BY MATT JONES

There are an estimated 300 tower cranes operating in British Columbia, which is a sign of progress and expansion, but also a measure of the importance of crane safety and ensuring that all possible measures are being taken. WorkSafeBC is introducing new crane safety initiatives this year, to focus on the differences between qualification and certification, operator competency for operation and maintenance, and ensuring that inspectors now check for preventative maintenance.

Al Johnson, vice-president prevention services at WorkSafeBC says that the overriding effort; however, is about ensuring all parties understand their roles and responsibilities regarding safety.

“It’s not that there’s absence of that interaction and absence of taking those responsibilities,” says Johnson. “It’s confirmation or affirmation that those parties are working together to take that shared responsibility. So when a tower crane, or whatever the case is, is being assembled or disassembled, that those who are involved in the engineering controls and engineering inspections are working collaboratively with the right people. It’s not a standalone effort.”

Johnson says that the focus on assembly and disassembly is due to WorkSafeBC’s findings that the majority of crane collapses and other incidents have occurred during those phases. Johnson says British Columbia is very fortunate that few such incidents occur in the province; however, when such an incident does occur, it can be catastrophic in nature.

“So we learn from those catastrophes, those horrific incidents that occur elsewhere, and we want to do everything we can to prevent them from happening here,” says Johnson. “When cranes, tower cranes in particular, are assembled and disassembled in urban areas, in closer proximity to all sorts of things, that’s when the risk of an event can occur.”

Johnson says he and the provincial crane inspection team focused not just on the assembly and disassembly of the cranes, but also on issues related to that process. They’ve co-ordinated with municipalities, for example, to review best practices for permitting and traffic restrictions during the erection and disassembly of cranes.

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor – Jay Koblun

jkoblun@annexbusinessmedia.com • 519-410-0600

Account Manager – Amanda McCracken

amccracken@annexbusinessmedia.com • 226-931-5095

Media Designer – Svetlana Avrutin

Regular Contributors

Saul Chernos, Doug Younger, Nelson Dewey, Matt Jones, Judy Mellott-Green Group Publisher – Todd Humber thumber@annexbusinessmedia.com

COO – Scott Jamieson

sjamieson@annexbusinessmedia.com

Audience Development Manager / Subscriptions – Urszula Grzyb ugrzyb@annexbusinessmedia.com • Tel: 416-510-5180 Fax: 416-510-6875 or 416-442-2191 • www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/ Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO:

Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: May 22, 2020

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: May 29, 2020 For writers’ guidelines and submission requirements get in touch with the editor, Jay Koblun, at +1-519-410-0600 Email: jkoblun@annexbusinessmedia.com

Last Saturday was the first day out of my house since I came home from CONEXPO. After 14 days of self-quarantine, I ventured out and celebrated my “freedom” by heading to the fanciest and most exclusive grocery store in Hamilton to buy some essentials my wife and I had run out of. So exclusive, it had a lineup, dress code, and a bouncer.

Once past the bouncer, I was greeted by several smiling workers, all giving me ample space to explore the store at my leisure and take my time shopping around. It was like the workers finally caught on that shoppers don’t need to be asked every two minutes if we need help finding something. No one talked to me at all actually. It seemed as if other shoppers were going out of their way to not cross paths with me entirely. Then it was time to pay. I was guided by a polite and well-dressed, pleasant worker to the selfcheckout, paid for my fruit, veggies and dairy-free ice cream in silence, got in my VW Golf, and headed home. Turning the key over in my ignition I realized just how much the world had changed in the last 14 days and how unsure and concerned the public is in regards to the COVID-19 pandemic. Rightly so. I hadn’t actually been shopping in the city’s most exclusive grocery store, and there wasn’t a dance-club-style line-up, dress code, or bouncer. The line was implemented to keep a regulated number of

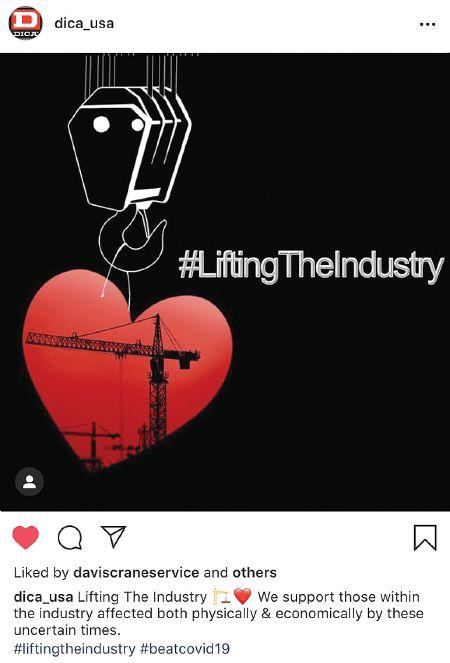

shoppers in the store, the dress code was simply facemasks, and the bouncer was a Fortinos employee letting people inside as he saw previous shoppers exit from another door. It would be hard to find an industry that hasn’t felt some impact from the virus, and the heavy lifting and crane industry is no exception. From layoffs, closed construction sites, delayed projects and more, the industry is really pulling together to face this adversary together. The amount of positive messaging, Instagram stories and companywide encouragements I’ve seen on social media has been uplifting in these uncertain times and we’ve curated a few of those posts in this issue to show what you in the industry have been up to.

The May/June issue of Crane & Hoist also has ample up-to-date COVID-19 coverage. From tips on how to keep your jobsite and office clean and safe, to government issued protocols, it’s there. And check out the CONEXPO/ CON-AGG coverage, along with features on tower cranes, and a section celebrating some trailblazing women in construction.

No one knows exactly what’s up with COVID-19 news and information updating daily but you can count on us to be there and stay as up-to-date as we can with the information we have. Crane & Hoist would love to hear from you and your team what you’ve been up to, or not up to, during this time. Reach out, we’d love to chat.

Do you have a story tip or a crane and hoists operation with a great story to tell?

Send me an email at jkoblun@annexbusinessmedia.com.

Have photos of unique cranes and hoists?

Email a photo and brief description to editor Jay Koblun at jkoblun@annexbusinessmedia.com.

he heavy lifting industry is feeling the effects of the ongoing coronavirus, or COVID-19, global pandemic. Several companies have withdrawn their outlooks, are requiring employees work from their homes, cancelling industry events and more. There are still a lot of unknowns facing the industry and managers and business owners are implementing what they can to help teach proper safety during this time and trusting that the future of the industry is hopeful.

New Strongco president shares goals for company and concerns on COVID-19

The new president and CEO of Strongco, Oliver Nachevski, is looking forward to running the company and is hopeful of an even stronger economy if the COVID-19 pandemic eases and industry returns to normal.

“My main goal right now is to get through the COVID-19 pandemic, it’s a very difficult time,” says Nachevski. “Trying to keep everyone employed right now as the government is making constant changes. No one really knows what’s going on. We need to be ready and willing to adapt.”

Nachevski was made president and CEO of Strongco on the heels of the recently completed acquisition of Strongco by Nors on March 18, 2020. Nors is a Portugal-based transport solutions and construction equipment company.

“We’re looking at everything on a regional basis. As far as the future of Strongco, it’s something that you’ll find will grow in Canada over time. That’s something we think Nors brings to the operations in Canada.

“Really right now with the economy and uncertainty of the situation, our goal is to do what we can to keep everybody safe, and then we work with the Nors team.”

Safety measures

Nachevski said the Strongco team will have had its first official board meeting with the Nors team on March 24 via Skype. And in the meantime, Strongco is taking steps to keep its workplaces safe.

“I’m having conversations with my regional teams daily. My regional vice presidents report to me daily on what’s happening in their workplaces. We’re allowing people to work from home. We have our workers who are fixing cranes and machines spaced out from one another as much as possible. We stagger our lunches and breaks and we have new cleaning processes in place,” he said.

“Depending on what the provincial and federal governments do, we will follow all the rules in place. We’re watching each market separately.”

Nachevski said if the virus stops spreading and manufacturing can return to a somewhat normal pace there is still a concern for a slowdown but is hopeful there won’t be.

“It’s all going to depend on how it moves. A lot of our product is built in other areas of the world right now—we have experienced no slow-downs yet. That turns in to a potential problem down the road depending on the affected areas of the world which manufacture our products.

“The biggest concern once we get past this is there may be a slowdown in getting some of our products from our manufacturers, but that’s something we will deal with then,” he said.

Nachevski said it took the team a long time to solidify the deal with Nors, but the Nors teams was one of his top choices if he could have picked the future partner himself future partner.

“I was part of the discussions with the finalist and Nors was my choice. We’re really excited to be a part of this,” he said. The combined entities now share a global footprint that spans over 17 countries on four continents Nachevski joined Strongco in 1996, and in that time, he made a significant impact on many facets of the business, from finance and credit to crane operations and construction equipment. He is a chartered professional accountant (CPA) and has held many titles, including most recently vice president and chief operating officer.

There are few people with more years dedicated to standards in Canada’s overhead crane industry than Judy Mellott-Green. The president and CEO of the All Canadian Training Institute (ACTi) has been active in the industry for nearly three decades, and is just as passionate as ever about promoting safety and improving standards across Canada, despite the current coronavirus pandemic.

Coronavirus or, COVID-19, has had an effect on hundreds of businesses across the country and the Alberta-based ACTi has felt its effects too. Judy shared some of the changes she’s made at her offices and her thoughts on the future of the safety and training industry post-COVID-19.

CHC: What’s the biggest change in how ACTi is operating now from before the pandemic?

Judy: Everybody is working from home, we’re out of the office. That’s the biggest change. We haven’t had to implement new cleaning measures or sanitation methods at the office because everybody is working from home now. We stay in contact with our computers. Everything that needs to be done is being done at home.

CHC: What are some ways the virus is affecting ACTi?

Judy: The boss is grounded. I’m not allowed anywhere near the place. I’m no spring chicken anymore. I trust my staff to do a good job and they know what they’re doing. All of our onsite training has stopped, because all of the training we do is done by an instructor at a site. People need to stay away from each other, and we work in a shop, with a crane, and a classroom, in a confined space—we had to stop.

CHC: What are some ways the virus is affecting your clients?

Judy: Several of our clients have all their sites because of what’s going on. Others too, are taking the pandemic seriously and not keeping their sites open. Which means there is less opportunity for us to train but that’s expected considering everything going on.

CHC: When did you realize the pandemic was as serious as it is?

Judy: I’ve seen similar illnesses affect the world in this way before, like H1N1. I wasn’t personally affected, but I’ve seen the world pull through. So, at first, I thought about the coronavirus in a similar way. That everything would be fine. But once it was announced a pandemic I started to think about it differently and through the advice of my staff I decided it was time to take it seriously and make the calls to keep people home and stay home myself.

CHC: How do you feel about the responses you’ve seen made by the industry in general?

Judy: We’re finding people begin to worry when they hear that training shuts down on a job site. People are really worrying about the number of layoffs too. What’s affecting us long-term is the cancellations of work coming at a later date. Right now, we’re coming into summer, which is fortunate for us, training slows down in the summer because a lot of people are away on summer vacation. Our busy season is September through April or May.

CHC: What do you think the industry will look like in the aftermath of the pandemic?

Judy: The economy in Canada is strong and there is a lot of positive things going on in Canada, a lot of our business comes from the U.S. and often Canada is more stringent with standards in our industry, so we will have to wait and see how it plays out.

“I think it’s going to make a lot of people do some serious thinking about the safety procedures on the job site, other than just learning how to operate a tool or a machine safely. This is something we’ve never had to consider before,” Judy Mellott-Green.

No one knows for sure what happens when we face something like this. What the Canadian Government is doing for Canada is the right thing right now. It could be a long recovery for some companies in the country but like everything else, we will survive.

COVID-19: What managers can do

Crane and heavy lifting companies across the country have been feeling the effects coronavirus, or COVID-19, is having on the construction industry. Whether it’s downtime at the site, sick employees, or lack of supplies—managers are doing whatever they can to keep their workers safe.

“I’m sure all crane companies throughout Canada are trying their best to balance financial obligations, and job site and contract commitments, while ensuring the safety and wellbeing of their employees and families,” said Sheena Baker, operations manager at Canadian Crane Rentals in Ontario. “We have implemented extra health and safety protocols to help reduce the spread and risk to our employees and customers.”

Baker said some of those protocols include; not slip seating, same operators will continue to run the same cranes daily; extra cleaning measures, operators have to disinfect their cranes daily; safety talks centred around social distancing and proper hygiene practices; Canadian Crane Rentals has provided extra personal protective equipment for workers, hand sanitizers, gloves, disinfectant sprays and wipes; and radios are being encouraged to communicate onsite, so operators can work safely from their cabs in isolation.

“Our shop facility has implemented daily disinfecting protocols for all common areas, tools, tool boxes, light switches, workbenches, phones, keyboards and all other main touch surfaces. Extra hand washing stations have been setup and we provided gloves to reduce the risk of spreading the virus or contracting it,” explained Baker.

“Canadian Crane Rentals understands the seriousness of COVID-19, it is a worldwide pandemic and everyone needs to work together to reduce the spread and the strain on our healthcare system,” said Baker. “We will continue to follow the advice of our prime minister and provincial premier. We can continue to operate our business with safeguard measures. We’re fortunate that our customers are still calling and continuing to work with extra precautions being implemented on-sites.”

Here is what Canadian Crane Rentals is suggesting its employees do at home:

• Clean your hands often.

• Avoid crowds, stay home as much as possible. Keep in touch with family though social media outlets, FaceTime, etc.

• Try to avoid touching high-touch surfaces in public places. Elevator buttons, door handles, handrails, handshaking with people, etc. Use a tissue or your sleeve to cover your hand or finger if you must touch something.

• Wash your hands with soap and water for at least 20 seconds after touching surfaces in public places.

• Clean and disinfect your home to remove germs.

• Avoid all non-essential travel.

CRAC AGM in Vancouver postponed due to COVID-19 concerns Crane and Rental Association of Canada (CRAC) board of directors have postponed the 2020 conference scheduled for May 27-30 in Vancouver, B.C., and sent out the following statement:

It’s not just the rental companies that are doing what they can to slow the spread of the virus. Baker said Canadian Crane Rentals is grateful to their suppliers for quickly implementing safeguard measures to focus on keeping their workers healthy and safe, while continuing to provide customer services and product delivery.

“We’re trying to do our part in reducing the spread and the risk to our workers. Healthy workers are productive workers for our customers,” she said, adding if an employee gets sick to stay home and call your doctor or Telehealth.

As we activate our crisis management plan, we are doing everything in our power to minimize the financial impact this cancellation/postponement may have on our association and will keep the membership informed over the next few months. In light of the economic crisis to be faced by all in the coming months, we will not reschedule the conference this year. We are presently considering 2022 to keep the East-West rotation but this may change. An electronic AGM will be schedule toward the end of May or early June.

If you are already registered, we would like to offer you the following options:

1. We can hold your payment until the new dates have been confirmed.

2. We can refund you in full. Email adm@crac-aclg.ca to inform us.

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

If you have contributed as a corporate Partners to sponsor the conference, Claire Bélanger-Parker will be reaching out to you personally to discuss options.

In these times of uncertainty, please take care of yourself and your family. If you are returning from any sort of travel, please self-isolate yourself to protect your loved ones. We will activate our social media platforms so we may stay better connected and informed about each other.

If there is anything, we can do to assist you, do not hesitate to reach out to us. The world as we know it today may never be the same but the friendships and relationships we have developed over the years will remain to support each other in these challenging times.

Feds offer help to companies to retool, pump out COVID-19 medical gear

The federal government is unveiling a plan to have companies quickly produce medical equipment to cope with the rapidly multiplying cases of COVID-19 across Canada.

Prime Minister Justin Trudeau says the plan will provide support to manufacturers that want to retool their assembly lines to make ventilators, masks and other personal protective gear. And it will also help those already making such products to quickly scale up.

Ottawa has been working with provinces and territories, which deliver health care, to determine where gaps exist in the system and to try to fill them before they become a significant problem.

Trudeau also says the government is in discussions with airlines to repatriate Canadians who are overseas.

Public Services and Procurement Minister Anita Anand and Industry Minister Navdeep Bains are to provide more details at a briefing early in the afternoon in Ottawa.

Canada’s chief public health officer, Dr. Theresa Tam, has said there has been no specific request for ventilators yet but the federal government is trying to pre-empt that by acquiring things that may be needed as the number of cases surges.

Speaking outside his Ottawa residence today, Trudeau said he is confident that Canadian companies will be able to quickly meet the demand for necessary medical equipment. He also repeated a request from public-health officials for people to practice “social distancing” as much as possible to help slow the spread of COVID-19.

Asked if the government is considering an order for everyone to remain at home, similar to one issued in California, Trudeau said the Liberals are looking at all possible measures.

Ritchie Bros. auctions expect increased online participation in wake of COVID-19 concerns

Information is moving fast and so is Ritchie Bros. With concerns about large gatherings growing around the world due to the COVID-19 pandemic, many trade shows and events have been cancelled. Ritchie Bros. will continue to conduct regular onsite auctions, with minor, temporary changes to the process and procedure of those events due to its online bidding system and mobile applications.

Ritchie Bros. will follow all local legislation on limiting onsite attendance to maintain the safety of all its customers and employees. Instead of bidding in person, the company

is encouraging customers to participate online or via its mobile application. An auctioneer will still be used to conduct all Ritchie Bros.’ onsite auctions, but all equipment and trucks will be sold virtually.

“The safety of our customers and employees is our first priority,” said Ann Fandozzi, CEO, Ritchie Bros. “The demand for equipment right now is high—as witnessed by the strong pricing we’ve seen in all our recent events. With our online bidding technology, we can keep the market moving while simultaneously keeping people safe.”

Today upwards of 78 per cent of winning bids in Ritchie Bros. live auctions are made online. Additionally, due to new efforts to drive online demand, Ritchie Bros. has seen visits to rbauction.com and web account creations increase by 15 per cent and 19 per cent respectively. Ritchie Bros. mobile application users have also risen drastically, up 90 per cent year over year.

“If you do not have an online bidding account, we encourage you to set one up—it’s easy and we have a customer service team available to handle any questions you may have,” Fandozzi continued.

For a complete list of upcoming Ritchie Bros. auctions, visit www.rbauction.com/auctions.

Konecranes withdraws 2020 financial guidance due to COVID-19 and updates demand outlook Konecranes revises its demand outlook and withdraws its financial guidance for full-year 2020. Konecranes expects COVID-19 to have an impact on demand for its products and services, particularly in the first half of the year, but as the situation is evolving quickly it is too early to make reasoned estimates that quantify this impact.

Due to the pandemic, countries around the world have imposed extensive restrictions on the daily conduct of people and businesses. As a result, many of Konecranes’ customers are limiting access to their premises, affecting Konecranes’ ability to complete the installation of new equipment and perform certain service operations.

Konecranes’ own operations are also impacted by the significant and increasing worldwide measures to contain the pandemic.

Beyond the virus, Konecranes expects the adjusted EBITA margin to be affected by an estimated cost overrun of EUR 18 million related to the execution of a port crane project in the US. This charge will be booked in Q1 2020.

The new demand outlook is: Due to COVID-19, the demand environment across our customer segments and regions is deteriorating.

The new financial guidance is: Due to the rapidly evolving situation as a result of the COVID-19, Konecranes considers that it is too early to make reasoned estimates or provide financial guidance for 2020.

The earlier demand outlook issued on February 6, 2020: Within the industrial customer segments, the demand environment in Europe continues to weaken but at a slower rate. The demand environment in North America is relatively stable overall and remains on a higher level compared to Europe. Asia Pacific is showing early signs of improving demand conditions.

Despite its recent decline, global container throughput continues on a good level. Although there is hesitation in the decision-making among some port customers, the longer-term prospects for orders related to container handling remain good overall.

The earlier financial guidance issued on February 6, 2020: Konecranes expects sales in full-year 2020 to increase 7-10 per cent year-on-year, including MHE-Demag.

Konecranes expects the adjusted EBITA margin to improve in full-year 2020 compared to full-year 2019. In full-year 2019, the Group’s sales were EUR 3,326.9 million and the adjusted EBITA margin was 8.3 per cent.

Konecranes plans to provide more information in conjunction with its January-March Interim report on April 29. Konecranes intends to provide its guidance for full-year 2020 once the visibility improves and a more stable estimate can be made.

List of industry events cancelled or postponed due to COVID-19

Several industry events are cancelled or indefinitely postponed considering recent travel limitations, and attempts to prevent the spread of coronavirus, or COVID-19 across the country. Here are the heavy lifting industry cancelled events to date:

CCA Annual Conference – March 15 to 18 www.conference.cca-acc.com

Konecrane Annual General Meeting – March 26 www.konecranes.com

SC&RA Annual Conference – April 14 to 18 www.scranet.org/SCRA

CraneSafe – April 28 to 29 www.cranesafesummit.com

Partners in Prevention – April 28 to 29 www.app.wsps.ca

SEAA Annual Convention & Trade Show – April 1 to 3 www.seaa.net/seaa-convention–trade-show.html

CRAC Annual AGM – May 27 to 30 www.crac-aclg.ca

Konecranes Capital Markets Day postponed – June 11 www.konecranes.com

AED tells mayors and governors to keep construction projects going during pandemic

Associated Equipment Distributors (AED) delivered letters to national organizations representing mayors, local elected officials and the nation’s governors, urging them to allow construction projects to continue while highlighting the equipment industry’s integral role in building and maintaining essential infrastructure.

In a letter to the U.S. Conference of Mayors and the National League of Cities, AED was joined by the Association of Equipment Manufacturers (AEM), delivering the message that, “shutting down construction projects in cities and towns not only jeopardizes continued relief and prevention efforts surrounding COVID-19, but will also exacerbate an already dire situation with little safety or health benefit.”

AED delivered a similar letter to the National Governors Association, imploring its members to reconsider halting construction projects across the country. Additionally, AED joined AEM and the Equipment Dealers Association in letters to all 50 governors stressing that equipment manufacturers, suppliers, dealers, and service technicians must be considered essential to economic continuity as governors continue to respond to the COVID-19 pandemic to protect the health and safety of all workers and residents.

In Washington D.C., AED has been working with business organizations to ensure lawmakers and the administration understand the importance of liquidity and access to capital for the equipment industry. AED joined allied business organizations outlining tax modifications that will help provide liquidity for small-medium-sized companies.

Low

High

Innovative

Nors, a transport solutions and construction equipment company, has purchased Strongco and will take over its Volvo Construction Equipment’s Canadian dealerships and distribution. The Portugal-based company finalized the deal to purchase Strongco on March 18.

Nors is taking over 22 Volvo CE locations, including those in the provinces of Alberta, Ontario, Quebec, New Brunswick, Nova Scotia and Newfoundland and Labrador.

“We believe that Strongco will benefit from Nors’ global presence and brand recognition, and from its long experience in the automotive and construction equipment industry to further enhance its superior performance and future growth. And we are very much looking forward to working with Volvo CE across Canada,” said Tomás Jervell, CEO of Nors. “We plan on investing heavily in staff expertise, as well as improving parts availability. The goal is to provide the highest uptime in the industry to Volvo CE customers, and we are ready to achieve it.”

Nors is the one of the longest-standing partners of Volvo Group. The family-owned company was founded in 1933 by Luís Óscar Jervell, the current CEO’s grandfather. It began as a Volvo Group partner in Portugal, selling and servicing trucks and buses, and in 1970 it started selling Volvo Construction Equipment products.

“It’s fantastic to have such a seasoned partner expanding its successful operations and business model further across North America, and we are looking forward to the improvements they will bring to Canada,” said Stephen Roy, senior vice president, Volvo CE North America. “Together we will enhance our Canadian sales and service efforts

Aston Martin Red Bull Racing Formula 1 driver Max Verstappen has opened Circuit Zandvoort near Amsterdam, the venue for this year’s Formula 1 Heineken Dutch Grand Prix. Earlier this year, Mammoet was selected as an official event supplier for the race.

The track, which was opened in 1939, has undergone a €4m upgrade over the last six months in order to improve its safety, infrastructure and accessibility. Mammoet has been on site for four months already, mobilizing its cranes and expertise to help deliver this change.

Specifically, Mammoet has aided renovation works to Circuit Zandvoort’s Hugenholtzbocht and Arie Luyendijkbocht corners; turns three and 14 respectively. The banking that is being added to these sections of the circuit will make it one of the most challenging and spectacular in Europe.

A total of six Mammoet cranes are currently at Circuit Zandvoort, ranging in capacity from 100-450t. As elsewhere for a range of customers across the petrochemical, mining and civils sectors, this equipment has been based on site for a number of months, performing a wide range of lifts according to the peaks and troughs of demand.

Dutch driver Verstappen, who finished third in the 2019 Formula 1 World Drivers’ standings, completed six laps around the redesigned course in his RB8 F1 car. After completing the opening ceremony, he was impressed by the two corners Mammoet helped to sculpt, which now feature slopes of up to 34 per cent.

“I liked it very much. In particular turn three and the last turn, that banking feels very special and there are many different lines that you can take in the turn. Really interesting,” said Verstappen.

J acob Bandy is the new parts marketing manager for LinkBelt Cranes. Bandy has over 10 years of experience in marketing in various industries, most recently in machinery.

“We are excited for Jacob to join the Link-Belt team. His marketing experience will allow him to be successful at Link-Belt and work well with our distribution network,” said Paul Campbell, manager service parts and logistics.

to improve the experience of our customers when working with Volvo CE. This new partnership has enormous potential.”

This strategic acquisition will strengthen Strongco’s presence in the marketplace and position them to provide greater support to our customers across Canada.

The Formula 1 Heineken Dutch Grand Prix will be held between 1-3 May. During the weekend, Mammoet will deploy cranes and specialists to key areas of the track in order to assist in recovery operations during practice, qualifying and the race itself.

It will be the first Formula 1 Grand Prix held in the Netherlands since 1985, when Niki Lauda took the checkered flag.

Specialized Carriers & Rigging Association (SC&RA) has welcomed the following new members:

Boomtrux, Inc – A dealer for both new and used truck mounted cranes, located in Tampa, Fla.

Broad Horizon Transportation – Specializing in the hauling of cranes and open platform freight, located in Clemmons, N.C.

Delron Safety Training and Rescue Services Limited – Providing safety training via National Safety Council, ECSI, ASHI, and IPED. Located in Princes Town, Trinidad.

Frontier Heavy Haul & Support Inc. – Transporting heavy equipment, wind energy, power transformers, boilers, generators, and pressure vessels, located in Fairfield, Texas.

Imperial Trucking – Specializing in providing logistics services for project cargo and forwarding to asset-based equipment, located in Red Deer County, Alberta, Canada.

Keller Engineers of NJ, LLC – Supporting OS/OW permitting systems, OS/OW regulations, FMCSA regulations and ITD program management. Located in Hamilton, N.J.

Shoppa’s Material Handling – Helping customers move goods safely, efficiently and productively. Located in Fort Worth, Texas.

Tenney Group – A transportation specific M&A advisory that provides buying and selling, side M&A, and business valuations, located in Franklin, Tenn.

Alittle more than a half-year into joining two businesses sharing 300 years of experience in the lifting industry, Tadano is making strides in integrating the Demag business into its operations. The acquisition added roughly 1,600 team members to the Tadano family, and Tadano is working to leverage synergies and take advantage of the extended team by increasing the level of support for all Tadano customers.

“Both Tadano and Demag share common values such as passion for the crane industry, delivering the best possible customer service and commitment to customer success,” says Kenichi Sawada, chief commercial officer for Tadano. “The merger is infusing the best of both worlds working together as ‘One Tadano.’ Demag is now owned by a company who focuses solely on the lifting industry, and this holds significant benefit for customers.”

Tadano has organized multiple cross-company teams with the mission to find and implement the best practices across the company and leverage technological and operational capabilities across Tadano. Demag integration in European operations has resulted in back-office departments like engineering, procurement, human resources, marketing and accounting being combined to better support Tadano and Demag as “One Tadano.”

Many regions have seen sales force realignment, allowing Tadano and Demag to deliver improved customer services and faster response times. New markets are being developed jointly between Tadano and Demag with combined back-office supporting processes being standardized.

Sawada continues, “We want to integrate Demag to offer a full range of lifting solutions from a single source to meet customer needs. We are moving forward with the objective of avoiding double structures with multiple Tadano and Demag representatives calling on the customer. We are showing one face to the customer.”

Sawada points to North America as an example of the successes achieved when working together as “One Tadano.” Tadano America Corporation (TAC) has combined the Tadano and Demag sales teams in North America to maximize sales coverage for rough terrain, all terrain and crawler cranes. The Demag Sales Operations and Tadano Sales Administration teams are also moving toward working under one Tadano America process. In addition to the marketing and customer service teams being combined, TAC is currently studying the Tadano and Demag parts distribution businesses to leverage synergies.

The Demag acquisition elevated Tadano to a full-range supplier of lifting solutions, as it filled product gaps for both companies, allowing Tadano to meet customer needs on a wider scale. As a result, Tadano has announced it will continue with the dual-brand strategy of Tadano and Demag for the foreseeable future. All models currently available today will be kept in order to increase market share worldwide, even cranes that compete in the same capacity class.

“We will allow Tadano and Demag products to follow their normal lifecycle, launch new products and phase out old for both brands,” says Jens Ennen, president and CEO of Tadano Demag GmbH and Tadano Faun GmbH. “As with other products that have been phased out, Tadano and Demag will continue to support these products and the customers who own them.”

The Tadano and Demag engineering teams are being integrated to jointly develop new crane equipment. Tadano is leveraging synergies and sharing technologies across both companies to infuse equipment with the best that both companies have to offer. “Centers of Excellence” for new product development are being created to reach the company’s commitment of increasing product performance and quality. The Centers will help Tadano deliver a faster new product development cycle to meet customer needs.

Tadano is launching several new products in 2020. Both, the Demag and the Tadano brand will present in the second half of the year new all-terrain cranes in different capacity classes, and with this will close further gaps in the product line up. In addition, a new Demag-developed telescopic crawler crane, the GTC-1800EX, will be introduced under the Tadano brand that incorporates some of the best that Tadano and Demag have to offer, including the Demag IC-1 Plus and IC-1 Remote technologies.

With an eye toward the future, Tadano’s long-term plan includes manufacturing lift equipment at both Lauf and Zweibrücken facilities in Germany. The cross-company teams are working to exploit and leverage synergies between the two facilities, while creating manufacturing “Centers of Excellence,” where team members from both facilities learn from each other and implement best practices across the company.

Tadano’s strategy includes investing in and increasing production at both plants, as evidenced by the recent announcement that a new paint facility in Lauf is being installed to improve machine paint quality and longevity. The company has a long-term goal of increasing market share significantly. To reach this goal, production capacities from all facilities are needed.

“Integrating Demag and developing synergies between both facilities will give Tadano more supply flexibility to meet our customers’ needs,” adds Sawada. “Working together and having both facilities will result in faster delivery and throughput times, improve product quality and deliver consistent quality for customers.”

“When cranes, tower cranes in particular, are assembled and disassembled in urban areas, in closer proximity to all sorts of things, that’s when the risk of an event can occur.”

One could assume that these initiatives have been undertaken in response to the crane collapses in Seattle and Halifax last year which created so much controversy and drew media attention; however, formulation of these initiatives actually started back in 2018.

Speaking with Crane & Hoist Canada shortly after the Seattle crane collapse, Fraser Cocks, executive director of the British Columbia Association for Crane Safety, lamented that regulations for industry are often ‘written in blood,’ meaning they only get enacted after someone is injured or killed in an incident. Johnson says that these new safety initiatives are intended to be more proactive.

“We are the regulator and fundamentally take our marching orders from the regulation,” says Johnson. “But regulation is only one thing—it’s better if you can appeal to the industry, get them to understand what is behind the regulation. Because often regulations are very prescriptive in nature and, on the other scale, they’re often very open ended in performance in nature. That’s why we focused on working with Crane Safety Association as well as the individual crane employers on best practices. The regulation is absolutely adhered to, but the best practices are also very much a part of how we collectively manage crane safety in this province.”

Regarding the initiative for inspectors to look for preventive maintenance, some members of the public might take that to mean that inspectors weren’t checking for preventative maintenance already. Johnson says it’s not that they weren’t checking for maintenance previously, but rather that the way that such inspections are carried out needed to evolve.

“Let’s make sure we’re looking at the mechanical components, let’s make sure we’re looking at the hydraulic components, let’s make sure we’re looking at the electrical components. It’s an evolution of the robustness of what we mean by preventative maintenance and the systems that require preventative maintenance.”

Johnson also notes that where the technology associated with cranes has also become more sophisticated, that preventative maintenance standards from the past would not include elements such as anti-collision devices.

“Some would say initially, ‘why are you changing the goalposts on us?’ and as a regulator, we’re not changing the goalposts,” says Johnson. “It’s the evolution of knowledge. It’s the evolution of practice. It’s the right thing to do. What was done in the past may have been good for that time period. But today, things need to be done a little differently.”

In other words, the goalposts are not moving independently—the entire game has changed and the goalposts have to change with it.

Mammoet was contracted by Siemens Gamesa to transport three 94-metre-long blades from the storage area at the Siemens Gamesa factory in Aalborg, Denmark, to the nearby quayside. The wind blades are destined for a new prototype wind turbine that Siemens Gamesa will be testing.

With their extensive knowledge of the equipment’s applications, Mammoet developed a safe and efficient transport solution that guaranteed the necessary stability throughout the 1km route. The blades were also delivered directly to a vessel, so they could be loaded directly, which avoided having to store them at the quay.

Instead of using SPMTs, a custom trailer consisting of 2 x 6 Nicolas MDEL axle lines combined with a four-axle truck was built. The total length of the new trailer combination with the blade measured more than 100m. The trailer was built with conventional axle lines at the Mammoet yard in Brande and then transported in one piece to the storage area in Aalborg, saving 50 per cent of the time compared to other industry solutions.

In addition, Mammoet’s transport solution was also a greener choice as it enabled them to only use one truck for the operation, so emissions were reduced, and resources were conserved.

The blades will now be shipped, ready to be used in the testing of the new wind turbine. Once the turbine is fully-functioning, it will provide enough electricity to power 10,000 households each year.

Load King announced that all Terex Services locations will be authorized service centres for Load King Cranes. As an authorized service location, Terex service centres will now provide maintenance, repair and parts for Load King products.

“We are very excited to partner with Terex Services to offer their existing knowledge of after-sales support for our products in this important market,” said John Lukow, senior vice president of Load King Cranes.

“Through this exciting relationship with Load King Crane, we look forward to providing service support to their customers,” says Richard Gunderman, vice president, parts & service for Terex Services. “By working strategically with our customers, we are able to provide multiple avenues of assistance through our service offerings, parts support and equipment training throughout the United States.”

In all 19 Terex service centres in the United States, positioned coast-to-coast, Terex Services will now provide services for Load King boom trucks, truck cranes and Terex legacy products for Load King customers within 150-mile radius of each Terex service centre location.

BY SAUL CHERNOS

When Maeda releases its first battery-run mini-cranes this year, the Japanese manufacturer will hardly be the first to have done so. All-electric and hybrid machines have been steadily gaining traction the last few years, with customers enamoured by low or emissions-free operation and reduced noise levels, particularly when used indoors.

Manufacturers of equipment of all shapes and sizes have been moving at various speeds towards decarbonization, and small portable hoisting machines are a case in point.

“They haven’t come out with an official date but it’s going to be in 2020 at some point,” says Tony Inman, president of Maeda USA, a Houston, Texas company that distributes Maeda products from Canada down to Panama and the Caribbean but operates independently.

“Maeda hasn’t come out with them to this point because they’re working on the best battery system to make sure they have the best design and best engineering using the latest in battery power technology,” Inman said.

Inman is protective of Maeda’s proprietary rights. He acknowledges having “some ideas of what they’re talking about doing” but says Maeda isn’t prepared to reveal product details prior to an actual launch. “They’re playing their cards close to the vest,” he concedes. Small cranes come in many shapes, sizes and configurations. As Inman puts it, “they basically function just like any other bigger crane, with similar features, controls and safety features, except they’re packaged differently.” They generally lift relatively lightweight loads, everything from glass and building supplies to people, and they’re common in spaces where access is confined or limited, where larger machines won’t fit.

Maeda manufactures assorted spider-like mini-cranes, an informal descriptor Inman attributes to outriggers resembling arachnid legs. But the world of small hoisting machines is broader with companies offering an array of carry-decks, telehandlers and cherry pickers, some with eco-friendly attributes.

As senior director of engineering with JLG industries, a McConnellsburg Pennsylvaniabased manufacturer of telehandlers and aerial work platforms, Shashank Bhatia knows

all the intimate details of new electric product lines the company planned to introduce in March at CONEXPO/CON-AGG in Las Vegas, Nev.

“I’m the one who’s going to release it,” he teases, again acknowledging the proprietary nature of the business. Still, he’s eager to talk about JLG products, evolving customer demands, and how the sector has been responding.

JLG’s line of scissor-lifts, come in a range of sizes, with the tallest climbing 53 feet, and the company’s boom lifts can transport equipment and people up to 185 feet. “They’re on construction sites helping build stadiums, warehouses and big petrochemical plants,” Bhatia said, describing their role in welding, assembly and other detailed operations.

Bhatia says electrification has proceeded at different rates in different industries, and while diesel and internal combustion engines and electric over hydraulic technologies are common across many work machine categories, complete electric units beyond the chassis are close at hand thanks to increased imperatives to reduce greenhouse gas emissions and dampen noise.

Rapid urbanization, a resulting construction boom, a desire to contain costs, and steadily improving battery technologies are also fuelling change, particularly in terms of extending beyond the drive train to include hoisting and other functions traditionally managed by hydraulics.

“It’s not easy to control a hydraulic machine when you’re up at 60, 70 or 80 feet,” Bhatia said, noting that electrification opens new opportunities in precision and agility in reach and lift thanks to an emphasis on control system algorithms.

Electrification in these areas also spells an eventual end to fluid leaks. “There’s no oil in the systems, so there no possibility of hydraulic oil leaking onto the floor,” Bhatia said. “The only thing you’ll need is solid-state grease, and we’re going to seal that.”

At Up and Down Lifting solutions in Ayr, Ont., co-owner Jimmy Latta says demand is increasing steadily for equipment that’s all-electric.

“Until a few years ago we’d bring in a lot of dual-fuel units,” Latta says, explaining that scrubbers and venting are fairly good at thwarting emissions.

“Gas/propane and propane were typically fine for indoor use, but that’s changed now. Most buildings and job sites if you’re working indoors require straight electric or battery power. So, a lot of these mini-cranes and lifts that we bring in now are either straight battery or have a diesel or battery option on them.”

Latta says his fleet has included all-battery units for roughly half a decade. While a major driver has been avoiding fumes and emissions, quiet operation is also appreciated, particularly in shopping malls, factories, schools and other confined spaces where people are present.

“Battery-powered machines running on an electric motor are very quiet—so a lot of guys prefer that, but the main thing that’s driving this is the (lack of) fumes for interior use.”

With the drive to electric gaining momentum, Latta is keenly following new technology developments. “A lot of batteries are moving away from standard lead acid to lithium,” he says. “Lithium charges more quickly, holds the charge longer and has a longer life-span.”

While prices for advanced technologies tends to be higher closer to their introduction, Latta expresses confidence these will come down in the long-term. “I would assume, as we go on, that the costs will decrease as they become a little more common.”

BY MATT JONES

Denika Mitchelmore says she was always a private person, who suffered from social anxiety and struggled in school. But a love and fascination with cranes gave her life focus and now the native of Green Island Cove, N.L., is the first female level 3 offshore crane operator in Atlantic Canada. But that accomplishment, earned while working at the West Aquarius oil rig, doesn’t compare to the simple joy of working with the machines that she’s become so obsessed with.

A memorable encounter

“I’m from a very judgmental place,” says Mitchelmore. “If you don’t have book smarts and you aren’t a certain way, you aren’t fitting in. So obviously, I didn’t fit in. I felt so sad my whole life. Skill trades were never really talked about in school, it was always university, university, university. So, I thought my life was going nowhere–that I would be in a grocery store for the rest of my life. There was no mention of skill trades, just courses that I couldn’t understand and being told that I won’t have a future, that I’ll never be anything. The amount of times I heard that in my life, I can’t count on my hands.”

“I want to feel like I’m actually doing something with the trade. It’s about more than the money for me, I enjoy the machines. I enjoy the equipment.”

A surprise encounter; however, changed the course of Mitchelmore’s life. At 17 years old, she came across a mobile crane off the side of the road. She watched the operator perform lifts and adjustments for quite a while before, to her surprise, he waved her over.

“He was an older gentleman, and he was so encouraging and supportive,” says Mitchelmore. “He told me that he never went to school for the crane job, he just got grandfathered in. It gave me a lot of encouragement. I wasn’t good at learning, I wasn’t book smart at all. But if you gave me something to do with my hands, I could do it no problem.”

While Mitchelmore remembers the details of the crane she saw that day–a 62 inch truck mounted Terex–one of her great regrets is not making a note of the gentleman’s name.

“I’ve always been trying to find him, but I can’t remember his name for the life of me. I don’t know where he was from. And he never asked my name or anything, he didn’t care that I was a girl, he just told me his story and we went from there.”

From that point on, Mitchelmore became obsessed with cranes. She began to subscribe to crane and construction magazines. “I thought my mother was going to lose her mind, she didn’t know what to do with them all.”

Challenges along the way Mitchelmore spent several years working her way up through the ranks on projects both on the island and out west. Moving up a ticket level; however, requires hundreds of hours with a mentor, which could be very hard to come by. In her experience, Mitchelmore says that many people would see someone who was young and eager to learn and immediately assume ‘this person is coming for my job’ and would be reluctant to train what could be their own replacement.

So those who did support her, like brothers Brad and Francis Tobin, who she met at the Muskrat Falls Hydroelectric project, made a significant impact.

“[Francis] was the first journeyman who said, ‘let’s go over stuff, I’ll help you.’ I learned a lot from him. He took me under his wing and he didn’t care that I was so eager—it made him excited. And along the process, he learned stuff just from me asking questions. It was fun.”

It doesn’t feel real

After spending the better part of eight years out west, Mitchelmore landed a job with the West Aquarius oil rig, where she received more support from important mentors, such as Luke Jarvis, the offshore installation manager and Steve D’Entremont, the operator who mentored her through her stage 3 training. In November of 2019, she became the first female operator in Atlantic Canada to earn stage 3 offshore qualification which allows her to perform all inboard and outboard lifts, including personnel transfers.

“We’re all in this world together. It’s not at all about who you are as a gender, it’s about who you are as a person. That’s what I focus on.”

“It’s almost like it’s not even real,” says Mitchelmore. “I try to be as humble as possible. If I’m bragging about something, you don’t know if someone else is struggling, you know? I might be talking about I did this and I did that, and then there’s some poor soul alongside me that’s not been given the same opportunities and maybe they can’t afford to pay for their training.”

“We’re all in this world together. It’s not at all about who you are as a gender, it’s about who you are as a person. That’s what I focus on,” Denika Mitchelmore.

While she is humbled by earning that ticket, she downplays being the first female operator in the Atlantic Provinces to do so.

“I don’t focus on it. I am a gay woman. People accepted me as a woman, but not everyone accepted me as a gay woman. Just like not everyone accepts men, not everyone accepts transgenders or bisexuals. To me, we’re all in this world together. It’s not at all about who you are as a gender, it’s about who you are as a person. That’s what I focus on.”

While many would be content to rest on that laurel and stay in the seat of the Liebherr BOS 4200-80 at the oil rig as long as they could, Mitchelmore’s love of the cranes themselves drives her to seek her next opportunity and her next challenge.

“I would love to opportunity to get back on land cranes because there’s still a lot of different cranes that I want to try. When you’re offshore, you’re limited to just the pedestal cranes. There’s no different cranes coming in. So it doesn’t feel like a challenge, it’s the same thing every day. It’s great, and I’ve had a lot of great opportunities, but it’s not the same as being on land and having the opportunity to learn different types of cranes. I want to feel like I’m actually doing something with the trade. It’s about more than the money for me, I enjoy the machines. I enjoy the equipment.”

In addition to the support of mentors such as Tobins, Jarvis and D’Entremont, Mitchelmore is quick to credit the rest of the support system that helped her as she worked her way up–her parents and her partner, Stephanie. She also wanted to give special credit to her role model, her cousin Tina.

“She’s the strongest woman I know. She’s been there for me every step of the way. She was hard on me, but it was tough love. She knew I needed that and that I needed that push to go for cranes. If it wasn’t for her, I probably wouldn’t have taken the chance because I was so timid. She made sure that I was going to be okay. What if I fail? It’s okay to fail, just try and try again. I owe her a lot.”

Isabella Lopes is 19 years old, lives in Surrey, B.C., and has been a tower crane operator since January 2020. She studied to be an excavator operator but says she can’t see herself doing anything other than operating cranes. When Crane & Hoist Canada reached out to Isabella she had just finished operating roughly 350feet up on a Liebherr 200 HC. Check out Crane & Hoist Canada’s Q & A with editor Jay Koblun and Isabella on; Isabella’s role as a tower crane operator, being only one of a handful of female tower crane operators in the province, and her thoughts on why more women should work in the heavy lifting industry.

Jay: Hi Isabella. Do you wish there were more women in the crane industry? Can you tell me a little about your role as a tower crane operator?

Isabella: No problem. As a tower crane operator, I help set up concrete pouring jobs, help put up panels for walls, help install steel columns, move materials around the job site and store materials like wood. It’s my job to organize the job site and keep it clean.

Jay: Has it ever bothered you that there aren’t more women in the crane industry?

Isabella: It’s a shame there aren’t more. There’s only a handful of female tower crane operators in British Columbia. I know of three that work for my employer, myself included. And I know of two more working somewhere else. I definitely would like to see more and I think you will as time moves on. A female presence is definitely lacking in the tower crane industry so I would love to see more.

Jay: Do you wish there were more women in crane?

Isabella: Yes—100 per cent. I really hope to see more in the future.

Jay: You’ve been a tower crane operator for a few months now, what makes you proud of your work?

Isabella: I take a lot of pride in my work. It’s a really hard industry to get into and I love and appreciate my job so much. I love waking up every day to climb a few hundred feet and operate a crane. It comes with a lot of responsibility and I’m proud to have a career that comes with such a high level of responsibility.

Jay: What’s a goal you have for yourself and your career?

Isabella: I want to make a name for myself in the industry. There are roughly 300 operators in the province and word travels fast in this small industry. I want to be recognized as a good and safe operator who demands respect. Getting

into tower crane operating at my age is rare, it takes some people years to get into the position so I want to make sure I do my job well and to the best of my ability.

Jay: How do you think construction can attract more female candidates?

Isabella: In my experience I’d say it’s more reaching out to women and letting them know it may not be as bad as they may hear it is. It’s just like any job; there will be people you do and don’t get along with. When I first started people would tell me things like, “The guys are animals, you will hate it.” But it’s more important to encourage women and let them know that there are men in the industry who are genuinely there to support and help, and don’t care if you’re a woman or not. They see you and your skills only.

Jay: What is the biggest challenge of being a woman working in the heavy lifting industry?

Isabella: Feeling the need to prove yourself and being able to carry yourself in the professional manner that a crane operator needs to. It’s an important role. My confidence level wasn’t really where it needed to be when I first started and I learned from that. I wanted to have the respect without having to ask for it. I want people on the job site to see me as an effective boss, as a leader, and also as a peer.

Jay: What are some of the benefits hiring more woman brings to a company?

Isabella: It’s 2020, companies love the diversity. A lot of companies are still run by old timers who many never choose to hire a woman or who may think “Nah, don’t bother—they’ll only be a distraction to the guys.” But it looks good for a company to have diversity. Why shut down a woman who may end up being the best crane operator your company has ever had? Take the risk because it could really pay off.

When I was in school for excavator operating I heard that women make better operators. I don’t know if it’s true or not but I was told women can be easier on machines, often have better attitudes and can be more safety conscious. Of course, it depends on the person, but women sometimes have better attitudes and tend to not come in with the same pride and egos men can have. We come in with a different attitude. In a way we know we have more to prove so it translates to how we present ourselves on the job site.

Jay: If a female friend of yours, or not necessarily even a friend, asked you if they should begin a career in the crane industry, what would you tell her?

Isabella: Whatever trade you’re thinking of starting in, don’t be afraid to ask for help. If you know what you’re doing, and look like you know what you’re doing, sometimes the guys will try to tell you something you know is not right. Just do what you know is right! Be safe. Be confident. It’s an amazing career to get into. I love my job and I love the guys I’ve met. There’s many that are awesome at supporting me in my career as a crane operator and I really appreciate them.

BY JAY KOBLUN

North America’s largest construction trade show had a few things thrown its way in 2020 that may have majorly slowed down other events, but CONEXPO/CONAGG was still a success despite the rain and growing concerns surrounding coronavirus disease.

Coronavirus disease (COVID-19) is an infectious disease caused by a newly discovered coronavirus and was not initially a large concern to some Canadian business owners when first discovered.

“I’ve seen similar illnesses affect the world in this way before, like H1N1. I wasn’t personally affected, but I’ve seen the world pull through. So, at first, I thought about the coronavirus in a similar way. That everything would be fine,” said Judy Mellott-Green, president and CEO of the All Canadian Training Institute. “But once it was announced a pandemic I started to think about it differently and through the advice of my staff I decided it was time to take it seriously and make the calls to keep people home and stay home myself.”

The disease was deemed a global pandemic a few days into the show and it wasn’t long before you saw an empty booth here or there after several companies decided amidst the health concerns and potential travel bans it was to go home. Despite some rain, and the show being cancelled one day early due to the virus, dealers, customers, heavy-equipment aficionados, and more still saw a great show and took time to take in tech demonstrations, witness new machinery in action and sit in on some informative sessions on the crane industry. Here are some of the show highlights:

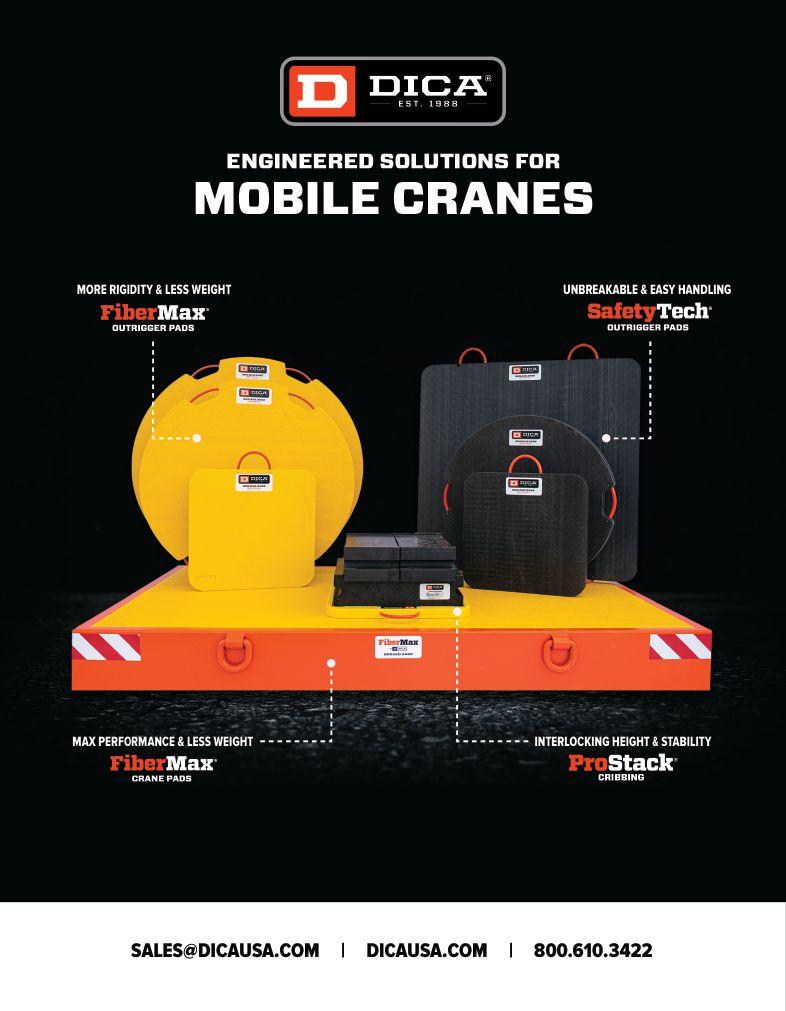

DICA announces purchase of Linton Edge Protector Products at CONEXPO-CON/AGG Ray Linton introduced a line of rigging supplies in the ‘90s that DICA says made a big impact on safety and functionality in the rigging industry. Such an impact that DICA recently purchased Linton Rigging Gear Supplies and will be adding it to its line of products.

“We just purchased Linton Rigging Gear Supplies and are in the process of finalizing the purchase agreement,” said Kevin Koberg, DICA marketing director. “Ray Linton, he was a crane operator in a shipyard for 40 years and could never get adequate sling protection on a lift, so when he retired over 20 years ago he developed this product line.”

DICA made the agreement with Linton and will assume all ongoing operations following the completion of the acquisition. DICA is a family-owned and operated company that specializes in building high performance engineered outrigger pads, crane pads, and cribbing blocks that are lightweight, easy to use, and long-lasting.

“We started with $1000 and an idea,” said Linton. “We are happy this idea became a product that reduces risk in the crane and rigging industry.”

Linton Rigging Gear edge protectors prevent sling damage and potential failure from sharp corners or load edges, and increase D/d ratios—the ratio of the diameter around which the sling is bent, divided by the body diameter of the sling—preserving sling capacity around corners. Made of solid nylon, the edge protectors are 1/7th the weight of steel and are available with Velcro straps to ensure slings stay in place. The patented edge protectors attach to metal surfaces with magnets, requiring no tools to install.

“Much as DICA was founded on the quest to build a better outrigger pad, the Linton edge protector was born out of an industry need,” said Kris Koberg, DICA CEO.

ASME regulations require slings to be protected in scenarios when slings are in contact with edges, corners or protrusions.

“Ray Linton’s design was a revolutionary concept when he introduced nylon sling protectors to the rigging industry nearly 20 years ago. Linton’s engineered products are designed to be lightweight, easy to use, and improve safety and productivity. These are the type of qualities customers expect from all DICA products,” said Kris.

Linton and his wife, Patty, who have operated Linton Rigging Gear Supplies as a team, are ready to retire. “We are glad the legacy of our work will continue under the care of DICA,” said Linton, who will serve in a consulting role with DICA to provide product support through the transition.

Regular, Heavy Duty, Plate Edge Groove and other examples of the nylon edge protectors were displayed along with DICA products at CONEXPO/CON-AGG.

At the show Kevin described the new product line to several potential customers and interested buyers.

“These are magnetic sling protectors,” Kevin said to customers. “They work with synthetic slings, wire rope, or chain. And you’ve got multiple sizes for different applications whether its I-beams or steel coil. The coating shouldn’t matter as long as it’s got a ferrous metal, iron, in it.”

IPAF at CONEXPO and releases report giving insight into MEWP accidents worldwide Accidents while using Mobile Elevating Work Platforms (MEWPs) are proportionally more likely when working in public areas or alongside roads than on controlled work sites such as construction sites, commercial or rental premises, according to the latest detailed safety analysis from the International Powered Access Federation (IPAF).

IPAF participated in CONEXPO/CON-AGG in Las Vegas, Nev., by setting up a MEWP Safety Zone on the fairgrounds. Faith Cobaine, IPAF marketing and membership manager, explained what IPAF does and directed individuals who want to know more to the IPAF website.

“IPAF promotes the safe use of powered access equipment worldwide by providing technical advice and information,” said Cobaine. “IPAF also influences and interprets legislation and standards through safety initiatives and training programmes.”

IPAF is a not-for-profit organization owned by its members, which include manufacturers, rental companies, distributors, contractors and users. IPAF members operate a majority of the MEWP rental fleet worldwide and manufacture about 85 per cent of platforms on the market.

The company’s goal at the construction show was to help visitors learn the answers to the following key questions:

• Why should I follow ANSI standards to keep my workers safe?

• What is a MEWP-specific safe-use plan – and why do you need one?

• Why must you train MEWP operators and those who supervise them?

• How can selecting the right MEWP save both time and lives?

• How can IPAF’s safety campaigns assist you in managing risk?

IPAF’s Global MEWP Safety Report 2016-2018 presents key findings from the federation’s analysis of accident statistics gathered through its worldwide accident reporting project, which has incident reporting from 25 countries around the globe. The report is now available to view or download on www.ipaf.org.

Accidents on construction sites account for the joint highest average number per year, but as MEWPs are used much more widely in construction than in other sectors and locations, they are in fact proportionally less likely to occur on a controlled work site than in a remote location or a public area, such as alongside a road, the report shows. As well as the increased proportional risk of an accident occurring when working away from controlled job sites, the new report identifies recurring underlying causes of incidents involving MEWPs as falls from the platform, electrocutions, entrapments, MEWP tipovers and MEWPs being struck by another vehicle. This is in line with previous years’ fatal

accident analysis and demonstrates yet again that the industry should focus on ways to reduce underlying factors common to these types of incident.

“With this report there’s a new methodology to much of the analysis and the way the findings are presented, plus the report is interspersed with key recommendations to mitigate common risk factors,” says Richard Whiting, IPAF’s general market manager for UK and Ireland, who has been working to finalize the report and present the findings. “We’ve worked hard along with a dedicated group of IPAF members to analyze, interpret and present the data in a new way, to assist the wider industry to stay safe.”

“One key change is that, rather than comparing a full year’s accident data to previous years, the most recent three full years of available data have been combined to produce an aggregate and average number of incidents – combining data into a larger overall set allows trends over time to be more readily identified,” he says.

The industries in which deaths most frequently are forestry and construction, with maintenance and electrical service sectors third and fourth respectively. Both forestry and construction had an annual average of 19 reported fatalities, but the total number of days worked using MEWPs in construction worldwide is far higher than in forestry, so a fatal accident is proportionally more likely in the latter than on a construction site.

“Renewed focus must be brought to bear to warn managers and operators of the relatively higher proportional risks of a major or fatal accident when not working on a controlled, segregated work site. IPAF’s Street Smart safety campaign already seeks to do this; we must look at how best to evolve this campaign to help reduce electrocutions or other accidents in forestry, for instance,” says Whiting.

Peter Douglas, IPAF’s CEO & MD, a member of the UK Country Council was instrumental in initiating the ongoing worldwide incident reporting project in 2012.

“MEWPs are still among the safest ways to conduct work at height. When unplanned incidents do occur, it is vital we capture that data and analyze the resulting statistics to see what trends are occurring and to influence IPAF’s technical guidance, adapt our training programme and inform our safety campaigns.

“We must work with our members and all industry stakeholders to improve incident reporting. It’s vital that all incidents including minor mishaps and near misses are logged; this helps identify heightened risk and mitigate underlying factors to reduce the number of major accidents or fatalities that do occur using the knowledge gained,” said Douglas.

Sany America planning on re-introducing cranes to Canadian market

A little rain didn’t slow down the Dancing Excavator demo at Sany America’s CONEXPO/CON-AGG booth in Las Vegas on Mar. 10. Nor did it stop CEO Doug Friesen from talking about the company’s vision for the Canadian market and its plan for the crane industry.

“We’ve got a little Sany stunt show we’re going to show you,” said Mark Sullivan, owner of Lime Biscuit. “We’re not going to let some rain stop us from showing you just some of the capabilities of our excavators.”

Sany brought in three highly skilled excavator operators to show the crowd how far the machines could be pushed and what customers can expect of them.

“We want you to know how well they’re built; how smooth they operate,” the presenter said. “These machines you see right here are built in the state of Georgia, made for America.”

The slogan “Built in Georgia, Made for America” was shared often around the large outdoor booth. And CEO Doug Friesen spoke on how that translates to the entire North American market. He said Sany began working on how to better serve the Canadian market Jan 1, 2020.

“Our approach to the Canadian market has started to shift,” said Friesen. “The Canadian market is a part of the North American group and we’ve been supporting the Canadian markets completely. What we would like to do is to have it become its own entity. Just like we have Sany America, we’d like to see that in Canada. We believe that the Canadian market is important.”

Friesen said during this transitional period Sany will continue to support the Canadian market as it has been as he is expecting it to grow; however, those looking for Sany cranes may have to wait a bit longer.

“I come from the crane world. Was with Terex for many years. Demag cranes for a time. When I first came to Sany we were still selling cranes, but I asked us not to,” said Friesen, adding when he first came to Sany the company was having a little bit of an issue with cranes so he stopped selling.

“Immediately we put engineers on the R and D [Research and Development] side, starting to reengineer cranes for this market,” he said. “And then any crane that we had in the market, we tried to take care of them from the Sany perspective. Now we are ready to come back to cranes. Slow. But we are going to come back right.

“I’m not eager that I have to flood the market with cranes. I want to make sure we do it right. So we are going to put this in the hands of a few good people, make sure they are right before we go into any mass production, or mass sales if you will.”

There were two cranes on display on CONEXPO/CON-AGG and Friesen said those will be the two Sany leads with and they are expected to come to America around July.

“I’m not in a fired hurry; I want to do it right,” he said.

Liebherr unveils new cranes at CONEXPO/CON-AGG

Andreas Böhm and Peter Mayr started CONEXPO/CON-AGG off with updates from the company and information on its latest cranes and tech innovations announced at the show. Böhm, Liebherr German manufacturing group’s CFO, and Mayr, managing director, shared from the Liebherr booth on Mar. 10.

“There are all kinds of wonderful things to see and do at CONEXPO, so we’re grateful you chose to stop by our stand,” said Böhm.

He said 2019 was a successful year financially for the company.

“Overall turnover of over 11 billion Euro was a new record for the company, making it our third record year in a row,” he said. “Compared with the previous year, we enjoyed a double-digit increase in turnover. These figures are quite impressive as the International Monetary Fund’s research showed global economic growth slowed to 2.9 per cent in 2019.”

Another area of growth was Liebherr’s headcount. The company created 3,000 new jobs over the financial year, bringing the total number of Liebherr employees to 48,000 worldwide. Böhm stated the company is looking forward to another positive year.

“We’re expecting stable to slightly positive sales development in 2020. The international Monetary Fund has forecasted economic growth to ride 3.3 per cent, with growth in emerging and developing countries expected to increase to 4.4 per cent. This bodes well for our continued focus on modernizing company locations and intensifying the Group’s global market presence,” he said.

Mayr presented on several new innovations Liebherr is bringing to North America.

“The earthmoving equipment and material handling product area is an important one for Liebherr USA,” said Mayr. “We have increased out footprint, just covering a few states on the east coast to almost one hundred per cent coverage today. We hope to continue to expand I 2020 with the equipment and innovations we are presenting today.”

Here are some of new cranes and tech announced at the show:

The Latest Generation of Liebherr´s LR 1300 SX Crawler Crane

The LR 1300 SX, which belongs to the newest generation, has a lifting capacity of 661,387 lbs (300 t). For heavy loads, the crane can be fitted with a derrick boom in combination with an additional counterweight. The new suspended counterweight of the LR 1300 SX no longer has a fixed counterweight radius and instead can simply be hydraulically displaced.