MAY/JUNE 2009

MAY/JUNE 2009

From t H e lagoon to t H e green H ouse

m onitoring t H e air

i nnovations: m anure t ankers

8

Hog house tomatoes

A North Carolina swine producer is diverting a portion of his operation’s liquid waste stream to help produce greenhouse tomatoes. 12

Less litter being applied

University of Arkansas researcher shows farmers in northwest Arkansas and northeast Oklahoma have reduced their use of poultry litter for pasture fertilizer by 75 percent since 2003. 16

Monitoring the air

New hydrogen sulfide detection system one of the topics being discussed at the 2009 Upper Midwest Manure Handling Expo. 22

Liquid manure project launched in Alberta Government and community supported program hopes to shift liquid dairy manure spreaders to injection or surface banding applications.

Low temperature digestion

System used at Quebec swine operation shows potential for treating swine manure according to research out of McGill University.

New report released on swine manure management

U.S. Department of Agriculture releases in depth examination of manure management practices in the U.S. hog industry between 1998 and 2004.

May/June 2009

Volume 7 • No. 3

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Tony Kryzanowski, Margaret Land, Manitoba Livestock Manure Management Initiative, Ross Muhlbauer, Randy Swestka

Advertising Manager

Laura Cofell • (519) 429-5188, (888) 599-2228, ext 275 lcofell@annexweb.com

Sales Assistant

Ryan Culver • (519) 429-5183, (888) 599-2228, ext 219 rculver@annexweb.com

Production Manager Angela Simon

Group Publisher Martin McAnulty mmcanulty@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions (GST included) $37 Cdn, one year - $65 Cdn, two years

U.S. Subscriptions: $37 US, one year - $64 US, two years

International Subscriptions $70 US, one year

From time to time, we at Manure Manager make our subscription list available to reputable companies and organizations whose products and services we believe maybe of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2009 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

OBy Margaret Land

ne morning a few weeks ago, I was distracted from my normal morning routine by the rumblings of a large tanker truck. I don’t know about the rest of you but having grown up on a farm, I always notice unfamiliar vehicles and this was a big one.

It stopped on the side of the road across from our neighbor’s hog operation and soon thick lines were twisting across the farmyard to behind the barn. Being the curious type, I decided to walk on over and have a look.

At first, I wasn’t quite sure what was going on – was the manure coming or going? But my neighbor soon explained that, having already emptied both of his own operation’s manure lagoons, he was having slurry from a nearby hog farm trucked in to apply to his adjacent fields before planting began. With the high price of fertilizer, my neighbor was doing his best to supply most of the required crop nutrients through spring manure applications. He was also working to cultivate new manure supply relationships in preparation for his retirement from hog production, expected within the next few years.

He was preparing for the future, both for this season and growing seasons to come. Here at Manure Manager, we try our best to give readers the best information possible. Through the publication’s On Track and Innovations sections, suppliers are provided an opportunity to promote their products, which hopefully are of assistance to producers. Sometimes, things don’t always work as planned:

Dear Manure Manager Magazine, When your magazine first appeared some years ago, we were thrilled. Finally someone is addressing manure! This is the last, most important, and most difficult problem farmers face.

We enjoyed your stories and technology reviews to help solve our concerns. But recently we felt betrayed. Google brought us to your article URL: http://www.manuremanager.com/content/view/1212/97.

Your story on EnviroLagoon failed to make mention of (ASABE abstract 054072). Testing was done on this product under ASABE standards in 2005. The results completely contradict claims made in your story.

I quote: “In experiment four, odor emissions were monitored for five months from simulated lagoons to which three commercial additives, BioZyme®, Martin BioChem®, and EnviroLagoon®, were applied. All three additives had higher OERs and lower HTs than the control, indicating they were not effective in reducing odors.”

How can readers continue to trust Manure Manager if it doesn't report the facts? Farmers should not have to waste their money on products to find out if they work.

They say they have a guarantee. You might explain how that works.

I trust this was an oversight.

Please keep up your effort to provide information on this important and costly problem.

Best Regards

T. J. Tooley, Ag Systems International

While Manure Manager editors make every effort to be objective when reporting on new products, they cannot be held responsible for claims made by companies. Readers are encouraged to contact the companies themselves for more details.

Now, more than ever, pork producers recognize the impact their operations can have on the world around them.

Proactive eco-management with MicroSource S can help reduce environmental burdens. The result:

• Reduction in noxious manure gases, like ammonia and VFAs, for less odor

• Increased nitrogen retention in manure for an improved N:P ratio

• Lower manure viscosity so less power is required for pump outs

• Decreased stickiness of manure for easier/less cleaning.

MicroSource S contains selected microbes that digest the solids in hog manure. It begins to work even before the manure hits the floor and continues to act on manure during handling and storage. MicroSource S can help you balance today’s environmental challenges with efficient pork production.

To learn more, contact your feed supplier or go to www.unlimitednutrition-na.dsm.com.

• Funding available to reduce air emissions

• Continued growth in digester projects

• New $500,000 biomass grant program

• There’s money in managing manure right

• Iowa legislators pass manure restrictions

• CAFO numbers up in Maryland, Delaware

• GHG regulations could be devastating

• Washington law broadens digester menu

This year’s spring flooding and blizzards have caused many livestock deaths. Methods of disposing of dead animals include burning, burying and composting, but burning and burying have drawbacks, according to Chris Augustin, area nutrient management specialist at North Dakota State University’s Carrington Research Extension Center.

One of the problems is finding a suitable burial site during flood times, he says. When burying dead animals, you need to avoid areas with sandy soils and shallow water tables.

Read the full story at www.manuremanager.com

AGCO offering rebates on batteries

AGCO Parts is offering a $10 cash rebate on select FieldStart batteries purchased from any U.S. AGCO Parts dealer.

This includes batteries for different tractor and combine brands, trucks, lawn and garden tractors, and automotive and pickup applications. Rebates are available for many of these applications.

For more details, see your local AGCO Parts dealer or go to www. AGCOParts.com and click on AGCO FieldStart Battery Rebate. To locate a dealer near you, visit www. AGCOCorpDealers.com.

Adoodle, Inc. recently announced the release of NOXO, a new special gel substance that, when applied topically under the nostrils, blocks nauseating, offensive and unpleasant odors.

NOXO, which consists of 14 all-natural ingredients including important essential oils, does not work by masking odors, but rather is based on advanced olfactory perception altering technology. It effectively blocks extremely offensive odors such anaerobic bacteria volatiles, urine and feces and more.

NOXO product information can also be found at www.noxoinfo.com or by calling 1- 888-383-1743.

The 2009 Manure Manager Buyers Guide is your key reference tool to bring the entire industry together in just one directory.

To sign up for a free trial of Manure Manager’s digital version, go to www.manuremanager.com.

By Tony Kryzanowski

The need to safely dispose of manure from concentrated animal feeding operations is resulting in some imaginative approaches. One North Carolina hog producer thinks one approach might be to attach a commercial greenhouse operation to the hog business, where a portion of the liquid manure is used to generate another cash crop – in this case, tomatoes.

The Julian Barham Farm in Zebulon, North Carolina, has created two new income streams from its liquid manure. Firstly, it has installed an ambienttemperature anaerobic digester to capture biogas from the manure to generate electricity. Secondly, some of the stabilized liquid manure discharged from

Average tomato production from the greenhouse is 920 lbs. per day of largefruited cultivars and 92 pints per day of grape tomatoes. Submitted photo

the digester is used to fertilize tomatoes in a commercial greenhouse operation.

Why tomatoes? Barham chose tomatoes because he felt they would absorb a higher volume of treated wastewater than other vegetable crops.

Some of the water is also used to recharge hog barn manure pits, because by the time it has been treated in the digester, 92 percent of the harmful organics have been destroyed. For odor control, wastewater diverted to the farm’s greenhouses and hog barn manure pits undergoes a biological nitrification process. The remaining liquid waste stream is stored in a lagoon and eventually applied to cropland.

The Barham Farm is actively participating in research to develop manure management systems to help North Carolina cope with a major increase in the generation of hog manure. Swine production increased in the state from

2 million hogs in 1987 to 10.1 million in 2001. Because of the huge increase in hog production, this raised environmental concerns regarding animal waste management practices. So North Carolina State University (NCSU) is working with Julian Barham to evaluate an integrated manure management system involving anaerobic digestion for waste treatment, biofilter nitrification for odor control, and greenhouse tomato production as a possible method to divert some of the wastewater away from cropland irrigation.

The Barham farm is a farrow-to-wean swine operation with approximately 4000 sows, generating 36,720 gallons per day of wastewater flow. The manure pits are drained to release the wastewater and recharged with nitrified water from the storage lagoon every eight days.

The farm’s manure management system consists of an ambienttemperature anaerobic digester,

cogeneration of electricity and heat through combustion of biogas produced from the digester, a storage pond, nitrification biofilters for ammonia emission control, and tomato production for nutrient recovery.

Installation of the Barham Farm manure management system started in 1996 and has evolved over the years.

“We wanted to try to get out in front of the environmental and odor issues,” says Barham.

Until recently, that area of North Carolina was experiencing substantial residential growth, so Barham wanted to keep good relations with his neighbors. When raw liquid manure is applied to cropland, this often leads to complaints and Barham wanted to avoid that. Once he discovered the amount of biogas that could be generated from the liquid manure, he worked through the Environmental Protection Agency’s AgStar program, which hired California consultant, RCM Digesters, to build the ambient-temperature anaerobic digester. It is 20 feet deep, has a surface area of about 265-feet by 265-feet, has a threefoot clay liner at the bottom, and holds about 865,500 cubic feet of wastewater. The swine wastewater flows by gravity to the digester where bacteria interact with the raw liquid manure and generate biogas. About 1383 cubic feet of biogas is generated per hour, consisting of about 63.7 percent methane and 20 percent carbon dioxide. The hog farm installed a Caterpillar 3406 engine with a 120-kilowatt generator to burn the biogas coming off the digester to generate electricity. Barham says the Cat engine is capable of handling gas containing significant amounts of hydrogen sulfide, so nothing is done to clean the biogas before it is burned.

Once the farm had harnessed the biogas, started producing power, and selling it to a local utility, the next issue was how to manage the treated wastewater stream coming off the digester. Its disposal on cropland in that part of North Carolina is challenging because of the area’s clay soil, rolling terrain, and wet winter environment. So, Barham came up with the idea of building a greenhouse to grow tomatoes and to use some of the liquid by-product from the digester as organic fertilizer in tomato production. At present, the farm has two, 28,000 square foot greenhouses.

“We added the greenhouses really just to make the water go away,” says Barham. “Originally, we thought we could get rid of about 8000 to 10,000 gallons of

The Julian Barham Farm in Zebulon, North Carolina, has installed an ambienttemperature anaerobic digester to capture biogas from hog manure to generate electricity. Submitted photo

The operation has also built a commercial greenhouse operation that uses a portion of the stabilized liquid hog manure discharged from the digester to fertilize hothouse tomatoes. Submitted photo

water per day. That was overly optimistic. We are moving about 2000 gallons per day, which helps, but is not anywhere near what I need to be moving.”

The farm also installed a 400,000 BTU boiler and a 10,000 gallon hot water tank, with the intention of capturing and using waste heat from the Cat engine to heat the water. NCSU estimates that using the waste heat from the engine is one way the farm could cut down on its greenhouse heating bills, particularly in winter. Right now, they and the hog barns are heated using liquid propane.

The greenhouse facility is easy to build, Barham says. The management requirement to produce the tomato crop

is a whole different matter. He says it is important for hog producers to evaluate whether they want the extra challenge of operating a commercial greenhouse business in addition to a hog farm before taking the plunge. It was an entirely new venture for the Barham’s that required that they learn a lot about growing and marketing a vegetable cash crop. The liquid manure is not simply applied randomly to the tomato plants. The farm has installed a nutrient control system to ensure that the tomato plants are fed the right nutrient mix to optimize production. Average tomato production from the greenhouse is 920 lbs. per day of large-fruited cultivars and 92 pints per

The farm installed a Caterpillar 3406 engine with a 120-kilowatt generator to burn the biogas coming off the digester to generate electricity. The engine is capable of handling gas containing significant amounts of hydrogen sulfide, so nothing is done to clean the biogas before it is burned. Submitted photo

For odor control, wastewater diverted to the farm’s greenhouses and hog barn manure pits undergoes a biological nitrification process. Submitted photo

day of grape tomatoes. Recently, the large tomatoes have been selling for about $1.99 per lb. and $1.50 per pint of the grape tomatoes, meaning that daily income is about $2000. From that, the hog farm needs to pay its expenses. The greenhouse has six dedicated employees.

Like other cash crops, production is also weather-dependent. Barham Farm aims for most of its production in winter

when local field tomatoes aren’t available.

Barham has found it difficult to compete with tomatoes grown elsewhere, and being dependent on a single product has left him somewhat dependent on what buyers are prepared to pay.

“Unfortunately, somewhere on this earth, there are field tomatoes being grown and they bring them in,” says Barham. “The only advantage we have is

that we are local, and it depends on how much the customer feels that they are worth.” He’s investigated the possibility of being certified as an organic producer, but is so far not convinced that the time and effort is worthwhile, given the mixed reviews he has received.

He is looking at possibly diversifying his line of vegetables and marketing the operation directly to local consumers more as a market garden, because he feels customers might be more willing to visit the operation to purchase several vegetables rather than just tomatoes, especially if he can make a variety of fresh garden vegetables available in the off season.

It’s obvious that Barham and NSCU have made a considerable investment in time and money to put a number of novel ideas for making better use of the farm’s manure resource, and are even studying the use of the carbon dioxide stream from the biogas to improve tomato production.

However, what Barham has discovered recently is that theory is not always in step with reality.

At the present time, the biogas is being flared because he is trying to negotiate a new power purchase agreement with the local utility. Unlike many other states, North Carolina does not have a Renewable Portfolio Standard (RPS) requiring local utilities to purchase a portion of their power from renewable sources, although state legislators are moving in that direction. So this has made negotiations with local utilities more challenging.

“Everybody knows that renewable energy makes sense and there are a lot of lawmakers behind it,” says Barham. “Eventually, it’s going to work.”

Right now, if the system was operational, the power produced from the biogas would provide about 75 percent of the hog farm’s power needs, which is why Barham is still dependent on the local utility for electrical services.

In an attempt to possibly circumvent that dependency and also to generate more biogas in winter when the greenhouse operation really needs it for heat, the hog farm is thinking about installing a smaller, separate, thermophilic digester. This type of digester accelerates the digestion process by operating at a higher temperature, but it requires a greater amount of monitoring and control to ensure that the internal bacteria culture remains healthy.

Despite some of the hog farm’s immediate challenges, “I still like our approach,” Barham says.

Researchers document reduced poultry litter being applied to pastures in Arkansas and Oklahoma

Farmers in a northwest Arkansas and northeast Oklahoma watershed have reduced their use of poultry litter for pasture fertilizer by 75 percent since 2003, according to the University of Arkansas system division of agriculture team that has helped farmers develop and implement nutrient management plans on their farms.

The Eucha-Spavinaw watershed in Benton County, Arkansas and Mayes and Delaware counties in Oklahoma feed into lakes used by municipal water systems and for recreation. Changes in the management of poultry litter and other sources of nutrients added to the watersheds were agreed to in a 2003 settlement of a lawsuit by the City of Tulsa against selected poultry companies, municipalities and others.

To help implement the settlement, a team of advisers was assembled with support from the Arkansas Natural Resources Commission and the Oklahoma Conservation Commission.

For three years, Tommy Daniel, a professor of crop, soil, and environmental sciences with the University of Arkansas, led a division of agriculture team to create the Eucha-Spavinaw Phosphorus Index (ESPI), which has been used to develop nutrient management plans for farmers since 2003.

“A great deal of science and research went into developing and supporting ESPI,” Daniel said. “We had to make the index extremely rigorous and scientifically sound so that farming in this area could remain economically sustainable, yet be environmentally responsible.”

The ESPI tool assesses the risk of phosphorus runoff by considering such factors as the amount of phosphorus in soil as determined through soil testing, the amount and timing of manure applications, the probability of runoff and soil erosion, and pasture and grazing management, Daniel said.

More recently, other members of the division of agriculture – Andrew Sharpley, a professor of crop, soil, and environmental sciences; Mike Daniels, a Cooperative Extension Service nutrient management specialist; Brian Haggard, director of the Arkansas Water Resources

Center; and H.L. Goodwin, professor of agricultural economics – have studied results to see what changes have occurred in the watershed.

“ESPI is used by farm advisers in the Eucha-Spavinaw watershed to determine how much litter can be applied to pastures and keep the risk of phosphorus runoff low,” Sharpley said. “A similar approach is now used in 47 states.”

“During the past five years, ESPI has been used exclusively to develop nutrient management plans that guide poultry litter applications to pastures within the watersheds,” Mike Daniels said. “From these plans, an extensive and detailed database has been developed on nutrient management. Such a large-scale database does not exist anywhere else in the world. The database is providing researchers with insight and verification that was not possible before.”

Based on this database, a research paper – “Outcomes of phosphorus-based nutrient management in the Eucha-Spavinaw watershed” – by Sharpley, Daniel and others, is being published in the proceedings of the Farming with Grass: Sustainable Mixed Agricultural Landscapes in Grassland

Environments conference, held in Oklahoma City in October 2008. Other research papers have been published in the Journal of Environmental Quality and Journal of Soil and Water Conservation on the management of poultry litter under lawsuit settlement agreements in this watershed.

The 75 percent reduction in land application of poultry litter in the watersheds over the last four years, as documented in the ESPI database,

is twice the reduction called for in the settlement, Sharpley said.

Haggard has been studying water quality in the Eucha-Spavinaw watershed since 1998. As required by the settlement, one rural municipal wastewater treatment plant has significantly reduced phosphorus levels in its effluent discharge, he said. The phosphorus concentrations downstream from this effluent discharge have significantly

decreased in the last several years.

The Oklahoma Conservation Commission in a recent press release reported “continual improvement in water quality in Beaty Creek within the EuchaSpavinaw watershed.” The commission said water quality monitoring data show a 66 percent reduction in phosphorus loading into Beaty Creek in Delaware County, where best management practices (BMPs) had been implemented on farmland as part of

demonstration projects, compared with a nearby stream that had no BMPs.

“The use of ESPI in plan development has reduced the average poultry litter application from 1.5 tons per acre in 2004 to 1.2 tons per acre in 2007,” said Mike Daniels. “Before 2003 and before the use of ESPI, the common practice in Arkansas was to spread enough poultry litter to supply the nitrogen requirements of pasture, which may have been between three and five tons per acre on average.”

Poultry litter has long been used as an economical source of nitrogen and other nutrients for pastures and other crops. However, application rates that meet nitrogen requirements of plants may provide an excess of phosphorus, which can build up in the soil and eventually run off into steams. Too much phosphorus can accelerate growth of algae and other water quality problems, Sharpley said.

H.L. Goodwin, an agricultural economist with the division of agriculture, puts the overall cost to farmers of litter management changes in the watershed at $6.25 million since the settlement. The cost is primarily due to the loss in nitrogen value from reduced use of litter, but includes loss in the liming effect of litter.

Goodwin’s analysis credits the sale

of litter exported from the watershed to farmers in areas where soils do not contain excess phosphorus. But returns from litter sales are well below the actual value of nitrogen contained in the litter as compared to equivalent amounts of commercial fertilizer, he said.

The average soil test phosphorus level of all agricultural fields within the Eucha and Spavinaw watershed has remained stable at around 175 parts per million (230 lbs per acre) since 2004, Daniel said. Soil levels are measured by soil testing laboratories in Arkansas and Oklahoma to guide farmers as to nutrient levels needed by their crops, he said.

“Because phosphorus bonds strongly with soil, and pastures don’t remove a great amount of phosphorus each year, it is not uncommon for these levels to take several years to decline,” Sharpley said, adding that “95 percent of farmlands for which plans were written had soil test phosphorus values below the settlement imposed cut-off of 300 parts per million of phosphorus or 400 pounds of phosphorus per acre.”

“With such evidence from Oklahoma and Arkansas, we feel that the plan-writing process and use of ESPI has led to more restrictions on where, when and how much poultry litter can be applied to pastures,”

Sharpley said. “Basically, use of ESPI met the strict requirements of the lawsuit settlement agreement, and it is apparent that it reduced the application of poultry litter in the Eucha-Spavinaw Basin.”

This reduction in poultry litter application and the implementation of BMPs will result in improved water quality within this basin, Brian Haggard said. He added that the effects of reduced phosphorus runoff might not be visible in streams and lakes in the short term, because of phosphorus stored within the stream channel, especially downstream from the historic contributions of the effluent discharge.

“Like all watersheds, there are many sources of phosphorus, and past management can leave a legacy that is slow to change,” Sharpley said. “However, we are seeing that the use of ESPI and the advice farmers are getting are making a difference by decreasing phosphorus runoff and achieving an appropriate balance between water quality and economic vitality of farming in the watershed.”

A pdf of the research paper “Outcomes of phosphorus-based nutrient management in the Eucha-Spavinaw watershed” is available online at http:// cses.uark.edu/1864.htm.

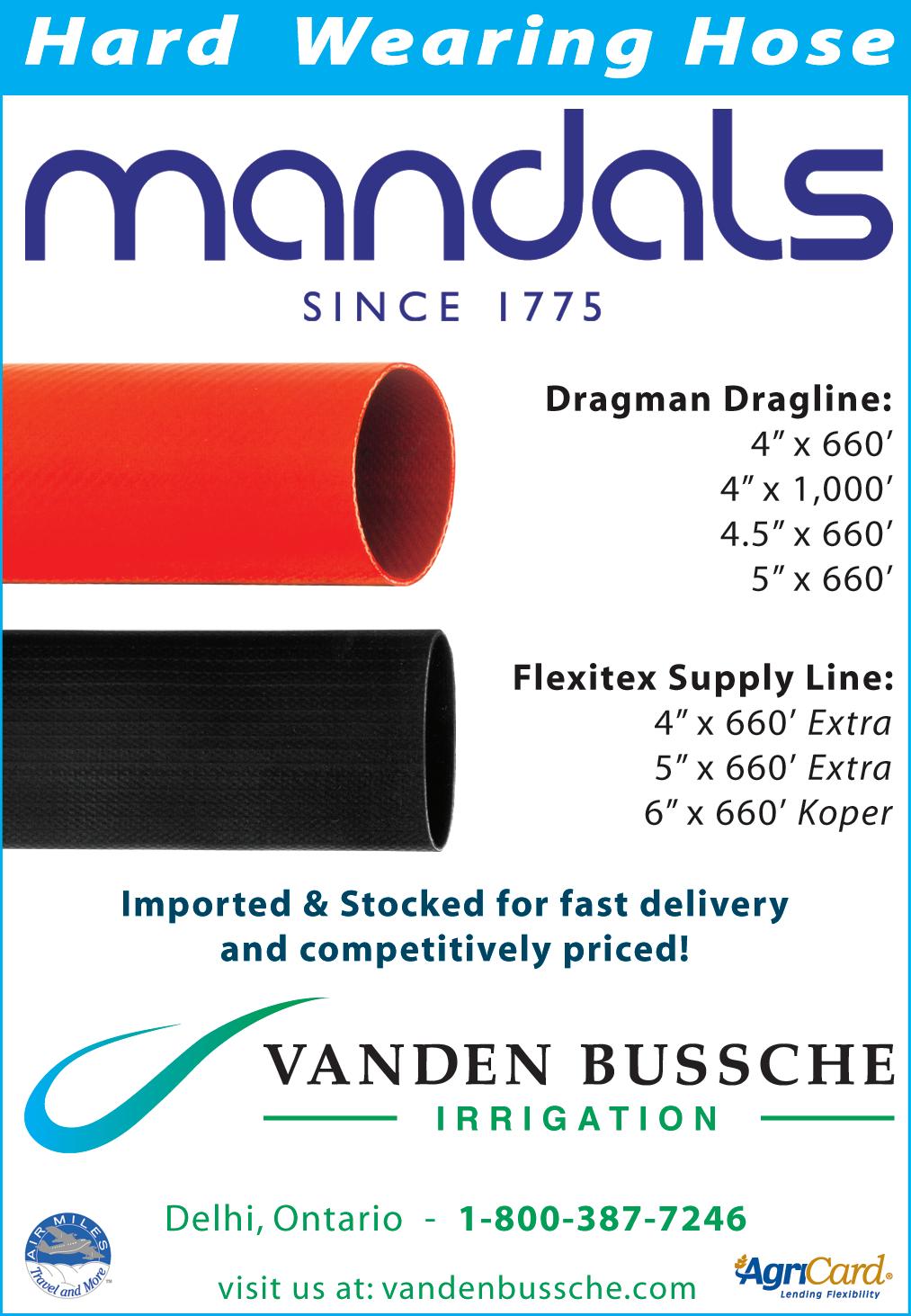

By Ross Muhlbauer & Randy Swestka

Hydrogen sulfide detection system being discussed at 2009 Manure Handling Expo

Aportable, wireless H2S detection system developed by researchers at Iowa State University will be one of the topics of discussion during the 2009 Upper Midwest Manure Handling Expo being held July 22 in Boone, Iowa.

The Agricultural Waste Management Laboratory in the Agricultural and Biosystems Engineering Department at Iowa State University developed the system for use in swine production systems during manure agitation and removal from under-floor swine slurry storage pits.

Each year swine are lost to hydrogen sulfide (H2S) poisoning from unexpected burst releases during slurry removal from deep pit swine housing. Commercial slurry applicators, producers, and previous research agree that increased ventilation can be required to dissipate dangerous H2S bursts when they occur during pump-out events. However, continuous increased ventilation during cold weather can lead to increased heating costs and stressful conditions impacting swine health.

Previous research has also shown that H2S concentrations can change from harmless to dangerous in a matter of minutes. It is this burst characteristic of H2S gas releases within the pit that make it dangerous.

The ability for applicators and producers to monitor H2S levels during slurry removal would be beneficial. Instead of utilizing high ventilation at

precautionary levels or low ventilation to reduce costs and to reduce animal stress, ventilation could be adjusted accordingly to disperse H2S gas and decrease the chance of swine loss. Although it is never recommended a person enter a swine house during slurry agitation, monitoring H2S levels and managing ventilation and agitation techniques to prevent hazardous conditions could also increase human safety in the event of an inadvertent entry. Previously, no system had been developed for manure applicators and producers to safely and remotely detect H2S gases in swine housing.

Initially, several different commercially available H2S sensors were tested by ISU researchers in a controlled laboratory environment. From those results, a prototype wireless H2S detection system was developed for testing in swine housing by commercial slurry applicators. A two-piece prototype consisting of a

Field testing at an empty swine confinement. An Iowa State University Mobile Air Emissions Monitoring Unit housed the receiver and the laboratory H2S gas analyzer.

The handheld receiver (left) is used by the operator outside the swine facility to monitor the H2S concentration measured by the sensor inside the facility. An alarm light and beeper activate on the receiver when an operator-programmed concentration is detected by the sensor inside the swine house.

battery operated sensor/transmitter and receiver was constructed. The sensor/ transmitter is placed in the swine housing area before agitation/removal begins; the operator can then monitor H2S concentrations from outside the building. An operator-programmed visual/audio alarm can be set to activate at a desired concentration to alert the operator of dangerous H2S conditions. Once alerted,

the operator can take action to dissipate the H2S gas.

The prototype detection system was field tested in swine confinements where it was used to detect H2S gas bursts during agitation of sub-floor slurry pits. Besides a quick reaction time, it showed good accuracy when tested against laboratory H2S measurement equipment. Testing confirmed that if monitored,

dangerous levels of H2S gas can be dissipated by adjusting ventilation during slurry agitation and removal. This testing also showed that eliminating above surface slurry agitation greatly reduces H2S burst releases.

H2S detection system prototypes are currently being used by two commercial slurry applicators during slurry application events from swine housing with sub-floor slurry storage. A data recorder within each prototype collects information on sensor run-time and H2S exposure. The units are being evaluated for durability, effectiveness, accuracy drift, and userfriendliness. So far, the units have performed well but limitations have been identified. The system is limited by its single-point monitoring scheme. While the system monitors H2S concentration at one point, dangerous levels could be present elsewhere in the swine house. During testing, methods were devised to minimize this problem. Use of interior circulation fans equalized H2S concentrations in the building, thus increasing the effectiveness of the single-point monitoring scheme.

The H2S detection system is intended for use by custom manure applicators and producers that handle their own slurry. The portable system is battery powered so it can be easily transported and it requires minimal setup. The battery lasts 14 hours, which is compatible with most slurry removal events. The sensor/transmitter is placed inside the swine house before slurry removal. The H2S concentration can then be monitored by the operator from outside the building via the receiver. With the sensor/transmitter in the swine house, the signal can be received via the receiver unit up to approximately 400 feet from the building. The range increases to approximately two miles line-of-site with long-range antennas. The receiver unit can be configured for internal battery or connection to a vehicle accessory DC power outlet making it ideal for use in a vehicle or carried around a site.

Additional information about the wireless H2S detection system will be provided during an educational session at the 2009 Upper Midwest Manure Handling Expo in Boone, Iowa (http:// www.ag.iastate.edu/wastemgmt/expo_ home.htm). Results from field testing and H2S mitigation techniques will also be discussed by the development team.

Ross Muhlbauer and Randy Swestka are with Iowa State University’s Agricultural and Biosystems Engineering Department.

The Alberta government has joined forces with several counties in the province plus the local agriculture industry to launch a four-year project aimed at increasing the amount of liquid dairy manure being injected or applied through surface banding.

The project, which hopes to reduce the amount of manure-applied nitrogen being lost to the atmosphere and reduce odor from liquid manure application, was launched in the fall of 2008. It involves Alberta Agriculture and Rural Development, Red Deer County, Leduc County, the County of Wetaskiwin, Alberta Milk plus Reduced Tillage Linkages, and targets dairy producers, custom manure applicators and other stakeholders in the three partnering counties.

“We’re looking at increasing the adoption of liquid manure injection or surface banding application technology,” said Stephanie Kosinski, a forage specialist at the Alberta Ministry of Agriculture and Rural Development’s Ag Info Centre. “(We’re) trying to get those dairy producers that have liquid manure

A four-year project, dedicated to increasing the amount of liquid manure injected or surface banded in the province, was recently launched by the Alberta government, several counties in the province and the local agricultural industry.

Photo by Margaret Land

moving from traditional broadcast and incorporation to liquid manure injection or surface banding,”

During the first year of the project, four demonstration sites were established – one large-scale demo plot, which was set up with custom applicators in the area, and three smaller scale demonstration plots that use smaller application equipment. Surveys were also mailed out to all dairy producers and custom manure applicators in the three partnering counties to determine current manure handling and application practices. Two producer appreciation days were also held during February 2009 in Millet and Innisfail, Alberta.

“At those days we invited the dairy producers that participated in our surveys as well as some of the councilors and ag service members from our participating counties,” explained Kosinski. “We kind of just went over where we’re at with the surveys and gave some information on the value of manure, some of the new manure calculators we have coming out and getting their input on what they would like to see and where they would like the project to go this year.”

Currently, researchers are examining the data collected from the producer

surveys. There are plans to establish additional plots this year and host field days during the summer and fall.

“We will invite those producers who participated with us and maybe even some others who are interested to come out and see our plots,” said Kosinski. “(They can) look at the types of injection equipment available, how they operate in the field and look at some of the benefits of moving toward surface banding or injecting liquid manure.”

It’s also hoped the project researchers can work one-on-one with the involved dairy producers to examine the economics of moving from broadcast to liquid manure injection.

During years three and four of the project, researchers hope to continue with the demonstration plots and collect yield data. There are also plans to continue with field days and workshops to help educate producers about different manure calculators and how to sample liquid manure.

“We’ll probably be doing some more economic analysis and a bit more extension work,” said Kosinski. “We’ll keep touching base with the dairy producers we’re working with as well as the counties and see where their needs are and what they would like to see.”

It is an unlikely application, but researchers in China have discovered that chicken manure can be used to biodegrade crude oil in contaminated soil.

Writing in the International Journal of Environment and Pollution the team explains how bacteria in chicken manure break down 50 percent more crude oil than soil lacking the guano.

Bello Yakubu, Huiwen Ma, and ChuYu Zhang of Wuhan University, China, point out that contamination of soil by crude oil occurs around the world because of equipment failure, natural disasters, deliberate acts, and human error. However, conventional approaches to clean-up come with additional environmental costs. Detergents, for instance, become pollutants themselves and can persist in the environment long after any remediation exercise is complete.

A more environmentally benign approach is bioremediation, which uses natural or engineered microbes that can metabolize the organic components of crude oil. Stimulating such microbial

degradation in contaminated soil often involves the use of expensive fertilizers containing nitrogen and phosphorus, and again may come with an additional environmental price tag despite the bio label. Soil hardening and a loss of soil quality often accompany this approach.

Ma and colleagues suggest that animal waste, and in particular chicken manure, may provide the necessary chemical and microbial initiators to trigger biodegradation of crude oil if applied to contaminated soil. One important factor is that chicken manure raises the pH of soil to the range 6.3 to 7.4 which is optimal for the growth of known oil-utilizing bacteria.

In tests, the team added chicken manure to soil contaminated with 10 percent volume to weight of crude to soil. They found that the almost 75 percent of the oil was broken down in soil with the fowl additive after about two weeks while additive-free soil was naturally remediated to just over 50 percent.

The team carried out a microbial analysis of their samples and identified 21 different microbial species known as aerobic

heterotrophs. The team explains that Bacillus species and Pseudomonas aeruginosa were the best oil-munching microbes but of the 21 isolates 12 were capable of metabolizing components of crude oil. Other microbes included Proteus, Enterobacter, and Micrococcus species. Bacillus represented the most prevalent species.

“The use of chicken manure to stimulate crude oil biodegradation in the soil could be one of the several soughtafter environmentally friendly ways of abating petroleum hydrocarbon pollution in the natural ecosystem,” the team concludes.

By Margaret Land

Low temperature (psychrophilic) in storage digesters have been used for years in many temperate parts of the world – mainly developing countries –as a way to treat human and livestock waste and provide cooking fuel. They are cheap to construct – just throw an impermeable cover over an existing manure pond or storage tank – and can help control odors and stop nitrification.

In Canada, they have been slow to catch on, as it has been assumed that low temperature digestion is not effective. According to Quebec researcher Susan King, past trials of the system have been too short to show the benefits of the process and the microbial populations within the manure haven’t had an opportunity to acclimate to the psychrophilic conditions. She is currently conducting research that may change opinions about the usefulness of the system in Canada.

Environmental concerns

Environmental issues are one of the greatest challenges facing the Canadian pork industry. Complaints of nuisance odors and concerns about greenhouse gas emissions and nutrient management issues have increased as population densities grow in rural areas. There have also been serious problems in Quebec with cyanobacteria – blue-green algae – caused by eutrophication from agricultural nutrients entering waterways.

According to King, “Legislation and rules involving ammonia volatilization and nitrification issues are something important in Europe and will be coming to North America soon.”

King, a PhD student in the Department of Bioresource Engineering at McGill University in Quebec, is studying psychrophilic digestion at a commercialscale swine operation located near St. Francois-Xavier, Quebec, in the Eastern

townships by the Canada-U.S. border. The farm owner had decided to cover his existing manure storage tank as a way of controlling odor. A polymer membrane floating cover, designed by Geomembrane Technologies Inc. (GTI) of New Brunswick, was constructed on top of the 100-foot wide by 12-foot deep concrete storage tank. The tank’s sides were surrounded by soil and plastic pipes filled with concrete are used to keep the cover from lifting off the surface. Due to the abundant supply of electricity within the province of Quebec, there is currently no market for energy produced from biogas. The farmer has considered using the biogas in some capacity on the operation, such as a heat source for the barn during the winter months, but currently the methane that accumulates under the cover is vented.

Dr. Suzelle Barrington, a professor in the bioresource engineering department at McGill and King’s PhD supervisor, was looking for a site to study the development of anaerobic digestion under a cover. During her search, she contacted GTI, who directed her to the Quebec swine operation.

King’s specific interest in the system involves the role played by microbial communities within the manure storage system and how quickly they can acclimate to different temperatures. She recently discussed her research during the First Annual Canadian Farm & Food Biogas Conference in Ontario, Canada.

When manure is excreted from swine, it has a temperature of about 39 Celsius (102 Fahrenheit). On the Quebec operation, the manure is collected in a pre-pit area for a few days before it enters the farm’s covered manure storage system, which has an average temperature range anywhere from between 0 to 20 Celsius (32 to 68 Fahrenheit). This can be a shock to the microbes that are naturally found within the manure and aid in its digestion.

“At first, it looks like they’re dead,” said King. “But they slowly acclimate to the temperature.”

She decided to study and confirm whether the microbial communities in swine manure can acclimate to a covered manure storage system and digest the

swine manure within the tank.

“Previous laboratory work suggested that the microbial community in swine manure could develop a robust anaerobic digestion process given an acclimation time of at least 100 days,” she explained.

Using manure samples taken from the full-scale pilot site, King compared them to fresh manure right out of the pig and manure from an open manure storage tank. From the laboratory tests and solids analysis conducted, she was able to measure the ultimate methane potential for each sample, the methane production rate and the time required for the microbes to acclimate. Dr. Serge Guiot with the Department of Environmental Bioengineering at the Biotechnology Research Institute (BRI) in Montreal, Quebec, supervised her lab work.

According to King’s results, “A robust, acclimated microbial community is present in the pilot installation.”

In light of the development of this robust microbial community, the researchers decided to call the system In Storage Psychrophilic Anaerobic Digestion (ISPAD).

“The covered tank never goes above 35 Celsius (95 Fahrenheit) but the microbial community was very active,” said King. “Even at a temperature of 8 Celsius (46.5 Fahrenheit), the microbes in the covered storage manure sample keep right on producing methane with no lag time.”

This compares to the more than 450 days it took to acclimate the fresh manure sample and the one year it took for the open pit manure sample to acclimate at 8 Celsius (46.5 Fahrenheit).

Also with the ISPAD sample, 63 percent of the methane was extracted from the system and 24 percent of the manure solids were consumed. This compares favorably to the midtemperature (mesophilic) digestion process, which results in 75 percent methane extracted and 50 percent of the solids consumed.

“This is close enough to say this is making a difference with what’s in your (manure) tank,” said King.

While microbes in the ISPAD tank, which had been in operation for three years, where fully acclimated, King suggests it would take no more than one year to acclimate the microbes if one covered an existing uncovered manure storage tank.

“This is because the microbes are partly adapted from being in the uncovered tank already,” she explained. “A brand new tank could take longer,

though I can’t say for sure how long.”

Besides digesting manure solids and producing methane, King says other benefits of the ISPAD system include: slowing down the conversion of organic nitrogen to ammonia, settling out the manure’s phosphorous content and keeping rainwater from filling the storage tank.

“By eliminating the rainfall, that’s an extra meter of depth you don’t have to deal with,” she said.

King hopes to continue her research and examine nitrogen conservation

and land application of manure from the ISPAD system, including wind tunnel tests to see what is released at application. She hopes to monitor two more swine production sites using covered manure tanks and optimize the ISPAD design.

“I don’t know what kind of pattern I’ll get with biogas production,” she said. “I just know we are producing methane.”

King’s research work at McGill was

The Economic Research Service (ERS) of the U.S. Department of Agriculture (USDA) recently released an in depth examination of how manure management practices have evolved in the U.S. hog industry from 1998 through to 2004.

According to the 23-page report, written by Nigel Key, William D. McBride and Marc Ribaudo with ERS, “The changing structure of hog farms is altering manure management practices as larger operations seek to manage nutrients on a limited cropland base.” The report, entitled “Changes in Manure Management in the Hog Sector: 1998-2004,” suggests that increased regulation of the Clean Water Act and state legislation plus more local conflicts involving odor issues are also forcing producers to change their management practices.

“Over 1998 to 2004, the total number of U.S. hog operations fell by about 40 percent, and the average inventory grew from 2,589 to 4,646 head per farm,” the report states. “Data from hog producer surveys administered in 1998 and 2004 indicate that large hog producers (1,000 animal units or more) are altering their manure management practices to mitigate the environmental effects of increased concentration. In particular, the largest farms removed more manure from their operations (especially by giving it away for free) and applied less commercial fertilizer to crops receiving manure in 2004 than in 1998. Also, in accordance with Environmental Protection Act (EPA)

regulations, large hog operations conducted more nutrient testing of manure, increased the use of microbial phytase in feed (which reduces nutrients in manure), and increasingly followed comprehensive nutrient management plans.”

The report also states there’s been:

• a decline in the spreading of solid manure and liquid manure without physically injecting it into the soil;

• a decline in the quantity of manure applied per acre;

• a decline in the nutrients excreted per animal due to an increase in feed efficiency; and

• an increase in the share of farms removing manure from their operation.

“The increasing concentration of hog production on large operations is expected to continue, meaning that manure management will continue to be an important issue to the hog industry and to others concerned with its environmental impact,” the report concludes. “Results of this research imply that hog producers have responded to policy incentives, both positive and negative, designed to address the manure management issue. The findings also suggest that there still is significant room for reducing the environmental impact of manure through improved management. For example, hog operations, on average, apply manure

to less than 30 percent of available crop acreage. Policy incentives, along with technological innovation, are likely to play an important role in the future of hog manure management and its environmental impact.”

The study used information from surveys of U.S. hog producers conducted in 1998 and 2004 as part of USDA’s annual Agricultural Resource Management Survey (ARMS). The detailed surveys covered a cross-section of U.S. hog operations and collected information on production costs, business arrangements, production facilities and practices, and farm operator and financial characteristics. The surveys also provided information about manure storage and handling, fertilizer use, manure application techniques, Environmental Quality Incentives Program (EQIP) payments, the use of comprehensive nutrient management plans, and manure application rates. The data allowed the authors to document the current state of manure management and track producers’ responses to existing and anticipated manure-related regulations. Data from the surveys was analyzed by farm size according to the number of animal units (1,000 pounds of live animal weight) produced.

Visit www.ers.usda.gov/ publications/eib50 to access a copy of the full report.

Trevor Borduzak knew he wanted to be a custom applicator since he was eight years old and rode in the three-wheeled TerraGator that was spreading fertilizer on his family farm.

That commitment to the job made the 12-year veteran applicator from Legal, Alberta, the winner of the 2008 Canadian Ag-Chem Operator of the Year contest and the owner of a new Arctic Cat.

Borduzak works for Sturgeon Valley Fertilizers, Ltd., and was named the Operator of the Year during the 2009 Canadian Association of Agri Retailers (CAAR) Conference in Regina, Sask.

“I was shocked this all took place,” Borduzak said. “Getting nominated for the Operator of the Year award was an honor in itself, and winning the award has been amazing. There are a lot of people out there who work really hard. And, I can’t be a good operator without all the people behind me to help make it happen. It was quite humbling to hear they thought that much of me.”

Borduzak began working for Sturgeon Valley Fertilizers after high school. “I really like the machines,” he said. “There aren’t many people who get the opportunity to run iron like this.” And, starting a relationship with a new Ag-Chem dealership, Selmac Sales, with locations in Camrose and Stony Plain, Alberta, he’s been able to keep his TerraGator running smoothly.

Great custom applicators must know what they are doing in the field at all times, Borduzak added. “You need to have knowledge in several areas – agronomy, crop inputs, technology – and understand all phases of the production cycle in order to do your job well. It’s important to know crop planning, crop production and crop nutrition. If you are involved in all of that you are going to be a better operator, because you want that much more to come out of the job you do.”

Borduzak sprays up to 20,000 acres per year, and runs the floater over an

additional 15,000 acres. When he’s not spraying or spreading, he farms 1,200 acres of canola, oats and barley, and raises cattle.

The other three finalists for the 2008 Canadian Ag-Chem Operator of the Year program were: Jason Morrow, Double Diamond Farm Supply, Pilot Mound, Manitoba; Gordon Moore, KARE Ag Services, Radisson, Saskatchewan; and Norman Schmidt, Platinum Farm Services, Ltd., Smoky Lake, Alberta.

Recognizing the importance of honoring the unsung contributors in a successful custom application business, the Ag-Chem Canadian Operator of the Year program was introduced in 2007 with the help of CAAR. Judging criteria includes experience, quality of work, customer service, community involvement, customer appreciation and overall dedication to the job.

“We started this program to recognize the good work of our customers,” said Mark Sharitz, director of marketing for Ag-Chem. “They are the guys on the machines doing their best work all day, and who are always willing to work when called on.”

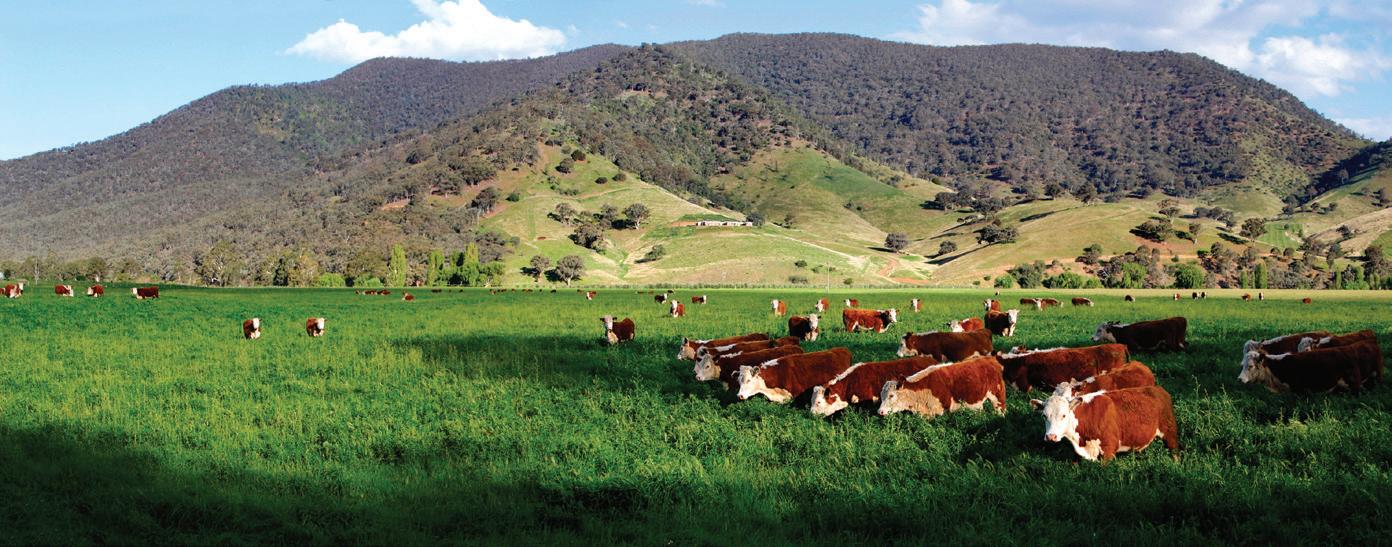

The Ontario Cattlemen’s Association (OCA) recently announce that Amos and Heidi Brielmann are the winners of the 2009 Environmental Stewardship Award (TESAward), sponsored by RBC Royal Bank and OCA.

The Brielmanns operate a 1500 head cow/calf ranch near Pinewood, Ont., and were nominated for the award by Kim Jo Bliss, a fellow producer in the Rainy River District.

Pine River Ranch (PRR) has a goal of making a profit with healthy cows, healthy land and healthy family. The Brielmanns continue to make improvements that not only benefit the environment but also the livestock they raise – which should,

in turn, increase productivity as well as profitability.

“Here in Rainy River we are truly lucky to have such an environmental role model and steward,” said Bliss. “Amos Brielmann, his wife Heidi and children, Susanne and Timo, have worked hard on their farm and are very deserving of this award. They have undertaken numerous environmental improvements. Not only have many been completed, and more are in progress, as the family works to continuously improve their operation.”

PRR operates approximately 2000 hectares of hay and pasture land, breeding 600 Angus/Angus Cross beef cows – wintering all calves and grazing them the following year. Examples of environmental projects undertaken include fenced off waterways and installation of solar pumps (a real challenge was to provide fresh water for up to 600 calves, even when it is -40 degrees C).

“The family and staff at Pine River Ranch have been the active force behind achieving the goals we have set out for ourselves,” says Brielmann. “We have also been fortunate enough to have support from the Ontario Soil and Crop Improvement Association, the Rainy River Soil and Crop Improvement Association, the Rainy River First Nation’s Watershed Program, the Ontario Ministry of Natural Resources, the Ontario Ministry of Agriculture, Food and Rural Affairs, and the Green Cover Canada Plan.”

The Brielmanns have created riparian areas over 12 kilometers and expanded their wintering lots from seven hectares to 43 hectares, which in turn has reduced the animal density to less than five animal units per hectare. More than 15,000 trees have been planted on the ranch. The Low Water Cattle Crossings that have been installed are very impressive. One of PRRs major improvements – installing the solar watering system – has proven to be very beneficial to the Rainy River District. Since the Brielmanns started the remote watering systems, there was a

strong acceptance from the larger farmer community. These systems have provided many others with the tools to be able to fence off creeks, rivers and dugouts.

PRR has also been helping other farmers to design solar-powered winter watering systems. These systems have given others the option to feed cows during the winter months away from the conventional barnyard. This practice is reducing the manure loads in the farmyards during the winter and in the spring with runoffs.

The Brielmanns will go on to represent Ontario at the National Environmental Stewardship Award competition to be held the week of August 9, in Regina, Sask.

ADI Group Inc. recently announced the addition of Noel Eustace (Jr.) to the ADI team.

ADI Group created the new position of manager of marketing and sales for

ADI Systems Inc. and Geomembrane Technologies Inc. (GTI), two of ADI’s companies. This new position allows ASI and GTI to place greater emphasis on worldwide marketing and sales efforts.

Eustace comes to ADI with more than 20 years experience in marketing, sales and business management, plus strong academic credentials (BBA, Acadia and MBA U. de Moncton). His background in sales management complements the strong technical abilities of existing staff at both ASI and GTI.

The ADI group of companies offers a range of services including design-build, project and construction management services plus planning, architectural design and consulting engineering.

Members of the Western United Dairymen (WUD) are continuing to follow California air quality rules even after they were suspended in May.

Recently, the environmental group

the Association of Irritated Residents (AIR) won a court order directing the San Joaquin Valley Air Pollution Control District (SJVAPCD) to suspend the air quality rules pending further study. The group challenged the air quality rules believing they weren’t tough enough.

WUD president Ray Souza said the organization’s members continue to follow the air quality rules. “This is not a responsibility that dairy families will shy away from,” he said “We are proud of the role that we play, along with our fellow Californians, in making our state a better place to live.”

The San Joaquin Valley district has prepared a draft health assessment that is available for public review and comment. District staff recommended at the May board meeting that the rule’s enforcement be suspended until the health study is completed. The board will consider the health study at its June meeting and decide whether to re-adopt the rule in its original form or to direct staff to being the public process for amending the rule.

“We are disappointed that attorneys representing AIR rejected our proposal to leave the rule in place and continue the progress that we have made in significantly reducing dairy emissions,” said Seyed Sadredin, the air district’s executive director and air pollution control officer. “Setting the rule aside at the peak of the valley’s ozone season is not in the best interest of the valley residents.”

There are now 125 livestock manure anaerobic digester systems in operation in the U.S., according to the Environmental Protection Agency.

An additional 26 systems are currently under construction and another 70 digester projects are planned states a report recently released by the EPA’s AgStar program.

In 113 of the operational systems, the captured biogas is used to generate electrical power, with many of the farms recovering waste heat for the electricitygenerating equipment for on-farm use. These systems generate about 244,000 megawatt-hours (MWh) of electricity per year. The remaining 12 systems use the gas in boilers, upgrade the gas for injection into a natural gas pipeline, or simply flare the captured gas for odor control. Most digester systems (78 percent) operate at dairy farms and are largely concentrated in the Midwest, West, and Northeast.

The majority of commercially operating digesters (78 percent) are plug flow and complete mix systems operating at mesophilic temperatures (95ºF105ºF). The next most popular system is covered lagoons, operating at ambient temperature. More specific details about the systems are posted in AgSTARs Anaerobic Digester Database.

Although the majority of systems are still farm-owned and operated with only livestock manure as the feedstock, other approaches are emerging. These include the codigestion of high strength organic wastes (e.g., food processing wastes) to increase gas production per unit volume of reactor; third-party owned/operated systems; centralized systems handling manure from multiple farms; and direct gas sales to customers or gas utilities.

The Ohio Department of Development is currently accepting proposals for $500,000 in funding available for the Biomass –Waste to Energy Program.

The funding is available to projects that demonstrate technologies that utilize farm waste to produce energy in Ohio’s farming communities

The Biomass – Waste to Energy program is funded through the Advanced Energy Fund administered by the Ohio Department of Development’s Ohio Energy Office. The program encourages private investment in projects that use anaerobic digestion or similar technologies to produce electricity, thermal energy and/ or conditioned methane gas from farm waste. Eligible projects must demonstrate completion within two years, job creation and retention during the construction and operation phases, and the use of Ohio manufactured components and/or ownership by an Ohio partnership or company. One award of $500,000 or two awards of $250,000 will be selected through a competitive process.

For more information about the program and funding requirements, visit: http://www.development.ohio.gov/ cdd/oee/GrantsLoans.htm.

Quick action by a manure applicator kept a 4,000-gallon manure spill from becoming worse.

According to a report in the Globe Gazette, Tim McCandless was land-applying manure when a line supplying manure to the applicator came undone. McCandless constructed a berm across a ditch on the farm to keep the manure from flowing downstream.

The spilled manure was pumped up and land applied.

Officials with the Iowa Department of Natural Resources praised the quick action and urged producers to have emergency plans in place.

“Alertness and fast action on the part of the applicator had helped avoid further contamination,” said Jeff Vansteenburg, supervisor of the Iowa DNR’s field office in Mason City.

Farmers interested in reducing air quality emissions are invited to apply for 2008 federal Farm Bill funding.

“The primary goal of this new portion of the Environmental Quality Incentives Program (EQIP) is to help farmers and ranchers attain the standards set by the National Ambient Air Quality Standards (NAAQS),” said Ed Burton, California State Conservationist for the USDA’s Natural Resources Conservation Service (NRCS).

There are 36 counties in California eligible to use the new funds to help achieve compliance with the ambient air quality standards for eight hour ozone and PM10 and PM2.5 (particulate matter smaller than 10 and 2.5 microns, respectively). The eligible counties are: Alameda, Amador, Butte, Calaveras, Contra Costa, El Dorado, Fresno, Imperial, Inyo, Kern, Kings, Los Angeles, Madera, Marin, Mariposa, Merced, Mono, Napa, Nevada, Orange, Placer, Riverside, Sacramento, San Bernardino, San Diego, San Joaquin, San Mateo, Santa Clara, Solano, Sonoma, Stanislaus, Sutter, Tulare, Tuolumne, Ventura, and Yolo.

NRCS has worked with academic, conservation, regulatory and industry groups to identify agricultural practices that will reduce ozone precursors [oxides of Nitrogen (NOx) and Volatile Organic Compounds (VOC)] and particulate matter [respirable (PM10) and fine (PM2.5)] emissions from agricultural sources. Applications will be ranked according to the amount of emission reductions achieved in the proposed plan.

Funded practices include the NRCS’ combustions system air emissions management practice to improve high polluting, fully functional engines with newer, reduced-emission technologies that meet or exceed current emission standards. Stationary, portable and heavy-duty off-road mobile systems will be included. Other covered air quality practices will include conservation tillage, dust control on farm roads, precision pest control, and manure injection.

For the complete list of practices and for information on how payments will be calculated, see www.ca.nrcs. usda.gov/programs/eqip/2009/ index.html or visit a local NRCS conservationist.

➤ Manure Pits,Channels & Covers

➤ Suspended Slabs - up to 40’ clearspan

➤ Hog & Cattle Slats - up to 25’ clearspan

➤ Weeping Walls - manure separation

➤ Milking Parlors

➤ Strainer Boxes

➤ Commodity Storage

➤ Bridges

➤ Bunker Silos (8 types)

➤ Syloguard Concrete repair

➤ Retaining Walls

➤ L & T Walls up to 16’ high

• Built to engineers’ specifications

• All sections are high strength, pre-stressed,reinforcedconcrete for longer life

• Quick & easy to build

• Air-tight seals and protectant using Syloguard products

Bobcat Company and Polaris Industries Inc. recently announced a long-term strategic alliance aimed at penetrating global work-related markets.

The alliance will include codevelopment of work vehicles, supply of highly differentiated work vehicles and technology sharing, with a planned launch by the second half of 2010.

“We are thrilled about the long-term implications of this alliance,” said Richard Goldsbury, president, Bobcat Americas. “Bobcat’s and Polaris’ long traditions of innovation, product passion and similar cultures complement each other very well.

“We are combining the strengths of the number-one compact construction equipment manufacturer with those of the number-one off-road vehicle manufacturer to deliver innovative product solutions for our customers,” Goldsbury said.

Scott Wine, CEO of Polaris Industries, said the alliance is consistent with Polaris’ goal of diversifying beyond power sport segments and will enhance efforts to accelerate the growth of the company’s military and international business.

“Initially, Polaris will produce and sell highly differentiated work vehicles to Bobcat for sale through the Bobcat dealer network,” he said. “The breadth and depth of our cooperative efforts will expand thereafter to include co-developed vehicles for both Polaris and Bobcat and further technology-sharing.” www.bobcat.com www.polarisindustries.com

John Deere adds new skid steer attachments

John Deere Construction & Forestry has added three new Worksite Pro™ attachments for its skid steer and compact track loaders, including a side discharge bucket.

Four side discharge buckets, ranging in widths from 60 to 84 inches, are available in two styles. The SD (dust) models are for lighter materials such as mulch, sawdust and straw, while the SA (aggregate) models are for materials such as lime, sand or gravel.

Worksite Pro side discharge buckets feature a direct drive hydraulic motor on the discharge belt and allow unloading from either the left or right side of the bucket. Manually adjusted discharge gates control material flow.

The SD models have an agitator driven by a separate motor to prevent light materials from bridging and to ensure a more consistent flow of material. SA models have a bridging plate to keep weight off the belt and prevent motor stalling.

All side discharge buckets are compatible with standard-flow Deere machines.

www.deere.com

Octaform Systems Inc., a North American manufacturer of finished concrete forming systems, recently completed the requirements of the NSF Drinking Water Certification Program.

Acquiring this certification allows Octaform to be used in municipal water treatment facilities. In addition to water

treatment plants, Octaform can be utilized in agriculture and food processing facilities that require potable water certification.

NSF/ANSI Standard 61 – Drinking Water Treatment Components: Health Effect – is certification that applies to every water contact material, product and system. This standard is required by regulation or policy in 43 of 50 U.S. states and 11 of 13 Canadian provinces and territories. NSF is an international, non-profit, non-government certification organization located in Michigan who supplies health and safety based risk management services. www.octaform.com

Parkson Corporation recently opened the new Parkson Water Research Facility, located in Pompano Beach, Florida, near Parkson’s headquarters in Fort Lauderdale, Florida.

This new facility provides for the piloting of water and wastewater technologies and includes an onsite laboratory designed to speed the evaluation of process-effectiveness testing. The on-site laboratory also supports product design and development activities, as well as, management of necessary maintenance for installed pilot units.

The primary objective of the new Parkson WRF is to facilitate water related research and to accelerate the development of new water and wastewater technologies. In addition, the facility will investigate and enhance valueengineering improvements to existing Parkson products on an ongoing basis.

Several pilots of Parkson products are installed at the facility and provide a hands-on training platform for both internal and external clients. The facility can also serve as a small-scale operational training facility for new users with specific product training needs. www.parkson.com

Continued on page 34

June 21-24, 2009

2009 International Meeting ASABE, Reno, Nevada. Visit www.asabe.org/meetings/ aim2009/index.htm

July 8-9, 2009

Water Quality Credit Trading Workshop, Atwood Lake Resort & Conference Center, Sherrodsville, Ohio. Visit www.conservationinformation.org.

July 21-23, 2009

Third International Symposium on Management of Animal Carcasses, Tissue and Related By Products, University of California, Davis, California. Visit extension. umaine.edu/ByproductsSymposium09/ default.htm.

July 21-23, 2009

Wisconsin Farm Technology Days, Crave Brothers Dairy, Waterloo, Wisconsin. Visit www.dodgefarmtech.com.

July 21, 2009

Manure Science Review 2009, Rowe Dairy, Strasburg, Ohio. Visit www.oema. osu.edu.

July 21, 2009

Profitable Environmental Options for Livestock Producers, MSU Beef Cattle Research Center, Lansing, Michigan. Visit www.animalagteam.msu.edu.

July 22, 2009

2009 Upper Midwest Manure Handling Expo, Central Iowa Expo Center, Boone, Iowa. Visit www.abe.iastate.edu/ wastemgmt.

July 23, 2009

Manure Science Review 2009, Brown Dairy, New Bremen, Ohio. Visit www.oema.osu.edu.

July 29, 2009

Conservation In Action Tour 2009, located at various locations around Indiana. Visit www.conservationinformation.org

August 16-20, 2009

Managing Agricultural Emissions Symposium, Washington Convention Center, Washington, DC.

August 21, 2009

Manure Treatment Technologies Demonstration Programs, an online webcast hosted by the Livestock & Poultry Environmental Learning Center. Visit www.extension.org/pages/ Live_Webcast_Information.

Continued from page 32

New Holland’s new 900 Series utility backhoes attachments for tractors have significant improvements in operator visibility and ease of operation.

Consistent with New Holland Boomer™ tractor styling, the new 900 Series curved boom design provides increased visibility and complements New Holland’s compact and utility tractors.

Four new tractor-mounted backhoes offer digging depths of 6 feet, 7.5 feet, 8.5 feet and 9.5 feet with transport heights of 65 inches, 79 inches, 84.7 inches, and 96 inches, all with a full range of bucket sizes. The 910GH, 920GH, 930GH, and 940GH workhorse backhoe attachments have 180° swing arc and bucket rotation.

The 900 Series utility backhoes feature two-lever control for easy operation of boom, dipper stick, bucket, and swing. The controls are mounted in a low-profile console for unobstructed vision, giving operators a view of the bucket and worksite without stretching and straining. www.newholland.com

During these difficult economic times, poultry producers are seeking a litter amendment for their broiler houses that can minimize the harmful effects of ammonia and pathogenic microorganisms, promote bird health and productivity, and lower their costs, without adversely affecting the surrounding environment.

DSM’s new LitterGuard™ is a natural, organic, microbial-based poultry litter amendment that reduces ammonia and pathogenic bacteria levels, improves the health and performance of birds, and remains environmentally-friendly to poultry, people, and natural resources.

Used as a component of an ongoing maintenance program, LitterGuard can help enhance cost savings by minimizing

energy needs, increasing organic waste decomposition, decreasing litter cleanout and replacement, and helping to preserve the integrity of groundwater and soil.

DSM provides technical service, production, distribution facilities, plus sales and marketing in more than 100 countries.

www.unlimitednutrition-na.dsm.com

A company in British Columbia, Canada –Air Phaser Environmental – is producing non thermal plasma technology to control odor and volatile organic compounds (VOCs).

The technology removes vent air odors from compost, manure, biosolids and animal feeding operations by converting the odor, VOCs and complex organic compounds into water and carbon dioxide. It can handle air flow from 1000 to more than one million CFM.

The compact technology can easily be installed into existing operations and can replace bio-filters, scrubbers and thermal oxidizers with less energy use. www.airphaser.com

MobyDick has introduced the Automatic Wash Bay Module for tire, undercarriage and chassis washing. The wash bay system uses high flow washing technology with a scraper-conveyor system that automatically collects, dewaters and discharges settled solids, eliminating the need for vacuum truck, backhoe or front end loader cleaning. The MobyDick wash bay is suitable for permanent or mobile applications at agricultural sites.

www.mobydick.com

Besides its four and five meter slurry mixers, Veenhuis has a new six-meter mixer available. With this new length, Veenhuis is responding to the need for longer mixers to accommodate larger manure pits.

The six-meter mixer combines low traction with high paddle propulsion. This enables the mixer to blend large quantities of slurry into a homogenous substance quickly and without issues. For optimum results, a reversing box can be fitted to the main axle, allowing either a pulling or slowing direction.

The mixer can be coupled to a tractor through a three-point linkage and quickly and can be positioning and repositioning by one person. A guiding frame is available for guiding the mixer into the manure pit. An accompanying frame in the pit (bricked or poured in) guarantees a stable construction.

Because the mixer requires minimal power, it is also suitable for use with light tractors. The mixer is fully galvanized and the paddle is sprayed in dual-component lacquer. This makes the mixer resistant to the effects of slurry, guaranteeing long life and minimizing maintenance costs. www.veenhius.com

FSI Fabrication Inc. of Sunnyside, Washington, recently released the EzSpred Fp2 compost spreader. With more than 30 years experience building spreaders, FSI goal with the EzSpred Fp2 was to produce a unit that could evenly spread compost at widths of up to 60 feet and rates between six to eight tons per acre. FSI started the process with the Fp series EzSpred design, which the company had been produced for more than 10 years. They added the additional hydraulics necessary

to power two, 38-inch spinners with six blades each with a variable speed range from 350 to over 900 RPM. A beater was installed between the metering gate and the spinners, designed to insure that a more uniform material would be spread. The “tip out” feature of all EzSpreds was incorporated for ease of maintenance. All controls are mounted together in a separate panel for operator ease of use. Several models are available to meet different users needs, including spreaders as short as 14 feet for mounting on new or used TerraGator-style movers up to 35 foot long semi trailer units. www.fsifab.com

Send your product items to: Manure Manager welcomes submissions from all manufacturers/dealers of new manure management-related products.

All submissions will be considered for inclusion in On Track. For electronic submissions, please send digital photos as a TIFF file or maximum quality JPG file, along with product and contact information to: mland@annexeb.com

If the material is being sent by mail, please send it to:

On Track Editor Manure Manager Magazine

105 Donly Drive South Simcoe, Ontario N3Y 4N5

Jamesway Farm Equipment introduces a new family of Tanker Transfer Kits. These kits may be added to highway tankers or truck mounted field tankers to allow quick and easy unloading into another tanker. Many large operations use highway tankers to supply manure to a trailer tanker. This “tanker nursing” allows the field tanker to apply a far greater number of loads per day, plus the tanker and tractor tires are not subject to the wear associated with road travel. Additionally, the road stays clean since the field equipment stays in the field and the road equipment stays on the road.