BY NAOMI SZEBEN

BY NAOMI SZEBEN

As I write this, Torontonians are approaching their second month of social isolation. While bakeries and cafés have been deemed essential services by the Federal Government, many are struggling. Though the Prime Minister’s press conference on Tuesday, April 24 announced a commercial rent relief program, many smaller companies may not be able to afford to continue regardless of rebates, loans and reimbursements.

However, all is not doom and gloom. Bakeries are creative industries, and they know that means more than staying on top of food trends and colour schemes. In this issue, you’ll read about bakeries that reached out to customers in innovative ways. Some connected with charities that were close to their hearts as well as their favourite customers.

Necessity is the mother of invention, and you’ll learn about bakeries that learned to adapt quickly. Kitchen Smidgen of St. Mary, Ontario learned how to change their delivery model on a dime. They affiliated themselves with similar service-oriented industries to help survive together. By marketing Kitchen Smidgen’s baked goods as a package with their local florist, both companies were able to stay afloat, and in turn, kept their community financially and emotionally alive.

During the influenza pandemic in 1918, when homes and business were shut in to prevent the spread of disease, people craved human connection and small sweet treats. The term ‘comfort food’ wasn’t part of the popular lexicon at the time, but eating treats for a quick fix for anxiety is timeless. The German language has a term for stress-eating: Kummerspeck, literally, “grief bacon.” This is the time for bakeries to offer a small gesture of comfort by presenting something rich and sweet, a treat that awakens a memory of a happier, more nostalgic time.

This is the time for bakeries to offer a small gesture of comfort by presenting something rich and sweet, a treat that awakens a memory of a happier, more nostalgic time.

Both The New York Times and IDDBA reported a marked increase in cakes, small pastry and baked goods in general. This is the time where bakeries should be marketing their treats online through newsletters, social media, and create affiliations with similar service companies. Pubs are now offloading their meat and frozen foods and selling them off as precooked meals, or in their frozen state as meal kits to be prepared at home. A bakery could easily team up with a local bar and offer a pie to finish off a comforting meal.

This is also a time when people want a small, affordable comfort more than ever. Bakeries can provide the idea of comfort or small luxury. Cake used to mean the company of friends to share it with, but a bakery can now market smaller cakes as single-serve pastries to cheer up those who can’t share it with others.

“I also think that people will need inexpensive small treats here and there, and bakery small treats are the perfect items,” said our marketing expert, Diane Chiasson in one of our recent discussions.

Bakeries will think of ways to supply their demand, but the bakeries that do not work on their marketing plan or adapt will not thrive. Bakers Journal wishes the best for its readers, yet hopes they will not have to plan for the worst. / BJ

JUNE 2020 | VOL. 80, NO. 5

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254

1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION bolechnowicz@annexbusinessmedia. com

Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 32.00

USA — 1 Year $73.50 Foreign - 1 Year $84.50 All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2020 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Callebaut Group helps chocolatiers and chefs during pandemic | AMF welcomes expert to expand their speciality lines | for more news in the baking world, check out our website, www.bakersjournal.com

The Callebaut Group established an online initiative to help chocolatiers and bakers delivery and boost their marketing during the COVID-19 lockdown. The initiative was born from the desire to support the community of chefs, pastry chefs and chocolate makers, hard hit by the quarantine situation during the most important of the year: Normally, graduations, spring holidays, Mother’s Day and Father’s Day would be a rush season. Their Chocolate Academy is offering free chocolate making

courses to those in the food industry, and offers to help broadcast existing social media posts for bakers and chocolatiers.

The distance learning offers to turn spare hours into extra skills, with a live chat where chefs can ask questions from Callebaut’s chocolate experts.

To make this possible, professional chocolate brands from around the world came together to offer their support in collaboration with an expert in relational analytics.

Around 150 attendees gathered at Hydrosol’s biannual sales network meeting in Hamburg, to present the current trends and expectations in the different markets.

According to this year’s attendees the plant-based trend continues to have extraordinary potential around the world, Hydrosol CEO Dr. Matthias Moser stated.

“We reacted to the growing demand for plant-based alternatives to meat and dairy products some years ago, and continue to develop solutions for this market segment.”

In addition to plant-based alternatives, Hydrosol found “free-from” products is another growth driver on the market. Whether free from lactose, gluten or soy, less sugar, salt and fat, or free from animal ingredients, this trend and the plant-based segment have turned into an important market for differentiated products. Hydrosol found that the main motivators driving consumers to clean and clear-label products is indulgence with a good conscience.

AMF Bakery Systems, global manufacturer of complete bakery solutions, welcomed Terry Bartsch to support business development and product line improvement for mixing and dough system technologies worldwide. Bartsch joins the company with over 35 years of sales, marketing, and leadership experience in the commercial bakery industry.

“Terry is a strong addition to our team as we look to further strengthen our leadership position with dough systems in the soft bread and bun segment while also expanding more aggressively into new product segments including cookie, cracker, and specialty breads,” mentioned Jason Ward, president of AMF. “Many of us at AMF have known Terry as a capable, effective, and high integrity competitor over the years. We are thrilled to now call him our teammate.”

Throughout his career, Bartsch has developed and led numerous sales teams and driven brand and product development initiatives on behalf of a variety of capital equipment suppliers. His strong track record of success in business development, product development, brand management, strategic planning, training, as well as sales and revenue growth will be major assets in executing AMF’s future plans.

Bakers journal extends its congratulations to Terry Bartsch for the next

From the latest in cheesecake pans to the newest in gas detection and bulk bag fillers, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Bacharach announces the MGS-402 gas detection controller for refrigerant, toxic and combustible gas detection applications. The system is designed for safety compliance in mechanical rooms, cold storage facilities, walk-in freezers, and cold room applications to -40° F/C.

LloydPans unveils their latest pans

LloydPans launched two new pan launches that push the boundaries of length and size. LloydPans’ pizza experts will be showcasing a new Long Pizza Pan that comes in dimensions as long as 27 x 4 x 1.5 inches and their bakery solution experts will be debuting an extra-tall round cheesecake pan, measuring 8×4 inches.

The Long Pizza Pan comes in several lengths with a standard width (4 inches) and depth (1.5 inches). Pizzerias can produce long personal pizzas with the 12-inch long pan, feed a family with the 18-inch long pan or serve a whole party with the 27-inch long pan. Each pan features LloydPans’ proprietary PSTK® coating that offers operators a durable pan that requires no pre-seasoning.

Lloyd’s new tall cheesecake pan was

The MGS-402 is part of the MGS-400 series gas detectors that connect through Modbus to up to two remote MGS-410 gas detectors at up to 1000ft (305m). The MGS-402 is powered by 110-240V AC and provides three 10A output relays (fault, low alarm, high alarm) to initiate auxiliary ventilation or restrict refrigerant flow, two analog outputs for interface to a BMS or fire/ safety panel packaged in an IP66 enclosure.

The MGS-402 has a built-in audible alarm and high-visibility visual alarm that eliminates the need for an external horn/strobe in close proximity. The remote silence input enables silencing the alarm from outside the monitored environment. Configuration of the MGS-402 is simple and intuitive, reducing installation time.

originally launched as a custom pan, but due to popular demand, it has now found a permanent home in their line of loose-bottom cheesecake pans. The 4-inch-high pan features a stick-resistant coating that allows for easy release. The coating also makes the pan steam resistant, which means a baker can de-pan cheesecakes now or later and they won’t damage the pan or the integrity of the cheesecake.

Bulk bag fillers manufactured by Best Process Solutions, Inc. (BPS) are designed to fill any size bulk bag with high accuracy, while offering years of trouble-free maintenance.

BPS’s Model BBF loader features an inflatable fill head that offers a dust-free seal when loading, dust port with dust cartridge, and manually adjustable bag supports for varying

A national initiative, #ServingHospitality, aims to keep Canadian restaurants resilient to the financial challenges caused by COVID-19 by providing them with a cash injection at a time when they need it most.

Customers can purchase e-gift cards to the restaurant of their choice – whether that’s a pizzeria, café, restaurant, coffee shop or bar – to be redeemed once the business reopens its doors. Registered businesses will also be offering an additional value credit on customer purchases between 10 per cent and 30 per cent, at the discretion of the business itself.

Customers can purchase e-gift cards to the restaurant of their choice – whether that’s a pizzeria, café, restaurant, coffee shop or bar – to be redeemed once the business reopens its doors. Registered businesses will also be offering an additional value credit on customer purchases between 10 per cent and 30 per cent, at the discretion of the business itself.

One hundred percent of purchases (excluding credit card fees) will go directly to hospitality businesses, and customers will be able to redeem their e-gift card through the inKind app. Customers also have the option to share any portion of their gift card with friends and family through the inKind app. Customers can support their favourite restaurants by visiting servinghospitality.org.

bag heights—great for low ceiling heights. Many options are available.

BPS manufactures a complete line of custom-engineered, bulk-processing equipment and systems. With more than 100 years’ combined experience, the company serves a wide variety of dry processing industries from chemicals and food to aggregates and recycling.

BY DIANE CHIASSON

Ways to help your bakery survive an economic downturn:

Two easy tips to get ready after lockdown

When businesses face tough times, the first thing most businesses do is to stop marketing their operation. Many marketing experts, including myself, will tell you that cutting marketing costs is a disastrous business decision. Doing so will leave your brand in a less competitive position when the economy recovers. It has been proven repeatedly that cutting marketing and advertising during a downturn will delay recovery. Many bakery owners behave the same way. Fearful of declining revenue, they will cut marketing, reduce prices and postpone new projects. It’s a normal reaction. However, I insist that marketing and website improvements are not the things that you should suspend. Budgeting for marketing and advertising is as necessary as your electrical bill or your payroll. Now is not the time to cut promoting, advertising, and marketing. Over the years, research studies have confirmed that the best strategy in terms of long-term return on investment is to either steadily continue or aggressively increase marketing spending during an economic downturn. In previous recessions, bakeries that continued to invest in marketing saw an overall growth in their businesses at the expense of the competition, while those that stopped their budgets saw a decrease in sales. You should always be marketing to new potential customers as well as marketing to your existing customers.

mean the same, but they are not the same thing. Advertising is a one-communication; it is something that you would do to promote your bakery business, products, or services. Think of an ad in a magazine, TV or radio commercials, and website banners. Promotion includes all the particular activities and ways available that are intended to announce or promote your business, products, or services. Examples include team or league sponsorships, contests, events, coupons, social media, and direct mail. Promotion campaigns are often done to get the media to promote your message at no cost. Promotions usually don’t cost a lot of money the way advertising does, and you may want to do some daily promotions. Don’t forget to get involved in charitable events, whether by hosting or sponsoring an event, which will be a great way to create a positive attitude about your bakery in your community.

}Budgeting for marketing and advertising is as necessary as your electrical bill or your payroll. Now is not the time to cut promoting, advertising, and marketing.

The result in doing both, advertising and promotion, at the end is to create brand awareness, getting leads, and increase your sales.

It’s important that you spend your marketing budget wisely. You need to know how much you can spend. You also need to have a strategy on how to spend it, where to spend it and what you want to achieve. It’s also very important to understand that any purchases depend on consumers’ having disposable income, feeling self-assured about their future, and trusting in business and the economy. You should definitely analyze your POS data for food cost savings. Check which menu items you can temporarily eliminate (products ordered less frequently) and which products your most loyal guests tend to buy. What can you offer right now that no one else can? Can you think of some creative and unique ways that you can help your customers?

2. FOCUS ON EXISTING CUSTOMERS AND CARE ABOUT

Below, are two simple tips in a two-part series on marketing your bakery during a slowdown.

Promotion or advertising?

You may think that these two words

If you suddenly decide to stop everything in terms of marketing, you will have to start over by building momentum from zero. If your customers haven’t heard from you in a while, you will have to work twice as hard to get their loyalty back. If I may give you a piece of advice, rather than suddenly stopping your marketing efforts, you are better off maintaining or even increasing your efforts to make sure that you are in a position of strength when this economic downturn passes. Remember that increased spending in marketing and advertising during a downturn will pay off exponentially in the months and years to come. I certainly believe that you should keep marketing during an economic downturn, especially if your competitors aren’t!

1. ANALYZE AND TRACK EVERYTHING RIGHT AWAY

Your bakery brand’s biggest asset during an economic downturn will be your existing customer base. Your marketing strategies should focus on your most valuable and loyal customers. Happy customers will always help you back by recommending your bakery and make reviews on social media platforms. The importance of honest communication with your customers cannot be overstated. Find out what kind of customers come to your bakery, get to know them better, and find out what they want. You may consider asking each customer what they would like to buy would be a good strategy. Develop meaningful relationships with your existing customers, and most particularly with your new customers. Customers appreciate bakeries that care about their experience and make them feel welcome.

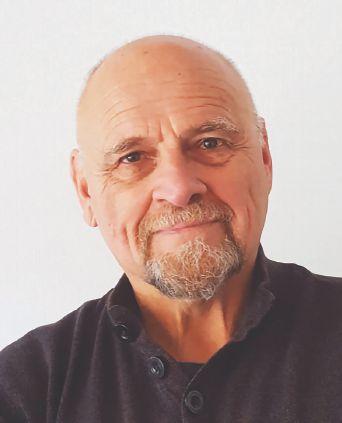

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultlants.com , or visit www.chiassonconsultants.com

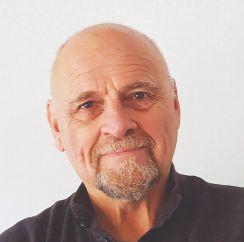

NAOMI SZEBEN

Bakers Journal chatted with the owners of Luscious Bakery Deli Café, to find out how they are reaching out to their community, especially during the pandemic. Despite being a seasonal bakery, Luscious has seen “double digit” growth since its inception in 2012. What’s their secret? Karen and Chris Koos embody what they call an “attitude of gratitude,” that wins clients and neighbours alike. Their cookies reflect the bakery’s

creativity, and charitable heart.

“In 2017 and 2018, our focus was our $2 Purple Ribbon Sugar Cookie Campaign.

Following our son’s lifechanging surgery in December 2016, we decided to bake, decorate and sell purple ribbon cookies, donating all the proceeds to Epilepsy Southwestern Ontario,” said Chris Koos.

“The purple ribbon cookie, of course, is near and dear to our hearts. Our son suffered with epilepsy for 20 years… we’re happy to say he has now been seizure free for three

years since his surgery,” added Karen Koos.

The bakery still updates its inventory with “brains” cookies that are a hit with fans of zombie lore and cookie lovers alike.

Despite having a personal connection to epilepsy, it’s not the only cause the bakery supports. “In 2019, our charity of choice was the Canadian Mental Health Association with the sale of decorated unicorn cookies. At the end of the season, an In Memoriam donation was made on behalf of one of our young employees who passed

away suddenly due to suicide last year.”

Luscious Bakery had the blessing of her family for the memoriam donation to the Canadian Mental Health Association. “We already had a ribbon campaign happening,” explained Karen about the unicorn design, inspired by the deceased employee whose name the bakery asked not to be printed. “When she was having a bad day, she would try to remind herself of rainbows, butterflies and unicorns, so we chose a unicorn sugar cookie. All of the proceeds of the unicorn

sugar cookies went to Mental Health Grey Bruce, with her name and her birth date and the year she passed away.”

The pair understands that everyone has difficult times and sometimes need a leg up. Chris informs Bakers Journal that the bakery’s motto is ‘interaction before transaction.’ “That’s that was kind of our slogan for the longest time because Daniel loves to talk, and we do too...we’re genuinely interested in people’s story, whether they are a tourist or our neighbour.” His wife chimes in, “Basically, we don’t say no to anyone. Everyone gets something, whether it’s a gift certificate to raffle off, or a basket of product for their charity. You kind of get to know everyone. We just wanted to be a part of their lives. And we’re genuinely interested in other people and what their story was.”

Luscious Bakery weaves itself into the fabric of Sauble Beach’s life by promoting its local attractions and businesses. “We have a map posted, where you can find this or that activity. Great for the kids on a rainy day, and our whole concept was based around it.” Using that map as a cross-promotional tool, other businesses return the favour by placing orders and take out.

}“Our concern for the community in itself is has really been our success. I think we believe that to the heart, only because we are so happy with the choices we’ve made in this area.”

bakery, we thought we’d be able to do this for fifteen years but we’ve become so busy.”

“We’re heading into our ninth season now,” says Chris. “Like Karen said we increased our business, double digits every year since 2012. It’s a family run business with Karen, myself and Daniel…but it’s been tougher and tougher, every year since. Definitely since 2014, to try to get the staff we require considering the amount of volume that has increased.”

Karen chimes in, “I’d like to work a little less and I’d like to grandparent a little more. When we first bought the

The couple is selling the bakery that has been the hub of the Sauble Beach community, but they are looking for owners with similar values, first and foremost.

“Our concern for the community in itself has really been our success. I think we believe that in our hearts, only because we are so happy with the choices we’ve made in this area,” states Karen.

“The interactions we’ve been able to gain has allowed our success as well; we truly believe that can’t be trained. I think it has to be innate to the

purchaser of our business. They will enjoy similar or, even better success.” Chris adds, “basically, it’s all about the amount of interest and care people have; the passion for serving a community. That’s really what we’re looking for in a buyer.”

The pandemic has put a new twist in the baking power-couple’s plans. Since the bakery was posted for sale just before the lockdown began, realtors had not been able to enter nor sell the property. However, that didn’t stop the Koos from selling bread to the neighbourhood (from a safe, contact-free distance, of course.)

The bakery continues to sell cookies and has teamed up with Reunion Island Coffee Roasters, and they deliver coffee, cookies and breads to customers who call in their orders.

“We’ve had a chance to observe what other similar industries are doing. As far as contactless pick up goes, we won’t be open as a storefront. But people like us, and they can call in pre orders and prepay through e-transfer. When they pull up their car to the door, we have them pop their trunk or we’ll just open their backseat door and pop in their prepaid order.”

It’s through partnerships with other companies and connections to people that keep this bakery running in tough times. / BJ

Ardent Mills discusses FLOUR TRENDS AND NEW GRAIN options for bakers and pizzerias. From high-end dining to food truck fare, Bakers Journal explores options for balancing consumers’ need for healthy ingredients with their demand for indulgent food experiences. Where does the connection between nostalgia and health lie? Elaine O’Doherty of Ardent Mills fills us in on what’s new with ancient grains.

Who and what types of businesses/ operators does Ardent Mills work with?

Ardent Mills serves a wide variety of customers who are looking for highquality grain ingredients, as well as support from our experts who can help with everything from product development and sourcing to distribution and packaging.

We serve North American distributors, CPG manufacturers, artisan and commercial bakers, retailers and the foodservice industry, including both commercial and institutional foodservice operators.

What types of ingredients are you currently using to develop flours?

We’re leveraging industry and consumer trends to drive innovation in flour. Ardent Mills has put a stake in the ground marking our commitment to organic with a broad portfolio of certified organic flours, grains and mixes.

Additionally, we are riding the wave of plant-based eating, and with the rising popularity of chickpeas as a source of protein, chickpea flour is trending. We recently introduced chickpea flour, and we’re confident it will fill the demand for operators looking to deliver plant-based and protein-focused options.

What properties make them suitable for use in flours?

Aside from their unique flavour, chickpeas offer a host of nutritional and operational benefits. Our chickpea flour contains approximately 20 grams of protein per 100-gram serving and is rich in vitamins and minerals, such as iron and folate. It’s also available in three varieties: coarsely milled, ultra fine and gluten free, allowing operators to cater to their customers’ dietary preferences.

Many flours milled from ancient grains can offer the benefits of whole grain nutrition, including the possibility of high amounts of fibre, omega-3 fatty acids, antioxidants and trace vitamins. Certain varieties, such as quinoa, amaranth, buckwheat, teff and millet, are also naturally gluten-free. Ancient grains can also bring a unique texture to flour for added variety and opportunity to drive culinary innovation.

Is there an ingredient you plan to work with in future – that you can share with us? Why?

We’re continuing to keep an eye on industry and consumer trends, and we’re excited to share that on February 18 we purchased substantially all of the assets of Andean Naturals, Inc., which operated a gluten-free quinoa sourcing, cleaning and packing facility in Yuba City, California. This reinforces our commitment to innovation and growth in specialty grains.

looking for more transparency and “cleaner-label” ingredients.

Operators should also consider toppings – items like roasted root vegetables can pack a delightful flavour and nutritional punch, and crust add-ins, such as quinoa, chickpea flour and spelt, could offer even more nutrition, texture and flavour.

Which specialized markets – certified organic, gluten-free, non-GMO and organic compliant – do you think the fresh-pizza industry should pay the most attention to? Why?

At Ardent Mills, we encourage our customers to see organic as a great messaging opportunity, even if they don’t go 100 percent certified organic. With organic flour, restaurant and bakery operators can offer bread, flatbreads or pizza “made with organic flour.” Even if all the other toppings and ingredients are not 100 percent organic, diners will appreciate having organic options available.

“Consumers want to connect to the specific ingredients they eat — from local heirloom tomatoes to organic and ancient grains.”

Is it important for bakeries to adjust their menus to meet demand for more nutritional food? Why?

An ideal menu is balanced with healthconscious and indulgent options. Pizza, depending on the crust and the toppings, can fit into both categories. Offering pizza menu items that are on the lighter or more nutritious side can capture the attention of consumers who are looking to include pizza in their healthy lifestyle or who want to partake without going overboard. Crust options suitable for consumers who follow vegan or gluten-free diet guidelines can help meet this niche (but growing) consumer demand; similarly, whole grain crusts or crusts made with organic flours can satisfy those consumers

This is key as demand for organic continues to heat up. According to the Canada Organic Trade Association (OTA), the current organic-food market is estimated at $4.4 billion, representing 1.8 percent of the total foodservice market. The Canada OTA reports 66 percent of grocery shoppers are now purchasing organic items weekly – and 83 percent of those weekly organic shoppers are millennials , a large and influential purchasing demographic.

Can you share any tips for bakers in developing a signature experience?

From food trucks to fine dining, today eating out is as much about the experience as it is about the food. Consumers want to connect to the specific ingredients they eat – from local heirloom tomatoes to organic and ancient grains. When developing a “multigrain pizza crust,” consider the flavour profile and functionality of each individual grain. Chefs should experiment with several types of flour and grain combinations to find the right balance for their best-selling toppings. / BJ

Bakers Journal would like to thank Founding Sponsor Ardent Mills for the Jake the Baker award.

Thank you for recognizing the heart and hard work Canada’s bakers bring to their communities.

Stay tuned for the big reveal in November, when Bakers Journal unveils the winner of 2020’s Jake the Baker contest at the Bakery Showcase.

MIKE WOULFE, VP ENZYMES, KERRY

The Government of Canada released its draft assessment report for acrylamide on February 21, 2009, and the US lists acrylamide as a chemical causing either cancer or developmental/ reproductive toxicity. While neither New York nor Washington State specifically list acrylamide, both state laws hold the potential to set standards for its use in the United States; this is in addition to requiring disclosure. In Washington State, there is also the potential for an outright ban on listed chemicals.

“Given the significant, ongoing monitoring and regulation of acrylamide in products selling in California, food manufacturers selling into that state are advised to make sure their acrylamide content is ALARA: as low as reasonably achievable,” stated Mike Woulfe of Kerry Foods.

On November 7, 2019, the International Agency for Research on Cancer (IARC) posted its scientific advisory group recommendations for the next five years in its cancer research monographs and gave acrylamide a “high priority” classification. The significance of this is that California’s Office of Environmental Health Hazard Assessment (OEHHA) adapts IARC’s analysis in developing and maintaining its chemical listing for Proposition 65. OEHHA lists acrylamide as a risk for causing cancer, male reproductive toxicity and developmental toxicity.

On November 11, 2019, the EU issued regulations expanding the new food groups and products to be monitored by member states for the presence of acrylamide. The results are to be submitted to the EU by October 1 each year. These include the following (list is not exhaustive):

• Rolls: Hamburger rolls, whole wheat rolls, milk rolls, etc.

• Flat breads: Pita bread, Mexican tortillas

• Pastry: Croissants, Doughnuts

• Speciality bread (such as pumpernickel bread, ciabatta with olives, onion bread, etc

• Pancakes and blinis and crêpes

• Crisp cookies from thin strip of dough and deep fried, such as Churros

• Cereal products: Rice and maize crackers as well as cereal snacks (such as extruded maize and/or wheat products)

• Other products listed were roasted grains and nuts such as honey

roasted muesli, Roasted nuts, including cacao beans and derived cocao products.

(Source: EN Official Journal of the European Union 11.11.2019 L pp 290/33)

“The EU continues to both expand and tighten its ongoing regulatory overview of acrylamide’s presence in a wide variety of foodstuffs. Bakery, and cereal products appear to be a top priority for continuous monitoring, and results are to be submitted each October

In an April 24, 2020 letter to the Prime Minister, 14 food industry associations including BAC, made two sets of recommendations in support of the immediate and long-term challenges facing Canada’s food industry. The first set identified the immediate financial support required by food processors to address the long list of immediate challenges facing the industry. These included modifying the Canadian Emergency Wage Subsidy to make it more available to food companies, expanding existing business risk management program to include food makers particularly to address new costs associated with COVID -19 such as protective equipment other social distancing measurers.

In addition, the early weeks of the crisis revealed that there is a critical need to enhance understanding of how the entire food system functions. In order to do so the signatories recom-

mended the federal and provincial governments should, when we enter more of a recovery phase, initiate an armslength review of how the food system managed in COVID 19. This review

should examine questions such as:

• What public resources – including regulatory, policy and program – are currently focused on the food system (and on which parts) and where are there gaps?

• How should governments structure their resources to ensure there is appropriate and adequate leadership, as well as policy and program capacity to support the entire food system?

• How do federal and provincial governments, and different government departments, coordinate their policy analysis and resources?

• How do governments and industry work together as partners to further economic and food security goals?

• How do we balance our enhanced food security objectives with Canada’s role and opportunities as a food exporter?

Much work has to be done over the coming weeks and months in support of our recovery from this pandemic. However, BAC would not like to lose sight of the essential contribution of all members and Canada’s baking community over this crisis period. Thanks to you all in ensuring Canadians had and continue to have access to marvellous baked goods.

MONDAY AUGUST 24, 2020

Bond Head Golf Club - 4805 7th Line, Bond Head ON, L0G 1A0

Registration & BBQ lunch starting at 12:00 p.m.

Shotgun - SCRAMBLE – Start 1:00 p.m.

Contact: _____________________________

Email: ____________________________ Phone #: _______________________________ (Please include email address as registration will be confirmed by email.) PLAYERS - FORMAT - Scramble Only

________ TICKETS @ $225 (golf, cart, lunch & dinner)

TICKETS @ $80 (dinner only)

________ TICKETS @ $240 (golf, cart, lunch & dinner)

TICKETS @ $110 (dinner only)

Gold Sponsorship - $750 ___ Silver Sponsorship - $500

Bronze Sponsorship - $250 (choose 1 sponsorship only)

Please reserve _________ X $60 Hole Sponsorship

PLEASE RESERVE ____ Spot(s) for Golf & Dinner @ $150 each ____ Spot(s) for Dinner only @ $50 each

____ Golf Passport (Booklet covers mulligans, prizes, 50-50 draw) @ $50 each

____ Platinum Sponsorship @ $500

• Sponsorship identification at the registration area

• Sponsorship identification at the banquet dinner

• Tee sponsor signage

$______________ (GST included in prices Tax# 887064798RT)

Please enter us as a foursome Please place me on a team As always - we appreciate your prize donation! Prize = Yes No

(beginning this year). Many of these items are consumed by children, whose exposure to acrylamide is an important concern to the EU and other governments’ regulatory bodies.”

Kerry launched one solution to fight acrylamide in their Acryleast product. “Many customers have initiated lab-scale and plant-scale trials with it and found it reduces acrylamide levels in many different food products without changing any manufacturing processes. To date, in both lab and manufacturing plant-scale testing, Acryleast has delivered exceptional reductions in the production of acrylamide. Dosage and application methods vary between the different food products, achieving results that range from an 85 per cent reduction in children’s cookies (lab) and 93 per cent in crackers (plant).

“One observation is that plant-scale results are generally better than lab-scale tests of the same product. The takeaway from all of these applications is that Acryleast can be highly effective in many different products, most notably baby biscuits and snacks, digestive and morning biscuits, crackers, bread for toast and burger buns and crispbread.”

When asked to inform Bakers Journal if there was a technical, cost, performance, or taste benefits to the yeast, Woulfe stated that it is similar to a traditional baker’s yeast, but unlike that,

}tion, process flows, contact time with Acryleast and the recipe,” stated Woulfe. “Our customers have reported a much higher acrylamide reduction in full-scale manufacturing trials. We have seen this theme throughout applications such as crackers, biscuits and bread.”

Bakers Journal asked if Kerry Foods wold say food manufacturers are taking the necessary steps to reduce acrylamide? Is there any way to know what

”Bakery, and cereal products appear to be a top priority for continuous monitoring, and results are to be submitted each October (beginning this year). Many of these items are consumed by children, whose exposure to acrylamide is an important concern to the EU and other governments’ regulatory bodies.”

it does not provide the same functionalities as a yeast rather its sole functionality and purpose is to reduce acrylamide. It’s intended to be added for the reduction of acrylamide and not to provide a ‘’yeast-like function.’’ As such it is considered a processing aid and does not require labelling.”

Bakers Journal mentioned its awareness of that Kerry’s findings regarding a study stating Acryleast reduces acrylamide by up to 90 per cent in your own trials. What has the company learned about its effectiveness in customers’ processing facilities? Does the yeast work better in some conditions than others? What about in different product types?

“The level of acrylamide reduction using Acryleast depends on the applica-

proportion of that effort comes just from process – such as lower temperature cooking/frying – versus enzymes, yeasts or other ingredient side solutions?

Woulfe replied, “Since launching Acryleast we [Kerry] have seen a steady increase in engagement with customers over their concern of acrylamide reduction. Kerry is working hand in hand with our customers and supporting them in carrying out plant trials with Acryleast. They are choosing to use Acryleast for a variety of reasons, such as having no impact on taste or texture and its organic suitability,( in the US region). This is particularly relevant for organic children foods since regulations are expected to get more stringent in this area. And the fact that it is the only truly

non-GMO solution available on the market.”

“We are aware that large global companies are setting their own internal standards,” he added. “We also know that customers exporting into regions covered by legislation like California with Proposition 65 are taking action to be compliant. Therefore, the food and beverage industry is addressing this as a serious concern and see it as the right thing to do globally.”

“In addition to this some NGOs are looking for access to data submitted to the European Food Safety Authority on acrylamide levels for products, to further highlight the concern. They are calling for the introduction of mandatory maximum levels. This shows that NGOs are keeping pressure on the acrylamide issue and getting more hard-hitting. This creates considerable brand risk for the F&B industry.”

Bakers Journals inquired about which applications areas Kerry has seen with Acryleast and what percentage of reduction was achieved.

“We have had successful results with a broad range of applications,” stated Woulfe. “We are constantly exploring new applications to meet our customer needs and to tackle the wide variety of products where acrylamide levels are an issue. Among the best results we have achieved so far in a manufacturing plant setting was an acrylamide reduction of 93 percent in crackers.” / BJ

The food industry was abuzz in the lead up to the legalization of cannabis in Canada. Professionals, both users and non-users alike started to contemplate new products to satisfy customer curiosity and to gain a competitive edge.

Government laws restricting how companies produce and sell edible cannabis products and the costs involved have slowed many, if not halted altogether. It isn’t surprising that

consumers have decided to start making their own.

In summer of 2018, Vanessa Labrecque, an avid baker and her boyfriend Joshua Tuck, a cannabis grower for 28 years, were watching television together, when in the middle of a cooking show they came up with a business plan. What about opening a cooking school based on making cannabis products?

Labrecque had long been adding infused cannabis into her homemade chocolate brownie recipes. “I was using the old-fashioned method

with a double boiler, which had to be tended for a period of up to four hours,” she remembers.

Once she perfected the brownie recipe, she needed to decrease the preparation time in order teach classes that did not take a full day. Enter the Magical Butter Machine reducing the infusion time of the cannabis--- into a wide variety of fats such as vegetable oil, olive oil, coconut oil or cream-- down to just one hour.

And then very quickly, in October of the same year, the

couple opened The Cannabis Cooking Company, in Toronto, Ontario, located in a rented 1500 square foot food photography studio.

“We wanted proof of concept, without buying a place ourselves. Now, for every class we roll out our cooking school,” says Labrecque, referring to the 10 cooking counters on wheels, filled with all the equipment and utensils needed to allow 20 students to create. After class, the carts are neatly rolled out and packed away.

And what was the main

thing students wanted to learn how to make? “Honestly, it was my chocolate brownies,” she exclaims, with a laugh.

Lebrecque feels the success of the cooking school is largely based on a lack of edible products legally available and the underground movement selling products containing uncontrolled amounts of cannabis. “We really need to teach people about microdosing in small increments of 2.5 milligrams. It’s about finding the right dosage for each individual person.”

}Instructors help student make products that are baked in small portions instead of cut. “We can control the amount of cannabis in each, like brownies made in small muffin tins, breakfast muffins, mini cheesecakes, butter tarts or cake pops,” she says. “Instead of adding the infused cannabis into the whole batter, each piece gets an individual dose.”

Class names include Wake and Bake; Candy Making; Cannabis Cake Pops and even Donuts Glazed with Daze. Students of legal age arrive to class, after having purchased their own legal, unopened

cannabis. Once the infusion is made, students use it for their creations. The rest is taken home in a well labelled, child-proof mason jar.

In the future, Lebrecque sees more advanced classes in the works. Once students have learned how to infuse the cannabis, they can bring their homemade infusion to class and focus on making more intricate recipes. Legally the school cannot pre-make the infusion and supply

not have a good understanding of the variability that exists in scent profiles of different cultivars or strains of cannabis,” says Lilien. “This may be a result of the high prevalence of the terpene myrcene, the most commonly occurring terpene in cannabis, which smells earthy, musky and mildly fruity.” she says.

Terpenes are the organic compounds found in the plant kingdom that give each a unique smell. Over 100

“The general public may not have a good understanding of the variability that exists in scent profiles of different cultivars or strains of cannabis,” says Lilien.

students with it.

Tamara Lilien is a certified cannabis sommelier and chief information officer at The Cannabis Cooking Company. She starts her day by purchasing four or five different types of legal cannabis. Then, she does a taste and smell profile together with Brent Leitch, the company’s executive chef, to find foods that will complement both the primary and secondary notes of the cannabis.

“The general public may

are two methods, passive, which preserves the terpenes and active which evaporates many of the terpenes. In both methods the cannabis is first ground or chopped.

With active decarboxylation the cannabis is baked in the oven at 240 F for 30 minutes. “This will activate the cannabinoids, like THC and CBD, at the expense of many of the terpenes evaporating,” Lilien points out.

For passive decarboxylation the cannabis is added directly into the infusion.

“With this method, you can expect a loss in potency of about 60 per cent, but many of the natural flavours of cannabis are preserved because the terpenes do not evaporate,” she says.

“Cultivars with citrus notes, like Jack Haze by 7Acres or Tangerine Dream by San Rafael are highly versatile as they complement a wide variety of recipes. If you were preparing a custard, you might select Pedro’s Sweet Sativa by Color Cannabis due to its sweet scent of berries. “

different terpenes have been found in cannabis. “This varies based on both the genetic variety of cannabis, and the way the genes are expressed in the environment. The smells and tastes can be affected by the climate the plant was grown in, the geographical environment and the growth medium, for example in organic soil, with chemical fertilizers.” Lilien explains.

Heat and cooking time activate cannabis in a process called decarboxylation. There

Baking quality products, that contain controlled amounts cannabis, keeping in mind the method of decarboxylation used and the countless flavour and smell profiles is a much more exacting and scientific approach than one may have originally thought.

The Cannabis Cooking Company is currently running 14 classes per month. It will be interesting to watch this little company on the forefront of something new and unexplored to see what they will come up with next. / BJ

Karen Barr writes about arts, culture and cuisine. She is a George Brown graduate and a Red Seal pastry chef.

Bakers Journal spoke with Crisp’s founder, Are Traasdahl, about the AI-driven program he created. Though Crisp was invented with the intention of reducing food waste, the pandemic generated a new use for it: anticipating food shortages of finished goods or scarcity of ingredients before a product was made.

Traasdahl spoke of his travel-inspired invention. While staying in New Zealand, he witnessed an apple orchard that had 70 per cent of its apples rotting in the field after the end of the season. Similarly, the opposite was happening in India, he noted, and his mission to find out why began.

“We did research on this…we see that often more than a third of the food that’s being produced does not reach the consumer at all. I’ve been aware of that for a long time and we all try to do something about it. But one of the really big issues is all that food being lost before it reaches the consumers,” he stated.

According to Traasdahl, Crisp tracks the supply all the way through the food industry chain. For many products such as baked goods, many companies may be involved. Other considerations include the cost of imports and exports, manufacturing costs, packaging and finally, marketing.

“We capture data along the whole supply chain and use that data to produce very accurate sales forecasts. We interviewed over 100 executives in the in the food industry, and it all came down to one thing: it’s incredibly hard to have an accurate sales forecast; That’s the reason that sometimes we have too much; If you have too much you have to throw it out. Have too little, then you lose out on revenue and have upset customers because you have too little.”

Traasdahl’s twenty years of

Crisp is a tool that helps predict availability and demand and stop food waste at the source.

technological experience with data mining came in handy. According to him, the use of the program is easy and can allow for a sales forecast that allows any baker to know how much they will sell in three months or in a year. “That’s been very helpful in terms of the

reduction of food waste but also in terms of creating more revenue.”

While bakeries experience seasonal peaks and valleys, the system uses a bakery’s own inventory history and past sales to isolate demand.

While holidays are a “demand driver,”

Bakers can use Crisp to gauge demand for their products and reduce food waste; this in turn helps artisanal bakers save money.

events like pricing and promotions also influence the date. “What the software does is go back three to five years and it takes all that data. Crisp uses machine learning and artificial intelligence, for lack of a better word, and then it separates all of these different demand drivers so when you see the same combination, you know what to expect.”

“We typically say that we need at least two years of data. We’d like to have three years, and if we can get five years, great, but if somebody has 10 or 20 years, that makes our algorithms and our technology work even better.”

“It’s incredibly hard to have an accurate sales forecast; That’s the reason that sometimes we have too much; If you have too much you have to throw it out. Have too little, then you lose out on revenue and have upset customers.”

“We spent a lot of time making this as simple as possible and easy to use. So, getting the data into this platform was very important. The bakery just creates a sales report that goes back to the number of years they want and they feed that into our system and we do everything on our end. We fit that all in, then minutes later they can go in and get a forecast for it…typically some data clean-up needs to happen, first. There might be a situation where a bakery found 10 new stores to sell products or there was some particular promotion that happened that created a big spike, or the bakery was missing one particular ingredient for a long time so they couldn’t make that product.”

“So they typically kind of go through the history of the products and we identify for them. If these data lines seem

like our players, all of a sudden we have a big spike or big drop. So then, the software allows them to put it in. We take that into our calculations when we measure future projections.”

“Most ERPs or all ERP systems that we work with, do not have great forecasting functions. So we do the forecasting based upon received data we get from the ERP and then we can push it back into the system as well so that it then has our accurate forecast; based upon this they can do bot sourcing of products, they can do production planning, they can do labour planning, they can do all those things that the ERP system is built for, for forecasts that are very accurate.”

Food waste in Canada is a growing concern, outside of pandemic planning. Prior to the outbreak, Toronto agency Second Harvest reported that $4.82 million is lost or wasted during shipping and processing (baking and packaging.)

Some 2.38 million tonnes of food, or more than $10 billion worth, is lost before consumers can buy it. Many restaurants reported that their sauces, breads, salads and sides won’t keep and are often wasted. Few perishables can go to food banks or be donated to households.

Finding a way to prevent waste at its source by determining demand and gauging circumstance can reduce further waste and prevent financial loss for any restaurant or bakery.

Some may feel that machine learning has little place in a bakery, but if the wild swings of availability during the pandemic have taught us anything, it is to evaluate the past to better determine our future. / BJ

Our high-quality maple syrups are 100% natural with absolutely no chemic or preservatives

Maple Syrup provides several essential nu One 60 ml (1/4 cup) serving of maple syrup contains 72% of the daily nutritional re of manganese, 27% of riboflavin, 17% copper and 6% of calcium

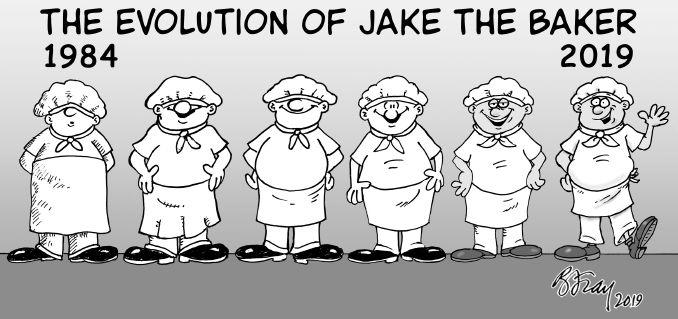

Bakers Journal interviewed with BRIAN FRAY, the cartoonist who creates the lively cartoon character who has appeared in Bakers Journal over the last forty years. Jake the Baker was such a fixture in the magazine, that a commemorative 80th Anniversary Edition without Jake would be unthinkable. He remains the iconic face of the Jake The Baker Contest.

BAKERS JOURNAL / When was the first Jake the Baker cartoon published?

BRIAN FRAY / I believe the first Jake cartoon appeared around 1980, although I’m not sure of the exact date. So, about 40 years ago.

BJ / When did you first start drawing?

BF / I have been drawing ever since I could hold a pencil. I just picked it up and started scribbling.

Bakers Journal approached me, first. I was doing a trade show to promote another character that I was doing, Le Grand Chef Pierre, and the publisher at the time, Ernest Naef approached me and asked if I’d be interested in doing some cartoons for his magazine, Bakers Journal.

BJ / What (or who) was the inspiration for Jake? Is he modelled on anyone you know? (If he is, do they ever complain about showing up in your cartoons?)

BF / The publisher, Ernest Naef, gave me some back issues of Bakers Journal to look at as reference material. Jake is a compilation of some of the bakers I saw in the magazines back then. And, no, I’ve

never had any complaints from them. I suppose my favourite is always the last one I’ve done because it means I’ve got it finished and haven’t missed a deadline in forty years.

BJ / Did you ever get complaints about any one of your cartoons?

BF / I have never once had a complaint about a Jake cartoon. It’s always been very positive. I was also the editorial cartoonist for the Guelph Tribune. In

“I was also the editorial cartoonist for the Guelph Tribune. In one editorial I referred to the city council as a bunch of clowns. I actually got a complaint — from a professional clown. That’s a true story.”

one editorial I referred to the city council as a bunch of clowns. I actually got a complaint — from a professional clown. That’s a true story.

BJ: Share your creative process with your readers. How do you start on your cartoons?

BF / This is my job, so I treat it like one. I keep regular work hours and don’t wait for a divine spark of creative inspiration. I sit down at my drawing board and read over any reference material that I have available on a

Through the many iterations of Jake the Baker over the years, readers can see Jake’s eyes slowly emerge from under his toque. Here’s his gradual evolution over the years to today’s version.

particular subject about which I’m cartooning. In the case of Jake, it’s Bakers Journal. Then, I start doodling ideas on a blank piece of paper until something takes hold. Sometimes ideas pop into my mind quickly, other times it’s a hard grind. But I never wait for for “inspiration” to come to me, I track it down.

BJ / What do you do to keep inspired?

BF / It’s easy to stay inspired when you love what you do. I still get a kick out of developing an idea from a doodle, coming up with a funny gag and seeing it come to life on paper. And knowing that people enjoy my work is always a bonus.

BJ / How do you deal with Writer’s Block, or “Cartoonist’s Block?”

BF / After over forty years as a cartoonist, I rarely get “Cartoonist’s Block”. My mind is always working away at something. And if I do have a bit of a creative lull at times, I sit down at my drawing board and keep working until I come up with an idea that I’m happy with.

BJ / Bakers Journal readers want to know – what is your favourite baked good?

BF / Probably chocolate brownies. Or pretty much anything with chocolate in it. / BJ

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell

Phn: 905-819-7000

Fax: 905-819-9768

Email: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

Ardent Mills is working for the good of grain and committed to pioneering what’s next, with value-added, nutrient-rich on trend grain solutions that deliver superior performance and consumer appeal. But that’s just the beginning, because we are also the company behind some of the most trusted brands in the commercial bakery and food service industry today. Our premium white, whole wheat and whole grain flour, oats and savoury baking and pizza mixes are backed by over a century of milling heritage and excellence.

6860 Century Ave., Suite 301 Mississauga, ON L5N 2W5

Contact: Reid McEachran

Phone: 905-494-2600

Email: info_ca@ardentmills.com

Website: www.Ardentmills.ca

Plants: Flour Mills in Mississauga, ON, Montreal, QC, and Saskatoon, SK. Bakery Mix, Oats and Durum plant in Saskatoon, SK. Products offered: A full line of high-quality flour with legacy brands that include Baker’s HandTM, Keynote®, Rapido®, Tulip®, Velvet® , Peach Pastry® and All-O-WheatTM. As an industry leader in innovation we also offer Primo Mulino® Neapolitan-Style Pizza Flour, Simply Milled by Ardent Mills® certified organic flour and Ultragrain® white wheat whole grain flour. This is complimented by our line of oats, durum, specialty grains

and savoury baking and pizza mixes, many formulated specifically to customer’s needs.

Delivery: Across Canada by rail or truck and throughout North America.

Distribution: Direct from plants, regional warehouses or distributors, depending on product availability and location.

Major Customers: Bakery and Food Processors, Retail & Wholesale Bakeries, Grocery Retailers and In Store Bakeries, Food Service Operators, Bakery and Food Service Distributors.

1150 Rang Saint-Edouard, Saint-Liboire, Qc, J0H 1R0

Contact: Doug Phelan

Phn: 438-622-5260

Email: dphelan@farinart.com

Website: www.farinart.com

Products offered: Our name, Farinart, has its origins in French and literally translates to ‘’Flour Art’’. We are commercial baker partners who provide custom formula grain blends and stone ground flours, both organic and conventional. We create innovative taste profiles using the freshest ingredients and aspire to continuously exceed service expectations. Our processes include stone milling, sprouting, caramelization, roasting, flaking, cracking and cold milling. Also, Simply Grain is our newly launched line of bread bases and sweet mixes.

Distribution: North America

Delivery: 20kg, 50lbs and totes

Company comments: Farinart is a lean privately owned company with extensive bakery experience able to meet your needs faster & better.

No. 1 Grain Millers Drive

Yorkton, SK S3N 3Z4

Sales Contact: Andrew Eilertson

Phn: 1-800-232-6287

Fax: 952-829-8819

Email: andrew.eilertson@grainmillers.com

Website: www.grainmillers.com

Plants: Yorkton, SK and U.S.

Distribution: Throughout Canada and U.S.

Products Offered: Full line of conventional, organic, & certified gluten-free oats including quick & rolled flakes, flour, bran, steel cut, food-grade fiber, and other innovative products. Complete product line includes other milled grains and custom blends of wheat, corn (yellow, white, non-GMO), barley, rye, triticale, and other specialty grains.

Certifications: Organic, Gluten-Free, Kosher, GFSI

Pack Type: Bags, totes, bulk, retail pack (500g-2.25kg)

Company Comments: Privately owned,

Grain Millers delivers whole-grain solutions to the modern world of food manufacturing. Customers rely on our quality, service, and innovation to meet today’s high expectations and tomorrow’s challenges. Learn more what about we can do at www.grainmillers.com.

105 Commander Blvd., Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

Email: gbjr@grainprocess.com

Products offered: Over 2,000 products including a full range of whole grains. Hard/ Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending facilities for multigrain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

HOWSON & HOWSON LTD.

232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson

Phn: 519-523-4241, Ext. 60

Fax: 519-523-4920

e-mail: jeff@howsonandhowson.ca

Contact: Dan Greyerrbiehl

Phn: 905-792-2962

Fax: 519-523-4920

e-mail: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States.

Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers. Assistance offered: Technical assistance. Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

49888 Nova Scotia Line RR2 Aylmer, ON, N5H 2R2

e-mail: info@jamestownmills.com

Phone: 519 933 2648

Website: www.jamestownmills.com

Products Offered: stone ground, non gmo gluten free flours

teff, pulses, quinoa, amaranth and millet

Supplier of sorghum, corn and rice flours, as well as starches and gums

Supplying the gluten free industry

MARQUIS MILLING AND GRAIN LTD. & NUNWEILER’S FLOUR CO.

P.O. Box 310

Rosthern, SK S0K 3R0

Contact: Russ Schroeder – President

Phn: 1-306-225-2222

e-mail: info@nunweilersflour.com

Website: www.nunweilersflour.com

Plant: Hague, Sask.

Certifications: Our products are Certified organic by Pro-Cert Organic Systems and Certified Kosher by Kosher Check. We are members of the Baking Association of Canada. Company info: Marquis Milling and grain was incorporated March 2016 to facilitate the purchase of Nunweiler’s Flour Co. Nunweiler’s Flour was established in 1988. Our new production facility is located in Hague Saskatchewan. Our whole grain flours are milled at low temperatures (typically less than 25C) from high quality certified organic Canadian grown grains. No additives or preservatives, No GMO’s. Superior quality for optimal nutrition.

Products offered: We currently mill 8 varieties

of certified organic whole grain flour: Hard Wheat, Soft Wheat, Rye, Spelt, Buckwheat, Kamut, Barley, Durum and Red Fife Wheat. We package the flours and grains in to 1,2,10,20 and 1000 KG bags. We offer private label, custom milling, blending andpackaging services. Major customers: Retail and wholesale bakeries, specialty product bakeries, retail mass market and natural food stores.

6201 E Primrose Green Drive

Regina, Saskatchewan S4V 3L7

Phone: 306-751-2040

Contact: Kerry Keating, General Manager Phn: 306-519-7931

Website: www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certification, HACCP, FSSC 22000:2011, ISO 22000:2005, HACCP and Non-GMO Project Verified.

Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Conventional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours.

In addition to flour, we are continuously expanding our product line of organic and conventional bakery mixes and bases to include breads, muffins, cookies, pancakes and whole grain pizza crust mix or base. We also offer customized grain blends and organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 20 kg, 25 lbs and 50 lbs bags, one-tonne totes, bulk truck loads and trans-loading. Our retail packaging line uses re-sealable pouch packs for weights ranging from 600 grams to 2.5 kg.

Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed re-sealable pouches.

Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region.

NutraSun Foods contracts directly with producers across western Canada in sourcing the highest quality grain to ensure consistency and quality for our flour and mixes.

Corporate Office: 1060 Fountain Street N.; Cambridge, ON N3E 0A1

Phone: 1-800-621-0588 or 519-650-6400

Fax: 519-653-2125

Email: sales@phmilling.com

Website: www.phmilling.com

Products: Hard, Soft and Organic Flour

Company Comments: P&H Milling Group is the largest Canadian-owned milling company. Built on the strength of nine mills strategically located across Canada, P&H Milling has been an important part of the agriculture and food community for nearly six decades. We are focused on providing high quality flour and grain-based products with a commitment to delivering customer value every day! P&H Milling strives for excellence through integrity and teamwork to ensure all our products and services meet customer, regulatory and industry standards. For information about our products contact: Sales & Customer Service: 1-800-621-0588 or Email: sales@phmilling.com

(P&H Milling Group)

817 48TH St. East; Saskatoon, SK S7K 0X5

Contact: Geoff Wright

Phone: 1-800-621-0588 or 519-650-6400

Email: sales@phmilling.com

Website: www.phmilling.com

Products: Pulse – Protein, Starch, Fiber, Flour and Organic

Company Comments: Parrheim Foods produces pulse concentrates (starch, protein and fiber) and flours from locally grown peas, beans and lentils. From our BRC Certified plant located in Saskatoon, we produce high quality products that are natural and functional as well as free from any additives. Our unique milling process ensures our starch, fibre and protein concentrates remain not only economical and functional but nutritious as well. Being in this industry since 1989 has enabled us to perfect our separation process which means that we can create the right product to meet your needs whether it be conventional or organic. For information about our products contact: Sales & Customer Service: 1-800-621-0588 or Email: sales@phmilling.com

240 Industrial Parkway S.

Aurora, ON L4G 3V6

Contact: Skylor Petrovich

Phn: 905-713-1712

Fax: 905-713-0074

Email: orderdesk@portroyalmills.com

Website: www.portroyalmills.com

Plant: Aurora, ON

Certifications: SQF, Certified Organic by ProCert, Kosher Kashruth

Products offered: Custom blended whole grain cereals, partially stone ground flours, cracked, flaked, pearled and whole grains including: rye, spelt, barley, quinoa etc. Importers and distributors of other fine bakery ingredients. Delivery: Canada and USA

Major customers: Bakeries, cookie manufacturers, frozen dough plants, bakery mix manufacturers, food processors and pet food manufacturers.

Company comments: At our milling facility in Aurora, Ont., we meet the continuing

demand for whole grain milling and custom blending. We at Port Royal continue to provide the highest quality products and personalized service to our customers with industry leading food safety standards.

2800 One Lombard Place

Winnipeg, MB R3B 0X8

Contact: Richard de Kievit

Phone: 1-877-984-7246

Website: www.richardsonmilling.com

Company Comments: We value our strong relationships with local growers and together we are able to create world-class oat products while employing state-of-the art technology. With the most extensive oat supply in North America, we source the best ingredients to create a full range of safe and high-quality custom products that are sold worldwide, including a wide variety of organic oats and certified gluten-free options. Our product development teams are highly experienced, and we are proud to be first in class for quality and food safety programs. We’re constantly evolving to an ever changing market, ensuring that we are always delivering and exceeding our customer’s expectations. Richardson Milling

is a division of Richardson International, Canada’s largest agribusiness. Recognized as a global leader in agriculture and food processing, Richardson is headquartered in Winnipeg with more than 2,900 employees across Canada, the U.S. and the U.K.

Rogers Foods has been proudly milling quality flour and cereal products from Canadian grain for over 60 years. With 3 mills in both Armstrong and Chilliwack, British Columbia, we produce wholesome cereals and highest quality flour and grain products for home and commercial bakers alike.

Plant and Head Office

4420 Larkin Cross Road

Armstrong, BC V0E 1B6

Toll free: 1-800-356-8735

Fax: 250-546-8228

e-mail: store@rogersfoods.com Website: www.rogersfoods.com

An up-to-date, comprehensive guide to understanding and applying food science to the bakeshop.

The essence of baking is chemistry, and anyone who wants to be a master pastry chef must understand the principles and science that make baking work. This book explains the why’s and how’s of every chemical reaction, essential ingredient, and technique, revealing the complex mysteries of bread loaves, pastries, and everything in between.

For both practicing and future bakers and pastry chefs, How Baking Works, Third Edition offers an unrivaled hands-on learning experience.

$62.95 Item #0470392676

BY JANE DUMMER, RD

Tropical fruit lends a warm element to comfort foods.

During stressful times, people seek nostalgic flavours.

Thanks to social media, consumers tastes have grown globally. At the beginning of 2020, prior to the global pandemic, consumers in Canada were welcoming adventurous new international flavours and global cuisines. Today with the current pandemic protocols and measures in place, we have seen a shift in consumer behaviour to a preference of what is familiar, even nostalgic.

Self-isolation and physical distancing have created a new level of home baking. With more people baking from scratch, they are interested recognizable recipes like banana bread, lemon meringue pie and date squares. All those fruits and fruit flavours are internationally sourced; however, they have long been in the Canadian marketplace.

Dufflet Rosenberg CEO, Dufflet Group Inc., confirms, “With the times being what they are, our customers still reach for reassuring, authentic desserts that have traditional meaning in their lives and the lives of their loved ones. The thing about a cake made with nostalgic and comforting ingredients is that you can serve it to the whole family and know that everyone will have a slice! We make a Chocolate Banana Cake that has been a cornerstone item since forever, and a Banana Loaf which is a go-to slice for lunch bags because it travels so well. We are launching a Hummingbird Cake made with bananas and pineapple. It’s a classic southern spice cake that is a wonderful blend of flavours and textures. Our lemon desserts are very Instagrammable because they are so eye-catching, and the ones that match lemons with a second flavour, like our Lemon Coconut Layer Cake and Lemon Raspberry Cakelet®,

are extremely popular. Date Squares, which originated in Canada and are known as known as a traditional dish of Newfoundland are a classic bestseller from our selection of bars and brownies.”

Lemons are a comfort ingredient that have been used in baking for centuries. However, there are a variety of citrus options that work well in baking. Christina, Director of Global Brand Marketing at Sunkist Growers in California identifies, “Modern-day artisans and commercial bakers are using more than just lemons. Specialty citrus varieties bring an exotic and unique flavour to the menu. Commercial bakers like to utilize and take advantage of the entire citrus fruit from zest to juice. Citrus zest is an exceptional and unique ingredient in that it contains essential oils that provide a sweet flavour

}Self-isolation and physical distancing have created a new level of home baking. With more people baking from scratch, they are interested recognizable recipes like banana bread, lemon meringue pie and date squares.

and a bright aromatic fragrance and does not change the chemistry of the treat while baking in the oven as the juice would. Segmenting citrus and adding it to a dish adds another layer of flavor and texture that can bring a recipe to the next level, and the juice itself is a perfect solution to balance the sweetness in a baked item. Candied citrus is another way to top and elevate a recipe.”

Sunkist collaborates and develops recipes with professional chefs. Chef Sally Camacho-Mueller, a partner and executive

pastry chef at Tesse Restaurant in West Hollywood, CA, has developed cakes, cookies, and pies with Sunkist® citrus specialty varieties, including Sunkist® Cara Cara oranges, Sunkist® Blood oranges and Sunkist® Navel oranges. Ward comments, “One of her creations, the Maple Upside Down Cake with Sunkist® Blood oranges provide that hint of citrus and raspberry flavour to the sweetness of the maple to get the perfect balance of flavour in one bite.”

Dates are another international fruit that have been a mainstay in Canadian baking for years. With the food supply changes due to the global pandemic, on a positive note, Charlene Rainey, Founder, Date Research Institute in California, explains, “Exports to Canada will probably increase because the freight is a lower cost than other markets. Also, the demand in Canada is high. The 2020-2021 crop year for dates looks very promising. Many of the date farms in California have been organic for a long time and the standards are the highest. We have tracked that breads, cakes and cookies remain the top applications for baking with dates. Bars are more for the no bake alternatives. The new uses of dates are in savoury flat breads and pizza.”

Today with the global pandemic directives: international fruits like bananas, citrus and dates, although not extremely exotic, have won first place in kitchens across Canada. / BJ

Jane Dummer, RD, known as the Pod to Plate Food Consultant, collaborates and partners with the food and nutrition industry across North America. www.janedummer.com