$105-million bridge replacement project requires serious lifting power

hen the crane used to erect the new Johnson Street Bridge in Victoria crossed the Strait of Georgia from its home base in Vancouver, it didn’t take the ferry.

“It could lift the ferry,” Jonathan Huggett, project director with the City of Victoria, said with a laugh when Crane & Hoist Canada asked, tongue-in-cheek, if the Dynamic Beast, a leviathan in the world of barge-mounted cranes, hitched a ride.

All kidding aside, the $105-million project is serious business. The original bridge, which dates back to 1924, was rusting badly and didn’t meet modern earthquake standards spelled out in recent revisions to Canada’s National Building Code.

“Victoria is now seen as having a higher risk than Vancouver because the San Juan Fault is right off the coast,” Huggett explained. “A lot of people in the community said the existing bridge should have been rehabilitated, but it would not have been seismically stable.”

The Crane Rental Association of Canada is celebrating its 20th anniversary at The Fort Garry Hotel in Winnipeg from June 6 to 9, 2018.

The milestone conference and annual general meeting will feature the first-ever CRAC Safety Awards; the Boom Dolly Research Committee Report; a presentation on the future of EN13000; a review of the latest update of the CSA Z150; and the latest developments at Manitex.

There will also be several keynote speakers including bestselling author, insurance expert and financial adviser Jane Blaufus; and, Dr. Grant Cool, chief operating officer of Hybrid Enterprises, who will present on the Lockheed Martin Hybrid Airship.

The conference will also feature a tour and presentations on the construction of the Canadian Museum for Human Rights; the CRAC’s annual golf tournament; and a guided tour of the City of Winnipeg.

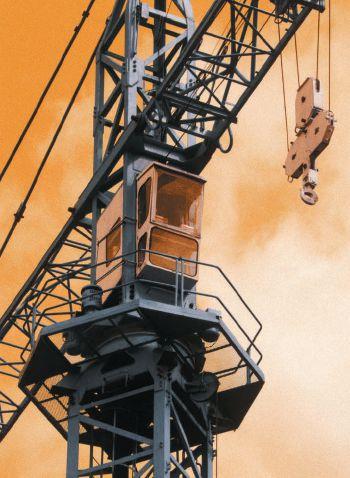

For the first time in more than a decade, tower crane professionals across British Columbia came together for the Tower Crane Industry Safety Conference, hosted by WorkSafeBC at the Sheraton Vancouver Airport Hotel in Richmond, B.C. this past March.

Jaret Swanson, manager of WorkSafeBC, kicked off the conference by welcoming more than 150 crane professionals that travelled to Richmond to attend a variety of sessions related to tower crane safety. Dan Strand, director at WorkSafeBC, then offered his welcome remarks and discussed the importance of industry coming together for events like this one.

“It’s been 12 years since we’ve held a conference like this,” he said, adding that much has changed in the tower crane industry since the last conference. “But what hasn’t changed is a need to keep people safe.” Strand told the crowd that everyone involved in the industry need to work together to address tower crane safety issues to find solutions that ensure that everyone goes home safely. He added that, on average, every month in B.C. there’s a near miss reported or an actual incident.

“We’ve had 12 serious incidents in the past 12 months,” he told the crowd. “Behind these statistics are people, people that are at risk.”

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

Editor – Andrew Snook • asnook@annexweb.com, 289-221-8946

Advertising Manager – Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Art Director – Svetlana Avrutin

Regular Contributors

Saul Chernos, Jeffrey Carter, Nelson Dewey, Matt Jones

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

COO – Ted Markle • tmarkle@annexbusinessmedia.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552 Fax: 416-510-6875 or 416-442-2191

www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $36 per year in Canada. For subscriptions in the USA the price is $36 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: May 25, 2018

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Jeremy at our Advertising Department - Toll Free 1.877.936.2266 jthain@annexweb.com

Next Editorial Deadline: May 30, 2018 For writers’ guidelines and submission requirements get in touch with the Editor, Andrew Snook, at 289.221.8946. Email: asnook@annexweb.com

If you checked out the front page of this issue, then you probably know that this year marks a significant milestone for the Crane Rental Association of Canada.

Celebrating 20 years as an association, the CRAC is a strong voice for Canada’s crane rental industry. The association’s annual general meeting and conference is a great oppor tunity for industry leaders to get together to help solve complex issues affecting the industry as a whole; as well as seek out advice from fellow industry experts on existing challenges on jobsites.

While speaking with 20-year CRAC member and board secretary-treasurer Ryan Burton (to read more about the managing partner of Bigfoot Crane Company, check out page 19), he said that the association has grown a great deal over the past two decades. The association’s annual conference started off as a place where industry across the country could come together and build professional relationships.

W hile that remains true today, he said that the association now focuses on other ways to add value to its members, like organizing committees to solve industry-wide issues.

One of those committees is the boom dolly committee, which is looking at ways to move cranes safely across the country.

Other ways the association is focusing its energy to improve the industry as a whole, include looking into training opportunities for members, and making industry aware of the products and services available to keep workers safe.

S peaking of safety, the 20th anniversary of the CRAC’s conference and AGM will include the presentation of its first-ever CRAC Safety Awards.

The CRAC Safety Awards are open to member crane rental companies. Companies receiving the awards will be listed on the CRAC website and covered in partner publications (including Crane & Hoist Canada).

If you want to look at the way some other associations have evolved over time, just look south of the border to the Association of Equipment Manufacturers (AEM), which started out as a representative for farming implements manufacturers in the late 1800s, and is now a super-powered voice for the agriculture and construction industries, with its influence affecting additional industries such as forestry, mining and utilities.

It ’s hard to imagine that the founders of AEM ever thought it would be running the largest trade show in North America in CONEXPO-CON/AGG.

That massive triennial show attracted nearly 128,000 people to Las Vegas during the 2017 edition, injecting more than $120 million in spending into the local economy, according to Chris Meyer, vice-president of global business sales for the Las Vegas Convention and Visitors Authority (The next edition of CONEXPO-CON/AGG will take place from March 10-14, 2020).

Yes, the AEM has a much larger membership pool to draw from than the CRAC, and has been around about a century longer. Even still, just seeing how the AEM has evolved over time makes me wonder where the CRAC could potentially be 100 years from now.

Will the CRAC end up running the largest trade show on the continent? Unlikely.

Will the association continue to grow and evolve, becoming a stronger and stronger voice for Canada’s crane rental indsutry? Sounds plausible to me. I suppose only time will tell. Of course, a hundred years is a long ways away, so for the time being I’m going to focus on heading over to Winnipeg, chatting up the indsutry’s best and brightest, and enjoy taking part in the association’s 20-year celebrations this June.

Happy 20th birthday CRAC!

Terex Cranes distributor Cropac Equipment Inc. with locations in Ontario, Québec, and Alberta, has recently placed an order for four Demag all terrain cranes. The order includes Demag AC 300-6, AC 220-5 and AC 160-5 all terrain cranes.

“We are committed to serving the needs of our customers,” explains Bill Finkle, president of Cropac Equipment. “Our customers are among the area’s top construction companies, and we are proud to be a part of that success. The role we play is sourcing the industry’s best equipment and providing outstanding service and parts support after the sale. The people at Terex Cranes have always been our partner to help deliver on that customer promise.”

Since being reintroduced to the global market in 2016, Demag all terrain cranes have continued to gain traction among lift and access companies. Demag all terrain cranes are among the most compact units in each of their respective capacity classes, are easy to transport, setup and rig. Each unit also features the latest crane innovations, including the optional IC-1 Plus control system that calculates the crane’s lifting capacity for every boom position as

a function of the superstructure’s slewing angle, and in real time to boot. Demag all terrain cranes’ design, features and functionality deliver high productivity and exceptional return-on-investment.

“We know our customers will be impressed with the performance and quality of these new all terrain cranes,” concludes Finkle.

The Vancouver Fraser Port Authority released the 2017 year-end statistics for cargo through the Port of Vancouver.

Overall cargo volume through the port reached a record high of 142.1 million tonnes, up five per cent from 2016. Sectors experiencing strong growth include containers and bulk grain, both of which hit new records in 2017.

“The record year for cargo movement and healthy growth across the port reflects the strength of the Canadian economy in 2017, as well as the Port of Vancouver’s ability to accommodate the most diversified range of cargo of any port in North America,” said Robin Silvester, president and CEO at the Vancouver Fraser Port Authority.

Notably, overall container traffic (measured by TEUs or twenty-foot equivalent units) saw a significant increase of 11 per cent over 2016 to reach a record of 3.3 million TEUs, with loaded imports up by 11 per cent. Volumes were driven by a global upswing in economic activity, which boosted Canadian export sales and overall strength in the transpacific container market. Overall, 2017 saw an 6.6 per cent increase in cargo-filled containers, setting a new record of 2.8 million TEUs.

“Year over year we continue to see an increase in the global demand for Canadian products shipped in containers and Canadian demand for consumer and manufacturing goods from Asia,” Silvester said. “To meet future demand, we are taking steps to ensure the Port of Vancouver is ready to handle growing container volumes through Canada’s West Coast.

“A number of investments in infrastructure are already underway in the port to build container capacity.”

Strong global demand for Canadian agriculture was met with a bumper harvest in Canada and increased exports of grain through the Port of Vancouver. Bulk grain saw another record year in 2017 at 23.6 million metric tonnes, an eight per cent increase over 2016, making this the Port of Vancouver’s fourth consecutive year of record grain volumes.

The auto sector saw a nine per cent increase in 2017 from 2016, boosted by a record year for auto sales across Canada and an increase in consumer confidence. This is the third consecutive year of an upward trend in autos through the Port of Vancouver.

The breakbulk sector saw a two per cent increase over 2016 due to strong wood pulp exports and increased movement of domestic consumer goods along the Fraser River and between the Lower Mainland and Vancouver Island.

The cruise industry in Vancouver is experiencing stable growth as demand for cruises to Alaska continues to increase.

In 2017, the port welcomed 236 cruise ships and 842,928 passengers compared to 826,820 passengers in 2016, an increase of two per cent.

“This record year is a success shared with all the port terminal operators, many of whom have made investments in infrastructure and technology that have increased the capacity of the Port of Vancouver, and with the many shippers and marine carriers whose continued confidence in the gateway we appreciate,” said Silvester.

Source: Vancouver Fraser Port Authority

Port Saint John will host the Association of Canadian Port Authorities’ (ACPA) 60th Anniversary Conference and Annual General Meeting.

The event will take place from September 10 to 13, 2018 in Saint John, N.B. at the Delta Hotels St. John.

The conference will feature engaging keynotes, industry speakers, and panels; as well as industry exhibition opportunities. Other conference highlights will include the Maritime Kitchen Party Gala (September 12) and technical tours of Port Saint John’s port and terminals on September 13.

Port Saint John is Eastern Canada’s largest port by volume and has a diverse cargo base, handling an average of 28 million metric tonnes of cargo annually, including dry and liquid bulks, break bulk, and containers.

The hotel block is now open for booking at Delta Hotels Saint John. Sponsorship opportunities are still available. For more information on the agenda, venue and sponsorships, visit: http://acpa2018.ca.

For information on Port Saint John, visit: www.sjport.com.

Liebherr-International AG, one of the world’s largest manufacturers of construction machinery and earthmoving equipment recently announced it is investing $45 million in the expansion of its Newport News, Va., facility.

Liebherr has been manufacturing and operating in Newport News for over 48 years. The new expansion will include the construction of three new buildings on 28 acres adjacent to the Liebherr’s current manufacturing facility. Once completed, the new facilities will total over 251,000 square feet and will be occupied by Liebherr USA, Co. The expansion will offer space for Liebherr USA Co.’s new headquarters and administrative building, a production and workshop facility, and a warehouse and distribution building.

Construction is expected to begin in July 2018 and be completed by summer of 2020.

“Since 1970, our continued success and commitment to customers in the United States has always been at the forefront of everything we have done and continue to do,” said Torben Reher, managing director of Liebherr USA, Co. “This expansion

underlines our commitment and further strengthens our position in North America to deliver sustainable long-term growth and to offer exceptional and consistent experience to customers across the United States.”

“I am excited that Liebherr has chosen to again expand and grow its Newport News facility,” said McKinley Price, Mayor of Newport News, Va. “Employing over 400 people, Liebherr is an important industrial employer and has been a committed corporate citizen during its 48-year tenure in Newport News. This $45 million investment indicates confidence in our city as a place to grow and be successful.”

Source: Liebherr.

Alarge fleet of Mammoet equipment and personnel are in the process of being mobilized as Mammoet Canada prepares for a busy season of shutdown projects in Alberta.

Mammoet will assist in over 10 shutdowns, many of which are large oil producing facilities. Personnel and equipment will work around the clock for the next three months to safely and efficiently carry out the scopes of work.

Planning for these shutdowns occurred up to nine months ago. Mammoet has worked closely with its clients to shorten schedules and optimize the use of on-site resources by carefully planning project work at the same time as shutdown work. This will minimize the costs associated with mobilization and increase efficiencies by right sizing the required crane fleets to handle the scopes of work.

Mammoet Canada’s western managing director, Tom van der Enden, said the increased activity is welcomed following a slowdown in the second half of 2016 and 2017.

“The coming shutdown season, coupled with planned project and day market activity, will bring back a healthy utilization of our fleet,” he said. “Our forecast for project and day market is also looking favourable.”

Over many decades, Mammoet has built up extensive experience managing and executing shutdown activities, using practical, industry-specific expertise to carry out a safe and efficient execution.

Source: Mammoet Canada.

magine capturing video from a training session so prospective operators can literally have a bird’s-eye view of their manoeuvres; or no longer having to dismantle your crane and lay it on its side for inspection.

When we think about drones, a commonly conjured image is of teenagers flying them recreationally.

Every so often, newspapers carry stories about close calls with aircraft, or users illicitly photographing their neighbours. Drones are used for search-and-rescue, threedimensional mapping, storm tracking, even warfare. So why can’t they help us work with cranes?

In fact, that’s starting to happen. A Toronto drone data and software provider, Industrial SkyWorks, is field-testing BlueVu software designed to deliver crane-related imagery taken in realtime to a user’s computer.

Michael Cohen, president and CEO of Industrial SkyWorks, is a director of Unmanned Systems Canada, a drone industry trade association, and his own sights are trained on commercial uses. The company has already released BlueVu modules specifically designed to capture images of building exteriors and oil and gas facilities, to assist with their inspection.

Last year, Cohen was approached about facilitating the use of drones to inspect crawler cranes.

“They’re forced to take these cranes down once a month for a visual inspection,” Cohen explains. “Imagine the time, cost, labour and lost productivity that goes with that. So we’ve engaged with one of the leading construction companies to design a drone-meets-software program for them.”

Users with BlueVu software on their

computers can dispatch remote-controlled drones, just like the teenager next door.

Except the optimal drone is built to commercial-industrial scale with a high-pixel camera designed to capture extremely strong resolution images from whatever vantage points are needed.

“The photographs are georeferenced and converted into three dimensional models,” Cohen says, explaining that an inspector can view the imagery using a computer or mobile device.

“You would see anything that’s misshapen in the geometry, corrosion, cracks and broken welds — any distortion whatsoever to the integrity of the surface or the support structures,” Cohen says. “The drone collects the data, the software converts it into something that’s usable, and you can perform an inspection (on your computer).”

While Industrial SkyWorks already offers modules for building and oil-and-gas inspection, the version for crane inspectors is new enough that it’s still at the proof-ofconcept stage.

“We’re actually flying [around] the cranes with drones, collecting data, and then proving whether or not that data is sufficient enough for visual inspection,” Cohen says.

“The results are very promising.”

While the testing is currently being done with crawlers, Cohen says the technology should work with any kind of crane, including tower cranes. “There could be an application for those, as well, but we haven’t been asked to do that.”

What is immediately evident is that drones should be commercial-industrial scale and not those meant for recreational flying.

“Your cellphone could take really good pictures of the crane, but the sensors with [high-end drones] could be 40 megapixel

cameras that are taking ultra-high resolution imagery down to sub-centimetre level resolution,” Cohen says.

“The best-in-class will have obstacleavoidance, so you could literally program the drone to say you want it to be 30 feet from the crane and no closer, or otherwise for safety because you’re on a job site.”

Could drones do more than supply highresolution images for easy inspection? We asked, half-joking, if drones could deliver lunch to a tower crane operator or ferret things back and forth.

“Delivering lunch is certainly an interesting idea — I think that’s entirely possible,” Cohen says. “I can also imagine you could put a drone on-station and live-feed images to an operator. If you have a couple hundred feet out on the boom and you need to look at something, this might be an obvious way to do it.”

Shawn Galloway, an instructor with Atlanta, Ga.-based Crane Industry Services (CIS), says the training and certification company is actively exploring the use of drones to help with many aspects of crane work.

Drones equipped with visual and even thermal cameras could provide prospective operators, riggers and lift directors valuable overviews of a job site, Galloway says, explaining that mapping sof tware could help determine the optimal placement of a crane for the safest, most efficient lifts.

“You can get down to the detail of where to put a piece of equipment for the lift all before mobilizing the equipment,” Galloway says. “Then, after a lift is planned, the drone could be used to verify placement based on the previous survey conducted by the crew.”

Drones could come in handy right before a manoeuvre or if a situation suddenly arises.

“On a tower crane you could fly your drone to check the cords and lacings of the tower and boom,” Galloway says. “If a tower

crane has a collision and something needs to be checked very quickly, a drone could be deployed to do a cursory check. If there is no room to boom down a lattice boom or really any other mobile crane but a boom check needs to be made, a drone can be used to accomplish this without having to use a lifting device to get an inspector up there.”

For now, CIS remains at the exploratory stage. “Before CIS actually uses drones for inspections, parameters, skill levels and applications would have to be set into place,” Galloway’s boss and company CEO Debbie Dickinson says.

Dickinson says the company is working with the Georgia Institute of Technology on construction technology research that includes the use of drones, and their work may result in drafts of standards for drone use in construction and simulation systems for training personnel.

North of the U.S. border, Transport Canada regulates the use of drones, and new, updated rules governing issues such as privacy, public safety and operator training are in the works. <www.tc.gc.ca/eng/ civilaviation/opssvs/proposed-rules-dronescanada.html>.

CIS’s Shawn Galloway says he strongly supports user training in the commercialindustrial space.

“Drones occupy and have the capability to occupy the same airspace as manned aircraft,” he says. “Training for advanced users can entail weather, airspace, airworthiness, rules and regulations, and a program of real flight time.”

Ultimately, Galloway sees drones as a natural fit for cranes. “The construction industry has used aerial photography for decades in project planning. Drones, in the hands of skilled pilots who understand construction and machines, just make the job of the helicopter perspective easier and more affordable.”

® The New GMK 5250L and the Complete Line of Grove All-Terrain Cranes Available for Immediate Delivery

2111-80th Avenue

Edmonton, AB, T6P1N3 1-800-319-7787

Tel: 780-440-4010

Fax: 780-440-4787

Contact: Kevin Maguire kmaguire@essltd.com

1030 Martin Grove Rd. Toronto, ON, M9W4W3 1-800-268-0679

Tel: 416-249-8141

Fax: 416-249-8912

Contact: Drew Paton dpaton@essltd.com since 1946 essltd.com

The project has been loaded with challenges, and Huggett said these have been met through advanced planning, careful engineering, and employing the heaviest-duty barge-mounted crane available in British Columbia.

Just four years ago, when Huggett joined the team, another barge-mounted crane, the Arctic Tuk, was the reigning heavyweight. Rented from Amix Group, it featured a rebuilt Manitowoc 4600 Series-3 crane with a Series-2 ringer attachment. It had a 600ton lifting capacity and saw duty removing an old railway crossing and installing concrete beams on the approach span to the new bridge.

In early 2017, while preparing to erect the new single-leaf bascule bridge, billed as one of the largest of its kind in the world, the project team caught wind of the Dynamic Beast, a new, heavier-capacity barge-mounted crane available through Dynamic Heavy Lift.

The timing was prescient because the plan was to assemble the bridge off-site in order to reduce time spent hoisting on-site and ease the impact on commercial-industrial marine traffic underneath. By integrating a 900-ton-capacity Manitowoc M-1200 Ringer crane with a Manitowoc M-250 crawler, the Dynamic Beast exceeded the Arctic Tuk’s capacity by 50 per cent, essentially making it possible to lift the enormous prefabricated sections.

The Dynamic Beast is essentially the sum of its components. Clarke Longmuir, general manager with Dynamic Heavy Lift, said the M-1200 was built in 1997 and acquired from a construction firm in South Korea.

“It was 20 [years old] when we bought it, but it hadn’t had a lot of use,” Longmuir said. “It was well cared for and all the structural

components were in very good condition. We replaced most of the hydraulic lines and connections, and replaced or reconditioned various parts on the crane.”

Dynamic Heavy Lift sourced the barge from a U.S. company using it in Mexico. Longmuir said its flat-bottom hull offers stability for crane operations and a raked bow and stern with large skegs makes it tow well for a barge of its size.

The 330-by-120-foot barge, rated to carry 10,000 tons of cargo, easily accommodates the M-1200 ringer and M-150 crawler as well as a 230-ton Manitowoc 4100W mobile service crane.

Longmuir said ringer crane configurations are designed to maximize lift capacity by increasing counterweight, lengthening the distance between the boom and counterweight, and using a larger, stronger boom — basically, making it a bigger crane.

While the Dynamic Beast’s rated lift capacity is 900 tons, improved reach also mattered. Crews use the service crane to help switch between different booms, which range

from 150 to 400 feet and offer dexterity.

In all, the Dynamic Beast hoisted two 270-ton rings and a 470-ton span in three separate lifts, each taking a full day.

The rings and span were lifted into place on supports, and crews used hydraulic jacks to fine-tune their placement to the nearest millimetre before bolting them together.

The highly complicated manoeuvres took months of planning and project engineers surveyed from multiple angles, including the position of the barge itself and the position of the crane on the barge.

“When you lift the pieces you need to know with certainty you’re going to be able to place them down exactly where you want them,” Huggett explained.

Still, there were tense moments, particularly with the 470-ton span.

“We didn’t know exactly how much this thing weighed until we got it in the air,” Huggett said. “We calculated what we thought it weighed, but our calculations weren’t quite right. One end tipped up very slightly — not very much, but enough to stop the attachment. We knew this might happen, so we loaded some heavy concrete blocks on one end to bring it down so it was exactly horizontal. We would not have been able to place if it was tilted in one direction.”

In the end, Huggett said, the lifts proceeded seamlessly. “One challenge was that we were doing it in the middle of the downtown of a major city, in a very confined space, under the gaze of every member of the public.”

Huggett spent much of the time watching from different vantage points and speaking with TV journalists who had joined large crowds of onlookers.

“Watching the people actually do the work was a great sense of joy,” he said. “To

I was concerned about the math prior to coming. The approach that the Instructors took helped me to take on the challenge and gain confidence. I would definitely recommend NLC to other students and to employers. And I’d come back here in a heartbeat for Mobile Crane Third Period, especially with these teachers.

– Matthew, Graduate of the Crane & Hoisting Equipment Operator - Mobile Crane Apprenticeship 3rd Period

Northern Lakes College offers a unique mobile delivery where training is provided in locations across Alberta where apprentices are working. Bringing the classroom to you!

For dates and locations please visit us on our website www.northernlakescollege.ca or call 1-866-652-3456.

the average untrained eye, you wouldn’t have realized what the operator was doing. But on a couple of occasions he did what’s called feathering, where you give the load a slight nudge so it swings where you want it to go. But you don’t nudge it too much because you lose control — just enough so it generally goes where you want it to go. The skill in doing that, the fine-tuning, was amazing.”

Huggett said he was impressed by up to 50 unionized ironworkers holding ropes and helping out, and supervisors giving direction. “PCL brought in at least two experienced superintendents from other projects around North America who had done this kind of heavy lift work before. We had an army of experts floating around, and Dynamic had its own crane operator who does nothing but operate this Dynamic Beast.”

The scheduled launch was March 31, and when the new bridge opens to traffic, crews plan to use the Dynamic Beast to help demolish the old structure, which has remained in place during construction in order to maintain traffic flow on Johnson Street. The barge will then haul the steel for recycling.

While the Dynamic Beast works hard, it’s towed like royalty on a sedan from job to job. A non-powered vessel, a single tugboat tows it at a speed of roughly 4.5 knots, with trips between Vancouver to Victoria taking about 20 hours.

As a rental unit, the Dynamic Beast’s work never ceases. Another ongoing project has been helping install a ship-loader system at Alliance Grain Terminals at the Port of Vancouver, and future travels could land the barge and crane anywhere along the

or beyond.

continued from cover

The annual festivities will also take place in the Journey to Churchill exhibit at the Assiniboine Park Zoo. In the heart of the exhibit is the Gateway to the Arctic, which is the main viewing point for polar bears and seals. This is where CRAC will host its 2018 annual Get Together!

For information on the 2018 CRAC conference, or to register, visit www.crac-canada.com.

WEDNESDAY, JUNE 6

7:45 a.m. to 3:45 p.m. Board of Directors’ meetings

9:00 a.m. to 9:00 p.m. Pre-registration

Welcome! The pre-registration for the Crane Rental Association of Canada’s 2018 Conference is now open.

8:00 p.m.

The Spreader Bar – Concert Hall

The traditional Spreader Bar will be hosted at 8:00 p.m. in the Concert Hall.

THURSDAY, JUNE 7

7:00 a.m. to 9:00 a.m.

Breakfast – Provencher Room

7:30 a.m. to 3:15 p.m.

The 2018 annual golf event

Departure: 7:30 a.m. Tee-off: 9:00 a.m.

Registration fee is $185. Departure is from the front of the Fort Garry, arriving at Glendale Golf and Country Club approximately at 8:30 a.m. Breakfast, buffet lunch, power cart, bottle of water, sleeve of golf balls, and personalized cart plates, GST and provincial taxes, gratuities, and transportation are all inclusive. Golf club rentals will be available at a cost of $45 per set. No shoes available.

9:30 a.m. to 2:00 p.m.

Winnipeg City Tour

Registration fee is $130. The Winnipeg City tour includes an overview of Winnipeg’s rich culture and history, with a professional guide who will provide stories and anecdotes along the way. The fee includes transportation, lunch, all type of taxes and gratuities.

6:30 p.m. to 9:45 p.m.

The Get Together – Journey to Churchill Registration fee is $150. In the heart of Assiniboine Park Zoo is Journey to Churchill, and in the heart of Journey to Churchill is the Gateway to the Arctic where CRAC will host its 2018 annual Get Together! This is the primary viewing point for polar bears and seals. Interpretive media helps visitors learn about physiological adaptations to life on and under the sea ice. Underwater viewing tunnels, known as Sea Ice Passage, give visitors the rare opportunity to view these amazing creatures swimming from below the surface of the water. With only a clear wall bisecting the two species’ habitats, the polar bears and seals see and smell each other, creating a dynamic and enriching environment. This interaction between the seals and polar bears will be part of what puts this exhibit at the forefront of Arctic zoo experiences. Attire: Business Casual.

10:00 p.m.

The Spreader Bar – Concert Hall

The traditional Spreader Bar will be hosted every night at 10:00 p.m. in the Concert Hall, due to Journey to Churchill.

FRIDAY, JUNE 8

7:00 a.m. to 9:00 a.m.

Breakfast – Provencher Room

9:00 a.m. to 9:15 a.m.

Ted Redmond – Opening remarks

9:15 a.m. to 10:00 a.m.

Jane Blaufus – Crystal Ballroom

Courageous conversations

Suddenly widowed after the tragic death of her husband, Jane knows first-hand how important it is to have a solid plan in place. Join her as she shares tips and strategies to have the ‘courageous conversations’ with your loved ones, your business partners and other important people in your life. Blaufus is the bestselling author of the book, “WITH THE [STROKE] OF A PEN: Claim your life,” that has become recognized as one of the most comprehensive, actionable, personal and financial planning resources available today for families, individuals and business owners alike.

She brings to the table more than 25 years of insurance expertise as a financial advisor, sales manager and executive.

Today she is the principal of The Blaufus Group Inc., based in Ancaster, Ont.; and is a highly sought after international keynote speaker, a frequent guest expert on both national and local TV and radio, and a contributor to the Huffington Post.

10:10 a.m. to 10:45 a.m.

Andre Brisson – Crystal Ballroom

Review of the latest update of the CSA Z150

10:45 a.m. to 11:00 a.m.

Health break

11:00 a.m. to 12:00 p.m.

Klaus Meissner, Terex Cranes – Crystal Ballroom

Future of EN 13000

Under the title “Future of EN13000,” the current status of the European safety standard for mobile cranes and its future version is discussed. Root causes of crane incidents are analyzed and discussed to determine appropriate countermeasures for design and use. The presentation includes a number of simple experiments demonstrating the background.

12:00 p.m. to 1:15 p.m.

Lunch – Provencher Room

1:15 p.m. to 6:00 p.m.

Canadian Museum for Human Rights (CMHR)

The Friday afternoon program will move from the Fort Garry Hotel to the Canadian Museum for Human Rights (CMHR). Delegates and spouses will attend a presentation on this project from inception to completion by architect Grant Van Iderstine (MAA, OAA, SAA, MRAIC Practice Leader, Architecture 49), and postconstruction project manager John Kozlowski (1:30 p.m. to 3:00 p.m.). These presentations will be followed by tours (3:00 p.m. to 4:00 p.m.) of this fascinating building and will end in the Garden of Contemplation with a cocktail reception (4:30 p.m. to 6:00 p.m.).

Creating this world-class showpiece of architecture and construction presented unparalleled challenges. The complex nature of the building form - an intricate integration of concrete, steel and glass - pushed the boundaries of the conventional design process, application technologies, and construction delivery. The use of technologies including 3D modeling will forever change the way complex projects are designed, managed and built.

8:00 p.m.

The Spreader Bar – Concert Hall

The traditional Spreader Bar will be hosted at 8:00 p.m. in the Concert Hall.

SATURDAY, JUNE 9

7:00 a.m. to 9:00 a.m.

Breakfast - Provencher Room

8:30 a.m. to 9:30 a.m.

Annual General Meeting - Crystal Ballroom

Annual General Meeting will include the presentation of first-ever Safety Awards and the Boom Dolly Research Committee Report.

9:45 a.m. to 10:15 a.m.

Tami Helgeson - Threads of Life

Threads of Life, is a Canadian registered charity dedicated to supporting families after a workplace fatality, life-altering injury or occupational disease. Tami will speak of her experience following a tragic workplace accident that impacted her life.

10:15 a.m. to 10:30 a.m. Health break

10:30 a.m. to 11:00 a.m.

Randy Robertson - Manitex

Latest developments at Manitex.

11:00 a.m. to 11:30 a.m.

Keynote speaker #3 – Crystal Ballroom TBA

11:30 a.m. to 12:00 p.m.

Dr. Grant Cool - Chief operating officer, Hybrid Enterprises

No roads, no problem

The Lockheed Martin Hybrid Airship introduces the next revolution in affordable transportation for heavy lift cargo to remote operating sites around the world.

Dr. Cool is the chief operating officer of Hybrid Enterprises. Prior to the establishment of Hybrid Enterprises, Dr. Cool was the operations subject matter expert for Lockheed Martin on the Hybrid Airships program.

Dr. Cool is a professional engineer, holds a Ph.D. in aerospace engineering in spacecraft design, and a BASc in metallurgy and materials engineering.

6:00 p.m.

Closing banquet - Concert Hall

Cocktails will be served in the Concert Hall at 6:00 p.m. Dinner will be served in the Crystal Ballroom at 7:00 p.m.

Attire: Formal attire.

“We’ve

from cover

Doug Younger, occupational safety officer for WorkSafeBC, offered an overview of the 2018-2020 WorkSafeBC Crane Industry Initiative.

The agency’s tower crane strategy is “to identify and eliminate specific tower crane hazards and unsafe work practices that have the potential to cause serious injury, death, or catastrophic equipment failure.”

Younger told the crowd that the large number of serious incidents related to safe operation of tower cranes is what spurred WorkSafeBC’s focus on tower cranes.

In addition to the 12 tower crane incidents that were reported in 2017-18 in B.C., there have been 250 tower crane incidents reported between 2008 and 2017. The majority of the incidents were caused by crane and hoist equipment failures; contact with overhead conductors, tower cranes and concrete pumps; and workers being struck by falling loads or by rigging and other objects.

Younger said that the true number of incidents is most likely more than this, since WorkSafeBC may not hear about all incidents, and its officers may not actually document every single incident that takes place.

All of these serious incidents had the potential for serious work injury or death, and all of them were avoidable, Younger told the crowd. He added that he is amazed at how many close calls and near misses he has seen over the years; and that there have been no fatalities stemming from these incidents over the past 10 years.

“This industry cannot rely on luck,” Younger said. “It’s unbelievable how nobody got seriously hurt [in these incidents]… we need to take a serious look and improve our safety stats, we need to improve our record.”

Not surprisingly, the bulk of the incidents in B.C. have taken place in the Vancouver area, where most of the lifting work is taking place. Out of the 250 incidents from 2008 to 2017, 126 occurred in Vancouver West and 14 occurred in Vancouver East.

Other cities in B.C. where a significant number of incidents have taken place include Surrey (15); Victoria (14); Kelowna (13); and Courtenay (8).

Of the 12 incidents that were reported in the past 12 months, 10 took place in the Lower Mainland, with the others happening on Vancouver Island. Eleven of the 12 incidents were close calls. One reported incident resulted in a worker being injured with fractured vertebra when they fell backwards three feet and landed on a rock adjacent to a footing excavation, while being involved in a footing pour, positioning a loaded bucket of concrete rigged from a tower crane.

Younger discussed WorkSafeBC’s various tower crane initiatives, which include:

• Crane operator certification changes and updates;

• Pre-erection and annual inspection requirements to the CSA standard;

• Rigging standard and rigger qualification;

• Equipment zoning (slew-limiting devices); and

• Below-the-hook lifting device design and documentation.

Fraser Cocks, executive director for the BC Association for Crane Safety, offered an update on the association’s activities and discussed the crane operator certification scheme.

Cocks said there are currently a total of 364 B.C. certified tower crane operators in the province (235 active full scope, and 129 active provisional); with an additional 86 certified crane operators working in B.C. with recognized credentials from other provinces. Albertans make up the bulk of those operators, accounting for 70 of the 86 operators. He told the crowd that there is a need to watch out for false credentials, and that an operator having the necessary credentials is only one step for ensuring safe operations.

“You, as employers, are responsible for making sure your operators are qualified,” he told the crowd, adding that companies need to enforce that their operators are properly trained and fit to operate the cranes safely, including not arriving to work under the influence of anything that would inhibit their abilities to operate cranes safely.

Cocks discussed the challenges that come with every province having its own types of certifications, and that work is currently being done at the federal level to try and align credentials for operators across the country.

CSA

Unirope president Knut Buschmann presented on wire rope inspection and safe use during the conference, and discussed updates and noteworthy changes regarding the Z 248 Tower Cranes and Z 150 Mobile Cranes CSA standards:

Z 248 TOWER CRANES

• Non-rotating ropes must meet ASTM 1023, Class I (Class 35 x 7)

• Temperature rating +82C to -40C (Consult rope manufacturer if higher or lower)

Z 248 TOWER AND Z 150 MOBILE CRANES

In the absence of any Canadian or U.S.

(ASTM) safety standard on wire rope fittings now referred for guidance by EN 13411. (Note: EN fitting designs shall withstand a 75,000 cycle test. But not required in Canada). Hence, all spelter, swaged and loop back terminations need to be proof tested. (Note: A one-time proof test is no guarantee for continuous performance).

Kristin Leversage, program development officer with the Industry Training Authority (ITA), offered attendees an update on the new requirements of the Red Seal program. The Red Seal Certification Program for tower crane operators was launched on Dec. 1, 2017. The ITA is now issuing Red Seal endorsements for tower crane operators.

Red Seal program completion requirements include:

• Minimum of 3,000 hours;

• Three written exams: Level 1, Level 2 and Interprovincial Red Seal exam; and

• A practical assessment (no change).

For trade workers who are already certified, she said that all ITA certifications are still valid and no action is required. However, if a certified trade worker wants to obtain a Red Seal endorsement on their Certificate of Qualification, they can do so by passing the Interprovincial Red Seal exam.

Cathy Lange, consultant for the BC Construction Safety Alliance (BCCSA), offered an overview of the Technical High Angle Rope Rescue Program (THARRP). The THARRP program prepares fire department personnel in technical rope and tower crane rescue procedures for workers in distress working at heights. The program was created in 1991 by the Greater Vancouver Regional District Fire Chiefs, is administered by the BCCSA, and overseen by the Technical High Angle Rope Rescue Steering Committee. The committee is comprised of representatives from the BC Professional Fire Fighters’ Association, BC Fire Chiefs’ Association, participating employers, labour, BCCSA and WorkSafeBC.

New products for improving safety were also on display at the conference, including zoning devices and anti-collision technologies and cameras.

Paul Roussel, manager for Opticrane, discussed some of the latest innovations for improving safety for tower crane operations. Roussel discussed how zoning devices and anti-collision (AC) devices are able to warn operators about hazards and prevent

encroachment on prohibited areas, when partially or fully integrated. All cranes manufactured in Europe after 2006 have to be able accept any manufacturer’s AC technologies. Although AC systems have been around for 20 years, Roussel said they are still new to some people in the industry, and that there is a new layer we can add to these anti-collision systems.

“They all have software that can be run in conjunction with these systems and can send you alerts,” Roussel explained. “You now can have a system that tells you how much mileage a crane is doing in a day for preventative maintenance, how many alerts you get in a day, and how often two tower cranes may be ‘fighting’ for the same lifts… with data logging monitoring system you can basically log anything.”

Companies can then use this data for a variety of applications, in addition to things like preventative maintenance and alerts, such as defending itself against accusations of breaching limits of approach, since the data can record how the tower crane has been operating.

“Why should data be tracked? We can prevent incidents, we can demonstrate our due diligence, ensure our return on investment… we can re-think the way we do things,” Roussel told the crowd, adding that he believes the industry is moving in the right direction, but that there is much more that can be done to improve the safety of tower crane operations through adopting innovative technologies. “Technology is there is help us… it can make our lives a lot easier.”

PREVENTATIVE MAINTENANCE

Bigfoot Crane Company’s Ryan Burton discussed tower crane preventative maintenance best practices and the pros and cons of having a preventive maintenance program.

“The primary goal of preventative maintenance is to prevent the failures of equipment before they occur,” he told the crowd. “There are lots of advantages of preventive maintenance.”

Advantages mentioned included:

• It is cost effective in many capital intensive environments;

• Provides flexibility for periodic adjustment of maintenance tasks;

• Increases the life cycle of components;

• Reduces equipment failures and downtime costs; and

• Is said to result in 12 per cent to 18 per cent cost savings over a reactive maintenance program.

That said, there are challenges to running preventative maintenance programs, Burton told the crowd.

He said the disadvantages include the program not eliminating catastrophic failures (although it does help prevent them) and that these types of maintenance programs are always more labour intensive. They also require maintenance management being willing to stock more parts and potentially replace parts that are still in good operating condition.

Additional presentations that took place during the conference included limits of approach to overhead electrical contractors; meeting CSA standards when making modifications to tower cranes; tower crane inspections and requirements for B.C.; and a Canadian standards review and discussion by the SCC, CSA, and CSA Standards committee members.

crane operators, certification is just the first step

of new lien procedures, more flexible lien limitation periods and enhanced trust obligations

On December 12, 2017, Ontario’s Construction Lien Act Amendment Act, 2017 was passed into law. Its substantive changes will come into force on a date to be determined (or “proclaimed”) later this year. Among other things, these will change the name of the Construction Lien Act to the Construction Act.

In addition to the new prompt payment requirements and adjudication procedures set out in the legislation, the changes include new procedures, longer lien timeframes and enhanced trust obligations. We will review some of the more substantial changes, below.

In keeping with the ‘prompt payment’ and ‘adjudication’ provisions that have been introduced into the new legislation, new provisions in relation to holdback are designed to help contractors and subcontractors be paid more efficiently.

Under the current legislation, of course, the holdback cannot be released until all liens that might be preserved against the improvement have expired, been vacated from title or resolved. Once that point is reached, however, the holdback ceases to be holdback. Rather, it becomes monies potentially due and owing to the contractor under the contract. Significantly, the owner can apply a set-off against those funds, for backcharges or for any other debt allegedly owing.

This puts the contractor in a difficult position: if he does not preserve a lien, he has to trust the owner to pay the holdback. Similar dilemmas face subcontractors who have to decide to either lien for their holdback or have faith that it will be released by everyone above them in the payment chain.

The new Act addresses this problem by making the payment of the holdback mandatory once it becomes due, unless notice to the contrary is given in a prescribed (or mandatory) form and manner. These provisions will give those awaiting their holdback the opportunity to preserve claims for lien. Participants in the industry will have to understand, and meet, their notice obligations in this regard. If you think you have a set-off against the holdback, you will have to give notice. Also, those awaiting holdback must understand and look out for a notice that the holdback is not going to be released.

Other significant changes to the holdback provisions include the following (which will assist to get the holdback into the subtrades’ hands in a timelier fashion):

a) provisions which allow the holdback, in some circumstances, to be released on an annual, or phased, basis; and

b) provisions which allow the owner and contractor to carve out a portion of the work from the calculation of substantial performance, so as to allow for an early release of holdback.

Contractors and subcontractors have long complained that 45 days is not enough time within which to preserve a claim for lien. Many would point out that because their payment terms are 30 days and they are rarely paid on time, they have to decide whether or not to lien before they really know if they have a problem. The notices now required in relation to holdback (see above) will help. In addition, under the new provisions, the 45-day time frames within which a lien had to be preserved will be extended to 60 days. In addition, while a lien claimant used to have to commence an action to enforce the lien within 45 days from the last day it could have preserved the lien, it will now have 90 days to do so. This, hopefully, will allow for more settlements and less litigation.

In addition, and to ensure that the adjudication process is allowed to work, no one’s lien rights will expire while they are in the middle of an adjudication that has not been delayed or extended. This allows anyone with a lien to assess the results of an adjudication before deciding whether or not to preserve that lien. If it has not already expired, a lien will not expire until 45 days after the receipt of documents by the adjudicator in accordance with the adjudication proceedings.

Currently, the contractor’s lien expires relative to the completion or abandonment of a contract. The new provisions add “termination” to this list. The practical effect of the change is that if the owner terminates the contract, notice of the termination must be given and, at that point, everyone’s liens for services or materials provided under the contract (including those of subcontractors) will expire no later than 60 days following the termination (subject to the timeframe being extended by an active adjudication).

The law as it relates to liens against premises that are subject to a lease has been clarified and in some ways changed. Landlords can still be liable as “owners”

of an improvement, so long as they meet the definition of “owner” under the Act. However, contractors who contract with the tenant (and those underneath them) will no longer have to send out a s.19 notice requesting that the landlord does meet that test. Rather, the determination will be made automatically by virtue of a test set out in the legislation.

Monetary adjustments

A contract will now be deemed complete when the lesser of 1% and $5,000.00 (rather than $1,000.00) worth of work (including the rectification of deficiencies) remains to be corrected. Substantial performance calculations will now be based on $1,000,000.00 instead of $500,000.00. To vacate a lien from title to a premises (by paying in cash, bond or letter of credit) the quantum of the claim for lien plus 25% or $250,000.00 (instead of $50,000.00) will now have to be paid into court. This will be significant for some.

The Act continues to deem that monies which are intended to pay for an improvement and are received by or owed to anyone who owes those beneath them in the payment chain for their supply of services and materials to be trust funds. It has often been debated whether or not someone who receives such trust monies should hold them in a separate account. The new provisions allow the monies to be co-mingled in a single account, with other monies, but will not require the person receiving them (the trustee) to maintain detailed records of the monies in and out, on an improvement by improvement basis. These changes appear designed, in part, to give unpaid contractors and suppliers a potential claim on the trust funds in the event the trustee goes into bankruptcy protection. Whether or not the changes will suffice for that purpose remains to be seen and will be for a court to decide based on federal bankruptcy and insolvency legislation.

The definition of “Repair”

The Act will be changed in an effort to clarify that only “capital” repairs to the land will give rise to lien rights. This appears directed, in part, at the argument (and recent case law) suggesting that certain maintenance activities, including “grounds keeping” should be considered lienable. To clarify, the new definition of “capital repair” will include for “any repair intended to extend the normal economic life of the land or of any building, structure or works on the land, or to improve the value or productivity of the land, building, structure or works, but not including maintenance work performed in order to prevent the normal deterioration of the land, building, structure or works, or to maintain the land, building, structure of works in a normal, functional state”. We don’t believe that including the “productivity of the land” was necessary. It appears that many agricultural

activities will now be lienable. It certainly remains to be asked: what portion of a landscaper’s maintenance work could be said to improve, as opposed to maintain, the value or productivity of the land. If, for example, I spray for weeds or to make flowers grow bigger and brighter, am I improving the land’s value or productivity? This is to be determined.

The procedures to be followed in a construction lien action have been largely removed from the legislation. The extent to which we will now fall back on the usual rules of court set out in the Rules of Civil Procedure remains to be seen. This is because much of the procedures will be addressed in regulations (if at all) that are still to come. However, certain changes have been made in the new Act. In this regard, and subject to what is said in the regulations, interim steps that do not result in a final decision on the merits (such as motions or discoveries) will no longer need the consent of the Court. In addition, parties will be able to join a trust action with a lien action and will no longer need leave of the Court to bring third parties into a lien action.

The requirement that a lien action be tried as summarily as possible will be maintained. However, the above noted changes appear destined to take much of the ‘teeth’ out of the requirement. It appears, subject to any corrections that occur by way of regulation, that many lien actions will take longer to conclude, given that interlocutory steps and the joinder of trust claims and third parties will apparently be allowed as they would in any other action. This may be done, however, in the expectation that only matters that could not be solved by way of the timely adjudication processes will proceed by way of lien action.

Addressing the lien that should not have been preserved

The court will now be able to discharge a lien on a motion if it finds the claim for lien to be frivolous, vexatious or an abuse or process. In addition, the threshold for finding someone personally liable for improperly preserving (or giving written notice of ) a lien has been lowered. In this regard, the concept of “gross exaggeration” of the lien giving rise to damages has been replaced. Now, a person will be liable where he or she knows that there is no lien or that the amount of the lien has been “willfully” exaggerated. The changes also clarify that a motion may be brought to reduce the amount of an exaggerated lien.

“P3”, municipal and “broader public sector” projects

The definitions and procedures have been changed to address “public-private partnerships” (or “P3”) projects, and improvements in which municipalities are potential owners. These changes will largely be of a concern to lien lawyers, who have to ensure that liens are properly preserved. The

changes are certainly intended to, and will, clarify previous confusion in some circumstances.

Of note, performance bonds and labour and material payment bonds will now be mandatory on P3, municipal and “broader public sector” improvements. The latter includes virtually any project paid for by tax dollars, including hospitals and school boards, etc. Of particular interest is the fact that, as drafted, the required labour and material payment bonds will have to be available to all subcontractors, and not just the first-tier subcontractors of the principal under the bond. It is not clear how sureties will respond to, or price, this requirement. Given that the definition of subcontractor includes anyone beneath the contractor who provides services or materials to an improvement, including trades, consultants and suppliers, the scope of risk to be undertaken by the surety will be substantial and hard to assess. On the other hand, of course, this is good news for those further down in the construction pyramid.

Over the years, lien lawyers have characterized the monetary impact of a delay on a project as being the increased cost of actually providing the services or materials in question. This was necessary to avoid the argument that the impacts claimed were pure “damages” which had no relationship to the cost of the actual work. The Act will now expressly give the suppliers of services or materials lien rights for “the reasonable costs of performing the contract or subcontract during the extended period of time, including costs related to the additional supply of services or materials (including equipment rentals), insurance and surety bond premiums, and costs resulting from seasonal conditions, that, but for the extension, would not have been incurred, but do not include indirect damages suffered as a result, such as loss of profit, productivity or opportunity, or any head office overhead costs.”

In summary, in becoming the Construction Act, the (soon to be former) Construction Lien Act just got a lot more complicated. Care must be taken in addressing lien issues, procedures and timeframes, in meeting the new trust obligations, and in preparing for and taking advantage of the prompt payment and adjudications procedures.

Robert Kennaley has a background in construction and is now the principal of Kennaley Construction Law, a law firm with offices in Simcoe, Toronto and Barrie, Ontario. He speaks and writes regularly on construction law issues and can be reached for comment at rjk@kennaley.ca. This material is for information purposes and is not intended to provide legal advice in relation to any particular fact situation. Readers who have concerns about any particular circumstance are encouraged to seek independent legal advice in that regard.

Hiab, part of Cargotec, invites the world’s best crane operators to submit their entries for the third World Crane Championship.

Local heats begin soon, and the winner will be crowned at the finals, which will take place at the IAA Commercial Vehicle Show in Hannover, Germany on Sept. 22 and 23, 2018.

The World Crane Championship aims to showcase the skills and abilities of loader crane operators from around the world, and give them the chance to test their skills against their peers, using the latest load handling products from Hiab. The first-ever World Crane Championship in 2015 started a new tradition in the industry, and generated such huge interest, that Hiab decided to make it a biannual event.

The idea of the contest is quite simple: using a Hiab X-HiPro 232 crane, move water cans from a truck, accurately and with precision, around a circuit of obstacles, in the shortest time possible. The operator with the lowest time and fewest faults is crowned the winner, and takes home a prize worth €25,000.

The first qualification rounds for the 2018 contest will take place in Germany and Austria in early March. To date, there are entries from 16 countries, including Finland, Sweden, Norway, Denmark, Austria, Switzerland, Italy, The Netherlands, Germany, Belgium, U.K. and Ireland, Spain, France, Poland, Slovenia, and Israel.

The winner of the second World Crane Championship in 2016 was Tim Hansen, from Denmark, with a time of 2 minutes, 51:42 seconds. Aged just 25, Hansen, of Tim S Hansen ApS, and the third generation of crane operators in his family, said, “Winning was a bit unreal, but it felt pretty good to win the prize and be able to call myself World Crane Champion.”

His modesty belies his dexterity and agility at operating the Hiab X-HiPro equipped crane with pin-sharp precision and accuracy whilst in the glare of the spotlight.

The operators are the key people in any crane business. It is their skill and precision in operating a crane that determines how quickly and safely goods can be delivered to end-users.

“The competitors take their entry into the competition very seriously,” says Lotta Sjöberg, global marketing manager, loader cranes, Hiab. “I have been told that some set up a replica course in their work yards, and practice on a daily basis to hone their skills. They ask me all sorts of questions about the rules, the penalty system, and the course. So, this year, we are keeping all elements of the test course, the crane, and the truck the same, because contestants want to test themselves against the two previous winners on a like-for-like basis, and try to beat them.”

There is intense, albeit good-natured, competition amongst the contestants, who are proud to represent their companies and their countries.

“Afterwards, they swap contact details, so they can stay in touch with one another,” says Sjöberg. “If you are part of this competition, you become part of a wider Hiab family, and people really like that.”

Indeed, feedback from contestants and their companies is very positive. Being the country-level champion is almost as good as being the world champion.

For more information, and to sign up to compete in the qualification rounds, visit www.worldcranechampionship.com.

Source: Hiab

BY SAUL CHERNOS

Halifax developer’s brand new tower crane is playing a key role in the construction of 400 luxury apartment units.

Earlier this year, Cosmos Developments took delivery of a brand new Terex CTT132-6 flat-top tower crane and immediately put it to work on the second of its four 12-storey Grandhaven Estates apartment buildings in the city’s Clayton Park West neighbourhood.

Cosmos is promoting Grandhaven Estates as luxury rental apartments. The four buildings, laid out in circular formation, will have a swimming pool and recreation centre at their heart. But it’s the towers, themselves, that propelled company president Peter Giannoulis to make his first foray into the world of tower cranes.

“I had limited experience with them,” Giannoulis said, explaining that, until now, his projects have all been low-rise, at seven storeys or less. “When required, we sub-contracted a mobile crane.”

Cosmos bought a used a Liebherr HC 130 from another local developer for the first of the four buildings. When that building was completed, Giannoulis decided to sell the machine and find a newer one.

“It was quite old — I believe it was built in 1979 — and not surprisingly it had a lot of problems; a lot of breakdowns.”

Giannoulis consulted with colleagues, scoured the internet and considered his options.

“I looked at a couple of used cranes. One guy was asking for $150,000 for one, but it didn’t look like it was well-maintained. I looked at the frame structure and there was a lot of rust. I just didn’t feel comfortable. I didn’t know what I’d be getting into.”

Giannoulis set his sights on a new

machine, deciding it would be more costeffective than acquiring another used model, albeit one that would be much newer. Lost productivity due to breakdowns was the deciding factor, he explained.

Eventually, Giannoulis settled on Terex as a manufacturer and the CTT132-6 as the model best suited for the mediumrise projects he envisions building in the near future.

While the crane cost roughly $370,000, Giannoulis said Cosmos entered into a lease-to-buy arrangement with Cropac Equipment, which holds exclusive distribution rights for Terex tower cranes in Atlantic Canada’s four provinces as well as Quebec and Ontario.

Giannoulis said this kind of arrangement is more cost-effective in the long-term than pure rental because monthly rental costs tend to be high whereas lease payments are not only lower but, in the end, help finance something his company owns.

Lease-to-own might be Cosmos Developments’ plan when the fourth building is completed. “We have some possible plans of doing more projects that we’re currently looking into,” Giannoulis said. “And if I’m not using it I can always sell it.”

In the short period of time Cosmos has owned the crane, maintenance has been straight-forward. A local company, SOS Electric, erected it, and Terex flew in a mechanic from New York to assist.

When SOS Electric later had to modify the brakes and safety limiter to cope with the strong winds Halifax frequently experiences, Terex again supplied a specialist, this time from Italy.

with the old continued from page 17

“Terex included all that in the sale,” Giannoulis said.

The newer machine also comes with air-conditioning, heating in the cab, an adjustable operator’s seat and remote-control operational capability. Computerized safety limiters warn the operator when wind speeds climb too high.

“We have a lot of wind here,” Giannoulis said. “We’re at the highest point in Halifax, elevation-wise, at about 460 feet above sea level, and the winds are especially high in the winter.”

During a couple of nor’easters — powerful storms which pound North America’s East Coast — winds were so blustery Cosmos shut down crane operations entirely.

“It’s too dangerous to use the crane on those days,” Giannoulis said, adding that operators are required to shut down when wind speeds exceed 55 kilometres per hour.

Most days are fine for operating, however, and when the second building is completed, Giannoulis said the crane will be immediately moved to commence work on the third building, with the fourth following immediately afterwards.

“We’re using it for everything, not just the formwork and concrete buckets,” Giannoulis said. “We use it to lift up the steel studs, the windows, the roofing materials, the drywall sheets, the flooring, the granite countertops — everything. Whereas most developers around here, all they do is just the concrete and frame structure of the building and then the crane comes down, we’ll have it there from the beginning of construction to the end.”

The sale to Cosmos was the first for Oakville, Ontariobased Cropac in Atlantic Canada since becoming the official sole distributor of tower cranes for Terex in Atlantic Canada.

James Graham, who manages the tower crane side of Cropac’s business, said the CTT132-6 has a 65-metre jib and a 6-metric-ton maximum lifting capacity.

“It’s an ideal machine for low-to-mid-rise commercialresidential buildings,” Graham said.

The CTT132-6 is a fairly recent model, launched in

2016 to replace an earlier CTT121 model that offered a 55-metre jib and a 5-ton capacity.

What makes it flat-top? “The jib and the counter jib,” Graham explained. “It’s all level across the top. Instead of relying on pennant bars and an apex to hang it, all the stress is run through the jib itself.”

While tower cranes are nowhere near as prevalent in Canada’s four easternmost provinces as they are in the country’s larger commercial centres, adding Terex’s Atlantic Canada distributorship to Cropac’s roster is still significant, Graham said.

“It’s an emerging market. Construction is busy all across Canada, but there has been considerably more tower crane activity in the Atlantic provinces in the last few years than there has been previously. So it’s good for us in a territory that we already service with mobile cranes, and it’s good for Terex because they have some representation in that area, someone knocking on doors.”

As for Cosmos Developments and Grandhaven Estates, one of the benefits of owning a tower crane and having it on-site throughout construction is the builder has access to hoisting whenever they need it, Graham said.

“If they receive deliveries early in the morning or after hours, they have hoisting all day long at their job site, compared to where a customer might have to hire mobile cranes to offload materials and work around scheduling.”

Does it always make sense to own a crane, or are there times where rental might be optimal? It depends on the situation, Graham said. “If you have three to five years worth of work you’re planning to do, a machine like that absolutely makes sense.”

As for lease-to-own, Graham said this can also makes sense at times. “If you have a long enough duration project you can build some equity in the machine through a rentto-purchase option while not committing to it entirely. So if you come to the end of your project and find you have more work lined up, you can buy that asset at a lower cost and use it on your next project.”

BY ANDREW SNOOK

yan Burton has been servicing the heavy lifting needs of businesses across Western Canada for more than 25 years. The managing partner of the Bigfoot Crane Company in Abbotsford, B.C. has been operating cranes since 1992.

“I worked with a road building company in British Columbia in Vancouver and we were building the Island Highway and just learned how to run cranes, pretty much selftaught, which is scary,” Burton recalls. “You look back at how I ran cranes, and other people ran cranes back in 1992, versus now, it’s incredibly different.”

In 1997, Burton decided to leave the road building company he worked for to try his hand working as an operator for a crane rental company called Eagle West Cranes in Abbotsford, B.C. He worked his way up to a sales position and remained in that position for a few years before being promoted to a management position, and later, promoted again to the position of general manager.

“I was looking after all of our crane operations in British Columbia,” Burton says.

In 2011, Burton left Eagle West Cranes to run another crane company for three years, DLB Cranes, located in North Vancouver, B.C. and Regina, Sask.

“We did lots of work in plants, mills and mines in Western Canada so I ended up spending quite a bit of time in the Prairies,”

Burton recalls, adding that the company did a lot of work servicing potash mines in Saskatchewan and the oil sands in Alberta, renting crawler cranes, rough terrain cranes and all-terrain cranes.

Then in 2014, another exciting opportunity presented itself.

“Eagle West was selling their company,” Burton says. “They were selling all their mobile cranes to a company out of Houston called TNT Crane, and they had all the tower cranes that were still for sale, so they called me and asked me if I was interested in buying it.”

The purchase of 100 per cent of the company was a little too much for Burton at the time, so he partnered with the former owners and secured a 50 per cent stake in the company, and took over running the operation.

“At that point we renamed it to Bigfoot Crane Company,” he says. “I’ve been

running Bigfoot Crane Company for just over three years now.”

An active member

In addition to running Bigfoot Crane Company, Burton’s busy schedule includes being an active board member for the BC

Association for Crane Safety (BCACS).

“I’ve been involved in that board since 2007,” he says. “It is the association that designed all the operator ticketing for British Columbia. We were the last province to have mandatory crane operator licensing, so we designed a special licence system to test operators in B.C.”

Burton was named the BCACS Chairman of the Board in 2017 for a fouryear term. As if he wasn’t busy enough, he’s also an active member of the Crane Rental Association of Canada (CRAC).

“I’ve been a member there for 20 years and I’ve been on the board for four years now,” he says. “Now, I’m the secretary treasurer for the board there.”

Burton says being an active member of the CRAC allows him the opportunity to form relationships with crane companies across Canada.

“I can phone them at any given time and ask for help on certain things,” he says, adding that being able to get together and work on industry-related issues that affect companies across the country is a big part of why he’s such an

continued from page 19

active member of the CRAC. The majority of Burton’s work with the associations has revolved around improving safety within the crane industry.

“It’s important to me for sure,” he says. “I’ve had really close relationships with our workers wherever I’ve been, and the thought of sending them out to unsafe situations everyday just scares the hell out of me. We do everything we can to make sure we’re safe; and the environments we’re working in everyday are safe.”

Future goals with CRAC

Although the CRAC’s annual conference is a great place to network with industry members across Canada, Burton says one of his goals is to continue growing the conference to include more value to its membership.

“It used to be just a relationship association, but the last three years we’ve been changing the way we look at the organization, and its power to create synergies across the country. We’re changing it over to more practical

applications that are really serving the members,” he says. “We’re working on different safety committees – right now we’re working on a boom dolly committee, looking at the way to move cranes safely across the country. We’re looking at training, making industry aware of the products and services available to keep workers safe… we’ve gone from a relationship organization to relationships and finding ways improve the industry.”

One initiative the CRAC is working on this year is the implementation of its first-ever safety awards, based on set criteria that use safety data collected by the association from its members.

“If companies hit a certain benchmark that we’ve got, then they’ll be receiving a safety award from the Crane Rental Association of Canada,” Burton says. “The companies that are out there, being a good example, we want to have recognized.”

Burton says being an active member within the CRAC can only make a business, and its owner, improve their operations.

“The more engaged you get in it, the more it happens,” he says. “I started out in sub-committees working on different projects, then moving onto the board… the more time you spend with all these people, the more you learn, and the more value you’ll get.”

BY LAURA SUTTON, ALL-WEST CRANE & RIGGING

There’s no doubt that cranes are one of the most expensive pieces of construction equipment to own and operate. From the initial cost of the machine itself, to the expensive and extensive maintenance schedule, the labour, certification, staffing costs of the operators, supporting employees, the costs of storing and transporting cranes from site to site, and, finally, the expense of running the cranes per hour. The costs can build up and quickly overrun your budget if you’re not careful.