qu’il a fondé avec son épouse Karine et ses enfants Annie et Donald pour gérer en commun le volet biologique de leurs fermes avicoles a enfin trouvé le partenaire idéal. Les poulets de la Ferme Bio-Rard, à l’Ange Gardien, en Montérégie, sont abattus à la Ferme des Voltigeurs, de Drummondville, qui les met en marché dans son réseau de disbributeurs.

La production biologique ne faisait pas partie des plans de carrière de Mario Bérard.

Son élevage de poulets et sa meunerie conventionnels connaissaient une belle croissance quand il y a cinq ans, sa fille Annie, au terme de ses études, propose de diversifier la ferme familiale en y ajoutant un volet biologique. Son frère Donald est tout aussi emballé par l’idée.

DE

Annie, 28 ans, et Donald, 26 ans, ont convaincu leur père Mario de se lancer avec eux en production de poulets biologique.

Visiblement, Mario Bérard avait sous-estimé l’impact des valeurs que son épouse et lui avaient inculquées à leur enfants. Depuis des années déjà, le recyclage et le compostage des déchets domestiques est pratique courante à la maison. La récupération est même imposée aux employés de la ferme. Dans les champs, des bandes riveraines et des

haies brise-vents font partie du paysage depuis plusieurs années.

« Si tout le monde faisait les mêmes petits efforts que nous, cela ferait une véritablement différence pour l’environnement », affirme Mario Bérard. « Je suis un planteux d’arbres, dit son fils Donald. Je crois qu’en agriculture, nous devons réduire l’utilisation d’herbicides et d’engrais. »

UNE AFFAIRE

VALEURS

Photos courtesy André Dumont

Systems

MELLER PULLET CAGES

Meller brings you a world class pullet cage system proven in thousands of installations around the world, with features such as revolving belt manure removal roomy cages, solid galvanized dividers and adjustable front gate. Chain feeder or self propelled feed carrier with proportioner augers are available.

MELLER LAYING CAGES

Egg producers across the country have increased the efficiency of their operation with Meller Cage Systems, the Egg-Ease Egg Saver and faster egg collection. Sliding doors open the full width of the cage and the horizontal bars prevent feed spillage.

L’aventure biologique a débuté il y a cinq ans, par la remise en état d’une meunerie devenue trop petite pour le marché conventionnel que dessert Mario Bérard. La meunerie abandonnée reprend vie pour desservir les éleveurs biologiques de mouton, poulet, dindons, porcs et bovins laitiers.

Production

« Notre premier client n’a acheté qu’une seule poche! », se rappelle Donald. Ce n’est qu’aujourd’hui que la meunerie affiche une certaine rentabilité. Les prix offerts aux producteurs de céréales biologiques se sont raffermis, leurs productions sont en croissance et la demande pour les moulées est supérieure à l’offre.

Parallèlement, la Ferme Bio-Rard se lance dans l’élevage de poulets biologiques. On met à contribution des poulaillers à un étage sur une ferme que Donald vient d’acquérir. Ici aussi, le démarrage impose son lot de défis.

« Nous avons dû apprende la technique. C’est très différent du conventionnel », soutient Mario. Les bâtiements sont modifiés pour offrir plus de lumière naturelle aux poulets et on leur aménage des parcs extérieurs. La régie est modifiée pour qu’ils profitent d’une plus faible densité et d’une alimentation biologique, sans antibiotiques

Après environ quatre ans d’expériences, les gains de poids sont maintenant plus uniformes et les taux de mortalités ont beaucoup chuté. « Il n’y a pas de recette miracle », affirme Donald en parlant des contraintes en santé animale. D’après lui, si d’autre éleveurs disent ne pas réussir à produire sans antibiotiques, c’est tout simplement parce qu’ils s’attendent à des taux de réussite élevés à chaque lot. Les producteurs biologique ont une meilleure tolérance aux pertes, croit-il.

« Plus tes animaux sont performants, plus ils sont vulnérables aux maladies », rappelle Mario. Les poulets de la Ferme Bio-Rard grandissent en 50 à 60 jours. Quand le temps le permet pendant l’été, ils sortent au grand air. Par contre, Donald et Annie croient que c’est plutôt la faible densité dans le poulailler et la moulée de meilleure qualité qui fait une différence. « Ce qui pollue le plus, ce sont les herbicides et les pesticides utilisés dans les champs », affirme Annie.

C’est plutôt du côté de la commercialisation que les Bérard se buttent aux plus grands obstacles. Ils ont tout essayé : vente à la ferme, dans des kiosques à des expositions, aux marchés Atwater et Jean-Talon à Montréal. « C’est beaucoup de travail, dit Annie. Notre force, c’est plutôt la production. »

En février dernier, leur distributeur principal tombe en difficultés financières. Des lots de poulet biologique risquent de se voir écoulés dans la filière conventionnel. Après des mois à subir des commandes en dent de scie, on

songe carrément à abandonner la production biologique.

C’est alors que le partenariat avec la Ferme des Voltigeurs voit le jour. « Nous avons une belle entente. C’est une ferme familiale aussi et ils ont déjà leurs réseaux de distribution », explique Mario. Depuis, leur poulet se retrouve chez les détaillants aux côté du poulet de grain de la Ferme des Voltigeurs, sous l’étiquette « Poulet biologique Ferme des Voltigeurs, élevé par la ferme Bio-Rard ».

Avec trois poulaillers qui peuvent être utilisés pour la production biologique, la Ferme Bio-Rard est capable de produire

des volumes suffisants pour absorber les frais de transport et d’abattage. De plus, la production peut suivre l’évolution de la demande, puisque les Bérard peuvent aisément attribuer à leur production biologique une partie du quota que chacun détient, qui leut permet d’élever entout environ 200 000 poulets à la fois. « La Ferme des Voltigeurs peut annoncer à tout le monde qu’elle offre du poulet biologique ! », dit Donald.

Les Bérard n’en sont pas rendus à envisager la construction de nouveaux poulaillers biologiques. Pas question non plus d’abandonner la production

Web Exclusives

Canada Publishes Special Agricultural Safeguard Price and Volume Triggers

The Government of Canada has given notice of the volume and price triggers that will be used to operationalize the World Trade Organization (WTO) Special Agricultural Safeguard (SSG) for Canada’s supplymanaged products.

The Special Agricultural Safeguard is a provision that allows additional duties to be triggered automatically when import volumes rise above a certain level, or if prices fall below a certain level.

The full report is available on our website under Web Exclusives.

WTO Releases New Edition of World Tariff Profiles

The 2008 edition of World Tariff Profiles presents a comprehensive and updated compilation of the main tariff indicators for the WTO’s members as well as for other countries and customs territories. World Tariff Profiles provides detailed data on the bound and applied tariffs of WTO members. Information on each country’s market access is presented in summary tables — allowing crosscountry comparisons — and in country pages.

The full report is available on our website.

conventionnelle, puisque la plupart de leurs bâtiments ont trois étages. Avant d’investir davantage en production biologique, le marché devra faire ses preuves. On dit qu’il croît de 20 % par année, mais les risques sont encore élevés, prévient Mario.

Productions conventionnelle et biologique continueront donc à se cotoyer, sans contradiction dans l’esprit des propriétaires de la Ferme Bio-Rard. « Parce qu’on fait du biologique, on pense un peu plus en fonction de l’environnement, dit Mario. On ne change pas le monde, mais on ne contribue pas à le déteriorer! » ■

NEW PRODUCTS

Phyzyme XP TPT

Danisco Animal Nutrition has recently received the Canadian Food Inspection Agency’s (CFIA) approval of its highly thermostable phytase product – Phyzyme XP TPT – into the Canadian livestock feed market.