Innovation, automation and regulation

Manure vacuums come of age. | 14

A little rain must fall

Incorporating manure into a rainfall simulation. | 16

Return to EuroTier A preview of overseas innovations. | 18

January/February 2025

Innovation, automation and regulation

Manure vacuums come of age. | 14

A little rain must fall

Incorporating manure into a rainfall simulation. | 16

Return to EuroTier A preview of overseas innovations. | 18

January/February 2025

• Python, Hybrid II, & Rotary models have pivoting design built in for forward weight & contour following.

• No need for a 2nd bolt on pivoting bar & all the associated weight out the back.

• 3 year warranty on all models

• Best Warranty

• Best actual injection/coverage of wide gallonage ranges

• Best options for various requirements

• DSI’s signature injector

• High performance Coulter down pressure design

• 4 Sweep options for lower rates to 20,000+ GPA

• 4 Tube options, including plug-free wing drop

• Liquid stays where injected, properly placed for full utilization by crop

• Clozr option for different operation requirements

• Patented Conical blade creates a wider furrow for higher GPA than conventional rotary injection

• Patented Cupped covering blades aggressively move soil to cover excess liquid

• Heavy down pressure on covering blades

• Combination of rotary injector & disc incorporator

• 24” – 30” spacing

• Highest GPA actually injected/covered in the industry

• Non-grease hubs on all models for maintenance free operation

• Swivel coulters reduce side loads

• 30° left & right pivot angle to accomodate contours & end row turning on dragline

• 18” – 30” spacing

• Patented Conical blade creates a wider furrow for higher GPA

• 18” spacing, 8 wave Conical blade, & 2 Clozr blades on dragline result in higher GPA injected/covered than a single closer blade design

• Same time-proven Series 70 ability/reliability

• Special design for tank or dragline toolbars

JANUARY/FEBRUARY 2025 Vol.23, Issue 1

Some of the best “future” innovations are driven by a pressing present need. Our features focus on future-proofing by reactivity in the present.

4

Equipment mods, like the ones made to W.D. Farms’ spreader, solve niche problems . See page 10. Photo courtesy of W.D. Farms.

14 16 18

Manure vacuums With new functions focused on automation and labor saving, the tech comes of age.

BY TREENA HEIN

A little rain must fall

Using a rainfall simulator to show infiltration and runoff properties.

BY RONDA PAYNE

Highlights and AIlights at EuroTier Manure and livestock equipment showcased at the annual farm technology show.

BY CHRIS MCCULLOUGH

Let’s get philosophical for a moment and talk about the real versus the realistic. Many of us are familiar with 1929 painting, The Treachery of Images by René Magritte, known by many by its caption “Ceci n’est pas un pipe” (“This is not a pipe”). It’s often cited as a meta commentary that the depiction of something, even if realistic, is still not the object itself.

(Don’t worry, I’ll get to the manure part soon).

Similarly, the future and futuristic aren’t the same. In fact, some philosophers and futurists use the phrase “the future does not exist.” The Cole’s Notes version: because the future has not yet been written, it’s only a concept, not a real thing.

When we do the innovation issue, it’s easy to use phrases like “futuristic technology,” “the future is now” or “planning for the future.”

Tech innovation is a long process, so innovators must solve the problems of the “future.” But not every expert predicts the same future. Look at personal mobile technology. Google

fail for several reasons, all of which boil down to an incorrect idea of the future.

Ahem – back to manure.

Most of the innovation highlighted is either already successful or buzzworthy because it feels like it was created for the future in which we live (or as some call it, the present) and not some faraway idea of the future someone envisioned. It’s easy to do that when your research is based on the empirical, historic data and trends. For example, on Page 8, University of Missouri’s Teng Lim explains why a multi-state team is looking at swine manure as an effective fertilizer for corn, which is based on current facts, needs and trends – all of which will only be truer decades down the road.

On Page 10, we look at applicators and entrepreneurs who customize their own equipment – some even make a business out of it. The best customizations are born out of today’s needs, but also have kept in mind that today’s needs might intensify in years to come. On Page 14, we look at manure vacuum technology. Autonomous

“Not every expert predicts the same future... some miscalculate.”

Glass is one of the most memorable failures of the 2010s. There’s been lots of ink spilled on why: no major marketing campaign, privacy concerns, aesthetic/design criticism. More simply, though: 10 years later (the “future” to a 2015 consumer), smart glasses still aren’t common. Other wearables like smart watches are popular, but Google miscalculated the “future” need in this case. Look also at the makers of the Blackberry, who by their own admission thought the iPhone would

vacuums are already in the market, with more in the works, to meet the growing need to address labor costs.

The need to feed the world continues to intensify, while inputs, labor and equipment have become more expensive, and the pressure to reduce emissions continues to increase. The tech must be built to last into an even further future. Whether you think the future is real or simply an “idea,” the more well-informed your vision of the future is, the better the innovation.•

Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

The USDA-backed, $70 million Transforming the Farmer to Consumer Supply Chain Project Dairy Manure Management Incentive (Transform F2C) program, will provide up to $7 million in funding for eligible dairy farmers to adopt climate-smart manure management practices.

The new initiative is available to farmers across 15 states – California, Idaho, Indiana, Kansas, Maryland, Michigan, Minnesota, Nebraska, New Mexico, New

York, Ohio, Pennsylvania, Texas, Utah and Wisconsin – who meet other eligibility criteria. Applications opened earlier this month, and will close Jan. 30. Up to $1 million can be received by a single farm entity.

Transform F2C’s mission is to help farmers integrate sustainable on-farm solutions that create a positive environmental impact.

Practices that quality for funding include storage, separation, composting and nutrient management practices. Funding is awarded based on the impact of the practice adoption as assessed in metric tons of CO2 equivalent reduction.

Visit TransformF2C.com/dairy-manuremanagement for details.

Earlier this year, Agriculture and Agri-Food Canada (AAFC) brought back its Plowdown Challenge, a call to Canadian farmers to work toward an even more sustainable agriculture sector through beneficial management practices.

P.E.I. organic vegetable farmer Matt Dykerman was the winner by guessing the correct yield of potatoes grown in Charlottetown using manure and leftover nitrogen from

According to the latest report by Farmers National Company (FNC), a Nebraskabased management and professional solutions provider for U.S. farms, despite various pressures – lower net farm income, declining commodity markets, higher interest rates and increased input costs – land values have remained stable across the Midwest.

With a larger number of motivated land buyers in today’s market, this could lead to strong demand.

Land listings are currently down 25 percent, according to FNC’s dada, from the market rate between 2020 and 2023, which was considered to be a highly active and accelerating market. With supply down, that naturally puts demand high.

a cover crop instead of commercial fertilizer.

Dykerman’s guess of 275 hundredweight per acre, which was closest to the final result of 293 hundredweight per acre. The yield was strikingly close to the 2024 estimated P.E.I. average (304.7) for potatoes.

And, at 293, the 2024 yield was 73 per cent higher than last year’s crop, when no manure was used.

The challenge was hosted by AAFC’s

Over the latter half of 2024, FNC’s eastern region (Indiana, Ohio, Michigan and Kentucky) saw a continued decrease in land for sale compared to the previous three years, which were active on a regional scale similar to the national scale.

A number of factors including commodity market lows and lowerthan-average yields

Charlottetown Research and Development Centre and was conceived in 2023 by AAFC knowledge transfer specialists Scott Anderson and Roger Henry. That year, Anderson and Henry planted the Mountain Gem potato variety on a field without using traditional fertilizers following a cover crop of red clover at AAFC’s Harrington Research Farm, located on P.E.I.

The crop relied on leftover nitrogen from the soil and cover crop.

This year’s challenge added manure as a twist. Like last year’s challenge, farmers were encouraged to guess the potato yield of these fields.

Anderson said in a statement that manure “put the potato plant grown into hyper speed” when combined with the nutrients left over from the red clover crop. The result was good-sized, uniform potatoes that would be ideal for table stock or processing.

thanks to spotty weather in the Eastern Corn Belt have led to less farmer buyer interest. However, despite these conditions, interest from farmers and investor buyers remains strong.

Such qualities also drove weaker demand for low-performing farms in the central region (Iowa, southern Minnesota).

Such qualities separated the top performers – which at times drove auction

prices to levels that compared to the peak several years ago – from the rest, although the region still saw drops from five to 10 percent overall from the peak.

Land sale values increased slightly in FNC’s east-central region (Illinois, Wisconsin).

Farm values are still being sold at historically strong levels, although with fewer recordbreaking sales than in the busy 2020-2023 period.

Off-highway manufacturer BKT las launched the new Ridemax Frost, which is geared to provide optimum performance during tougher winter operations.

Equipped with an advanced tread design, featuring multiple sipes on the tread blocks for additional contact, the tires aim to provide greater traction on snowy and icy surfaces with reduced risk of skids. The tread is also able to trap snow in its grooves, which further improves traction.

The tire is also made with an advanced elastic compound which can maintain its elasticity even at extremely low temperatures, rather than stiffening. The compound consists of natural rubber enriched with polybutadiene and silica.

The tire is designed to improve operators’ riding experience through reduced vibration, ensuring better conditions and less driver fatigue.

Case IH was among the most awarded agriculture companies at the 2025 AE50 awards presented by the American Society of Agricultural and Biological Engineers. Seven products were recognized, including its Automatic Productivity Management 2.0 for Magnum Tractors, as well as combines, baler automation technology and other systems.

Case celebrated its own innovations over the last year, which included the expansion of its harvesting lineup, automation for balers, planter technology and enhancements to its tractors. It introduced the Quadtrac Heavy-Duty Suspension, designed for faster transport speeds of up to 26.5 mph, and less shock to the machine and operator due to a fully suspended track system conforming to the ground.

In addition to the Quadtrac systems, Case has announced that model-year 2025 Magum tractors with 21 by 5 PowerDrive transmissions will have Automatic Productivity Management 2, which manages the driveline and engine to control ground speed while optimizing fuel economy.

For more info visit huskyfarm.ca or call 1-800-349-1122

Trailing shoe booms from 6m to 30m in width. BlackBird trailing shoe booms in stock Summer 2024. Various incorporation options available. Contact us for more info on tank sizing options.

Think “multi.”

A new study that looks at the efficacy of pig manure as a nutrient source is multi-state, multiyear and highly multifaceted. A core tenant, says Teng Lim extension professor of agricultural systems technology in the University of Missouri Division of Plant Science and Technology, is understanding that the study looks at more than just yields.

The five-year study (which Lim clarifies is “at least five years”) is taking place in multiple Midwestern pig-producing states. It’s funded by the National Pork Board, with South Dakota State University acting as the lead institution on the study. It looks at corn yields and soil health indicates under three separate treatments – injected pig manure, a combination of manure and starter fertilizer, and chemical fertilizer alone.

The first year of the study concluded with the

2024 harvest season. The inorganic plots (treated solely with chemical fertilizer) had the lowest corn yield (about 150 bushels per acre). However, the differences among treatments were not statistically significant, with the highest yield (from pig manure only) only being around 20 more bushels per acre. Despite cautioning that the yield differences were not “statistically significant,” researchers say there are multiple reasons to be excited about this study.

Manure Manager caught up with Lim to discuss the first year of the study and what’s been learned.

Although early results do not indicate a great difference in the yield, Lim emphasizes that things will only get more interesting from here. “Keep in mind, this is just the first year, and we don’t even have the soil health data yet,” Lim tells Manure Manager.

Soil samples at various depths up to 24 inches

were taken by at the start of the study, and additional samples will be taken throughout the study.

“We’re not just looking at typical NPK values that a lot of the growers tend to think of,” says Lim, referring to the key performance indicators the team will look at when it comes to soils.

“We’re focusing more across the spectrum of health indicators. Things like the propensity, the holding capacity, the wet aggregate stability. A lot of those additional measurements are important to consider. Like, for example, infiltration. A field that has bad infiltration, you’re not going to be able to keep that much water. It’s just going to be running off the field, so that’s a waste of resources.”

The indicators are so plentiful, says Lim, that this is why the study is ideally at least five years long.

Little is known about the soil health impact yet, but Lim says even when results come, they will surely vary over the years. “Part of the reason we call this at least a five-year study is we expect variability over time,” he says.

A research plot at the MU Bradford Research Farm fertilized with pig manure.

RIGHT

Another plot at Bradford fertilized with pig manure and starter fertilizer.

The team anticipates that changes in weather, soil conditions and field conditions will affect the variables it’s observing. “Hopefully over the course of five years, we’ll be able to see on this more intensive corn-corn operation, what are the semi-long-term impacts that those different fertilizer treatments have on the yield and soil health indicators.”

All states participating are states with large swine production industries. Corn was chosen largely because it is known to need a lot of fertilizer.

The fields chosen – as well as the chemical fertilizers used –were chosen to be as reflective as possible of local conditions and operational norms. For example, in the Missouri region where Lim’s team is observing results, there is no irrigation on the plots, because irrigation is not typical for the region.

The team is keeping an open mind about what variables to expect – from super wet years to super dry years. “We don’t know how it will pan out.” •

Farmers and commercial applicators flex their equipment engineering muscles.

BY JACK KAZMIERSKI

In a perfect world, manure equipment would be inexpensive, easy to find and always fit for purpose. In reality, costs are rising and sometimes equipment needs to be modified to make it more suitable for the task at hand.

This is why some farmers and commercial applicators have put on their engineering hats in order to think through a challenge, find practical solutions, and make modifications to their equipment.

“Farmers are always looking for better ways to transport, apply, or utilize the manure from their animals,” says Glen Arnold, field specialist, manure nutrient

ABOVE

management systems and professor at Ohio State University Extension.

“Modifying existing equipment that a farmer currently owns is a way to save on purchasing new equipment.”

Arnold notes that most farmers are handy with equipment such as welders and cutting torches, and they can do much of the work themselves.

“If a farmer sees a piece of equipment that is working for another farmer, they can decide if they want to buy a similar piece of equipment that is new or used,” he says, “Or they can look at the equipment they currently have and decide if it could be modified to accomplish the same task.”

Spare parts for these modifications

A modified frac tank with hydraulic legs and an open top can either load or unload trucks.

aren’t necessarily difficult to find. “Farmers rarely throw away items they feel they might have a use for at some time in the future,” says Arnold. “There is also a substantial amount of used equipment available on social media sites such as the Facebook page Manure Kings. Local equipment dealerships also often have used equipment or used parts for sale.”

Since prices for new equipment have risen rapidly over the past few years, “Any new or used equipment purchase on the farm is going to be a significant cost,” says Arnold. That’s why it makes sense to repurpose parts from other sources.

“Farmers looking to add a drag hose system to their farm, for example, can often find used hoses from a drag hose operator who has replaced their main line hoses or drag hoses a few times,” says Arnold. “And used manure tankers become available as their owners look for newer or larger tankers. The key is to start with a mixture of new and used manure equipment and work towards upgrading equipment as the business progresses.”

the farmer to capture this nitrogen so they can save money on purchased nitrogen expenses and opens additional days of the year to manure application.”

When it comes to bang for the buck, some modifications offer a better return on investment than others. “For liquid manure, modifications that allow the farmer to take advantage of the nitrogen in the liquid manure might be their best return,” says Arnold. “For example, the nitrogen value in swine manure is worth more than the phosphorus and potassium values combined. If the equipment modification efforts work, this allows

Bill Tenhove is the owner of Ten Hove’s Custom Farming, which specializes in forage harvesting, liquid manure and large square baling. Tenhove started modifying his own manure application equipment more than 30 years ago.

“We cut our manure boom in half and spread it out because we were getting overlap,” he says. “We had to move our nozzles further apart, and we made the modification not for financial reasons, but in order to do the job right.”

Since then, Tenhove and his crew have tackled other projects. “I built a dribble bar to prevent the manure from being blown about by the wind,” he says, “We built our own manure boat, and we’re always building high-pressure manure pumps. We put Smart Turner pumps on the back of diesel engines. We use them ourselves, and we sell them to other people.”

Multiple fittings were added to six-inch pumps now have more options.

The old adage, “Necessity is the mother of invention,” certainly applies to Tenhove’s situation. Chopping the boom in half and building a dribble bar were necessities at the time, simply because there were no solutions available for him to purchase. On the other hand, the high-pressure pumps that were commercially available were too expensive, so Tenhove decided it would be cheaper to build one himself.

“As for the manure boat,” he says, “there was one available commercially, but it was too big, too clumsy and too expensive. We actually went to [the manufacturer] to ask them to build us the kind of boat we needed, but they wouldn’t hear it, so we built one ourselves.”

Tenhove credits his employees with helping him find the solutions that made sense and made a difference. “We sat around the table, usually with a few beers, and we talked about what we should do,” he says. “Needs, wants and costs are a good way of looking at it.”

He recommends keeping things simple. “We made the boat so simple, that it’s easy to work on,” he says. “Since we’re the end-user, when we have to fix it, we’re the ones who have to get dirty. So the easier

The added hitch on W.D. Farms‘ honeywagon allows the machine to pull its nine-shank chisel plow.

you can make it to fix, the better.”

Many of the parts that were needed for the modifications were available off-theshelf, explains Tenhove, but many had to be custom-made. “We put a plasma table in our shop, and we also have a milling

machine and a lathe,” he says. “So, we made a lot of our parts ourselves.”

The process didn’t always go as smoothly as expected, and it sometimes took a while to complete. “Things worked out as planned about 90 percent of the time,” Tenhove says, “And then we had to make some tweaks. Our manure boat took us five years to perfect, since we had some bearing problems and some pump problems. Now, we have no problems. On the other hand, the dribble bar worked as planned, right off the bat.”

For some entrepreneurial individuals, like Tenhove, who not only builds highpressure manure pumps for his own needs but also sells them to others, modified equipment can translate into new business opportunities.

Joe

Dias

Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc. Cell: 514-792-9220 Web: www.bkt-tires.com

“Some people are mechanically inclined,” says Kevin Erb, program manager, conservation professional training program, UW-Madison Division of Extension Natural Resources Institute. “They look at something sitting brand new at the dealership and say, ‘Why did they do it that way?’ and modify it before it ever hits the dirt to begin with. For other folks, the equipment that’s out there doesn’t do the job. A lot of [Wisconsin equipment companies] started out as manure applicators or farmers who knew that what they wanted, couldn’t find it on the open market, ended up creating their own, and turned it into a business.”

Erb explains that sometimes manufacturers are inspired by modifications made by famers or commercial applicators. “Thinking back to when manure agitation boats were coming out” he says, “we had two companies come out to an event with boats, along with three or four manure applicators who brought their own homemade boats to go head-to-head with the competition. Three of those four no longer build their own. They bought what industry has to offer. So, a lot of times, industry looks at these innovations, they improve on what the manure applicators and farmers have done, and then bring that to market.”

Many of the modifications and upgrades to equipment that Erb has seen over the decades have led to improved efficiencies and better crop yield. “When I first started in this industry some 30 years ago, guys were very happy to get 600 gallons a minute through a six-inch hose,” he says.

“And if they did 400,000 gallons a day, they were happy. Today, I’ve got guys who constantly hit two million gallons, and others that are not happy unless they move three million gallons of manure a day.”

Besides employing larger hoses, Erb explains, these innovators have had to wrap their minds around concepts like friction loss and the need to properly space booster pumps. “The benefits are improved efficiencies and economics,” he says. “They know that every day they delay planting corn in the spring, they’re losing a bushel per acre. So if they can shave a week off their manure application, they’re saving money, and improving their yield.”

Eric Dresbach, president of W.D. Farms LLC has been in the manure business since 1987. His children, Megan and David Dresbach are VPs of W.D. Farms and work alongside their father in the business.

Eric started modifying equipment in 1987. “I modified my honeywagon to be able to suck off semis,” he explains. In the many years since then, he modified the ladder on his tractor to “stair style,” started using double conical stainless steel tankers instead of straight round or ovals to reduce carry back, added a flange to a lagoon pump to make gearbox removal easier, built a pull-type chisel plow with a hitch pin versus hanging on wagon, built a three-point caddy for a drag hose spray bar, and much more.

Some of his creations made it back

to the factory and were incorporated in future designs by manufacturers. “That’s life,” he says. “I could have patented my ideas, but all they would have to do is change a couple of bolts and the patent would no longer apply.”

“I think it’s a compliment,” says Negan. “The factory saw this as a good idea, and they used it.”

Good ideas seem to come to the Dresbachs on a regular basis, and they’re always working on ways to improved equipment and boost efficiencies. “We

are fortunate to have more than just a farm shop,” says Eric. “We have a lot of tools and machines to do our own manufacturing. My cousin had made several modifications on his own farm, so he was a great sounding board and advice giver. Today, my son runs the shop and constantly has ideas on how to make things better, bigger, faster and safer.”

“The industry is still growing,” says Eric, “You don’t have to reinvent the wheel. Just find a wheel and then modify it to suit your situation.” •

BY TREENA HEIN

In the increasingly competitive dairy market, anything that keeps money in farmers’ pockets is of interest. Penn State University agricultural engineer John Tyson (Mifflin County Extension) says, “History would show us farms are always looking to lower labor, and sometimes that comes with specialized equipment.”

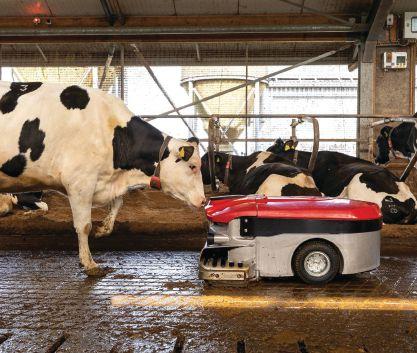

In barns, robotic milkers are thought to be the biggest source of labor savings. But manure vacuums may be in second place.

There are several vacuum systems that remove manure from the floor and barn alleys on the market, but Robb Meinen, director of the Pennsylvania nutrient management education program at Penn State, says they’re still not common.

Vacuums like the Alley Vac from Nuhn Industries and the Mensch Manure Vacuum from Mensch Manufacturing efficiently

clean inside dairy barns. But they have other advantages. For new barns, the structure needs no integrated manure handling system (pumps, augers and concrete channels) to transport manure from barn to lagoon. Auxiliary suction hoses can also be used to clean spills of manure, water and more.

For smaller operations, Greystone USA manufactures the Maxi Vac, which holds the equivalent of about six wheelbarrow loads and can be towed behind a quad, small tractor, etc. Spokesperson Danielle Steffen says Greystone has several new designs in the works for the next year, prioritiesing enhancements in automation and, potentially, larger-capacity models for larger farms.

Greystone isn’t the only company with an eye on automation. Already available on the market is a small autonomous, batterypowered manure vacuum system, about the size of a pushmower, which Tyson has seen in use on a few farms in Pennsylvania.

“It follows a pattern around the barn collecting manure,” he says. “[It] then ‘dumps’ into a small transfer pit within the barn.”

This is the Lely Discovery Collector (C1 for short), launched in 2016. Daniel Schreiner, proposition manager (feed and manure) at Lely North America in Pella, IA, estimates around 1,000 units are running across North America. Last year, it released the C2 model in Europe, which is expected to achieve full commercial release across North America in early 2025. Identical to the C1 in tank size, the C2 has a higher removal capacity over time due to its lithium-titanium battery and its charging system. Automation continues to an attractive attribute, says Schreiner. “Automating the manure system allows the barn to be much cleaner through more frequent cleaning, automated cleaning of the crossovers and programable zone cleaning to focus on the areas that need to be cleaned more often.”

With anything automated comes safety concerns, and in early December, automated farm equipment such as the Collector were discussed at the two-day Safety for Emerging Robotics and Autonomous Agriculture (SAFER AG) Workshop, hosted by the University of Illinois Urbana-Champaign department of agricultural and biological engineering. There, farmers, scientists, industry and governmental discussed developments in designs, knowledge gaps, risks, insurability, regulations, and more. The workshop also featured a demonstration of current and upcoming autonomous systems, sensors and robotic platforms. John Shutske, professor and agricultural safety and health specialist at

University of Wisconsin, led a session on unanticipated risks and safety consequences beyond typical machine accident scenarios. He and others discussed fire risk, uses of new machines inside buildings that might normally only be used outside (due to electrification or other factors), the impacts of newer power sources like electric or hydrogen, cyber-related risks and more.

One of the workshop organizers, Jennifer Lincoln (director for the National Institute for Occupational Safety and Health and associate professor at University of Washington), notes, “Increased use of robotics is a two-sided coin for worker safety, health and well-being.” For example, a robotic vacuum system is designed to provide labor-saving benefits, but could pose potential risk of injury through unanticipated contact or distraction.

“Typically, we would not think of ‘regulation’ first in the design of any traditional or novel agricultural machine,” says Shutske. “That said, design engineers and technologists rely heavily on design and safety standards, which are promulgated by groups that include ASABE, SAE, ANSI and ISO.” He says most of the standards are

independent of regulation and are technically voluntary. Developing products that meet standards is essential, but can also be difficult when marketing to a global audience. Varying standards and regulations across the globe, whether voluntary or mandatory, can pose a challenge for manufacturers. For example, Lely’s Schreiner explains that with one unit covering all Lely’s global territories, it must meet the standards in each market, creating a different challenge than if focusing on market-specific built units. Shutske says it’s not quite right to say there is no connection between engineering design standards and regulations/laws. “There are instances when a law, regulation, rule etc. incorporates a standard,” such as the Roll Over Protective Structure on tractors, where the standard (SAE/ASABE/ASAE) dictates

The PSS8 is an innovative solution for large-scale dairy and biogas production.

Key Features:

• Ecological Efficiency

• High Capacity

• Lower energy consumption and operational costs

• Durability, long service life with easy maintenance

• Robust Design: Heavy-duty auger with sturdy bearing head

• Powerful Operation: 30 kW electric motor, compatible with 400V/50Hz supply

• The PSS8 enhances productivity while minimizing environmental impact

BY RONDA PAYNE

Demonstrating science in ways that show the processes and outcomes makes the principles much easier to grasp. For Ashley Waggoner, a soil scientist with the USDA Agricultural Research Service, illustrating how rainfall impacts dairy forage fields is important to understanding erosion, runoff and leaching. Still, even the best field day can’t show what happens with soil on a rainy day.

Waggoner works at the U.S. Dairy Forage Research Center in Madison, Wisconsin as the engagement coordinator on the Soil Health Alliance for Research and Engagement (SHARE). She’d been asked to develop a display for the 2024 World Dairy Expo. A rainfall simulator was ideal to show attendees how different soil types, including those treated with manure, respond to rainfall.

The simulators she used are somewhat akin to a fridge water filter: water is poured into the top receptacle, which has perforations in the bottom. As the water flows, it drips onto the soil in patterns similar to rainfall. The soil matter is stored in a tin with perforations. This flows into another receptacle that captures the water that infiltrates through the soil, while a front container captures runoff water from the top of the soil sample. The samples were collected with the help of Landon Baumgartner, an Iowa county-based extension specialist who knew farmers who allowed them to collect two samples each, and displayed in jars at the World Dairy Expo.

She says the five principles of soil health (maximize biodiversity, maximize cover, maximize living roots, minimize disturbance and incorporate livestock where possible) are all important, but are dependent on the important sixth principle of context.

Water samples from the rainfall simulator, shown at the World Dairy Expo.

“Context is going to impact all of those,” says Waggoner, of the principles. “That’s what I was hoping to display, was context. I really wanted to demonstrate how these different principles of soil health can help with the soil.” In perfect conditions, she says the water would flow through the soil, infiltrating into the lower reservoir, remaining clear. In a poor soil health scenario, the water would run off the top and come out muddy in the reservoir.

One sample was from a field with cover crops that had been planted after manure was applied. The second was solid manure applied, the field left fallow. “I’d never done [a rain simulator] with that manure crust still on [the sample],” says Waggoner. “The cover crop will hold the manure [and] the soil in place.”

Both exhibited minimal erosion and cloudiness in the water that ran through the simulator, but knowing why is the key. She’d expected more runoff on the fresh manure sample, but recognizes that the organic matter in solid manure will absorb moisture. However, once the absorption is maximized and the manure begins to break down, the initial assumption of runoff and particles in the soil infiltration will reveal itself.

“That manure, without the cover crop, that manure is going to break down and that protection is going to go away. Then you’ll start to see erosion,” she says. “Any rain that’s happened after that, we would expect erosion like there was no cover.” •

For an expanded version of this story, check out the March 4 edition of the Manure Manager e-newsletter. Subscribe to our eNews here.

ABOVE

The ManuRob Loadix

Autonomous Handler, one of the autonomous pieces on display at EuroTier 2024.

Farmers’ current appetite for technology is undoubtedly high, given the number of new machines and equipment being developed for this lucrative market on a daily basis.

That’s exactly what EuroTier, the world’s largest livestock equipment trade fair, held in November, showcased to the 120,000 visitors.

WER MFG

Phone: 519 887 9319 Toll Free: 877-557-7527 www.wergroup.ca

Blyth Rd. Walton, ON, Canada, N0K 1Z0 Email: wer@tcc.on.ca

• Available in 30’ and 40’

• Full galvanized frame

• WER Distributer

• Rear hitch (max towing 5000 lbs)

• Available in 30’/40’/60’

The four-day event in Hannover hosted 13 halls of the latest machinery, equipment and technology from 2,193 exhibitors hailing from 51 countries.

AI developments were a major player, either at the forefront or in the background of the innovations showcased. For example, there were calf feeders that talk to humans, reporting how their animals are performing.

And of course, the use of robots within all the livestock sectors was highlighted on many stands such as robotic feeding systems, robotic washing units, and even an autonomous loading shovel.

MANUROB: LOADIX AUTONOMOUS HANDLER

French company ManuRob showed its Loadix autonomous handler at EuroTier.

With a hefty price tag of €359,000 (CAD $534,000; USD $370,000), this machine comes with two loading attachments and is initially designed for the biogas industry. Livestock farm

20 HOSE COILER SYSTEM

20 X 6” Hose Capacity. Lead & trailed units can be operated in unison or independently.

• Full galvanized frame

• WER Distributer

• C/W ball blow-out

• Rear hitch (max towing 5000 lbs)

TPH COILER

Use as a stand alone unit, or as an addition to a developing drag line system. (3 models available).

The telescopic hyd width adjustment provides a large surface radius when moving hose.

INLINE CHOPPER

Improve productivity by reducing blockages in the drag line system and reduce pump repairs.

DISTRIBUTOR

The high grade chopping system, and auto-reverse function, ensure an obstruction free distribution. HOSE MOVER

SPREAD BOOM

Maximize Efficiency with better spread. Heavy duty construction & galvanized frame.

use is also anticipated with the next version of the loader sometime in 2025.

Powered by a Lithium LFP battery, the Loadix can lift two tonnes up to 4.1M and uses GPS RTK to move around. It detects any obstacles via LiDAR and has cameras to identify its load material. Two electric motors power the transmission and the hydraulic lift pump. The company says the machine will work between six and 24 hours before recharging, depending on the material and distance it must travel.

Fliegl has expanded its portfolio with the new chain manure spreader KDS 255 Muck Control. This model closes the gap between the large tandem spreaders and the more compact KDS 140.

The KDS 255 has a permissible total weight of 18, 19 or 20 tons and a stable tandem chassis, which ensures excellent driving characteristics and can optionally be equipped with a steering axle. Filling with the front loader is easy and efficient due to the low body design. The conical trough of the KDS 255 has dimensions of 5500 x 2000 or 1200 mm. It has a spreading width of up to 26m and a hydraulic tailgate with a mechanically adjustable fall angle.

CalfGPT is a new management tool that allows farmers to check on the health status of individual calves by using simple voice commands.

Based on the leading AI system from OpenAI, the system enables the farmer to enquire about individual calves using a voice connection via the farm’s own WiFi.

The farmer can receive specific information about the calves vocally and via alarms on a mobile phone or tablet in direct response. Pre-formulated commands are not necessary and new information concerning individual calves can also be sent directly and verbally to CalfGPT for further documentation.

The system gathers the data from the company’s range of calf feeders, to which it can be connected via Bluetooth.

Swedish company Moving Floor Gotland AB has developed a pen for weaned or finishing pigs that effectively cleans itself by rotating the floor and scraping away

the manure and urine.

The conveyor belt rotating floor is powered by air compression requiring eight bars to operate at previously set time intervals. The company says this has the advantage of a pig unit with up to 85 percent lower ammonia emissions, compared to a normal pig barn.

The unit weighs 1,200kgs, measures 5.4M by 2.4M, covering an area of 11.6 square metres, and is 1.6M high. It is a wooden structure covered in stainless steel with an average energy consumption of under 100 kWh/pig/year.

No water is required to clean the floor and the system saves on labor costs. •

For an expanded version of this story, check out the Feb. 4 edition of the Manure Manager e-newsletter. Subscribe to our eNews here.

When the going gets tough, turn to the toughest pumps in the field. Vaughan has unique configurations for:

• Barn Finish Pits

• Separator Feeds

• Lagoons

• Digester Mixing

• Scraped Manure

• And More! 888-249-CHOP | CHOPPERPUMPS.COM

JASON OLIVER | Cornell College of Agriculture and Life Science

We all recognize that farming is one of the most dangerous industries. It does not have to be.

While the U.S. Bureau of Labor Statistics routinely ranks agricultural workers in the top 10 for both occupational injury and fatality rates, there are many things we can do to ensure our businesses thrive while our farm families and employees stay safe.

It starts by creating a culture of safety. Think of a highly reliable organization, such as a U.S. aircraft carrier, that must operate in high-hazard and constantly changing environments under significant production pressures.

To ensure aircraft successfully takeoff and landing every minute or less for extended periods of time serious incidents and catastrophic failures cannot be afforded. In fact, according to the Bureau of Transportation Statistics, since 2010, there have only been three years where there were more than 20 serious injuries, and any fatalities reported on these vessels. The Navy has been able to achieve this by adopting a culture of safety where all personnel regardless of rank and position consistently train for and prioritize safety and have both the authority and the responsibility to make changes that ensure safe operations.

• Decommission a below-barn manure storage. Substitution changes out materials or processes to reduce the hazard.

• Purchasing a manure tanker equipped with adequate safety features to replace outdated equipment.

Engineering controls reduce exposure by separating the hazard from the worker.

• Fences around manure storages, PTO guards, grates over confined spaces

Administrative controls include better informing the worker and changing the way the work is done with standard procedures, trainings or warmings.

• Safety trainings, signage warning of manure gases, preventive maintenance

Personal protective equipment (PPE) includes clothing and devices to protect workers.

• Safety glasses, high-visibility clothing, calibrated personal gas meters

We can similarly prioritize safe and accident-free agricultural enterprises, particularly around manure, not only to improve production but also to show your team that they and their safety are valuable.

The Hierarchy of Controls is a safety concept that helps one identify risks and rank safeguards to protect workers. Arranged from most effective to least effective they are, with examples. Elimination makes sure the hazard no longer exists.

Work through one hazard at a time, prioritizing the most substantial. Discuss all possible effective controls. While all are not always feasible, stacking other controls (engineering controls, protocols and PPE) is often necessary.

Though it may take time to implement the most effective controls, you should invest in interim controls until permanent solutions can be achieved. Consider reaching out to your advisors, safety professionals, agency personal, and consultants for resources and help. Work collaboratively to help our industry cultivate a culture of safety. •

CHRYSEID MODDERMAN | University of Minnesota Extension

Whether you apply liquid or solid manure, applicator calibration is an important step that is often overlooked. I know you’re busy, but just taking a few extra moments to adjust your speed and settings will greatly improve your confidence that you haven’t over or under-applied nutrients. And eyeballing it isn’t going to work. A study from Michigan State University found that only a quarter of farmers who didn’t calibrate were within 20 percent of their desired application rate. If you’ve already done the work of soil sampling, manure nutrient testing, and calculating application rate, why wouldn’t you calibrate your spreader to ensure you’re actually applying the amount you had planned? You should calibrate every couple of years or whenever manure consistency or equipment has changed. Note that the application methods described here are for broadcast applications of solid and liquid manure; manure injectors tend to rely on flow meters for accuracy.

Math time!

For both the weight and tarp method, you just need to extrapolate the amount spread over the small area/tarp to amount per acre. To do this, you first need to figure out how much manure was spread over the small area/tarp. Subtract the after-application spreader weight or empty bucket/tarp weight (in pounds) from the full spreader or full bucket/tarp weight to get pounds of manure spread. Then, divide that number by the area spread/tarp area (in square ft.). Multiply by 21.8 to get tons of manure applied per acre. Note that 21.8 is derived from 43,560 sq ft per acre divided by 2000 lbs per ton – a different number will need to be used for metric units. For solid manure, that is all you need to do!

Why not ensure you’re applying the amount of manure planned?

Calibration is a surprisingly simple process. The easiest method that works for both solid and liquid manures alike is to weigh the spreader before and after application to a small area. Measure the length and width of the area to which manure was spread.

If you don’t have access to drive-on scales, the tarp method can be used for solid manure. You’ll need a scale, five-gallon bucket and a tarp.

First, weigh the empty bucket and tarp. Then, lay the tarp in the field with bricks or rocks to hold down the edges. Measure the length and width of the tarp to get spread area. Next, apply manure normally to the area with three passes (one directly over tarp, the other two on either side of the tarp) to account for overlap. Then, fold up the tarp and place in bucket. Weigh the bucket and tarp full of manure.

For liquid manure, since it is applied in gallons per acre, not tons, you’ll need to do an extra step. To convert tons per acre to gallons per acre, you’ll need to find the density of your manure – yes, it’s different than the density of water.

This is also fairly simple: Just weigh an empty five-gallon bucket (or any container of known volume), and then weigh it again full of manure. Subtract those numbers to find how much manure occupies a five-gallon space. Divide five gallons by the manure weight in pounds, then multiply by 2,000 to get gallons per ton. Finally, multiply that number by the tons per acre you calculated earlier to get gallons per acre.

And that is all! From here, you can decide to adjust speed or equipment settings to spread more or less per acre. It is a good idea to repeat the calibration process a few times to get a good idea of application rate. Make sure to record your settings for future reference. Happy spreading! •

‘‘ All future tankers I’m going to add to my fleet will be outfitted with this new suspension. ’’

Because you want the Best.

‘‘ Over rolling hills, even little bumps, it’s smooth working with a tanker fitted with the XT suspension. The tanker is independent from the tractor and its draw bar is no longer rigidly attached to the tractor. It is flexible and it actually follows the contour of the terrain. There’s a customer that we go to and there’s a 1-and-a-half-foot drop we need to drive through and there’s only one tanker that I will go there with, the one fitted with the XT suspension.

’’

Yvon Guérard Forfait Somerset, Plessisville, QC