recent report on the carbon neutrality of biomass has ruffled some feathers in the biomass community.

The Impacts of the Demand for Woody Biomass for Power and Heat on Climate and Forests, a report created by Chatham House, a London, U.K.-based international affairs think tank, questions treating biomass as carbon-neutral at the point of combustion. The U.K.’s Renewable Energy Association (REA) appeared to be less than impressed.

The REA responded by stating that the report had several misleading claims, including that carbon emissions from biomass energy production are generally at higher levels than from fossil fuels. The REA responded to this particular claim by stating the following:

report “ignores the significant body of peerreviewed academic studies that verifies the contributions from biomass power in mitigating greenhouse gas emissions and in supporting forest growth… The fact is that biomass cuts carbon, supports forests, and delivers reliable energy at a lower cost. This report just makes vague statements without evidence and repeats claims that have been analyzed many times and found wrong, which is disappointing.”

The REA were not the only ones to quickly discount the report.

This misses the entire point of the use of biomass. Carbon contained in woody biomass is already part of the atmospheric cycle, whereas burning fossil fuels is adding carbon to the natural carbon cycle. Biomass is low-carbon because the carbon released during combustion is reabsorbed by the growing forests where it was sourced.

Other claims in the report that the REA discounted include that it can take decades or even centuries to reabsorb carbon released by biomass power; that U.K.’s biomass use is resulting in decreased U.S. forest stock; that feedstock derives from harvesting whole trees; that when sawmill residues are diverted from use as wood products to use as energy, net carbon emissions will be higher as a result; and that biomass energy may be more likely to displace other sources of renewable energy rather than fossil fuels.

The REA went on to state that the

FutureMetrics’ William Strauss, a well respected consultant in the wood pellet sector, responded by publishing a white paper called, “Alternative Facts” in the Recent Chatham House Paper, which focuses on discussions related to the sourcing of raw materials for industrial wood pellets.

Strauss states that he is unsure if the author is “naïve about how the forest products industry operates or is purposefully presenting ‘alternative’ facts,” going on to call the study one-sided and wrong in its conclusions.

Want to judge for yourself? Read about the Chatham House report, as well as the REA’s detailed response and FutureMetrics’ white paper by going online to www.canadianbiomass.ca.

I never thought I would be using the term “alternative facts” in an editorial. How times have changed.

Andrew Snook, Editor

Volume 17 No. 2

Editor - Maria Church (416) 510-5143 mchurch@annexweb.com

Editor - Andrew Snook (905) 713-4301 asnook@annexweb.com

Contributors - Gordon Murray, Taylor Fredericks, Lesley Allan

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Angela Simon

Circulation Manager Carol Nixon – cnixon@annexweb.com 450-458-0461

COO Ted Markle – tmarkle@annexweb.com

President/CEO Mike Fredericks

Canadian Biomass is published six times a year: February, April, June, August, October, and December. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $49.50;

Single Copy - $9.00 (Canadian prices do not include applicable taxes)

CIRCULATION

Tel: (416) 442-5600 ext 3552 Fax: (416) 510-5170 blao@annexbizmedia.com 80 Valleybrook Drive, Toronto, ON M3B 2S9

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2017 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.ca

The Alberta government is giving 31 bioenergy companies shortterm funding while a new policy is drafted to support the growing industry.

According to a government news release, a third-party adviser and other stakeholders are advising government on new policy options to build on the expired Bioenergy Producers Credit Program. A report was expected by the end of March. The grants have been given to producers of biofuels, electricity, heat or wood pellets, and are based on how much bioenergy each company generates. Three of the recipients getting funding have projects under construction, representing $200 million in new investment for the province.

“We are excited to hear that bioenergy’s role in the fight against climate change is recognized,” stated Stefan Michalski, director

Equipment and operational issues as well as an uncertain market for wood pellets are behind Rentech’s decision to idle its pellet plant in Wawa, Ont.

The Wawa facility replaced problematic conveyors last fall but continued to experience equipment and operating challenges, the company recently stated. Idling the plant will allow Rentech to conserve liquidity as it formally explores “strategic alternatives for the plant including ongoing discussions with third parties.”

“While we believe that the issues we have been

experiencing at the facility can be resolved with additional capital investments, we have concluded that it is not economical to pursue those investments or to continue to operate the facility at this time,” the company stated in a recent news release.

Rentech expected the idling period to be completed in early March, during which time a small group of employees will maintain the plant to keep it in working order for potential buyers.

Rentech’s Atikokan wood pellet facility is reducing its

of operations, Lethbridge Biogas LP. “This money is important to support biogas facilities like ours and to keep Albertans working as we build a self-sustainable, lower-carbon future.”

The funding is part of the province’s $60-million Bioenergy Producer Program.

“Bioenergy producers are job creators and technology innovators. The Alberta government is committed to supporting them, their employees and local economies as we diversify our energy sector, boost our economy and reduce emissions in Alberta,” said Government of Alberta Minister of Environment and Parks Shannon Phillips.

Alberta’s bioenergy industry powers the equivalent of 200,000 homes and contributes about $800 million to Alberta’s economy.

production to a level of 45,000 tonnes per year, which meets the company’s contract with Ontario Power Generation. The facility will stop shipping pellets to the Port of Quebec.

“We expect the Atikokan facility to generate cash flow in the range of break-even to slightly positive in 2017 under

Cascades and the Quebec government are investing $11.3 million in two residual forest biomass boilers at the Cascades Containerboard Packaging Cabano plant in Témiscouata-sur-le-Lac, Que.

this revised operating plan,” the company said. Sales at the company’s New England Wood Pellet were negatively impacted by the warm winter and low cost of heating oil and propane, but the company believes the issues are temporary and expects business to return to historical levels of profitability.

The Quebec government will contribute financial aid in the amount of $5.2 million for the two projects, while Cascades will invest $6.1 million.

“Projects like the ones announced today are part of a long list of environmental initiatives that have made Cascades a leader in sustainable development,” said Mario Plourde, president and CEO of Cascades.

The projects involve modifying two residual forest biomass boilers. One boiler will be upgraded with automated controls. The second, more ambitious project involves installing a new combustion chamber and combustion air preheater to the other boiler. These projects will allow the plant to improve boiler operating time and efficiency while limiting the use of another boiler that consumes heavy-fuel oil.

Pinnacle Renewable Energy Group, a major pellet producer in B.C., is responsible for the majority of the Port of Prince Rupert’s success in 2016, according to port representatives.

Michael Gurney, manager of corporate communications for Port of Prince Rupert, told The Northern View that the port’s Westview Wood Pellet Terminal moved 896,257 tonnes of cargo last year, an increase of 22 per cent from 2015 numbers, and the most volumes the terminal has ever moved.

“[It’s] such a great made-inB.C. success story, with Pinnacle Renewable Energy Group producing the wood pellets from essentially waste products,” Gurney said.

Pinnacle Renewable Energy Group owns and operates seven pellet plants across British Columbia.

Airex Energy officially inaugurated its biomass torrefaction plant, located in the La Prade industrial park in Bécancour, Que. in late February.

The industrial-size demonstration plant, which required around $10 million in public and private investments for its design, construction, and start-up, showcases biomass torrefaction technology CarbonFX. This technology, designed by Airex Energy, significantly reduces greenhouse gas emissions for many industries still using coal or coal by-products.

Airex Energy’s torrefaction process transforms biomass residues into biocoal pellets, a clean and renewable fuel that can replace coal and oil.

Biocoal’s unique properties allows it to easily disintegrate, so it can be ground up and combined with bituminous coal in thermal power stations producing electricity, without major changes to existing systems for handling, storing, and grinding coal.

The CarbonFX system also produces biochar, a product with a high carbon content used for soil remediation, liquid filtration and metal reduction. Biochar, when mixed with compost or peat moss, promotes plant growth. Biochar also helps reduce metals and enables rehabilitation of

former mining sites.

Airex Energy’s business model is to export its CarbonFX systems worldwide. The entire forest industry, including sawmills, pulp and paper, and wood pellet producers, is Airex’s primary market for the CarbonFX systems.

The processing of wood residues into value-added products can allow companies in the sector to increase their profitability while diversifying their sources of income. And because of its simple design and small footprint, the CarbonFX technology is cost-competitive.

Since December 2015, Airex Energy has conducted a gradual commissioning of the plant’s equipment and performed several tests to optimize the process. The company started commercial biocoal and biochar production with the goal of producing 15,000 tonnes annually from residual biomass such as forest residues, sawdust, bark, and recycled wood for current and future clients in Canada and the U.S. Canadian Biomass recently published a full-length feature on Airex Energy’s biomass torrefaction plant titled, “Airex Energy poised to scale up biochar technology.”

To read the full-length feature online at www.canadianbiomass.ca or check out the January/February digital edition.

Harbour City Solutions (HCS) consortium has been selected as the preferred proponent to build the Hamilton Biosolids Management project in Hamilton, Ont.

The announcement was made by Maple Reinders Group Ltd., which has a 50 per cent interest for design, construction and capital works of HCS.

The project is being delivered through a public-private partnership (PPP) using the design-build-financeoperate-maintain model, with a 30-year contract operations term.

The Hamilton Biosolids facility will treat all of the city’s biosolids processed by their wastewater treatment system using an advanced thermal drying process, the first of its level of quality and reliability in the province.

The new facility will produce ‘Class A’ pellets which will be sold to the agricultural community as a slow release organic fertilizer, or to coal burning industrial facilities as a renewable fuel replacement for coal.

This technology will also greatly reduce the number of transport trucks required to remove solids from the plant on a daily basis, greatly improving air quality in the area.

“A large number of the civil projects that Maple Reinders has constructed in our 50-year history have been in the water and wastewater sector,” said Reuben Scholtens, Maple Reinders’ director of infrastructure development. “As an established leader in the design, construction and commissioning of these types of treatment facilities, we

welcome the growing popularity of the PPP model to deliver projects in this sector. The City of Hamilton’s leaders and their advisors were able to transfer risk from the municipality, while retaining cost certainty and maintaining ownership. They should be commended for making this project a reality for their citizens.”

The Hamilton Biosolids project is the third municipal biosolids-focused public-private partnership project in Canada and the second to secure federal funding from PPP Canada.

HCS plans to reach financial close in March of this year and immediately upon notification thereof will commence with design and construction.

Source: Maple Reinders Group.

By Taylor Fredericks

Arecent study aimed at identifying untapped biomass hotspots in Canadian forests has produced findings that could help Canada to mobilize its wood-based bioenergy supply chain.

The study – a collaboration between researchers with the Canadian Forest Service’s (CFS) Laurentian Forestry Centre and Université Laval’s Faculty of Forestry, Geography and Geomatics – used remote sensing technologies to estimate the spatial distribution and theoretical availability of biomass sourced from harvest residues and fire-killed trees nationwide.

“We were trying to quantify, estimate, and locate where the potential for bioenergy existed from harvest residue and fire-damaged stands,” explains Nicolas Mansuy, a forest landscape researcher and the principal author of the study. “We wanted to see if you could use these resources, and gain an idea of the variability and volume available each year.”

Using maps detailing Canada’s forest attributes, as well as annual fire and harvest data between 2002 and 2011, Mansuy and his fellow researchers were able to calculate annual estimates of biomass availability for both harvest residues and fire-damaged trees – no small feat given the unpredictable nature of forest fires.

“The harvest residue is pretty stable year over year,” he acknowledges, “but the fire is more volatile, because we don’t know where the fires will hit the forests each year.”

What the researchers found was an abundance of untapped and potentially viable biomass material.

“We have a lot of clearcuts in Canada, and a lot of fires, and based on those disturbances we have a lot of residues that are not being used by traditional forestry.”

The study’s findings, which were first published in the scientific journal Biomass and Bioenergy, could have a significant impact on the provincial, national, and international outlook for the biomass supply chain in Canada. First, though, researchers will have to work with regional and provincial stakeholders to validate their findings on the ground and assess the viability of establishing cost-effective supply chains.

For his part, Mansuy is hopeful that the study, which is the first of its kind to attempt a nationwide biomass inventory using a remote sensing approach, will ultimately facilitate comprehensive assessment of biomass location, costs and logistics, support decision making in the bioenergy sector, and help to establish consistent national biomass metrics in the years to come.

“It’s really hard to knock on the door of each province and ask about their biomass inventory,” he explains. “The benefit of the remote sensing is that we can work nationally, and use the same method to collect new information and reach our calculations each year. Besides, the quality and the resolution of the product are going to improve in the near future.”

While the study’s findings could prove a real boon for biomass stakeholders in Canada – where they could help spur BioFuelNet Canada’s vision of a sustainable and globally competitive Canadian bioeconomy – they will likely also be well-received in Europe, which depends on bioenergy to a much greater degree than Canada due to government policy and its relative dearth of oil and natural gas reserves.

“The demand for renewable energy is very high in Europe,” Mansuy says. “The European market is already very robust, so they require a lot of imported biomass both from the U.S. and Canada.”

Mansuy stresses, however, that the key in any future development – whether it’s the establishment of regional supply chains, or more significant export agreements – will lie in developing practices that are environmentally sustainable, an important facet of supply chain development that other nations have overlooked in the past.

“In Canada, the sustainability of biomass harvesting is very important,” he says. “It’s a great advantage for us to have so much biomass here in our country, but we want to ensure that we’re managing it properly to maintain healthy ecosystem resilience. It’s important to leave an appropriate amount of residue in the forest to maintain the ecosystem there, so we have sustainability constraints that we have to take into consideration.” •

TBy Gord Murray, WPAC executive director

he Government of Canada and the Wood Pellet Association of Canada (WPAC) jointly sponsored the Central European Biomass Conference (CEBC), which took place in Graz, Austria from Jan. 18 to 20, 2017. One of our ongoing objectives is to position Canada as a reliable source of high-quality, sustainably produced wood pellets and the CEBC presented a good opportunity to do this. It is essential to continually reinforce to our European customers that our raw material comes from the most sustainably managed forests in the world.

In his opening remarks at the conference, Mark Bailey, ambassador of Canada to Austria, described Canada’s commitment to forest management and the government’s support of the wood pellet sector.

David Patterson, on behalf of the Canadian Council of Forest Ministers (CCFM), also gave a presentation, as did I. My presentation focused on Canada’s wood pellet sector, while David’s presentation described Canada’s forests, our country’s forest management regulatory framework, and Canada’s rank as the No. 1 country in terms of third party certified forests. With 166 million hectares of certified forests, Canada’s total is nearly four times that of second place United States at just 47 million hectares.

The CEBC is held every three years, attracting more than 1,100 participants from all over the world.

There is a home building fair attached to the conference, which showcased the latest in biomass boiler technology. The fair attracted 40,000 visitors. Austria is a leading bioenergy user with 17 per cent of its total energy and 57 per cent of its

renewable energies being created with biomass.

In addition to attending the conference and hosting our exhibition booth, together with Canadian Trade Commissioner Nicole Mothes we met with several companies – including numerous pellet boiler manufacturers – who are interested in co-operating with WPAC and in doing business in Canada. These included Bioenergy 2020+ GmbH, Die Österreichische Forschungsförderungsgesellschaft (FFG), ETA Heiztechnik GmbH, Kraft & Wärme aus Biomasse GmbH (KWB), Fröling Heizkessel- und Behälterbau GmbH, Hargassner GmbH, HERZ Energietechnik GmbH, H. Stocker GmbH, Schmid Energy Solutions, and WVT Breiding GmbH.

As a result of our meetings, WPAC is co-operating with Bioenergy 2020+ GmbH. This federally funded Austrian company is engaged in applied bioenergy

research including wood pellet combustion.

We are trying to put together a joint project with two objectives: (1) to convince Canada’s provincial boiler safety authorities to accept the Austrian biomass boiler standard EN 303-5 so as to facilitate the import of Austria pellet boilers to Canada; and (2) to establish a biomass boiler education and demonstration centre, likely in Eastern Canada.

If successful, Austrian boiler manufacturers will benefit by increasing their exports to Canada and potentially by establishing Canadian manufacturing.

Canadian wood pellet producers will benefit from increased pellet demand as more boiler systems are installed in Canada.

During the CEBC, a full day was devoted to the European pellet sector. This included presentations from Austria, the Baltics, Bosnia and Herzegovina, Croatia,

France, Germany, Italy, Serbia, Slovenia, Sweden, and Ukraine. Here are a few highlights:

• The ENplus quality certification now exceeds 700 certified companies and 8 million tonnes of annual production.

• Europe’s pellet production in 2015 was 14.1 million tonnes. Total consumption was 20.3 million tonnes. Interestingly, the pellet heating sector, at 10.3 million tonnes, made up 51 per cent of consumption – outpacing the highly-publicized utility mega-projects like Drax Power and Dong Energy. Assuming each European home consumes about 2.5 tonnes per year, the European pellet heating sector has an estimated 4 million customers.

• The top six producing countries were Germany (2.0 mn t), Sweden (1.7 mn t), Latvia (1.6 mn t), Estonia (1.3 mn t), Austria (1.0 mn t) and France 1.0 mn t).

• The top countries consuming

pellets for heat were Italy (3.1 mn t), Germany (2.3 mn t), Denmark (1.8 mn t), Sweden (1.6 mn t), France (1.0 mn t) and Austria (0.9 mn t).

• Stoves continue to outpace boilers. In Italy, stoves make up 95 per cent of consumption and boilers just five per cent. In second place is Germany, where stoves make up 60 per cent of consumption and boilers 40 per cent.

• Small European countries are rapidly building pellet production capacity, nearly all of which is ENplus certified. Production from new market participants as of 2016 included: Ukraine 360,000 t (plus 1 million tonnes of pellets made from straw, peat, and sunflower husks), Serbia (250,000 t), Croatia (232,000 t,) and Slovenia (110,000 t).

Europe continues to be Canada’s most important market for wood pellets, accounting for more than 80 per cent of Canadian exports. Most are destined for

the industrial power sector in the U.K., Belgium, and the Netherlands.

Canada continues to have a small but steady presence in the Italian residential heating market.

Our participation in the CEBC enabled us to reinforce the reputation of Canada as a reliable supplier of high-quality, sustainably produced wood pellets for the power sector.

It also gave us an opportunity to pursue co-operation with Austrian boiler manufacturers, which could help us grow pellet consumption in Canada. It is remarkable to see how two tiny countries like Estonia and Latvia have emerged as major producers that together rival Canada. And other European countries are rapidly increasing their pellet production.

To sell pellets in Europe, the most important factors are: (1) evidence of sustainability, (2) quality, (3) financial strength and reliability and (4) competitive pricing. Canada must continue to build its reputation in all these areas in order to maintain and grow market share. •

AMANDUS KAHL USA Corp. 105 Hembree Park Drive, Suite L Roswell, GA 30076, USA 001-770-521-1021 sales@amanduskahlusa.com akahl.us

AMANDUS KAHL GmbH & Co. KG SARJ Equipment Corp. 29 Golfview Blvd Bradford, Ontario L3Z 2A6, CANADA 001-905-778-0073 rbmacarthur@sympatico.ca

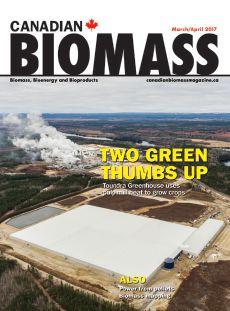

Heat and CO2 coming from the Resolute pulp mill will power one of the most efficient greenhouses in the country, the Toundra Greenhouse.

By Guillaume Roy

It’s -10 °C outside

48.65° North.

and a foot of snow already covers the ground. An intense orange light appeared in the Northern Lac Saint-Jean skies just over a month ago showing some signs of industrial development. But forget about any forestry or aluminum development like the region is used to. This time around, it’s all about cucumbers.

And it’s big – a $38 million greenhouse project spreading over 8.5 hectares of land. Inside, state-of-the-art Dutch technology produces amazing results: 360 cucumbers growing per square metre, much more than the forecasted 275 per square metre.

“It is now the most productive greenhouse in Canada,” states Eric Dubé, Toundra Greenhouse general manager, who compares the productivity to Quebec’s (80 cucumbers per square metre) and Canada’s (200 cucumbers per square metre) average. This means the production that started in November should reach a much bigger figure than the 45 million cucumbers projected.

At the greenhouse’s inauguration on Dec. 14, 2016, everybody was celebrating the creation of 200 new jobs in this rural area. Local investors, Eric Dubé, Caroline and Bertrand Fradette, are particularly thankful to Richard Garneau, CEO of Resolute Forest Products, who not only believed in the project, but also convinced his board to invest in the project to become a 40 per cent shareholder of Toundra Greenhouse.

Quebec Premier Philippe Couillard,

who is also the local MP, was also a key player in the project.

“The government officials never saw a project like that before and all doors were closed at first, even when I was asking,” Dubé said. “We need to learn lessons and use this story as a case study to be more open to innovation, because we have great opportunities to innovate in rural areas.”

Indeed, the project had to go through many phases and countless problems before the first cucumber was harvested in November.

When I moved to St-Félicien, Que. in 2008 – a village of 10,000 people about 450kilometres north of Montreal – the agrothermal park dreamt by the local mayor, Gilles Potvin, was already a latent project looking for a promoter.

Potvin started dreaming about this in 1989 when he was the town’s industrial commissioner. Back then, wood residues were a problem and people were looking for ways to use them to create value.

That’s when a co-generation plant idea came up. The plan: turn the wood residues into power. A good but kind of wasteful idea when we know that 80 per cent of the power generated is lost in the form of heat.

Potvin then came up with the idea of an

agrothermal park. The extra heat could be used as an industrial economic development lever to develop a 30-hectare greenhouse hub and a 20-hectare industrial area for forest products.

At first, the project looked perfect, but as time went by, wood residues gained value and became scarce as more projects arose.

From $5/ton when the plant was built in 2000, the wood residue price reached $18/ ton in 2006. And since the co-generation plant negotiated a 25-year deal with Hydro-Québec at six cents per kWh, the plant’s future was shaken up.

In 2009, St-Félicien received a $5-million subvention to build the heat-transfer infrastructure from the co-generation plant to a 28-hectare field they bought across the street.

Many promoters evaluated the project but nothing serious came out of it. Who would make a big greenhouse investment that relies on an uncertain energy source?

But everything changed when a new guy in town, Eric Dubé – a Royal Bank investor from Montreal – moved to the region when the bank was heavily investing in agricultural lands.

When accused of land grabbing, the bank stopped its plan, but Dubé stayed in the region to invest in a potato business and other agricultural projects.

Our competitors say we’re old and slow to change. That our machines are ugly. That we’re not on the cutting edge.

We say, “Yup.”

“Old” means we’ve been around for over 100 years—and we’ll be here for 100 more.

“Slow to change” means we don’t do fads. Oh, we’ll turn on a dime to make changes that our customers need. But fads? Nah. We’d rather protect your investment.

“Not cutting edge” means we’re proven. We build what works and we stick with it.

And “ugly”? Well. You don’t need to be pretty to make a damn good pellet mill.

When he met the mayor, he learned about the agrothermal park, a big and ambitious project he liked right away. He then met local investors, Bertrand and Caroline Fradette, who owned a lumber mill back in the 1970s, who also had interest.

In 2015, the co-generation plant was for sale and they prepared to make an offer, but Enel Renewable Energy sold their 21-megawatt power plant to Greenleaf Power.

To find a reliable source of thermal energy they decided to look away from the co-generation plant.

Who was the other industrial partner with heat available nearby? The answer: Resolute Forest Products, with its pulp mill 15 kilometres away from the downtown area.

When Dubé asked for a meeting with Richard Garneau, Resolute’s CEO, in February 2014, he was offered just 10 minutes for his pitch.

“We ended up spending an hour together. This was the beginning of a successful relationship,” Dubé recalled at the greenhouse’s opening ceremony.

Stunned by the proposal to make a business partnership to grow cucumbers, Garneau readily asked, ”Is there a market?” because he needed this kind

of information to convince the Resolute board to jump in.

And Dubé provided it quickly. By July, he came back with a promise from grocery retailer Sobey’s to buy all their cucumber needs after meeting with Yvan Ouellet, the company’s procurement and merchandizing vice-president.

From then on, Resolute agreed to be a 40 per cent partner in the project and to allocate a field close to the pulp mill, but Garneau stated his conditions. Local partners had to come up with a good business plan and use an efficient and recognized technology. The municipality also needed to be a partner and the workforce should be found locally.

“We believed in this bold and crazy project. And today, cucumbers produced here can be found in 450 points of sale in the province,” Dubé said.

Sobey’s commitment helped find the funds, but the hardships were not over. For example, the agricultural zoning had to be changed.

Local acceptability was challenged when the mayor proposed to invest millions of dollars in the water-diverting infrastructure. Construction workers also protested when Dutch workers came to build the greenhouses.

But in the end, the project was completed according to the planned schedule and budget. This is in part

due to the world-renowned greenhousemaking experience of Kubo and Stolze, the Dutch consortium in the venture, which made projects in cold areas like Russia, Finland and Alberta. AAB, a Dutch consulting company, also supervised all stages of the projects.

“We are able to provide the world’s best technology because we have so much experience and knowledge,” notes Peter van der Kraan, Kubo’s financial director. “We can provide the highest productivity at the lowest cost. We can also realize a project like this one very fast.”

Kubo – which has also worked on other projects across Canada – received a $10-million contract with Toundra Greenhouse.

In the greenhouses, an integrated computer system controls more than 700 environmental parameters, ranging from lighting, humidity, fertilizers, and CO2 level controls.

To improve plant growth, extra CO2, coming from the natural gas combustion is injected in the greenhouse, increasing the concentrations from 340 ppm to 800 ppm.

But that’s not all, since CO2 solutions, a carbon capture specialized business, will build its first commercial $7.4-million project to feed the greenhouses with 30 tons of CO2 per day captured from the pulp mill – the equivalent of 2,300 cars off the road. To do so, CO2 Solutions, who already has a 10-ton per day demonstration unit in function, uses an enzyme-based proven technology, says Evan Price, the company’s president and CEO. The project will be completed in 2018.

And that’s not the only byproduct coming from the mill, since 25 per cent of the energy comes from the heat released in the pulp-making processes. The remaining energy comes from TK Topboiler natural gas boilers.

Another particular aspect in the greenhouse is that the plants grow off ground on a stone wool artificial substrate, used primarily as a physical support. Those plants, which receive 20 hours/day of lighting, are irrigated and fertilized simultaneously – a process called fertigation – and all elements not absorbed are recycled.

Likewise, 98 per cent of the water is

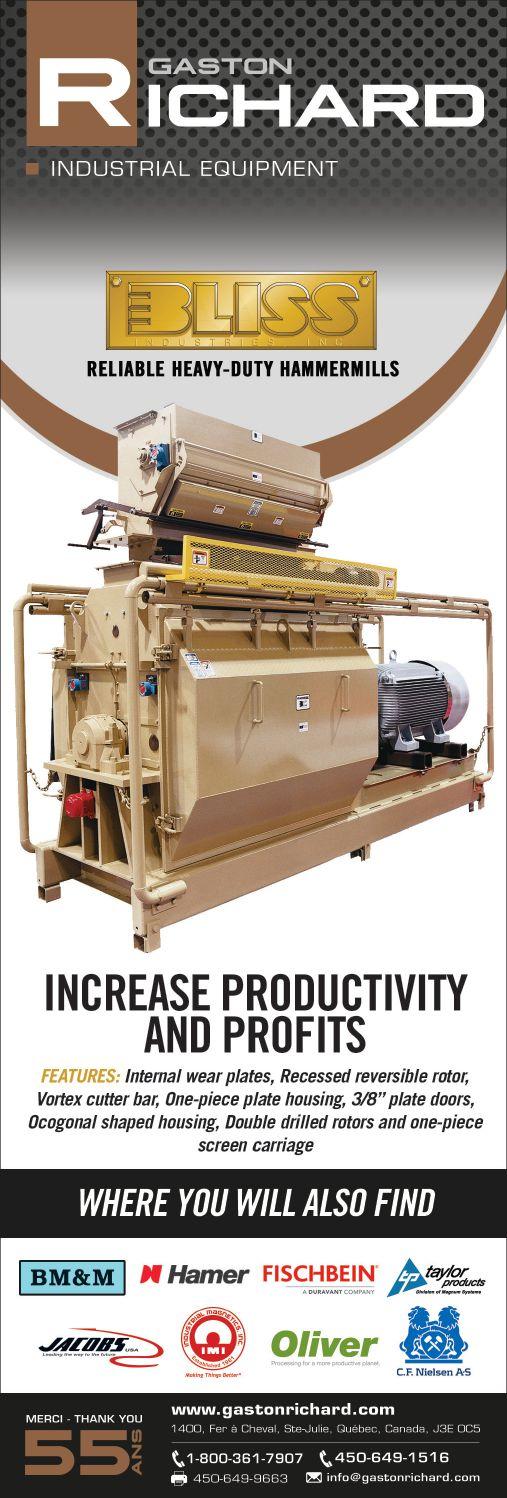

Bliss Industries has the experience combined with 21st century technologies for your size-reduction or pelleting needs. Call today!

Bliss Industries, LLC is a leading manufacturer of pelleting, cooling and size reduction equipment. Founded in 1981, Bliss Industries maintains a reputation of manufacturing the most efficient, reliable and well-built equipment in the industry.

Developed from a design concept proven worldwide, the range of Pioneer Pellet Mills continues to expand. Overall reliability, maximum efficiency, ease of operation and maintenance combine to provide lower operating costs to each owner. With the ability to provide a wide range of die sizes, die speeds and drive power, Bliss can more than meet your requirements for high quality at a reasonable cost.

recuperated from precipitations stocked in basins or recycled through the recirculation system.

Toundra Greenhouse does not use pesticides and prefers to do integrated pest management.

All of this is just the first phase of the $100 million project covering 34 hectares planned over the next years. It’s hard to say when the next phases of the massive project will be built, but the promoters are optimistic. Other vegetables could make their way in the greenhouses and more good news for them: Subway just signed a contract to supply all 600 of Quebec’s and 250 of Eastern Canada’s restaurants with Toundra’s cucumbers. Another step to increase the proportion of locally made cucumbers on the market, previously at five per cent before the Toundra project.

For Gilles Potvin, this project exemplifies the birth of a new ecological industrial era, where waste can become huge opportunities for others. •

By Maria Church Wood

ASCanada works its way to becoming coal free by 2030, Resolute Forest Products, the largest sawmill company in Eastern Canada, is making headway to achieving its goal of fossil-free operations.

One cog in that wheel is a pellet plant that opened on site at Resolute’s sawmill in Thunder Bay, Ont., in October 2014. The pellet plant was built to supply

Ontario Power Generation’s (OPG’s) first fully pellet-fuelled power plant, which opened in Atikokan, Ont., 200 kilometres northwest of Thunder Bay, after a two-year conversion project that same year. (Read about that project at www.canadianbiomass.com.)

“The pellet mill is achieving our capital project forecast,” says Michael Martel, vice-president of forest products operations for Resolute in Ontario and

Quebec, following a tour of the operation in December. The pellet plant is producing 45,000 tonnes per year, with a design capacity of 60,000 tonnes.

The $10-million plant receives sawdust from the Thunder Bay sawmill directly by conveyor, which makes up 81 per cent of the plant’s fibre diet. Another 13 per cent is from planer shavings, which are added to the sawdust mix. The final six per cent is sawdust

shipped in from Resolute’s sawmills in Atikokan and Ignace, Ont.

The resulting pellets are made up of spruce, pine and fir, and are six millimetres in diameter with moisture content between four and six per cent, which is according to specifications by OPG. OPG does not require the pellets to be certified, however, all fibre harvested for Resolute’s sawmills is from certified woodlands.

IS THE FIRST PELLET PRODUCTION FACILITY FOR RESOLUTE.

“We’re fully integrated right now. If you look at Thunder Bay, Atikokan and Ignace, we make lumber at three facilities, we make pulp, we make paper and we make power,” Martel says.

The pellet plant is located just steps from the Thunder Bay sawmill, connected by a series of ducts and conveyors. An outdoor Wellons burner fuelled by bark from the sawmill provides heat for the pellet plant’s TSI dryer. Rodrigue Métal out of Quebec supplies the duct system. Dried wood biomass is then

channelled into the pellet plant where two 400-hp pellet machines, both supplied by Andritz, compress the sawdust and shavings. Law-MarotMilpro (LMM), which at the time was associated with Andritz, supplied the coolers and screens. Once the pellets are cooled, three 100-tonne silos store them before they are shipped to OPG’s power plant.

In 2016 Resolute upgraded the TSI dryer by adding a $500,000 vapour recycling system.

“It’s basically a big pipe with a dampener that allows the system to recycle the air at the outfeed of the dryer and send it back to the dryer,” says Maxime Langlais, general manager for Resolute’s northwestern Ontario sawmills. “It’s giving us more capacity and more stability for drying and also reduces the risk of internal fires.”

Since hot air from the burner is fed directly into the dryer and the sawdust, the plant has a sparks and heat detection system supplied by Flamex. A mist and deluge line prevents accumulation of flammable pitch in the ducts after the dryer. As well, a contractor cleans the ducts with water pressure every month.

There are no further upgrades planned for the plant, however, Langlais says ideally they would consider a system to automatically feed the planer shavings into the dryer, similar to how the sawdust is conveyed directly from the sawmill.

Langlais, who also manages Resolute’s three sawmills, says he’s relatively hands-off the pellet plant now that it is operating as expected. The plant requires just one dedicated staff member, Jeremy Palmer, who is the general supervisor of the pellet plant and kilns. Palmer supervises a crew of around 11 other Resolute employees.

“It’s running well so I don’t have to intervene, Jeremy is taking care of it,” Langlais says. “He was a sawmill supervisor so he had to learn the pellet process, but now he knows more than us and has done very well.”

Learning to run a pellet plant was an adjustment for the Resolute sawmill team, Langlais adds, but “At the end of the day, it’s screws, conveyors, drying and other things that we are used to.”

Yo ur g l ob a l equ ip men t su ppli e r

ANDRITZ is one of the world’s leading suppliers of technologies, systems, and services relating to equipment for the biomass pelleting industry We offer single machines for the production of solid and liquid biofuel and waste pellets. We have the ability to manufacture and supply each and every key processing machine in the pellet production line.

ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb us@andritz com

www.andritz.com/ft

Resolute Forest Products pellet plant in Thunder Bay currently produces 45,000 tonnes a year to supply Ontario Power Generation’s biomass-fuelled power plant in Atikokan. Jeremy Palmer, general supervisor of the pellet plant and kilns, is one of 12 Resolute employees who operate the plant.

The present impediment to increasing production at the pellet plant is a matter of

markets – finding new customers.

“At Thunder Bay we’d like to produce more, but we’re very far from the market,” Martel says. “We’ve had some small shipments here and there that were test shipments, but to produce more we need to reach out and develop our customer base. We’re committed at the current production level with 100 per cent going to OPG.”

Resolute has a 10-year contract to supply OPG with pellets to run the power plant, but Martel is optimistic it won’t be long before the plant is producing more to meet new domestic demand.

“As we go into a fossil-free economy in Ontario – the Ontario government says, ‘Off coal, off natural gas’ – there will be an incentive for people to look at alternatives and those pellets could find their way into that,” he says.

While Resolute has no known plans to build pellet plants at its other sawmills across Eastern Canada due to lack of demand, the company has several other

green projects on the go.

In northwestern Ontario, bark and sawdust from Thunder Bay, Ignace and Atikokan sawmills are funnelled into a 65-MW turbine at the nearby Thunder Bay pulp and paper mill, which is the largest green energy combined heat and power unit in Ontario.

The company has similar co-generation facilities at six other sites, producing a combined 520.7 MW. Those in Canada include a 43-MW facility at Resolute’s softwood kraft pulp mill in Saint-Félicien, Que., a 28-MW facility at their specialty paper mill in Dolbeau-Mistassini, Que., and a 15-MW facility at their newsprint plant in Gatineau, Que.

“We believe in energy and we have a huge drive over the last many years to reduce our carbon footprint,” Martel says. “Our goal is fossil fuel free. We want everything to be green energy. We do use some natural gas in Atikokan for drying wood, and we use some natural gas in Thunder Bay pulp and paper as well, but we’ve dramatically reduced our emissions.” •

By Maria Church

2012, a small algal bioreactor has been operating quietly at St Marys Cement plant in Ontario, absorbing small volumes of C02 and other emissions from cement production to grow microalgae. In 2016, the small pilot project graduated to a full demonstration facility that is capable of churning out up to 50 kilograms of dry microalgae each day, offsetting nearly 100 kilograms of C02 emissions daily.

St Marys Cement was founded in 1912 as a Canadian family business in St. Marys, Ont., 170 kilometres west of Toronto. The company has since had a number of owners including Blue Circle Industries, Lafarge and its current parent company Votorantim Cimentos, which is based in Sao Paulo, Brazil.

The company is a major producer of cementitious materials in the Great Lakes Region with a capacity of more than five million tonnes per year. In addition, the company has 17 aggregate operations in Ontario (CBM Aggregates) to supply limestone and other products.

“C02 is a by-product of the cement manufacturing process and, given the scale of these operations, we have been focused on energy consumption and exploring innovative, new ways to reduce the amount of C02 we produce for a number of years,” says Bill Asselstine, vice-president of technical, sustainability and safety for Votorantim Cimentos’ North American operations.

Over the years the cement producer has reduced its emissions by improving fuel burning to heat its production process. But the algal project has, for the first time, enabled the company to offset emissions created by the chemical process of making cement.

The demonstration project uses a

photobioreactor – essentially a large tank that uses light and concentrated C02 supplied directly from the cement plant to rapidly grow microalgae. Research is now underway to find ways to produce enough microalgae to create a reliable source of biofuel for the facility.

The photobioreactor technology used in the algal project was created by Pond Technologies (then Pond Biofuels), a Canadian company that formed in 2007 to produce algae for nutrients and as a carbon capture solution. In 2012 Pond Technologies partnered with St Marys Cement to introduce the pilot algal biorefinery. The refinery is built next

to the cement plant in order to receive emissions directly from the kiln of the plant.

The National Research Council of Canada (NRC) became involved as a partner in the project not long after it launched, and its scientists continue to provide operational and research expertise. Chief among those scientists is Dr. Stephen O’Leary.

O’Leary is the director of the Algal Carbon Conversion Flagship Program for the NRC, and has been involved in the NRC’s algal research activities for a decade. NRC’s expertise in algae, based in the Halifax area, began in the 1940s when scientists began to study seaweed as a source of gelling and suspending

agents to meet a demand that arose during World War II. In 2008 NRC researchers switched their focus to producing biofuels from microalgae.

“What we found is that, yes, biofuel is an interesting product and environmentally relevant, but what was even more relevant was the fact that to produce the microalgal biomass required to make fuels, we needed large quantities of carbon dioxide and also forms of nutrients like phosphorus and nitrogen; and we wanted to derive those from industrial, municipal, and agricultural waste streams,” O’Leary says.

From there, in 2011, the Algal Carbon Conversion program was born and the NRC began a worldwide search for companies devel oping algal biorefinery technolo gies that would work in Canadian climates. Enter Pond Technologies and St Marys Cement.

“We knew that Pond

Technologies had some experience in developing their technology for real industrial deployment. It wasn’t just something that they would make work in the lab but wouldn’t work in the real world,” O’Leary says.

As with many other industrial processes, the conversion of limestone into cement uses heat and therefore requires fuel. “It requires an immense amount of heat and, as a result, takes a significant amount of energy to manufacture cement,” Asselstine says.

The St. Marys plant fuels its

the removal of carbon dioxide.

At the St. Marys plant, a pipeline has been outfitted to funnel emissions from the cement kiln directly to the algal biorefinery, which is located onsite. The gasses are then released into the photobioreactor – a 25,000-litre box-like structure filled with water and outfitted with LED lights.

Algae cultures are then introduced into the water and feed off the C02, other nutrients and bursts of light from the LEDs, causing them to multiply rapidly. Within a few days, the photobioreactor is filled with the dense microalgal biomass. Once established, that biomass can then be harvested and regrown in a continuous around-the-clock process.

NRC researchers select which strains of algae to introduce into the photobioreactor according to how well they will grow with the cement kiln’s flue gas emissions. Those emissions are mostly C02, but also contain trace quantities of sulphur oxides and nitrogen oxides.

Algae harvested from the St. Marys plant is being used by the NRC to further research the development of biofuels and other bioproducts at NRC labs across Canada. The goal of the project at St. Marys is to recycle C02 emissions and eventually produce biofuels onsite for use in the cement-making process. As with many biomass projects, “Scaling up is the next step, but it’s a challenge,” Asselstine says.

“There are challenges to ramping it up to industrial volumes and amounts. We currently have a 25,000-litre bioreactor. It’s one thing to fill a little beaker with algae, squeeze it and get a drop of oil and it’s another thing to be producing hundreds of tons of it a day. When you get to those huge amounts of material it’s the same process but the logistics get complicated: you have store, move it, ship it and keep it flowing,” he says.

O’Leary says the challenges they face are the same for all research bodies that are studying microalgae for carbon mitigation. The demonstration stage is when researchers can determine how and if the project should scale up.

“It’s giving us data that we can use to begin to do a true empirical analysis of what this looks like at a commercial scale... what the benefit is to the carbon cycle of a commercial scale technology, and if there is an economic business case to deploy at that scale.”

The head researcher says he is optimistic that within 10 years or less the technology for producing microalgal biomass from flue gas will be commercially viable for industry partners. “We’re at the tipping point now,” he says. “Assuming that we’re not hugely disappointed with the data that we collect over the next year and a half, the next iteration of this will be small-scale commercial production within the next two or three years, and then ideally large, full-scale commercial production in five or six years.”

Asselstine confirms Votorantim Cimentos’ St Marys Cement business is in the process of evaluating much larger trials for the algal biorefinery, which could see algae produced onsite in a one million-litre photobioreactor.

“There is a wealth of opportunities that can be addressed by algae, and if we can grow it using our emissions gases than that’s fantastic, and ultimately our industry, and other industries, may be able to convert a waste product into a valuable resource,” he says. •

The Brunette BioSizer is a rugged highspeed wastewood grinder specifically designed for production of a fine consistent product. The Brunette BioSizer is built to be low maintenance with a high inertia rotor with four rows of staggered hammers to provide maximum bites per revolution. This grinder allows for processing of oversized ‘bush-grind’ hog fuel, trim blocks, wood chips, all converted to a small consistent product size for the biomass industry.

www.brunettemc.com

CPM Biomass hammer mills are highly efficient machines, designed to meet the needs of almost any particle size-reduction task. They’re capable of fine-grinding friable and fibrous materials. Biomass hammer mills have standard and optional features for custom grinding and size-reduction solutions and total dependability, so you meet

your pellet standards. The HM Series is a heavy-duty choice for grinding things like wood chips and shavings. They’re built with double-wall box construction filled with vibration-dampening material; double-pivot, full-access doors; replaceable AR235 abrasion-resistant wear liners; a patented regrind chamber; and a mechanical steel tube base to keep your entire operation running smoothly.

www.cpm.net

KAHL’s pan grinder mill is designed for the crushing of wood chips, wood shavings, sawdust and other lumpy biomass. This grinding process is appropriate for wet raw material. The capacity ranges from a few hundred kilograms up to 40 t/h and more. Appropriate for G30 and G50 wood chips pre-grinding for trouble-free fine grinding in traditional hammer mills. Its features include silent operation; minimum energy consumption; low space requirement; without aspiration system, cyclone, filter and exhaust air plants; no ATEX problems; low energy consumption; and no noise protection measures. www.akahl.de/en

TerraSource Global’s Jeffrey Rader brand offers a wide range of hammermills

including F1 and FTE Flextooth Crushers for larger products and Mini-Mill E, 30ABE, and 34ABE models for smaller products and sampling. “E” designations in each model signify the brand’s exclusive E-Z Access technology, which allows for safe, fast and easy access to hammers, rotors and liners. All models are equipped with heavy-duty rotors that can be set up with three, four or six rows of hammers. www.terrasource.com

The Andritz series 6 hammer mill is engineered for maximum mettle. The series 6 features unlimited hammer and horsepower configurations and countless screen and hammer mill sizes, which deliver the perfect configuration for your needs. The key benefits are: high-volume inlet; heavyduty rotor; rugged and durable bearings with temperature sensors; easy access and maintenance; and NFPA compliance. Andritz’s reputation for quality, professionalism and aftermarket support delivers confidence to you to meet your particle distribution requirements. www.andritz.com

BRUKS was selected to provide complete engineering and equipment to process and feed raw wood chips at the Colombo Energy pellet plant wood yard in South Carolina. Material is reclaimed and sent to four BRUKS high capacity hammermills. These BRUKS hammermills have the ability to turn 50 tons per hour of 1” chips into 95 per cent less than 7 mm chips. This size reduction enhances dryer performance and lessens the required dry hammer milling downstream. This complete pellet facility produces 500,000 metric tons of premium wood pellets annually. www.bruks.com

WSM’s Biomass Super Shredder sets a new standard in high volume biomass fibre preparation. Built to be bigger, stronger, and faster – with a massive 48” diameter hammer circle and throat openings from 60” to 88” wide and operating with up to 1,000 hp. Convert high volumes of pre-processed biomass materials (including wood chips, hogged wood, and shredded fibre materials) into consistently sized fibre for use in pellet production, biomass power, co-firing, mulch/ bedding, compost, and numerous other value-added products. WSM Biomass Super Shredders are just part of WSM’s complete line of biomass processing equipment and systems, including bulk feeders, conveying, screening, cleaning, and grinding/milling equipment. www.westsalem.com

The machine is used for preparation of organic substrates for biogas produc tion, wood dust for energy and heat generation, wood-flakes for pellet pro duction and many other applications. The working principle is based on the impact effect. Inside the impact chamber the material is resized with high kinetic energy by the fast rotating rotor and interaction of the particles itself. A final calibration is realized by screens. The ClassiSizer is able to process different and inhomogeneous input materials to variable sized final particles. www.dieffenbacher.com

Bliss Eliminator hammer mills are used in a variety of applications including wood, paper, oil seeds and more. They feature internal wear plates, recessed reversible rotor, vortex cutter bar, one-piece plate housing, 3/8” plate doors, octagonal shaped housing, double drilled rotors and one-piece screen carriage to maxi mize your grinding efficiency. They are offered in diameters ranging from 19” to 52” horsepower ranging from 5hp to 600hp. With a wide range of diameters, tip speeds and drive power available, Bliss can meet all your requirements for high quality equipment. Bliss also man ufactures an extensive line of pellet mills and coolers for biomass pelleting, pro cessing and cooling.

http://en.gastonrichard.com/home www.bliss-industries.com

By Lesley Allan

Edmonton-based Innovative Reduction Strategies Inc., (IRSI) moves forward in alternative energy production with the testing of Ulysses in Drayton Valley, Alta. The pyrolysis system once focused on waste management now looks to biochar and carbon sequestering.

Incorporated June of 2014, IRSI is the industrial equipment designing and fabricating company started by Chris Olson and Bruce Saunders.

The pair met while attending school at the Northern Alberta Institute of Technology (NAIT), where they were part of the alternative energy (AE) program.

With diverse backgrounds, the idea of what is now known as Ulysses, came about following an eye-opening work experience where Olson was the environment manager for another Edmontonbased company.

“I realized that about 60 to 70 per cent of the waste that company was

taking into the landfill was either wood waste, or mixed C&D waste, which, in most situations, is predominantly wood waste,” Olson says.

With this idea in mind, during the last semester of the AE program, Saunders and Olson began a capstone project that allowed them to evaluate the application of pyrolysis for the purpose of waste reduction.

Through the use of an existing updraft gasifier, the two students were able to test their theories, garnering positive results and eventually leading to the cornerstone of their business.

“It was pretty clear that with a wellbuilt system that could operate fairly efficiently you could save anywhere from $300,000 to $600,000 a year in reducing fees,” Olson shares. “So that was the jumping off point for us.”

Through experimentation, as well as experience gained through Saunders’

previous work with similar machines, IRSI was able to simplify the pyrolysis system and address a number of the issues facing current designs.

According to Olson, a continuous feed, and a wider acceptance of feedstock characteristic is one of the things that gives Ulysses an upper hand compared to other machines that thermally treat wood waste.

“Seeing some of the issues with these other types of systems we worked that into the design of our system so that we could get a consistent end-product through the process,” he states.

Ulysses operates by using a conveyor to pull material through the system, where it is met with indirect heating from above and below creating the temperatures necessary for pyrolysis.

A draft affect pulls any syngas coming off the material through the system where it is fully combusted in the thermal oxidizer. Working in tandem with the syngas, propane burners help to

produce the proper temperatures to cook materials.

According to Olson, IRSI chose to reuse rather than capture any wood vinegar or syngas because it can be used by the machine and helps to bring down the cost of running the system.

He points out, however, that these byproducts could be used in additional ways.

“One of the possible additions to our system with future iterations would be a combined heat and power option,” he explains. “Right now electrical energy generation really makes no sense in Alberta because of how cheap everything is, but like a district heating loop, if you were on a site where they had a large thermal requirement our system could combine with that and provide some heat and power there.”

With the engineered ability to run five tons of feedstock an hour, the Ulysses system burns at roughly 450C to 500C and creates an output that is essentially an 80 per cent mass reduction in waste volume.

The length of time required for the material to cycle through Ulysses depends on the moisture content of the feedstock and this information is currently being investigated by IRSI as they work with National Resources Canada (NRCan) and other partners, during their demonstration period in Drayton Valley.

Currently, IRSI is testing how the system works, and the quality of biochar produced, through the use of baled forestry biomass.

Simultaneously the company has also been working with Weyerhaeuser Lumber and processing planer shavings produced by the lumber mill.

“I just think the flexibility and options available for the machine is the selling point,” says Tim Keddy, a wood fibre development specialist with Canadian Wood Fibre Centre, a part of NRCan.

According to Olson, Ulysses is able to produce biochar from a wide variety of biomass, but the operating parameters and quality of the char may vary, which is why

they are working in Drayton Valley to test the machine’s ability to operate with each type of feedstock.

The three main sources available in Alberta from which the pyrolysis system can produce char are:

1. Wood waste, which comes out of construction and demolition sites;

2. Saw mills or the lumber industry,

planer shavings from Weyerhaeuser have been successfully used to create high-quality biochar; and

3. Forestry and agricultural residues, such as the baled forestry biomass currently being tested.

“A lot of technologies that I’m aware of looking to specifically produce biochar do it in batch systems, so they operate a

kiln or some version of that that they load up, cook their material and then empty it out, and then load up and recook again,” Olson says.

“Our system runs in a continuous fashion, so with that comes more consistency in how the end product is produced, and it gives us the ability to treat a wider variety of feedstock characteristic,” he explains. “Essentially only wood is what we would make biochar out of, but we could do it with anything under three-

inch nominal sizing, so we could get right down to very finely ground up sawdust or up to three-inch chips of material.”

Once the tests are complete and IRSI has all the information it requires to consistently produce high-quality biochar the company will become a large producer in Canada.

This is something Olson says was not necessarily expected when the company

first got started as the market was not where it was today.

“We have made a fairly significant pivot in the last six months to a year and our focus as a company is now on producing biochar,” he shares, adding that waste management was a reliable focus for the company to start with because the benefits and versatility of biochar were not yet fully recognized on a commercial scale.

“All of the reports that I’ve been reading over the last six months to a year are saying that the compound annual growth rate for the biochar market is going to be anywhere from 15 to 20 per cent for the next five years,” Olson shares. “So we’re going to see a fairly significant growth in that market and that has kind of developed as we’ve gone through the process.”

Keddy says that the biomass and biochar industry has been getting a lot busier these days as governments, companies, and citizens look at things differently.

“There’s a lot of interest in this industry right now,” he says. “And as we move forward with the bioeconomy, a green economy, and a low-carbon economy so I’m sure it’s a positive for the future.”

With biochar now being the main focus of IRSI and Ulysses, Olson says the system will go through some changes as they look at downscaling due to reduced feedstock, explaining that a waste management focus didn’t always mean that the

quality of the biochar was at its best.

“Realistically the process and the design of the system would stay very similar to how we have it now, just tailored a little more specifically to those wood feedstocks,” Olson says. “Whereas our initial design was to accept a wide variety of feedstock to reduce the waste rather than produce a valuable end product.”

According to Olson, some of the process changes will be small, such as air-fuel ratios, and will continue to be worked out over the next few months as the company focuses in on production in hopes of finally entering the biochar market.

“We have a few people interested in purchasing biochar from us based on meeting certain testing results, which we have met with our initial runs of the planer shavings,” he says. “So from here we want to be able to increase our throughput, if we can, and start building up an inventory, then we’ll be looking to sell that at wholesale in the biochar market hopefully here in Alberta.”

When it comes to Ulysses itself, Olson says the system will take longer to get to market as they continue to test its capabilities, and areas that need improvement.

“In terms of getting another system out and operating, within the next six months would be a good goal to at least to be getting to that area,” he says. “We’ve got a few more months running through the demonstration here and we’ll have to confirm our throughput and show that

we can produce consistent reliable biochar and I think once we get to that point, in the next six month to a year, we’ll be looking at getting another system out and improving upon the things that we’ve learned with this system here.”

And these developments are what peaks the interest of NRCan researchers, who say they will continue to monitor the work being done at IRSI with Ulysses, possibly making use of it in the future.

“[Our] idea is to evaluate the equipment, look at the possibilities and then use it where it fits in the future,” Keddy says. “We look at all different types of equipment for using woody biomass and evaluate the economic feasibility of using different types of feedstocks for that. As more feedstocks become available and as we try, test, and evaluate different types woody feedstocks we will be maybe using

that machine (Ulysses).”

Olson says the types of businesses interested in the Ulysses system itself are those that require or will produce a large amount of biochar and then when the time comes when IRSI is ready to begin releasing individual units they will take a hands-on approach that could be personalized for businesses.

“With the production of biochar and a reduction on what we want to run through the system, we’re now thinking that it makes a lot more sense to be a bit more involved in the actual operation of the system,” he shares. “So realistically what we could see ourselves doing is instead of an all-out sale of the system, we work with the site to set up more of a joint venture type of application.” •

Learn more about the Ulysses system at www.irsi-inc.com.

MONITORING SYSTEM

4B Components Ltd. has released the all-new fourth generation Watchdog control unit for preventative maintenance

monitoring of bucket elevators and conveyors. The Watchdog Super Elite (WDC4) is easy to install and simple to set up. The system processes signals from up to 27 sensors for belt slip, belt misalignment, bearing temperature, pulley misalignment and plug conditions on bucket elevators and conveyors. When an alarm condition is detected the system will log the details, sound an alarm and provide shutdown control of the elevator/conveyor and feeding system.

A new 3.5” colour graphic LCD screen displays the entire system status at a glance. The WDC4 model now supports belt speed monitoring for variable frequency drives (VFD’s), and belt misalignment inputs for contact, pulse and temperature (brass rub block) sensors. The WDC4 also has jog and acceleration monitoring for detecting any equipment issues during the startup sequence.

protected, and can be set up either directly on the LCD screen, or by a free PC software application and transferred to the WDC4 via an SD card. The Watchdog Super Elite can be connected directly to a PLC using Modbus TCP/IP (standard) or Ethernet/ IP protocols. It can also be integrated into HazardMon.com, a secure cloud based solution that provides live system status, graphs and historical data that is viewable on any web-enabled device (smartphone, tablet, desktop PC). The Watchdog System is Class II dust hazard area approved by CSA/NRTL for use in Canada and the U.S. www.go4b.com/watchdog

The controller settings are password

The Martin QB1 Cleaner HD can be retrofitted onto any existing Martin Engineering tensioners, as well as most competitive systems. The QB1 HD design features a square mainframe positioned to shed dust and spillage. The urethane blade formulation

can accommodate belt speeds of up to 900 fpm (4.6 m/sec) and service temperatures of -40° to 160°F (-40° to 70°C). The QB1 HD is available in lengths of 18 to 96 inches (457 to 2438 mm) and can also be ordered in 10-foot (3.05 metre) sections, allowing distributors or customers to cut to length for increased versatility.

The new cleaner features Martin Engineering’s unique CARP (Constant Angle Radial Pressure) technology to maintain the most efficient cleaning angle throughout service life, with a no-tool replacement process that can be performed safely by one person in less than five minutes. The new design also features a special alignment system to facilitate precise installation. The new design is one of the many belt cleaners covered by the company’s new Mr. Blade program, under which Martin Engineering’s mobile technicians provide fresh, factory-direct replacement blades, delivered and custom-fitted on site and installed free of charge. www.martin-eng.com

The distribution of Seppi products in Canada has changed. Instead of one

company now there are two distributors working side by side: Maximum Equipment and Western Mulching & Crushing Equipment (WMCE). Maximum out of New Brunswick has been distributing Seppi products for several years and now is servicing all of eastern Canada including Ontario, Quebec and Atlantic Canada. The newly formed company WMCE is operating out of Saskatchewan and is covering all the western provinces including Manitoba, B.C., and Alberta. Both companies have staff with hands-on experience in the field of mulchers, crushers, and mowers, whether it be related to heavy equipment or agriculture; and each distributor is able to help with spare parts for older machines according to model numbers.

www.seppi.com

Caterpillar’s Cat 950 GC wheel loader is now available in North America and is configured to meet Tier 4 Final/EU Stage IV emissions regulations. The loader is well-suited for stockpiling, load-and-carry work, hopper charging and truck loading.

Caterpillar’s Z-bar loader linkage on the 950 GC delivers excellent digging capabilities

and a breakout force of 33,238 lbf. It also offers best-in-class hinge pin height of 13’9” (4 188 mm) and 12’0” (3 649 mm) loader arm clearance for easy loading of high-wall trailers and charging of large hoppers.

A range of available work tools include Performance Series buckets, which boast a long floor, wide opening and curved side plates. The Cat Fusion quick coupler and controls are also available, allowing the 950 GC to use a number of Cat work tools across multiple wheel loader models for added versatility.

The Cat C7.1 ACERT engine generates a maximum power rating of 241 hp (180 kW) and meets U.S. EPA Tier 4 Final/EU Stage IV emissions standards with a fully automatic and passive regeneration system. This system lowers operating costs without the need for an ash service interval and has an overall DEF consumption of just 2 to 3 percent of fuel burned. No operator intervention is required, nor is there an impact to jobsite productivity.

The interface panel display contains six analog-like gauges, coloured indicator lights and an LCD screen, all within view of the operator. Low-effort, pilot-operated implement controls, along with optional joystick implement control, feature an integrated kick-down switch and a remote directional shift switch.

To further enhance machine operating efficiency and assist with loader preventive maintenance and servicing, the 950 GC can be equipped with Cat Product Link telematics. Deeply integrated into machine systems, Product Link allows remote monitoring using VisonLink. www.caterpillar.com

TBy Bruno Zrno, LEED Green Associate and business development engineer at Viessmann

wenty years ago, enthusiasm about a green, energy-efficient and sustainable environment would likely have made you pretty isolated. However, over the last 20 years, that enthusiasm became a way of thinking and living, and is soon (if not already) becoming mainstream. The green energy and sustainable technology markets are growing. This is not an opinion, it‘s a fact. It‘s also a fact that the Green Building Energy Council plays a big role in those markets. I personally support the idea of

LEED certified projects use less energy and water resources, save money, reduce carbon emissions and create a healthier environment for people in the community. There is a huge potential with LEED implementation in various industry sectors, municipal development and renewable energy development, towards a greener future.

also the first building in Canada featuring a biomass heating system to obtain LEED Gold certification. It was the first project with wood pellets for all parties involved: architect, mechanical designer, contractor and LEED consultant. Renewable energy contributed to around 10 per cent of the overall points achieved towards LEED Gold certification.

“Using renewable sources for your building’s energy needs will contribute towards LEED certification.”

LEED certified buildings and I also understand that there are people that don’t share my enthusiasm. But again, LEED is out there, regardless of what our opinions are. Canada has more than 2,500 LEED certified projects – second highest in the world. LEED Silver has been the minimum standard for new government funded buildings since 2006 in Alberta and Manitoba. BC Housing has implemented energy and sustainability design standards for the design and construction of all new social housing. Large supportive housing developments, such as those being constructed with funding from the Provincial Homelessness Initiative and the Aboriginal Housing Initiative are required to be built to LEED Gold. There are also mandates set by cities and municipalities where provincial mandates are missing.

Using renewable sources for your building’s energy needs will contribute towards LEED certification. It is commonly forgotten that wood biomass coming from sustainable sources is a green fuel. Canada has almost 10 per cent of world’s forests and 94 per cent Canadian forest is publicly owned. On top of that, Canada is a world leader in sustainable forest management, with 166 million hectares of forest land that is independently certified (sustainably managed), representing 40 per cent of the world’s certified forests.

Contributing toward LEED certification using biomass fuels can be achieved with the implementation of biomass heating and/or combined heat-and-power (CHP) systems. Another benefit would be an implementation of a district heating system. Finally, wood biomass is considered a carbon neutral fuel.

The Bluenose Academy in Lunenburg, N.S., is a perfect example of how a successful pilot project is utilizing and promoting green energy solutions. The school is the first provincial government building in Nova Scotia with a fully-integrated wood pellet-fired biomass heating system. It is

Reminding and educating people about the benefits of biomass (wood heating) technology is an urgent necessity for the bio-heat market – a market that is not growing as fast as it should be. Simply put, the word is not spreading fast enough and, amusingly, we sometimes cannot see the forest from the trees.

Looking back on 2016, I can comfortably say that I am more than optimistic about the development of the bioenergy sector in Canada. We helped our partners and customers make a positive impact in their lives bringing renewable biomass and biogas solutions to their communities. Last year was a great “bio-year” for Viessmann, with 15 new commercial-industrial biomass projects across Canada.

On top of that, with the Muskoka Timber Mills project we have yet another wood biomass boiler installation in Ontario. With new emission regulations introduced in January, I envision a greener Ontario and more people following bio-heat pioneers and champions.

Finally, we are finalizing installation of a 390 kW (1,330 MBH) wood biomass boiler at our Canadian head office in Waterloo, Ont. Together with an already installed solar system, our facility will be fossil fuel independent, promoting sustainable and carbon neutral technology. •