A TASTE OF NATURE

BY NAOMI SZEBEN

THE END IS NEAR!

If someone had told me over a year ago that we would be in quarantine for roughly a year, I would have asked them if they spent their weekends being a doomsday prophet, like a New Yorker cartoon. You know the kind: long, unruly hair, wandering the city streets in a toga and holding up a “the end is near” placard?

Today, I sit at my desk with my long, unruly hair and write “the end is near” for a different reason. I’m not predicting the future, but forward-looking studies are optimistic that the end is in sight – for the pandemic. Statistics from consumer polls and Restaurants Canada have shown that Canadians are willing to re-enter cafés and various food industries once the quarantine lifts. Many are willing to be vaccinated, cutting the chance of spread. More consumers have faith that the food industry is taking every precaution to protect its staff and customers. The end to the fear of eating indoors with friends is in sight.

This issue is indirectly about change. Winter is slowly giving way to spring and we’re looking tentatively, but eagerly toward summer. Bakeries are signaling this seasonal shift with brighter, summery colours on their baked goods, cafés are redecorating during any down time and many are just taking some time for a complete overhaul. Some want to increase seating space or install barriers between seating arrangements. Others simply want customers and staff to feel “safe.”

While the optimism surrounding the gradual opening of industries is rising, many are still bracing themselves for another wave of COVID. Some office places are remodeling their workplaces to make social distancing possible, and chefs like Drew Munro find opportunity in the absence of communal dining areas. UpMeals caters healthy meals via vending machine for buildings that see a meal plan as both an investment in the health of their staff and a perk to provide nutritious, delicious meals.

I do not profess to see the future, but forward-looking studies are optimistic that the end is in sight – for the pandemic.

Remodeling can also mean acquiring funding to support PPE (personal protection equipment) such as masks, shields and customer barriers for booths or registers may help offset some of the costs. A recent consumer research study conducted by Restaurants Canada indicated that clients are more likely to enter an establishment that is visibly clean, has clearly indicated social distancing measures and staff are using PPE safely. A potential client’s peace of mind may be the key to your bakery’s revenue.

Safety and esthetics don’t always go hand-in-hand. Where some companies have found revenue by creating masks that match restaurant colours or a chef’s uniform, building safety can sometimes be less easy to implement. In this issue, you’ll read about how Ceilume had met expectations for “old world charm” and safety with their ceiling fixture. Providing healthy food choices available to workers is now a perk; more so now than ever these days due to lingering pandemic concerns. Chef Munro found a way to service the food industry without the daunting prospect of opening (and being forced to close) a dining area. Read on in this issue to find out how he used technology to supply catering services to offices in B.C. While colours and textures may be the theme for this issue, so is change. Beyond the change in temperature, or the change of rules and regulations, we have learned to adapt in ways that we wouldn’t have imagined a year ago. Yes, the end is in sight, and some may mourn the old way of thinking or of running a bakery or café. But many in the food industry are embracing a contact-free way to reach out to new venues like apartment buildings by using vending machines to sell baked goods or grocery staples.

The first step to finding a successful business means finding the gap in the industry. May you find opportunity in these uncertain times. / BJ

MAY 2021 | VOL. 81, NO. 4

Reader Service

Print and digital subscription inquires or changes, please contact Beata Olechnowicz, Audience Development Manager

Tel: (416) 510-5182

Fax: (416) 510-6875

Email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING

MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER | Curtis Martin

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

Subscription Rates Canada — 1 Year $ 32.00 USA — 1 Year $73.50 Foreign - 1 Year $84.50 All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2021 Annex Business Media. All rights reserved. Printed in Canada.

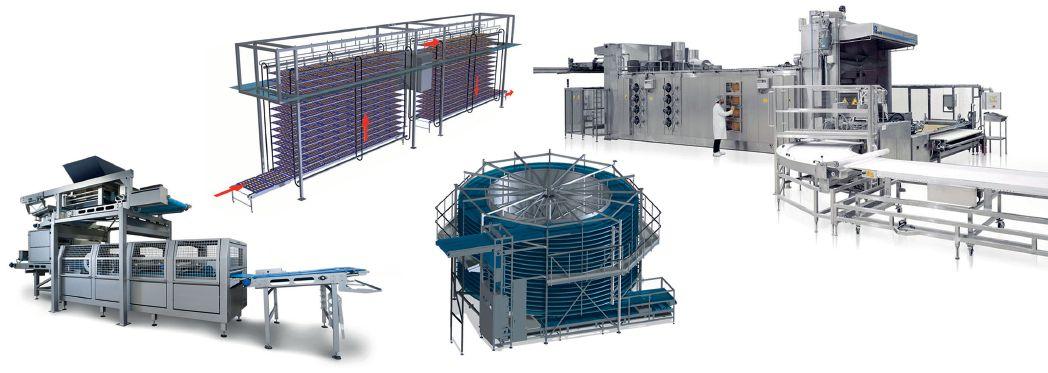

The Vemag Dough Divider produces uniformly spaced dough portions onto the conveyor, eliminating doubles and downtime The Vemag can be easily converted to a two-lane set-up to produce up to 200 cuts per minute

What makes the Vemag Dough Divider so special? Versatility and weight accuracy. The Vemag Divider adds versatility to every production line and is perfect for all types of breads, buns, rolls and English muffins It features a positive displacement double screw system that is the most gentle divider on the market. The Vemag is easily adjust able to produce a range of exact-weight portions, dough absorptions and crumb structures Test the Vemag for yourself – cont act us to arrange a demo at our Reiser Customer Center.

The Vemag is easily adjusted to produce b oth open-crumb and uniform tight-crumb structures.

Batch after batch, the Vemag consistently produces precise weight portions at 1% standard deviation.

The Vemag does not require mineral oil, saving thousands of dollars annually while eliminating product air pockets and surface blisters

The Vemag is easily adjustable to produce a wide range of portion sizes – from 5g to 20kg.

The Vemag can handle absorption rates from 45% to 95% – from stiff bagel doughs to soft English muffins.

briefly | RBS celebrate promotions, a new Business Relief Fund offers help for struggling bakeries, and IBA is postponed. | for more news in the baking world, check out our website, www.bakersjournal.com

New project services manager for RBS

Reading Bakery Systems (RBS), manufacturers of snack production systems, has announced the promotion of Shane Hanlon to Manager, Project Services.

Hanlon, a manufacturing veteran with 29 years of experience, has been with RBS since 2013. Throughout his career, Shane has excelled in a wide range of disciplines, including management, sales, customer service, technology integration, manufacturing engineering as well as all facets of project management.

complex data and customer requirements.” said Tremaine R. Hartranft, technical sales director at Reading Bakery Systems. Hartranft continued, “Shane has the leadership and vision to drive the Project Management department forward, aligning opportunities to create value and deliver solutions to our customers.”

Canada United Small Business Relief Fund

RBC created Canada United, a movement to support local businesses like bakeries across the country.

The Canada United Small Business Relief Fund (CUSBRF) was established to help small businesses offset the cost of expenses to open safely or adopt digital technologies to move more of their business online.

“Shane has personally contributed to the success of many projects at RBS, necessitating the harmonization of

As the Manager, Project Services Shane will lead the overall day-to-day project management activities, as well as continue to manage individual projects. Hanlon is a native of Westchester, PA and makes his home in Sinking Spring, Pennsylvania.

Sesotech welcomes new VP of sales

Johannes von Stein took on the role of vice president of sales for the food industry at Sesotec GmbH, joining the management team in the Lower Bavarian headquarters of Schönberg.

Born in Franconia, von Stein studied at the Les Roches International School of Hotel Management in Crans-Montana, Switzerland before attending the IPADE Business School in Mexico City. Over the course of his career, he has worked in a number of roles in international companies.

During the past eight years, von Stein worked for Krones AG, first from their offices in Mexico City, and later from Regensburg, Germany. In his role, he was responsible for advising customers as well as sustainable product development

and market growth for northern Latin America. Through his position with the manufacturer of process technology for the production, filling, and packaging of liquid foods and beverages, he gained extensive experience in food safety and food industry processes.

On his goals at Sesotec, von Stein commented in a statement: “The company’s ambition, and mine too, is to provide customers with optimal solutions that bolster food safety, increase efficiency, and minimize food waste.” He adds: “Our products must reliably deliver on the promises we make to our customers. In this sense, the responsibility of sales does not end with the purchase, but rather begins there.”

IBA postponed to 2023

GHM Gesellschaft für Handwerksmessen mbH, the organizer for IBA, announced that they are postponing the international baking industry trade show to 2023.

IBA, the trade show for the baking and confectionery industry will not be able to go ahead as planned from 24th to 28th of October 2021: The next show is set to take place in Munich from 22nd to 26th of October 2023. This is a result of global uncertainty surrounding the pandemic, and the trade show would like to “be able to maintain its international character and the need to provide the industry with a global offer and long-term

Over $14 Million has been contributed by the Federal Government, RBC, and Canada United partners to support recovery efforts due to COVID-19. It has already provided relief to over 2,000 small businesses across the country. Canada United is now able to extend relief grants to more small businesses and restart accepting grant applications from small businesses across all provinces for expenses incurred no earlier than March 15, 2020.

If you have already applied but have not heard from us yet, you should be contacted by February 15, 2021. If you can’t find an answer to your question, feel free to contact us at cusbrf@occ.ca.

The CUSBRF will be managed by the Ontario Chamber of Commerce on behalf of the national chamber network in support of other chambers and partners to help small Canadian businesses with their recovery efforts as a result of COVID-19.

Successful applicants will receive a relief grant of up to $5,000. We intend to support local businesses of all kinds from across the country (from delicatessens, cafés to bakeries).

planning security,” as a recent press release noted.

Due to the uncertain development of the pandemic with continuing global travel restrictions, as well as a busy international trade fair schedule for the coming year, a staging of IBA in 2022 is assessed as not advisable for all parties involved.

The IBA’s Advisory Board welcomes the decision to postpone, they admit it has been a difficult one to make. Michael Wippler, President of the German Bakers’ Confederation said in a statement: “...As bakers, we are optimists by nature and we are already looking forward to catching up with each other in person at the IBA 2023!”

From the latest in plant-based protein to the newest industrial bulk bag fillers, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

ChickP offers non-GMO protein

FoodTech start-up ChickP Protein, Ltd. launched a native starch developed from chickpea for food and beverage applications. It is non-GMO and a co-product of ChickP protein process using a proprietary technology.

This new chickpea starch eliminates food waste during processing and ensures a sustainable, clean ingredient. It has a uniquely high amylose to amylopectin ratio, with neutral taste and no aroma. Due to its narrow granules size distribution compared to pea and potato starches, ChickP Native Starch provides better gelling and thickening properties. As a result, it can be used as a thickening/ binding agent in a variety of food applications, including soups, sauces, confectionery, dairy, baked goods, desserts, meat, plant-based meat analogs, and many more applications. ChickP Native Starch also is an excellent raw material for production of extruded snack products.

“The inspiration for developing a native chickpea starch was to offer another purified fraction from chickpea – similar to ChickP’s isolated protein, which contains

90 per cent protein,” explained Ram Reifen, MD, founder and CSO of ChickP. “We’ve extended the purity approach by introducing our pure native chickpea starch, with more than 98 per cent starch content.”

The company’s ability to separate and purify the solid components of the chickpea (protein, starch, and fibers) allows it to offer food manufacturers pure, functional ingredients that bring flexibility to incorporate other ingredients into the formula based on targeted nutritional and functional properties. This can be accomplished without compromise due to existing impurities, such as oil (which leads to rapid oxidation and decreased shelf life), fibers (that can impart rough textures in some food applications), and other micronutrients that negatively impact flavour and color.

“The ChickP technical team currently is developing food applications using our Native chickpea starch,” adds Ron Klein, CEO of ChickP. “We invite companies to collaborate with us to create new plant-based products that meet all the demands of today’s informed consumers.”

HERZA Schokolade offers organic product line

As more consumers are looking for sugar free or sugar-reduced options, many look to natural options like coconut flower sugar, and HERZA Schokolade answered that call.

Also known as palm sugar, this natural sweetener is derived from the flowers of the coconut palm and is popular with consumers. With its malty, caramel-like flavour, it harmonises perfectly with chocolate. HERZA Schokolade proves this with its new “Inspired by nature” organic product line. The chocolate pieces are available in eight exciting flavours.

The product line focuses on chocolate pieces with very diverse fruit components, like creamy milk chocolate with banana flakes that give a crunchy effect.

The dark chocolate leaves with sour cherry powder are an unusual combination, with the powder giving the full-flavoured chocolate a tart fruity note.

A perfect addition for ice cream and snack mixes are the chopped dark chocolate pieces with fruity raspberry pieces and vanilla.

The dark chocolate cubes with light ginger notes and a hint of lemon are a real innovation in chocolate pieces, and the dark chocolate leaves with their robust cocoa note, refreshing orange oil and crunchy cocoa cores.

The new creamy milk chocolate chips provide contrast, with coffee and cardamon for an exotic blend.

¦ concepts for success ¦

BY DIANE CHIASSON

IMPLEMENTING CUSTOMER SERVICE

Part two of a three part“bakery system implementations” series, a guide to getting your bakery system in place.

As an independent bakery owner, you should be most passionate about building a successful business. Part of a successful bakery operation is implementing an effective system. These will ensure high quality customer experiences and give you the advantage over your competitors.

Focus on developing and improving your bakery’s systems and processes: This is the only way your bakery will be able to consistently produce and deliver high-quality food, service and an all-around great experiences for your customers. By streamlining daily operational activities, you will be able to reduce and eliminate waste in your operation. Then, you’ll be able to focus on growing your business.

}1. BAKERY CHECKLISTS

Offering personalized service is the key to excellent quality customer service, where customers feel they are being valued and are looked after. Just remember, a little personal attention goes a long way. Train your staff members to remember the name of returning customers. Ask your customers about the products they are looking for, or ask them about their birthdays and anniversaries. Implement this customer service checklist to ensure a welcoming bakery:

• Welcome guests immediately with eye contact and a smile

• Make each client feel welcome, important and special

• Allow guests time to look over the menu and be available to answer questions

• Make appropriate personal recom-

A little personal attention goes a long way... ask your returning customers what they are looking for, or ask them about their birthdays and anniversaries.

mendations and suggestions

• Be genuinely interested in their responses

• Suggest some specials and point to new, unusual or discounted products

• Check all the menus, and signage

• Unlock the cash register and turn on the POS system

• Enter daily specials to POS system

• Review cash flows and managers’ notes from the previous day

• Check available inventory of food, beverage, and packaging

• Check the bakery’s voicemail/emails

• Ensure that all employees are on duty and kitchen staff are completing their preparation sheet for the day

• Make sure that every staff member follows your uniform policy

MANAGER’S CLOSING CHECKLISTS

• Check to make sure that employees arrive on time for their shift

• Check voicemail and emails

• Ensure that the first shift kitchen staff have finished their daily food prep list; check these lists at every station

• Recheck the entrance area, cash area, counters, fridges, retail shelves, and restrooms to make sure that everything is cleaned and well-stocked

• Check the inventory to ensure that the kitchen and retail areas are fully stocked for the next day

Use checklists below as a guide to creating the quality products, eating experience and operating results you expect in every area of your bakery. consider implementing the following:

• Ordering/Purchasing checklist

• Receiving checklist

• Utensil, smallware and equipment checklist

• Customer service checklist

• Manager opening checklist

• Manager shift-change checklist

• Manager closing checklist

• Preparation checklist

• Cashier/Server training checklist

• Employees’ training checklist

• Catering/Delivery checklist

• Storage checklist

• Safety checklist

• Cleaning checklist

2. FOCUS ON YOUR CUSTOMER OFFER THE BEST CUSTOMER SERVICE

• Answer telephone promptly

• Serve quickly, efficiently and courteously

• Handle special requests and issues graciously

• Reinforce guest decisions when appropriate

• Thank them for visiting your bakery

3. ASSEMBLING MANAGERS’ CHECKLISTS

Managers use these documents to ensure essential management tasks are properly done from opening to closing. It is also used for checking off daily staff change and operational tasks. You can create checklists in an Excel or Google Docs sheet, print and place on a clipboard.

Manager’s opening checklist

• Walk inside/out of the bakery to check for any damage or equipment failure during the closing hours

• Check customers’ orders

• Review with the kitchen staff that food is stored according to the instructions on the food prep sheet

• Follow the cleaning checklist so cleaning goes quickly and smoothly

• Analyze the end-of-day sales report Compare the closing stock to the sales for the day, and try to find if there were any misappropriations in the bakery

• Check that all equipment (ovens, gas stoves, and heaters) is turned off.

• Lock all the doors and put the alarm system on. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultlants.com , or visit www.chiassonconsultants.com

FOOD TRENDS FOR 2021

Prior to the pandemic, consumers were already asking about gut-friendly foods, probiotics and asking for low sugar, clean label and ‘free-from’ ingredients. Once provinces began quarantine measures, bakeries were delivering more comfort foods, nostalgic treats to bring some measure of pleasure during a trying time for all.

The International Dairy, Deli and Bakery Association (IDDBA) reported in 2020, that the bakery industry experienced a sales spike of 78.8 per cent in the third week of March. During the summer of 2020, as more businesses closed down, the decrease in income meant fewer sales.

AFFORDABLE LUXURY

Offering an affordable taste of luxury through cookies,

bars or sandwiches lift spirits. In a time when very little is affordable, providing comfort food gives everyone a much-needed lift. Large party-sized celebration cakes will not see the same sales they did in 2019. However, individual servings or smaller “personal size” cakes or cupcakes have seen record sales in the last year. Cookies and bar treats like brownies had spiked since. IDDBA reported that the week of

April 26, 2020 saw renewed engagement with packaged baked goods, cookies and crackers. “Packaged cookies increased nearly 25 per cent,” that year.

IMMUNITY BOOSTING

FOOD TREND GROWING

Where do food trends stand today? Are clients asking for more indulgence, or healthier options, or something that delivers both? Food experts say that supplying luxurious

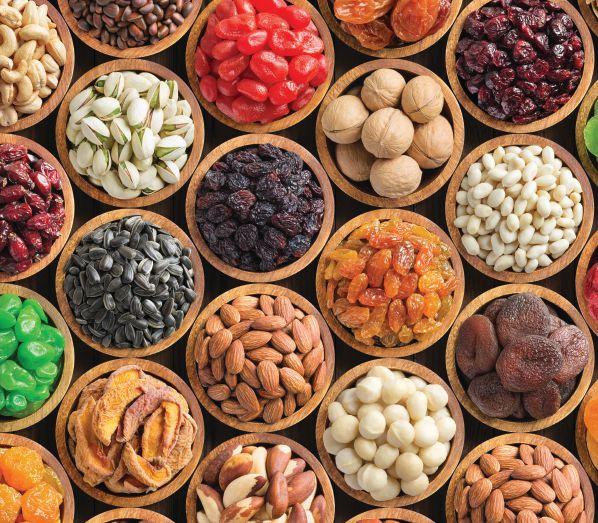

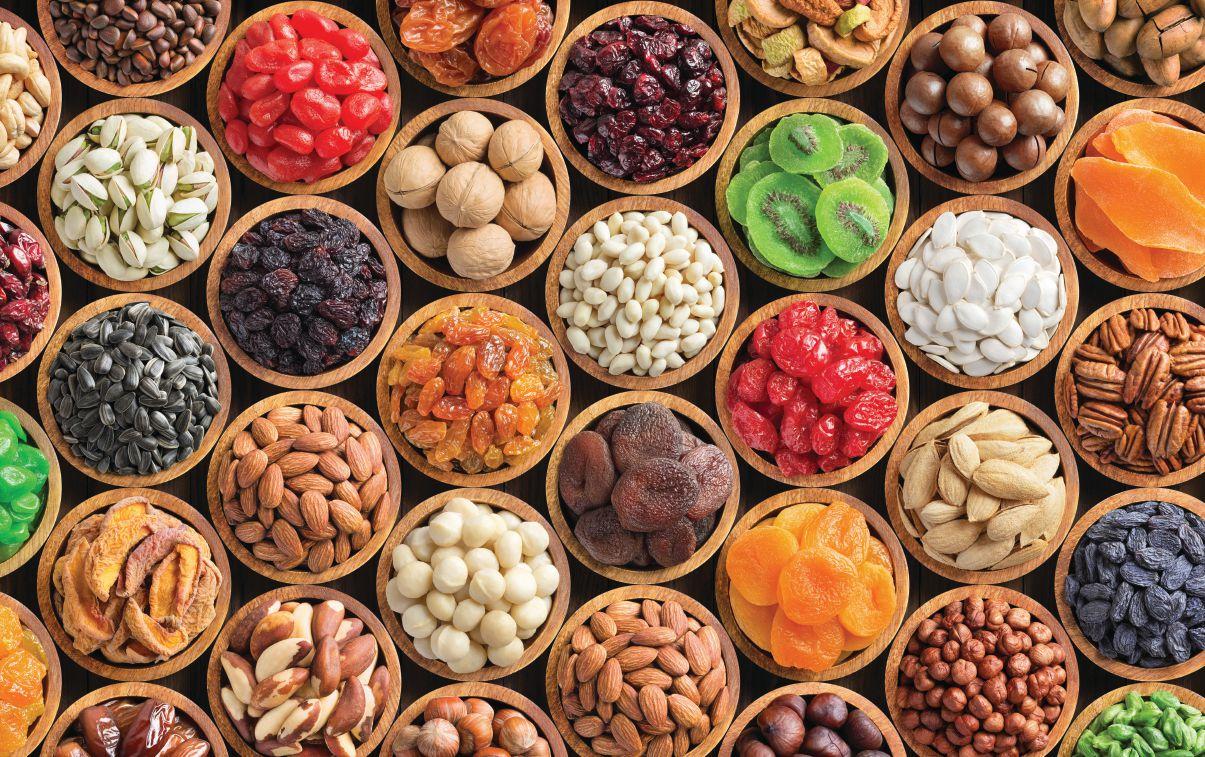

Adding nuts or using dehydrated fruit and vegetable powders add texture, colour and nutritional value to baked goods.

treats will bring in the customers, and it doesn’t necessarily mean that healthy eating and decadence are mutually exclusive. By adding whole ingredients or labeling your food as free-from artificial colours or flavours can reassure customers that they are still choosing a better-for-you option when treating themselves.

}“Superfoods were big in 2019, with conflicting movements between comfort food or healthy options,” says Sylvain Charlebois Senior Director of Agri-food Analytics Lab, at Dalhousie University. Charlesbois says that data isn’t encouraging when it comes to healthy foods. “We’re seeing that people are just focused on the virus and the variants, and they want to see the other side of the pandemic, and then they’ll deal with healthier choices. “COVID 15 can wait for a while, and I think that’s kind of what we’re seeing right now... I suspect things are going to shift in months to come which I hope they do. But for the time being, I’m not seeing a marketplace overly concerned about health.”

Vince Sgabellone, Foodservice Industry Analyst at The NPD Group doesn’t see food trends in black and white. “It changes and evolves. Right now, it’s all about keto, vegetarian and plant-based, which is wonderful. And the industry adapts and evolves to accommodate that. But it’s always going to be a niche because as Sylvain was

a renaissance as a main ingredient in keto and plant-based diets. While still banned from many schools, nuts are used to add flavour, texture and protein to all but the allergen-free diets.

ACCOMMODATING DIETARY RESTRICTIONS

Andrea Johnson, Chief Storyteller, Brain Candy

“Food service is about treating yourself, and it’s about indulgence. It’s about getting something you can’t get somewhere else. It’s not about going out and having a salad.”

saying, ‘it’s about the comfort foods right now,’ but it always has been. Food service is about treating yourself, and it’s about indulgence. it’s about getting something you can’t get somewhere else. It’s not about going out and having a salad.”

Ketogenic and plant based diets had surged between 2018 and 2019, and more bakeries are providing dairy-free, egg-free options. Brands like Sweets From The Earth offer cruelty-free treats, and Sugar Daddies who provide keto-friendly goodies are profiting from a market that was once considered “niche.”

Nut-based foods are seeing

Marketing Ltd., feels that accommodating more dietary restrictions could be a key to balancing a menu.

The big question that the food industry will be answering is, how will the industry re-emerge from the pandemic and move forward with a solid understanding of what’s ahead?

We’re seeing a movement towards supporting independent operators, and buying local. Knowing your community’s buying preferences will be the defining moment that will help your industry stay the ground during this uncertain shift. Overall, the food industry is seeing an uptick in sales, either from

delivery, order out, or providing meal kits or grocery services.

BEING AGILE

Restaurants Canada’s data indicates that bakeries and cafés have every reason to feel optimistic. There will be an increased tendency to buy both freshly baked and pre-packaged goods, and sales are climbing for the food kit industry; Bakers can profit from providing cookie decorating kits, or all the ingredients for brownies, marketing it as a healthier alternative to cookie and cake mixes. More bakeries are marketing their goods for larger scale, big box stores or supermarkets, like Sugar Daddies’ Ketogenic baked goods. Even Dufflets, once exclusively sold in its bakery chain is finding its way to the grocers bakery section.

Bakeries such as Khaos Artisan Kitchen provided sourdough starter, and offered lessons online; Many can reach out to their local community through social media and market their wares and skills. This pandemic may have closes some doors, but opened many entrepreneurial opportunities for bakers. / BJ

While the market is currently heating up for Keto-friendly treats, accommodating wider ranges of dietary restrictions can widen your client base.

Companion Chocolate Caramel Pretzel Bread Pudding (serves

CHOCOLATE CARAMEL

PRETZEL BREAD PUDDING:

• 2 cups whole milk

• 2 cups heavy cream 3 whole eggs

• 3 egg yolks

• 1/2 cup light brown sugar

• 1/4 cup bourbon

• 1 teaspoon salt

12)

• 12 ounces bittersweet chocolate, chopped

• 24 ounces Companion Pretzel Sticks, preferably stale, cubed

• 6 tablespoons salted caramel (recipe follows)

DREAM. GROW. THRIVE.

You’re invested in your business We’re invested in your success

Our new FCC Food & Beverage Report digs into 2020 sales numbers by sector, what influenced them and looks ahead at trends and projections for 2021. Get all the information you need to take on new opportunities.

Check out the report at fcc.ca/Economics.

Preheat the oven to 325°F. Butter 9x13 baking pan.

In a medium saucepan, bring the milk and cream to a simmer over moderately high heat.

In a large bowl, whisk the whole eggs and yolks with the sugar, vanilla and salt. Slowly whisk the hot milk mixture into the egg mixture, then whisk in the chocolate pieces and stir until mostly melted.

Spread the pretzel cubes in the prepared baking dish and pour the chocolate custard over the top. Press the pretzel into the custard until evenly soaked, then let stand for 20 minutes.

Drizzle the caramel over the bread pudding. Set the baking dish in a roasting pan and fill the pan halfway with hot water. Bake the bread pudding for 50 minutes, until a knife inserted into the center comes out clean. Remove the dish from the water bath and let stand for 20 minutes.

Drizzle with more caramel before serving, if desired.

SALTED CARAMEL:

• 1 cup sugar

• 1/4 cup water

• 3/4 cup heavy cream

• 3 1/2 tablespoons unsalted butter

• 1 teaspoon sea salt

In a heavy-bottomed saucepan, combine the sugar and water over medium-low heat until the sugar dissolves. Increase the heat and bring to a boil, without stirring. If necessary, use a wet pastry brush to wash down any crystals on the side of the pan. Boil until the syrup is a deep amber color, about 5 to 6 minutes.

Remove the sugar from the heat and carefully whisk in the heavy cream. The mixture will bubble. Stir in the unsalted butter and salt. Transfer the caramel to a dish and cool.

We’d also like to thank our Keynote speaker and everyone participating in the roundtable discussions:

Opening Keynote speaker:

Justine Martine

Owner of Guilty Pleasures Bakeshop + Catering, she won the 2019 IBIE Cake Sculpting division and also was named Canada’s Cake Designer of The Year for 2020 by the Ontario Wedding Awards. She’s recently been a contestant on the Food Network Canada’s “The Cake Wars.”

Bonny Koabel

CPA, CGA, President of AKR Consulting Canada

Steve Fox

Owner of Fox’s Bakery, has kept his bakery running for a little over 43 years.

Chef Kymm St-Amour

Owner of Khaos Artisan Kitchen, Chef St-Amour singlehandedly provided bread for her community through arranging a safe pick up and delivery in her area. She kept those in the area in the loop with breadmaking techniques with her ‘sourdough school’ where she kept customers informed on techniques to keep starter alive and healthy, while showing them how to shape loaves.

Paul Hetherington President and CEO of Baking Association Canada

Chef Anthony Borgo

Coordinator Baking and Pastry Arts program at Georgian College

PINPOINTING METAL FRAGMENTS

Too often, metal detection technology can be eclipsed by the hype surrounding other types of inspection systems, notably x-ray, occasionally leaving the wildly inaccurate impression that the older technology is some sort of fringe, anachronistic throwback. For a few short years, some even speculated that x-ray would become the default technology for end-of-line contamin-

ant inspection.

That scenario never materialized. In fact, metal detection today not only remains the backbone of food safety compliance for the majority of the baked goods and wider food sector as a whole, but has also made huge strides forward in the last few years in terms of accuracy and the avoidance of false positives. Specifically, simultaneous multi-frequency scanning makes it much easier for food manufacturers to identify

hard-to-find metals in food products with high conductivity (so-called ‘wet’ products). These items may, literally, have high water content, but above-average conductivity may also be linked to high levels of minerals, particularly salt. Other variables such as temperature and density can also affect readings.

Product effect has posed a challenge for North American baked goods producers for years. Salt content is a significant factor in generating

product effect. But moisture content and temperature can also create challenges, especially in batch production where there may be major differences in these variables over time. Density variations and inclusions (such as seeds) in bread can also complicate the situation.

Manufacturers of ‘wet’ products have often had little choice but to tune their metal detection in a way that reduced margins of error and consequently tended

Improvements in the accuracy and reliability in food production metal detection allow it to pinpoint even the smallest fragments and most elusive grades of stainless steel.

to trigger excessive numbers of false positive rejects. It should come as no surprise that there is a hefty price tag attached to such levels of inaccuracy, in terms of product losses and line stoppages. This is especially true of lines running highervalue artisanal products. One general food industry estimate puts potential costs per production line at up to $18,500 per annum, depending on food type, cost, and line speeds.

Recent improvements to metal detection technology have dramatically reduced this type of problem. In practical terms, some of the newest systems are capable of pinpointing metal fragments with dimensions half those detectable with the previous generation of equipment, with the same degree of reliability.

for stainless steel, on the other hand, can easily be swamped by this product effect.

address this challenge – and clear this high bar.

}Any reputable supplier of metal detection equipment understands that, while compliance with Hazard and Critical Control Point (HACCP) requirements for food safety is of the utmost importance, manufacturers increasingly have their own overall equipment effectiveness (OEE) targets too. If the metal detector on a given line cannot distinguish between the ‘product effect’ and metal contamination and this problem repeats itself, it can have a massive impact on line performance and wider OEE.

There are two distinct components to metal detection: magnetic permeability and conductivity. Most bakery products will leave a ‘fingerprint’ that combines elements of both, though the overriding component is likely to be conductivity. Metals also exhibit telltale combinations of both types of effect. For example, the majority of ferrous metals display stronger magnetic permeability, while non-ferrous metals will signal higher conductivity. Indicators

The tendency can be especially pronounced with grades of stainless steel typically used in processing and packaging line equipment, which tend to exhibit low magnetic permeability and low conductivity. This makes these grades of steel among the most difficult metals to detect, but

“Some

Until a decade ago, the development focus in food metal detectors was on the coils, which transmit and receive multi-frequency signals. Once this simultaneous multi-frequency capability was built into equipment, Fortress took the next step with its Interceptor food metal detector, separating the

of the newest systems are capable of pinpointing metal fragments with dimensions half those detecable with the previous generation of equipment, with the same degree of reliability.”

even these tricky characteristics tend not to cause problems, or trigger false rejects, in low-conductivity dry foods. That is far more likely to happen in more conductive ‘wet’ products.

For all these reasons, the bar in metal detection has to be set where the combination of contaminant signature and product effect is most problematic. In other words, for manufacturers of wet products, the ‘acid test’ for HACCP compliance in checking for potential contaminants has to be the detection of hard-tofind stainless steel in their hard-to-scan product matrices. The last few years have seen equipment manufacturers such as Fortress Technology

product and metal detection signals before linking them for a final analysis.

Access to such granular detail, even at high line speeds, has been made possible by applying the same powerful microprocessor technology utilized in today’s most advanced smartphones.

To explain this approach in slightly different terms, the newest systems override the propensity of ‘wet’ product effects to drown out the signal from stainless steel, in particular, by singling out low-frequency signals to eliminate the product effect while leaving the signal from stainless steel more readily identifiable in the higherfrequency range. For the first

time, software algorithms are making this possible by distinguishing between signals specific to the product and those that flag up anomalies.

These new levels of performance and reliability have been a game-changer for baked goods producers, and one which can be applied to metal detection not just of finished packs but also of dry mixes and pumpable doughs. Other valuable benefits include the ability to more accurately inspect product packaged in metalized film or foils such as longer-life, dried snacktype products, flatbreads and breadsticks, for example.

Far from falling under the shadow of x-ray inspection, metal detection can rival it in some of the toughest contamination challenges posed by the baked goods sector, while retaining a far more affordable capital cost and cost of ownership. We have witnessed a step change not only in terms of neutralizing the most obstructive types of product effect, but also in key areas such as vastly increased sensitivity and single-pass product learning, allowing much higher levels of OEE, compliance and product safety. / BJ

Wet products like puddings, filled or iced cakes present more of a challege in detecting metal.

BY LIZ URAM

MOTIVATING THE UN-MOTIVATED

Don’t give up too soon on your staff: You could be asking the wrong questions to unlock their drive

When Mary started working, she was enthusiastic, energetic, and consistent. She got along well her co-workers and was known for her superior customer service skills.

Over time something changed. Mary began starting work late, leaving early, and taking long lunches. Interactions with co-workers usually turned into complaint sessions. Customers were frustrated. John, Mary’s manager, was at his wits end. He wanted Mary to return to the level of work he knew she was capable of. He tried money. Then, he tried disciplinary action. Both resulted in short-term change that didn’t last.

}If this situation sounds familiar, don’t give up: The challenge is determining what motivates employees.

willingness to speak for the group. They are the ‘go-to’ person when others need answers or reassurance. They are the person the team looks to for direction.

Keep this employee motivated by asking them for their opinion on matters that affect the group. “How do you think the team is going to react to this change?” is a simple, yet very effective way to let this person know that their position within the group is clear.

3. Appreciation: A sincere thank you is what motivates employees with this motivational factor. They just want acknowledgement for their efforts.

Employees who are motivated by appreciation talk a lot about their accomplishments. They might come to their one-on-one with a list of what they’ve done. Managers who don’t understand what clues to look for may mistakenly assume the person is full of themselves or bragging. These employees

Asking an employee outright what motivates them usually doesn’t work. Look for clues that identify the motivational factors of each individual.

are looking for some appreciation.

Asking an employee outright what motivates them usually doesn’t work. Look for clues that identify the motivational factors of each individual.

Here are six common motivational factors and the clues to look for:

1.Belonging: People motivated by a sense of belonging get energized by being part of a group.

You’ll find them coming up with creative ideas for celebrations or social events. Listen for what they do outside of work. Do they spend a lot of their free time with friends and family? Do they participate in group events like book clubs or sports teams?

Keep this employee motivated by asking them for ideas; designate them as the celebration coordinator. Include them in projects.

2.Influence: A formal leadership title isn’t needed to have influence. Many are happy with an informal leadership role where they can influence others.

You can identify them by their

Keep these employees motivated by giving sincere, specific, and timely appreciation for their efforts. Catch them in the act of doing something right and comment on it immediately.

4. Achievement: People who are motivated by achievement are always looking to outdo themselves. While they enjoy friendly competition, they are more interested in pushing themselves. They are usually self-starters who take an interest in their productivity. They set goals both professionally and personally. They love the feeling of accomplishment when they can check off a goal and then they are on to the next one.

Keep them motivated by communicating key performance measures, encouraging them to set bigger goals, and sharing their progress with them on a regular basis.

5. Security: People with this factor have a high need for job or financial security. Anything that threatens their sense of security can demotivate them.

They might obsessively worry about their performance. They ask a lot of questions. They are excessively concerned about change. Some managers assume the person is needy: They need security, reassurance, and confidence.

A manager can help this employee by taking time to answer questions; communicating changes early and often; and boosting their confidence by giving them opportunities to prove they are capable.

6. Growth: Employees have career goals and they want opportunities to advance.

One of the most obvious clues is asking about career advancement when they interview for a job. They’re willing to take on extra responsibility in order to prepare.

Keep them happy and motivated by asking what they interested in doing next and creating a career path for them that clearly outlines a plan for advancement. Delegating projects could provide growth opportunities if you can’t promote them.

Back to John and Mary. Once John saw the clues, he realized that what Mary really wanted was appreciation. John wasn’t known for giving out verbal praise but he was willing to give it a try. Instead of waiting for Mary to tell him about her accomplishments, he looked for opportunities to praise her. Before long, John saw improvements in Mary’s attitude and she began to have the same energy and enthusiasm she had when she started.

It wasn’t easy for John to get out of his comfort zone, but it was a lot less expensive and stressful than what he had been doing.

Before you give up on an unmotivated employee, challenge yourself to search for clues about how to motivate them. You might be surprised at what a big change can come from a small adjustment to handling motivation issues. / BJ

Liz Uram is a nationally-recognized speaker, trainer, consultant, and author. She equips leaders with the tools they need to communicate like a boss so they can make a bigger impact, get better results, and motivate others to do their best. With 20 years of experience, she’s developed systems that work. Uram’s written four books packed full of strategies leaders can implement to get real results, real fast. For more information, please visit www.lizuram.com.

THE VOODO THAT THEY DO

On February 28, Groupex and American Express Canada presented a talk at the Restaurants Canada Show, featuring the daring doughnut company, “Voodoo Doughnut,” featuring its CEO, Chris Schultz.

The internationally recognized brand has been growing its cult following since day one, with its unconventional flavors and memorable branding. Within a month of opening, Voodoo Doughnut received its first mention in the national press, and it has not slowed down since. What started as a tiny shop in Oregon, has appeared on The Tonight Show, The Cooking Channel and even The Wheel of Fortune, to name a few.

How to get your food brand recognized as widely in such little time? Schultz insists that you shouldn’t worry about your brand as you start out, just focus on the quality of your product and connect with your surrounding community in person, and online. A marketing team can figure out the business of the logo or the branding, but he feels start-ups should focus on “not going stagnant,” and “let the top people continue to challenge themselves.”

}performance counts.”

The founders of Voodoo Doughnuts, Tres Shannon and Kenneth “Cat Daddy” Pogson wanted to stand out in doughnut industry. Schultz attributes part of the chain’s success to the duo’s previous experience as bartenders, which may have contributed to their unique approach in combining unexpected flavours. Schultz says that on any given day, a long lineup of eager customers “wraps around the building in downtown Portland.”

Both Shannon and Pogson had tremendous success with their maple bacon doughnut and moved on to other flavours. Some did not have as much appeal, such as their infamous NyQuil Doughnut. “We tried to roll it out, and then the FDA came by and said, ‘you can’t put medicine on a doughnut. That little thing on the side of the bottle says it’s for medicine only.’” Schultz said the maverick doughnut team made another attempt with their equally infamous Pepto Bismol Doughnut, which was also removed from the menu. Undeterred by past failures,

Voodoo Doughnuts is also credited with inventing the Pickle and Sriracha Doughnut; “Sounds delicious doesn’t it?,” asked Schultz mischievously.

The CEO also added that despite being head of a chain himself, most people who do visit them don’t like the concept. He wants those in the franchise industry to consider Voodo Doughnuts a “string of pearls,” he said. “People want to visit a series of stores. They don’t want to visit a chain.” He explained that bringing a unique element of culture to each one helps makes a client feel like they are taking part in an experience, not merely making a transaction. Part of that experience means ensuring staff are treated well. “We want to be a culture to a company that means taking care of our people. We have to truly understand

Voodoo Doughnuts is also credited with inventing the Pickle and Sriracha Doughnut; “Sounds delicious doesn’t it?,” asked Schultz mischievously. “No! We tried it, and it’s not even photographed because they just were not even good enough for us to take a picture of them,” he laughed. His anecdotes illustrate three lessons, aside from letting the fearless founders’ creativity speak for itself. First, there’s no such thing as bad publicity; even the idea of a doughnut flavoured with over-the-counter medication can spark interest. Second, don’t consider a failure a complete set-back, get back to doing what you love and try again. Third, laugh and learn from your mistakes. One mis-step was not having electron-

Voodoo Doughnuts earned its fame through creative doughnut flavours and charitable social currency.

ic payment options available from the get-go. “We thought we’d be cash only,” explained Schultz. Once the pandemic hit, and many were uneasy about the idea of handling money, and debit and credit processing provided an opportunity to order online, and in May of 2020 Voodoo Doughnuts even offered delivery.

Whichever way Voodoo chose to make doughnuts available, the company stood by its values to help its community. The company gives a quarter from every doughnut sold to a national charity of the shop’s choice. When the pandemic hit, Schultz asked his team, if they should put that money back into the stores. “Our answer was, no, we’re going to continue to stay the course. It’s needed even more now.”

Another way Voodoo Doughnuts each shop stand out is through its human “spiritual leaders” found in each shop. From Kenny Rogers to Wes Anderson, each shop features a black velvet painting of its chosen icon, which lends a quirky “mojo” to the ambiance, as Schultz puts it. And what makes better mojo than providing a much-needed service? “In all of our stores we have ordained folks that work for us, that do weddings. Talk about becoming an iconic brand, we’re making a difference, we’re doing something different and unique.” / BJ

KAREN BARR

FIVE DECADES OF TRADITION

For Andrea Mastandrea, founder, and owner of Forno Cultura, Italian baking runs in the family. It has been part of his everyday life for as long as he can remember. “I am a third-generation baker, who grew up watching my father and grandfather baking naturally leavened semolina bread, made with my family’s Lievito Madre,” he says. “‘Forno’ means oven and ‘Cultura’ means culture. Mother yeast is the base of all baking that we do.”

Today he owns six bakeries in Toronto. Two have large production spaces of over 3000 square feet. There are 168 workers. Mastandrea cannot talk about his business, which he started 10 years ago, without giving a family history about how it all began.

His parents started an Italian bakery, in the city, back in 1971. It appealed to new Canadians, from Italy, who missed the authentic baking they loved, as well as customers born in Canada, who had travelled to Europe. What was totally unique at the time, is that it sold both pastry and bread, unlike bakeries in Italy, which specialized in one or the other.

The concept was a ‘success! Today, Aida’s Bakery celebrates 50 years in business.

}“I am a third-generation baker, who grew up watching my father and grandfather baking naturally leavened semolina bread, made with my family’s Lievito Madre.”

Mastandrea says his late father Giuseppe, was raised on a farm in Puglia, a peninsula at the heel of the boot-shaped Italy. There, the family grew and pressed olives. This farm is what became the heart of the communal village. “People would bring the breads they made in their kitchens to bake off. The oven was always in operation and at different temperatures throughout the day and night, heating soups, legumes, or braised meats.” Then he adds, “In Italy people are a representation of the land. Puglia

is hard, bitter, salty and with a minerality. Hard on the outside and loving on the inside.”

About Salerno, on the Amalfi coast, where his mother Michelina grew up, he says, “Salerno is delicate and floral, with citrus, honey, anise and fennel. I like to say in our kitchen my father was the oven, and my mother is the stove.”

Mastandrea says his parents were supportive in letting him help out in the bakery, even as a child. He was always curious to see how things were made, even doing some research on his own,

“My father always received baking magazines from Italy. Bakers Journal was the only one in English. I used to sit in my father’s office and read it cover to cover.”

After years of crafting his skills in authentic Italian baking, Mastandrea started Forno Cultura. His goal was to keep the classic flavours, without compromising ingredients, yet simplifying the form. “We like to think of ourselves as a bakery rooted in the craft and tradition of Italian artisan baking, yet we are born out of these unique cultural extensions we find here in Toronto,” says Mastandrea, who was born and raised in the city. “This allows us to constantly explore the limits and push the boundaries.”

When it comes to making bread he says, “The bakery concentrates on

RILEY SNELLING

Old world breadmaking in a modern setting hasn’t changed the flavour nor the passion for the craft of Italian baking.

offering our client base, both a locally grown semolina, as well as a specially imported semolina, made from 100 per cent durum wheat, from Altamura, Puglia, Italy. This is one of the few DOP protected wheats, which we still have access to, in today’s world of modified varieties.”

DOP is short for Denominazione di Origine Protetta which translates into Protected Designation of Origin. This certification ensures that products are locally grown and packaged.

As for top selling breads he says, “Semolina sourdough, a semi sourdough that we use a special blackened method of applying olive oil to the crust during the bake.” Then, he also mentions, “Focaccia Barese and our Curry Olive Oil Brioche are other top seller.”

These breads form the bases for pizzas and sandwiches, that are rapidly purchased and enjoyed. The olive oil brioche is turned into a breakfast sandwich, made with egg frittata, smoked provolone, and black kale. A stuffed calzone contains aged ricotta and fior di latte, which is a semi-soft

fresh cheese. Paninis, of all varieties are popular, as are tramezzini (Italian triangle sandwiches), made with cotto prosciutto, speck, Emmental and thinly sliced preserved lemons.

At Forno Cultura, the sweet side has been dominated by the world of laminated doughs. “We have taken a departure from the mainstream, with a different flavour profile and structural esthetic. People ask why our products don’t look like traditional Italian Cornetti, or even French croissants.”

Easter is one of the most important holidays in Italy. During this time, the bakeries do a swift sale of traditional desserts, such as Zeppole di San Giuseppe, the cream filled donut shaped pastry, Colomba di Pasqua, the traditional Easter egg bread, made with citrus peel and almonds and Pastiera di Pasqua, the Italian Easter tart, made with ricotta. Then over Christmas, customers line up for pandorno and panettone, of course!

The there is the Forno Cultura, not to be forgotten, sister bakery Biscotteria Forno Cultura. This celebrational

bakery of Italian cookies, is located at Union Station. “The train station is the arrival and departure point for travellers, and they want to buy gifts for friends.” Here customers can choose from up to 30 different kinds of cookies. The Italian recipes come from four generations of family, each one perfected along the way.

At Biscotteria Forno Cultura, our recipes have been paired down to the basics, without compromising the ingredients. We are in constant research and development, creating simpler products that are more refined.” What are the three sellers? “Cantucci Mosaic, Frolla di Limone, and our landscape of Pasta di Mandorla.”

The traditional of true Italian baking, both savoury and sweet continues at Forno Cultura bakeries and the original Aida’s. For 50 years now, this multigenerational family of bakers have been able to bring a piece of Italy to Toronto. / BJ

Karen Barr writes about arts, culture and cuisine. She is a graduate of George Brown College and is a Red Seal pastry chef.

FROM SILO TO TRUCK

PANDEMIC-PROOF CATERING

Chef Drew Munro and Brad Pommen, the founder of SMRT1 were thinking of collaborating long before the Coronavirus hit North America. Pommen designed the SMRT1 kiosks with touchless interfaces and Chef Munro is the founder of UpMeals. The two saw an opportunity in busy office settings, for employers looking to provide meals as a perk, and as part of a corporate wellness program.

Chef Munro spoke of the inspiration, “I had a master plan: take a ‘normal job’ in an office, save up some money and eventually go to Europe to work in Michelin starred restaurants, come back home, and open up a restaurant here. You know, in that experience, that I had working at that office environment, that’s actually where I got the idea to start this venture, because there was such a demand. So I started an office lunch catering service there at the office where I was working, which then became quite busy and quite successful. And that spawned me with this new entrepreneurial spark to create this catering company.”

A part of the appeal was the space and cost-savings advantages of a kiosk compared to catering or full cafeteria services: Providing a way to keep staff and employees safe and healthy was another. Pommen saw how healthy food kiosks already had a foothold in Fresh, Vancouver’s version of “Whole Foods Market.”

“UpMeals partnered with a number of different locations. That’s a place to get not only the sandwiches, but also offer other marketing and advertising for specialty products. But then, Upmeals are also servicing the offices of software companies where there’s 100 employees. This is a perk of three meals a day that they supply for corporations.”

With many companies making their offices safe for working, through measures like social distancing or providing touchless vending services,

Munro, CEO and Co-Founder, is an experienced chef and caterer who saw the need for an accessible, branded meal service solution.

cafeterias may be phased out. One option to provide the safe and nutritious perk of breakfast, lunch and supper is through touchless vending instead of investing in a cafeteria. Challenges like dietary restrictions and employee attendances are also a part of the machines’ programming.

UpMeals has also thought of ways their service could be accessed without

waste or having someone take advantage of the meal plan. “There’s a number of different ways that this system can be configured; in scenarios where it is just about sheer numbers so that they know they needed to order 60 meals today. And based on you attendance rate at the office, they should have 70 per cent available for tomorrow,” explained

Ultra Soft. Ultra Tasty.

Fresh®

Make

Pommen. “Those would be the type of scenario where they might have ID cards. They could use facial recognition technology. A lot of these things come from what the customer might already be comfortable with. So, if it’s just using their cell phone as an identifier, or if they have an employee card, those can all be tied in to identify them and restrict usage.”

Munro was impressed with how the SMRT1 technology can offer everything from food safety to office help. “Our goal is that there is never an overlap and that fresh products are constantly being stocked in the machine before everything has the risk of expiring. And the other really cool level of functionality is that with Brad’s technology, what he’s built in conjunction with us, is that as soon as our products are stocked into a machine, there’s an automatic timestamp that will start counting down right from that expiration date of that valid one. This also help facilitate our donation program - any meals that are not sold within their freshness time frame can be donated to local charities that distribute meals to the homeless, like the Vancouver Food Runners program.”

}The collaboration began roughly seven months ago, but it originally began in the fall of 2019, when Pommen contacted Chef Drew Munro. Both saw how small restaurants, cafeterias or diners were struggling to find a space due to the price of real estate. Neither of them saw the pandemic coming, but the new COVID-19 capacity and space restrictions has opened up a new opportunity for UpMeals.

“I think [the pandemic] is going to drive up the demand for our type of product. We’re able to tap into the standard vending machine, we can use a locker, or we can use pretty much any new delivery mechanism... the hardware is no longer the restriction.”

— Brad Pommen, founder of SMRT1

“I heard a statistic that 25,000 restaurants have closed due to COVID across Canada, and that means there’s a lot of commercial real estate space that will not be filled by Restaurants needs in the next couple of years,” said Pommen. “Because of hesitancy to either reopen, or associated costs, I think it’s going to drive up the commercial real estate for ghost kitchens and those types of services… I think [the pandemic] is going to drive up the demand for our type of product. We’re able to tap into the standard vending machine, we can use a locker, or we can use pretty much any new delivery mechanism on the market as part of our offering. The hardware is no longer the restriction.” / BJ

Dominic Messier is a Quebec-born, bilingual writer who loves to explore the latest in food trends and pop culture. He writes about film and television for www.skipitorloveit.com .

GIVE US A LISTEN!

“On The Rise” podcasts for busy bakers

Full length podcasts are not for everyone. That’s why Bakers Journal offers short form, “flashcasts” for busy bakers. In five minutes, you can hear an inspiring story about a bakery that helped its neighbourhood during the pandemic, or learn about the latest in ingredients, food trends, nutrition and ways to save your bakery money. Find out what other bakeries from coast-to-coast are doing, without leaving your seat.

Short-form flascasts are the perfect way to stay informed or just be entertained. If you have a fifteen minute break, or are commuting give “On The Rise” a listen. It could lift your spirits!

“On The Rise” is available through Apple Podcast, and Spotify. You download them to listen to later, or you can go directly to Bakers Journal’s website and give a listen today: Go to: www.bakersjournal.com/podcasts

frozen dough guide & directory 2021

BAKEMARK CANADA

Canada Headquarters: 2480 Viking Way, Richmond, BC V6V 1N2

Corporate Headquarters: 7351 Crider Ave, Pico Rivera CA, 60660

Corporate Line: (562) 949-1054

Contact:

Richmond: Ryan Ward (604) 303-1700

Calgary: Chris Rossnagel (403) 243-5493

Edmonton: Renee McCarty (780) 483-2831

Toronto: Sabatino Cipro (647) 821-9975

Montreal: Nancy Beecraft (450) 667-8888

Winnipeg: Frank Santilli (204) 774-2424

Website: https://yourbakemark.com/en/ Products offered: Clean labelled and kosher dough conditioners for use in the production of frozen dough, par-baked and frozen baked goods. Deliveries: Supply bakers across most of Canada from key locations in B.C., Alberta, Manitoba, Ontario and Quebec.

Major customers: Wholesale bakery manufacturers, independent bakeries, in-store bakeries, foodservice and the food industry. Assistance offered: Sales, marketing and technical expertise.

Company comments: BakeMark Canada offers a variety of frozen dough conditioners. We also supply pre-made and par-baked products for your baking ease and convenience. Contact your local branch for all your bakery ingredient needs.

MIMI FOOD ARTISTIC DOUGH PRODUCTS

Address: 1260 Creditstone Rd, Vaughan, ON, L4K 5T7

Office Tel: 905-660-0010

Store Tel: 289-217-6269

Email: info@mimifoods.ca

Website: mimifoods.ca

Products offered: Pizza Dough Balls in 8 different varieties and 7 different sizes ranging from 8oz – 32 oz (MiMi Brand All-Purpose Flour, Garlic Rosemary, Carbon Vegetable flour, Mulino Caputo “00” flour, Wholewheat flour, Focaccia, Gluten Free and High-in-Protein) Ciabatta (4x6 wraps and buns), Flatbreads (12x4 and 14x5 various flavours: Garlic and

Rosemary, White Plain flour, Wholewheat flour, Multigrain flour) Focaccia (6x9 and 12x9 Herb, Tomato, Pomodoro, Potato and Onion) Panuozzo Buns (Slider size 2x2, 4x6 and 18x5 ) Pinsa Romana / Crokkia (4x6, 6x9, 12x9 White Plain flour) Par-Baked Pizza Crusts (8”, 10”, 12”, 14” 12x9, 12x17 Plain White flour, Wholewheat flour, Multigrain flour, Thin and Thick Crusts, Pressed and Non-Pressed) Sheeted Dough (8”, 10”, 12”, 7x7”, 11x15”, 23x15”) and also offering Gluten Free and GMO Free Pizza Crusts, Baguettes, Dinner Rolls, and Hamburger Buns in 4 flavours: Beetroot - Broccoli - Cauliflower – White. NEW: ARE OUR 300 g GLUTEN FREE RAW FROZEN PIZZA DOUGH BALLS in 3 flavours: Beetroot – Cauliflower - White. Major customers: Foodservice + Hospitality Industry, Grocery Industry, Bakery Industry, Wholesale Bakery Manufacturers, Restaurant + Catering Industry

Assistance offered: Custom product development and packaging, customized pizza programs, training and support. Production Method: choice of production method that best suits the client. We offer: raw dough, par-baked, fully baked, topped, and/or fully customizable.

Company comments: CFIA Certified, BRC Certified, HACCP Certified, FDA Registered Facility, Winner of the 2012 GIC New Product Award for Innovation and we are a full-service dough manufacturer from product development stage to full support training at the retail store level. For our retail customers we now have on location a Cash-N-Carry shop open to the public 6 days a week.

OK FROZEN DOUGH

4145 Spallumcheen Pl., Armstrong, BC V0E 1B6

Contact: Bruce Glaicar

Tel: 250-546-0311

Email: bruce@okfrozendough.com

Website: www.okfrozendough.com

Products offered: Complete line of frozen bread and roll dough, including white,whole wheat, multigrains, ryes, sourdough, and other specialty items.

Deliveries: Snow Cap and other major bakery

distributors in Western Canada. Customers Instore bakeries and food service suppliers. Company comments: OK Frozen Dough has been providing quality frozen dough for 25 years. Our variety of product compliments any bakery program and our dedication to consistent quality has made us the trusted frozen dough supplier of Western Canada’s Grocery Industry. Remember our moto: We help YOU make DOUGH!

OLYMPIC WHOLESALE CO. LTD.

75 Green Ct., Ajax, ON L1S 6W9

Tel: 905-426-5188

Email: info@olympicwholesale.ca

Website: www.olympicwholesale.ca

Products offered: Complete line of dry and frozen products for all your bakery needs including paper, cleaning supplies, cake decorating and frozen finished products. Suppliers of house brands: Olympic, Tasty, Bakers and our all natural Pure Foods Products line since 1936. A variety of spelt, organic, all natural and retail products are available. Areas serviced: All of Ontario (some northern areas excluded) and Quebec.

Assistance offered: Technical support from all manufacturers as well as providing technical documentation upon request. Company comments: Committed to Service Excellence.

RICH PRODUCTS OF CANADA LTD.

149 Rowntree Dairy Rd.

Woodbridge, ON L4L 6E1

Contact: Peter Melnyk

Tel: 905-265-4300

Website: richproducts.ca

Product Offered: The products you need. The insight you rely on. At Rich’s, we offer a valuable variety of frozen dough products for all of your culinary creations. From Pizza and Breads & Rolls to Cookies and Sweet Goods, we have gluten-free, gourmet and plant based options to satisfy any consumer demand.

Deliveries: National distribution through local and broadline distributors. Mimimum orders vary across Canada.

• Same day pick-up on stock orders • Minimum order 24 pieces • We ship anywhere • Two locations to server you better

1-800-661-4122 ext. 244 jbredo@drader.com

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND RAW INGREDIENTS FOR THE BAKING INDUSTRY

Tel: (416) 252-4660 Fax: (416) 252-9993

25 - 8 Connell Ct., Toronto, ON M8Z 1E8

BY JANE DUMMER

NATURALLY IN DEMAND

Using nature for colour in baked goods to create clean-label and entincingly bright baked goods

Natural dyes including plants, insects, and minerals have been used to colour food for thousands of years and date back to several civilizations. Today, due to consumer demand, natural colours are trending in the baking industry. However, choosing natural colours have not always been the simplest nor most cost-effective. Sandy Golden-Dukes, VP Business Development, IFC Solutions describes the consumer demand, “People are more ingredient conscious and interested in what they are putting in their bodies. While synthetic dyes are still approved in Canada, many consumers want to see a recognizable ingredient on their product label vs a “chemical sounding” name. Given the choice between ‘Allura Red’ and ‘Beet Red’, they’re starting to prefer the latter.”

like the one above made with beets are the result of increasing requests for natural colours.

}“52 per cent of shoppers worldwide look for ingredients they do not recognize when checking labeling, while 62 per cent have concerns about ingredients that ‘sound chemical’.”

Jeannette O’Brien, Vice President, GNT USA, explains, “Plant-based colours are proving increasingly popular as consumers seek out products with clean and clear labels. For example, research gathered by FMCG Gurus in 2020, shows 52 per cent of shoppers worldwide look for ingredients they do not recognize when checking labeling, while 62 per cent have concerns about ingredients that ‘sound chemical’.”

Natural colours can be problematic because of several factors including heat stability, pH range, and fat content. In the baking industry, these factors are necessary to think about when choosing colours. Susan Frecker, Senior Application Scientist, Chr Hansen Natural Colors LLC illustrates, “When thinking about a baked product, there are now pigments available that are more heat stable. Our Hansen sweet potato™ provides a more heat stable alternative

for a red-based product at neutral pH. There are innovative pigment sources available providing a broader, brightly colored pallet and are both water and oil dispersible for frosting/icing/fondant and fat fillings. Spirulina, from algae, works for frostings and icings and allow for a wide range of blue, green and purple.”

O’Brien concurs, “Plant-based colours are not a plug-and-play solution. To ensure the best results, it’s essential to understand the technical aspects that affect the chosen application. With the right approach, EXBERRY® colours can be used to achieve the full spectrum of shades, but we continue to add new products to our range to make life even easier for manufacturers. For example, we often introduce products in specialized formats to ensure optimal results in challenging applications such as chocolate and fat-based coatings.”

Overall, these innovations and improvements in natural colour production have resulted in more cost-effective ways to incorporate them into baked formulas and recipes. Frecker explains, “Innovative colours that

contribute less flavour and require lower dosages are gaining in popularity and allow for the bakery product’s texture and leavening to be maintained. The lower dosages are beneficial for ease of use in production, and potentially offer a cost savings.”

Red continues to be popular; consumers want bakery products that stand out and make an impact on social media, but is challenging to create. Golden-Dukes explains, “Of the sources of ingredients that are used to make colours, the ones that make red are some of the hardest to work with. Anthocyanins have pH instabilities, beets are not very heat stable, and cochineal is not kosher. Finding an easy to use ‘drop in’ red colour from natural sources is often difficult. We learn as much as we can about what our customer is looking to achieve and then offer something for that specific application.”

Recent improvements in ingredient technology have resulted in brighter and more stable natural food colours. Providing a clean label, and proving to be cost-effective are both welcomed outcomes. / BJ

Jane Dummer, RD, known as the Pod to Plate Food Consultant, collaborates and partners with the food and nutrition industry across North America. www. janedummer.com

Breads

2021 TRANSIT

Count on the dependable and versatile Ford Transit to help make building your business easier. We’ve also loaded our cargo vans with an available suite of smart driver-assist technologies*, so when you’re ready to get to work, you can be condent behind the wheel.

3 HEIGHTS 3 LENGTHS 58 CONFIGURATIONS AVAILABLE ALL-WHEEL DRIVE

JUST GOT CLOSER TO H ME Cake inspiration

Select Cake Mixes from Dawn are now made in Canada. The high-quality ingredients that inspire your amazing cake creations are now closer than ever. Our facility in Burlington, Ontario gives you domestic access to our high-quality, flavourful cake mixes—and we’re always just a phone call or a click away with delicious recipe and decorating inspiration to help you create more memorable moments. To learn more, call 1-866-277-3663 or visit www.dawnfoods.com/ca/madeincanada

For a complete listing of all of our Dawn cake mixes and assorted bakery ingredients made in Canada, visit www.dawnfoods.com/ca/madeincanada