CUSTOMER SATISFACTION ACROSS CANADA

...“The strength and durability of the system told me that this was going to last more years than I had left in the business. ... As we got into the reality of using the system, I knew we had made the right decision.”

Al Dyck, Harman Poultry Farm, Prince Albert SK

...“My Hellmann Cage System is awesome. An excellent system to work with on a daily basis.”

Doug Pauls, Highplain Farms, Niverville MB

...“With the Hellmann Cages I am getting results I cannot believe. Uniformity in the mid 90’s...Feed conversion also improved dramatically (5.9 kilos/bird). The Hellmann troughs keep the feed in the troughs and not on the floor.”

Gerard Hoftyzer, Londesboro, ON

... “With 94% uniformity, excellent feed conversion, very good air quality; all accomplished with minimal labour inputs; I am extremely pleased with my decision to purchase Hellmann Pullet Cages.”

Paul Overmars, St. Andrews, NS

HELLMANN NORTH AMERICA

Tel: (519) 453-3913 • Fax: (519) 453-3996 • e-mail: hellmannpoultry@bellnet.ca www.hellmannpoultry.com

Maritimes

Contact: Herb Jansen

Phone: (902) 680-1267

Fax: (530) 430-2020

e-mail: janse17@attglobal.net

Manitoba, Saskatchewan & British Columbia

Contact: Greg Olson

Phone: (306) 260-8081 or (306) 492-2266

Fax: (306) 492-2265

e-mail: gaolson@sasktel.net

Eastern Ontario & Quebec

Contact: Stephane Chouinard

Phone: (450) 266-9604

Fax: (450) 263-2638

e-mail: stef@greenfarmline.com

Alberta

Contact: Len Mandel

Phone: (403) 308-7288

Fax: (403) 320-5866

e-mail: doubledd@shaw.ca

Western & Central Ontario

Contact: Jack Lepelaars

Phone: 1-866-767-2986 or (519) 348-8483

Fax: (519) 348-9271

e-mail: jack@newtechag.com

U.S.A.

Contact: Jim Currie

Phone: (519) 868-1882 or (519) 453-3913

Fax: (519) 453-3996

e-mail: hellmannpoultry@bellnet.ca

GENETICS: Concentration of Global Poultry Genetic Resources

By Treena Hein 16

PRODUCTION: Free-Run

Baildon Colony fills gap in Saskatchewan By Kristy Nudds 22

INDUSTRY: Fighting Fire With Fire EFO turns a challenge into an opportunity By Kristy

Nudds

PIC UPDaTE: Managing Disease-Free areas

By Tim Nelson, Executive Director, and Kimberly Sheppard, Research Co-ordinator 30

RESEaRCH: Free-Range Behaviour a new study may point the way to breeding laying hens to be more accepting and productive in free-range conditions

By Wiebke Icken, Lohmann, Tierzught GmbH

RESEaRCH: aviary Versus Furnished Cage

By S. Platz, E. Heyn, F. Hergt, B. Weigl and M.H. Erhard, Institute of Animal Welfare, Ludwig Maximilian University, Munich, Germany

WaTER MaNaGEMENT: The Watering System for Cage-Free Eggs

By the Technical Team, Ziggity Systems, Inc.

FROM THE EDITOR

By KRISty nuddS

The Big Question

Ihave to admit I was a bit surprised with the answer I received when I asked Paul Wipf, the poultry boss of the Baildon Colony just south of Moose Jaw in Saskatchewan, why he chose to install an aviary system to replace his aging cage system (see cover story page 16).

The decision of the colony to install an alternative system was not based on worry that the egg industry was headed in this direction, but rather on the desire to avoid shorting the market in his province. a cagefree market had been developed, and there was not enough product to fill it.

This leads me to the “big question” – will this type of market grow? What exactly is the market for cage-free eggs? What will the market be, in say, five years, 10 years?

Recently, Vencomatic North america held two producer sessions in Ontario called “Managing Freedom” and these questions were top of mind. There is great frustration among egg producers and the industry. Simply put, right now nobody seems to know.

Without doubt there is a push for developing this market by animal activist groups, namely by Humane Society International’s Canada branch, an arm of the very political Humane Society of the United States (HSUS), the group responsible for pushing Proposition 2 in California. These groups are determined to force the egg industries in both Canada and the U.S., through legislation, to discontinue using traditional systems.

But what these groups can’t see through their ideological blinders is that on the ground, implementing such a change might not be the only option, and might not necessarily be better for the birds or for consumers.

They often claim that North america should look towards Europe which has

“banned” cages as of 2012. This is not entirely true. While Sweden, Denmark and the Netherlands do not allow enriched cage systems or have a system that requires the eggs to be identified as caged in an enriched system, many other European countries allow them. Some countries have simply ignored it or are not members of the EU and, therefore, do not have to comply. although an EU directive to outline housing for laying hens exists (regarding where nipples are to be placed, how much light, scratching area, etc.), each country can ultimately set its own regulation.

The EU expected a “one size fits all” rule and it hasn’t worked. The ironic thing is, cages can be banned, but a ban on caged eggs doesn’t exist. although 63 per cent of voters in California voted yes on Proposition 2, a recent survey of these voters showed that they purchase traditionally reared eggs.

I think consumers are confused and easily swayed by groups opposing egg production. It’s up to the industry to set the record straight. It isn’t fair to tell consumers that one system is better than another when the facts don’t necessarily support such a claim. If opposition groups say that consumers should be offered choice, then they, as well as industry, need to make sure that consumers are correctly informed.

In this issue, we’ve provided several articles exploring European research on alternative systems to show you that the issue isn’t black and white. We’ll continue to provide relevant information on this issue, as it is sure to bring continued debate. n

March 2009

Vol. 96, No. 3

Editor Kristy Nudds – knudds@annexweb.com

888-599-2228 ext. 266

Contributing Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-429-5193

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Production Artist

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

REtuRN uNDEliVERABlE CANADiAN ADDRESSES tO CiRCulAtiON DEPt., P.O. BOx 530, SiMCOE, ON N3Y 4N5.

e-mail: cnowe@annexweb.com.

Periodicals postage paid at Buffalo NY. USPS 009-324, ISSN 1703-2911. Published monthly by Annex Publishing and Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St. Buffalo NY 14240. US Postmaster send address change to PO Box 611 Niagara Falls NY 14304.

Printed in Canada iSSN 1703-2911

Circulation

e-mail: cnowe@annexweb.com Tel: 866-790-6070 ext 207 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 25.44

(includes GSt – #867172652Rt0001)

uSA – 1 Year $ 60.00

From time to time, we at Canadian Poultry make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2009 Annex Publishing & Printing inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. We acknowledge the financial support of the Government of Canada, through the Publication Assistance Program and the Canada Magazine Fund, toward our mailing and editorial cost. Nous reconnaissons l’aide financière accordée par le gouvernement du Canada pour nos coûts d’envoi postal et nos coûts rédactionnels par l’entremise du Programme d’aide aux publications et du Fonds du Canada pour les magazines.

www.canadianpoultrymag.com

60 Years A Tradition of Innovation.

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

When Ludwig Bening founded his mechanical engineering company in 1949 he probably never imagined it would grow to become such a significant company in the livestock production markets.

Over the course of 60 years LUBING has established itself as one of the leading companies developing innovative products for poultry watering and egg conveying systems. It's our Tradition of Innovation that has contributed to our success and will continue for years to come.

We hope you will join us this year in celebrating our 60 years of innovation. We take this oppor tunity to express our gratitude to all of our customers who have helped in our success.

HATCHING HATCHING

ACA Job Cuts

ACa Co-operative Ltd., Nova Scotia’s only poultry processor, will soon make major cuts at its two annapolis Valley poultry processing plants.

aCa will permanently close its Eastern Protein Foods subsidiary and seek creditor protection for it. at its main primary processing plant in New Minas, aCa will change its sales mix and end its tray pack operations.

The New Minas facility lost about $6 million in 2008 and aCa’s CEO and board chairman, Ian Blenkarn, said that without major changes, it was expected to incur further significant losses this year.

The Eastern Proteins Foods plant in Kentville also lost millions over the past several years, including $1.8 million last year.

The retrenchment in late February and early March will lay off 75 union workers at aCa, and mean the perma-

nent loss of 40 non-union aCa and Eastern Protein jobs and a further 187 union jobs at Eastern Protein, out of 650 aCa employees.

Blenkarn conceded that the Jan. 22 cutback announcement was, “a very sad day for many of our staff and their families. However, the past few years have been very challenging ones for us and we arrived at a point where we either had to make major changes to the way we do business or risk losing our entire operation.”

He said aCa is currently negotiating with Canada’s largest independent chicken processor, Maple Lodge Farms of Ontario, to ensure there is a long-term, solution for poultry processing in Nova Scotia.

Last September the Nova Scotia government announced a $3.5-million working capital loan for aCa. The provincial government’s support, “helped us stay in business,

maintain jobs in the short term and develop a business plan for the future,” Blenkarn said.

“While we recognize how difficult this decision is; changing our business model will ensure we will be able to provide services to Nova Scotia poultry farmers, allows us to process chicken and turkeys more efficiently and keeps us viable for our customers for years to come.”

The co-operative, operating since 1943, is owned by 63 Nova Scotia poultry producers and has annual sales of $110 million, while contributing a further $450 million to the provincial economy.

aCa’s other divisions, unaffected by the cutbacks, are the hatchery, farm equipment and retail outlet store and divisions in New Minas, the feed division in Greenwich and the egg division in Port Williams.

By Dan Woolley

Farmland Bears Scars Turkey

AlbeRtA

Farmland throughout alberta is bearing permanent scars from oil and gas wells that have not been properly reclaimed, a researcher says.

agrologist Ty Faechner of the agriculture Research and Extension Council of alberta recently presented his findings to the Pine Lake Surface Rights action Group. His research indicates that while alberta Environment requires

that land be reclaimed to its former state, affected farmland falls far short of its production capacity.

Don Bester, a member of the Pine Lake group and the United Landowners of alberta, said they are now pushing the province to respond to the research.

“The landowner is still suffering considerable crop loss on these sites, even though they’ve got reclamation done,’’ Bester said.

“Some sites that are seven years old are still not producing the total amount of grain (that they should). Some are as high as 80 per cent less.’’

There are about 300,000 active wells that will be reclaimed at some point in alberta.

Problems identified at reclaimed sites include clay mixed with topsoil and contaminants, he said.

Source: The Canadian Press

Low-path H5N2 Discovered

bRitisH ColuMbiA

In late January a flock of 12-week-old turkeys in abbotsford, B.C., tested positive for avian influenza after showing signs of respiratory distress. The farm was quarantined, as were farms within a three-kilometre radius, by the CFIa. The positive flock was humanely destroyed and composted in house. Further testing at the National Centre for Foreign animal Diseases in Winnipeg confirmed that the virus was H5N2 and of lowpathogenicity.

Newest

Pizza Item

oNtARio

Ontario-based Double Double Pizza & Chicken has become the first and only North american pizza chain to put turkey on the menu.

“We chose a local product grown in Ontario to ensure freshness, to follow suit with making our wings, chicken and wedges fresh in the stores. Double Double is also a socially responsible company that believes in promoting local Ontario products, even at a higher cost to us,” says general manager Sheila Jalili.

The Turkey Farmers of Ontario have been working to promote local turkey products with Homegrown Ontario, an alliance formed with the provincial sheep, pork and veal marketing associations and the Ontario Independent Meat Processors.

COMING EvENTS

MARCH

March 17-19, 2009

Midwest Poultry Federation (MPF) Conference, Saint Paul River Centre, Saint Paul, Minn. For more information, e-mail lara@ midwestpoultry.com; telephone 763-682-2171 or visit: www.midwestpoultry.com.

ApRIL

april 8-9, 2009

Poultry Industry Conference and Exhibition (the London Show), Progress Building, Western Fairgrounds, London, Ont. For exhibitor information, contact Sharon Pook (ext. 222) or Lena Lindberg (ext. 228), telephone 519-438-7203. Registration is available at the door or contact pic@poultryindustrycouncil.ca.

MAy

May 12, 2009

PIC Research Day“What’s Eating Us in What We Eat? Fighting Foodborne Pathogens,” Guelph, Ont. Location and speakers TBa.

at press time, 36 premises remain under quarantine as a precautionary measure. These premises are either located within the three-kilometre radius of the infected premises or had some known contact

with the infected premises during the time the virus may have been present. The CFIa indicated that none of the quarantined farms have tested positive but monitoring and surveillance would continue.

June

June 7-9, 2009

Canadian Poultry and Egg Processors Council (CPEPC) Annual Convention, Moncton, N.B. Registration information available at www.cpepc.ca.

WHAt’s HATCHING HATCHING

Diamond and Moba Merge

As of Jan. 9, 2009, the North and South american sales and service operations of Diamond and Moba, two manufacturers of egg grading and packing equipment, have merged. The newly combined organization is now known as “Diamond Moba americas.”

Diamond Moba americas combines the operations of

Diamond automations, Inc. in Farmington Hills Mich., and Moba USa, Inc. in Lancaster Pa., and is headed by Douglas P. Mack, president. Regional support offices are located in Michigan, Pennsylvania, California, Florida, Brazil and Canada, and provide close proximity to the customer base in North, Central and South america.

Merial expands business

Merial Limited has grown its avian business by becoming the exclusive distributor and technical service provider of the in ovo injection systems of aviTech, LLC. as a result, Merial can now offer worldwide poultry customers its portfolio of avian vaccines together with the latest in ovo technology.

Merial is a leader in the production of vaccines for the treatment of prevalent diseases, such as Marek’s Disease and Infectious Bursal Disease, that are especially suitable for in ovo administration. Merial has exclusive distribution of aviTech’s IntelliJect® and ManualJect™ in ovo injection systems.

COMING EvENTS

JuLy ILDEX India, Pragati Maidan, New Delhi, India. For more information: www.ildexindia. com.

July 20-23

Poultry Science Association Annual Meeting, Raleigh, N.C. Hosted by North Carolina State University. For more information, visit www. poultryscience.org/psa09

SepteMBeR

sept. 29 – Oct. 1, 2009 Poultry Service Industry Workshop, Banff Centre, Banff, alb. For more information: e-mail info@poultryworkshop. com or visit: www.poultryworkshop.com

OCtOBeR

Oct. 9-10,2009

Poultry Innovations Conference, hosted by the Poultry Industry Council (PIC), Sheraton Fallsview Hotel and Conference Centre, Niagara Falls, Ont. For more information, visit: www.poultryindustrycouncil.ca.

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Publishing, P.O. Box 530, 105 Donly Drive S., Simcoe, Ont. N3Y 4N5; e-mail: knudds@ annexweb.com or fax: 519-429-3094.

Feed costs!

When feed efficiency matters most.

Cobb products will reduce your feed cost through outstanding feed efficiency and lower nutrient density diets.

Cobb products will help keep feed costs from slipping through your fingers.

Genetics

Concentration of Global Poultry Genetic Resources

by Treena Hein

Concern over the diminishing worldwide genetic resources has reached new heights with the recent announcement of an alliance between poultry breeders CobbVantress and Hendrix Genetics.

This marks the beginning of a worrying new reality for the global poultry industry, because all of the world’s turkey-breeding and egg-laying stock, and most broiler stock, now originates from this new alliance and one other major corporation: German-based EW Group, which owns aviagen (Ross, arbor-acres, Lohmann-Indian River meat chicken brands, plus BUT and Nicholas Turkeys), Lohmann, HyLine and H&N International layers. The only two “independent” breeders are Hubbard broilers (France) and the very small layer breeder Babolna-Tetra (Hungary), which only supplies local markets. Experts agree there is little chance any new breeding start-up companies will be created.

extReMe COnCentRAtIOn

Dr. Fred silversides, an agriculture and agri-Foods canada (aaFc) researcher at the avian genetic Resource centre (agRc) in B.c., says that in the last 65 years, the world has gone from 300 breeders down to two and that, as geneticists retire or pass away, genetic diversity is further compromised.

“The industrial genetic concentration is really extreme,” observes Dr. Fred Silversides. “There were 300 Canadian breeders in the 1940s, and now we have none.” Silversides is an agriculture and agri-Foods Canada (aaFC) researcher at the avian Genetic Resource Centre (aGRC), a partnership between University of British Columbia (UBC) and aaFC, located at the Pacific agricultural Research Centre in agassiz, B.C.

The world’s white-egg-laying breed contains significant amounts of just one line of birds says Silversides. Turkey genetics are even less diverse, while brown egg layers and broilers both have a somewhat more diverse background that is based on three or four lines instead of one.

Unfortunately, the other major cause of disappearing genetic diversity besides industry consolidation is also

gaining ground. “as researchers retire, the chickens they worked with get thrown out,” says Silversides. “The lines get discarded because the only way of keeping the lines is to keep the chickens and that’s expensive. There’s so little genetic diversity and it’s being eliminated so quickly.”

Why genetic diversity matters

Lack of genetic variation, simply put, equals greater risk. Members of a population that shares the same set of genes can all be overcome by a disease, but if a population’s members contain different gene sets, there is a chance some will survive.

a small genetic pool is also risky because it leaves little room for the industry to address any changes in consumer preferences, says Silversides. He is also gravely concerned that the current worldwide economic downturn may lead to even lower genetic variation if one of the two current players is absorbed or eliminated.

Cryopreservation is one way to save the remaining diversity. This technique involves freezing tissue for storage in such as way that it can be successfully thawed and used in breeding. “However,” says Silversides, “the freezing techniques we have are really limited. The problem with poultry is that there isn’t a good way of freezing the material to achieve good fertility. Mammalian cryopreservation techniques don’t work for poultry eggs and embryos, and only work poorly for semen.”

That’s why over the last four years, Silversides, Dr. Yonghong Song and other colleagues have been experimenting with cryopreservation methods that work. They have successfully transplanted ovarian and testicular tissue between newly hatched chicks, and are working on transplanting frozen and thawed

AN iNteRNAtioNAl ReseARCH teAM HAs ANAlyzed tHe GeNetiC liNes oF CoMMeRCiAl CHiCkeNs ANd FouNd tHAt tHey ARe MissiNG MoRe tHAN HAlF oF tHe GeNetiC diVeRsity NAtiVe to tHe sPeCies. ReseARCH teAM MeMbeR ANd PuRdue uNiVeRsity PRoFessoR bill MuiR HAs stAted tHAt tHis FiNdiNG iNdiCAtes it’s iMPoRtANt to PReseRVe NoN-CoMMeRCiAl bReeds ANd Wild biRds FoR tHe PuRPose oF sAFeGuARdiNG GeNetiC diVeRsity.

tissue. Dr. Song is also conducting experiments to transplant ovaries between different species of ducks. Silversides says, “Successful interspecies breeding in this manner may become critically necessary in future.”

aGRC scientist and UBC avian science professor Dr. Kimberly Cheng says that because of the Silversides/Song techniques, genetic materials from most of the chicken lines breeds from the Nova Scotia agricultural College, the Universities of alberta and Saskatchewan and the aaFC agassiz Research Centre are now kept in the aGRC deep freeze for preservation.

The aGRC also houses nine lines of chickens and nine lines of Japanese quail – currently 3,500 birds – that are being carefully bred, pedigreed and studied. “Collectively, these lines build a living genetic library consisting of a wide variety of genetic mutations,” says Cheng. “The aGRC’s genetic resources allow scientists the world over to study how genome affects size and meat quality, disease resistance, how well particular breeds could adapt to farm facilities and how we can help industry improve housing environments and breeding practices.”

Genome research on birds may also lead to further advances in human health. Cheng’s research from almost three decades ago recently helped successfully reverse congenital blindness. In 1980, Cheng discovered a gene mutation in a line of Rhode Island Red (RIR) chickens that were blind at hatching. (Genetic material from these birds is still housed at aGRC.) The gene was sequenced by scientists at the University of Florida and found to be the same as a human gene that causes a form of congenital blindness called Leber’s Congenital amaurosis. Last april, a team of researchers from the University of Pennsylvania used the research and techniques to partially restore sight to three human patients.

Other pOultry genetics research

an international research team has analyzed the genetic lines of commercial chickens and found that they are missing more than half of the genetic diversity native to the species. Research team member and Purdue University professor Bill Muir has stated that this finding indicates it’s important to preserve non-commercial breeds and wild birds for the purpose of safeguarding genetic diversity. He also believes interbreeding additional species with commercial lines might help protect the industry.

Muir also is project co-leader in a current $10 million international effort to test a breeding strategy called whole-genome selection that could be used to improve the accuracy and efficiency of breeding methods. Companies may be able to use this technique to select for important parts of the DNa of donor birds from standard or ancestral breeds and integrate those into commercial lines without having to also insert DNa that causes unwanted traits.

industry perspective

Both Cobb Vantress Inc. and aviagen provided comments on issues related to genetic diversity preservation; these comments are presented in shortened form here.

In terms of how much genetic “backup” each company possesses in case of disease outbreak or a similar situation, Brian Cosgriff, director of marketing for Cobb Vantress Inc., says, “as Cobb continues to increase the number of pedigree lines in its gene pool, we increase the likelihood of finding a line or lines with good resistance to any specific disease which may increase in importance…Cobb currently supports several projects designed to

Genetics

identify genes related to disease resistance.” He adds, “as backup to internal production, Cobb goes to great lengths to carefully divide product pedigree lines among multiple pedigree farms located in the U.S., and also on a new pedigree farm in the Netherlands….as added backup to the duplication of pedigree birds, great grandparents…are also strategically isolated and placed in flocks located in the several facilities within the U.S., and also on farms in the U.K., Brazil and australia.”

Dave Burnham, head of Global Marketing at aviagen says, “In addition to lines being selected for ongoing genetic improvement or change, aviagen maintains two distinct sets of pure lines which are not being subjected to genetic selection. The first of these groups was established in 1972 and the latter group in 1996.” He adds, “aviagen maintains and improves distinct duplicate populations of lines in different continents in order to ensure security, both in terms of genetic integrity and in terms of product supply.”

When asked to describe how the need for preservation of genetic diversity fares in importance compared with breeding direction priorities, Cosgriff stated, “We have a good balance between our breeding program, which has specific traits for selection, and those which maintain good genetic diversity. In the last eight years alone, we have purchased over 30 new genetic lines of chickens which add to the significant existing library of lines already in house.”

He adds, “We actively support research with coloured bird and indigenous chickens which offers the possibility of crossing these lines with modern commercial white chickens to fit opportunities in the future.”

Burnham says, “aviagen manages a large range of commercial and experimental pure-lines with varied genetic backgrounds, characteristics and improvement objectives. Some of these are constituents of long-standing products and are based on continuing genetic improvements in large populations under selection, while others are experimental lines displaying novel combinations of traits that address new or emerging markets.”

With regard to how genomics can serve to perhaps reduce the importance and need for having preserved genetic diversity resources, Cosgriff says, “Genomic analyses of genetic differences among our lines…is already helping Cobb identify the combinations of lines which are most diverse from each other as potential for new product crosses in the future….Technology like the utilization of gene markers, is now just developing to the stage where it offers the feasibility to identify useful genetic variation for incorporation into current lines and help maintain genetic diversity for the future.” Burnham adds, “The use of genomics will be a useful tool to improve the accuracy of selection and will allow us to manage our genetic resources even more effectively.” n

One person can’t do everything.

That’s why there’s the Alberta Immigrant Nominee Program. The labour shortage is a reality in Alberta. So is the need to recruit beyond our borders when efforts within our province are not enough. The Alberta Immigrant Nominee Program can help. Your new hires will have their permanent residency papers in hand significantly faster thanks to our fast-tracked program. Everyone benefits. Your new workers can proudly call themselves Albertans and you no longer have to rely on a temporary workforce. Learn more at www.AlbertaCanada.com/Immigration

CPRC Update

In the December 2008 issue of Canadian Poultry magazine, we updated you on a workshop hosted on October 1 by the Canadian Poultry Research Council (CPRC). One of the main outcomes of that workshop was a consensus among participants that CPRC should take on a greater role as a national coordinator to increase the voice for Canadian poultry research as a whole. The CPRC Members met January 23 to discuss, among other things, how it can best fulfill this role. It was agreed that the CPRC must provide improved service to Canada’s poultry sector from the bottom up - that is, work with regional, provincial and federal organizations to enhance our research and technology transfer capabilities. CPRC staff will contact these organizations to see if CPRC can provide any services or resources to help their operations reach our collective goal of a more robust poultry research community in Canada. The CPRC will also keep these organizations up to date on national initiatives that may benefit Canada’s poultry sector, such as emerging programs from agriculture and agri-Food Canada (aaFC) and the Natural Sciences and Engineering Research Council (NSERC).

GR o W i NG F o RWAR d

During their annual meeting in July 2008, Canada’s federal, provincial and territorial Ministers of agriculture endorsed a new initiative to support agricultural research entitled “Growing Forward” and announced $1.3 billion over five years in funding for new programs. This funding represents $330 million more than in the former agricultural Policy Framework (aPF) and will be cost-shared between the Government of Canada and the provincial and territorial governments on a 60:40 basis. aaFC was on hand at the January 23 CPRC meeting to provide details and to discuss how programs emerging from Growing Forward might impact Canada’s poultry sector.

Growing Forward has a strong emphasis on science and innovation programming to enhance sector productivity, profitability and competitiveness. The expected outcome is an accelerated pace of innovation and streamlined adoption of new technologies. Growing Forward will put a great deal of emphasis on research and innovations that can be commercialized in a relatively short timeframe.

There are promising opportunities for the poultry sector to collaborate with aaFC in this respect. approval of relevant programs is still forthcoming and final details have yet to be announced, however CPRC will continue to keep the lines of communication with aaFC open and stay abreast of all developments. The CPRC will also continue to work with aaFC and other organizations to ensure that projects close to commercialization are balanced with “discovery phase” research; discovery research is that which forms the foundation on which future innovations and commercial products are built.

A NAtio NA l s C ie NC e st RAte G y

The CPRC is developing a science strategy document for Canada’s poultry sector. Having a national strategy to address the major research, technology transfer and education priorities of Canada’s poultry sector will be crucial to developing stronger partnerships and expanding the voice of poultry research with organizations such as aaFC. The document under development is based on strategic planning sessions held by CPRC, the Poultry Industry Council, alberta’s Poultry Research Centre, the Saskatchewan Chicken Industry Development Fund and the atlantic Poultry Research Institute. a preliminary draft is under review by CPRC Members. all federal, regional and provincial poultry industry organizations across Canada will be asked for input on the document in the coming months. CPRC is promoting a collaborative effort among all these organizations to produce a truly national Strategy. This document will be revisited on a regular basis to ensure it continues to represent the needs of our sector. Having a cohesive science strategy for Canada’s poultry sector will provide it with an ongoing reference point not only for use by the sector but also for those with whom it collaborates.

t e CHN olo G y t RAN s F e R

The CPRC has also begun preliminary discussions with aaFC regarding a potential partnership on technology transfer and extension activities – that is, getting research results and general information to the people who can use it. It is envisioned that information gleaned at the national level would be shared with the many regional technology transfer and extension specialists across the country. as mentioned, talks thus far with aaFC are preliminary; we will keep you informed of developments.

W H e R e do W e G o FR o M H e R e?

It appears that there is both a need and desire for Canada to build a stronger voice and support system for its poultry sector. The CPRC is examining how it will address this challenge in a transparent fashion and, as mentioned, plans to consult with the various industry organizations across Canada in determining where its resources would be best used. We welcome any input as we go through the process.

For more details on these or any other CPRC activities, please contact Gord Speksnijder at The Canadian Poultry Research Council, 483 arkell Road, R.R. #2, Guelph, Ontario, N1H 6H8, phone: (289) 251-2990, fax: (519) 837-3584, e-mail: info@cp-rc.ca, or visit us at www.cp-rc.ca. n

*The membership of the CPRC consists of the Chicken Farmers of Canada, Canadian Hatching Egg Producers, Canadian Turkey Marketing Agency, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

buildi

PLeASe cHecK ONe:

❑ Poultry Producer or Employee

❑ Government, Libraries, Schools, Universities

❑ Hatchery, Hatchery Employees

❑ Fancy or Show Poultry

❑Wholesale Produce and Processors, Further Processing

❑ Equipment Manufacturers

❑Drugs, Laboratories, Vaccine Companies, Chemical

❑ Veterinary and Lab Technicians

❑ Feed Manufacturers, Feed Additives, Distributors and their Salespeople

❑ Other (please specify) SubScribe TODAY

Cheque - Payable

Production

Free-Run baildon Colony fills gap in saskatchewan

by Kristy Nudds

For the last two years, Paul Wipf, poultry manager at the Baildon Colony located south of Moose Jaw in Saskatchewan, considered installing a freerun operation to replace the colony’s aging layer barn.

at an open house held at the colony on Jan. 16, Wipf clearly stated to attendees that the colony’s decision to produce free-run was not because they see the egg industry in Canada going in this direction, but because they wanted to supply the provincial market with a locally produced product.

“We didn’t do this because we see this as the way of the future,” says Wipf. “We didn’t want the niche market here in Saskatchewan to be shortened, and didn’t want to see product coming from elsewhere.”

Wipf says that all members of the colony were part of the decision to install an alternative style of housing, and that a vote was taken, with 100 per cent of members voting yes.

Prior to the Baildon Colony, Saskatchewan only had one operation producing a commercial free-run product, after the province’s only egg processor, Star Egg, developed a niche market. However this operation is too small (5,000 birds) to fill demand, leaving Star Egg with a gap to fill.

The Baildon Colony chose to install an aviary housing system manufactured by Hellman Poultry Equipment, after speaking with the poultry manager at New Rockport colony in alberta. New Rockport was the first operation in North america to install an aviary, implementing the Hellman system, which the company says meets or exceeds European Union (EU) regulations.

Baildon tore down their old pullet barn and built a new split barn to house the aviary. The former layer barn is currently being gutted with plans to convert it into a floor-rearing pullet

barn, which Wipf says should be ready in the fall.

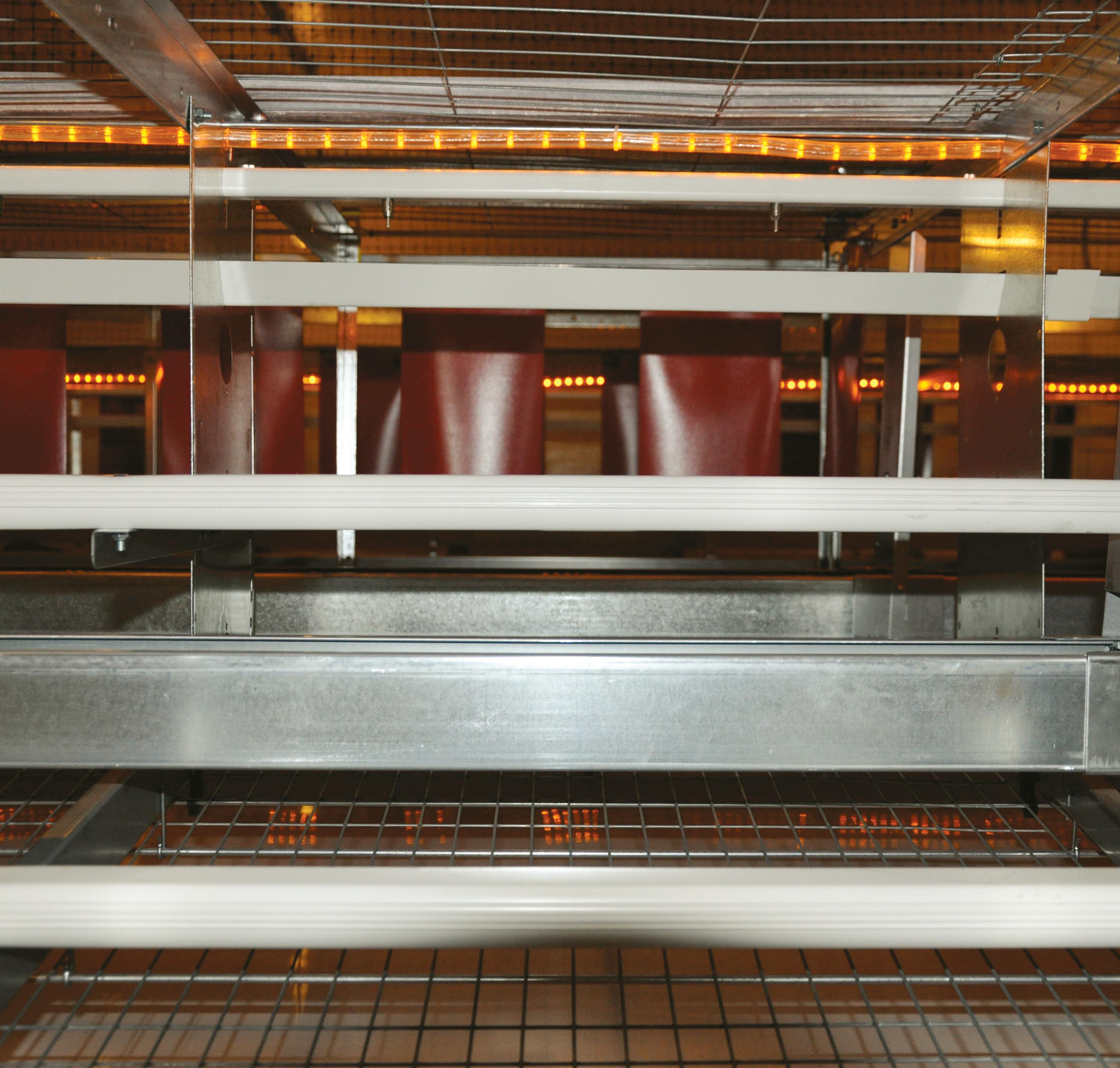

Baildon installed four rows (each 280 feet long) of aviaries. Each row is two tiers high, consisting of laying nests behind plastic curtains and two rows of perches that have grooves to allow for easy gripping. One row of perches runs along the bottom of each tier, the other above the feeder chain so that the rears of the hens hang over and no fecal material contaminates the feed.

Running along the bottom edge of each aviary tier near the egg belt is a stainless steel bar that acts as a “landing strip” for flying birds, and several wire ladders are placed along each row from the floor to the bottom of the top tier to allow birds to walk up to this level.

Under each tier is a manure belt, with the exception of the “gutter” below the bottom tier of each row, which has a manure scraper to collect dust, feathers and some droppings from the birds as they are walking on the floor. access to this area can be opened up to allow more square footage, and can be closed off during the night while the birds are sleeping. Plastic netting has been placed from the top tier to the ceiling to prevent hens from jumping up into this region.

all lights in the barn are on winches, allowing proper placement of the lights so that reflected light shines on the curtains, which makes the hens feel safe while in the nest. LED rope lighting has also been installed along the length of each aviary at the top over the feed chain.

The barn utilizes roof ventilation instead of tunnel ventilation to maximize square footage, with inlets running on each side of the barn. The system also features two hanging weigh scales per side that can sense how many birds are on it at one time. This will provide Wipf with accurate bird weights so that he can manage feed intake, which is important since the aviary will house brown

new expeRIenCe

Baildon colony poultry manager Paul Wipf says that the free-run aviary system has presented some management challenges but he’s already learned so much by observing the birds.

birds, which “tend to gain weight,” he says. These scales can be moved to different areas, depending on where the birds are most active, he says.

The aviary barn can house 20,000 birds, although the colony only has quota for 16,000 birds, allowing them the option to expand. This setup allows for 1.5 square foot/bird.

On Jan. 19, 10,000 floor-raised pullets reared in Manitoba were placed in the aviary system at Baildon Colony. Several weeks later, when asked how things were going Wipf said the “barn looks so good with the birds in it. The birds are so happy – when I turn the lights on in the morning they fly and run around, just like wild birds in the trees in springtime.”

Wipf says “it’s so different” from the former system and he finds it to be both interesting and challenging. But he was ready for the challenges and seems to take them in stride. “I knew it was not going to be like conventional housing,” he says. “Management of the birds requires watching the birds and their behaviour.”

He says that in the first few weeks he “definitely” spent more time observing the birds until he got to know them and what they needed.

His powers of observation have already been tested. One of his first challenges was determining why the birds weren’t eating enough. The LED lighting, which was turned on before the regular lights went out and kept on for an additional 15-20 minutes to signal the hens to come into the aviaries and roost on the perches for the night, didn’t seem to be having the correct effect on the birds. Wipf says he went into the barn to check and see if the birds were roosting and was surprised to see many still roaming the floor and being active.

This made him think that perhaps the birds couldn’t really see the LED lighting properly within the aviary. So, he decided to keep the LED lighting on all day, which seemed to do the trick. Wipf believes that by keeping the LED lights on all day, the birds can see the feed and water much better in the aviary and now when the regular lights go out, all of the birds are roosting.

To solve the other challenge he has faced so far, Wipf utilized the experiences of New Rockport, consulting with the poultry manager there. Into the first week or two of lay, Wipf says he’s having “a few too many” broken eggs than he’d like to see. after discussing it with his New Rockport colleague,

tHe AViARy FeAtuRes tWo leVels oF PeRCHes WitH GRooVes FoR eAsy GRiPPiNG.

Production

SolarWall

• SolarWall has been installed on hundreds of agricultural and live-stock buildings, reducing heating costs by up to 30%. The system, which uses the sun to pre-heat incoming fresh air, also dramatically improves air quality and decreases humidity.

There are many reasons to consider SolarWall for your new or existing buildings:

• SolarWall provides thirty years or more of free heat.

• SolarWall means more fresh air can be brought into the building improving air quality without increasing heating costs.

• SolarWall is maintenance free and has no moving parts.

• SolarWall is cost effective - As of September 1, 2008 there is a federal contribution of $70.00/m2 of solar panel area and a matching $70.00/m2 contribution from the Ontario provincial government.

• SolarWall also contributes to cooling a building in the summer by shading the existing outside wall from the sun.

Call Exacon or an authorized SolarWall dealer near you for additional information and to obtain a free quote.

Wipf says it appears some of the birds are laying eggs while on the top perch, creating too far a distance for the eggs to fall and hence creating cracks.

But Wipf isn’t worried, and says that he’ll have to “wait and see” what new challenges, if any, arise. “I’ve already learned so much.”

Wipf says it’s now clear to him that once the new pullet barn is ready and he is raising his own pullets on litter, he will need to “facilitate a similar environment” for them so that they are better prepared for the aviary. This will include installing LED lighting above perches so that the pullets are familiar with it, as well as ladders to get them used to travelling at different levels. These will be manufactured by members of the colony. n

Additional photos of the aviary system can be found on our website under “Current Issue” accompanying this article.

AboVe: tWo sCAles ARe PReseNt oN eACH side to WeiGH tHe biRds to AdJust Feed. leFt: tHe AViARy sHoWiNG A lAddeR to AlloW biRds ACCess to tHe seCoNd tieR

The Improved Ronozyme® P Product Family

For processed or non-processed feed, we have the phytase to meet your needs.

Ronozyme P-(CT) – Patented coating technology keeps phytase effective even under extreme conditions. Ideal for pre-processing addition to pelleted feeds.

Ronozyme P-(M) – High potency and easy to handle, this dustless form was specially designed for use in premixes, base mixes and dilutions used in non-processed feeds.

Ronozyme P-(L) – Perfect for post-processing spray application, the product has excellent shelf life and handles well.

Combine these formulation options with the feed cost savings and environmental benefits of Ronozyme P and your phytase choice is clear

Learn more. Contact your DSM Nutritional Products Account Manager or visit our website at www.nutraaccess.com.

Product forms to match your needs.

ReAd tHeSe StORIeS And MORe At www.CAnAdIAnpOuLtRyMAg.COM

The Aftermath of the Pigeon King

WhenPigeon King International (PKI) went bankrupt last year, many of the producers that bought into owner arlan Galbraith’s claims were left with debt and no market for their pigeons. The Ontario Ministry of agriculture and Food (OMaFRa) stepped up and utilized the experience and assistance of the Ontario poultry industry to deal with the problem and minimize the impact on pigeon welfare and producers.

tHe FuLL StORy IS AvAILABLe On OuR weBSIte

ILT, an Emerging Disease

By N.C. Kirkpatrick, H.P. Blacker, S. Rubite, D. O’Rourke and A.H. Noormohammadi

In 2007 and 2008, a series of Infectious Laryngotracheitis virus (ILTV) outbreaks were recorded in commercial layer and broiler flocks, mostly occurring in Victoria, australia. The control of these outbreaks was complicated by the shortage of the key commercially available australian vaccines (Sa2 and a20).

ILT has been identified in many countries worldwide and remains a threat to the intensive poultry industry.

tHe FuLL RepORt IS AvAILABLe On OuR weBSIte

Blog

Water and the Poultry Industry

By Mojtaba Yegani

We all have seen so many articles in poultry magazines, fact sheets and websites discussing water from different aspects. Supplying an adequate quantity of high quality water is very important to bird health and production performance. Monitoring of water consumption, as it also relates to feed intake, can be a useful tool for evaluation of a poultry flock’s status.

It is recommended that poultry drinking water should be regularly tested for microbial (total bacterial count and coliform bacteria) and chemical characteristics including pH, total hardness, calcium, magnesium, chloride, sodium, sulfate, iron, and nitrates.

This becomes even more important if vaccination through drinking water is a common practice in a poultry farm. another important point regarding water quality is regular cleaning of water lines.

Considering all these issues, I think that we are usually not as concerned about water as we are about feed in poultry farms. Why?

How often do you take water samples and send them to lab for chemical and microbial analyses?

BUYERS’ GUIDE

Our Buyers’ Guide is the only reference tool to bring the entire Canadian Poultry industry together in one directory. On our homepage, the link for our Buyers’ Guide is at the top beside the search bar.

DIGITAL MAGAZINE

To sign up for a free trial of Canadian Poultry magazine, the digital edition, please go to www.canadianpoultrymag. com.

E-NEWSLETTER

To register for our bimonthly e-newsletter, visit www.canadianpoultrymag.com. It’s free!

POLLS

Recently we asked: What will be top of mind for you in 2009?

38.1% said cost of inputs; 28.6% replied retail sales poultry ; 28.6% said WTO negotiations; and just 4.8% said disease affecting poultry.

Industry Fighting Fire With Fire

The Egg Farmers of Ontario turn an activist challenge into an opportunity to educate and inform city councils

BY K RISTY NUDDS

last year and early 2009 have been challenging for several egg marketing boards in Canada, as they have had to deal with an aggressive political campaign from the Humane Society International-Canada (HSIC).

What makes this campaign unique is that the HSIC has shifted from typical activist-like behaviour and has been lobbying municipal governments, primarily in British Columbia and Ontario, to convince councils to pass a resolution encouraging retailers and restaurant operators to highlight their preference for and provide citizens with certified organic, free-range or free-run eggs.

The HSIC campaign first claimed success in British Columbia in 2007 when the city of Richmond passed a motion requesting the removal of eggs from caged hens from all city-run facilities. Since then 12 other cities in the province have passed similar motions, and numerous universities in Canada have followed suit.

The Egg Farmers of Ontario (EFO) found out “by accident” that HSIC was approaching municipalities in their province, says EFO Chair Carolynne Griffith. She says the EFO discovered the motion had been sent to municipalities when general manager Harry Pellissero, a former member of the Legislative assembly of Ontario, received a telephone call from a confused city councillor asking whether

chair carolynne griffith says the EFO saw an activist threat as an opportunity to communicate with city councillors on the topic of egg procurement in a positive way while contributing to the municipal agenda.

or not the motion came from the EFO.

Not wanting to escalate the situation, the Ontario Farm animal Council (OFaC) continually monitored HSIC activities for the EFO, but were unable to determine how many municipalities had received a motion from the HSIC. Griffith says that EFO public affairs manager Janet Hartwick called most of the rural municipalities to see if they had received it, and many had not.

However, in December and early January three cities in Ontario passed the HSIC’s motion – Orillia, Pickering and Port Colborne – without asking the EFO for input on how laying hens are raised in

the province or the care they receive.

The EFO decided to “fight fire with fire,” says Griffith, “because our voice wasn’t being heard. We saw this as an opportunity to endorse to city councillors the topic of egg procurement in a way that is positive while contributing to their municipal agenda.”

The EFO drafted its own motion and sent it to municipalities across the province. “This motion is great chance for us to say that we do what we’ve always done – supply the local market with a local product.” She adds that because of the supply management system, Canadian egg

Continued on page 43

CHAlleNGe iNto oPPoRtuNity

Managing disease-Free Areas

University of Montreal researchers explore the concept of zoning disease-free regions to lessen the impact on industry business during outbreaks

B Y T IM N ELSON , Ex ECUTI v E D IRECTOR , AND K IMBERLY S HEPPARD , R ESEARCH C O - ORDINATOR

Avian influenza outbreaks, including the 2004 outbreak in British Columbia, have directly cost the North american poultry industry hundreds of millions of dollars. The cost of outbreaks in asia is in the billions. When an outbreak occurs, control measures involve following the trail of the microbe and its spread. Preparation for an outbreak involves ensuring the response will be fast and well co-ordinated.

But what about the disease-free areas? In response to major animal epidemics around the world, the concept of compartmentalizing or zoning disease-free areas has emerged. In the Netherlands, zoning was used with great success during the 2001 foot-and-mouth disease epidemic.

In order to assist the Ontario poultry industry with a plan of action in the event of an outbreak of highly pathogenic avian Influenza, Drs. Heather Labelle and Jean-Pierre Vaillancourt and their research team at the University of Montreal have been examining the feasibility of zoning the commercial poultry

To assist the Ontario poultry industry with a plan of action in the event of an outbreak of highly pathogenic avian influenza, researchers are examining the feasibility of zoning the commercial poultry industry in Ontario.

industry in Ontario.

The overall goal of zone creation is to identify separation borders that minimize all deficits in production within each zone, as a production deficit could

hinder a zone’s ability to function. Based on needs stated by the poultry industry, the formation of an independently functioning zone would require sufficient production capacity from four allied industries: egg grading stations, feed mills, hatcheries, and slaughter plants.

The database used in the analysis consisted of the total production capacity per Statistics Canada census subdivision, for each type of poultry production, including the capacity of allied industries. Eight census divisions were deemed critical to any zoning attempts. They are: Bruce, Grey, Simcoe, Dufferin,

MitiGAtiNG iMPACt oN busiNess

PIC Update

Toronto, York, Durham, and Kawartha Lakes. The researchers analyzed over 40 different zoning scenarios, always using these eight census divisions to redefine the border between the zones. Of these numerous scenarios, four were retained because they best minimized the deficits in production for the whole industry. None included Quebec. although the proposed zone borders do not eliminate all deficits for all aspects of the industry, they provide the necessary information for discussion within industry about the feasibility of this approach in controlling avian Influenza. To read more, please visit www.poultryindustrycouncil.ca.

FeAtuRed ReseARCHeRs

Dr. Jean-Pierre Vaillancourt, whose research interests include poultry health and public health issues in Veterinary Medicine, is a full professor at the College of Veterinary Medicine of the University of Montreal. Dr. Vaillancourt received his doctor of veterinary medicine and his master’s of science in clinical sciences from the University of Montreal, and his doctor of philosphy in veterinary medicine from the University of Minnesota. Prior to returning

Pto the University of Montreal, he taught at the University of Guelph Veterinary College in Ontario, at North Carolina State University in Raleigh, and was a visiting professor at the National University of Mexico in Mexico City. In 1998, he received the Outstanding Extension Service award, and in 2000, he was inducted into the academy of Outstanding Faculty Engaged in Extension at North Carolina State University. In 2004, Dr. Vaillancourt received The Lamplighter award from the US Poultry & Egg association for his contributions to the american poultry industry on infectious disease research and on biosecurity. In addition to his position at the University of Montreal, Dr Vaillancourt has served as co-ordinator of the Quebec team for the design and implementation of emergency measures for the poultry industry in this province, and has been the auditorin-chief of avian influenza and foot-and-mouth disease simulations in Ontario and New Brunswick. He is currently director of the University of Montreal Poultry Research Centre.

Dr. Heather Labelle is currently completing a master’s degree in epidemiology at the Université de Montréal with Jean-Pierre Vaillancourt as her research advisor. Her research project examines the feasibility of zoning the commercial poultry industry of Ontario as a method of minimizing

Modulation of gut immunity in chickens by beta-1,4 mannobiose

oultry are a major reservoir of the bacteria Campylobacter jejuni (C. jejuni), and various strains of salmonella that colonize the mucus lining the chicken’s intestine. Poultry products and eggs have been shown to be important vehicles of human infection. Therefore, determining methods of reducing intestinal carriage of these pathogens can ultimately improve food safety. antibiotics have traditionally been used to reduce intestinal carriage, but this has led to concerns about potential development of antibiotic-resistant strains of bacteria. Therefore, alternative approaches are being investigated.

In previous PIC funded studies, Dr. Yoshinori Mine and his research team at the University of Guelph found that including a type of sugar (ß-1-4 Mannobiose, MNB) in the diet of broiler chicks reduced susceptibility to Salmonella Enteritidis and C. jejuni colonization during infection.

These discoveries led to curiosity about exactly how MNB modulates gut immunity. In the current study, Dr. Mine used DNa microarry technology, which allows scientists to analyze many gene expressions. Mine wanted to determine which

genetic markers are associated physiological responses of the intestine to MNB.

Their findings? among the genes for which expression was affected by MNB administration, the researchers found that MNB stimulates genes associated with antibody production (especially Iga) in the mucosal surface of chicken gut, thereby helping to prevent bacterial invasion. In addition, they found a stronger response for all genes responsible for defence against organisms and concluded that MNB can enhance gut immunity and prevent colonization of C. jejuni and salmonella.

These findings strongly suggest that one of the major physiological and immunological effects of dietary MNB administration is immunomodulation in the small intestine of chickens. This research has identified an important and commercially applicable method to combat bacterial invasion in the chicken gut, thereby improving food safety of poultry meat and eggs. To read more, please visit the website at www.poultryindustrycouncil.ca.

PIC Update

the spread of highly pathogenic avian influenza during an outbreak. Dr. Labelle is a native of Chicago, and received her degree of doctor of veterinary medicine, as well as a bachelor of science, from the University of Illinois at Urbana-Champaign. Before arriving in Canada she worked as an associate veterinarian in a small animal practice in the Chicagoland area. Her research interests include infectious diseases of major importance in animal production, with a focus on those diseases with a zoonotic potential, and the agricultural and public health policy issues surrounding their control.

Research Hastens Into Practice

Turning research results into practice usually takes a long time – anything up to 15 years is not unusual when we look at the adoption of new technologies on-farm.

However, occasionally we see exceptions and this is the case with the work featured in this edition of Canadian Poultry magazine from Dr. Yoshiri Mine at the University of Guelph. In fact almost before the ink on the final report had dried the technology that he developed for including a type of sugar (ß-1-4 Mannobiose), in the diet of broiler chicks was

already being used by one of the largest poultry processing companies in Canada in Quebec. By reducing the susceptibility to Salmonella and Campylobacter, this technology not only provides a cost-effective tool in the fight against foodborne illness, it also moves us closer towards finding useful alternatives to antibiotics.

Your Research Dollars at Work

This step forward comes as a direct result of the research you pay for, working for you.

Congratulations to Dr. Mine for working diligently to produce this result but thanks must also go to you, the producers who through your collective investment in research such as this help bulletproof our industry against the current and future challenges it faces.

Maintaining industry funding for research was a theme that was picked up in a talk given by Dr. Helen ann Hudson at the recently held poultry conference in Nova Scotia. The role of research in ensuring the sustainability of industry through welltargeted research was articulated by Dr. Hudson.

She highlighted the plethora of new and existing challenges our industry faces, including everything from the usual suspects (disease and productivity challenges) to marketing, welfare, and the new threat of losing genetic diversity in our commercial breeds. On the subject of diminishing genetics, old researchers do eventually fall off the perch and need to be replaced so Dr. Hudson also made the point that we are currently faced with the very real threat of losing the basic human resource capacity to undertake work such as Dr. Mines.

Because times have changed and the University sector can no longer afford to support senior research scientists devoted to specific industries, this issue is central to discussions currently underway between the PIC and the University of Guelph. It’s up to us to make some decisions about where we invest to get the best bang for our limited buck and “people” is one area we cannot afford not to invest in, as it’s very expensive. So at a time when all governments are looking to develop new “smart” industries for the future prosperity of Canada wouldn’t it seem logical that underpinning the success of existing “smart” agricultural industries such as poultry and supporting the brightest and best to work in our industry and keep us at the leading edge would be a “smart” investment?

On the subject of diseases and the smart people working in that area, planning is well underway for our May research day for 2009. This year our focus is on food safety, and at the Guelph arboretum on May 12 you can hear from a group of national researchers and one international, who are working to find solutions to the constant threat to our industry of foodborne pathogens.

The half-day workshop entitled, “What’s eating us in what we eat?” features a great lineup of industry supported researchers and the day will be well worth a look. See the flier in this month’s polybag for more details and don’t forget to come and say g’day to us at the London Poultry Show. n

PiC’s PiCks

By joining forces in the Americas we offer you:

• Most efficient service, support and spare parts network.

• Total solutions for all your egg grading and packing needs.

• One stop shop; most extensive portfolio in the egg industry.

• 135 years of experience.

www.dma-group.com

PRODUCTS PRODUCTS

Medicator for Poor Water

Dosatron International, Inc. has introduced the new DM11F medicator for the livestock market. The DM11F’s patent-pending technology is the result of over five years of research and development, and has been field-tested and approved by industry professionals. The new Dosatron medicator works unlike any other Dosatron, making it ideal for low flow,

Black Tunnel Doors

Chore-Time has recently introduced tunnel doors that are black in colour. The black Chore-Time Tunnel Doors can be used in all types of poultry barns and offer poultry producers a reduction in the amount of light reflected into the poultry house as well as improved in-house air mixing and potential energy savings for tunnel ventilation systems. The black tunnel doors produce a

cyclone-shaped air movement that generates desirable airflow at bird level throughout the poultry house.

The unique air movement helps to eliminate dead-air zones at the side- and end-walls typically found in curtain sidewall or double-door barns. The tunnel doors direct cold air upward, away from birds until it has mixed with air in the barn.

Chore-Time’s Tunnel Doors are constructed of thick extruded foam insulation sandwiched between thick, pebbled fibreglass-reinforced plastic, providing greater rigidity and dent resistance. When closed, the new tunnel doors insulate approximately eight times better than curtains during winter, helping to provide energy savings.

hard water, and water treatment applications. Its superior performance in low-flow applications allows users to medicate animals as young as one day old; the maximum flow rate is 11 GPM, allowing for higher flow as the animals grow.

The DM11F uses a completely redesigned hydraulic motor that is piston-free, which allows the medicator to work

properly even in environments with sand, algae, or high mineral content in the water supply. The DM11F also features a highly chemical resistant housing to allow for use of a wide range of chemicals, including Ph water treatment chemicals and other substances commonly used to combat bio-film.

For more information, telephone: 800-523-8499 or visit www.dosatronusa.com.

WSS-6 Sprinkler Controller

Responding to requests from poultry farmers, Weeden Environments has launched the latest in its Weeden Sprinkler System. The WSS-6 Sprinkler Controller utilizes the latest microprocessor technology specifically designed for poultry applications.

as birds age, aggressive cooling is required in extreme heat. When used in cooling and activity mode, the new Weeden Sprinkler controller acts as the “brains” managing the duration and frequency of sprinkling, starting at the age desired by the grower or integrator.

With the incorporation of heat sensors, the need for reprogramming for temperature changes is eliminated.

The Weeden Sprinkler System is the only

sprinkler system to offer: automatic turn on/off • depending on the age of the bird

Transition from activity • promotion or dust control to cooling mode based on barn temperature

For more information, telephone: 800-552-1064, e-mail info@weedenenvironments. com, or visit www.weedenenvironments.com.

Thanks for waking up to Ontario eggs.

Research

Free-Range behaviour

new study may point the way to breeding laying hens to be more accepting and productive in free-range conditions

B Y W IEBKE I CKEN , L OHMANN

T IER z UCHT G mb H

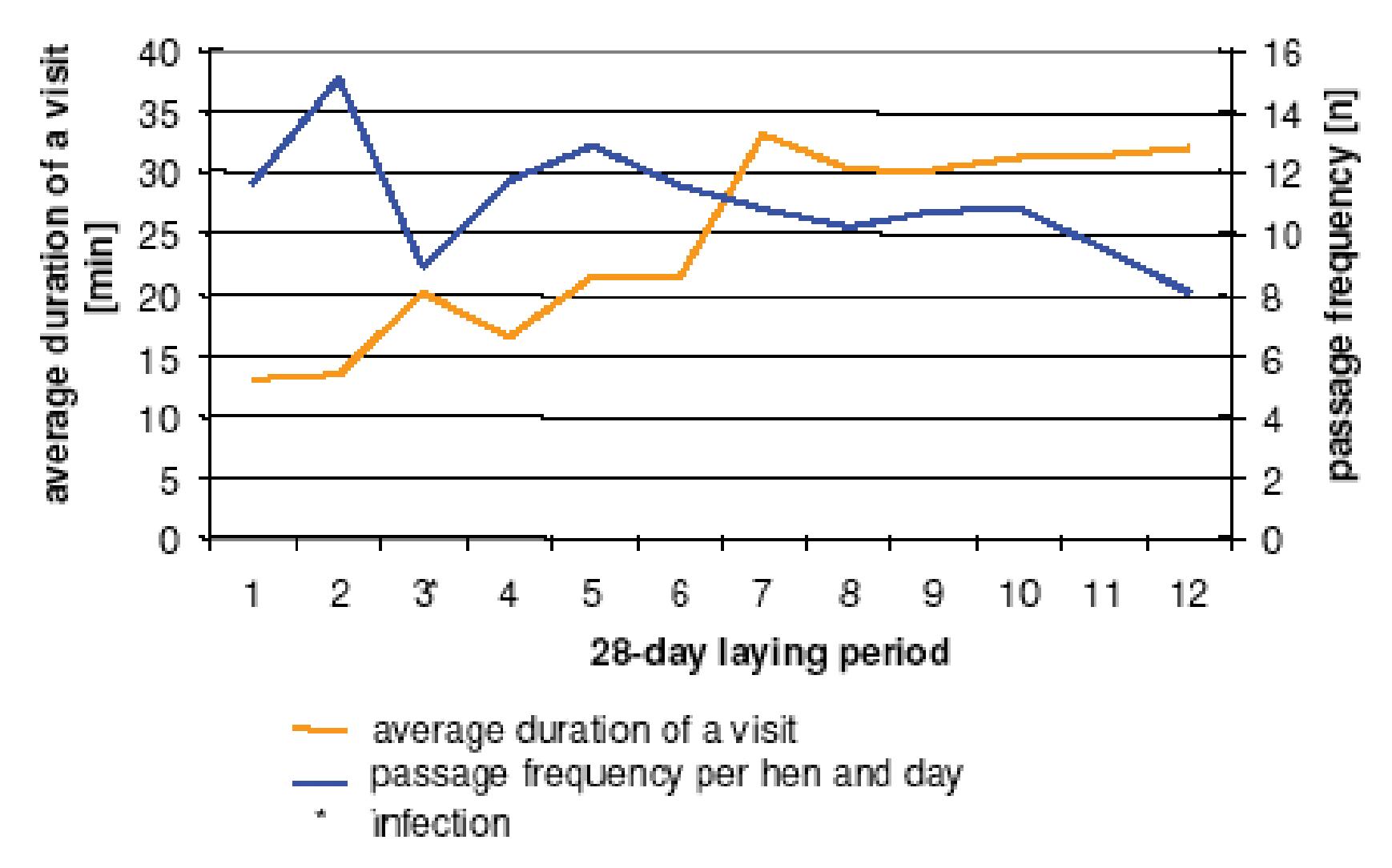

With the aid of a new transponder technology, the freerange behaviour and laying performance of 272 Lohmann Silver hens were tested simultaneously. Therefore, Lohmann Tierzucht GmbH investigated together with the Bavarian State Research Centre for agriculture, Institute for agricultural Engineering and animal Husbandry, Electronic Pop Holes (EPH) and Funnel Nest Boxes (FNB).

These systems made it possible to record automatically each separate visit to the free-range area as well as the egg number by every single hen in the flock. The hens were housed in an aviary with an adjoining winter garden at the experimental station Thalhausen (Technical University of Munich).

To identify each single hen in the EPH and FNB, every hen was tagged with a transponder on one leg. During the whole investigation period of one year, the winter garden was continuously accessible for the hens. The frequency of passages (number of passages between the in- and the outside area) and the duration of stay in the free-range area of each hen was recorded daily.

a large fraction of the hens (35 per cent), did not use the winter garden at all. The percentage of hens that used the winter garden (at least once in a 28-day period), increased during the observation period. as soon as a hen was

PeRFoRMANCe studied

a study of laying hens with access to a free-range “winter garden” has shown a big variation from hen to hen. some hens merely glanced outside while others stayed nearly day and night outside.

familiar with the winter garden, she visited the free-range area nearly every day. Expected effects, like a reduction of the share during autumn and winter, were not found.

The highest number of passages through the EPH was registered in the

second laying period (15 passages per hen and day). Thereafter, the frequency decreased from a level of 13 passages in the fifth laying period to eight passages in the 12th laying period. The average length of stay in the winter garden showed an antagonistic trend to the frequency of passages.

at the beginning of the observation period, the average visit to the winter garden had a duration of 14 minutes, whereas from laying period seven to the end of the observation, a single stay took an average of more than 30 minutes.

The number of passages and the duration of stay in the winter garden showed a big variation from hen to hen. There were some hens that returned to the

Research

barn after a short glance into the winter garden, whereas others stayed nearly day and night outside. Most of the passages through the EPH were registered in the morning between 6 a.m. and 8 a.m. as well as in the afternoon between 4 p.m. and 5 p.m. The average stay in the winter garden per hen and day was about 21/2 to four hours.

at four o’clock in the morning, the artificial light in the barn was switched on and at 8 p.m., it was switched off. From 8 a.m. onwards, the hens were looking intensively for the FNB to lay their eggs. The laying performance of the hens was calculated for each 28-day laying period, beginning with the first correct registered egg in the FNB. a

bacterial infection in the third laying period caused the very late peak of the laying performance (94.2 per cent) in the sixth laying period. The laying performance stayed on a slightly lower level thereafter, with a drop to 86 per cent during the 12th laying period. The estimated heritabilities for the egg number were generally at a low level, varying from one laying period to the next.

Genetic and phenotypic correlations were estimated for the traits: frequency of passages, length of stay in the winter garden and laying performance. a highly positive correlation between the frequency of passages and the length of stay were expected and validated by the close relationship between both

Laying performance (h2), heritability and standard error for each 28-day laying period.

* bacteria infection

traits. Negative genetic correlations were estimated between both parameters for the ranging behaviour and the laying performance. Only a slightly negative trend could be found in the correlation between the traits: frequency of passages and laying performance, whereas a moderate negative correlation (rg = - 0.34) was detected between the traits: length of stay in the winter garden and laying performance.

Until now, no literature could be found to describe the correlations between the two free-range parameters (frequency of passages and length of stay) and the laying performance, like in this investigation. Therefore, the EPH and FNB first showed the possibility to simultaneously record the free-range behaviour and egg number for each hen in a group housing system, with a justifiable effort under field conditions.

The analysis showed interesting information and very promising results for layer breeding, which should be confirmed in further investigations. Furthermore, it is being reviewed, as to how the recorded data could be integrated into the current breeding program to improve and sustain the nest and freerange acceptance. n

Figure 2: Passages of frequency during the day and season

Figure 1

Compact Cut-Up System

PRODUCTS PRODUCTS

Foodmate has announced the development of a flexible Compact Cut-Up System. after months of research, development and testing, Foodmate is offering its new

cut-up system for worldwide distribution.

Company owner David Hazenbroek says that the new system is completely designed and developed by the Foodmate team and that durability and practicality are two of the main design considerations for this system.

The Foodmate Compact Cut-Up System, which requires minimum installation time,

Energy Efficient Sorter Technology

FKI Logistex® announces that its new LS-4000E tilt-tray and LS-4000CB crossbelt sorters, which feature linear synchronous motor (LSM) technology, consume approximately 75 per cent less energy than comparable sorter

systems using linear induction motor (LIM) technology.

The LS-4000’s LSM generates propulsive force via electromagnetic energy, as opposed to mechanical friction between moving parts. This operation reduces energy

consumption and noise levels, while increasing speed, reliability and positioning accuracy.

For more information, please contact Emily Smith, marketing supervisor, FKI Logistex North america, by

offers superior cutting accuracy at higher line speeds. It provides accurate cuts on up to 6,000 birds per hour.

The system is versatile enough that the individual modules can be placed in different places on the cut-up line. The stainless-steel design makes clean-up easy.

For more information, visit www.foodmate.nl. to view equipment and spare parts, or telephone +31 (0) 186 63 02 40.

telephone at 513-881-5239 or by e-mail at emily.smith@ fkilogistex.com.

Ontario Eggs: local and fresh

As consumers embrace the “100 Mile Diet” and seek ways to buy food produced close to home, Ontario egg farmers are proud to provide consumers with locally-produced eggs that travel from farm to table in approximately 4 to 7 days.

Supporting local communities

Ontario egg farmers are proud to provide their local communities, as well as the province, with a supply of safe, reliable and reasonably-priced eggs.

Many of these farms have been passed down through generations! Although times and technology have changed, the level of care today’s modern egg farmers give to their hens remains the same. Egg farmers across Ontario are proud of their contribution to the health and economy of their local communities.

Many choices to consider

There are more varieties of eggs available in Ontario than ever before. Ontario’s family-run farms provide you with a variety of choices. All eggs, no matter which type you prefer, are produced according to the same Grade A standard of quality, freshness and cleanliness.

If your family uses a dozen eggs each week, a local farmer houses, feeds and cares for two hens all year long to provide those eggs.

About Egg Farmers of Ontario

Egg Farmers of Ontario (EFO) is a non-profit organization that represents more than 400 egg and pullet farm families. EFO works to ensure that consumers have access to safe, reliable and reasonably-priced eggs with a fair return to the farmers.

For more information about Egg Farmers of Ontario, the farm families they represent and the types of eggs available visit www.getcracking.ca.

Egg Farmers of Ontario 7195 Millcreek Drive Mississauga, Ontario L5N 4H1

Phone: (905) 858-9790

Fax: (905) 858-1589 Website: www.getcracking.ca

Egg farmers Adam (left) and Gary (right) are a father and son team who manage their family farm near Stratford, Ontario.

Adam, a third generation farmer, is proud to provide consumers with locally-produced eggs.

Research

Aviary Versus Furnished Cage

The behaviour, health and productivity of laying hens in furnished cage and aviary housing systems

B Y S. P LAT z, E. H EYN , F. H ERGT, B. W EIGL AND M.H. E RHARD

,

I NSTITUTE OF A NIMAL W ELFARE ,

L UDWIG M A x IMILIAN U NI v ERSITY, M UNICH , G ERMANY

Groups of 270 Lohmann Silver laying hens each were studied in furnished cage (FC-S) versus aviary housing (aV-S) systems. In terms of animal health, egg quality, laying performance ( FC-S 89.4% vs. aV-S 87.0%) and nest acceptance (> 99%) there was no evidence of a difference between the two systems.

The dust bathing activity of the hens in aV-S corresponded to natural circadian behaviour patterns. In contrast, FC-S hens invariably exhibited incomplete dust bathing patterns on the mat and on the grid floor without any diurnal rhythm. In FC-S 15.6% of all hens used the perches during the light phase vs. 74.9% during nighttime. 26.1% of the hens rested on grid floor in spite of the available perch space 17 cm in width.

Furnished cages

The development of furnished cages was the result of efforts to combine hygienic and economic benefits of cages with animal friendly enrichment of the husbandry

study methOd

comparative studies on behaviour, use of the structural elements offered, as well as health and productive parameters in furnished cage (above) vs. aviary housing systems was studied.

environment (e.g., laying nests, perches and dust baths) that enables the animals to achieve hen-specific behaviour patterns. It is important to evaluate the actual welfare status of hens in these novel systems (Blokhuis et al., 2007). This investigation presents the results of comparative studies on behaviour, use of the structural elements offered, as well as health and productive parameters in furnished cage (FC-S) vs. aviary housing (aV-S) systems.

Using 540 hens of the Lohmann Silver breed, aged 18 weeks, 270 hens were allocated to six Furnished Cage systems (FC-S, type 715/725, Salmet, Berge), the other 270 animals to three aviary housing systems (aV-S, type natura, Big Dutchman, Vechta). The stocking rate of the three aV-S groups was 90 animals each vs. 45 animals each in the FC-S groups. Each individual animal was provided with 1600 cm2 of useable space (in addition to the nesting area) in the aV-S and 1004 cm2 in the FC-S.

The study examined the question of whether the frequency of nest use correlates with light intensity. Therefore, in each FC-S the hens were offered a bright nesting space located on one side of the barn with an outside light intensity of 193

CoMPARiNG

Research

lx on average, and a dark nesting space on the opposite side with outside 20 lx on average.

In FC-S two astroturf mats served as sand baths, each with a base area of 1800 cm2, automatically dredged with feed (1000 h, 1200 h, 1400 h; amount of substrate: approx. 35 g). Four low perches ran crosswise to the grid floor and had a length of 125 cm. The distance to the grid floor varied between 13 cm (around the feed chain) and 7 cm (in the middle, around the nipple troughs). apart from that, two perches with a length of 135 cm were positioned alongside the running area, 22 cm above the grid floor. The total length of the perches was 770 cm.