Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Studies prove and customers agree that higher flow rates grow BIGGER birds FASTER with BETTER results. Low-Volume flow drinkers ultimately restrict a birds' water consumption and have a negative effect on the birds' growth rate.Take the Upgrade Challenge and let us show you how much more can be going in your wallet with a quality Lubing Watering System.

Got Lubing? Contact your local Lubing Distributor for more detailed information.

Tel:

INDUSTRY:The XXIII World’s Poultry Congress

Brisbane, Australia, offers the perfect stage for meeting of poultry professionals and scientists

By Dr. Peter Hunton 12

PIC UPDATE:Improving Productivity Through Research

Relevant research is a key to optimizing performance

By Tim Nelson and Kimberly Sheppard

BREEDERS: And Then There Were . . . ?

Recent consolidation amongst top breeders presents challenges to farmers and companies

By Dr. Peter Hunton

ÉMISSIONS:

La pollution de l’air examinée

Découverte de taux élevés de particules fines s’échappant des poulaillers

Par Ashley McCarl

PLANNING: Farm Succession

Do you have the right plan?

By Peter van Dongen, P.Ag

BY KRISTY NUDDS

While attending the Alberta Poultry Industry conference recently, I sat in on a very interesting presentation given by Brian Payne, Director, Commissary and Supply Chain Management for Pizza Pizza Ltd. and a member of the Canadian Restaurant and Foodservices Association. He also sits on the board of directors for the Chicken Farmers of Canada.

Canada’s foodservice industry is, as Payne pointed out, “a very large customer” of chicken, responsible for 33 per cent of total sales. As such, it is not surprising that product quality is of great importance.

But what is “quality”? Payne said a better question should be “Who decides what quality is?”

Consumers, of course, are who decides what quality is. And how do they form their perception on what quality is? Marketing affects that perception to a large degree.

Payne used the following analogy: both Coke and Pepsi are comprised primarily of sugar and water. Essentially, they are the same product, but how each product is marketed is what makes consumers choose which one they would rather consume.

He also spoke of how current prices for pork can sway consumer perception. Although many hog producers in North America are losing money, their product is currently selling at rock-bottom prices. Just a few days ago, most of the major grocery stores in Ontario were selling pork tenderloin for 99 cents per pound.

What does this say of quality? It doesn’t say anything about how pigs are raised, fed, the regulatory safety programs in place or the true quality of the product,

but that the product is not as valuable as other similar products in the marketplace.

This is where the poultry industry has a definite advantage. With supply management, producers are paid a fair price for their product, which is reflected in the marketplace. Poultry products continue to be in demand, as reflected in the 2007 Usages and Attitudes Survey conducted by the Chicken Farmers of Canada.

Interestingly, in this survey 92 per cent of respondents agreed that it is important that the Canadian government actively defend the interests of Canadian chicken farmers.

This needs to be used to our advantage. If consumers are willing to defend our product, to maintain its “quality” in their minds it’s key all those involved in the value chain play a role in maximizing the production of a high-quality product.

I’ve had several producers over the last year ask me what the marketing boards do for them, in terms of consumer perception. This is a tough question to answer, as each board is unique – some have been aggressively pursuing such efforts while others not so much.

It’s essential that marketing efforts from poultry organizations go beyond their traditional efforts and start addressing some of the questions that are top of mind for consumers, such as food safety programs, drug use, and animal welfare. I don’t think simply saying we raise a quality product is going to cut it anymore. We need to start actively showing “quality” to consumers at trade shows and consumer events, as well as on industry websites. Maintaining consumer confidence and listening to their needs will continue to brand Canadian poultry products as being of high quality. ■

March 2008

Vol. 95, No. 3

Editor

Kristy Nudds – knudds@annexweb.com 888-599-2228 ext. 266

Contributing Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 888-599-2228 ext 234

Production Artist

Brooke Shaw

Editorial Director

Drew McCarthy – dmccarthy@annexweb.com

VP/Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: cnowe@annexweb.com.

Periodicals postage paid at Buffalo NY. USPS 009-324, ISSN 1703-2911. Published monthly by Annex Publishing and Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St. Buffalo NY 14240. US Postmaster send address change to PO Box 611 Niagara Falls NY 14304.

Printed in Canada ISSN 1703-2911

Circulation e-mail: cnowe@annexweb.com Tel: 866-790-6070 ext 207

Fax: 877-624-1940

Mail:P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 25.44

(includes GST – #867172652RT0001)

USA – 1 Year $ 60.00

From time to time, we at Canadian Poultry make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. We acknowledge the financial support of the Government of Canada, through the Publication Assistance Program and the Canada Magazine Fund, toward our mailing and editorial cost. Nous reconnaissons l’aide financière accordée par le gouvernement du Canada pour nos coûts d’envoi postal et nos coûts rédactionnels par l’entremise du Programme d’aide aux publications et du Fonds du Canada pour les magazines.

www.canadianpoultrymag.com

“We are very pleased with our decision to purchase Hellmann Layer Cages with Manure Air Dry.Manure drying has eliminated flies in this layer house. “We have observed productivity gains and improved feed conversion. Mortalities are very low and the hens are staying at peak (production) for a longer period of time.”

Andre Merks,Merks Poultry Farms Ltd., Avonport,Nova Scotia

Iwas impressed with Hellmanns’product engineering.The equipment is strong and easy to operate.The deep feeder troughs and reliable chain feed system are a bullet-proof combination.My weekly results consistently exceed the productivity charts.My production numbers are making me money. Money makes me smile.”

David Drain,Telford Egg Farms, Norwood,Ontario

“To date,we are very pleased with the results from our Hellmann system.Bird mortality and labor inputs are very low.As we know crews can be tough on cages,but the system strength and design of the Hellmann equipment eliminates any equipment damage concerns.The pullet inspection carts, which travel on the pullet trough,are awesome!!”

Fred & Sheila Fleischhacker Paynesville,Minnesota

The revised modalities paper on agriculture, issued Feb. 8 by Crawford Falconer, Agriculture Trade Negotiations Chair for the World Trade Organization (WTO), is not satisfactory for Canadian poultry, egg and dairy farmers.

National dairy, egg and poultry organizations in Canada feel that Falconer continues to ignore the explicitly stated position of the Government of Canada, which is to defend Canadian farmers, including those with supply-managed products. The organizations feel that certain proposals within Falconer’s text are still entirely unacceptable for Canada, as they would devastate the livelihoods of Canada’s dairy, poultry and egg farmers. The text on sensitive products

does not reflect the concerns that Agriculture and Agri-Food Minister Gerry Ritz brought to Ambassador Falconer’s attention in a letter on August 31, 2007, and reiterated publicly in early January 2008.

“A ‘one-size-fits-all’ approach to these negotiations will not allow the WTO to reach an agreement,” says David Fuller, chair of Chicken Farmers of Canada. “We’d hoped that countries’ special needs would be addressed in a thoughtful way. We are concerned that Chairman Falconer has done this for some countries, but not for Canada. The new text includes no improvements for Canadian dairy, poultry and egg farmers. There has been no progress in this regard since the first paper was presented.”

The press release stated that the situation could be worse than it was in the first draft, as the text on sensitive

products treats such products more harshly than ever. “The selection and treatment of sensitive products outlined in the revised draft modalities still does not provide enough coverage for dairy, poultry and egg products. The government must work to ensure that all supply-managed products are included in the sensitive products category, without having to pay an additional cost,” the release says.

The organizations feel that the government must also negotiate to make certain there are no reductions to over-quota tariffs for sensitive products and no increases in market access, as was outlined in Minister Ritz’s letter to Falconer.

“We have already provided significant access to our markets. With the stronger Canadian dollar, the effectiveness of the current overquota tariffs is already diminished.”

MANITOBA

Major changes to rules covering farm workers in Manitoba are being hailed by a big union and criticized by the province’s largest producer organization.

The provincial government says starting June 30, farm workers will have the right to paid vacations, overtime pay, lunch breaks and other benefits enjoyed by most other workers.

The changes stem from a move by the province to extend its Employment Standards Code to cover the agriculture sector.

Labour Minister Nancy Allan says the new rules are the first major reform for farm workers in 50 years.

The United Food and Commercial Workers union welcomes the move, saying farm workers deserve the same rights as other labourers.

Spokesman Stan Raiper says Alberta, Ontario and other provinces should follow Manitoba’s lead.

But the head of Keystone Agricultural Producers says the changes will mean extra costs.

Ian Wishart says many cattle and hog producers don’t

NOVA SCOTIA

In late January Halifax resident Louise Hanavan, who was ordered to remove her three hens from her backyard, spurred a debate over whether or not chickens could be kept in the urban area.

Both supporters and

non-supporters rallied city council in early February, but no decision will be made until the summer.

The regional councillor for Hanavan’s area, Sheila Fougere, asked municipal staff to look into how other cities regulate urban poultry.

Granny’s Poultry’s gleaming new 10.5-milliondollar Winnipeg hatchery hatched its first chicks on Feb. 21.

They’ll emerge in what the company says is the most energy efficient and technologically advanced hatchery in the world. State-of-the-art climate control ensures that the chicks will be healthier

have the money right now.

He says the group supported many of the changes, but is worried how overtime pay and guaranteed holidays will affect farm operations who have to run full-tilt during certain times of the year.

APRIL

April 8-9, 2008

Poultry Industry Conference and Exhibition (The London Show), Progress Building, Western Fairgrounds, London, Ont. For more information, visit www.poultryindustrycouncil.ca.

MAY

May 15, 2008

Poultry Industry Council (PIC) Research Day, The Arboretum, University of Guelph. For more information, telephone 519-837-0284; e-mail pic@poultryindustrycouncil.ca, or visit www.poultryindustrycouncil.ca.

May 28-29, 2008

and stronger than chicks born in other hatcheries. Brian Walker of Granny’s Poultry says the computer systems that monitor and control humidity and air flow, as well as equipment that minimizes egg movement during hatching, help produce strong chicks that have the potential to grow faster.

The new facility, which will produce 12 million broiler chicks a year, was designed

That report, and any recommendations to councillors, is not expected for another five to six months.

Hanavan was originally given until the end of January to get rid of her three hens, but the deadline was extended until late February.

by U.S., British and local engineers and uses geothermal technology. It’s even equipped to harness the heat given off by the embryos to help warm the 36,000-squarefoot building.

Ontario Association of Poultry Practitioners (OAPP) technical symposium, Holiday Inn, Scottsdale Dr., Guelph, Ont. The symposium will feature several internationally recognized speakers. The first day will focus on antimicrobial use, development of antimicrobial resistance and alternatives for poultry production. The second day will include discussions on emerging diseases and animal welfare. For more information or to register, please contact Dr. Emily Martin at 519-824-4120, ext. 54523 or by e-mail at emartin@lsd.uoguelph.ca.

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Publishing, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont.N3Y 4N5; e-mail: knudds@annexweb.com or fax: 519-429-3094

Chicken Farmers of Canada (CFC) is celebrating 30 years of delivering the economical, safe, quality chicken that consumers want. The industry has come a long way. Now, chicken is Canada’s number one meat choice and is offered in a vast array of cuts, convenient packaging and nutritious meal options for Canadian families.

Thirty years ago, the average Canadian consumed

about 15.7 kg of chicken per year; now Canadians enjoy 31.8 kg each. Production has increased in response, with farmers now producing more than 175 per cent more chicken than they did in 1978.

“We take pride in celebrating the fact that 30 years on, Canada’s 2,800 chicken farms are still raising quality chicken that Canadians can trust,” says David Fuller, chairman of CFC.

nthony Keyburn (above), and a team of Australian scientists recently outlined in the Feb. 8 edition of PLoS Pathogens the discovery of a new toxin and the finding that alpha-toxin protein – long thought to be required for necrotic enteritis to develop – is not the main cause of the chicken disease. Keyburn, said necrotic enteritis is caused by Clostridium perfringens, a bacterium,that only causes disease when it proliferates to high numbers, producing extracellular toxins that attack the bird’s intestines, causing lesions.

Alltech has named Ty Yeast as the new director of sales for North America. Yeast brings 12 years of experience with Alltech and has also directed its Canadian region for three years.

Jackie Heyden joins the Alltech team as marketing coordinator for Ontario. Previously, Jackie held an account executive position with AdFarm working on Novartis Animal Health and Bayer CropScience accounts. She comes with an advanced marketing and business administration diploma from Conestoga College.

Keyburn said the research team at AAHL began to question the involvement of alpha-toxin when a survey showed that local diseasecausing bacterial strains produced low levels of this toxin.

The team genetically altered the bacterium so it would not produce alphatoxin. Despite its absence, they found that bacterial isolates still caused disease in chickens.

The team is to expand its search for the real cause of necrotic enteritis, finding a novel toxin – NetB.

Kate Roberts joins the Alltech team as Marketing Coordinator for Western Canada. Kate held a previous position as marketing and communications co-ordinator with Land O’Lakes Canada, and has a marketing management degree from the University of Guelph.

Don’t

For processed or non-processed feed, we have the phytase to meet your needs.

Ronozyme P-(CT) – Patented coating technology keeps phytase effective even under extreme conditions. Ideal for pre-processing addition to pelleted feeds.

Ronozyme P-(M) – High potency and easy to handle, this dustless form was specially designed for use in premixes, base mixes and dilutions used in non-processed feeds.

Ronozyme P-(L) – Perfect for post-processing spray application, the product has excellent shelf life and handles well.

Combine these formulation options with the feed cost savings and environmental benefits of Ronozyme P and your phytase choice is clear

Learn more. Contact your DSM Nutritional Products Account Manager or visit our website at www.nutraaccess.com

BY DR. PETER HUNTON

The World’s Poultry Congress is held every four years. Congresses are sponsored by the World’s Poultry Science Association (WPSA), an international organization with more than 7,000 members in about 80 countries around the world.

Brisbane holds the XXIIIrd Congress in a series that began in 1921, when the first Congress was held in The Hague, the Netherlands. At the Congress in The Hague, 384 delegates representing 23 countries attended. Following this, the second Congress was held in Spain and the third, in Canada, in Ottawa in 1927. Over 500 delegates registered in Ottawa. Held each three years until the Second World War, and every four years thereafter, the Congresses have taken place in 17 countries in all the world’s continents. This is the second congress for Australia, the first being in Sydney in 1962. Only six countries have hosted the Congress twice; the Netherlands, Spain, Canada (the second Canadian Congress was in Montréal in 2000, with more than 2,400 delegates), U.S., U.K., and Australia. Brazil will hold its second Congress in 2012.

The WPSA was founded in 1912, when it was known as the International Association of Poultry Instructors. Although primarily initiated by British and American scientists, 14 countries, including Canada, were involved in the original organization. The Association has evolved over the past century, and now

The 2008 World’s Poultry Congress is being held in Brisbane, Australia, and will feature industry trends and research from global experts.

welcomes not only instructors but anyone with an interest in poultry science. Thus it has a very strong industrial connection, with many members from the commercial poultry industry. The three pillars of the Association are Education, Research and Organization.

The Association publishes the World’s Poultry Science Journal, which is sent to all current members. It is also available to members online. Abstracts and table of contents can be viewed at

http://journals.cambridge.org/WPS. The Journal contains scholarly reviews of all aspects of poultry science. The Journal is published four times annually, and each issue contains roughly 160 pages. Each issue will contain up to 10 review articles and also short papers on national industry news, particularly from developing countries. Many of the review articles are originally from some of the symposia and conferences that the Association sponsors. These draw relatively small

audiences (50-300) so the publication of such reviews in the Journal gives them a much wider distribution. Since the introduction of electronic publication, all back issues of the Journal have been digitized and are available on subscription at http://journals.cambridge.org/WPS. For subscription enquiries, contact usjournals@cambridge.org.

The Congresses extend the reach of the Association by bringing together the largest single audience of poultry scientists in the world. Depending on the location and the vagaries of travel and politics, Congresses attract anywhere from 1,000 to 3,000 delegates. In most cases, more than half are Association members but the remainder are simply attracted by the subject matter and the opportunity to interact with people of like mind. WPSA members receive a discount on the registration fee for the Congress. In the case of the Brisbane Congress, this is $100 or $200, depending when you register. The Congress proceedings, starting with the Montréal event, are published in electronic form, on a CD. Abstracts are sometimes printed in hard copy. Copies of all past Congress proceedings are held in the WPSA Archive at the American National Agricultural Library in Beltsville, Md.

Australia, while having a relatively small population, has a prosperous poultry industry and a thriving community of poultry scientists, well able to mount a successful Congress. The Australian branch of the WPSA has more than 200 members. There are at least five important centres of poultry research: in Brisbane in Queensland; Sydney and Armidale, New South Wales; Melbourne; and Adelaide. Until relatively recently, the Commonwealth Scientific and Industrial Research Organization (CSIRO) had a section devoted to the study of poultry genetics and breeding, although this is now closed. The poultry industry has a history of self-sufficiency, partly due to geography: Australia is a long way from many potential suppliers. In addition, until the late 1980s, imports of breeding stock were not permitted, and local breeders had essentially a monopoly in both eggs and meat. In the past 15 years, however, the international breeders have been permitted to import grandparent stock and have become well established.

Brisbane is an ideal location for the Congress, being located about halfway up Australia’s east coast and, therefore, having a subtropical climate. In addition, it is home to the University of Queensland, one of the major poultry research centres in the country. Dr. Bob Pym, president of the branch and chairman of the Congress, lives and works in Brisbane. The Brisbane Convention and Exhibition Centre is relatively new and offers state-of-the-art facilities, with the conference and exhibition under one roof. It is right downtown, within walking distance of most major hotels, and close to the Brisbane River, which offers spectacular views of the city as well as a wonderful means of transportation.

The Congress program follows a traditional pattern; Plenary sessions addressed by invited speakers involving all delegates, and concurrent symposia and oral and poster presentations of submitted papers. For full details of the program and registration, visit the Congress website at www.wpc2008.com.

While we don’t yet know the extent of the Canadian presence, we do know that one graduate student from the University of Saskatchewan will attend. Samira Dadgar won the Canada Branch Graduate Student Competition, and will enjoy an expense-paid trip to the Congress, sponsored by the Canadian Turkey Marketing Agency. The title of her paper is “Effect of microclimate temperature during transportation of broiler chickens on quality of the Pectoralis major muscle. The Canada Branch WPSA secured funding from CEMA and CHEP as well as other industrial contributors to assist Canadian scientists to attend the Congress.

With the opening date fast approaching, Canadians interested in attending should make arrangements as soon as possible. It’s going to be a great meeting! ■

For more information about the WPSA, readers can check the website at www.wpsa.com. For information, or to join the Canada branch, contact the secretary, Karen Schwean Lardner, Department of Animal and Poultry Science, University of Saskatchewan, 4C16 Agriculture Building, Saskatoon, Sask., S7N 5A8, e-mail: karen.schwean@usask.ca.

BY TIM NELSON, EXECUTIVE DIRECTOR, AND KIMBERLY SHEPPARD, RESEARCH CO-ORDINATOR

Want to hear some wise words about feeding poultry to improve productivity? Well you can!

PIC is running an afternoon in May focusing on recent poultry nutrition research and its impact on production. The meeting will hear about the impact on poultry production of different feeds, management techniques and supplements and how they can be used to optimize growth, and improve bird health and other production traits.

Can you afford to miss this? No, you can’t!

What does it cost? $30 (students with current card have free admission, but still need to register).

When is it on? May 15 Where?

The Arboretum, University of Guelph Registration starts at 12 midday and we’ll break into a wine and cheese “Mix ’N’ Mingle” at 4 p.m. It’s an intense, high-impact afternoon. For a map, more details and a registration form, see our website, call 519-8370284, or e-mail pic@poultryindustrycouncil.ca.

VERY IMPORTANT: For catering purposes, you will need to book.

The speaker list is impressive (Steve Leeson, Doug Korver and Rob Renema –just for starters) and the topics cover all sectors: layers, broilers, turkeys and breeders. This is cutting edge stuff of relevance to all poultry producers who are interested in the bottom line.

Ticket price includes hearing the speakers, a full copy of the proceedings, light buffet lunch and a wine and cheese afterwards (see box).

The first Ontario poultry industry Research and Education (R&E) strategy can be found on the PIC website. The first draft was made public to coincide with our 2008 call for project proposals, which

was launched on Jan. 27. This is a dynamic document and we expect, with continued input from across industry, that there will be positive additions and changes over time.

Whilst the document has a sound focus on the practical producer issues of feeding poultry, productivity and disease management, there are some interesting forays into researching the changing market, trade and economic situation across the globe. This is complimented by a large section on meeting consumer demand. It’s obvious that those who helped pull the strategy together were clear about the fact that external influences, rising energy costs, alternative uses of feed, changing world diet, changing world production patterns, changing

climate, etc., will have a direct impact on our industry at some level and that industry needs to be prepared for this.

Focusing closer to home, there is an entire section dedicated to building and maintaining the capacity of the Ontario poultry industry to ensure it remains a stable, secure and profitable industry for many years to come.

The Board of PIC would like to thank all those involved in the development of the strategy and particularly the University of Guleph Office of Research, for their financial support. PIC invites any comments and feedback from people involved in the industry. If you haven’t got web access please contact PIC at 519837-0284 for a copy.

TPIC has pulled together a summary report for the first six months of our financial year.

The report gives an overview of PIC activities and a financial report to Dec. 31, 2007. You’ll also find a summary of research results for all projects funded by PIC since 2003 and a list of current research projects that are still works in progress. You can request a copy or simply download one from our website.

urkey coryza, is a respiratory tract disease caused by the bacteria Bordetella avium (B. avium). Symptoms usually last around two to three weeks, and the disease is normally cleared up by the bird’s immune system. However, the disease spreads quickly throughout a flock and causes poor weight gain and stunted growth, while at the same time making the birds more susceptible to other diseases. B. avium, which is very contagious, is also difficult to remove from production units.

Antibiotics have variable success in controlling the disease; it is thought that, in general, antibiotics are merely treating secondary infections. Currently available vaccines are based on attenuated (weakened) B. avium and, although these have been shown to reduce the chances of infection, they have little effect on the severity of the disease. Very little is known about B. avium or the mechanics that it uses to infect turkeys, so in order to develop effective control strategies, we need to know more about the bacterium.

genome sequence. The list produced from this analysis was further refined by identifying genes that have the code for specific disease-causing components of the bacteria – components similar to virulence factors in other bacteria. The ultimate goal of this research is to develop a novel, improved vaccine against B. avium infection.

Their findings?

It was found that B. avium contains a number of genes that are predicted to enable the bacterium to grow fimbriae (tiny threads) on its cell surface. Fimbriae are used by bacteria to adhere to one another and to animal cells. They are, therefore, important factors in allowing the bacterium to establish infection. The role of these B. avium fimbriae in infection and in inducing immune responses was characterized. Fimbriae were found to indeed be present, and the presence of fimbriae was found to be temperature dependent.

If you missed out on a fax or e-mail advising you of our call for 2008 proposals, please check the website for details. The call closes on Friday, March 28 – so there’s still time.

Dr. Max Hincke, just after a shave-a-thon fundraiser for pediatric cancer research. Hincke has been studying the matrix proteins of the eggshell.

Max Hincke is currently a full professor

and head

of the anatomy division of the Department of Cellular and Molecular

Dr. Andrew Preston, University of Bristol, together with Dr. John Prescott and graduate student Stewart Loker at the University of Guelph, have been working towards identifiying and characterizing the components of the bacterium (specifically genes), that allow it to infect turkeys, by analyzing the B. avium

Medicine at the University of Ottawa. He received his PhD (biochemistry) from the University of Alberta. His research program in hard tissue biology during the past 15 years has utilized the avian eggshell as a model system for biomineralization. Hincke’s group studies the matrix proteins of the eggshell, seeking to learn more about their func-

Further work is in progress on the role of the interaction between bacteria and turkeys, by infecting respiratory tissue in the lab and testing the involvement of fimbriae in the attachment of bacteria. Overall, an important first step has been achieved in characterizing the mechanism by which B. avium causes disease. To read more about this project, visit www.poultryindustrycoun-cil.ca and click on “Research Results.”

tion during eggshell formation by investigating the purified proteins, characterizing them by immunochemistry, and using molecular biology to clone and produce recombinant proteins. These studies have been pursued in collaboration with academic, government and industrial colleagues in Canada and Europe. ■

BY DR. MAX HINCKE, UNIVERSITY OF OTTAWA

As a flock ages, the hens tend to lay larger eggs with weaker shells. This accounts for the well-known decline in average shell quality of eggs from older birds. The eggs crack more easily, and flaws in the eggshell permit increased microbial contamination of the egg contents. Therefore, the economic cost of eggs from older flocks is higher due to increased loss of cracked eggs and greater risk of foodborne illness.

Shell quality is dependent on the structure of the shell. This structure is comprised of a matrix of proteins on which calcium carbonate crystallizes into a pattern. Although the most important aspect of shell strength is the amount of mineral in the shell, the microstructure (pattern) formed by this mineral also influences shell strength. Although eggs with weaker shells are a problem of older flocks, individual birds within the flock vary in the extent to which age influences shell quality.

This observation suggests that the genetics of individual birds affects how the type of shell being produced changes as

birds get older. Dr. Max Hincke at the University of Ottawa has investigated the genetic link between the genes of certain proteins that influence eggshell calcification. Thus, with the co-operation of Dr. Al Kulenkamp and Dr. George Ansah at Shaver Poultry Breeding farms, Hincke identified groups of birds with three types of DNA linked to the proteins that influence eggshell calcification. The birds were followed throughout an extended laying period to determine commercial impact of selecting breeding stock on this basis. Eggs collected at 40, 60, and 80 weeks of age were analyzed for specific gravity, shell thickness, shell breaking strength, shell deformation, egg weight, egg width and egg length.

His findings?

The older birds with one of the three types of DNA produced eggs with thicker shells that tended to be stronger. Using this method of genetic selection, it should be possible to breed for improved overall eggshell quality in aging flocks.

To read more about this project, visit www.poultryindustrycouncil.ca and click on “Research Results.”

Canadian Poultry Magazine recently launched a new, more comprehensive website. The website now offers:

•Daily news updates of issues and developments of relevance to poultry producers

•Archived articles

•An extended events calendar

•Our complete Buyers’ Guide

•Links of interest

•Classifieds

•Web-exclusive material

We also have opinion polls of current issues and blogs from our writers. We encourage you to check out our new website and let us know what you think, and if there is anything you would like to see. Share your ideas, what is on your mind, or comment on current topics.

Companies can also upload press releases, photos and information about new products or any other information they would like to share with our readers.

Check out the new website by visiting us at: www.canadianpoultrymag.com.

BY DR. PETER HUNTON

The recent announcement from Cobb-Vantress and Hendrix Genetics of a strategic alliance makes the world of poultry breeding smaller again. The poultry industry now faces a situation in which all of its turkey breeding and egg-laying, and most of its meat chicken stock, originates from two major corporations. The EW Group (named for Eric Wesjohann) in Germany owns Aviagen (Ross, Arbor-Acres, Lohmann-Indian River meat chicken brands, plus BUT and Nicholas Turkeys), Lohmann, HyLine and H&N International layers.

Hendrix Genetics (named for its founder, Thijs Hendrix, who is still active in the business) based in the Netherlands, owns ISA, Shaver, Babcock, Warren, Bovans, Hisex and Dekalb brands of layer, plus Hybrid and Orlopp turkeys. Hendrix owns the Hybro and Pilch broiler brands and, with the newly announced alliance with Cobb-Vantress, vaults into the big league of meat chicken development and marketing.

The only breeders “independent” of these two conglomerates are Hubbard broilers and Babolna-Tetra layers. Hubbard is owned by Grimaud Frères Sélection in France, which is also a major player in duck, guinea and rabbit breeding. Babolna-Tetra, a very small player in

FEWER AND FEWER

All of the layer and turkey breeding stock (and most broiler stock) in the world now originates from only two companies.

laying stock with limited distribution, is family owned and based in Hungary.

Most of these breeding companies began as relatively small, family-owned and -operated companies. In Canada, Shaver began as a small operation in the 1930s but quickly developed after the Second World War into a major breeder. Donald McQ. Shaver built the business

quickly in the 1950s and 1960s before selling a minority interest to Cargill Inc., a grain merchant from Minneapolis and one of the world's largest private companies. Following Don's retirement in 1985, the Shaver company became 100 per cent owned by Cargill, but was quite quickly sold to the French company ISA. More recently, ISA became a part of Hendrix

Genetics, along with the other brand names listed above.

Babcock was another family-owned business, started by the Babcock family as long ago as 1905. It was expanded by Munroe Babcock and his son, Bruce, in the 1950s and ’60s and distributed its stock, like Shaver, through joint ventures and franchise arrangements around the world. Babcock was eventually sold to the A.H. Robins pharmaceutical company, but this arrangement did not last long and Babcock became a part of ISA in the 1980s.

Hope sold its birds as a pure line. It is probably true to say that no leghorn breeder ever got very far without some Mount Hope blood in its gene pool, and this was all acquired legally and above board! Subsequent acquisitions of one company's stock by another involved all kinds of subterfuge, bribery, outright theft, and any amount of skulduggery.

The pharmaceutical industry in the 1980s seemed to believe that poultry breeding formed a useful adjunct to its main business. Over time, Pfizer owned H&N Inc. and Merck owned Hubbard and BUT; however, the synergies thought to exist did not materialize and all of the connections between pharmaceutical companies and breeders have now been terminated.

Dekalb and HyLine both started because of supposed applicability of corn breeding hybridization techniques to laying chickens. This primarily involved creation of inbred lines followed by multiple crossing to produce the commercial generation. While there may have been similarities in breeding techniques in the early years, these have not survived and most breeders today use a combination of pure line and cross-line testing to maintain continuous improvement of their commercial products.

Before many of these companies emerged, the Kimber family in California began to breed White Leghorns using genetic selection tools, and were the first to hire a professional geneticist, in 1943. However, the Kimber name did not last long and the remnants of the company were bought by Dekalb in the 1970s. Even prior to Kimber, Mount Hope Farms developed its own strain of White Leghorn, which was highly productive in its own right. However, this was prior to the emergence of hybrids and crosses, and Mount

The meat breeding business was largely separate from the layer industry, as they have little in common from a genetic standpoint. At one point, cockerels from some dual purpose or brown-egg strains were grown for meat, but they were quickly supplanted by specialist strains. Early breeders of meat chickens had only to place large numbers of birds from an existing meat strain, and select the heaviest at market age for reproduction. Male line breeders such as Vantress, LedBreast, Hubbard, Peterson and Indian River based their selections on descendants of the White Cornish breed, while breeders of female lines used White, along with Barred Rocks, New Hampshire, and several other breeds and synthetic strains, as the basis for their work. Arbor-Acres, Pilch, Cobb, Hubbard and Nichols are examples. Many of the original meat varieties started development in North America, but soon were exported to Western Europe and elsewhere. Most originated as family farms and businesses. As late as the 1960s, Hubbard, Cobb, Peterson, and Pilch were still operated by family members of the same name. The Saglio family, who started the Arbor Acres company (and later, Avian Farms, and currently, Pure Line Genetics) are one of the longest-standing families in the breeding business. Ross, now one of the largest names in meat breeding, came into the game relatively late, and in fact the name originates from a fishing company in Grimsby, England. Ross Foods purchased a company called Chunky Chicks (Nichols) Ltd., who had imported a range of breeding stock including Nichols’ New Hampshires, and set up a large breeding and selection programme in Scotland in

the mid-1960s. At that time, they also bred layers, turkeys and pigs. This company, like some of its North American competitors, also had a large meat chicken production business and was its own largest customer for many years. Eventually, after a series of corporate manoeuvres, the production and breeding businesses became separate entities with different (and frequently changing) ownership.

What are the consequences of this consolidation of ownership for farmers and companies in the egg and meat production sectors?

Although there are a number of brands available, egg and turkey farmers now buy breeding stock and/or commercial chicks from one of only two companies – EW Group or Hendrix Genetics. The likelihood of a new entrant to this industry is virtually nil. The egg industry is not expanding significantly. Any growth in population or consumption is taken care of by annual increases in production at the commercial level. Prices for breeding stock have remained almost constant for many years and are not highly profitable, when one considers the investment necessary for research and development to accomplish regular and consistent performance improvements. Some economies of scale have been achieved by merging of different companies; the presence of fewer geneticists and consolidation of research facilities have made this possible. But the companies still have to provide service and deliver breeding stock all over the world, even to markets that are too small to justify it.

Diseases such as avian influenza can cause serious disruption of supply. While both companies maintain stocks, and often research facilities, in different areas of the world, and claim to be “immune” to interference from disease, they are extremely

Continued on page 22

OLYMAIR is a heat recuperator air exchanger made of 100 per cent polymer that is resistant to the corrosive conditions found in poultry barns, such as high humidity and dust.

The exchanger was developed by the Research and Development Institute for the Agri-Environment (IRDA) in partnership with Quebec-based plastics specialist Plastique Polyfab Inc. Plastique Polyfab Inc. is the fabricator of POLYMAIR and sole distributor.

The heat recuperator air exchanger POLYMAIR is an effective way to reduce ventilation costs during winter and improve the environment inside poultry barns. During winter, 72 to 91 per cent of

heat loss or energetic expense in a broiler breeder barn is associated with ventilation.

The POLYMAIR allows a heat transition between two-air circuits counter-currently.

A volume of air from outside enters the exchanger. At the same time, a volume of air from inside the building enters the side of the exchanger, where it circulated around the rib tubings within the unit. Cold air inside the tubings heats up and exits the end of the POLYMAIR into the building warm and dry. The humid and dustry air from the building is expelled outside.

•Size: 3 x 0.9 x 0.8 metres

•The unit has two axial fans, one for the heating circuit (air from inside the building) and another for the cooling circuit (fresh air from outside the building)

•Theoretical discharge of 0 to 700 litres per second (0-1500 cube per feet/minute)

•No defrosting cycle necessary

•Accessible core for easy cleaning

•Thermal efficiency of 45 to 55 per cent

For more information, contact Donald Cyr at 800-363-5247.

The right people with the right financial tools can help you make the most ofyouragricultural business.

At CIBC,you can count on us for insightful and practical advice aswell as flexible borrowing products* to fit your business plan:

• CIBC Farm Operating Loan

• CIBC FarmTerm Loan

• CIBC Farm Mortgage Loan

Talk to us about the solutions that are right for you. Call1-888-493-2422 orvisit cibc.com/agriculture.

*Subject to credit approval.Some conditions and restrictions apply.Credit limit and rates will depend on an assessment of each application.“For what matters.”is a TM of CIBC.

Continued from page 18

vulnerable when political responses to disease outbreaks come into play. Although moves have been made to limit such responses they can play havoc with companies’ distribution systems. When avian influenza was reported in 2004, in British Columbia, Hybrid Turkeys and Shaver, both based in Ontario, were essentially shut out of several of their worldwide markets for many months. However, because of political and industry action, the recent outbreak of AI in Saskatchewan did not have such dire outcomes for the breeders.

Meat chicken producers have a slightly wider choice: they can get stock from EW Group, Hendrix Genetics (via the new arrangement with Cobb-Vantress) or Hubbard. Again, a handful of brand and varietal names give the impression of wider choice, but the fact is that only three suppliers exist. They are highly competitive. Companies that failed to keep up have been ruthlessly weeded out and even some relatively sound breeding companies have left the field. Contemporary breeding programs are a far cry from the early days of placing enormous numbers of chicks and selecting the heaviest at market age. In some respects, the meat breeding businesses of today are more complex than those involved with layers. Not only must production traits be considered, but also the ability to reproduce efficiently, and to flourish in many climates and management systems. Welfare advocates have also made it necessary to breed specialist varieties for the various niche markets and welfare-friendly production systems that are now commonplace.

Vulnerability to catastrophic disease is the same for meat breeders as it is for layers; an outbreak near to a grandparent or great-grandparent facility could have huge repercussions in terms of disrupted supplies of parent stock and/or commercial chicks. The fact that there is only one, or at most, two, alternative suppliers of breeding stock is a challenge we hope commercial hatcheries don't have to face, but it remains a possibility. ■

New VIR-KIL™ is a premium quality, broad spectrum surface disinfectant designed for effective, sustained antimicrobial activity against a broad array of viruses, bacteria, molds and yeasts.

VIR-KIL’s powerful, sustained and synergized biocidal action makes it ideal for swine and poultry operations where biosecurity is a priority.

VIR-KIL:

• contains two active ingredients which work together in a powerful, synergistic manner to deliver sustained biocidal activity

• contains a detergent and water softener to cut through dirty surfaces when mixed with either soft or hard water

• will not corrode metals or plastics and is odourless

Now, for a limited time, receive $20 OFF the retail price of every 5 kg pail of new VIR-KIL you purchase, or $80 OFF every 20 kg pail purchased. For all the details please see your farm supply retailer or veterinarian, or contact Engage Animal Health at 1-866-613-3336.

Découverte de taux

élevés de particules fines s’échappant des poulaillers

PAR ASHELY McCARL

Des chercheurs de l’Université de Guelph affirment que les émissions de matière particulaire sont dix fois plus élevées qu’antérieurement estimées.

Bill Van Heyst, professeur de l’école d’ingénieurs et Taylor Roumeliotis, étudiant diplômé, soutiennent que le taux de matière particulaire expulsée dans l’air par les exploitations agricoles est substantiel.

Les estimations précédentes ne reflètent pas les taux réels d’émissions, signale Bill Van Heyst, mais grâce à une nouvelle technologie, nous pouvons évaluer la concentration de matière particulaire avec plus de précision, nous permettant ainsi d’établir des comparaisons valables avec d’autres secteurs d’activité.

Dans le contexte actuel où l’opinion publique est de plus en plus sensibilisée à l’environnement et où les conséquences du smog et autres polluants sont mieux comprises, il importe de déterminer l’apport des divers secteurs agricoles à la pollution atmosphérique. Des particules fines, invisibles à l’œil nu, et jouant un rôle dans la formation du smog sont typiquement relâchées par les installations animalières et par de nombreuses autres sources, précise M. Van Heyst.

Ce sont les secteurs porcins et avicoles qui émettent le plus de particules fines et d’ammoniac. En raison de la nature des poulets à griller et de l’uniformité des soins animaliers et de la conception des bâtiments, l’équipe de recherche a choisi de commencer leur étude par le secteur de

Des chercheurs ont découvert que les émissions de matière particulaire sont dix fois plus élevées qu’antérieurment estimées.

la volaille. En collaboration avec le Poultry Industry Council et LEL Farms, Bill Van Heyst a commencé à collecter des données.

L’air extrait d’un échantillon représentatif de ventilateurs a été forcé sous une hotte unique où des capteurs optiques ont été placés. Le flux d’air et la concentration des particules de moins de 1 µm, 2,5 µm et 10 µm de diamètre ont été mesurés à l’aide de ces capteurs. En comparant la concentration de particules en suspension à l’intérieur du poulailler et dans l’air évacué, il a été possible d’estimer le taux

de matière particulaire relâché dans l’air. Les résultats sont ahurissants: les taux sont dix fois plus élevés que les taux canadiens antérieurement estimés.

« Les particules fines sont problématiques parce ce qu’elles se logent dans les crevasses des poumons lorsqu’elles sont aspirées. En revanche, les particules grossières sont expulsées des poumons lorsque l’on tousse » , souligne Bill Van Heyst.

« En raison de l’intérêt suscité par l’empreinte écologique et de l’étalement urbain, il importe plus que jamais de

>

déterminer jusqu’à quel point l’agriculture est source de pollution atmosphérique » , enchaîne-t-il. Les particules fines proviennent de la nourriture, de la litière, des matières fécales, des plumes et des phanères. Elles peuvent également être formées par une réaction chimique à partir de l’ammoniac présente dans l’atmosphère. De plus, l’ammoniac est un précurseur dans la formation du smog. Certaines statistiques indiquent que l’agriculture est à l’origine de 80 pour cent de tout l’ammoniac relâché dans l’air au Canada. Ces importantes émissions d’ammoniac sont en partie attribuables aux bâtiments d’élevage et à l’épandage de fertilisants et de fumier.

Le chercheur Bill Van Heyst a effectué trois essais – en hiver, au printemps et en été – à l’exploitation de poulet à griller afin de déterminer si le climat a un effet sur les émissions de polluants. Fait étonnant, les émissions sont similaires quelque

soit la saison. Bien que la concentration de particules fines soit moindre en été, le débit de renouvellement d’air est accru, de sorte que le nombre de particules émises demeure stable d’une saison à l’autre.

L’objectif de Bill Van Heyst et son équipe est d’obtenir une évaluation valable des émissions agricoles, de manière similaire aux évaluations des émissions industrielles régies. Dès que tous les secteurs agricoles seront évalués par Bill Van Heyst et d’autres, des normes d’émissions pourront être établies. Ensuite, l’attention sera dirigée vers la réduction et le retrait des polluants atmosphériques.

La prochaine étape pour les deux chercheurs sera d’étudier les émissions d’azote et de matière particulaire par les poulaillers. Par la suite, ils passeront à l’étude de la pollution atmosphérique engendrée par les autres types de production animalière tels que le porc. Ils n’auront pas la tâche facile puisque la

conception et l’aménagement des bâtiments d’élevage varient d’une exploitation à l’autre. Les soins animaliers et le nombre d’animaux diffèrent également. Chaque changement entraîne un accroissement de la variabilité, laquelle rend difficile l’interprétation des données recueillies.

Ce projet est financé par le Poultry Industry Council, le ministère de l’Agriculture, de l’Alimentation et des Affaires rurales de l’Ontario, Agriculture et Agroalimentaire Canada et la School of Engineering de l’Université de Guelph. ■

M. Lloyd Weber de LEL Farms et le professeur Steve Leeson du Department of Animal and Poultry Science à l’Université de Guelph sont également impliqués dans cette étude.

Ashley McCarl est rédactrice au programme SPARK (Students Promoting Awareness of Research Knowledge) de l’Université de Guelph.

1-888-292-2249

Bus.519-367-2848

Fax.519-367-2829

www.brianspoultry.com

At CPSI we take pride in being a solution driven company. We are a Proactive, industry leader that provides long-term commitments to our Customers.

We offer 30 years of experience with a network of crews in various provinces.

We are always looking to expand our network, so whether you operate in British Columbia, Nova Scotia or any point in between, give CPSI a call!

Do you have the right plan?

BY PETER VAN DONGEN, P.AG

If you own a farm today, you live with this simple truth: one day it will no longer be yours. Whether you sell it by choice or through some involuntary circumstance depends to a large extent on having a farm succession plan.

“Succession can be defined as the transition of labour, capital and management of the farm operation,” Allen McWilliam told a diverse group of Island and Mainland farmers at a succession workshop in Nanaimo, B.C., last year. Farm Credit Canada hosted the event, titled “Leave on your terms,” as part of its AgriSuccess series.

“Notice there is no mention of children in that definition,” McWilliam points out. “You have to remember that the successor of the business may not be a family member.”

McWilliam speaks from both personal and professional experience. A chartered accountant for 33 years, he and his wife are active partners in Tannadice Farms Ltd., a commercial pork, beef and chicken farm in Courtenay that caters to local markets.

“We have a succession issue ourselves because we don’t have children,” McWilliam explains. “What we’re doing about that is we’ve included a young couple in the ownership of our farm corporation.”

One of the first steps in the succession process is to understand the complexities of a family business. Whereas a non-family business can apply a “business-first” policy in its planning and operation, a successful family business also requires a shared vision and healthy relationships among family members.

In addition, McWilliam stresses that

succession “is not something that the founder determines alone. It has to involve all of the players, all of the family. And it’s not about dividing up an inheritance equally; it’s about trying to be fair and equitable.”

To simplify the process, he recommends a “three-circle model” that involves three different, often overlapping, areas: family, ownership and management.

The family circle deals with issues of “emotional capital,” such as the key goals, vision, objectives and values of all the family members. Success in this area requires a foundation of empathy, support and trust.

Matters of “wealth capital,” such as tax planning, estate planning and personal financial planning, fit in the ownership circle. This is where you might face

difficult questions like, “What happens if a spouse of the son or daughter in the farm operation leaves the fold?”

The day-to-day decisions that allow the farm to continue to generate wealth are reserved for the management circle. Think of it as the “wealth engine.” Issues addressed in this circle might include strategies for adapting to changes in the market, and managing human resources to avoid burnout.

“The principles are different in each of the three areas of the business,” McWilliam emphasizes. For example, he notes one of the principles of the family circle is to ensure “equal treatment of all members of the family.” However, attempts to treat people equally in the ownership area may cause conflict.

“[Succession planning] is not about dividing up an inheritance equally,” he

• White polyethylene flush mount housing (black available in some sizes)

• Standard design – self draining

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan or Performa+ Leeson motors

• 10" - 60" sizes available

• Available in 24" Variable Speed and 36" Single Speed

• One piece polyethylene housing creates the most efficient venturi, resulting in incredible C.F.M.performance. (24" =10,200 C.F.M. @ 18 cfm/watt and 36" = 15,300 C.F.M. @ 26 cfm/watt.)

• A multi-position bracketallows youto tilt and lock the fan angle and air flow direction

• A cooling system without using nozzles

• Adjustable water volume

• Mobile or stationary unit available

• Use for cooling air, humidity, recirculation, dust and odor control

RECIRCULATION FANS

Circular Recirculation Unit

❑ Poultry Producer or Employee

❑ Government, Libraries, Schools, Universities

❑ Hatchery, Hatchery Employees

❑ Fancy or Show Poultry

❑ Wholesale Produce and Processors, Further Processing

❑ Equipment Manufacturers

❑ Drugs, Laboratories,Vaccine Companies, Chemical

❑ Veterinary and Lab Technicians

❑ Feed Manufacturers, Feed Additives, Distributors and their Salespeople

❑ Other (please specify)

- Payable to Annex Publishing & Printing Inc.

• 16" and 20" diameters

• 3600 coverage using directional wind vanes

• Superb alternative to race tracking

• With Multifan or Performa+ Leeson motors

Circulating Fan

• 12" – 24" diameters • Polyethelyne housing

• with Multifan or Performa+ Leeson motors

The ‘Wave’Environmental Control

• Large 2.75" X 5" LCD Display Screen and 12 Quick Key Pads (to grouped settings) allows easy and precise Temperature, Humidity, Heating, Lighting and Airflow Management

• The ' Wave ' manages 4 variable stages and 8 or 16off/on relays for cooling, up to 8heaters, 4 clock outputs and up to 8 inlet zones

• Humidity control by increasing ventilation and heat activation

• History of water consumption, temperature, humidity and birdcount

• High quality material and aerodynamic air inlet

• Variable speed Performa+ motor

• Dual voltage, fully enclosed motor

• Low energy consumption and noise level

• 16" and 20" modelsproducing 2792 and 4770 cfm

• Includes hanging hardware

Tel: 866-790-6070 Fax: 877-624-1940

Mail: Canadian Poultry Magazine

c/o Annex Publishing & Printing Inc. P.O. Box 530, 105 Donly Dr. S. Simcoe, Ontario N3Y 4N5 e-mail: cnowe@annexweb.com www.canadianpoultrymag.com

GST#867172652RT0001

A SMARTER OPTION FOR ADMINISTERING SOLUTIONS INTO WATER SYSTEMS

• Select Doser performance yields highly accurate dosages all the time.

• Accuracy is 95+ percent, superior to water or electric powered pumps.

• Longer lasting with less maintenance than water powered dosers.

• A diagnostic tool for your watering system.

Unvented Unit Heater

• Total stainless steel construction

• Hi-Low switch

• Watertight enclosures

• Propane and natural gas

• Available in 20,000 to 225,000 BTU units

Totally Controlled Heat from

' The Ultimate Brooder '

• Maximum radiant surface area

• Reliable spark ignition

• Dual safety pressure switches

• Easy, unobstructed access to control components

• Various models for multiple applications (Farms, Garages, Workshops etc.)

• LX-641, LX-642 and LX-644 with optional SVM-1 (Smart Ventilation Inlet Module)

• DIP-1 digital Inlet Positioner

• ECS"M" Series 1, 2, 3, 4 and 5 stage controls

• IC-610 Programmable Logic Computer controls

• Plus numerous ‘Special Application’controls

• 2 yr.warranty

• Material polypropylene

• Will not harbour bacteria

• Easily cleaned

• Large 2' x 4' panels

• Reduces floor problems and breast blisters

• Keeps birds warmer, dryer, more productive

• Durable - minimal maintenance

• Easily installed

• Will not rust or corrode

• High light reduction

• Low resistance to air flow

• Simple Installation • Easy to clean

• Uses P.V.C.snap release spacers

clarifies. “It has to be fair and equitable. Some children may deserve to be treated differently than others.”

Thus, a good place to start is to ensure that succession issues are dealt with in the correct area. For example, business decisions should be based on what is right for the operation, not necessarily what’s best for the family, and vice versa. This helps to avoid what McWilliam calls, “succession paralysis,” where everyone is concerned about doing something and yet nothing gets done.

Common obstacles that cloud the succession process include the fear of losing wealth (“We’ll lose everything if the kids take over!”), fear of losing control (“No one can run this business as well as I can!”) and fear of conflict (“I just don’t think we’ll ever be able to work together.”)

The first two concerns may be addressed by building up wealth outside of the business, training the potential successor or arranging for a more gradual

transition of control. The secret to overcoming the fear of conflict, McWilliam notes, is to focus on the future.

“You need to create a vision of the future of your family and farm business that can be visualized by everyone involved,” he explains. “For some, it might turn out that the only thing they have in common is a vision of not working together.”

The workshop materials included a lengthy list of governance structures and tactics that could be used to improve communication and planning in each of the family, ownership and management circles. At the very least, McWilliam says an annual family business meeting is “almost a necessity.”

“One word that could probably sum up today is communication,” McWilliam told the group. “I think the whole basis of succession is being able to communicate the issues and see them through.”

Agriculture and Agri-Food Canada (AAFC) provides support for succession planning activities through the following two programs:

• The Canadian Farm Business Advisory Service provides up to $2,000 to help producers gain an accurate picture of a farm’s financial status and develop an action plan.www.agr.gc.ca/ren/cfbas/consult_e.cfm.

• The Specialized Business Planning Service (SBPS) provides up to $8,000 on a 50 per cent cost share basis for more indepth planning services. www.agr.gc.ca/ren/cfbas/spec_e.cfm. ■

For more information, contact Peter van Dongen, Sincera Group Communications Inc., at 250-951-0077 or mailto:peter@sincera.ca

This article was originally published in the April 2006 edition of Country Life in B.C.

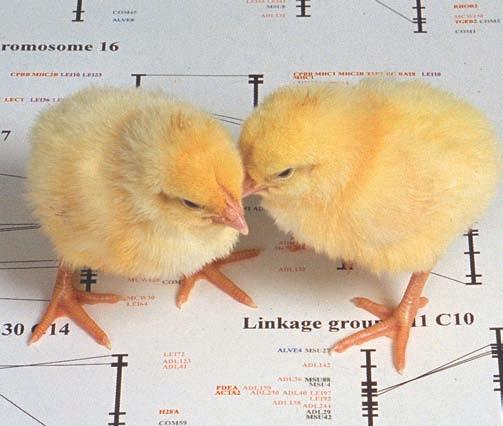

BY AGRICULTURAL RESEARCH SERVICE INFORMATION STAFF

In all animals, obesity results from an energy imbalance that occurs when more food energy (calories) is consumed than the body actually needs.

The excess energy is stored mostly as fat. Over the years, poultry breeders have bred chickens that grow faster and produce more meat in response to a growing worldwide consumer demand. But modern broiler/breeder chickens don’t adequately balance their feed consumption to match their energy requirements. When these birds are given unrestricted access to feed, they will overeat and become obese.

An important biochemical pathway was discovered in animals that maintains energy balance in the body. A key component of the pathway is an enzyme called “AMP-activated protein kinase” (AMPK), which helps to regulate both energy use by individual cells and food intake by the animal. This pathway is currently being studied in chickens and turkeys.

Animal scientists Monika ProszkowiecWeglarz and Mark Richards in the ARS Growth Biology Laboratory at Beltsville, Maryland, along with research leader John McMurtry and Penn State University collaborator Ramesh Ramachandran, recently identified and sequenced the genes responsible for the AMPK pathway in birds and showed that they function in different tissues throughout the body of the broiler chicken.

According to Proszkowiec-Weglarz, AMPK plays a central role in sensing cellular energy levels. It begins a series of events

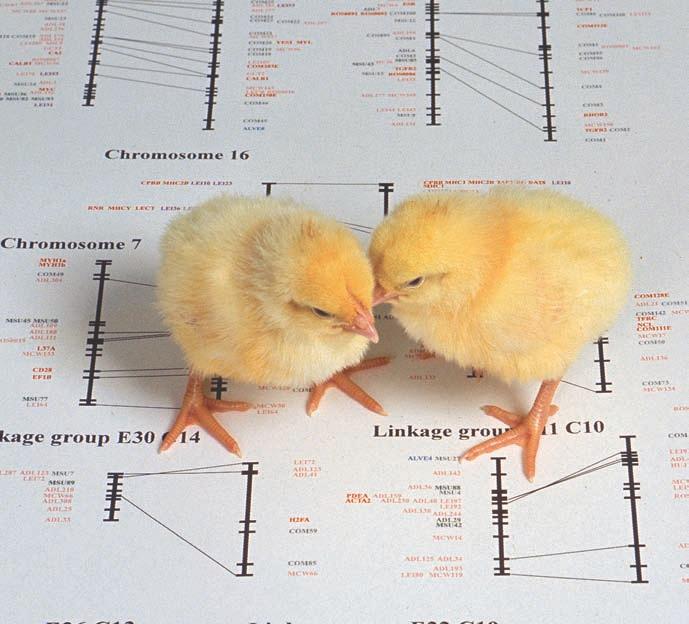

of a genetic map of a chicken. The chicken genome has 39 pairs of chromosomes.

that affect food intake and metabolism of fat, carbohydrate, and protein. “AMPK is really a molecular fuel gauge and a master metabolic regulator in cells,” she says. “It responds to fluctuations in the levels of cellular energy and of specific extracellular nutrients and hormones.”

Cells obtain energy from conversion of adenosine triphosphate (ATP) to adeno-

sine monophosphate (AMP). “AMPK senses the ratio of AMP to ATP and works to raise the level of ATP within cells” says Proszkowiec-Weglarz. “Our goal is to learn how the AMPK pathway functions in birds to achieve energy balance, so growers can efficiently produce chickens of optimal weight while minimizing excess fat.

Genetic research is for the birds – and it's a good thing, too, as scientists with the Agricultural Research Service (ARS) are using their knowledge of avian genetics to improve the health of poultry. Genetic information is leading to better vaccines and breeding techniques to protect poultry against health threats such as exotic Newcastle, avian influenza, Marek’s disease, coccidiosis, and mycoplasmosis.

Coccidiosis is an avian disease that costs the poultry industry an estimated $350 million annually. Researchers in the Animal Parasitic Diseases Research Unit, part of the Henry A. Wallace Beltsville Agricultural Research Center (BARC) in Maryland, have been investigating Eimeria, the intestinal protozoans responsible for the disease.

The team, which includes microbiologist Mark Jenkins, zoologist Ray Fetterer and molecular biologist Kate Miska, is conducting research to improve the detection and characterization of the parasites that cause coccidiosis and to improve the effectiveness of poultry vaccines.

The researchers have already developed a method to quickly identify Eimeria species in poultry litter – information that is essential for targeted vaccine application. Their work highlighted the need for a vaccine to control E. praecox, a species for which no broiler vaccines currently exist, even though it occurs in U.S. poultry operations. The BARC researchers have also identified proteins that may contribute to immunity and susceptibility, and they’re collaborating with university colleagues to develop a novel Eimeria vaccine.

“Our research uses a multifaceted approach that combines pathogen genomics with biochemical and immunological techniques,” Jenkins says. The resulting tools could have significant benefits for U.S. poultry, and for those who produce and consume it.

AND MAREK’S

Resistance or susceptibility to diseases such as Marek’s disease virus (MDV) is an inherited trait. Many poultry breeding programs have attempted to breed resistance to MDV, a devastating disease that causes tumors in chickens. By using marker-assisted selection, poultry breeders have improved the speed and accuracy of traditional breeding methods in recent years. Genetic studies have contributed not only to prevention of Marek’s disease, but to treatment as well.

At the Avian Disease and Oncology Laboratory at East Lansing, Mich., geneticist Hans Cheng and his colleagues have developed a clone of a virulent and infectious MDV genome that is contained within a bacterial artificial chromosome, which they will use to investigate the functions of specific genes. This information can be used to improve MDV treatment.

“It will enable us to associate specific genes and variations within these genes to variations in phenotypes,” Cheng says. “For example, we could identify what genetic changes lead to greater virulence. Then we could develop vaccines that target the individual genes involved.”

Cheng’s genetic studies have also shed light on the nature of MDV. In one study, Cheng and his colleagues observed an unusual immune response in MDV-infected chicken cells. Unlike other viruses, MDV leads to an increased presence of an antigen known as “MHC class II” on the cell surface.

“Most of the time, viruses try to fly under the radar without attracting the immune system’s attention,” Cheng says. Increasing the presence of MHC class II proteins, however, attracts T cells to the area. But it does so without harming the virus. The ARS team suspects that MDV may upregulate MHC class II in order to manipulate the T cells, which it uses to spread to new cells. Further research is required to confirm the accuracy of this hypothesis.

Scientists at the Southeast Poultry Research Laboratory (SEPRL) in Athens, Ga., are determining the gene sequences for two major poultry respiratory diseases. Avian influenza virus (AIV) and Newcastle disease virus (NDV) target chickens, turkeys, and wild aquatic birds. A recent study compared North American H5N1 subtype viruses to the pathogenic viruses that have been causing trouble in Asia.

“The analysis revealed that the North American viruses are nonvirulent and distantly related to the viruses in Asia, with 75 to 79 percent similarity between the genes for the North American and Asian viral surface proteins,” says microbiologist Erica Spackman.

Spackman and her colleagues are investigating how AIV spreads, but further research is needed to determine how genes are involved in the process. Initial studies show a complex relationship between the virus and its avian hosts, with the disease’s progression affected by the interaction of multiple gene products. A related project, in which scientists are sequencing the complete genomes of 1,000 AIV specimens, could help by significantly expanding the existing information on AIV sequence data.

Safe to use humans, animals, environment

Multiple applications foam, spray or fog

Proven effective against most harmful disease causing agents

Non-corrosive to your equipment

Cost-effective based on your real needs THE PERFECT CHOICE in your Cleaning and Disinfection Program !

Genetics research can also identify potential problems before they become problematic. While examining the virulence and diversity of NDV, SEPRL scientists identified 11 previously undescribed viral genotypes.

“Some of the wildlife viruses were found to be closely related to isolates from U.S. live bird markets and genetically distinct from NDV used in live vaccines,” says microbiologist Claudio Afonso.

This, coupled with the discovery that the USDA real-time assay used to identify NDV was unsuccessful at identifying class I viruses, suggests that the virus could circulate undetected between wild birds and poultry. This information can help scientists, poultry industry professionals, and policymakers decide how to best use their resources. ■

•

•

• LivestockDairy

• Poultry-Farm Positions

• Organic Farms

• Agricultural Warehouse Jobs

• Horticulture & Greenhouse jobs

• Berry/Fruit/Vegetable Farm jobs

• Tree Planting Crew CONTACT

130 ROSSLAND ROAD EAST BOX # 51118 AJAX,ONTARIO L1T 4S0 647-242-6560 (t) 647-722-3751(f) Email:farmplacement@yahoo.ca www.optimafarmplacement.com

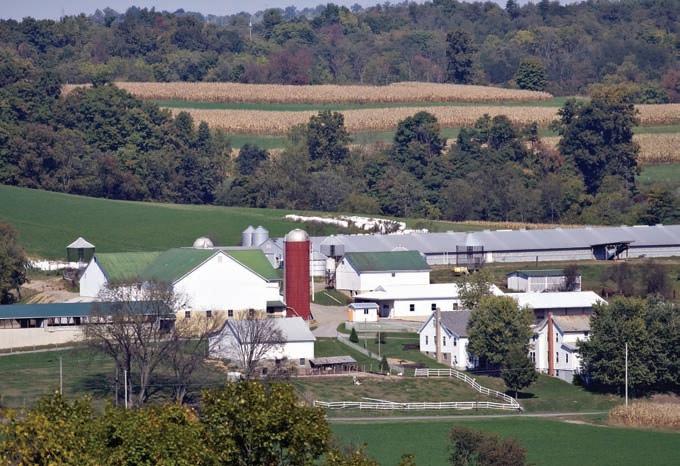

BROILER

Good location with 18,658 units broiler breeder quota. 1 grower barn and 2 layer barns.

10 acre broiler farm with 36,600 units broiler quota. 3 Barns and insulated and heated shop. Beautifully renovated log home with 5 bedrooms.

BROILER BREEDER FARM

60 acres with 2 barns (50’ x 300’ and 44’ x 289’), 9126 + 1300 units annualized quota.Vencomatic & Van Gent nesting & egg gathering systems. 1230 sq. ft. bungalow with 5 bedrooms.

K. MILLER REALTY, BROKERAGE

Each office is Independantly Owned And Operated 220 BROAD ST EAST, DUNNVILLE, ONTARIO N1A 1G2 Phone 905-774-7624 or Toll Free 1-888-718-8445 Fax 905-774-5960

MODERN BREEDER FARM: 12,000+ HEMS. 2 barn operation. Jansen Nests, plastic stats, nipple drinkers. Standby generator. Drive shed. 4 bdrm, 2 bath home. 48 acres sandy loam soil.Tiled. Paved Road.Call Jack.

GRIMSBY AREA: 32,000 sq. ft. of barns with auto generator. 3 bdrm century home, pool. 40x60x2 building used as retail outlet. Call Jack for more details.

NIAGARA AREA: 45,000 sq. ft. of barns, small acreage, 3+2 bdrm home, natural gas heat. Nipple drinkers, pan feeders, radiant tube heaters. 14,000 Quota available at market price. Indoor pool and paved road location.Call Jack.

EXECUTIVE FARM ON 30 ACRES: Brick 4 bdrm, 4 bath home. Hardwood floors and ceramic, full finished basement with 2nd kitchen. 2 car garage-workshop and large barn rented long term at $800.00/month. Paved road. Priced at $599,000.00 Call Jack.

QUOTA: 8,000 H.E.M.S available. 200,000 lbs Turkey Quota. Call Jack for details.

Okanagan Broiler Farm with 30k quota, new barn with Chore-Time equip, large 2500+ sq. ft. rancher style home, large shop, 43 prime farmland acres, close to city, schools and all amenities, on city water, pavement, 3 phase power,10 mins to processor, hatchery and feedmill. Andre 250-215-1223

JUST LISTED: Broiler Breeder Farm. 19,000 H.E.M.S. 2 barns 45’ x 480’. 90 acres. 4 bdrm home.Call Jack for more details.

Jack Huitema,Broker of Record (res.) 905-774-8291 jack-huitema@coldwellbanker.ca Richard Vyn, Broker (res.) 519-674-2434 rvyn@ciaccess.com

Ross Emerson, Sales Rep. (res.) 905-899-1056 remerson@sympatico.ca www.coldwellbanker.ca

Big

Braemar

Veens, Real Esate Broker Tel: 519-522-0667 Fax: 519-522-0668 aveens@tcc.on.ca

acearle@ripnet.com

Steinbach Hatchery & Feed ................................31

Sure Foot Slat Systems.......................................25

Turkey Farmers of Ontario ...................................27

Vétoquinol ............................................................17

W. Murray Clark .............................................11, 27

Weeden Environments ..................................20, 25

This new book provides an up to date look at all aspects of broiler breeder production and management,starting with specialized genetic programs as developed by the primary breeders and ending with two chapters on very practical, hands-on aspects of breeder management.There is extensive coverage of: health management,feeding systems,environmental control, lighting programs and all aspects of male and female reproduction.Together with extensive tabular material and line diagrams,there are numerous photographs that fully depict critical aspects of breeder management.

Item #: 0969560036

$68.00 $70.00 Broiler Breeder Production Commercial Poultry Nutrition - 3rd Edition

Commercial Poultry Nutrition has become the standard text for all involved in the various poultry industries.This new 3rd edition is a major revision with virtually all sections being updated to accommodate the ever-changing genetic potential of broilers,layers, turkeys and waterfowl.The new edition emphasizes nutritional programs that allow for genetic potential to be realized in both meat and egg birds.However, it is realized that achieving maximum growth rate,for example,may not always be the most economic way to feed birds in certain situations,and so there is emphasis on alternative strategies for feeding and nutrition. Item #: 0969560052

BY JIM KNISLEY

Aman walks up to the bar and says: “I’ll take 100,000 tonnes of wheat.” The lady behind the counter replies: “Certainly sir.” She then yells to her co-worker: “100,000 thousand tonnes of oats.”

The customer perks up and says: “I’m sorry, I want wheat.” The lady says: “Certainly sir,” but doesn’t change the order.

When the order appears from behind the counter, it’s oats.

“What’s going on, I twice specifically ordered wheat and you’ve given me oats.”

“Well sir since we’ve run out of wheat, oats is the new wheat.”

He ponders the problem. “Oats,” he says, “are for horses and Scotsmen. I have no horses and I’m not Scottish. How about some barley?” “Certainly sir. 100,000 tonnes of oats,” she shouts.

“Oats is the new barley,” she explains.

“But I don’t want oats. I don’t need oats,” he says.

“Well sir, in that case, we can put you on our special priority, enhanced delivery program for wheat and barley.”

“That’s terrific,” he says. “When can I expect them?”

“Would next November be too early,” she asks?

“Next November,” he sputters.

“Yes sir,” she says. “But, of course, delivery is conditional on availability which is conditional on weather and whether there is any left after we serve our triple and double priority customers.”

“Of course you could always order corn,” she said “and you might just get some if some of those new ethanol plants in Iowa don’t come on line this year.”

The customer leaves muttering, sputtering and shaking his head. “What was all that?” a voice calls out from the back room.

“Just more shock and awe as another customer gets used to the new world order,” she says.

Barley also looks attractive. When brewers start complaining about tight supplies, you know more is needed.

But everything else looks good too. Corn prices are down from the record highs of a year ago, but some analysts, who believe acres will move out of corn this year, are forecasting $5 a bushel corn and tight supplies.