BY DON HORNE

BY DON HORNE

Ithink I’ve finally recovered from CONEXPO… but I digress.

We have a couple of associations that are marking anniversaries: the Specialized Carriers & Rigging Association (SC&RA) celebrating 75 years and the Crane Rental Association of Canada (CRAC) a quarter century.

Both are looking back and looking forward, reflecting on the good work they have done and what still needs to be done to ensure that the crane and hoist industry remains competitive, safe and above all efficient.

One of the major initiatives coming from the CRAC is the first-of-its-kind, nation-wide study of the industry itself.

Ambitions for the study are high indeed, aiming to gather insights for use by crane rental companies, as well as to collect meaningful and timely data that may be used to inform advocacy efforts on behalf of the sector.

Ideally, the study will be used to develop a profile of the crane rental industry that will help the association better understand the sector’s employment structure and fleet composition.

The ambitions are simple for CRAC: to better serve and better represent the crane industry.

“We need to demonstrate our presence and our impact. This survey is the first step taken in achieving this goal,” says Ryan Long, Chair of the Membership Committee.

Adding to this input is CRAC’s annual conference in Vancouver, B.C. in May, where crane rental companies, owners, manufacturers, and suppliers gather to hear about the latest trends and technologies.

All part of “looking forward” that I mentioned earlier.

Trevor Eckert, the Chairman of the Board of CRAC, took the time to explain to me how the association is reflecting on its 25 years and what it is planning to do in the next quarter century.

“Today we are 134 member companies strong, the highest it has been in our history. We have a voice, and it grows stronger every day,” Eckert told Crane & Hoist magazine ( look in the magazine for our interview with him).

In the article, he lays out the good work being done by the Diversity & Inclusion and the Technical committees that ensure fairness, working to improve regulations to provide a more safe and secure jobsite.

Eckert tells one great story from those who have worked in the crane industry for years, of a young Art Blumers, who shared with him a story from his youth many years ago, remembering the first time he tried to navigate a crane up a series of mats several feet high, earning a few grey hairs in the process.

SC&RA’s annual conference in April turned into a celebration, as members gathered to mark 75 years as an association.

Here are a few words from members past and present:

“It’s a story of growth to me,” says Jim Vitez, President of Kreitz Motor Express, KMX International. “More people joining over the years, more talent coming in.”

“To me, 75 years starts with relationships – across all levels,” says Randy Server, Executive Vice President of PSC Crane & Rigging. “Without them, nothing else gets done… The doers, the volunteers that make SC&RA what it is today – the generational businesses that feed into that legacy.”

“It comes down to relevance,” says Dan Bumby, retired, an SC&RA Golden Achievement winner. “So, when the association advocates for all of us as an organization, we gain credibility, and ultimately, relevance –which feeds the longevity.”

There will be one more chance to gather again to reminisce and look forward to another 75 years at the Crane & Rigging Workshop in Oklahoma City, Okla. Sept. 26-28.

I look forward to seeing you there.

Speaking of anniversaries, Crane & Hoist Canada magazine will be 15 years young next year, and we’d love to share your stories once again from over the years.

If you have a copy of the magazine, an article we’ve done on you or a favourite story you would like to see again, drop me a line at dhorne@annexbusinessmedia.com.

We want to make 2024 a special year for us, and hope that you can help us out to make it so.

Don Horne

VOLUME 14, ISSUE 3 | MAY/JUNE 2023

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | DON HORNE dhorne@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | KRISTINE DEOKARAN kdeokaran@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Emily Newton

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

PRESIDENT/COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X

Publications Mail Agreement #PM40065710

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2023 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: June 30, 2023

Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: July 5, 2023. For writers’ guidelines and submission requirements get in touch with the editor, Don Horne, at dhorne@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER:

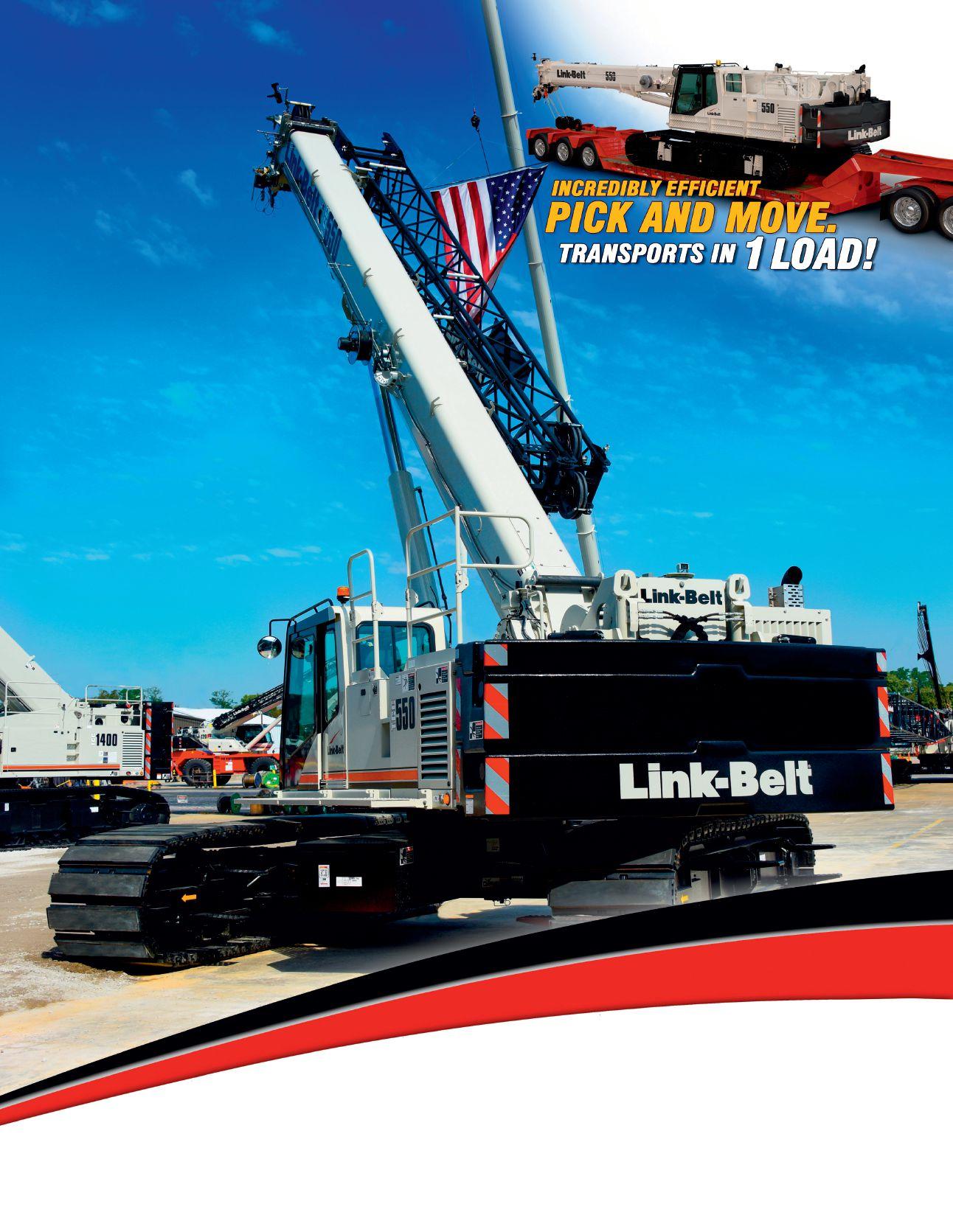

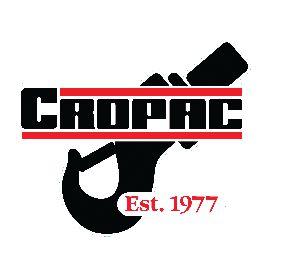

With the market for rough terrain (RT) cranes continuing to boom, the ALL Family of Companies is adding nine more to its rental fleet.

“These cranes are ideal for general construction where there’s great need for work with concrete and rebar. They can easily fold up, come off outriggers, and move onto other tasks quickly and efficiently,” said Chad Rados, project coordinator for ALL.

The new RTs from Tadano range in capacities from 35 tons to 80 tons. Included in the package are two 35-ton GR-350XL, four 55-ton GR-550XL, and three 80-ton GR-800XL-4.

These much-used utility players for construction sites are all two-axle machines for maximum maneuverability and efficiency. The five-section, full-power telescoping booms enable ease of set-up that makes each unit ideal for performing multiple tasks from end-to-end of a job site. Maximum boom lengths start at 101.7 feet for the 35-ton units, go up to 113.9 feet for the 55-ton, and 154.2 feet for the 80-ton cranes.

Their independent front and rear steering enables these cranes to get up close in confined spaces, making them popular for plant outage work as well.

“We expect the high demand for RTs to continue, and these will be welcome additions to the fleet,” said Rados. “These units will have no problem finding work shortly after we take delivery.”

The nine cranes will be strategically deployed across the ALL Family’s 33 North American branches.

Terex Cranes is separating tower cranes and rough terrain cranes into two entities: Terex Tower Cranes and Terex Rough Terrain Cranes.

The reorganization includes independent leaders and brand identities as well as expansion of manufacturing capacity, including a brand-new facility to manufacture self-erecting cranes. Terex Tower Cranes and Terex Rough Terrain Cranes will sit within the lifting category of Terex Materials Processing’s equipment portfolio.

Each new brand now has its own general manager with independent growth strategy to expand each product portfolio and find new distribution partners globally while enhancing support for the existing network.

Hutton Strader has been named the new Product Manager for all terrain cranes throughout the Americas for Tadano America Corporation.

“We’re looking forward to leveraging Hutton’s prior experience and expertise to really help grow the all terrain business. He will be working directly with Tadano’s Regional Business Managers and distributor sales teams to grow their knowledge of what we have to offer,” says Lance Rydbom, Tadano Director of Product Management and Engineering.

Strader will focus on supporting the Pan American customers and sales teams with product knowledge and technical expertise for Tadano all terrain products. He will also work closely with the factory teams in Germany to answer customers’ questions and represent the needs of the Pan American market in the new product development projects.

“Having worked with all terrain cranes for over 20 years, this position provides a unique opportunity to help develop products that really fit the needs and wants of our diverse customers,” says Strader, who holds a mechanical engineering degree from Virginia Polytechnic Institute and served as a Business Development Specialist at ALL Family of Companies prior to Tadano.

While there was a lot going at CONEXPO in Las Vegas, Nev., there was a lot of other activity going on to shape the future of cranes and lifting devices.

“It was a pleasure connecting with our members at CONEXPO, the largest construction trade show in North America,” states Claire Bélanger-Parker, the Executive Director of the Crane Rental Association of Canada (CRAC), adding that the massive construction show coincided with the International Crane Stakeholders Assembly meeting.

Attended by CRAC’s Trevor Eckert, Chair of the Board, Paul Walchuk, Chair of the Technical Committee and Bélanger-Parker, they met alongside representatives from Europe (ESTA), Australia (CICA) and the U.S. (SC&RA) to discuss common issues impacting the industry, agreeing to collaborate on the preparation of a white paper on the technical assessment of the machinery directive, “concerning cranes and lifting devices near energized power lines and the revision of three existing guidance manuals,” states Bélanger-Parker.

Queen’s Park announced that it is preparing young people for in-demand and well-paying careers by allowing students in grade 11 to transition to a full-time, skilled trades apprenticeship program.

“These changes provide students with exciting pathways to good-paying jobs and rewarding careers and support our government’s ongoing work to attract more young people into the skilled trades,” said Premier Doug Ford. “Whether it’s enhancing trades education in our schools, breaking down barriers for newcomers or upskilling workers, we’re leaving no stone unturned to train the skilled workforce that will build Ontario.”

Upon receiving their Certificate of Apprenticeship, they can apply for their

Cropac Equipment Inc.

Cropac carries a wide range of equipment:

• Boom Trucks

• Tower Cranes

• Forklifts & Telescopic Handlers

• Crawler Cranes

• Rough Terrain Cranes and much more!

SINCE 1977, CROPAC EQUIPMENT HAS BEEN COMMITTED TO PROVIDING QUALITY EQUIPMENT, PARTS, AND CUSTOMER SERVICE ACROSS CANADA. Cropac has branches in: ONTARIO - QUEBEC - ALBERTA - B.C.

Ontario Secondary School Diploma as mature students. At a time when the province continues to face historic labour shortages, this change means that more students will be able to enter the trades faster than ever before to help build Ontario.

In the construction sector alone, 72,000 new workers are needed by 2027 to fill open positions because of retirements and expected job growth. To help deliver the province’s infrastructure plans, including building 1.5 million homes by 2031, more people are needed in the skilled trades.

“For far too long, parents and students have been told the only path to succeed in life is by going to university, which is simply not true,” said Monte McNaughton, Minister of Labour, Immigration, Training and Skills Development. “When you have a career in the skilled trades, you have a career for life. Our government will continue to provide students with the tools they need to land well-paying and life-long careers.”

Following its December 2022 delivery to A.W. Leil Cranes and Equipment, the first Grove GMK6400-1 to arrive in Canada has sparked a revival in fortune for the Nova Scotia-based rental services provider.

Due to fleet capacity constraints, the company had been excluded from many opportunities in its market — particularly in providing maintenance services to the dozens of wind turbines it had erected during the last wind construction boom in the early 2000s.

“Our largest crane was 400 USt, which usually left us just shy of being able to service larger wind towers, so we recognized there was a need to upsize,” said Ryan Long, A.W.

Leil’s president. “We were initially looking at 500-650 USt machines, but once we started doing careful comparisons, plotting out every tiny detail in a spreadsheet, the GMK6400-1 kept shining through.”

There are nearly 600,000 construction workers in Ontario, but only one in 10 are women, so Queen’s Park is working to make washrooms on construction sites private, clean and safe. These changes, if approved, would make the skilled trades more accessible to women by ensuring they have access to at least one women’s-only washroom on jobsites and properly fitting equipment such

as uniforms, boots and safety harnesses.

“Access to a washroom is a basic human dignity and something every worker should have the right to,” said Monte McNaughton, Minister of Labour, Immigration, Training and Skills Development. “Careers in construction offer six-figure salaries with pensions and benefits, and it is an injustice only 10 per cent of them are filled by women. Under the leadership of Premier Ford, our government will continue to stand with these heroes. Everyone has the right to a safe and welcoming workplace.”

The government is further improving portable washrooms by requiring them to be private and completely enclosed, have adequate lighting and hand sanitizer (where running water is not reasonably possible). Additionally, the government is doubling the number of toilets on most jobsites.

“Workplaces that are safer and more equitable help increase women’s participation in the workforce,” said Charmaine Williams, Associate Minister of Women’s Social and Economic Opportunity. “Our government is taking action to remove barriers and empower women to excel in sectors where they are underrepresented – because when women succeed, Ontario succeeds.”

These regulatory amendments are part of a comprehensive strategy to meet labour demand, bring better jobs and bigger paycheques within reach for more people, and attract and equip people to thrive in today’s world of work.

Linamar Corporation’s Skyjack was celebrated by Crime Stoppers Guelph Wellington (CSGW) as the 2022 Cornerstone Award Winner. Incorporated in 1988, CSGW is a non-profit charitable organization that coordinates the efforts of the media, the community and the police in promoting awareness and education, making the community safer.

“We’re thrilled to be named the 2022 Cornerstone Award Winner,” said Malcolm Early, Vice President of Marketing at Skyjack. “We were more than happy to get involved with this initiative. We look to get involved in community events like this not just from a support point of view, but also to get employees at Skyjack engaged whether it be on the day or a benefit from the program itself.”

A corporate partner of the organization, Skyjack hosts the annual Guelph Shredding Event at their Woodlawn Road plant, also covering the costs associated with the shredding service. In addition to fundraising, the event helps prevent identity theft and allows personal and business documents to be professional shredded. Skyjack’s central location, ample space and high visibility made for an ideal drive-thru shredding location.

“This is a true partnership that has grown from its initial concept of a stable place to conduct an awareness, crime prevention and fundraiser with Skyjack,” said Dave Elloway, Vice Chair of CSGW Board of Directors. “Skyjack has embraced the concept of preventing identity theft for itself as an organization and has encouraged staff to get behind the concept of protecting themselves and their families. Skyjack has become more than just a location for an annual event, they have embraced the opportunity to contribute to community safety.”

Announced during Crime Stoppers Month, the Cornerstone Award is presented annually to a business organization or individual who demonstrates outstanding support to their community through CSGW.

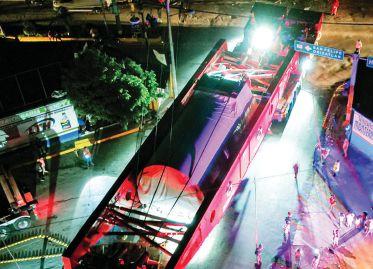

The massive earthquake near the border between southern Turkiye and Syria that killed more than 50,000 people has spurred one company to help with the donation of a crane.

According to a statement from Tadano, “the devastating consequences of this earthquake have caused great consternation at Tadano. We would like to express our heartfelt sympathy to those affected by the disaster and our appreciation to all those who are working hard for recovery and reconstruction.”

The company is donating an ATF 50G-3 all terrain crane to the Turkish government to help in the ongoing recovery and reconstruction efforts in the affected areas of the Turkyie-Syria earthquake. The crane will be delivered through ENKA Pazarlama Ihracat Ithalat A.Ş., a distributor of Tadano products and services based in Istanbul, Turkyie.

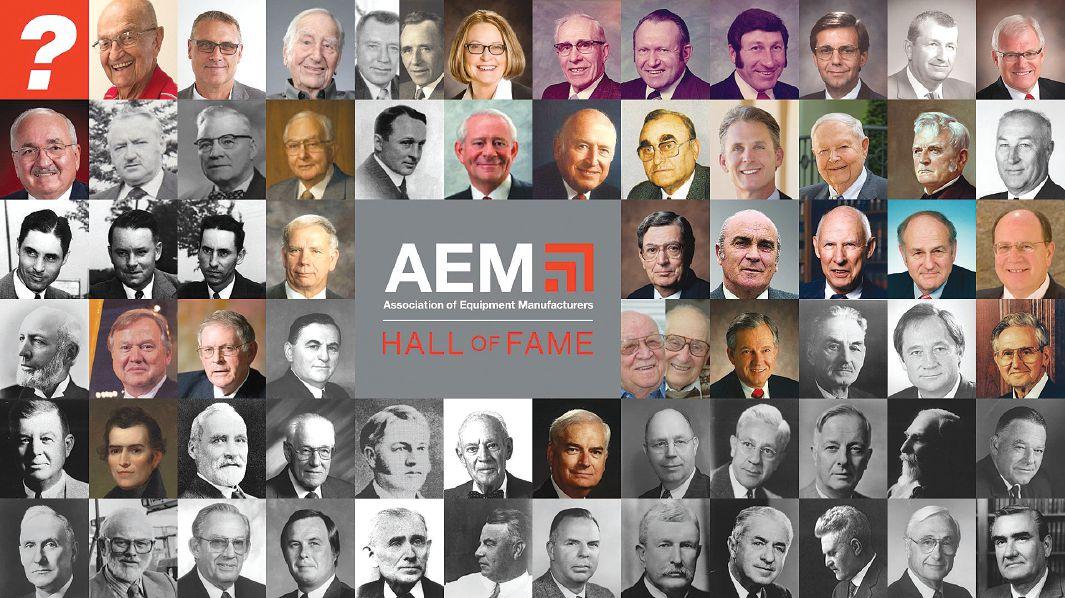

Time is running out to nominate a manufacturer for 2023

By Don Horne

Do you know of an equipment manufacturer deserving of a Hall of Fame nomination?

The Association of Equipment Manufacturers’ (AEM) Hall of Fame celebrates the men and women who create the equipment and technologies that build, feed, and power

our world – people like John D. West, the former Chairman, CEO & President of The Manitowoc Company, who was inducted in 2014; and Dr. Hans Liebherr, founder of Liebherr Company, who was inducted in 2010.

“When you look at the members of the AEM Hall of Fame, it’s clear none of them

“When you look at the members of the AEM Hall of Fame, it’s clear none of them would be there without including the people around them, on both a professional and personal level.”

would be there without including the people around them, on both a professional and personal level,” said AEM President Megan Tanel. “That’s why it’s important we include not only the innovators themselves, but also those that empowered the people and communities that made their success possible.”

You can nominate by going to this website: https://www.aem.org/about/hall-offame/nomination-form

Last year’s inductee Sherman Ward “Bud” Bushnell, founder of Genie, was recognized for the way he treated his people and built his teams, in addition to his products.

“Leading by example, putting the customer first and focusing on the team to make it happen has made us the company we are in

the last 55 years,” said Simon Meester, president of Genie, Inc. in support of Bushnell. “We have a lot of exciting products coming our way in the next 10 years and I would say Bud’s spirit are in all of them because they are all focused on addressing unique customer challenges, and they are built by teams, not individuals.”

In 2021, Bryn Fosburgh, senior vice president of Trimble, was inducted into the Hall of Fame for a broad range of contributions in developing and advancing technologies that support the construction industry.

Fosburgh led the creation of the SITECH network, the first fully dedicated global construction technology distribution network to sell, install and support 3D machine control systems for mixed equipment fleets. He spearheaded Trimble’s first joint development project with Caterpillar called CAES, a 3D grade control system for ore mining machines.

He was also part of a team that pioneered the development and validation of high-accuracy, low-latency GPS systems, including

real-time kinematic (RTK) technology, for mining and construction machine control. RTK is an innovative technique used to significantly improve the accuracy of a GPS receiver for many precision applications including surveying and heavy equipment operations in construction.

“I am honored and humbled to stand alongside so many of the true pillars of our industry,” said Fosburgh during the ceremony. “I have had the good fortune to work with great teams at Trimble as well as collaborate with very talented industry peers

who are dedicated to solving some of our biggest challenges. Together, we can continue to move our industry forward.”

The AEM Hall of Fame is accepting nominations for 2023 until June 16.

Other industry greats who have made it into the Hall of Fame include Ronald M. DeFeo, Chairman & CEO of Terex Corporation (1999); William Dana Ewart, the founder of Link-Belt Machinery Company (1996), and John L. Grove, co-founder of JLG Industries & Grove Manufacturing Company.

Crane & Hoist Canada magazine was on hand in Las Vegas, Nev. for CONEXPO, and needless to say it was a blast. So much to see; so much to do – and everyone came out after the 2020 event was abruptly cut short due to COVID.

The show crushed expected attendance numbers, drawing over 139,000 construction and fluid power professionals from 133 countries, making it the largest trade show in North America with more than 2,400 exhibitors from 36 countries spread out over three million square feet of exhibit space.

“Live events in the construction industry are very important, because you can see, touch and experience the products. That

value was reaffirmed this past week across the show floor,” said Phil Kelliher, Caterpillar senior vice president and CONEXPO-CON/AGG show chair.

This year’s show emphasized how the construction industry is evolving in many ways to adapt to sustainable technologies, products and practices. Show attendees were treated to sustainability in action, from electric and hydrogen powered construction equipment, to more recyclable materials and waste reduction opportunities.

Here are a few photos we took from the show that we shared on our social media channels.

With the push to “go

green,” a shift to emission-free cranes in downtown Toronto would be a healthy move

By Emily Newton

Battery-powered tower cranes are spearheading innovation at a major redevelopment project in the heart of London, England – the first of their kind to be used in the UK, using cutting-edge charging technology, which significantly reduces GHG emissions.

Reducing greenhouse gas emissions is a priority here at home in Canada – but just how effective are these electric cranes, and are there any benefits other than not producing exhaust?

Battery-Powered Tower Cranes in Operation

A major redevelopment project in London is taking a step toward sustainability using battery-powered tower cranes. This is the first project in the UK to use battery-powered cranes, marking a turning point for the British construction industry.

The Future Olympia project is valued at £1 billion (CAD)$1.67 billion. It includes offices, hotels, a live music venue, restaurants, retail space, a school and public

spaces. The battery-powered tower cranes will be used throughout the project.

How does a construction project of this scale run its cranes on batteries? The construction company behind Future Olympia — Laing O’Rourke — is using large portable batteries made of recycled shipping containers. The batteries are Amped Energy’s “Enertainers,” specific -

ally designed to power electric construction equipment.

Enertainers are estimated to be 30 times quieter than a diesel generator and create zero air pollution. The cube design of the electric generators allows them to be easily stacked or tucked away on crowded construction sites.

Ian Flemming — one of the Olympia Redevelopment’s project leaders — explained a few of the top benefits of switching to an electric generator in an interview on the project. “Not only does [the Enertainer] enable us to power the crane on a small grid connection, but the innovative design allows us to feed it with small power cables and charge it when site demand for power is low.”

Enertainer electric generators are being used to charge three battery-powered tower cranes at Olympia. The redevelopment project began in December 2022 and is slated for completion in 2025.

Why use battery-powered tower cranes?

This is a question that more and more

people in the construction industry are asking today. Electrification is becoming more common and effective for large construction equipment. Switching to battery-powered equipment has several benefits, including lower reductions and cost savings.

These benefits don’t just apply to construction, either. Tower cranes are essential equipment in many industries, including telecommunications, the steel industry and even shipping. Businesses in any of these niches can benefit from electrification by adopting battery-powered tower cranes.

One of the top benefits of electric construction equipment is lower greenhouse gas emissions. Sustainability is a top priority for the Olympia Redevelopment project, so it’s no surprise the developers opted for battery-powered tower cranes.

Experts estimate 25% of global GHG emissions are created by construction. Switching to fully electric construction equipment can significantly reduce the emissions produced on construction sites. This is particularly true for large equipment like tower cranes, which typically need hundreds of gallons of fossil fuel.

Businesses can improve their ESG portfolios by reducing their carbon footprint.

Reducing emissions in construction isn’t just good for the planet, either — businesses can improve their ESG portfolios by reducing their carbon footprint. Construction companies can even impress clients by advertising their use of electric equipment, which enhances the sustainability of new construction projects.

When you consider the amount of active operating tower cranes in downtown Vancouver, B.C., Toronto, Ont. and Montreal, Que., the reduction in GHG emissions would be considerable.

A clear benefit of shifting to electric battery-powered tower cranes is a reduced need for diesel fuel. This is important to note, given rising fuel costs around the world. For example, diesel prices in Canada hit almost $3 per litre in 2022. While they have decreased somewhat over Q1 2023, prices remain higher than in Q1 2022 and nearly double those of Q1 2020.

Electricity prices are not only lower than fossil fuel prices but also tend to be more stable. Of course, construction organiza-

tions still need to invest in electrical equipment and charging infrastructure. However, the cost of this equipment will be lower than the fuel costs for conventional diesel-powered equipment over time. Additionally, construction enterprises can reduce their energy costs and carbon footprint depending on where they source their electricity. Portable solar panel arrays can supply some of the electricity necessary for battery-powered tower cranes and other electric equipment. This reduces energy costs even more and ensures electricity for construction projects comes from a renewable source.

Investing in equipment like a portable electric generator for battery-powered equipment might sound like an unnecessary expense to some. However, this new infrastructure comes with many benefits. For example, the primary use for an electric generator might be to charge battery-powered tower cranes on-site. The generator can also power additional electric equipment, such as hand tools.

The need to have a generator on-site for electric equipment also allows construction sites to be energy independent. Some critics argue electric vehicles — especially large construction equipment — will strain local power grids too much. The Olympia project proves these vehicles can run primarily off external power supplies like the Enertainer, minimizing their impact on the power grid.

With electric construction equipment, construction companies can be more resilient to fluctuations in diesel fuel costs. They can also reduce reliance on local power grids with an external power supply for charging.

Construction projects can significantly impact the neighbourhoods surrounding them, including the people and wildlife living there. Electric equipment like battery-powered tower cranes lowers the negative effects of construction on local communities.

In fact, conserving the local ecology is key to achieving net-zero status in construction. This applies in urban environments, too, not just rural areas. Many types of plants and wildlife thrive in cities, which can be even more welcoming to the natural world by reducing harmful emissions. Battery-powered tower cranes and other electric construction equipment help new urban development benefit communities while decreasing pollution. Cleaner construction zones help everyone breathe easier as infrastructure is expanded and revitalized – especially for urban centres like Toronto, which leads North America in active crane construction.

Battery-powered tower cranes are leading the way in innovation in the construction industry. The successful implementation of fully electric equipment at the Olympia Redevelopment project is an inspiring proof of concept for construction leaders worldwide. Adopting this emerging technology can reduce projects’ carbon footprint, lower energy costs and minimize the impact of construction on local environments.

What’s next for the nation’s crane rental association as it marks a quarter century?

By Don Horne

Isat down with Sterling Crane’s Trevor Eckert, the Chairman of the Board of the Crane Rental Association of Canada (CRAC), to talk about the association’s 25 years of growth in the industry, and the plans for the future.

Don Horne: CRAC is celebrating 25 years – what does that mean to you?

Trevor Eckert: What an achievement, I’m very proud to be involved with this association and to be Chairman of the board and able to celebrate 25 years is special. It goes to show what this association represents and the work that we do matters.

Collectively our member companies help build Canada, while we are competitors we have a respect for each other that you don’t often see. I know I can reach out to any member, and they go out of their way to help if able to.

I have built some lifelong friendships with a lot of folks in this industry and can’t wait to see what the future holds.

How has the association evolved since the late 1990s?

Eckert: In 1997 a small group of Crane owners (4 in total) in Western Canada held a meeting, where it was decided that a Canadian Association should be established.

In subsequent years many common issues were raised by members. the board would assign committee members to address these concerns in order to advance safety and professional expertise across the country.

Our Association sits as one of seven active members of the International Crane Stakeholders Assembly. The assembly facilitates information sharing and meaningful dialogue between crane industry stakeholders on safety, technical and

regulatory issues of concern to the international crane industry in an effort to promote the harmonization of international standards.

Today we are 134 member companies strong, the highest it has been in our history. We have a voice, and it grows stronger every day.

What are some of the most impressive initiatives launched by CRAC?

Eckert: Our longest standing initiative is the Boom Dolly Research Committee. Many thanks to those members who have volunteered their time over the years to keep pushing this initiative. We are finally starting to gain some traction. We have

successfully completed the first “pilot project” in Alberta and are very close to having that be extended in order to continue to collect the data necessary to gain increased axle weights for our cranes during ban seasons. We were also invited to participate on the task force for vehicle weights and dimensions at the national level. This invitation was a direct result of the work being done on the Alberta pilot project. It is very good to have our collective voice heard at this level.

Our Diversity & Inclusion committee was formed to create awareness of the importance of Diversity & Inclusion at all levels of our member organizations.

We have recently established a technical committee to work with the regulatory

bodies such as CSA Z150 and WorkSafe BC so any proposed changes to regulations can be reviewed by actual stake holders in industry prior to becoming law.

What are the benefits of being a member of the association?

Eckert: The association has experienced constant growth over the past decade due to a shift toward advocating for members across Canada. We are working hard to connect all crane rental companies from coast to coast. The power of association is simple: a company alone does not have the strength to tackle major government policies or regulations but collectively, that’s what we do.

Our moto is simple, “we do business with people we know, like and trust” and by connecting to industry leaders, you get to grow your network, develop new partnerships, and learn from best practices from other parts of the country.

There are some great stories working in the crane industry. What is your favourite?

Eckert: I have been working in this industry for more than 35 years now. I went through the apprenticeship program and worked my way thru some difficult jobs along the way. I used to love sitting down with older operators and listening to their stories. It’s amazing to me what memories operators have. It seems they can recall most every detail of lifts they performed even years later. Who was there, how they set up, what they did to pull it off successfully. The following is my favorite of all time.

When I was in High School I was downtown at the local mall, I stepped outside the front doors and seen what was a large crawler in those days up on top of a stack of crane mats. They were adding a second story onto the mall. The crane was an American 9310 (225 ton) crawler with 300’ main boom and 80’ jib. The bottom of the tracks were eight feet from the ground; it was a spectacular sight and I wondered how on earth did they get that big machine up there.

Fast forward 15 years and I came to be the Branch Manager for Sterling Crane. The Crane & Rigging Supervisor who worked for me was a man named Art Blumers. I was telling Art one day about seeing that huge crane up on that stack of mats. Art said, “I was the operator of that crane” and went

on to tell me all about it. They built the eight-foot-high stack of mats like a stairway, then leaned 20-foot-long mats up the stairs to make a ramp in order to drive the fully erected crane up.

They needed to get the crane up that high in order to reach all of the work areas. He went on to tell me that he could not sleep the night before doing this.

He slowly started crawling up the ramp, booming down tight to the building in front of him to try and balance the crane. Once he was at midpoint of the tracks at the top of the ramp, the crane slowly started to lean forward, every inch he crawled forward the more he would boom up to avoid touching the building. Slowly but surely the crane leveled out and he crawled into final position.

Knowing what I know today, there is no way a job like that would be allowed to proceed. I also forgot to say this was also on top of an underground parking lot that was shored up as well. Stories like this really make you think of all the innovative ways the people before us worked to find solutions to get the job done.

When Art told me the story he said getting up there was the easy part, backing down off that pile of mats was a lot more nerve racking, and he had to do it four times. He said that was the job that turned his hair grey. I can believe it.

So, if you see a grey-haired operator, chances are he has a hell of a story to tell.

What can we expect from CRAC in 2023? In the years to come?

Eckert: A unified voice to lobby on issues that matter to our industry;

• Advance Safety and Professional expertise within the Canadian crane rental industry;

• Successfully complete the Alberta Pilot Project for increased axle weights;

• Continue our work with the task force for vehicle weights and dimensions at the national level;

• Showcase the fantastic work our member companies do with the Canadian Lift of the Year presentations; and

• Increase our membership of Canadian based crane rental companies and suppliers.

By Don Horne

It wasn’t all that long ago that one major lubricant manufacturer decided to take a step back and reorganize their marketing department, looking to focus more on customer feedback so they could design a product that reflected what they wanted.

So began the process of Chevron asking the customers who use their products what they wanted to see – and they listened, reformatting the colour codes and information on their tubes of grease and lubrication, simplifying the selection and application process.

“We’ve re-done all our packaging,” says Zach Sutton, Chevron Lubricants Industrial & Services Sector Specialist. “So, for the customer who is operating a crane, or operating something that needs to be lubricated with grease, we simplified how our products are recognized. We did a lot of study in terms of understanding what drives customers when making decisions on product selection; a simplified product name and a simplified package design were really important to them.”

That customer feedback included putting a double colour band on the tube (red

Two bands of colour coding and a clear description were part of the rebrand.

“For the customer who is operating a crane, or operating something that needs to be lubricated with grease, we simplified how our products are recognized. We did a lot of study in terms of understanding what drives customers when making decisions on product selection; a simplified product name and a simplified package design were really important to them.”

for grease, for example), and also identifying the viscosity in clear numbers, “a key element for understanding what an OEM is looking for in a grease application.”

“All these things – from an operator to a mechanic who is applying the grease – are clearly defined and easily distinguished on which product to install,” says Sutton.

For Sutton, the new packaging design is hoped to be seen as a success for the company and customers.

“It is something from our view we are really excited about, as it is important to the customer that what it is they wanted to see changed has been changed for the better,” says Sutton. “These changes are all from customer feedback, and feedback from those who are selling our product.”

In addition to the repackaged tubes, Chevron is releasing a potential alternative for lithium complex: the Rykon calcium sulfonate complex grease.

“Eighty per cent of our grease portfolio didn’t need to undergo a formula change,” says Sutton. “But we are excited about the new Rykon calcium sulfonate complex formulation. We have identified our grease line by thickener types, and we’re excited to introduce Rykon later in 2023. We’ve seen four times the performance vs the standard GB-LB NLGI high temperature.”

While a tube of grease may be a small item purchase, it can extend of the life of big-ticket machinery, Sutton points out.

To learn more, take a look at “What you can’t see can hurt you.”

Up to $20,000* in help is available right now!

Apply for your grant at

Here is a selection of what’s new on the Crane & Hoist Canada website, presenting a highlight of new products and equipment from the past few months.

If you would like to be included in the next issue of Crane & Hoist Canada magazine in this section, please email me, Don Horne, at dhorne@annexbusinessmedia.com, and put in the subject line New Products

Please keep the submissions to five (5) paragraphs or less –under 200 words – and attach a high-res image in a png or jpeg format. We cannot guarantee that all submissions will be included, due to time and space constraints.

OTH Pioneer Rigging has partnered with Ludwig System GmbH & Co. KG, creator of the remote-controlled lifting system, LudwigHook, to bring the solution to North America. The LudwigHook lifting device is an alternative to traditional lifting hooks. It is proven in steel erection and building supply delivery applications as a way to speed up the rigging process and reduce risk to workers by keeping them from

manually unhooking rigging.

The LudwigHook system was introduced to the European construction market in 2012 and originally designed to meet CE Certification standards.

“In order to bring the remote-controlled lifting solution to North America, we worked with the creator to implement the necessary safety features to comply with federal safety regulations,” said Oliver Gleize, Product Manager for OTH Pioneer Rigging, adding that the hooks are OSHA, ASME, UL/CSA, and FCC/IC compliant, and there are more than 500 units are already in use in North America.

OTH Pioneer Rigging has permanent customer service for North American users and provides 24-hour shipping on spare parts to any job site within the U.S. and Canada. OTH Pioneer Rigging also offers annual

inspections and allows new users a one-week trial free of charge. Radio remote control with a range of 200 feet is used to trigger the opening mechanism. The opening mechanism of the hook switches off when lifting over 55 lbs., ensuring that the load cannot be dropped during a lift. When the load is set down, the opening mechanism switches on allowing the user to release the hook.

Available in two models, one individual LudwigHook has a working load limit of 4,400 lbs., and one XL hook is rated for 11,600 lbs. However, users can synchronize an unlimited number of hooks on the same remote, in any combination, to achieve scalable lifting capacity. Both models can be used with vertical, basket, or choker setups and any kind of attachment (wire rope, nylon rope, chains, eye bolts, etc).

Liebherr’s LRT 1100-2.1 rough terrain crane was upgraded in 2022. The upgraded steel counterweight is increased by one metric ton resulting in an increased lifting capacity, allowing the LRT to hoist loads

beyond what’s capable for the rest of its class.

The counterweight is also more compact providing a better rear view in the cab, minimizing blind spots. This upgrade also allows for increased load charts as well as inclination charts, aiding in operation up to 2 degrees from level.

The upgraded LRT was taken to Virginia to assist in quick assembly of an on-site mining truck. The rough terrain crane allowed for a smooth and rapid assembly of the T 264 mining truck and fulfilled any lifts needed at the site. Due to its top-of-the-line safety features and high lifting capacity, the rough terrain crane was the top choice for this job. With no down time, the LRT crane also allowed the job to be finished four days ahead of schedule, saving both time and money.

Tadano announces two new truck crane models for the United States and Canada, expanding the range of lifting solutions for customers in those markets. With their low axle weight, narrow transport width and long boom designs, the new Tadano GT-1200XL-2 and GT-800XL-2 can easily get special permitting for transport, making them ideal for taxi crane

service. Tadano displayed the new GT-1200XL-2 model for ConExpo 2023 attendees to see in Las Vegas, Nev.

The new Tadano GT-1200XL-2 and GT-800XL-2 truck cranes offer 120- and 80-US-ton (110- and 72.6-tonne) maximum lift capacities respectively. Built with many of the same field-proven, reliable components as Tadano GR Series rough terrain cranes, these new models offer the same high quality and rugged durability that customers have come to expect from Tadano. Their narrow, 8.5-ft (2,59 m) travel width combines with a low base machine weight and optimized axle width to meet weight requirements, so special permits for transport are easy to get. To meet the most stringent axle load limits, a boom dolly trailer is available.

CanLift Equipment Ltd., a family-owned aerial equipment and material handling company, welcomes two new XCMG telehandlers to its product line this spring 2023. With the XTF1056K and XTF1256K telehandlers available for rent and sale, CanLift aims to solve the current telehandler shortage and provide customers with

efficient and versatile solutions for their material handling needs.

“We are excited to announce the latest additions to our fleet, two telehandlers that are set to enhance CanLift’s product line,” said Johnny Dragicevic, Managing Partner at CanLift.

“With a current telehandler shortage, we are confident that these machines will not only address the pressing need but also provide our clients with exceptional performance and reliability.”

At CONEXPO, Broderson Manufacturing Corp showcased product upgrades on the model RT-400, 20-ton capacity cabdown rough terrain crane, and on the model IC-400, 25 ton capacity carry deck cranes.

The upgrades harmonize drivetrain, hydraulic, controls and RCL systems between both crane models. Both models feature a product class leading 72’ 6” 4-section, full power boom. The upgrades that the models share are as follows:

Cummins QSF3.8L Tier 4 Final / Euromot stage V diesel engine rated 154HP@2500 RPM for the highest-level emissions compliance and clean operation. (A Euromot stage II engine option is available for export). There are multiple throttle control modes: foot throttle, electronic speed presets, and auto-idle that will increase the engine speed during lifting operations and return the engine to idle once the lifting is completed.

A newly designed, formed high-strength steel main boom that incorporates a telescopic cylinder and a wire rope and

sheave system for the synchronous extension of the boom. An upgrade for serviceability includes the ability to remove the boom extension cylinder without having to disassemble the boom.

Unique to the RT-400, an upgrade to the swing down outriggers provides increased ground clearance to allow leveling of the crane on up to a 4-degree slope.

portfolio

Grammer AG was looking to cement its status as an international innovation leader and systems supplier for ergonomic seating systems and vehicle control systems at CONEXPO in Las Vegas, Nev. Highlights include the world’s first six-way control pod carrier ErgoPlus as well as headrest loudspeakers and other products improving the interface between the vehicle, the seat and the user. With several aftermarket seats which can be ordered today, customer expectations will also be met to optimum effect at the sales show.

The ErgoPlus control pod carrier features maximum comfort and ergonomics, allowing the driver to adjust the armrests six ways – forward/ back, up/down, tilt left/right. This adaptability, which is unique in the world, is of particular benefit for machinery in which the operator moves hydraulic control levers or joysticks with both hands for hours on end, for example in excavators. Regardless of their size, stature and arm length, drivers can always work in maximum comfort and thus with full concentration free of fatigue and back strain. ErgoPlus is based on a modular platform and can thus be used in a wide variety of vehicle classes and applications worldwide. An easy-entry function, in which the door-side armrest can be folded up completely, is also available for ErgoPlus.

Allied Safety Systems Inc DBA

Sigalarm and Syscomak Technologies, division of Rayco Electronic System Limited, are moving forward on an exclusive partnership.

Each company’s respective products will be integrated in one wireless display to better serve the heavy equipment industry and crane businesses worldwide.

Sigalarm and Rayco | Syscomak are established leaders in electronic safety products and on-board instrumentation. The new partnership goal is to combine the respective industry knowledge and improve safety on the broader market segment.

Sigalarm recently developed a wireless CAN bus module presently on demonstration at Conexpo 2023, which allows OEM integration of the Sigalarm propriety high voltage wireless sensors straight into their internal system.

Likewise, RaycoWylie’s new i5000 series was turning heads at Conexpo. This state-ofthe-art system reaches the highest level of machine integration ever offered by the company.

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

CM Labs Simulations, leading vendor for simulation-based training in the construction and ports industries, has announced the release of its Telehandler Simulator Training Pack.

It is the only simulation-based solution on the market that accurately replicates machine stability and engine behavior, resulting in effective, efficient operator training. The Training Pack also helps organizations address key industry issues such as safety, sustainability, and equipment maintenance.

Incorrect load handling or misuse of the telescopic boom can result in injury, collisions, or equipment tipping. CM Labs’ Telehandler Training Pack offers a safe, effective, and comprehensive alternative for initial training while mitigating the increased fuel costs and wear and tear that typically result from inexperienced handling.

The Training Pack’s progressive learning exercises gradually build skill and confidence. Trainees work on skills such as controls familiarization, trailer loading and unloading, lifting from ground and heights, live attachment change, and shuttle operations. Performance metrics tracked during training exercises include safety violations, such as collisions, tipping or flipping, loads dropped, machine stability, and fuel efficiency.

In response to industry demand for durable and engineered equipment stabilization at a lower price point, DICA introduced EcoMax Crane Pads at CONEXPO-CON/AGG 2023 in Las Vegas.

EcoMax Crane Pads combine alternating solid composite “timbers” and steel I-beams connected with through-bolts for maximum load distribution. This patented product has similar stiffness, strength, and performance properties as DICA’s FiberMax Crane Pads or steel pads but is less expensive than either of those options.

“We designed EcoMax specifically for customers that don’t need the significant weight savings that FiberMax offers but still want an engineered crane pad for everyday use,” said Kris Koberg, CEO of DICA. EcoMax is ideal for distributing concentrated loads from equipment with outriggers, such as mobile cranes, concrete pump trucks, and self-erecting tower cranes. While EcoMax is heavier than FiberMax Crane Pads, it is lighter than solid steel mats.

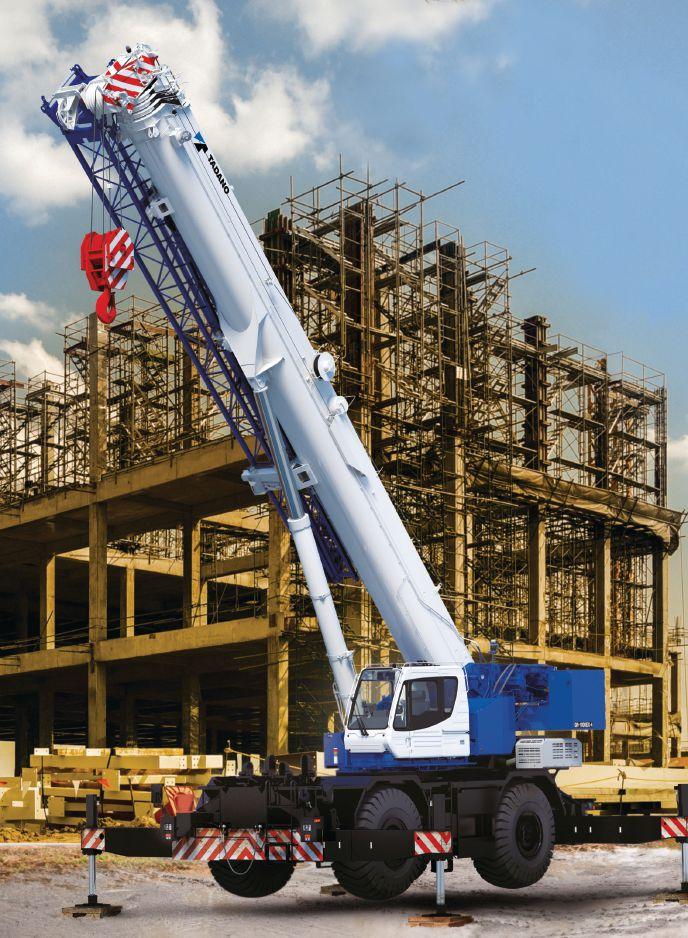

Increase Efficiency and Productivity

- 110 Ton Lattice Boom Crawler Crane

- Power Hoisting / Lowering on Both Drums

- Wide Body Cab Increases Operator Comfort

- Designed for Easy Transport with Minimal Loads

- Self-Assembly System Allows for Full Assembly Without Assistance

- Crane Control System "CCS" Allows for Troubleshooting Through Control System and Diagnostic App

Wide Variety of Inventory Immediately Available

We are offering immediate availability on today’s most popular cranes from Manitowoc, Grove and National Crane. All backed by North Americas leading distributors. Capacities range from: 110-716 TON LATTICE BOOM CRAWLER CRANES, 65-550 TON ALL-TERRAIN CRANES, 30-165 TON ROUGHTERRAIN CRANES, 40-115 TON TRUCK MOUNTED CRANES.

Our HC-L series luffing jib cranes enable quick, safe and reliable operation almost anywhere. Maximum lifting capacities of up to 64 tonnes, hook heights of more than 1,000 metres and a small slewing radius ensure efficient construction site work, even in the tightest spaces and under extreme conditions.

Contact your dealer at www.liebherr.com/tc-partner