Slippery when wet

Mitigating risks when moving manure. | 8

Reducing phosphorus in watersheds

Vermont looks to clean up excess nutrients. | 12

Weed seeds in the feed

Curbing palmer amaranth at the manure level. | 22

Slippery when wet

Mitigating risks when moving manure. | 8

Reducing phosphorus in watersheds

Vermont looks to clean up excess nutrients. | 12

Weed seeds in the feed

Curbing palmer amaranth at the manure level. | 22

Turning agricultural waste into renewable natural gas (RNG) is a win-win for farms: it generates an additional source of income and also mitigates the methane emissions from livestock manure. Clean Energy is a one-stop shop for the development, operation, financing, marketing, and distribution of RNG. With 550+ fueling stations nationwide, including 127 in California, we provide the shortest path from farm to fleet.

Staying liquid

This

Phosphorus solutions

Vermont

A “cover and flare” method can help curb emissions.” Photo courtesy of Dale Stein.

BY JAMES CARELESS

BY RONDA PAYNE

BY JACK KAZMIERSKI

Have you noticed that a “tech savvy” kid in 2022 is different than a “tech savvy” kid in 2000? When I was young, knowing how to code a simple website made you a computer genius. Now, the basic HTML I learned for extra credit in the seventh grade is taught to children as young as six. The same goes for elite athletes; just look at the performance of elite hockey and basketball prospects compared to their eighties counterparts. As a result, teachers and coaches need to keep up to ensure they’re always challenging students. What does this have to do with manure? Well, manure is also changing, and the industry needs to keep up. This past summer, a team at the University of Minnesota undertook a project to ensure that manure “book values” – the approximate amounts of nutrients in manure – are several decades old. The team compared recent data from labs in the U.S. midwest and found that manure nutrient data has changed compared to previous book values. The university is now

from the previously published book values. There were changes noted in dairy manure and poultry manure in both liquid and solid forms, with some information yet to be factored into the analysis of swine manure, such as age or manure storage systems. With more work to be done, more knowledge will only make the manure industry – and agriculture in general – better.

Manure management is nutrient management, and those nutrients are important for the food we grow and the land on which it is grown. Understanding the current state of manure helps producers care for their land and the food which they produce better. After all, we’re talking about the big picture, here.

With this issue focusing on liquid manure, we thought it was important to look at those “big picture” issues that come from liquid manure management. For example, staying fresh as a driver when it comes to transporting – and potentially cleaning up – liquid manure (page 8).

We also have a feature on reducing

“Everything from diet to storage impacts manure.”

creating a manure nutrient database, ManureDB, to update those values.

It makes sense that manure nutrient models have changed over the years. Everything from diet and housing to storage and handling impacts the nutrients of manure. To better understand how current conditions affect manure the university and its laboratory partners compared the nutrient averages of beef, dairy, poultry and swine manure in liquid and solid forms. Some of the analysis results did differ

methane emissions, which includes innovations on storing liquid manure (page 18). This issue also highlights forward thinkers in Vermont with a feature profiling the participants in the Vermont Phosphorus Innovation Challenge (page 12). And, we cover new research on the pesky Palmer amaranth weed, which is becoming a problem on fields, possibly through manure (page 22).

Keep focusing on the big picture and keep a flexible mindset. Manure literally isn’t what it used to be! •

A team at West Virginia University will study the use of manure as an organic fertilizer. The three-year study, led by faculty member Elizabeth Rowen, was made possible by a $750,000 grant from the USDA. The study will look into the most effective ways to reduce insects and pathogens that threaten crops. It will take place at the WVU Agronomy Farm where four different crops will be planted. Liquid, raw and composted manure will be applied to the soil before

corn, soy and wheat is planted. A control group will not receive any fertilizer.

“In organic production, manure is very common because it is one of the only sources of nutrients that you can have,” said Rowen in a statement. “You can’t use chemical sources of nutrients... You have to produce them with manure or other types of composts.” The research team will also look at ways to make an organic farm more profitable.

The governments of Canada and Ontario are working in partnership with SWIFT to increase broadband access for farms. The following regions have received upgrades (note: all financial figures come from each level of government):

• Waterloo Region –

$429,000 from each level of government supporting 470 customers in Woolwich and Haysville; $430,000

supporting 250 customers in Orr’s Lake and Clyde;

• Lambton, Middlesex Counties – $741,000 supporting more than 1,000 customers in Ravenswood, Gustin Grove, Cedar Point, Glendale Beach, Hillsborough Beach and Highland Glen; $575,000 supporting more than 290 customers in Thedford, Springvale and Jura; $450,000 supporting more than

20

Total N (lbs/1,000 gal) found in liquid dairy manure by the University of Minnesota and three partner labs in a recent study

1,686,330

170 customers in Kerwood, Strathroy and Napperton and more than 100 curstomers in Ballymote;

• Perth County –

$219,500 supporting more than 110 customers in Slabtown, Bornholm and Willow Grove; $613,000 supporting more than 270 customers in Britton and Tralee;

• Elgin County –

$616,000 supporting

Number of farm acres in Canada where liquid manure is injected or incorporated*

2004

Last year manure “book values” were published by the Midwest Plan Service

more than 740 customers in Tyrconnell, Duttona Beach, New Glasgow, Port Glasgow and Churchville; $1.1 million supporting 390 customers in Iona, Iona Station, Lawrence Station and Southwold (December 2022);

• Bruce County –$429,000 supporting more than 300 customers on the Chippewas of Nawash Unceded First Nation.

61,336

Number of farms in Canada applying manure*

1,234,631

Number of farm acres in Canada where liquid manure is applied (not injected)*

Timac Agro U.K. has launched a new slurry (liquid manure) conditioner to preserve nitrogen, phosphorus, potassium and sulphur, enhancing the nutrient profile in order to maximize manure’s fertilizer potential.

Dubbed ActiPost 360, the product is a powder conditioner that can be used in ruminant, pig and poultry liquid manures (as well as solids). It can be applied in the shed or, in the case of liquids, directly to the pit.

The product is a combination of microorganisms, brown algae and marine calcium, which activate the composting process in manure, capture ammonium and reduce losses and odors. The reduction of odors is also considered an important factor for farmers looking to reduce their greenhouse gas emissions through on-farm practices.

The company estimates that nitrogen reduction can be improved by 27 percent and phosphorus reduction by 33 percent with the product.

Dane County, WI, will commit $3 million in the 2023 county budget to study the feasibility of a local commercial-grade manure processing plant in the county.

Such a facility could, according to the county, “substantially reduce phosphorus runoff, advance the community’s clean lakes efforts and benefit the climate… This type of project will also offer smaller producers an opportunity to better manage animal waste streams with technical solutions they may not otherwise be able to afford on their own.”

The plant will collect methane from manure and reduce greenhouse gas emissions. Excess nutrients and RNG could also be exported out of the local watershed.

Dane County is already home to two community digesters in the towns of Waunakee and Middleton, which last year processed more than 90 million gallons of manure and removed 168,000 pounds of phosphorus.

New Holland has introduced its new Discbine Plus Series targeted at hay producers.

The new machines include a maneuverable center-pivot tongue and standard swivel gearbox hitch that permit confident, fast operation and easy, trouble-free headland turns.

All models utilize New Holland’s newly redesigned MowMax Plus disc cutter bar with the QuickMax knife-change system.

The slimmer cutter bar is designed to improve cut quality, while a 30 percent lower cutting height leaves less behind to save on hassle.

The models also utilize ShockPro disc drive hubs that absorb impacts to protect drive components. These components are designed to be quick to replace in the field, enabling haymakers to keep mowing when conditions are right.

Models include the Discbine 310 Plus, the Discbine 312 Plus, Discbine 313 Plus and the Discbine 316 Plus. The 313 recently made its first appearance at the 2022 Farm Progress Show in Boone, Iowa in September 2022.

Biogas specialists will present its new MiniFerm concept at the Energy Decentral trade fair in Hanover, which takes place Nov. 15 to 18. The MiniFerm concept is a small-scale plant which would allow smallersized agricultural businesses, as well as medium-sized industrial companies to enter the self-supply market. The 50- to 80KW plants are highly compact and can convert small quantities of pumpable substrates into electricity and heat.

British Columbia-based Fraser Valley Biogas, a renewable energy company wholly owned by EverGen Infrastructure, has signed a term sheet for a long-term off take agreement. The proposed agreement is expected to cover the purchase of up to 190,000 gigaojoules of RNG annually from Fraser Valley Biogas, which accounts for existing and incremental RNG volumes expected from the facility post-completion of the Core RNG expansion project.

This agreement would replace the existing RNG offtake agreement that is approaching the end of the original term in an environment where current market pricing is significantly stronger than when the facility originally commenced.

The deal supports EverGen’s Core RNG expansion project at Fraser Valley Biogas, which is expected to double the RNG production of the facility to approximately 160,000 GJ per year

The expansion project will commence construction this fall with anticipated completion in Q1 2023.

Fraser Valley Biogas is British Columbia’s first anaerobic digester. EverGen acquired Fraser Valley Biogas in 2021.

Tips for safe manure transport and spill response.

BY JAMES CARELESS

Moving manure from the farm or manure storage to an application site can seem like a harrowing, hazardous business, especially if it results in a vehicle turnover that loses the load while injuring the driver. But it doesn’t have to be a harrowing or hazardous experience – if you’re well-prepared.

University of Wisconsin Extension (UWEX) regularly updates area applicators and farmers on safety, particularly road safety and spill response, in order to ensure those in the industry are adhering to standardized procedures – and that individuals stay safe.

A load of manure is heavy and messy to move, and the strain it puts in tractors, trucks and trailers can be too much if they are not in tip-top shape. So to ensure safe manure transport, “make sure that you’ve inspected the equipment at the beginning of the day and walk around several times per day,”

ABOVE

says Kevin Erb, director of UWEX’s conservation professional training program.

Points to check include:

• Are the hydraulics and hoses properly connected?

• Did you use the right size hitch pin, and are the safety chains attached?

• Is the tractor large enough to safely stop a loaded spreader?

• Does the spreader have a lid or tarp to prevent splashing/spilling if you have to hit the brakes?

All of these questions need to be answered before departing on your trip – not during.

Worth noting: “A major factor for safety is to make sure that all warning lights and flashers are working on the equipment, and that marking tape and reflectors are visible and in place,” says Jerry Clark, UW-Madison agriculture educator. If drivers can’t see you, they can’t avoid you.

+ Low Life-Cycle Costs

+ Turnkey from a Single Source: Separator Pump(s)

Control Unit

Stationary or Mobile Skids

+ Patented Auger with Counter Bearing

+ No Auger Screen Contact

+ Multi Disc Technology

+ Large Capacities

844-647-7867 www.boerger.com

Smart route planning plays an important part in maximizing safety during manure transport, while just setting off to the application site without first planning for potential road and traffic hazards can be a recipe for disaster.

To stay safe, “choose the right route to the field,” says Clark. “A right turn on [or onto] a busy road is easier than a left turn, and safer too. Yes, the safer route may be a mile further and take two minutes longer, but it is worth it. As well, choose loaded routes with less oncoming traffic.”

Another smart traffic tip: Send empty manure haulers along a different route than they used to reach the application site. This will avoid the need for loaded and empty haulers to slow down and pull partly off the road when they meet each other on a shared route.

“Manure applicators need to adhere to road and traffic laws just like any other vehicle on roads,” says Erb. And, given the potential for damage, pollution and injuries plus negative bad media attention when accidents do occur, he says manure haulers indeed need to be extra careful when moving along public roadways.

Drivers should be aware that operating on the public roads is a major stressor for manure transport drivers, especially when operating on busy public roads with other motorists. “Width of equipment and the fact that most applicator trucks and tractors often operate slower than other vehicles makes for impatient drivers from the public,” explains Clark. “Dust and odor also add stress to applicators as many public drivers don’t appreciate being behind manure application equipment.”

“Other drivers are a huge problem,” says Erb. “They don’t understand why you are driving slowly, that you can’t stop on a dime, that swinging right before turning is not an invitation for them to pass you. So always know what other drivers are behind you, and expect those drivers to cause a problem for you. Drive defensively.”

It also doesn’t hurt to have some form of dash-cam within the cab of the hauling unit, to prove the applicator’s innocence when another driver causes an accident – such as by cutting off the hauler.

Moving manure can be tough even in good weather. But when the rain or

University of Wisconsin’s Kevin Erb demonstrates proper manure spill cleanup procedure at a previous North American Manure Expo.

snow comes down, making roads slick and visibility poor, it can add a whole new level of danger to the drive. This is why manure transport drivers need to keep their eyes on the skies (and the weather reports on their smartphones) to anticipate bad weather and avoid driving in it. Keeping the radio tuned to a station with regular weather radio reports, rather than sticking to music or podcasts, is also a smart move.

“Farmers and manure applicators do a very good job operating safely even with very long days,” says Erb. “Where we tend to see more problems is when drivers are both working long days and have the added stress of rain in the forecast or needing to wrap up so they can get to chores or attend an off-farm gathering. That additional stress leads to unconscious safety shortcuts.”

The proof of his point can be found in the accident numbers. “Data from Wisconsin’s drier years shows fewer human error caused spills occurring, but the number goes up in the days before forecasted rain or snow,” says Erb.

Weather-related accidents can also occur during a spring thaw when the frost melts in a dirt roadbed, leaving it weak, soft and potentially hazardous to heavy machinery. “That’s why some states have ‘frost laws’ or seasonal weight limits,” he notes.

Every jurisdiction has its own rules about the maximum allowable weight and dimensions of manure transportation machines/trailers – often classified as “implements of husbandry” (IoH) – and a law-abiding, safetyminded manure transporter always works within these limits.

For instance, in Wisconsin “agricultural weight limits are 23,000 pounds per axle or 92,000 pounds gross

BY

vehicle weight (GVW), dependent on number of axles and axle spacing, and subject to seasonal or special postings,” says Clark. “Certain IoH may be given an axle weight exemption on local roads. These higher weight limits are not allowed on interstate highways.”

Every jurisdiction is different when it comes to their IoH rules, so it’s important to be familiar with your state/province’s rules and regulations. As well, “some farm equipment is just too wide, too long, and or too heavy to operate on the road,” says Erb. “It’s not uncommon for a tractor (with no equipment attached) to exceed a state’s per-axle weight limit.”

When things go wrong and manure spills do occur, “human safety is more important than environmental safety,” says Erb. “So make sure the driver and all involved receive any medical aid they need first, before you do anything else.”

Next, “if you’re on a busy road, or near a curve, bridge or safety hazard, have the local police block off the road,” he advised. This is common police procedure at accident scenes, because

“If you don’t decide to give your body a rest, your body will decide for you.”

they don’t want a secondary accident to occur. As well, an important aspect of safety management is to limit the number of bystanders and neighbors at the scene who might get in the way of first responders.

Once human safety has been assured, it is time to move onto the five steps of spill control. According to Clark, the proper steps are:

1. Control and contain the spill.

2. Notify your supervisor.

3. Contact appropriate authorities.

a break every few loads, like taking a walk around the equipment while it is loading to inspect for common problems,” says Clark. “The biggest stress factor for manure applicators is long work days especially during the busy seasons of spring and fall, when most of the manure is applied before or after the growing season. Equipment breakdowns, weather delays, and fatigue only add to the overall stress of the work and applicator faces.”

This is why “applicators need to

eat healthy and try to get some sort of physical movement when occupying the seat of a truck or tractor for many hours of the day,” says Clark.

“Applicators also need to get enough rest, especially when they are destined for long work days when the application season is in full swing,” adds Erb. “One of my favorite motivational posters states, ‘if you don’t decide to give your body a rest, your body will decide for you, and it’ll be in the middle of harvest or calving season’.” •

MADE IN THE USA.

4. Cleanup the spill.

5. Document the spill.

A long day spent shuttling and applying can be exhausting for applicators. As such, “we recommend that drivers take

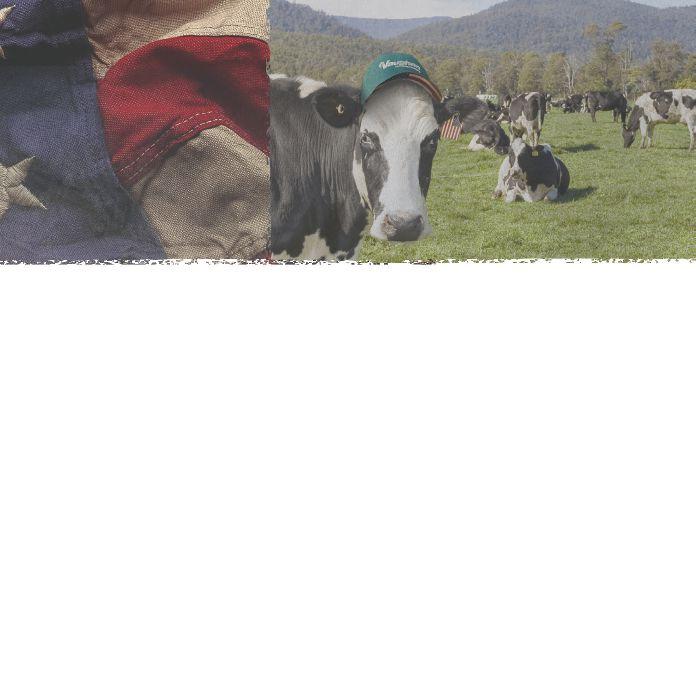

When the going gets tough, turn to the toughest pump on the planet. Since 1960, the unrivaled Vaughan Chopper Pump has been on the cutting edge. This original chopper pump was built first and made to last.

Choose the unmatched reliability of Vaughan. Ask about our free trial program and on-site demos.

• Barn Flush Pit

• Separator Feed

• Lagoons

• Digester Mixing

• Scraped Manure

• and More!

New solutions may soon assist in ensuring waterways stay beautiful and usable.

BY RONDA PAYNE

Farming practices of the past have created issues for the present. The state of Vermont wants to mitigate some of those issues before they become even larger problems in the future.

Although phosphorus has an important place in plant growth, accumulations from decades of unchecked application have caused runoff issues with undesirable and unsafe plant and algae growth in the state’s waterways.

It isn’t that Vermont’s farmers of the past had the wrong idea. Their application of phosphorus-rich sources to the soil indeed helped with crop health and vigor. But the volume and timing of those applications were, in retrospect, excessive. Finding ways

to remove those phosphorus stores before they hit waterways, control future phosphorus applications and reuse captured phosphorus will improve the future for everyone who values the state’s water sources.

Modern farmers have been employing nutrient management planning to control phosphorus application rates and timing in recent decades, but that historic buildup continues to be a chief polluter. Add to this changing weather patterns that lead to increased runoff of both sources and the issue has grown exponentially, making a number of favorite waterways unsafe for swimming, smelly for humans and harmful to animals.

ABOVE The team at Green State Biochar, which is a past recipient of a grant from the Vermont Phosphorus Innovation Challenge for its use of biochar.

Cornell’s 81022MPL with the robust, yet compact EM19DBK Frame and Run-Dry™ Option tackles the toughest manure slurries. Featuring:

6000 GPM / 420’ TDH at BEP at 1800 RPM

7500 GPM max flow

High Efficiency

Low NPSHr

Proven Cornell construction for handling sand laden manure

Hard face seal with run-dry seal protection

With an 8” discharge, 10” suction and 3.5” solids handing, and built for high-operating pressures, MP pumps are specifically designed for coarse-abrasive slurry applications. Constructed of high chrome iron, with a Brinell hardness rating above 650. Talk with your authorized Cornell dealer about finding the best model for your application.

653-0330

The state wanted to take a new approach to the problem. In 2018 governor, Phil Scott announced the Vermont Phosphorus Innovation Challenge (VPIC). This unique competition invited organizations to submit proposals to develop proof of concept methods for removing phosphorus from manure and/or other waste streams, recovering it and making it available for beneficial reuse. The challenge is now in its third stage with three organizations proceeding from agreements in November 2019.

Jeff Cook, administrative coordinator for the challenge, and administrative services manager III with the Vermont agency of agriculture, food and markets says through the challenge, the state is looking for entrepreneurs that can scale up reliable phosphorus management solutions.

“Hopefully this initiative will result in a reduction of phosphorus levels in our waters,” says Cook. “Even if it does not, challenges like this one are beneficial as they highlight water quality concerns which could result in future breakthroughs or technology. Solutions will not be easy but ways to encourage thinking out of the box should be encouraged.”

He adds that often, these types of efforts are hampered by finding resources. But through the challenge, the state is committed to partner on the development of solutions that will create environmental benefits for the future.

Composting, drying and other strategies are the cornerstones of Agrilab Technologies’ plan to capture and redistribute phosphorus in Vermont according to Brian Jerose, president and co-founder of the organization. This processing of manure will allow for continued soil improvement and fertility while also helping the environment on a number of levels.

“There are plenty of nutrients, including phosphorus in farm manures,” he says. “Too many of those nutrients are getting into Lake Champlain and other surface body water in Vermont.”

He says his organization’s efforts and subsequent involvement in the challenge stem from a number of things – not the least of which is that he, his wife and their daughters like to swim in Lake Champlain

and other Vermont waterways.

“[There are] times when that’s not possible due to pollution,” he says.

Currently, working with Magnan Brothers Dairy, Agrilab Technologies has established its compost aeration and heat recovery unit at Burnor Farm in May of 2021. The unit is mounted inside an insulated 20-foot shipping container and produces compost from P cake (from dairy manure solids, scraped manure and pen manure), wood chips, leaves, sawdust and waste feed.

P cake has not yet found markets in Vermont for a range of reasons, so Jerose sees an opportunity in creating a range of phosphorus-based products for various uses such as agricultural, municipal, landscaping and residential applications. He intends to host different product demonstrations and trials for the various uses to educate potential users.

“We’re trying to build a network of farms,” explains Jerose. “The center hub of the site would be with the Magnan Brothers Dairy. We jointly operate an onfarm compost site.”

Because of the variety of practices that exist for manure handling, housing and management, the manure from other sites will be combined with that of the center hub site and the other waste materials. This will be stabilized, dried, blended and become a value-added end-user ready soil amendment.

Air is heated from thermal energy created through decomposition, then pushed and pulled through the pile (about 200-yards per batch) to aid the decomposition process. In some future batches, a phosphorus concentrate obtained from fellow challenge participant, Digested Organics, through its ultrafiltration unit, will be added to the dried end product.

“It helps the material be more stable and more readily stored during the winter months and it also makes it lighter and less expensive to transport,” he says of the process that creates a drier composted product.

Filtration is being used by Digested Organics to show how phosphorus can be removed from manure, says the company’s CEO, Bobby Levine.

“We believe this is a cost-effective solution to protect sensitive watersheds in Vermont and beyond,” he says. “Phosphorus contamination of waterways from manure runoff is something critical

to address to protect our environment and we believe direct filtration can be a critical tool.”

Through participating in VPIC, Levine hopes to collect enough data to prove that the overall costs of manure filtration are low enough to justify widespread use and implementation in any areas that would benefit.

Setting up at Green Dream Farm ensured Digested Organics had access to the necessary three-phase power required as well as a manure screw press

to process material for running through the ultrafiltration (UF) unit. The UF system is contained in a portable trailer with the goal of removing >95 percent of phosphorus, >99 percent of suspended solids and >99.9 percent of pathogens from liquid manure. The fertilizer concentrate is collected in an on-site tank then transported to Agrilab Technologies and the resulting transparent liquid is ready for field application.

Because the phosphorus and liquid nitrogen in the fertilizer concentrate

TURNING

Fan produces bedding material with a dry matter content of

represents about 20 percent of the initial liquid manure volume, it’s easier to transport and efficient to apply on sites where it is needed.

In some cases, the problem is also part of the solution. Struvite, a crystalline

compound created by magnesium ammonium phosphate ions dissolved in a waste stream’s liquid water phase above saturation concentrations can cause scale in treatment plant surfaces. It can also be used to remove phosphorus from waste streams.

While struvite generation to remove phosphorus isn’t a new technology,

ABOVE

The composting and processing of manure will allow for continued soil improvement and fertility.

the systems currently available exponentially exceed the needs in Vermont facilities like Essex Junction Wastewater Treatment Facility. The PePhlo system controls the formation and removal of struvite and other phosphorus forms outside of the treatment process. It’s a small-scale method that that is mobile, flexible and scalable to enhance struvite generation into crystals and phosphorus removal.

The system’s proprietary filter, complete with an electrical field, ensures the struvite crystals are captured and made available for future processing and use. The intent of the project is to prevent scaling in wastewater treatment sites and enhance the controlled creation and recovery of the phosphorus-containing minerals from wastewater streams while also providing a source of fertilizer through processed struvite.

Initial testing of the PePhlo reactor was successful enough to garner another grant to finalize the innovation and creation of a portable unit for transport to wastewater treatment facilities.

All of these innovations look like they can benefit the environment and achieve the goals of the challenge to: capture and ideally reuse phosphorus; convert manure and other organic waste to beneficial products; and determine the amount of support needed to create successful solutions.

BKT provides you tires that are reliable and safe, sturdy and durable, capable of combining traction and reduced soil compaction, comfort and high performance.

BKT: always with you, to get the most out of your agricultural equipment.

Clearly the positives, if financially viable to obtain, can benefit regions outside of Vermont. But, there is no silver bullet to solve the excess phosphorus and runoff problems that occur in numerous regions around the world. As seen with the collaboration between multiple challenge participants, solutions that piggyback on others are the real answer when combined with solid farm management practices.•

Diet and storage management can make a difference and protect the bottom line.

BY JAMES CARELESS

The dairy and beef industries are under a lot of pressure to reduce their greenhouse gas emissions. Whether it’s through fertilizer usage – a contentious issue in Canada – or the methane produced from cow manure, livestock industries have been under the microscope and have been challenged to mitigate emissions, all while keeping the bottom line secure.

Fortunately, research has revealed new insights and has introduced ways for producers to reduce such emissions, which can make a significant difference to the environment. Some of these methods can even make cow production more profitable. Two key ways of reducing greenhouse gases on a dairy farm are by managing cattle diet and manure storage.

Manure produces methane gas, while the food eaten by cows produces manure. Theoretically, it should be possible to reduce methane emissions by changing their diets, while taking care not to deprive them of the nutrients they need for optimal productivity.

Thankfully, this methane reduction approach is more than just theory: It is fact. “We’ve been doing a lot with the environmental impact of the dairy herds and changing feeding management to improve the efficiency of nutrient use and decrease emissions to the environment of nitrogen phosphorus ammonia and methane,” says Larry Chase. Chase

is a professor emeritus of dairy nutrition at Cornell University in Ithaca, NY. “Basically, it’s just a matter of putting together all the little pieces we know about their food including the quality ratio, formulation [and] daily feed.”

One of the simplest yet most effective ways to reduce methane emissions through food management is “to make sure we’re not overfeeding nutrients to cows relative to their actual requirements,” says Chase. “For example, if we’re feeding protein at 10 percent higher than the requirement, can we reduce it to five percent higher without affecting their milk production and quality? In most cases, the answer is yes. So we’re just trying to minimize the range of oversupply of nutrients to cattle. Now you always want to be just a touch over for a safety margin, but we want to reduce the size of the safety margin.”

Cornell University has formulated this approach, along with other methods for optimizing cattle nutrition and waste management, into a software program known as the Cornell Net Carbohydrate and Protein System (CNCPS). As explained online at https://cals.cornell. edu/animal-science/outreach-extension/ publications-resources-software/ cncps, the CNCPS program can help farmers customize their herd’s feed mix to deliver desirable levels of energy, metabolizable proteins, amino acids and mineral requirements for optimal maintenance, tissue deposition, and milk synthesis. It can also help them predict:

• The intake and ruminal degradation of feed carbohydrates, protein fractions, and microbial growth;

• Rates of intestinal digestion and excretion;

• The metabolism of absorbed energy, protein, and amino acids in their cattle’s feed; and

• The nutrient excretion and feed requirements of individual cows and the entire herd, which can be altered to reduce methane emissions.

management isn’t the only option available to cattle farmers. “A farm can hire their own nutritionist, or a group of smaller farms can hire one to work across farms,” says Jennifer Wightman, a senior extension associate in Cornell’s school of integrative plant science soil and crop sciences section. “A nutritionist can help farmers take advantage of forage quality and create mixed rations for different stage animals to optimize their rumen’s well-being. A well-balanced rumen will

milk with less feed – and generally produce less methane. Farms can also minimize the protein and phosphorus levels to reduce nitrogen and phosphorus impact on the watershed.”

Better diet management is definitely good for the environment, and good for the bottom line as well. “Estimates on pilot farms found a net gain between $140 and $160 per cow per year,” based on recent unpublished work by extension colleagues working with

According to Chase, the CNCPS can make a real contribution to reducing bovine methane emissions. “In most of our field studies, we can reduce emissions anywhere from five to 20 percent depending on how far above the herd’s nutritional requirement a farmer is when they start this program,” he says.

Adopting the CNCPS for feed

The “cover and flare” system approach used by Dale Stein involves a 60-millimeter thick plastic layer stretched over the top of a manure storage area when it is about one quarter fill. It covers and captures the methane gas produced by manure for disposal by direct burn-off.

Wightman. “Managing high quality forages on farms is a great way to maximize on-farm nutrition.”

Even with the best dietary measures in place, manure will still produce some amounts of methane gas. This is where the “cover and flare” system approach used by Dale Stein, chair of the New York State Soil and Water Conservation Committee and a “semiretired” dairy farmer working on the multi-generational Stein Farms in LeRoy, NY can make a further difference. The genius of this system is that it covers and captures the methane gas being produced by manure for disposal by direct burn-off (hence the term “flare”),

or by using that gas as a free fuel for other purposes.

In the cover and flare system, “a 60 millimeter thick plastic layer is stretched over the top of the manure storage area when it is maybe only a quarter full,” says Stein. “A trench is dug all the way around the area, with the cover being cemented into that trench so no gas can escape.”

In warm weather, when the manure decomposes and methane is produced, the gas is captured from under the cover using a perforated tube line. “That line is connected all the way around the surface,” he explains. “It travels underground to a flare about a hundred feet away from the manure storage area. The flare is a stainless

steel tube, about three feet in diameter and 14 feet high with a solar-powered, computer-controlled igniter and gas detection system. When the system detects methane being produced above a threshold of so many cubic feet per minute, the computer makes the igniter flash and burn the gas off.”

In New York State, methane tends to be produced by manure cover and flare systems from early July to early November. According to Stein, his burnoff system will run “nonstop through that whole period at about 1500 degrees Celsius, with a foot tall flame just ripping inside the flare stack.”

The only downside: when burned, methane turns into CO2, which is another greenhouse gas. However, CO2 is less damaging to the environment than methane, so producing it is at least an improvement. As well, it is possible to use the methane being produced by the manure to heat water and provide heat to barns, rather than just burning it off via a flare stack.

Dale Stein’s farm has hired a team of designers to create a hot water heating system that could use methane as fuel. “We’re hoping that sometime this winter they’ll have that figured out,” he says. The goal is to have a pumping system attached to the manure storage area that will pump the methane into propane tanks on wheels. These tanks would then be driven to the farm’s milk house, “which uses an enormous amount of 170 degree water to wash everything. Doing this with methane would allow us to eliminate our current diesel-fuelled heating system, which is backed up by propane.”

Meanwhile, the manure within the storage area will still be removed as needed to fertilize this farm’s corn fields. The Stein family pushes liquified manure vertically into the soil using the knife injection system, rather than just broadcasting it over the earth’s surface. “Knifing allows you to save the manure’s nutrients, with very little evaporating away,” says Stein. “And by doing that, we reduce our cost of manmade fertilizer by 90-plus percent.”

By using dietary and manure management measures, it is possible for cattle farmers to significantly reduce their herds’ methane emissions. These approaches can reduce the industry’s contributions to climate change, and give it a defensible moral position, should complaints ever come in. •

This pesky weed is no joke – and it might be hiding in manure.

BY JACK KAZMIERSKI

Palmer amaranth is a fast-growing weed that is spreading quickly across North America.

According to Anthony Brusa, researcher with the department of agronomy and plant genetics at the University of Minnesota, this weed is native to the southwestern United States and northwestern Mexico, but has managed to spread throughout the southeastern part of the States, up through the Midwest and even as far north as Canada.

Not only is this weed spreading quickly, but it’s also difficult to control since it has developed a resistance to multiple classes of herbicides. Moreover, Palmer amaranth is a prolific seed producer, and can grow as fast as two to three inches per day.

“A single individual plant, if it manages to reach maturity, can produce somewhere in the area of a quarter of a million seeds or more,” explains Brusa. “So once it reaches seed, you have a big problem.”

Once Palmer amaranth matures, it can reach heights of between six and eight feet, thereby inhibiting crop growth. Brusa says crop yield losses are as high as 90 percent for corn and 80 percent

ABOVE

for soybean in some states. He adds that Palmer amaranth affects other types of crops as well.

This pesky weed first appeared in Minnesota in the fall of 2016. Brusa was hired to help tackle the problem soon thereafter, and says that the best way to deal with this weed is with a three-pronged approach. The first is tracking and monitoring. “The Minnesota Department of Agriculture is extremely aggressive at tracking it down and monitoring the fields after it’s been discovered,” he says. “If it has reached seed, you have to monitor it for five years, because that’s the duration of it in the seed bank.”

Education is the second prong, and is very important, he adds, because growers need to be aware of the problem, and they need to be able to recognize Palmer amaranth when they see it in their fields. “Every sighting we’ve had has come from growers reporting it, so it’s extremely important that you get the people out there doing the work involved,” says Brusa.

The third prong is research, which includes genetic testing to help identify Palmer amaranth plants already growing in the field, as well as

Palmer amaranth is quickly becoming a problem in Canada and the U.S., and growers need to learn to recognize the weed in their fields.

Palmer amaranth seeds that might be hiding in manure.

Doing so is critical to preventing the spread of contaminated manure.

Brusa explains that two types of genetic tests have been developed. One is used to identify the plant, while the other identifies the seed. “Palmer amaranth looks very similar to other amaranth species,” he says. “For the average person, who just sees it growing in their field, you don’t want to run the risk that you misidentify something. And sometimes, weeds growing out in the field don’t look like they do in a textbook. There’s always a little bit of a variation. So genetic testing of a plant leaf is one of the main ways that people have been using to identify Palmer.”

The seeds are extremely difficult to identify correctly, Brusa adds. “They’re about a millimetre in size. They basically look like poppy seeds, and they’re very, very hard to ID. So you take the seed, you mash it up, you get DNA out of it, and you run it through genetic tests. That’s the most reliable way to tell if you have Palmer.”

“Although genetic testing is making detection easier, methods to separate seed from manure are needed.”

Brusa says that this tiny seed spreads through feed, manure and even through agronomic seed. “You can take a subsample of any of these, and use genetic testing to determine if you have a problem,” he adds.

In Minnesota, agronomic seed has to be certified as “weed-free” before it can be sold, Brusa explains. “It must be certified as not having Palmer amaranth and it must have a genetic test to prove it,” he adds. “Every state is different, so you have to determine whether your state has these programs in place.”

Palmer amaranth can also spread through the sharing of heavy equipment, like combines. “If it’s not properly cleaned, you can have seed stuck in the machine, and then it spreads into a new

field that way.”

Heavy machinery is very expensive, and not every grower can afford to have their own, adds Brusa. “So growers will lease it from companies, or from another grower, and sometimes Palmer amaranth can spread that way across multiple state lines. You can get very, very long-distance spread that way.”

Earlier this year, a research paper was published looking at how Palmer

amaranth seeds can be recovered from manure in order to prevent the spread of this weed through land application.

The paper, entitled “Comparison of methods to recover amaranth weed seeds from manure,” explained that “if contaminated feed is suspected, detection tools are needed to test manure, but traditional methods are time consuming and often inconclusive.”

While the genetic tests explained by Brusa can help determine whether Palmer amaranth seeds are present in

www.yokohama-oht.com

With our premium Alliance branded agricultural tire lineup, Yokohama Off-Highway Tires has the perfect tire for the unique challenges you face. High-speed flotation tires for covering the miles. VF flotation tires to help minimize compaction. Alliance brand Agriflex VF and IF tractor tires for high performance at low inflation pressures. Plus tires for loaders, skid steers and more—all backed by our great warranties.

Ask your tire dealer about Alliance brand farm, tanker and implement tires, call us at (800) 343-3276 or visit www.yokohama-oht.com.

a subsample of manure, the paper explained: “Although new genetic seed testing is making detection easier, methods to separate seed from contaminated manure are needed.”

Researchers compared six methods for their effectiveness in recovering the tiny Palmer amaranth seeds from both bedded and non-bedded cattle manure: dry sieving, rinse sieving, manure saturation sieving without blending and with blending, and dispersion sieving without blending and with blending.

One of the authors of this study is Melissa Wilson, assistant professor and extension specialist, manure nutrient management and water quality, department of soil, water and climate at the University of Minnesota. Wilson and her team of researchers determined that “seed recovery was highest (more than 90 percent) with the rinse sieving method, regardless of manure type.”

While this experiment proves that it is possible to use a sieve in order to eliminate the vast majority of Palmer amaranth seeds from a subsample, more work needs to be done in order to use these findings in the real world where large quantities of manure may need to go through a sieve in order to eliminate as many seeds as possible.

“Just as we can’t test all the manure that’s being spread for nutrient analysis, but instead we test small samples, we may have to use a similar approach when testing for Palmer amaranth,” explains Wilson. “There’s only so much you can do, however.”

Wilson says it could be possible to sieve large amounts of manure at a time. “There are commercial products where they are essentially sieving manure to separate the liquids and solids,” she

Carrying Capacity Range 13-30 Ton Heaped (cu. ft.) 453 - 1,159

Palmer amaranth can be sprayed if caught early enough – at aroudnu two to three inches in height.

says. “So if we get a small enough screen size into these liquid/ solid separation systems, we may be able to recover the seed with the solids portion. Then the liquid would be uncontaminated and could be land applied.”

The solids that are left behind, in turn, “could be composted or treated in some way that would kill the Palmer amaranth seeds,” adds Wilson.

Before techniques are developed that will allow growers to filter large volumes of manure through a sieve on an industrial scale, Wilson recommends sticking with preventive measures, including avoiding any feed that might be contaminated with Palmer amaranth seed. “We’re really just starting to develop, or to think about how we’re addressing this [on a larger scale],” she adds. “So for now, the strategy is to stop it at the source, which means looking at your feed to make sure you’re not introducing any contaminated feed into your operation.”

Wilson notes that storing feed in a silo before using it can help “because it heats up in there and the heat can help reduce the viability of seeds.” She adds that composting solid manure can help for the same reason - the heat will impact the viability of the Palmer amaranth seeds.

If all fails, and Palmer amaranth still makes it into your fields and starts to grow, although it is resistant to herbicides, Brusa says you can still spray it if you catch it early enough. “You need to catch it when it’s about two to three inches. That’s the problem with herbicide application. The window of effective application for Palmer is pretty limited because of how quickly it grows.”

Ideally, however, Brusa says a team effort is necessary if we ever hope to eliminate the problem, or at least prevent Palmer amaranth from continuing to spread uncontrollably.

“Communication is really important,” Brusa says. “All of the control efforts in Minnesota, for example, have come about because growers reached out to the Department of Agriculture and everyone was willing to communicate.” •

You did the work of taking a good, representative manure sample. You sent it off to a nutrient testing lab and the lab sent you a results report. Great! But how do you interpret the results and use them for accurate manure application?

Let’s first walk through the common tests, and then look at how to use them for application.

Moisture and dry matter are pretty selfexplanatory. It’s just the measure of how wet or dry the manure is. It’s reported as percent, and the two values (percent moisture and percent dry matter) should add up to 100 percent.

Nitrogen usually takes up a hefty portion of the report because there are many forms that are relevant for plant growth. Total nitrogen is all of the nitrogen forms combined. Ammonium nitrogen is the fraction of nitrogen that is immediately plant available; and organic nitrogen, which is sometimes called “slow release N”, is the fraction that will need to be mineralized before a plant can use it.

you live in an area with sodic (high sodium) soils, adding manure with high sodium can make the problem worse.

Soluble salts is reported as EC, which stands for electrical conductivity. Much like sodium, manure with high salts can damage crops and make saline soils worse.

How acidic or aklaline manure is is indicated by its pH levels. The scale ranges from zero to 14, with seven as neutral. Over seven is alkaline, and below seven is acidic.

The most obvious use of your manure test is to calculate application rates. Of course, to do this, you also need to have a recent soil test to know what nutrients already exist in your soil. If your manure test shows a high P content and your soil is already at a high P level, consider applying at a rate that meets the P needs of the crop. This will likely under-apply N, but it will avoid P buildup which can lead to runoff and pollution.

“Many forms of nitrogen are relevant for plant growth.”

Phosphorus might be reported as P2O5 or simply P. Even though P2O5 is not a P form used by plants, it is the preferred form for calculating application rates since it is what’s used in fertilizer recommendations. If your lab reported phosphorus as just “P”, you’ll need to multiply by 2.29 to convert P to P2O5

Potassium may be reported as K2O or K. Similar to phosphorus, though plants don’t use K2O, it is the preferred form for reporting since it lines up with fertilizer recommendations. If potassium is reported as just “K”, convert to K2O by multiplying by 1.2.

While N, P, and K usually get all the attention, other nutrients may be important to test for if you are concerned that your soil has a nutrient deficiency for the planned crop.

Sodium, while not an essential nutrient for plant growth, may be a good test to include as very high sodium levels can damage plants. If

Besides application rates, there are other nuances that your manure test results can help with. For example, potatoes tend to be fond of slightly acidic soil. If you’re applying a very alkaline manure to alkaline soil, it might not be the best growth environment for your potatoes. Similarly, sodic and saline conditions are not conducive for the growth of many plants. So, if you have a saline soil, and your manure also has a high EC, you might want to choose to plant a crop with high salt tolerance such as barley.

There are many tests out there for manure, and what’s available may vary based on your location. Which tests you choose to order and how you use them are up to you; and in the end, it comes down to what is important for your situation. If you’re trying to save some money, you certainly don’t have to order all the tests described here. It’s generally recommended that manure, at a minimum, be tested for moisture, total nitrogen, phosphorus, and potassium. •

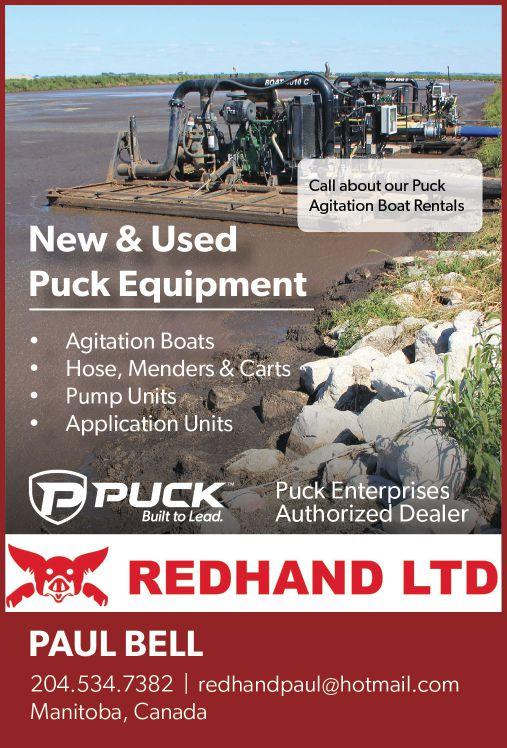

If you are transporting manure more than 4 miles, it’s time to consider a safe and economical solution.

The GEA Manure Semi-Tanker is a road ready solution to save time and reduce hours on your tractor.

• Field tested reservoir proven to be manure ready.

• Partnered with a galvanized undercarriage from one of the largest trailer manufacturers in North-America.

The new HD pumps are built to pump manure, built to run smoother to save fuel, run at a lower rpm with larger and wider impellors to reduce engine wear and plugging issues.

Proudly made in Canada since 1871.