Pellet producers may need to limit their fossil fuel use to meet European sustainability standards.

16 Bioenergy in use

A study tour through southern Sweden shows how bioenergy can bring wealth, new jobs and reduce a country’s reliance on fossil fuels.

20 Pellet gear guide

From fibre to pellet, this listing is a comprehensive source for the equipment involved in the pelletizing process.

24 Biomass boom

Prince George has become a focal point for B.C.’s biomass industry thanks to commitments made by the community’s forestry, biomass, government and education leaders.

Ingelsta CHP

There’s a ready-made solution to many of our problems.

anadian Biomass joined a group of Canadian delegates at World Bioenergy in Sweden. We gathered in Stockholm, taking a scenic route with stops at a CHP plant and logging site before arriving in the host city. The Conference’s theme was “Taking you from know how to show how” and our group was interested in finding solutions that could be adopted in Canada. After the conference was over, we visited a neighbourhood in Stockholm where many of the conference’s principles have been in practice.

We saw that there isn’t one answer to our dependence on fossil fuels but a myriad of solutions that have been proven to be profitable in Sweden. Rather than looking for one solution that could solve emission and waste problems, there is a diversity of answers as unique as our municipalities.

We saw great examples of how traditional manufacturers have found viable solutions to their waste problems. Researchers at a Swedish university have turned pulp and paper mill sludge into biogas through co-digestion with municipal sludge under thermophilic conditions. Since the sludge has a high moisture content, it is expensive to dry and burn, but when mixed with municipal waste, it can be a great source of biogas, which then has many uses. What was once a waste product and a liability can be a new source of revenue. The technology has been in use in Europe for decades in some cases.

Volume 14 No. 4

Editor - Amie Silverwood (289) 221-8946 asilverwood@annexweb.com

Associate Editor - Andrew Macklin (519) 429-5181 amacklin@annexweb.com

Contributors - Gordon Murray, Christopher Rees, Ken Shields

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Brooke Shaw

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Business Media.

In Sweden, the focus of legislation was on increasing the cost of all kinds of fossil fuels rather than providing subsidies directly to renewable energies. This allowed all emerging technologies to compete on a level playing field while giving them a leg up on heavy polluters rather than having politicians pick and choose favourites.

Clustering biomass businesses together is a practice that we’ve found quite interesting at Canadian Biomass, and it has been a strong focus of our magazine this year. But in Sweden, this idea has been taken further through legislation that forbids the disposal of organic materials in landfills. This means industries that use organic material must find a solution for the disposal of their waste and this requirement has provided a driver for industries to invest in solutions and partner with bioenergy companies.

Any of these ideas could be adopted in Canada with the support of legislation but politicians won’t put their necks out and propose these ideas until the general public demands better solutions. With an economy so reliant on fossil fuels from our oil sands and natural gas, and blessed with vast hydroelectric resources, the conversation in Canada has stagnated around pipelines to get our fuels to new markets as traditional markets shift away from this source of energy.

A turnaround in our focus on producing fossil fuels to supporting the production and use of biofuels in Canada won’t happen overnight but it is nice to know a sustainable future is attainable and has been a profitable investment for the Swedish economy. It would pay off to add more diversity to our energy mix, reducing our reliance on landfills would be a bonus.

Printed in Canada ISSN 2290-3097

Circulation

Carol Nixon email: cnixon@annexweb.com P.O. Box 51058

Pincourt, QC J7V 9T3

Single Copy - $9.00

(Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2014 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.ca

November 17-19, 2014

Vancouver Marriot Pinnacle Hotel – Vancouver, BC

North American wood pellet exports are projected to grow at an unprecedented rate.

At the WPAC AGM & Conference you will receive the insider information that you need in order to meet the dramatic increase in Europe bound pellet exports.

Get the insider news and connections by joining us at this must-attend event!

Expert, comprehensive insight from industry experts on the following:

• Canadian pellet industry developments

• Developments in Europe and Asia

• Fibre sourcing

• Domestic pellet market development

• Transportation and logistics

• The sustainability debate

• Safety practices and much more Media Sponsor

Enerkem officially inaugurated its first full-scale municipal waste-to-biofuels and chemicals facility in Edmonton, Alberta.

This facility, operated by Enerkem Alberta Biofuels, is among the world’s first commercial facilities to be built for the production of renewable chemicals and advanced biofuels. During its construction, more than 600 direct and indirect jobs were created for the modular manufacturing of the facility’s systems and their on-site assembly.

This industry breakthrough is a collaboration between Enerkem, the City of Edmonton and Alberta Innovates - Energy and Environment Solutions. The pioneering facility will have a production capacity of up to 38 million litres per year, will help the City of Edmonton increase its residential waste diversion rate to 90 per cent, and is expected to generate net economic spending in the local area of nearly $65 million annually.

The start-up of the biorefinery follows a rigorous

TimberWest is considering construction of a $60-million pellet facility in Nanaimo. CEO Brian Frank discussed the proposed plant at a Nanaimo business function, which could see construction begin as early as late 2014.

The proposed plant would have a maximum capacity of 200,000 tonnes and would use residual waste fibre from its own operations, such as tree tops, limbs and other waste material that would otherwise be burned. The facility would also use hogfuel and sawdust from other forestry and manufacturing companies.

The proposal would mean less burning of wood waste and it would add value to materials that would otherwise be wasted.

The engineering and designing of the proposed plant is underway, Frank told the Nanaimo Daily News in June, but a final decision has not been made on whether or not to make the investment in the plant.

commissioning plan, which is nearing completion.

Biomethanol production will begin progressively during the

start-up. A module converting the biomethanol into advanced ethanol will be added by the end of 2015.

After more than three years of consultation and negotiations between Gitxsan Bio-Energy Ltd. and the Suskwa and Gitsegukla First Nations, agreements have been reached for the construction and operation of the region’s first bioenergy facility capable of producing 200,000 tonnes of both white and torrefied black pellets for the Korean market from regional fibre sources. Construction is expected to start this summer and will take about nine months to complete. Engineering and related tasks are currently underway and business details are being finalized.

Gitxsan Bio-Energy is structured to be owned jointly by a group of First Nations and Korean investors and will be the first largescale commercial deployment of torrefied black pellets in B.C. destined for export markets.

The plant is planned for First Nations property in Carnaby, adjacent to the CN Rail line 216 km east of Prince Rupert, and the $26-million facility will create 40 local, full-time jobs at the plant and an additional 30 in forest operations.

Natural Resources Canada (NRCan) has contributed $10 million under the Investments in Forest Industry Transformation (IFIT) Program to support the implementation of a commercial-scale lignin recovery process at West Fraser Timber’s plant in Hinton, Alta.

West Fraser’s Hinton pulp mill will be the first in Canada

to extract the lignin from its black liquor recovery stream, enabling it to produce the quantities needed to meet the supply requirements of end-users, using a proprietary process developed through past federal investments in R&D with FPInnovations and NORAM Engineering, called LignoForce.

By Gordon Murray

t has been more than two years since the January and April 2012 explosions that destroyed the Babine and Lakeland sawmills in central British Columbia, tragically killing four workers, injuring forty-four more, and putting hundreds out of work.

Investigations by WorkSafe BC (WSBC) and BC Safety Authority (BCSA) determined that both explosions were preventable, having been caused by ineffective control of combustible dust. Each mill was cutting beetle-killed pine, which produces a considerably greater volume of wood dust and much finer dust than

“Surely employers must understand by now the catastrophic consequences of a dust explosion and the means of prevention...”

from cutting green wood. Suspended dust, confined space, oxygen, and an ignition source combined to cause both explosions. Regulators and forest industry leadership responded swiftly and aggressively.

WSBC developed a combustible dust strategy to cover all categories of wood processing plants. Their strategy included reminding employers of their obligations under the Workers’ Compensation Act and the Occupational Health and Safety (OHS) Regulation and advancing a combustible dust management program for employers, consisting of facility risk assessment, development of a combustible dust management plan and employee training. WSBC issued orders for all employers to clean combustible dust in their plants and followed with four successive

phases of inspections to assess compliance. Similarly, BCSA (administrator of the Safety Standards Act) issued a safety order regarding combustible dust to 403 active and inactive sawmills, pulp and paper mills, pellet mills, remanufacturing mills, and other wood processors. Forest industry leaders formed the Manufacturers’ Advisory Group (MAG) to focus on industry efforts with respect to combustible dust. MAG engaged FPInnovations to improve industry’s understanding of dust sampling, analysis and explosibility and to provide an analysis of how to apply National Fire Protection Association standards to wood processing plants. MAG also developed a dust audit tool and set about organizing workshops and other educational resources for industry members.

WSBC, BCSA, MAG, the BC Office of the Fire Commissioner, and the Steelworkers Union formed the Fire Inspection and Prevention Initiative to enable multi-stakeholder cooperation and to provide management and worker training.

Yet, given the experience of the Babine and Lakeland tragedies, it is extremely distressing that a significant number of wood processing plants (including pellet plants) continue to fail regulatory inspections. BCSA reported in March that 34 per cent of plants failed their safety inspections due to inadequate dust management plans; dust accumulations adjacent to electrical and gas equipment; lack of understanding of the level of dust that is hazardous; and poor housekeeping.

Similarly, fully 61 of 144 employer lo-

cations were not in regulatory compliance during WSBC’s third phase of inspection and 93 orders were issued in relation to combustible dust. Most orders were for “unacceptable levels of dust accumulations outside normal production areas; i.e. basements, crawl spaces, overhead areas, areas hidden behind motor control centres or cabinets, and outside areas.”

While WSBC and BCSA acknowledge that many employers have made substantial progress at implementing systems and equipment to control combustible dust, the number of non-compliant employer locations is simply unacceptable. Surely employers must understand by now the catastrophic consequences of a dust explosion and the means of prevention. It is beyond comprehension that combustible dust remains a crisis issue to be solved.

Recently, B.C. Crown prosecutors announced their intention not to pursue criminal charges relating to the Babine or Lakeland explosions. This caused a wave of public protest putting the B.C. government and WSBC under extreme pressure to prevent such injuries and loss of life from ever happening again. Yet, a substantial portion of our industry remains non-compliant with respect to combustible dust and the risk of another mill explosion remains substantial. And now, given our experience and all we have learned, the consequences would be unimaginable.

For more on combustible dust and the new regulations, go to http://www.woodbusiness.ca/harvesting/dust-control. •

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want to support and benefit from the growth of the Canadian wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-837-8821 or by email at gord@pellet.org.

See the latest biomass equipment, including grinders, pellet mills, bre dryers, boilers, conveyors, silos, packaging, mill yard equipment, and more!

Your show badge gives you admission to all events AND all seminars! Information will be presented on hot topics, including...

• Pellet Market Opportunities (John Arsenault, Wood Pellet Association of Canada and QWEB)

• Maximizing Value at the Softwood and Hardwood Sawmills (Eugene Wengert, The Wood Doctor’s RX)

• Monetary losses associated with lumber manufacturing processes (Jacques Lajoie, FPInnovations)

• Combustible Dust Explosion Protection (Ed Chovanec, IEP Technologies)

• Drying – Do Not Let Profits Evaporate (Eugene Wengert, The Wood Doctor’s RX) AND MUCH MORE!

By Christopher Rees

any recent world conferences have focused less on bioenergy and biofuels and more on value-added chemicals and biomaterials. And yet at the recent World Bioenergy 2014 in Jönköping, Sweden, the leader of the CanBio delegation, Pat Guidera, observed, “the conference confirms once again that biofuels and bioenergy innovation and priorities remain high in the European Union and other areas of the globe.”

and Jason Naccarato of the

Ste. Marie Innovation Centre.

A case in point is British Columbia. CanBio Chair, Ken Shields’ company, Conifex Timber, will start producing power from its $100-million biomass plant in Mackenzie by September. This plant represents the first major biomass power producer in the province since Williams Lake. Shields has been a leader in the bioeconomy, looking beyond cost-savings for forest products to the value that can be generated from the forest resource.

“Conifex Timber will start producing power from its $100-million biomass plant in Mackenzie by September.”

The opening session of the 2014 CanBio Annual Conference in Thunder Bay features a panel on the Bioeconomy Horizon in Canada facilitated by Catherine Cobden, Executive VP at FPAC and a CanBio Board Member. Panel members include Rory Gilsenan, NRCan; Bill Thornton, ADM, Ontario Ministry of Northern Development and Mines; Michael Toombs, Director of Research and Innovation, Ontario Agriculture and Food; and Pat Guidera. They will debate value-added versus bioenergy pathways.

Scott Thurlow, President of the Canadian Renewable Fuels Association, will talk about what cellulosic-based fuels mean for Canada. He will be joined by Lorne Morrow, CEO of the Centre for Research & Innovation in the Bioeconomy

Other B.C. companies are also gearing up in the bioenergy game: West Fraser will commission two 12-megawatt biomass power plants in Fraser Lake and Chetwynd, and Dalkia is building two 40-megawatt biomass Power plants in the B.C. Interior. These projects are a result of the provincial government’s bioenergy strategy launched in 2008.

A Biomass Power Panel will be led by Brent Boyko, Director of Biomass Business Development at OPG. The conference will coincide with the firing-up of OPG’s Atikokan power plant, which will be North America’s largest capacity 100 per cent biomass-fuelled power plant. Bob Cleaves, President of the U.S.-based Biomass Power Association will be on hand to compare strategies between Canada and the U.S.

Bioenergy is also at the forefront in On-

tario as the province looks at regulatory standards for bioheat applications. Colin Kelly of Confederation College leads a discussion on Ontario Bio-heat and CHP advances and looks at what the proposed regulatory changes could mean for equipment suppliers.

Located in Thunder Bay, both Lakehead University and Confederation College are involved in researching higher-value streams for forest resources. Sudip Rakshit, the Canada Research Chair in Bioenergy and Biorefining based at Lakehead, will be joined by Tom Browne of FPInnovations to kickoff the conference session on Tomorrow’s Biorefineries.

In southern Ontario, where agriculture is king, Sarnia represents the most-developed biochemical and biofuels cluster in Canada. Murray McLaughlin, CEO of Bioindustrial Innovation Canada will champion the value-added pathway and the opportunity for Canada to develop more bioeconomy clusters based on biochemicals and biomaterials. Sean McKay, CEO of the Composites Innovation Centre in Winnipeg, will also be on hand to describe the exciting advances of his centre in developing biomaterial substitutes for oil-based plastics and metals.

The CanBio conference will have an innovative session about getting projects off the ground, led by Michael Weedon, Executive Director of the BC Bioenergy Network, who has a wealth of experience in this area. John Hawkes, CEO of Angus Power, Tony Madia of Conifex and Ed Fukushima of Great North Bioenergy will also share their secrets.

See you in Thunder Bay! •

Pellet producers can limit their fossil fuel use.

By Amie Silverwood

Woodpellets have become a major player in the Canadian bioeconomy, and rightly so since we have abundant forest resources and vast amounts of wood going to waste each year. Extracting the unwanted resources from the forest floor, where they have been abandoned, or from the sawmills, pelletizing them and shipping them off to Europe for a profit is a no brainer. But as European sustainability standards get increasingly stringent, pellet exporters may need to identify emission sources and reduce carbon footprints.

The U.K., for example, has a carbon plan with mandatory rules to reduce greenhouse gas emissions over time so that by 2025, it will see an 80 per cent reduction on gas emissions from the 1990 levels. Other European nations, such as Denmark and the Netherlands, are in the final stages of negotiating their rules with their power sectors. Anyone looking to export wood pellets into Europe must accurately account for the carbon that has been accumulated in the supply chain. Anything that uses fossil fuels in the process of obtaining the wood fibre, processing the fibre and transporting it from the forest to the mill and from the mill to the port must be included in the analysis.

Canadian pellet producers have a head start on our international competition because of our sustainable forestry practices, explains Gordon Murray, President of the Wood Pellet Association of Canada. “Virtually 100 per cent of our working forests are certified in Canada. So that gives us an advantage on the sustainability front.”

The Wood Pellet Association of Canada recently did an analysis of pellet plants in B.C., which is the farthest province from the European market.

Murray explains the results: “the bottom line is we already meet the most stringent standards, and a couple of reasons are that, in B.C., we use clean hydro electricity, which gives off no GHG emissions, and that we ship our pellets in bulk using ocean vessels which are incredibly fuel efficient compared to rail or truck transport.”

Murray explains that the amount of fossil fuels burned to deliver pellets to Europe is only a tiny fraction of what would be required for trucks or trains to deliver them over a similar distance on land. “We’re working on an analysis of what the situation will be in Eastern Canada.”

One of the first steps in setting up a new pellet plant requires a careful auditing of the carbon created in the process from the harvest to delivery. Futuremetrics has created a carbon footprint calculator that is free to access and has been very popular on its website. It assesses the amount of carbon generated throughout the process, including harvesting (if applicable), truck transportation, electricity in the pellet mill, transportation to the port by truck or rail, ship loading and the trip across the ocean.

“Each of these steps requires the use of fossil fuels,” explains William Strauss of Futuremetrics. “The policy that supports the use of wood pellets in Europe is all about carbon so they’re very interested in how much carbon has accumulated in the process of getting those pellets to the utility’s power plant. It has to be very carefully accounted for.”

Strauss has set up the calculator to give developers an idea of the feasibility of their ideas by measuring what kind of carbon footprint a project will generate so developers can take steps to minimize any accumulation. “Between now

and 2025, which is quite a ways away, you’re going to have to do some work on the supply chain, minimizing carbon impacts of transportation and electricity,” he warns.

Electricity is a major factor in the carbon footprint generated by wood pellets. Power generation in B.C. and Quebec is primarily from hydro, and thus it is a clean source; but some other areas, for example Alberta and Atlantic Canada, rely on a high proportion of coal-powered electricity. Changing the power source can go a long way in minimizing carbon impacts in regions where the electrical grid or the pellet mill itself uses fossil fuels.

“Regarding GHG emissions, probably the biggest controllable factor for producers is the chosen method of biomass drying. Generally speaking, those who operate dryers that run on fossil fuels will have a problem, but those who run dryers that are based on biomass (burning a portion of the incoming biomass to oper-

Phone: +1 (864) 476-7523

sales@jeffreyrader.com

www.terrasource.com/cb

ate their dryer, which most pellet plants do) will have substantially lower GHG emissions,” says Gordon Murray.

Another way to reduce a pellet’s carbon footprint is to use less carbon in transportation, explains Strauss. “That might mean better diesel engines, but what many people are thinking is that because of low cost natural gas, much of the transportation structure is going to be changing to compressed natural gas or liquefied natural gas.”

Natural gas is cheaper at today’s prices and could cut transportation costs in half. On top of the pocketbook advantage, natural gas would cut the carbon footprint by a third compared to diesel fuel.

“The transportation sector is going to shift to natural gas,” Strauss predicts. “It’s going to lower the cost of wood, which means it’s going to lower the cost of pellets and it’s going to help.”

Though ocean vessels are more efficient than trucks or rail, there’s room for

improvement when ships are traveling great distances. This is a challenge shared by exporters in all industries that share the desire to bring down costs and conserve fuel usage.

“Ships are also getting way more efficient,” says Strauss. “That’s obviously in the best interest of the shipping companies because they spend less money for every mile they move but there are expectations of seeing fuel use cut in half in the next few years by different hull shapes, bigger ships and slower speeds. They go a little bit slower, calling it Ecospeed. If they lower their speed by just a few knots (nautical miles per hour), they cut their fuel consumption by about 20 per cent.”

Gordon Murray claims that efficiencies have already been achieved in Canada, though he notes that the possibility of introducing biofuels for ocean transport and switching from diesel to biodiesel for land transport would further improve GHG emissions. We’ve also been trending to larger ships as the industry has

Jeffrey Rader® EZ-Access® Wood Hogs are designed for safe, fast and easy access to hammers, rotors and liners, allowing routine maintenance to be performed safely, easily and with minimal downtime. Our EZ-Access technology even lets operators remove the wood hog’s rotor without moving the feed chute. Plus, our heavy-duty rotor discs allow maximum flexibility of hammer arrangements, up to 3, 4 or 6 rows for premium efficiency on smaller products, while our Duratip® high-alloy hammers with replaceable tips provide increased shredding action and quick change-outs.

Rader® Disc Screens (RDS) are the industry’s #1 scalping screens. When it comes to removing oversize rejects from unscreened wood chips, hog fuel or bark, our RDS is the undisputed workhorse of the industry. With more units in operation than all other suppliers combined, you can depend on us to select the ideal disc profile, interface openings and screen size for maximum screening efficiency.

matured and more pellets are exported overseas.

“We started using Handysize ocean vessels with around 30,000 tonnes of capacity. Eventually we worked up to Handymax ships carrying around 50,000 tonnes in Vancouver. Now, out of Prince Rupert, they’re shipping in Panamax carriers, which hold about 80,000 tonnes. And so the bigger the ship, the more fuel efficient it is and the better impact it has on the bottom line – both in terms of cost and GHG emissions.”

A similar story is being written in Eastern Canada as ports are building the infrastructure to accommodate larger ships for their pellet cargo but the carbon and fuel efficiency savings potentials are even greater. Much of the Eastern pellets are shipped on coaster class ships that can hold a range of between 5,000 to 8,000 tonnes of pellets.

“Now that the Port of Quebec City has put in new domes and they’re going to be handling the new Rentech product, they’re going to be using all Handy-

max or even Panamax-sized ships out of there,” explains Murray. Switching from 8,000 to 80,000-tonne capacity will improve the carbon footprint substantially.

There’s a new initiative in Europe that will make the research on a new pellet mill’s carbon footprint and other sustainability measures easier to understand. The Sustainable Biomass Partnership has been formed between six of the larger power utilities, both the U.S. and Canadian wood pellet associations and the European Industrial Pellet Association, to come up with a sustainable biomass certification system that incorporates the requirements of all the parties involved.

“We’ve got utilities from Denmark, Belgium, the Netherlands and the U.K. all represented on this and we’re doing our best to incorporate the sustainability criteria from all of those countries so that our certification will cover trade into any one of those countries,” explains Murray. “We’ve taken absolute

pains to understand what each country is doing and we reflected that in our certification system.”

The goal is to develop standards to allow biomass providers with the tools to demonstrate compliance with legal, regulatory and sustainability requirements for woody biomass. The group is doing this by adopting existing credible systems whenever practical, such as the forest management certification that is already in use in Canada.

The move to sustainable power and heat is a groundswell push to healthy air, land and water in Europe. The desire to limit pollution has driven the push from coal and fossil fuels for waste heat, and Canada has been a winner by providing pellets for this burgeoning market overseas. But as the critical public eye turns from the fumes expelled from the coal burning power plant to the source of the new fuel, pellet producers must be able to stand up to public scrutiny to demonstrate reductions gained in Europe aren’t offset by emissions at the source. •

By Amie Silverwood

has the reputation for being expensive and risky, but on a recent trip to Sweden, Canadian Biomass was given the opportunity to see how technology that has been in use for decades in Sweden has brought wealth, new jobs and reduced the country’s reliance on imported fossil fuels.

Sweden, like Canada, is a sparsely populated, northern country with long, cold and dark winters. It has a landscape that resembles Ontario with a largely urban population, as 85 per cent of the 9.7 million people who populate the country live in cities. It also has a long coastline and forest covering 53 per cent of the land.

There are some 300,000 forest owners in Sweden, creating a management mosaic that is restricted by legislation and, for owners who choose to comply, by certification standards. Large areas of the forest have been set aside for conservation (5.5 million hectares), while 21.2 million hectares of productive forestland is under active management. Like Canada, forest products are one of the country’s traditional exports.

Because forestry is one of the country’s major industries, it supplies a great deal of the country’s biomass for energy and heat production. Canadian Biomass had the opportunity to tour a combined heat and power plant (CHP) run by Söderenergi, one of the largest district heat producers in Sweden. In the company’s five plants, the majority of its fuel comes from forestry by-products (forest clippings, recovered wood waste) and industrial waste. The industrial waste consists of paper, cardboard, plastic and wood that has been crushed, sieved, and cleaned of metals, sand and other contaminants, and cannot be used in any other way. The company aims to use renewable fuels whenever possible and is slowly increasing the amount of industrial waste that it burns, which includes demolition waste. Wood

LEFT MAIN: Igelsta CHP plant mainly uses wood chips for district heat and power production. It also uses sorted paper, plastic and wood waste from industry and offices, which cannot be recycled. LEFT TO RIGHT: Most of the fuel arrives at the Igelsta CHP plant by boat at the Igelsta port (500,000 tonnes). About 200,000 tonnes of wood chips are transported by rail and about 300,000 tonnes are trucked in. Wood waste from local forestry operations is a major feedstock for district heat and power production. This truck has a loader and grinder that chips the wood directly into the back of the truck and is owned and operated by one contractor.

recovered from demolitions contain chemicals from paints and other contaminants that can damage the burners so the staff is monitoring the boilers closely and increasing this kind of fuel gradually. At the time of the visit, 45 per cent of the fuel used was recovered wood.

Igelsta is Sweden’s largest bio-fuelled CHP plant and is located in Södertälje, about 30 kilometres from Stockholm. Fired up in 2010, it produces 200MW of heat and 85 MW of electricity.

The majority of the fuel burned at Iglesta is shipped to the plant by boat (about 500,000 tonnes) and arrives at the small port onsite. The port handles around 200 ships a year from Sweden and other parts of Europe. Fuel from nearby forest operations arrives by rail and is then trucked the short distance (15 kilometres) to the CHP plant.

The company has placed strict requirements on its fuel suppliers, taking samples from every load delivered. Quality checks are based on a fuel specification, which has been agreed upon by Söderenergi and the supplier. Random samples are taken mechanically from various places in the load

in order to obtain a representative result. Monthly samples are collected for each supplier and sent for analysis to an accredited laboratory. The company uses a data system, Safirs, to monitor the fuel quality and economy. It provides information on the fuel flow from supplier to combustion with data on fuel consumption and analysis results through a weighing system.

Once on site, the fuel is stored in large silos at the back of the property. The wood chips or industrial waste pellets travel from the silos to the boiler on a system of conveyor belts that feed the boiler. The boiler heats water to produce steam, which turns a turbine to power a generator that produces electricity. This electricity is fed into the power grid, while the surplus heat from the process is used in the district heating network for homes and industries (about 70 per cent). Heat, in the form of hot water at around 120 degrees Celsius, is pumped through underground pipes to a network of buildings where it supplies heat and hot water. Once these homes have been heated, the water is returned to the source where it is reheated to begin the process anew. The

district heating network Igelsta supplies is 450 kilometres long.

District heating and co-generation facilities like the Igelsta CHP plant are part of the Swedish shift to a more sustainable and cleaner future. The shift began in the 1970s when residents became concerned with the levels of smog and acidification of the country’s lakes and forests. District heating meant a shift from inefficient stoves in every home to a shared heat source run by professionals that would include sophisticated cleaning equipment to ensure the chimney plumes release steam rather than dirty smoke.

The chimneys in both the Igelsta DH plant and the CHP plant contain fully equipped laboratories. Though the smoke may look hazardous as it flows from the chimneys, the exhaust is constantly monitored to ensure it is clean air and steam. The white smoke is the hot water in the flue gas, which forms droplets in the air. No matter which fuel is used to power the turbines, the proportion of contaminants in the steam is very small.

There are many district heating grids throughout the country that use whatever fuel is regionally available. In forested areas, forestry by-products are the obvious choice, and in the city of Stockholm, household waste is the fuel of choice. Organic waste is collected to produce the biogas used to power the city buses. Whatever the feedstock, chimney exhaust is monitored so that the air is kept free of contaminants.

Johan Thorsell is the business support manager for Växjö, the “Greenest City in Europe.” He credits brave politicians for creating a carbon tax that required the “bad guys pay the good guys.” Priority was given to increasing the cost of all fossil fuel-based energy rather than giving subsidies to renewable energy. All renewable energy competed on equal terms, thus developing the whole industry rather than the political favourites.

“The road map must be simple and easy to understand,” said Thorsell who championed a simple pyramid to illustrate his key principles. Avoid energy needs (at the bot-

tom level of the pyramid), streamline and reduce energy demand (mid layer) and use renewables (on the top).

His city plans to be fossil fuel free by 2030. One of the main components in this plan is to encourage the use of wood as a building material in order to provide additional wood waste for biofuel. Twenty-five per cent of each tree is used for biofuel in Sweden. Ten thousand square metres of a forest harvest makes 15m3 of oil and 1,000 kg of oil provides 11MWh of energy. The city is currently building its third-generation power plant that will cover 50 per cent of local demand for electricity from wood waste (tops, roots and bark). It will provide 39 MW of electricity and 64 MW of heat and consume at top load 140 m3/h reducing the city’s CO2 production by between 10,000 to 20,000 tonnes a year. The estimated cost is 1.2 billion SEK.

The city of Växjö is an interesting example of a green city because of the benefits it has reaped from its efforts. As the city has invested in technologies and programs to reduce CO2 emissions, there has been a notable economic growth at the same time.

Bengt-Erik Löfgren, CEO of ÄFAB (a bioenergy consultancy), explained that green cities attract businesses that want to be associated with a sustainable vision.

“The use of locally produced biomass has reduced the dependence on fossil fuels and has raised the GDP by 43 per cent,” said Löfgren. He pointed out some impressive gains experienced in his town. Replacing fossil fuel-derived energy with locally sourced renewables added 23,650 jobs. Curbing energy use has added 13,000 jobs and recycling has added 18,600 jobs.

A Swedish construction firm recently conducted a survey that found seven out of 10 Swedes want to live in a building with an eco label and would pay more for it. There are a number of choices of new construction built to high eco standards to use less energy or passive houses that are heated primarily with the heat generated by the electrical appliances, lighting, sunlight and through

Welcome to the Canadian Biomass Pellet gear buyers’ guide.

Designed for readers interested in developing or updating a wood pellet manufacturing facility, this guide is a handy reference tool of the major manufacturers and service providers for this industry in Canada. From fibre to pellet, the listing is a comprehensive source for equipment involved in the pelletizing process.

The Canadian Biomass Pellet gear buyers’ guide is organized into two sections. The first section is an alphabetical listing of companies that provide the relevant products or services for each of the following categories: dryers, pneumatic conveying, hammermills, pellet mills, screens and coolers, fire/spark detection and sup-

pression technology, bagging and palletizing, dies and rolls, quality control equipment and services, building contractors and engineering firms and Canadian ports for pellet exports. The second section is an alphabetical listing of all the companies, with contact information for each.

Altentech

Amandus Kahl

Andritz

Anhydro

Baker-Rullman

Bruks Rockwood

Buhler Inc.

Büttner

Certified Labs

CPM Wolverine Proctor

Dieffenbacher

Duske Drying Systems

Earth Care Products

Energy Unlimited

GEA Barr-Rosin

Jiansu Yongli

Kesco

M-E-C Company

Münch-Edelstahl

Muyang

Player Design

Saimatec Engineering

Siempelkamp

Silvana Import Trading

Solagen

Stela

Swiss Combi

Thompson Dryers

PNEUMATIC CONVEYING

Allied Blower

Amandus Kahl

Baum Pneumatics

Buhler Inc.

Certified Labs

Clarke’s Industries

Concept-Air

Jeffrey Rader/TerraSource

Global

Kesco

Koger Air Corporation

M-E-C Company

Rodrigue Métal

Silvana Import Trading

Walinga

HAMMERMILLS

Amandus Kahl

Andritz

Bliss Industries

Bruks Rockwood

Brunette Industries

Buhler Inc.

Buskirk Engineering

Certified Labs

CPM

Crushmaster

Dieffenbacher

Jeffrey Rader/Pensylvannia

Crusher

Jiangsu Yongli

Kesco

La Meccanica

M-E-C Company

Münch-Edelstahl

Muyang

Schutte-Buffalo Hammermill

Silvana Import Trading

West Salem

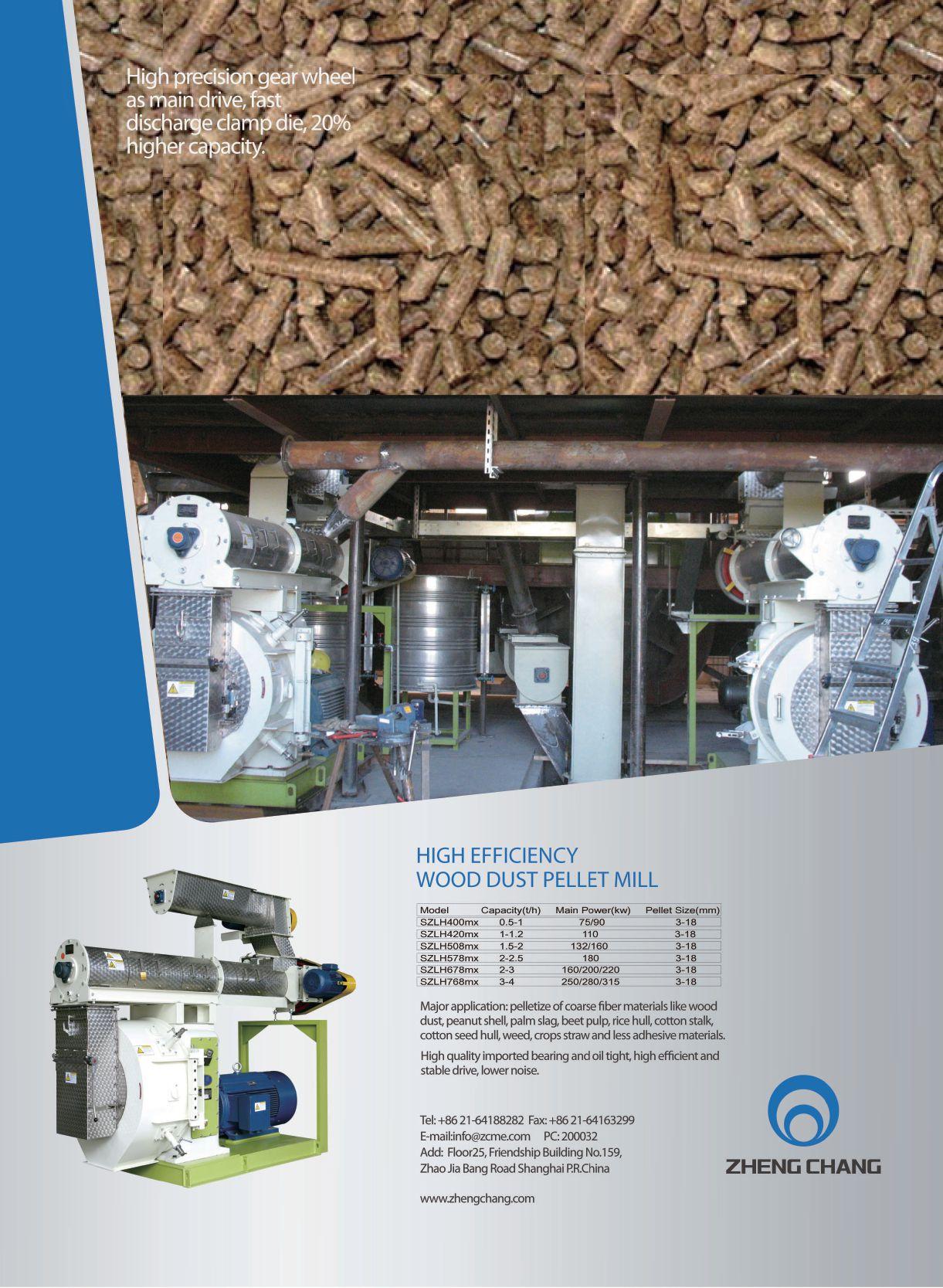

PELLET MILLS

Agico Group

Amandus Kahl

Andritz

Astec

Bliss Industries

BTI

Buhler Inc.

Buskirk Engineering

Certified Labs

CPM

Dieffenbacher

Jiangsu Yongli

Kesco

La Meccanica

Münch-Edelstahl

Pelleting Technology

Nederland

Silvana Import Trading

Zheng Chang

SCREENS AND COOLERS

Amandus Kahl

Andritz

Baum Pneumatics

Bliss Industries

BM&M Screening Solutions

Bruks Rockwood

Brunette Industries

Buhler Inc.

Buskirk Engineering

Certified Labs

CPM

Dieffenbacher

Jeffrey Rader/TerraSource

Global

Kesco

La Meccanica

Law-Marot

M-E-C Company

Münch-Edelstahl

Pelleting Technology

Nederland

Silvana Import Trading

West Salem

FIRE/SPARK DETECTION AND SUPPRESSION

Allied Blower

Amandus Kahl

Buhler Inc.

Clarke’s Industries

Concept-Air

CV Technology

F.E. Moran

Fenwal-IEP Technologies

Fike

Firefly

Flamex

Grecon

Hansentek

Kesco

M-E-C Company

Rodrigue Métal

Scheuch

Silvana Import Trading

BAGGING AND PALLETIZING

Amandus Kahl

Buhler Inc.

Bulldog Bag

Certified Labs

Creative Packaging Inc.

Hamer

Möllers North America Inc.

Polypro Solutions

Premier Tech

Primary Packaging

Rethceif Packaging

Silvana Import Trading

Trinity Packaging

DIES AND ROLLS

Amandus Kahl

Andritz

Buhler Inc.

Certified Labs

CPM

Dorssers

La Meccanica

Münch-Edelstahl

Silvana Import Trading

Zhangjiakou Hong Xing

Machinery

QUALITY CONTROL EQUIPMENT AND SERVICES

Amandus Kahl

Andritz

Buhler Inc.

Domosystem

Electromatic Equipment

Grecon

Kesco

Münch-Edelstahl

Biomass Energy Lab

Timber Products Inspection

Twin Ports Testing

Silvana Import Trading

ENGINEERING AND CONSTRUCTION SERVICES

Andritz

Buhler Inc.

Buskirk Engineering

DelTech

Dieffenbacher

Earth Care Products

Energy Unlimited

Kesco

Pellet Systems International

Player Design

Process and Storage Solutions

Solagen

Stolberg Engineering Ltd.

TS Manufacturing

PORTS

Belledune

Halifax

Montreal

Prince Rupert

Quebec City

Saguenay

Trois-Rivières

Vancouver

AGICO GROUP www.agicogroup.com 0086-372-5965148

ALLIED BLOWER www.alliedblower.com 604-930-7000

ALTENTECH BIOVERTIDRYERS www.altentech.com 604-568-9848

AMANDUS KAHL GMBH & CO. KG www.akahl.de 905-778-0073 (Sarj Equipment, Canada)

ANDRITZ GROUP www.andritz.com 570-546-1253

ANHYDRO INC. www.spx.com/en/ anhydro/ 708-747-7000

ASTEC www.astecinc.com 423-867-4210

BAKER-RULLMAN www.baker-rullman.com 920-261-8107

BAUM PNEUMATICS INC. www.baumpneumatics.com 604-945-4507

BIOMASS ENERGY LAB www.biomassenergylab.com 218-461-2579

BLISS INDUSTRIES, LLC www.bliss-industries.com 580-765-7787

BM&M SCREENING SOLUTIONS www.bmandm.com 800-663-0323

BRUKS ROCKWOOD www.rockwood.net 770-849-0100

BRUNETTE INDUSTRIES LTD. www.brunettemc.com 604-522-3977

BTI www.rockbreaker.com 519-599-2015

BUHLER INC. www.buhlergroup.com 763-847-9900

BULLDOG BAG LTD. www.bulldogbag.com 800-665-1944

BUSKIRK ENGINEERING www.buskirkeng.com 260-622-5550

BÜTTNER www.buettner-energydryer.com 704-522-0234

CANADIAN BIOENERGY CENTRE UNIVERSITY OF NEW BRUNSWICK www.unb.ca/fredericton/ forestry/wstc/cbec 506-453-4507

CERTIFIED LABS www.certifiedlabs.com 905-691-0492

CLARKE’S INDUSTRIES, INC. www.clarkes-ind.com 541-343-3395

CONCEPT-AIR www.concept-air.ca 866-644-0041

CPM www.cpm.net 800-428-0846

CPM WOLVERINE PROCTOR www.cpmwolverineproctor. com 267-282-4346

CREATIVE PACKAGING INC. cp22243.tripod.com/ baggingsystems 423-825-5311

CRUSHMASTER www.crushmaster.com sales@crushmaster.com

CV TECHNOLOGY, INC. www.cvtechnology.com 561-694-9588

DELTECH www.deltech.ca 250-564-3585

DIEFFENBACHER www.dieffenbacher.com 770-226-6394

DOMOSYSTEM www.domosystem.fr/en +33(0)1 45 87 29 09

DORSSERS INC. www.dorssers.com 519-676-8113

DUSKE DRYING SYSTEMS http://www.uzelacind. com/duske/ 414-529-0240

EARTH CARE PRODUCTS, INC. www.ecpisystems.com 620-331-0090

ELECTROMATIC EQUIPMENT COMPANY INC. www.checkline.com 516-295-4300

ENERGY UNLIMITED INC. www.energyunlimitedinc.com 608-935-9119

F.E. MORAN SPECIAL HAZARD SYSTEMS www.femoranshs.com 847-714-8193

FENWAL-IEP TECHNOLOGIES www.ieptechnologies.com 855-793-8407

FIKE CORPORATION www.fike.com 816-229-3405

FIREFLY AB www.firefly.se +46 (0)8 449 25 00

FLAMEX, INC. www.sparkdetection.com 336-299-2933

GEA BARR-ROSIN www.barr-rosin.com 630-659-3980

GRECON, INC. www.grecon.us 503-641-7731

HAMER LLC www.hamerinc.com 763-231-0100

HANSENTEK www.hansentek.com 905-607-5780

JEFFREY RADER/TERRASOURCE GLOBAL www.terrasource.com 514-822-2660

JIANGSU YONGLI MACHINERY CO., LTD. www.primtechnology.com 408-829-2379

JIANGSU ZHENGCHANG

www.zhengchang.com/ eng +86 21-641 88 282

KESCO, INC. www.kescosolutions.com 803-802-1718

KOGER AIR CORPORATION

www.kogerair.com 276-638-8821

LA MECCANICA SRL DI REFFO www.lameccanica.it +39 049 941 9000

LAW-MAROT

www.lawmarot.com

800-461-6276

M-E-C COMPANY

www.m-e-c.com 620-325-2673

MÖLLERS NORTH AMERICA INC. www.mollersna.com 616-942-6504

MÜNCH-EDELSTAHL GMBH

www.muench-edelstahlgmbh.de 02103 58996

MUYANG www.muyang.com 0086-514-85828990

PELLETING TECHNOLOGY NEDERLAND

www.ptn.nl +31 73 549 8472

PLAYER DESIGN www.playerdesign.net 207-764-6811

POLYPRO SOLUTIONS www.polyprosolutions.ca 514-730-2433

PORT METRO VANCOUVER www.portmetrovancouver. com 604-665-9000

PORT OF BELLEDUNE www.portofbelledune.ca 506-522-1200

PORT OF HALIFAX www.portofhalifax.ca 902-426-8222

PORT OF MONTREAL www.port-montreal.com 514-283-7011

PORT OF QUEBEC www.portquebec.ca 418-648-3640

PORT OF TROIS-RIVIÈRES www.porttr.com 819-78-2887

PORT SAGUENAY www.portsaguenay.ca 418-697-0250

PREMIER TECH CHRONOS www.ptchronos.com 418-867-8883

PRIMARY PACKAGING www.primarypackaging. com 800-774-2247

PRINCE RUPERT PORT AUTHORITY www.rupertport.com 250-627-8899

PROCESS AND STORAGE SOLUTIONS www.processandstorage. com 256-638-1838

RETHCEIF PACKAGING www.rethceif.com 866-298-1876

RODRIGUE MÉTAL LTÉE www.rodriguemetal.com 418-839-0400 ext. 231

SAIMATEC ENGINEERING www.saimatec.fi +358-10 525 8100

SCHUTTE-BUFFALO HAMMERMILL, LLC www.hammermills.com 716-855-1555

SIEMPELKAMP ENERGY SYSTEMS GMBH www.siempelkamp.com 49-511-589-79-0

SILVANA IMPORT TRADING INC. www.silvanatrading.com 514-939-3523

SOLAGEN INC. www.solageninc.com 503-366-4210

STELA LAXHUBER GMBH www.stela.de +49(0)8724-899-0

STOLBERG ENGINEERING LTD. www.stolberg.com 604-273-1915

SWISS COMBI www.swisscombi.ch +41 56 616 6030

THOMPSON DEHYDRATING www.tcdryers.com 785-272-7722

TIMBER PRODUCTS INSPECTION www.tpinspection.com 770-922-8000

TRINITY PACKAGING CORPORATION www.trinitypackaging.com 914-273-4111

TS MANUFACTURING www.tsman.com 705-324-3762

TWIN PORTS TESTING INC. www.twinportstesting.com 715-392-7114

WALINGA www.walinga.com 519-824-8520

WEST SALEM MACHINERY CO. www.westsalem.com 800-722-3530

ZHANGJIAKOU HONG XING MACHINERY CO. LTD. www.hongxing.en.alibaba. com 86-313-4872140

ZHENG CHANG www.zhengchang.com/ eng +86 21 6418 8282

Prince George is at the centre of B.C.’s booming biomass industry.

By Andrew Macklin

Tenyears after a report identified a surplus of wood waste going to landfills for incineration, B.C. has become the heartland of the wood bioenergy industry in Canada. Sawmill and forest residues have become a staple for the expanding wood pellet industry and the growth of co-generation facilities across the province. At the centre of that growth is Prince George, the “northern capital” of the province.

Natural Resources Canada released a report in November of 2005, in conjunction with the Forest Products Association of Canada (FPAC), highlighted the opportunities for the biomass industry in British

Columbia. The report, entitled Estimated Production, Consumption and Surplus Mill Wood Residues in Canada-2004, analyzed the surplus of wood residues across Canada, how they were being disposed of, and the potential for future uses. It was estimated that a surplus of 1,814,955BDT of wood residues were being disposed of either in managed wood residue landfills or by incineration in B.C. alone.

The report went on to say that “Possible future energy projects to utilize the surplus wood residue include the conver-

sion of sawmills from natural gas to hog fuel energy systems, wood pellet, board and panel manufacturing and standalone power generation. These projects could decrease the surplus available to virtually zero in some parts of the B.C. interior.”

The industry responded to this report and Prince George, a community of nearly 90,000, has become a focal point for B.C.’s biomass industry thanks to the commitments made by the community’s forestry, biomass, government and education leaders.

Established in 2004 in Vancouver, Pacific Bioenergy has been a driving force for the Prince George bioeconomy. The company’s flagship pellet plant, located just south of the city, was established in 2007.

Just a few years later, in February of 2010, Pacific Bioenergy announced a $24 million expansion. The expansion would help the company meet the demands of a new supply contract: 10 years at 250,000 tonnes per year to GDF Suez. The expansion, and the new contract, helped Pacific Bioenergy grow its annual production capacity to 400,000 tonnes, the second largest pellet plant capacity in Canada.

Pacific Bioenergy has worked diligently to secure a long-term fibre supply, one of the biggest issues facing the wood pellet industry in B.C. The company currently holds a forest license in the Quesnel timber supply area (TSA) for 700,000m3 for 15 years. The contract covers an area of over one million hectares in the heart of mountain pine beetle infected wood from the City of Quesnel to the boundary of Tweedsmuir Park. Coupled with medium- to long-term contracts already in place with regional logging contractors and sawmills, Pacific Bioenergy has as stable a biomass supply as can be found in B.C.

The sawmill industry, as well as pulp and paper industry, have long since been staples of Prince George’s industrial community. Canadian Forest Products (Canfor), TimberWest and Sinclar Group Forest Products (Lakeland Mills) are all established both in Prince George and throughout the region.

In November of 2003, Canfor announced that they would be building an $81-million cogeneration facility at its Prince George pulp mill. The facility, in cooperation with B.C. Hydro, would create enough power for 39,000 homes and significantly reduce the company’s dependence on electricity and natural gas resources.

The construction of the cogeneration plant provided benefits on several levels for Canfor, B.C. Hydro and the community.

For Canfor, the move also helped to retire two of Canfor’s beehive burners,

in Bear Lake and Isle Pierre, as the new cogeneration facility would require an annual volume of 225,000 tonnes of hog fuel. The greenhouse gas emission reduction from eliminating the beehive burners vs. using the hog fuel in the cogen facility was the equivalent annual volume of natural gas used in approximately 5,500 homes.

For B.C. Hydro, it meant that much of the power demand needed for Canfor’s two mills (at the time) would be covered by the new electricity generation. Canfor was producing 390GWh with the new plant, while it used 415GWh of electricity. The 390GWh now freed up for use by B.C. Hydro was equal to the company’s projected increase in hydro use for the 15 years to follow.

For the community, it meant stabilized hydro rates thanks to savings in the purchase price of power for B.C. Hydro. It also meant lower emissions in the region.

The Canfor project also opened the door for the expansion of biomass for heat and power generation in the community,

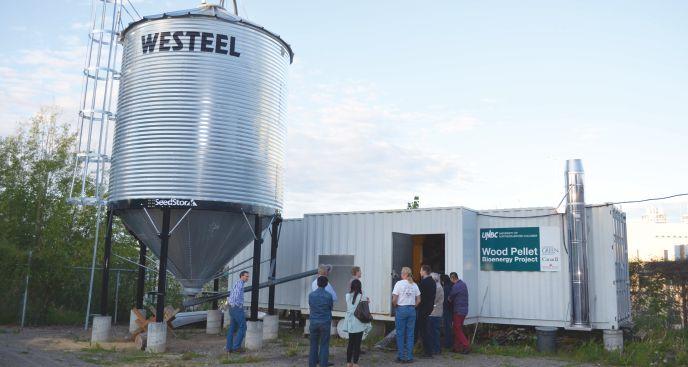

as evidenced by the developments since 2007 on the campus of the University of Northern British Columbia (UNBC).

In 2007, the university completed its green energy plan, looking for ways to reduce the campus’ carbon footprint and adopt green solutions for its expanding energy needs.

In 2009, UNBC became the first university in Canada to own and operate its own biomass system. A pellet boiler, with a peak capacity of 400kW, was installed to heat the Enhanced Forestry Lab greenhouse. The pellets for the boiler were donated to the campus in an agreement with Pacific Bioenergy.

In 2011, the university introduced Phase II of the campus’ bioenergy system, the installation of a Nexterra biomass gasification system. The $16.7-million bioenergy plant project was introduced to help reduce the cost of natural gas heat used to power the core of the campus. The biomass supply is provided as part of a five-year supply agreement with Lakeland Mills sawmill in Prince George. The

mill sells biomass to UNBC by the bone dry tonne. To date, the use of the biomass has reduced the campus’ annual purchase of natural gas by approximately $700,000 per annum.

The university isn’t the only group in Prince George to adopt the use of biomass for heat and power for its core buildings.

The community’s municipal council has also adopted the use of biomass for heat and power. Approved by City Council in June of 2010, the Prince George District Energy System (DES) was intro-

duced to provide carbon neutral green energy and improve the air quality in the community.

Construction of the Peaking Backup Energy Centre began in July of 2011 and was completed in March of 2012. The system provides power and hot water in coordination with the Lakeland Mills sawmill, which provides the power to the system through its energy system that uses woody biomass.

Since the system became active in the spring of 2012, eight buildings have become part of the DES in Prince George’s downtown core, including the RCMP headquarters, City Hall, Civic Centre,

and the Wood Innovation and Design Centre (under construction). In 2013, use of the DES reduced the city’s natural gas consumption by 17,000 gigajoules, enough to supply heat for 110 homes annually.

The Prince George Civic Centre is also home to Canada’s largest bioenergy conference: the International Bioenergy Conference & Expo (IBCE). The biennial event has called Prince George home since its humble beginning in 2004, when it was held in conjunction with Forest Expo.

In June of 2014, at the 6th IBCE, over 300 attendees, 43 presenters and close to 50 exhibitors descended on the community to discuss important issues affecting Canada’s bioeconomy (see www. canadianbiomass.magazine.ca/content/ view/4594/133/). Among those presenters were some of the community leaders who have helped push the community bioeconomy forward, including Brad Bennett of Pacific Bioenergy, Ken Shields of Canfor, Rob van Adrichem of UNBC and Prince George MLA Shirley Bond. The conference also included a pre-conference tour throughout the B.C. Interior with stops at the Canfor cogeneration plant and both of the UNBC biomass facilities.

This commitment from partners throughout the community’s biomass industry drives Prince George’s growth as one of Canada’s emerging bioeconomies.

the warmth of the people in the buildings themselves.

Canadian Biomass visited Hammarby Sjöstad, Stockholm’s largest urban construction project, which is on a former brownfield between the inner city and suburbs; it was transformed to house 26,000 people by 2017. Designed to be a model of sustainable housing, it has been a popular destination for city planners and politicians worldwide.

From the moment of the author’s arrival in the neighbourhood, it was evident that Hammarby Sjöstad is more vibrant than most urban densification projects. The population on the street in early June was primarily young parents and their children who were enjoying the green public spaces between residences (children aged 0-5 make up 13 per cent of the area’s population). This generation of parents makes an obvious fit for a neighbourhood designed to preserve the natural resources for the next generation, but diapers and picky eaters generate a great deal of waste regardless of a parent’s good intentions.

The waste generated in Hammarby Sjöstad is not wasted, however, it is the fuel that powers the neighbourhood. Waste is separated into organic, combustible and newspaper and transported underground through a waste vacuum system to a nearby handling facility. Other waste is collected onsite and recycled so that there is no waste bound for landfills. Combustible waste that has no other use is burned and the heat and electricity is fed back into the district’s grid.

Following the success and lessons learned from the construction of Hammarby Sjöstad, the Stockholm Royal Seaport has been designed with similar values in mind to produce 10,000 homes and 30,000 offices, to be built by 2025. City planners have gained enough experience and confidence to aim to build this new development into a fossil fuel-free zone in 2030 and to reduce the CO2 emissions produced to less than 1.5 tonnes per person by 2025.

Waste is transported underground through a waste vacuum system and processed at a nearby facility.

Some areas of focus for the development team include: wave power, pyrolysis oil, advancing the rapid adoption of electric vehicles, district heating, nuclear CHP, and the NURES liquid treatment system for radioactive liquids. There will be methods for individuals to monitor their uses of heating, waste and electricity and benchmarks they’re expected to meet.

This neighbourhood is being built to support innovation with extra space allotted to educating visitors on the sustainable technology being developed, schools, daycares and a former gas container reconstructed for an opera house.

As cities around the world look for best practices for remediation of brownfields and industrial lands and as we look for places for our cities to grow without diminishing our parks and nature preserves, Stockholm has taken up the gauntlet to lead the way. Sweden has proven that a fossil-free future is not only within reach, it is within our means. •

ANDRITZ is one of the world’s leading suppliers of technologies, systems, and services relating to equipment for the biomass pelleting industry. We offer single machines for the production of solid and liquid biofuel and waste pellets. We have the ability to manufacture and supply each and every key processing machine in the pellet production line.

The theme of the conference this year was “Taking you from know how to show how,” and there were plenty of exhibitors poised to show attendees how to grow their bioeconomy. Here’s a selection of the exhibits at the show.

LEFT: The only Canadian exhibitor was InterWrap which boasts a BioBlanket that is popular in Scandanavia. It’s a paper-based, laminated cover for forest residuals that protects them from rain and snow to speed up the drying process. The blanket is then chipped and burned along with the forest residual.

RIGHT: There was a variety of pelleting presses on hand that could pelletize anything from wood to waste, including this one from KAHL that is designed for universal use on a wide range of products. Powdery, fibrous, lumpy and pasty products can be processed into uniform pellets of different sizes, the company boasts.

If biomass quality is the concern, moisture metres of all shapes and sizes were on hand that would be able to test the moisture content onsite rather than in a lab.

ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb.us@andritz.com

www.andritz.com

Bulk material handling experts (Bruks and Noxor) were on hand to show how their systems would gently transfer pellets or general biomass handling from the mill to the transport vessel.

September 9-11, 2014

2014 CANBIO CONFERENCE & TRADE SHOW

Thunder Bay, Ont.

www.canbio.ca

September 24-25, 2014

7TH BIOFUELS INTERNATIONAL CONFERENCE

Ghent, Belgium

http://biofuels-news.com/conference

October 1-3, 2014

USIPA 4TH ANNUAL EXPORTING PELLETS CONFERENCE

Miami Beach, Florida

http://theusipa.org/conference

October 15-17, 2014

TIMBER PROCESSING & ENERGY EXPO

Portland, Oregon

http://timberprocessingandenergyexpo.com

November 5-6, 2014

4TH COFIRING BIOMASS WITH COAL CONFERENCE

State College, Pennsylvania http://cofiring4.coalconferences.org

• Vibration Resistant

• Waterproof, IP68 Rating

• 700 TV Line

• 2.9, 3.6, 4.3, 6, 8, 12, 16 mm lenses

• All Weather, Extreme Environment

• All Weather, Extreme Environment

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Tri-Axial Mounting System

• –60°C to +60°C

• Tri-Axial Mounting System

• –76°F to +140°F

• –60°C to +60°C and –76°F to +140°F

• Waterproof, IP68 Rating

• Vibration Resistant Available from leading electrical wholesalers throughout North America

www.toughestvideocamera.com

– Ph. 604-569-3240 • US – Ph. 269-966-2900 1-800-578-1853

November 17-19, 2014

2014 WPAC CONFERENCE AND AGM Vancouver, B.C. http://pellet.org

December 1-3, 2014

CANADIAN BIOECONOMY SUMMIT Toronto, Ont. http://greenfuels.org

April 20-22, 2015

INTERNATIONAL BIOMASS CONFERENCE & EXPO Minneapolis, Minn. http://www.biomassconference.com

June 1-4, 2015

INTERNATIONAL FUEL ETHANOL WORKSHOP & EXPO Minneapolis, Minn. http://www.fuelethanolworkshop.com

July 19-22, 2015

BIO WORLD CONGRESS ON INDUSTRIAL BIOTECHNOLOGY

Montreal, Que. http://bio.org/events

The

• 560 TV Lines

• 2 9, 4 3, 6, 8, 12, 16 mm lenses

• All Weather, Extreme Environment

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Tri-Axial Mounting System

• Waterproof, IP68 Rating

• Vibration Resistant

• –60°C to +60°C [–76°F to +140°F]

Available from leading electrical wholesalers throughout North America

Canada – Ph. 604-569-3240 US – Ph. 269-966-2900 www opticomtech com 1-888-410-2447

ROpportunity lies in the production of high-valued products from the dead wood in forests.

By Ken Shields

ecently, I had the pleasure of returning to my home town of Prince George, B.C., to address the Natural Resources Forum, a gathering that provides an opportunity for a cross section of forestry, mining, energy, and pipeline industry officials to liaise with representatives of the Government of British Columbia as well as First Nations Leaders.

Dr. Ralph Sultan, Member of the Legislative Assembly for West Vancouver-Capilano and a PhD (Economics) graduate from Harvard University, asked the question that is central to the future prospects for the British Columbia forest products industry: “With the mountain pine beetle epidemic leading to forecast declines in B.C.’s sustainable harvest from 70 million cubic metres annually to 40 million, what is our plan?”

My personal view is that too much public discussion in B.C. has been focused on the dwindling sawlog supply resulting from the mountain pine beetle (MPB), and too little on exploring how bioenergy and bioproducts-related harvest increases can offset inevitable decreases in the sawlog harvest.

Our thoughts differ from others because of our belief that, over time, British Columbians as well as other Canadians will find ways to profitably use low-valued wood fibre as feedstock for higher-valued bioenergy and bioproducts production. Simply put, we believe the emerging wood-based bioenergy and bioproduct businesses presently under commercial development have the potential to provide benefits to forest health, local economies, as well as forest sector em-

ployees, suppliers and shareholders.

To date, much of the bioenergy and bioproduct development in B.C. has been in the mass production of lower-valued products such as pellets and cogeneration, but the real opportunity lies in the production of high-valued products, such as biofuels, bio-based pharmaceutical products, plastics, etc. Here are some examples of developments from other regions that may have future application in B.C.:

Sweden and Finland utilize about 16 million cubic metres of logging residuals annually as feedstock for more than 1,000 heat and power plants in operation in both countries. These two countries operate 10 times the number of heat and power plants we operate in Canada by using fibre that typically ends up in burn piles in B.C.

A U.S. company is now making commercial shipments of woody biomass-based diesel and gasoline additives. This company produces 70 gallons of saleable product to a refinery from one ton of wood chips.

Forward-thinking Europeans expect pulp mills to resemble chemical plants in the future. They believe the real value-added in the pulp sector comes from separating wood fibre into its component parts and pursuing biochemical applications. The Finnish pulp and paper industry research scientists believe that by 2030, 50 per cent of pulp mill revenues will be derived from products that currently do not exist.

At last year’s Council of Forest Industries convention, B.C.’s Chief Provincial Forester Dave Peterson presented compelling statistics concluding that the in-

terior region of B.C. has sufficient fibre inventory to host a vibrant pulp sector and a growing bio-economy business. He went on to outline how he and his Ministry colleagues are exploring how the tenure system in B.C. can transition away from its historical focus on sawlogs to one co-dependent on sawlogs, but also providing assured access to lower-quality fibre for utilization as feedstock in the pulp, pellet and bioenergy/bio-product sectors. Tenure modifications may need to be designed and implemented to provide greater certainty of supply for non-sawlog harvesting.

In the next few years, we expect heightened European and Asian interest to be directed towards B.C.’s sustainably certified and plentiful softwood fibre resources. They see the benefits of using beetle-killed wood for renewable fuel production. Accessing B.C. fibre circumvents food-versus-fuel concerns, complies with their forest certification requirements, and is highly favourable in terms of carbon balance.

The Interior B.C. forest products sector has an incredible opportunity to co-locate exciting new businesses with robust revenue and cash flow streams alongside traditional forest products facilities. By focusing on these new businesses, we can ensure that the best days of the forest industry in B.C. lie ahead of us, not behind us. •

Ken Shields is the CEO and President of Conifex Timber. This column was originally published online by the Forest Product Association of Canada (FPAC) at www.fpac.ca.