“I’m John Kirkpatrick

I’m a member of Reiser’s team of customers to improve their product. When it comes to buns and rolls, I have

I’ll help you keep pace and succeed in this fast-changing market. Are you ready to add more versatility to your bun and roll production line? Let me show you how.”

www.reiserexperts.com

Reiser Canada

Burlington, ON • (905) 631-6611

Reiser

Canton, MA • (781) 821-1290

BY NAOMI SZEBEN

Three weeks ago, everyone here at Annex thought the quarantine would simply last two weeks. Fourteen days, surely that would be enough to flatten the curve? As I write this, we’re now in the second month of social isolation, and we can see the toll it has taken on individuals, businesses and our communities.

The columnists and contributing writers were optimistic when writing their pieces. Diane Chiasson writes of sunny decks and patio season, conjuring images of happy groups of people seated next to each other, sharing treats off the same plate. Bonny Koabel offers resources for securing financial aid; the two articles are different side of the same coin. Both offer vital information for today’s bakers.

As I write this, I’m contemplating going out in the evening, when I don’t have to behave like a live-action version of the old Pacman video game: Go out, avoid others, get some fruit. There are multiple reactions to this pandemic. We could wander about in the dark, avoiding others, like Pacman. But, we’ve learned that as a whole, Canadians work better together. We’ve learned to think outside of the delivery box, and look to our community for support.

Internet resources have never been more useful. Online orders are flourishing. Restaurants and cafés are pushing their creativity to new limits, finding ways to raise revenue and bring people together. Chefs used to focus on menu changes to lure clients in; today, chefs are redefining the dining experience to bring in business, even if it’s done remotely.

Urban Acorn Catering owners Marie Fitrion and Daniel Holloway created an online supper club to support their catering company. They found their niche in the pandemic dining market. The flicker of computer screens replaced the warm glow of candlelight, but it worked to fight cabin fever while sampling good food. The pair modified their menu to be delivery-friendly. They avoided dishes that would become soggy or fall apart if transported.

The catering company prepped and packaged dishes before delivery, and included instructions for assembly and re-heating, as well as the coordinates for their Zoom meeting.

And just like that, the Urban Acorn Catering company reinvented the supper club.

The pair emailed newsletters to their clients, announcing their first virtual supper club featuring a price reduction that was sure to attract new customers. The catering company prepped and packaged dishes before delivery, including instructions for assembly and re-heating as well as the coordinates for their Zoom meeting.

The pair reported that the supper club didn’t feel forced or awkward, proving that clients need a human connection as much as they need food. Acorn’s business motto is, “food should unite, not divide people,” and it has brought strangers successfully together.

I hope Acorn’s story is an inspiration to other cafés, bakeries or restaurants. Food does unite us in ways we don’t expect, whether we meet a work colleague in an office break room or take a client out for coffee. If your business has not already done this, I would recommend companies create a “virtual coffee break” for offices, offer a discount on delivery and create pre-packaged snacks with hot coffee. (Online meetings are optional for those who might want a break from a screen.)

Think of the ways that people normally connect over food and find a way to bring some strangers together online and share a new dining experience. While we may not have originally thought of social isolation as a global experience, much less a business model, together, we can get through this. / BJ

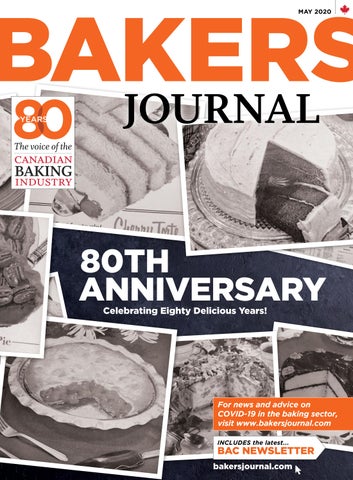

MAY 2020 | VOL. 80, NO. 4

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION bolechnowicz@annexbusinessmedia. com

Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 32.00

USA — 1 Year $73.50

Foreign - 1 Year $84.50 All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com

Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2020 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Canada’s Outstanding CEO Award winner; Electrolux wins design award | AMF announces new director of sales. | for more news in the baking world, check out our website, www.bakersjournal.com

Saputo Inc. announced Lino Saputo, Jr.’s achievement as Canada’s Outstanding CEO of the Year® for 2019, an award for chief executives in Canada. Saputo, Jr. was honoured at the Outstanding CEO of the Year Award Gala in Toronto, Ontario, on February 12, 2020.

The members of the Advisory Board unanimously selected Saputo, Jr. as the 30th recipient of the Award – amongst all Canadian CEOs. They recognized his leadership and identified Saputo as an organization that has experienced stellar growth and built a significant global presence. The selection committee also felt the company’s story serves as an “example of true Canadian leadership and success.”

On March 18, the Federal Government announced a relief plan that would help many businesses recuperate from losses experienced during the COVID-19 quarantine.

Emergency benefits to be made available in April for those who don’t qualify for EI: The new Emergency Care Benefit can pay up to $900 biweekly, up to 15 weeks, to provide income support to workers, including the self-employed, who have to stay home and don’t qualify for paid sick leave or employment insurance. The measure could disburse up to $10 billion in total.

Details still depend on the businesses’ provincial rate of employment and the number of hours each employer has worked in the last 52 weeks. It is recommended that those affected apply as soon as possible to find out if they apply, as waiting more than a month after your last day of work might mean losing access to those benefits: If approved, the maximum amount paid out for Canadian Employment Insurance is $573 a week.

The Federal Relief Plan includes Emergency Care Benefit and the Emergency Support Benefit: Those who tested positive for COVID-19, the Emergency Care Benefit provides up to $900 every two weeks for up to 15 weeks.

For businesses that have been affected by reduced hours and/or staff, visit the Government of Canada’s Benefits page: https://www.canada.ca/en/services/benefits/ei/ ei-sickness/apply.html

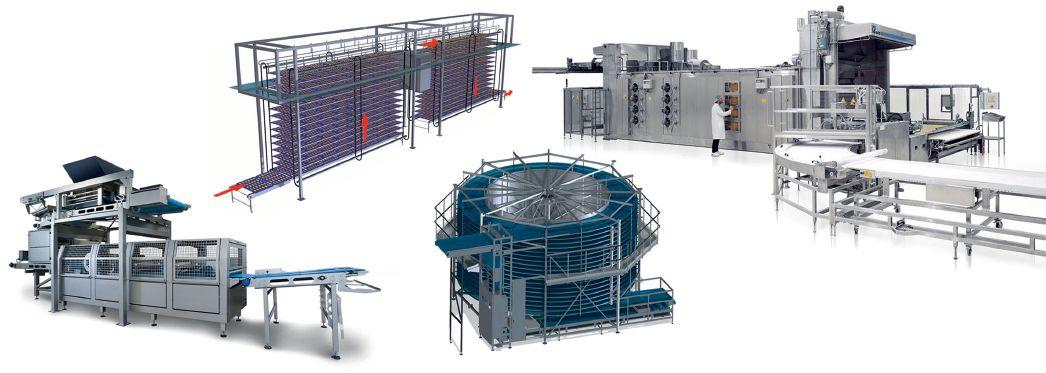

AMF Bakery Systems (AMF) announced that Guillaume Joly, previously global business development manager, will transition to the role of director of sales for U.S. and Canada focusing on artisan bread and rolls, pizza and flatbreads, cakes and pies, as well as pastries and croissants.

As the Company’s expertise in developing innovative production solutions for artisan breads and specialty baked goods continues to grow throughout North America, Guillaume will lead the sales team focused on offering complete mixing through packaging solutions, including AMF Tromp sheeting and laminating as well as AMF Den Boer baking system technologies throughout the region.

Guillaume will continue to work closely with AMF’s director of sales, U.S. and Canada, for the soft bread and bun segment, Blake Millard, as the duo aim to expand AMF’s reach across the complete range of best-in-class technologies from mixer to marketplace.

lectrolux Professional announced that it has made several changes to its manufacturer’s representation across North America. These changes will help better align the strategy for the brand and consolidate representation between Electrolux Professional and Grindmaster Corp.

The upstate New York area, Lake Effect Sales and Marketing will act for Electrolux Professional foodservice as well as its beverage brands. This change took effect on April 3, 2020.

“Electrolux Professional is excited to announce our new rep group food and beverage consolidation across the county. These actions will make us a stronger company that will lead us to greater efficiencies to better serve our food and beverage customers,” said Mark Ortiz, head of national sales – North America in a statement.

This news comes after its winning the coveted Good Design Award. The company won an award for its design of the Skyline series of Cook&Chill products. The awards honour the yearly achievements of the best industrial and graphic designers and well-established global manufacturers for their pursuit of extraordinary design excellence and innovation.

With their nutty crunch and sweet mild flavour, California Walnuts are the perfect addition to your creations.

Consumers are eating more nuts and good fats.

73% would purchase a food product knowing it contains walnuts.*

From the latest in chocolate to the latest in technological innovations for confectionery, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Callebaut launches plant-based chocolate

Barry Callebaut’s new chocolate satisfies the growing demand for plant-based indulgence, particularly among millennials and centennials. The new chocolate is part of a wider portfolio of ‘Plant Craft’ products ranging from chocolate, cocoa, nuts and fillings to decorations.

The launch comes at a time when sustainability-conscious consumers are increasingly adopting a ‘flexitarian’ or ‘freegan’ lifestyle – navigating seamlessly between plant-based products one day, and consuming animal products the next. The new, dairy-free ‘M_lk Chocolate’ has a creamy mouthfeel and has the typical milk chocolate flavour and texture. It is made with an ingredient of natural origin, exclusively available to Barry Callebaut. It took a Barry Callebaut R&D team two years to develop.

BPS saves installation time and cost

Best Process Solutions (BPS) systems are designed to utilize networking technologies available from major control manufacturers such as Rockwell Auto-

mation, Siemens, and ABB. Utilizing these networking and control technologies allows BPS control systems to be installed and implemented in shorter periods, thus reducing installation costs.

BPS has the capability to produce controls for full systems from start to finish and also can design and fabricate control systems for a customer’s existing operation. BPS does the upfront engineering and sizing of control components based on the mechanical design and specification of the customer’s equipment and bulk processing control needs. BPS can handle the startup and commissioning of the system, including installation oversight of any mechanical equipment and electrical paneling.

Syntegon Technology unveils confectionery manufacturing innovation

Syntegon Technology presented several innovations for confectionery manufacturing at interpack 2020. For mass candy production, Syntegon Technology has unveiled the BDS weighing, dosing and mixing system for batchwise production with energy savings of 50 per cent.

The portfolio now comprises two systems with low energy consumption: the BDS system for batchwise and the BDK system for continuous production. In addition, the BMV mixing system will be on display at the fair, featuring a hygienic magnetic stirrer. For the production of jellies, Syntegon Technology is showing the Makat mogul system with new components, including an inline weighing system, a newly designed chain-free de-stacker and innovative rotation nozzles for more effective cleaning processes. “Cleanability, ease of operation and resource efficiency play a key role for confectionery manufacturers. These values feature in all our process solutions,” Frank Jansen, product manager at Syntegon Technology, explained in a press release.

Syntegon Technology sets its focus on intelligent and sustainability solutions, in particular with regard to resource efficiency. With the BDS weighing, dosing and mixing system, confectionery manufacturers can produce sugar masses in an energy-efficient manner. Traditionally, water has to be added to the mass during mixing and then boiled out again later. This step is now largely eliminated, resulting in energy savings of around 50 percent. As an alternative to the continuously producing BDK system, the new BDS system doses the candy and binding masses in batches, which allows for more individual mixtures and thus offers manufacturers a higher degree of flexibility.

“I’m Jeff Zeak and I’m a member of Reiser’s team of Bakery Specialists. I work with customers to improve their products. When it comes to the challenges of producing gluten-free baked goods, I’ll help you every step of the way. With decades of experience, I’ll show you how to streamline production so you can easily process everything from stiff dough to sticky batter. Are you ready to consistently produce the highest-quality, gluten-free products? Let me show you how.”

Watch Jeff’s video Contact Jeff at (905) 631-6611

www.reiserexperts.com

Reiser Canada

Burlington, ON • (905) 631-6611

Reiser Canton, MA • (781) 821-1290

The Allied Trades of the Baking Industry was established in 1932, and Canada’s first baking industry that represented our country was the National Council of the Baking Industry or NCBI. The Independent Master Bakery Association of Ontario later opened in 1937.

The late thirties and early forties were a time of rationing, and the motto, “Food Will Win The War” was on the lips of commercial and household bakers alike. This meant that the cost of ingredients and production rose substantially: Many flour mills and sugar refineries reported a loss of manpower due to conscription.

The first issue of Bakers Journal was published in July 1938, during a time when many bakeries formed councils or professional associations. Canadian bakeries learned to adapt their formulations with alternative ingredients. Bakers Journal included a recipe that was to become famous within Canada: Tomato Soup Cake.

The popularity of gelatine desserts began during the war. With much beef being processed for the boys overseas, factories found ways to turn bone waste into profit by processing gelatine. Households made cakes, mousses or jelly desserts using gelatine as a base. As an added advantage, gelatine took well to artificial colouring, and could take on cheerful hues. Children who grew up during the war grew to associate gelatine with a strong sense of nostalgia; gelatine desserts would also re-emerge in the sixties and seventies.

Supreme Aluminum Industries Ltd. created a rectagular pie pan in the 1940’s. This new shape was designed to save oven space and satisfying the growing industrial bakery field.

}Fun fact: In 1949, a baker could buy an established bakery, including trucks and equipment for only $17,000. Buyers would contact the Bakers Journal office at the time on King Street East, Toronto.

larger chain bakeries operating in ever-widening circles?”

More industries were contemplating turning to large-scale equipment to boost their productivity. Commercial pie pans turned to rectangular shapes to create more slices and use oven space more efficiently.

recent, 21st century fad. Bakeries were looking into ways to create flour alternatives at a lower cost back then, and ways to use less salt without compromising flavour and texture.

In 1949, Canadian bakers were eager to see recovery on the horizon. February 1949’s edition of Bakers Journal reported on the milestones achieved in its previous decades. “How many, for instance, realized that the introduction of machinery would eventually lead to

Fun fact: In 1949, a baker could buy an established bakery, trucks and equipment for only $17,000. Interested buyers would reply via the “Opportunity Ads,” (now called the Classified section) through Baker’s Journal’s office on 21 King Street East, Toronto, ON.

1950S

Alternative ingredients are not just a

While we are currently focused on gluten-free flours, grain alternatives like fish flour were considered as far back as the fifties. An October 1954 article in the “What’s Cooking?” column in Bakers Journal reported that fish flour “should be suitable for white or brown bread and mealie meal.” Dr. G. M. Dreosti, the Director of the Fishing Industry Research Institute of South Africa admitted that South Africa had “not produced a perfect fish flour.”

The nation’s interest in sodiumreduced applications dates back to 1954, at the Institute of fermentation in Ghent, Belgium. Our magazine reported that Professor E. Maes gave a lecture outlining the problem of

As an essential food supplier to people around the world, The Maple Treat Corporation is committed to maintaining the supply of our maple products to our business customers in the over 50 countries we serve. We are also responding to the health and safety needs of our valued employees, with work from home initiatives, work flow distancing, screening protocols, enhanced disinfection and more.

Our offices, bottling plants and warehouses will remain open, as we continually adapt our practices and operations to keep our food supply moving, while working diligently to control the spread of COVID-19. We, like you, will emerge from these grueling times more resilient than ever.

To our dedicated customers and cherished employees alike, we stand with you for a brighter tomorrow. Please take care of yourself and your loved ones, and do what you need to stay healthy.

TMTC offers a diverse product line of 100% pure maple syrup with no colourings or preservatives, in a variety of different grades and formats. From maple syrup, cookies, candies and treats… to maple sugar, flakes and more. Our sugarmasters sample, test and ensure that every batch of our syrup is at its finest taste, while its vitamins, minerals and antioxidants contribute to good health.

improving the ‘dull taste’ of unsalted bread, with ways to achieve a ‘better appearance’ to unsalted bread.

Speaking of replacements, margarine was reformulated for baking purposes. While it was first introduced during world war II as ‘Oleo Margarine’, it was beginning to be used for the first time in industrial baking applications, but with limitations. It was advised even then that it not be used for deep frying. Fleischmann’s began selling margarine to consumers in 1972. However, as early as of October 1949 Sven Young of Canada Packers Ltd. wrote how Canada Packers Ltd “were the first in Canada to produce margarine.”

Cordon Bleu-trained Chef Julia Child changed the way domestic baking and the way American professional bakers saw French cuisine. Her weekly television show stoked consumer interest in European foods among North Americans. This was no great change to Quebec, what with its existing French tradition in bakery, but it did help expand the province’s export baking industries.

While an interest in international cuisine was piqued, the early sixties was also a time of industrial food revolution: Instead of tin cans, aluminum cans were used in food processing for the first time. An interest in providing quick food options for on-the-go consumers began in earnest. Domino’s Pizza launched its take-out chain business model. Frozen bread dough from Bridgeford Foods Corp., launched its product line in 1962.

In 1963, General Mills unveiled ‘Wondra,’ flour. The boom in wheat and food production made ‘buffet meals’ a trend in many restaurants and cafés, where abundance was the focus.

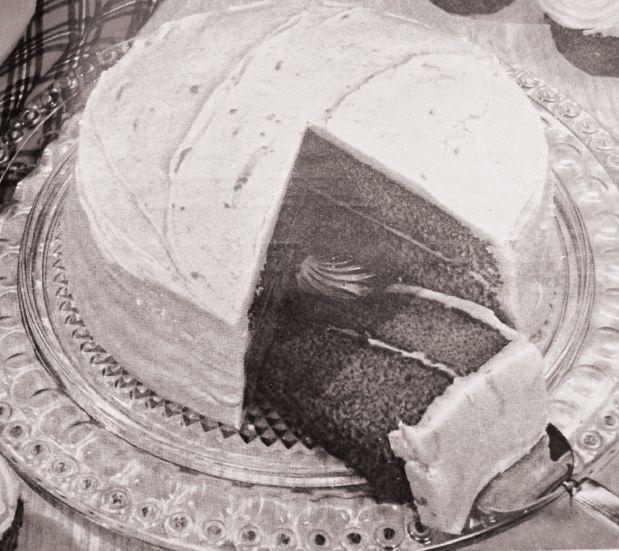

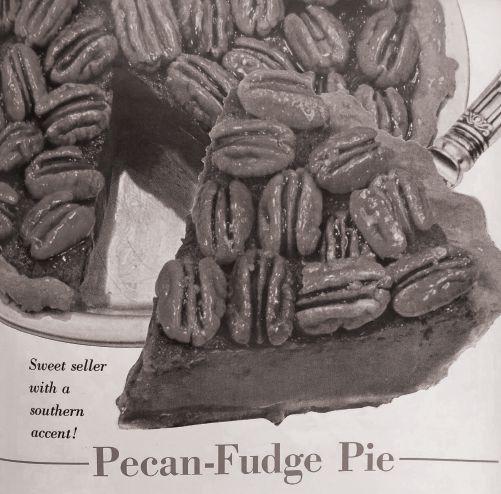

A love of French style desserts, like fondant-iced cakes or buttercream topped cakes were all the rage. Delicate pastel colourings also added to its appeal.

The new boom in convenience meant grocery stores really started ramping up their pastry counters; where the stand-alone bakery offered cakes and pastry, grocery stores began offering more affordable options.

The grab-and-go trend really began in

FRITSCH is part of the MULTIVAC group

FRITSCH is part of the MULTIVAC group

FRITSCH is part of the MULTIVAC group FRITSCH is part of the MULTIVAC group

FRITSCH IMPRESSA bread – great-tasting, natural products with an artisanal look are no challenge. Proven SoftProcessing technology guarantees exceptionally gentle processing of soft dough and allows high output and absolutely stable operation. With the new Soft Dough Sheeter, the system is now ideal for artisan bread products of the highest quality. Find out more at www.fritsch-group.com

FRITSCH IMPRESSA bread – great-tasting, natural products with an artisanal look are no challenge. Proven SoftProcessing technology guarantees exceptionally gentle processing of soft dough and allows high output and absolutely stable operation. With the new Soft Dough Sheeter, the system is now ideal for artisan bread products of the highest quality. Find out more at www.fritsch-group.com

earnest; McDonald’s first launched its take-out breakfast, the ‘Egg McMuffin’, in 1973, and while bakeries and cafés had been offering a possibly less processed version, it initiated the launch of the commercial take-out breakfast sandwich.

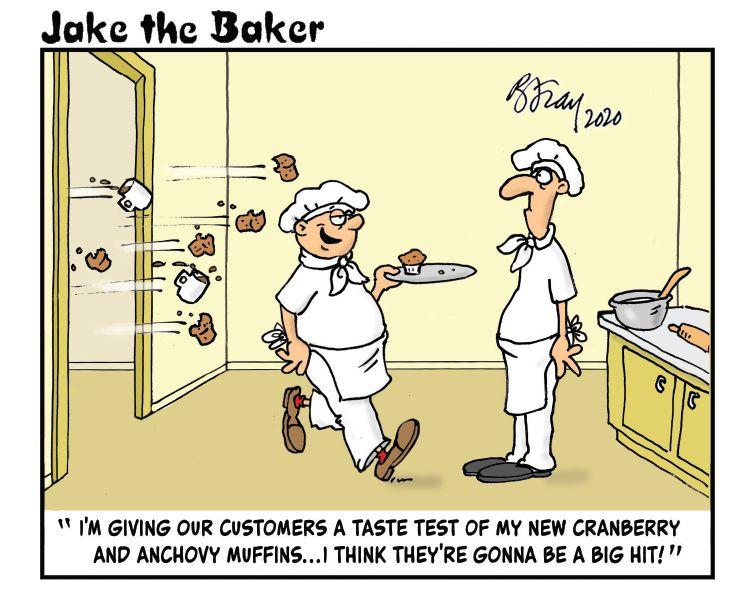

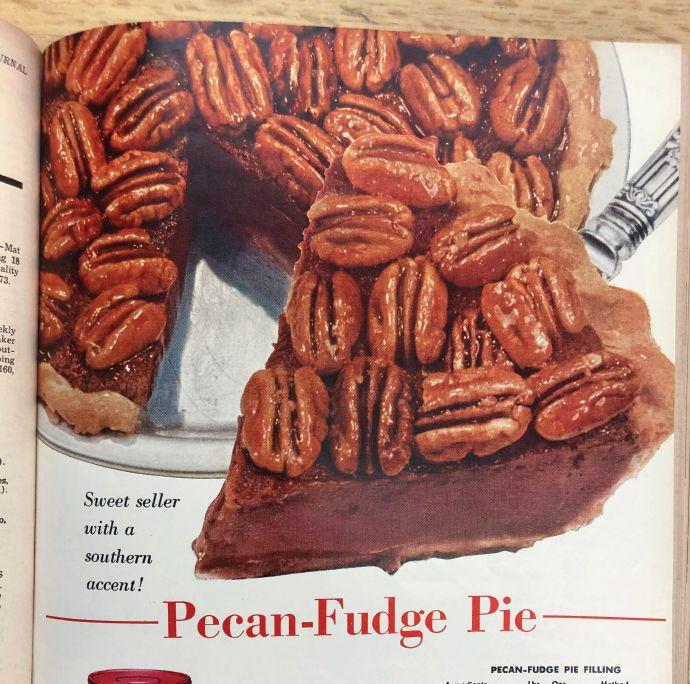

Mail-order gourmet options gained popularity; The Fruit Of The Month Club launched in 1972, inspiring other players the food industry to promote and export their goods via mail order. The most popular cakes were fudgy and/or included gelatine in their filling like the fudge pecan pie.

In December of 1981, the U.S. News and World Report informed readers of America’s “Great New Food Craze”: Brunch. This can be seen as an extension of the buffet experience, where consumers wanted more variety. “Once criticized for their traditional ‘meat and potatoes’ mentality, many consumers are seeking better quality, greater variety — and much more enjoyment — at mealtime,” wrote Lawrence D. Maloney and Jeannye Thornton.

The article stated that consumers were more aware of their health in relation to food choices, and that many were choosing “lighter, less fattening foods.” The demand for yogurt was reported to have increased from 1970 to 1980 by over 207 per cent. Thanks to clever marketing, demand for margarine increased in that same time frame by 3.7 per cent, while butter sales decreased by 17 per cent.

This awareness for sugar-reduced goods took its toll on the food industry: Del Monte launched a line of ‘Lite’ canned

fruits which boasted 50 per cent less added sugar and a third fewer calories. This, in turn, made food producers use less sugar in their baked goods like bread. Chocolatey dishes that used dark, Dutch-processed cocoa became popular; recipes had names like ‘Death By Chocolate’ but used less sugar than most. Mud Pies and Dirt Cakes were particularly popular. In Canada, the decline in the use of sugar from 1960 onwards was of particular interest. Baked goods like Monkey Bread gained popularity, as did ‘Nouvelle Cuisine.’

The ‘bigger is better’ motif of the decadent ‘80’s continued well into this decade. The hottest plating trend moved from the artsy Nouvelle Cuisine to architectural structures. Heaping plates piled high with artistic layers of food ushered in the age of “Tall Food.” Triple decker sandwiches, high cheesecakes and improbable looking towers of cream were on every menu.

Molly O’Neill of The New York Times wrote in 1993, “When Gotham Bar and Grill opened in the early 1980s, it epitomized the high-living, brash-spending decade...The dishes soar in height as well as flavor [sic]. Gotham Bar and Grill is the home of tall food. The salads look like mountain ranges…the diner’s initial response is to call for a pitchfork and start making bales. Inevitably, the soaring constructions collapse and the diner becomes the clean-up crew.”

At this point, the interest in healthy ‘clean living’ is slowly making its way to bakeries, but the dichotomy between healthy and luxurious is still evident. People want something nostalgic but also want low sugar, clean label and healthier foods.

Bakers start adding terms like ‘reduced sugar’ or ‘free-from’ to their labels to bring in clients. ‘Plant-based’ adds a healthy halo, but doesn’t clearly define if a dish is vegan, vegetarian, or simply includes fruit or vegetables.

At this point in time, plant-based baked goods that are ‘free-from’ animal by-products are gaining popularity, yet the traditionally made baked goods that include sugar, dairy and wheat are still a consumer’s go-to for comfort food and luxurious eating.

Statistics Canada has created a report that measured how much sugar consumers used between 1960 and today: The findings were surprising, to say the least. While there are no shortages of pastry shops, chocolatiers and confectioners, the overall amount of sugar that Canadians are consuming is actually less than it was prior to 1960.

According to the report, the average amount per kilogram per person peaked in 1969, with the average person consuming 45.26 kilograms of refined sugar per year. Its popularity began to wane as of the ‘70’s, presumably when more artificial sweetners became available.

Though most recent data for sugar consumption in 2019 is still being tallied, in 2018, the average person consumed an amount of 30.32 kilograms of refined sugar per year.

We may have become wary of sugar and turned full circle to a time that respected artisanal bakeries for their craft, but we have grown greater appreciation for the ingredient providers and producers, and will continue to love our sweets. / BJ

driven by COVID-19 CFIA “Won’t prioritize” Compliance Activities with Safe Food for Canadian Regulations

With the continuing dynamic situation with COVID- 19 food and beverage buying behaviours are changing. Pearl Strategy and Innovation Design is sharing their Top 5 Insights here.

1. There is a decrease in brand loyalty as consumers try new brands due to the low stock environment.

2. Centre store sales are booming with quarantine orders in place, consumers move to shelf stable categories and brands which they continue to stock-up with more meals eaten at home.

3. Continued stock up behaviour with

large format grocery, mass and club the “go to” retail formats.

4. Increased purchases of comfort, indulgence and entertainment much needed opportunities for enjoyment during difficult days of at home confinement.

5. Shift to online purchasing and click and collect as more consumers taking stay at home orders more seriously.

Source: IRI “COVID-19 and the Economy” March 2020

Visit Pearl Strategy Innovation and Insight at www.pearl-strategy.ca/blog/ for more information on consumers’ perspective on Health and Wellness

July 15, 2020 Deadline

The Canadian Food Inspection Agency (CFIA) has announced “until further notice the CFIA will not prioritize compliance activities associated with the July 15, 2020 coming into force of the Safe Food for Canadians Regulations (SFCR) for the manufactured food sector. Any changes to the CFIA’s prioritization of these compliance activities will be announced with adequate lead time once the situation allows.”

However, the CFIA does offer that despite the change in prioritization it is encouraging businesses to apply for a licences under the Safe Food for Canadians Act (SFCA). However, importers of manufactured food will generally not encounter delays or disruptions in their imports simply because of not having a Safe Food for Canadians licence yet. Domestic manufacturers can continue to operate while they apply for a licence. CFIA’S RESPONSE TO COVID-19: bit.ly/3cgd0Lk FOR INFORMATION ON THE SFCR, PLEASE SEE OUR TOOLKIT FOR FOOD BUSINESSES: bit.ly/2VnhY28

Iwas stopped on a small goat trail high up near the peak of Mount Fitzwilliam in the summer of 1996 following my buddy Terry Brock and for a moment I was frozen. I could neither go forwards and I knew that I couldn’t go backwards. Looking down the mountain, I quickly understood that one mistake in my footing would result in a tumble that would take me a thousand feet down the rocks to certain injury or perhaps worse. I was scared and I couldn’t move.

We have all been there, frozen by indecision about what is the best way forward when challenged by precipitous choices. I had a client who was frozen last week, unsure of what he should do in his business. The moment I walked into his establishment; I knew something was up. The staff were tense and he looked upset. As we walked to his office, he voiced concerns about the changes that were happening and how his staff were taking it. He had made some notes about what he thought he might do but told me that he had just been staring at the options for hours, not sure of what to do next. He was overwhelmed by his own inaction and ability to make a decision.

What is facing most businesses today is something that leaders in our western world have not faced for decades. Only in times of war have businesses been forced to close for extended periods of time, and we haven’t seen war really affect the western world since WW2. Not only has the supply chain dried up for many businesses, so have their customers. People are not coming into businesses and their sales teams are not permitted out. The challenge for many people is overwhelming and many leaders are frozen by indecision about what to do next.

When another one of my clients was forced to shut down his business last

High up on the goat trail, I had to evaluate my options to overcome my fears. Once I started walking again my anxiety of falling subsided. My second client came up with a plan that enabled him to move forward as well and by the time I left his establishment he was smiling and so were his staff. The current times are challenging for many organizational leaders but having a plan and examining your options will reduce your stress and the stress of your employees. To assist members in these trying times BAC is providing a series of 3 short articles by Award Winning Professional Business Coach Dave Fuller. Dave is also the author of Profit Yourself Healthy and can be contacted at dave@profityourselfhealthy.com

week, I asked him what he was going to do? He told me that he was contacting his landlord, bankers and suppliers to communicate what he was doing and to ask for extended terms. He was laying off his employees so that they could collect unemployment money as he couldn’t pay them. He also told me that he was going to take this time to re-evaluate and reset his business. He had a plan and moved through the steps to make it a reality.

This was a different approach than my first client took. He didn’t have a plan, and as a result was overwhelmed. He hadn’t considered the best, worst or most probable options and then worked through them like the second client did. Without a plan, we become frozen. When we try to do things alone, we cannot lift the burden. The burden is heavy right now and most business owners have only day to day plans as they feel this is what they are forced to look at. However, by taking a few hours to work through the options for the longer term of 90 days, businesses and organizations can develop plans that not only spur on

action but reduce stress.

In order for leaders to shoulder the burden of decisions, they need help. If you haven’t created a culture in your business where you tap into the brains and wisdom of your employees, the time is now. Developing a process of 90 day planning will not only help you get through the current crisis, it will help you position your business for future successes. If you need guidelines on how to create a 90 day plan with your team please fire me off an email and I will send you my template dave@profityourselfhealthy.com.

Like you, I have been really scared a few times in my life. You know the feeling, the adrenaline rush that hits you when you believe that you are about to lose something. That increase in heart rate, tightening of your muscles, shortness of breath, narrow focus of time and your surroundings. If you think back to times when you have been afraid, I bet, you can remember with vivid detail what was happening. I like you can remember the feeling of being out of control and scared, in speeding cars, of heights, in dangerous situations, and even in relationships. In fact one of the most fearful times of my life was in the hour before I got married. At 31 I was successful, lived by myself, and had a good life. Yet as I stood up by the altar that day, my knees were knocking and I was almost panicked and was literally shaking in my boots.

Fear is not necessarily a bad thing. Healthy fear will stop us from making stupid decisions that might put the lives or livelihood of ourselves or others at risk. Fear spurs that fight or flight response that tells our brain that we better get off our butts and do something or there are going to be serious consequences.

Yet the acronym for FEAR is False Expectations Appearing Real.

So what are some false expectations that appear real when we make day to day decisions in our lives or our businesses? Often we fear that if we lose one of our staff members that our business will fail. We prolong making tough decisions to keep people accountable, because we are afraid they are going to quit. We are afraid that competitors are going to take all of our business. We are afraid that if we take holidays, our staff will fail us. We fear that someone is going to steal from us, that we don’t have enough money to pay our bills, that people will see that we don’t know what we are doing, that we are going to get sick and die.

Our fears seem endless and in many cases we believe in our minds that the possibilities of our destruction are considerable. Unfortunately, the more we focus on these fears, the more we become frozen by inaction and surround ourselves with the worst-case scenarios, the more those fears appear to be a real possibility. Science shows us that our brains will attempt to give us what we focus on most. If we seem to dwell on being afraid, our brains want to help us get more of that.

There have been times in business where I was afraid that a key member of my staff would quit and the business would fail. The result though, was that when that person quit, others stepped up, and ended up doing a better job. I remember being worried that a competitor was coming to town and was

going to disrupt my business. I was afraid that my sales would drop and that fear spurred me into making some changes to the business resulting in a more proactive approach. Not only did I not notice any drop in sales, I ended up selling more product! I can honestly tell you that I had some serious reservations about selling my business at the age of 52 and facing the unknown. Yet looking back these years later, I still believe I made the right decision.

Yet fear is a part of life for many people, because we have those false expectations that do appear real. So what can we do to face and overcome these fears? Here are 4 steps to help in overcoming Fear:

1. Name the fear – What are we really afraid of? What is it that we are imagining? I am afraid that if the competitor comes to town all my customers will flock to them and I won’t have any sales; I will have to lay off my staff; I won’t be able to pay my bills and I will have to declare bankruptcy.

2. Write down the possible outcomes:

a. Best outcome: Competitor comes our sales stay the same or grow

b. Probable outcome: Competitor comes and our sales drop by x%

c. Worst Outcome: Competitor comes and takes most of our business and we are forced to shut down.

3. For each outcome write down the possible consequences: For example, if our competitor comes and our sales drop by X% we will have to lay off 2 employees and spend more money on advertising.

4. Write down a plan for each scenario or outcome. Worst outcome, we are forced to shut down. If this happens we will liquidate our assets, and our owners, managers and employees will find other jobs paying $x, some of these will go work for the competitor.

Tragic as some of the outcomes we can imagine for our fears, the reality is that life will go on, if not for us, for the next generation. When we have clarity about what the plan is if our worst fears come true, we are less likely to panic.

Writing down outcomes allows us to get these false expectations that appear real, out of the darkness of our mind and into the light of day on a piece of paper where the truth can become more apparent. Perhaps if I had done this before I got married 24 years ago I would have been shaking less at the altar.

As leaders, our job is to instill a sense of calm into those around us. When we have a plan and can demonstrate that we have considered the options and consequences of actions, we show confidence and as a result those around us feel more secure and less panicked.

The founder of Hershey Chocolate, Milton Hershey had a couple of failed attempts at business before he founded and built an empire of Hershey Chocolate. If the story of Milton Hershey ended there, Hershey would have been seen as a success and an inspiration to many. However, there is much more to Milton Hershey than just a successful business, because Milton Hershey was a man who cared about his employees and his communities!

Started in 1886, Hershey’s had success in making and selling cocoa, syrup and chocolate. Because he knew that happy employees were key to his success long before Disney or Google became famous for taking care of employees, Hershey built a community with housing, schools and parks to look after his workers between the years 1903-05. In 1909 he opened a school for orphaned boys to give them opportunities similar to more advantaged children. However, the deciding difference that Milton Hershey made in many people’s lives was in the great depression.

Between 1929 and 1939 the stock market crashed, jobs were hard to come by and men travelled the country on the tops of trains to find even a week’s work in order to support their families. Milton

Hershey decided that he needed to help people through the crisis and started building. He is quoted as saying “There are 600 men here who need jobs. If I don’t give them work, I will have to feed them” and he did! He built hotels, golf courses and skating rinks in his community. At one point when he saw two excavators on site, he asked the foreman what was going on. The man proudly announced that this latest technology was going to save time and money because it can do the work of 40 men. Hershey was dismayed and demanded that the excavators be removed so that they could put 80 men back to work.

So, what can we do as business leaders in this time of economic crisis that will make a difference? The obvious achievement would be to put people to work, so, we need to do that if we can. Before you lay people off, think about all those jobs you have been putting off for weeks, months and years. Why not try to get them done now during this quiet time. Invest in your future. Hershey came out of the depression much better than he went into it because of his investments in people and assets. Use your money wisely to develop your teams, your marketing, and your sales and service materials. Once the economy is

rolling again you will have an advantage on your competition who have been complacent and waiting for handouts.

Think about supporting other business owners who aren’t as fortunate as you are. The Professional Business Coaches Association of Canada has offered their services to help other business owners who are affected economically by the Covid 19 Crisis www. pbcacanada.com. What could you do that might benefit other business owners and keep people working?

Many businesses are struggling right now. Can you order in from a local small restaurant? Think about what purchases you can have delivered to your home or office from a local business. Use your wisdom to share ideas that will improve your business community or give moral support to those around you.

Milton Hershey stepped up when times were tough and made a difference in the lives and families of the people he hired and businesses he supported. Yes, he made money during the depression from his economic activities but even in death he was generous, creating a foundation to continue his work. What can you do now that will make a difference for your employees and for the community at large?

BY DIANE CHIASSON

COVID-19 will not last forever. Here are ways to prepare your bakery for online deliveries and for summer once the quaratine lifts.

Summer is almost here. Is your bakery ready for the business rush once the quarantine lifts? If not, it’s the right time to make the most of your time and to properly set up your business plan.

Here are 5 easy tips and tricks to prepare your bakery for the summer’s post-COVID rush:

A well-designed and well-equipped outdoor patio is a great opportunity to boost traffic and revenues. The design and décor of your outdoor patio is equally as important as the interior design of your bakery. Your outdoor patio space should be a continuation of your indoor space, with the exception of perhaps being slightly more casual. You can create a complementary space by just sticking within the same colour scheme, design, theme, and concept from your interior. You bakery should be inviting, and should invoke your brand and story.

}power pressure washing and sanitizing these areas is a must for health and safety reasons. Power washing will clean dirt, mildew, and other types of grime from any surface

Staffing is the main juggling act of bakery café owners and managers in the summertime. I would suggest that you take a good look at your last year’s sales and staff reports to review and plan ahead for this year’s projections. Depending on the size of your bakery, you may need to hire some additional staff to handle the guests that will be sitting outside. Check kitchen staff to make sure that they are able to handle the extra covers that your patio or take-out may generate.

Your bakery menu is probably your most important marketing material. It’s time to consider a light and unique summer-inspired menu. From leafy

You don’t need a full menu overhaul, just rething your menu layout to emphasize your existing bakery and beverage products in some new and exciting ways.

You can spruce up your take-out space by adding some greenery, potted plants, trees, trellises, shrubs, hanging flower baskets, as well as some colourful umbrellas, or string lights/lanterns. All of these items will help create a memorable outdoor space.

Take this time to inspect your equipment. Guest will definitely judge your bakery by its exterior, and it’s now the ideal time to freshen up your bakery patio that has been neglected since last season. Start by power-washing your walls, concrete walkway, walking surfaces, decks, fences, outdoor furniture (chairs, tables, etc.), awnings, umbrellas, windows, signs, sidewalk, curb/parking areas, and most particularly your trash disposal areas. Regular

green salads to light fruit-based desserts, you should also consider launching a new and exciting summer menu as well as integrating an outdoor coffee-bar experience. Think of adding some new, interesting, and colourful bakery items as well as some unique and fun beverages on your menu. By keeping your menu small and inviting, it will help you reduce inventory, preparation time, and waste as well as staff requirements. You don’t need a full menu overhaul, just rethink your menu layout to emphasize your existing bakery and beverage products in some new and exciting ways. Make sure to always choose a colour scheme for your patio menu that reflects your bakery brand. You should, above all, focus on good food and great guest experience.

4.

First and foremost, your business logos,

patio easels, sidewalk signs, neon signs, and all of your other bakery signs should be visible at all times. Your bakery sign should always be properly seen by those walking or driving by. You may consider some roadside and billboard signs to get hungry out-of-town travellers to come to your bakery store. Consider placing an illuminated sign on your windows, built-in awning, or rooftop; this will help advertise your bakery when it is dark out. Above all, let your bakery products do the talking! Use your window space areas to advertise freshly made breads, pies and cakes as well as your unique and colour bakery displays, or even show how products are being made.

A marketing plan may hurt your brain just a little bit, but I promise that the pay off will be worth it in terms of customer numbers and revenue. Start by asking what are the bakery products, beverages, and services that you will offer at your bakery. What price will you offer your products and services for? What kind of promotion will you do? Will you do newspapers, magazines, website, Facebook, Instagram, Twitter? Or will you simply rely on word-of-mouth marketing? What makes you stand out from the bakery, café, or restaurant the next block down? How are you different from your competition? You should use both traditional and digital marketing methods in order to get your patio going. Be sure to get the word out about your bakery and your special spring promotions. Don’t’ forget to regularly update your website by using pictures of delicious bakery items as well as your new beverages; it will help boost your sales. Don’t forget to right updated and relevant social media posts. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultlants.com , or visit www.chiassonconsultants.com

Do you know about our ability to extend the shelf life of pita from 10 to 21 days? Or that, every day, our expert technical team solves bakery formulation challenges at our Baking Centers around the country? Did you know that Lesaffre has eliminated the need for susceptor boards from microwaveable pizzas and flatbreads? That Lesaffre’s ingredients make tortillas more rollable and enjoyable, all with a clean label? You may not know Lesaffre for the baking challenges we’ve helped customers overcome—but you’ve likely enjoyed the result in the form of a bread, soft pretzel, snack cake, pizza, donut, or other baked delight.

for our world-class baking yeast and 167-year heritage, but you may not be familiar with our elite technical team and the other innovative ingredients we’ve developed.

You

To those a ected by the pandemic, our hearts are with you.

To our nation’s healthcare workers, we are deeply grateful.

To our customers, we are eager to help you put baked goods on family’s tables.

With care and perseverance, Lesa re, Red Star, and Saf-Pro

In 1512, the Portuguese reached the Moluccas (Eastern Indonesia) and hit the nutmeg myristica jackpot.

The Dutch would later dominate taking over the East Indies spice trade. They maintained control by cleverly dipping nutmeg seeds in lime juice to prevent germination and therefore smugglers. The British found a way to snatch the seedlings and plant them in Trinidad in 1806, St. Vincent in 1812, and Grenada in 1843. While Indonesia still supplies 75 per cent of the world’s nutmeg, tiny Grenada supplies 20 per cent. That spice is so important to Grenada, that the country features nutmeg prominently on its flag.

The first small harvest from a nutmeg tree takes seven years. A heavy tree with a shallow root system, it can easily fall victim to tropical storms.

Growing up to 20 meters tall, with large leaves and white flowers, it bears a light-yellow fruit, resembling a plum, with white and green markings. Once ripened, it makes a delicious jam. The nut reveals a hard core coated in an avril or red mesh covering, which is used for the spice, mace.

}The nuts are left to dry in the sun, for a couple months until the seed rattles. Then the shell is cracked using a club or machine to reveal the grey-brown nutmeg.

Can you tell the difference between authentic cinnamon and its more affordable version, cassia?

How can a savvy baker tell the difference in cinnamon and cassia? When purchased in bark form, genuine cinnamon is light brown, papery and brittle whereas cassia is reddish and studier.

Freshly grated nutmeg tastes superior to the purchased powdered form. Tiny nutmeg graters are designed specifically for the task or use the small holes of a box grater. A sewing needle can be inserted into the nut, extracting a small drop of oil, as a sign of freshness.

Out of fresh nutmeg? Substitute for dried mace. It has a similar flavour to nutmeg, but with lighter, almost citrus notes.

CINNAMON

In the first century A.D. a Roman pound of

cinnamon Cinnamumum zeylanicum, measured then as 350 grams, cost 5 kilograms of silver. The Portuguese found cinnamon in immense amounts in Sri Lanka, in 1505. The fickle King of Kandy, owned most of it and sold it at his whimsey. The Portuguese also had to face the Dutch, who slowly took over the European cinnamon trade. Soon, they had their own plantations thereby eliminating the King. With such as abundance of cinnamon it was burned in Holland to keep the prices high. The French conquered Holland during the Revolutionary wars, nabbing Sri Lanka. In 1795, the English took control. But the Dutch and French outwitted

everyone by smuggling out Sri Lankan cinnamon sprouts and transplanting them in their controlled regions.

The dark, shiny-leaved bush grows to 2.5 meters high, from either seeds or cuttings. The bark must be extracted with a special knife, then left in the sun to dry for up to five days. The outer layer is then scraped off.

Cassia or Cinnamomum aromaticum is the less refined, less expensive cousin. It has its origins in China, but today is also cultivated in Vietnam and Indonesia.

Both are sold as cinnamon; the ingredient list will not show the tree source. So, how can a savvy baker tell the difference? When purchased in bark form, genuine cinnamon is light brown, papery and brittle whereas cassia is reddish and studier. The first has a much floral smell, while cassia is hot and spicy.

In 1494, during Christopher Columbus’ second voyage, his team almost all but ignored the allspice Pimenta dioica tree, while in Jamaica. Europeans hadn’t learned of the culinary value of the trees until 1570. Francisco Hernandez, a scholar sent to the Americas by King Philip II, observed the Aztecs flavouring their chocolate drink with the dried berries of the allspice tree.

The bushy tree, has a long thin trunk has a soft grey-brown bark that sheds every year. It blooms with white spidery flowers, producing round berries, each containing two kidney-shaped seeds. Berries are picked when green, order to preserve their flavour and later ripen to a reddish brown. Each mature tree can produce 30 to 40 kilograms of allspice per year.

Today, Jamaican allspice is most treasured for its flavour that has the unique taste properties of cinnamon, cloves and nutmeg combined. Home bakers may mistake it for a spice blended of the three!

Vanilla or Vanillia Planifolia has its roots in Central America, the West Indies and northern South America. Christopher Columbus was the first European to taste it, through the hospitality of a Nicaraguan village chief, in 1502.

Of the 20, 000 different types of orchids identified only one has a purpose beyond beauty--- the genus Vanilla, with approximately 50 species. Only one produces genuine vanilla and that is Vanillia planifolia.

The exquisite flavour comes at a high cost due to the

time-consuming nature of cultivation in countries such as Madagascar, French Polynesia, Tahiti, Indonesia and Mexico. Wild vanilla has all since vanished, leaving botanists to debate which specific species of bee or butterfly was once responsible for pollination. Cultivators must now hand-pollinate, using the climbing plant’s own pollen for this finicky orchid to thrive.

Of the over 1000 blooms that appear at dawn on a mature plant, the pollinator selects only the best dozen. By dusk the flowers will wither. It takes four to nine months for the vanilla beans to emerge and harvest begins when the beans start to turn from green to yellow, later maturing to a dark chocolate brown.

The flavour of the vanilla bean develops in processing. One traditional method is to dip the bean in boiling water before picking it, stopping the ripening and developing the enzymes in the fruit. The beans are left to cure in the sun for up to six months and are sealed for shipping to trap in the delicious aroma. Vanilla beans are graded by quality and size: The longer, the better.

So, the next time you pick up a spice to add into your recipes, think back to its historical journey and labourious growth cycle. This will lend new appreciation on how spices have travelled from tree to table. / BJ

Karen Barr writes about arts, culture and cuisine. She is a graduate of George Brown College and is a Red Seal pastry chef. She was a former Government-appointed member of the Industry Committee for Baker-Pâtissier for Ontario.

The following article discusses COVID-19 financial compensation measures that were put in place by the Federal and Provincial Government and Banks as of March 25, 2020. These measures may have changed and additional financial compensation may have been added since this date. To fully maximize the compensation it is recommended that you review this information with your accountant or bookkeeper.

Wage subsidy for existing employees:

To support businesses that are facing revenue losses and to prevent lay-offs, the government is providing small businesses a temporary wage subsidy for a period of three months. The subsidy is applies to all remuneration paid to T4 employees between March 18th and June 20th, 2020. Businesses will be able to benefit immediately from this support by reducing the tax portion of their Payroll Tax Remittance paid to the Federal Government every month. The subsidy will be equal to 10 per cent of gross wages paid during that period, up to a maximum subsidy of $1,375 per employee and $25,000 per employer.

For more information on the Wage Subsidy Program see: https://www.canada.ca/en/ employment-social-development/ services/work-sharing.html

https://www.canada.ca/en/ revenue-agency/campaigns/covid-19-update/frequently-asked-questions-wagesubsidy-small-businesses.html

Employee EI compensation for reduced work hours:

The EI Work Sharing Program, which provides EI benefits to workers who agree to reduce their normal working hours as a result of developments beyond the control of their employers such as COVID-19. Under the EI Work Sharing

Program employees agree to work a reduced number of hours per week and are compensation by EI for those reduced hours. The Federal Government is extending the eligibility to 76 weeks, easing eligibility requirements, and streamlining the application process.

For more information on the EI Work Sharing Program see: https://www.canada.ca/en/employmentsocial-development/services/worksharing.html

Business Credit Availability Program (BCAP)

This program ensures businesses have access to credit: BCAP allows the Business Development Bank of Canada (BDC) and Export Development Canada (EDC) to provide more than $10 billion of additional support, largely targeted to small and medium-sized businesses.

Relief measures include:

• Providing Working capital loans of up to $2 million

• Flexible repayment terms, such as postponement of principal payments for up to 6 months,

• Reduced rates on new eligible loans

In order to qualify contact your bank and they will need to make a referral to BDC or EDC.

BDC Contact information: https://www.bdc.ca/en/contact_us/pages/ default.aspx

EDC Contact information: https://www.edc.ca/en/contact-us.html

Tax-filing flexibility:

The Canada Revenue Agency will allow all businesses to defer until after August 31, 2020, the payment of any income tax

amounts that were owed as of March 18, 2020 and before September 2020. This relief would apply to tax balances due, as well as instalments.

and Interest Relief on Corporate Tax,

and Payroll Tax: Penalties and Interest Relief applies to any penalties and interest charges that your company receives on HST, Payroll and Corporate Taxes late payments due to extraordinary business circumstances such as COVID-19.

To learn more go to: https://www.canada.ca/en/revenueagency/services/about-canada-revenueagency-cra/complaints-disputes/ cancel-waive-penalties-interest.html

Provincial governments also provide deferred payments for workplace insurance (WSIB) and property tax. To find out the deferral period have a look at your City’s website or call or email your City Counsellor to find out details. In the City of Toronto there is a grace period without penalties for 60 days as of March 16, 2020.

The CRA will allow all taxpayers to defer, until after August 31, 2020, the payment of any income tax amounts that become owing on or after today and before September 2020. This relief would apply to tax balances due, as well as instalments. No interest or penalties will accumulate on these amounts during this period.

EI

The new Canada Emergency Response Benefit (CERB) will provide a taxable benefit of $2,000 a month for up to 4 months to:

• Workers who must stop working due to COVID-19 and do not have access to paid leave or other income support.

• Workers who are sick, quarantined, or taking care of someone who is sick with COVID-19.

• Working parents who must stay home without pay to care for children that are sick or need

additional care because of school and daycare closures.

• Workers who still have their employment but are not being paid because there is currently not sufficient work and their employer has asked them not to come to work.

• Wage earners and self-employed individuals, including contract workers, who would not otherwise be eligible for Employment Insurance.

To read the entire Federal and Provincial

Government announcements, please see the following links: https://www.canada.ca/en/departmentfinance/economic-response-plan.html

https://budget.ontario.ca/2020/marchupdate/action-plan.html / BJ

Bonny Koabel CPA, CGA, is President of AKR Consulting Canada – a Mississauga, Ontario firm specializing in Government Grants, Subsidies, Tax Credits, Refunds and Rebates since 2003.

For the dough:

2 cups (480 ml) water, heated to 110°F (43°C), divided

1 package (8 g) active dry yeast

2 tsp (8 g) Redpath® Granulated Sugar

5 ½ cups (660 g) bread our

1 ½ tsp (9 g) salt

¼ cup (60 ml) olive oil, divided, plus more for oiling the bowl

For the topping:

¼ cup (60 ml) olive oil, divided

100 g (½ large) red onion, thinly sliced

400 g (2 medium) rm bosc pears, cored and cut into ⅜ inch (1 cm) slices

¼ cup (54 g) Redpath® Golden Yellow Sugar, packed

1 cup (60 g) grated parmesan cheese

1 tbsp (5 g) chopped fresh rosemary

1 tbsp (3 g) chopped fresh sage

½ tsp (2 g) ground pepper

½ tsp (2 g) coarse sea salt

Preparing the dough:

1. In a small bowl whisk together ¼ cup (60 millilitres) of the water, yeast and Redpath® Granulated Sugar. Rest for 10 minutes, until foamy.

2. Place the our and salt in the bowl of stand mixer tted with the paddle attachment.

3. Mix on low speed for 1 minute. Add the remaining water, yeast mixture and 1 tablespoon (15 millilitres) of olive oil on top of the our. Mix on low speed until dough comes together.

4. Switch to the dough hook and increase speed to medium-low, scraping down the sides of the bowl as necessary, until dough is smooth and elastic; about 7 minutes.

5. Grease a large bowl with olive oil. Transfer the dough to the bowl and turn to coat with oil. Cover bowl with plastic wrap and allow to rise until doubled; 1 hour and 15 minutes.

6. Oil a 18 x 13 inch (46 x 33 centimetre) rimmed baking sheet pan with 3 tablespoons (45 millilitres) of olive oil.

7. Gently press down on the dough to release any gas and turn into the prepared pan.

8. Pat dough out so it reaches the edges of the pan.

9. Cover with plastic wrap and allow to rise again, until doubled; 1 hour. Preheat oven to 400°F (200°C).

Preparing the topping:

1. In a large nonstick skillet, heat 1 tablespoon (15 millilitres) of olive oil. Add the onions and sauté until golden. Remove from skillet and set aside.

2. Add the pears to the same pan and cook on one side until lightly browned, about 2 minutes. Flip and sprinkle in the Redpath® Golden Yellow Sugar. Cook, ipping pears occasionally, until the sugar is melted and bubbling; 3 minutes. Remove from heat and set aside.

1. Press deep indents all over the dough. Drizzle with remaining 3 tablespoons (45 millilitres) of olive oil.

2. Place the pears evenly over the dough.

3. Sprinkle with the onions, rosemary, sage and cheese.

4. Sprinkle with pepper and coarse sea salt.

5. Bake until golden brown; 25 to 30 minutes.

6. Remove and cool in the pan for 10 minutes.

7. Transfer warm focaccia to a cutting board. Cut into squares - we cut ours into 3 x 4 inch (7.5 x 10 centimetre) portions. Focaccia is best served the day it is made. Visit RedpathSolutions.com

see how we can can help you fulfill your needs.

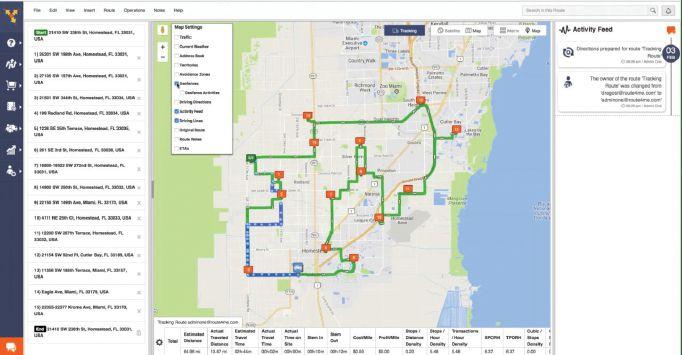

Global route optimization network, Route4Me reported that with cities under lock-down, restaurants or bakeries offering deliveries are experiencing faster delivery times. Founders George Shchegolev and Dan Khasis knew the pain of driving through a city they were partially familiar with, only to find there were parking restrictions or had multiple orders in various parts of town. They founded Route4Me as a way to help bakeries in a pandemic; if there’s only one car and multiple requests, this program can help small companies stay safe and fulfill multiple orders. They do say that this product may not be best for bakeries or caterers with less than twenty orders a day, but it could be an investment for a growing food industry company. Many bakeries may not want to hire a driver or use online delivery apps such as UberEats or Foodora.

Bakers Journal spoke with Route4Me co-founder George Shchegolev about the

Co-founder George Shchegolev of Route4Me.

Logistics can be complex during the best of times; a pandemic makes deliveries more complex.

app and how it can help bakers create a friction-free route.

“A lot of bakers may want to explore delivering directly to people because people don’t want to leave to go to the bakery.” Route4Me was inspired when the two co-founders were driving about their city themselves, and found existing routing and logistics software either incompatible or incorrect. “The beauty is, if you’re starting a delivery business today, and you just have very few stops you could do it practically for very little money. As you scale up and you have more complexity and more things that you want to do, you can do it. And then if you get to thousands of vehicles and thousands of things, we can still support yours.”

The app integrates with Google Maps and navigation apps such as Waze. “What we do is we tell you what is the most optimal way to visit all the locations, and in what sequence. When you get on the road, you can use an app like Google Maps, Waze or Apple Maps,” he explained.

“The way the app works is that depending on the business complexity, you may have a set of destinations you need to visit, but you have the right to park between a set time or a situation, or where you need to deliver something before they close. With our system, you can put all of this into our form, and we’ll give you a route that’s going to give you the most optimal way to locations,” he added.

“Depending on the size of your bakery, you can automate the process very heavily where you can just do it simply. As the orders come in, you input them into the system. If you have one vehicle, you just optimize and it gives you the best route. If you have multiple vehicles, we can solve that problem too.”

The app allows for both recurring orders and dynamic ones for first time orders. Route4Me uses Zoom for onboarding for training and is available in Canada. /BJ

Total time: 20 minutes

Preparation time: 15 min

Cooking time: 5 min

Yield: 2-3 pizzas

INGREDIENTS:

• 500 grams of pizza dough

• 400 grams of fine tomato sauce

• 10 fresh basil leaves

• 100 grams mozzarella cheese

• 1 tablespoon of extra virgin olive oil

• 150 gr of champignon mushrooms

• 80 gr of olives

• 3 eggs

• 120 gr of cooked ham

• 60 gr of artichoke hearts in oil

• 3 grams of fine sea salt

• 1 tablespoon of extra virgin olive oil

DIRECTIONS/COOKING INSTRUCTIONS:

1. Pre-heat the pizza stone on an electric hob (maximum power) or on a gas hob (medium heat) or directly in the oven (240°C / 500°F). The Pizza Stone must be pre-heated for at least 15 minutes.

2. Divide the dough into 2 or 3 equal balls.

3. Roll out one ball of dough on a floured work surface with a flour covered rolling pin applying light pressure.

4. While kneading the dough, cut out the circle of pizza using the Lagostina Pizza cutter.

5. Season the tomato sauce with salt, oil and basil.

6. Ladle sauce onto prepared dough, starting from the middle and working out in circles. Top with shredded mozzarella, finely chopped champignon mushrooms, olives, raw egg, pieces of cooked ham and artichokes in oil.

7. Move the pizza on preheated pizza stone.

8. Bake the pizza in the pre-heated oven at 220°C/425°F for about 5 minutes. The pizza is ready when the topping is golden and bubbling and the dough along the edge is nice and crisp.

9. Cut pizza into wedges.

10. Enjoy.

BY JANE DUMMER,

Natural flavours and colours are having a moment in the bakery industry.

Consumers are becoming more concerned about the long-term health effects of artificial ingredients and additives in food products. This has resulted in the clean label movement. The trend towards natural flavours in baking industry has increased because of this change in consumer demand. As a result, the flavour industry is shifting towards making more natural options available to bakers across North America.

Starting out with natural flavours in a formulation or recipe is different than switching from artificial to natural.

}Mel Mann, Director of Flavor Innovation at Wixon explains, “There are four main considerations when switching to natural flavours. They include intensity of flavour, profile of flavour, consistency of flavour and ultimately the cost. Artificial flavours survive the heat process better, whereas, natural flavours can be less stable and may lose some intensity, requiring more to be used in the formula. Also, the shelf-life of a natural flavour may be shorter than its artificial counterpart. Mann recommends, “Bakers should test products to understand how a switch to natural will affect their product’s flavour throughout the baking process and its shelf-life.”

most popular format, followed by non-GMO and organic. Both nostalgic flavour profiles and fantasy flavour profiles are popular. Forté can mimic these profiles in all three formats. Examples of fantasy flavours are cookie dough and blue raspberry. They are profiles that do not exist in nature; however, we can create these using natural flavouring ingredients. Our most popular nostalgic flavour requests are caramel, butterscotch and maple.”

“When it comes to sourcing natural flavours, the raw materials or molecules in natural form may be difficult to find.” — Miguel-Angel Escareno, Senior Flavorist, Foodarom.

The high cost involved in the production of natural flavours is the major consideration. Stacey Hawley, Co-Founder of Forté Flavors agrees, “Artificial flavours are typically less expensive than natural flavours, so making the switch means increased ingredient costs. Plus, packaging plays a role in flavour stability, therefore, that is an additional factor to consider. However, Hawley identifies, “Natural flavours continue to be our

Natural flavours are manufactured from a variety of plants, fruits, vegetables, roots, and minerals. Miguel-Angel Escareno, Senior Flavorist at Foodarom identifies, “When it comes to sourcing natural flavours, the raw materials or molecules in natural form may be difficult to find. Also, there are strict labeling regulations surrounding natural flavours at the industrial level. This is to provide transparency of the source. Plus, you might have non-GMO, dietary restriction like gluten-free, religion restrictions like kosher or halal, organic certification, or organic compliant which are other obstacles to face as the flavorist or flavour designers moving from artificial into the natural field. However, Escareno remains very optimistic that natural flavours are here to stay not just in North America but globally.

As a general flavour trend in baking, we’re seeing a resurgence in nostalgic flavours. Escareno agrees “Over the past three years they have received many requests for nostalgic, fantasy and

fruit itself has very little taste or aroma; consumers have become accustom to a blueberry taste that can sometimes only be achieved by adding a blueberry flavour. As a significant number of consumers have gained interest towards purchasing clean label products, this has propelled the demand for natural flavours. The industry is evolving and growing to meet this market need. However challenging, it continues to work with bakers to create customized natural flavour profiles that compete well with their artificial equivalents. Continued interest in baked goods with exotic or global flavours is next on the list for these talented flavour companies to supply stable, robust, natural flavour profiles to their key clients in the baking industry. / BJ

Jane Dummer, RD, known as the Pod to Plate Food Consultant, collaborates and partners with the food and nutrition industry across North America. www. janedummer.com