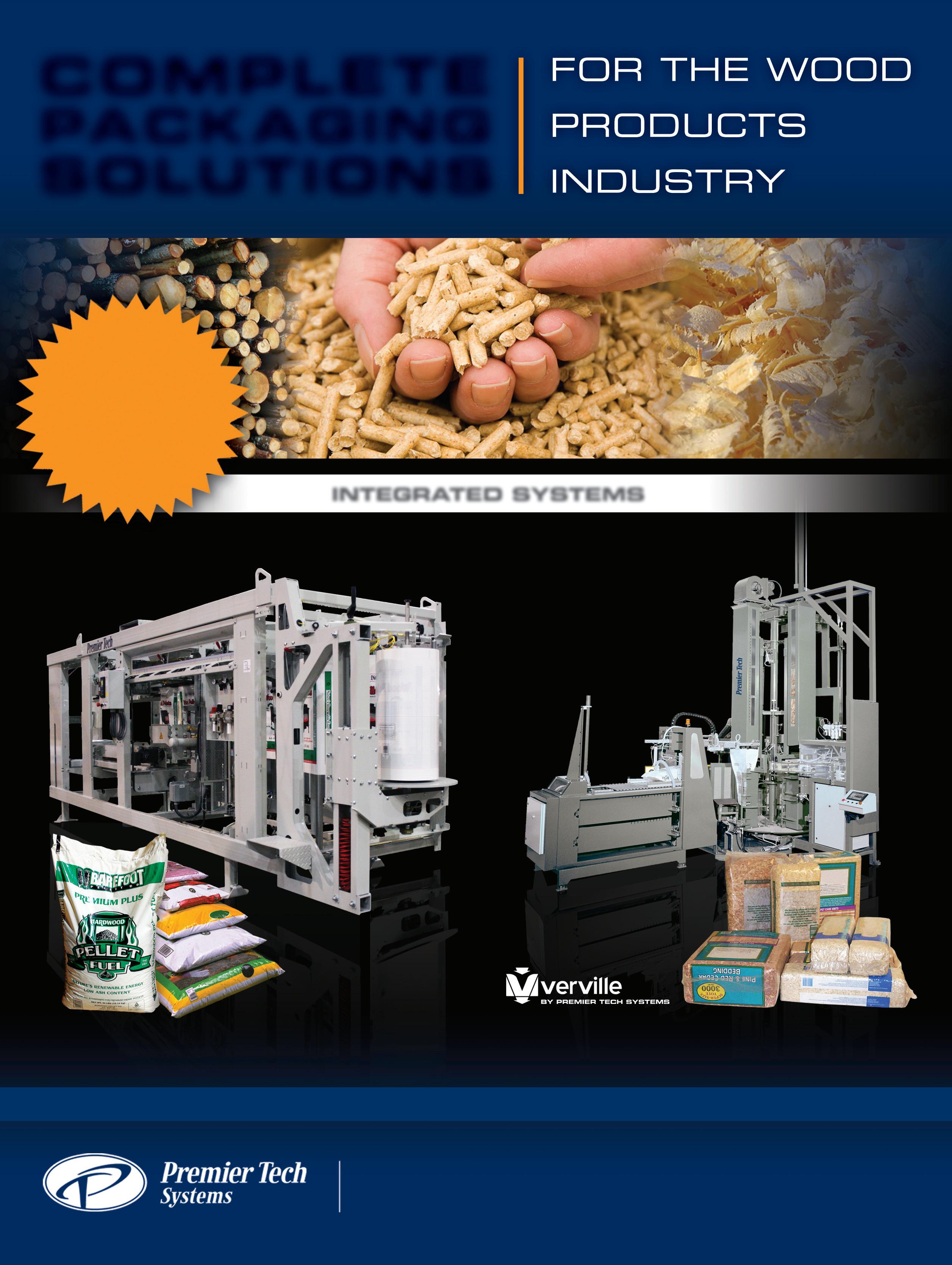

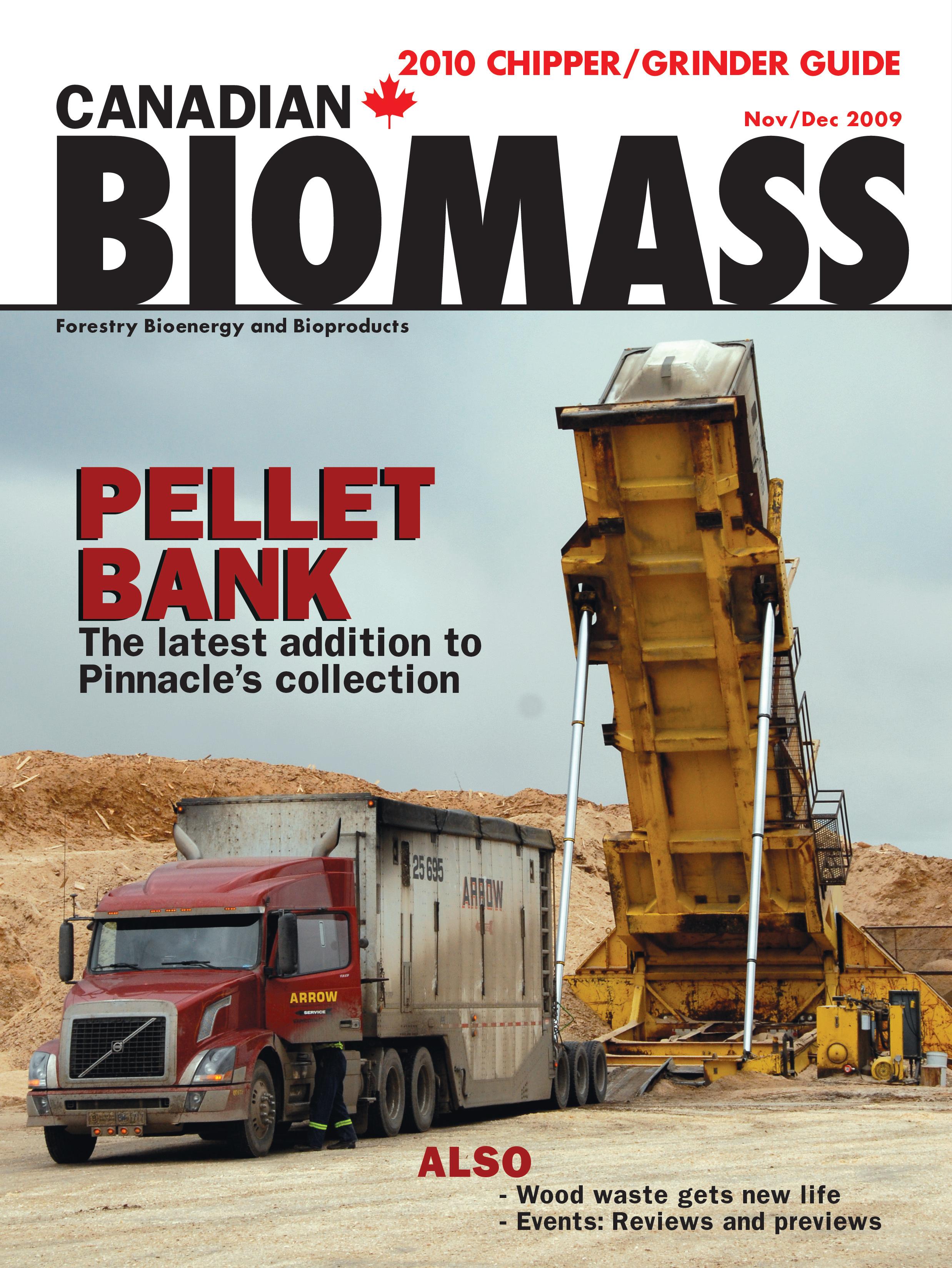

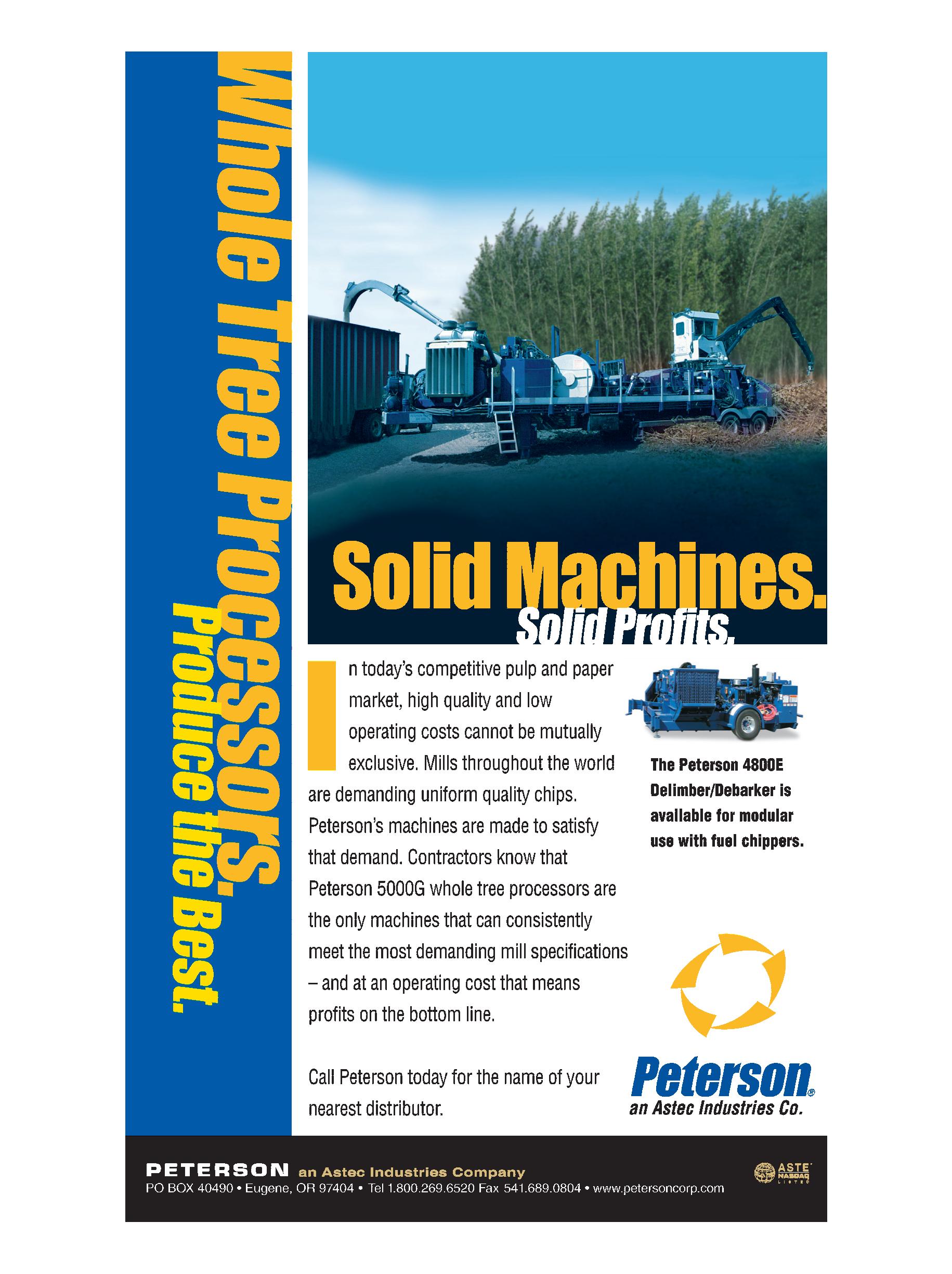

Pinnacle Pellet’s Meadowbank facility has been up and running for just over a year. It’s a streamlined affair that works 24/7 to keep up with the demand for wood energy.

Industrial waste management specialist Enfoui-Bec is diverting waste wood from landfill. Since the recycling began, the volume of recycled wood waste going to power neighbouring pulp and paper mills has increased by 30%.

The CanBio annual conference and trade show in Edmonton showcased expanding technologies and successful bioenergy projects.

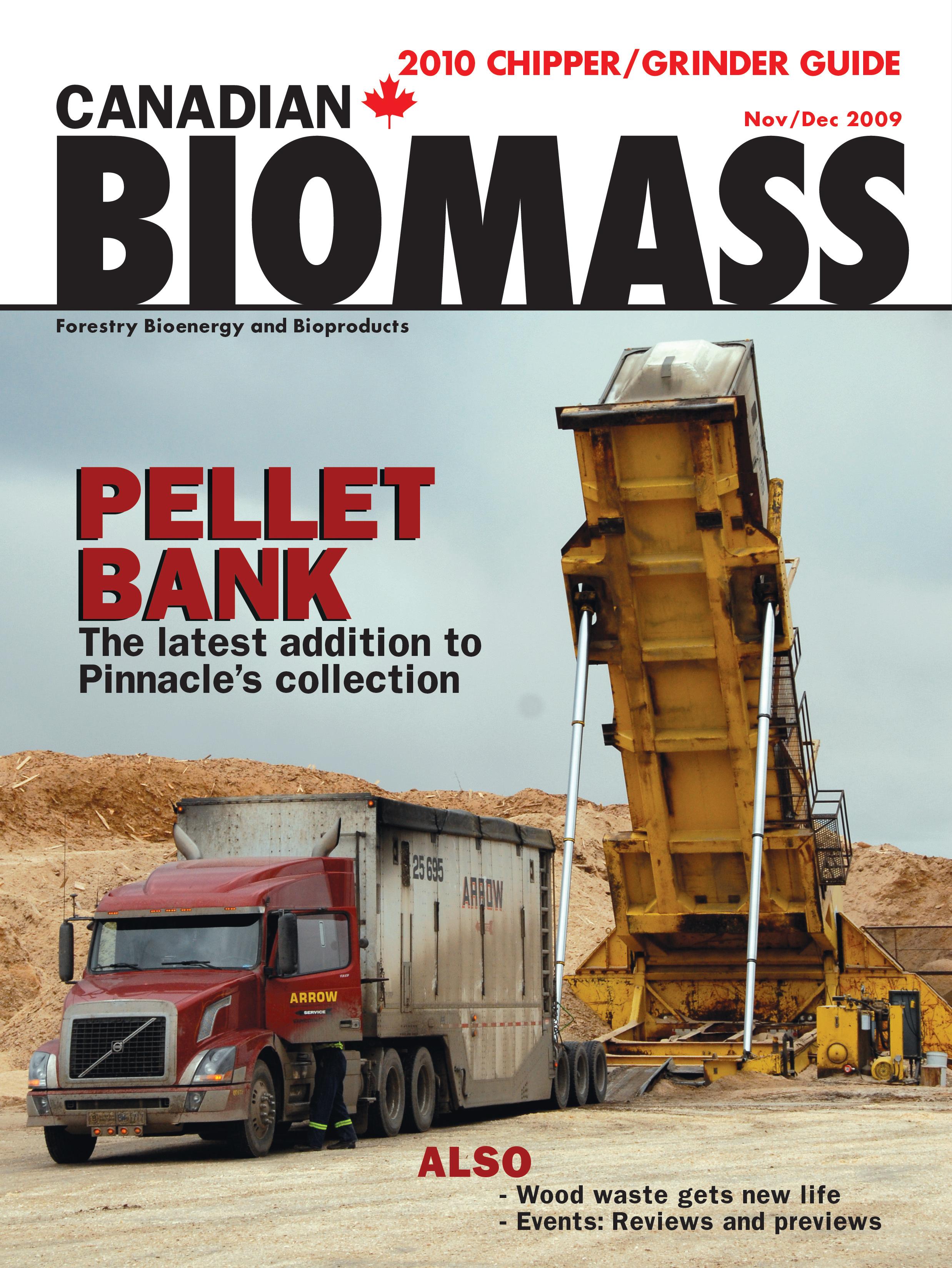

This year’s annual guide to portable chippers and grinders has a new look. The specs listings give an idea of what’s available in technology and capacity to suit a user’s needs.

“The

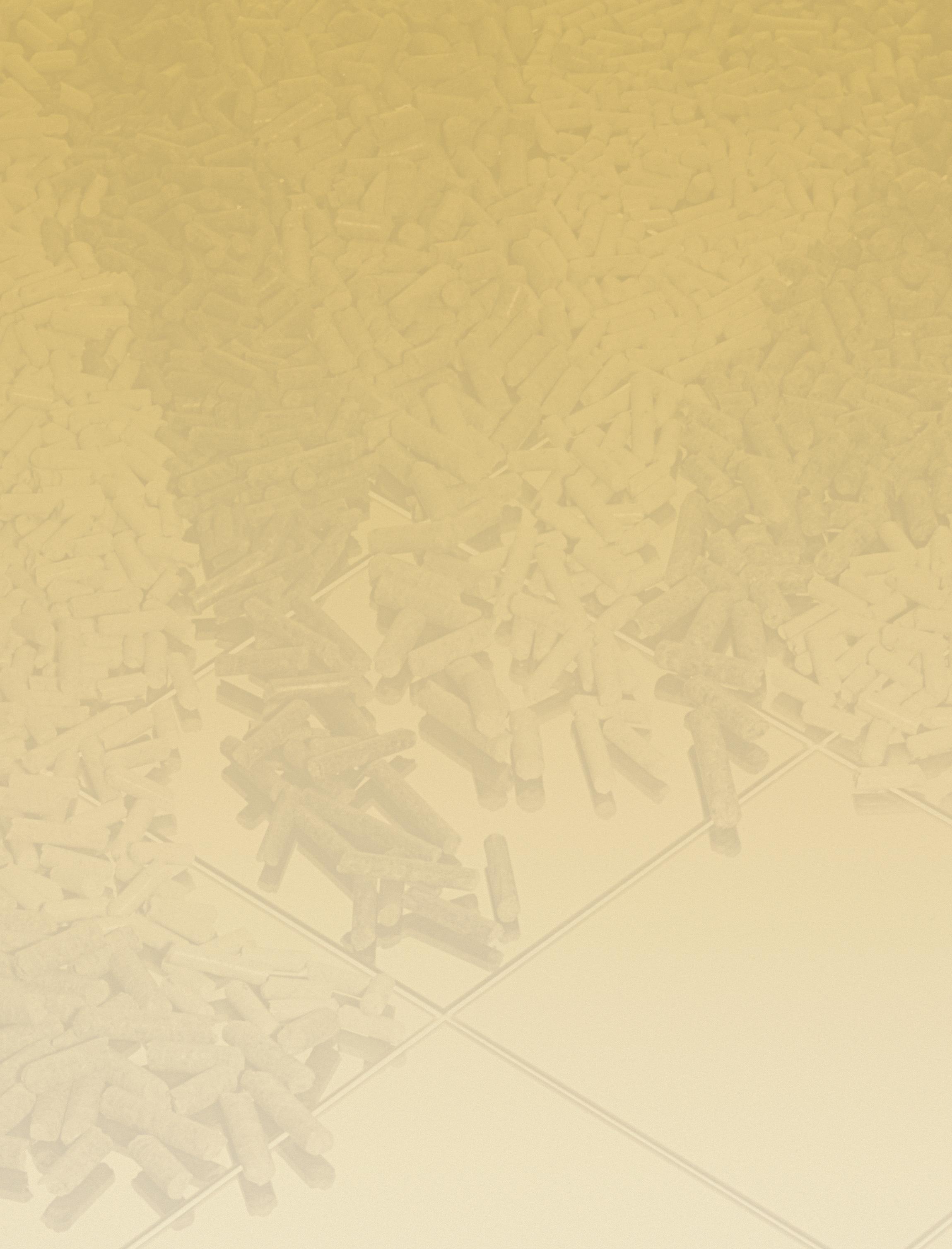

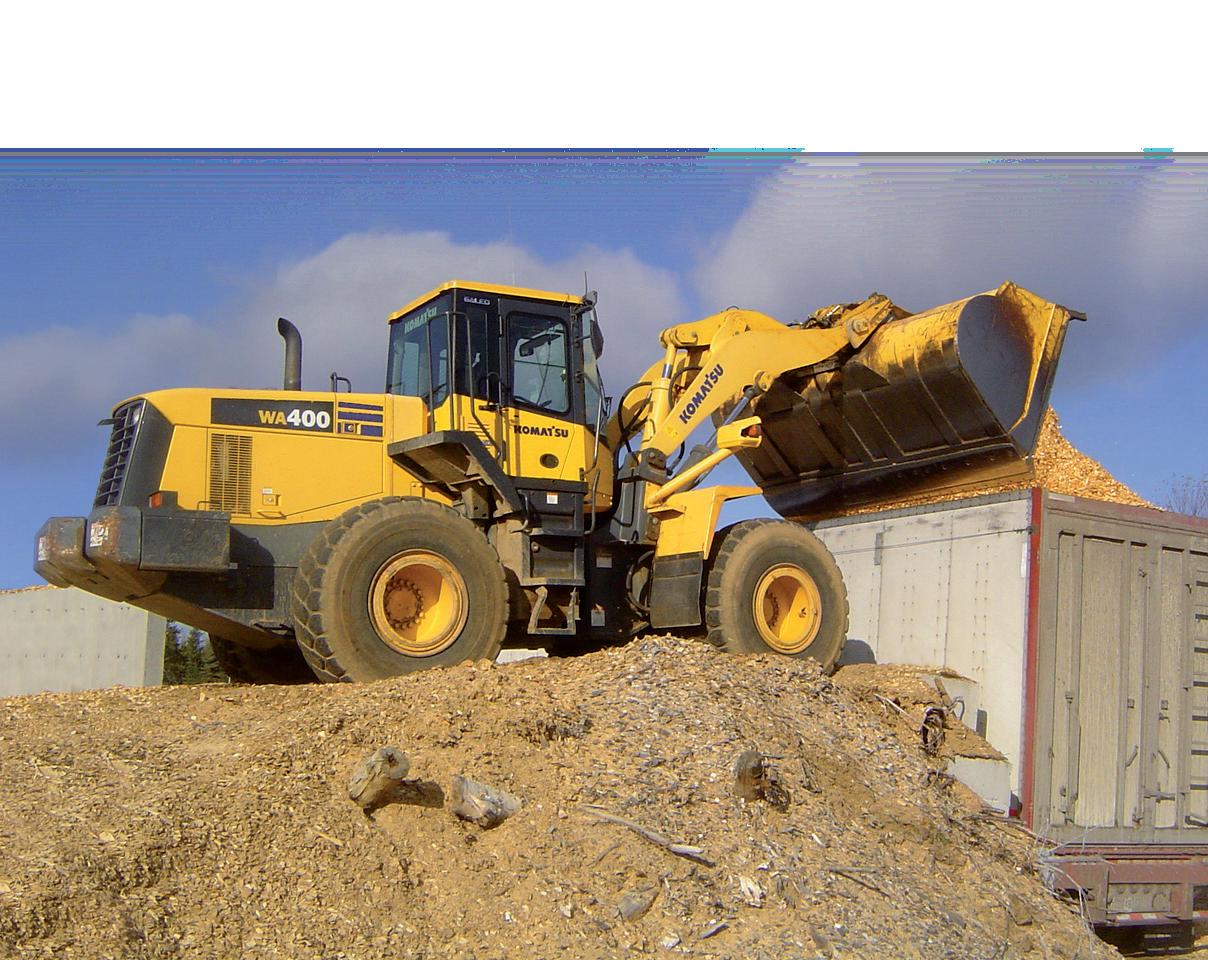

Residuals from nearby sawmills are trucked to Pinnacle Pellet’s Meadowbank facility in British Columbia and used to supply the flourishing wood pellet market. Story on page 16.

Photo: Bill Tice/CanadianBiomass

Biomass is losing ground to other renewable energy options because of its poor public image.

n the popularity contest among alternative bioenergy options, biomass is the kid getting shunned in favour of its better-dressed classmates. Consumers, media, and government subsidies are being charmed by solar, wind, and geothermal energy while biomass becomes the outcast child. The public has touted biomass as worse than fossil fuels, and at least one person (who clearly skipped math class) has stated that it requires two trees planted to replace each one removed for biomass.

How did the public become so misinformed? The biomass industry has not been effective at educating people about biomass energy. Certainly, not as effective as proponents of other complementary sources of renewable energy. It’s not that the other renewable energies don’t have their faults. Each option has its own environmental pros and cons. But a forest-based industry like biomass is at a prior disadvantage because of forestry’s long history in North America—it already has black marks against it for previous clear cutting and perceived lack of forest regeneration. It is little wonder that the current perception is that forests will be mowed down and burned to produce energy, putting more carbon into the atmosphere than burning fossil fuels, and removing the trees that were previously absorbing carbon.

unmerchantable timber (now biomass) were simply burned in the forest anyway. And they don’t know that the residuals from sawmilling were landfilled, burned in beehive burners, or piled unused, without harnessing the available energy. By using biomass, the waste is combusted under emissions-controlled conditions to provide heat and energy and is diverted from landfills.

However, this so-called waste wood will not remain the only source of biomass. Roundwood is already being made into wood pellets, for example. So the biomass industry has a vested interest in ensuring that biomass sources are harvested sustainably. After all, if the biomass harvest is not sustainable, the industry will not be sustainable. The biomass industry is not exempt from forest harvesting guidelines whereby the cut is counterbalanced by new growth. In addition, the provinces are developing and evaluating policies for sustainable biomass extraction, and those policies will continue to evolve with additional research and industry development. These messages must get out to the public. Finally, third-party sustainability certification for biomass and its products would give consumers a tangible assurance of responsible resource use.

Volume 7

Editor/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Associate Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Contributors - Colleen Cross, Melissa Damota, Guy Fortin, Bill Tice

Market Production Manager

Josée Crevier (514) 457-2211 ext 21 jcrevier@forestcommunications.com

National Sales Managers Tim Tolton - ttolton@forestcommunications.com 514-237-6614

Guy Fortin - gfortin@forestcommunications.com 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8 Ph: (514) 457-2211 Fax: (514) 457-2558

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Brooke Shaw

Canadian Biomass is published five times a year; March, June, August, October, and December. Published and printed by Annex Publishing & Printing Inc., and distributed as a supplement to Canadian Forest Industries and Canadian Wood Products magazines.

Printed in Canada ISSN 0318-4277

Circulation e-mail: cnixon@annexweb.com Tel: (514) 457-2211 Fax: (514) 457-2558

Mail: 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8

Subscription Rates:

Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $6.00

(Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

It’s time to brush up this image of biomass if it is to remain a viable renewable energy option. A good start would be to clarify what biomass is. Comments from outside the industry make it clear that people assume that trees are being cut to provide biomass. The majority of people have no idea that, previously, when trees were cut for timber harvest, thinning, and fire risk reduction, the slash and

Although the solar, wind, and geothermal sectors seem to be getting their message across clean and clear, biomass is not. And until it does, it will continue to be the last player chosen for the team and to relinquish potential market share to other forms of renewable energy. •

Heather Hager, Associate Editor hhager@annexweb.com

From time to time, we at Canadian Biomass make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2009 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

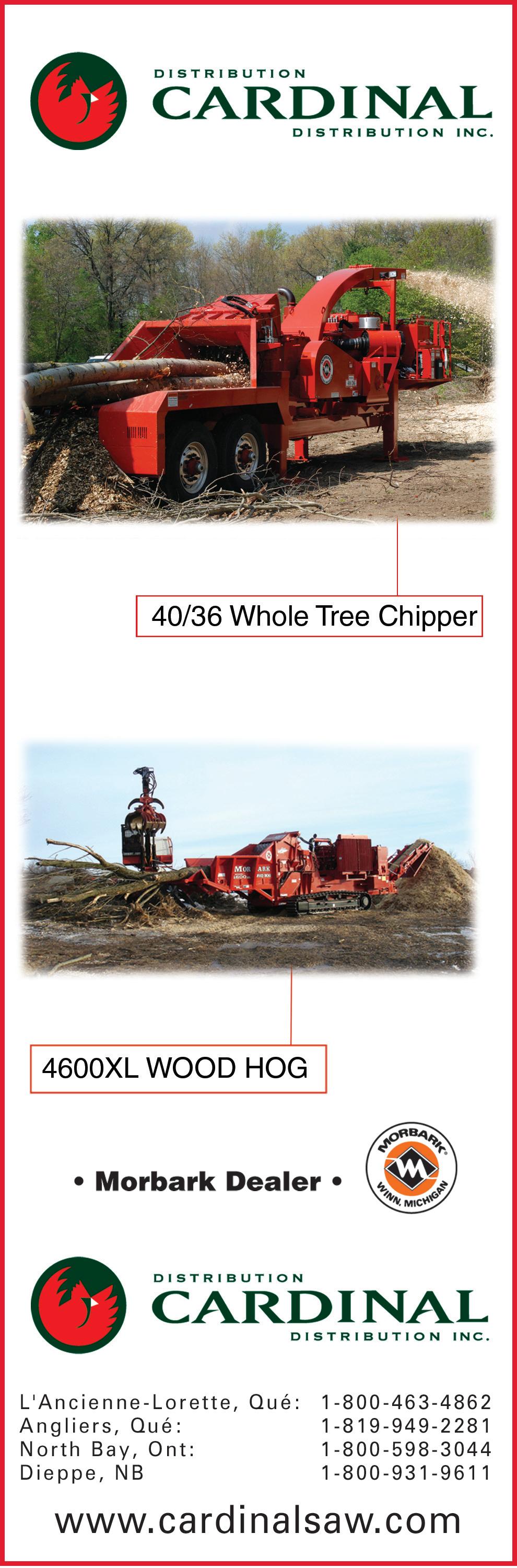

More Versatility. More Opportunity. Normally, high-quality chips and mulch are produced on separate machines, but with the Morbark Quick Switch, you can produce both products and virtually double your market opportunities with a single Morbark grinder. The best horizontal grinders on the market are now the most versatile with the introduction of the Morbark® Quick Switch Grinder-to-Chipper Conversion Kit.

Horizontal Grinder-to-Chipper Conversion Kit. Turn grinder downtime into profit by modifying the hammermill of your Morbark horizontal grinder in the field – without special tools or heavy equipment. Make the switch and produce high-quality biomass fuel chips in only a few hours!

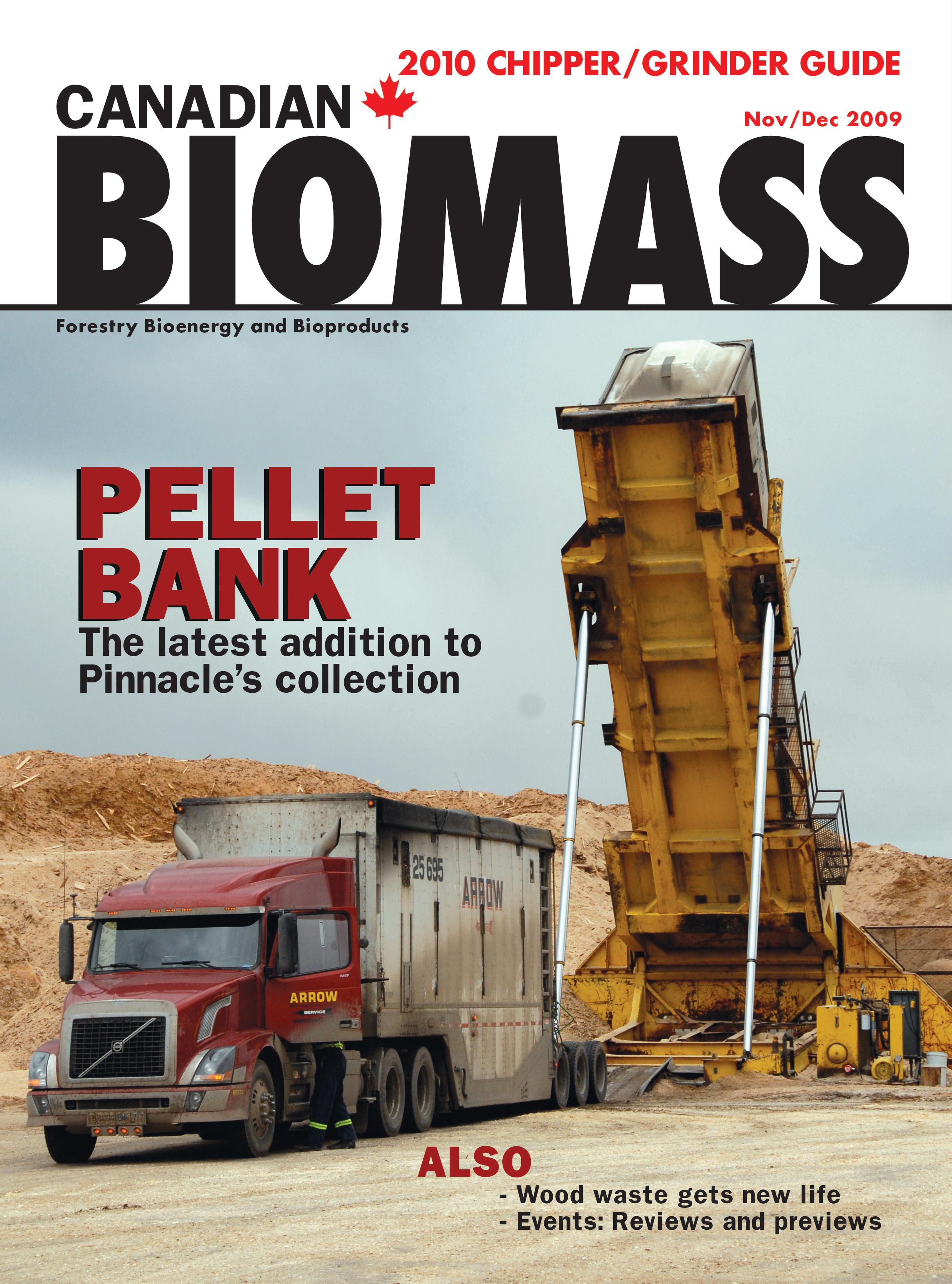

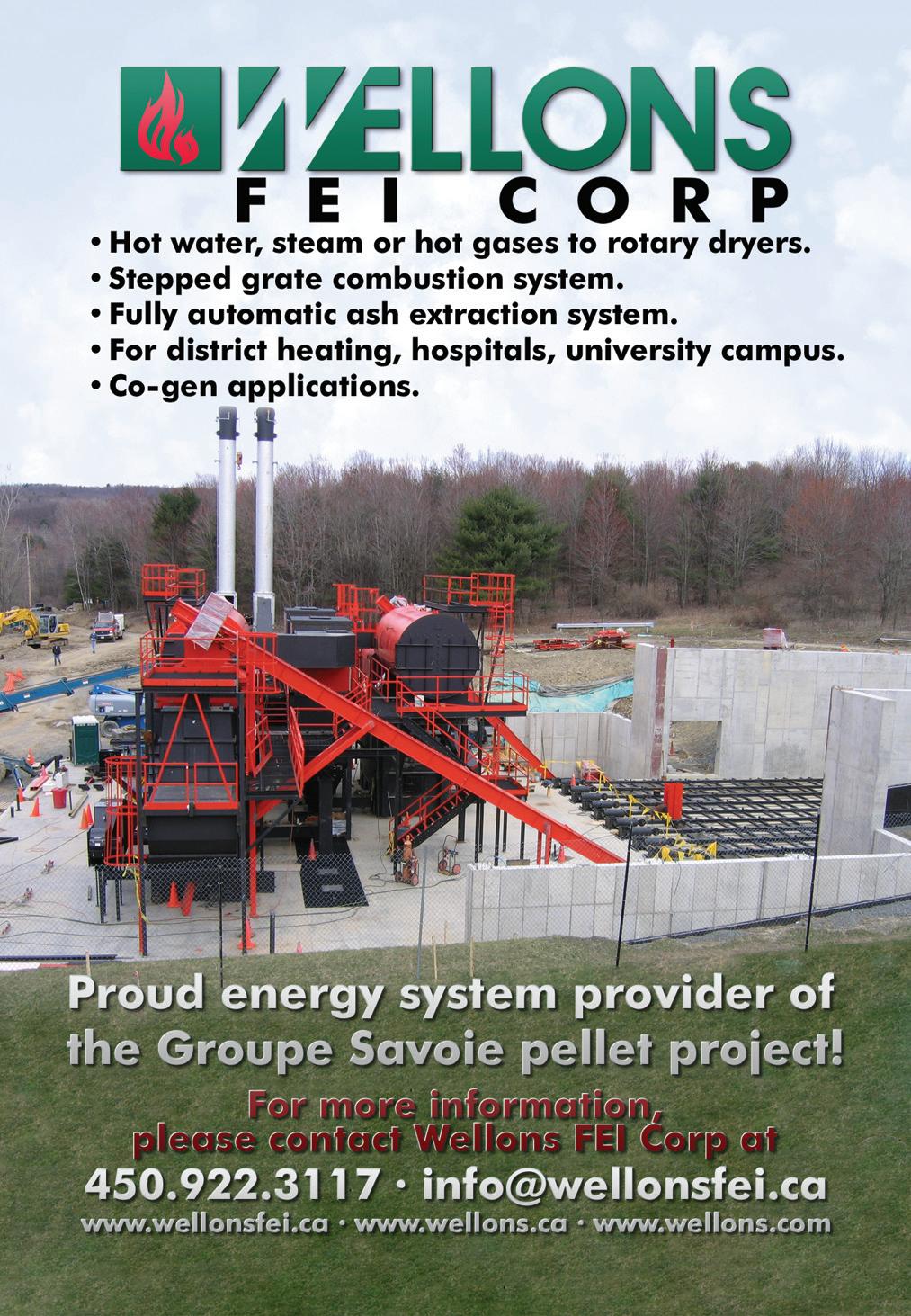

Sainte-Julie, QC – Groupe Savoie is investing in its northern New Brunswick sawmill operations by building a 55,000-tonne/ year wood-pellet plant. Using a Wellons FEI stepped grate combustor, the plant will burn bark to dry white wood in an M-E-C rotary dryer for the pelletizing process. The Wellons FEI stepped grate burner has an automatic ash extraction system, which makes it possible to burn wet bark without stopping operations to clean out the grate. Using bark for the drying process gives a use for this low-grade fuel and keeps all of the white wood

for the finished product. Many of the early pellet plants use part of the dry white fibre coming out of the dryer to operate a dry wood burner. This means up to 20% of the value-added production that leaves the dryer has to be burned to operate the dryer. With the Wellons FEI stepped grate burner, the wet bark can be burned directly in the combustion chamber without any special fuel treatment. Thus, the dryer yields 20% more value-added product or a 20% smaller dryer is required. The pellet plant is currently in construction and will be operating in spring 2010.

Chattanooga, TN – Astec Industries has acquired Industrial Mechanical & Integration (IMI), located in Walkerton, Ontario. IMI is a small company that has woodpellet-making machine technology. Rick Minke, president of IMI, and key employees have agreed to remain with the company to further develop and promote this new technology. IMI has been testing the technology for two years and is now making the first group of production machines.

"We are excited about the potential of this new technol-

ogy,” says Dr. J. Don Brock, chairman and chief executive of Astec Industries. “Conventional pellet production machines were designed for easy-to-use materials and do not always work well with a wide variety of wood species. With this acquisition, Astec Industries can provide a one-stop solution to customers desiring to own a pellet plant that can process material from roundwood all the way to the finished product. We are well positioned to be a turnkey supplier to the growing wood pellet industry.”

Halifax – Wood pellet manufacturer Enligna Canada is expanding its production capabilities in Upper Musquodoboit, Nova Scotia, to meet international demands. The province, through Nova Scotia Business Inc. (NSBI), is supporting Enligna Canada with a $2.42-million term loan. This financing will help the company improve and upgrade its pellet mill facilities. Headquartered in Germany, Enligna's Canadian operation is the fourth largest producer of wood pellets in Canada. The company uses sawmill, chipping waste, and other wood byproducts to

Winn, MI – Morbark, a manufacturer of wood reduction equipment, has forged an agreement with Heat Transfer International (HTI) of Kentwood, Michigan. HTI is a technology company that provides turnkey waste-to-energy biomass gasification systems. The agreement, which will create new jobs in Michigan, includes a manufacturing agreement for Morbark and an equity investment in HTI.

Morbark’s investment in HTI is in line with its vision of sus-

produce wood pellets.

tainable energy through responsible forestry. “Not only will we manufacture wood reduction equipment, we’ll be producing the systems which convert wood and other organics into usable electricity and steam,” says Lon Morey, president and CEO of Morbark. “Our agreement with HTI will allow us to manufacture large custom equipment systems with world-class quality, and will allow HTI to focus on managing the rapid growth of its exciting sustainable energy technology.”

"As a veteran exporter to European markets, we are seeing more and more demand for renewable energy sources such as wood pellets," said Fraser Gray, president of Enligna Canada. "This financing has helped us purchase new machinery to meet growing international demand for our products."

Enligna has expanded its operations on the former MacTara site and currently employs 58 people. The company works with about 20 independent harvesters who supply raw materials.

Drayton Valley, AB – Scrap treetops and branches from forestry operations in Alberta will soon be converted to electricity at the Drayton Valley Energy Campus. The Alberta government is providing $25 million to develop a waste-toenergy production facility in the town of Drayton Valley. Minnesotabased Otoka Energy Corporation is receiving a $20-million grant from Alberta’s share of the Canada ecoTrust for Clean Air and Climate Change. The project also received $5 million in July 2009 through Alberta’s Biorefining Commercialization and Market Development Program, administered by Alberta Energy.

“The Town of Drayton Valley is delighted to have Otoka Energy Corporation as part of our community,” says Drayton Valley Mayor Moe Hamdon. “We have a shared interest in finding clean, renewable

and rewarding energy solutions, and this project complements our bio-mile development, an ongoing initiative to create industrial development without waste.”

Otoka’s Drayton Valley Energy Campus will convert an estimated 380,000 tonnes/year of wood waste into electricity once the project is fully operational. The project will reduce Alberta’s greenhouse gas emissions by about 400,000 tonnes/year.

Otoka has plans to develop its Drayton Valley operations in three phases. Phase one includes the construction and operation of the Drayton Valley Energy Campus. The total cost of this development is estimated at $100 million. The next two phases are estimated to cost an additional $140 million and will add a methanogenic reactor to produce natural gas and an upgrader to produce ethanol.

Prince George, BC – The BC Bioenergy Network, a provincially funded industry association supporting the growing bioenergy sector in British Columbia, has announced funding of $52,500 to Initiatives Prince George to support the work of the Northern Bioenergy Partnership. The Partnership is an industry-led collaboration with government, communities, and the University of Northern British Columbia (UNBC) to establish northern B.C. as a leader in the bioenergy industry. Objectives of the Partnership include attracting further investment of capital in the bioenergy sector to serve growing demand for renewable energy globally and establishing an industry-led research initiative at UNBC.

“With the support of the BC Bioenergy Network, Prince George will lead the way in facilitating the growth of a competitive bioenergy cluster here in Northern British Columbia,” says Tim McEwan, president and CEO of Initiatives Prince George. “UNBC’s strength as a research institution and our region’s current leadership in commercial-scale bioenergy applications are strategic assets. This initiative will greatly support integrated economic development for the province of B.C.”

Des Plaines, IL – Italian power company Industria e Innovazione has selected Envergent Technologies’ rapid thermal processing (RTP) technology for the development of a facility to convert biomass into pyrolysis oil for renewable power

generation. The RTP works by rapidly heating biomass at ambient pressure to generate high yields of pourable, liquid pyrolysis oil. The oil can then be burned in industrial burners and furnaces for heat or electricity generation.

Industria e Innovazione and Envergent, a joint venture of UOP and Ensyn, have signed an agreement to pursue the development of an RTP facility to convert a mix of pine forest residues and clean demolition wood into pyrolysis oil. The facility

will be designed to process approximately 150 bone-dry tonnes/day of biomass to pyrolysis oil for the generation of renewable electricity. Envergent will provide engineering for the facility, which is projected for start-up in 2012.

Ferndale, WA – Sea 2 Sky Corporation has received the endorsement of the Lake Babine Indian Nation (LBN) of Burns Lake, British Columbia, to proceed with agreements to develop Lake Babine biomass resources for alternative energy uses in North America. LBN has substantial volumes of fibre under its control. It and other indigenous peoples have been in consultations with the BC Department of Forestry and various

industry sectors to develop these resources to improve the local economy by salvaging pinebeetle-killed trees to provide employment for local people in the bioenergy industry.

Sea 2 Sky would process the biomass locally for sale into the North American bioenergy market. LBN would provide the biomass. Sea 2 Sky is planning a local plant to produce pellets and other bioproducts.

Atikokan Renewable Fuels aims to take delivery of pellet mills in January 2010 to begin wood pellet production in March, reports Thunder Bay’s ChronicleJournal An assembly plant to manufacture pellet machines is also planned for Thunder Bay, Ontario. About 110 jobs could be created at the two plants.

The Williams Lake Tribune reports that the First Nations communities of Anaham, Redstone, Stone, and Toosey have purchased the Sigurdson Brothers Sawmill near Hanceville, British Columbia. The communities are exploring the possibilities of reopening the mill and building a bioenergy plant. Community members could be back to work by next summer if the economy continues to improve.

Michigan Wood Pellet Fuel is increasing its production and workforce to keep up with pellet demand, reports WZZM13. com. The company plans to fill two million bags of wood pellets in the next year, producing at 100% capacity.

Co-owners and brothers Stan and Dan Stasko broke ground for a new pellet plant in August 2009, reports Cornwall’s Standard Freeholder. However, the $80-million facility remains in the design phase. The Canadian Bio Pellet plant will be located in Ingleside, about 20 km west of Cornwall, Ontario. The plant is licensed to produce 360,000 tonnes/year of pellets when completed, with a planned capacity of 450,000 tonnes/year.

The province of Nova Scotia has approved the sale of timber from Crown land to the proposed NewPage Port Hawkesbury biomass power facility in Cape Breton, reports the Chronicle Herald. The approval should allow NewPage Port Hawkesbury to move forward with the project, which would supply electricity to Nova Scotia Power.

The Enfoui-Bec sorting and grinding plant in Bécancour, Quebec, is diverting waste wood from landfill to local power plants.

By Guy Fortin

Notall that long ago, wood waste from construction and demolition sites would have been landfilled in this part of Quebec, about 100 km east of Montreal. The contaminated mix of materials had no local value. The times have certainly changed, as a number of industrial waste specialists, among them Yvon Lemay of Enfoui-Bec Inc., are now recycling the maximum volume from this one-time waste stream.

For more than two years now, the company has been running a massive and dynamic sorting yard, spread across the company’s 200-ha site. With few exceptions, metal, concrete, plastic and, of course, wood from demolished buildings all find a second life here. Plastic remains the most problematic, but wood is not an issue. Since the recycling began, there has been a 30% increase in the volume of recycled wood waste going to the energy plants of neighbouring pulp and paper mills. It’s a long way from the company’s origin as a landfill site.

“In the 1980s, we would have received a fine if we did not bury pallet waste and other wood waste in our yard,” recalls Lemay, company president. “Still, I was stubborn even back then. I didn’t see the point in throwing away that wood, so I rented grinders to recycle it as best I could.”

This visionary entrepreneur had a point. Today that wood is

almost worth its weight in gold, thanks in large part to a localized shortage of waste wood for uses that vary from panel manufacturing to energy generation.

Mostly composed of softwood residuals from construction and demolition sites, chips from this site are suitable only for power plants. Still, that frees up purer sources for other forestry biomass needs. The proactive businessman’s approach is for the company to go out to the actual work sites and to collect the mixed waste itself. EnfouiBec manages an inventory of 150 waste containers of various sizes (12, 25, and 40 cubic yards). Relying on a business network built up over decades, these are sent to various construction and renovation job sites across the greater Trois-Rivières region (the regional centre across the Saint Lawrence River from Bécancour). These are then collected every two weeks (or sooner as required), and typically contain over 50% wood waste of different kinds.

On the south shore of the Saint Lawrence River, just below the massive Laviolette Bridge, the Enfoui-Bec site is a hive of activity. One

A Komatsu 300 works off the piles of sorted waste wood, feeding the Morbark 1200 XI tub grinder. Chips go exclusively to local pulp and paper power plants.

large area at the edge of the site is reserved for contaminated waste, another substantial area holds pulp mill sludge (the region is home to several pulp mills), and a third area holds concrete, asphalt, and brick waste. The pride and joy of the owner lies directly on the shores of the historic river. There, on almost five hectares of riverfront grow over 20,000 majestic hardwood trees planted in rows: walnut, oak, and ash. This gives a rural facade to the otherwise heavily industrialized site.

In all, 30 employees work for the company, of which a dozen work in and around the new sorting station. Large piles of bulk waste surround the building. Employees work to the rhythm of an immense vibrating conveyor, installed by Quebec supplier Vibrotech, and a complex dust collection system from another Quebec specialist, Concept-Air. A Komatsu 200 excavator from local dealer SMS Equipment uses a Rotobec recycling grapple to work from the tops of the piles, feeding a John Deere wheel loader that in turn feeds the conveyor. Fine materials are handled outside, and larger materials head inside. There, five employees drop various solid materials into their respective bins, all arranged around the perimeter of the building at ground level.

Dany Lemay, Louis-Marc Bourgouin, and Jacinthe Lemay, the owner’s nephews and niece, have been shareholders in the company for almost a year. Dany takes care of the sorting and wood recycling, and Louis-Marc manages the rehabilitation of contaminated soils and crushing of debris. Jacinthe works in accounting and administration. Raymond Lyonnais heads the overall operation as manager. The three shareholders don’t hesitate in qualifying their uncle as a visionary.

our Biomass video at www.jeffreyrader.com/videoB

LEFT: At the entrance to the sorting centre, bulk waste is placed on a Vibrotech vibrating conveyor. The centre is also serviced by a Concept-Air dust recovery system.

LEFT BELOW: Yvon Lemay manages some 200 hectares of land in Bécancour, almost all dedicated to extracting the maximum in recyclable material from the region’s construction and demolition waste stream.

“Even if he doesn’t say much,” Dany explains, “once he decides on a course of action, his decisions are precise, deliberate, and bang on.”

Over half of the volume of the solids recovered through the sorting is wood-based products from sites mostly within 40 km of the plant. Of this volume, the overwhelming majority is dry wood, although Dany adds that they are seeing an increasing volume of wet wood mixed in such as roots, trees, and branches.

“Right up until July 2008, we were using a Morbark Wood Hog 3600 horizontal grinder,” Dany says. “This worked very well on dry demolition and construction waste. But as soon as Yvon saw the Morbark Tub Grinder 1200 XI in action, which could double our production volume and handle the large roots and tree trunks we were starting to see, he bought it on the spot.”

The new Morbark grinder is supplied by Canadian distributor Cardinal Equipment and can produce up to 35 dry tonnes of chips per hour depending on the raw material, meaning that Enfoui-Bec’s annual production of 10,000 tonnes of chips is now expected to reach 13,000 tonnes. “We try to maintain a level of 1,000 tonnes of dry and wet chips each month to feed the paper mills. We have as many as five clients, although right now just one is truly active, and that’s Cascades.” In fact, two seven-hour days will meet that current demand with the right wood. “We can double our production when running wet wood,” Dany adds, revealing an oddity of the current Canadian grinding market in which biomass is bought by weight, rather than caloric value.

A Komatsu 300 with three-yard bucket supplies the Morbark, which in turns feeds chips to a Komatsu 380 wheel loader that builds the chip inventory. A company truck and 30-tonne trailer with live floor delivers the biomass to the client. At times the company’s 40-cubic-yard containers can be called into delivery service.

Foreign objects like iron, concrete, and rocks can make life hard for the grinder, although at the time of Canadian Biomass’ visit, there had been no major issues. “Our main problems remain plastic film and hard plastic pieces, as well as sand, which can contaminate our chips and which our clients do not appreciate. We have to be vigilant.”

More than 20 pieces of heavy equipment are at work sorting and moving Enfoui-Bec’s raw and finished goods. In addition to the Morbark grinder and seven Komatsu excavators, there are seven Komatsu wheel loaders, two bulldozers, two tractor-trailers, three container trucks, and a new Rubble Master crusher for the rock and concrete material. These millions in rolling stock allow the company to recycle over 85% of the material arriving on site.

Although wood constitutes the largest volume recycled annually, more than 25,000 tonnes of pulp mill sludge is also transformed into compost each year. This sludge occupies several hundred acres of the site and will stay there for three years before being screened and used as compost. There is also a site dedicated to applying oxygen and necessary nutrients to contaminated soils for their rehabilitation. Enfoui-Bec also started a crushing service late in 2008 to handle concrete, brick, and asphalt for the roadbuilding sector. All that remains to be landfilled is a small portion of plastic and other non-recyclable material such as asphalt roofing shingles.

Despite more than 25 years of use, a large portion of Enfoui-Bec’s landfill area is still available for service. The secret? The company’s penchant for recycling has greatly increased the lifespan of its on-site landfill. “Right now it’s actually impossible to say when the landfill site will have to close,” Dany concludes. “There are in fact parts of it that still contain recyclable material, if we can get to them.”

And even though municipal regulations changed after January 2009 to disallow the landfilling of dry materials in the region, the company has access to another site less than 40 km away that will allow it to continue disposing of its increasingly smaller volume of true waste material. •

Guy Fortin is editor of Opérationsforestièresetdescierie,CanadianBiomass’sister publication serving Canada’s French-speaking solid wood products and forestry markets. He is based in Montreal and has been covering this market for over 30 years.

In just five short years, British Columbia’s Pinnacle Pellet has increased production more than tenfold. Its latest plant is a streamlined affair that runs 24/7 to keep up with the demand from a “substitution-fuel”-hungry energy market.

By Bill Tice

thelatest pellet plant to grace British Columbia’s Cariboo country has been up and running now for just over a year. In that time, the plant staff has forged an economic and environmental success story in what has been an extremely tough period for a region that relies heavily on the forest industry for its economic strength.

The plant, called Meadowbank, is the latest addition to British Columbia-based Pinnacle Pellet, a home-grown company that has blossomed from producing just 60,000 tonnes/ year of wood pellets from one plant in 2004 to a group of five plants that today churns out a combined volume of close to 750,000 tonnes of wood pellets annually.

“Just at this plant alone, we are capable of producing over 200,000 tonnes of wood pellets on an annual basis,” says Jack Levesque, plant manager at the new facility, which is strategically located about 70 km south of Prince George and adjacent to the major north–south thoroughfare for the province, Highway 97.

Levesque is like a proud parent as he shows off the plant. “This is a very efficient facility,” he explains. “It was designed on a small footprint, which minimizes material handling and streamlines the process. We can operate 24 hours/day, seven days a week, with a total of just 24 people.”

In addition to the efficiency of the new plant,

Levesque says the facility’s ravenous diet of sawmill residuals has had the environmental benefit of extinguishing several sawmill burners in the region. In the past, these burners were the main method of disposing of unwanted sawmill waste. “We’ve shut four burners down since we started up,” he explains.

“That includes the Dunkley Lumber mill just next door to us, Canfor’s Clear Lake Sawmills near Prince George, and both the Conifex and Northern Interior Forest Products burners in Fort St. James.”

Most of the sawmill residuals from nearby

mills are trucked to the Meadowbank plant by Arrow Transport in trailers with walking floor systems. Residuals from further afield, such as the fibre making the four-hour trip from the mills in Fort St. James, are shipped in larger Btrains. The plant also uses what Levesque calls “mill grind”, which is essentially solid waste products from sawmills, including trim blocks, bark, and log ends. This material is trucked to the pellet plant, and then an on-site Peterson 4710 portable grinder owned by Pinnacle and a Morbark drum grinder operated by a contractor process the material to usable fibre for the

plant. “This is essentially any solid wood waste that sawmills can’t use, but we can,” Levesque explains.

Another growing source of fibre for Meadowbank is bush waste, which includes stumps and limbs left over from logging activities. Currently, this represents up to 30% of the fibre required for the plant, but Levesque says they expect that number to grow in the future. He

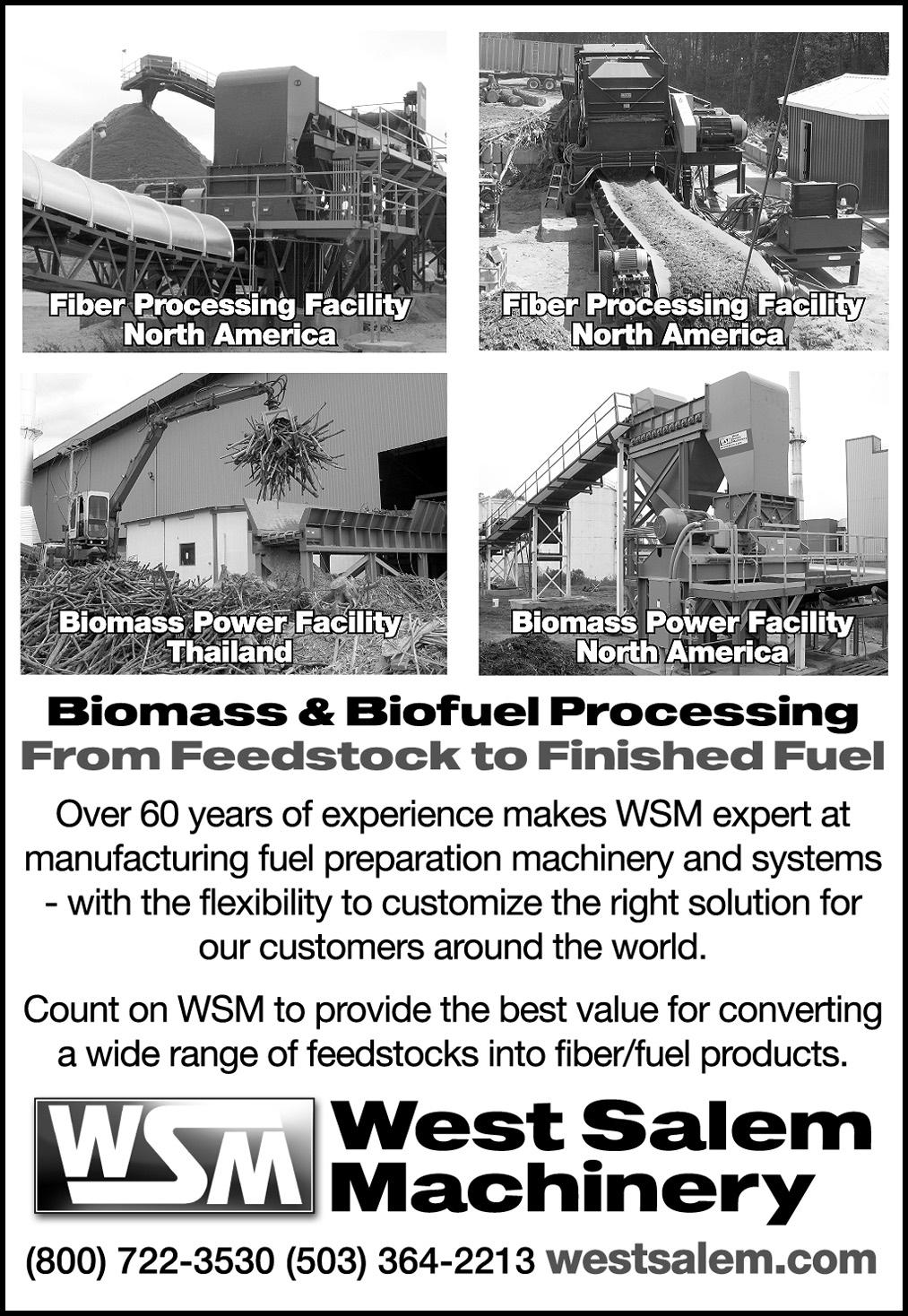

adds that the bush waste is ground at the logging block to a four-inch size and then further refined at the plant with a large stationary hogger manufactured by West Salem Machinery.

The mill’s dependence on fibre is evident from the huge piles of sawdust, mill waste, and logging debris that surround the infeed to the

plant, and the continuous flow of trucks that back up to the facility’s hydraulic tipper where their trailers are emptied. A pair of Cat 950 wheel loaders moves most of the fibre from the storage piles to one of the mill’s three infeed bins, one of which is reserved for shavings that have been placed in covered storage on arrival at the plant, as they are already dry and can bypass Meadowbank’s drying process.

From the infeed bins, all material goes to one of two Bliss hammermills, where the fibre is further refined to a more consistent product that is better suited to pellet production. Next are the mill’s massive dryers, a pair of M-E-C

S1360 single-pass drum models that measure 60 feet long and 13 feet in diameter.

The next step is for the material from the dryers to be fed into a surge bin and then to one of six Andritz Sprout pelletizers, where natural resin from the wood binds the product together, and metal dies form the quarterinch round pellets. From the pelletizers, the pellets drop to a cooling bin and then a vibrating conveyor system that features Optimil screens, where any fines drop out. The fines and any leftover dust are collected and used to power the mill’s dryers. The finished pellets go to either a 3,000-tonne storage silo or

a 100-tonne rail load-out silo, both manufactured by Westeel. The load-out silo sits above a CN Rail spur that can accommodate up to 27 rail cars. The rail cars are loaded using a method similar to grain handling.

Smaller but necessary equipment used in the Meadowbank plant includes Grecon spark detectors that are positioned at various points in the process, rare earth magnets for detecting any metal that may have been inadvertently introduced to the system, two MoistTech in-line moisture sensors to check the moisture content of the product coming out of the dryers, and a Baldor 500-kW generator. Levesque says the generator is an important safety feature, as in the event of a power outage, it will automatically kick in, powering the dryers and the fans that keep the product moving through the system. “If everything just stopped it could create a fire hazard in the dryers, so this is a critical piece of equipment for us,” he explains.

All pellets from Meadowbank are transported by rail to the Port of Vancouver, where they are loaded onto ships for major markets in Europe, including the Netherlands, Belgium, and the United Kingdom.

Pinnacle Pellet’s president Craig Lodge says that the design, planning, and construction of the Meadowbank plant took just over 10 months and was a team effort. He notes that the actual construction was done in about 100 days, but planning, permit approvals, and securing suitable fibre contracts took the extra time. While building the plant, Lodge says they turned to other Pinnacle

plant managers and internal specialists for input, and worked closely with major contractors that included Del-Tech’s BID Construction Group in Prince George, Service Electric in Quesnel, and Allied Blower in Williams Lake.

As for the timing and location of the Meadowbank plant, Lodge says they have three basic requirements when looking for a location for a pellet plant. “We need access to raw material, we need access to a power supply, and we need access to a rail line. In this case, we had all three.”

Lodge also notes that the best scenario is to be close to a host sawmill for the raw materials, and Dunkley Lumber, which is just 4 km away, fit the bill. “We have a company objective to grow the business when suitable opportunities arise, and Dunkley had an uncommitted supply of sawmill residuals,” he explains. “It was a good fit.”

He also says the process has been getting easier with each facility they build. “When we built the Meadowbank plant, we enjoyed the fact that it wasn’t the first time through this process for us,” he says, referring to their past track record, which includes building

three successful greenfield pellet plants –the two south of Meadowbank at Quesnel and Williams Lake, and another plant to the northwest in Houston, B.C., that is jointly owned by Pinnacle, Canadian Forest Products (Canfor), and the Moricetown First Nation. The company’s only other pellet plant was an existing plant they acquired in Armstrong, B.C. “Every time we build a plant, we gain experience and we take the best of what we have learned and incorporate it into our next project,” Lodge adds.

As for plant manager Levesque, he came on board in August 2008, when most of the construction was complete. He says that although he missed the permitting, approval, and construction stages, he was here to experience the plant’s start-up curve first hand. “We had our challenges, but we had a great group of people and we got through it,” he says. “It was a tough winter in terms of weather – very harsh, long, and cold – so it took some work to get the dryers where we wanted them. And with all of the sawmill shutdowns and curtailments last year, we had to make sure we had a sufficient source of fibre.”

Looking down the road, both Levesque and Lodge say they foresee steady growth in biomass and the wood pellet industry over the next decade. “We believe the utilization of biomass will continue to grow,” says Lodge, who grew up in a logging family in Fort St. James, B.C., and is a forester by profession. “Biomass is environmentally friendly, it is derived from a source that is ultimately renewable, and pellets will continue to play a key role in the industry as they provide an efficient way of providing fuel for biomass power.”

It’s an opinion shared by many, especially in Europe, Japan, and Ontario, where Lodge says wood pellets are increasingly viewed as a substitution fuel for coal or other fossil fuels. With an investment in Meadowbank of nearly $25 million, it’s also an opinion Pinnacle is banking on. •

Bill Tice is Canadian Biomass’ western editor based in Vancouver. In addition to working in the forest industry for such companies as Canfor and West Fraser, Bill has been covering the forest sector for more than 20 years.

JANUARY 11-13, 2010 • Pacific West Biomass Conference & Expo Sacramento, CA 701-746-8385 or service@bbiinternational.com http://pacificwest.biomassconference. com

JANUARY 26-27, 2010 • Energy from Biomass and Waste London, UK www.ebw-uk.com

FEBRUARY 2-3, 2010 • Pellets 10 Söderhamn, Sweden +46-8-441-70-77, +46-73-941-70-11, or Jonas.Hoglund@svebio.se www.svebio.se/?p=1388

FEBRUARY 3-5, 2010 • RETECH 2010: Renewable Energy Technology Conference & Exhibition Washington, DC www.retech2010.com

FEBRUARY 15-17, 2010 • National Ethanol Conference Orlando, FL www.nationalethanolconference.com

FEBRUARY 23-25, 2010 • Renewable Energy World Conference & Expo Austin, TX 918-831-9736 or rewna-conference@ pennwell.com www.renewableenergyworld-events. com/index.html

MARCH 3-5, 2010 • World Sustainable Energy Days & European Pellet Conference Wels, Austria +43-732-7720-14380 or office@esv.or.at www.wsed.at

MARCH 16-17, 2010 • Global Wood Fiber Conference: Trade in Woodchips and Biomass São Paulo, Brazil www.pulpwoodconference.com

MARCH 18-21, 2010 • Bois Energie Saint Etienne, France www.boisenergie.com

MAY 4-6, 2010 • International Biomass Conference & Expo Minneapolis, MN 701-746-8385 www.biomassconference.com

OThe connection between comminution and transportation is a key link in the supply chain.

By Mark Ryans

ne of the critical cost points in the recovery of roadside residues is the interface between the comminution and transportation phases. In Canada today, the most common recovery method is to discharge the comminuted material directly from the chipper’s blower or grinder’s conveyor into a van. This is known as a “hot” biomass recovery system.

Large grinders and chippers are capable of very high outputs of 25 dry tonnes/hour or more, so a standard van can be loaded in 30 to 40 minutes. With a steady diet of easy-to-reach residues, one or more trucks need to arrive each hour. However, the ideal scenario of having a truck always under the spout is rarely achieved on a continuous basis. Contractors running inwoods chipping operations know this scenario well: a truck is often waiting to be loaded. A worse case is an idle grinder waiting for a truck to arrive. The nightmare scenario is a line of trucks waiting as the grinder moves locations because it has run out of readily available biomass. Add mechanical breakdowns to the mix, and it can easily snowball into an inefficient operation.

A large grinder with a suitable loader and grapple will cost $350 to $500 per productive machine hour, including wages. The operating cost is high because capital costs can run up to $1 million, and there are substantial added fuel costs. An even more important factor is the utilization rate, defined as the productive time divided by the scheduled hours. In a hot system, a high utilization rate is hard to achieve. In fact, in most of FPInnovations’ studies conducted to date, the average utilization rate is rarely above 65%. This puts the owing and operating costs on a smaller number of machine hours.

Truckers are often the first to complain about excessive queuing times at either end of the trip. One way of solving excessive queuing times at the grinder in the bush or for unloading at the mill is to reduce the number of trucks. However, it doesn’t make sense for

the most expensive machine in the system to be waiting for a truck, whose operating cost is three to five times less. To further complicate matters, the overall efficiency of the system is not only controlled in the woods, but also at the mill. Short unloading times are needed at the plant to reduce queue times. However, unloading schedules become harder to control as the scale of operation increases, with a greater number of deliveries from numerous suppliers. The unloading capacity at the plant often needs to be improved.

Juggling truck arrivals and mill deliveries and optimizing the grinder utilization rate is a difficult task.

A more efficient system can be achieved by better planning, starting with having a good handle on the volume of residues, their location, and their preparation prior to the arrival of the chipper or grinder. Some factors to consider include:

bulldozer. Pre-piling operations should plan where the grinder will be stationed.

For a trailer-mounted chipper, pile residues as high as possible, close to the road. For a machine with a discharge conveyor, establish stations within the residues; To reduce fuel consumption, shut down

• the grinder when there is no van; Forwarding residues to central locations

•

may be an option, but Canadian examples are few;

Monitor productive time and downtime

Scope out the residues to get a better es-

• timate of volume, concentration, travel distance, and road conditions; Owning the trucks can allow better con-

• trol and balancing of the transportation phase;

• daily to manage utilization rates.

If the same contractor is conducting the

• conventional harvest, handle and organize the residues for optimal recovery. Clean residues result in less downtime throughout the supply chain;

If there are separate operations, pre-pile

• the residues in advance. This concentrates the debris for easier handling and improves the quality by reducing moisture content and contamination. Do not use a

It is also possible to use alternate recovery methods that separate the comminution from the trucking, which I will discuss in upcoming columns. Methods include: “cold decking” the comminuted material close to the roadside and then loading it into a van in an independent operation; using containers to ship uncomminuted residues (typical in Sweden and also used by a couple of operations in British Columbia); and bundling residues for transport on self-loading logging trucks. •

Mark Ryans is with FPInnovations’ Feric division and can be reached at mark.ryans@fpinnovations.ca.

Biomass and bioenergy are moving beyond processing methods to project development as the industry takes off in Canada.

By Heather Hager

therewas a whole lot of networking going on at the Canadian Bioenergy Association (Canbio)’s annual conference and trade show. Over 100 participants and various exhibitors from Canada, Finland, and Sweden converged on Edmonton in late October 2009 to discuss Canada’s developing biomass economy. Topics during the two days of talks ranged from biomass supplies, quality issues, and harvesting guidelines to emerging biomass technologies, project overviews, and financing. The conference concluded on day three with a tour of local upcoming projects such as Enerkem’s waste-to-ethanol facility and Highmark Renewables’ massive anaerobic digester.

Canbio VP Prairies Jamie Bakos opened day one by setting three goals for the conference. He challenged each participant to make

10 new contacts and to strengthen relationships with existing contacts, with an overall goal of moving the biomass business forward. Certainly, participants were keen to meet these challenges, as was evidenced by the bustle of activity. During breaks throughout the conference, participants could be found visiting the adjoining trade show and talking with fellow attendees.

The first topic of the day, and the primary consideration in any bioenergy project, is where to get a long-term supply of biomass. Prior to the recent major sawmill shutdowns, there was plenty of sawmill residue to go around and more, says Douglas Bradley, Canbio president. Over the past couple of years, however, that surplus has disappeared, and operations have had to find residue elsewhere or shut down.

So the focus has shifted to nonmerchantable timber and slash, previously ignored because of high costs associated with its removal and delivery.

But bioenergy developers aren’t always involved in forestry. “Bioenergy companies don’t necessarily want to manage the forest, but rather, they want to concentrate on the new bioenergy industry,” remarks Larry Stanley of Saskatchewan Energy and Resources. This means that bioenergy companies are looking to contract long-term biomass supplies from reliable providers.

The move to forest-based sources of biomass brings its own issues. “The weakness we’re seeing across Canada is a lack of emphasis on the quality of forest residues that suppliers are delivering,” notes Mark Ryans of FPInnovations. “The customer sets the feedstock requirement, and wants homogeneous and predictable

quality.” He says the top three quality factors are appropriate moisture content, consistent particle size, and clean material.

The seasonal variability of the resource means that suppliers need to figure out how to deliver a year-round supply with appropriate moisture content. Methods such as pre-piling and covering with a tarp are being tested. A 10% reduction in moisture content can have a good return on investment because it means a supplier transports more energy content and less water per tonne of biomass, says Ryans.

Of course, a discussion of the biomass supply would not be complete without considering sustainability. These days, the public perception is that bioenergy will cause the large-scale decimation of old- and second-growth forests. An overview of provincial forest residue harvest policies and guidelines by experts such as Evelyne Thiffault of Natural Resources Canada, Don Gosnell of the British Columbia Ministry of Forests and Range, Pat Guidera of Alberta Sustainable Resource Development, and Larry Stanley of Saskatchewan Energy and Resources indicates otherwise. Rather than burning slash in the field or leaving it at the roadside, some provinces are now re-allocating leftover fibre to

On day two, a panel of resource specialists discussed forest residue harvesting policies. Left to right: Don Gosnell, B.C. Ministry of Forests and Range; Pat Guidera, Alberta Sustainable Resource Development; Larry Stanley, Saskatchewan Energy and Resources; Evelyne Thiffault, Natural Resources Canada; JP Gladu, Aboriginal Strategy Group.

other parties if the primary harvester does not want to use it. Other provinces are implementing guidelines for where and how much biomass can be removed with the timber harvest.

Uses for the harvested and delivered forestbased biomass are expanding as new technolo-

gies move forward. Gasification, cellulosic ethanol, biorefining, pyrolysis, biocarbon—these are the potential future of biomass. Presenters from Enerkem, Lignol, Taylor Gasification, and Alterna Energy talked about the status of their technologies and projects and answered attendees’ questions about settings and specs. Participants also heard from individuals and

groups from Finland, Sweden, and Canada that provide project development services. As more experience is gained in putting together bioenergy projects, it makes sense to take advantage of that knowledge and avoid past mistakes. Several speakers stressed the importance of using proven equipment and technology to avoid failures and develop good projects as successful demonstrations. “The new stuff will be developed later,” says Jouko Parviainen of Wenet (Wood Energy Network), Finland.

An example of a highly successful project in eastern Finland was presented by Dominik Röser of Metla (Finnish Forest Research Institute). The Eno Energy Co-op uses local biomass resources to provide district heating for the municipality. According to Metla, about 52% of forest in Finland is privately owned and supplies 80–90% of wood used by the forest industry. After several years of planning, the co-op began in 1999 with just 12 members. It now owns two and operates three combustion plants supplying district heating and boasts 51 members. It is one of the most visited projects in the European Union as a successful model of district heating, says Röser. The project resulted in cost savings by replacing more expensive

oil heating and created jobs in the community.

A Swedish example of efficient biomass use was provided by Christofer Rhén of GreenExergy, which designs and commissions combined heat, power, and pellet (CHPP) plants. Two reference plants have been producing CHPP in Sweden since 1996 and 2008, respectively. Adding pellet production to combined heat and power (CHP) results in greater efficiencies of energy use, even with wet biomass, says Rhén. He estimates efficiencies at 35% for electricity alone, 88% for CHP, and up to 98% for CHPP.

Up-and-coming showcase technologies and projects provide examples of where the bioenergy industry can go, but unless a person is independently wealthy, capital investment and financing are a second key consideration. A show of hands elicited by Reg Renner of Atticus Financial indicated that various participants were actively seeking financing for equipment and other costs. However, a second show of hands, or rather of no hands, revealed the absence of people looking to finance bioenergy projects.

“Preparing a project to apply for financing is like training for the Olympics,” says Renner. Focus, a coach and team, equipment, timelines,

and preparation aren’t just for world-class athletes, he says. They can go a long way towards showing a potential financier that the project can be successful and profitable.

“You must prepare to approach an investor like you’d prepare for a job interview,” says Corey Keith of Keith & Associates. “Make sure you do your homework.” He emphasises that a clear, simple, targeted approach is best and that potential investors will want to know that worst-case scenarios can be addressed successfully. A realistic valuation of the enterprise is critical. Keith notes that most applicants on the Canadian television show Dragon’s Den fail to hook an investor because they value their company at way more than it’s worth.

There’s enough biomass available in Canada to support many more projects, be they wood pellet plants, biorefineries, community heat and power, or industrial CHPP. The cost of accessibility is the limitation. In Europe, people are willing to pay more for wood energy because they value it as more environmentally responsible than fossil energy, says Röser. Biomass and bioenergy must also become more valuable in Canada to support the domestic industry’s expansion. •

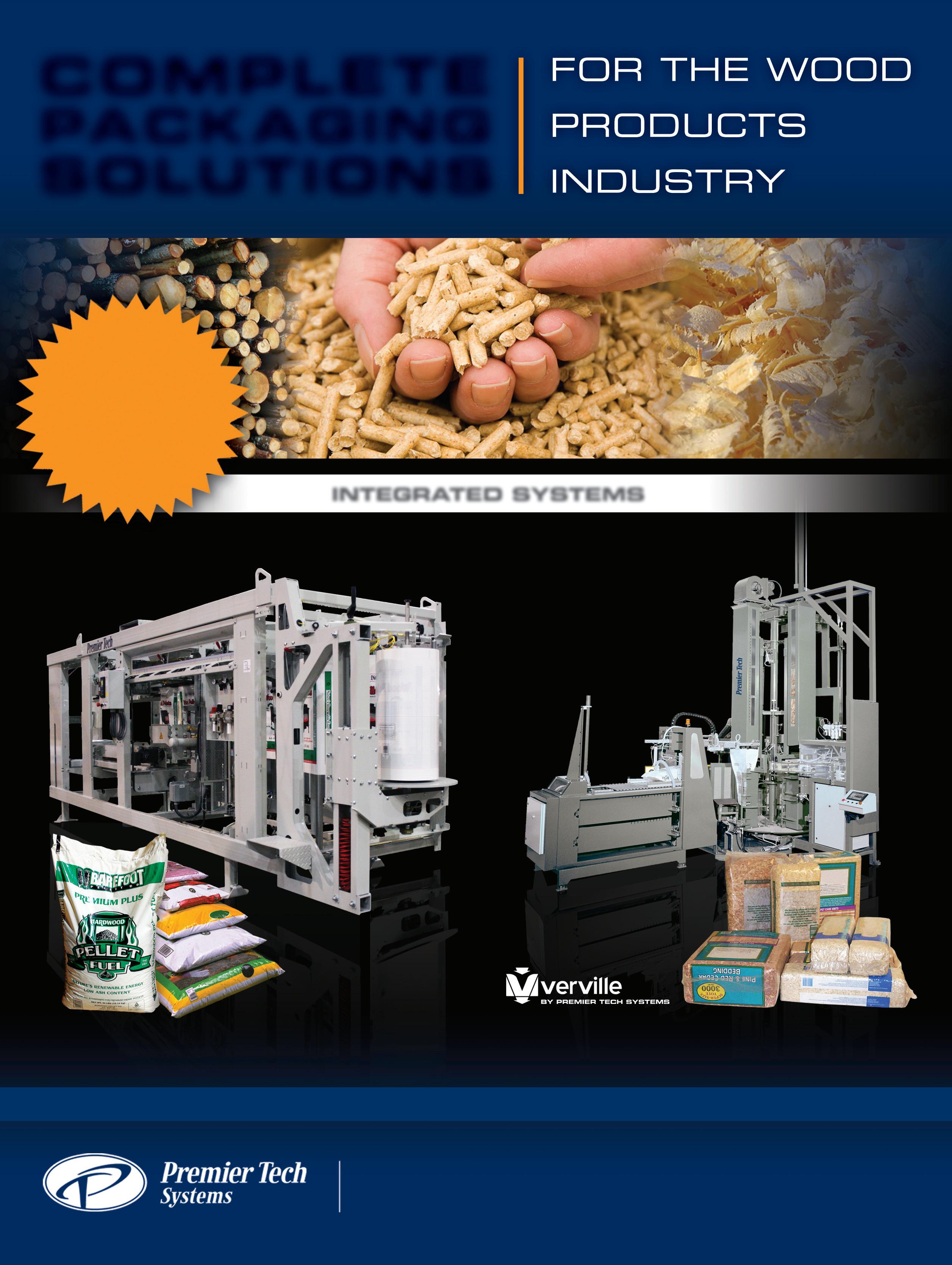

Bandit Industries provides the equipment necessary to produce low-cost wood fibre and agricultural residues for the growing bioenergy market. Its complete line of biomass chippers and high-capacity horizontal grinders transforms unused biomaterial into a valuable, marketable product. Users can produce dimensional chips for wood-fired boiler systems, a uniform sawdust-like product for use in pellet operations, and can even convert agricultural residues such as grass and straw into valuable biomass feedstocks. Bandit offers six drum-style whole-tree chippers and four Beast Recyclers.

www.banditchippers.com, sales@banditchippers.com, 800-952-0178

doing something special for our annual guide to portable/mobile chippers and grinders this year. To make the equipment more accessible to our readers, we provide a short list of specs for each manufacturer to give an idea of what’s available in technology and capacity to suit a user’s needs. All information has been supplied by the manufacturers and assembled by Canadian Biomass into one easy-to-read reference guide. Contact the manufacturer or local dealer for more information. – Compiled by Melissa Damota

The Bruks 805 forwarder-mounted chipper with self-contained chip bin enables offroad chipping and transportation of the chips back to a roadside trailer. The chip bin raises and dumps into any chip trailer. With high-capacity chipping of logging residue and whole logs, this machine is highly flexible and mobile. It mounts on any brand of forwarder and has computerized control systems and load-sensing hydraulics.

www.mobilechippers.com, sales@bruks.com, 770-849-0100 ext. 132

Model

Infeed opening (inches)

x28.5

x 35.5

Configuration options Forwarder-mounted Trailer, truck-mounted

Made to grind and regrind, Duratech’s industrial grinders can handle biomass materials from stumps and logs to slash, pallets, and green waste. Turn your waste into useable cogeneration fuel in no time with help from a powerful Cat engine featured in each grinder. Duratech affordable grinders are built to tackle heavy-duty jobs and come available with a pintle hitch, fifth wheel, or on tracks. www.duratech.info

Model 2009 3010

Engine (hp) 325 475 or 540

Infeed opening at flare 9 feet, 6.4 inches diam. 10 feet diam.

Configuration options Pintle hitch, 5th wheel, 5th wheel w/goose neck hitch, track Pintle hitch, 5th wheel, track

These industrial grinders handle a range of biomaterials.

Diamond Z offers a broad range of new and used tub grinders, horizontal grinders, and metal recycling equipment designed to suit any industrial application. Diamond Z grinders are powered by Cat engines. From high-volume composting to disaster cleanup and from land clearing to stockpile tire disposal and solid waste reduction and recycling, Diamond Z provides performance for the job. www.diamondz.com, diamondz@diamondz.com, 800-949-2383 or 208-585-2929

Model

(inches)opening

x

Configuration options Trailer, track, track with transport Trailer, track with transport Trailer, track with transport

The 1200-hp DZH7000 tackles large-scale projects.

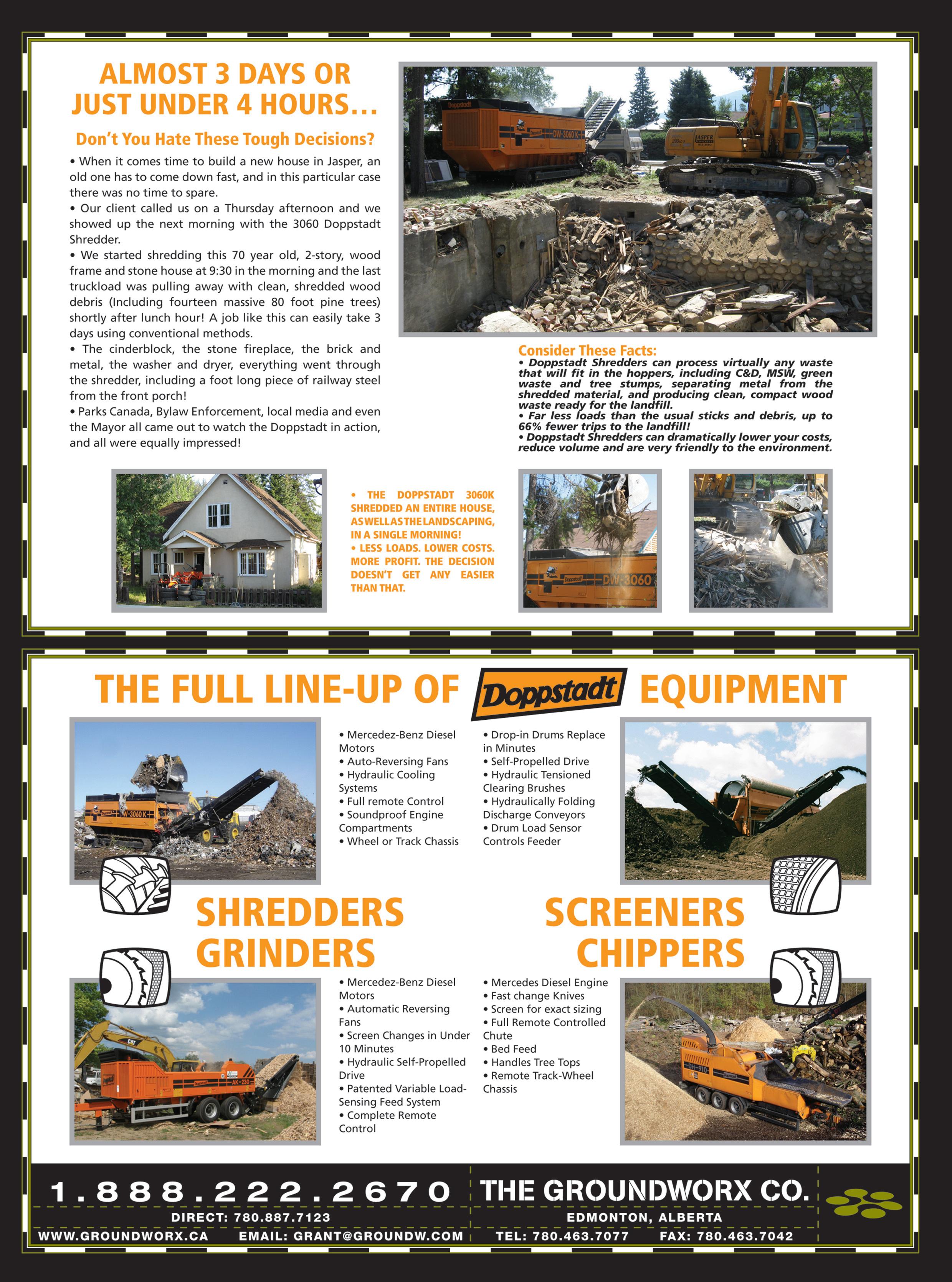

Doppstadt offers a complete range of shredding, grinding, chipping equipment, and trommel screens for wood biomass and waste processing. Its AK grinders, powered by Mercedes Benz diesel motors, process any kind of woody biomass from tree stumps, green waste, and slash to railway ties and demolition debris. Its DW shredders have slow-speed, high-torque, heavy-duty design rotors with hydraulic release for built-in protection against unshreddable contaminants. Doppstadt is a one-stop solution for biomass and recycling operations. Voghel (eastern Canada) and Groundworx (western Canada) are the Canadian distributors for Doppstadt. www.voghel.com, info@voghel.com, 514-990-6636 www.groundworx.ca, 888-222-2670, 780-887-7123

For more than 30 years, Rawlings Waste Wood Recovery Systems has manufactured and marketed several series of portable and stationary wood grinders. It offers these machines in electric or diesel on stationary, portable, and skid-mounted systems. Both vertical and horizontal models are available in various sizes to produce your desired finished requirements. Rawlings is dedicated to advancing this technology and providing excellent support to their customers. www.wastewoodhogs.com

Numerous options supply a range of project requirements.

Morbark manufactures equipment for a variety of applications involving wood and organic materials, including forestry, sawmill, tree care, and recycling. The product line runs from hand-fed chippers to self-feeding whole-tree chippers, tub and horizontal grinders, debarkers, sawmill equipment, and attachments to get the job done. The equipment is available in towable versions, track, or electric powered. Morbark’s extensive line of equipment is known for uniform predictable quality, tailored to meet the customers’ needs for many years. www.morbark.com, 800-831-0042

Peterson Pacific continues to produce high-production chippers, horizontal grinders, and blower trucks. For 2010, Peterson is introducing the new 4300 drum chipper. It’s designed for biomass producers who have wide variety of feed material from logs up to 26 inches in diameter to brush and small feedstock. Powered by a Cat C18, the 4300 is available in three power ratings: 630, 700, and 765 hp. www.petersoncorp.com

Vermeer Canada offers a large variety of brush chippers, horizontal grinders, and tub grinders for demanding jobs. Vermeer provides powerful options, including Cummins, Cat, and John Deere engines. New progressive products and attachments are available for the product line, such as Vermeer’s new Fuel Chip Attachment for the HG6000 grinder. This attachment converts the machine from grinding to chipping in a short time. Visit Vermeer’s website to find its nearest Canadian location. www.vermeercanada.com

Rayco’s new line of compact horizontal grinders and 8-inch capacity chippers creates affordable solutions for your wood waste needs. The RH1754 grinder and RC814 chipper are easy to tow and manoeuvre while saving on fuel consumption. The RH174 is designed to grind pallets, brush, green waste, lumber scraps, and construction debris. It is easily moved behind a one-ton truck or self-propelled on small job sites that are inaccessible to larger machines. The RC814 is equipped with VersaFeed automatic feed control, hydraulic down pressure, and feed wheel lift, with diesel engine. www.raycomfg.com, 800-392-2686

GRINDERS CHIPPERS

Model RH1754 RC814

Engine (hp) 140 44

Infeed opening (inches) 17 x 54 8 x 14

Configuration options Track 2-inch ball hitch

Rotochopper horizontal grinders are the “perfect in one pass” solution for producing biomass fuel from forestry slash, whole trees, slab wood, and other wood fibre resources. Rotochopper’s distinctive grinding rotors deliver finished products with less downtime, lower chipper knife wear, and better efficiency than typical grinder teeth. The system can produce a half-inch or smaller end material that packs densely into trailers in a single pass. www.rotochopper.com, info@rotochopper.com, 320-548-3586

GRINDERS

Model B-66 MC-266

Engine (hp) 765 475 - 540

Infeed opening (inches) 66 x 32 66 x 18

Configuration options Trailer, track, track & transport dolly-mounted Trailer, track

Universal Refiner’s Hypocyclonic Action Waste Grinder (H.A.W.G.) is simple, durable, and fast. It shreds waste using a unique pan and disc system and will grind almost anything to a finished product in one pass. The R-MAG portable wood waste grinders can grind lawn clippings, leaves, land clearing waste, construction/demolition waste, logging slash, stumps, railroad ties, and storm waste. The simple design and construction makes them nearly indestructible, resulting in a long running life. www.universalrefiner.com, UniversalRefiner@techline.com, 800-277-8068 GRINDERS

Heavy-duty model 460 is designed for high-production biomass producers. The unit is designed with a straight-in opening that allows whole trees and large tops to be processed with ease. It is equipped with a 50-inch diameter by 60-inch wide cutting drum. www.woodsmanchippers.com, sales@woodsmanchippers.com, 989-588-4295

Model 460

Engine (hp)

630–1125

Infeed opening (inches) 32 x 60

Configuration options Track, 5th wheel, loader/cab

Aftera huge success in 2008, World Bioenergy is back. The 2010 event is slated for May 25–27, and once again, the Elmia organizers have taken a threepronged approach to maximize attendee travel dollars, with tours, conference, and trade show. The 2008 event drew almost 4,500 highly specialized visitors from over 60 countries, with a large Canadian contingent. Despite a slower overall economy, global interest in biomass and bioenergy means that interest in World Bioenergy 2010 will be higher still. Visit www.worldbioenergy.com for more details.

Visitors are picked up from their flights at airports in either Stockholm or Copenhagen on May 24 and enjoy a coach tour of bioenergy sites en route to the Elmia conference centre and opening reception in Jönköping. Following World Bioenergy, tours will stop along a different route while taking visitors back to their airports in time for evening trans-Atlantic flights. The tours offer attendees the chance to see a bioenergy economy in action.

The driving focus in 2010 is on applied and currently available technology, as well as efficient, sustainable, and economic solutions. In brief, the focus is on bioenergy solutions that work. Visitors can choose from the following themes, each complemented by related exhibitors and daily study tours.

1. Combined heat and power, combustion, heating and co-firing

A range of technologies and installations will be presented, not only boilers and burners, but also fuel handling, logistics, flue gas cleaning, and other support systems. Study tours visit combined heat and power plants in the Jönköping region.

2. Forest residues – Slash, stumps, small tree harvest

World Bioenergy repeats the popular slash conference from Elmia Wood 2009. How to recover biomass from felling and thinning operations, plus environmental effects, and ash recycling. Learn from the Scandinavian experience. View machinery and equipment at the exhibition, and take one of the daily excursions to see chippers working at a forest site.

3. Pellets – The new large energy commodity

Learn about market development, production technology, projects and investments, new burner technology. Take a study tour to a pellet factory.

4. Waste to energy

Waste is available in every society. It can be used for heat and power

Three full days of business-based presentations from around the world makes it easy to justify this event to the bean counters. Talking is often mixed with walking at World Bioenergy, as daily local facility tours are part of the program. The 2010 themes have been selected and range from materials and uses to bioenergy policies (see sidebar for details).

A blend of indoor booths (technology, technical experts, finance, engineering, new equipment) and large outdoor show (the big forestry and processing gear), World Bioenergy 2008 boasted over 200 exhibitors in the bioenergy field, most showing new technology and equipment. Look to Canadian Biomass and www.canadianbiomassmagazine.ca for regular updates.

production, and for biogas production, through fermentation or thermal gasification. Modern combustion and cleaning methods guarantee low emissions. Daily tours visit a waste incineration plant and biogas production units. A pre- or post-study tour drops by a willow waste-water treatment plant.

5. Energy crops, agricultural residues, and byproducts

Sugar cane, jatropha, willow, poplar, rape seed, reed canary grass, and many other energy crops, as well as straw, manure, corn husks, bagasse, and other biomass resources show that agriculture offers great potential for bioenergy. A pre- or post-study tour drops by a willow waste-water treatment plant.

6. Biofuels for transport

Bioethanol, biodiesel, and biogas can offer sustainable solutions. First-generation biofuels are often much better than their reputation, and the second generation is around the corner. But what about the economy? A pre- or post-study tour visits a wheat-toethanol factory. There are also daily excursions a to biogas production plant.

7. Policy – Making it happen

Learn how policy is stimulating the increased use of bioenergy and guaranteeing sustainability and greenhouse gas reductions. What works best: general incentives or targets? What kinds of standards, certifications, and criteria are needed?

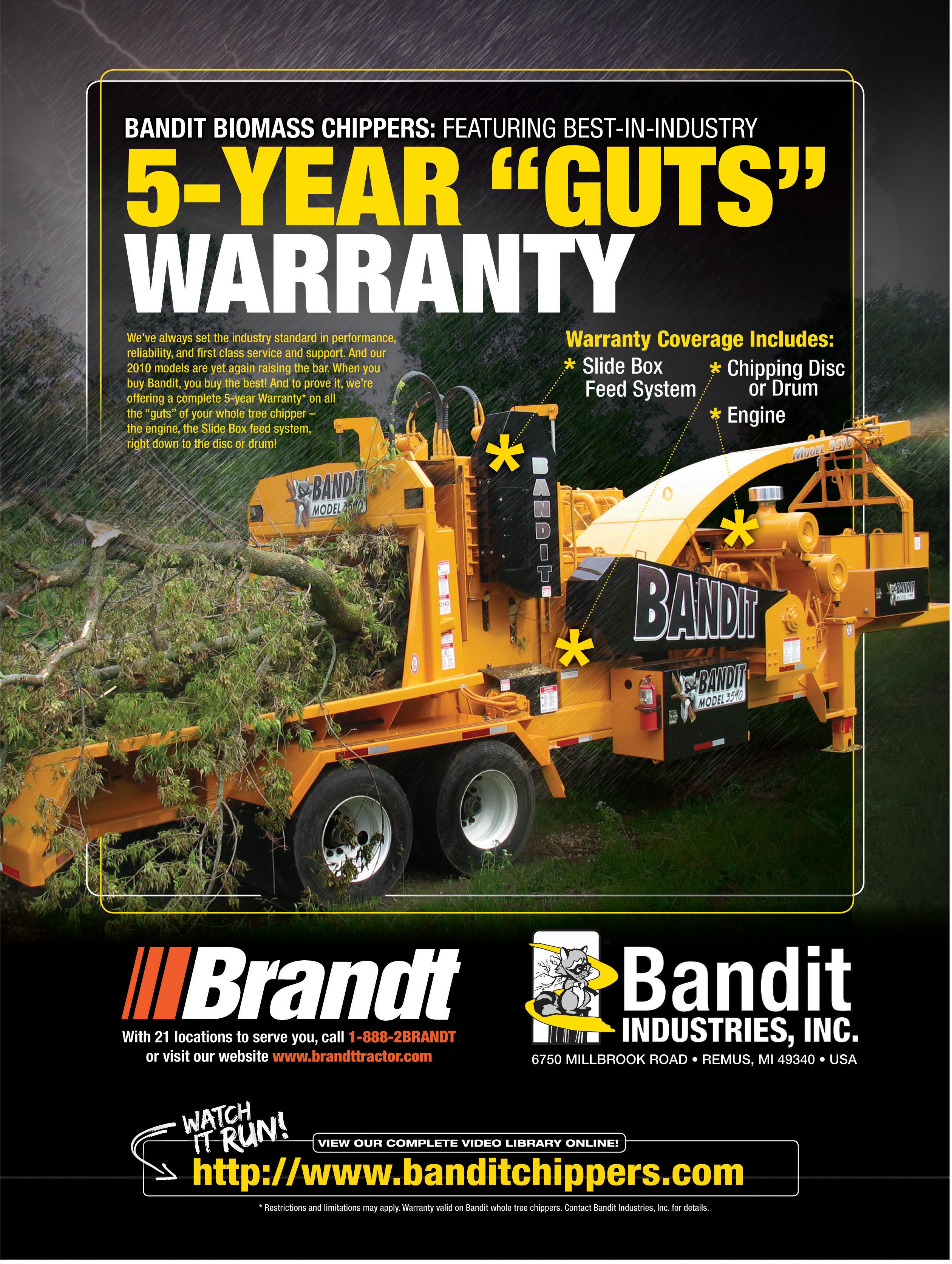

started as an insurance policy to protect Groupe Savoie against the shrinking pulp and paper market has become the final step towards selfsufficiency. The Saint-Quentin, New Brunswick-based forestry and forest products firm has brought together a fleet of sawmills and component plants in New Brunswick, Nova Scotia, and Tennessee over the past 31 years. Its latest addition is an $11-million plant in Saint-Quentin that will convert its leftover sawdust, bark, treetops, and branches into hardwood pellets and briquettes. Slated to begin production in April 2010, the plant will produce up to 55,000 tonnes of pellets and 8,000 tonnes of briquettes.

“We’ve had three major pulp and paper mills close down within 150 km of us,” recounts Roland Dufour, vice-president of sales and marketing. “It’s scary when you look at all that. We are basically a lumber company, but we need to get rid of the sawdust and the chips and the bark. Historically, it has been the paper industry that has used that.” Pellet production was one avenue for growth.

The pellets will make their way to Europe, where export sales of pellets and briquettes are estimated to reach more than $9 million. An estimated 80% of the pellets will be used for power generation and 20% for home and district heating. Strict environmental rules have forced Europeans to burn pellets rather than coal or oil, a reality that has put pellets at a premium. This is a switch that Groupe Savoie hopes Canadians will also embrace.

Europeans have a technology that requires only replacement of the oil burner with a pellet burner, which makes switching over relatively easy, explains Dufour. “There are a lot of possibilities. Years ago Europeans were using oil or coal, and now a lot of them have switched to pellets,” he says enthusiastically. “We are

actively pursuing that type of technology and we are trying to convince the government that we can do that in Canada as well. It’s not an easy task, but if we keep on hammering them, sooner or later they’ll switch.”

The federal and New Brunswick governments have recently shown support for the ambitious project, announcing that they will invest $7 million in Groupe Savoie. The funding will allow the company to purchase and install equipment and provide training for the plant. The province is providing $5 million toward the project through a nonrepayable contribution and a loan. The federal government, through Atlantic Canada Opportunites Agency, is

contributing $2 million.

The company’s pellet plant project continues to move forward. In late October 2009, the project was in the concrete-pouring stage. Dufour predicts that machinery will begin arriving in late November, and as of press time, looked to include: Hammer mills from Cardinal, rotary dryers from M-E-C, boilers from Wellons FEI, fire protection from Vipond, and an automated packaging system from Premier Tech. Finar Steel Buildings of Saint-Nicholas, Quebec, will handle building construction. The entire process will be self-sufficient. Using a Wellons FEI stepped grate combustor, the plant will burn bark to dry white wood

in the M-E-C Rotary dryer for the pelletizing process (see more details on this system in our news section).

Groupe Savoie’s industrial facilities comprise two sawmills, a pallet plant, a component plant, and dry kilns in Saint-Quentin; a component plant and a dry kiln in Kedgwick, New Brunswick; a pallet production and recycling plant in Moncton; a sawmill in Westville, Nova Scotia; and an assembly and finishing plant in Tennessee. The company’s sawmills produce 75 million thousand-bdft (175,000 m3) of hardwood lumber annually and more than two million pallets.

For the community of Saint-Quentin, the construction project means jobs. Twenty jobs are estimated for the plant, with more in forestry and trucking. For Groupe Savoie, the project means self-sufficiency. “The real advantage is that we have our own raw material. We do not have to rely on another industry or another mill that we don’t have control of to get the material,” says Dufour. “We are totally vertically integrated.” •

-Colleen Cross

TBy Crystal Luxmore

alk to me about wind power and I picture a great white turbine. Wax poetic on solar energy and I see fields of long, black photovoltaic cells. But biomass? Well, there are wood chips, elephant grass, garbage, and chicken feces. Then there are biogas converters, wood stoves, heat and power plants, waste-toenergy plants, and biorefineries. Or we could go with the end product. But wait: should I be picturing oils, gas, heat, or chemicals?

And therein lies the public relations conundrum of bioenergy: it’s confusing and wholly unsexy. If bioenergy wants to get higher up on the government and public agenda, it needs to become more tangible and more appealing.

So how can biomass companies reach key decision makers and make them listen? Try following these rules for better communications.

Start with the end in mind. Figure out what result you want from your communications activities. Do you want to win a government grant? Lobby a ministry to change its policy? Get the local community onside? Identifying your audience and desired outcome makes reaching it much easier.

Focus on your project, but highlight the bigger benefits. Gear your message and imaging to the type of bioenergy or project you are promoting, but communicate the overall benefits of switching from a fossil-based to a bio-based economy. An easy way to communicate the bigger message is by joining an industry association, whereby you effectively lend another voice to the regional, provincial, or national voice of

the bioenergy industry.

Stick to the message. Confine yourself to two or three key messages that focus on the positive outcomes and benefits of your product or service. Journalist Ann Medina says that every company should be able to say what it does in seven words. If you can’t do that, then the media, busy government officials, and potential financial backers won’t understand it—and chances are, you don’t either. Back it up. Turn facts into short stories that appeal to people’s emotions and needs. Keep them short and simple. Think in headlines and sound bites. Get others to tell people how great you are by providing testimonials. Debunk myths. Myths about biomass live longer than any scientific facts. Keep abreast of any myths out there about your project and its risks and benefits and make sure your messaging addresses them.

Spend money on a website. Most people approach a website as they do a first date: if it’s good-looking, professional, and easy to get to know, they will answer when you phone to ask for a second date.

Climb the pyramid of influence. Pick out the people at the top who you would most like to get your message to, especially those who

“Debunk myths. Myths about biomass live longer than any scientific facts.”

Be honest. People are smart and they are hungry for honest information that helps them make meaningful choices. This is just as true for the general public as it is for politicians and CEOs. Don’t sound like an advertisement; communicate all of the benefits, but also have a handle on any negative factors (the environmental footprint caused by transporting biomass, for instance) and have all the facts ready.

have the power to pass your message on to hundreds more. Find key allies and opinion leaders and win their support from day one.

Sing from the same hymnbook. Wind, solar, and biomass are all complementary renewable energy solutions, and it’s only when they’re taken together that they can build a critical mass to supplement fossil fuels. So why aren’t we all singing from the same hymnbook? Look locally for other renewable energy companies and combine your communications efforts. Approaching government and even investors as a consortium can give you an advantage. •