The effects of avian influenza this year on Canada’s duck industry have been severe.

by Brett Ruffell

The effects of avian influenza this year on Canada’s duck industry have been severe.

by Brett Ruffell

As we close out another year filled with challenges, it’s time to look back on the defining moments of the past 12 months once again. For this, I turned to leaders from the chicken, egg and turkey sectors. All three agreed on the story of the year – the dual challenge of COVID-19 and the ongoing avian influenza outbreak.

On the pandemic front, things have begun to normalize for poultry since governments loosened restrictions. Foodservice demand has picked up with many Canadians returning to in-person dining and families have returned to having traditional gatherings.

“Coming out of COVID, I think our industry did really well,” says Michael Laliberté, executive director of Chicken Farmers of Canada (CFC). “Our allocation numbers are quite good.”

Tim Lambert, CEO of Egg Farmers of Canada (EFC), shares similar sentiment. “I wouldn’t say we’ve quite returned to normal but we’re certainly getting there,” he says. “I’d say by the first quarter of 2023, barring some other dramatic change, we should be largely back to normal.”

But just as the industry was getting some relief from pandemic restrictions, along came H5N1, the high path avian influenza strain that’s been wreaking havoc in North

America. First discovered on the continent in Newfoundland in late 2021, the disease has since spread to every province and throughout the U.S., causing numerous farms to euthanize their flocks.

While it slowed a bit in the summer, it returned with a vengeance in the fall. Darren Ferrence, chair of Turkey Farmers of Canada (TFC), says his sector was hit particularly hard during the fall wave. “I think in total 44 turkey flocks and 19 mixed flocks with turkeys in them were hit, which is 40 per cent of total avian influenza infections,” he says, adding that this meant the industry had to work to get lost product regrown in time for seasonal markets.

“So, it’s pivoting, maintaining one eye on challenges but then the other eye is on future growth opportunities.”

Tim Lambert says that Canadian producers have fared better than their American counterparts. “The U.S. has been far harder hit proportionately than we have by avian influenza,” he says. Lambert largely credits supply management for Canada’s resiliency. For instance, he touts the country’s high levels of biosecurity that are reinforced by annual thirdparty audits. He also says Canada’s smaller-scale farms

that are spread out throughout the country lessened the impact of H5N1. “If we have an outbreak in one area, we’re generally able to continue to support supplying product from other areas,” he explains. “So, it’s been tough, but I think we’ve come through it in a really resilient way.”

The industry was focused on more than just putting out fires in 2022. Indeed, poultry continued to make progress on the sustainability front. For instance, TFC conducted it’s first life cycle analysis (LFA), the results of which will be available in early 2023. (Both EFC and CFC have already conducted LFAs.) The organization plans to use the results to set sustainability benchmarks for producers.

EFC hit a sustainability milestone as well. Specifically, it launched the National Environmental Sustainability Tool (NEST). It’s an electronic tool that allows egg farmers across the country to input and share their data anonymously into a program. The tool then enables them to compare their sustainability performance to other producers on more than a dozen measures. EFC launched the beta version in 2022 with the full program, which will be free for producers, launching in 2023.

“So, it’s pivoting, maintaining one eye on challenges but then the other eye is on future growth opportunities,” Lambert concludes.

To hear my full year in review conversations with Ferrence, Laliberté and Lambert, visit canadianpoultrymag.com/podcasts.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer

Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes) USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

From the first day your chicks and poults are placed, water is one of the first things they look for, and for decades farmers and poultry have relied on our drinkers for a consistent flow of fresh water.

Our drinkers provide poultry the single most important ingredient for the BEST POSSIBLE START, AND HEALTHIEST LIFE DURING LAY PERIOD AND GROW-OUT.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

The governments of Canada and Ontario are investing up to $1.5 million to help eligible non-supply-managed poultry operations and related agri-businesses increase biosecurity efforts to reduce the spread of the highly pathogenic avian influenza. The Poultry Biosecurity Preparedness Initiative is a new, cost-share initiative to assist eligible non-supply-managed poultry and waterfowl farmers, meat processors in the sector and other related businesses in taking a variety of actions to increase biosecurity and reduce the risk of disease.

With another case of highly pathogenic avian influenza confirmed in a commercial poultry flock in Abbotsford, B.C., on December 1, B.C. became Canada’s province with the most confirmed cases to date in 2022. According to information from the Canadian Food Inspection Agency, with that additional case the province had 39 commercial flocks affected by HPAI. Alberta, previously the province with the most confirmed cases, had 38 cases.

Over 50 million birds have died amid a record-breaking outbreak of avian flu in the United States, according to the Department of Agriculture (USDA). This year’s total of 50.54m birds –including chickens and turkeys – has surpassed a previous high set in 2015. Flocks in over 40 states have been affected, more than double the number of states in the previous outbreak.

Newfoundland and Labrador’s poultry sector is the second largest agricultural contributor in the province.

$8M is how much the federal government pledged to help the company boost productivity and reduce its environmental impact.

To support its growth, Joanne Thompson, the MP for St. John’s East, announced in early December a federal investment of up to $8 million for Country Ribbon, the province’s only fully integrated chicken producer and processor.

The funding will help the company adopt advanced equipment that will increase productivity, while reducing its environmental footprint.

The announcement was made on behalf of the Minister of Agriculture and Agri-Food (AAFC), Marie-Claude Bibeau, and the Minister of Official Languages and Minister responsible for the Atlantic Canada Opportunities Agency (ACOA), Ginette Petitpas Taylor.

AAFC is providing up to $5

million and ACOA is providing up to $3 million. These investments will help Country Ribbon purchase and install an air chilling system to replace its current water chilling system.

Air chilling comes with a range of benefits such as chicken products that contain less water and more flavour, decreased risk of contamination and reduced water use in the chilling process.

Ian MacKinnon, president of Country Ribbon, welcomed the news.

“As a result of today’s announcements, Country Ribbon is able to begin major investments in its operations. We will immediately begin a $20-million investment over the next year, including an air chill system that will allow more local chicken to be delivered to more major retailers in Newfoundland and Labrador.”

Multi-tier true aviaries

Single-tier aviaries

Enriched colony systems

Aviary rearing systems

See Big Dutchman’s proven and industry leading layer and rearing systems on display at the National Poultry Show February 8-9, 2023

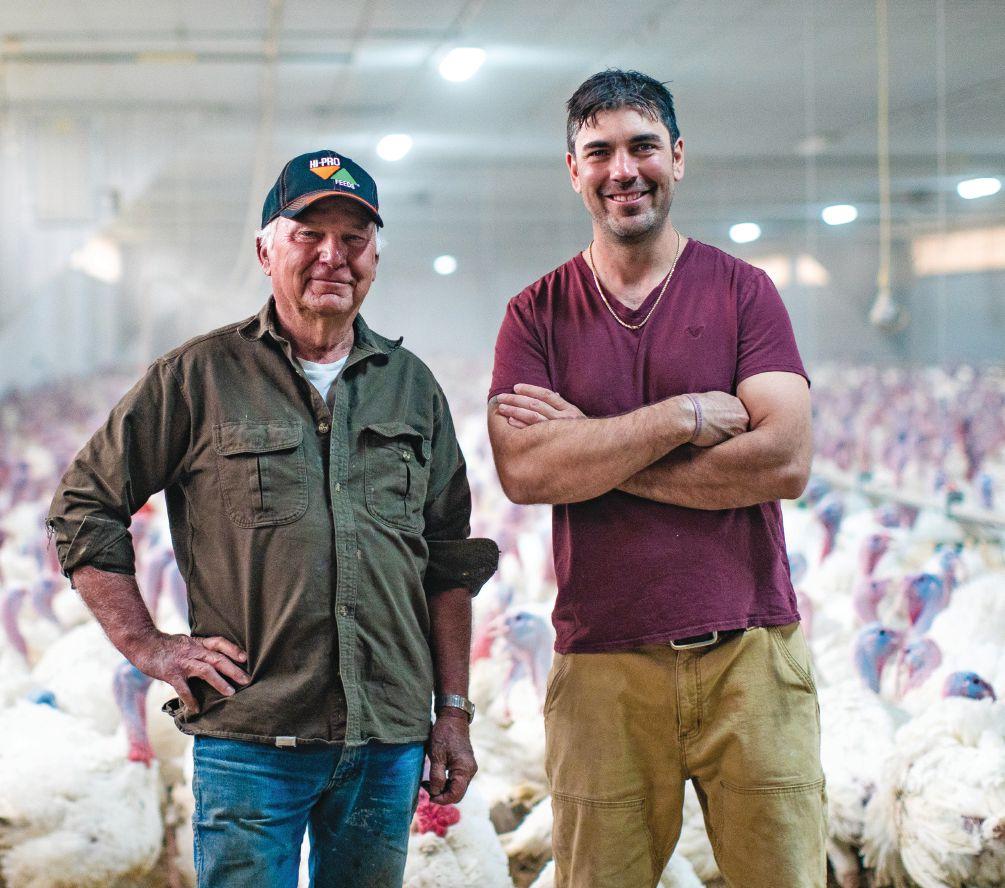

The Olson family’s turkey farm was hit by avian influenza twice in the past year. Here’s what the producers learned from the experience.

By Treena Hein

On April 13, Alberta turkey farmer Scott Olson entered his barn as usual in the morning. Right away, he could tell something was different. “It was a flock of toms and they didn’t get up and come towards me as they usually did,” he says. “They were also quiet. I walked around and saw 20 dead birds. Another 30 died in the afternoon. Two days later, the same thing happened in the other tom barn.”

Olson suspected strongly it was avian influenza (AI) and was worried. “It knocked the wind out of me,” the third-generation farmer and Alberta Turkey Producers (ATP) director says. “There was uncertainty about everything, the whole process, and my first thought was if I would receive compensation. I knew there was government compensation when you get a destruction order from the government and I worried at that point

that by the time the government personnel arrived, there wouldn’t be any birds left to destroy.”

Indeed, along with many other poultry farms in Canada this spring, Olson’s farm near Red Deer Lake was hit with the strain of highly pathogenic avian influenza (HPAI) that crossed the Atlantic in late 2021. It was the first of a long twopart saga.

ATP put Olson in touch with a Canadian Food Inspection Agency (CFIA) veterinarian on that first day he’d noticed something wrong. They had an virtual discussion and real-time barn tour.

The next morning, Olson took carcass samples to Edmonton to the CFIA AI testing facility and, later in the day, he was told they were positive. He had another interview with the vet to go over symptoms, the history of flock and so on, and did another barn inspection.

He received the order from CFIA to euthanize all birds in the first barn, which had originally been 7,600. On day four, the biocontainment officer came to the farm, and two days later, a CFIA euthanasia team arrived.

“At that point, there were only about 50 birds still alive in the two barns, so there was no need to gas them,” Olson explains. “They used bolt guns.”

A few days later, with the help of

“I lost a lot of sleep the first time, but this second time I was in a different mindset.”

a CFIA team, Olson began making compost inside the barns of litter and dead birds. He pushed this into piles and then put it in a line, capping it with wood shavings that he’d had dropped off.

“I wondered if it was going to work – if the heat would get up to where it needed to be. But we checked the temperature and everything went well,” he says. “If I can do it, anyone can, but the CFIA was really helpful. They have composting specialists and had people checking on how I was doing. There were always people to answer my questions on anything.”

Four weeks after he saw the first symptoms, Olson had cleaned out the compost and started washing and disinfecting both barns. He also spent time covering some areas of plywood in the barn walls with tin.

About three weeks later, CFIA did an inspection to check his cleaning and disinfecting efforts. “They were very thorough, just as you’d want them to be,” he says. “They see things that a producer might not. It’s a new set of eyes and they would point something out, and after, I would wonder how I missed this or that. I did some more cleaning and disinfection over about 10 days, and I remember thinking that the last time the barns were that clean is when they were brand new.”

His second inspection went well and Olson then had two weeks’ downtime.

All went smoothly this summer, but in mid-September, the disease struck a second time. “We had 9,000 and 10,200 young birds in the same two barns, although I rotate use of barns at another farm we own,” he says. “I knew right away when I

opened the barn door and saw a pile of dead birds. I thought for a second it was a smother from a power outage, but I’d had no alerts, and when I saw another 15 birds dead down the wall, I knew what it was. Gas had to be used this time.”

Although it was hard to believe he was going through another outbreak, Olson didn’t have the nervousness of the first time. He knew all the unknowns and that was a comfort. “I had all the contact numbers; I knew where to take samples; everyone knew me and I knew them and we had built really good relationships,” he says. “I lost a lot of sleep the first time, but this second time I was in a different mindset. I was able to ask a few more questions and made some suggestions, just about small things like how to clean my vents. Everything and everyone was like a well-oiled machine.”

This second outbreak was also a

lot easier because during the walkthrough, a CFIA person suggested that a whitewashing process (spraying a mixture of lime, salt and water) could be used to kill and seal in any remaining virus on and in any plywood sections that producers happen to have in barn walls. Olson says it would have been great to have that option in the spring, but he did use it in his second barn cleaning and disinfection.

On November 21, he was finished his two weeks’ downtime, but he’s chosen January 3rd as his next flock placement date, just to be sure the virus is gone from his barns. He also chose this date because fall migration is over and the geese that spend the summer at the two nearby lakes are gone.

Yes, in Olson’s case, these geese living nearby and migrating in the spring and fall likely resulted in his outbreaks.

There are thousands of geese that pass over Olson’s farm during the two annual migration periods. He believes the virus came into the barns through the air inlets, in fecal dust and feathers.

“My biosecurity is very tight,” he says. “I always use fresh boots and coveralls, and I’m the only one that goes into the barn except for my dad, who occasionally covers for me. I have no employees and no service people enter the barn. I have no insect or rodent issues. I do have curtains on both sides of the barns, but they were not up in the spring or fall. But I may have to switch to using air inlets instead of curtains. I’m not sure if this will make a difference and have to research it.”

What Olson does plan to do is use air cannons in his nearby fields to scare the geese away in the spring from the farm premises, but he says

Outbreaks by the numbers

Facts and figures related to the two avian influenza outbreaks the Olson family’s farm experienced.

1958 is when Scott Olson’s grandfather, Archie Olson, started the family’s turkey farm.

20,000 is how many turkeys the Olson family has in continual production across two flocks.

20,000 is also the number of birds the farm has euthanized due to avian influenza outbreaks.

Mid-April is when the farm experienced its first outbreak. The second came in mid-September.

27 is the number of days the producers spent composting dead birds after their first outbreak.

Olson’s insights

Olson remembers that at a Turkey Farmers of Canada meeting in March, his fellow director from B.C. who had had an AI outbreak said, “You don’t want to become an expert in AI, trust me.”

“But, unfortunately, I’m a bit of an expert now,” Olson explains. “It was accurate foreshadowing of what was to come.” He offers three pieces of advice for those who have an AI infection.

His first piece of advice: “I found out after the fact that compensation is dependent on when you take action on high mortality, and I am very happy I contacted my vet that first day. Your destruction order starts from that point so it’s important to report right away.”

Secondly, he advises producers to forge good relationships with their vet, board and fellow farmers. “My first outbreak

was on a Saturday and both my vet and board answered right away,” he recalls.

Olson also had farmer friends going through an AI outbreak at the same time, and they would check in with each other to see where they both were with the process.

“If they were a step ahead, they could give me advice or say, don’t forget about doing this or that,” Olson says. “So, having those relationships in place really helps during a crisis. You don’t feel like you are going it alone.”

Lastly, he advises producers to be grateful and thank those who help them. “I developed a great relationship with CFIA staff, and some of them came from B.C. and were far from home,” the turkey producer says.

“I was very grateful and appreciated all their efforts, and I thanked them often and sincerely.”

By Lilian Schaer

Anew study out of the U.S. shows that using antimicrobials in feed and injecting them into embryos at the hatchery are the main causes of antimicrobial resistance in Canadian turkey flocks. The good news for the industry is that more widespread implementation of stewardship methods is leading to a reduction in resistance.

Antimicrobial resistance has long been identified as a threat to global human and animal health, with limited options for treatment.

In poultry production, antimicrobials help to treat and control bacterial infections, but also lead to increased resistance because the surviving bacteria pass on their resistance genes not only to their offspring but also to other bacterial species.

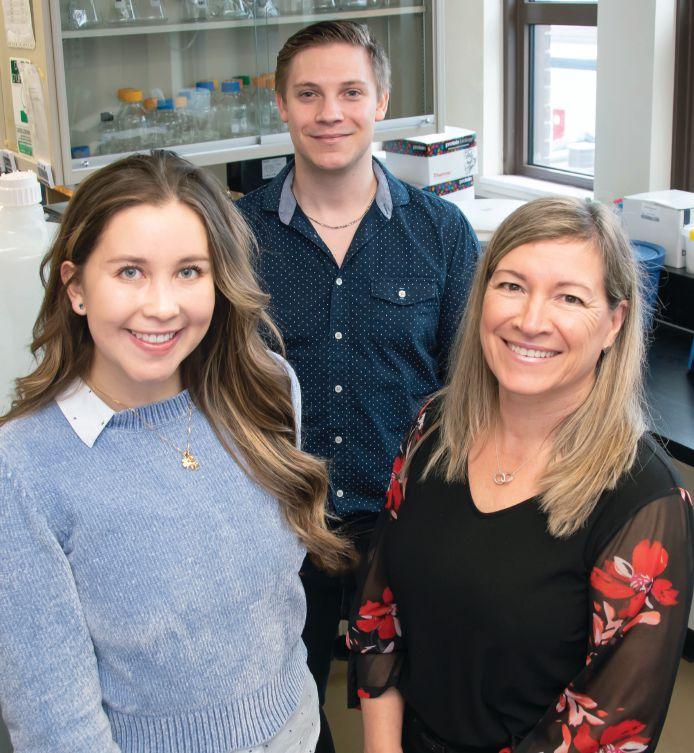

Dr. Csaba Varga, an assistant professor of infectious disease epidemiology at the University of Illinois at Urbana Champaign, leda team that used data collected by the Canadian Integrated Program for Antimicrobial Resistance Surveillance (CIPARS), a program of the Public Health Agency of Canada, to model the link between antimicrobial use and resistance.

“Antimicrobial resistance development in food animals and poultry is an issue because multi-resistant bacteria can be transmitted through the food chain or contact with infected animals,” Varga says.

Although there have been several studies examining this issue in broilers, very little work has been done in turkeys until now. According to Varga, this study is the most comprehensive in North America involving turkeys, as it takes analysis to the farm level. Previous research has looked at sales of antimicrobials to make associations with resistance, but that’s too far removed from the farm to generate real insights into use and resistance, he notes.

What made this study possible was the CIPARS data, collected by Canadian veterinarians visiting turkey farms annually in each province between 2016 and 2019 to collect data on antimicrobial use and fecal samples from randomly selected flocks. In B.C.’s turkey industry, data collection had already started as far back as 2013. This type of data isn’t available in the U.S., as long-term surveillance isn’t in place.

Varga had completed his graduate work in Canada and worked for the Ontario Ministry of Agriculture, Food and Rural Af-

fairs (OMAFRA) as a lead veterinarian in poultry disease prevention. OMAFRA funded the initiation of antimicrobial use surveillance in turkeys in Ontario, which led to Vargas’ involvement with the program.

The research team used E. coli as an indicator organism for the presence of antimicrobial resistance, as they are bacteria that are present in the gut flora of both humans and animals. At the same time, they can easily be detected in fecal and environmental samples.

“E. coli can harbor antibiotic resistance genes that they can preserve and transmit to other bacteria in the gut, making them good indicators of for the selection pressure of antimicrobial use,” Varga says.

E. coli isolates from the fecal samples of turkeys were tested for their susceptibility to 14 different antimicrobials. Then, to study the links between antimicrobial use and resistance, researchers used new modelling techniques that looked at disease

indications for antimicrobial use, bird weight, and how many antimicrobials were used for how long and how they were administered. Additional work is underway with Salmonella and Campylobacter, with results expected next year.

“The main driver of resistance is antimicrobial use, but the industry is developing stewardship programs like reducing the use of antimicrobials critically important in human medicine, and banning use of antimicrobials to promote growth,” Varga explains.

His team is currently finalizing research that found efforts to reduce the use of certain antimicrobials are contributing to lower resistance rates, which is a good news story for the industry, he adds.

Research into antimicrobial alternatives is underway at various institutions and companies in North America and Europe that will help producers transition away from antimicrobials, as use of those products continues to be phased out.

Basic farm management and animal health practices are the foundational pillars that make antimicrobial use reduction work. That includes implementing and following biosecurity practices to keep diseases on farm to a minimum.

Reducing the potential for birds to get sick lowers the amount of infection, which in turn reduces the need for treatment with antimicrobials.

Another significant development, according to Varga, is a regulatory change in Canada that ended over the counter purchases of antimicrobials; instead, producers must now have a veterinary prescription for their use.

“We are going to expand this (research) to the U.S. but much of the data doesn’t exist there. That’s the beauty of the CIPARS data – you can compare resistance level changes when changing use practices and we can see that resistance is going down for most antimicrobials,” he says. “To know what to change you need to have data and you need to analyze it.”

Last year was a tough one for poultry health, experts say. By Lilian Schaer

From a poultry health perspective, 2022 will remembered as the year of avian influenza in Canada. But AI wasn’t the only challenge facing poultry producers across the country, noted Dr. Teryn Girard of Prairie Livestock Veterinarians and Dr. Jessalyn Walkey with Production Poultry Veterinary Services in Ontario.

The two veterinarians presented poultry disease updates from Western and Eastern Canada, respectively, at the 2022 Poultry Service Industry Workshop held in Banff, Alta.

“Disease is one of the major things that gets in the way of our production. When it comes to high performance, everything matters, and disease is one of the big barriers to that high performance,” noted Walkey in her presentation. “Health is the difference between stress level and stress threshold and resilience is the capacity to keep performing while facing disease challenge.”

Starvation was the number one commonality affecting meat turkeys in Western

Canada. It’s a multifactorial issue, Girard said, caused by issues like poor water quality and availability, poor lighting and barn ventilation problems that keep birds from getting enough feed or water.

Round heart was also reported in Western Canada, usually during the first four weeks of life, with birds suffering from enlarged heart, swollen liver and congested lungs.

“The frustrating thing about this one is similar to starvation in that it could be (caused by) so many things – ventilation, temperature or generics,” Girard said, adding one vet noted improvement by increasing the number of dark hours in some barns to six to eight, from four to six.

The last quarter saw the emergence of colibacillosis in Saskatchewan, Manitoba and Alberta, possibly linked to difficult starts causing immune suppression or water sanitation. As well, a few vets in Alberta and B.C. have been finding coccidiosis outbreaks at four to five weeks of age; in Manitoba, where most turkeys are raised without antibiotics, ongoing challenges include enteritis and E. coli. According to Walkey, early and late

bacterial challenges dominate in Eastern Canada, particularly E. coli, but veterinarians are also reporting enterococcus, staph aureus, necrotic enteritis, gangrenous dermatitis and salmonella. Blackhead and coccidiosis represent additional challenges. In Quebec, reovirus has been an issue, whereas in Ontario, autogenous vaccines have had significantly improved control.

Western Canada dealt with high first week mortality this year, caused by supply chain disruptions resulting in chicks arriving on-farm in poor health, early systemic bacterial infections by E. coli and enterococcus, and yolk sac infections.

Egg yolk peritonitis, although stable, was mentioned by vets in three of the four western provinces; E. coli is the primary agent of this problem.

Bacterial lameness is consistently common and seen mostly in males, Girard noted, which suggests excess weight as a cause. Gut integrity could also be a factor, so coccidiosis control may play a role.

“It’s interesting to see how provinces

manage coccidiosis differently in breeders – in Alberta, it’s managed more with medication, whereas B.C. relies more on vaccines and in Saskatchewan it’s a bit of a mix,” she said.

Blackhead, although at levels higher than normal, is still low, but has been found in B.C., Alberta and Saskatchewan. And management issues continue to pose problems, with three of four western provinces reporting challenges – the biggest being overweight birds, which can lead to femoral head necrosis, staph infections and tenosynovitis.

Bacterial challenges are dominant in Eastern Canada, including early bacterial and pre-lay infections, in-lay septicemia, bacterial lameness in males and salmonella. Vets are also seeing mycoplasma synoviae, mycotic pneumonia and infectious bronchitis virus, of which Delmarva (DMV) is the most common strain. Coccidiosis is stable, but still present, and some cases of intussusception, cannibalism, blackhead and Marek’s Disease are also being reported.

“We’re talking about an amazing amount of bacteria ranging from E. coli to clostridium perfringens to staph –and we’re seeing multi-drug resistant and multi-bacterial infections,” Walkey said, adding that bacterial lameness in males continues to be a problem in Quebec at around seven weeks of age and before or after transfer in Ontario.

Yolk sac infection and early or late systemic bacterial infection were reported across Western Canada.

Like broiler breeders, E. coli and enterococcus were the two most commonly cultured bacteria.

“It’s been a tough year for poultry in general with chick shortages and stressed chicks,” Girard explained.

As with broiler breeders, broilers in Eastern Canada are particularly dealing with early and late bacterial infections, led by E. coli but also caused by enterococcus, clostridium, staph, and salmonella.

“ E. coli is becoming more complicated; we’re seeing mixed infections

and we’re also entering an era of multi-drug resistance,” Walkey said. “It’s both concerning and reassuring to see other provinces documenting this as well.”

Of particular concern is a rise in enterococcus since 2019, particularly in Quebec, and the shift in clinical pattern from kinky back at 28 to 30 days to age to osteomyelitis and septicemia as early as 15 days of age. The good news is that a PCR test for enterococcus is now available through the University of Montreal, she noted.

“Our bacterial profiles and available drugs are shifting. E. coli is highest in chickens,

followed by turkeys, broiler breeders and layers and we are seeing the highest concentration of bacteria in yolk sacs, followed by heart and bone marrow,” Walkey said of culture results from her own practice.

On the viral side, inclusion body hepatitis has been the most common cause of high mortality in Ontario with

Quebec reporting increases at the end of 2021. Serotype 8b has been the most common strain in both provinces.

Both field and vaccine strains of infectious bursal disease have been major players in Ontario this year, and the industry has been actively increasing screening and onfarm testing. Reovirus is stable to decreasing, with Quebec reporting vertical transmission from U.S.-sourced eggs causing issues between 13 and 21 days of age.

In Atlantic Canada, cecal coccidiosis is top of mind, caused by drug program changes, litter moisture and ventilation challenges. Heat stress also caused issues this year, resulting in mortalities in Ontario and poor growth in Atlantic Canada facilities with inadequate ventilation.

Egg yolk peritonitis has been stable in B.C. and Saskatchewan but increasing in Alberta, which Girard attributed to possible water quality problems and lack of E. coli vaccine use. Pullet vaccination titres are still an issue, although pullet vaccination has been improving. When pullets coming into production are moved into a layer barn, there can be issues of significant production decrease in the older birds, linked to bronchitis and avian encephalo -

myelitis.

In B.C., Iinfectious laryngotracheitis has been constant but stable over the last two to three years. Although it spreads and infects easily, mortality is typically low, and recovery is in about one week.

In Eastern Canada, E. coli and other bacteria pose significant problems for layer production. These include early bacterial infections like yolk sacculitis and septicemia, inlay septicemia, bacterial peritonitis, necrotic enteritis and salmonella. As well, focal duodenal necrosis is common and increasing and infectious bronchitis is reported as severe in non-vaccinated flocks in Quebec.

Atlantic Canada is seeing cases of cannibalism, as well as vets reporting hypocalcaemia and increased starve-outs in a free-run operation.

The B.C. floods in late 2021 had an impact on all sectors of poultry production in that province. Ten farms in the Fraser Valley were affected, with one farm still renovating almost a year after the event, and general rebuilding is still in progress, including remediation work on the dike and pumping system, and repairs to drinking water and transportation infrastructure.

“It’s been a difficult year for poultry and even though AI has taken over our world, B.C. has been hit really hard and is still dealing with that,” Girard said.

Transatlantic migration of wild birds brought avian influenza (AI) to North America in

Poultry farmers across Canada are no doubt excited about the federal government’s $630 million Poultry and Egg On-Farm Investment Program. But navigating the application process can be complicated and time consuming. Our expert, Jonathan Giret from Elite Agri Solutions Inc. will detail how to take advantage of this program. He will also highlight several different projects, provide an overview of how the program works and much more! Don’t miss this unique and valuable learning opportunity.

www.canadianpoultrymag.com/webinars

the fall of 2021. The spike in cases in wild bird populations was soon followed by infections in domestic commercial and small or backyard flocks in Canada and the U.S. in the spring of 2022. After a bit of a lull over the summer months, infections once again trended upwards in the fall.

“When you look at the impacts on poultry in Canada, the total case number continues to increase and we’re seeing a significant number of small flocks affected,” explained Noel Ritson-Bennett, operations manager at the Canadian Food Inspection Agency (CFIA), speaking at the PSIW. “In Western Can-

Avian influenza by the numbers

A summary of avian influenza’s impacts on Canadian poultry as of September 30, 2022:

Top affected provinces by number of farms

• Alberta (49 farms)

• Ontario (30 farms)

• British Columbia. (22 farms)

• Saskatchewan (21 farms)

SOURCE: CFIA PRESENTATION AT POULTRY SERVICES INDUSTRY WORKSHOP, 2022

ada, it came back faster than any of us would have liked to imagine possible. We were hoping for a quieter fall…that doesn’t appear to be the case.”

It’s the CFIA that leads disease outbreak response, and although there have been AI cases in Canada in the past –

Top affected provinces by number of birds

• Alberta – commercial chickens and turkeys

• Ontario – commercial chickens, turkeys and ducks

• Quebec – commercial ducks, turkeys and chickens

Note: Commercial chickens includes broilers, layers and broiler breeders.

an outbreak in B.C. in 2004, one infected premise in Manitoba in 2010 and one in Saskatchewan in 2009, for example – this was the first time the agency faced simultaneous outbreaks not just across Western Canada but the whole country.

That broad outbreak pressure, combined with significant travel distances in Western Canada in particular, posed a major challenge for CFIA.

“It is tremendously difficult trying to respond to outbreaks in all four provinces. We don’t have the staff to manage separate incident command centres in all provinces, so we have one command structure and four provincial governments we’re meeting with,” Ritson-Bennett said, adding this makes real-time communications challenging.

At the height of the outbreak in the spring, he estimated CFIA had about 350 of its staff

This book gives a comprehensive overview of the mode of action of probiotics and the theories behind it.

In addition, it highlights the main benefits of using probiotics in poultry production, such as maintaining gut health and integrity, reducing gut inflammation, modulating the immune system, preventing bacterial lameness, preventing reproductive tract infections, combating various enteric pathogens and improving performance. The chapters of this book illustrate various studies, which show the efficacy of probiotics in reducing livestock and poultry diseases, potentially reducing the need for antibiotic intervention, in addition to improving production performance.

$74.40 | Item# 0955501180

in Western Canada, with some living out of hotel rooms for 60 days or more. And although restrictions were lifting, COVID-19 was also a concern for the response teams on the ground.

Another major challenge was sourc ing carbon dioxide for depopulation due to a North America wide shortage of CO2. And even if CO2 was available, trucking it to affected sites was also dif ficult at times – so much so that, in some instances, scheduled deliveries had to be cancelled as the birds had al ready died from the virus before the flock could be depopulated, he recalled.

On the positive side, the outbreak has been marked by tremendous support from the industry, including with pri vate veterinarians and staff supporting sampling efforts. Two years of virtual work due to COVID-19 also proved useful, he added, as all the needed infrastructure was already in place, en abling different provinces to work together efficiently.

Veterinarians across Western Canada track unique cases of poultry disease they encounter in their practices. Here are two particularly interesting exam ples producers should keep an eye on.

Blackhead in turkeys – B.C. record ed fewer cases of blackhead this past year, although the cases were observed earlier than usual, and a cluster of cases has emerged in the last couple of months.

sub-optimal peak lay level of 90 per cent instead of 97 to 98 per cent, and low production continued after the peak at approximately 80 per cent. Interestingly for a bronchitis case, Girard noted, there was no change in eggshell quality, but during a

veterinary analysis, infectious bronchitis California strain was isolated from cecal tonsils.

“That’s a bit scary, as we don’t have a vaccine for that here, so just be aware that it’s out there,” Girard said.

“This is something to note; as blackhead becomes more common in B.C., we will see it more. We saw it in Saskatchewan last year, so it’s important to be ready in other provinces too,” Girard said.

Morbidity and mortality vary greatly between affected farms in B.C., with some flocks getting really sick and others not as much. Blackhead is a protozoa infection for which there is no real prevention or treatment. Common risk factors include darkling beetles and hot weather.

Infectious bronchitis in layers – In another case, a B.C. producer noticed

When it comes to poultry systems, you can’t a ord to get it wrong – especially when industry standards are constantly changing. Count on Chore-Time to give you the right advice. The right innovative solutions. And the right customer support. It’s what we’ve been doing since 1952.

Talk to your independent authorized Chore-Time distributor today. And get it right the rst time. Learn more at choretime.com/GetItRight Visit us at County Line Equipment’s booth during the

Research is closing in on additional necrotic enteritis vaccine options.

By Lisa McLean

Necrotic enteritis (NE) is a devastating poultry disease that can strike within hours, leaving young birds with irreversible lesions causing death or poor growth. It’s a significant threat that Canadian broiler farmers manage with preventative antibiotics, but as the industry transitions away from this tool, new strategies are needed.

NE occurs when a pathogenic strain of the naturally occurring bacteria Clostridium perfringens teams up with specific farm conditions. Dr. Martine Boulianne, poultry research chair, Faculty of Veterinary Medicine of the University of Montreal, has completed work that has led to a more thorough understanding of the problematic pathogen, putting her team closer to developing vaccines to prevent NE.

“The more we study C. perfringens, the better we understand how this disease develops,” Boulianne says. “In the past, researchers believed the pathogenic strains were associated with the presence of specific toxins, but as we study the bacteria closely using bioinformatics tools, we have found that belief is not necessarily the case.”

One potential vaccine solution Boulianne’s team is investigating is a delivery mechanism from an unlikely source: “mini cells” that are produced by the pathogen itself. Under a microscope, she says the material, known as extracellular vesicles (EVs), appear under magnification as small bubbles on the surface of the bacteria.

“Many types of cells including bacteria will produce EVs, which are basically a bit of the membrane packaging a variety of lipids, nucleic acids and proteins from the bacteria. We see this as a communication pod, a way of sending information or messages to other bacteria in the environment,” Boulianne says.

It’s what’s outside that counts Boulianne says it was the EV’s structure that got her team thinking about using EVs as potential vaccines. Her team has zeroed in on the value of using a byproduct of the bacteria to see if it could stimulate immunity.

“The membrane is the first point of contact for a host, and what a host encounters on the surface informs how it will mount its immune response,” Boulianne says. “When we saw that C. perfringens also produces EVs, we got the idea to use EVs as potential vaccines to protect against the pathogen. “

The team pursued the production and characterization of EVs from C. perfringens. In their lab, they were able to determine the EVs’ size, weight and various conditions where the bacteria was most productive. They sent their EVs to a partner for further analysis.

“We wanted to understand what sort of

proteins the EVs contain, because if we know the proteins, we can better understand how the bacteria communicates,” Boulianne says.

Next, the team will administer a small amount of EVs to chicks orally, and monitor their blood response to see if antibodies develop. At three weeks of age, the chicks will be challenged to test if they have developed immunity against C. perfringens

“This is the first time EVs are being used to protect chicks against C. perfringens, and it’s very exciting,” Boulianne says. “We are in the early stages, looking for proof of concept. If the work is successful, these EVs could be an interesting alternative to antibiotics.”

Reverse vaccinology approach

Boulianne says the EV project is complementary to her team’s other work, which involved developing three purified proteins that are ready for testing both in ovo and post-hatch vaccination, thanks to a “reverse and subtractive” vaccinology method.

“Researchers often work with a gene or protein to see if it is immunogenic,” Boulianne says. “But our work does the reverse, by looking at all the genes from pathogenic or harmful strains of the bacteria and comparing them with all the genes from the commensal or not harmful strains. It helps us understand what genes are important to the disease.”

The team categorized a total of 79 C. perfringens strains from different geographical regions and tested each strain to determine whether it was pathogenic or commensal. They determined a list of criteria they wanted in a potential vaccine, and created a process of purifying the top three candidates.

Next, those proteins will be shared with a collaborator who will inject them into embryos as in ovo vaccination, while Boulianne’s team uses them to vaccinate day-old chicks. All birds will undergo a challenge study, and researchers will measure their immune response to NE.

“So much of our work is prediction based, and now it is time to test if our purified proteins are immunogenic and protective – because that’s what we want

in a future vaccine,” Boulianne says. “We hope to see the embryos develop an immune response, and that in front of a challenge from the bacteria and the risk factors that would normally produce NE, our birds are protected.”

Both studies will be completed by March 2023.

What happens when

Boulianne’s team is working on another project she hopes will provide a more fundamental understanding of how NE develops in the body.

“We have a project that is looking not at DNA, but RNA – the message that the pathogenic bacteria sends at specific times,” Boulianne says. “We want to understand the arsenal that bacteria use at different times.”

Researchers have shown that within seven hours after exposure, toxins begin to produce, leading to intestinal lesions. Boulianne says the goal is to understand what happens at specific times within those seven hours.

“All of these projects complement each other and will help us to design better preventative and controlled means of controlling this disease in young birds,” Boulianne says. “If we plan to eliminate antibiotics, we need as much knowledge and as many tools as possible.”

Boulianne is working closely with Drs. Joshua Gong and Dion Lepp at Agriculture and Agri-Food Canada, Dr. Faizal Careem at the University of Calgary, her University of Montreal PhD student Nicolas Deslaurier and MSc student Laura Guerrero, in collaboration with Drs. Christopher Fernandez-Prada from University of Montreal and Dr Martin Olivier from McGill University.

This research was funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster, which is supported by Agriculture and Agri-Food Canada (AAFC) as part of the Canadian Agricultural Partnership (CAP) program. Additional support was received Natural Sciences and Engineering Research Council of Canada (NSERC) and the Claire and Jean-Pierre Léger Foundation.

We wish you many blessings and good health in 2023! to our poultry friends!

- Alberta Chicken Producers Board and Staff

The effects of avian influenza this year on Canada’s duck industry have been severe. By Treena Hein

The highly pathogenic avian influenza (HPAI) strain that arrived from Europe caused outbreaks in many types of poultry operations across Canada. But it devastated Canada’s duck industry. However, its fighting spirit remains strong and a new era of extreme preparedness has begun to prevent future outbreaks.

Once the variant entered premises at Canards du Lac Brome (Brome Lake Ducks) in Knowlton, Que., and King Cole Ducks in Stouffville, Ont., about 85 per cent supply was wiped out. This significantly affected the wide variety of ethnic retail and restaurant markets served by the industry, explains Patti Thompson, director of sales and marketing at King Cole. At this point, both King Cole and Brome Lake are well into the recovery phase and both have made very significant changes in biosecurity infrastructure and protocols. It has been a colossal effort and very difficult on many levels for leadership and

staff. “The re-launch of our operations has me busy 25 out of the 24 hours in a day,” says Angela Anderson, general director at Brome Lake.

But before getting into what both operations are doing to re-launch, here’s an overview of their truly terrible experiences. First, Brome Lake.

Last April, HPAI was detected in four of Brome Lake’s 13 production sites. This included its main site where parent stock was raised. Hundreds of thousands of ducks had to be euthanized and over half a million hatching eggs were destroyed, representing most of the firm’s production.

“The impact is major for the company and its staff,” Anderson says. “It has taken enormous financial effort and creativity to keep our operations going. This is a crisis situation that we could never have imagined, even though we have experienced a few disasters in during our 110 years of existence.”

After a lengthy period of inactivity, the Brome Lake team conducted a detailed evaluation of their operations and biosecurity regulations. They planned for a future in which avian influenza (AI) would be a constant threat.

“Despite the lack of cashflow that AI caused by the halt of our operations, we decided to invest in modifying the Danish entries to include showers between the dirty and clean zones in all our barns and hatchery,” Anderson reports.

“We converted two rearing sites into breeding sites to allow us greater flexibility. We also did extensive training of our management and staff on the revised biosecurity protocols.”

It had been over seven decades since King Cole Ducks had been impacted by AI. As with Brome Lake, the outbreaks started in April and over the following eight weeks, outbreaks impacted 10 of the 22 farm locations. About 86 per cent of production

was wiped out – hundreds of thousands of meat birds, breeders and eggs had to be destroyed.

“Recovery has been a six-month seven-days-a-week process to eradicate the virus in over 750,000 ft 2 of space,” Thompson says. “Our heritage site is home to our admin office, federal-compliant processing plant and three grower barns. When one flock was hit with AI, it quarantined the entire address.

“We were forced to demolish non-infected barns that couldn’t be cleaned and disinfected quickly enough to allow our processing plant to operate and protect the welfare of healthy flocks. We were forced to lay off 50 per cent of our plant staff during the crisis and redeployed farm and maintenance teams to try to keep staff employed.”

As at Brome Lake, King Cole made significant biosecurity infrastructure and protocol changes. The firm will no longer farm ducks at its 100-acre heritage site to ensure the processing plant is never again in jeopardy. The company moved from a very efficient system of shared teams for wash, vaccination and overall management to a siloed system of one manager per farm and dedicated equipment.

“The viral load in our region was significant so we have recognized the need for a wider geographic placement,” Thompson says.

“It’s not as efficient but reduces risk. This requires a significant change in transportation system from open wagons to modules, allowing humane transportation at greater distances.”

The firm is also in the process of sourcing contract growers throughout the province and has added a formalized audit program.

In addition, the company will expand its use of technology that was extremely helpful during this crisis to track and trace AI to reduce traffic in and out and on its farms.

Thompson reports that they were back to 50 per cent production by mid-November and she expects a return to full production by spring 2023.

• Exacon’s brand name since 1987

• Polyethylene or fiberglass flush mount housings available in white or black

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan, MFlex, or AGI motors

• Available in sizes ranging from 12” to 72”

• Produced out of high-quality polyurethane, TPI inlets are designed to optimize airflow

• High insulation value is ideal for cold weather climates

• Easy to assemble, maintain, clean and adjust to meet your specific ventilation needs

• Wall inlets, ceiling inlets and tunnel inlets

• TPI wind hoods are available with a builtin light trap option

• The V-FloFan creates a uniform climate in poultry houses

• Equipped with a water and dust resistant

IP55 rated, low noise

Multifan motor

• Helps control the humidity of the litter resulting in an active microclimate at bird level

• Special aerodynamic shaped conical outlet optimizes vertical airflow contributing to lower energy costs

• 3 year warranty on complete fan

• Available in natural gas(NG) or liquid propane(LP)

• CSA Certified variable heat output and highly efficient direct-fired design

• Manufactured with high quality, corrosion resistant components and Tri-Shield coating to provide years of worry-free performance in even the harshest livestock environments

• Features high temperature protection, air proving switch and a totally enclosed motor to assure safe, dependable operation

• User-friendly livestock production control equipped with a 10” colour touch screen for easy navigation

• Cutting-edge technology facilitating the management of ambient air(ventilation, heating, humidity, static pressure, CO2), animal populations, feed levels/consumption, lighting, and more

• Access real time data 24/7 and manage your operation remotely from anywhere you can access the internet using the FarmQuest online management tool

LIGHT TRAP BY EXACON

• Lightweight, corrosion resistant and easy to assemble on site using PVC spacers

• Provides maximum light reduction with very little resistance to air flow

• Also available assembled with a galvanized frame

As those in the poultry industry know, the duck industry is not supply managed. “There is no insurance available to the duck industry,” Thompson explains. “Recovery is on our own dime and time.” She adds that the duck industry is vertically integrated, so AI affected all levels of the business from breeding to production to processing.

However, Thompson says that her staff’s experience with the teams at Canadian Food Inspection Agency (CFIA) was very positive. “CFIA assigned a case manager who helped us navigate the hundreds of re -

revised standard operating procedures to daily updates, meetings, questions, concerns, etc.,” she says.

“These managers kept the timelines organized and helped us connect with senior and national level operations, policy, veterinarians, etc. Because our outbreaks and recovery were stretched over months, we rotated through a number of different case managers who not only cared for our file but cared about us. Continuity was impressive. It is an excellent model and was essential to us being educated, understood and heard.”

She adds that although duck

side its purview, she praises the Feather Board Command Centre in Ontario. “They did an incredible job of communicating to the poultry industry as a whole through the crisis. They were instrumental in understanding that we are in this together and supported bringing the duck industry to the table in discussions around recovery. All stakeholders need to be part of AI conversation at federal, provincial and industry levels for the benefit of Canada’s food supply.”

In addition, strong partnerships with banks and suppliers allowed King Cole to manage through this crisis as it re -

son praises their understanding and appreciation for the industry, which allowed company leadership to make significant decisions and changes.

Both Anderson and Thompson have come to some solid conclusions about the future direction the duck industry needs to take after this year’s crisis. “Nothing will ever be the same again on many levels,” Anderson stresses. “You have no idea what this can mean in terms of biosecurity alone. Colossal investments are required.”

HALIFAX CONVENTION CENTER, HALIFAX, NS

Early Bird Registration

$150 plus HST

She adds, “We still believe

For information on registration, trade show & sponsorship opportunities. Visit the Conference website atlanticpoult r yconference.com Early Bird Registration $150 plus HST Student Registration $75 plus HST For information on

“THE MEETING PLACE OF THE ATLANTIC POULTRY INDUSTRY”

“THE MEETING PLACE OF THE ATLANTIC POULTRY INDUSTRY”

Student Registration

$75 plus HST

Tuesday Afternoon – Pre-Conference Workshop

Tuesday Afternoon – Pre-Conference Workshop Theme: Ventilation – Mike Czarick

Innovations in barn design – leveraging science and new technologies for a new approach to building your best barn.

Tuesday Afternoon – Pre-Conference Workshop Theme:

Ventilation – Mike Czarick

Wednesday and Thursday – Poultry Conference Topics Include: Alternatives to Antimicrobials

Wednesday and Thursday – Poultry Conference Some topics include:

AI Panel Discussion

Avian influenza update and its impact on the Nova Scotia poultry industry

Wednesday and Thursday – Poultry Conference Some topics include:

Carcass disposal options in Atlantic Canada Alternative to antimicrobials

Avian influenza update and its impact on the Nova Scotia poultry industry

Salmonella Reduction Strategies in Layers On Farm Application of Energy Options And much more……

Alternative bedding

Carcass disposal options in Atlantic Canada Alternative to antimicrobials

Alternative energy systems

Alternative bedding

For information on registration, tradeshow and sponsorship, visit the conference website: atlanticpoultryconference.com

Salmonella in layer flocks

Alternative energy systems

Cultured meat

Salmonella in layer flocks

Cultured meat

that our industry has a bright future ahead of it if everyone pitches in.” But she notes that “we have already taken our large share of investment and involvement. It’s now the turn of our governments to get involved if we want our industry to grow and if we want to reduce duck imports from Eastern Europe and elsewhere. If food autonomy is an important value for our society, we must work together, especially in times of crisis.”

Thompson highlights building of the industry’s influence.

“Our industry is small and so is our voice,” she says. “We didn’t know who to call or who to count on to help us through

this crisis, whether it was with funding opportunities, guidance or questions. The Canadian Waterfowl Producers

Association will work together to add members (interested waterfowl producers please contact us) and step into a

more vocal role to share the importance of the duck industry in food security for Canadians.”

She adds that because AI will hit again, it’s critical that industry and government continue to learn from each other and each outbreak.

“Hotwash [immediate postevent discussion and evaluations] by industry and government is extremely important for continued improvement and all stakeholders need to be at the table,” she explains.

“Let’s learn from other countries. Research and practices done in AI-impacted regions through the U.S., Europe and Asian can help guide us.”

By Mary K. Foy

Do you consider water to be a nutrient? Surely, most of us would answer, “Yes, absolutely!” But then why is water often the last item on our list when it comes to problem solving for bird performance issues, educating ourselves or keeping up with barn maintenance?

If we had feed with bugs crawling around in it, we would immediately begin to remedy the situation. But we tend to ignore the water on our farms even though we all know it is a vital nutrient that contributes to the performance of our birds.

How exactly does water contribute to the performance of your flock? It is well known that, just like people, our birds will live longer without food than they will without water. Great work has gone into making sure our birds have

water in the hours that follow hatching.

Several research studies have shown that chicks that have water and feed restricted in the first 24 hours of life have stunted development of the intestinal tract. Villi (the organelles that absorb nutrients in the intestinal track) have stunted development when food and water are restricted in the first 24 hours. In fact, a study done on specifically withholding feed and/or water showed that the absence of water in the first 24 hours caused a more inhibited growth and lack of proper morphological development of the intestine and villi than even the absence of food.

What about that food? Water is also a necessary component in the intake and digestion of poultry feed. Dry feed, by itself, can form large clumps in the crop of a bird. If this is not mitigated by drinking water,

We tend to ignore the water on our farms even though we all know it is a vital nutrient.

the clump can begin to press on the carotid artery, causing a decrease in the blood flow to the brain and putting the bird’s life in jeopardy.

Beyond that, the water is used to transport the feed throughout the bird’s system as it moves from the proventriculus to the gizzard and into the intestines.

Water is also vital to the enzymatic reactions that occur in chickens and turkeys that allows feed to be broken down and absorbed in the digestive system.

The water itself may also be providing a mineral source for bird development. We don’t depend on this source, but minerals such as calcium and trace available phosphorus in

our water supply can be a good thing for the development of the bird.

On the other hand, excess amounts of minerals found in our water like sulfates and magnesium can cause birds to “flush” or have diarrhea that allows the feed to pass through at such a rapid state that no nutrition is absorbed.

It’s true that we usually don’t factor in the minerals that an individual water source may be providing when calculating a feed formula. That said, the complete absence of minerals altogether can in and of itself be an issue.

Water that has all minerals removed (such as reverse osmosis water) will leach minerals from the body of the bird and from the feed it mixes with in the digestive system of the bird and can create some dangerous health conditions.

Water serves a multitude of purposes on the farm when it comes to the performance of our birds. But perhaps the most impactful purpose is that of an additional nutrient in their diet.

Just as you probably know all about the feed your birds are eating, you should also know all about the water being consumed.

Location

Aldergrove, B.C.

Sector

Broiler breeders

The business

Royal Columbian Poultry, owned and operated by the Cross family, has been in the hatching egg business for 30 years. The farmers started out with 6,000 layers a year and they now produce 55,000 annually as well as their own pullets and males. The business includes 14 barns across two sites.

The need

Over the years, with changes in bird genetics, barns and equipment, the Cross family has learned the importance of making smart purchasing decisions. “Our knowledge and experience are our most vital assets – superior equipment is next,” Allan Cross says. With that mindset, the family recently invested in modernizing their many barns, retrofitting them with new nests, ventilation and controllers.

The barn

The producers had new Big Dutchman nests installed. They liked their wide perforated belt, which allows for a bigger collection window and less egg movement. “This results in fewer dirty or damaged eggs and more shippable product,” Cross says. They also went with Big Dutchman for new feeders, which feature fit and finish details that Cross says enable them to feed more birds more comfortably. Then, they completely overhauled their ventilation equipment, installing new fans, inlets, winches and computers all from SKOV. “They integrate so efficiently that we could justify a complete ventilation equipment changeout,” Cross says.

Chicken Farmers deliver on Public Trust

Canadians want Canadian chicken – They want it, because they know it stands for excellence in food safety, excellence in animal care, and a commitment to excellence in all aspects of sustainability.

As farmers, you deliver on this – you help to create and maintain public trust in our product.

The standards we uphold each day have an impact, and absolutely drive the credibility that chicken farmers have with consumers.

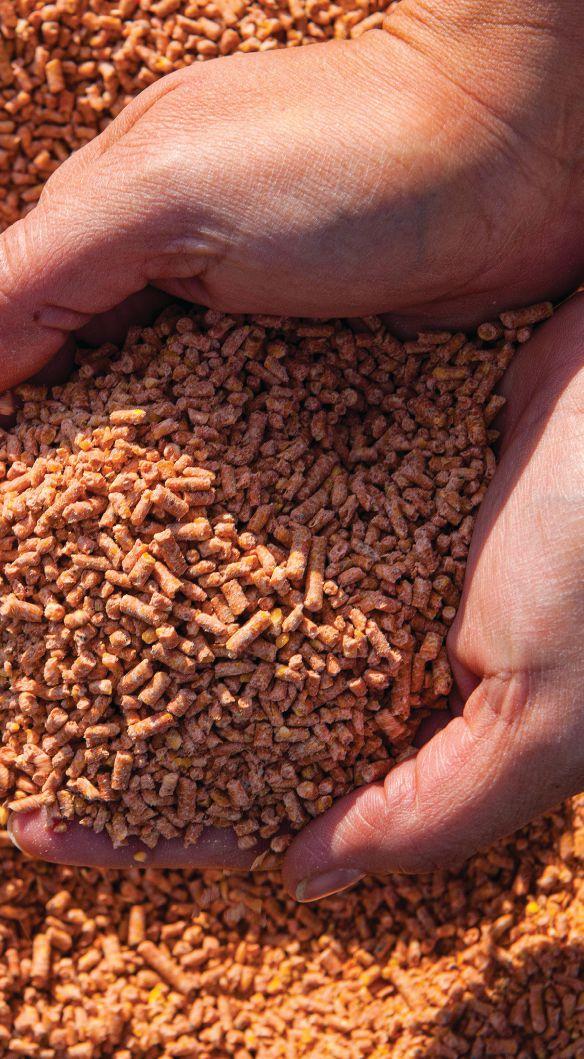

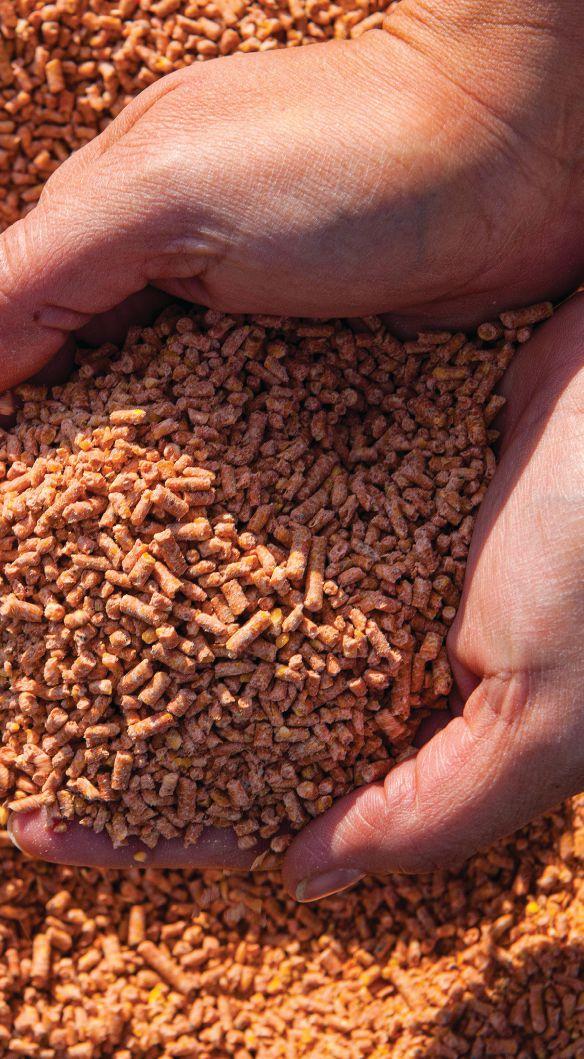

The Konavi® Feeding System is a breakthrough in global broiler feeding. It features an angled cone with anti-rake fins that helps keep birds out of the feeder to maintain fresh, clean feed. With its low pan height and patented scalloped edge, the Konavi Feeder invites chicks to eat from the pan from day one and gives birds

comfortable, easy access to feed throughout their growth cycle. Plus, the streamlined design permits more complete cleaning between flocks for better bird health. The Konavi Feeder lets beaks in, and helps keep feet out. Learn more about clean, open-style feeding at choretime.com/KONAVI-Broiler-Feeder