1971 and 1972 Canada’s egg industry was headed over a cliff. Farmers and politicians decided it was time to take a different course

Knisley

By KRISty nuddS

1971 and 1972 Canada’s egg industry was headed over a cliff. Farmers and politicians decided it was time to take a different course

Knisley

By KRISty nuddS

The attacks on supply management in the media came fast and furious in november. With the announcement that the federal government was moving forward with its plan to abolish the Canadian Wheat Board (CWB) Act and with its stance on protecting supply management relegating it to “observer” status in the trans-Pacific Partnership (tPP) talks, the attacks were inevitable. that doesn’t mean all of the criticism is valid. What’s missing from the arguments is context. It’s easy for journalists to jump on the “if the feds get rid of the wheat board they are hypocrites for supporting supply management” bandwagon when they have no understanding of what supply management is, or why it was created in the first place.

numerous articles have essentially rehashed the same critical views – that supply management is on the same level as the CWB and should, therefore, be treated equally; that the system results in increased costs to consumers; and that it is a barrier to trade talks. It doesn’t matter which media outlet started the rollercoaster ride that ensued; very few outlets actually did their homework.

As for the media’s criticism, let’s start with the CWB. As my esteemed colleague Jim Knisley points out in his column, critics forget that the CWB is a sole federal entity, whereas supply management is an agreement between the provinces and the federal government. If the federal government wanted to dismantle supply management on a national level, it would still exist on a provincial level. Agriculture minister gerry ritz says farmers want marketing freedom, and results from a CWB plebiscite show many of

them do. the same cannot be said for farmers under supply management.

to say that supply management is the sole cause of the price disparity in dairy, poultry and eggs between Canada and the u s. is simply naive. time after time, the fact that the u.s. treasury subsidizes its country’s agricultural production via consumer taxes and thinly veiled consumer and energy support programs is left out of the discussion. If comparisons are to be made, let’s compare apples to apples and not apples to oranges.

When Canada declared its desire to join the tPP, it was blocked by the u.s. and new Zealand due to its refusal to decrease tariffs on imported dairy products. this led many to believe that trade opportunities with Asia would not be possible without giving up supply management. not so, according to university of Waterloo professor Bruce Muirhead, who participated in a panel discussion on supply management on tv ontario’s news program The Agenda. Muirhead said that in the globalization of trade, every country has something to protect and Canada will still be able to make trade deals with participating countries.

What gives such criticism of supply management momentum is the lack of understanding of the system, and its roots.

In this month’s issue, we’ve done our homework, and present a “look back” on the beginnings of supply management, and why it was formed, in order to arm you with information so that when the critics come calling, you can let them know how and why the system makes sense. n

January 2012

Vol. 99, No. 1

Editor Kristy Nudds – knudds@annexweb.com

888-599-2228 ext. 266

Associate Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com

519-429-5193

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Production Artist

Emily Sun

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

REtuRN uNDEliVERABlE CANADiAN ADDRESSES tO CiRCulAtiON DEPt., P.O. BOx 530, SiMCOE, ON N3Y 4N5.

e-mail: jmatheusik@annexweb.com.

Printed in Canada iSSN 1703-2911

Circulation e-mail: jmatheusik@annexweb.com

Tel: 866-790-6070 ext 207

Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 24.00 (with GSt $25.20, with HSt/QSt $27.12)

GSt – #867172652Rt0001

uSA – 1 Year $ 60.00 uSD

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

CORRECTION

In our December 2011 issue, it was erroneously reported that former Egg Farmers of Canada (EFC) chair Laurent Souligny served on the EFC board of directors for 24 years. Mr. Souligny served on the board for 17 years.

Got Lubing? Contact your local Lubing Distributor for more detailed information about our innovative products or vist our website at www.lubingusa.com

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

With more than 60 years of experience developing innovative products for poultr y producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Our innovative products are produced with the most modern manufacturing capabilities giving our customers a profitable advantage in productivity.

Nipple Drinking Pullets, Breeders, Broilers, Layers,Turkeys

Egg Conveying Curve Conveyors, Belt Conveyors, Dirty Egg Return Conveyors, Transfer Tables

Dead Bird Removal

AFederal Court judge has ruled that Agriculture Minister gerry ritz breached the Canadian Wheat Board (CWB) Act by making changes without holding an official plebiscite among producers.

Justice douglas Campbell says section 47.1 of the act requires the minister to consult farmers before making change to the board’s structure. his decision was released december 7 in a Winnipeg court.

Campbell says he accepts the arguments of the board and its supporters about the “unique democratic nature of the CWB” and its strong support among Western grain producers.

he says this support is

worthy of respect.

the board was set up following the great depression to have farmers band together and seek higher prices.

ritz introduced legislation in october to end the board’s marketing monopoly on western wheat and barley as of August 1, 2012. the government introduced the “Marketing Freedom for grain Farmers Act,” which ritz stated would give Western Canadian grain farmers the right to choose how they sell their wheat and barley.

government lawyers argued a plebiscite was not needed to make the change.

CWB chairman Allen oberg is calling on the federal government to respect the ruling and cease actions to pass the legislation into law.

After the court’s decision, human resources

Minister diane Finley told the Commons the government disagrees with the ruling and will appeal.

But despite opposition questioning, Finley would not explicitly say whether the government will put the legislation on hold while the case is before the courts.

the CWB held a plebiscite in september 2011. results showed that the majority of farmers wanted to maintain their ability to market wheat and barley through a singledesk system. sixty-two per cent of respondents voted in favour of retaining the single desk for wheat and 51 per cent voted to retain it for barley. A total of 38,261 farmers submitted mail-in ballots in the plebiscite, which is a participation rate of 56 per cent.

With files from the Canadian Press

Grand river Foods recently announced the sale of its fresh poultry processing division to Maple Lodge Farms. the completion date of the sale agreement was scheduled for december 1, 2011. Financial terms were not disclosed.

Both companies feel the sale further focuses each company’s operations on

Michael and gwen van gurp of norwich, ontario (right) have been selected as the recipients of the egg Farmers of ontario’s (eFo) 2011 new entrant Quota Loan Pool (neQLP) program. their selection was announced at eFo’s annual Councillor’s Workshop at the delta Meadowvale hotel in Mississauga, ont.

t he selection committee comprised Laurent s ouligny, past e F o director and former chair of e gg Farmers of Canada; d arryl Ball, o MAF r A; Craig Bremner, td Canada trust; r obert Loree, Ward & u ptigrove; and s hannon Kelly, past president of Junior Farmers’ Association of o ntario, who came to a decision after reviewing all applications. t he van g urp’s were selected out of a pool of 84 applicants.

eFo Chair Carolynne griffith said in a release that the neQLP program was designed to ensure constant

their respective strengths in prepared food production and primary processing, while reaffirming both companies’ commitment to ontario’s food processing industry.

grand river Foods will now concentrate resources on its fast-growing foods division, serving customers in the grocery and food service sectors. Maple Lodge Farms is expected to scale up its primary

processing operations to more effectively serve its customer base in the retail, foodservice, further processed and other market sectors.

the Chicken Farmers of ontario has recently provided regulatory approval for the transfer, which includes conditions to benefit ontario growers who were previously shipping their chicken to the grand river Foods processing facility.

renewal of the egg industry and foster the opportunity for individuals to join the

ontario egg industry. the program will take place annually.

evidence of Molotov cocktails was found at the scene of a fire that caused more than $500,000 in damage to a construction site for sunnymel’s new chicken processing plant in Clair, n.B. the suspected arson destroyed a truck and damaged a number of utility trailers at the construction site for

Claude Chapdelaine has been appointed as manager of sunnymel’s future chicken slaughtering and cutting facility, currently under construction in the Village of clair, new Brunswick. mr.

chapdelaine has over 20 years’ experience within olymel l.p, one of the partners in sunnymel.

Christina Couture has joined alltech canada as the territory marketing coordinator for ontario. couture graduated from university of guelph with a bachelor’s degree and completed a marketing management post-graduate degree from humber college, with honours.

the new $40 million plant in Clair about 30 km southwest of edmundston.

the rCMP said it appears someone, or several people, also tried to start several smaller fires on the site.

groupe Westco Ceo thomas soucy said the damage would not stop work at the site, underway since last August and is “currently ahead of schedule.”

daniel frechette has joined alltech canada as regional sales representative in Quebec. he graduated from laval university with a bachelor of science in agriculture economics and has extensive experience in the agriculture industry.

On november 18, the World trade organization (Wto) ruled against the united states’ Country of origin Labelling (CooL) initiative. CooL rules were imposed by the u.s. in 2008 on the Canadian livestock industry. the Wto ruled that CooL violates international trade rules by limiting free trade with Canada and Mexico. Canada argued that CooL raised costs and distorted trade across the

shared border. the labelling regulations came while the Canadian livestock industry was recovering from losses from Bse, which was discovered in Canada in 2003.

Canada first requested Wto involvement in 2008. on May 20, 2011, a preliminary ruling found CooL requirements violated the Wto’s technical Barriers to trade agreement. As a result of the most recent ruling the u s has 60 days to file an appeal.

Apaul mcCarten (l) from lilydale presents Al Richards with the 2011 poultry service Worker of the Year award.

l richards is the recipient of the 2011 Poultry service Worker of the year award. the award was presented during the 36th Poultry service Industry Workshop (PsIW), held this past october in Banff, Alta.

Born in Medicine hat, Alta., richards began his working career at only 14 years of age, as a messenger for CPr telecommunications. By the age of 19, he was operating the teleprinter, receiving a position in Lethbridge. his career path took a very different turn however, when he was asked several years later to work in sales for shur-gain Feeds.

February 7-9, 2012

Canadian International Farm Show toronto International Centre, Mississauga, ont. For more information, visit: www.torontofarmshow.com

march 13-15, 2012

Midwest Poultry Federation Convention saint Paul river Centre, saint Paul, Minn.

For more information, visit: www.midwestpoultry. com

April 11-12, 2012

The London Poultry Show Progress Building, Western Fair entertainment Centre, London, ont.

For more information, visit: www.poultryindustrycouncil.ca

may 8, 2012

PIC Research Day victoria east golf Club, guelph, ont.

not having any knowledge of chickens or selling feed, richards bridged his knowledge gap by taking correspondence courses from the university of guelph. during his employment with shur-gain, he was named top serviceman three times.

richards accepted a new challenge when he joined Lilydale, where he managed the hatchery and held several other positions, and served as a director for the Canadian hatchery Federation.

richards then chose to return to feed sales, first with Masterfeeds, and most recently with viterra.

For more information, visit: www.poultryindustrycouncil.ca

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont. N3Y 4N5; e-mail knudds@annexweb. com; or fax 519-429-3094.

The Poultry Club at the university of guelph’s ontario Agriculture College came in a close second place for the prize of top fundraising team in the annual tractor tug for tots event in november. For the event, teams of eight to 10 people pull a tractor down reynolds Walk, and the fastest teams win. the event raises money for a local children’s charity each year, and this year the Big Brothers/Big sisters guelph chapter was the recipient. the oAC Poultry Club raised $400.

Anewly expanded Aviagen poultry feed mill in Athens, Ala. is producing 30 per cent more feed while consuming far less energy, reducing its carbon emissions by hundreds of tons, and cutting its annual utility expenses by more than $160,000.

Aviagen completed a multimillion dollar expansion of its feed mill in June of 2010. the expansion added production capacity with new equipment and procedures that ensure the biosecurity of pelletized and crumbled feed for Aviagen’s Pedigree operation in tennessee and to 115 Aviagen poultry farms in Alabama.

now with a full year of

operation behind it, the mill is reporting its results: even though the facility has increased feed production by more than 30 per cent, Aviagen’s more efficient processing equipment has allowed it to reduce its electric, natural gas and diesel costs by $169,836 and cut its overall carbon dioxide (Co2) emissions by 615 tons.

to bring those carbon savings down to earth, a 615-ton reduction in Co2 is like pulling 126 passenger cars (or 92 pickups and suvs) off the road for a year, according to estimates from the environmental Protection Agency.

electricity powers nearly everything at the Athens facility, which requires more than two million kilowatt hours (KWh) of electricity a year. After the upgrade, consumption dropped 15 per cent, cutting the mill’s overall electrical costs by $31,126.

Aviagen has reduced its natural gas consumption in large part by making innovative use of the 360-degree exhaust from a natural gas-

powered steam generator. By redirecting the exhaust from the steam generator, Aviagen avoids having to pay for heat needed drive up temperatures during the conditioning stage, an essential phase in feed production that kills pathogens and creates starch bonds needed to produce a sturdy pellet. As a result, the mill uses 12 percent less steam and has cut its natural gas consumption by 28 per cent – resulting in $75,510 in savings annually.

the Athens mill today produces pellets that are denser, by about 12 percent, than they were prior to the upgrade. denser pellets allow Aviagen trucks to deliver more feed per load – 2.22 tons more, in fact. And that means fewer trips in Aviagen’s dieselpowered semi-trailer trucks. during the mill’s first year after the upgrade, the company reduced its total truck load count by 236, resulting in a total fuel savings of $63,200.

For more information about the Aviagen feed mill sustainability efforts, visit www.aviagen.com.

beak treatment (trimming, shortening) is a common practice intended to maintain the welfare of commercial layer, turkey and breeder flocks. While there are clear benefits to beak treatment, the practice does require scrutiny to ensure that it is done properly and does not cause undue pain or suffering. hank Classen, Karen schweanLardner and their team at the university of saskatchewan have been studying the short- and long-term effects of common beak treatment techniques, and the accuracy with which they are performed in the field.

Birds naturally explore their environment by pecking items around them. they also peck each other to work out where they fit into the flock (i.e. establish pecking order). this behaviour can become a problem in the commercial setting where aggressive birds, and those that learn aggressive behaviours, may interact with many others. Feather-pecking and cannibalism can quickly spread throughout the flock. treating the beak dulls its sharp point and makes it harder for a bird to pull feathers from its flock-mates. Properly treated birds can drink, feed and preen normally, but are less likely to cause injury to others.

Beak treatment is sometimes performed with a heated blade (hB). A more recent and increasingly common technique exposes the beak to a short burst of high energy infrared light (Ir) that initially leaves the beak intact and results in the sharp tip eroding off a week or so later.

d r. Classen’s group observed layer chicks shortly after being treated as well as throughout their production cycle. h B treatment resulted in less chick activity and more resting behaviour one-day post treatment, which suggests there is some initial pain associated with the procedure. Ir-treated chicks showed no such behavioural changes and are probably experiencing little to no pain at this time. Proper beak treatment does not appear to cause chronic (long-term) pain.

Ir-treated chicks weighed less than non-treated chicks early in life, but moderate treatment (either method) had no long-term effects on body weight. egg production of the mature flocks was also not affected. Aggressive behaviours, feather pecking and mortalities due to cannibalism were significantly decreased with beak treatment. the latter was almost non-existent in Ir groups. Feather condition scores were much improved in beak-treated flocks.

the researchers assessed the accuracy and consistency of beak treatment on four commercial layer flocks from different hatcheries (two hB, two Ir) at 21-24 and 53-60 weeks of age. overall, Ir treatment was more precise (less variable) than hB and resulted in fewer beak abnormalities, the frequency of which was very low regardless of treatment method.

It has been established that it is best not to treat too much of the beak. the researchers therefore worked with hatcheries to see if equipment should be adjusted to account for differences in

chick size. hatching eggs (and therefore resulting chicks) were sorted into small, medium or large categories. All chicks were treated using the same Ir procedure. there were no treatment effects on the behaviour or production parameters measured in the experiment, suggesting it is not necessary to sort eggs/chicks on size prior to Ir treatment.

overall, dr. Classen’s results suggest that both hB and Ir methods are accurate and can effectively maintain the welfare of layer flocks. neither method appears to have negative long-term effects on the bird when treatment is moderate and completed at day of hatch. Ir results in less immediate pain, maintains an intact beak during early brooding, permits beak healing before loss of treated tissue, is slightly more precise, and is more consistent, even among different equipment setups or hatcheries. the researchers are currently working with commercial hatcheries to develop standard operating procedures for industry.

this research was supported by CPrC and the natural sciences and engineering research Council. For more details on any CPrC activities, please contact the Canadian Poultry research Council, 350 sparks street, suite 1007, ottawa, ontario K1r 7s8, phone: (613) 566-5916, fax: (613) 241-5999, email: info@cp-rc.ca, or visit us at www.cp-rc.ca. n

The membership of the CPRC consists of the Chicken Farmers of Canada, the Canadian Hatching Egg Producers, the Turkey Farmers of Canada, the Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

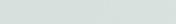

taking a look back at the roots of the system

b Y J IM K NISLEY

Today supply management is under assault again. What is lost in the fury of the attacks and the staunchness of the defence is why it emerged. It is not a simple tale. It took, for example, 11 years from the founding of the first poultry marketing board in British Columbia to the formation of the Canadian egg Marketing Agency. Along the way there were fierce challenges. some, fewer over time, producers were adamantly opposed. some politicians fought it at every step. there were court challenges, somber declarations from economists and corporate denunciations.

But the times dictated that something be done. In the early 1970s most if not all of agriculture was in turmoil. demand was tepid and when prices weren’t stagnant they were falling. overproduction was a ruinous reality. It was farmer against farmer, province against province and devil take the hindmost national trade policies. other parts of the economy were also struggling. the 1973-74 recession was sharp, deep and severe.

If one were to invent a time machine and go back to those times the only certainty would be the realization that something had to be done to at least stabilize the situation. For poultry and dairy the federal and provincial governments of the day agreed upon supply management. using hindsight, the future implications of that agreement can be debated. But what is clear is that at that time doing nothing was not an option.

much of the debate over marketing boards in the provinces played out in the pages of Canada Poultryman, the former title of this magazine.

supply management was the farmers’ and governments’ way to fend off chaos. this article and the one that follows will provide some context as to why supply management was created.

In the late 1960s and early 1970s, Canadian agriculture was – not to put too fine a point on it – a mess.

Incomes were low, prices were dropping, and surpluses piling up. Long established trading patterns were in flux, rural and farm populations were dropping, and governments were struggling to come up with answers.

royal commissions, white papers, studies and analyses proliferated.

In 1969, the situation was so severe

that saskatchewan Premier ross thatcher tried to barter wheat for other goods with foreign customers in an attempt to boost his province’s grain economy.

In 1970, 200 farmers went to the Alberta legislature and gave away 2,000 dozen eggs to protest low egg prices.

But the farm economy was not alone. As Canada moved from the 1960s into the 1970s, the economy slowed, inflation rose, and worse was to come, culminating in a steel crisis that gave rise to the term “rust belt,” the Arab oil embargo that shocked the world economy, and, in 1973-74, the worst recession since the 1930s.

A new economic term also entered the lexicon – stagflation. the mix of a stagnant economy and high inflation was toxic. Jobs were disappearing and prices surged.

everywhere, people were trying to

understand what was happening and governments – the Canadian government included – were trying to get a handle on the situation and temper the economic blows. Wage and price controls were tried in Canada, the united states and elsewhere; new farm programs were unveiled and unique monetary measures tested. the situation was so severe that American investor Warren Buffet, commenting on the recent recession, said it wasn’t as bad as 1973-74 – yet.

Canada also introduced the Food Prices review Board in 1973 in response to rapidly rising food prices. under its chairman, Beryl Plumptre, the board set out to look into just about everything. over the previous two years, housing costs increased 18 per cent, clothing costs increased 17 per cent, but food costs rose by 37 per cent.

A Toronto Star article published in August 1973 said: “since August, she (Plumptre) has tweaked Whelan’s nose, chicken and turkey marketing, prodded for better beef support schemes, probed into prices and income ideas, monitored chain store prices, called for a more coherent agriculture policy, issued ominous food price reports, and chided members of parliament for seeking large pay increases.”

In 1969, a major report on agriculture done for the federal government was released. “Canadian Agriculture in the seventies” recommended the government reduce its involvement in agriculture plus phase out subsidies and price supports. It also said the farm population should be reduced, younger low-income farmers should leave farming while older non-viable farmers should be assisted to achieve a better standard of living. the report recommended that farmers shift from wheat and dairy, where surpluses were a chronic problem, to producing other commodities.

the Liberal government went in a different direction. Perhaps this was due to the forceful representations of its rural members, including Bud olson and eugene Whelan, or it might have been due to memories of what happened in 1957.

In 1957, the diefenbaker Conservatives

won prairie farmers’ votes after the st. Laurent Liberals had alienated the region by taking a hard-line against agricultural support, grace skogstad of the university of toronto writes in the June 2007 edition of The Canadian Political Science Review.

“When the Liberals were returned to office in the 1960s, farmers were able to pressure the government to enact a series of legislation to support agriculture, including price stabilization measures. As a result, government financial transfers to farmers tripled between 1957-58 and 1972-73.”

the government also enabled supply management.

By the late 1970s, dairy, poultry, and egg producers were all under national marketing boards that regulated domestic supply and prices and protected domestic products from foreign imports, she wrote.

Prairie grain farmers didn’t get the same level of protection. they received stabilization programs designed to blunt the impacts of depressed prices.

But things were changing for grain farmers. years of burdensome supplies, depressed prices and competition from u.s. sales that masqueraded as food aid to qualify for export subsidies came to a quick end in 1972-73.

In 1972, the soviet union embarked on what is called in the u.s. the “great grain robbery.” the soviet union had a massive crop failure and was in desperate need for grain. the soviets had bought on world markets before. In 1963, they quietly negotiated a deal to buy 6.8 million tonnes of wheat from the Canadian Wheat Board, much to the distress of the Americans. By the late 1960s, that looked like a one time thing. surpluses were again building.

In 1968, Prime Minister Pierre trudeau called u.s. President richard nixon and urged him to help save the International Wheat Agreement that had at least provided some price stability. nixon declined. In the face of lost sales, Canada dropped its wheat price by about 10 per cent and joined the fight.

But it seemed futile. grain inventories reached the point in 1970 where Canada and other nations established programs that paid farmers not to produce. this reduced production, but demand was so

low that inventories remained high.

But in mid-to-late 1972, the russians were back negotiating grain deals in Washington, Winnipeg and geneva. When the dust had settled, the soviet union had agreed to buy more than 24 million tonnes of grain from Canada, the u.s., Australia and others. Between 1971 and 1975, world trade in grains increased by 50 per cent from around 100 million tonnes annually to more than 150 million tonnes. the grain surpluses, which had been such a problem, evaporated. Farmers, who just a few years earlier were being paid to idle land, were encouraged to plant fence row to fence row.

All this was good for longsuffering grain farmers but livestock producers were caught. Prices for their biggest input had surged but many consumers, battered by the recession, were struggling and in no position to pay more.

the government was scrambling to find programs that would inject some stability. Marketing boards and supply management were areas in which they had legislative framework that could be built upon. this was most important for dairy, which continued to be in crisis. the opportunity was offered to others, including the hog and cattle industries, but only poultry and eggs joined dairy in adopting full-blown supply management.

In the context of the times, the roots of supply management may be traced back to political and economic events. the Liberal Party’s defeat in the 1957 election taught it that ignoring troubles on the farm would cost it votes and make it unelectable in large parts of the country. It was a mistake they wouldn’t repeat through the 1960s and 1970s. through those years, much of the policy that emerged came from a search for ways to stabilize agriculture.

In the early 1970s, the search for stability spread into other parts of the economy to counter the effects of a deepening worldwide recession. In this sense, supply management was not just a standalone program to stabilize chronic problems facing dairy and poultry, but part of a larger move to counter a deteriorating national and international economic situation. n

For a fully enriched future, get the “real results” and proven performance from the AVECH™II Enrichable and fully Enriched systems.

With over 50 million birds living and thriving in the AVECH™II, you get the peace of mind that comes from investing in a system that has a consistent and proven track record.

Customers are experiencing real results from installed and working AVECH™II systems:

in 1971 and 1972 canada’s egg industry was headed over a cliff. farmers and politicians decided it was time to take a different course.

b Y J IM K NISLEY

Forty years ago, ontario’s Progressive Conservative Agriculture Minister William (Bill) s tewart saw that ontario’s and Canada’s egg industries were heading for disaster. the only option was to change and the only sensible course was supply management.

speaking at the London Poultry Conference in June 1972, stewart said: “Anyone who has had anything to do with egg production in the last few months, yes, in the last few years, will know that it has been on a disaster course.”

stewart said the ontario government’s decision to give up on a failing system of laissez-faire wasn’t popular with consumer groups, some economists, and many corporate interests, but it was necessary.

“I recognized it was not popular,” he said. “I took (it) because I could see no other way to bring about some order out of what was definitely a chaotic situation.”

the chaotic situation in ontario in 1971 was caused by a massive oversupply of eggs that resulted in low prices and an estimated $6 million in lost income. harvey Beaty, chairman of the then almost powerless egg and Fowl Producers Marketing Board, said: “We are now in an entirely new ball game with a new set of rules. the old rules of supply and demand no longer work.”

he added that voluntary efforts to cut production weren’t working, lower

A sINGUlAR

AChIEVEmENT

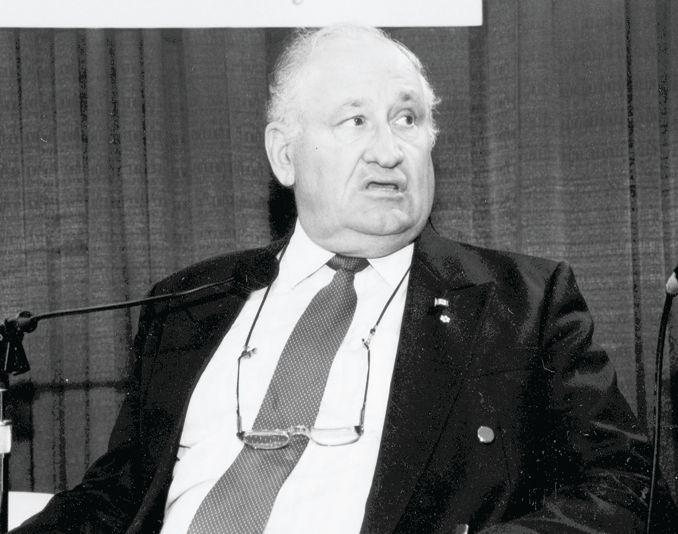

for former federal agriculture minister eugene Whelan, supply management brought order out of chaos and was a major step on the road to replacing rural poverty with prosperity.

prices were accomplishing little and “bankruptcies don’t seem to solve the problem either.”

ontario was far from alone. nova scotia set up a fund to offset losses by commercial egg farmers in 1970 and 1971 and was asking for federal assistance.

But the drive to supply management as a solution to the need for subsidies and an end to the chaos, as noted by stewart, was far from unanimous.

the Canadian Poultry and egg Council’s brief to the house of Commons standing Committee on Agriculture on January 12, 1971 strongly opposed Bill C-176, which would allow, with provincial and producer support, the formation of national marketing agencies.

the council, which represented the egg ad poultry processing industry, said marketing boards and national supply management would deny consumers “their right to the best value for their dollar, which can be achieved only through freedom and competition in the market place.”

Agriculture policy “should not be used as a vehicle for a social welfare program,” the council’s brief stated, adding: “A policy of regional balkanization, quotas and price fixing is not in the best interests of our nation or its citizens.”

John enns, a member of the ontario Broiler Chicken Producers’ Marketing Board, said “industry people” are selling politicians a bill of goods by saying “that

Canadian Trial Demonstrates the Performance Improvements of Vaccination with VAXXITEK® HVT + IBD.

In one of the largest Canadian field studies of its kind, more than one million broilers were vaccinated with VAXXITEK® HVT+IBD over four periods from June 2010 to February 2011. 1 At the end of the trial, the conclusion was clear. Vaccination with VAXXITEK HVT+IBD resulted in a substantial improvement, particularly in livability, number of condemnations and profitability.

Here’s what satisfied customers are saying: Learn more about the field studies, visit www. .ca or talk to your veterinarian today.

We started using VAXXITEK shortly after its launch and noted a big improvement in chick quality right from the start. Our customers reported fewer condemns and reduced mortality. Now we have customers asking for VAXXITEK-vaccinated chicks. We’re extremely happy with the results.

Ernie Silver, Hatchery Manager, Western Hatchery, Abbotsford, BC

any power granted to farmers or farm organizations is detrimental to the overall Canadian economy.”

What was detrimental to the economy was the chaos that sprang from a “loosely organized egg industry in Manitoba and ontario” that overproduced.

that overproduction formed part of the Chicken and egg War. Former Canadian Poultry (then known as Canada Poultryman) editor Fred Beeson summed up the war in a June 1971 editorial:

“Producers in some provinces have, through self-discipline, regulated their supply to fit the available market while other provinces, with no regulations in force, have consistently overproduced and dumped their products into regulated areas, many times at below cost.”

Quebec had no controls on broilers and was, Beeson said, “overproducing” broilers and shipping them into ontario and as far west as B.C. Meanwhile,

Quebec did control its egg production but ontario and Manitoba did not and they poured eggs into Quebec and Alberta. In response, the provinces decided to try to control product coming from other provinces.

that was unconstitutional. the power to regulate inter-provincial trade lay with the federal government.

“All industries need some regulation today and the poultry industry is no exception,” wrote Beeson.” Without regulation, we continually face a market collapse.”

the annual meeting of the Canadian egg Producers’ Council in August 1971 was filled with gloom tempered with a sliver of hope.

the gloom came from province after province reporting weak to terrible prices. As an example, nova scotia producer John Fisher said farmers in his province were experiencing the worst prices ever. henry Law of new Brunswick also told of

during the debate over provincial marketing boards and the eventual creation of supply management for the poultry and egg industries, the editorial position of Canada Poultryman was crystal clear – it was in favour.

not only was the long-time editor of the magazine, fred Beeson, in favour, he was leading the charge. he first wrote of the need for supply management in 1948. in 1964, when the industry was again in turmoil and provincial marketing boards were being proposed, debated and emotions were at their peak, he pulled no rhetorical punches. Beeson’s position was never clearer than in a november 1964 editorial.”hoping the other fellow will go broke is a poor way of evaluating the profit prospects of a business,” he wrote. “that’s the present state of affairs, let’s face it.

“don’t let us waste time pointing fingers at one another. (it’s) far better to face the fact we are not living in a period of scarcity anymore. We can, in any one season, quite easily double our production across canada. in fact, that’s the way we have been heading for several years; not making it because too many grow broke each year.

“it may well seem that we harp on this problem of overproduction and consequent low prices eternally in these editorials. We don’t apologize because this is the no. 1 problem of the industry.”

Within months of the establishment of the board, “here we were with no surplus broilers in B.c., none in the neighbouring provinces and a rising price.” in april 1964, Beeson argued the industry needed more than the marketing control allowed under some provincial laws. “one cannot help but feel that that it is not marketing control that is needed but production control,” he wrote. “our feeling is that it is this form of control that all other poultry groups need to ensure a continuing healthy marketing setup.

“if an industry has a surplus,” he continued, “there is no known method of maintaining a satisfactory price with or without a board short of destroying the surplus.”

a disastrous year. saskatchewan reported low prices because it is next door to Manitoba’s unmanageable surplus. Peter dyck from Manitoba said the production was the result of a heavy grain crop and poor grain markets.

harold Crossman of saskatchewan said he was tired of listening to Manitoba’s grain excuse. “Let me tell you that saskatchewan produces four times as much grain as Manitoba and if you want a fight, we’ll compete with your producers any day,” he said.” But if it comes to that, you won’t make money and neither will we so let’s be sensible about this.”

Meanwhile, A.d davey, director of the poultry division at the federal agriculture department, said: “Last year has shown what havoc results from a lack of planning.”

But planning in the egg industry was difficult. In ontario, broiler producers had approved a marketing board that could regulate production and imports

but the ontario egg and Fowl Marketing Board “is really only a step above a social club. the board has only been given the power to promote its products and do research into the market,” the Toronto Star reported in early 1971.

As the war raged, ontario egg producers balked at adopting a provincial board similar to the one for broilers. Brian ellsworth, secretary manager of the ontario board, told the Toronto Star (in an article reprinted in Canada Poultryman) that: “the pressure now is for a quota and price system, but it doesn’t appear that ontario producers will agree to it.” however, ellsworth said he believed producers would accept quotas under a national scheme, but not a provincial plan.

But the national plan met stiff opposition. the Toronto Star reported that not only were consumer and industry groups aligned against it, they were joined by the Progressive Conservatives and Creditistes in Parliament. s.J. Korchinski, Conservative member from saskatchewan, said Bill C-176 was the most “damnable” legislation he had ever seen. he claimed the legislation would allow the government to tell farmers what to do, where they are to do it, how much they are to produce and at what price. Quebec Creditiste MP said the legislation would turn the Canadian farmer into a “government employee with no freedom whatever as to his production.”

BIOvatorTM in-vessel composter. Quality compost in as little as four days.

Federal agriculture minister Bud olson said the authority contained in Bill C-176 was not new and the federal legislation simply allowed farmers to co-ordinate on a national level.

“this bill provides an opportunity for the agriculture industry to work together when it is in their interest to co-ordinate their efforts more effectively on a national basis,” he said.

It was “completely erroneous” to say the legislation would give government the power to take over an agriculture industry. “this legislation only provides for control over inter-provincial and export marketing, and gives the government no authority whatever to control marketing or production within a province,” olson said.

After Bill C-176 was passed, olson said in a memo to farmers that, “for the first time, farmers will be able to co-ordinate the programs of provincial marketing boards into a more effective national marketing plan.”

the legislation set the stage for the creation of the first national agency in the poultry industry, the Canadian egg Marketing Agency (CeMA) – now known as the egg Farmers of Canada –which was established in 1972 by the following proclamation:

“Know you that We, by and with the advice of our Privy Council for Canada, do by this our Proclamation establish an agency to be known as the Canadian egg Marketing Agency, consisting of fifteen members appointed in the manner and for the terms set out in the schedule hereto.

And Know you Further that We are pleased to specify that the farm product in relation to which the Canadian egg Marketing Agency may exercise its powers is eggs from domestic hens, and such powers may be exercised in relation to eggs produced anywhere in Canada.”

For eugene Whelan, supply management was a singular achievement: it brought order out of chaos and was a major step on the road to replacing rural poverty with prosperity.

In a recent interview with Canadian Poultry Magazine, Whelan said if he could travel back in time, he would continue to push for supply management because it was the best and only solution to the problems confronting farmers.

“I knew what we were doing. We’ve got a good system,” he said.

Before supply management, the insecurity on the farm ripped through the supply chain with feed mills never knowing how much they would sell, or, in some cases, if they would get paid, he said.

As for the recent debate on whether supply management should be abolished, he finds it lacks substance. “the writers don’t know a thing about agriculture.”

Comparing beef to dairy or grain with perishable commodities is just wrong, he said.

Looking back at the debate and discussions that took place 40 years ago and comparing it to what passes for debate today, he said when it comes to agriculture and agriculture policy, people are “less knowledgeable today than they were then.”

e stablishing supply management was far from easy, according to ralph Ferguson, charter member of the national Farm Products Council and former federal agriculture minister. even before he was elected to Parliament in 1980, Ferguson was active at the grassroots level and played a large role in ensuring that supply management was accepted as part of the policy platform of the Liberal Party.

In addition to the Liberal Party, Whelan said that Ferguson also played a major role in ensuring supply management was accepted in the countryside.

this wasn’t easy, Ferguson said. But by the end of a raucus debate at the Liberal Party convention, rural party members and rural MPs had carried the day, making national supply management official party policy.

An egg producer himself, Ferguson knew the problems on the farm. you’d order supplies months in advance and never know the price you would get for the eggs. “After supply management, we were able to establish a stable price,” he said.

Ferguson said he and other rural party members “saw that something had to change.” the situation was bad and getting worse with unstable prices and increasing corporate control of farming. Marketing boards and supply management allowed farmers to work together and “take control of their own destiny,” he said.

the current attacks on supply management are nothing new, he said. “It sounds like the old debate.”

Carolynne griffith, chair of the egg Farmers of ontario, said there was chaos in the marketing of eggs and poultry 40 years ago and most farmers recognized

Continued on page 39

Your input costs are at record levels—and we know you need better flock performance.

delivers.

cantly

a successful innovations conference ended a very busy year for the Pic

bY T IM N ELSON , Ex ECUTI v E D IRECTOR

At this time of year, it’s good to reflect on what the past year has brought, and what is to come in 2012. We’ve had a very busy year at the PIC, culminating with the Poultry Innovations Conference, held nov. 10 and 11 at the Best Western Lamplighter Inn hotel and Conference Centre in London, ont. this was the first year the conference was held in London… and it certainly won’t be the last! this was clearly a good move as, despite incredible weather for farming, attendance rose by approximately 25 per cent from the previous two years to a tremendous 265 attendees. What follows are some of the highlights of the conference. should you require any further information, please don’t hesitate to contact us at PIC.

the conference was preceded on the morning of nov. 10 by a special forum, “Better Farmer health, Better Farm Business.” the forum presented some very sobering statistics on farmer health from Australia, which according to regional general practitioner dr. rob Annis from the Listowel Family health team, is likely to be repeated in ontario. however, we don’t know how we truly fare because we don’t have statistical information in Canada that separates farmers out from rural populations.

It turns out that producers do not fit the popular stereotype of being “robust, fresh air, plenty of exercise, healthy lifestyle” individuals. In fact, the situation is quite the opposite. hypertension (high

a change in venue and a stimulating mix of technologies and tools for the future led to an increase in attendance at the Pic’s Poultry innovations conference.

blood pressure), obesity, high cholesterol, alcohol abuse, chronic fatigue, suicide, cancers – all very serious, life threatening conditions – are significantly higher in producers than the national average.

In Australia, a program called sustainable Farm Families, developed by farmer, professor and public health nurse dr. sue Brumby, is tackling the issue head on.

dr. Brumby was the keynote speaker at the forum, and she described how farmers identify their health risks and make necessary changes and the beneficial effect it has on their lives, and consequently their businesses. the point was made quite clearly that if you are unwell, your business suffers and you put yourself at risk of having an accident, which will exacerbate the existing situation on the farm caused by your illness.

dean Anderson, chair of the Canadian Agricultural safety Association (CAsA), left us in no doubt that the risks involved with cutting corners on safety (and let’s face it, when we’re below par or in a hurry, we all do it) far outweigh the cost and time of keeping safe. What do we do? Plan to ensure you stay well. get regular health

checks, don’t push yourself beyond the limit when you are not 100 per cent – you could risk losing more than a few dollars. do we need an awareness-raising, proactive program such as sustainable Farm Families in ontario? Probably, but the first step is to engage with the health profession. this profession was well represented at the forum, with half of the 67 people in attendance at the session coming from the health sector. Feedback from the workshop is that health professionals want to engage with agriculture, so over the next year PIC will be working to facilitate this and we look forward to industry support.

If you feel that your health is and should be an important issue that you may not have been addressing or if you’re not sure whether you look after yourself properly, ask your wife.that’s what they did in Australia and they got a pretty definitive response, which I’ll leave you to ponder.

the Innovations Conference was a stimulating mixture of current issues and future

On April 25, 2011, the Quebec and Canadian agricultural communities lost one of their greatest builders, Ovila Lebel Mr Lebel was an egg farmer based in Saint-Félix-deKingsey from 1964 to 1982 and he also served as founding president of the Fédération des producteurs d’oeufs de consommation du Québec (Egg Farmers of Quebec).

Thanks to his efforts, Quebec’s first provincial joint plan was created in 1966 Mr Lebel also oversaw the creation of the province’s first compulsory marketing board FEDCO, which operated from 1970 until 1985, as well as the founding of the Canadian Egg Marketing Agency in 1972 (now Egg Farmers of Canada). A man of action and of his word, he was able to break the ice for the other farmer-led commodity groups in Quebec

As a visionary and forward thinker, Ovila Lebel fought some epic battles over the course of his career “Nothing can resist the strength of a group united under common objectives,” he declared to egg farmers in 1975 at their annual general meeting.

“ … Nothing can resist the strength of a group united under common objectives”

His exceptional involvement in the agricultural cooperative movement earned him a place in the Temple de la renommée de l’agriculture du Québec in 2002 : “What is important is that which remains. What really counts are the successes of the Fédération.”

The Fédération des producteurs d’oeufs de consommation du Québec, the Union des producteurs agricoles (UPA) and Egg Farmers of Canada wish to honour Ovila Lebel’s memory to ensure the important role he played in the history of our agriculture will never be forgotten

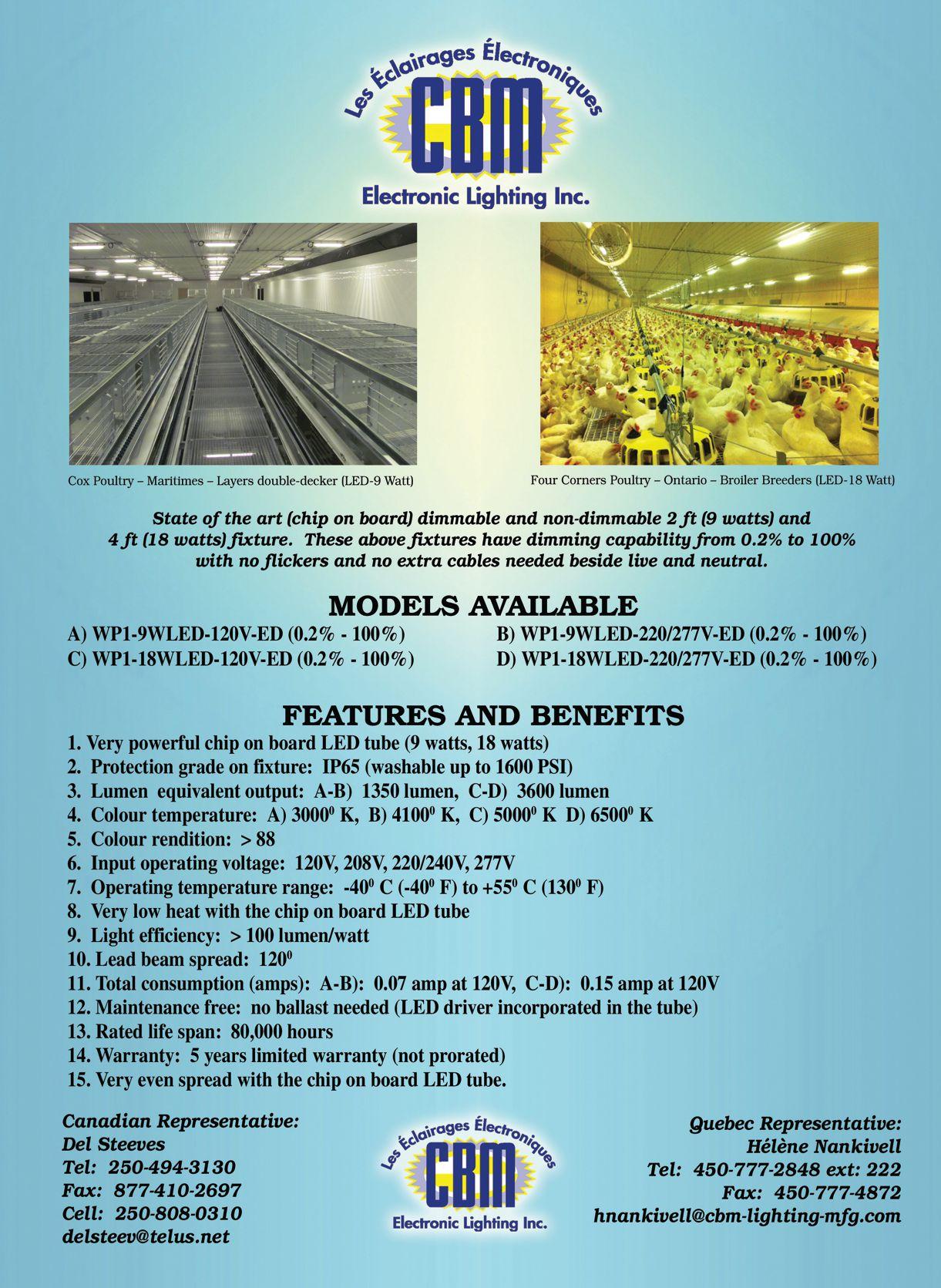

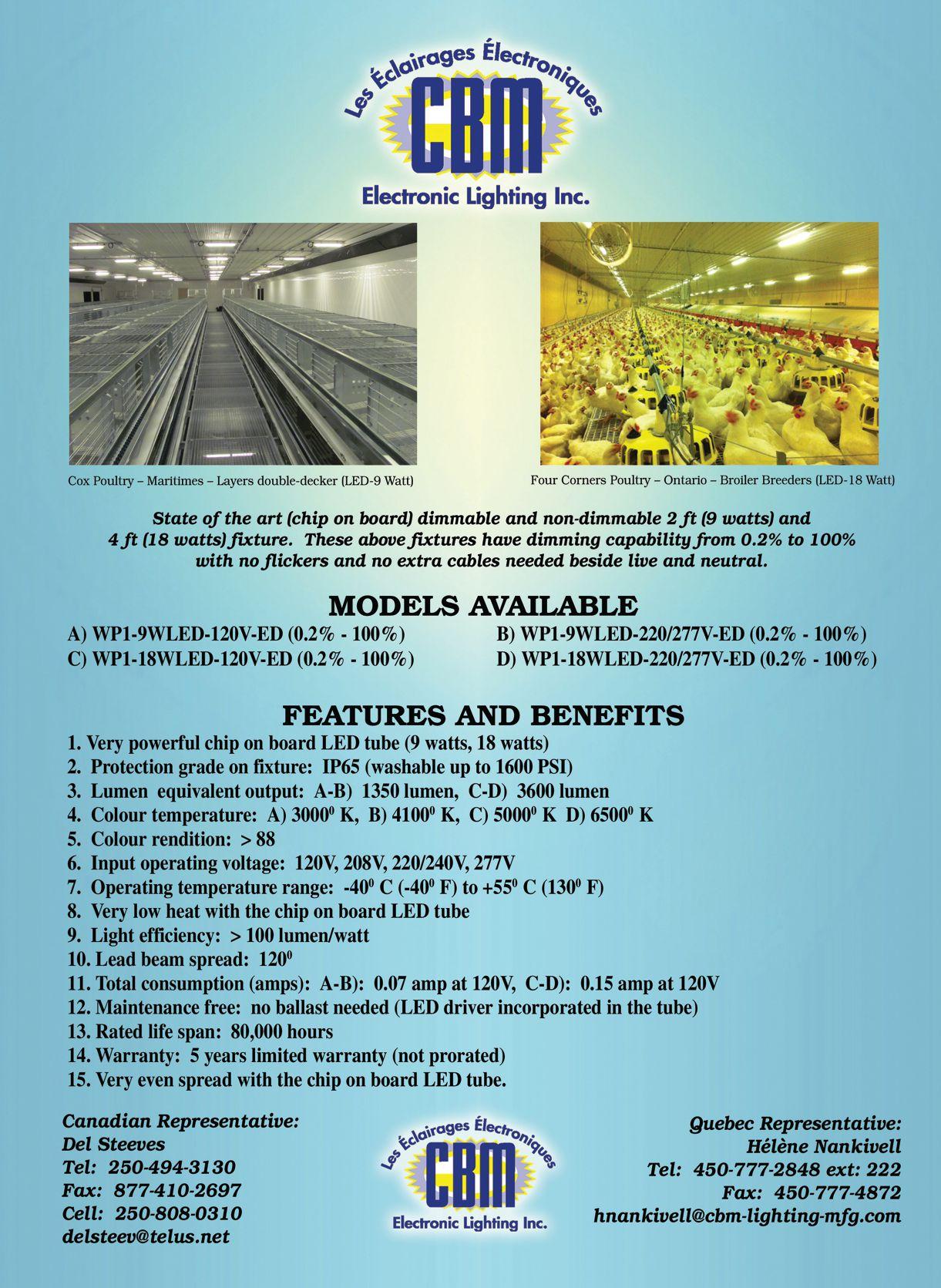

tools, delivering information on how to make your businesses more efficient and profitable. Lighting took up a significant portion of the discussion both in the lecture hall and around the coffee and lunch tables. We heard from local, interprovincial and international speakers, all of whom had a very similar message – to some extent, we’ve taken lighting for granted. times have changed. With a much greater emphasis on the productivity impact of light intensity and light spectrums, we now have the potential to manage our flocks using light to positively influence productivity and flock care, in addition to daylength manipulation.

Led lights are now being manufactured that will meet specific needs of the animal that will be exposed to it. they are also getting tougher – it’s likely that many of you reading this will have at some point wished for a bulb that didn’t explode when you hit it with the hose or knock

it when moving equipment. good news, there’s one on the market that you can throw across the room and it won’t break. new information technologies were demonstrated and discussed at length. It seems we’re a bit behind other agricultural sectors in the development of smart tools to assist with business decisions and increase our efficiencies. rob hannam from Agnition, a technology company that specializes in developing mobile applications for agriculture, demonstrated for us a phone application that advises the sowing rate for soybeans and phone tools that advise which elevator is paying the best price at a particular time. I’m not sure we have this sort of poultry business tool available yet – but we should and will. We also heard how Abbotsford, B.C. poultry manager scott salter has implemented cameras in his barns, and learnt that this type of time saving technology is slow to be adopted. other high-quality

technical information presented included everything from calibrating medicators to identifying egg defects.

At the PIC, our aim is to bring you more of this type of information over the next 12 months, combined with the usual messages and information about general good management and best practices. As we said at the end of the conference, if you attended this conference you would be able to go back to the farm and save money – no question. the conference is also a great time to meet old friends, make new ones and it provides an unprecedented opportunity to discuss similar issues amongst the sectors and learn from one another. don’t miss it next year.

Also look out for the upcoming Producer updates and the last of the growing Forward funding workshops in the next month or so.

From all of us at the PIC, we wish you a prosperous and healthy 2012. n

bY T REENA H EIN

Effective food safety is a matter of using many tools on many fronts, and the more tools we can use and the more effective they are, the better. While standard methods of safeguarding cleanliness and safety along the entire supply chain will never diminish in importance, new biotechnologies have the potential to boost food safety in industrial settings.

“Food processors have been slow to harness defence systems that Mother nature has provided, but are making progress,” says dr. ron Wasik, president of delta, B.C.-based rJW Consulting Canada Ltd., which specializes in providing technical services to the food processing and food service industries. “health Canada and the Canadian Food Inspection Agency are aware of the potential of using these types of technologies, and have approval procedures in place for both viral and bacterial applications. At the same time, consumers are now more knowledgeable, open-minded and willing to try naturallyprotected products.”

A new technology on the packaging front promises to make ready-to-eat and raw meat safer through the use of certain viruses (phages). “’Bioactive paper’ offers one of the best approaches for food safety monitoring because of its low cost, simplicity and rapid response time,” asserts dr. Mansel griffiths, director of the Canadian research Institute for Food

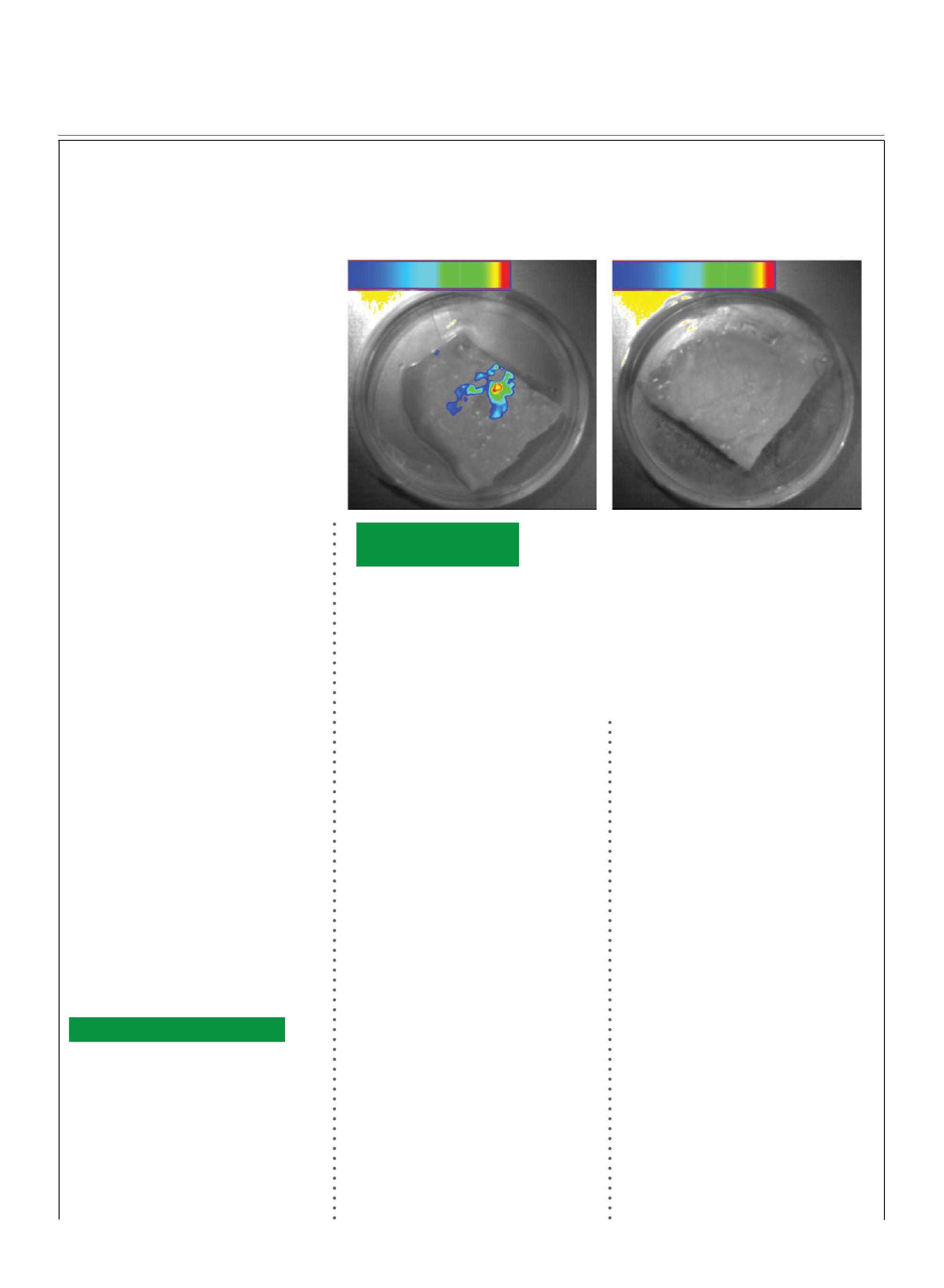

ready-to-eat meat covered with the tested cellulose membrane without phage present shows E.coli present. (right) ready to eat meat covered with the tested cellulose with the phage present in the cellulose membrane shows E.coli no longer present.

safety at the university of guelph.

griffiths is also a researcher at the sentinel Bioactive Paper network (see sidebar). he and his sentinel colleagues have developed a system where phages attached to packaging paper attack pathogens such Listeria and E. coli o157:h7 that can lurk on the surface of meat. “Phages” is a short form for bacteriophages, which are viruses that are harmless to us but that can kill bacteria. While the discovery of phages was accomplished by Canadian-born microbiologist Félix d’hérelle in 1917, they have not been studied to any great extent in europe or north America (instead, the food safety focus here was put on chemical antimicrobials). however, scientists in russia and eastern european countries have been using phages with some success for over six decades.

After attachment to the surface of a bacterial cell, phages enter and take over the cell’s genetic machinery to produce new copies of themselves. once a critical mass of phages is created, they synthesize

enzymes that dissolve the bacterial cell wall, causing it to break apart.

the main challenge in creating the sentinel technology was to genetically manipulate the phages so that they adhere to the paper but then move into any bacterial cells on the surface of the meat. “We’ve been working for five years on achieving stabile immobilization of the phages at levels that make it effective for pathogen control,” griffiths explains. “the phages have to stick, but stay alive, and we have demonstrated that phages attached to cellulose paper are still active after nine months.” sentinel’s technology works on meat kept at refrigeration temperatures, as well as meat kept in modified-atmosphere and vacuum-packs.

In terms of pathogen control, the sentinel scientists have yet to fully optimize the system so that control can be achieved more quickly. In studies published by griffiths and his colleagues so far, it took 12 days at 4˚C to eliminate 100 E. coli o157:h7 cells/gram in raw, whole beef pieces. griffiths acknowledges

that under these storage conditions, “to a certain extent it’s true that the beef would have been spoiled in four to six days.” In their trials involving control of the pathogen Listeria monocytogenes (Lm) on oven-roasted turkey breast, the sentinel scientists found that after about three to six days in most treatments, Lm recovered from initial levels of inhibition caused by phage attack, and then grew slowly (that is, the biopaper initially reduced Lm growth but did not prevent it over 15 days at 4˚C). Many lunch meats normally have a 30 to 60 day shelf-life at 4˚C. overall, griffiths calls sentinel bioactive paper “another weapon in our food safety armoury. Like any technology or technique, it’s not a magic bullet.” one of the technology’s limitations is that it targets bacteria on the surface, while bacteria could also be lurking inside (in items like ground meats and uncooked sausage). griffiths says that newly created phages on the surface could possibly migrate into the meat. however, viruses have no propulsion systems and so their movement in non-liquid environments is severely limited (many types of bacteria and other microbes have mobility mechanisms such as whip-like flagella). Another limitation is that bacteria will

eventually develop resistance to phages, but griffiths says this can be overcome by using a battery of different phages. Limitations to any surface-focussed food safety technology or technique are why, according to experts such as rick holley (a professor of microbial ecology of food and food safety at the university of Manitoba, and a former member of the Canadian Food Inspection Agency academic advisory panel), other methods that control pathogens throughout meat tissues have greater potential to reduce pathogen risk. these include irradiation of fresh meat or using substances such as

Quick facts:

• Key goals include production of paper that gives instant visible indication of pathogens, and high-speed manufacturing using inexpensive coating and printing technologies

• Bioactive paper could be used to create:

| face masks that protect health-care workers

| paper towels that immediately detect contamination on kitchen counters

| wipes that detect bacteria in hospitals such as Clostridium difficile

| paper that detects and/or removes pathogens from water

| air filters that could detect air-borne pathogens such as the bacteria that causes legionnaires’ disease.

| dressings that better prevent infections after surgery

• location of administrative centre: mcmaster university in hamilton, ontario

• Brings together 28 researchers and more than 50 graduate students and postdoctoral fellows from 10 universities, with industry and government partners

• operating with $7.5 million in funding over five years (2010-2015) from canada’s natural sciences & engineering research council/national research council and another $4.5 million from industry partners such as sc Johnson and fPinnovations for more information, visit: www.sentinelbioactivepaper.ca

lactate plus diacetate in cured meats. Applying phages to the paper involves creating an electro-static charge on the paper and then dipping it in a solution containing the phages. At the same time griffiths and his team are optimizing the pathogen control aspect, another sentinel team is making good progress on developing a commercial-scale biopaper production process. After the product is fully commercialized, griffiths says sentinel scientists will move on to creating systems that control other pathogens and systems that detect contamination (see sidebar).

Besides viruses, naturally occurring bacteria can be added to food to prevent the growth of dangerous bacteria. the added bacteria reach large numbers that result in conditions less conducive to the growth of other microbes, by doing things such as limiting access to nutrients or modifying the ph of the environment. one such commercial product is Micocin, a food additive containing a strain of naturally occurring bacteria, produced by toronto-based Micocin Worldwide. It was approved by health Canada a year ago for use in vacuumpacked products such as wieners, and sliced roast beef, ham and turkey. It provides targeted protection against Listeria and is applied to the product surface. In hot dogs/ sausages, a small liquid solution is applied to the package and when vacuum packed, it distributes throughout the surface of the product. In sliced products, the solution is

The Poultry Service Industry Workshop thanks the following sponsors for their continued support which allows the planning committee to provide a strong education program as well as various social networking opportunities.

sprayed over each face of the slice during the slicing process.

there are other non-biological food safety developments as well. In June 2009, Canadian Poultry magazine reported that u.s. department of Agriculture (usdA) researchers had developed a process that further protects pasteurized liquid eggs from food safety threats such as spoilage bacteria and pathogens such as salmonella. the technology, called “crossflow microfiltration membrane separation” (CMF), removes more pathogens than thermal pasteurization without affecting the eggs’ ability to foam, coagulate, and emulsify. this means CMF-treated eggs can be substituted for pasteurized eggs in products where those characteristics are desired, such as cakes and mayonnaise. however, research leader dr. Peggy tomasula says using CMF in combination with pasteurization is best to maximize reduction of pathogen threat. her colleague, usdA research Chemical engineer dr. sudarsan Mukhopadhyay, says they have signed an agreement with Michael’s Food, the largest liquid egg processor in north America, and hopes for commercialization in the next two to three years.

Purac is one of a number of companies that offer substances that extend the shelf life of meat/poultry products. their offerings include PurAsAL (sodium and potassium lactate formulations) and ProteCt-M, a compound containing Lauric Arginate that’s applied to the surface of meat products, and approved for the north-American market.

AiroCide, based on technology developed at nAsA in the 1990s, is an air-based decontamination system that claims to completely destroy a wide range of airborne pathogens, as well as volatile organic compounds and odours. It can be used anywhere from barns to processing plants to meat packing plants. It works by drawing air over a titanium dioxide catalyst that is irradiated with uv light. the technology is extremely low maintenance and requires little power.

Wasik notes that other substances and substrates are being investigated as well. For example, antimicrobial elements such

helps protect your birds against both Marek’s Disease and Infectious Laryngotracheitis with no risk of spreading ILT.

Innovax-ILT is a brand new kind of vaccine that protects your flocks from both Marek’s Disease and Infectious Laryngotracheitis (ILT). Applied at the hatchery, it makes field vaccination unnecessary. As well, since Innovax-ILT does not induce ILT, potential reactions or house to house spread that may be associated with some other classic live ILT vaccines are virtually non-existent1

Talk to your veterinarian or hatchery today about making Innovax-ILT the cornerstone of a new vaccination program that can improve the overall respiratory health of your flock.

b Y J IM K NISLEY

light emitting diodes (Leds) appear to be the light of the future in the poultry industry. speakers at the recent Poultry Innovations Conference described the energy savings, the durability, the environmental benefits and even the prospects or possibility of improved production.

susan sullivan from the Center of excellence for Poultry science at the university of Arkansas said recent field tests and studies showed that Leds provide significant energy savings compared with incandescent lights, they are more durable and longer lasting than compact fluorescents (CFLs), maintain their lighting effectiveness and support good bird performance.

sullivan noted that light-emitting diodes (Leds) are up to 80 per cent more energy-efficient than traditional bulbs, depending on brand and use. this can result in significant savings off the electricity bill for a typical poultry farmer.

sullivan said the university took a hard look at energy when it decided to retrofit its barns. An energy audit revealed that about 31 per cent of the electricity used in a poultry barn goes to lighting, and about 50 per cent of the electricity was used by the big fans. While the fans are the biggest energy users, the replacement costs were high and only limited energy savings would be realized by replacing the fans. Changing lights was much easier and lighting technol-

ENERGY sAVINGs

studies show that leds cut energy costs significantly, and have greater durability than cfls. shown here are 30-watt agrilamps from glo lighting.

ogy has advanced rapidly in a very short time, she said.

“Lighting technology has come a long way in a few years and presents a great opportunity for savings.”

When the project began in 2006, Leds weren’t available, but CFL’s were. s tudy results indicated that replacing forty 60-watt incandescent bulbs

with energy efficient lighting, such as 8-watt cold cathodes or 15-watt CFLs, resulted in a 66 per cent saving in lighting energy usage in a six-week growing period and 75 per cent lighting energy saving for an eight week grow-out when the 60-watt incandescent bulbs were replaced.

But there were challenges. Many poultry

producers have installed CFLs and while the savings are real, there can be problems, including short life span and significant loss of light output due to lamp lumen depreciation and dust accumulation – particularly on the spiral compact fluorescents.

Another problem came when the university decided to replace 600 CFLs and were told that because they contained mercury they had to be treated as hazardous waste and shipped to a disposal site. sullivan said that if she had tried to transport the bulbs herself, she could have been charged with transporting hazardous material. the total cost for transport and disposal was $625.

When Leds became available in 2008, the Arkansas study team decided to see if Leds were a viable option.

they found significant energy savings over incandescent, and greater durability than CFLs.

the field study was then expanded to include 20 farms that had two years of documented energy use, and light readings were taken across the barns.

some barns had used strictly 100watt incandescent bulbs for their broilers, some used 60-watt and 100-watt incandescent bulbs and one grower used fluorescent tubes, she said.

After the Leds were installed, farmers reported the birds were getting off starter feed faster, growing bigger and birds were more passive.

All lights were first evaluated in one of the four broiler houses at the ABrF unit. three different Led lamps were evaluated, and energy savings was found to be 80 per cent or more compared to incandescent bulbs and bird performance was not compromised.

In the field demonstration, three Led bulbs were compared to the energy efficient lighting technology currently used by the industry which included cold cathodes dimmable compact fluorescent lamps (dCFL).

the 19 demonstration farms represented different bird slaughter weights ranging from 3.6 to 9.5 pounds and grow-out cycles ranging from 37 to 66 days.

the majority of participants were fourbarn farms with one three-barn farm; two two-barn farms, one 10-barn farm and one six barn farm.

the majority of the barns in the demonstration had grow lights on 20 foot centres over the feed lines with brood bulbs located every 10 feet between the grow lights on the brood end of the house.

Light intensity at floor level was measured in a grid pattern and averaged to provide a reading for the barn.

the most significant finding was how little brood light farmers had prior to installation of the new brood and grow bulbs.

the second most significant finding was the dramatic loss of average light (50 to 80 per cent) over time from the CFL lights installed for brooding. over the same time period, the Led lights lost 16-28 per cent.

however, one brand of Leds failed. this was the result of poor chip quality from a supplier who opted for lower quality in order to cut cost.

sullivan said that the use of lower quality lights in a poultry barn environment can be very costly.

the farm study found that the Leds demonstrated enormous energy savings compared with incandescent lights. the savings averaged 81 per cent compared to incandescent bulbs – $126 per flock with an electricity price of 10¢/kWh.

Another significant finding came when one farm experienced a lightning strike, which knocked out the electrical meters as well as other equipment. none of the Leds was lost.

the bottom line is that Leds are an option for broiler production. Quality Leds designed for poultry environments are durable and support optimal bird performance. the overall costs are comparable to energy efficient alternatives.

the study also determined that Led lights need to be cleaned regularly to assure peak performance.

John Matcham, of glo Lighting, surrey, u.K., said that Leds are far superior to incandescents and CFLs. the company’s AgriLamp has an expected lifespan in excess of 35,000 hours while maintaining 75 per cent of its original output – 10 times longer than incandescent light, which results in long-term cost savings. It is also non-toxic and can be safely and easily recycled.

It flickers less than CFLs, which results in a calmer flock because birds are more susceptible to flickering than humans, and is fully dimmable, which results in an improved feed conversion rate.

CFLs were a quick fix for the energy issues facing society, but are not a long-term answer, he said. they contain methyl mercury, which is a hazardous substance, and require special disposal. they are also fragile and can be damaged or broken by cleaning and by pressure washers.

Led also allows the light to be modified so that it is best suited to poultry, as the wavelengths required by the birds are not the same as those for humans. n

Our Growth. Your Gain. Pfizer Animal Health Global Poultry’s recent acquisitions of Alpharma Animal Health and Synbiotics products mean more solutions for better results in your poultry operation. From devices to vaccines to feed additives to diagnostics—with comprehensive support behind it all—we are more prepared than ever to help you run a healthier, more productive operation. For more information, talk to your Pfizer Animal Health representative or visit pfizerglobalpoultry.com.

King/Alpharma is now part of Pfizer Inc. The integration of King/Alpharma and Pfizer entities may be pending in various local jurisdictions and integration may be subject to completion of various local legal and regulatory obligations. All content in this message is subject to works council and/or union consultations, if applicable, and other legal requirements where appropriate.

maurice and alain richard are the first to use enriched cages in Quebec, and their layers are taking

full advantage of the extra space and accessories

After being housed in conventional cages for decades, you’d think layers would have forgotten some of the natural behaviours of their ancestors. At least that’s what Maurice richard thought, but in his all-new layer barn, he’s observing hens doing things they never do in his other two barns.

Ferme Paul richard et fils is located in Abitibi, Quebec’s northernmost agricultural frontier. the farm is the first in the province to install a fully enriched housing system. the layers arrived in mid-september, and co-owners Maurice and Alain richard immediately noticed how the birds took full advantage of the extra space and the accessories the system offers.

In the new 28,000-layer house, birds are housed in groups of 60, in cages 3.6 m long and 1.25 m deep. the system chosen by the richard’s was Farmer Automatic’s Layer Cage eCo system, distributed by Clark Ag systems Ltd. this system meets europe’s 2012 animal welfare regulations (directive Cee 2012). each cage provides perches, a large nesting area, a scratch area, 80 per cent more floor space and a volume of air that is three times greater than in conventional cage systems. the cages are designed specifically for layers to express their natural behaviors. “At night, they all get on the perches to sleep, and 95 per cent of them use

maurice richard (second from right) and his brother alain (right) are pleased with their decision to install fully enriched housing. also shown is maurice’s sons Jean-Phillipe (left) and alexandre (second from left).

the nesting areas to lay their eggs,” says Maurice richard. he says the birds are also fond of the scratch pads and seem to enjoy using the ample space to open and stretch their wings. the system also features automatic manure removal. the manure is dried with a drying system and each row of cages has a manure belt underneath. the richards also installed Farmer Automatic’s Manure Pellitizer, which takes the dried manure and compacts it into small pellets. the richards some of these pellets to other farms or for mine site rehabilitation, and use the balance on the farms’ 1000 acres.

Before making the change to enriched housing, richard says he weighed out the options for two and a half years before going ahead. he visited farms in england, France, the netherlands and germany and read several studies. Although he incurred a cost overrun of $400,000 for a total construction cost of $ 1.5 million, he is convinced he made the right decision. the difference with conventional cage systems is stunning, says richard. “It’s a lot better for the birds and we also feel better when we look at it. the hens are a lot calmer. they feel at ease and they are not the least bothered when we walk by them.” on october 11, 2011, the richard

There are plenty of phytase choices in the market, each trying to break through the clutter by introducing a unique “benefit” that may not be any benefit to you at all. At DSM we’ve decided to level the playing field. The bottom line: when comparing phytase sources, all that matters is the cost of product form to release equivalent amounts of phosphorus.

To learn more about how to evaluate phytase, go to www.phytasefacts.com, or call 1 800 526 0189.

family held an open house for industry members. they insisted on hosting the event after the birds arrived. “People were allowed to go everywhere in the building. they saw the difference in the birds’ behavior,” richard says. the guests had to abide by biosecurity measures, even Pierre Corbeil, the provincial agriculture minister and the local Member of the national Assembly.

some of the system’s benefits can already be measured. the hens start laying at a younger age and mortality is a lot lower, says richard. If it wasn’t for the few birds that fall asleep below the perches and remain stuck too long before they are freed, mortality would be almost inexistent, he says.

the birds also seem to be eating a little less, but richard suspects this could be because the building is better insulated than the farm’s two other houses. According to richard, layers in enriched

cages are more active, but this does not translate in higher feed consumption than in conventional cages.

humidity levels are also lower in the building. that could be due to better ventilation, but also to the greater volume of air per bird, allowing excrements to dry faster.