BY ANDREW SNOOK

BY ANDREW SNOOK

Put your people and projects in the spotlight!

It’s no secret that finding young people to fill positions for almost all of the skilled trades is a daunting task. Most trades have not done a great job of promoting their amazing and challenging industries to the next generation of workers, and the heavy lifting industry is no exception.

Every year, Crane & Hoist Canada looks to do its part to help change that by showcasing some of the amazing young people rising through the ranks, and by highlighting some of the amazing projects the industry is a part of.

The team at Crane & Hoist Canada is excited to announce we will be kicking off our brand-new Cover Photo Contest for the industry! The winner’s photo will grace the cover of the September/October issue. Many additional photos will be showcased inside the magazine.

What kind of photos are we looking for?

Here are a few ideas to get you started:

• Construction jobsites

• Ports

• Oil and gas projects

• HVAC lifts

• Manufacturing applications

• Any unique type of lift

To enter the contest, send a hi-resolution image to editor Andrew Snook at: asnook@annexbusinessmedia.com, along with the following information:

• A brief summary of the project (50 to 100 words)

• Date the photo was taken

• Location where photo was taken

• Model of equipment (if applicable)

Top 10 Under 40 is back!

Have a young up-and-comer on your team that you believe should be recognized for their hard work, dedication and innovation? Then nominate them for Crane & Hoist Canada’s Top 10 Under 40 awards program!

The deadline for submitting nominations of your best and brightest is September 15, 2022. This means you’ve got ample opportunity to submit those names via the Crane

& Hoist Canada website and give your young stars the recognition they deserve.

This program will recognize 10 outstanding individuals from across Canada who had made significant contributions to the industry before their 40th birthdays. This can include anyone who was under the age of 40 as of December 31, 2022.

Nominees can come from anyone who is involved in Canada’s heavy lifting industry, including business owners and management, crane operators, engineers, software programmers, technicians, industry educators, and research and development staff.

What are the qualifications to nominate an individual, you ask?

Here are the guidelines to the Top 10 Under 40 contest:

• Nominees must be younger than 40 before Dec. 31, 2022.

• Nominees must either be working in Canada or of Canadian nationality.

• Nominations are due by Sept. 15, 2022.

What type of information should be included?

Potential information to submit about the nominee can include: Projects or initiatives the individual is/has been involved in; results from past projects; job responsibilities; workplace initiatives outside of regular duties; and community involvement.

All nominees that are selected will receive a framed certificate recognizing their achievement, and will be featured in the November/December 2022 issue.

Still have more questions?

For more information on the Top 10 Under 40 program, or how to nominate an individual, contact editor Andrew Snook at asnook@annexbusinessmedia. com, or visit: craneandhoistcanada.com/ top-10-under-40

Good luck to all the nominees for this year’s program. We look forward to featuring the industry’s best and brightest upand-comers and projects in our upcoming issues of Crane & Hoist Canada!

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb,

Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

INTERIM EDITOR | ANDREW SNOOK asnook@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | KRISTINE DEOKARAN kdeokaran@annexbusinessmedia.com

CONTRIBUTORS

Saul Chernos, Matt Jones, Richard Phillips

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-5106875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: May 27, 2022

Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: May 27, 2022. For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at asnook@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER: RANERENTALASSOCIATONOFCANAD A TO A D D O

Tadano America Corporation has expanded Cropac Equipment’s area of responsibility as an authorized distributor of Tadano rough terrain, all terrain, and telescopic boom crawler cranes in Canada.

Cropac’s area will now include Saskatchewan, Alberta, British Columbia, Yukon, and the Northwest Territories.

The revised agreement adds to Cropac’s existing eastern territory, making the company an authorized Tadano distributor for all of Canada.

“Cropac is thrilled to be expanding our distributor footprint with Tadano into the western provinces,” said Cropac Equipment president Bill Finkle. “Combined with our local, full-time factory trained technicians serving Canada coast-to-coast, Cropac provides tremendous value and service to its customers throughout the country.”

Established in 1977, Cropac has locations in Oakville, Ont.; Laval, Que.; Nisku, Alta.; and Abbotsford, B.C.

“Tadano has a long-standing partnership with Cropac, and we are excited to be expanding its distributor territories to cover all of Canada,” said Ken Butz, vice-president of sales for Tadano America Corporation. “This new chapter in our relationship gives Tadano the opportunity to offer a consistent value package to the Canadian market that is reinforced by Cropac’s expansive and unparalleled service.”

The Crane Rental Association of Canada (CRAC) and Alberta Transportation are amending the Alberta AT Cranes Pilot Project to include dollies.

Following a thorough analysis of the data collected between September 2020 and September 2021, the results demonstrated the most active all-terrain cranes are in the Peace Region and the Regional Municipality of Wood Buffalo in northern Alberta.

The analysis also demonstrated a small number of all-terrain cranes can operate without dollies, even at the increased weights. To properly measure the impact of all-terrain cranes in Alberta, the pilot project is being amended to include the use of dollies, beginning this spring.

“We expect this amendment to the pilot project will demonstrate that all-terrain cranes are engineered to protect pavement integrity and travel safely on Canadian highways,” said Mark Danderfer, co-chair of the Boom Dolly Research Committee (BDRC).

“This important amendment would not have been possible without the collaboration of the Ministry of Transportation and the extraordinary input and dedication of my co-chair, Justin Andrews, regional business manager for western U.S. and Canada for Tadano America.”

The BDRC has a three-pronged approach, including:

• Advocate for changes to provincial regulations;

• Develop best practices; and

• Research technical solutions.

The pilot program between CRAC and Alberta Transportation began in late 2020.

The CRAC’s members are crane rental companies, manufacturers and suppliers of cranes and equipment, as well as suppliers of services used in the specialty crane rental business in Canada.

Falcon Equipment has opened its second branch on Vancouver Island.

The new location opened March 1 on the South end of Vancouver Island in Sooke, B.C. The branch offers sales, service, rentals and parts support for all of Falcon Equipment’s core product lines.

“We are excited to open our second location on Vancouver Island. Falcon is on an

aggressive growth plan; we are continuously evaluating the market and our customer’s needs. This branch opening helps to continue to position us as market leaders in Western Canada,” said Falcon Equipment president Dan Kielan.

Al Zinger will manage the new branch. Zinger has been with Falcon Equipment for 17 years in a variety of positions and has been managing the company’s Nanaimo branch since it opened in 2017.

“We are eager to continue to expand on Vancouver Island. Being a one-stop shop for our customers is our top priority,” Zinger said. “Since 2017, we have continued to grow our fleet of mobile service trucks to ensure we are able to service our customer’s equipment anytime, anywhere, keeping their downtime to a minimum.”

Falcon Equipment was founded in 1988, and provides sales, service, rentals and parts support to the lifting, rail, municipal and utility industries within Canada and some areas of the United States.

The new Vancouver Island branch is the company’s six location, joining stores in Nanaimo, B.C.; Surrey, B.C.; Edmonton; Regina; and Winnipeg.

Alberta has passed the Prompt Payment and Construction Lien Act and supporting regulations to help enhance protections in the province’s construction industry.

The framework sets out clear timelines and rules for payments and liens as well as a new adjudication framework for payment disputes within the industry.

The regulations will come into force on Aug. 29, 2022, and will be available online at alberta.ca.The prompt payment framework addresses long-standing industry concerns, protects jobs and keeps investment moving throughout our economy.

“We’ve been hard at work over the past two years collaborating with the construction industry to develop a prompt payment framework,” said Nate Glubish, Alberta’s Minister of Service. “This important effort will ensure that hard-working Albertans will be paid on time. These measures support our economic recovery – as well as economic growth – and I’m excited to see them come into force this summer.”

In the fall of 2020 and spring of 2021, the Alberta legislature passed several changes, including a new adjudication process for the construction industry to address payment disputes. As well, owners will be required to pay proper invoices from general contractors within 28 days.

Contractors and subcontractors are required to pay their own subcontractors within seven calendar days of being paid themselves. The province has also extended timelines for registering liens from 45 days to 60 days for the construction industry, and 45 days to 90 days for suppliers within the concrete industry.

“This framework has been a long time coming. It’s great to see that this government took a problem and consulted extensively with industry to reach a solution,” said John Winter, chair of the Alberta Construction Association. “This framework will be beneficial for all levels of construction, and I look forward to seeing it come into force.”

XCMG says it has set a new world record after its XGC15000A 1,000-ton crawler crane completed its first single-arm wind power hoisting operation at a height of 172+12 metres for a wind farm in China.

Weighing in at 118 tons, the 4.5-megawatt wind power turbine was hoisted to a record-setting height of 170 metres with the diameter of the impeller reaching 156 metres.

It adopts the prestressed, fatigue-resistant framed steel pipe wind power tower that greatly increases the height of the wind turbine when compared with the common 120 to 140 metre flexible tower in the industry, which better utilizes wind resources and increases power generation efficiency.

However, the higher installation height posed greater challenges for the crawler crane.

The flat and open project site usually experiences strong wind greater than Level 5, and the construction team quickly completed the operation during a short “wind-free” timeframe, thanks to the XGC15000A.

The successful installation makes the XGC15000A the world’s first wind power

crawler crane to achieve a hoisting height of 170 metres.

With a rated load of 70 tons, the crane has a broad range of applications and was designed for the hoisting operations of large-scale wind turbines and equipment. It is equipped with exclusive spreaders that increase hoisting and handling efficiency three-fold.

The U.K. Competition & Markets Authority (CMA) has blocked the proposed merger between Cargotec and Konecranes.

To alleviate concerns, Cargotec and Konecranes planned to remove all overlapping businesses of the two companies, a remedy that was accepted by the European Commission (EC).

However, according to the CMA’s final report, the remedies would not be effective in addressing the authority’s concerns.

The completion of the merger would have required approvals from all relevant competition authorities. Without CMA approval, Cargotec and Konecranes have decided to cancel the merger.

“The Board of Cargotec is convinced that the merger would have created substantial value for the entire industry as well as shareholders by improving sustainable material flow,” said Cargotec chairman Ilkka Herlin. “The combination would have created a strong European company enabling accelerated shared abilities to innovate without harming competition. We have done all we could to realize the merger

and are disappointed that our plans have had to be abandoned. After a long and extensive regulatory review process and merger planning preparations it is time to shift our full focus on executing Cargotec’s own strategy and value-creation opportunities.”

Now, Cargotec and Konecranes will immediately cease the pursuit of the merger and the related processes and continue to operate separately as fully independent companies.

“The combination of Konecranes and Cargotec, as planned and announced on Oct. 1, 2020, would have created a company that would have been greater than the sum of its parts. The merger control process has been extensive and the investigations thorough, and Konecranes board of directors is disappointed that the remedy package offered did not satisfy the concerns of all regulators,” said Konecranes chairman Christoph Vitzthum. “At the same time, we believe that further remedies would have not been in the best interest of Konecranes’ shareholders as they would have changed the strategic rationale of the transaction. Konecranes will continue to drive its strategy and pursue value-creation potential on a stand-alone basis.”

The merger obtained clearances from numerous competition authorities. As announced on February 24, the EC conditionally approved the planned merger between Cargotec and Konecranes based on the same remedy package rejected by the CMA, which included commitments to divest Konecranes Lift Truck business and Kalmar Automation Solutions.

In response to feedback received from the CMA during their investigations, the boards of directors of Cargotec and Konecranes considered amending the remedy package offered to the EC, as well as offering alternative remedy packages to address the concerns raised by the CMA. However, the boards were unable to find a solution that would not jeopardise the rationale of the proposed merger.

By the end of 2021, Konecranes had booked EUR$56 million and Cargotec EUR$57 million of merger-related transaction and integration planning costs.

From machinery to service, parts and certification. Your trusted partner for every project.

Grove all-terrain cranes deliver powerful li ing performance, superior off-road mobility and fast highway speeds. Combine these benefits with industry leading reliability, service and support and you’ll agree that Grove all-terrain cranes are a smart choice for your business.

Terex Cranes has appointed Giancarlo Montanari as general manager of rough terrain cranes, effective Feb. 1.

Giancarlo, who served as business line leader of rough terrain cranes before the promotion, will be responsible for all functions within the business. He will report to Kieran Hegarty, president of Terex segment MP.

“I am honoured to have this opportunity. I really believe in our products and organization. This market is a competitive one, but we believe we are shaping our future to be an important brand for years to come,” Montanari said. “The premium materials, modern technology and unique optimization of our cranes make us stand out from the crowd. This added to the uniqueness of the brands, and their target-driven focus on being best-inclass is what makes us the first choice.”

Giancarlo is an experienced manager and a natural choice to lead a new focused strategy for the rough terrain cranes, the company stated. With the new structure, Terex aims to focus on the individual strengths of each crane business to best suit their own unique brands.

The Manitowoc Company has announced that David J. Antoniuk will step down as chief financial officer effective May 2.

Manitowoc also announced that Brian P. Regan will become the company’s CFO. Antoniuk will transition into an advisory role to the CEO until January 2, 2023, at which time he will retire from the Company.

“On behalf of the Manitowoc team and our board of directors, I want to extend our deepest thanks to Dave,” said Aaron H. Ravenscroft, president and CEO.

“Over his six years of service, Dave has made many contributions to the success of Manitowoc. These efforts included the successful transition of the company to a profitable standalone crane company in 2016; the refinancing of our debt in 2019; and most recently the closing of two acquisitions, which was the first major step in transforming the company’s strategy. It has been a pleasure to work hand-in-hand with Dave over the years, and he will be greatly missed by the Manitowoc family. We wish him and his family the very best in his retirement.”

As part of Manitowoc’s succession planning process, Brian P. Regan, who currently serves as vice-president of corporate controller and principal accounting officer, will be promoted to executive vice-president and chief financial officer, effective May 2.

“I’m excited to announce that Brian Regan will succeed Dave as the company’s CFO. Since joining the company in 2018, Brian has taken on growing responsibilities and played an integral role in our acquisitions.

Brian is the ideal candidate, and it’s a testament to our succession planning process,” Ravenscroft said.

Regan has served as vice-president, corporate controller, and principal accounting officer since November 2018 and has also been responsible for treasury over the last 12 months.

Prior to joining Manitowoc, Regan served in positions of increasing responsibility at SPX Corporation from 2006 to 2018 where he most recently served as vice-president of finance, chief financial officer of SPX Transformer Solutions. Prior to SPX Corporation, Regan served in positions of increasing responsibility at Ernst & Young LLP and Ogilvy & Mather.

Regan holds a Bachelor of Arts in economics and accounting from the College of the Holy Cross and earned his Certified Public Accountant license in New York.

Brendan Nobes will become chair of the Canadian Construction Association’s (CCA) 2022-2023 board of directors. Nobes was elected during the CCA’s annual general meeting (AGM) held March 7. He replaces outgoing chair, Ray Bassett.

Nobes is the director of major projects for rcs construction, a general contracting firm based in Atlantic Canada.

“I know the last two years have tested us all and presented us with great uncertainty, but it truly feels like a tide is turning for the better,” Nobes said during his address to the CCA at the AGM.

“This is the year to capitalize on the advancements made in technology, make our corporate cultures more inclusive, and put Canada on the path to green.”

A 35-year veteran of the construction industry, Nobes has worked as a site superintendent, senior estimator, senior project manager and project manager representing the owner.

Working at all levels in construction from design review and document preparation to scheduling, budgeting, cost forecasting and tender package preparation, Nobes has adopted a “cradle to grave” approach to construction management.

The Mount Allison University graduate and Gold Seal Certified project manager and estimator is active in several industry associations. He is CCA’s representative to the Canadian Construction Documents Committee. He is also past chair of the Construction Association of Nova Scotia. Nobes was also the 2017 recipient of the CCA Robert Saunders Trophy for his commitment and dedication to the industry, particularly to the general contractors’ sector.

In addition to delivering a refreshed strategic plan, Nobes looks forward to advancing three initiatives during his tenure including expanding CCA’s engagement with members, in person in their hometowns; launching new services to elevate best practices in project delivery; and strengthening the bonds between CCA and its partner associations.

Strongco Corporation has announced that François Simard is joining the company as regional vice-president of construction equipment for Quebec. Simard has several years of management, sales and operations experience in the heavy equipment industry. He also holds a degree in industrial relations from the University of Montreal. As well, Simard has a certificate in health and safety, experience as a human resources advisor and is an international volunteer for the Canadian International Development Agency.

“Working together in the interim with Stephen George, our eastern region vice-president for our construction equipment division, who has diligently structured out Quebec and Atlantic operations, we believe François will be a significant asset in the future growth of Strongco,” said Oliver Nachevski, president and CEO for Strongco.

Simard will be based in the Strongco Laval branch overseeing the construction equipment division operations for Quebec.

Mi-Jack Canada is your authorized Manitowoc® and Grove® Distributor in Alberta & Saskatchewan. New and used sales, rental purchase options, unsurpassed customer support, and factory-trained service technicians. As part of the Lanco Equipment Group, Mi-Jack Canada is part of the world’s largest Manitowoc dealer group, and North America’s largest parts inventory, all on-hand and ready to ship.

This 150-ton crawler brings more productivity to every jobsite with faster assembly than ever before. The boom butt mounted sheave enables self-assembly without the boom top, it features a button style rope termination for quicker attachment, and a gantry-raised counterweight system that reduces components. The boom cap, luffing jib butt, and struts even transport as a single package for fewer connections.

New and used Manitowoc and Grove Sales, Parts and Service, all in-stock and available throughout Alberta and Saskatchewan.

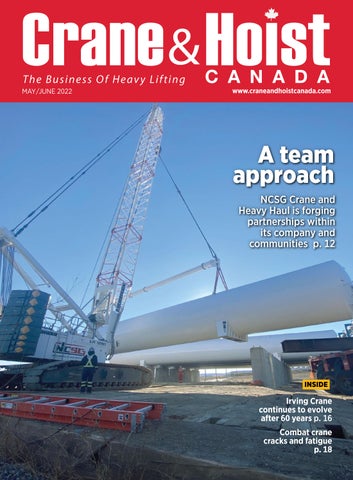

NCSG Crane and Heavy Haul is forging partnerships within its company and communities

By Bill Tremblay

As president and CEO of NCSG Crane and Heavy Haul, Heather MacCallum views the business as a team sport.

With about 300 employees throughout nine locations in Western Canada, NCSG provides crane and heavy haul services to various industries, including refining, upgrading, upstream oil and gas, utilities, forestry, mining and wind energy.

To ensure success throughout the Acheson, Alta.-based company’s various projects in Canada’s energy corridor, MacCa-

llum applies the fundamentals of a team mentality she learned throughout her youth playing sports.

“I think it’s really important to understand that everyone is contributing to our overall success,” she said. “I can’t do my job without the people in the field doing their jobs. I don’t think anyone would do well just being captain of a team of one.”

Using cranes as an example, MacCallum explained completion of a single lift requires numerous team members, from dispatchers to truck drivers to operators, to successfully finish the job.

“When I think about team sports, and certainly as I spend more time in the field, you really see the coordination that’s required to do what we do and to do it safely,” MacCallum said.

The company’s teamwork approach also extends beyond its immediate employee base to the communities that are home to its projects. For example, its partnerships with Indigenous communities in Western Canada have become a key to the company’s success.

NCSG signed its first Indigenous partnership in 2012 and has since provided $9.7 million in revenue royalties to First Nation communities. In fact, 65 per cent of revenue generated by NCSG is part of majority owned First Nation partnership.

“It was new to the crane industry. I think we were one of the first to do this. Now we have 18 partnerships across Western Canada that are active,” MacCallum said.

The relationships have evolved since the first agreement was signed a decade ago. Now, the partnerships include a goal of creating a lasting community impact. For example, NCSG is adapting its hiring practices to attract First Nation residents to consider a career in the crane and heavy haul industries.

“At first it was more of an economic agreement. Now we really are seeing the benefit of working together and teaming up to be successful,” MacCallum said. “Overall, that’s having a benefit to us as a company with more success because we’re really working together as a team.”

The Red Seal certification required to become a crane operator is one of the biggest hurdles to entering the industry. To overcome the challenge, NCSG is working with its partners to create apprenticeship opportunities in the industry.

“It’s not easy to bring people in without training. So, they’re creating apprenticeship opportunities so we can bring in people, educate them and bring them onto jobs,” McCallum said. “They’re looking at these

Formerly known as Northern Crane Services, NCSG began as an Indigenous company. Today, NCSG has grown via numerous acquisitions and is private equity owned.

projects as opportunities to build a workforce. Part of that is making sure we’re connecting with the communities that are impacted by these projects as well.”

Formerly known as Northern Crane Services, NCSG began as an Indigenous company. Today, NCSG has grown via numerous acquisitions and is private equity owned.

“Our commitment to Indigenous communities in Western Canada is still very strong. And these partnerships are a way we can demonstrate that,” MacCallum said.

NCSG’s commitment was recently honoured with the Partner of the Year award, presented by the Fort McMurray First Nation Group of Companies (FMFNGOC).

“The profits that come back from this relationship, in turn, support the First Nation in many of the community goals: economy, education through sponsorships, employment and infrastructure through building homes and improving lands,” said Steve Jani, CEO of FMFNGOC.

Jani added both companies share similar values, which created a positive and profitable relationship as they move forward together.

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

“The partnership began in 2014 and it has been positive and on a consistent rise each year,” Jani said.

MacCallum’s journey to the president and CEO position began on the finance side of the business. After becoming a chartered accountant (now a certified public accountant), NCSG was one of the first clients she audited in 2012.

“At that point and time, they were acquiring a lot of companies and doing a lot of exciting things in the Edmonton area,” she said. “I really enjoyed my time here. It’s an interesting space and industry.”

After working as an accounting consultant for NCSG, MacCallum was hired as its vice-president of finance in 2013.

“One of the things I’m most passionate about is people and team building,” she said. “Being in an external consulting role wasn’t really something I thought would make sense for me long term.”

As vice-president of finance, MacCallum worked through the oil price crash of 2014 and helped navigate the economic fallout.

“We had some pretty challenging time periods, so being able to work with the teams and figure out how we would manage these difficult situations really had me laser focused on the people,” she said.

In 2019, MacCallum was promoted to chief financial officer, and became president of NCSG a year later. This January, she stepped into the role of president and CEO. Without an operations background in cranes or heavy haul, she explained there was some hesitation about taking on the role.

“Transitioning into the president and CEO position was really never something that was on my radar to be completely honest. I didn’t put that on my vision board,” MacCallum said. “What drew me into the role and kept me interested was I knew I could lead this team of people. The industry has certainly captured my attention, but it’s the people that are attracting me to the role.”

As CEO, MacCallum leads an all-female C-suite at NCGS. While she agrees she brings a different approach to the company, her unique perspective isn’t driven by her gender.

“I’m coming at it from a different area of expertise. My professional development experience brings a different perspective as opposed to a true operational perspective,” she said. “I definitely think there are new perspectives that weren’t there before, but it’s not fundamental with being a woman.”

For example, NCSG has incorporated environmental, social and corporate governance (ESG), which is an evaluation of the company’s collective conscientiousness for social and environmental factors.

“Everybody is talking about ESG right now,” MacCallum said. “We are talking about it at NCSG in a meaningful way and how we can create differences.”

She added her perspective also delivers different methods to attract a new workforce. As a woman leading a crane and heavy lift company, MacCallum believes other women may see the typically male dominated industry as a possible career path.

“I think being a crane operator and working in this industry creates some incredible opportunities for people and families,” MacCallum said. “Seeing a woman in a leading role creates an opportunity for you to think about how you may shape your career. If you see it, you can be it.”

By Matt Jones

Irving Equipment Limited was formed in 1957 in Saint John, N.B., part of the larger J.D. Irving, Limited (JDI) group of companies – founded almost 100 years earlier.

JDI holds interest in a wide variety of industries, including forestry products, consumer goods, shipbuilding and transportation. Over time, Irving Equipment has evolved from performing crane work primarily for other Irving companies to taking on any customer within Atlantic Canada.

A long history

“Cranes were there from the very beginning,” said Ryan Long, director of business development. “And, at that time, also civil construction equipment, like dump trucks and dozers, which later split off into its own business. It was in the late 1970s when we hired our first lift engineer to start preparing engineered lift plans and professional services.”

In the 1980s, the company opened a new branch in Moncton, N.B., and in 1987 purchased their first all-terrain crane and developed their own in-house Computer Aided Design-based planning software called CraneCAD.

“We still use it today,” Long said. “It’s won awards over the years, and it is a fantastic tool that we use to help set us apart when we’re bidding on work.”

The company has continued to diversify, adding piledriving services in the late 90s and taking on wind energy projects and adding large crawler cranes in the 2000s, along with receiving ISO 9001 and 14001 certifications. Around this time, the company had expanded into New England but eventually consolidated back to the four Atlantic provinces. The company currently operates out of nine locations across the region.

Crane focused

While the business is diversified, Long says most of their work today is still crane-related, including pile driving, drilling and deep foundation work, which are mostly based on adding piling and drilling attachments to the cranes. While the company once primarily served other J.D. Irving, Limited companies, the bulk of their jobs now come from third-party companies.

While the exact number fluctuates, Long said Irving Equipment’s fleet currently includes about 100 cranes and 48 axle lines of self-propelled modular transporters (SPMT), as well as tractors and trailers to move the cranes and perform other support functions. As the company is not focused on a specific market, their priority is having a wide variety of crane offerings.

“We have cranes ranging from eight tons to 660 tons in capacity,” Long said. “We have crawler cranes, hydraulic mobile

cranes, boom trucks and industrial cranes. And we have them from all the common manufacturers. We have cranes to suit all different needs and we also have several specialized rigging systems to complement them. SPMTs, hydraulic gantry, a hydraulic skidding system, all sorts of rigging, spreader beams and below-the-hook goodies that add value and versatility to the cranes.”

In Long’s time with the company, the main evolution he has seen is the market demanding faster, more efficient and better equipment, which has been driven by a more competitive marketplace.

“You need to be sharp; you need to be responsive,” Long said. “We always do our best to try and make the schedule work, but the demand for excellence just continues to go up and up and up. So, you need to be faster, stronger, safer and add more value every year.”

Long added the biggest challenge for Irving Equipment today is operating in a market with somewhat limited industrial activity. This creates a challenge when developing a modern fleet in an area where the volume of work is less than it would be in a major urban centre.

“You have more road miles between your job sites, you have less frequency between your jobs,” Long said. “And, for the last number of years, there’s been no major industrial developments taking place in Atlantic Canada.”

Looking to the future, Long says the company is planning on making further revisions to the CraneCAD software, to make it more approachable and collaborative for their clients. One revision will be the incorporation of augmented reality features, where a user can point their smart device at a paper lift plan and will be able to view a fill 3D model without the use of a special printer or goggles.

“I think it’s going to be a game changer when you’re talking to less technical folks on certain teams because you’ll be able to show them exactly what’s happening,” Long said. “We also picture it on the job site – when you’re sitting on the tailgate of a pickup truck and you’re about to make a lift. It’s a great opportunity for everybody that’s about to be involved with that lift to see for one last time about who should be where, which direction is the crane going to swing first. Any crew member would be able to point his phone at it and see.”

“We’re excited about the future at Irving Equipment,” Long added.

After more than four years of construction, the renovation of Toronto’s Union Station is complete.

The result is a more modern aesthetically pleasing and innovative station.

The improvement work at the Union Station Bus Station — one of the busiest in the world — and the construction of Toronto’s innovative CIBC Square has been made possible thanks to years of effort and major partnerships with Sarens.

The main work was focused on creating more modern infrastructure, increasing capacity, and building CIBC Square’s two towers, which resulted in a unique creation.

The bridge connecting the two towers is a portrait of modern architecture, mixing the classic structure of a hanging bridge with the view of a more than 4,000 square-metre park.

To construct the bridge, Sarens had to work by adapting to passenger traffic. So, they started working on a night schedule to interfere as little as possible and avoid negatively affecting the lives of pedestrians who walk along Bay Street, where the station is located.

For the project, Sarens had to install and lift large iron beams weighing a total of 9,434 kg, which support and enable the development of the one-acre flying garden that connects the north and south towers of the station. Thanks to this method, it has been possible to carry out the project effectively in just four months.

“The newly renovated Union Station will have an enormously positive impact on the community,” says Lee Rowe, Sarens regional director NAM, after expressing his gratitude for being able to take part in a project of this relevance for the Canadian city.

The completion of architectural ensemble is a real milestone for Toronto, as it is unique construction, representing the first skyway bridge in Toronto and one of the first in Canada.

Due to the social and economic importance of the station, transport was never suspended. The work had to be carried out with an extra degree of complexity, which is where companies such as Sarens come in helpful with an extensive experience in similar situations, that allows the company to adapt to the needs of each project.

Ports are pushing their container cranes harder for longer, which can lead to cracks and other

Richard Phillips, mechanical engineer, Casper, Phillips & Associates

Lately, it seems ports are delaying crane purchases and want to use their existing cranes past their design life. As well, cranes have been pushed harder than ever as they move record amounts of container traffic.

These two factors have led to an increase in maintenance issues related to fatigue on older container cranes.

Although steel can have an infinite design life in low stress environments, designing cranes to have infinite life would increase the cost to the point where it is not competitive.

Container cranes 20 years ago did not service ships as large as they do today, so it was unheard of to have a crane with an outreach of more than 61 metres. Back then, the largest cranes could pick up a single 40-ft. or twin 20-ft. containers, whereas today the largest cranes can lift tandem 40-ft. containers or four 20-ft. containers.

Many people think of fatigue as “wearing out” of the steel but this is not quite right. Fatigue failure occurs in components subject to a high number of fluctuating stresses. Under these conditions, it is possible for failure to occur at a stress level significantly less than the tensile or yield strength for a static load. If the fluctuating stress is low enough and in an ideal environment, steel has infinite fatigue life.

Cracks can initiate from many sources, such as high cycle fatigue, poor manufacturing, corrosion, or overload events such as snag, earthquake, or storm winds. The initial flaws may be microscopic or macroscopic. Growth rate increases with crack size, so a flaw that has grown from microscopic to a detectable size is well along toward reaching critical size. However, if the steel lacks reasonable notch toughness, the critical crack length will be significantly smaller than steel with excellent notch toughness.

It’s unlikely that someone without training would be able to detect the first signs of cracking or fatigue. It is also unlikely an operator would notice a change in the performance of the crane, even if they are very familiar with it.

Fatigue and corrosion failure of container cranes have been rare, but there has been at least one incidence of total collapse and several close calls where imminent failure was avoided because cracks were discovered just in time. Numerous fatigue failures of individual members and connections have occurred but usually loads shift to an alternate load path, avoiding total collapse. Therefore, alternate load paths are an important fatigue design consideration.

Stress concentrations on a container crane forestay led to crack formation.

Just how critical is the problem when cracks appear? The answer depends on how much damage the area can safely withstand and the consequences of its failure. Damage due to a crack is directly related to how fast the crack can grow. The study of crack propagation is known as fracture mechanics, which combines analytical methods with experimental research to quantify a crack’s growth potential.

A single trolley ship-to-shore crane with forestay (a structural member that supports the cantilevered boom that sticks out over the water), and other parts labelled.

The consequences of a member or joint’s failure also plays a part in determining the criticality of a crack. A member or joint that has no alternate load paths and whose failure would cause a crane to collapse is called fracture critical.

Within fracture mechanics, one methodology to manage cracks and other defects is using damage tolerance. Pioneered by the aerospace industry, the idea behind damage tolerance is the engineer assumes there is a crack of the smallest size with a given

This forestay crack was discovered just in time.

inspection method. From there, the engineer can calculate the crack growth rate that will occur during normal use. This analysis is then used to set the appropriate inspection intervals based on the criticality of the member or joint. By calculating the crack damage tolerance of a crane and implementing the resulting inspection program, chances are much better that repair work can be identified and scheduled to minimize operational downtime.

Design specifications for container cranes have been developed by consulting engineers, port authorities, and shipping companies. The specifications usually require the design of various elements comply with domestic and international design codes.

A consultant is often hired to validate if the crane structure and its components meet the specification requirements. The consultant must have engineering expertise and knowledge of local and foreign codes. Ensuring a crane design meets the design specifications reduces the risk of structural failures by ensuring appropriate materials and loads are used.

Unlike other industries, the container crane industry has no formal body for investigation, documenting or reporting structural failures. These failures are often a source of embarrassment, liability, or litigation and, therefore, remain confidential. If an accident occurs, disputes are usually settled through private litigation. Best practice is to prevent accidents, so it is always a good idea to have a qualified engineer review the crane manufacturer’s design before construction, as well as having a good maintenance program once the crane is in service.

Another vital point to consider is corrosion. Of course, container cranes exist in a relatively hostile environment surrounded by saline and acid laden air. Techniques and materials for preventing corrosion are well known and the failure to maintain a corrosion-free crane is tantamount to accepting a reduced life for the affected crane components.

In this current economic environment, there is uncertainty surrounding steel fabrication. Steel prices, component availability, labour prices, and workforce availability are all volatile. Crane owners want to protect themselves by procuring cranes on a firm fixed fee contract. Such a contract includes all costs associated with crane procurement including delivery and commissioning for a single price. Likewise, crane manufacturers protect themselves by building in costs due to the uncertainty surrounding steel fabrication.

This has further increased the number of crane owners taking interest in extending the life of cranes. A crane may have been designed for two million cycles, but the crane owners want to study the business case for upgrading the crane structurally and mechanically to extend the life up to three or even four million cycles.

As cranes are used beyond their original design life structural strengthening is a common method to extend the useful life. If a critical area has been properly strengthened, it will be less likely to develop cracks and will require less frequent inspections.

If a crack is detected it can be repaired. However, due to residual stresses, and other limitations from the on-site crack repair, detectable cracks may re-develop after fewer load cycles. If cracks are found, further engineering analysis should be conducted to determine what repairs should be made, plus due consideration should be given to increased inspections and possibly reinforcement. The most common fix for cracks is to grind out and weld repair them. Remember though, the best solution is prevention.

The most important defence against structural aging is targeted inspections performed at specified intervals. Of course, operators and maintenance personnel should be trained to inspect constantly at every opportunity. However, this should not replace inspection by trained technicians working at known intervals.

Periodically, all cranes should be examined by a technician with broad, generic experience with structural maintenance problems. Dangerous cracking and deterioration can escape even the most conscientious visual inspection. A sizeable fatigue crack can close so tightly it may not be visible to the naked eye even if known to exist. The only reliable way to find fatigue cracks is by non-destructive testing (NDT) methods by a qualified technician.

An engineered inspection manual can tell inspectors where and how often to look for cracks. A good inspection manual will show which NDT tests to run on the welds most likely to have fatigue cracks develop. For container cranes, maintenance windows are available in between berthing vessels. During this time, the cranes are not in service, and NDT can be performed. The inspection methods most used are visual, magnetic particle, or ultrasonic, and will depend on how critical the member is to the load carrying capacity of the crane.

Inspection by outside technicians is expensive but can save property and lives. Like all other risk/benefit alternatives, there is no universal answer to how much one should spend to reduce risk. The key to getting the best life out of these cranes is to have a good inspection manual and a responsive maintenance program. Creating post design life structural inspection manuals is a widely accepted service many crane owners currently utilize. Discovering a crack early can not only limit the scope of the repair but also limit unscheduled downtime.

By Bill Tremblay

Liebherr has announced the introduction of the 470 EC-B flat-top, the largest crane in its Tough Ones series.

The flagship crane, equipped with intelligent assistance systems, offers a jib length of 80 metres. Its reach can be increased to 83 metres by means of a jib extension, breaking new ground in the market.

With a jib length of 80 metres, the 16-tonne version of the 470 EC-B has a jib head load capacity of up to 3,200 kg. The 20-tonne version delivers a jib head load capacity of up to 3,000 kg. The jib can be divided into two-and-a-half metre sections so it can be adapted to meet a variety of operational requirements.

During development of the flat-top crane, Liebherr focused on performance as well as assembly and transport. As a result, the jib and counter-jib can be attached to the slewing platform easily and safely. Liebherr’s quick assembly connections make it all possible. According to Liebherr, five trucks are needed to transport the slewing part with jib, including counter-ballast, to the construction site.

The 470 EC-B features a connection for both 24 HC 420 and 24 HC 630 tower systems. The 24 HC tower system is an ideal match for large cranes with high lifting capacities. Its compact dimensions allow individual elements to be moved cost-efficiently from A to B.

The 470 EC-B has been optimized for the 24 HC 420 tower system; together they are a cost-effective combination for freestanding hook heights of up to 67.8 metres. The maximum freestanding hook height of up to 96 metres is achieved with the 24 HC 630 system.

The top-slewing crane is available with one of three versions of the LiCAB crane operator’s cab: LiCAB Basic, LiCAB Air or LiCAB AirPlus. All three offer a floor space of more than two square metres, an unrestricted view for precision lifting and an ergonomic control stand. The features enable the crane operator to stay focused on the job at hand. Thanks to the cab’s extensive field of vision, the crane operator has a clear view of the site and its load, which contributes to the safety of both operator and machine.

The new Liebherr 470 EC-B crane is available to order now as a 16-tonne and 20-tonne version.

Clear overview: The Tower Crane Operating System (TC-OS) impresses with its streamlined menu structure on a 12” multi-touch display.

Also included in the cab is the newly developed 30-cm display screen with intuitive operability.

The Tower Crane Operating System (TC-OS) provides crane operators and assembly engineers with specific menus, languages options and user-friendly units of measurement. The intention is every user should be able to find the parameters relevant to their work without difficulty. Users navigate their way through the streamlined menu structure via touchscreen. To maintain an overview during crane operation or scaling, display masks can be combined in various ways. The usability of the TC-OS means that training and familiarization times are reduced.

LED advertising panel lighting can be configured to ensure a substantial long-distance effect and visibility, particularly at the onset of twilight and at night. With a total area of 8.6 square metres, the lighting delivers effective promotional impact. The panels don’t have to be mounted separately during assembly and can remain in place on the counter-jib end section during transport. Signage is easily applied.

As they don’t have a tower head structure, several EC-B series Flat-Top cranes are able to work together safely on the same site, even in tight conditions. EC-B cranes are specifically designed to meet the requirements of modern construction sites. They cover a wide performance spectrum, ranging from small city to large handling cranes. The new 470 EC-B completes the top end of Liebherr’s successful series, with the crane reflecting the construction industry’s trend towards ever heavier components.

Bill Tremblay

The Association of Equipment Manufacturers (AEM) is predicting 2022 will deliver strong demand for its members, as the industry continues an uphill climb to achieving a pre-pandemic business climate.

According to new business intelligence data from AEM, the global economy expanded by 5.1 per cent in 2021.

For the construction equipment market, the industry value is expected to grow 4.5 per cent this year, largely driven by residential construction. AEM member perceptions show strong demand, as 83 per cent see year-over-year growth ahead. As well, it’s reasonable to expect growth of six to 10 per cent over the next 12 months on the heels of six to 10 per cent stronger growth than was expected in 2021, according to AEM.

“I believe it’s going to get better in 2022. I don’t believe it will be back to normal in 2022,” said Rodney Schrader, vice chair of the AEM board and Komatsu North America chairman and CEO.

“The overall industry looks to be heading in a positive direction, but we do have to watch some of the headwinds.”

Those headwinds include aggressive cost increases, the ongoing labour shortage and a stressed supply chain.

According to AEM’s most recent quarterly survey of its members, more than 95 per cent of ag and construction equipment manufacturers that responded said they are experiencing supply chain issues. However, it appears either demand is beginning to normalize, or supply chain signaling is improving, as 44 per cent of respondents noted the issues are beginning to turn around.

“Equipment manufacturers have been working very hard to keep vital industries supplied in the midst of the COVID-19 pandemic.”

“We have all gotten very creative in the last couple of years. We have all adapted our resources, processes and actions to mitigate significant impact to our customers and dealers,” said Robert Crain, chair of the AEM board. “No doubt we are still going to face some challenges in the coming months, but we are cautiously optimistic that 2022 will see some improvements across most areas.”

Schrader added manufacturers have taken numerous actions to navigate a difficult supply chain, including using a variety of shipping ports, finding additional suppliers and incorporating new transportation modes that were not typically utilized in the past.

“The challenge has been real for the last 18 months,” Schrader said. “Equipment manufacturers have been working very hard to keep vital industries supplied in the midst of the COVID-19 pandemic.”

Although AEM sees stabilization on the horizon, the pandemic has previously derailed positive outlooks. When the omicron variant emerged earlier this year, a high infection rate meant more employees were forced to call in sick.

“We have had periods where it appeared to be getting better, but got worse,” Schrader said.

The labour force remains a factor for ag and construction equipment manufacturers. According to the results of AEM’s most recent quarterly member survey, 84 per cent of all respondents have experienced recruitment issues.

Inflation is another challenge for AEM members. For construction equipment, the industry has recorded an inflation rate of 9.7 per cent in the last quarter.

While the pandemic created its share of challenges for equipment manufacturers, Schrader noted the challenges are also learning experiences.

“Our teams in our individual companies are spending a lot of effort to adapt in order to minimize risk,” Schrader said. “Not only today, but in the future, so we are more flexible and adaptable to these things happening again.”

Here are some possible photo ideas to get you started:

Construction jobsites | Ports

Oil and gas projects | HVAC lifts

Manufacturing applications | Any unique type of lift

• MODEL OF EQUIPMENT (IF APPLICABLE) LOOKING FOR A LITTLE INSPIRATION?

ALONG WITH A HI-RESOLUTION IMAGE, PLEASE ADD THE FOLLOWING:

• A BRIEF SUMMARY (50 TO 100 WORDS) ON THE PROJECT

• DATE OF PHOTO

• LOCATION WHERE PHOTO WAS TAKEN

Please

By Matt Jones

Atower crane operator at a Halifax construction site played a key role in the rescue of a co-worker who suffered a medical incident.

In February, Arnoldin Form Work Ltd. crane operator David Mason was in the tower crane conversing over the radio with his rigger about the day’s planned lifts when he noticed something wrong with a co-worker.

“I saw him fall over on the 14th floor and he started having a seizure,” Mason said. “My foreman and my rigger went over to assist him. A few minutes later he started to come to, but he didn’t have any idea who he was, where he was or what happened.”

Mason said in the state of confusion and panic, the worker attempted to lash out at those around him and had to be restrained.

“He was grabbing people, he was screaming nonstop,” Mason said. “He was trying not to let them restrain him and he was trying to hurt himself.”

In less than 10 minutes, Halifax Regional Fire and Emergency Services (HRFES) arrived on scene and began strategizing how they could get the worker to the ground so paramedics could attend to him. In the end, the crane Mason was operating was used to lift an Emergency Medical Technician (EMT) and medical equipment and then to lower the EMT and the ailing worker to the ground.

While HRFES representatives were not available for comment about the decision making that led to using the crane for the rescue, the building had not yet had elevators installed. But regardless of how that decision was made, Mason was ready to assist.

“This is my first year working with this company,” Mason said. “I’m from Vancouver, I’ve been there the last 10 years, that’s where I got all my training. In Vancouver, we usually did a test once a month, have somebody lay down fake injured or fake sick and we would do a practice run.”

Mason said lowering the worker and the EMT was ‘pretty straightforward’ and was completed without incident. The crane used was a Terex Peiner SK 206, though Mason generally uses a different crane on site.

“I’m normally in the Terex Peiner SK 315 but this particular day they were raising our third crane another 60 feet,” Mason said. “My crane and the crane they were raising were overlapping so my usual crane was not allowed to run.”

Regardless of his previous training, it was nerve-wracking for Mason to perform such a rescue for the first time in his career.

“It’s one of our worst fears, we are never really prepared for it,” Mason said. “No matter how many practice runs you do, it’s a totally different story when you’re there in the moment. As it was happening, I felt helpless. They had great open communication the whole time, but I felt helpless. You work so long together; you learn to look out for one another and keep each other safe and become a family. Then when you’re sitting there in a 4-ft by 5-ft box and can’t do anything, you feel helpless.”

HRFES district chief Brad Connors told local media that “with the assistance of Emergency Health Services we packaged the patient, we lowered the construction member down from the crane in a basket with one of our rescue technicians and now we have turned over the patient to EHS’s care.”

No official word has been released regarding the status of the worker who suffered the incident, but Mason said that two hours later someone on site received a call from him and he was laughing and in good spirits.

A representative for Arnoldin Form Work Ltd. confirmed the worker was “OK” after the incident but had been advised by doctors to wait until the completion of medical testing before returning to work.

Tadano introduces the first crane under its one brand strategy

Tadano’s AC 2.040-1 all-terrain crane. PHOTO: TADANO.

The new AC 2.040-1 all-terrain crane is the first member of the future Tadano AC family. It’s introduction also signals the completion of the announced brand merger, and now all Tadano Group cranes will be sold exclusively under the Tadano brand name. As well, it is the first all-terrain crane developed jointly by Tadano’s Lauf and Zweibrücken locations in Germany.

“That’s why this market launch is really special for us – after all, the new AC 2.040-1 is the first crane to

combine the best of our two worlds with the know-how from Zweibrücken and Lauf,” said Dr. Frank Schröder, Tadano’s all terrain crane product line vice president.

The AC 2.040-1 is part of the company’s innovation push, which will see 15 new crane models come onto the market in the next few years under the Tadano brand name. All future models will share the same DNA with the AC 2.040-1, including a standardized crane control system, cab and technologies.

“The slogan for our one-brand strategy is Your Passion. Our DNA. As far as we’re concerned, cranes are more than just a product we sell,” said CEO Jens Ennen.

“In addition, we also want to convey an exclusive sense of purpose and dedication: No other manufacturer is as focused on lifting equipment as we are, and this goes both for our company

as a whole and for each individual member of our team. For us, ever single lift that is performed out there is just as important as it is to the customer carrying it out.”

For the AC 2.040-1, the Tadano engineers from Lauf and Zweibrücken combined the best of both worlds. Like all future models, it features the innovative IC 1 Plus control system with automatic counterweight detection, a capacity radar and a work area display.

The system determines the crane’s lifting capacity for every boom position as a function of the superstructure’s slewing angle. This enables the AC 2.040-1 to always make use of the maximum available lifting capacity with any outrigger configurations. The advantage is maximized when combined with the Flex Base system, which makes it possible to extend the outriggers to any point

within their range. In addition, the crane features the one-of-a-kind Tadano surround view camera system, which shows both the possible extension lengths for the outriggers and the counterweight tailswing radius.

The ESTA-award-winning E-Pack with its 32-kW electric motor is available as an option and enables the AC 2.040-1 to quietly work and with zero emissions indoors and at nighttime in residential areas. Like all future Tadano cranes, the AC 2.040-1 comes with an ergonomic cab, previously only used on Zweibrücken produced all terrain cranes.

Furthermore, the AC 2.040-1 offers an entire series of model-specific advantages. As a two-axle crane, it is extraordinarily compact and perfect for use at constrained jobsites. For maneuverability, the crane

includes a steerable rear axle with automatic programs for extremely tight radii and crab steering. As well, the compact design, with an optimized weight, also improves roadworthiness, giving it advanced taxi crane capabilities, and the ability to carry up to 2,425 lb. of counterweight while staying under an axle load limit of 12 tonnes.

Equipped with a 310-hp Cummins diesel engine, the AC 2.040-1 will not need any extra permits thanks to its EU Stage V classification, which means it fulfills the latest emission standards.

Tadano also decided to split production responsibilities of the new crane between the two locations, with superstructures to be made in Zweibrücken and carriers in Lauf in the future. “This will allow us to take full advantage of the unrivaled carrier development and manufacturing know-how of our Lauf location,” Schröder said.

BKT’s AiroMax AM 543 tire.

PHOTO: BKT.

Mobile cranes perform various tasks in the industrial, construction and infrastructure fields. They can usually travel at high speeds and reach 80 km/h.

It is important for mobile crane tires to work at lower temperatures, making radial products ideal.

The tires must be suitable for applications on both roads and

highways and on the more aggressive and uneven terrain of worksites. BKT tires for mobile cranes are designed and built specifically to face the challenges of demanding jobs, when heavy loads are being transported on a range of surfaces.

To obtain high performance in terms of productivity and safety, BKT has developed products that provide stability during pick-up and transport.

As well, all tires in the specific BKT ranges for mobile cranes are equipped with a robust structure in steel and particularly cut-resistant compounds to guarantee long duration. The structure is, of course, suitable for high speeds during movements on roads and motorways.

Currently BKT offers two different product lines dedicated to mobile cranes, even if the portfolio is particularly wide and aimed at other types of cranes and industrial or construction machinery. Both the ranges are radial and classified with the speed indices E and F.

The AiroMax AM 27 is suitable for movements on roads and highways that require high resistance to wear and tear, while maintaining excellent traction and resistance on aggressive and uneven terrain. It has been made with a casing and belts in steel layers to guarantee robustness and resistance.

The AiroMax AM 543 is suitable for cranes used in the construction sector, thanks to its and stability. The deep and knobby tread guarantees performance on rough terrain, ensuring protection to the tire structure. Given it is subject to extreme conditions, the tire has been designed to resist severe stress, a fundamental characteristic for this type of machinery and application.

The LTM 1150-5.3

Capable of carrying nine tonnes of ballast with an axle load of 12 t, together with a powerful 66 m boom. That reduces the number of transport vehicles required. Global mobility and convenience thanks to ECOmode, ECOdrive, Hillstart Aid and VarioBase. It does not get more economical than that! www.liebherr.com