Identity

( 902 ) 680-5731

Candid camera

FROM THE EDITOR

by LIanne appLeby

Up Before the 10 count

boxing isn’t just two people who hit each other until one gives up or gets concussed, my Uncle (an amateur boxer himself) used to tell me. “That’s what you and your sister do. Boxing is mental.” So is my sister, I remember thinking.

It took me a bit of growing up to understand what he meant, but later on, I realized that training for a match isn’t done exclusively in a gym. Boxing well means being sharp-minded, not just fit, so that you can keep your opponent off guard and land unexpected hits.

It’s a good probability that the majority of egg farmers are feeling like they’ve taken one such sucker punch, of late. In October, the television program W5 broke the story – with devastating undercover video footage – that an egg farm in Alberta was allegedly treating animals unethically.

Yes, it was one farm, and yes, spokespeople quickly jumped in with statements like “what was shown in the video is inappropriate and unacceptable.” Nevertheless, Canada’s egg industry was left sporting a black eye. Secondary to the on-camera happenings was the likelihood that with one blow, a lot of good work to win public trust would be quickly overshadowed.

Boxers have the advantage of realizing that they’re actually in a fight, knowing who their opponent is, and having access to all the stats about their opponent’s previous bouts.

Those of us in agriculture aren’t so lucky, and success lies in how we parry the blows. After all, in the never-ending battle against activist groups like Mercy for Animals, there is no referee to call a time out.

What is said to be one of the most strategic boxing matches of all time took place between boxing maestro Sugar Ray Leonard and Roberto Duran II. The first

time they had met, Duran simply overwhelmed Leonard with what has been described as “punishing body shots and relentless aggression.” Afterwards, Leonard speculated that to win their next fight, he would have to do it mentally. And that’s what he did.

In their November 1980 rematch, Leonard demonstrated a mastery of psychological warfare by boxing smartly. Although it’s argued that Duran was in better physical shape, he was unsure how to react to the unprecedented tactics he was faced with – and Leonard capitalized on that to score points. In the eighth round, Duran famously quit the bout with the surrender “No mas.”

The fight card may seem a little skewed where animal agriculture is concerned. Activist groups have more resources and certainly more money. But with the public looking on, whether hits are below the belt or not, how they are handled counts.

Here’s where the egg industry is in its element. The sector has put in the time and training that make it possible come out on top. PAACO certifications, Codes of Practice, transparency, superb marketing campaigns and an inherent commitment to continuous improvement all are part of the strategy. If, when and how they are used – and if, when and how they are talked about – are paramount to success.

Canada’s egg farmers can take a lesson from the Leonard v. Duran fight. Sure, unexpected left hooks may do temporary damage, but even champions usually emerge with a welt or two. n

JANUARY 2014

Vol. 101, No. 1

Editor Lianne Appleby – lappleby@annexweb.com

888-599-2228 ext. 266

Associate Editor

David Manly – dmanly@annexweb.com 888-599-2228 ext. 261

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Gerry Wiebe

Group Publisher Diane Kleer – dkleer@annexweb.com

President

Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

REtURN UNDELiVERABLE CANADiAN ADDRESSES tO CiRCULAtiON DEPt., P.O. BOx 530, SiMCOE, ON N3Y 4N5.

e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada iSSN 1703-2911

Circulation

e-mail: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GSt $31.50, with HSt/QSt $33.90)

GSt – #867172652Rt0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing & Printing inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

A Tradition of Innovation.

Scan code to see What’s New at Lubing or go to www.lubingusa.com.

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

OptiGROW Nipple

The ultimate Broiler nipple Optimized for Growth!

SprayCabinet

Spraying/Disinfecting your chain... Simpli ed!

DripCanopy

Keep your oors mess-free with a DripCanopy!

Cantilever Drive Unit

Keep the clutter out of processing!

ChainKeeper

It’s like life insurance for your conveyor system!

BaitStation

Keep your rodent problems under control!

Got Lubing? Contact your local Lubing Distributor for more detailed information about our new, innovative products.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

(780) 963.4795 Fax: (780) 963.5034

I Transport Safety WhAT’S

HATCHING HATCHING

The new livestock emergency van from Farm and Food Care ontario, with Kristen Kelderman, a farm animal care coordinator for FFC.

n the agriculture industry, transportation of animals is a necessary part of any operation. And what happens when animals are being moved and there is an unfortunate accident mid-transport?

Luckily, Farm and Food Care (FFC) Ontario has created a livestock emergency awareness van that can respond to animal accidents and provide the tools necessary for first responders. “It is a van that is fully equipped with multi-species set of tools that, if you were to respond to an emergency with livestock, such as a barn fire or truck rollover, that you could use all the tools inside the van to help you get through the emergency,” said Kristen Kelderman, a farm animal care coordinator for FFC.

The van is still in its pre-

liminary stages, so FFC is taking it to events in order to start conversations with the general public and first responders to raise awareness on the need for such a vehicle in Ontario. “First responders are not really equipped to deal with these sort of emergencies – so, we’re having a conversation about it and letting them know is what it is all about,” she said.

Kelderman also added that because animals are moving across the province every day, accidents could be very traumatic, especially with police officer and firefighters trying to ensure human safety.

The livestock emergency awareness van was a pilot project, inspired from one in Alberta, which received partial funding from the Growing Forward program.

The FFC van was unveiled at the Canadian Outdoor Farm Show in late 2013, followed by the launch of a new website, www.livestockwelfare.com at the beginning of October, which has a series of livestock emergency resources

available for training and education.

“We will also host a series of videos that run across the various principles of animal welfare - animal handling, responding to an accident involving animals, etc. for anyone to use,” said Kelderman.

The van is primarily geared towards smaller livestock, such as swine and poultry, but they are exploring the possibility of extending its reach and making it multispecies. “In the van, we have flashlights, batteries, garbage bags, bio-security equipment, heavy duty equipment that include saws to cut through metal, a generator, snow fence and more. Everything from a pitchfork to saw!” she said.

“We are still in the process of collecting equipment – I don’t think it will ever be complete – it is an ongoing process.

“We are really excited about this pilot project,” Kelderman said, “and it is a great link between agriculture and first responders.”

PGC readies to lead pullet industry

the Pullet Growers of Canada (PGC) held their annual Board of Directors Business Planning session to set the stage for the year to come, in anticipation of a positive answer on agency status from the Farm Products Council of Canada (FPCC).

During the past year, the PGC underwent legal hearings as part of the application process for Part II Agency Status with the FPCC. If the application is successful, it will give PGC the required legal powers to represent and make decisions on behalf of

‘Faces

of

status quo is no longer good enough.”

member provincial pullet grower organizations on issues related to cost of production, disease control, and animal welfare, among many other issues facing the industry.

Stable pricing under supply management will allow pullet growers to reinvest in their farms and address social and environmental responsibilities to the standards expected by Canadians with consistent national programs.

“We have a number of issues that must be moved forward in order to ensure the long-term viability of our industry,” said Andy DeWeerd, PGC Chair. “The

Farming’ calendar unveiled

oNTARio

the ninth edition of an award-winning calendar showcasing the photos and stories of 13 Ontario farmers and farm families was unveiled at a gala in Milton. The “Faces of Farming” calendar, featuring this year’s theme of Real Farmers with Real Heart, is produced annually to introduce the public to a few of Ontario’s passionate and hardworking farmers. The calendar is produced by Farm & Food Care Ontario.

With this year’s calendar, the stories of 114 Ontario farm families have now been featured within the calendar’s pages since it was first produced. The stories of all calendar participants are now featured in a new website at

www.facesoffarming.ca.

All of the calendar’s models are real, working farmers and hail from all parts of Ontario. Their farms produce a variety of crops and livestock from strawberries and corn to mink and pigs.

The artistic, black and white photos, taken by Kitchener photographer Terry Scott White, include:

• Sarah Brien and Erin McLean who are turning to blogs and YouTube to talk about their sheep and berry farms;

• Harry Eisses who has been egg farming since he was 15 – and his grandson Colton who started helping at the age of 4;

• Dana and Adam Thatcher, winners of Ontario’s Outstanding Young

Among those priority issues is animal welfare. In the coming year PGC will lead industry consultations to establish strong, measured and transparent animal welfare standards through the development of national Animal Welfare policies that encompass the full range of care, welfare, handling and transportations needs of the pullet life cycle from a oneday old chick through to 19 weeks.

A state of activities along with elections will take place at PGC’s annual general meeting to be held March 19, 2014, from 1 - 4 p.m. at the Westin Hotel in Ottawa.

Farmer competition;

• Dairy farmer Kevin MacLean who invited his whole community to a Christmas party with his cows last year;

• Pig farmer Scott Richmond who, with other Ontario farmers, is donating pork to provincial food banks;

• Sisters Jennifer and Heather Peart who bought their first farm when they were only 20 and 18 years of age;

• And many more.

A complete list of the participants can be found online at http://www.agannex.com/ business-policy/faces-of-farming-calendar-unveiled.

Copies of the calendar are available through the Farm & Food Care office in Guelph, by using the online order form at www.farmfoodcare. org. A list of retailers is available on the Farm & Food Care website.

JanUary

January 14, 2014

Science in the Pub –Food Safety: How much responsibility lies with the producer, processor and consumer?

For more information, visit: www.poultryindustrycouncil.ca

January 14-16, 2014

Salon de l’agriculture, Saint Hyacinthe, Que. For more information, visit: www.salondelagriculture.com

January 28-30, 2014

International Production and Processing Expo (IPPE) 2014, Georgia’s World Congress Center, Atlanta, Ga. For more information, visit: www.ippe14.org

febrUary

February 12, 2014

PIC Producer Update Western Beacon Harbourside Hotel, Jordan, Ont. For more information, visit: www.poultryindustrycouncil.ca

February 19, 2014

PIC Producer Update

Mount Forest Community Centre, Mount Forest, Ont. For more information, visit: www.poultryindustrycouncil.ca

February 12, 2014

PIC Producer Update Best Western Stoneridge Inn, London, Ont. For more information, visit: www.poultryindustrycouncil.ca

PRODUCTs PRODUCTs

Thies introduces LED solution

Thies Electrical Distributing Company

Inc. is pleased to announce a new revolutionary LED Spectrum Light bulb solution AgriLux.

In collaboration with Dr. Grégoy Bédécarrats of the University of Guelph, the LED light was designed, developed and validated specifically for the Poultry Industry. Research on the spectrum distribution of this new prod-

uct was performed over the past five years, and recent design improvements have strengthened construction and durability of the bulb.

Major benefits are to promote egg production while achieving significant energy savings with retrofit bulb that can withstand harsh barn environments.

For further information please contact Alex Thies at thiestedcca@aol.com.

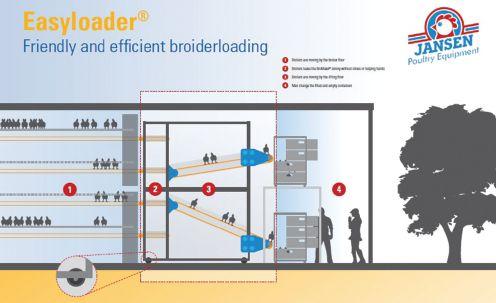

Harvest broilers without catching from Jansen

Since the introduction of the BroMaxx broiler colony system, it is no longer necessary to catch birds during harvesting. The manure belt that runs underneath the FlexFloor and the FlexFloor itself become very handy tools during the unloading of the broilers. The FlexFloor can be pulled out of the system with the result that broilers end up on manure belt underneath and can be transported to the end of a BroMaxx row. From this location there are different solutions to transport broilers into containers or crates.

During the harvesting it is very important to retain the quality of the broilers that is achieved by the BroMaxx colony system. This is why Jansen Poultry Equipment developed the EasyLoader harvesting system that transports broilers in a straight line into containers, avoiding any bends or transfers. The risk of broken wings, legs and bruising are minimized which improves the meat quality of the broilers.

Besides this, the EasyLoader harvests broilers fully automatically which means that employees only have to make sure that the containers are situated in the right position so that they can be automatically filled with broilers. This highly efficient harvesting system can harvest up to 12,000 broilers per hour. The EasyLoader can be transported to other houses, which makes the return on investment even higher.

For more information, please visit www.jpe.com.

COMING EVENTs

marCH

March 19-20, 2014

Midwest Poultry Convention

Saint Paul RiverCentre, Saint Paul, Minn. For more information, visit: http:// midwestpoultry.com/

aprIL 2014

april 9-10, 2014

London Poultry Show

Progress Building, Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict.com

JUne 2014

June 18-20, 2014

Canada’s Farm Progress Show

Evraz Place, Regina, Sask. For more information, visit: www.myfarmshow. com

OCtOber 2014

October 7-9, 2014 XXXIX Poultry Service Industry Workshop

The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop.com

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail lappleby@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

Gorrill

CPRC Update giving birds a boost

Poultry disease prevention draws on a broad range of tools. Management, biosecurity, genetic selection, vaccination and antimicrobials all play important parts. While often used to great effect, these tools are not without their shortcomings. For example, vaccines are not available for certain diseases and are not effective when an immediate protective effect is required, as is the case in a disease outbreak.

Furthermore, the use of antimicrobials is under increasing scrutiny and pressure is mounting to find alternatives to these compounds. The Canadian Poultry Research Council (CPRC) is therefore supporting research designed to investigate the possibility of stimulating natural immunity in poultry to complement existing disease control strategies.

NATURe’S DeFeNCe

The avian immune system is the product of a remarkable evolution that defends the body against a range of pathogens. Immune responses can be broadly categorized as adaptive or innate.

Adaptive immunity involves recognition of specific components of invading organisms called antigens. Organisms or objects presenting these antigens are recognized as foreign and, through a complex cascade of events involving many molecules and cell types, are attacked and eliminated from the body. The adaptive arm of the immune system remembers the invading organism and is primed to launch a robust attack if it recognizes the corresponding antigen again.

The innate component of the immune system can clear an infection even before an antigen-specific immune response is developed. Years of immune system research has led to the development of the danger hypothesis, whereby the immune system can rapidly respond to characteristic features, or molecular patterns,

of invading pathogens. This innate or natural immune response is the first line of defence against a broad range of pathogens, including bacteria, viruses, parasites and fungi.

Researchers are attempting to enhance the innate immune system by presenting it with elements typical of various pathogens – fooling it into thinking a pathogen is present. Dr. Susantha Gomis at the University of Saskatchewan used small pieces of DNA with molecular patterns characteristic of bacterial DNA to stimulate innate immune responses. When injected into the egg, these molecules can protect chicks from Escherichia coli and Salmonella typhimurium infections. The protective effect is relatively short-lived, however.

Gomis’ group is experimenting with different formulations that protect the molecules from degradation in the body; the longer they stick around, the longer the immune system remains primed and ready to combat potential invaders.

Similarly, Dr. Mohamed Faizal Abdul Careem at the University of Calgary has demonstrated that other compounds typically present in bacteria can be used to stimulate innate immunity and protect chickens from challenge with the Infectious Bronchitis virus. Lab studies also showed the ability of these compounds to inhibit replication of Infectious Laryngotracheitis (ILT) virus. A paper on the mechanism of ILT virus inhibition was published in the October 2013 issue of Veterinary Immunology and Immunopathology.

day 18 of incubation for applications in the industry and in academia. If so, they could easily be incorporated into egg vaccinations routinely performed at many commercial hatcheries. This research may provide industry with another tool to help protect poultry from disease. We’ll provide more updates as things progress.

Funding for Dr. Gomis’ work is provided by CPRC, the Natural Sciences and Engineering Research Council of Canada (NSERC), Saskatchewan Chicken Industry Development Fund (SCIDF) and Alberta Livestock and Meat Agency (ALMA). Dr. Careem’s work is funded by CPRC, the University of Calgary Faculty of Veterinary Medicine, NSERC and ALMA.

SUmmARY

• Progress continues to be made on ways to stimulate natural immunity and help protect poultry from various infections.

• Results thus far are promising, showing protection from bacteria and respiratory viruses.

• Work is underway to further enhance protection, make it last longer, and make the technology practical for industry use.

For more details on any CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ont. K1R 7S8. Phone: 613-566-5916, fax: 614-241-5999, e-mail: info@cp-rc.ca, or visit us at www.cp-rc.ca. n

Drs. Gomis and Careem are currently testing to see if their formulations are effective upon injection into the egg at

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

eNhANCiNg NATURAl immUNiTY

iNDUSTRY APPliCATioN

THE BEAkER

by Karen daLLImOre

Feeding Pea to Poultry

Researchers at the University of Saskatchewan have recently completed a series of experiments investigating feeding pea to poultry.

Pea production is increasing in Western Canada and while the pea (Pisum sativum L.) is mainly produced as human food, there is the potential for surplus and feed grade pea to be used in poultry feed based on availability and price.

But how does pea perform for poultry?

“The nutrient profile of pea is suitable for most poultry production, but it is not used to its potential because of incomplete and variable poultry nutrient data,” states PhD candidate Salaheddin Ebsim in his doctoral thesis.

In his study, entitled Establishing the Nutritional Value of Pea as Affected by Feed Processing and Pea Cultivar for Poultry, Ebsim and his supervisor, Dr. Hank Classen, were curious to clarify the nutritional value of pea in poultry diets to maximize its utilization and possibly reduce the cost of poultry production.

“The nutritional evaluation of pea for poultry has been mostly investigated elsewhere, but under local conditions these data are not sufficient for accurate feed formulation,” writes Ebsim, noting that different pea cultivars and growing conditions may also affect the nutrient composition and availability of pea for poultry.

Starch is the main source of energy in poultry feed, and while pea seed has high starch content, the starch is different from that found in cereal grain. Pea starch is less accessible to digestive enzymes in the small intestine, making it digest slowly. In humans, this has been shown to be a good thing, but research on chickens is rare.

As Ebsim explains in his thesis, “The slowly digestible nature of pea starch has been suggested to have a unique nutritional value for poultry with evidence that the presence of slow degraded starch reduces the amino acid requirements of broilers and that a mixture of rapidly and slowly degraded starch improves broiler productivity in contrast to diets containing only rapidly digested starch.”

The three overall objectives of the research included studying the effect of various feed processing on nutrient digestibility of pea; the effect of the interaction between locally grown pea cultivar and feed processing on pea nutrient digestibility; and the impact of feeding pea to laying hens, broiler breeder hens and broilers.

Ebsim found that fine grinding and pelleting improved both pea energy and protein utilization and that this effect was much more pronounced than for classical feeds like barley, corn, and wheat cereal grains. Of note, all cultivars

reacted to processing in the same way.

Using laboratory and animal testing, Ebsim further demonstrated that pea cultivar had an important impact on both the rate and extent of starch digestion and that these improvements resulted in differences in broiler performance. This suggests that cultivar selection has the potential to improve the nutritional value of pea for poultry and possibly other animals as well.

The third objective of the thesis involved feeding pea to various classes of poultry at relatively high levels. In both broiler and laying hen trials, Ebsim found little evidence that the effect of amino acid intake on bird performance depended on the level of slow digested starch from pea. However, in all chicken classes, the production response of birds fed pea was higher than expected based on their digestible nutrient content. The reason for this response still requires clarification.

Some of Ebsim’s most interesting research came from feeding pea to broiler breeders during the brooding and rearing period. In feed restricted broiler breeders, feeding pea reduced the postprandial blood glucose level and altered bird metabolism in a way that may reduce bird hunger. Broiler breeders are most often fed every other day during the brooding and rearing period and feed nutrients are stored for a short period of time after feeding (approximately 24 hours) as fat in the liver, and then utilized until the hens are fed again. In some cases, the liver nearly doubles in weight and then returns to its initial weight during this period. When birds were fed pea, liver weight increases were less than for birds fed a more conventional diet. This research suggests that feeding pea to broiler breeders may have beneficial metabolic effects, but research is required to confirm this.

Ebsim sees increased potential to include feeds such as peas to meet future production requirements. “The use of new grain or pulse cultivars with higher nutritional value will also see increased interest, particularly those that grow well in a wide range of environments,” he states. “Pea is a good candidate for further development in this regard as it can be grown in most of places in the world.”

The research received scholarship support from the University of Tripoli, Libya, as well as support from the Saskatchewan Pulse Growers and the staff and students at the Poultry Centre, University of Saskatchewan. n

This new regular series of articles is part of the communications plan of the Poultry Welfare Centre. For more information, visit the Canadian Virtual Centre for Poultry Welfare at http:// poultrywelfarecentre.ca/

Business motivating Poultry Farm employees

Managing employees isn’t just about telling them what to do; it’s also about respecting their psychological needs

B Y R ONNIE P. C ON s, C&C PAC k ING , I NC

every successful manager knows that a motivated employee is a productive employee. The key to motivating employees, however, is to create an internal drive in the employee’s mind to carry out their duties at the most optimal manner that is consistent with the objective of maximizing the profitability of the operation.

Many job functions have to be carried out successfully by poultry farm employees in order to create a successful and profitable poultry operation. Broiler farm employees, for example, have to manage and be concerned with many details: receiving and placing new chicks, determining that the temperature and other environmental factors are just right for the chicks, making sure feed is of good quality and accessible, adhering to the farm owner’s biosecurity protocols, and looking after many other details related to codes of practice and animal welfare.

If employees are not motivated in their tasks, a lapse in biosecurity can occur – which could be very costly for the farm operation. Worker apathy and lack of interest in monitoring things like feed intake will, in effect, lead to reduced chick growth, lower-quality chickens and even welfare issues that will need to be addressed.

On the other hand, motivated employ-

given recent headlines regarding treatment of animals on poultry farms, some farm managers are keen to hire motivated, ethical workers – and to keep them that way.

ees will genuinely care that the chicks are well taken care of and grow up to become healthy chickens of high quality.

But is it really possible to motivate employees to care about the operation and their job duties at such a high level? The answer is yes, but the right strategies must be developed and implemented by management.

Managers in any kind of operation must decide how to motivate the persons under their charge. But sadly, many man-

agers have misconceptions about which approach is best and resort to tactics and strategies that actually result in indifferent personnel.

The two basic approaches to motivate employees are the “negative reinforcement” approach where employees are penalized for poor performance (insults, penalties, demotions and even job loss) and the “positive reinforcement” approach where employees are rewarded for adequately performing their duties (praise,

leADeRShiP leSSoNS

pay raises, promotions, stock options, etc.).

Interestingly, research shows that money is not the biggest motivator of behaviour, so it is not the best strategy for every manager and employee.

Kenneth Kovach of George Mason University conducted a study that found some surprising results regarding what

employees really want (the details of his work can be accessed online). Kovach found that the most important factors, in descending order, were interest in work, appreciation of work, feeling “included,” job security, and wages. Kovach’s results also indicate that psychology-based issues are what affect motivation the most.

Just see a veterinarian? We see more.

We see the numbers that connect us. We see the number of visits our veterinarian, Dr. Helen Wojcinski, makes to improve your flock performance. We see the countless hours of training and experience that come with Helen wherever she goes.

Together by understanding the numbers, we understand the industry.

Strength in Numbers.

11 years of formal Animal Health education

10 0,000 miles travelled to visit customers each year

16 industry presentations delivered per year

120 people trained through Hybrid Hatchery Workshops

In conformance with this study, managers of chicken farm employees can try the following strategies to motivate their employees:

1. Make sure that employees find their positions interesting. The more interesting the position is to the employee, the more likely it is that managers will see better performance. Later, job satisfaction surveys can be done with the potential for a job transfer to another duty more to the liking of the employee.

2. Show your appreciation of the employee’s work with verbal feedback and congratulations for a job well done. A good word goes a long way to make the employee feel he or she is appreciated, which will in turn make them feel a part of the company, and thus lead to higher motivation. An informal, regular, face-to-face meeting with employees should be instituted where the employees get a chance to express their feelings and any concerns they may have. Managers must make sure to convey that comments are appreciated and that the employees will not “lose” by them.

3. Show respect to your employees by making them feel involved. The opinions of the employees must be appreciated and considered, as they are on the front lines and have the feedback information that managers need. A valued employee is a motivated employee who will feel more committed to the operation and the success of the poultry operation.

4. Make sure that employees feel that they have job security – that they will not be fired without sufficient reason. By doing this, they will focus on the long-term success of the operation.

5. Pay fair wages for the duties required. Following the above advice should lead to happier and more motivated employees who truly care for the birds in their care, and thus build a more profitable poultry operation. n

Don’t let Salmonella damage your reputation

When Salmonella hits your layer flock, there’s more at risk than your bottom line. An outbreak can also impact your reputation. And, as you know, no insurance can safeguard a good reputation. Help protect your business against the consequences of Salmonella Enteritidis with new Bron-Newcavac™-SE vaccine.

For many years you’ve relied on Bron-Newcavac-M to fight against Newcastle disease and infectious bronchitis*. Now you can look to our new Bron-Newcavac-SE vaccine for the same great benefits with added SE coverage for Salmonella Enteritidis.

PART OF THE MERCK POULTRY PROGRAM OF TOTAL BIRD HEALTH.

For the vaccination of healthy chickens 10 weeks of age or older

• Aids in the reduction of Salmonella Enteritidis, phage types 4, 8 and 13a colonization of the reproductive tract and internal organs.

• Aids in the prevention of the signs and lesions associated with Newcastle disease and infectious bronchitis.

Industry identity Crisis

Illegal importation of meat from broiler chickens should be a concern for all in the industry

BY T REENA H EIN

Spent fowl meat is a byproduct of the egg and hatchery industries. After about 60 weeks, the egg production of laying hens declines, and they are taken out of production and processed for their meat, which is usually used to make further-processed foods. Although spent fowl meat processing is an important source of economic activity in some parts of Canada, its potential use as a front to import regular broiler chicken meat without import quota is causing headaches for the broiler industry.

The gooD

Canadian spent fowl meat production provides about one quarter of Canadian demand, and the rest must therefore be imported, says Robert de Valk, general manager at the Further Poultry Processors Association of Canada (FPPAC). “We’ve worked hard to find uses for this byproduct meat,” he says, “due to our success, we are exporting fowl meat products to 34 countries.”

Chicken products made using spent fowl meat are usually less expensive than broiler meat, de Valk notes. “It’s used to provide consumers and restaurants with lower-cost nuggets and patties. It has a legitimate and important place in the Canadian market.”

The bAD

The problem arises because there seems to be collective agreement that broiler meat,

cFc says that significant imports of broiler chicken meat are being mislabelled as spent fowl products in order to avoid import controls.

mostly from the U.S, is being imported into Canada under the guise of being meat derived from spent fowl.

Importing regular chicken meat as spent fowl is lucrative because the cost of the import permit is avoided, allowing cheaper, imported “spent fowl” meat to be legally sold on the Canadian chicken market, de Valk explains – thus, it is undercutting Canadian wholesale chicken prices.

De Valk adds, “Ironically, having a strong spent fowl meat product market – availability of lower-priced chicken products – is one of the reasons supply management has been able to last as long as it has in Canada, significantly longer

than it has in its current form in other countries, because consumer demand for lower-priced chicken products is met.”

The Chicken Farmers of Canada (CFC) 2012 Annual Report states that in 2012, spent fowl meat imports were 28 per cent higher than in 2011, but de Valk says the increase has slowed down this year, likely because the issue has become public. He notes that illegal spent fowl meat is often marketed to unsuspecting small provincial processing plants and restaurants. “Our members are likely the biggest users of imported chicken meat, including fowl, and have always followed the applicable rules,” says de Valk.

All TogeTheR NoW – ARe We oN The SAme PAge?

The ACCURATe?

Mike Dungate, CFC executive director, says that significant imports of broiler chicken meat are being mislabelled as spent fowl products in order to avoid import controls, and this is having a very large impact on chicken farmers and on the economy of Canada. “This year so far, Canada has imported 112 per cent of the entire U.S. production of spent fowl,” he explains. “For this to all be spent fowl meat is completely impossible, as it would assume that no spent fowl meat is being used in the U.S. for various products. And if we just count the 12 per cent, that represents $66 million in lost import taxes to our country’s coffers.”

Because the issue has been paid attention to, Dungate says the smugglers are becoming inventive and perhaps blending the meat with shipments containing no more than 49 per cent broiler meat. And imports of spent fowl currently equate to 10 per cent of Canadian chicken production.

Dungate also points to a report from the Guelph, Ont.-based George Morris Centre (GMC) that says this results in 8,900 fewer jobs being created in Canada and a $591 million lower contribution by Canadian chicken farmers and processors to Canada’s GDP per year.

De Valk counters that GMC’s loss estimates are taken from calculations that he does not see as realistic. “These calculations of losses assume that if consumers were presented with cheaper products such as nuggets labelled as containing spent fowl meat, they would automatically choose to buy the broiler meat ones, but that’s not necessarily true,” he states. Moreover, he says spent fowl meat activity creates just as much economic activity and jobs at the further processing level as broiler chicken meat, another point, he says, that the authors of the GMC report glossed over.

WhAT To Do

De Valk reports that all poultry industry groups in Canada and the pertinent ones in the U.S. are working to stop ship-

ments of broiler meat that are coming into Canada as spent fowl. These efforts also involve regulatory elements such as the U.S. Department of Agriculture (USDA), the Canada Border Services Agency (CBSA), as well as the Canadian Food Inspection Agency (CFIA). While genetic testing is not an option because

layers and broilers are the same species, Dungate says CFC is supporting research into ways spent fowl meat and broiler meat can be distinguished.

In terms of what CFC sees as a solution, Dungate states that firstly, the CFIA must implement a mandatory certification process. “Secondly, the CBSA must

classify blended products as chicken because there is no test to distinguish spent fowl [meat] from broiler [chicken meat], and the blended content cannot be verified,” Dungate explains. “Thirdly, the CFIA must require truth in labelling to inform consumers; spent fowl is not chicken and carries egg

allergy risks. Consumers do not know if they are buying spent fowl because it is all labelled as chicken. As my chairman says: if it’s not ‘chicken’ at the border how can it be ‘chicken’ in the grocery store.”

He also notes that recent survey results undertaken by Leger Marketing

show that 74 per cent of Canadians want spent fowl to be clearly labelled.

To lA bel o R No T T o lA bel

“We understand that processors and importers are not in favour of consumer labelling of spent fowl. It’s fine in the eyes of chicken farmers to not have spent fowl labelled as such for consumers as long as it is labelled as chicken when it comes across the border,” Dungate says.

“There is a tariff rate quota system in Canada wherein all chicken imports up to 7.5 per cent of Canadian chicken production are duty-free, but the over-quota tariff beyond that point is prohibitive. But there’s a problem for if we don’t label spent fowl that can affect consumers and the entire industry.”

Labelling isn’t a solution in de Valk’s view for several reasons. “It distorts the issue. Yes, if consumers are offered more information, they will always say yes, but to say that labelling will stop the illegal chicken imports is misleading.”

All AgRee iT’S illegAl

De Valk continues, “No one wants illegal activity. We need to focus on stopping illegal chicken imports, and not using this issue as an excuse to push for labelling and make spent fowl meat look inferior to consumers. CFC is using this as an opportunity to try and do exactly that, to try and make it seem to consumers that they must pay the price for ‘real chicken.’ But spent fowl meat is chicken meat.

Dungate adds, “CFC has been contacted by the USA Poultry and Egg Export Council and is aware there have been meetings on certification to which CFC has not been invited,” he says. “We do sincerely hope that processors and further processors are pursuing real certification that will stamp out this illegal activity and are not engaged in setting up a paper exercise that looks good but does not have any actual impact.”

No matter the age, ROVI M IX® HY•D® makes hens stronger.

Whether a pullet or a mature hen, peak lay performance requires a well developed skeletal frame built with only the strongest bones Research indicates that bones with the best strength come from diets supplemented with ROVIM IX® HY•D® Science suggets that ROVIM IX® HY•D® provides birds with all the 25-hydroxyvitamin D3 they need to develop and maintain bones that can withstand the stresses of egg production. In young pullets, stronger bones are necessary for optimal lay persistence which can translate into more eggs As the hen ages, ROVIM IX® HY•D® will help promote better egg shell quality

To learn more about how ROVIMIX® HY•D® can strengthen your flock, contact your DSM Nutritional Products Account Manager or go to www.dsm.com or call 1 800 526 0189.

Management Stirring Things Up

Using stir fans to improve poultry barn conditions

BY sHAw N C ONLEY

high heating costs, wet floors, elevated carbon dioxide levels, uneven bird distribution: these are all problems that can be influenced by the use of stir fans.

heAT STRATiFiCATioN

A situation that many producers may be dealing with is outdated heating systems. Older-style brooder heaters and box furnace heaters (which may be the best option for breeder barns) have some inherent problems. The biggest issue is the percentage of heat that rises to the ceiling instead of the floor, where the heat is needed. In brooder-style heaters, this can be nearly 50 per cent, and in the case of furnaces, almost all of the heat rises instead of heating the floor, resulting in a temperature difference of up to 15 F. In open-truss barns, the stratification of air was as much as 20 F.1

This would be fine if gas were a penny a litre, but obviously that’s not the case, so we need to mix that hot air at the ceiling with the cooler air at the floor. During brooding or extreme cold, even with a proper minimum ventilation system, there won’t be enough mixing to even this out, so stir fans are the best way to mix the air. Within five minutes of turning on stir fans, a temperature difference between ceiling and floor of under 3 F is easily attainable.

Creating more air movement over the litter – especially the newly heated fresh air

no matter how tightly sealed barns are, or how well-managed they are, stir fans will always pay back with better floor conditions, lower heating costs and improved performance.

– will create more opportunity for moisture evaporation and result in less caking. The fresh air that has been heated to 40 F, for example, as it enters the barn and travels along the ceiling, will double its water holding capacity twice. What that means is, even with 80 per cent outside humidity levels, that fresh air would have a relative humidity level of 20 per cent after heating, and the ability to pull a lot of moisture out of the litter if it reaches the floor. An additional side-effect of reducing the litter moisture and caking will be lower ammonia concentrations.

CARboN DioxiDe

Another benefit is decreasing the level of carbon dioxide at the bird level. This can be a problem particularly during the first week of brooding when moisture control hasn’t yet become a problem. Because heaters produce a unit of carbon dioxide for every unit of natural gas and three for every unit of propane, and the birds are also producing the gas, buildup can occur quickly near the floor. Carbon dioxide is heavier than air, and can easily be 10 to 20 times the normal

liTTeR moiSTURe

STiR CRAzY

PROTECT PERFORM PROFIT POULVAC® E. COLI

outdoor level (400 parts per million) with under-ventilation in a poultry barn. A level of 5,000 ppm can begin to affect performance, but it is recommended that levels be kept below 2,500 ppm. With stir fans running, levels at the floor can decrease as much as 50 per cent as carbon dioxide is dispersed throughout the barn.

SYSTem DeSigN

The purpose of stir fans are to mix the air, not to circulate the air at a high speed, so the sizing and speed of the fan should reflect this goal. In general, for most applications, an 18- to 20-inch fan will do a great job of stirring the air

UNDERSTANDING YOUR NEEDS IS OUR FIRST STEP. DELIVERING INNOVATIONS THAT IGNITE POSITIVE RESULTS FOR YOUR OPERATION IS OUR GOAL.

We are constantly striving to find ways to make you more productive and profitable. All of Big Dutchman’s products, from our AVECH enrichable and enriched system and new cage free solutions, to the Gladiator turkey feeder and our re-designed feeding pans, are as ground-breaking as they are practical.

without chilling young birds, especially if fans are angled slightly toward the ceiling. A second factor to keep in mind when purchasing fans is the grill. The fewer ribs in the grill, the cleaner the fan will stay, and the better the airflow will be.

An ideal system will be sized to move about 10 to 15 per cent of air in the building. For example, a typical 20-inch fan that can move about three to 5,000 cubic feet per minute (cfm) of air, and a 40 foot x 500 foot building with a 10-foot ceiling.

Calculation of 40 x 500 x 10 x 15 per cent gives us 30,000 cfm capacity for our stir fan system, so if using 3,000 cfm fans, 10 will be needed. If you need 36-inch fans for wind chill in the summer in curtain side barns, they should be variable speed so they can be used as stir fans in the cold months, or it may be worthwhile to have a second system with smaller fans.

There are a few schools of thought on stir fan layout, the most common are the “racetrack” and “straight-line” configurations. It works well to run a straight line down the centre in 40-foot-wide barns, spaced about 50 feet apart. But in wider barns, a racetrack configuration makes more sense because it is difficult to stir the air wall to wall more than 40 feet.

No matter how tightly sealed barns are, or how well managed they are, stir fans will always pay back with better floor conditions, lower heating costs and improved performance. They are a relatively small investment, and if you already have them, they should be in working condition and in use. n

ReFeReNCeS

1 University of Georgia’s Poultry Housing Tips, Volume 18 Number 10, https://www.poultryventilation.com/ sites/default/files/tips/2001/vol13n1.pdf

THE NEXT GENERATION

Research and Development

At Cobb® we are always looking ahead to serve our customers through the use of innovative research and development. Investing in R&D is the best way for us to create value and deliver it to our customers. We’re the world’s oldest poultry breeding company. We’ve achieved that by listening to our customers, utilizing innovation, and leveraging technology to deliver annual genetic progress.

Genetic Improvement

DNA profiling using genetic markers and computer programs to optimize selection of pedigree stock will enable Cobb to maintain its leadership as a broiler genetics company. Applying these techniques to the key performance and welfare traits will increase efficiency and speed of bringing genetic improvements to the market.

Delivering Continuous Progress In Genetic Potential

A Critical Part of Doing business

PIc and PaacO’s continued partnership meets a growing need in the poultry industry

There are more people trained to ensure good poultry welfare on Canadian farms, thanks to the PAACO (Professional Animal Auditor Certification Organization) Poultry Welfare Auditor Training Course, offered for the second time in Canada this past fall, in partnership with the Poultry Industry Council (PIC).

PAACO’s mission is: “To promote the humane treatment of animals through education and certification of animal auditors, as well as the review and certification of animal audit instruments, assessments and programs.” And while PAACO has been training poultry welfare auditors since 2006, the 2013 course was only the second offering in Canada.

The first Canadian offering of the course, organized by PIC in the fall of 2012, quickly sold out, and a number of hopefuls had to be placed on a waiting list. This year was also very well attended.

The popularity of the Poultry Welfare Auditor Training Course stems from the fact that it is all encompassing, applying to welfare criteria within and across all sectors of industry, and is offered locally.

“We have producers and farmers, packers and processors, academia, government, and what we call ‘customers’ such as Sobeys and Walmart. They all require knowledge in welfare auditing, and they all have different reasons for being validated,” says Mike Simpson,

PAACO executive director

“I would say about 40 per cent or more take the course purely for educational value, so that they are familiar with animal welfare issues, terminology and criteria,” continues Simpson. “For the remainder, they might want a PAACO certified auditor on staff because they are doing internal audits and want them done routinely with the same rigour and the same standards as would be expected in a third-party audit situation. In addition, they want assurance that when an official audit is done it is being done right. Important also would be training to become a third-party auditor.”

processor fairly, objectively, and equitably across Canada,” says Cooley. “This requires appropriate, standardized training and accreditation for all auditors, particularly in the area of live animal production and processing.”

In the course, students learn the commonly audited poultry welfare criteria, addressing the relevant welfare-specific areas for each of the commodity groups, including broilers, turkeys and egg layers and covering specific production segments: breeders, hatchery, grower/producer, transportation and processing.

The PAACO Poultry Welfare Auditor Training Course is an important step toward proving business integrity to customers and consumers, but it also objectively assesses if, and where, there are any issues. Leanne Cooley of Gray Ridge Eggs Inc., and a member of the PIC board of directors, is a PAACO-certified poultry welfare auditor and holds a master of science in animal behaviour and welfare from the University of Guelph.

“Canadian farmers have many excellent, existing on-farm programs that are achieving the goals and standards set out, and that should be maintained,” she says. However, Cooley feels that the Canadian food industry would benefit from more Canadian PAACO-certified auditors with good knowledge of Canadian animal agriculture and existing on-farm programs.

“If the goal is to truly improve animal welfare through the supply chain, then as an industry we need to ensure that all auditors, whether first, second or third party, are able to evaluate each farm and

Trainees also learn poultry husbandry and management best practices based on U.S. course material. However, leading up to the first Canadian delivery of the course, PIC helped to revise the material to work with the Canadian poultry industry structure. The course is also largely in line with the Canadian Codes of Practice for the Care and Handling of Poultry. PAACO will ensure continued alignment in future course offerings, as the Codes are a nationally recognized standard of care across Canada.

The course runs over three days and begins with two days of classroom instruction, with the first day on management and husbandry related to welfare criteria and audits, and the second teaching trainees precisely how to audit those criteria. The third day is spent travelling to farms for audit demonstrations at broiler, layer and turkey facilities, followed by a closed-book exam. In addition, training for certification requires three shadow audits over a time period of 12 months, where trainees are evaluated by a certified and experienced auditor.

To learn more about becoming a PAACO Certified Poultry Welfare Auditor, please visit www.poultryindustrycouncil. ca or www.animalauditor.org. n

imPoRTANCe iN bUSiNeSS

Euro 2012 Meller’s Alternative Housing

Meller offers the “Euro 2012” Enriched Group Housing System for Laying Hens

Integrated into each cage are perches, large nesting area, scratch area, LED lighting and manure drying capabilities. The Euro 2012 System offers heavy duty manure drives, chain feeding systems, overhead or lift type egg collection and the “Egg-Ease” egg saver system.

MELLER POULTRY EQUIPMENT INC.

“The Cage Specialists”

RR#1 Jarvis, Ont. Canada N0A 1J0 For more information call Louis or Chris Bill Phone (519) 587-2667 Fax (519) 587-2959 E-mail: meller@optionsdsl.ca Website: www.meller.ca

Meller poult sept 13.indd 1

Industry building a better Website

The Feather Board command centre has created a novel way to disseminate secure information

B

With the everincreasing reach of the Internet, technology has become an important part of how any business or organization communicates with its customers, the industry and the general public. One of the best ways to do that is through a website – but how do you communicate in a secure and efficient way during a serious event, like a disease outbreak, and make sure that everyone receives the information they need?

The Feather Board Command Centre (FBCC), an organization has served as an informal information hub since 2003 for the four poultry marketing boards in Ontario – Chicken Farmers of Ontario, Egg Farmers of Ontario, Ontario Broiler Hatching Egg and Chick Commission, and Turkey Farmers of Ontario – now plays a leadership role in emergency disease management.

Dr. Tom Baker, a consultant and incident commander at FBCC, says that over the years, the FBCC has made progress in a variety of ways to help the poultry industry: geo-spatial coding of poultry farm locations, disease outbreak simulations, biosecurity practices and more.

As well, the Canadian Agricultural Adaptation Program provided financial assistance to make the collaboration with the marketing boards official and

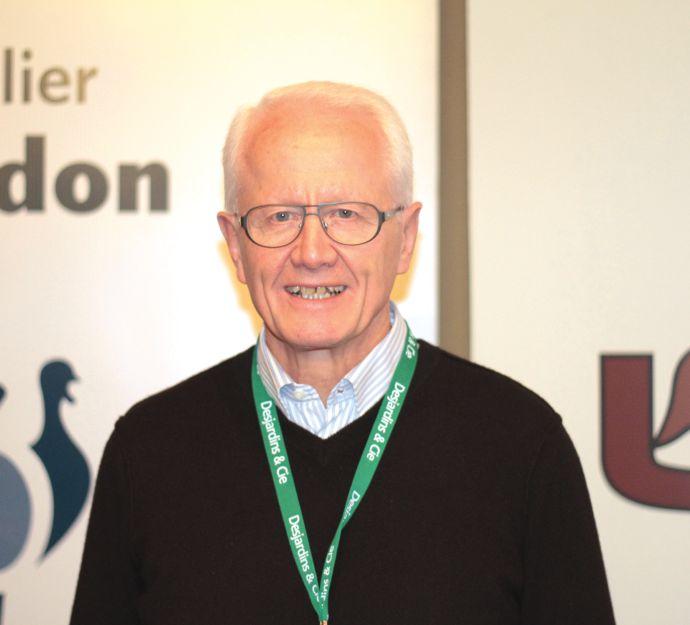

Dr. Tom Baker has helped the Feather Board command centre create and implement a new secure website for use during serious events, like disease outbreaks.

improve emergency management planning and rapid response/recovery capacity, including the development of an Emergency Management Plan.

Thanks to the funding, the FBCC was able to create a new and secure website to help co-ordinate emergency responses, convey communication and recovery initiatives as well as provide access to maps and other useful resources.

“FBCC aspires to have an emergencyfree Ontario poultry industry through industry-led disease incident risk management,” said Baker.

“When notified of a disease incident, FBCC maps the involved area and advises all farmers in the affected zone to institute heightened biosecurity measures.

Poultry industry associations and poultry veterinarians are also alerted of the need for heightened biosecurity and provided with a buffered zone map.”

The website will be used as a way to avoid constant e-mailing among staff, agencies, experts, etc. and centralize all the information, including manuals, test results and biosecurity resources.

Added Baker: “Previously, feather boards communicated with their members and stakeholders primarily through their own websites and newsletters. It was long recognized that timeliness, security, and consistency would be enhanced with an integrated secure (or ‘dark’) website. The new website went live in the spring of 2013 and was used successfully in the

Web mANAgemeNT

Y D AVID M ANLY

two-day FBCC Foreign Animal Disease (FAD) Simulation in collaboration with the Canadian Food Inspection Agency (CFIA), Ontario Ministry of Agriculture and Food (OMAF), Animal Health Laboratory (University of Guelph) and the Ontario Livestock and Poultry Council (OLPC).”

WebSiTe FeATUReS

The goal of the new FBCC website, according to Baker, is to provide:

• efficient and secure internal information exchange with access based on the individual’s response role and information needs

• common timely messaging of disease incident status

• alignment of key messages with those of government

• access to critical information resources, such as the Emergency Response Plan, biosecurity resources, technical fact sheet, etc.

• documentation access

• efficient staff management according to the Incident Command System functional structure used by emergency responders

• entryway to government regulatory processes (for example, movement permit applications)

• timely and common messaging amongst the four feather boards to co-ordinate information sharing with all government, laboratory and industry stakeholders and partners.

• archival information to learn from past incidents

• forum to discuss policy and scientific issues

• access to the website via mobile devices

iNViTATioN oNlY

One of the most notable features of the new FBCC website is that the general public cannot access it in any way; it is securely protected and offers only limited access to individuals within the industry.

Continued on page 34

2013 Poultry Service Industry Workshop

The Poultry Service Industry Workshop thanks the following sponsors for their continued support which allows the planning committee to provide a strong education program as well as various social networking opportunities.

Industry moving Forward From here

Industry

reinforces commitment to

constant improvement in wake of damaging video

B Y T REENA H EIN

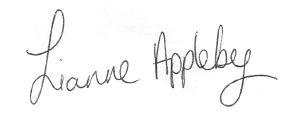

When W5, a CTV current affairs and documentary program broke a story in October 2013 about alleged inhumane practices on two poultry farms in Alberta, those inside and outside the industry had many questions.

The video, filmed last summer at two Alberta farms – Ku-Ku Farms (layer hens) in Morinville, and Creekside Grove Farms (pullets) in Spruce Grove, seems to depict housing and euthanasia practices that are not compliant with industry recommendations and standards.

For poultry producers across Canada, the story was a heartbreaking one, yet many will only have had a chance to read and see reports from the mainstream media. Canadian Poultry is fortunate enough to enjoy good relationships with Canada’s egg industry, and spoke with representatives candidly about what was shown the video, levels of responsibility, recommended practices and, most importantly, continuous improvement.

eFA WeighS iN

Amin Valji, owner of both farms, is a director on the Egg Farmers of Alberta (EFA) board, as well as an alternate Egg Farmers of Canada (EFC) director. EFA says Valji will remain on the board. “As a second-generation egg farmer with

While the instinct is to batten down the hatches when activist stories hit, it is important that industry answer the difficult questions.

over 35 years of experience, [he] brings a wealth of knowledge ... EFA strongly believes the immediate and long-term benefits of working together with producers to resolve issues and correct problems are significantly greater than what would be accomplished with discipline alone.”

When asked if all EFA members, including Valji, had adequate knowledge of the proper and humane practices they should be using, and whether EFA shoulders any responsibility for the ongoing

barn conditions and specific actions at the two farms presented on W5, they said: “EFA works hard to keep farmers informed of industry standards and best practices, as well as industry trends and innovative research.”

EFA says that to ensure hens are treated humanely, the egg industry follows practices outlined in a national Animal Care Program (ACP), based on the Recommended Code of Practice for the Care and Handling of Pullets, Layers and Spent Fowl (or Code of Practice), which

heADliNeS To mAKe YoU CRiNge

was developed in consultation with veterinarians, animal care scientists and representatives of the Canadian Federation of Humane Societies. “The ACP ensures hens have a safe and comfortable environment by not only providing guidelines, but monitoring on-farm compliance,” EFA states. “The ACP provides guidelines for space, water, feed, lighting, temperature, air circulation, and more. One hundred per cent of our farms voluntarily participate in the ACP, which includes annual auditing by EFC.” EFA continued by saying that measures are taken immediately to address departures from accepted industry practices outlined in the ACP and that the National Farm Animal Care Council is currently reviewing the Code of Practice.

Additionally, EFA notes that Alberta’s egg industry has historically been proactive on the subject of hen housing: In 1990, Alberta became the first province

Industry

in Canada to regulate cage density, and in 2009, an Alberta egg farmer installed the first fully enriched housing system in Canada.

“Since 2006, a growing number of egg farmers have either built new barns or renovated existing barns, and have chosen to install an alternative housing system such as enriched, free-run, aviary or free-range. In 2006, 98.5 per cent of the province’s egg farmers utilized conventional housing, but that number is now down to 82.8 per cent. Over the past two years (2012 and 2013), every Alberta egg farmer who has faced a hen housing decision has chosen an alternative system over a conventional cage system. Egg Farmers of Alberta’s board of directors adopted a provincial hen housing policy earlier this year, which states that ‘no new conventional or enrichable cage systems will be allowed to be installed in Alberta after December 31, 2014.’”

With regard to on-farm inspection, EFA explains that their field inspectors visit every Alberta egg farm a minimum of twice per year to conduct tests for Salmonella Enteritidis and flock verifications. EFC field inspectors visit every Alberta egg farm a minimum of once per year to audit both the Animal Care Program and the “Start Clean – Stay Clean” on-farm food safety program. EFC audit reports are sent to EFA in order to follow-up with any required corrective actions. “EFA (and sometimes EFC) field inspectors will often visit farms to verify that corrective actions have been resolved. All farm visits are announced, typically only a few days in advance. The national on-farm programs are regularly reviewed and we are moving ahead with several planned enhancements, including the introduction of third-party auditing of the Animal Care Program. EFC has also approved the development of

an Animal Care Program review panel to help guide future enhancements, which will likely include moving toward a ‘no notice’ policy for inspections.”

EFA adds: “EFA and EFC are always working to find new and better ways to improve and enhance the quality of care provided to egg laying hens in Canada.”

However, EFA did not comment on whether inspection results should be reported to the public.

egg FARmeRS oF CANADA

When asked if EFC takes any responsibility for the ongoing barn conditions and specific actions at the farms presented on W5, they refer to the ACP. They also repeat EFA’s message that, “the video footage shown on W5 contains scenes that depict practices that are unacceptable and not representative of what happens on Canadian egg farms. EFC made a statement to this effect upon the airing of the W5 show and an independent panel of experts commissioned to perform an assessment of the video confirmed its position. However, as noted by one of the experts, the short clips make it difficult to ascertain whether the images truly represented the way this farm was being managed.”

When asked, in light of the W5 episode, if its voluntary code of practice for treatment of animals needs to become mandatory, it stated that EFC’s ACP, which is based upon the Code of Practice, is already mandatory in some provinces and EFC has requested that all egg boards explore moving in this direction.

With regard to on-farm inspection, EFC states that in accordance with the ACP, “each regulated egg farm in Canada is inspected once per year at a minimum. Where required, Corrective Action Reports are provided to the producer and egg board to ensure that issues identified are corrected. For EFC’s “Start Clean – Stay Clean” program, which is a mandatory on-farm food safety program, each regulated egg farm in Canada is inspected once per year, minimum. Additional inspections by EFC or the provincial/territorial egg board could be necessary to ensure a problem identified

Industry

in a Corrective Action Report had been addressed.”

Regarding whether the EFC on-farm inspection policy needs to change, EFC states that its on-farm programs are regularly reviewed and that they are moving ahead with several planned enhancements including introducing third-party auditing of their ACP. EFC has also approved the development of an ACP review panel to guide enhancements going forward, including moving toward a “no notice” policy for inspections.

“We expect everyone on the farm to show a high level of respect toward their hens. When things go wrong, we expect immediate corrective measures and a commitment to continuous improvement. In this case, the farmer immediately reinforced and reviewed training with all staff with the help of poultry veterinarians and is enhancing compliance measures. Egg Farmers of Alberta continues to work with the producer on a number of corrective measures.”

EFC states that it has conducted an independent, third-party expert review of the footage to confirm its initial assessment of some of the farming practices depicted and is working with the entire industry, including upstream and downstream stakeholders, on concrete actions that are appropriate to each entity’s relative responsibilities/authorities. “The Canadian egg industry took immediate action and considers this an opportunity to address gaps and strengthen animal care in the egg industry,” they said. As to whether on-farm inspection results should be reported to the public by EFC, EFC says: “Any farmer can provide its Animal Care Program results to those in their value-chain who may need that information.”

ChiCKeN FARmeRS oF CANADA

Steve Leech, CFC’s national program manager (Food Safety, Animal Care & Research), says its ACP involves annual audits, when discussing CFC’s policies on on-farm inspection. “[This program] provide assurances that farmers are meeting appropriate animal care standards and

has been supported for implementation by the Canadian Federation of Humane Societies and the Canadian Veterinary Medical Association, amongst others,” he notes. “Over 80 per cent of farms are certified on the program and CFC expects this number to climb significantly in the coming months.”

When asked whether CFC will move to a “no notice” inspection regimen, Leech says CFC’s ACP also provides the opportunity for triggered audits based on stakeholder complaints and concerns, which can involve audits with limited notice.

As part of the program’s educational component, CFC has developed communication material on appropriate euthanasia techniques and is currently in the process of developing further educational material on reasons for culling and appropriate culling practices. These materials will be incorporated into future farmer outreach campaigns. Leech adds, “Further modifications to CFC’s ACP will be based on the Recommended Code of Practice for Chickens, which is currently in the process of being updated.”

PReVeNTiNg A RePeAT

EFA says that it has been “working closely with Mr. Valji, who is deeply concerned about what happened on his farm. After a description of the video was shared, both EFA and EFC inspected the farms. Mr. Valji immediately reinforced and reviewed training with all farm staff with the help of poultry veterinarians, and is enhancing compliance measures. Working through a situation like the one he’s currently facing provides Mr. Valji with unique insight and experience, which will be a valuable lesson to be shared with the EFA Board, his fellow producers and the Canadian egg industry.”

Canadian Poultry will do its best to follow up with Mr. Valji about this experience, and lessons learned later in 2014. n

With over 34 years of experience, Smithway can handle your hauling needs no matter the size or age of your birds. Our new curtain sided trailers allow easy side loading of your cages while providing protection from the elements. Smithway continually strives to meet and exceed the needs of our Customers.

SMITHWAY, INC. (828) 628-1756 / 628-2381 PO BOX 188 FAX: (828) 628-7662 HWY 74A EAST E-MAIL: SMITHWAY@ATT.NET

FAIRVIEW, NC 28730 WEB: WWW.SMITHWAYINC.COM

IPPE BOOTH # A-1065

“The Number One Way Is The Smithway”

Continued from page 27

Baker says that one of the main reasons for this drastic change in access is due to the risk of misinterpreted information getting into the public domain.

“In several international disease incidents, media curiosity has been a significant deterrent to effective information exchange amongst responders,” he said. “And in some cases, the biosecurity on site was threatened.”

There are three levels of access for the website:

Level 1 – those who manage content (update messages, assign staff, verify completed tasks, document), such as assigned Incident Command staff and Section Chiefs

Level 2 – staff with Incident Command co-ordination responsibilities

Level 3 – those who view only, in declining order of access:

Industry

• designated government liaison and communication staff

• FBCC Board members

• Advisory Group members (view and participate in Forum discussions)

• key stakeholder and partner associations

• individual key enterprises and producers

• guests and media (location map with zones, disease summary)

FUTURe APPliCATioNS

The FBCC site is also extremely versatile and could be developed into a news source.

“This website could be expanded into a livestock and poultry web portal that would allow other livestock and crop organizations faced with emergency response challenges to have secure access

to its customized features.”

However, he is quick to point out that the FBCC site currently only meets the most basic initial emergency response needs, as it is only a skeleton framework for a potentially more comprehensive site. Visitors to the site, Baker adds, have been incredibly useful.

“Users of the site see many new possibilities for enhancements that can serve industry needs throughout the whole emergency management continuum from report of disease suspicion, through to response, movement controls and recovery,” he said.

The goal is to make the FBCC website a “one-stop” website for emergency disease management resources. n

Research

To Trim or Not to Trim?

University of saskatchewan research provides new insight into turkey toe trimming

B Y A NDR é D UMONT

Toe trimming in turkey production is a wellestablished practice, but is it really necessary?

Last November, professor Henry L. (Hank) Classen presented his research team’s findings at the AQINAC poultry conference in Drummondville, Que. Assisted by graduate student Jocelyn Fournier; Classen investigates behaviour and performance of treated and non-treated turkeys.

Classen pointed out that existing research on toe trimming was rather outdated. “The genetics of these birds has dramatically changed since the 1970s and 1980s. The technology used to trim toes has also changed.”

Because of this significant evolution in turkey production, several important questions remained unanswered. With toes being important for balance and mobility, how do shorter toes affect birds with considerably more breast muscle than 30 years ago? Now that Nova-Tech Engineering’s Microwave Claw Processor has replaced surgical scissors or cauterizing hot blades, do birds suffer less from the toe trimming procedure?

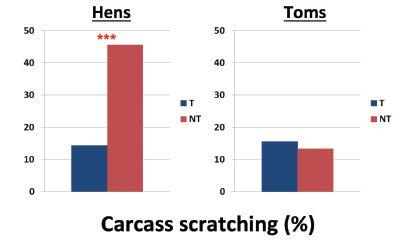

Classen’s research was based on the hypothesis that toe trimming can decrease carcass scratching without negative effects on bird welfare. The effect of toe trimming was measured on production criteria (growth, feed efficiency and carcass damage) and bird welfare criteria (toe length and variability, toe healing,

Hank classen is a professor at the Department of animal and Poultry science of the University of saskatchewan. His research shows toe trimming may not be necessary on heavy toms.

gait score/stance and behaviour).

Classen said there was a need to assess animal welfare other than by measuring carcass damage from scratching and condemnation. Treating toes using microwaves may reduce bacterial infection, but could the trimming be too severe?

The experiment was conducted on groups of 32 Hybrid Converter hens per

pen, from zero to 15 weeks of age, and groups of 17 Hybrid Converter toms per pen, from zero to 20 weeks of age. Two treatments were compared – no toe trimming and toe trimming – using the Microwave Claw Processor. The birds were grown to ages older than what is common practice in Canada but comparable to world standards.

goiNg WheRe FeW hAVe ReCeNTlY goNe

Photo courtesy of a ndré Dumont

c hart courtesy of University of s askatchewan

ReSUlTS

There was no significant difference in body weight between treated and non-treated hens after 15 weeks. However, at 20 weeks, untreated toms did weigh around half a kilogram more than treated ones.

A closer look at body weight gain over time revealed that both treated and untreated toms had comparable body weight gain for the first 70 days, but things changed as the birds got bigger. “This lends itself to the idea that the treated birds were somewhat reluctant to go to the feeder,” Classen said.

For both hens and toms, treated birds had a reduced feed intake from zero to seven days. According to Classen, this suggests that birds are affected by the treatment.

Treated toms also had a reduced feed intake at 126 to 140 days, confirming the hypothesis that there is a reluctance to feed and grow to genetic potential.

However, in agreement with previous experiments, the overall feed to gain ratio seemed not to be affected by toe trimming. Mortality was higher with treated birds, but in the context of the experiments, the difference was not statistically significant.

Of much greater concern was the number of treated toms that by the age of three weeks had a rotated tibia, a condition that can be found in birds that suffer physical damage to their legs because they are exposed to slippery surfaces. In this case, researchers suspect the cause may be the absence of claws on straw bedding.

The experiment’s most interesting finding relates to scratching. With hens, a very significant reduction in carcass scratching was observed among treated birds. Among the toms, there was very little carcass scratching in both treated and non-treated groups. “At 20 weeks of age, those toms weigh more than 20 kilograms. They are big birds. It’s possibly their size alone that reduces the potential for scratching,” Classen said.

As for toe length, it turns out treated birds have toes that are about eight per cent shorter. Toe regrowth is very variable. A close look at toes shows that by 14 days, most of the healing is done. In three out of four samples, bacterial colonies were found in treated toes, suggesting the microwave treatment is probably not a complete barrier to bacteria entry. But overall, the treatment was found to be consistent and effective.

Researchers were surprised to find that when encouraged to walk, both hens and toms showed good mobility despite their large size. However, during the first week, treated birds did have a reduced activity level. “These effects were basically gone by the end of a week,” Classen said. “The effect was slightly less in hens than in toms, but the bottom line is that these birds probably experience some type of discomfort or pain.”

Because the toe is innervated (it has nerves that can send pain signals), there is undoubtedly pain caused when severing it with microwaves, Classen explained. “There is no question that these birds probably need a little additional care after the treatment.”

CoNClUSioNS

Although the research was conducted on a small flock in experimental infrastructures, conclusions may be relevant to commercial turkey breeders.

In the case of hens, toe trimming is recommended despite welfare issues early in life. Classen says that this is counterbalanced by reduced scratching.