Reduction of heating costs by up to 65%

Improvement of animal welfare

Fast payback (ROI of 2 to 3 years)

Reduction of CO2, humidity and ammonia levels

Better returns, more income

Nicole Stewardson, OntarioTim Cox, Nova Scotia

« This is the best my bedding has ever looked in a long time. »

« Thanks to my ESA-3000 air exchangers on my first four flocks, I reduced my propane consumption by 61%! »

Energy Solutions Air 4350 Robitaille Street, door B Sherbrooke (QC) J1L 0B5, Canada esaseries.com info@esaseries.com 1 855 573-2877

by Brett Ruffell

Welcome to our annual sustainability issue, where we put a holistic focus on the longterm viability of Canada’s poultry industry. One aspect of sustainability I’d like to address is mental health, which I believe to be an essential pillar of sustainable agriculture.

In a recent conversation I had with Dr. Briana Hagen, chief executive officer of the Canadian Centre for Agricultural Wellbeing (CCAW), the strong link between mental health and sustainability resonated deeply. She clearly laid out the inherent connection, underscoring how the welfare of poultry producers deeply shapes the health of our agricultural industry.

“Mental health stands as a foundational element of sustainability,” Hagen said. “When farmers experience poor mental health, productivity wanes, and the long-term viability of the industry is compromised.”

This underscores the critical need to prioritize mental well-being within the agricultural landscape. The challenges confronting Canadian poultry farmers, from disease outbreaks to generational legacies, are compounded by the strain on their mental health. Addressing these challenges necessitates a broad approach that nurtures both our flocks and the individuals who tend to them.

In response to these challen-

ges, CCAW has embarked on ground-breaking initiatives, buoyed by recent federal funding. For instance, Hagen shed light on the development of a series of toolkits, including one tailored to assist poultry producers in navigating the mental health aspects of an avian influenza outbreak at their barn.

“Our aim is to equip farmers with the resources and support they need to navigate challenging situations,” she explained. “This toolkit, developed through qualitative interviews and environmental scans, provides evidence-based guidance on supporting farmers’ mental health during crisis situations like avian influenza outbreaks.”

“When farmers experience poor mental health, productivity wanes, and the long-term viability of the industry is compromised.”

To ensure widespread dissemination and utilization, CCAW plans to collaborate with industry organizations and government agencies to distribute the toolkit to poultry producers across Canada.

By tapping into existing networks and channels, CCAW aims to reach farmers in need and empower them with the tools to safeguard their mental well-being.

Moreover, CCAW’s initiatives extend beyond crisis response. Hagen explained how efforts are underway to enhance mental health literacy education for agriculture educators, empowering them to recognize and support farmers facing mental health challenges.

Additionally, CCAW is collaborating with the Rural Physicians Society of Canada to provide rural physicians with tailored education on handling farmer mental health concerns, ensuring that frontline healthcare providers are equipped to handle some of the unique challenges that producers present.

Along with these efforts, CCAW has launched two new events. The Circle of Care Summit brings together stakeholders from across the sector to discuss priorities and strategies for advancing farm mental health. Additionally, CCAW’s National Symposium for Agricultural Wellbeing serves as a platform for research presentations and discussions on best practices in farm mental health.

Hagen, in reflecting on the progress made, expressed optimism: “We have made significant strides in addressing mental health within Canadian agriculture. With continued collaboration and dedication, we can build a future where the well-being of our farmers is truly prioritized, ensuring a sustainable and thriving agricultural sector for generations to come.”

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Brooke Shaw

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

Canada – 3 years $78.54

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

and BEd at Brock University. Callie is a busy mom of three, but makes time to educate the public about the broiler industry and agriculture, and to connect with other farmers through social media.

JESSICA SZMIETT owns and works on her broiler and cash crop farm in Kerwood, Ontario. She also works at TD Bank Agriculture Services, she and her husband have three kids. They got into chicken farming through the New Entrant Program with Chicken Farmers of Ontario in 2019.

FRÉDÉRICK CLOUTIER owns his farm in St-Hugues, Québec, with his sister. After high school he went to work on a farm in Western Canada. He likes to try new practices and technology, as he’s passionate about the environment, and producing sustainable chicken.

The Chicken Farmers of Canada (CFC) announced its 2024 executive committee, elected at the Annual General Meeting in March. Tim Klompmaker of Ontario, a stalwart with over four decades of experience, leads as re-elected chair. Joining him is Nick de Graaf from Nova Scotia, first vice-chair, and Ray Nickel from British Columbia, second vice-chair. Luce Bélanger from Quebec completes the lineup as an Executive Member. With a focus on sustainability and innovation, the committee aims to advance the Canadian chicken industry.

Chicken Farmers of Ontario (CFO) announced recently that its head office will be relocated from its current location in Burlington to Guelph. This move is slated to take place in early 2025. CFO’s board of directors made the decision to relocate with the aim of positioning the organization closer to the heart of the Ontario agricultural community. Guelph, known as a central hub for agriculture in the region, offers strategic proximity to government offices and industry stakeholders.

A partnership between Schippers Canada and Farmers Depot, forged in 2023, now yields reduced costs directly benefiting Canadian livestock producers with lower retail prices. Known for innovation and high-quality products in Canada’s livestock sector, the collaboration has streamlined operations, cutting warehouse costs and improving ocean freight efficiency. The savings are particularly notable as Schippers now manufactures its top hygiene products locally in Canada, eliminating international shipping and boosting local economies.

Egg Farmers of Canada is aiming to amend the code of practice for layers so that they incorporate the latest scientific insights and societal expectations.

Dr. Bettina Bobsien, vice-chair of NFACC, lauded the commencement of the code amendment process.

In a move aimed at further strengthening animal welfare standards in Canada, Egg Farmers of Canada (EFC) has embarked on an initiative to amend the Code of Practice for the Care and Handling of Pullets and Laying Hens. The National Farm Animal Care Council (NFACC) is overseeing this effort, which seeks to incorporate the latest scientific insights and societal expectations into the guidelines governing the treatment of farm animals.

Following a comprehensive review of the existing code in 2022, an expert panel comprised of industry stakeholders identified three key areas necessitating refinement.

These include evaluating round feeder space, determining appropriate space allowances for pullets in aviaries, and setting limits on the maximum number of tiers in housing systems.

EFC chair Roger Pelissero, underscoring the importance of this initiative, says, “Canadian egg farmers are dedicated to the health and welfare of the hens under their care.” He further highlighted the collaborative nature of the amendment process, which involves engaging with various stakeholders across the value chain.

The codes of practice developed by NFACC play a crucial role in guiding the care and handling of farm animals in Canada. These codes not only reflect national standards but also serve as educational resources and reference materials for regulatory purposes.

Dr. Bettina Bobsien, vice-chair of NFACC, lauded the commencement of the code amendment process, recognizing the leadership shown by producer associations and the dedication of stakeholders to advancing animal welfare.

Aviagen recently announced that Yingxin Zhao, a graduate student from the University of Alberta, is the recipient of the 2023 Poultry Science Scholarship. This scholarship, part of Aviagen’s annual support for the Canadian Poultry Research Council (CPRC), highlights the company’s dedication to advancing research and nurturing future leaders in the industry.

Zhao, pursuing doctoral studies in Animal Science at the University of Alberta, stands out for her exceptional academic background. With a Master of Science degree in Agricultural Product Processing and Storage Engineering and a Bachelor of Science in Food Quality

and Safety, Zhao brings a wealth of expertise to her research endeavors.

The selection panel, comprised of Aviagen specialists, was impressed by the quality and potential impact of Zhao’s proposed doctoral research, particularly in enhancing animal welfare. Her ongoing collaboration with a prominent poultry processing company in Alberta further demonstrates her commitment to improving poultry health and meat quality.

Expressing her gratitude, Zhao says, “This scholarship not only supports my academic pursuits but also affirms the value of my research in the broiler meat industry. I am now more motivated

than ever to make meaningful contributions to both my field of study and the poultry industry. Thank you to Aviagen and the CPRC for the scholarship award!”

Matt Klassen, Canadian account manager for Aviagen, commends Zhao’s dedication and passion, emphasizing her potential to drive transformative change in the poultry industry. He extended his congratulations to Zhao and wished her success in her promising career.

Caroline Wilson, executive director of CPRC, expresses gratitude for Aviagen’s longstanding support, highlighting their collaborative efforts in fostering the next generation of poultry scientists in Canada. She affirms the CPRC’s commitment to continued successful collaboration with Aviagen.

By Mary K. Foy

How many times have you had to defend growing poultry on a large scale versus growing a backyard flock?

We may all dream of the ideal situation where we each individually grow our own food, but the reality is that land, feed, water, and other resources are not equally available to all eight billion of us. Thus, some of us will have to grow food for those that cannot.

One might argue that this concentrated growth is a drain on our resources. But a life cycle assessment Chicken Farmers of Canada performed found that water usage alone (not to mention land and energy usage) over the past 40 years has decreased by a whop -

ping 45 per cent.

At the same time, poultry consumption has increased from about 9.5 kg per person annually in the mid-1960s to about 35 kg per person annually in the last five years. We can grow more than three times the amount of protein using almost half the resources than we could 40 years ago. That sounds like an industry that has worked hard to feed the world while consciously reducing the use of resources.

So, as an entire industry, it is satisfying to see a drop in the number of resources it takes to grow a bird. There are many things that an individual grower can do to reduce their resource consumption. This being a column about water, however, I’m going to stick to

that topic! Here are some straightforward ways to be more conscious of the water used on your farm.

Leaking water lines are probably the most common area of water loss in the barn. We get used to seeing that big patch of damp litter halfway down the barn and forget that is telling us we are losing water. It not only compromises the quality of our litter (and the birds’ foot pads), but it also contributes to humidity in the barn and uses unnecessary amounts of water. What’s more, because the drinker is not sealing, it allows bacteria, yeasts, molds, fungus, and more into the water line.

How do you correct this? Often, leaking water lines are

due to the buildup of mineral scale in the system locking a drinker in the activated position. Once a year, when the barn is empty, descale the water lines using an acid product to lower the pH to five and allow it to sit for 24 hours. Be sure to trigger the drinkers so the acid reaches the individual drinker wells. After 24 hours, flush the system with fresh water and trigger the drinkers again. Another common cause of a leak is worn-out rubber seals in the individual drinker. These seals can be damaged by the continued use of chlorine plus acid products during the flock. Replace the individual drinker and be conscious of the products you use in the water line.

We hear it all the time. Reducing heat stress is important for the productivity of the bird. Reducing heat stress is also a way to reduce water consumption. Heat-stressed birds can use two to three times more water than birds that are not heat-stressed.

This may seem like an obvious red flag, but we can all admit that sometimes we just get used to seeing something, like a constant muddy area in the driveway, and we don’t dig into why. An underground water line that goes under an area that the feed truck drives over, or even your truck drives over, can get cracked. If you continuously see water on the surface around the chicken barn, check it out.

By Erika Prewitt

The basic concept of an aviary is a multi-level system that provides feed, water, and a nest. The configuration of these necessities and additional features are what makes each aviary system unique.

Equipment companies work to design these systems to optimize density, create a good environment for the birds, and to meet standards placed by accreditation bodies.

The systems pitched to a producer can stand out based on additional features that reduce workloads for the producers. I’m going to highlight some of these features that producers should consider when not only selecting an aviary system, but also designing a barn.

When selecting an aviary system, there are several points producers should consider. An important factor is if the system will be fitted into an existing building or a new construction. If fitting a system into a specific ceiling height or width, it can instantaneously narrow down your choices. It’s best to allow 24 to 36 inches from the top of the system to the ceiling to allow enough room for ventilation and airflow.

This aspect can help producers decide whether a two-tier or three-tier system is a better fit. Advantages of a two-tier system, besides fitting into an existing lower ceiling height house, are being able to visually inspect each tier easily. And if necessary, it also allows you to work on the equipment with ease. The advantage of a taller three-tier system is bird density. Often, with a new build, a producer will opt for a three-tier to bring down the overall cost per bird.

A factor that is very important and contributes greatly to the overall environment of a cage-free barn is aisle width. I recommend at least six to eight feet of aisle width to create the best environment for the birds. Ideally, you want the birds jumping down into litter, not crashing into the equipment in the next aisle.

Wider aisles also allow for the birds to easily move around you when walking the aisles. With the wider aisles, you can visibly see under the system better for inspections. And lastly, proper aisle spacing allows for air flow to get to the litter, allowing it to dry.

Some additional features that are optional, but I encourage you to consider, revolve around system egg collection. Like floor eggs, if system eggs are not collected promptly when laid, it can encourage hens to lay even more in that area.

It is often hard to manually collect system eggs promptly if you are, at the same time, picking up floor eggs,

ensuring feed is running properly, and or overseeing the morning egg collection.

Likewise, to help decrease floor eggs underneath a system, make sure you have underneath lighting that doesn’t create shadows and keeps the area bright. Producers can also use a litter reduction system in the morning to disrupt hens that might want to lay under the system.

The final factor I would like to discuss when selecting an aviary system is the egg quality you expect to get from this system. When trying to optimize egg quality, your goal is to get as many eggs laid as possible in the nest. Having a nest with curtains, an astro-turf style mat, and having isolation from movement of hens and bright lights are imperative to nest acceptance.

I find having your nest all in one level of the system contributes to better egg quality also because it allows all the hens to lay in the same level and have enough nest space and room on the egg belt.

A look at Burnbrae’s new Solar Free Range Eggs, future sustainability plans and more.

By Treena Hein

Burnbrae Farms is no stranger to sustainability and innovative egg products, and recently unveiled two new products focussed on renewable electricity. The company, which has operations in five provinces and ships coast to coast to coast, has been owned and operated by the Hudson family since its start in 1891. It began tracking its carbon footprint in 2018.

The two new products are produced using 100 per cent solar energy: Naturegg Solar Free Range eggs and Naturegg Omega Plus Solar Free Range eggs. They’re both currently available in select grocery stores across Ontario, Quebec and Atlantic Canada. The latter product is a source of EPA and DHA omega-3 fatty acids and lutein to promote brain, heart, immune system and eye health; these hens are fed a diet including corn, soy, vitamins, minerals, plus omega oils, flax seed and marigold extract.

Both types of eggs are being produced at the Burnbrae farm in Woodstock, Ont. where the company finished four new barns in 2019, one pullet barn and three free range layer

barns. “The farm is the largest solar-powered egg laying farm in Canada, producing more power than it uses and sharing power with an adjoining Burnbrae farm,” says Burnbrae Farms Director Communication & Digital Marketing Sue Hudson. “The farm does not feed power to the grid.”

The solar panels are located on the roofs of the three layer barns. Battery banks are installed for power at night or during extended cloudy periods. The farm also has a backup diesel generator.

Grid electricity in Ontario is mostly renewable and emissions-free due to Niagara Falls and nuclear generating stations, with only 27 per cent coming from natural gas power plants. We asked Burnbrae about how much greenhouse gas emissions reduction the company is roughly achieving at this Woodstock farm by replacing the electricity it used to source from the grid electricity with solar generation.

Sonya Fiorini, director of corporate social responsibility & community investment, could only say at this point that “company-wide, we track our greenhouse gas emissions at enterprise level and report these numbers in our annual sustainability report.” The new report became available in May.

The Woodstock farm’s layer barns are open-concept, equipped with private nests, perches and dust-bathing areas. “The hens have access to the outdoors, weather and environmental conditions permitting,” says Hud-

son. “The industry protects the birds by keeping them inside during spring and fall wild bird migration timeframes to protect from exposure to potential wild bird diseases.”

Every barn is designed starting with the view from the chicken, Hudson adds. “Consideration is given to optimal bird movement, feeder placement, drinking water location and nest access are among the most important requirements during design. Being that this farm is running on solar, special consideration was placed on energy-efficient ventilation design. Air flow was maximized, and fan motors were placed on energy-efficient, variable-frequency drives.”

Indeed, all the barns’ motors, lighting and ventilation systems are high-efficiency and ensure they run using as little power as possible.

Fiornini reports that in 2019 and 2021, Burnbrae installed solar power at two other sites. “Burnbrae’s Ralos farm is 100 per cent solar-powered and our solar field on the original family farm in Lyn, Ont.,” she reports. “This solar field offsets electricity consumption and generates 500 kW of energy – enough to power 85 houses.”

While many other poultry operations in Canada have some solar panels, Green Acres Colony, a Hutterite Colony outside Bassano, Alta. with egg, poultry swine and crop production, has the largest solar array of any farm with poultry production in Western Canada. The Colony has a population of about 80 people.

Calgary-based SkyFire Energy did the installation, and has also completed two poultry barn roof solar generation installations in Alberta. “Klassen Farms installed a 175 kWdc system near Linden, Alta. in late 2016, which has produced nearly 1500 MWh of electricity during its lifetime,” says Greg Sauer, SkyFire Energy vice president of business development. “Brant Colony is a 25.5 kWdc system which was installed earlier in 2016 and has produced nearly 250 MWh of electricity in its lifetime.”

The Green Acres Colony array came about because the Colony has been operating an electricity-intensive plastics recycling facility. It started Crowfoot Plastics in 2010, where giant grain bags (over 5 million pounds of them every year) are recycled into pellets that are sold to make products like garbage bags. Because this process requires a great deal of electricity, the Colony decided many years ago to seek a loan for

solar power generation.

Financing of $4.8 million was secured and the ground-based solar array was finished in 2015. The 2-MW array has 7,686 solar panels, which covers the needs of the Colony’s poultry barns, swine barns, houses, other buildings and Crowfoot Plastics, and also enables electricity sale to the grid. Green Acres will reach ROI on the project in perhaps as little as one more year, which depends on past, current and future electricity prices in its part of Alberta.

As leaders in the Canadian poultry sustainability space, Burnbrae has many other plans to continue reducing its carbon footprint and otherwise reducing operational environmental impact. For about ten years, the company has had a volunteer expert ‘Green Team,’ whose members identify and promote projects that decrease the energy use for production, processing and grading,

and that also decrease water usage and waste. Waste diversion and composting initiatives have led to a 20-per cent reduction in Burnbrae’s greenhouse emissions in recent years.

Right now, Fiorini notes that “we’re focused on increasing our use of renewable energy, exploring alternative fuels for our fleet, reducing natural gas use across our facilities and continually implementing new operational efficiencies.”

Burnbrae is currently working to increase the efficiency of its fleet of tractor trailers, including the addition of side skirts and tracking idling time. The firm is also making plans to convert its sales fleet to electric vehicles.

“In 2024, we will install data loggers to track electricity use at our Mississauga facility to identify opportunities that will help us become more energy efficient,” says Fiornini. “Our intention is to roll this out to other facilities over time.”

By the numbers

Below are essential details and statistics regarding Burnbrae Farms’ extensive sustainability strategy.

2

Is the number of egg products

Burnbrae Farms launched this year that it produces using 100 per cent solar energy. They include Naturegg Solar Free Range eggs and Naturegg Omega Plus Solar Free Range eggs.

2018 Is when Burnbrae began tracking its carbon footprint.

2019 Is when the business finished building four new solar powered barns in Woodstock, Ont.

500 kW Is how much energy a solar field built on its family farm generates –enough to power 85 houses.

20% Is the amount Burnbrae’s waste diversion and composting initiatives have reduced the company’s greenhouse emissions by in recent years.

2050 Is Burnbrae’s self-imposed deadline for achieving net zero carbon emissions.

By Ronda Payne

Being more environmentally conscious is a refrain farmers have grown used to hearing. While everyone wants to ensure environmental consciousness is part of their operation, it must be balanced with costs, animal welfare and other trade-offs for the greatest potential good of all aspects of food systems. When it comes to heating and cooling, are conventional HVAC systems good? Or just good enough?

Léandra Vanbaelinghem, a M.Sc. candidate in interdisciplinary graduate studies in sustainability through the University of British Columbia set out to find out how alternative HVAC systems could potentially improve environmental sustainability and support poultry operations in various regions and climates.

With Nathan Pelletier, temporary director of UBC’s sustainability program and Egg Farmers of Canada research chair in sustainability, overseeing her project, she ex-

plored ground-source heat pumps (GSHP) and earth tubes in comparison with conventional natural gas boiler-style heating systems and air conditioning for egg coolers.

“Egg Farmers of Canada has made a commitment to achieve net zero greenhouse gas emissions industry-wide by mid century,” says Pelletier. “HVAC systems are key consumers of energy on poultry farms. However, installing alternative HVAC systems is costly. It’s important that farmers understand which systems will provide the greatest energy efficiency and emissions reduction benefits.”

Vanbaelinghem sought to develop a range of information to arm farmers with facts about the environmental trade-offs of and benefits of potential new systems. Livestock operations, including poultry, have been particularly interested in finding new ways to ensure beneficial outcomes from these newer HVAC alternatives.

Jean-Luc Messier, owner of laying hen farms, Ferme Famelie and Avi-Oeufs was one of the farmers leading the charge. While Vanbaelinghem’s work was conducted primarily through modelling and data analysis, she acquired source data from Ferme Famelie and visited Avi-Oeufs east of Montreal in Quebec, Canada. Both farms have two layer barns and one pullet barn. The GSHP Messier has provides all the heat required except for about two weeks of the year when pullets require additional propane-based heat.

“The study’s energy and farm-specific data are from Ferme Famelie,” Vanbaelinghem says. “I visited Farme Famelie and his other farm, Avi-Oeufs, which is also run by a ground-source heat pump and is identical to Ferme Famelie’s, but is more recent.”

Her initial task in the research was to identify suitable HVAC systems through consideration of thermal requirements of poultry houses in different regions, environmental impact mitigation potential

and technological maturity and feasibility.

“The results showed that ground-source heat pumps and earth tubes are promising priority systems to be explored, compared to air-source heat pumps, water-source heat pumps and ground-source air heat pumps,” she says.

Messier is already a believer in the GSHP system for his birds.

“These are two new buildings,” he says of the 18,000-bird Avi-Oeufs. “We have adapted to heat the floors of the nests and refrigerated the cold room for the eggs and bring air conditioning to the chickens in bad heatwaves.”

He says he is extremely satisfied with the system and saw the economy of it compared to a propane system.

“No downside, just positive,” he adds. “I plan to continue and other nests will be installed with geothermal energy.”

While Messier’s results are indeed promising, there is more to consider before rushing off to arrange a new HVAC system. Vanbaelinghem says there are other farms like Messier’s that use GSHP, but they are rare. She couldn’t find any poultry producers who use earth tubes.

Installation of these systems is expensive and her research didn’t include a breakeven point, but rather the environmental impacts of installation, usage and end-of-life.

Her study looked at free-run poultry houses in Quebec, Ontario, B.C, Alberta and Nova Scotia. An Italian researcher provided regional climate input nestiamtes and Messier’s barns provided source data for modelling.

“It’s important to understand the applicability and suitability for these systems across Canada because their environmental implications can differ,” she says. “There’s

also different electricity grids. The sources of the electricity need to be considered to get a better picture of their suitability. Ground source heat pumps rely heavily on electricity use compared to earth tubes.”

As Pelletier explains, each province has its own electricity grid powered by different sources and proportions of energy. Some have “dirty” grids, which mean they are powered primarily by fossil fuels like coal and natural gas, which would negatively impact the environmental benefits of seemingly beneficial systems.

Vanbaelinghem found that given the various energy grids, earth tubes are likely to be positive contributors in all the

provinces studied as they rely on less electricity than ground source heat pumps. Groundsource heat pumps are of benefit in Quebec and other green-grid regions.

“The ability for these systems to reduce energy use and related emissions varies by province,” she says. “Earth tubes are a very promising system. They reduce the heating needs of a poultry house. A conventional system attached to this system would need to run less. It’s quite a passive strategy to reduce energy needs.”

Ground source heat pumps contributed the least total average environmental impact compared to earth tubes and conventional systems in Que -

bec, but she notes there are environmental trade-offs, even in a green electricity region.

“For other provinces [outside Quebec and B.C.], this type of system was almost worst,” she says of the ground source heat pump system. “It doesn’t help that in Alberta, for example, GSHP electricity requirements are high as their winters are really cold.”

Trade-offs can include higher impacts like: human carcinogenic toxicity, freshwater ecotoxicity, mineral resource scarcity and many other aspects that take away from benefits of the ground source heat pump. For example, in B.C., GSHPs could be seen as a good option, but some of the trade-offs were undesirable impacts, higher than a conventional system.

These trade-offs are important considerations.

“Who am I to say that this impact category is better than this one?” she asks.

Considering all factors that go into HVAC systems and their trade-offs is part of what farmers must balance themselves.

It isn’t just about heating and egg cooling. The study revealed that ventilation, in some regions, actually surpasses heating and cooling in contributions to environmental impact.

“Through these three systems that were modelled, there was a constant ventilation need that was applied to all of them,” she says. “Because ventilation is an important source of electricity use, in dirtier electricity grids, the impacts of ventilation

In Quebec, when ground source heat pumps were compared to conventional HVAC systems, there was a decrease of 2.4 per cent to 95.1 per cent of 10 of the 16 impact categories of environmental trade-offs.

While alternative HVAC systems may appear better in many ways, they may be worse in some of the environmental trade-off impact categories that matter to a farmer or the municipality they operate in.

Ground source heat pumps show the most promise in green energy grid regions while earth tubes may be beneficial in all regions.

Ventilation can create greater negative environmental impacts than heating due to its high electricity consumption.

are even higher than heating itself. In a way this research also showed that ventilation is a hot spot, as a place to reduce energy use.”

On the flip side, in geo-thermal systems, there was no need for active refrigeration of the egg cooler.

“Because the ground temperature is between five and 15°C, these systems could meet the demand of an egg cooler room,” she says. “We can be saving a lot of energy every year just from these, passive cooling sources.”

Ultimately, Vanbaelinghem says this study is just a starting point in comparing the technologies. Farmers can arm themselves with data to consider options for their own facility. Each poultry house will have different factors to determine whether it’s better to stay with a conventional system or branch out into something different.

The National Environmental Sustainability and Technology Tool is a first-of-its-kind system that egg farmers can use to track, assess and benchmark the environmental impact of their farm.

How the tool can help you

You can use the tool to:

Understand the environmental impact of your farm

Compare your results to other egg farms

Improve your operations with tailored recommendations

Access the latest on-farm sustainability resources for egg farmers

How to access the tool

By using the tool, you’re supporting the broader movement of egg farmers who are collaborating and innovating for a more sustainable future.

All you need to get started is your Farm Registration ID!

By Emily Leishman, Nienke van Staaveren, Ryley Vanderhout, Xuechun Bai, Owen Willems, and Christine Baes

In 2017, a team led by Dr. Christine Baes at the University of Guelph joined forces with Hybrid Turkeys to apply genomic selection for improved health, welfare, efficiency, and production in Canadian turkeys. This five-year project finished in 2021 and made significant contributions to advancing turkey research.

In particular, a large proportion of research focused on the development of novel phenotypes related to health, welfare, carcass, and meat quality traits. In collaboration with Hybrid Turkeys, a commercial abattoir, and the U of G research team, over 44 weeks of data collection were performed by the team on >12,000 birds. This resulted in one of the largest datasets available worldwide for investigating the relationship between genomic variation, meat quantity, meat quality, and novel health/welfare-related traits in turkeys (see sidebar).

The novel phenotyping pipeline in abattoir conditions was retained by Hybrid Turkeys to continue data collection to measure selected carcass and meat quality traits for

future breeding program (i.e., colour, image analysis to estimate carcass components).

Due to a lack of knowledge available on traits related to health and welfare, meat quantity, and meat quality in turkey production, several studies were performed to provide necessary direction and context. An innovative methodology to assess hypothalamic-pituitary-adrenal (HPA) axis activity via feather corticosterone was investigated as this would be a practical, non-invasive phenotype related to stress levels to collect at the abattoir.

Methodological and biological validation

was performed to provide context to this novel measurement. The influence of external factors (e.g., temperature stress, season, post-mortem muscle activity) on carcass and meat quality traits was assessed and deemed possible but with relatively small effect sizes. Regarding future health/welfare traits, a large survey among turkey producers benchmarked current housing and management practices within Canadian turkey farming and provided their perspective on bird health/welfare issues. Important issues such as footpad dermatitis and injurious pecking were investigated further, and risk factors

Traits considered throughout this project included:

Health and welfare traits: Walking ability, feather corticosterone, fault bar traits, pendulous crop.

Meat quantity: Carcass portion weights and yield.

Meat quality: Colour measurements, pH measurement, drip loss, cooking loss, shear force, white striping.

Production and fertility: Body weight, feed conversion ratio, broodiness traits, egg numbers, fertile eggs, hatch of set eggs, hatch of fertile eggs.

identified.

As only 30 per cent of the variation could be explained by management, this highlights the potential to address these issues in part through breeding approaches and lays the foundation for future research.

All in all, the project facilitated the expansion of a database of genomic information for turkeys with over 87,000 birds genotyped. For all the collected traits, heritability, and genetic and phenotypic correlations between traits were evaluated as well as further genetic analyses like identifying regions of the genome associated with specific traits.

For many of these traits, the estimates from this project were the first available for turkeys. Novel statistical approaches were developed which were shown to outperform traditional methods and have since been implemented to the breeding program.

The project resulted in one of the largest datasets available worldwide for investigating the relationship between genomic variation, meat quantity, meat quality, and novel health and welfare-related traits in turkeys. This provided some of the first heritability estimates of traits related to carcass and meat quality as well as health and welfare traits that can contribute to sustainable turkey breeding.

Hybrid Turkeys has expanded genotyping as part of their standard practice and single-step genomic selection developed within the project has been implemented, resulting in 30 per cent gains in accuracy for economically important traits. This has led to a realized economic gain of approximately $19 million to the turkey industry.

Ultimately, the theoretical and applied improvements to the genetic selection of turkeys developed through this project provide an integrated approach to incorporating health, welfare, efficiency, and production traits in the breeding of commercial turkey, thus contributing to more sustainable food production in Canada.

This work manifests the benefits of deep integration of research results from multiple disciplines, providing tangible benefits to turkeys and turkey farmers in Canada and around the world, as well as training of more than 20 highly qualified personnel.

The research project team is continuing to collaborate with Hybrid Turkeys to integrate study results.

However, the collaboration between U of G and Hybrid Turkeys will not be stopping there.

The past project resulted in one of the largest datasets available worldwide for investigating the relationship between genomic variation, meat quantity, meat quality, and novel welfare-related traits.

However, it identified clear needs with regards to decreasing mortality and improving livability, which inspired the current project.

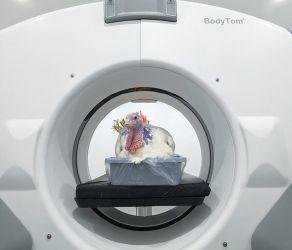

A new project has been funded to apply genomic selection for body composition traits in turkeys using data from computed tomography (CT) technology.

Computed tomography is an imaging procedure that uses combinations of many

X-ray measurements taken from different angles, which are then used to construct cross-sectional images (slices) of specific areas of an object.

Using measurements derived from CT images is expected to increase the rate of genetic gain for breast meat yield by providing a detailed view of muscle volume. This technology can also be used to improve livability by identifying animals susceptible to health problems.

In particular, an increased frequency of circulatory disorders such as ascites, aortic rupture, spontaneous cardiomyopathy (round heart), and cardiomyopathy causing sudden death, each accompanied by poor meat quality, lower muscle production and/or high mortality, have been identified in parent stock birds.

The use of CT technology allows animals with a predisposition for these disorders to be identified early.

For example, animals with bulges along the length of the aorta are more likely to suffer from aortic rupture.

The ability to clearly identify animals with anatomical abnormalities and associate genomic regions with them for use in a selection program offers an incredibly important opportunity for genetic improvement.

Preliminary analyses have shown high correlations between muscle volume obtained via CT scan and body weight. Internal simulations have shown that a combination of genomic information, optimal modelling, and improved phenotyping can increase genetic gain for breast meat yield by up to 38 per cent.

The objective of this ongoing project is to implement a genomic selection program using traits derived from CT technology for genetic improvement of turkey parent stock, enabling continuous genetic improvement in both production and livability traits, including those affecting health and welfare.

Introducing liveability traits derived from CT technology is expected to substantially decrease mortality, equating to economic gains for Canadian turkey producers and healthier birds.

Next to genetics and management, nutrition is one of the biggest factors influencing successful poultry production. In order to be productive, birds need high quality, consistent and nutritionally balanced feed – and to support producer profitability, that feed also needs to be cost-effective.

It’s estimated that about 70 per cent of poultry production costs are linked to feed, so getting it right matters. A feed mill is a complex environment, however, with many different factors influencing the quality and quantity of the feed that’s produced.

That’s why the industry is actively looking for ways to increase the precision and uniformity of feed being produced, reduce errors and harness the skills and experience of its older workforce approaching retirement for the next generation of employees.

Dr. Mark Malpass, director of poultry nutri-

tion at Masterfeeds, and Dr. Jennifer Ellis, Associate Professor in Animal Systems Modelling at the University of Guelph, believe machine learning, which is a form of artificial intelligence, could provide the solutions the feed industry is looking for.

“A feed mill is not a perfect laboratory; it’s a real world environment where there will be variation in pellet quality from time to time between formulations, ingredients and even different operators,” says Malpass. “So can we use artificial intelligence to investigate that variability and help teach and manage feed mills in the future?”

It’s an idea that began to form when Malpass and Ellis, former work colleagues at Trouw Nutrition Canada, got into a conversation at a conference about a modelling trial she had just completed. The trial wasn’t successful, but the idea of using machine learning models to predict feed quality stayed with her as she joined the faculty at the University of Guelph in 2019.

“There were a lot of discussions about

what the future of modeling represents in agriculture and how we can we best position ourselves to ride the digital wave – not just collecting data, but using it to bring value,” Ellis says.

“My background is in modelling and Mark has an ear to the ground in terms of what will work in the industry, so this partnership came together.”

With funding from the Ontario Agri-Food Innovation Alliance and a partnership with Trouw, Ellis, University of Guelph computational biology professor Dan Tulpan, and PhD student Jihao You embarked on a three-year project on the use of machine learning models to predict feed pellet quality.

The team collected manual and automated data from the Trouw mill in St. Marys on manufacturing conditions, nutrition formulation and the environment in-

side and outside the mill, and then developed a series of machine learning algorithms to determine the best predictive model they could build.

The project is finished, resulting in a proof of concept model with reasonable prediction accuracy. Although work had previously been done on the link between pellet quality and one or two variables, no real research had to date ever been done on integrating all the factors in a commercial setting that can impact pellet quality.

“What happens in a mill and how you make feed is different in January than it is in July in the middle of a heat wave, so how does this impact pellet quality?” Malpass

While the immediate focus of the work is being able to predict pellet quality, the end goal is to be able to make those predictions accurately and then use that information to optimize feed production for efficiency or for sustainability parameters, such as a certain level of greenhouse gas emissions per tonne of feed, for example.

Long-term, this information could be tied into on-farm precision feeding systems, waste reduction and optimizing instead of maximizing production. To date, the work has only focused on pelleted feed for monogastric livestock, but the team hopes to expand into both other types of feed and

and Molesworth Farm Supply. As each location will have slightly different processes and methods, collecting a broader spectrum of data will help make the models more robust and accurate.

“Machine learning is only as good as the data that it learns off of, and their strength is when they’re built on large volumes of data,” Ellis says. “Partnerships like this with industry are so important and by expanding the work and having multiple feed companies collaborate on the overall goal, we can support the Ontario agriculture industry in feed manufacturing.”

“As far as we understand, we’re the first lab group anywhere in the world to have

Clark Ag Systems are the experts in installing & servicing complete layer systems since 1950!

BENEFITS OF ENRICHED SYSTEMS

More space for birds while optimizing density

Built strong for maximum stability

Additional feeders, perch, nest & scratch area

Transversally positioned perches for optimal comfort

Multiple tiers options with intermediate catwalks

Easy to clean, inspect & operate

Anti-waste profile feeders

Delivers high quality & clean eggs

Complies with the Canadian Code of Practice

From mill to farm, here are some key strategies to minimize feed waste.

By Andrew Catlett

Depending on the production system , broilers or broiler breeders, up to 70 per cent of the production cost can be allocated to feed. However, feed wastage isn’t just a cost issue. It can also be a biosecurity issue as feed spills can attract wild birds, rodents, beetles (Alphitobius) and other vermin that can carry pathogens onto the farm.

At the feed mill, correct processing, preventing contamination, and accurate formulation can help reduce feed waste. Incorrect processing can lead to pellets that are too hard or soft. Birds may flick these pellets out of the feeder. Likewise, poor pellet processing can increase the amount of fine particles. Correct particle size and uniformity is also important in mash feeds because birds may select larger particles and leave fines.

Contaminated feed can occur during the milling process in places such as the mixer (carry-over) and post-processing can lead to feed being reworked, or even be completely lost. In the case of rework, time, labor, and energy costs are increased.

Consider potential spillage points as spillage is a direct loss. A good maintenance schedule is important in preventing spills by replacing or repairing components in the feed mill.

Good quality raw ingredients should always be used to produce feed. A robust quality assurance program needs to be in place to monitor quality of the raw materials which then helps determine accurate formulation matrix values, as well as finished feed to ensure that the feed formulation is being made accurately.

Using the correct feeding system and ensuring that the feeding system is well maintained can help prevent feed wastage. There are several feeding systems available for broilers that work very well. Recently, some European companies have been evaluating relatively small, round feeders that measure 18 cm in diameter. These feeders can be used

for broilers up to 4 kg. Some field observations include:

• Flooding the feeders for day old chicks is easy and efficient.

• As of day two, no additional chick feeders are needed.

• Chicks cannot sleep inside the feeders keeping the feed clean.

• Smaller feeders allow birds to empty them relatively quickly, activating the feeder line more often compared to large pans.

• Three levels of feed height in the feeder can reduce feed spillage.

• With these small feeders, the lighting program must be adjusted so that birds can eat ad libitum.

With broilers, a correct feed withdrawal program is also important and can help

minimize feed wastage. Optimum recommended time for feed withdrawal is eight to 12 hours (beginning when birds do not have access to feed in the poultry house until shackling at the processing plant). Less than eight hours may result in excess feed and fecal residues in the digestive tract.

The excess feed residue will also cause yield, processing, and contamination problems in the plant. Feed withdrawal longer than 12 hours causes the intestines to lose their tensile strength, making them easy to tear and rupture during evisceration at the processing plant. This will cause carcass and equipment contamination in the plant.

Feeder management is an important factor to control feed wastage. When using pan feeders, ensure that feeders are locked and do not swing. Swinging feeders not only make it difficult for birds to access feed, but feed can also spill out of the pans if they swing.

To prevent spills when using chain feeders consider:

• Check for worn feeder troughs and spillage at the return to the feed hoppers. Replace worn out parts.

• Maximum feed levels in the troughs should be set at one-third full. When feed levels are set too high, feed can spill out of the troughs.

• Chain feeders with high corners prevent spilling out of the trough.

For both broilers and breeders. it is essential to manage feed quantities ordered, especially towards the end of the production cycle. This help reduce the amount of feed left over at the end.

Birds consume, digest, and absorb the nutrients from the feed. Nutrients then are used for maintenance, growth and/or egg production. The efficiency of digestion and absorption is dependent on a healthy gut and good water quality and intake. For these reasons, poor gut health will reduce the bird’s ability to extract the nutrients, and, in turn, they will require additional feed.

A high feed intake and fast passage rate means good gut health is necessary for optimal feed digestion and nutrient absorption. Disruptions in gut health can cause feed to pass undigested and deposited in excreta, which negatively impacts costs and generally impacts the environment on both the feed and poultry sides.

To support good gut health, biosecurity programs are important to minimize pathogenic challenges. Other points to consider include making sure drinker lines are clean and provide fresh, cool water. Keep the litter dry with good ventilation and correct any dripping nipples or water line connections.

When temperatures are below the thermal comfort zone, birds must allocate energy to produce metabolic heat. If temperatures are too low, the birds will consume more feed to generate body heat to keep comfortable. Keep in mind that even with a pure heating

fuel, it is still less expensive to heat with, say, propane than with feed consumption.

For broiler breeders, it is important to follow the feeding programs recommended by your genetics supplier as overfeeding has consequences beyond feed waste. Cobb’s recommendations for each of our products are available at cobbgenetics.com. In addition to feed waste, over feeding birds can cause the following issues:

• Overfeeding pullets or having the wrong feed formulations can lead to extra breast muscle deposition and create complications such as early mortality after photo stimulation.

• Overfeeding hens can lead to multiple ovulations, egg peritonitis, sudden death syndrome and a prolapsed cloaca.

• Overfeeding males causes overweight males to have difficulties mating.

By Jane Robinson

If you’ve spent any time in a room with flickering lights, it might have triggered a reaction ranging from annoyance, fatigue to a splitting headache. When Karen Schwean-Lardner was invited to tour some Ontario turkey farms that were having light flicker problems, she got a migraine and an idea.

Not much is known about the effect of light flicker on poultry, especially turkeys, and those barn visits left the University of Saskatchewan researcher wondering about the impact unstable lighting might be having on the birds.

“There is very little information on the productivity or behaviour of birds raised with exposure to light flicker,” says Schwean-Lardner. “Some work has been done in laying hens and broilers, but the more work we do, the more we realize that turkeys don’t often respond the same way as broilers, and nobody had looked at light flicker in poults.”

Schwean-Lardner and graduate student

April Hammond recently completed a project studying the effect of light flicker on turkey hens, looking at a wide range of measures related to performance, health and well being. Hammond’s work on the project earned her a Masters degree.

“We’re always trying to look at a big picture in our studies,” says Schwean-Lardner. “If we only looked at the effect of light flicker on bird behaviour, we’d be missing the effect on production, which is what producers really want to know about.”

Light flicker is visible when the frequency (hertz) of the transition between light and dark is slow enough to be seen. This type of flicker is common with artificial light sources, and can occur in barns where newer LED lights are used in incandescent sockets.

Schwean-Lardner and Hammond evaluated three different light-flicker frequencies

(30 Hz, 90 Hz and 195 Hz) in turkey hens raised from day old to 11 weeks. The researchers exposed the birds to the light flicker during daylight hours.

The study used infrared cameras to monitor behavioural activity including stress and fear, and also gathered performance measures throughout for body weight, feed consumption and feed efficiency.

“We were trying to mimic what would happen in barns, as much as possible, using purpose-built control boxes to deliver the different flicker frequencies,” says Schwean-Lardner.

The 30 Hz frequency flicker is visible to humans and turkeys. At 90 Hz, there is some indication light flicker may be visible to turkeys, but not to people. And the highest level tested – 195 Hz – is not visible to people or birds. “Turkeys have better vision than people with much wider peripheral visions for numerous reasons, including that light can penetrate through the skull,” says Schwean-Lardner.

Overall, flicker had minor effects on turkey hen behaviour, with many stress and fear responses unaffected by visible or non-visible (90Hz and 195 Hz) flicker. There were differences in behaviour when the birds were young, with 30 Hz reducing some comfort and exploring behaviour.

“We did notice that on the day the birds were placed in visible flicker, they tried to hide under the feeders to get away from it,” says Schwean-Lardner. “We weren’t able to measure this effect, be we could see the young birds were trying to avoid the flicker when they were first exposed to it.”

When looking at bird performance, they found some lower body weights at the 30 Hz frequency at an early age. But as the birds grew, there were no overall changes in final body weight or feed efficiency between the birds. “We could not find differences overall, with body weight being equal de-

spite the treatment,” says Schwean-Lardner. All in, she expected to see bigger differences when birds were exposed to flicker. “I thought we would see significant reductions in body weight and significantly higher mortality, but the differences were not what we anticipated between the different levels of flicker frequency,” she says.

Although the productivity impact on the turkey hens was not significantly different when they were exposed to varying levels of light flicker, Schwean-Lardner says it’s always better to fix the flicker as it is known to impact anyone working in barns.

Call us on: 519-587-2667

“I think producers should know that in the 90 Hz range, we did see higher levels of aggression so flicker may have some negative effects on birds, even if we can’t see it,” says Schwean-Lardner. “So, if you go into a barn and don’t see flicker, it might still be

Or visit our website: www.mellerpoultry.ca

there and might be impacting the birds.” An oscilloscope can be used to measure non-visible light flicker.

Then there’s the additive effects of stressors for birds in the barn. Flicker is a stressor that can be corrected, and doing that will likely mean those birds are able to withstand other stressors a little bit better.

Schwean-Lardner wants to do more work in this area, but admits it was really tough conditions for the whole team to work under. “Working under flickering lights on this project meant it was much tougher to see birds that needed to be culled,” she says. “And culling is one of the most important animal welfare things we can do.”

She’d also like to be able to do brain MRIs on birds to see what was going on under flicker, and also repeat the work in turkey toms as their behaviour is different from hens. “Toms spend longer in the barn so we might see very different results.”

Authorized dealer VDL Jansen VDL Agrotech

Authorized dealer VDL Jansen

The Comfort 2.0 aviary system is an open, multi-tier system making optimal use of the space in a new or existing house. Perches, feed, and water are situated at different levels in the system to stimulate the natural behaviour of the birds.

The Comfort 2.0 aviary system is an open, multi-tier system making optimal use of the space in a new or existing house. Perches, feed, and water are situated at different levels in the system to stimulate the natural behaviour of the birds.

OPTIMAL HYGIENE

OPTIMAL HYGIENE

OPTIMAL HYGIENE

Each floor of the aviary system is equipped with plastic TwinWorld slats or wire slats with an open structure and manure belts for good manure removal and hygiene in the house. An integrated ventilation tube provides good ventilation of each tier. The ventilation tube also has a positive impact on the manure drying process.

Each floor of the aviary system is equipped with plastic TwinWorld slats or wire slats with an open structure and manure belts for good manure removal and hygiene in the house. An integrated ventilation tube provides good ventilation of each tier. The ventilation tube also has a positive impact on the manure drying process.

Each floor of the aviary system is equipped with plastic TwinWorld slats or wire slats with an open structure and manure belts for good manure removal and hygiene in the house. An integrated ventilation tube provides good ventilation of each tier. The ventilation tube also has a positive impact on the manure drying process.

GOOD OVERALL VIEW

GOOD OVERALL VIEW

MAXIMUM EGG PRODUCTION

MAXIMUM EGG PRODUCTION

The system gives a good overview and the birds are easy to manage.

The system gives a good overview and the birds are easy to manage.

Both LayMaxx and Premium+ nests are possible in the Comfort 2.0. These laying nests provide an optimal environment for the hen to lay eggs.

The Comfort 2.0 aviary system is an open, multi-tier system making optimal use of the space in a new or existing house. Perches, feed, and water are situated at different levels in the system to stimulate the natural behaviour of the birds.

GOOD OVERALL VIEW

The system gives a good overview and the birds are easy to manage.

System and floor eggs are kept to a minimum.

Both LayMaxx and Premium+ nests are possible in the Comfort 2.0. These laying nests provide an optimal environment for the hen to lay eggs. System and floor eggs are kept to a minimum.

MAXIMUM EGG PRODUCTION

Both LayMaxx and Premium+ nests are possible in the Comfort 2.0. These laying nests provide an optimal environment for the hen to lay eggs. System and floor eggs are kept to a minimum.

New study shows regular consumption improves health. By Jane Robinson

Anew U.S. study has found that when eggs are included in a healthy diet, they are linked to fewer cardiometabolic health risks.

Dr. Lynn Moore, a Professor of Medicine and director of the Nutrition and Metabolism graduate programs at Boston University Chobanian & Avedisian School of Medicine, led the study that compared the long-term health status of people who ate five eggs per week versus just half an egg per week. What she found was further confirmation of the nutrient powerhouse packed into eggs.

“For people with an overall healthy lifestyle, eating eggs regularly contributed to even better health outcomes,” she says. “We found no health outcomes that were worse among regular egg consumers.”

Egg consumption has endured a yoyo of accusations. “It was in the late 1960s that the theory first emerged that dietary cholesterol would raise total serum cholesterol and therefore promote the development of heart disease, since eggs are a major contributor to dietary cholesterol intake,” says Moore. In the years since, more and more studies

failed to confirm the correlation between egg consumption, elevated serum cholesterol and heart disease. “To some extent, the body seems to be able to self regulate total cholesterol levels. When more dietary cholesterol is ingested, less is produced endogenously,” she says.

Moore wondered whether the earlier dietary advice around the ill effects of eggs on heart health – advice that’s still followed by many clinicians – may actually have had unintended consequences on overall health.

“There are so many important nutrients in eggs, particularly in the yolk, I wanted to see what effects egg consumption was actually having on health outcomes.”

To look for connections between eggs and heart health, Moore dug into decades-deep public health data gathered by the Framingham Heart Study Group – established in the late 1940s to investigate the epidemiology and risk factors for cardiovascular disease. More than 5,200 men and women – aged 30 to 60 – were recruited from Framingham, Massachusetts as the original cohort and regularly monitored throughout their life for various health indicators including

height, weight, body mass index, blood pressure, fasting glucose and cholesterol, as well as diet patterns. The group is now in its third generation and includes descendants of many of the original cohort to provide a unique, longstanding set of health data.

The extensive data that’s been collected allows researchers like Moore to investigate specific aspects of diet and heart health, including how egg consumption impacts various health conditions over time to make new discoveries.

“We knew from previous studies that regular egg consumption was often associated with less healthy diet patterns,” she says. “But there was also a group of people in the study group who were regular egg consumers that had healthier intakes of other foods, and we wanted to look at these people.” They purposely selected data from study group participants with healthy eating patterns and no cardiac health issues.

Moore and her team created egg-based diet patterns from the data to look closer for the effects of egg consumption on cardiometabolic disorders – glucose levels, insulin, blood pressure, body fat and lipid levels

Our egg conveying systems safely transport a large volume of eggs from the nest to the processing area, which is why the majority of all eggs produced in North America are riding on a LUBING egg conveying system.

Our conveying systems are flexible, and can be adapted to nearly any configuration with curves, angles, heights and distances.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

(including cholesterol). “If you eat eggs regularly, and consume more dietary fibre, more whole grains, more fruits and vegetables, and fish, we wanted to see what that does to your overall health,” she says.

They looked at data collected on 2,349 adults, aged 30-62, as part of the Framingham Offspring (second cohort) and tracked them over a four-year period to look at their cardiometabolic health outcomes. They were particularly interested in comparing different levels of egg consumption with several aspects of cardiometabolic health to uncover what was happening over time with people who were regularly eating eggs.

Moore found in her research that eating five eggs per week lowered the long-term risks of high blood pressure and diabetes. “I was really surprised that the positive effects of egg consumption were as strong

as they were,” says Moore.

The beneficial effects of egg consumption were even stronger in combination with other healthy dietary patterns. People who ate five eggs a week as part of a balanced diet with fibre, whole grains, fruits and vegetables, were less likely to develop type 2 diabetes and high blood pressure.

When they looked at lipid levels in the same group over time, they found more good news for eggs. Regular egg consumption in combination with a higher fibre diet – with its beneficial effect on glucose and lipids –resulted in lower LDL “bad” cholesterol levels and the lowest LDL:HDL cholesterol ratio, a heart healthy measure.

When regular egg consumption was combined with eating more fruits and vegetables, the result was lower triglycerides levels – another heart healthy measure as high levels of these lipids are important indicators for heart disease and diabetes.

And when they looked at individuals with regular egg consumption and higher fish consumption, there was a 40 per cent reduction in LDL cholesterol levels.

“We consistently found no adverse side effects of higher egg consumption in any of the categories related to cardiometabolic disorders,” says Moore. “It was something of a surprise as I didn’t expect so much consistency in the beneficial effects of eggs that we observed in the context of a healthy diet. In addition, we found no adverse effects of egg consumption even among those with less healthy diet patterns.”

In their analyses, Moore’s group was able to isolate the contribution eggs make to long-term health, when part of a healthy diet. “People with healthier diet patterns who didn’t eat eggs – maybe following the advice of their doctor at the time – did not do as well in general as people who ate eggs regularly as part of a healthy diet.”

This book is to educate the readers on the role of dietary fats in poultry on production aspects, health effects, growth and product quality. In addition, the role of poultry food products in meeting the human requirement of much needed functional nutrients such as omega-3 fatty acids is discussed. The authors have attempted to include as much up to date and relevant information on the roles of fats and fatty acids in poultry nutrition, health and product quality.

| Item #1899043378

Location

Carp, Ont.

Sector

Small layer flock

The business

A decade ago, the Marginsons – Corbin and Krista and their now-adult kids –moved from Ottawa to a 105-acre hobby farm in the rural suburb of Carp. Since then, they’ve populated their love project with a collection of several dozen layer chickens of various breeds, as well as geese, guinea fowl and pygmy goats. They also raise broilers and turkeys.

The need

The handful of birds the Marginsons started out with – including Leghorns and heritage breeds – soon grew into a flock that no longer fit into the wooden coop with roosts and nests the family built when they moved to the farm.

The bus

Two years ago, Corbin exchanged an old dump truck for a yellow school bus at a local scrap yard. After removing the engine and seats, it was towed to their property next to a small goat barn. Corbin equipped the bus with nesting boxes, roosts, and an automatic door that opens at 7:00 a.m. and closes at 8:00 p.m., allowing birds into a fenced yard. People access the bus through the sliding front door to collect eggs and provide water and feed. The back emergency door is used to remove manure, deposited into a trailer and spread on a hay field. The birds inhabit the bus year-round, with open windows for air circulation, and in winter, they huddle on 2X3 roosts for warmth.

S T R EN G T H EN Y OU R

B R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use