TIFIED

CERTI F I É PASAF

March 19, 2013

Dear fellow chicken farmers,

Today, Agriculture and Agri-Food Canada awarded Chicken Farmers of Canada with full federal, provincial and territorial government recognition for our On-Farm Food Safety Assurance Program (OFFSAP). This was no small feat and you can be proud that we are the first in Canada to achieve this level of government recognition.

I would like to congratulate the Chicken Farmers of Canada for the successful implementation of this food safety program. By working together to improve the management of food safety risks at the farm level, we are strengthening Canada’s food safety system. – Gerry Ritz, Minister of Agriculture and Agri-Food

This is a major milestone for Chicken Farmers of Canada and the result of years of hard work by us all. This achievement, and the program itself, demonstrates our commitment to meeting the expectations of consumers for safe, quality, Canadian chicken. Your ongoing dedication to OFFSAP will help us write another exciting chapter in our homegrown success story.

Sincerely,

Dave Janzen, Chair

Emergency Planning Large animal veterinarians and municipalities don’t plan for livestock emergencies

Karen Dallimore

understanding of your obligations is fundamental to being a good employer

FROM THE EDITOR

BY LIANNE APPLEBY

Go On, Ask Us to Prove It

Regardless of how you feel about it, your role as a producer of food has changed since your grandfather was farming. No longer are you simply trusted to produce safe chicken, eggs and turkey; now, you’re expected to prove it. Whereas 50 years ago, “agvocacy” wasn’t really necessary because most people were intimately connected with agriculture, today’s shoppers are typically two or more generations removed from the land. So, as a farmer in 2013, it’s your professional duty to help debunk myths about the sector.

If you’re not reading something in the mainstream media that makes your blood boil, you’re probably overhearing uninformed conversations about the safety of food and suddenly finding yourself “on duty.” Regrettably, I recently witnessed a hair stylist orate to the impressionable mind in his chair. He was telling his client, quite seriously, that he buys only organic food because there are all sorts of things in meat, nowadays, even if it is from a real animal. None of it is regulated, did you know? And in Europe they’re making horses into burgers!

There really was only one thing that I could do – that we all could have done. In situations like these, we stop the cynic right there and find ourselves doing a live, unplugged version of Agriculture 101 – the rendition that we reserve for when the uninformed have the bad luck of casting aspersions in our presence. We take the time to explain reality, and while we won’t wholly convert the oblivious offender, we may make him think twice before serving up fallacies with the next cut-and-blow.

It’s an uphill battle to correct misinformation, but consumers are more concerned about their food than ever before. Gaining and retaining their confidence isn’t optional; it’s imperative. And the more proof we’re able to hold up regard-

ing what’s being done to ensure wholesome Canadian-produced food, the better.

The struggle to keep that public support, however, is now a lot easier for Canada’s chicken farmers. On March 19, The Honourable Gerry Ritz, Minister of Agriculture and Agri-Food Canada, announced that Chicken Farmers of Canada (CFC) has been awarded federal, provincial and territorial government recognition of its On-Farm Food Safety Assurance Program (OFFSAP).

The distinction has been a long time in coming and the convoluted timeline to get to this point only serves as proof that this is not some willy-nilly rubber-stamped program. Developing the system so that it is in line with Hazard Analysis and Critical Control Point (HACCP) principles, then submitting it for technical review to the Canadian Food Inspection Agency (CFIA), and having it implemented, audited and assessed, means that consumers can be assured that chicken farmers are serious about producing a safe, quality product.

It’s one thing to say you’re committed. But, as the longtime CFC mantra illustrates, chicken farmers can say what they’ll do, do what they say, and then prove it when challenged. It’s all in the certifications, the statistics – and the records.

So, when a Canadian chicken farmer overhears one of those ignorant diatribes, he or she can fight the good fight because they have OFFSAP backing them up. And that’s one more step towards sustaining confidence in Canadian chicken purchases at the grocery store level.

Congratulations, CFC. n

MAY 2013

Vol. 100, No. 5

Editor

Lianne Appleby – lappleby@annexweb.com

888-599-2228 ext. 266

Associate Editor

David Manly – dmanly@annexweb.com 888-599-2228 ext. 261

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Emily Sun

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation

e-mail: subscribe@canadianpoultrymag.com

Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2013 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

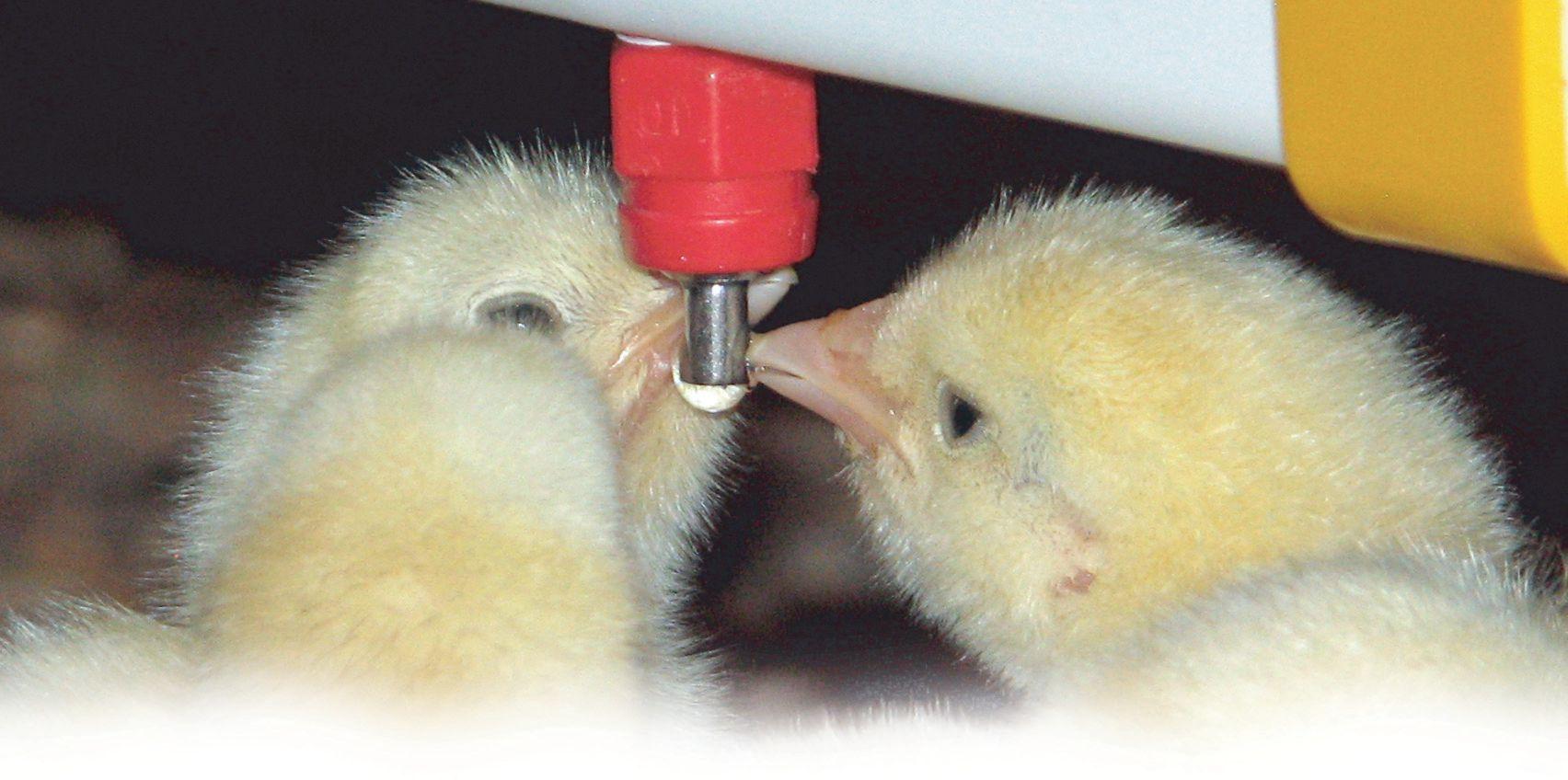

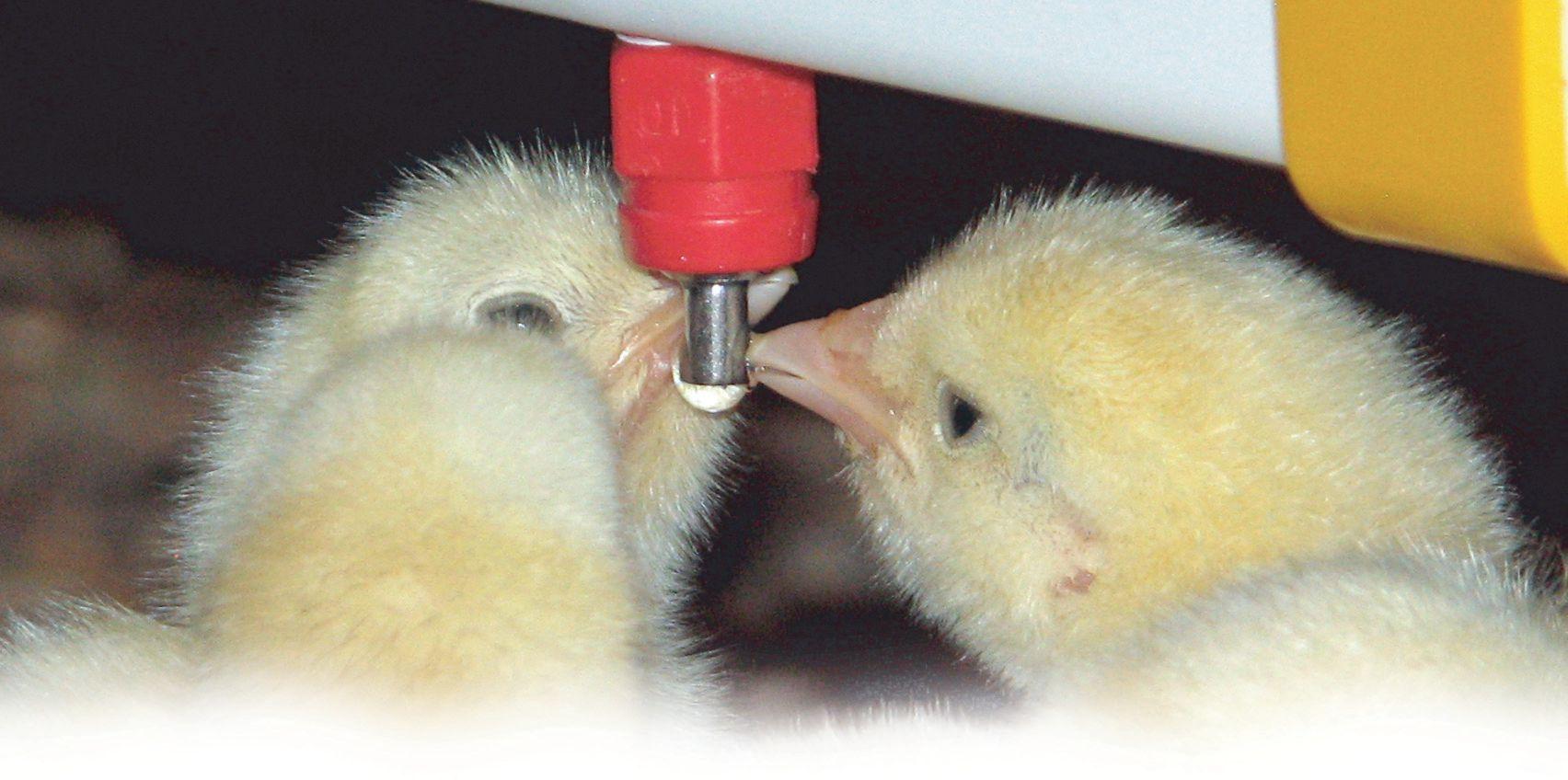

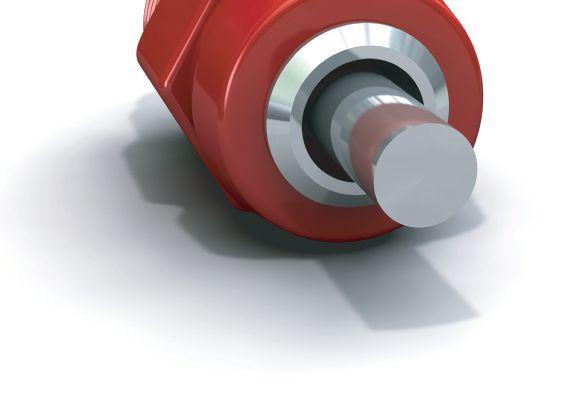

specktacular

Nothing says specktacular like OptiGROW!

Lubing's all-new OptiGROW Nipple is designed to work in today's challenging broiler environment. Because the nipple has been optimized for growth, you will be amazed by the first-week performance and explosive bird growth. OptiGROW offers:

Large body and pin

Acid resistant design

Easy triggering for day-old birds

Low mortality

Increased side-action flow

Larger flow range for jumbo birds

Increased weight gains

Improved feed conversions

To find out more about OptiGROW and it’s outstanding performance, please contact your local Lubing Representative.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

H5 Avian Influenza in Models WHAT’S HATCHING HATCHING

A Vaccine Blocks

new vaccine has proven highly effective against the lethal H5N1 avian influenza virus when tested in both mice and ferrets. It can also be used against the H9 subtype.

The research is published in the Journal of Virology. The new vaccine uses attenuated, rather than “killed” viruses (killed viruses are broken apart with chemicals or heat, and they are used because they are safer than attenuated viruses). Killed virus vaccines against avian influenza are injected into the bloodstream, whereas this vaccine is administered via nasal spray, thus mimicking the natural infection process and stimulating a stronger immune response.

The danger of current

attenuated virus vaccines is that they might exchange dangerous genetic material with garden variety influenza viruses that strike annually, potentially creating a mutation that allows a lethal but very hard to transmit influenza virus, such as H5, to be easily transmissible.

The study authors, led by Daniel Perez of the University of Maryland, came up with an ingenious design to mitigate the risk of the virus exchanging genetic material with other viruses. Influenza viruses carry their genetic material in eight “segments,” explains coauthor and University of Maryland colleague Troy Sutton, and when viruses reassort, they exchange segments. However, each segment is unique and all eight are needed, therefore the viruses are unfit if they contain more than eight segments.

The vaccine is based on an

attenuated version of the H9 virus, with an H5 gene added into one of the H9 virus’ segments, to confer immunity to the H5 virus.

The World Health Organization (WHO) recognizes avian influenza subtypes H5, H7, and H9 as potential pandemic viruses, because they all have in rare instances infected humans, and because they circulate in wild birds. Single reassortants could be sufficient to breach the species barrier, and since they do not circulate among humans, we lack any immunity. Moreover, H5 is unusually lethal, having killed roughly half of those few it is confirmed to infect.

A copy of the manuscript can be found online at http:// bit.ly/asmtip0313d. The paper is scheduled for formal publication in the second May 2013 issue of the Journal of Virology.

EFO Accepting New Quota Pool Applications

• Be a permanent resident of Ontario;

Egg Farmers of Ontario (EFO) is once again giving individuals an opportunity to become Ontario’s newest egg farmer by applying to the 2013 New Entrant Quota Loan Pool (NEQLP). Applications are being accepted until May 31, 2013.

“We are once again pleased to offer this opportunity,” said EFO chair Scott Graham. “This program has been wellreceived the past two years and we look forward to welcoming another egg farmer into the industry.”

To be eligible for EFO’s 2013 New Entrant Quota Loan Pool, an applicant must:

• Be a Canadian citizen or landed immigrant;

Outstanding Ontario Farmers

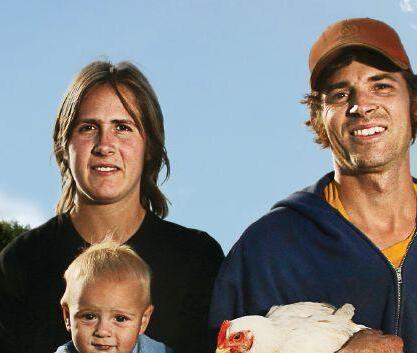

Dana and Adam Thatcher, of Thatchers’ Farms in Rockwood have received the top honour at the Outstanding Young Farmers awards ceremony held in Guelph.

Nominated by Ontario Farm Fresh, the Thatchers went from being a struggling hog farm in 2007 to a thriving 250 ewe sheep operation and farm gate retail shop featuring their own naturally-raised meats, including additive-free lamb, beef, pork and chicken. In addition, they sell Omega-3 eggs, honey and more.

In the spring of 2012, thanks to a grant from the Ontario Cattleman’s

• Not have held quota, currently or in the past, of any type in the supply-managed sector (egg, pullet, chicken, turkey, dairy or hatching eggs);

• Successful applicants will be required to purchase quota to match the quota loan, based on a 1:2 ratio;

• Priority will be given to persons between the ages of 18 and 45.

“We again encourage all prospective candidates to submit an application for this program. It’s an ideal way for potential egg farmers to join this exceptional industry.” said Graham.

Applicants who meet the above criteria will be reviewed by a selection committee comprised of well-respected and knowledgeable industry representatives and EFO will act as a resource for the committee. Committee members are selected by EFO and may include:

• An accountant;

• A financial representative;

• An OMAFRA staff person;

• A non-director egg farmer;

• A representative from the Junior Farmers Association of Ontario.

To apply, interested individuals must complete and submit an application form (available through EFO or at www. getcracking.ca/news.asp) along with a $113.00 non-refundable fee. Applicants are encouraged to submit a Business Plan with their application.

Association, they added an on-site butcher shop, which ensured they had complete quality assurance and control.

In the future, the Thatchers would like to bring people out to the family farm as a destination, making the connection between farming and the future.

Dana and Adam will now represent Ontario at the National competition being held in November in Regina,

Dr. Sandro Cerrate has been hired as a poultry nutritionist with Aviagen and will provide poultry nutrition advice to Aviagen customers. Cerrate received his PhD in poultry nutrition from the University of Arkansas in 2008, and has been the postdoctoral research associate in Poultry Nutrition at the University of Arkansas since 2009.

Bill Mitchell has been appointed by the Egg Farmers of Ontario as its new director of public affairs and will be responsible for all corporate communications, government relations and public affairs counsel. Mitchell spent 26 years in a similar government and media communications role with the Dairy Farmers of Ontario.

Saskatchewan, where they compete against other provincial winners for the 2013 “Canada’s Outstanding Young Farmers” title.

For 2014 nomination information, visit www.oyfontario.ca.

Dr. Cynthia Philippe is the new manager of veterinary services/QA for Hybrid Turkeys and ISA North America. Philippe comes from Maple Leaf Foods where she was responsible for quality assurance, biosecurity, animal welfare and veterinary services for 14 years.

The Thatchers have been named Ontario’s 2013 Outstanding Young Farmers.

BILL MITCHELL

DR. CYNTHIA PHILIPPE

DR. SANDRO CERRATE

WHAT’S

HATCHING HATCHING

CFA Reacts to Budget 2013

The Canadian Federation of Agriculture (CFA) welcomed several measures in the federal budget tabled recently that will help to promote the growth of the agriculture industry, but have some concerns.

“Overall, we are pleased to see Budget 2013 outline several important contributions essential to the growth of the sector – reaffirmation of the $3 billion in funding for Growing Forward 2 programs and

investments in research and innovation, in particular,” said CFA president, Ron Bonnett.

“However, CFA and its members have concerns around taxation barriers to new entrants in agriculture and small-scale farmers.”

For more information on CFA’s reaction to the 2013 budget, please visit http://www.agannex.com/ business-policy/cfa-reacts-tobudget-2013.

4-H Council Awards Volunteers

Six 4-H volunteer leaders across Canada were honoured for their dedication to local youth, recently, with the annual Co-operators/4-H National Volunteer Leader of the Year Award.

“The lives of countless young people in Canada have been greatly enriched over the last 100 years thanks to the dedicated 4-H leaders,” said Rob Black, president of the Canadian 4-H Council.

Each winner selected for the award receives a $100 gift and 4-H anniversary tumbler. In addition, one volunteer is recognized as the grand prize winner with a $1,000 prize, and a trip to the 4-H Canada AGM this month.

Maria Enright of Richmond, Que. (holding flowers), was the

MAY

May 7, 2013

Poultry Industry Council Research Day, Victoria Park East Golf Club, Guelph, Ont. Visit: www.poultryindustrycouncil.ca/

JUNE

June 16-18, 2013

CPEPC/CMC Convention, Fairmont Banff Springs Hotel, Banff, Alta. Visit: www.cpepc.ca

June 19-21, 2013

Canada’s Farm Progress Show, The Co-Operators Centre, Regina, Sask. For more information, visit: www.myfarmshow.com

JULY

July 21-25, 2013

Poultry Science Association (PSA) Annual Meeting, Town & Country Resort & Conference Center, San Diego, Calif. For more information, visit: www.poultryscience.org

grand prize winner of the 2012 Co-operators/4-H Volunteer Leader of the Year Award. With her in the photo are Quebec 4-H executives and the Richmond 4-H members who nominated her for the award: (left to right) Quebec executive director Lorelei Muller, Quebec VP Tiffany Nelson, Richmond member Leah Driver, Quebec executive member Emily Simms, Quebec president Mathieu Rouleau, Richmond president Andrew Boersen, and Richmond member Emma Redburn.

Also awarded as leaders were Cheryl Johnson, British Columbia; Tim Belec, Alberta; Brad Eggink, Ontario; Sheila Fanjoy, New Brunswick; and Alfreda Farish, Prince Edward Island.

SEPTEMBER

September 10-12, 2013

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont., N3Y 4N5; e-mail lappleby@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

Management

Emergency Planning

Veterinarians and municipalities underwhelmingly prepared

BY KAREN DALLIMORE

Producers are commonly asked if they are prepared to handle an emergency (such as a disease outbreak) on their farm. Now, farm animal veterinarians are being asked a similar question: how are they equipped to cope with a large-scale emergency in their region of practice? Coupled with this, are municipalities considering livestock in their community emergency response plans?

The answer may surprise you.

While data is still being collected, early reports from a survey being conducted by Dr. Cathy Furness, a graduate student at the Ontario Veterinary College, show that 72 per cent of large animal veterinarians have not considered emergency response planning.

What’s more, 75 per cent of those surveyed are not sufficiently prepared to maintain their own practices during an emergency.

Furness presented her preliminary findings at an Incident Commands System workshop funded jointly by the Ontario Ministry of Agriculture and Food and the University of Guelph, and hosted by the Ontario Livestock and Poultry Council. She reported that while veterinarians indicated an eagerness to participate in emergency response, many also voiced uncertainty regarding their role in an emergency response plan.

WHAT IS AN EMERGENCY?

Some emergencies are obvious, like heavy rains and snow or hurricanes such as Katrina or Sandy. Canada has its fair

Dr. Cathy Furness is studying the level of emergency preparedness among farm animal veterinarians and municipalities, and the stats do not look good.

share of weather events across the provinces, with Ontario having experienced tornados, snow, ice storms and power outages. Manitoba, Nova Scotia and New Brunswick also have their share of weather events; as well, flooding can be a major issue. And, all across the country, the risk of wildfires is ever-present.

Disease outbreaks such as avian influenza or foot and mouth disease also require large-scale response planning, but there are some emergencies that are not so obvious.

Furness asked: What about when a

border closes? Production doesn’t stop and those animals in the pipeline need to be dealt with.

She said that any situation where an animal cannot receive normal care is an emergency: A barn collapse or fire, an accident or injury of livestock caregivers, a truck accident or even an economic emergency where a producer simply cannot afford to feed their animals anymore - these are all situations that require an emergency plan of some sort.

“To me it’s all under emergency preparedness,” she said. “It’s an emergency

BE PREPARED

for that producer; it’s an emergency for the animal. If that animal’s not getting fed, that’s an emergency.”

WHO SHOULD TAKE THE LEAD?

The first 24 hours are the most critical time for emergency response, said Furness. “I feel it has to start with the producer. [If it’s not a road accident] they’re typically the first responders at the scene. They need to take the initiative. The government help will come, but it’s slower.”

A farmer’s plan needs to be tailored to their own needs. The best generic plan is useless if it doesn’t match their production requirements and resources. The plan needs to be designed for the hazards that are most likely to impact production, which will vary with individual farms.

Every farm should prepare and enact an emergency response plan that makes it clear to others what the farmer needs. How many animals are there? How many generators will you need to milk the cows? The river is rising: How many trucks will you need to evacuate the animals? Where will you take them? And so on.

Having answers to questions such as these will speed up the response process.

If help arrives to evacuate 10 cows and finds there are a couple of horses, a few pot-bellied pigs and a handful of pocket pets, the process can quickly get complicated and slow.

Involving your veterinarian in the process is helpful, whether in discussions about overall planning, biosecurity or humane euthanasia. But as Furness pointed out, when an emergency arises, the vet needs to ensure that they’ve got their own preparedness plan in place for their family, their animals and their business, or they won’t be able to help the farmer.

Commodity groups play an essential role as well, not only in communications, but also as a resource hub through providing education, not only in case of emergency but also throughout the year.

WHO GETS INVOLVED?

“Poultry is amazing,” said Furness, because of the strong biosecurity and response measures already in place.

While she hasn’t included the feather boards in her survey, she still encourages them to participate. Industry groups that have signed on for the survey so far include Ontario Pork and Alpaca Ontario. Furness is still in negotiations with other commodity groups and has reached some beef producers through the National Farmers’ Union. These groups have supported the research by distributing the survey to their members, and Ontario Pork has also become actively involved through initiatives surrounding humane euthanasia.

The Canadian Food Inspection Agency (CFIA) has emergency plans in place for foreign animal disease (FAD) outbreaks, for example, avian influenza, foot and mouth disease, and vesicular stomatitis in horses.

If the disease is not reportable, the plans become province-specific,

June 23, 2012 14th 2013

Management

Despite the lack of pre-planning on the part of municipalities, more and more first-responders are being trained on how to deal with road accidents involving farm animals.

and Furness points out that some provinces have more detailed plans in place than others. In Ontario, the Emergency Measures and Civil Protection Act governs the response. Once the situation escalates beyond the farm boundaries, it may require assistance from the municipality.

But if it reaches beyond the municipality, two more groups – the Ministry of Agriculture and Food and Emergency Management Ontario (EMO) – will provide advice and guidance. EMO responded to the 2003 SARS epidemic, for example, and the 2011 tornado in Ontario.

Municipalities have their own response plans in Ontario, and it is their job to carry them out unless they’re overwhelmed or the emergency encompasses multiple municipalities, said Furness. They are required by law to have a plan in place, but there is no requirement for livestock to be considered.

“Lots of agricultural municipalities recognize animal welfare is important, so they’re investigating the issue and how to cope with livestock,” said Furness. As it stands, many are unaware of livestock numbers in their jurisdiction, and many make the assumption that someone else will take the lead.

THE NEXT STEP

With the majority of data already in from veterinarians, Furness will focus on gathering and analyzing data from producers throughout the summer of 2013.

Her goal is to find out where emergency response planning is at before making suggestions for other plans with veterinarians, governments and emergency operations groups. As she said, this survey will lay the groundwork for what comes next.

Results will be confidentially shared with participating commodity groups, followed by the release of the abstract to a wider audience, from veterinarians to emergency responders. Full results are expected by the fall of 2013. n

Photo courtesy of Karen Dallimore

CPRC Update Fighting the Flu

The February 2011 issue of the CPRC update introduced a new avian influenza (AI) research program, initiated as part of the Poultry Science Cluster.* Since that time, scientists from across the country have been working collaboratively to answer the following questions about AI:

HOW DOES AI VIRUS ADAPT?

Certain subtypes of AI virus have moved beyond their natural reservoir of wild birds and have developed the ability to infect domestic poultry, sometimes with devastating results. To better understand the biological basis for this adaptation, Dr. Yohannes Berhane and his team at the

Canadian Food Inspection Agency (CFIA) are using modern molecular biology techniques to, in essence, tear apart and reassemble the viral genomes in different configurations in order to mimic mutations observed in the field. Many so-called “reassortment” AI viruses have been developed and characterized. These studies are revealing how the virus induces immune responses and causes disease in chickens.

HOW IS IT TRANSMITTED?

Avian influenza viruses are mainly transmitted by direct bird-to-bird contact and by contact with virus-contaminated materials; however, indirect contact or airborne transmission has been implicated

in a number of AI outbreaks. By studying aerosolized viruses in carefully controlled experiments in the lab, as well as under commercial conditions, Dr. Jiewen Guan’s lab, also at CFIA, has confirmed that infectious viruses can be transmitted to chickens from the air and from other chickens through indirect contact. The amount of virus required to cause infection through indirect contact is surprisingly small. The results of this research have important implications for how AI is spread.

HOW DOES THE CHICKEN REACT?

Dr. Shayan Sharif at the University of Guelph is the lead on research that continues to produce new information

CPRC Update

on chicken immune responses to AI virus infection and to a commercial vaccine (not approved for use in Canada). Dr. Sharif’s team has identified components of the virus that elicit the greatest immune responses and may, therefore, be suitable components to include in vaccines. A number of molecules that act as adjuvants (immune system boosters) have also been identified that could improve the efficacy of these vaccines.

IS VACCINATION A VIABLE STRATEGY?

One of the main goals of the overall research program is to develop a rational strategy to control AI infection in commercial poultry. Such a strategy may include vaccination. Dr. Éva Nagy and her team at the University of Guelph have developed a vaccine system, based on fowl adenovirus (FAdV), that can deliver

AI virus antigens to the bird, and that can be administered via injection in the egg pre-hatch, or given orally in feed or water. Dr. Sharif’s group developed a different type of vaccine, based on what is known as a virosome, which can elicit protective immune responses against AI virus.

Dr. Dele Ogunremi and his team of researchers at CFIA have been working with Drs. Nagy and Sharif to assess various administration routes for candidate vaccine systems. The plan is to build upon the foundation laid by this research and to develop a strategy that combines virosome and FAdV-based vaccines. These two vaccines should complement and synergize each other, leading to enhanced protection against infection.

Furthermore, several adjuvants will be screened for their ability to further enhance vaccine efficacy. Candidate vaccine formulations will be tested against a range of low pathogenicity or highly

pathogenic AI viruses using various routes of administration to determine which is most protective and practically feasible for the purpose of mass vaccination. It is expected that this research will lead to the creation of vaccine formulations that can mitigate the negative health effects of AI and control spread of the virus from vaccinated and infected birds.

*This research is part of the 2010-13 Poultry Science Cluster, which is supported by Agriculture and Agri-Food Canada as part of Growing Forward, a federal-provincial-territorial initiative. CPRC and a number of industry and government organizations also provided funding for this work.

For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ont., K1R 7S8. Phone: 613-566-5916, Fax: 613241-5999, e-mail: info@cp-rc.ca, or visit us at www.cp-rc.ca. n

A poorly ventilated barn is a main contributor to

bird stress and low bird weight. Our ventilation

Labour Healthy, Safe and Successful

Everyone wins when farmers understand and fulfil their obligations as employers

BY HEATHER WEST, FRESH COMMUNICATIONS

Poultry farmers understand and adhere to strict standards when it comes to food safety, but surprisingly, there are still many who don’t realize that they must also adhere to standards of health and safety.

The good news is that it isn’t because farmers don’t care, it is really just a case of many not realizing that, as “businesses,” they fall under the Occupational Health and Safety Act (OHSA) and, if they do know it, of being unsure where to begin. In fact, according to the Canadian Agricultural Safety Association (CASA), 85 per cent of producers believe safety is a priority on their farm, yet less than nine per cent of operators have a written agricultural safety plan.

At a recent presentation made to members of the Poultry Industry Council, Kristin Hoffman, a consultant with Workplace Safety and Prevention Services (WSPS), noted that many producers were surprised to learn the scope of their responsibilities under the OHSA. Many didn’t realize that they are considered “employers” and are responsible for the health and safety of workers who come to their farms.

In fact, the Ministry of Labour in Ontario defines an employer as a person who employs one or more workers or a person who contracts for the services of one or more workers.

Attendees of the workshop were lucky enough to be learning about this in a

All of your workers, regardless of whether or not they are new hires, should know about the processes, equipment and safety gear required for each task.

meeting room, but some haven’t been so fortunate.

In her presentation, Hoffman shared examples of those who were fined because they failed to fulfil their responsibilities as an employer. In the three examples that were shared, two workers were injured and one was killed on the job. The employers were convicted for a variety of offences, including failing to take reasonable precaution and failing to provide information, instruction and supervision, and fines ranged from $50,000 to $80,000.

Producers regularly work with outside service providers to manage the various stages of production, which can include delivery services, catching crews, pick-up and transport providers, and cleaning

services. In some cases, providers offer more than one of these services, but occasionally different providers are used for each step and farmers aren’t working with the same people every time.

“The producer and the service provider need to share in the responsibility of training these workers to be safe on the farm,” explained Hoffman. The service provider should be training their employees on the basics of health and safety, such as fall protection and equipment safety. However, every farm is different and it is up to the operator to orient new workers to the hazards and risks that exist in their workplace.”

In addition to providing clients with information about legislated responsibilities, Hoffman also offered some tips on where to start.

SAFETY FIRST

Photo courtesy of Chicken Farmers of Canada

Labour

UNDERSTAND YOUR RESPONSIBILITIES

Hoffman and other WSPS consultants are working with individual clients and attending events like this to continue spreading the word about the responsibilities of farm operators and how they can create healthy and safe workplaces. However, there are also many resources available online from associations such as WSPS, the Ministry of Labour, Chicken Farmers of Ontario and CASA.

ASSESS WORKPLACE HAZARDS AND RISKS

Physical conditions of the farm are very important. Take stock of all of the hazards and risks that exist in your operation including things like equipment, processes, chemicals, etc. Create a list and prioritize them.

START WITH SIGNIFICANT RISKS AND DOCUMENT SIMPLE STANDARDS

You don’t have to start from scratch. Chicken Farmers of Ontario offers a Safe Work Practices tool on its website, which includes information about job planning and safe work practices, specifically written for broiler chicken farmers.

DEVELOP A PLAN

There are many resources available to assist farm operators with developing a plan.

The Canada FarmSafe Plan, available from CASA, is an adaptable guide for producers to use in developing, implementing and establishing an effective farm and ranch safety plan. And, as the delivery agent for Ontario, WSPS offers the OntarioFarmSafe Plan, which can be downloaded from the website for only $49 (and includes additional resources and templates). This version features provincial legislation and compliance information.

TALK TO SERVICE PROVIDERS

Consider asking service providers about their health and safety policies and practices when negotiating contracts. Find out if they are providing the necessary training to ensure that workers have the required qualifications, skills and general safety knowledge to work safely. That way, you will be sure they understand the basics when you’re showing them how to work safely on your farm.

Continued on page 32

Industry Nurturing an Early Interest

News of poultry-related projects at some Canadian universities

BY TREENA HEIN

Interest in poultry is alive and well among students at the University of Guelph, whose Ontario Agricultural College (OAC) and Ontario Veterinary College (OVC) Poultry Clubs have both worked with the Poultry Industry Council (PIC) on projects since 2009. “These projects help the students develop links with industry, and in some cases earn credits toward their degrees,” says former PIC executive director Tim Nelson. “Industry, in turn, benefits from the new ideas that the students work on.”

For the 2013 school year, the clubs will have extra money for a joint project, thanks to the legacy of the late Bruce Hunter, OVC Professor Emeritus, who, sadly, passed away in 2011. Hunter was an avian disease expert who had a long-standing relationship with the poultry industry, and was working on biosecurity research for small flocks in a joint project with PIC and the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). The PIC decided to make some of what remained of Hunter’s research grant ($3,500) available to the two clubs for a project that would both honour and respect Hunter’s memory.

RECENT OAC PROJECTS

The OAC Poultry Club is made up of students who share an interest in poultry, whether enrolled in an agriculture-related program or not. The club is responsible for data collection, artificial insemination and genetic selection of the Shaver Heritage

STARTING YOUNG

The OAC Poultry Club poses with club advisor Gregoy Bedecarrats (centre, with envelope) and Leanne Cooley, vice-chair, PIC, and Special Events Committee chair, (behind Gregory to the left).

hens at the University of Guelph’s Arkell Research Station. They also tour poultry facilities such as hatcheries, research farms and grading stations, as well as hold events featuring guest speakers.

During the 2011 school year, the OAC club created an educational DVD to promote proper on-farm biosecurity measures in collaboration with PIC and OMAFRA.

“We placed an emphasis on pathogen transmission and prevention,” says club president, Jacob Pelissero. “Following completion, we did a formal presentation to industry at the PIC Poultry Innovations Conference in 2011.”

During the following school year, the club worked with the PIC on a Turkey Careers Project, an online pamphlet designed to educate students on job opportunities in the turkey industry. Members also started working with PIC to create a safety awareness campaign called 1000 Ways to Die on a Farm

“It will contrast potentially dangerous

farming procedures with the proper safety precautions and procedures,” Pelissero explains. “In a nutshell, we will produce a DVD and an interactive website that will also have a smartphone version.”

The students are helping to generate the idea story-boards and interview questions for veterinarians, producers and industry technicians, as well as provide some information that will be presented on the website. Some students may also help with the filming of the DVD in the spring/summer. The proposed completion date for the project is November 2013.

“As a part of a class and on our own time, we have a weekly meeting to brainstorm ideas and discuss plans for the video,” Pelissero says. “We’ll present a slide show of ideas to a focus group of industry and the project committee members in the spring. The focus group will also be able to provide us with feedback and input on the ideas.”

Many students are also working with

Industry

OAC club vice-president and graduate student, Kayla Price, on a coccidiosis project.

“It will educate producers about methods of control and biosecurity measures that can help manage coccidiosis in various production and housing systems,” explains Pelissero. “The initial brainstorming on this project will be performed by undergraduate, graduate and veterinary students as well as other industry members. We intend to make this project as informed and end-user centred as we can.”

The project topic for this year, which will be shared between the OAC and OVC Clubs using the new funding, has not yet been decided. It could be focused, Pelissero says, on biosecurity research/education, genetic research and improvements, or new technologies and animal welfare.

Beyond the University of Guelph in Ontario, the Production Animal Club at the University of Saskatchewan’s Western College of Veterinary Medicine recently held a poultry-related lab.

“Province of Saskatchewan Poultry Extension people brought in some daily mortalities so that students were able to perform necropsies and determine causes of death,” says Club spokesperson and vet student Tara Zachar. “It allowed students that have had no experience with poultry to get used to the differences in anatomy from that of mammalian species, and also allowed for more hands-on necropsy experience.”

Zachar is also in the midst of planning tours of a local hatchery and processing plant to try to further broaden the industry knowledge base of vet students. However, neither the University of Calgary’s Association of Veterinary Students’ Production Animal Health Club nor the University of Prince Edward Island vet school’s clubs currently have any activities related to poultry in the works. n

FOR MORE INFORMATION

• Educational DVD on farm biosecurity measures: www.poultryindustrycouncil.ca/2012/06/04/biosecurityvideo-of-the-month/

• Turkey Career Project: http://poultrycareers.ca

Disinfection Foot Mat

Keeps your premises free of contamination

Reasons to use Disinfection Foot Mat:

Universal applicator for use with di erent disinfectants

E cient use of disinfectant – (min 75% less disinfectant than standard foot baths)

Ultimate solution for indoors & outdoors in all poultry farms, hatcheries and poultry processing premises

Non-splashing of disinfectant solution

Withstands heavy loads

www.atescoindustrialhygiene.com

E-mail: info@atescoindustrialhygiene.com

Tel: (604) 496 2004

Technology Smart Walls

A new technology may save farmers a lot of money

BY DAVID MANLY

In a cold-climate country like Canada, keeping your poultry barn heated is essential, not only to your flock, but also to all the other systems involved in keeping your birds happy and healthy. However, heating your barn can also be very expensive, especially when chicks are first placed in the large area and don’t quite utilize all the space that is available to them.

The Smart Air Wall, developed by the European company Sidijk (www.sidijk. com), can reduce overall heating costs associated with your barn by using an inflatable barrier to temporarily reduce square-footage. This can help lessen not only energy costs, but also the time and effort spent cleaning and walking the barn.

The wall is made of the same plastic used for children’s inflatable bouncing castles in parks and playgrounds, but simply takes a different shape. Sidijk is so reputable in the inflatable plastics business that the company has been retained to install the safety air rails for speed skating in Sochi, Russia, for the upcoming Olympic Games, according to Dave Loerchner, a sales representative for Smart Air Wall.

Loerchner spoke at a Poultry Industry Council event late last year about the possible benefits of the Smart Air Wall system for poultry producers. He began by saying that the wall is simply designed to minimize the amount of barn floor space needed for the chicks, thereby limiting the amount of heat and light needed to operate the whole barn.

“The whole idea of this is to condense your barn for approximately the first two

LESS IS MORE

By using the Smart Air Wall system, you can save up to 60 per cent of your heating costs, says Dave Loerchner, a sales representative for Smart Air Wall.

weeks of your flock, when you are usually heating the whole barn to keep the chicks on the floor warm,” he said. “If you move them all up to the front 40 to 50 per cent of your barn . . . it reduces your heating costs by up to 50 to 60 per cent, but will vary slightly from barn to barn.”

The double-lined plastic wall uses a standard 1.1-kilowatt fan on 220 volts to fill it with air, which acts as insulation between the two separated parts of the barn. And because it is plastic, Loerchner adds, it will fit perfectly along the floor and ceiling to make sure that no air (or errant chicks) will get through. In addition, there are flexible holes for feed and water lines that can be adjusted with no risk of air escaping.

While the initial cost can be high, he says that thanks to the cost savings on

the heating bill, the Smart Air Wall can pay for itself within a few years.

There are a total of five barns currently using the system: three in Holland, one in Germany and one in Ontario.

Jon Steenbeek, who owns and operates the only Smart Air Wall system in Canada at his Ontario farm just south of Varna, has been using it since his first flock was placed in early 2012. According to Loerchner, Steenbeek used 42,081 litres of propane to heat his barn in one year.

But, with the Smart Air Wall system, Steenbeek only used 18,588 – a savings of almost 60 per cent – or over $10,000, based on a propane price of $0.45 per litre.

“That’s pretty significant dollar savings for only having the wall up for the first two weeks of the flock,” he says. n

Summer’s here and at Vétoquinol we know your livestock welfare is important. For this reason, we offer you highly soluble solutions to provide them with optimal hydration during heat stress.

Ask your local retailer for our Electrolytes brochure.

Recognition Food Safety Excellence

A program developed for farmers, by farmers

BY TREENA HEIN

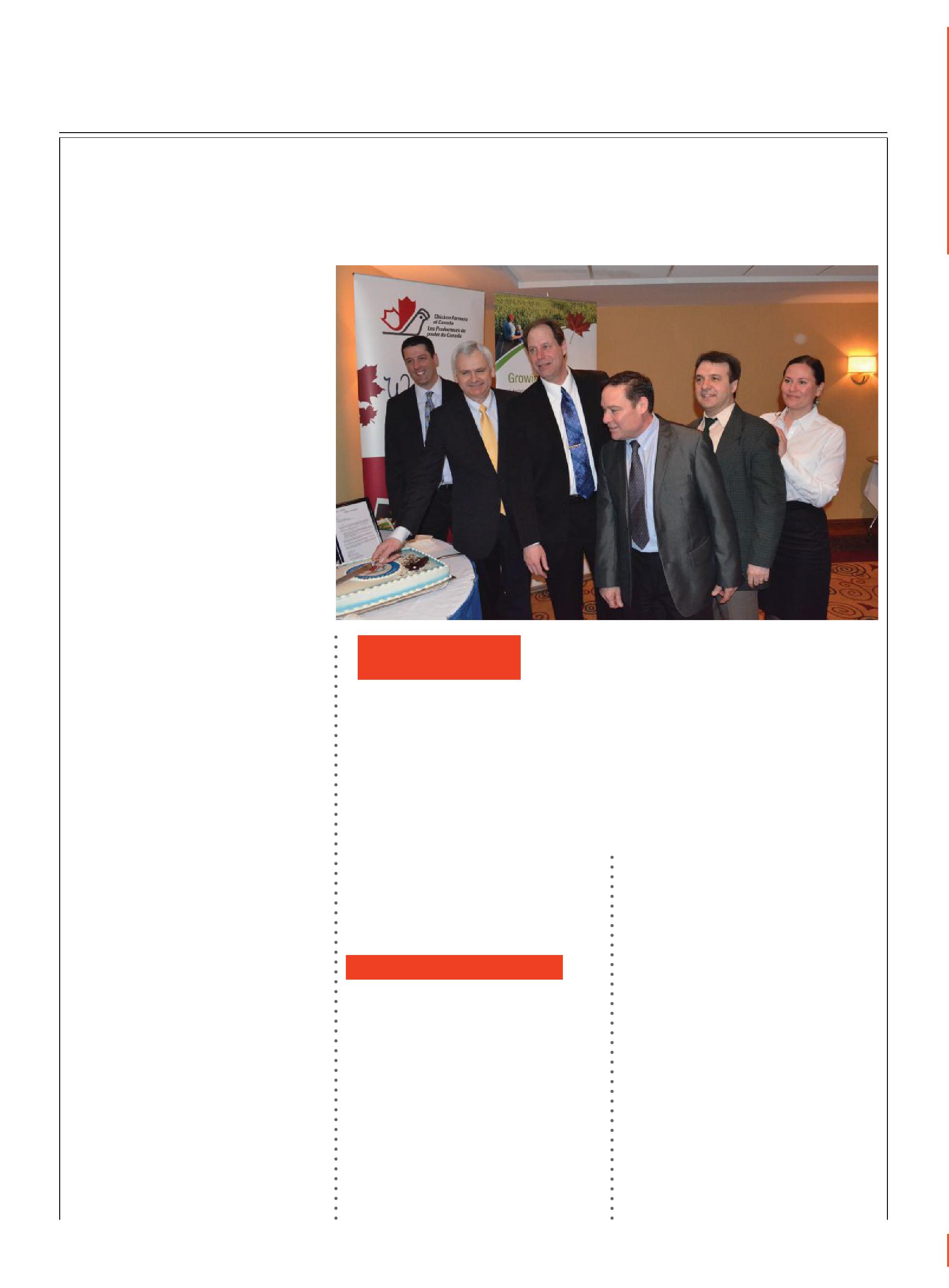

Attendees of the Chicken Farmers of Canada (CFC) Annual General Meeting, which was held in midMarch, took a break to celebrate a milestone achievement.

With about 150 in attendance and a cake-cutting ceremony, CFC became the first commodity organization in Canada to be recognized by Agriculture and Agri-food Canada (AAFC) for effective and consistent implementation of its On-Farm Food Safety Assurance Program (OFFSAP). Funding for the development of this program was provided under AAFC’s Canadian Integrated Food Safety Initiative

Thanks to committee work 17 years ago, which studied other industry food safety programs and adapted aspects of them into the current framework, followed by pilot testing, incorporation of feedback and industry-wide education, CFC was able to realize a mandatory enforcement of OFFSAP in each province from coast to coast.

“Chicken farmers know that this [achievement] was a long time in coming, but it was well worth it,” says Adrian Rehorst, an Ontario chicken farmer who also serves as CFC’s first-vice chair and chair of the CFC Consumer Relations Committee. Rehorst has been a board member of Chicken Farmers of Ontario since 2005.

“When you think that we can now say we are producing what is probably the safest chicken on the planet, all the hard work along the way was very much worth it,” he notes.

“On the Consumer Relations Committee, the theme that we are working with is that we require the confidence

CELEBRATING A MILESTONE

Pictured (left to right): Steve Leech, national program manager for CFC; Dave Janzen, chair of CFC; Martin Firth, CFIA, inspection systems (food safety), manager; Tim Mellor, CFIA, OFFS Recognition, Ontario area coordinator; Iliyan Staykov, CFIA, Inspection Systems (Food Safety), senior policy analyst; and Caroline Wilson, CFC, on-farm food safety co-ordinator.

of consumers, and this milestone will help us maintain that confidence. This recognition is the highest standard possible to achieve.”

A LONG ROAD

The Canadian Food Inspection Agency (CFIA) facilitated development of OFFSAP through its own On-Farm Food Safety Recognition Program (OFFSRP), an initiative that asks national food industry organizations to create food safety systems that are in line with Hazard Analysis Critical Control Points (HACCP). CFIA states that for any industry program to be recognized through OFFSRP, each organization must assess its food safety practices against the current HACCP principles. The finished

program is then submitted to the CFIA for technical review, and the program must be implemented, audited and assessed before the CFIA grants the recognition.

Ontario was the first province to make OFFSAP mandatory, and is Canada’s largest chicken-producing province, with 1,026 farmers who collectively add approximately $2.39 million to Canada’s Gross Domestic Product (GDP).

In its Annual Report, CFC states that on a national level, Canada has 2,682 chicken farmers and 185 processors, which collectively support over 23,500 direct jobs and almost 56,000 total jobs, and which add $6.5 billion to Canada’s GDP. As well, the CFC states that 96 per cent of Canadian chicken farmers currently are OFFSAP-certified.

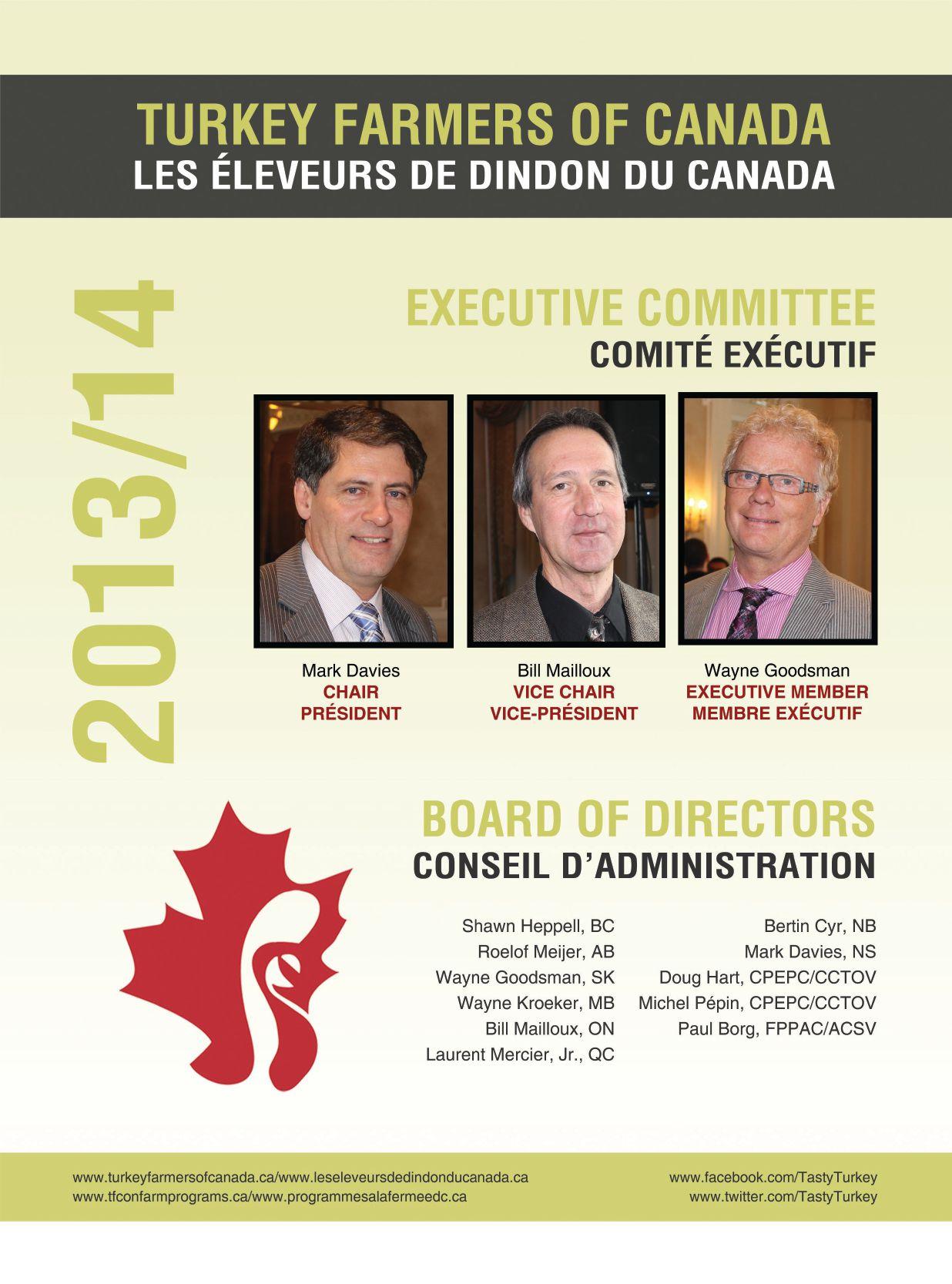

2013 Chicken Farmers of Canada

EXECUTIVE COMMITTEE

Dave Janzen

Dave Janzen, re-elected as the Chair of CFC, has represented British Columbia at CFC since 2006 and was named Chair in 2012. His family farm in Abbotsford is right next door to the Fraser Valley dairy farm where he grew up.

Adrian Rehorst, from Teeswater, Ontario, was re-elected as the 1st Vice-Chair for 2013. His family farm is about 20 km from Lake Huron and he represents the farmers of that area, Region 1, on the Ontario chicken board.

Martin Dufresne

Adrian Rehorst

Martin Dufresne, representing the province of Quebec, was re-elected to the position of 2nd Vice-Chair. Martin and his family farm near St. Félix-de-Valois and they produce approximately 1.7 million kilograms of chicken per year on the farm started by his father in 1954.

Yvon Cyr, re-elected as the Member at Large, has been a chicken farmer since 1987. He produces approximately 3.3 million kg of chicken each year on his farm near Saint-François-de-Madawaska in New Brunswick.

Yvon Cyr

“Long hours. It’s what we do.”

Recognition

A JOURNEY BEGINS

As a poultry farmer, you know that hard work and care for the farm today will ensure that it will be there for tomorrow. You also know that a helping hand can make it more profitable.

The Alltech on farm program is designed to help you along the way. Contact us and see what we can do…. together.

CFC initially started the OFFSAP development process back in 1997 with an eightmember committee that began to put together a definitive instructional manual that would lay out the new program from start to finish, says Marty Brett, CFC senior communications officer.

“This committee became the Food Safety Committee and continued to work on OFFSAP while studying programs used by other commodities,” he notes. “The program was tested in 1998 using farms in Alberta, Ontario, Quebec, Nova Scotia and New Brunswick. It was then rolled out to all farmers and the final touches were put on it in 1999. The program was developed for farmers, by farmers.”

CFC’s OFFSAP was the first commodity program in Canada to receive CFIA Phase I technical recognition in 2002, and the second commodity program to receive CFIA Phase 2 technical recognition of its management system in 2006.

BRINGING THE BEST

At the farm level, OFFSAP brought a heightened awareness to biosecurity on the farm, says Murray Opsteen, a broiler producer near Flamborough, Ont. “We were already doing many of the standard operating procedures required under the program, but during the process of implementation, we took a closer look and it focused us on the food safety reasons behind why we do them,” he says.

“We were already doing best practices such as regular water sampling, and now added documenting of those activities. Overall, minor changes were made but the biggest change between before and after having OFFSAP in place was the documentation.”

“All of this work goes a long way to maintaining our hard-earned consumer trust,” said CFC Chair Dave Janzen at the CFC AGM in mid-March. “[With this recognition in place], no one has to take our word for it anymore – we can prove that we are delivering on consumer expectations for safe, quality, Canadian food.

Recognition

Gerry Ritz, Minister of Agriculture and Agri-Food Canada, and Dave Janzen, CFC chair, pose with the official Letter of Recognition issued by the Government of Canada.

“We are great farmers, we have a great product, and we’re starting to let more and more people know about it,” Janzen continued.

“Through our branding strategy, people will be able to see that their chicken contributes to a healthier diet for themselves and their families. Through our public relations strategy, people will be able to see that their chicken farmers contribute to Canada and make a real difference when it comes to the Canadian economy. Both these things tell people that we’re important and that we work hard to deliver. I believe we are, and we do.”

“My request to you, and to all chicken farmers, is to reflect and think about how we can come together and continue this fantastic success story that is the Canadian chicken industry,” he said. n

UNEQUALLED VERSATILITY

The only telehandler designed and built to outperform the tractor and the loader Increase of your productivity by 20% to 50%

Best fuel economy of the industry

Cab as low as 5’9’’ (P25.6 L)

Merlo: undisputed worldwide leader in telehandlers

mERLo IN cANADA: from coast to coast!

QUEBEc manulift

Quebec City, (418) 651-5441

Varennes, (450) 652-5550

Garage Émile Larochelle Inc.

Saint-Isidore, (418) 882-5654

Équipements R.m. Nadeau

Sherbrooke, (819) 846-6828

Les Entreprises

Antonio Laporte & Fils Inc.

Notre-Dame-des-Prairies, (450) 756-1779

centre Kubota des Laurentides

Mirabel, (450) 434-0000

Location Blais

Rouyn-Noranda, (819) 797-9292

mANIToBA

Bobcat of central manitoba Ltd. Winnipeg, (204) 633-1058

oNTARIo manulift

Burlington, (905) 315-8881

corbeil Equipment Ltd.

Curran, (613) 673-5184

Hutchinson Farm Supply Inc.

Stouffville, (905) 640-2692

Delta Power Equipment

Essex, (519) 776-7374

Exeter, (519) 235-2121

Forest, (519) 786-5335

Watford, (519) 849-2744

Stoltz Sales and Service

Listowel, (519) 291-2151

Mildmay, (519) 367-2672

Elmira, (519) 669-1561

GJ’s Farm Equipment Inc.

Burgessville, (519) 424-9374

Anderson Equipment Sales Belleville, (613) 969-6246

SASKATcHEWAN E. Bourassa & Sons

Assiniboia, (306) 642-3826

Estevan, (306) 634-9444

Pangman, (306) 442-2033

Radville, (306) 869-2277

Weyburn, (306) 842-6626

meadow Power & Equipment Ltd.

Meadow Lake, (306) 236-4455

ALBERTA manulift

Langdon, (403) 936-8668

PANORAMIC

Management Using Plan ‘T’

A comparison of tunnel versus cross ventilation

BY SHAWN CONLEY, WEEDEN ENVIRONMENTS

It’s time to look at Plan B. Things aren’t working the way they used to anymore. Everything has changed – from climate to equipment to the birds we grow. The website Berkeley Earth (http://berkeleyearth.lbl.gov/ regions/canada) calculates that Canadian temperatures are trending upwards, close to an increase of nearly 7°C per century and they are accelerating.

According to the National Chicken Council, average live weight of chickens has increased by 12 per cent in the last 10 years, and the National Turkey Federation states that the average live weight of turkeys has increased by almost 12.5 per cent. During this time, we have also pushed densities into the 10 lb./ft.2 (50 kg/m2) range.

Along with these changes, housing and equipment options have evolved as well. Growers on the leading edge of the poultry business have adopted these new technologies along the way, some proactively but most reactively. On the broiler side in the southern United States, free range gave way to confined curtainsided buildings and solid sidewall crossventilated, then to tunnelled barns that required foggers to get to the next level.

Foggers then became the backup cooling method to cooling pads, but the latest trend is adding sprinklers to supplement cool pads or completely replacing cool pads to keep humidity and water consumption low. This has spread as temperatures rise, since birds get bigger and growers see positive results.

This trend is not limited to chicken. Turkey production has followed the same path, but resisted the changes, mainly due to producers insisting that turkeys

many benefits, all of which can positively affect your bottom line.

were too different from chickens to benefit in the same way. But, often 10 to 15 years behind, the turkey growers have grudgingly made incremental changes to improve performance. Many turkey growers in North America have now made the jump to solid-side or curtain-

side tunnelled buildings, adding sprinklers or foggers for cooling. Considering how much things have changed, maybe it’s time more of us started looking at these options, and not dismissing them as something that would never work for “our birds.”

Tunnel ventilation has

MASS AIR MOVEMENT

Management

THE DIFFERENCE

Tunnel ventilation differs significantly from that found in typical curtain-sided natural ventilation and typical cross-ventilated chicken barns. The average bird is producing 11 BTU/hr of heat per kilogram of body weight. There are only two ways a bird can release heat on its own – through respiration (72 per cent) or by releasing it to the air (28 per cent). Reduced feed consumption, combined with burning calories through excessive panting can be costly. All the way back in 1968, Siegel and Drury1 showed that at 85°F, taking wind speeds to 300 feet per minute or higher reduced panting rates from 150 per minute to approximately 20 – a nearly 85 per cent reduction. Additionally, Simmons, Lott and May2 showed that 600 feet per minute is the optimal air speed to take advantage of both cooling methods, but for a Canadian climate, 500 might be a more realistic target.

These results clearly show that tunnelling a barn does have benefits over natural or cross-ventilation, which simply cannot provide the air speed. We’ve built our cross systems based on air exchanges between 50 and 60 seconds, which means we have an average air speed somewhere in the neighbourhood of 50 to 70 feet per minute. If we’re lucky and are able to drive all of the air to the floor, we may see numbers close to 100. This cannot

possibly create the wind chill factor of 6-8°F that tunnel barns can create.

With natural ventilation, it’s obvious that we are at the mercy of the winds, unless we install a hefty circulation fan system or move to tunnel. A 60 x 500 feet turkey finishing barn would require 25 fans at 48 inches to accomplish what eleven large tunnel fans can. Not only is the initial setup cost similar, but also the power consumption for the circulation fans is nearly double that of the tunnel fans (17 kilowatt-hours versus 10 kilowatt-hours). And the actual wind speeds at bird level will still only be around 150 feet per minute.

Although this article is geared toward summer ventilation, it is important to realize that winter ventilation can be controlled more easily in a tightly sealed solid-sided barn. Adding ceiling inlets to a building with curtains that allow 40,000 cubic feet of air per minute (CFM) to pass through cracks and drop to the floor will not improve litter conditions, heater run times or bird health as much as expected, because there will still be a large amount of air entering before the inlets even begin to open. And that is not even touching the topic of light control with regard to bird behaviour such as picking and aggression, but I have received anecdotal feedback from those with solid-sided tunnel barns that this has been less of an issue. The option for a natural/tunnel combo should not necessarily be ruled out, as some people have had success with this in turkey grow-outs.

Wind chill is also a very important part of the equation when switching to tunnel ventilation, as is the management of tunnel levels. Additionally, air speed is the basis for CFM numbers when configuring and running the system. If we want to target 500 feet per minute, we need to figure out the crosssectional area (width x average ceiling height) of the barn and multiply by the target feet per minute (500), and then divide that result by 85 per cent (expected fan efficiency).

For example, in a 40 x 400 foot building with a 10-foot ceiling, the calculation would be 40 x 10 = 400 feet2, multiplied by 500 feet per minute to get 200,000 cubic feet per minute. Then, after you divide by 85 per cent, your end result would be 235,000 CFM. To meet that, you would need eight 30,000 CFM 54-inch fans.

You could also transition from minimum ventilation around 65,000 CFM (5 CFM/ft2), keeping in mind tunnel ventilation should start around 8°F above the target temperature. At that point, the ideal wind speed should be up to about 300 FPM, with the levels at 2°F intervals, then initiating supplemental cooling methods when fans are maxed out. One detail that can’t be overlooked is static pressure: expect to see static pressure levels in the range of 0.02 to 0.06 inches of water column at the inlet end and 0.08 to 0.12 at the fan end.

SUPPLEMENTAL COOLING

evaporation much more effectively than we can with cross or natural ventilation.

Using fog or mist in a tunnel building will provide better conditions than other ventilation methods, but adding as little water as possible with a sprinkler system is an ideal way to go in all barns. Foggers can reduce the temperature significantly on dry days, but on humid days and evenings, they can be a detriment by further raising humidity. Although tunnel barns move air at the highest air speeds, birds tend to sit and therefore insulate themselves against the floor. Sprinklers can use much less water than foggers and misters, as well as motivate these birds to stand, thereby allowing more air to move around them.

Tunnel ventilation can also greatly improve performance in both turkeys and chickens. In separate studies by Czarick3 and Yahav4, both species gained at least five per cent more weight when going from air speeds below 200 feet per minute to speeds over 400 at 85°F.

With all the other pressures on birds, including increasingly shorter growing times, increased live weight, lower feed conversions and high placement density, we need to do all we can to relieve the heat stress on the birds. There is no more effective way to accomplish this than by using tunnel ventilation – it is worth the time to do your own research on the method, as well as consult with professionals and other growers in the industry who use it. n

REFERENCES

1 Siegel, H. S., and Drury, L. N., 1968. Physiological responses of chickens to variations in air temperature and velocity. Poultry Science 47, 1120-1127.

2 Lott, B.D., Simmons, J. D. and May, J.D., 1998. Air velocity and high temperature effects on broiler performance. Poultry Science 77, 391-393

3 Lacy, M. P., and M. Czarick, 1991. Performance of broilers in tunnel-ventilated houses during warm weather. Poultry Science, 70 (Suppl. 1):168

4 Yahav, S. et al., 2001. Air velocity alters broiler performance under harsh environmental conditions. Poultry Science 80, 724-726.

•

•

SELECT DOSER

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

Cooling System

•

•

RECIRCULATION FANS

circular Recirculation Unit

• 16” and 20” diameters

• 3600 coverage using directional wind vanes

• Superb alternative to race tracking

• With Multifan or Performa+ Leeson motors circulating fan

• 12” – 24” diameters • Polyethelyne housing

• with Multifan or Performa+ Leeson motors

Genius picture Ge-430

• Genius 430LS Livestock climate control

• User friendly Interface (hot Keys)

• Large Display Screen for easy viewing

• Up to four variable stages and 30 off/on relays

• Expandable to 50 relays with relay module

• Up to 12 temperature sensors , one Humidity sensor

• Up to 12 heat zones, 12 cool stages, 2 light programs

• Up to 5 water metering, 2- 0-10volt outputs for dampers

• can operate Dual, natural and tunnel ventilation

• “Solarwall boost”, outdoor, humidity over-ride logic

Poultryhouse Fan

• High quality material and aerodynamic air inlet

• Variable speed Performa+ motor

• Dual voltage, fully enclosed motor

• Low energy consumption and noise level

• 16” and 20” models producing 2792 and 4770 cfm

• Includes hanging hardware

PSI

• Total stainless steel construction

• Hi-Low switch

• Watertight enclosures

• Propane and natural gas

• Available in 40,000 to 225,000 BTU units

• Available in pilot or spark Unvented Unit Heater

RECOV-AIRE HEAT EXCHANGERS

• Recovers wasted heat from exhaust and transfers to incoming

20 off/on • New Genius Dimmable Light control

New feed Bin monitoring control

New Genius 420LS control system – larger screen and capacity

72” fan

• Heavy Duty fiberglass housing

• Heavy Duty 6 blade alum. Propeller

• Twin gates Size A belts with Auto tensioner

• 3 hp , single or 3 phase motor

• Optional cone for max air flow

LIGHt traP/ Dark OUt

• High light reduction

• Low resistance to air flow

• Simple Installation

• Easy to clean

• Uses P.V.c. snap release spacers

Continued from page 17

SHOW AND TELL

It’s important to spend time with new workers arriving on the farm to make sure they know about the processes and equipment that they’ll be working with. Take the time to walk them around the area in which they’ll be working, as well as tell them what you expect. Health and safety should be managed with the same rigour that goes into every other facet of the business.

“Really, farm operators are well equipped to manage this responsibility. Collaborating on the health and safety of workers is no different than collaborating with food manufacturers on the health and safety of the flock. It’s really just a matter of understanding responsibilities, making the commitment and developing a plan that makes sense for your farming operation,” said Hoffman.

ABOUT WORKPLACE SAFETY AND PREVENTION SERVICES

WSPS provides industry-specific health and safety products, training and consulting services to 154,000 businesses and 3.8 million employees in Ontario’s agricultural, manufacturing and service sectors.

As one of four health and safety associations operating under the Health and Safety Ontario banner, WSPS is a trusted advisor to businesses, large and small, seeking to boost productivity and profitability by reaching zero work-related injuries, illnesses and fatalities.

For more information on farm safety and links to downloadable resources, visit www.healthandsafetyontario.ca or contact WSPS at 1-877-494-9777. n

THE BACK PAGE

BY ROY MAXWELL

Trade Talks and Media Attacks

In the spring of 1989, I glanced at a job ad in The Globe and Mail for a communications person, and then I saw the word chicken. The Ontario Chicken Producers’ Marketing Board (OCPMB) was looking for someone to “raise the profile and improve the image of the OCPMB.” I applied, got the job, and spent the next 16 years explaining, defending and promoting supply management in the poultry industry.

There was a reason supply management suddenly wanted communications people, and the reason was trade. The Uruguay round of the General Agreement on Tariffs and Trade (GATT) was heating up and the media were asking a lot of questions. The Board realized that the days of quietly going about the business of producing food in supply management were coming to an end. There would soon be a lot of noise about “orderly marketing” and the outcome of the GATT negotiations was poised to change everything.

With the stroke of a pen, the GATT agreement was signed and Article XI, which provided the ability to control imports on a quantitative basis, was dead. We could no longer close the door to imports when predetermined market access levels were reached.

Under the new rules, the door was to stay open, but tariffs could be used beyond that point to prevent destruction of supply management and the industry. Media organizations rarely mention the fact that high tariffs aren’t used until a tremendous amount of product has already entered the country, essentially tariff-free. They also neglect to mention that both the quantity of tariff-free imports and the level of tariffs beyond that point were negotiated. They were not just invented and implemented, but were agreed to.

because the issue was no longer about supply management. Instead, it was now about “irresponsible journalism.” After all, if the Globe insisted on repeating what we felt were factual errors about supply management, why should we trust anything else in that publication?

How we would know if it was true or not? Thus, we requested a meeting with the Globe’s editorial board.

Thorsell stated in a letter that our accusation about irresponsible journalism was a very serious charge. I wrote back, agreed with him, and asked when we could meet. That finally did it. There was no response and the Globe stopped writing about supply management for a good two years.

For the past couple of years, I have been monitoring the media for Dairy Farmers of Ontario. As you well know, media attacks have been vicious and relentless, often including words such as “price-fixing” and “racketeering.”

Unfortunately, these attacks can also be a problem for government because journalists often link government support to political weakness. That’s why it is important for poultry and dairy farmers to continue meeting with their elected members, whether provincial or federal, and show their support or frustration. Some have submitted letters to editors or written opinion pieces in response to the barrage of attacks on supply management.

Media attacks on supply management have been vicious and relentless...

In the midst of all the negative and critical comments, there have been other articles and reports that treat the trade and supply management story with respect and fairness. Those people tend to be reporters, not columnists.

There is nothing new about columnists in the media attacking marketing boards. Do you remember the series of Globe and Mail columns in the early 1990s, written by Terence Corcoran before he moved to the National Post? He liked to begin his attacks with “moo, moo, cluck, cluck.”

As a columnist, he was free to express his opinions, but the trouble was he based many of his opinions on things that we at the marketing board felt were untrue.

So, we sent a letter to the editor-in-chief, William Thorsell,

After reading hundreds of stories, there is one comment I heard on television that I would like to share in case you missed it. The comment was made by one of the most outspoken critics of supply management when he was talking about writing columns and being a commentator.

On June 6, 2012, while being interviewed by CBC’s George Stroumboulopoulos, the National Post’s Andrew Coyne said, “My job is a fraud. Let’s be frank, right? I’m supposed to be this instant expert on every subject under the sun. So, it is always a bit of a high-wire act . . . So, yes, there is always an element of fraud in this.”

How refreshing is that? I say, take heart and take action. n