DISEASE CONTROL GAME CHANGER

Tim Nelson, Be Seen Be Safe Ltd.

Your local Hog Slat store is the place you count on for service and repairs. We feature GrowerSELECT® parts as cost-effective replacements for all types and brands of live production equipment.

Stop by a store, shop online, or call us today.

The role of prevention in reducing

Broiler

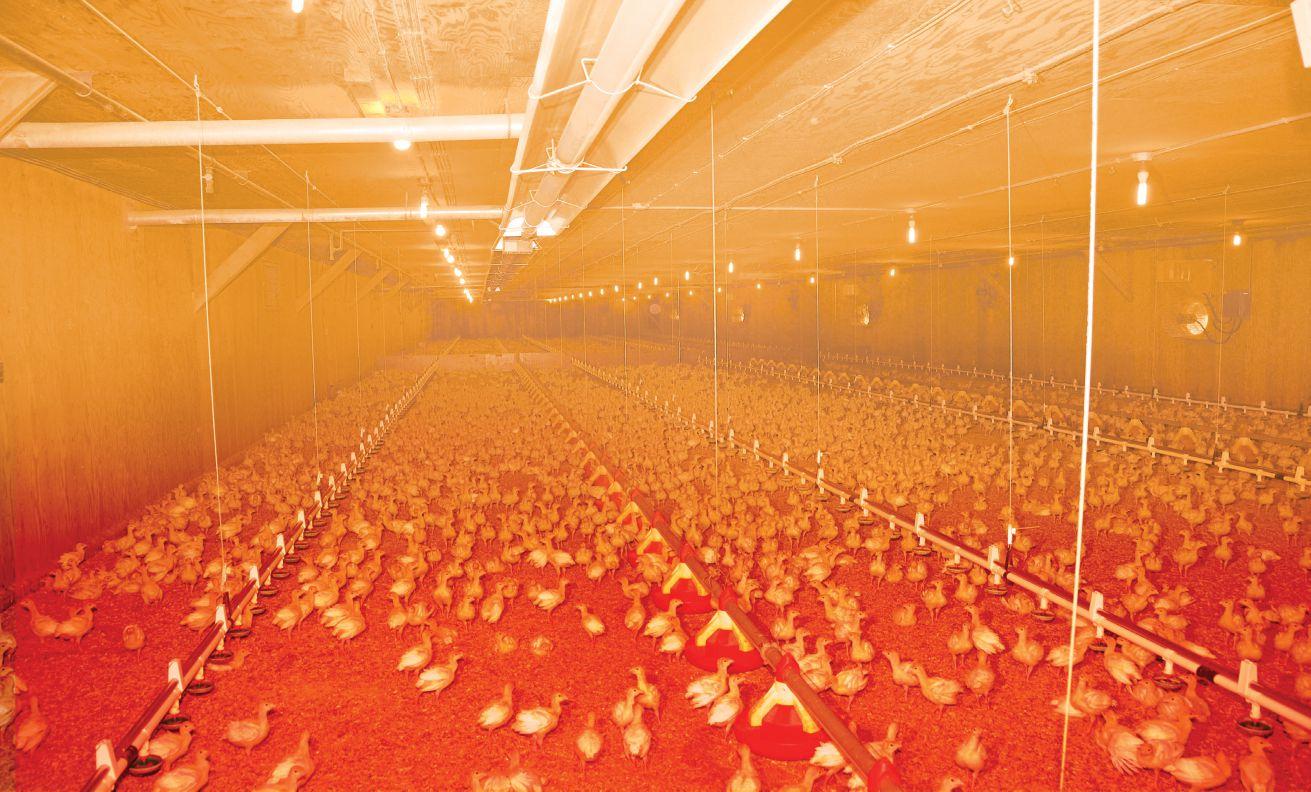

House design is critical for enabling flocks to reach their genetic potential.

Scientist employs innovative approaches to advancing cardiovascular health in broilers.

by Brett Ruffell

The poultry outlook for 2021

Happy New Year! Like many of you, I had a memorable – albeit, socially distanced – holidays. Sadly, it was my first Christmas apart from my parents. However, we took solace in the hope that we could return to our usual traditions next year thanks to the vaccines.

Indeed, there is light at the end of the tunnel thanks to the wonders of science. Still, the pandemic will continue to be the dominant factor for the poultry industry in the months ahead – whether it’s because of plant closures or reduced foodservice demand due to tightened public health restrictions.

When I spoke with industry leaders about the outlook for poultry in 2021, they acknowledged the challenges COVID-19 still presented. But they also highlighted other important issues for the industry going forward.

“COVID has been desperately challenging for everybody,” says Tim Lambert, CEO of Egg Farmers of Canada. “But I think we’re going to get through that – we still foresee driving towards our growth agenda over time.”

A major priority for each poultry sector this year revolves around trade. The leaders I spoke to said it’s imperative that they finally secure compensation from the government for market

access concessions made in free trade deals, specifically, for the Comprehensive and Trans Pacific Partnership Agreement (CPTPP) and the Canada-U.S.-Mexico Agreement (CUSMA).

They got some good news in late November on the CPTPP front. That’s when the federal government announced $691 million for 10-year programs for Canada’s chicken, egg, broiler hatching egg and turkey farmers.

While poultry leaders welcomed the announcement, they stressed that it’s just the start. They now say that it’s

“We

cannot give any increased access again if the U.S. does rejoin CPTPP.”

important that the federal government, firstly, work closely with industry leaders on developing these programs. Secondly, they say they’re still seeking compensation for CUSMA, which wasn’t included in the November announcement.

“Farmers have waited a long time to see action on this file and we believe that this is a step in the right direction,” says Benoît Fontaine, chair of Chicken Farmers of Canada. “We look forward to continuing our work on the

investment and market development programs for our sector.”

Lambert suggests the funding could go towards tax credit programs or “buy Canadian” messaging.

Darren Ference, chair of Turkey Farmers of Canada, says his industry has been bracing for when Chile ratifies the CPTPP agreement. That’s because the South American country is expected to take up the majority of the access granted to Canada’s turkey market under the deal. He says the government’s program funding will help the sector plan for that. “We’re looking at market investment to try and prepare farmers for when that access starts arriving,” Ference says.

One x-factor around trade is what direction the U.S. takes when president-elect Joe Biden takes office. His administration is widely expected to reengage with global agreements. Will the U.S. rejoin the CPTPP and then seek even more access to Canada’s poultry markets? “That’s absolutely a concern of ours that the Americans can essentially double-dip,” Lambert says, pointing out that the U.S. already obtained concessions under CUSMA. “They have their access. That should be enough.”

Ference adds, “That’s a political unknown. We’ve been discussing it with both the government and the opposition, saying that we cannot give any increased access again if the U.S. does rejoin CPTPP.”

canadianpoultrymag.com

Reader Service

Print and digital subscription inquires or changes, please contact

Anita Madden, Audience Development Manager

Tel: (416) 510-5183 Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Associate Publisher Catherine McDonald cmcdonald@annexbusinessmedia.com Cell: 289-921-6520

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Alison Keba

VP Production/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes) USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Stainless that’s Painless.

When you choose to install the LUBING 4023 Maximum Flow, All-Stainless Nipple with 360 degree action, you choose a real winner! It is constructed 100% from high grade, precision machined, stainless steel and is virtually indestructible.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

This nipple is designed to be used with our one-arm LitterGard cup and has a wide range of flow that can be adjusted down for small 4 lbs. birds or adjusted up to over 100 ml for large 9.5 lbs. birds. You can decide the flow you want! Combine this nipple with our 28 mm (1.10-in) drinker pipe, the largest on the market, and you have the water volume you need 24/7.

Join the club of thousands of growers that have enjoyed the longevity and performance of this nipple/cup combination that has been proven time and time again for well over 20 years.

Got Lubing? You can’t afford not to!

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

What’s Hatching

Respiratory virus hits Ontario poultry farm

Infectious Laryngotracheitis (ILT), a highly contagious virus in poultry which affects their respiratory system, has been reported in Ontario’s Niagara Region at a 41,208-bird broiler chicken operation in Smithville. In merely two days, 600 birds have died in one of three barns at the farm, according to a Dec. 1 industry biosecurity advisory from the Feather Board Command Centre. ILT is a herpesvirus that causes infected birds to suffer from shortness of breath, coughing and crackling in the lungs and can be accompanied by the presence of blood or mucus.

Costco transitioning to cage-free eggs worldwide

Costco Wholesale Corp. recently announced that it will ban the use of cages for chickens in its global egg supply. The company said it was the first U.S. retailer to issue a global policy on the confinement of animals in its supply chain. Costco’s new policy applies to all of its markets including mainland China, Taiwan, Japan, South Korea, Mexico, Australia, Canada and Europe. While it didn’t give a specific timeframe, the company say its goal is to go 100 per cent cage-free over the course of several years.

Prairie Swine Health Services expands into poultry

A new chapter in the history of one of Canada’s leading agriculture focused veterinary services is underway as Prairie Swine Health Services expands into poultry, led by the announcement of poultry veterinarian Teryn Girard joining the team. Girard brings with her the great relationships she has made with Cargill Animal Nutrition and other poultry industry teams.

Marie-Claude Bibeau, second from the left, announced the long-awaited funding in late November.

Feds unveil funding for producers hurt by free trade deals

Canadian egg and poultry farmers who’ve lost domestic market share due to two recent free trade agreements will soon have access to $691 million in federal cash, Canada’s agriculture minister announced in late November.

Marie-Claude Bibeau shared details of the long-awaited funds in a virtual news conference.

$691M is the amount of federal money Canadian egg and poultry farmers will have access to as a result of the announcement.

“Today we position our young farmers for growth and success tomorrow,” she said.

The money follows a previously announced $1.75 billion for the dairy sector linked to free trade deals with Europe and countries on the Pacific Rim, one that came into effect in 2017 and the other in 2018.

The dairy sector funds were to flow over eight years, and the first $345 million payment was sent out last year.

But in late November, Bibeau announced a schedule for the remaining payments that will see the money flow over three years

beginning with $468 million in 2020-21, $469 million in 2021-22 and $468 million in 2022-23.

The payments are based on formulas devised by working groups formed after the trade deals were signed, Bibeau said.

What that means is the money doesn’t reflect precisely how much the various industries have lost due to the deals, she said.

“It’s really our best understanding of the future impact and to give them the possibility to adapt.”

The funds announced by Bibeau in November are linked only to CETA and the CPTPP, but she said the latest arrangement does use up the balance of the previously announced funds.

“I think it’s a great day because there’s something on the table,” said Benoit Fontaine, chair of Chicken Farmers of Canada, who said he had yet to see the details of the funding arrangement for his sector.

Chicken farmer honoured for building public trust

Farm & Food Care Saskatchewan recently announced at their annual Cultivating Trust Conference that the winner of the 2020 Champion Award is Tiffany Martinka.

Each year, the Farm & Food Care Saskatchewan Champion Award recognizes a recipient who has engaged consumers about agriculture and worked to build public trust in Saskatchewan farming and food.

Martinka and her husband and family own and operate a grain and broiler chicken farm in northeast Saskatchewan.

She is a participant in the Chicken Farmers of Canada’s Young Farmers Program and has worked on numerous collaborations with the Chicken Farmers of Saskatchewan (CFS), Farm & Food Care Saskatchewan and Canadian Food Focus to provide consumers with more information on how their food is grown.

She has a strong presence on social media, where she shares openly about family life on the farm, production practices, food safety measures and the challen-

ges of farming.

“She is a leader in our farming community,” says Kim Hill of CFS. “Through sharing her farming experiences, it has brought a face to our producers and has provided a lot of support for other farmers to share their farming stories.”

“I feel so honoured to have been selected for this award,” Martinka says. “We have such a good news story to tell in agriculture, and I feel compelled to share that story. I want to share the beauty of the family farm with everybody.”

“Farm & Food Care Saskatchewan is pleased to recognize champions like Tiffany for our annual award,” says Clinton Monchuk, the organization’s executive director.

“Consumers today have very few opportunities to visit farms or speak directly to farmers, and that means that the work that Tiffany does to share her story is vital to building public trust in Canadian food. We’re very proud of the amazing farmers this award recognizes.”

Coming Events

JANUARY

JAN. 25

PIC Science in the Virtual Pub poultryindustrycouncil.ca

JAN. 25-29

IPPE, Virtual Event ippexpo.com

FEBRUARY

FEB. 1-5

Processor Member Sector & POTC Meetings, Virtual Event cpepc.ca

FEB. 23

Program and has worked on numerous collaborations with other agricultural organizations.

Canada’s Agriculture Day, Ottawa, Ont. agriculturemorethanever.ca

FEB. 10

PIC Poultry Producer Update, Webinar poultryindustrycouncil.ca

FEB. 9-12

Eurotier, Hanover, Germany eurotier.com

FEB. 24

PIC Poultry Producer Update, Webinar poultryindustrycouncil.ca

FEB. 24-26

Ag Expo, Lethbridge, Alta. exhibitionpark.ca/annual-exevents

MARCH

MAR. 10

PIC HR Day, Webinar poultryindustrycouncil.ca

Martinka is a participant in the Chicken Farmers of Canada’s Young Farmers

Saskatchewan’s Tiffany Martinka recently won the Farm & Food Care Champion Award.

What’s Hatching

N.S. poultry plant shut down following COVID-19 cases

In early December, two cases of COVID-19 were confirmed at a large poultry operation in Nova Scotia. The province then worked to contain the spread among the more than 400 people who work at Eden Valley Poultry. The plant in Berwick, N.S., is the only federally inspected poultry processor in the province.

New website houses Canadian poultry research results

The Canadian Poultry Research Council (CPRC) launched a new website – poultrysciencecluster.ca – as a central hub for CPRC-funded research. The site includes practical results of nearly 50 made-in-Canada poultry projects conducted over the last 10 years under the Science Cluster program established by Agriculture and Agri-Food Canada. The new bilingual site is intended for anyone interested in research results – producers, industry, researchers and students.

Fast spreading bird flu puts EU poultry industry on edge

A highly contagious and deadly form of avian influenza is spreading rapidly in Europe, putting the poultry industry on alert with previous outbreaks in mind that saw tens of millions of birds culled and significant economic losses. The vast majority of cases are in migrating wild birds but outbreaks have been reported on farms, leading to the death or culling of at least 1.6 million chickens and ducks so far around the region. In the Netherlands, Europe’s largest exporter of chicken meat and eggs, nearly 500,000 chickens died or were culled due to the virus this past fall.

The campaign encouraged Canadians to buy and cook with locally produced ingredients this winter season.

Supply managed industries rally to support local agriculture

Canada’s dairy, poultry and egg farmers joined forces to support local agriculture through their joint Canadian Comfort campaign. The four-week campaign, which launched in early December, encouraged Canadians to buy and cook with locally produced ingredients this winter season.

As more Canadians have been cooking at home in recent months, the appetite for feel-good comfort food and sustainably sourced, wholesome Canadian products has only increased. In light of this trend, Dairy Farmers of Canada, Chicken Farmers of Canada, Turkey Farmers of Canada, Egg Farmers of Canada and Canadian Hatching Egg Producers teamed up to help consumers better understand the value of high-quality local agricultural products produced in Canada.

From an iconic cheese master to a former celebrity chef, four handpicked social media influen-

cers from across the country helped drive awareness. They did so by sharing online how they cook their favourite recipes at home using Canadian dairy, chicken, turkey and eggs. Through weekly videos posted on Instagram and Facebook, these influencers showcased their mastery of the quarantine kitchen with locally produced ingredients. From the dedication of farmers to the stringent production standards focused on animal care, food quality and sustainable practices, more and more Canadians are recognizing the value of producing more of our food within our own borders. According to a recent study from Leger, more than 74 per cent of consumers deliberately buy Canadian products.

To help support Canadian agriculture, the industries’ national organizations encouraged Canadians to buy local ingredients whenever possible and then share their culinary creations on social media using the hashtag #CanadianComfort.

“Through this collaborative effort, we share the high-quality animal welfare and food safety standards in place on our farms,” Darren Ference, chair of Turkey Farmers of Canada. “We are proud that Canadians can feel good about selecting our commodities and continue to think Canadian-raised for their recipe and meal decisions.”

Above is a sample ad from the Canadian Comfort digital campaign.

Skills Knowledge Community Connection In this new way of doing business, Poultry Industry Council is helping you stay connected to the information and resources you need.

Success in the poultry industry relies on continuous improvements based on gaining new skills and knowledge on an ongoing basis.

Since 1997 Poultry Industry Council has served its members and the industry to ensure the best, most up to date information and knowledge is shared effectively. Membership is the best way for you to access the information, resources and events you need.

LRIC Update

By Lilian Schaer, Livestock Research Innovation Corporation

Livestock Research Innovation Corporation (LRIC) fosters research collaboration and drives innovation in the livestock and poultry industry. Visit livestockresearch.ca for more information or follow @LivestockInnov on Twitter.

New mentorship program builds bridges

Innovation requires many things, including sound research rooted in industry needs, strong working relationships between university faculty and industry and effective technology transfer involving many organizations.

Livestock Research Innovation Corporation (LRIC) supports all of those activities in various ways, including a mentorship program for new University of Guelph faculty in the Ontario Agricultural College (OAC), Ontario Veterinary College (OVC), and College of Engineering and Physical Sciences (CPES) to make connections to the provincial livestock industry.

The initiative was launched earlier this year with an initial cohort of nine new Guelph faculty from those three colleges.

“This is far more than we anticipated, which indicates there is a real need for this kind of program,” says LRIC CEO Mike McMorris. “There is a growing number of faculty who work on research for the livestock sector who are unfamiliar with the issues facing the industry, and this gives them a chance to gain some of those insights that will hopefully help them in their work.”

A 10-session program is planned for the mentees that is a mix of webinar-style learning and visits to Ontario livestock and poultry farms. And although the original goal was to roll out all sessions this year, the programming for the first cohort is being spread out over a longer time span due to COVID-19.

Some mentorship program participants recently went on a farm tour.

Name Faculty Research interests

Jennifer Ellis Department of Animal Biosciences, OAC

Amin Komeili School of Engineering, CPES

Huiyan Li School of Engineering, CPES

Heather Murphy Department of Pathobiology, OVC

Erica Pensini School of Engineering, CPES

Dave Renaud Department of Population Medicine, OVC

Rafael Santos School of Engineering, CPES

Charlotte Winder Department of Population Medicine, OVC

Samuel Workenhe Department of Pathobiology, OVC

In the first session, participants met each other and heard presentations from coalition industry groups including LRIC and Poultry Industry Council for a high-level overview of the sector.

The second session introduced mentees to Ontario livestock and poultry organizations. Representatives from Chicken Farmers of Ontario,

Dairy nutrition and poultry modelling

Soft tissue mechanics

Medical biosensing and micro/ nanofabrication

Water quality and public health

Green process engineering, soil remediation, water treatment

Dairy calf health and welfare

Carbon capture, use and sequestration; solid waste and wastewater treatment; environmental remediation

Dairy cattle and small ruminant health and pain management

Immunotherapies for cancer; vaccine and antiviral development for livestock diseases

Ontario Broiler Hatching Egg and Chick Commission, Egg Farmers of Ontario, Canadian Poultry Research Council, Ontario Sheep Farmers, Veal Farmers of Ontario, Ontario Pork, Beef Farmers of Ontario, and Dairy Farmers of Ontario each presented an overview of their sector, their support for research, and their advice for early career researchers.

“We had exceptional industry participation,” McMorris notes. “The key advice for researchers was around the importance of building a relationship with industry and a need for much improved technology transfer.”

The first farm visit day took participants to visit a beef farm near Fergus and a sheep farm in the Shelburne area so they could meet producers, see farming up close, and ask questions on a broad range of agricultural subjects, from animal health and welfare practices to environmental issues and carbon sequestration.

Heather Murphy is a new associate professor in the Department of Pathobiology at OVC working in the area of One Health. Her background is in engineering, water quality and public health. Being new to agriculture, the on-farm day has helped her better visually understand farm infrastructure.

“I gained a greater understanding of how operations can vary significantly from one farmer to another and that research priorities could be very diverse and will really depend on the type of farm and the farmer,” she says.

Getting ahead of early chick mortality

Innate immune stimulant shows promise as antibiotic alternative.

By Lisa McLean

Bacterial infection leading to early chick mortality in poultry flocks is a common concern on Canadian poultry farms. To manage risk, producers commonly use preventative antibiotics to ward off infections before they start. But with public health experts around the world expressing serious concerns about rising rates of antibiotic resistance in animals as well as humans, there is growing demand for antibiotic alternatives.

Arshud Dar, research scientist with VIDO-InterVac at the University of Saskatchewan, is leading research into effective, safe and economical non-antibiotics that allow for the prevention of microbial infection in neonatal chicks. His research has led to the development a non-antibiotic that may be a potential candidate for the control of yolk sac infection (YSI), one of the biggest contributors to early chick mortality.

“Yolk sac infection is the most frequent cause of early chick mortality, leading to death in the first two weeks post-hatch and poor carcass quality in the birds that survive,” Dar says. “When we began researching non-antibiotic alternatives, we first had to identify and characterize the bacterial pathogens associated with yolk sac infection in broilers.”

Dar’s team worked with more than 600 field samples from Saskatchewan broiler operations to narrow in on two avian pathogenic E.coli strains that were re -

sponsible for more than 90 per cent of the YSI cases studied. Next, his team developed an infection model in the lab to experimentally reproduce the disease.

The team identified and selected four innate immune stimulants. They applied each stimulant in ovo (directly to the amniotic sac) of 18-day embryos.

“We wanted to apply these in ovo because it would be much easier and cost effective for the producer to administer in a hatchery setting, and would require less labour,” Dar says.

Of the four innate immune stimulants researchers tested in these studies, in ovo administration of three of the stimulants tested showed promising results. One immune stimulant – known as CpG ODN – showed the highest protection activity against YSI, and Dar says it may serve as a potential candidate for replacement of antibiotics.

Now, as part of a Poultry Science Cluster 3 project, Dar’s team is continuing its work, with an eye toward determining optimal dosage, and combining other innate immune stimulants that may make the dose

more effective. The team is also working to determine the potential for interference with other in ovo treatments such as the Marek’s disease vaccine.

“It is possible that, with ongoing research, in ovo administration of CpG ODN alone or in combination with other innate immune stimulants could eventually become a routine hatchery practice to control YSI, and significantly improve disease resistance, growth rates and vaccine responses in young chickens without antibiotics,” Dar says. “Reduction of antibiotics is a very big issue. These studies will benefit not only farmers but human health as well.”

This research on non-antibiotic control of bacterial infection was funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster, which is supported by Agriculture and Agri-Food Canada as part of Growing Forward 2 and the Canadian Agricultural Partnership, a federal-provincial-territorial initiative. Additional funding was provided by Chicken Farmers of Saskatchewan and the Agriculture Development Fund of Saskatchewan.

Arshud Dar’s research has led to the development of a non-antibiotic that may be a potential candidate for the control of yolk sac infection.

Disease control game changer

A new mitigation platform developed by a Canadian tech company enables producers to quickly rein in disease spread.

By Melanie Epp

Although on-farm biosecurity has greatly improved over the last few decades, it’s difficult for even the most vigilant producer to stay on high alert all the time. But as producers transition to new alternative housing options, the risk of disease increases. New disease spread mitigation technology could be the answer.

The innovative platform, called Farm Health Guardian, quickly and accurately tracks in real time and shuts down disease spread within minutes of receiving a disease symptom report. The technology could be a virulent disease game changer if it’s widely adopted by the industry and its partners.

Lessons from the past Canada reported its first case of highly pathogenic avian influenza (HPAI) to the World Organisation for Animal Health (OIE) in 2004. The outbreak began on a broiler breeder farm in B.C.’s Fraser Valley. What started out as a low pathogenicity avian influenza (LPAI) quickly

and unexpectedly mutated to HPAI.

According to reports, by the time the outbreak was brought under control more than 17 million birds were culled and more than $380 million in gross economic costs were incurred. What quickly became apparent was that in order to protect the safety, stability and profitability of the sector it was necessary to create measures to quickly and efficiently contain incidents of disease.

Since that first outbreak, the poultry industry has taken great measures to improve disease detection and control, including self-quarantine, laboratory testing, biosecurity and surveillance. But according to Tim Nelson, founder and president of Be Seen Be Safe Ltd., those measures rely on human alertness and it’s impossible to stay on high alert all the time.

How it works

Farm Health Guardian uses multiple technologies, including geofencing, smartphones and GPS, to track and record the movement of staff, visitors and vehicles in and out of production facilities in real time. The different technologies communicate with an app and provide contactless digital pre-screening, paperless check-in, vehicle passport and GPS tracking.

Nelson says Farm Health Guardian offers many benefits. It’s touchless, which eliminates transfer risk by way of hands. In the event of an outbreak, reaction time isn’t slowed by illegibility of visitor logs due to poor penmanship. It’s quick and easy for visitors to use and it’s been

designed so the user can create their own set of questions.

It also draws on company protocols, Nelson says. Many companies use health pyramids or personal downtime charts, which can be fairly large spreadsheets that dictate the downtime between different properties within the network. Instead of having to update those and then emailing them to the different parties, they can be quickly and easily uploaded to the app. They’re then immediately available to individuals within the network.

Nelson says Farm Health Guardian is an excellent option for mitigating losses from production-limiting diseases that are transmitted by people, vehicles and equipment, including avian influenza and infectious bronchitis.

When an individual within the network approaches the farm, the questions will be sent directly to their phone. The questions could ask anything from whether or not the visitor is sick, if they’ve visited another farm in the past few days or if they’ve recently travelled abroad. If that visitor doesn’t meet all of the protocols, they receive a message saying they are denied entry. That same message is sent to the system administrator and the barn manager. The system also works in drive-on drive-off situations as it remembers where the visitor has been before and when.

Administrators have control over all questions and information in the system. If they don’t want to deny entry, they don’t have to. If, for instance, a visitor has to come onto the farm, there is a system in place

Farm Health Guardian users pay an annual licensing fee and pricing depends on the number of farm locations included in the network.

to override the denial.

“It’s a really smart system,” Nelson says. “It’s super efficient and it’s basically handsfree in that you’re just using your own mobile phone.”

User feedback

During a trial and development stage, Nelson received valuable feedback from the Alberta poultry sector. Many farmers, he says, were nervous about being tracked. Because of that feedback they developed a digital manual check-in option as well.

“The manual entry doesn’t rely on GPS coordinates,” Nelson says. “It just records the fact that you’ve entered the farm, the same as a paper system”

Farmers were also concerned about being blamed for carrying a disease and confidentiality if an

outbreak should occur on their farm. “The only people who know about the issue are the people who are or may be affected by it,” Nelson assures. “Nobody else needs to know.”

A connected world

Ideally, the network would include all moving players, including producers, feed suppliers, catching crews, egg collectors, manure haulers, barn cleaners and veterinarians. “We are inextricably connected to other farms if we are farming in 2020,” Nelson says. “It’s that connection that this whole system is built for.”

When an individual within that network gets hit with disease, within just a couple of minutes the system will be able to tell where visitors were previously and where they

went after that. It will also be able to see and alert all individuals who visited any of the other flagged farms as well. Nelson describes it as the layering of an onion. “We work outwards from the index property and it’s very fast,” he says.

Proven value

The system proved its value this past summer when it tracked down the point where a disease broke on a hog farm in less than 10 minutes. The farm in question was locked down within 60 minutes. A manual track-and-trace method would have taken four to five days to complete. If the disease had spread to a sow farm of similar size it would have cost them an estimated $750,000 to clean the disease up. “So, it does save money, it’s proven to work and it’s very fast,” Nelson says.

Farm Health Guardian by the numbers

The following are some important facts and figures related to the Farm Health Guardian disease mitigation system.

2013

Is the founding year of Be Seen Be Safe Ltd., which brought Farm Health Guardian to market.

230 is the number of farms in Manitoba’s pork sector that Maple Leaf Foods has connected to the system.

10 minutes is how long the system took to track down the point where a disease broke on a hog farm.

60 minutes is how quickly the hog farm was able to lock down as a result of using Farm Health Guardian.

4 to 5 days is how long a manual track-andtrace method would have taken the hog farmers.

$750K is how much it would have cost to clean the disease up if it had spread to a sow farm of similar size.

When an individual within the network approaches the farm, the system sends screening questions directly to their phone.

Collaborative effort

Nelson worked closely with Maple Leaf Foods, which played an instrumental role in the development of Farm Health Guardian. Maple Leaf Foods has since put the system to use in Manitoba’s pork sector, connecting over 230 farms and over 500 individuals. The company is encouraging all contractors to use the tool and mandating their own farms to use the tool. They are also encouraging visitors to adopt the tool as well.

Having the means to react quickly to a disease outbreak is crucial to the greater good of the industry, says Dan Di Salvo, VP of infrastructure and security at Maple Leaf Foods. “There is strength in numbers,” he says, pointing out that all players within the industry share the same challenges when it comes to disease.

Di Salvo admits, though, that challenges come with any digital disruption or trans-

formation. As such, Maple Leaf Foods plans to focus on awareness and adoption. “I would say we have good adoption, but I think it’s also an ongoing process that you cannot neglect,” Di Salvo says.

With the development of on-farm kiosks and mobility solutions, Maple Leaf Foods expects adoption to increase, but understands that it will take time.

“It’s not about the next big thing in tech

for us,” Di Salvo says in conclusion. “It’s how you use it and how you implement it with an eye to continuous improvement. So being smart, not experimental; working collaboratively, not in silos; the power of data is key and going at the right pace.

“In the end, we brought a tool to the table not just for Maple Leaf Foods but for industry and livestock businesses,” Di Salvo adds.

Tim Nelson is founder and president of Be Seen Be Safe Ltd., which developed the Farm Health Guardian disease spread mitigation system.

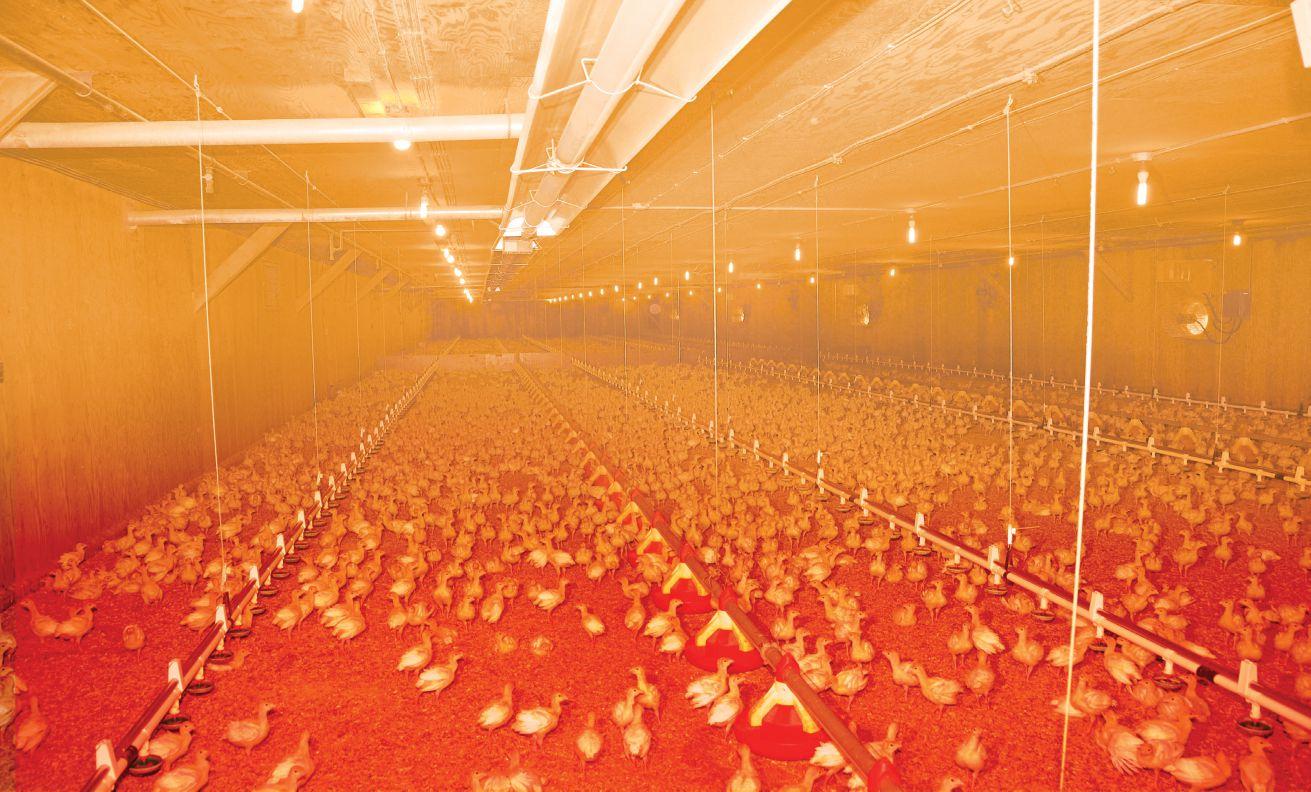

The SRP EVENGROW® ultimate heater offers the best premium features available in the poultry industry for optimum production and greater return on investment.

• Patented SRP EVENGROW® technology eliminates “hot spot”

• Improved growth rates

• Less bird dehydration

• Best reliability in harsh environments

• Anti-corrosion construction

• Sealed maintenance-free blower motor

• Low clearances above – minimal convective heat loss – safe for plastic drop ceiling

• Nickel plated “Jet Stream” burner cup

• High efficiency

• Maximum energy is delivered to the floor

• Optional energy efficient side reflectors

• Optional “Flapper” to prevent cold air infiltration

Model ALTX

ModelALTX

On-farm control of salmonella

Management tips to mitigate food safety risks.

By Lilian Schaer

Salmonella is among the leading causes of foodborne illness in Canadians.

Thus, it’s important for everyone in the poultry supply chain to take steps to address this issue. It’s an ongoing challenge for the sector, though, as there is no blanket solution that will work on all farms.

That’s according to leading salmonella expert Chuck Hofacre, president of Southern Poultry Research Group and Professor Emeritus at the University of Georgia. Rather, he says, success requires farm-specific approaches.

“Not all salmonella is the same. There are 2,500 different serovars of salmonella and they all behave differently. So, our strategies will be different depending on which one we are trying to control,” he noted during a presentation at Poultry Health Day hosted by Poultry Industry Council this past fall.

“We need to look within our own area of responsibility of the poultry business and recognize that salmonella can be transmitted from mother to offspring,” he added, referring to a U.S. study of 49 poultry farms where salmonella found at the primary breeder was genetically identical through all the generations right into the processing plant.

In Hofacre’s opinion, most transmission from one generation of birds to the next occurs through feces contamination on the eggshell. Hence, shell cleanliness is key to successful salmonella control.

Flock management significantly impacts a farm’s salmonella control program. Although there are many potential sources of the pathogen on-farm, Hofacre stressed the importance of farmers focusing on the principle causes on their specific farm and taking steps to address those.

Here are his tips for controlling salmonella on the farm.

Rodents and insects

The three types of rodents common in North America are the house mouse, roof rat and Norway rat. It’s important to identify which rodent is present in a barn because the species determines the location of the bait. Control of the roof rat, which lives in ceilings, won’t be successful if the bait is placed around the perimeter of the building, for example.

Rodents can be a significant source of salmonella on farms. They come indoors in the fall looking for a warm place to escape the winter. When cleaning and disinfecting a barn, pay attention to rodent control as well so they don’t just come back into the barn once a new flock of birds arrives.

Beetles are common throughout North America, and turkeys’ and broilers’ natural tendency is to eat a beetle before eating their provided feed. According to Hofacre, research has shown that salmonella can live inside beetles for 60 days, so controlling those populations is important.

As part of Chicken Farmers of Canada’s new national surveillance project, samples from randomly selected farms were tested for Salmonella enteritidis.

“Beetles go into the walls when we clean out a barn and come back when the birds do. If we have a barrier of insecticide around the inside surfaces of barns, the beetles and other insects have to migrate through that barrier when they come back inside,” he said.

Feed

Most of the time, feed isn’t the main source of salmonella outbreaks, Hofacre said, but it can be. Producers of breeders in particular should ensure their feed is decontaminated, heat treated and pelleted, and that pests are controlled in the feed mill.

Water

Drinking water can be a source for salmonella, producing a biofilm in watering systems. Research has shown that chlorination can have a significant effect on lowering salmonella and getting rid of the biofilm in the water system.

Litter

According to Hofacre, litter isn’t necessarily a source, but it can produce a favourable environment in which the

salmonella can grow. The pathogen likes an alkaline environment, so acidifying the litter will make it harder for salmonella to grow. He suggested treatments with propionic acid, aluminum sulfate or sodium bisulfate.

“What I’ve learned over the years is that nothing works all the time, and nothing works if the level (of salmonella) is too high,” he said. “And if a flock is colonized, it’s hard to eliminate but you can keep the numbers down.”

Interventions

Altering birds’ normal gut flora through the use probiotics, yeast products or organic acids, for example, can help chicks do a better job of resisting salmonella establishing in their systems.

Hofacre noted that as little as one salmonella cell can infect a newly hatched chick, but it can take up to one thousand or even one million cells to infect a healthy bird. So, establishing a healthy gut as soon as possible in a chick’s life will go a long way to protecting them.

A vaccination program for broilers or even at the breeder level will also help with salmonella prevention. And how a farm manages other disease challenges, like coccidiosis, will also impact salmonella control success, he added.

Salmonella in Canada

In January 2020, Chicken Farmers of Canada (CFC) launched a national surveillance project for Salmonella enteritidis (SE) across all 10 provinces.

Although some surveillance information does exist through the Public Health Agency of Canada (PHAC), CFC says the Canadian industry does not have a complete picture of how widespread SE is in various regions or provinces.

As part of the survey, individual farms were randomly selected in each province. Trained personnel from the respective provincial board office collected samples from one barn per farm.

Samples were tested at one of five provincial laboratories across Canada for the isolation of Salmonella spp.

Samples suspected positive for SE were sent to PHAC for serotyping and confirmation.

2,500 is the number of different serovars of salmonella and they all behave differently.

The takeaway

“No single type of response likely provides a solution. Salmonella is complex and there is no silver bullet, magic potion or single remedy to control it. You need multiple interventions to be successful,” he concluded.

To get a better understanding of Salmonella enteritidis prevalence in Canada, Chicken Farmers of Canada launched a national surveillance program in January 2020 (see sidebar).

A questionnaire was completed as well to gather information about pathogen reduction strategies and any risks that could impact control efforts.

The gathered data will help identify risk factors and measures to reduce the disease on-farm.

Poultry health update

Diseases on the rise in eastern and western Canada, as broiler producers deal with reduced use of preventative antibiotics.

By Treena Hein

The 45th annual Poultry Service Industry Workshop was held in early October. It included the usual disease updates from eastern and western Canada. Luke Nickel, the managing veterinarian at the Abbotsford, B.C., branch of Poultry Health Services, covered the western perspective and Jess Walkey of Joyce Veterinary Services in Hillsburgh Ont., provided the eastern overview. Both presenters, as is the norm, used their personal observations as well as information from other veterinarians and colleagues in the industry.

Without further ado, here is a summary of what’s stabilized and what were the biggest disease issues for each bird type in 2020. It includes a special emphasis on broilers as the phase out of preventative antibiotics continues.

Western Canada

A typical number of broiler breeder flocks

in western Canada were challenged with coccidiosis, leading to uniformity issues in pullets and potentially necrotic enteritis (NE). Nickel notes that there was also some infectious laryngotracheitis (ILT) and some sporadic Marek’s disease in B.C. this year. A few cases of blackhead were seen in breeder flocks across western Canada as well.

Layers in this region showed good overall production and health outcomes, with some E. coli infections, coccidiosis and staph arthritis cases in aviary and free-run systems.

And while it’s been a challenging year for the turkey industry in western Canada, “there were good overall production outcomes,” Nickel explains. “There were cases of Mycoplasma gallisepticum in B.C., along with cases of gangrenous dermatitis in Alberta and Manitoba. Increased breast blisters were seen in market aged toms, which can lead to downgrades at the plant and, in severe cases, higher condemns.

But the big story for turkeys in terms of disease this year was blackhead.”

Case numbers in B.C. have been significantly elevated this past year and there was the odd case in Manitoba. Nickel reminds producers that any age of turkey can be infected and mortality can occur at any age. “Submit birds to a veterinarian for quick diagnosis,” he advises. “Immediately fence the farm into as many pens as possible or move birds onto fresh litter. Top dress the litter with new shavings in the pens, and review your deworming program.”

To prevent blackhead, producers should also maintain strict biosecurity (no cracks and ensure doors seal properly), implement good pest control for rodents and beetles, spread salt along the outside of the barns to prevent earthworm entry and conduct thorough cleaning and disinfection between flocks.

Eastern Canada

This year in eastern Canada, E. coli was

In western Canada, the big disease story for turkeys this year was blackhead.

MAKING LIFE BETTER FOR MAKESTHEM, LIFE BETTER.

Elanco welcomes Bayer Animal Health.

Making life better means creating a healthier life for your animals. That’s why we’re coming together with Bayer Animal Health to make an even better Elanco. Together, we’re committed to providing a more comprehensive portfolio of products along with unparalleled service and support for the health of animals, and for the good of people and the planet.

the number one pathogen reported in broiler breeder flocks. Other bacterial challenges included S. aureus, E. cecorum, P. aeruginosa, Salmonella and C. perfringens. Coccidiosis, infectious bronchitis (IB) and roundworms were among the other challenges noted.

In layers, flocks in Quebec experienced colibacillosis, coccidiosis, IB and NE. “Infectious bronchitis driven by the DMV strain caused significant challenges to flocks in Nova Scotia,” Walkey explained. “In Ontario, seasonal spikes in IB cases were reported within expected limits for the time of year. Infrequent DMV strain infections were seen, but overall the vaccination programs are concluded to be working well.”

Ontario also consistently reported increased challenges with coccidiosis, NE and roundworms in laying hens raised on floors. Overall, the number one issue that continues to be the most concerning for the layer industry is the lack of approved antibiotics for laying hens.

In turkey flocks in eastern Canada, colibacillosis was a consistent struggle in 2020, Walkey reported. In Quebec and Ontario, there were some Salmonellosis, blackhead, reovirus and cases of Orthinobacterium rhinotracheale, with one persistent case in Ontario of multi-drug resistance.

“In 2020, reovirus presented a significant disease challenge in Ontario turkeys, most commonly presenting in toms,” Walkey says. “It is easy to imagine the economical significance of reovirus when lameness can affect 15 to 70 per cent of a given flock.”

Raised without antibiotics (RWA) flocks can be difficult to support against secondary disease pressures. TARV proves quite hardy in the environment. Ontario producers have been focusing efforts on barn cleaning and disinfection, and water sanitation.

Broilers across the nation

As the use of preventive antibiotics in broiler production continues to shrink, the need to closely watch flocks for disease threats becomes imperative. In eastern Canada, Walkey notes that E. coli was the predominant pathogen isolated in early and late systemic bacterial infections in broilers this year. “E. coli presents as a primary or secondary pathogen across all poultry production,” she explains. “We’ve seen a significant upward trend in the past 11 years.”

Maritimes broiler flocks also faced significant challenges with two Infectious bursal disease (IBD) strains. “Facing coccidiosis and NE are becoming the new way of life for eastern Canadian broilers,” Walkey notes. “IBH also made the charts across the eastern provinces with various impacts on flock morbidity, mortality and secondary disease challenge.” Reovirus-associated lameness was a concern in Ontario and Quebec, with some shifts

in the genetic composition of the variant strains.

In western Canada, Nickel reports that coccidiosis and NE continue to be a concern in RWA and conventional broiler production, with some potential resistance building in the causal pathogens. Colibacillosis was observed this year across western provinces and tended to affect chicks in the first week of the production cycle.

Inclusion body hepatitis (IBH) and reovirus continue to be a concern in broilers. “ARV (avian reovirus) is still observed on broiler farms, and can be prone to mutations,” Nickel says. “However, not all forms of ARV are pathogenic and so it’s important to have the samples sequenced. Also, remember that because it’s a virus that has no envelope, it tends to be quite resistant to disinfection.”

In terms of other diseases in western broiler flocks, ILT remains an acute and highly contagious concern, mainly in B.C. Nickel notes that broiler flocks with ILT can experience increased mortality and mortality has the ability to double each day. Prevention through vaccination and biosecurity are critical.

Many of the outbreaks are related to viruses in vaccines that have reverted back to virulence and infect a naïve broiler flock with no previous immunity. If a veterinarian diagnoses ILT in long-lived birds they can shed this virus, especially during times of stress.

Outlook for 2021

Looking forward, Nickel believes the disease challenges of 2020 across western Canada will continue. “Some of the common ones I forecast we will continue to struggle with include colibacillosis, reovirus, IBH, coccidiosis and NE,” he says.

“We will continue to work with our colleagues and allied trades to help problem solve and provide timely and effective solutions to poultry producers.”

Walkey adds that, “The industry will need to focus on gut health and integrity as we drive towards reduced antimicrobial usage.”

As the use of preventive antibiotics in broiler production continues to shrink, the need to closely watch flocks for disease threats becomes imperative.

The industry will need to focus on gut health and integrity as we drive towards reduced antimicrobial usage.

Proactive measures

The role of prevention in reducing antibiotic use in broilers.

By Babak Sanei

Poultry veterinarians routinely consider judicious use of antibiotic interventions based on proper diagnosis and antibiograms. They should only use these treatments for bacterial infections, as they are ineffective against common viral infections.

In Canada, colibacillosis caused by E. coli in broilers is among the leading causes of high mortality and subsequent antibiotic therapy. These bacteria are part of normal gut flora in birds. The pathogenic strains are in the minority and don’t cause problems in healthy birds.

Even though very pathogenic E. coli strains (APEC) can be a primary cause of concern in certain situations, many outbreaks are secondary in nature and can be established under stressor conditions (e.g., environmental factors, poor brooding temperature).

They can also be secondary to viral infections such as infectious bronchitis (IB), mycoplasma infections or immunosuppressive diseases.

The point is that by improving management practices at the farm level and addressing viral infections via biosecurity and proper vaccination, we can prevent primary or secondary E. coli infections and reduce overall antibiotic treatment.

INFECTIOUS BRONCHITIS

This respiratory viral infection can affect broiler flocks at various ages. It can result in higher mortality, inadequate water and feed consumption and performance losses. It can also lead to secondary bacterial

infections. When susceptible flocks are affected a few days prior to shipping, it can also cause higher airsacculitis condemnations at the plant. In recent years, exposure of flocks to the new Delmarva (DMV) 1639 strain of IB in Ontario and Quebec has been one of the main health concerns for producers.

In Canada, options for vaccination against this strain of IB are limited to only two registered type of vaccines available to prevent against DMV 1639 – Mass. type vaccines and Mass.-Conn. type vaccines. Poultry veterinarians advise application

of Mass. type at the hatchery via spray cabinet followed by Mass.-Conn. type during the second week of the flock’s growout.

Neither of the vaccines are 100 per cent protective against DMV 1639. However, the goal is for the vaccine strain to compete with the DMV strain and reduce the replication of field virus in affected birds. From this perspective, application of these vaccines can reduce the negative impact of DMV 1639.

Since IB infection can also result in higher secondary E. coli infections, appli-

Proper vaccination and biosecurity can help prevent E. coli infections and reduce antibiotic treatment.

cation of live E.coli vaccine has shown positive outcomes by lowering the mortality due to E. coli infection. It can also be used to lower the negative impact of IB outbreaks in broilers.

IMMUNOSUPPRESSION DUE TO IBD (GUMBORO)

An underdiagnosed disease that affects broiler flocks in Canada is IBD. We are fortunate that so far there is no sign of very virulent IBD (VVIBD) in Canada, which can result in high mortality and significant performance losses in affected flocks. Having said that, there is plenty of laboratory evidence of subclinical IBD strains, so called variant IBD strains that affect the commercial broiler industry.

Variant strains are immunosuppressive and affect the performance of flocks. In broilers less than two weeks of age, the immunosuppression can be more significant and damage to bursa is permanent. In flocks over 21 days, the impact is temporary, but still can result in elevated FCR, poor weight gain, higher condemnations and even secondary bacterial infections such as colibacillosis (E. coli infection) and bacterial lameness and in some cases subclinical coccidiosis (caused by Eimeria maxima and tenella).

These variant IBD strains don’t cause obvious lesions in birds, other than bursal atrophy, and proper serology at the right age and molecular diagnostics are required for proper diagnosis.

There are wide range of IBD vaccines. However, poultry veterinarians should properly diagnosis and select the right vaccine and age of vaccination to get the best result. When there is high level of contamination of broiler houses with field IBD strains, one important intervention is stepwise cleaning and disinfection (i.e., removal of litter, washing with detergent followed by disinfection) to reduce the load of virus in the barn.

GUT HEALTH AND COCCIDIOSIS

We know that pathogenic strains of E. coli are part of normal gut flora in birds. However, these strains in normal healthy birds are in the minority and don’t cause any problems.

Colibacillosis

When subclinical gut diseases such as coccidiosis affect birds, it can result in damage to integrity of gut wall and act as a portal of entry for a pathogenic strain of E. coli into the circulatory blood system. This can result in systemic colibacillosis or localized infections such as femoral head necrosis and general lameness. Therefore, proper coccidiosis prevention is an important part of broiler production.

Application of coccidiostats in feed ration by feed suppliers is the most common approach. However, proper rotation of these products is critical. Coccidiostats are classified into monovalent ionophores (such as monensin, narasin, and salinomycin), divalent ionophores (Avatec) and several non-ionophore coccidiostats (Robenz, Deccox, Coyden, Zoamix and nicarbazin).

There is one combination product that consists of nicarbazin and narasin.

Based on my experience, the following principles should be considered in a coccidiosis medication program.

1. A given ionophore to be used for six months at maximum and then rotate to a different class of Ionophore for subsequent one to two crops.

2. If chemical products are used with the exception to Nicarbazin, limit the use to two consecutive crops in shuttle form (e.g., chemical product in starter followed by an ionophore or different chemical in grower/finisher). Give rest to the same chemical for one year to minimize the risk of developing resistance.

3. With help of a poultry veterinarians, schedule a necropsy session at the end of each medication program (end of second crop) and assess the gut health status. Over time, data collected from these sessions can form a baseline to compare the efficacy of different medication programs for a given feed company.

PRIMARY E. COLI INFECTION

Most acute cases of colibacillosis can occur as a secondary infection in birds.

caused by E. coli in broilers is one of the leading causes of high mortality.

However, if a given flock is exposed to a large number of avian pathogenic E. coli (APEC) strains, for instance via respiratory route, it is possible to have primary infection with no major predisposing factors and high E. coli related mortality and lameness.

Obviously, poor management and poor air quality can always exacerbate the condition.

Proper management (such as paying attention to brooding details) and application of live E. coli vaccine is very important to minimize the impact and the need for antibiotic treatment.

Babak Sanei is national business and technical manager with Zoetis Inc.

Barn Management

Broiler breeder barn layout

House design is critical for enabling flocks to reach their genetic potential. By

Paul Welten

The decision you make for the layout of a poultry breeder house is a very important one. The configuration must operate effectively for many years. There are several layouts, systems and configurations available, but to obtain the full genetic potential of broiler breeders, the house design should be comfortable and attractive to the birds. This article outlines the main factors to consider for the layout of a broiler breeder house in closed controlled production environments.

1. Biosecurity

A rigid biosecurity program is mandatory for health, good welfare outcomes and obtaining the genetic potential of the flock. In general, the house should be designed for easy cleaning and disinfection to prevent and control disease. Ideally, houses should have concrete floors and washable walls and ceilings.

Facilities should have showers so that farm workers enter the house clean. For more information on biosecurity, see Cobb-Vantress’ management guides at cobb-vantress.com.

2. Feed equipment

Improved feed efficiency has contributed to a faster feed clean up time. The feeding system is a very important factor for good production performance. The period from 20 to 30 weeks of age is particularly important due to the fast feed cleanup times. Consider the following parameters:

• Feed should be distributed within three minutes, so all birds are able to eat at the same time. Place additional hoppers on every feed line to ensure a fast feed supply and uniform distribution, especially if the feeder lines are slow (old chain feeders).

• Do feed distribution in dark-out conditions to distribute the feed well and

over the whole chain length.

• Time the feed cleanup in minutes from 20 to 30 weeks of age and register this weekly in the data files.

• Birds should be able to eat comfortably (see feeder space in following sections).

• Place feeder lines at least 90 cm apart.

• The most common feed systems are chain and pan feeder. They both work well if they are used correctly.

Chain system

In new houses, install winchable chain feeder systems. These systems can be filled when winched up and the birds can immediately eat when lowered. The house design should consider the extra structural loads of these suspended feeding systems, which includes perching birds.

Ensure 15 cm of feed space per bird. Place a male exclusion system on the female feeder. Grill, bar, plank or wooden

An exclusion grill on female feeder should create a 45 mm horizontal by 60 mm vertical restriction preventing males from accessing the feeder. The high-profile grill will require enough height of the chain feeder line so that all birds can go under the track to the other side.

boards can be used. An exclusion grill should create a 45 mm horizontal by 60 mm vertical restriction to access the feeder.

Experts recommend placing the hoppers in the middle of the house. However, if they are placed in the front end, use extra dummy hoppers at the back end for fast feed distribution. Use a high-speed capacity of at least 36 m per minute with a frequency regulator to ensure a fast feed distribution.

The nests should be the darkest part of the house.

Pan feeder systems

To calculate the number of birds per feeder, subtract two from the number of holes in the feeder. For example, there should be 14 birds for a feeder with 16 holes. It is very important that the supply of the feed hoppers can easily fill the pans to ensure no pans will be empty.

On every feeder line, place a storage hopper. Ideally, there should be 90 cm between each feeder pan, but 75 cm is the minimum space for birds to have comfortable eating and passing space.

Male feeder system

The males and females should be fed separately. The male feeder system should be winchable so it can be refilled daily to prepare the feed for the following day and should distribute the feed quickly and uniformly.

Traditionally, pan feeders are used for males. But recently, chain feeders against the wall have also become an option. The feed system should be stable and not swing. Install one round pan for eight to 10 males or 10 to 12 males for an oval pan. For a chain feeder, 18 to 20 cm per male is optimal.

The male feeder height should be about 45 to 50 cm from the litter to exclude females and allow males easy access to the system.

3. Water systems

Water is one of the most important nutrients for the birds. Thus, it is important for producers to ensure a clean and consistent water supply.

Bell or nipple drinkers with or without a cup are suitable for any configuration. Experts recommend installing an automatic water flush system for nipples to consistently provide clean, fresh water.

Allocate 60 to 70 females per bell drinker and eight to 10 birds per nipple. In production, use a nipple with a water flow of about 90 ml per minute. For mechanical community nests with slats, install the drinker line over the slats and 60 to 70 cm from the nests.

Barn Management

4. Lighting

Lighting is one of the factors that stimulates the production of broiler breeders. It is important that the light is uniformly distributed through the house (less than 20 per cent variation in lux output) to prevent shadows. This ensures birds uniformly respond to light administration and prevents floor eggs.

When the females are coming into production, gradually increase light intensity with dimmable lighting. LED lighting is very energy efficient, does not flicker and has a longer life than other types of bulbs.

There are many different types but always use high quality LEDs that are designed for poultry houses. A light intensity of > 50 lux and < 100 lux is required in production houses. Use a warmer type of lamp in production (2,000 to 3,000 Kelvin) than in rearing (> 3,000 Kelvin).

In slatted production houses, concentrate the light intensity on the floor area. The nests should be the darkest part of the house. Prevent direct light from entering the house by installing light shutters on fans and inlets. Direct light can influence the birds’ day length and have negative results on production performance.

5. Nests

Mechanical nests automate egg collection. When producers use a mechanical community nest, experts recommend having 200 to 240 birds per nest unit (2.40 meters), depending on the depth of the nest. Install a slat area in front of the nest. To minimize floor eggs, use a 40 per cent slat area and a 60 per cent floor area. The height of the slat should be maximum 45 cm and have a maximum slope of seven degrees.

In mechanical nests with individual holes, allow five birds per hole. For manual nests with individual holes, make it four females per hole.

In Europe, the nest is placed in the middle of the house. Never place the nest against the wall, as generally this is the colder area and is more sensitive to drafts, which can increase the number of floor eggs.

6. Heating and Ventilation

The ventilation system is built on negative pressure in closed houses. To work properly, the house must be well sealed. When working correctly, the ventilation system creates an optimal comfort zone for the birds, delivering a consistent, fresh air supply, removing gasses as well as excess moisture to prevent wet litter.

The air should be evenly distributed in the house using circulation fans. The placement and number producers use will depend on house volume, circulation fan capacity and heater positions.

An ideal effective temperature for broiler breeders is between 21 to 22°C (70 to 72°F). Experts recommend heaters in colder areas to maintain this temperature.

Use calibrated sensors and place them at bird level. In warm climates, producers can use evaporative cooling systems, but only when the temperature is above 27°C (80°F).

Paul Welten is a breeder specialist with Cobb-Vantress, Europe.

Healthy hearts for healthy birds

Scientist employs innovative approaches to advancing cardiovascular health in broilers.

By Lilian Schaer

Next to infectious diseases, heart failure has become a leading cause of sickness and death in broiler chickens. With improvements in genetics and nutrition, modern broiler chicken strains are growing to larger market weights and reaching those weights much more rapidly than before, putting increased stress on their health.

According to research by Andrew Olkowski, Scientist Emeritus in the College of Agriculture and Bioresources at the University of Saskatchewan who has studied poultry heart health for decades, healthy hearts are key to healthy birds.

In addition to direct bird mortality, he suggests heart problems could be underlying causes of other poultry health issues related to muscles, bones and skin, impacting bird welfare and, ultimately, farm profitability.

“Fast-growing chickens are highly susceptible to heart failure, which is actually heart pump failure,” he explained during a presentation at the most recent Poultry Research Impacts Day hosted by the Poultry Industry Council. “Anybody involved in broiler production will have seen the signs of heart failure.”

Early symptoms of heart problems include cyanosis, which is a clinical sign

shown by bluish discolouration of the comb. Birds with more advanced cases will show ascites or what is commonly called water belly – an accumulation of fluid in the abdomen.

Earlier work

In early studies, Olkowski used echocardi-

ograms to examine and compare hearts of normal birds and those with heart failure. He found dramatic differences in the function and anatomy of the left and right ventricles or heart chambers.

He also found microscopic lesions on the small fibres responsible for contracting the heart and changes in the mito -

For his latest research, Andrew Olkowski worked with the Canadian Light Source synchrotron at the University of Saskatchewan to take a closer look at the proteins in the hearts of broilers.

Research

chondria, which supply the chemical energy for the heart to perform properly.

“The direct effects of heart pump failure are decreased cardiac output, which translates into poor blood oxygenation and poor blood circulation,” he said. “In the end, it is decreased oxygen delivery to the organs (of the chicken).”

Multiple studies led by Olkowski into the prevalence of heart failure in the broiler chicken population ultimately concluded that, whether they display visible symptoms or not, between 20 and 30 per cent of broilers may be affected by heart pump problems.

When he first began working in poultry research in the 1990s, heart health was a key priority for the industry due to high mortality from sudden death syndrome and condemnation rates as a result of ascites associated with chronic heart pump failure.

Due to rapid implementation of research findings by primary broiler breed-

ers in selection programs, the numbers around those direct losses are no longer as high today. Olkowski believes, though, that hidden losses caused by subclinical or underlying, non-visible heart problems may be a more significant problem because of the additional performance and health impacts they create.

“There is some correlation between insufficiency of heart pump function and growth,” he said. “The best performing chickens have excellent hearts.”

According to Olkowski, literature suggests insufficiency of heart pump function as a predisposing factor for other conditions, like skeletal problems associated with bone weakness, skin conditions and muscle necrosis that science has been trying to solve for years.

“Recent research from the U.S. did correlate hypoxia – low tissue oxygen levels – with general breast muscle myopathies that include white striping and woody

breast, so there might be more to heart failure than just death of the bird,” he noted.

New approach

Researchers have yet to find a treatment that is both effective and practical, although diet and environmental conditions like interior barn temperature have been known to have some positive impacts.

This is largely due to insufficient knowledge about the true underlying causes of heart failure, which led Olkowski to his latest research study, conducted with the help of the Canadian Light Source synchrotron at the University of Saskatchewan, that involved taking a closer look at the proteins in the hearts of broilers.

He examined samples of hearts taken from Leghorns, clinically normal broilers whose diets were restricted, broilers with subclinical heart issues fed ad libidum or free-choice and broilers with classic symptoms of heart failure who were also given an unlimited diet.

“I’ve never seen heart failure in Leghorns, so they are an excellent model of normal heart health,” he said. “It’s also a well-known phenomenon that when you restrict broilers to only 70 per cent of their ad libidum food intake, you can practically eliminate all problems of heart failure.”

The synchrotron scans showed pristine heart protein conformation in Leghorns, with some slight changes in the broilers on the restricted diet, and much more dramatic changes in the subclinical and clinical cases.

What this means, he noted, is that heart failure in broilers is associated with conformational changes, when misfolded and damaged proteins build up in the hearts of affected birds. And they are controllable by dietary restriction, he added.

Another important observation is that these are heritable changes associated with problems of gene expression and regulation, so they could potentially be controlled in the future through epigenetic intervention – a switching on or off of specific genes.

This latest project involving the Canadian Light Source was funded by Poultry Industry Council and Natural Sciences and Engineering Research Council.

Bertens Broiler Breeder Farms

Location

Brucefield, Ont.

Sector

Broiler breeders

The

business

The Bertens family entered the broiler breeder business 13 years ago. Their main farm, run by spouses Paul and Henriette with their youngest son Sander, includes three broiler breeder barns. Their oldest son Martijn runs a dairy farm they bought three years ago. And their daughter Lisa runs a broiler breeder farm they purchased last year.

The idea

While Paul and Henriette moved to Canada from Holland 13 years ago, they still keep in touch with producers from Europe. In recent years, they started hearing good things about pairing Van Gent nests, which are made from film faced high quality plywood, with hardwood slats and galvanized slat supports. “They all really liked those nests and had good results,” Paul says.

The change

Working with Glass-Pac, they decided to try the Van Gent nests with wooden slats at their main farm. They installed them this year in a barn they built five years ago that originally included a plastic-based system. Paul quickly noticed a difference. “Out of nest eggs are less than a quarter per cent now,” he says. With the layout being nearly identical to other systems, Paul attributes this success to the birds liking the look and feel of the new system. “It’s firm. It’s natural. It’s warm. They really like it.”

The broiler breeder operation is one of the first in Ontario to install Van Gent nests.

Paul (left) and his youngest son Sander run the main farm with Paul’s wife Henriette.

Floor eggs are down significantly since the Bertens family installed the new system.

The barn now includes hardwood slats with galvanized slat supports.

The producers feel the birds like the natural look and feel of the wood.