SEPTEMBER 2021

Vol. 37, No. 4

Established 1985

www.mromagazine.com

Twitter: @mro_maintenance

Instagram: @mromagazine

Facebook: @MROMagazine linkedin.com/company/mro-magazine

FMario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Maryam Farag, Associate Editor 437-788-8830 mfarag@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Melanie Morgan, Brand Sales Manager 437-218-0941 mmorgan@annexbusinesmedia.com

Alison Keba, Media Designer

Catherine Giles, Account Co-ordinator 416-510-5232 cgiles@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Machinery and Equipment

MRO is published by Annex

Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates.

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com, 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

or just over a year and a half now, many of the actions that used to be done in person, have been done virtually (when possible). A big part of being able to keep up with what is going on in the maintenance and reliability world was to go out and see it first-hand. When the pandemic happened, much like the rest of the world, Machinery and Equipment MRO had to pivot to a virtual way of doing things.

For the first time ever we held a virtual MRO Expo in partnership with Design Engineering magazine in February, which was a great event for both brands, as it brought together readers, exhibitors, industry experts, for a day of networking, learning, and interaction with exhibitors that some may not have seen in a while.

Last August we held our first ever. Maintenance and Reliability in a Changed World Virtual Summit. Presentations by Suzane Greeman, and James Reyes-Picknell, along with a open discussion helped maintenance and reliability professionals to learn techniques to optimize day-to-day operations. With the success of that event, we held our second annual event recently.

The Maintenance and Reliability in a Changed World 2021 Virtual Summit was headlined by a keynote address from Toyota Motor Manufacturing Canada’s Robert Ruggieri, General Manager. He spoke about the future of manufacturing from a TMMC perspective.

This was followed by a learning session by Hugh Alley, about the fact that The Skilled Labour Shortage is a Myth: The Real Shortage is Skilled Supervisors. The summit then featured a presentation by Cliff Williams about Asset Management and the MRO World - What are They and How are They Connected?.

The summit garnered nearly 200 registrations, which was on par with our 2020 event. This shows that while many people may be virtually ‘fatigued,’; meaning that they want to go to in-person events, sooner rather than later,there is still an appetite for virtual events. Not to mention that virtual events present relevant and important information, that can help maintenance professionals in their day-to-day operations.

We thank all those who a ended all our virtual events, and would like to let everyone know that we will be starting in-person MRO events in 2022.

Thank you,

Combining the SKF QuickCollect portable sensor and the SKF Pulse app allows you to quickly evaluate asset health on demand and prevent machine failure. Get expert advice without investing in complex technology.

• On-the-spot machine diagnostics with visual alarm indicators

• No need for training or diagnostic expertise

• Connect directly with SKF experts for analysis and diagnostic reports

• Pulse Check diagnostic reports, available via the app, include recommended corrective actions

How to improve long-term reliability of heavy equipment / 8 The strategies to improve equipment reliability have always been a subject of key interest within the community of reliability engineers. What’s up Doug / 14

Many companies are struggling to get back to normal as COVID-19 concerns are reduced, then raised again.

Slippage of rolling elements in ball and roller bearings.

Indoor air quality / 16

Indoor

In June, the Workplace Safety & Insurance Board released the largest quarterly rebate payout to businesses since the launch of its Health and Safety Excellence program.

This quarter, over 200 businesses strengthened their health and safety systems through the program, earning over $3.2 million back in rebates.

To date, businesses enrolled in the program, who have successfully enhanced health and safety in their workplaces, earned a total of approximately $6.2 million back in rebates.

According to WSIB, “The announcement about our largest record-size rebate so far, comes at a time where many businesses likely need it most and could also benefit from the pandemic-readiness related tools and resources offered through the program.”

MRO

Samotics has been selected for a 12-month trial by United Utilities Group PLC, a U.K.-based water and wastewater companies, to improve the reliability and efficiency of its operations.

The trial emerged from United Utilities’ CEO Challenge initiative, in which teams of graduates in different business areas work together to find innovative solutions to business issues, such as maintenance excellence and minimizing environmental impact.

Samotics’ SAM4 system analyzes current and voltage data from electric motors using a technique called electrical signature analysis (ESA). The system’s sensors install in the motor control cabinet, rather than on the machine being monitored, enabling the reliable capture of detailed health data regardless of the machine’s location and exposure to hazards.

The SAM4 system will be installed on 25 pumps at eight locations, testing a variety of pump types and processes, over 12 months before being evaluated. MRO

Nexii Building Solutions Inc. has acquired Omicron Canada Ltd. as a wholly owned subsidiary.

Nexii is a green construction technology company tackling the global environmental crisis through sustainable building products. Omicron is an integrated development services, design, and construction firms in Western Canada.

Nexii and Omicron have worked as partners since February 2019, when Omicron became one of the early shareholders and adopters of Nexii technology, followed by a range of project collaborations across both teams.

Collaborations include engineering and design assignments for plant operations, manufacturing, and specific product design for Nexii’s Squamish, Hazleton and Vancouver Island plants. Their most recent work together was on the Courtyard by Marriott hotel in Nanaimo, BC, currently under construction with their development partner PEG.

The leadership of both Nexii and Omicron will be unchanged: Stephen Sidwell remains as CEO of Nexii, and Bill Tucker will continue to lead the Omicron team as CEO. MRO

Fluke Process Instruments partnered with mobile robotics trailblazer Boston Dynamics to bring Fluke’s new SV600 Fixed Acoustic Imager capabilities to Boston Dynamics’ mobile robot Spot.

The SV600 Fixed Acoustic Imager enables users to detect, locate and visualize air and gas leaks or changes in mechanical sound signatures across their process and equipment in real-time before they become costly problems. By using an array of sophisticated sound sensors and powerful SoundMap technology, the SV600 translates the sounds that it hears into a visual representation to locate problem areas.

Spot traverses unstructured terrain to automate industrial inspections, monitor remote or hazardous environments and provide situational awareness in remote se ings. The robot can be reconfigured for various use cases to increase efficiency and greatly reduce safety risks. With the SV600 payload Spot will now be able to automate air and gas leak detection and identify mechanical sound signatures. MRO

Exair.com is renovated with a new look, allowing for easy browsing of Exair products, videos and other resources.

Exair.com continues to provide the critical tools to pick the suitable Exair product, with 64 native extensions for CAD drawings, PDF files, product videos, complete performance data, installation and maintenance guides,

air savings calculators, case studies, slide presentations and a huge application database including a solution pathway for learning what Intelligent Compressed Air products can achieve. Customer personalization has been upgraded giving users an improved account management experience when making changes, seeing order history and requesting information. MRO

Inhigh radial and axial load systems such as heavy-side manufacturing and processing applications, increased production demands, longer running times and more corrosive environments are putting machinery under pressure. To optimize system performance and keep maintenance to a minimum, bearings must be able to withstand these more challenging conditions, but until recently the bearing industry has not had the manufacturing technology required to develop a bearing capable of maintaining uptime under the increasing demand of modern industry.

To best serve the needs of high radial and axial load applications, many maintenance engineers use a combination approach - using a pair of bearings to accommodate the load in each direction. The shortcomings of this method mean more space requirements within the machinery - increasing its overall footprint on the factory oor - as well as potential complications with both assembly and access for ongoing maintenance.

While there is an increasing number of bearings on the market that are designed to handle both radial and axial loads, they work by inclining the radial elements to give some axial capacity. In doing so, they trade o radial capacity for axial - a solution that limits the axial load capacity, limiting application usage or putting the bearings at risk of failure.

Exceeding these speci cations in an application with a high axial load may result in damage to the bearing and have a di erent impact on e ciency. In fact, studies suggest that exceeding either radial or axial load speci cations by 10% may reduce the lifespan of the components by about 1,000 hours - as well as running the very real risk of unplanned downtime. For applications with a high axial load, these solutions are far from ideal.

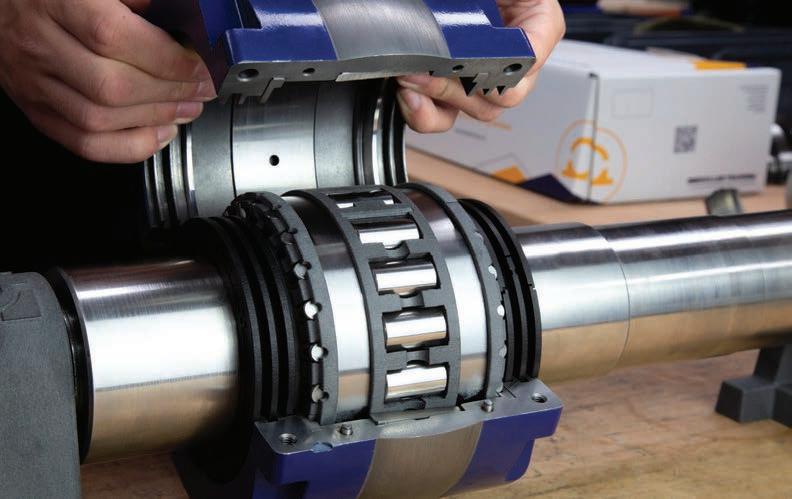

Thanks to the complex geometries possible with 3D printing, bearing innovator, Bowman International, has created a split roller bearing that o ers up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions. Meaning, for the rst time, maintenance engineers across all heavy-side sectors can specify a split roller

bearing that does not rely on race lips alone to accommodate axial force in high-load applications.

The new Bowman Advanced Split Roller Bearing comprises two independent 3D-printed axial bearings designed to accommodate greater loads, improving system performance with less maintenance and reduced unplanned machine failure.

In fact, compared to other market-leading split bearings, the Bowman Advanced Split Roller Bearing increases bearing L10 life by up to 500 per cent.

Delivering up to ten times faster bearing change times compared to solid bearings, split roller bearings, like the advanced designs from Bowman, have been designed with speed of maintenance in mind.

When space is limited, engineers often need to disconnect the coupling and move

other equipment, such as motors, gearboxes or pumps out of the way before they can slide solid bearings o the shaft for replacement or maintenance. Split roller bearings can be assembled radially around the shaft, eliminating these additional logistical challenges and making maintenance and replacement a lot faster and more cost-e ective.

For more information on Bowman’s new Advanced Split Roller Bearing, search ‘Bowman Split Bearings’ online.

BY BRYAN CHRISTIANSEN

Mathematically speaking, reliability is a statistical term that indicates the probability of failure-free operation of any equipment in a given operating condition over its lifetime. Within any industry, equipment of various capacities and complexities could be present. While some of the equipment can be small and inexpensive, the others can be heavy and complex, requiring periodic intervention to sustain its performance. Therefore, to optimize the reliability of

such heavy equipment, it is crucial that long-term planning is being carried out, which addresses the reliability over their entire life cycle.

Long-term planning for heavy equipment would involve careful analysis of different factors that can impact the operational effectiveness of the equipment. The factors would not just be reliability, but other parameters tied closely to it as well, such

as maintainability, availability, and safety. Effective long-term reliability planning is indeed a life cycle planning that balances the cost of reliability improvement measures against the achievable benefits over the equipment life cycle.

For example, it would be effective to simply replace inexpensive and non-critical equipment upon failure rather than investing excessive manhours to repair them. On the other hand, it may be worthwhile to implement proactive maintenance regimes for heavy equipment or even improve their design that enhances the reliability of future products. This is because the failure consequences associated with the heavy equipment significantly outweigh the cost of their reliability improvement measures. Following are some of the methods that can be adopted by any industry to perform long-term reliability planning:

The DfR is the selection of parts and the application of engineering design in such a way that reliability targets can be achieved even under worst-case operating conditions. It is a structured process to identify all possible sorts of reliability issues during the design phase and find-

ing a solution to them before they are manifested during the operation stage. Different well-known analytical techniques are available. They systematically analyze failure and achieve DfR such as Failure Mode Effect Analysis (FMEA), Fault Tree Analysis (FTA), Finite Element Analysis (FEA), and reliability prediction modeling, etc. In general, DfR is a process that is comprised of six stages as follows:

a) Identification of reliability goals

b)Developing a dra design based on reliability goals

c)Analyzing the design to overcome uncertainties

d)Verifying the dra designs and continuously updating it

e) Validating the final design against customer requirements and continuously improving it.

f) Continuously monitoring the current design by obtaining feedback during the operational phase of the equipment.

2. Implementing continuous improvement

The Continuous Improvement (CI) process is carried out when the equipment enters into its operational phase. The equipment generally has varying failure rates throughout its life and in turn, may have a different performance from infant mortality up to its wear-out period. The ISO 9001 defines this reliability improvement process as Plan Do Check Act (PDCA). The PDCA process can be a governance structure that stretches from establishing a culture of reliability to managing human, equipment and information.

a)Managing humans: It involves periodic training and developments to improve the competency of people operating the equipment. The purpose would

be to avoid human-related failure in the equipment that compromises its reliability.

b)Managing equipment: It involves continually improving the design of the equipment such that it continues to meet or exceed the long-range reliability targets. The purpose would be to capture the information on design-related failure occurring during the operating phase of the equipment and channel it to the DfR team such that the future design can be improved.

c)Managing information: It involves continually improving the quality of equipment li data, such as failure and maintainability data. The purpose would be to make the data suitable to perform necessary analytics and to support equipment reliability improvement decisions.

A computerized Maintenance Management System (CMMS) is a so ware-based platform that can facilitate reliability engineers performing a range of planning activities. CMMS collects, stores and processes equipment failure and maintenance data and provides useful analytics on equipment health. Some CMMS platforms also have capabilities to interface with equipment sensors and other Internet of Things (IoT) devices to fetch real-time data about the equipment’s health and its surroundings.

The presence of historical as well as real-time sensor data within CMMS provides immense opportunities for planners to advance maintenance strategies from simple time-based maintenance to more proactive strategies, such as condition-based maintenance and predictive maintenance. Such proactive maintenance strategies

provide a projected outlook of equipment performance over its useful life period –a crucial element of long-range life cycle analysis of the equipment.

4. Implementing parts ki ing process

Parts ki ing is a process to gather all tools and spare parts necessary to complete a repair, or perform maintenance on critical equipment. O en critical equipment have limited redundancies and also have specific time slots when they can be maintained or overhauled. They also have a high cost of downtime and have a significant impact on operational reliability as well as the safety of the plant. Such critical assets typically comprise a large number of subsystems. Each of the subsystems may have its own spare parts and specialized tools that are needed for repair and maintenance.

For example, a heavy reactor in an oil refinery requires an entire plant unit to be shut down before it can be maintained. Moreover, to sustain plant reliability and availability targets, it also allows only a short window of time before operation is required to be brought back to a normal state. To overcome this challenge of time constraints, parts ki ing can be adopted to expedite the maintenance process that would otherwise take a significant time to mobilize all resources.

CMMS aside, none of this is simple to implement in practice, but such is the case with most long-term business activities. When done smartly, investing in long-term reliability of heavy equipment is bound to reap a strong return on investment. MRO

Bryan Christiansen is the Founder and CEO at Limble CMMS (a mobile CMMS software). He can be reached at bryan@limblecmms.com.

C

BY JAMES REYES-PICKNELL

We are all living with a lot of uncertainty and an astounding lack of cohesion among those directing the responses.

On the COVID-19 front, we are learning a lot, and now we know what works and what doesn’t. As we exit the pandemic, we will be learning some tough lessons about reliability, maintenance, repairs and services and how to keep a business “pandemic proof” in the future.

The business impacts of COVID-19 are substantial

Our supply chains, highly networked

globally, are feeling the effects of our actions to contain, control and deal with the disease. Those measures will continue for a long time as those countries grappling most with the virus are also those least developed and having the lowest cost labour. They are also at the input end of our supply chains. Goods and services don’t simply flow freely anymore.

Further down those supply chains, we depend on those cheap sources of raw materials, processed goods, products, and parts. In maintenance, we are now experiencing much longer lead times for parts and materials. We need those

for our preventive maintenance, capital replacements, and of course, for repairs.

Maintenance impacts

Repairs that arise without warning have always been a challenge, and the more of them you do, the more challenged you are.

Where maintenance programs were less ineffective, there is more reactive maintenance – “break then fix” is the default strategy. Poor planning and materials forecasting are common hallmarks of organizations that have defaulted to this strategy. It’s expensive and it leads to lowered levels of production capacity, even in “normal” times.

That high cost was driven by purchase and shipping costs for parts that were not forecast, the need to rush them to site, and by delays in repairs that lead to

increased downtime. We now have even longer lead times and reduced supply entering the supply chain. Costs, lead times, and the opportunity cost of lost production capacity are all substantially higher than before the pandemic.

approaches

Smarter companies with proactive approaches had be er forecasting, planning and more effective reliability programs.

They, too, experience longer lead times and higher prices, but they are also in a position to manage them much be er. If their reliability programs were already well-defined using reliability centered maintenance, the only lasting impact of COVID-19 will be lead times, and their impact on stores quantities and procurement. They very likely have the spares they need to sustain operations during the transition period while their supply chains adjust.

“Fake reliability” is now widespread

Throughout the COVID-19 period, production assets continued to run, many at lowered outputs. Physical degradation of the assets was reduced, so assets ran be er and failed less o en. Even with reduced maintenance staffing, less overtime, fewer contractors, and no targeted reliability improvement efforts, their operations were stable and reliability seemed to have improved. However, that calm state is really a phenomenon that has now created a false sense of security when it comes to reliability.

Many pre-COVID-19 improvement initiatives were shelved as cost cu ing measures. The assets continued to run, seem to be running well, but what will happen with a return to normal as demand for products surges?

Old reliability problems will resurface and breakdowns will again increase to preCOVID-19 levels or higher. Compounding the problem

with increasing breakdowns is the fact that the ability to repair them has been dramatically reduced.

Discretionary doesn’t necessarily mean unimportant

COVID-19 survival cost containment measures led to cu ing of discretionary spending. In maintenance, the proactive aspects of maintenance programs and capital replacements are all discretionary. Some workers were laid off. Contracted services and the use of most

contractors were cut. Travel, consultants and training were all cut back, if not eliminated. Maintainers who remained on the job were heavily challenged to learn and respond with fewer resources and support. They rose to the occasion, and like front line health care workers, they’ve taken a beating.

Costs went down, companies survived, essential workers burned out.

Manufacturing and processing operations depend on regular maintenance to remain reliable. Deferred replacements

and proactive maintenance both have risks with potentially negative long-term impacts. The cumulative risk of failures has grown, more or less unchecked. In most cases, that growth is exponential. Improvement initiatives aimed at reliability stalled.

There is a rising trend in serious accidents

If you pay a ention to the news, you’ve probably noticed that chemical plants, food plants, refineries, and more are experiencing an upsurge in significant and o en dramatic failures with loss of lives, injuries, pollution and significant business losses. Have our industrial responses to COVID-19 created a ticking time bomb? I believe so.

If the proactive work doesn’t come back to normal quickly, those disastrous events will continue.

The “normal” proactive maintenance in many operations wasn’t actually all that effective. Reliability problems abounded before COVID-19. They are likely to be just as bad if not worse now. During COVID-19, cost reductions curtailed just about everything that was being done to improve except computer system implementations. We still haven’t learned that “systems are not substitutes for strategy.”

Good maintenance practices execute good reliability programs. The effort to put those in place is also discretionary, important, and all-too-o en, absent. Now, who will do that work?

Many of the engineers and technicians who would be needed to do that work were sent home, or laid off. Like your trades, you may find that you need new people with a need to learn before they’ll be effective.

Before COVID-19, it was increasingly difficult to find skilled trades. During COVID_19, reduced staffing on shi s, layoffs and furloughs sent many employees home.

Retirements of the most experienced, the baby boomers, continued. They would have le anyway, but their knowledge could have been transferred if anyone was thinking about it. The pandemic gave no warning, and took away that opportunity. Knowledge transfer didn’t happen and it’s too late for much, but not all of it.

Skilled trades are difficult to find and

Manufacturing and processing operations depend on regular maintenance to remain reliable. Deferred replacements and proactive maintenance both have risks with potentially negative long-term impacts.

replace. If they were laid off, they likely found new jobs. Many of them are gone for good, and their knowledge of your operation and equipment went with them. Replacements will need to learn, and they are likely to be more expensive. Unions that are in positions to bargain will now have a big advantage when it comes to asking for more pay. As I write this, we are seeing exactly that with the Canadian border services staff, and literally days before the border with the U.S. opens. The posturing is just beginning.

Training delivery methods changed during COVID-19

Live-virtual has replaced face-to-face

and works reasonably well, where your students can stand to sit by a computer for hours on end.

Completely online delivery methods are on the rise. They are less expensive and capable of delivering richer content while enhancing the learning through quizzes and assignments. Unfe ered by time zone and even language challenges, training can be self-paced and taken whenever the student can find the time. Pre-recorded, self-paced online courses are growing in popularity, particularly among younger workers – the ones you will be depending on. Your accountants like them too – they are the least expensive option.

Reliability is the key to future performance

Old ineffective break-then-fix approaches to operations and maintenance require high spending, a high tolerance for downtime and a fat maintenance workforce to handle all the fire-fighting. If your maintenance program had any more than about 30 per cent of repair work on non-critical assets, then you have room to improve. Doing so will require a re-definition of the maintenance tasks that your maintainers perform using reliability centered maintenance on critical assets, and PM re view/optimization techniques on the rest.

Deeper understanding of your plant and equipment func tions, failure modes and the proactive options for dealing with those, and their consequences is needed. That means training and then pu ing it to use in a critical examination of your maintenance programs. Increasingly, you can ill-afford to keep avoiding this reality.

into practice as we analyze the reliability needs of their plant equipment and systems. It is helping them learn those systems quickly and in greater depth than the experienced workers who are still there. They are finding problems that have been present for years and solving them.

Those new employees are ramping up fast with that sort of help. Without it, they would flounder and end up making the same mistakes that helped the older, now gone, workforce gain its experience.

Continue to cheap-out in cost cu ing mode and you will fall behind while your risks of failures, their negative consequences, and your inability to recover from them grow. Don’t just train and forget. It doesn’t work. Start investing in training of your new hires and in pu ing that training to work in mentored reliability analysis work. You can make up for the sins of the past with a conscious effort to do so. It won’t happen on its own nor naturally. Only chaos increases naturally. MRO

James Reyes-Picknell, PEng is Principal Consultant of Conscious Asset, providing business consulting and training services in Physical Asset / Maintenance Management and Reliability. He is author of several books, including Reliability Centered Maintenance – Reengineered in 2017 and Uptime – Strategies for Excellence in Maintenance Management, 2015. Reach him by e-mail him at james@consciousasset.com or visit www.consciousasset.com.

Companies that get it, will enjoy lower operating costs and higher availability for productive uses of those assets. Companies that don’t, risk becoming take-over targets, or fading into history because of their lack of competitiveness.

Younger new employees can be a competitive advantage in this challenging environment

Although less experienced and in need of training, newer employees are open to receiving it and pu ing it to good use. Give them the needed training to develop those needed reliability programs, mentor them as they put it into practice, and you are se ing the stage for a more reliable future.

We are already working with newer employees who are learning reliability methods. We are pu ing that new learning

BY DOUGLAS MARTIN

In this article, there will be a breakdown of the different forms of “slippage” and what some of the causes are.

The term “slippage”, meaning that at some point on the rolling element/race contact there is relative motion. One surface is going a different velocity (speed and/or direction) than the other surface. One important component of a bearing that will make a significant difference in whether that slippage causes damage or leaves no trace is the lubricant, and specifically the generation of an oil film between the two surfaces. This oil film is the buffer between the two differently moving surfaces.

Normal rolling contact:

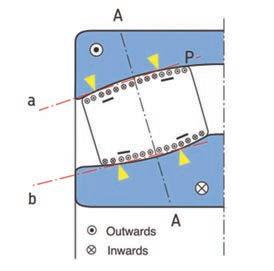

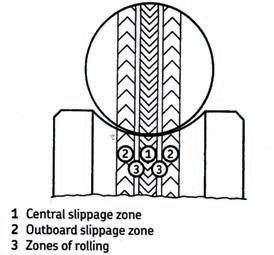

With rolling elements, there is always slippage across the contact ellipse. In this picture, the yellow triangles are where there is rolling contact, and all the other areas are sliding contact.

So even in a normally operating bearing, there is slippage, and hence, the importance of a lubricating film to separate the rolling surfaces.

Abnormal contact arises from these cases:

With a QJ Bearing (4 Point Angular Contact Ball Bearing), the bearing is designed internally to contact in either of two planes, however, there should only be one plane in contact at any given moment. This allows the bearing to accommodate a thrust load in either direction, saving space compared to a pair of single row angular contact ball bearings or a double row ball bearing. If a radial load is applied to this bearing, it will cause the ball to contact the outer race in two places, while still only in contact

with the inner race in one place. The ball will rotate in the plane with the outer and inner ring contact at 180 degrees apart, and the second contact on the outer race will be sliding. For this reason, these bearings are mostly installed with a relieved housing seat such that the outer ring outer diameter is not in contact with the housing bore, preventing an unintended radial load to be applied to the bearing.

With a pair of angular contact bearings, there is one bearing that is taking the thrust load and the other bearing is unloaded or sharing a portion of the radial load. With lower speeds, the unloaded bearing will contact the races in two places, and the ball will spin on a single plane with rolling contact with both races.

In higher speed applications, a centripetal force will act on the ball to shi it in a radial direction. When this occurs, the ball will contact the outer race on a different plane than the inner ring contact and one of these contact points, typically with the outer race, will slide.

In a radially loaded bearing, the rolling element is moving around the bearing and only in full contact with both races in the load zone. While it is in the load zone, the contact with the inner and outer ring provides traction such that the roller is driven and it rotates.

When the roller is out of the load zone, it is no longer driven by the race contact. It is pushed by the cage through the unloaded zone. While it is being pushed, the frictional contact with the cage bar will slow the rolling element’s rotational speed. Also, any frictional effects of the grease or oil may also contribute to a slowing of the roller rotation. Depending on the size of the bearing, there may be enough of a distance through the load zone such that the relative speed of the rolling element surface and the race surface becomes significantly different.

When the roller then enters the load zone, it quickly accelerates up to the speed of the races. O en with more massive roll-

ers, there will be some distance that the roller needs to get up to speed to equal the race surface speed since the larger roller mass has a greater moment of inertia. It is this brief distance that there is slippage, but o en there is adhesive wear.

In fact, this type of slippage occurs in other cases. The basis is the rollers experiencing cyclic loading and unloading. This can also occur with two row bearings with opposite contact angles (such as a spherical roller bearing) in which the axial load is oscillating, causing cyclic loading and unloading of the rolling element set.

One example that I came across was a spherical roller bearing in a newsprint machine. A new felt was installed in the press section, and due to some property of this felt, it introduced a rocking motion in one of the suction rolls. The rocking of the roll could be visually observed. In terms of the bearings inside the roll, there was a spherical roller bearing that experienced a cyclic axial load, in which one race was axially loaded and

then the other at a high frequency (i.e. a number of cycles per minute). With each cycle there was a touch down and li off of the rollers, and since this was a large bearing with massive rollers, with each touchdown there was a skidding event that caused early failures of the bearing.

In this case, the situation occurs with spherical roller bearings in an application, where the outer ring is rotating, the inner ring is stationary, and there is angular misalignment between the inner and outer ring.

Traditionally, the spherical roller bearing rollers are guided by the rotating inner ring, and due to the nature of the sphered bore of the stationary outer ring, the rollers always have a matching curved surface to run on. However, when the rotation of the rings is switched, and the outer ring is rotating and the inner ring is stationary, then the track of the rollers on the outer race has a differ-

ent vector than the rotation of the outer race. There is a slight angular difference that grows as misalignment increases. Although this may be difficult to envision, we can all see a similar case as a transport truck turns a corner and we observe the rear wheels.

A very common application for skidding is in electric motors with cylindrical roller bearings, and most o en when these motors are tested in the rewind shop. If there is not a radial load applied to the drive end of the motor during testing, then there is a high risk of roller slippage. Other factors can include the speed at which the motor is started up. In a “full speed” start, the immediate acceleration of the motor can cause slippage, a ramping up of the rpm is best practice to avoid the skidding possibility. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him at mro. whats.up.doug@gmail.com.

BY MARIETE F PACHECO

According to the United States Environmental Protection Agency (EPA), the quality of the air indoors can be twoto-five times more polluted than the outdoors. This can be a significant concern in many facilities, as employees start to return to work this coming fall.

The air quality in commercial spaces is believed to have deteriorated over the past few decades due to several factors, including; the increased use of synthetic building materials, improper ventilation (few commercial spaces have windows which can be opened), poor building design, such as improper placements of thermostats and humidity controls, increased use of products containing and off-gassing volatile organic compounds (VOC) or ozone, such as computers, adhesives, carpets, cleaning supplies and photocopy machines and more tightly sealed buildings in the quest for creating energy efficient buildings.

To determine if your facility is at risk of poor indoor air quality, there are some considerations both from a team member perspective as well as a physical environment perspective. For team members, review if there has been an increase in absenteeism due to health issues, in particular respiratory concerns, including allergies, may be associated with “sick building syndrome”, which can impact productivity as a result of poor indoor air quality.

Considerations regarding the physical environment of the facility include factors such as: increased dust or dirt on work surfaces, unusual deterioration of equipment or furnishings, inconsistencies in the air distribution (hot spots VS cold areas,) and mildew or mold growth.

Source of pollutants affecting indoor air quality can come from both indoor sources as well as outdoors. Indoor pollutants such as combustible sources, should be reviewed, like wood, coal or oil heating sources, which can release harmful combustion byproducts. They include particulate ma er and carbon monoxide into the building or the use

of older equipment or supplies which may contain VOCs or harmful chemicals, such as formaldehyde or other toxic materials.

Outdoor sources of pollutants may enter the facility through open entrances or exits, or in many instances from the shipping and receiving department’s large bay doors. Other outdoor pollutants may enter a facility through cracks in the facility. Such can be the case for radon or from chimneys, which may allow smoke to re-enter the building, especially on windy days.

There are several ways to combat and improve your facility’s indoor air quality, but first it is important to determine if there are air quality concerns that exist.

Having a professional test, the air quality throughout the facility not only helps to identify the existence of an issue, but also helps to determine if there are contained areas of the facility which can have targeted solutions applied as compared to large-scale facility-wide solutions that can generally be costlier to implement.

Plus having a professional measure, the air quality provides a benchmark to compare to a er implementing air quality solutions to ensure they are addressing your problem areas. A professional may test for a variety of contaminants and issues including air flow, ventilation, gaseous sampling, micro biological ma ers such as bacteria, mold or fungi, and air testing for airborne particulates or toxic gases such as carbon monoxide or nitrogen dioxide. Sometimes testing will include short-term monitoring over a period of several days to help establish a baseline and to rule out operational impacts, like if temperatures or carbon monoxide swing greatly in certain areas during limited time periods of the facility due to increased employee presence. For example, in the break room during lunch, or boardroom during staff meetings.

There is an array of indoor air quality solutions to fit a variety of budgets and applications, including portable solutions that can be moved from area to area in a facility offering a more target-

ed approach and more permanent solutions which affix to the existing HVAC system and address the entire space serviced by the HVAC system.

Air purification systems including electrostatic or electronic air cleaners, HEPA filters, plasma systems and UV technology are the most commonly available in the market. Electrostatic or electronic air cleaners are installed at the source of a forced-air system and operate with a low-level static pressure drop.

Essentially, any dirt or dust that passes through its filtration system is electrocuting it and stops it from passing through the remaining HVAC system. It prevents the spread of it throughout the facility via the ductwork. HEPA filters (high-efficiency particulate air or absorbing) trap air contaminants in its complex web of fibres; from larger to smaller particles as the filter material changes in density and construction. Some HEPA filters offer enhanced protection through the use of an ionizer, which first charges particles as they pass through with a negative electrostatic charge.

Heat Recovery Ventilators (HRV) is an air exchange system that helps to enhance the indoor air quality by introducing outdoor air into the facility and transferring heat. HRVs are commonly used in environments where high humidity is a major concern in the winter. In addition, HRVs tend to have a smaller footprint, making them ideal in smaller facilities. For tightly sealed building envelopes, HRVs are the preferred solution, as humidity will more likely stay indoors.

Energy Recovery Ventilator (ERV) is a mechanical air exchange system that also combines outdoor air into the stale indoor air. However, it offers the add-

ed functionality of transferring both heat and moisture. Since ERVs transfer moisture, they can prevent dryness during the cold months while reducing air conditioning demands in the summer months. ERVs are usually reserved for use areas where humidity extremes need to be moderated throughout the year or for colder climates.

HRV and ERV are similar pieces of equipment which introduce fresh outdoor air into the facility, and exhausting stale air out of the facility, while also recovering energy from the exhausted air simultaneously. Both maintain a continuous supply of fresh air from the outdoors and provide an energy-efficient method of exhausting potentially harmful indoor pollutants to improve the indoor air quality. The main difference between an HRV and ERV is that the HRV transfers only heat as compared to the ERV, which transfers both heat and moisture.

Portable air disinfection units are also available and can be used to address smaller areas, which offer flexibility if there are limited areas within the facility with poor air quality, instead of being prevalent throughout the facility. There are a variety of portable solutions that use diverse options such as UV lights, carbon filters or specialized coils surrounded by atmospheric plasma discharge, which provides a powerful strike that inactivates airborne pathogen cells. Lastly, there are general maintenance solutions that can also assist in improving a facility’s indoor air quality, including regularly changing filters in the HVAC system, performing regular preventative maintenance on the HVAC system to ensure it is operating at peak performance and is not contributing to poor air quality by spreading odours and regularly cleaning ducts. In addition, it is critical to maintain general equipment in the facility to ensure it is not contributing to airborne pollut-

ants, such as leeching fumes, smoke or other harmful chemicals, such as oil or natural gas.

Managing indoor air quality is paramount in maintaining the health and wellness of employees. There is no greater time than now with the ongoing COVID-19 concerns, especially as employers plan to welcome employees back this fall. Indoor air quality can be improved through a host of mechanical system upgrades to improve ventilation through the facility, such as adding HRVs and ERVs, but

as well through less costly approaches, such as conducting regular equipment maintenance. Indoor air quality is vital to all organizations regardless of the industry, especially since employees spend the majority of their time indoors. MRO

Mariete F Pacheco, MBA, PMP, Managing Director, FRW Services Inc. has over 15 years of procurement and supply chain management experience across a variety of industries including industrial, construction, retail and more.

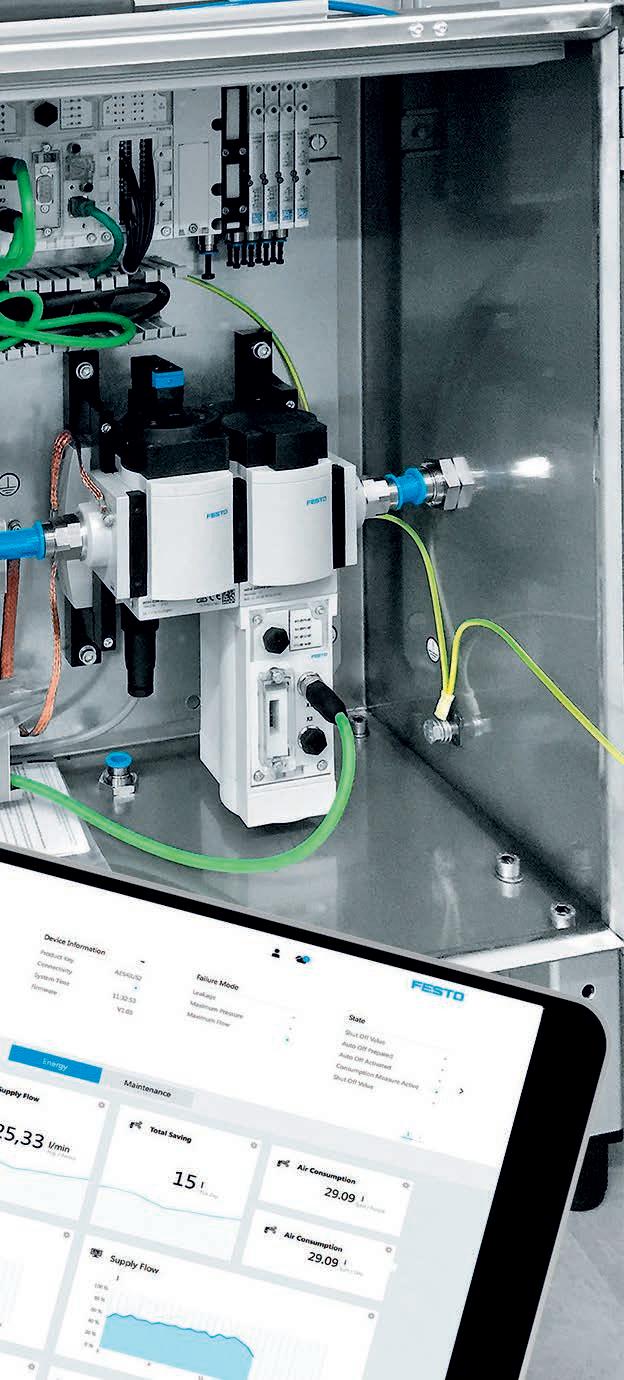

Saving energy is easier than ever before thanks to the Festo MSE6-E2M. Achieve your energy efficiency and sustainability targets while optimizing process equipment performance.

Intelligent assembly features include:

• Zero compressed air consumption in standby mode

• Monitors the system for leaks

• Ensures maintenance in the event of leaks

• Enables effective monitoring of relevant process data

A M

BY CLIFF WILLIAMS

Certainly, in the Canadian municipality forum where Governments are pushing to get more value from the money and efforts that they and the municipalities expend. Ontario has gone as far as mandating most aspects of asset management in their O.Reg. 588/17 – requiring asset management plans for their core assets initially and expanding to all of their assets.

But before we get ahead of ourselves, let’s take a look at how asset management is achieved, how it is built, how does it flow.

The driver for asset management is stakeholder requirements, and the context that the organization is operating in, they permeate through, and need to be borne in mind, in all of the subsequent steps. These requirements will be used for the organization to take what is really the first step in asset management as they establish the strategic objectives. This is where the desired organizational results are set and where we establish what value actually means to the organization.

The document that then guides the process is the asset man-

agement policy. This document states much of what has gone before, including the organizational context, needs and expectations of stakeholders the role of leadership and the approaches they should take and any decision-making guidance around those things that are key to the organization. Some organization take this even further and state the actual roles involved along with the responsibilities and authorities required to be successful in those roles.

Once we have the policy in place, we need to understand how we will use this guidance to actually achieve the strategic objectives and this is usually done in the strategic asset management plan or SAMP. This is the document that takes the high-level objectives and brings them more into specific goals and actions to achieve them. Coming out of the strategic asset management plan will come the focused asset management objectives, and quite o en guidance on the asset management initiatives required to achieve these objectives. It’s important that the strategic asset management plan is viewed with a number of things in mind – these are generally developed along side the strategic asset management plan.

The plan should not simply look at the context today, but take into consideration the future – a demand analysis, where we look at where the organization wants to be in a set future period, which markets do they want to be in, where they want to exit, what new products or offerings are anticipated and will they need to expand or contract to meet these. For municipalities, this means understanding the required levels of service for the residents and other stakeholders, so that they need to plan for growth or change in demographics in order to provide the required assets in the required amount to maintain the value to the stakeholders in the future. Of course, there will be risk to all of this, so these need to be considered, as nothing is ever guaranteed. And at this point, we need to look at business risks; the risks to the strategic objectives.

Later we will look at the tactical risks of assets not performing their function – as this is the document that describes the ‘how’ of achieving them. If we’re successful in taking all of these things into consideration, then we can take the asset management objectives that are identified and cascade them to the next level of asset management

This is where those who live in the MRO world may see the biggest differences, but, for some, it may not be in what they actually do as maintenance tactics if they have a mature program. What will change for most is in how they approach and who is involved in the different components that make up those solid programs.

The first thing that will happen is that when designing or purchasing equipment and processes, it will be done with life cycle costing in mind, and that the maintenance group will be heavily involved at this stage. Tactical risk analysis will take place through tools like FMECA or RCM – but remember that it is the risk to the strategic objectives that prompts and focuses on what assets are the priority. There will be a formal look at the resources required, the competencies and skills required, not just for today but for the period described in the demand analysis. As decision making and risk evaluation is to be data based, many organizations will have to improve and simplify the processes around gathering this data.

The biggest change for most organizations will be the point mentioned earlier; who is involved in maintenance? Studies have shown that departments such as engineering and design, procurement, and operations play as big a part as the maintenance department in enabling the reliability of the assets, and so their ability to support strategic objectives. In asset management, this means that they get involved and are held accountable for their part of delivering the strategic objectives. To ensure that there is no confusion, they need to have goals that relate to what has typically been thought of as belonging to maintenance.

Simple changes will mean that operations will need to communicate with maintenance to ensure the decided upon tactics are possible and implemented. Procurement will work with maintenance to jointly decide what spares in what amount are held in the stores, engineering will involve maintenance as early as possible in design or modification and ensure that what they do has reliability, operability and maintainability in mind. Key to this working is the development of collaborative goals; when we look at reliability goals, we need to identify the part that all of these groups play in delivering them, measure them and hold them accountable for them.

Maintenance will now need to clearly understand the constraints that the other departments face, and adjust their approach so that all succeed. This should lead to successful management and control the effectiveness of the asset management plans in support of the strategic management goals.

The last step is determining whether we have, in fact, been successful in implementing the various plans. There needs to be cascading goals, which start with the strategic objectives and cascading down to the measures of the performance on the shop floor level. With transparency through the process, it should allow all levels, including leadership, to evaluate, manage and improve their performance in support of the strategic goals. Obviously, there is much more that goes into building effective asset management, but it’s clear that there is need for alignment of goals and efforts throughout the organization, both horizontal and vertical alignment, and if that exists, then everyone will see they have a part to play in asset management. MRO

Cliff Williams is author of the bestselling maintenance novel ‘People – A Reliability Success Story.’ He is a maintenance and asset management educator, and a keynote speaker at conferences around the world, who believes success is achieved through people. Currently Cliff shares his knowledge and experience as an advisor on maintenance and reliability for people and processes, and asset management with TMS asset management and is a facilitator for PEMAC’s Asset Management Program.

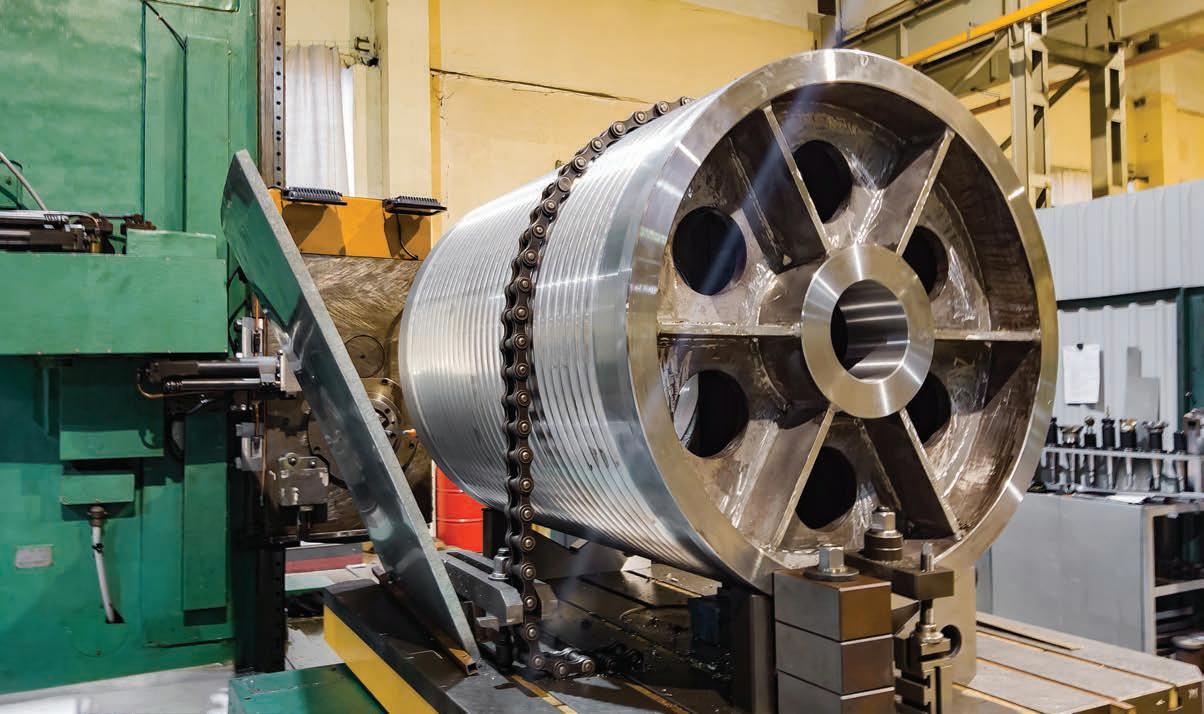

Chain drives operate through tension engagement, where teeth on both the drive and driven sprockets engage with and pull the chain links.

BY L. (TEX) LEUGNER

There are two basic types of industrial chain drives. Roller chains contain pins that pivot inside bushings with a free turning roller surrounding each bushing to provide rolling contact with the sprocket teeth. This chain type is commonly used in power transmission systems for both horizontal and vertical applications. The distance between pin centers is referred to as the pitch.

Extended pitch drive chain contain only half as many pitches and is lighter and less expensive than standard roller chain. Also called double pitch chains, these can be fitted with larger rollers

that act as wheels for use on conveyor systems. Many conveyor systems use chain drives that use polymeric or plastic rollers that are impregnated with self-lubricated materials.

Does the maintenance group have a well-designed drive chain inspection schedule?

Logic: A correctly sized and properly installed drive chain can be expected to provide at least 15,000 hours of service, provided regular inspections are carried out and potential problems dealt with immediately. In a 24/7 operation, it is recommended that at every shift change,

chain drives are visually inspected for adequate lubrication, obvious chain link or sprocket damage, unusual noise, evidence of vibration or improper alignment. At monthly intervals, the chain should be inspected for correct tension and any abnormal condition. If oil appears cloudy, dirty or darker than usual, it should be changed.

Annual maintenance should include an inspection for cleanliness of components and removal of all dirt and foreign material from chain and sprockets. Inspect the chain for side plate wear, fatigue, elongation or corrosion. Inspect shaft and sprockets for proper alignment

and adjust if necessary. Inspect sprocket tooth wear and replace if necessary. Inspect the lubrication system for clogged feeder pipes and ensure that the oil drip or oil stream rate is correct depending upon the type of system. If the sprockets are mounted using rolling element bearings, ensure that the bearings are lubricated. Depending on plant operating condition, oil should be changed and any filters should be replaced.

Does the maintenance group have a sound knowledge of chain lubrication?

Logic: Chain lubricants should not contain additives such as detergents that cause sludge, varnish or gummy deposits. The best general lubricant is rust and oxidation inhibited mineral oil of the correct viscosity based on the temperature/viscosity chart provided below. Some chain manufacturers accept the use of SAE 20/50 engine oils, but these are not the best choice because the additives may result in varnishing due to oxidation of the oil, particularly at high operating temperatures. For extremely high or low temperature or shock load applications, consider the use of synthetic oils containing molybdenum as the anti-wear agent.

Lubricating methods include brush or oil drip, oil bath or slinger disc and pressure stream or spray systems. Unless it is impossible to avoid, grease should not be used to lubricate chain drives. If grease is necessary, it should be heated to ensure that it penetrates the chain components and its use limited to chains operating to a maximum of 750 feet per minute. Brush or drip systems must have oil viscosity low enough to penetrate the chain joints, yet high enough to adhere to the chain component surfaces.

Does the reliability group understand the requirements of chain maintenance and repair?

Logic: On horizontal chain drives, sprocket sha s should be parallel and level. If not, the operation of the chain will

tend to cause wear on one side of the chain, while wearing the opposite side of one or both of the sprockets. This also applies to idler sprocket sha s if used.

Where a sha has axial movement position, the sha in its normal running position before aligning the sprockets. Ensure that the sprockets are aligned and ensure that sprockets are mounted as close as possible to the support bearings. Any excessively overhung sprocket will cause premature bearing failure. Although it is not always possible due to machine design, the sha alignment should also be parallel with the sha and sprocket centers perpendicular to each other on vertical chain drives. Measure chain tension to ensure that the slack span has four-to-six per cent free movement in horizontal drives and two-

to-three per cent in vertical drives. If elongation exceeds the available adjustment, remove one or two pitches or links and reconnect the chain. (If elongation exceeds three per cent or 0.36 inches per foot, replace the chain). Wherever long chain spans require the use of an idler sprocket, the idler should be positioned on the slack span, preferably nearer to the driven sprocket. The number of teeth in the idler must not be less than the smallest drive sprocket, and the idler should have a chain lap of at least three teeth with a free length of not less than four pitches between it and the nearest sprocket. Inspect the sprocket teeth for roughness or binding as the chain engages and disengages the teeth. Inspect the teeth for worn tooth surfaces and hooked tooth tips. Determine

the wear on sprocket teeth at the pitch circle diameter on the teeth. If the depth of tooth wear has reached 10 per cent or more below the straight edge of the sprocket, it should be replaced, otherwise rapid chain wear will cause potential chain breakage. (Where it is possible, the sprocket can be reversed to utilize the opposite side of the tooth). MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

BY MARYAM FARAG

For over 40 years, CMTS has been produced in partnership with industry OEMs and suppliers who know the challenges Canadian manufacturers face and the types of technology needed to advance the industry.

Over 150 technology and service providers will be at CMTS to address specific challenges and provide custom solutions. The trade show floor is the centre of the CMTS show. This year, for the first time, CMTS will offer a virtual iteration for those unable to a end in-person.

On day one, two presentations will take place. First, an opening keynote on Geopolitical Risks and How to Manage Them, by Courtney Ricket McCaffrey, Insights Leader, EY Geostrategic Business Group, Ernst &Young LLP.

Next, an industry panel titled Building a Resilient Supply Chain: Enabling Speed and Agility to Protect your Customer and your Bottom Line. The panelists will include Michelle Bockman from 3D Control Systems, Stewart Kramer from Next Generation Manufacturing Canada (NGen), and Alejandro Guerrero from Infor. Panelists will outline what a resilient supply chain looks like (key capabilities/characteristics), how to identify risk across a global value network, and what is being done to protect customers from a wide variety of supply chain disruptions.

On day two, a keynote will be presented by Mélanie Joly, Minister, FedDev Ontario, The State of Economy.

Then, Jason Myers, from NGen, will speak about A New Economy: Strategic Opportunities for Canada’s Advanced Manufacturing Sector.

On day three, a keynote will be held by Falvio Volpe, President of Automotive Parts Manufacturers’ Association. A erwards, Damien Johnston, Vice-President of Mid-Market Sales Ontario at Telus Business Solutions, will be joined by a panel of business leaders to discuss how they digitally transformed their businesses and flourished through the pandemic.

On the final day, an industry panel will take place, Welder Education for Today’s Workforce. This panel session will outline some of the current state challenges in the welding industry today. In addition, CMTS will feature Smart Theatre; small group discussions that will provide the opportunity to ask questions about specific manufacturing challenges, and get “the scoop” from industry experts in automation, advanced materials, additive manufacturing, IoT, 3D scanning and more. MRO

BY PETER PHILLIPS

One of the biggest changes will be travel for work. Many large companies have hundreds of people who travel on a weekly basis to support production and maintenance activities.

As COVID-19 has put a long pause on travel, companies have learned to adapt and use online meeting platforms to a end meetings, project groups and trainings.

This experience has helped companies realize a great deal of off-site activities can be replaced by online technology, and expect travel to be reduced by up to 50 per cent post-pandemic. From this experience, new travel policies have been implemented by many companies, stating any travel needs to be critical to company operations.

The new policies have had some mixed reviews; both positive and negative.

On the plus side, operational support people who in the past travelled two-tothree weeks per month are relieved to have their travel cut in half. From experience, life on the road is stressful and tiring. People work all day at a plant or a ending off-site meetings, and then spend most of the evening in their hotel catching up on emails and other correspondences.

Another plus for the company is travels expenses. As an example, many of our meetings with plant maintenance managers and other meetings with our counterparts in other divisions occurred every three months off-site. New policies have us meeting online, and face-to-face just twice a year.

On the minus side, some maintenance-support activities are difficult to perform when you are hundreds of miles away si ing in front of a computer screen. Project teams have been meeting online, developing project details without being able to walk out on the plant

floor as a team and see the equipment or process involved in the project. They found it more difficult to have the confidence in their decisions when they have not seen the project and people involved in person.

Here are a couple real life examples that will demonstrate this new way of conducting projects: For the past several months, I have been working with other team members on two large projects that will affect all our production facilities.

The first project is called Asset Care. The team has worked together designing the pilot project without meeting face-to-face or seeing the equipment, as most of us are working from home due to COVID-19 precautions at the plants. With the restrains, we realize the project is not perfect and it will need many adjustments when we finally meet at the plant, where we will conduct the pilot project before it is rolled out to other production facilities. To say the least, we are very anxious to see how the project works out with the new model of working remotely.

Another project we are working through is Cra Development. We know maintenance training must be a continuous process, and the past 18 months of COVID-19 restrictions have put a strain on training activities. Travel for training will also have a 50 per cent reduction, so our team’s mandate is to is develop alternatives methods to deliver training to

our trades people.

The team realizes the training needs to be focused on the training gaps that are identified through individual knowledge and skills assessments of our trades people. Once the gaps are identified, we need to look at available technology that will allow trades people to participate from their place of work. It is not difficult to find online maintenance knowledge courses, however, delivering the hands-on skills training online is difficult, and nearly impossible to find.

To cope with COVID-19 restrictions, we divided the training design into two distinct delivery methods:

1.Knowledge training will be delivered online though third party training partners. Individual training gaps will be filled with specific mechanical and electrical courses available online 24/7. Trade’s people will be able to access their training courses when it fits their work schedule.

2.Skills (hands-on) training will take place in-house using experienced maintenance technicians. The project team has wri en specific objectives and outcomes that must be achieved by the trainee to pass the skill. Our technicians who will deliver the training will be given facilitation skills training and instructions on how to deliver on-thejob training.

Again, our Cra Development project has been developed completely using online meetings. We know it will have deficiencies and we will need to adjust when we launch our pilot project at one of our plants once travel restrictions have been li ed. In the beginning of the pandemic, most companies thought travel restrictions would be temporary. However, as the months have passed, we have adapted to new ways of ge ing our jobs done.

As I write this article, the Delta variant is expected to be the dominant strain and will continue to affect the way companies do business. Travel restrictions may continue to be a big factor, and online technology that allows people and processes to interact will become the new norm that none of us could have possibly imagined two years ago. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902798-3601 or peter@trailwalk.ca.

How additive manufacturing trends affect the aftermarket.

BY REHANA BEGG

From aerospace to car parts and medical devices, 3D printing, also known as additive manufacturing (AM), is undergoing a manufacturing renaissance and shaking its reputation for producing trinkets, toys and doodads. The innovative potential of AM is now integral to the global vision for innovative, transformative digital manufacturing.

What makes AM different from subtractive manufacturing is that it enables the direct fabrication of parts with complex internal geometries, bypasses the need for product-specific tooling, reduces production cost and streamlines supply chains. Recent supply chain and manufacturing disruptions forced manufacturers to harness its capabilities for producing large-scale medical devices and components in inventive ways.

The ramp up is trending across the globe. OEMs are expanding their revenue models by adopting AM-related technology for production and commercialization. General Motors uses metal AM to develop enhanced jet engine components; Lockheed Martin and Boeing use AM for defense and aerospace; Siemens uses it for the development of high-efficient gas turbine blades; and Align Technology (the company behind Invisalign) uses it in customized orthodontics.

For all the hype, Canada has for the most part maintained low levels of output and is considered a small player relative to the U.S. and China. But according to analysts, the number of high-profile firms exploiting the technology’s flexibility and customizability is on the rise, and it could mean the competitive paradigm is shifting.

Case in point: Samuel, Son & Co. fully acquired Oakville, Ont.-based Burloak Technologies in February 2020. The metal processing multinational sized up the AM trend early on and embraced the opportunity to grow the company’s competency and competitiveness, said Samu-

el’s President and CEO, Colin Osborne.

“McKinsey or Bain would say that additive manufacturing is one of the ten most disruptive technologies, along with AI and blockchain,” said Osborne. “It’s going to be very disruptive to my business, and it’s going to be very disruptive to my customers. Forget about aerospace; it’s going to be very disruptive in industrial manufacturing and manufacturing in general. We thought we needed to be engaged in the technology in a serious way, and we needed to provide our customers a unique opportunity to access.”

With $4.5 billion in sales, Samuel consists of about 15 different metals industry businesses related to industrial manufacturing and industrial products. As Osborne sees it, Burloak was a perfect fit for two reasons: “The first is that we pride ourselves as a company to offer to our customers something truly unique. We offer any metal solution that you need, whether that’s global sourcing or processing of near-net-shape blanks for automotive manufacturers, or small diameter tubing, or roll forming for rail cars… or building pressure vessels for the pharmaceutical industry. We do all of these things for customers. Secondly, the next frontier is really printing components. When we speak to OEMs, we can say, ‘We can source for you and go all the way through the value chain right up to printing a finished component.’”

GE engineers first a empted to fabricate the nozzle using traditional casting methods, but the internal geometry proved to be almost impossible. The engineers turned to 3D printing to meet the walnut-sized fuel nozzle’s complex specifications. The part was prototyped to handle the task of mixing jet fuel with air. Instead of 20 pieces welded together, the nozzle’s tip was a single piece, four times lighter, five times more durable and 30 per cent more cost-efficient than a comparable part

In January, Samuel made good on this claim when Boeing qualified Burloak to manufacture aluminum AlSi10Mg components to the Boeing BAC 5673 specification. It was the first time an additive manufacturer achieved this qualification and demonstrated the company’s ability to commercialize this technology, said Osborne.

The aerospace industry was an early adopter of AM because making the business case for manufacturing additive flight components is palpable. “When pu ing things up in the air,” pointed out Osborne, “it ma ers if you can make them 80 per cent lighter, if you can make them five times stronger and half the weight. The justification was profound.”

In aerospace, the buy-to-fly ratio describes the amount of wasted material in a manufacturing process. “If you buy 10 kilograms of metal to make a one-kilogram part, that ratio is 10:1. That’s a horrible ratio, but that’s the average ratio,” said Osborne. “In AM—forget about aerospace—you can make 1:1 or one and a half, because you use powder to make a part, and use every [bit] of powder. Then you recycle the rest.”

Mark Kirby echoes Osborne’s sentiment. The capacity to provide innovative solutions at scale for the a ermarket is nowhere clearer than in the aviation industry. “The posterchild for AM parts has been GE Aviation’s LEAP fuel nozzle, which was prototyped to handle the task of mixing jet fuel with air,” said the Industry Training Manager for the University of Waterloo’s Multi-Scale Additive Manufacturing Lab (MSAM), which is one of the largest R&D additive manufacturing facilities in the world.

produced with conventional processing tools.

In 2015, GE set up a fuel nozzle facility in Auburn, Ala., and has since produced tens of thousands of fuel nozzle tips for the aviation industry. Kirby, an aeronautical engineer by training and an expert in metal AM, characterizes the additive breakthrough as a game changer because GE could procure spare parts for planes that have been in service for decades. GE’s additive production has since extended to a range of components, including sensors, blades, heat exchangers and other engine parts.

But he also points out that GE took all of the risk and all of the reward. “GE could do it; but very few companies can.”

For a scaled down repair story, Kirby points to Tronos. Founded in 2001, the Charlo etown-based company was set up to handle routine and heavy maintenance for a fleet of about 20 BAe 146 regional jetliners, as well as engines and spare parts. A few years ago, said Kirby, Tronos diversified its business by forming a manufacturing operation with the specific intent of entering additive manufacturing.

The company’s first replacement part was a thro le bracket. It was originally cast in magnesium, which makes it susceptible to corrosion. The plan, Kirby explained, was to print thro le brackets in titanium, which would make it stronger and corrosion resistant.

“This is an additive success story of a small company (30-40 employees) that leveraged knowledge of the marketplace,” said Kirby. “They understand what parts on the aeroplane would be suitable for AM and where there would be a business case for it. They’ve developed this bracket and it will have a parts manufacturing authorization from the FAA. These parts are about a thousand dollars each, so it’s not a huge volume for Tronos, but they understand the market, they understand the need. And that’s not trivial, because they’re replacing a bracket that was cast with one that’s been 3D-printed and machined.”

Both Osborne and Kirby agree that adding AM to the pro-

There are many reasons MRO-related businesses need to consider additive manufacturing solutions. Colin Osborne, President and CEO, Samuel, Son & Co., called attention to three:

• The first relates to cost. Having tens of millions of dollars tied up in spares is never cost-efficient. “Maybe have one spare on the shelf,” said Osborne. “As long as plants have the drawings, the specs and capabilities, they can produce parts overnight. Plants can massively reduce the amount of work

that goes with managing spares.”

• The second is efficiency. When you’re in the parts aftermarket and need parts at 50 locations, you’re not likely to take a die out of storage or reset your casting operations to make a small number of parts. “But that’s what plants end up doing, and it’s horribly inefficient,” said Osborne. “Of course, they’re not going to do it to make 10 parts, they’re going to make 500 parts, which they don’t need. I’ve seen literally millions of dollars

duction toolbox may not be the best fit for every manufacturing facility. The systems and infrastructure for having a CAD or computer model of a component that can be printed just in time is in its infancy. In this sense, the MRO market has a long way to go before it can declare its readiness to manage a “digital inventory” of spares, Kirby said.

Still, Osborne pointed out that there are many broad applications for additive that companies are not fully aware of or they o en don’t know just how much AM can be applied to their day-to-day business. The opportunity for Canadian manufacturers, he said, is that the government has recognized that having an embedded manufacturing base that is globally competitive – albeit small companies – means having to adopt Industry 4.0 technology.

“Companies will have to be innovators and embrace all aspects of Industry 4.0 – from applying artificial intelligence (AI) processes and industrial automation to applying additive manufacturing,” said Osborne. “In the area of AM, the government has provided funding to support development at colleges or universities or industry players like Samuel. Canada today, especially Ontario, truly has one of the most capable embedded infrastructures in the world to support AM. By nurturing AM, the government is asking: ‘Can we create the next Blackberry?’ In other words, can we create the next group of industry leaders? I think we can – I think there’s industry knowledge and academic knowledge in Canada that’s world class.”

There are alternative business strategies for smaller companies that don’t have the global research and technology capabilities, said Osborne. Strategic alliances and partnership models are among them. “Smaller companies don’t need to have the specialized AM capabilities,” said Osborne. “They can leverage our knowledge and the universities’ infrastructure. All they have to really do is open up their minds and bring applications that we can commercialize.”

MRO

Rehana Begg is a Toronto-based freelance editor. She has spent the past decade in the trenches of industrial manufacturing, focusing on engineering, operations, asset performance and management. Reach her at rehanabegg@rogers.com.

worth of tools and dies and casting equipment tied up, waiting for aftermarket spares to be produced. That can be eliminated.”

• The third affects reliability engineering. When a machine goes down for hours, it pays to calculate the cost of downtime. “Reliability engineers can now look at whether they can print the spare…They can look at the failing parts of equipment and decide whether they should replace it. With AM, they can also optimize it – make it stronger,

make it lighter, or improve the heat transfer, so it’s less brittle in this environment. They can actually replace it with something that’s better so machine uptime is better.

“Industries try very hard to get operating efficiencies of 85-90 per cent, and that’s world class,” said Osborne.

Much of the drive to get to those levels, he said, will come through innovation and decision-making, where plants are redesigning failed components so they don’t fail. MRO