Nitrification inhibitors are often added to fertilizers. Do they work for manure? | 14

Plowing ahead

Manure proves its worth again. | 18

One year of data

A deep-diving database has given researchers new manure insights. | 26

May/June 2025

Nitrification inhibitors are often added to fertilizers. Do they work for manure? | 14

Plowing ahead

Manure proves its worth again. | 18

One year of data

A deep-diving database has given researchers new manure insights. | 26

May/June 2025

• Python, Hybrid II, & Rotary models have pivoting design built in for forward weight & contour following.

• No need for a 2nd bolt on pivoting bar & all the associated weight out the back.

• 30° left & right pivot angle to accomodate contours & end row turning on dragline

• Same time-proven Series 70 ability/reliability

• Special design for dragline or tank toolbars

• Patented Conical blade creates a wider furrow for higher GPA than conventional coulter/vertical till injectors

• Patented Cupped covering blades aggressively move soil to cover excess liquid

• Heavy down pressure on covering blades

• Combination of rotary injector & disc incorporator

• 24” – 30” spacing

• Best Warranty

• Best actual injection/coverage of wide gallonage ranges

• Best Durability

• Best options for various requirements

• Highest GPA actually injected/covered in the industry

• Non-grease hubs on all models for maintenance free operation

• Swivel coulters reduce side loads

• 18” – 30” spacing

• Patented Conical blade creates a wider furrow for higher GPA than conventional coulter/vertical till injectors

• 18” spacing, 8 wave Conical blade, & 2 Clozr blades on dragline result in higher GPA injected/ covered than a single closer blade design

• DSI’s signature injector

• High performance Coulter down pressure design

• 4 Sweep options for lower rates to 20,000+ GPA

• 4 Tube options, including plug-free wing drop

• Liquid stays where injected, properly placed for full utilization by crop

• Clozr option for different operation requirements

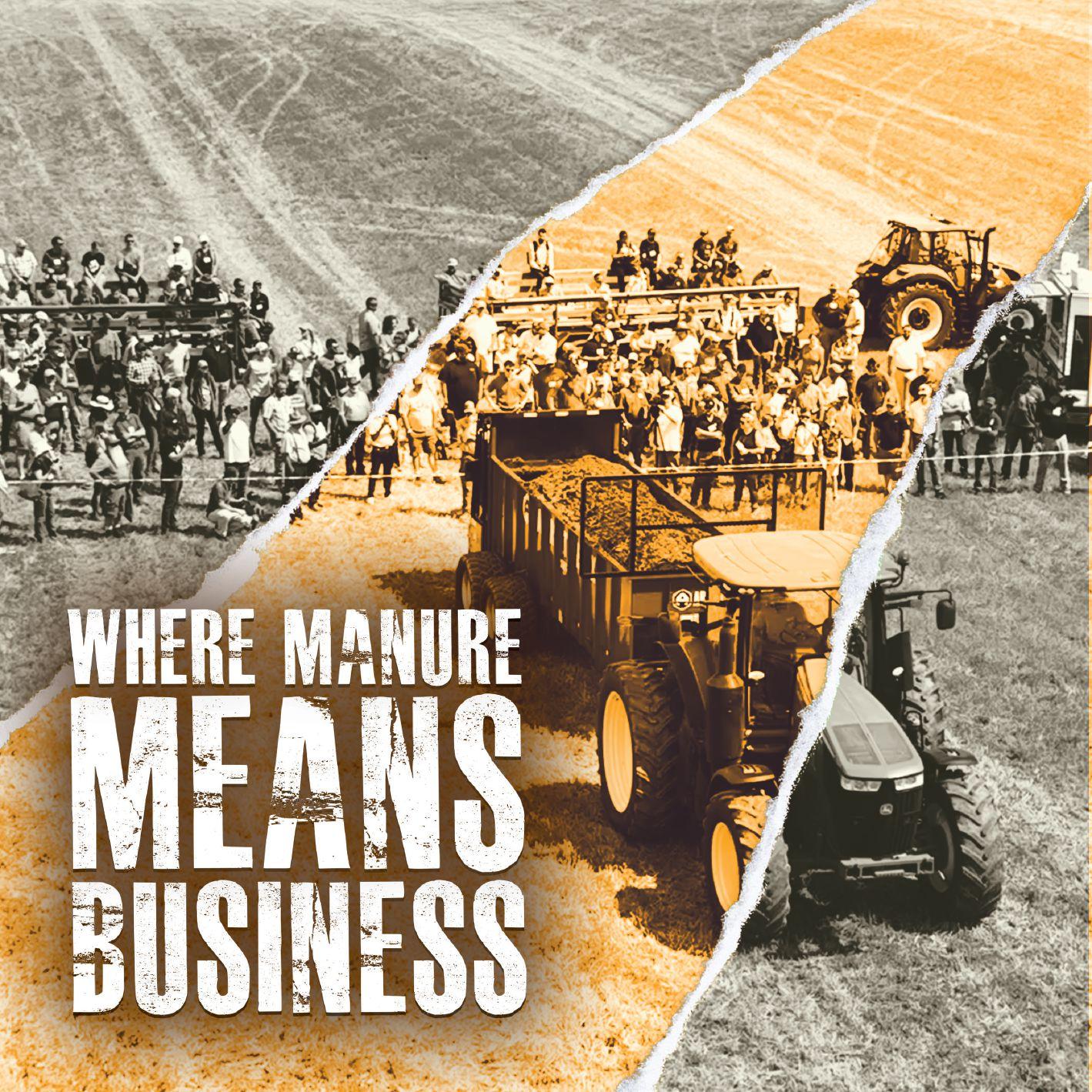

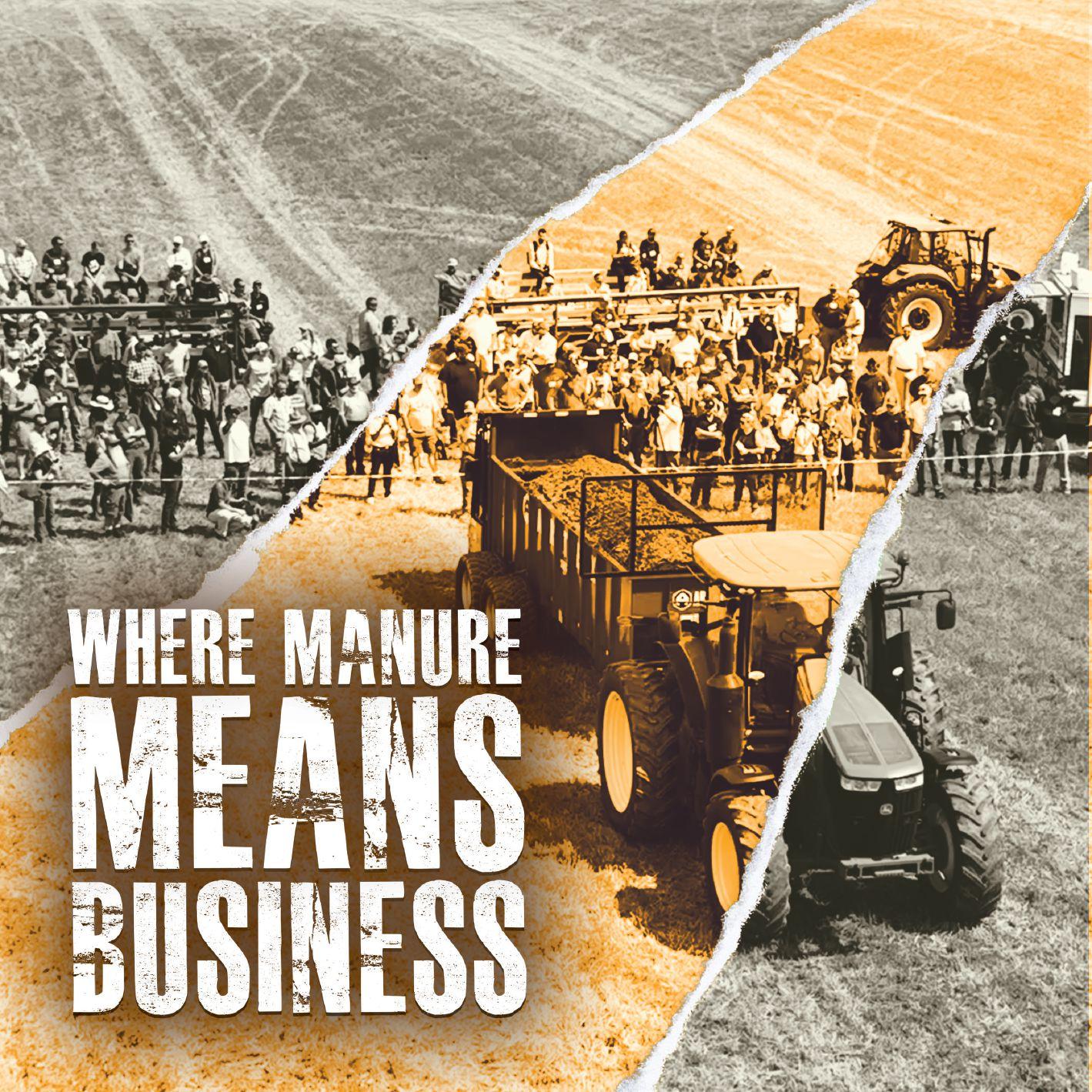

This issue focuses on the efficacy and management of solid manure. What better to lead with than a study proving the worth of solids?

BY TREENA HEIN

Plowing ahead

An experiment in a region not known for its manure supplies gave manure some good PR. But where can it go from here?

BY JIM TIMLICK

Manure measures get an update What have ManureDB’s founders learned about changes in manure since the launch?

BY RONDA PAYNE

In my nearly five years as your trusted editor, I’ve dropped a few personal details into these editorials – like the fact that I teach dance or didn’t grow up in an agricultural hub. Another important fact? I love The Simpsons.

Matt Groening’s iconic series debuted in 1989 (so did I!) and at times supervised me for several hours per day, teaching me lessons in history, vocabulary and life. For example, in Season 6’s Fear of Flying, Lisa tells Homer to look on the bright side after a setback, explaining the Chinese use the same word for “crisis” as they do for “opportunity.”

“Yes,” Homer replies, “Crisi-tunity!”

Lisa is sort of correct. According to various linguistic texts, the Chinese word for “crisis” (the characters aren’t easy to print here, but it is roughly pronounced “wei-jee”) consists of components that individually mean “danger” and “opportunity.” But together, there represent something more like what Anglophones would call a “turning point.” Nevertheless, that still seems appropriate for our current moment in agriculture.

So, the crisis? Tariffs (and countertariffs). Amounts and targeted countries may fluctuate or be difficult

It’s not enough to seize on a single crisis.

to predict in the coming weeks (trust me: I’m Canadian), but as of right now, import tariffs – and, in other countries, counter-tariffs – affect many components of agriculture: machinery and parts, seeds, chemicals… oh, and fertilizer.

Critical ingredients for fertilizer are mostly sourced abroad (Canada, Russia and Belarus hold roughly two-thirds of the global potash market). This last became an issue following the the 2022 invasion of

Ukraine, which drove fertilizer prices high, peaking in May of 2022. Many speculated that this could drive up demand for manure.

But did it? In terms of objective and long-term evidence, it’s a bit of a “jury’s still out” ruling. One 2022 report indicated an increase in demand for poultry manure in Colombia. Another report in Reuters posted anecdotes from spreader dealers and applicators indicating high demand, along with reports from a Nebraska applicator stating their prices had nearly doubled. Anecdotal evidence should not be discounted entirely, but the fertilizer price increases of 2022 were not sustained and even went down in the next two years. And we don’t have adequate, national data on manure application to indicate a long-term increase in spreading (as of 2020, manure is applied to less than 10 percent of the U.S.’s major crop fields).

I bring this up not to say the status quo will hold once again, but to say that it’s just that it’s not enough to seize on a single crisis. The good thing is, there’s increasing research out there not just about the efficacy of manure as a nutrient source for plant yields, but also about its positive effects on the environment and as a potential energy source.

As we at Manure Manager work to get that information out there and showcase real examples of manure and its positive effects on farms, we thank you manure fanatics for continuing to spread the word. The increase of manure adoption will not be driven by a single economic event, but by the long and tireless work of farmers, applicators and researchers.

Kang Xia has been named associate director of Michigan State University’s AgBio Research unit. Her appointment is official today, April 14. Xia comes directly from Virginia Agricultural Experiment Station (VAES) at Virginia Tech, where she also served as associate director. Simultaneously, during her time with Virginia Tech, she acted as director of Virginia Tech’s Center for Advanced Innovation in Agriculture, leading major initiatives in fields such as precision agriculture, agricultural biotechnology, cybersecurity in agriculture, and agrivoltaics.

will join director George Smith and fellow associate director James Averill. In her roll, Xia will promote the full spectrum of fundamental and applied research across MSU disciplines, working closely with MSU AgBioResearch-affiliated faculty to build synergies for future collaborations, identify research initiatives, seek funding opportunities and support team efforts in pursuing large grants and investments.

She’s been in a university faculty role since 1998, with her experience spanning Kansas State, University of Georgia, Mississippi State and Virginia Tech. She

She’ll also connect with external partners and stakeholders within the Michigan agricultural and natural resources communities to communicate impacts delivered by AgBioResearch’s scientists and gather input that will inform decision-making on prospective research activities and opportunities to work together.

Experts agree that applying nutrients to farm fields – be them in the form of synthetic fertilizer or from livestock manure – requires a plan. Nutrient management plans are a crucial part of keeping nutrients where they’re supposed to be and ensuring maximum nutrient uptake by crops. It also

helps make nutrient application more efficient.

Site-specific planning thresholds for phosphorus and nitrogen are now available through the new Geographic Information System (GIS) Site Risk for Water Quality (SRWQ) tool available on the NRCS Dynamic Soils

Hub (pictured). It is available to farmers, certified crop advisors, conservation planners, educators and more.

“There are significant differences between and within fields for nutrient loss in both leaching and runoff,” said Tim Pilkowski, NRCS national nutrient management specialist, in a statement. “This

new tool can help planners visualize how nutrient management can be more effectively integrated with other conservation practices to protect water quality.”

The goal is to support 4R nutrient management principles and address sitespecific risk for nutrient loss.

A nine-year study comparing a typical two-year corn and soybean rotation with more intensive three-year rotation involving corn, cereal rye, soybean and winter wheat found that the three-year system can dramatically reduce nitrogen runoff, without compromising yield.

Runoff is a concern for both commercial fertilizer and livestock manure, whose rich nutrients are most valuable when left to be consumed by plants – but have been known to cause water quality issues downstream. As such, with plants requiring nutrition, strategies such as cover crops and various rotations can be implemented to keep more nutrients on the field.

The recent, Illinois-based study, led by author Lowel Gentry, was designed to see if a more diverse crop rotation would reduce nitrate loss from tile-drained fields, while still remaining competitive with the conventional system of corn and soybean.

Nitrate loss was monitored from fields on a working farm from 2015 to 2023. This field was planted with corn, followed by a full season of soybeans, then winter wheat. A summer harvest of the wheat was followed by a second crop of soybean the same year, or double-crop soybean. Between corn and soybean, a winter cover crop of cereal rye was grown to protect the soil. The cereal rye was terminated with herbicide prior to soybean

planting and allowed to decompose on the soil surface, delivering nutrients to the next crop.

A key difference between the rotational systems was the amount of tillage. The control fields were fully tilled in the fall and spring, but the researchers strip-tilled only a narrow swath of the cornfield in the threeyear rotation, minimizing the area tilled to one-third of the total field every third year.

The researchers saw a 50 percent reduction in nitrate losses through tile in the three-year rotation when compared with the normal rotation. This was accomplished without compromising yields, the team found, which is a top concern among farmers.

There’s less than one month to go before the 37th World Pork Expo, held in Des Moines, IA. On June 4 and 5, producers from around the globe will descent upon the Iowa State Fairgrounds for the world’s largest pork-specific trade show, which offers a wide range of free seminars, networking and hospitality opportunities.

According to the National Pork Producers Council (NPPC), which produces the show, last year’s Expo hosted more than 12,000 producers and industry professionals from 37 different countries at the event, which highlighted trends such as precision feeding to reduce costs, sustainability, innovation, biosecurity, swine health, consumer trends and more.

Expo’s first-ever Young Pork Advocates Issues Meet, a two-day competition designed for youth age 17 to 22 to participate in collaborative discussions around industry issues and drafting innovative solutions, with winners and finalists receiving scholarships of up to $2,500. The initiative resulted in 12 youth from eight states participating in the inaugural event.

Other key figures for last year’s expo included 395 exhibitors and 45 sponsors, covering more than 300,000 square feet of fairground.

and various other networking and discussion opportunities.

Minnesota pork producer and NPPC president Lori Stevermer says the Expo is a great way for producers to stay current. “You will see the newest products and innovations, have access to educational seminars on current industry topics and get the opportunity to exchange ideas and learn from others.”

Young producers are more featured than ever before; new in 2024 was the

Other key events include Pork Academy, presented by the National Pork Board and Pork Checkoff, companysponsored business seminars

Also returning this year is the World Pork Open Golf Tournament, which invites attendees to compete for special prizes while cultivating new and existing industry relationships. The tournament takes place June 3, the day before the Expo begins, and is limited to 125 golfers.

+ Low Life-Cycle Costs

+ Turnkey from a Single Source: Separator Pump(s)

Control Unit

Stationary or Mobile Skids

+ Patented Profile Auger with Counter Bearing for No Auger Screen Contact

+ Continuously Variable Dry Matter Content

+ Large Capacities

844-647-7867

www.boerger.com

Canadian agri-food leaders visited Washington, D.C. this spring to meet with members of Congress and senior administration officials responsible for agri-food and trade policy amidst ongoing disputes over free trade and tariffs.

Delegates from the Canadian Canola Growers Association, CropLife Canada, Cereals Canada, Grain Growers of Canada and others are part of the group organized by the Canadian Agri-Food Trade Alliance (CAFTA). Their goal is to strengthen collaboration with U.S. counterparts and reinforce the value of rules-based, integrated agri-food trade between the U.S. and Canada.

“Canada and the U.S. are not just trading partners – we are production partners,” said Greg Northey, president of CAFTA and vice-president of corporate affairs at Pulse Canada in a statement. “Our integrated supply chains create jobs on both sides of the border and provide American consumers with stable, affordable access to food.”

This comes following some groups releasing warnings or dire reports on the impact of tariffs during the uncertain period of January to April, during which various announcements, implementations, delays and exemptions were passed. The Fruit and Vegetable Growers of Canada (FVGC) released a statement in April to state that in Ontario alone, between March 4 and 7 (when the initial set of tariffs were implemented on a range of goods covered under USMCA), greenhouse growers reported losses of $2.2 million per day in sales.

The association cited “limited tools to manage volatility and external shocks” due to the more perishable nature of its products, as well as intensive human resource and labor requirements. The association recommended the creation of a dedicated emergency fund to provide direct compensation to operators, and an overhaul of existing business risk management programs.

The agriculture brands of Annex Business Media have named this year’s cohort for the Influential Women in Canadian Agriculture (IWCA).

Now in its sixth year, the IWCA program celebrates innovative, hardworking and inspiring women across

Solid manure in Canada

*Source: Statistics Canada/Government of Canada, 2021

Canadian farmers produce and store plenty of manure – but manure management practices are still not as commonly used for solid manure in Canada as they are for liquid.

all facets of Canadian agriculture including leading producers, researchers and professors, advocates, agronomists and more. The program includes a podcast series in which each honoree tells her story through a dedicated podcast episode –

podcasts debut in June – and culminates in a half-day, free virtual event (Oct. 21) that includes panels, Q&As and more.

This year’s honorees are: AAFC’s Athyna Cambouris, Dalhousie University’s Jolene MacEachern, Hensall Co-Op’s Meghan Scott,

Quattro Farms’ Emily Ford, SaskFSA’s Candace Mitschke, Université de Montréal’s Martine Bouliane, and the Ontario Federation of Agriculture’s Cathy Lennon (pictured). Stay tuned for their podcast appearances, debuting this June.

Amount of Canadian livestock farms that employ solid or semi-solid storage systems.*

Amount of solid manure storage structures with concrete or impermeable pads.

Amount of Canadian beef producers whose solid storage structures have runoff containment.

Amount of Canadian dairy farmers who say they don’t use treatment practices on solid manure (composting, turning, etc.)

JOHN SHUTSKE | UW-Madison

I was honored to help launch California’s new Autonomous Agricultural Tractors Advisory Committee in late March. I presented at the kickoff meeting, and it was humbling, especially in a state that plays such a defining role in U.S. agriculture. I’m grateful to the committee organizers for making this effort happen, and it’s likely to have national and global implications, given the challenges we have in agriculture, such as a labor shortage and the need to improve safety. More on this event can be found here: https://www.agri-pulse. com/articles/22648-california-weighs-benefit-ofstandards-proxy-data-in-autonomous-agriculture

I’ve been working in this space for about five years now at UW-Madison in biological systems engineering, though my research work in safety sensors and control systems to reduce the risk of injury, fire, and other outcomes goes back several decades.

The California initiative is more than regulatory housekeeping. It’s a recognition that autonomy in agriculture brings both promise and complexity.

One thing I tried to reinforce during my remarks was that we can’t treat “data” as the only ingredient in building trust or ensuring safety. Operational hours alone don’t tell us how machines respond when things get close to the edge—when a child runs into a field, a tree wobbles in the wind, or a machine misreads a reflective surface as the sun is setting. We need detailed exposure data.

As we navigate this next chapter in ag tech, functional safety standards (think: your car’s automatic braking system) have much to teach us and their consideration is an absolute must for ALL manufacturers (and designers, engineers, roboticists, and innovators) whether they are large OEM companies or small startup companies.

My work over the past several years, including a landmark Hatch-funded USDA project and co-leading the USDA-supported SaferAG 1.0 and 2.0 workshops, has led to a focus on exactly these issues—how to think about safety where historical data is thin, how to involve farm workers and engineers together, and how to build trust through rigorous design, testing, and transparency.

Above all, I emphasized that safety isn’t just about tech. It’s about people, especially those closest to the work. Hernan Hernandez, executive director of the California Farmworker Foundation, said it best: “They know exactly what the terrain looks like. They know exactly how to do the work... We need more farmworkers in the discussion.”

That’s not just a nice sentiment. It’s a strategic imperative.

This is a moment of opportunity. We can use autonomy to reduce injury and health exposures, lessen repetitive strain, and make farm work more rewarding and attractive for the next generation— but only if we stay committed to smart engineering, risk-based design, and inclusive decision-making.

We can’t treat data as the only ingredient in ensuring safety.

What do embedded safety systems see when these machines are being designed, tested, and used in real-world conditions? How do designed safety systems respond? What is the performance of sensors and systems across real, often unpredictable conditions?

I also encouraged the committee to lean into engineering design and safety standards—especially ISO 18497 and ISO 25119—alongside other emerging ASABE and ISO resources. These aren’t esoteric academic documents. They are the bedrock of design. They reflect the hard-earned lessons of safety professionals across sectors, including agriculture, construction, and manufacturing.

I’m proud to represent UW–Madison and be part of this effort, and I’m looking forward to what comes next.

I’d love to connect and continue the conversation if you’re working in this space –designing, testing, researching, or regulating. •

John Shutske serves as a faculty member and extension specialist at UW-Madison. He is focused on engineering and management principles that reduce risk for the agricultural industry including injury prevention, workplace health, climate change (impacts, mitigation, adaptation), homeland and business-level security, and disaster preparedness. He also holds a professor appointment with the UW School of Medicine and Public Health.

WALTER GROSE

Editor’s note: All our safety articles are about important and at-times upsetting topics. This column mentions suicidal ideation. If you or anyone you know is struggling, please reach out to a service such as AgTalk (http://domore.ag/agtalk), an app that can connect you with resources. Canadian Crisis lines include the National Farmer Wellness Network at 1-866-327-6701 (1-866-FARMS01). U.S. residents can reach the National Suicide Prevention Lifeline by calling or texting 988.

This is not the first time I have talked or written about safety – and why we don’t seem to do it. After 35 years of advocating for farm safety I would hope someone has listened but here I am writing again because today feels different.

My name is Walter Grose, I am the past president of Husky Farm Equipment Limited, and I am the secretary for the Wellington County Farm and Home Safety Association in Ontario Canada.

Today, I received a phone call from one of my Farm Safety Committee Members – she wanted to know if the funeral home could donate to Farm Safety. “But why?” I asked. “Well, my son died yesterday in a farm accident, and I want the money to go to something useful” she told me. He has been looking after the farm since they retired. They were running a new water line, and he went in the trench to put the pipe in the bottom. The trench collapsed in on her son and he was killed. The paper reads: “62-year-old male died in a farm accident.”

fast with long hours and not enough help. But you can do it right. If you die in a farm or work accident you will never get the job done. Doing it right is the safe way, the way that makes sure you will be back at it tomorrow to complete the job. It means that you are around to have supper with the family and kiss the kids as you put them to bed.

I mentioned today was different, not just because of the call I received earlier about the accident, but because today, our son went in for brain surgery to remove a brain tumor. At 27, he should be doing other things. I am sitting at work writing this article and waiting for the call to hear his progress. I can build almost anything you want, and can fix most things, but I can’t fix that; I can’t perform surgery.

I can, however, save lives by teaching you to do things the safe way. Our son has struggled with depression for years, sleeping 14 hours a day, and suicide is constantly on his mind. Safety on the farm does not always mean physical safety. It can mean that when you are trying to accomplish too much, work too long of hours and the money is always short, you can struggle mentally as well. You believe it is just too much; nothing is going your way. That is when you need to know your family, your friends and your co-workers care for you. They are there if you want to talk, or you can pick up the phone and call a help line. Get a message to someone: you need help. Our grandchildren depend on our son to give them hugs and make them cookies. They want him around. We want him around. Someone wants you around.

Safety on the farm can mean struggling mentally as well.

What the headline does not say is the family is in mourning and the neighbors are shocked at the tragedy. I lost a schoolmate the same way 12 years ago. The contractor that was working on the site and had to dig him out has never really recovered from his death; it is always on his mind.

So, this year I created a keychain token, a round “toit” as some might call it, to carry in your pocket, hang from the rearview mirror or attach to the tractor keys – somewhere that is always nearby. Every time you go to the barn, to the field or leave the house in the morning, you see the etching in the tag: “FARM SAFELY. YOUR FAMILY LOVES YOU.” You need that constant reminder that you are not alone in the world, that someone cares.

(Just so you know, I need the same reminder; I have used all my nine lives, and I am not even a cat.)

We get all caught up in how to get the work done

I was at the booth at a farm show a while back and a man came up, looked at the liquid manure spreader and said, “I was the fourth man in”. He explained: “I was the fourth man in the manure spreader when those three men died in the tank. I got out.”

Years ago, three hired men were spreading manure on a farm in Ontario and one of them went in the tank to get a rock. He died with his first breath. The next two went in to rescue him. They died instantly. The fourth man went in, held his nose and his breath, then tried to lift a 200-pound man with one hand. He could not do it, so he climbed back out. The first employee was a tragedy. The next two died as heroes trying to rescue him. There was new legislation created from this accident. Safety bars on fill holes are mandatory in Ontario, as are pictorial safety signs depicting the presence

of dangerous gases (which we now have printed and displayed in three languages). The farmer had to create procedures for working on the farm and with manure. We all have to have procedures if we have employees and farms are no different. Owners or supervisors must read the procedure manual to the employees to ensure they understand it – not just hand them the book to read. Did we learn from

our mistakes?

After the summer of 2024 I am not yet sure we are on top of our training yet. The question I’m wondering about today is why do we still do things so unsafely. It takes two minutes to put on my chain saw pants, so why am I sitting in the hospital getting stitches - because I thought I could save two minutes. We need a culture of working safely. When

Former fire chief Tom Basher presents a tutorial on gas and confined safety measures at the 2024 North American Manure Expo.

my grandchildren were born, I changed how I do things: I wear my seatbelt on the tractor (which I have rolled three times now). My grandchildren were at the farm show with me last week and put on the seatbelt on every tractor they sat on. They are used to the culture of putting on a seatbelt – even the dolls buckle up. I don’t put the ladder in the bucket to get higher, and I don’t speed anymore when I’m driving. I am starting a culture of safety around my farm. Our employees follow safe operating procedures. We read them the training manual. We retrain on safety quarterly. We have adopted a culture of safety.

I got the phone call our son came out of surgery just fine. A four-centimeter brain tumor was removed, and now all the testing begins. Progress begins on the road to recovery.

Save someone else’s life, save your own life, start a culture of safety today. •

IN COOPERATION WITH:

7:30 - 11:00AM Tours

CEU’s available; limited seats; pre-registration required

• Smart composting and manure management

• Innovative manure and energy solutions

• Precision manure irrigation

• Water management and conservation practices

9:00AM Expo grounds open

11:00 – 5:00PM Agitation demos, safety training & more!

7:30AM Expo grounds open

8:00 - 10:00AM Educational Sessions

• 16+ sessions on composting, technology, water quality, safety, regulations, agronomy and more!

CEU’s will be available

10:30 – 5:00PM Explore exhibitor booths and equipment displays, view live side-by-side demonstrations, join industry sessions and grow your network.

Purchase expo & tour tickets online before July 1 to save!

VIEW THE FULL SCHEDULE AT:

BY TREENA HEIN

BELOW

The yellow container on top of the tanker contains a nitrogen inhibitor, which does not technically fully inhibit nitrification, but rather slows it down.

You don’t have to tell producers: nitrogen is a concern. It’s also necessary.

It’s a beneficial resource to plants and crops, but excess nitrogen leaching into waterways has undeniable negative effects on water supplies. Farmers and applicators alike are always looking for ways to mitigate such losses while ensuring nutrients stay where they’re supposed to: with the plants they’re feeding.

Although there’s more research to be done, and new products may also be introduced in the future, there’s solid advice available at this point about how today’s nitrification inhibitors are best applied with manure in order to get the most out of the nitrogen it contains.

Manure is, of course, a valuable resource, and if products can be co-applied to maximize its ability to boost yield, then all the better – but as with any fertilizer product, application of nitrification inhibitors must be done with care to make it worthwhile.

Nitrification is a natural process in the soil where certain bacteria (mainly in the genera Nitrosomonas

ABOVE

Fall nitrogen application in Minnesota.

“If you mix DCD as a certain percentage of your N, you get some delay of nitrification.”

and Nitrobacter) convert nitrogen to a form that’s more available for root uptake. This conversion of ammonium (NH4+) to nitrate (NO3-) can take a few days to weeks, depending mainly on soil temperature and water content, but also whether or not you apply a product to slow it down. That is, nitrification inhibitors do not completely inhibit nitrification, but slow down bacterial activity, providing a more gradual release of nitrate to plants.

But besides the benefits to crop performance, the amount of N that is present in nitrate form also matters to the environment.

“Because the nitrate molecule and microscopic soil particles are both negatively charged, they are not held together, so when it rains, especially excessively, the nitrate can leach down to lower levels in the soil beyond the root zone,” explains Dan Kaiser, UMN extension nutrient management specialist.

The nitrate can also leach away into nearby bodies of water. Substantial leaching can occur in the early spring (when snow is melting and spring rains arrive) from nitratecontaining fertilizers or manure applied to fields at that point. (Also note that besides leaching, in some conditions nitrate can be lost via the process of denitrification.)

Returning to our nitrification

inhibitors, good results using these products with manure can be achieved if application is precise in method and timing, explains Jeff Vetsch, soil scientist at University of Minnesota (UMN). There are a few factors involved with that, mainly how long these products themselves last in the soil, so the application needs to count.

Before we look at best application practices, it’s important to distinguish the two types of inhibitors currently on the market that are suitable to apply with manure. (That is, other inhibitors will only truly work well with fertilizers. Vetsch says Instinct NXTGEN works well with urea, for example, and N-Serve is used strictly with anhydrous ammonia fertilizer.) One type acts directly on bacteria, and because it does so, it’s classified as a general use pesticide in the U.S. Commercial applicators therefor need to check with their state to determine whether a commercial pesticide applicator’s license is necessary before applying it. However, in Canada, both nitrification and urease inhibitors are regulated* as soil supplements. The well-known active ingredient in many of these products is a chemical called nitrapyrin. It has been around for decades, but new forms have emerged in recent years.

Some solid manure with high organic matter or bedding will have two N conversion steps.

Instinct and Instinct 2 both contain microencapsulated nitrapyrin, for example, which greatly reduces volatization. Another product with direct action is CENTURO, which targets the ammonia monooxygenase enzyme of Nitrosomonas bacteria to disrupt its N conversion in two ways.

The other type of inhibitor does not act directly on bacteria (mechanism uncertain) and the chemical here is dicyandiamide (DCD). It’s offered in various products such as SUPERU. Vetsch notes that some retailers prefer DCD products as they are not as corrosive on equipment as products with nitrapyrin can be. The makers of CENTURO, who also make SUPERU, also claim CENTURO is less corrosive on equipment than nitrapyrin.

Melissa Wilson, UMN associate professor and extension specialist, reports that the operators she’s observed using nitrapyrin “have a separate tank on top of their tank where a stream of nitrapyrin is injected into the manure stream as it’s exiting, rather than having it mixed in.”

Returning to DCD, Kaiser explains that “it was first developed as a fertilizer. The molecule has an ‘amide’ in it, which is ammonia. The concentration of N in straight-up DCD is higher than it is with urea, so on paper it would seem to be a

very good fertilizer by itself, but when it was tested, there were a lot of issues with plant toxicity. But researchers also found that if you mix DCD as a certain percentage of your total N, you get some delay of nitrification.”

Comparing other factors, while DCD is more mobile in the soil than nitrapyrin, Vetsch says this is not a huge problem in medium-textured and fine-textured soils. That is, DCD products mostly stay in the root zone. “From a research standpoint, my studies have used medium to fine-textured soils and that dominates the other research as well,” he says. “There is some research in coarse-textured soils that shows better retention with nitrapyrin.”

Kaiser also notes that there’s better retention of nitrapyrin in soils with higher organic matter level and clay content. “Higher levels of these components result in better adsorption, so nitrapyrin levels stay steadier,” he says.

Nitrification inhibitors are also affected by temperature, with warmer soils having bacteria that are more active in degrading these chemicals. With nitrapyrin, there’s also evidence of interaction between soil type and temperature. Kaiser points to studies where the time it takes to get 50 percent degradation of nitrapyrin on a silty clay loam was investigated. “At temperatures 55°F versus 70°F, there’s 50 percent degradation in about three weeks,” he says. “At roughly about 50 percent degradation, we see really poor control of nitrification. But with a silt loam, and

about 65°F or 70°F, you go from about three weeks to one week to see 50 percent degradation.”

Because nitrification slows down in cooler weather, this means ideally, one would apply manure (or ammonium fertilizers for that matter) to fields later in the fall. As winter comes, nitrification greatly slows and then picks up again in the spring – at a slow pace if the spring temperatures rise steadily and smoothly, but very quickly if warm weather suddenly arrives. (And recall that with snow melt and spring rain, if a lot of nitrate is produced in a short time, it can get leached away to lower soil depths or lost through runoff).

In the fall however, as Vetsch explains, there’s typically not enough time and equipment availability to apply manure after the soil temperature has dropped down too low – and that’s where nitrification inhibitors are useful. Indeed, Vetsch and his colleagues have found that with application of manure and nitrapyrin to fields earlier in the fall, nitrification inhibition is roughly the same as delaying manure application only later in the fall when soil temperatures are colder.

“The old school rule of thumb is to apply manure in the fall when the temperature at a soil depth of about six inches is 50°F or below, which is usually the end of October in Minnesota,” says Vetsch. “Farther south, this will be later.

However, due to equipment availability and time pressures with harvest, some manure is applied in late summer and early fall, and there are benefits of an N inhibitor in some cases. We’ve found that in early October in Minnesota when you apply manure after soybean harvest, Instinct 2 worked well to slow nitrification. Dr. John Sawyer and his grad student Aaron Sassman at Iowa State had similar results in Iowa.”

Other research found that applying manure with nitrapyrin too early, however, may not work well. When soils are still warm from the summer heat, the inhibitor breaks down quickly and nitrification resumes in the soil. There is a sweet spot where inhibitors are most effective –usually early fall when soil temperatures are going down but have not yet reach 50°F or below.

Inhibitors still work in later fall, depending on temperature, says Vetsch, and can provide some effects following spring. Kaiser notes that in the spring, “in some soils and depending on the soil conditions, we can still see some impact of these products even into mid-to-late May.”

Vetsch says Instinct 2 works best when injected. “That way, it’s applied into in a concentrated volume of soil, in a relatively narrow band,” he says. “This is much more effective than broadcast.”

Looking at manure differences, Wilson tackled this on a recent UMN Nutrient Management Podcast.

She explains that one of the complicating factors with manure is that it contains both inorganic and organic nitrogen, and this ratio changes depending on livestock species.

“In manures with a lot of organic matter, anything with a lot of bedding, there are two N conversion steps, into ammonium and then to nitrate,” says Wilson.

“But in swine and liquid dairy manures, they generally have a lot more ammonium to begin with, and there’s only one step then, from ammonium to nitrate. So with those manures, you’ll see fast conversion to nitrate in warm conditions. Timing with those in the fall is therefore

particularly important. You want to wait as long in the fall as you can to apply those manures and if you can’t, an inhibitor is worthwhile.”

Looking at a few studies, Wilson also shares that more consistent results have been seen with swine manure.

Poultry manure is more complex. “It has the bedding in it, but it typically has so much N that even if it’s a small proportion that’s nitrifying, it’s still a lot more than some of our other manures,” explains Wilson. “So, we definitely recommend waiting until later to apply poultry manure as well. But remember it

The PSS8 is an innovative solution for large-scale dairy and biogas production.

Key Features:

• Ecological Efficiency

• High Capacity

• Lower energy consumption and operational costs

• Durability, long service life with easy maintenance

• Robust Design: Heavy-duty auger with sturdy bearing head

• Powerful Operation: 30 kW electric motor, compatible with 400V/50Hz supply

• The PSS8 enhances productivity while minimizing environmental impact

The field at AAFC’s Harrington Research Farm in Charlottetown, P.E.I. where the latest Plowdown Challenge took place.

With fears that the ongoing CanadaU.S. trade war could cause fertilizer prices to soar on both sides of the border, many farmers will be looking in the coming days at what kind options might be available to help them keep a handle on input costs.

A recent contest staged by Agriculture and Agri-Food Canada (AAFC) at the federal agency’s Harrington Research Farm in Charlottetown, P.E.I. provided a bit of insight into what some of those options could be.

In September 2024, Manure Manager wrote about the second iteration of the contest at launch; since then, a winner has been declared – and, more importantly, what’s been learned from the results.

The Plowdown Challenge is the brainchild of science coordinator Scott Anderson and technician Roger Henry, who both work at the AAFC’s Charlottetown Research and Development Centre. The pair conceived of the contest as a way to encourage producers on the island to reduce the amount of nitrogen-based fertilizer they use on their farms.

The contest was rolled out for the first time in 2023. That year, Anderson and Henry planted Mountain Gem potatoes on a field without the use of nitrogen fertilizers following a cover crop of red clover that was planted the previous fall. Farmers and other members of the public were subsequently asked to submit a guess on what the marketable yield would be after harvesting and grading. The winning guess was 169 hundredweight per acre which was submitted by cattle farmer Paul Smallman, who farms in western P.E.I.

Anderson and Henry followed that up with the second annual Plowdown Challenge in 2024. This time there was a twist: they followed all the same steps from the previous year’s contest but added manure to the mix this time around.

The actual yield for this years’ AAFC Plowdown Challenge field was a whopping 293 hundredweight per acre, nearly double the previous year’s winning total. The winning guess was 275 hundredweight per acre. It was submitted by Matt Dykerman, a former organic farmer who now works as a potato storage manager for Linkletter Farms in Summerside.

Anderson and Henry say the decision to add manure into the mix was made because an increasing number of farmers in P.E.I. have begun using manure again to boost the yield of their crops, but many haven’t cut back on the amount of fertilizer they use in those fields. The duo wanted to show growers who use manure they can safely cut back on nitrogen-based fertilizer without fearing a corresponding drop in yield.

“There’s various scientists in the region here who had done lots of work in that area trying to maximize crop production with minimal inputs and especially with respect to inorganic fertilizer,” says Anderson.

“But the adoption rate of that is slow because historically producers rely a lot on their fertilizer. What we’re trying to do is some sort of campaign that highlights that issue and does it in a sciency kind of way and fall back on some of that science just to show people that we can do good crop production with less

BY JIM TIMLICK

Scott Anderson (left) and Roger Henry of AAFC’s Charlottetown Research and Development Centre grade the potatoes grown for the most recent Plowdown Challenge.

Manure was incorporated into the soil as part of the most recent Plowdown Challenge.

fertilizer.”

The idea to incorporate manure into the contest this past year was actually suggested by the winner of the previous Plowdown Challenge.

“He [Smallman] is a beef producer and he was telling us, ‘You know, you guys would probably have got a lot more yield if you have put some manure on there too’,” Anderson says.

“It was kind of obvious, really. So we said, ‘OK, let’s do it again.’ We’ll do the same thing, but we’re going to add manure as well. What we were trying to do was push the envelope with our potato yields as much as we can without actually adding any inorganic nitrogen.”

This was the second time Dykerman entered the contest. He acknowledges he didn’t fare too well the first time around, finishing quite a ways back of the winning guess. “I guess my (first) guess was not very good,” he says, laughing.

Dykerman says he was encouraged to enter the most recent Plowdown Challenge by Henry, whom he bumped into at an agricultural trade show last fall.

Surprisingly, he didn’t spend a whole lot of time formulating his winning guess. He based it on the evidence he’s seen of what Mountain Gems can yield using traditional management practices on P.E.I. and adjusted that amount because of the alternative approach the contest organizers employed.

“I guess I had a bit of a competitive advantage in that I was quite familiar working in the past with a lot of manure and cover crops. I had a bit of a handle on what results that those types of inputs can produce,” he says. “Also, Mountain Gem is a variety of potato that we grow here on our potato farm (in Summerside) so I’m pretty familiar with them.”

And what did he think of the win?

“I’m not much of a public person so this kind of (attention) doesn’t come naturally to me,” Dykerman says,

laughing.

“But I was pleased to win … and that they got as good of a yield as they did. I think they were within a stone’s throw of traditional agronomic yields and I think that’s a really good sign of the potential that manure has for crops in P.E.I.”

While Anderson was confident that the addition of manure to this year’s contest would produce a positive outcome, he admits he was a little taken aback at the kind of crop it produced. The 293 hundredweight per acre was comparable to the 2024 estimated average for P.E.I. of 304.7 hundredweight per acre.

“Yeah, I was actually quite surprised,” he says.

“The crop was in quite early compared to the provincial potato crop. We certainly weren’t the first ones to put potatoes in, but it was still early in the season and early season was favourable. There was really good growth. Things tended to dry out here in August and that affected provincial production as a whole so we were quite happy with what we got.”

Interest in the second go-around of the Plowdown Challenge was up slightly over the previous year’s, a fact Anderson attributes to the use of social media and coverage from mainstream media. That interest included a number of farmers,

many of whom came up to Anderson and Henry in the weeks following the contest to speak with them about the use of fertilizer and manure.

“Ultimately, that’s what we were looking for, just to spur on this conversation like, ‘Look what these guys did, maybe I can cut back on (fertilizer) a bit too,” he says. “It’s more about getting people to think about this whole subject rather than just getting entrants for the contest. The contest was just kind of a byproduct of it.”

Dykerman says he doesn’t think the results of the contest are going to change the views of P.E.I. potato producers regarding to the use of manure since most of them are already proponents of incorporating it into on-farm practices.

He says what needs to change is the access farmers have to manure on the island. The amount of manure available to P.E.I. farmers has declined significantly over the past two decades, due in part to Mad Cow disease (BSE) which decimated the Maritime cattle industry in the early 2000s. That trend has recently begun

to reverse thanks in part to increased demand for beef products on the East Coast.

“I think most farmers already know the value of manure. I think if there were more available, there would be more widespread use … but there’s this imbalance between supply and demand,” Dykerman says.

“It’s a hard thing to manage if it’s not produced within your area. There’s some freight involved with it then and managing it in your field (is more difficult). I think a lot of farmers are kind of sitting on the sideline when it comes to using manure just because there’s a lack of capability here. I do see that situation improving from years ago, but I think it could still come a little ways more.”

The use of manure can impact potatoes and other row crops in two ways, according to Anderson. The first is that it can provide an important boost to overall soil health. The nutrients it provides means the soil receiving them won’t dry out as fast. That soil also has more fibre and better overall structure which plants love. Second, as manure decomposes it releases nitrogen into the soil which plants

can then uptake.

Anderson points out that one of the spinoff benefits of the Plowdown Challenge is that in addition to getting producers talking about reducing the use of fertilizer, its also promoted discussion about proper crop rotations including cover crops and the management of previous crops.

“That’s part of what we’re trying to do is create an awareness of proper crop rotations and proper management of previous crops,” he says. “You can get a bump of nutrients if you manage previous crops well.”

All good things come to an end, and so it is with the Plowdown Challenge. Anderson and Henry are preparing one final challenge for the 2025 growing season. This time, they are planning to conduct a side-by-side comparison using two fields: one with no fertilizer and another with manure. Members of the public will then be asked to submit a guess on what the yield difference will be between the two fields.• CO M M I T T E D TO Q UA L I T Y YO U C A N D E P E N D O N

For more info visit huskyfarm.ca or call 1-800-349-1122

Trailing shoe booms from 6m to 30m in width. BlackBird trailing shoe booms in stock Summer 2024. Various incorporation options available. Contact us for more info on tank sizing options.

BY JACK KAZMIERSKI

Nitrate leaching is a big problem in Nebraska, and it’s a challenge that a team of researchers from the University of Nebraska-Lincoln looked into with their “Integrated Best Management Practices to Minimize Nitrate Leaching in Corn” study, which took place over a two-year period in 2022 and 2023.

The study was conducted by Javed Iqbal and Swetabh Patel, assistant professor, University of Minnesota; Leslie Johnson, extension educator, University of Nebraska-Lincoln; Amy Millmier Schmidt, professor and livestock bioenvironmental engineering specialist, University of NebraskaLincoln; and Michael Kurtzhals, graduate research assistant, University of Nebraska-Lincoln.

Their research has yielded a number of interesting findings, including the fact that solid manure can significantly reduce nitrate leaching, making it a better option than commercially-available synthetic fertilizers when nitrate leaching is a concern.

“In Nebraska, we have been using more [synthetic] fertilizer since about the 1960s or ‘70s, and that nitrate has been contaminating the ground water,” says Javed Iqbal, one of the authors of this

study. Speaking to Manure Manager during the 2025 Waste to Worth conference in Boise, ID, where Millmier Schmidt presented a poster on the research.

He explains that a large number of townships in Nebraska have groundwater that has been contaminated with nitrate, which means that they also have a lot of drinking water that isn’t fit to drink.

The authors of this study reported that, “in Nebraska, approximately 117 out of nearly 550 groundwater-based community public water systems are required to conduct quarterly sampling due to elevated nitrate-N levels, with ten systems having already implemented costly treatment measures such as reverse osmosis to mitigate this issue.”

The cause of this problem, as reported by the authors of this study, is clear: “The intensive production of row crops under irrigation in the state are a primary reason for elevated nitrate concentrations in groundwater.”

Moreover, nitrate leaching is a much bigger issue that affects water systems far beyond Nebraska’s borders. “The environmental impact of nitrate leaching from agricultural fields is not confined to Nebraska; it is a widespread issue across the

U.S. Midwest, where intensive crop production is prevalent,” the authors of this study noted in their report.

The two-year study was conducted on drip-irrigated land where six treatments were randomly assigned to a total of 24 plots of land, employing a combination of two fertilizer sources (manure and inorganic fertilizer), two cover crops (rye cover crop and no cover crop), and two mulch treatments (woodchips of mixed species and no woodchips).

All the plots reeived the same total N rate: 30 percent of the total N was applied at planting in the form of Agrotain coated urea, and while the manure plots received the remaining 70 percent of N in the form of beef manure at planting, the inorganic plots received the remaining 70 percent of N in the form of UAN side-dressed at the V6 corn growth stage. In addition, researchers reported that, “the inorganic fertilizer plots received additional P, S, and Zn at the time of planting to balance the amount of these nutrients supplied by the manure.”

Researchers then collected data by analyzing soil samples, crop quality and yield, and water quality.

The research resulted in a number of important findings, including the fact that solid manure significantly reduces nitrate leaching because it provides, “a slower, more synchronized N release compared to inorganic fertilizers.”

Solid manure was also beneficial when analyzing aboveground biomass N uptake, since manure improved biomass N

uptake by 11 percent, compared with commercially available synthetic fertilizer.

“Unfortunately, many farmers still think of manure as a waste product,” says Iqbal, “so they just want to get rid of it and apply it on the surface. On top of that, they still apply nitrogen through synthetic fertilizers, which leads to excessive nitrogen input, and to nitrogen losses through gaseous emissions into the atmosphere and into the groundwater.”

Another key finding: “Woodchip mulch initially delayed N availability and biomass N uptake, but ultimately helped reduce nitrate leaching by improving soil moisture retention and temperature moderation.” Unfortunately, using mulch comes at a price. “Mulch decreased crop growth early in the season and reduced crop yield,” Iqbal says.

So there’s a tradeoff, Iqbal adds. “If you’re going to use mulch, it can immobilize some of the nitrogen on the soil surface and reduce nitrate leaching, but it will [negatively] affect crop yield.”

Researchers noted that although synthetic fertilizers boosted corn yields by 9%, compared to manure treatments, they also increased the risk of nitrate leaching. That said, there’s an important caveat to consider. “Compared with inorganic fertilizer, manure decreased crop yield by nine percent in year one, while in the second year there was not effect,” says Iqbal. “Manure had the same yield as the inorganic fertilizer [in the second year].”

So while the synthetic fertilizer improved yield in the first year, that difference was no longer there in the second year.

“And in both years, manure decreased nitrate leaching by up to 80 percent, compared with the inorganic fertilizer,” says Iqbal. “That’s because manure releases nitrogen more slowly, and

synchronizes nitrogen availability with the crop nitrogen uptake during the growing season.”

In other words, solid manure acts like a slow-release fertilizer, whereas synthetic fertilizer does not.

“Once they are applied to the soil,” says Iqbal, “synthetic fertilizers nitrify quickly into nitrate-nitrogen, and if we get early season rain, that nitrate will move through the soil profile into the ground water. That’s the risk you take with synthetic nitrogen fertilizer.”

Manure application on irrigated plots.

ABOVE

Growth in one of the irrigated plots that integrated woodchips.

using synthetic fertilizer, and switched to solid manure, Iqbal says that certain conditions would have to be met in order for manure to fix the problem completely.

“If everybody uses manure the right way, then we would see a big difference,” he says. “If they apply manure to keep up with the crop’s nitrogen needs, if they apply it at the right time, and if they do not over apply it, then we could eliminate the nitrate leaching problem.”

The key to success, Iqbal adds, “is the four R’s of manure. The right source, the right time, the right place and the right rate. If we follow these four R’s of manure then we can make a big difference.”

“Unfortunately, many farmers still think of manure as a waste product.”

Iqbal adds that farmers can invest in nitrogen stabilizers that will help synthetic fertilizers release nitrogen more slowly over time. Manure, on the other hand, doesn’t need a stabilizer, “because manure itself is a natural nitrogen stabilizer. It releases nitrogen slowly over time and takes care of any implications from rainfall,” he says. (For more on how manure functions with nitrogen inhibitors, see Page 14).

Having weighed all the pros and cons Iqbal concludes that, “Manure is your best option to keep up your yield and reduce nitrate leaching.”

Iqbal stops short of declaring manure a panacea for the US Midwest’s nitrate leaching problems. Even if every farmer in the Midwest stopped

Although cover crops were initially part of this research, according to the authors of this study, “cover crop failed to establish in 2023 spring due to dry conditions. Therefore, cover crop data and its effects are not reported in this paper.”

That said, Iqbal notes that other research projects have concluded that the right cover crop can reduce nitrate leaching significantly. However, researchers aren’t sure which combination works best. “We don’t know yet how a cover crop would perform with manure and with synthetic fertilizer,” he says. That will have to be the focus of a future research project.•

Brands Case IH and New Holland, part of the broader CNH Industrial group, have both launched automated technology that will benefit farmers and applicators.

Case IH’s SenseApply technology is an automated live variable rate application solution designed to, in the company’s words, “maximize the output of every input.” The technology consists of a single, cab-mounted camera system that offers multi-season and mult-application uses, including selective spray and live variable rate application (including nitrogen).

SenseApply technology includes lifetime live variable rate application use and a one-time activation fee for selective spray, eliminating both per-acre fees and annual fees for the life of the device. The technology is designed for simple and effective application, at speeds of up to 25 mph, with the camera self-calibrating to the crop within the first 150 feet during live application. The camera senses plant biomass and responds accordingly, depending on the application type the operator selected.

The technology also integrates Case’s FieldOps and Raven Slingshot systems, enabling operators to connect and manage application data through their preferred platforms.

For New Holland, its automation technology focuses on sprayers, with its new IntelliSense product for front boom sprayers: the SP310F, SP370F and SP410F. Like Case’s new product, the system is built around a cab-mounted camera system and can be used on a wide spectrum of crops, with application functions including herbicide, fungicide, nitrogen and more. The technology also eliminates annual subscription requirements or per-acre fees.

Tractor sales may be indicative of

The Association of Equipment Manufacturers released its figures for February 2025 on agricultural equipment sales, with figures indicating that the downward trend continues across facets of agricultural production. Agricultural tractor sales were down 17.7 percent in the U.S. compared to February 2024, with combines down 48 percent.

Canada saw a similar drop for combines at 32.1 percent year over year, although it posted an increase in tractor sales of 18.6 percent. Curt Blades, SVP of the AEM, said in a statement the recent and continued decline, which is in stark contrast to several years of healthy growth in the pandemic and immediate post-pandemic era, reflects current market challenges “including global trade concerns about tariffs,” the organization remains optimistic about the long-term future of the equipment industry.

“The resilience and adaptability of our industry have been proven time and time again. We are confident that, through innovation and collaboration, equipment manufacturers can navigate these challenges and emerge stronger, continuing to support the essential work of farmers and agricultural professionals worldwide.”

Despite the lower figures, so far the softer 2024 and 2025’s trend lines follow those of 2022, 2023 and the five-year average, with sales of both tractors and combines peaking primarily in April with a second, slightly smaller peak in October.

Joe Dias

BY RONDA PAYNE

There’s no debate over manure being beneficial as a soil amendment, but just what’s in the manure in terms of nutrients can cause a significant conversation. Manure isn’t always equal, even within the same type of livestock, so while applying it to crops can be a key part of yields and soil health, knowing manure’s potential nutrient contents is essential.

Manure “book values” are outdated with information coming from the late 90s and early 2000s. In 2017, Melissa Wilson, associate professor with the University of Minnesota from the department of soil, water and climate in the College of Food, Agricultural and Natural Resource Sciences, knew that things had likely changed over the course of 25 to 35, or more, years.

“How can we get more modern data?” was the question Wilson began asking with colleague Erin Cortus, a fellow associate professor with U of M and extension engineer. “Some of the questions I’d get, even back then, was ‘what can I expect from different manure types?’ And the only resources we had were… you can look them up in a book.”

“We’re trying to keep it updated on an annual basis,” she says. “There is no 2024 data in there yet, but hopefully in the next couple of months.”

Understandably, there is a backlog of data given the number of requests made to labs and the eventual flow of the previous year’s information.

“We have over 498,000 samples in the database,” Bohl Bormann says of the size of the database before the 2024 data is input. “We have a great amount of samples from the midwest, the southeast and northeast regions.”

With the advancements in manure testing over the last two decades, along with increased focus on leaching of nutrients like phosphorus, it was natural to assume things had changed.

In talking to testing labs, Wilson found that some of them were running thousands of manure samples annually. The idea for ManureDB was born with a ready supply of data from US testing labs. Now, the database at z.umn.edu/manuredb has about 2,500 users and has had about 28,000 individual event counts since going public in July 2023.

Now, two years in, the team is anticipating adding data for 2024 soon, and is reflecting on learnings, challenges and more, including what they’ve learned about the sheer amount of data with which they’re dealing.

At the start, Nancy Bohl Bormann, manure and nutrient management researcher at U of M, was tasked with setting the system up and managing the myriad details that came along. Now, she is looking at adjusting the system to make it more useful to users like researchers, farmers and agronomists.

The tool provides information in a way that protects source privacy. For example, state or origin is available as part of a dataset, but not if there are only one or two of a certain type of livestock producers in that state. If there were only two turkey growers in Michigan in the samples, the state wouldn’t be included in the results.

For samples to be available in the dataset, at least five samples per animal type per region per year are needed.

“We also do not show what lab it is coming from,” Bohl Bormann says.

Countries accessing the system include, dominantly, the United States, but also Canada, China, India, Brazil, Spain, the Netherlands and more, says Wilson. There is interest in adding Canadian data in the future, but because current funding is from a U.S. source, the data will be as well.

Wilson notes that perhaps the biggest surprise in inputting data and getting the system developed was learning that much of the data they were hoping for was not included in the lab data.

“We weren’t getting the storage information, the growth stage and other things,” she says. “It’s different in different areas and regions. In some areas, it seems like they have more questions on their intake forms.”

But she explains that more questions don’t necessarily lead to more answers.

ABOVE

Nancy Bohl-Bormann spent much of her PhD working on ManureDB.

“Some labs have said they narrowed down their question sheet,” Wilson says. “So people would fill it out more completely.”

Labs send the data with the percent of nutrients and the percent of moisture content which is helpful for users but needs some options applied to it. Rather than wondering what the percent of nutrients means to a manure application, the ManureDB team added the feature to change nutrient measures from percent to pounds per 1,000 gallons in a liquid manure or pounds per ton in a solid.

New features, like more visualizations, have been added in addition to these unit conversion options.

“Some neat data visualization features are being added,” says Bohl Bormann. “You can also more easily see how many samples are available for a certain data selection in the Data Explorer tab. For example, if I select goat as an animal type, it shows there are 82 sample results.”

Ensuring the tool is intuitive is driving many of the changes forward. As she explains, livestock producers could use it for benchmarking and understanding how their manure compares to manure from other producers in their area.

“We’re slowly trying to make it more user-friendly as well,” Wilson says. “We thought it might be cool to see if there are feed relationships with trends that are going on. That’s still pie in the sky.”

There have been learnings around regional differences and she says book values didn’t account for that. However, she hasn’t had any big surprises. As expected, she did see changes in the phosphorus content in swine manure.

“Phosphorus in swine has come down. It’s actually levelled off,” Wilson says. “People had thought that had happened and we did see that in some of our averages.”

She says the past 10 to 15 years were when the levels came down, then in the last few years, that shift levelled out.

Other than typically expected animals like swine, beef and chicken, there have been a few unexpected samples.

“There’s also a lot of other things that come in from research from wildlife to zoos,” says Bohl Bormann. “In an extension, you often get interesting questions about

manure. Sheep, horse, alpaca.”

Wilson rounds out the list, noting that duck, fish and insects have also made their way into the database.

“Bunnies and rats one time. Sometimes there’s deer,” she says. “All kinds of interesting things.”

While wildlife manure may not be a common search, other types are. Bohl Bormann says the database is allowing people to match available manure nutrients to their crops.

“There’s also a lot of data and manure

modelling,” she explains. “Several people who are starting to use this resource want to know if they have enough land for the manure they have.”

The project is partnered with the Minnesota Supercomputing Institute and other universities are making models from the data in ManureDB says Wilson.

“We’re always interested in adding more data as well,” she says. “Other partners are welcome to reach out and work together. We’re always in talks with other groups and organizations.” •

Discover how the toughest pumps in the field made a difference for this large-scale dairy farm. We’re at 23 billion gallons of manure and counting!

See The Results

CHRYSEID MODDERMAN | University of Minnesota Extension

One phrase I’ve said so many times that I might soon get it tattooed on my forehead: aged manure is not composted manure!

Proper composting needs regular, active management with the right combination of temperature, size, moisture, oxygen, and carbon to nitrogen ratio to keep the microbes happy and make the piles break down into compost. It’s is as much of an art as it is science.

The temperature of a pile indicates its health. In There are three temperature phases: (1) warmup, which is the time from pile construction until the internal temperature reaches 105ºF, (2) thermophilic, in which the microbes do the heavy lifting of decomposition, and (3) cool curing, when composting is complete, and the material stabilizes. Throughout all three stages, heat should be monitored with a thermometer probe.

If your pile should be in the thermophilic phase but will not heat up to at least 110ºF, or it’s reaching temperatures over 160ºF, there might be a problem with one or more of the components below:

The size of a compost pile will be determined by the size and needs of an operation. Some will have one large pile, while others will have multiple, smaller piles that may be at different decomposition

temperature. The optimum level for composting is 50 – 60 percent moisture, but many of the microbes will still do their job at 40 to 65 percent.

To check moisture levels, use the “squeeze test”. While wearing gloves, squeeze a handful of compost. If water drips out, the compost is too wet; if you open your hand and the compost crumbles apart, it’s too dry. Compost with optimal moisture will hold its shape without dripping, like a damp (not wet) washcloth. Do this a few times in different areas to get a sense of the overall moisture. Covering the pile with a roof or tarp protects from both rainfall and sun exposure. Additional aeration and turning can also help dry wet compost. And a too-dry pile can be moistened with water from a spray hose or bucket.

Aerobic conditions are required for composting. The need for high oxygen levels is greatest at the start of the process. Five percent oxygen in the pore space is the minimum;10 to 15 percent is optimal.

Within the compost pile, oxygen will be most abundant in the outer layers; and the compressed inner core of the pile will have the least pore space, and therefore, the least oxygen. Turning and mixing the compost is important to spread oxygen throughout the pile, bringing the center of the pile to the outside, and the outside to the center.

Proper composting needs regular, active management.

stages. A compost pile should, at minimum, be three-feet square by three-feet deep. Anything smaller generate the necessary internal heat. For maximum size, do not exceed the size that your machinery can effectively turn and mix.

Particles should be small, but not too small. Particle sizes of 1/8 inch to two inches are considered best. Manure is crumbly and can be broken into bits of that size, but coarse bedding such as corn stalks may need to be shredded if they are too large.

Moisture is crucial for the reactions needed to break down organic materials and regulating compost

Carbon sources in composting are typically bedding. Nitrogen can come from both manure and bedding, depending on the type. The optimal ratio for composting is between 25:1 and 30:1.

If the C:N is lower than 20:1, nitrogen will be lost to the atmosphere as ammonia. To remedy this, you can add carbon sources such as straw or wood chips to the pile. If it’s higher than 40:1, nitrogen will be tied up by the excess carbon. To remedy this, add nitrogen sources to the compost pile such as grass clippings or hay.

If the pile is not breaking down the way it should, and you’ve ruled out other factors as the culprit (moisture, size, etc.), you may benefit from sending samples of the compost pile to a manure lab to test for C:N.•

‘‘ All future tankers I’m going to add to my fleet will be outfitted with this new suspension. ’’

Because you want the Best.

‘‘ Over rolling hills, even little bumps, it’s smooth working with a tanker fitted with the XT suspension. The tanker is independent from the tractor and its draw bar is no longer rigidly attached to the tractor. It is flexible and it actually follows the contour of the terrain. There’s a customer that we go to and there’s a 1-and-a-half-foot drop we need to drive through and there’s only one tanker that I will go there with, the one fitted with the XT suspension. ’’

Yvon Guérard Forfait Somerset, Plessisville, QC