Celebrating Genetic Progress

Celebrating Genetic Progress

Original geneticists gather in Alberta

Original geneticists gather in Alberta

FROM THE EDITOR

BY KRISTY NUDDS

New Challenges, New Opportunities

In late September a Saskatchewan poultry producer faced a situation feared by poultry producers worldwide: AI. But the Saskatchewan poultry industry was ready to handle such a situation and did an exemplary job. Those involved credit the national agencies and the government for working with them to plan for such an event to ensure minimal impact and that media messaging was clear and concise.

It’s a great example of how the industry works together in the face of a challenge. But it also served to identify once again that there are many lessons still to be learned.

This month’s issue has a strong focus on how the poultry industry in Canada is preparing for new challenges in the years to come, and how it continually strives to learn from its past. Measuring how far we’ve come and how we utilize information is key to accomplishing, and measuring, significant and meaningful progress.

As we’ve seen in the past several years, consumer perception with regards to welfare and food safety will continue to be a key issue for the poultry industry. Several months ago the first National Farm Animal Care Council conference was held in Ottawa, where attendees discussed how consumer pressure is changing animal welfare and the challenges relating to how meaningful measurements of welfare can be determined (see page 32).

As identified by one of the conference presenters, Dr. John Webster from the University of Bristol, the genetics of the bird also play a significant role and that in Europe. For example, slower growing broilers are raised for those companies that demand increased welfare standards by requiring that broilers have greater leg strength.

To satisfy many of the welfare demands placed by consumers and retailers, the genetics of the birds used will likely play a key role

in satisfying these demands.

How genetics has changed poultry production was the topic of a unique gathering held in Edmonton in late November (see page 12). There, geneticists who worked to bring affordable chicken to consumers discussed how their early work led to the breeds that we know today.

Years ago, it was essential that birds grew faster on less feed to reduce costs for both the grower and consumer. However, as noted by several presenters, selecting primarily for growth and livability has had some serious metabolic and skeletal consequences, many of which have been identified as welfare concerns by interested groups. Changes demanded by consumers and interested groups to improve welfare and reduce chemical use have led many industries around the world to shift production from higher intensity to alternative systems. However, shifting to such systems presents its own unique challenges that are yet to be quantified.

As Dr. J.P. Vaillancourt discussed at the Poultry Industry Council’s annual health conference (see page 22), these new production systems could potentially have an impact on the epidemiology of disease. More than ever before, producers need to be vigilant with biosecurity and communicate with neighbouring producers, especially in areas of high density.

As we start the new year, it’s important to remember that these “challenges” can also bring opportunity. Consumer and retailer demands are offering new markets. Researchers at the University of Alberta are using preserved strains from the 1950s and 1970s to do comparative work with modern strains, helping them to identify the tradeoffs seen by selecting for accelerated growth. Not only with respect to welfare, but also with respect to food quality. ■

January 2008 Vol. 95, No. 1

Editor

Kristy Nudds – knudds@annexweb.com

888-599-2228 ext. 266

Contributing Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com

888-599-2228 ext 234

Production Artist

Krista Misener

Editorial Director

Drew McCarthy – dmccarthy@annexweb.com

VP/Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: cnowe@annexweb.com.

Periodicals postage paid at Buffalo NY. USPS 009-324, ISSN 1703-2911. Published monthly by Annex Publishing and Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St. Buffalo NY 14240. US Postmaster send address change to PO Box 611 Niagara Falls NY 14304.

Printed in Canada ISSN 1703-2911

Circulation

e-mail: cnowe@annexweb.com Tel: 866-790-6070 ext 207 Fax: 877-624-1940

Mail:P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 25.20

(includes GST – #867172652RT0001)

USA – 1 Year $ 60.00

From time to time, we at Canadian Poultry make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. We acknowledge the financial support of the Government of Canada, through the Publication Assistance Program and the Canada Magazine Fund, toward our mailing and editorial cost. Nous reconnaissons l’aide financière accordée par le gouvernement du Canada pour nos coûts d’envoi postal et nos coûts rédactionnels par l’entremise du Programme d’aide aux publications et du Fonds du Canada pour les magazines. www.canadianpoultrymag.com

WHAT’S HATCHING HATCHING

ABF Label Change Ordered

In late November the United States Department of Agriculture (USDA) ordered Tyson Foods Inc. to remove its “raised without antibiotics” label on some of its fresh poultry products.

The USDA told Tyson it made a mistake when it approved the company’s use of the label earlier this year. Tyson officials said in a statement that they disagree with the decision, but the company will submit modified labels for approval.

In a letter dated Nov. 6, 2007, the USDA alerted Tyson to the change and gave the company 45 days to change its label or adjust the feed rations it gives its birds. Tyson’s feeding plan lists animal medications known as ionophores, something the USDA has long considered to

be in the same class as antibiotics. This oversight prompted the USDA to change their mind on the original decision to allow Tyson to use the “raised without antibiotics” label back in May 2007.

In a statement Tyson said that “we do not believe ionophores are antibiotics. The FDA is the agency Congress has authorized to regulate animal drugs and it specifically excludes ionophores from the list of animal drugs deemed as antibiotics.”

“We stand by the truthfulness of our product labels and remain fully committed to our Raised Without Antibiotics chicken program.”

Tyson said it did not expect any disruption in its service to customers.

“We also expect no disruption in service to our customers.”

Last May, USDA officials approved Tyson’s labelling proposals for Raised Without Antibiotic chicken and were fully aware of our company’s

use of ionophores as a chicken feed ingredient. However, in early September, USDA suddenly reversed its position and gave Tyson several options, including the removal of the “Raised Without Antibiotics” claim, a change in its feed formulation or the submission of a new label application.

Tyson said that the additional wording on the modified label states that no ingredients have been used that could create antibiotic resistance in humans, which is the major reason anyone is concerned about antibiotics in poultry production.

In its statement Tyson quotes Margaret Mellon, director of the Food and Environment Program for the Union of Concerned Scientists, as saying she was concerned that the Department of Agriculture’s decision would cause consumer confusion and do nothing to promote human health.

Milestone for Poultry Research

through research.

The Chicken Farmers of Canada (CFC) recently announced that its National Research Endowment Fund has reached a milestone five million dollars.

The fund was created in 2002 to foster innovation, science and education within the poultry industry

Scholarship Winner

The first recipient of the Deborah Whale-Poultry Industry Council Graduate Scholarship is Milton Daley, a PhD candidate studying at the University of Guelph. Daley’s areas of emphasis are biomedical toxicology and poultry nutrition and his thesis topic is “The Effects of Mycotoxicosis and Coccidiosis Interactions in Poultry”.

He completed both his B.Sc. And M.Sc. at Texas A&M University. Prior to his B.Sc. he received an associate of science degree in general agriculture from the College of Agriculture in Pasley Gardens, Jamaica. After completing his PhD studies he hopes to return to his native Jamaica and work with the Animal Research division with the Jamaican ministry of agriculture.

The Deborah WhalePoultry Industry Council Graduate scholarship is awarded to a candidate who as an M.Sc. student, has demonstrated promise of

The fund will continue to support the research initiatives co-ordinated by the Canadian Poultry Research Council (CPRC), which was established by the five national poultry organizations in Canada. The mandate of the CPRC is to implement programs for poultry research and to develop ini-

tiatives that address industry needs, such as food safety, poultry health, environment and animal care.

CFC has contributed regularly to the Fund over the last five years. At its current level, it will generate approximately $200,000 annually to support priority research projects and initiatives in Canada.

research ability or to a PhD student who has demonstrated research aptitude, academic

standing and the benefits and outcomes of his/her planned research.

Increased Autonomy for NSAC

The Nova Scotia

Agricultural College will become an independent postsecondary institution under a proposed bill tabled by the Conservative government.

Under the bill the Bible Hill, N.S., college will no longer be a branch of the Department of Agriculture.

Agriculture Minister Brooke Taylor says the change will allow the school more autonomy and academic freedom and give it better access to future

JANUARY

January 21-22, 2008 –International Poultry Scientific Forum, Georgia World Congress Center, Atlanta, Ga. For more information, visit: www.internationalpoultryexposition.com

January 23-25, 2008 –International Poultry Exposition and International Feed Exposition, Georgia World Congress Center, Atlanta, Ga.

FEBRUARY

February 5-7, 2008 –Canadian International Farm Equipment Show, International Centre, Toronto, Ont. For more information, visit: www.torontofarmshow.com

February 20, 2008 –Feed Mill Workshop, Room 116/114, Haley Institute, Nova Scotia Agricultural College, Truro, N.S. For more information, contact APRI/NSAC tel: (902) 893-6657 or AgraPoint tel: (902) 896-0277 or visit: www.agrapoint.ca

federal funding for research.

College co-president Leslie MacLaren says it will enable the school to better compete in the future by helping it recruit high quality faculty, expand research programs and become more efficient.

Bernie MacDonald, a copresident at the college, says the school currently does about $6.3 million in research each year.

He says the change should help it to increase that figure to around $10 million over the next three to four years.

February 25, 2008 –Growing Quality: Today and in the Future, presented by the Alberta Chicken Producers, Capri Centre, Red Deer, Alta. For more information, tel: 780-488-2125 or e-mail: abcp@chicken.ab.ca

February 26, 2008 –Alberta Poultry Industry Conference, Capri Centre, Red Deer, Alta.

NOVA SCOTIA

MILTON DALEY, RECIPIENT OF THE DEBORAH WHALE-PIC GRADUATE SCHOLARSHIP

NEWS NEWS

Atlanta Trade Mission

Atlanta Convention & Visitors Bureau (ACVB) will partner with two tradeshows, the International Poultry Expo/International Feed Expo (IPE/IFE) and International Woodworking Fair (IWF) to host a trade mission to Canada. The trip is ACVB’s latest attendance promotion effort and will highlight Atlanta’s overall economy and the vitality of the poultry and woodworking industries.

IPE/IFE and IWF are based in Atlanta and the tradeshows provide education forums about two of Canada’s most important sectors.

ACVB is working with the U.S. Commercial Service and several Canadian industry associations, publications, producers and representatives. Scheduled for March 3-7, 2008, the trade mission will include one-on-one meetings and business briefings.

Hendrix ‘Business of Year’ 2007

HCanadian ambassador

endrix Genetics was recognized as “Business of the Year 2007” by the Dutch-Canadian Chamber of Commerce in Zeist, the Netherlands, on November 14. Thijs Hendrix, president of Hendrix Genetics received the award from Canadian Ambassador Jim Wall during Canada Food Day.

The Business of the Year is awarded annually to a Dutch or Canadian firm that has performed particularly well in the preceding year. Over the past years, Hendrix Genetics has established itself as a dominant player in expertise and sales of animal breeding stock in

Canada and worldwide. Previous winners of the award were companies like DSM Biologics (2003) and Nutreco (2001).

The award was presented during Canada Food Day, when Dutch companies and institutes were briefed on business, investment and research opportunities in the food and agricultural sector in Canada.

In Canada, over 350 people are employed in the company’s operations. The company is a leader in breeding for turkeys (Hybrid Turkeys), layers (Institut de Sélection Animale –ISA) and pigs (Hypor).

PEOPLE IN THE NEWS

Shawn Conley is First Choice Agriquip’s new general manager, overseeing sales and operations, as well as serving as territory manager for central Ontario. Shawn is new to the company. Raised on a hog farm, his background also includes working with various dairy and poultry operations. He studied molecular biology at Florida Tech, which gives him a strong background in biosecurity and his extensive business management experience will provide insight into many farm management challenges.

Nathan Bell is First Choice Agriquip’s newest territory manager for western Ontario, giving the company better coverage to assist its customers in every aspect of setting up and updating livestock operations.

Michael Osterman has been named product manager for Agile Mfg., Inc. Osterman will be responsible for product development and management of the company’s Roxell®, Shenandoah®, ProTerra® and Agro Logic™ poultry production products.

(L to R) Rob Vellekoop, chairman of the Netherlands Canadian chamber of commerce, Thijs Hendrix, president of Hendrix Genetics, Jim Wall,

NATHAN BELL

MICHAEL OSTERMAN

SHAWN CONLEY

reliability profitabilitytraceability

It’s what you need in a feed additive and Alltech delivers on all three counts.

Through 25 years of research-driven product development, we’ve created a range of natural products that support optimal animal performance — products that are proven reliable, traceable and profitable...naturally.

For more information on our products contact Alltech Canada at 1-800-285-8617

Farmer Innovation

Straw Spreading

Two Ontario brothers develop time- and cost-saving method

by Kristy Nudds

Brothers Paul and Peter Luyk of Shedden, Ont., wanted to reduce the time they spent preparing their barns for chick placement. Their idea: to develop a piece of equipment that could make this task much easier and faster while reducing the amount of dust.

Their idea came to fruition five years ago when the Luyks worked with a custom fabricator based in Walton, Ont. – TS Fabrication Inc.–to build a unique implement that not only saves them on labour, but offers significant fuel savings as well.

The brothers grow approximately 200,000 broilers on three different sites around the Shedden area in three two-storey and four single. Before the development of the straw spreading implement, Paul says it used to take him and his brother and a hired man all day to do one of their sites that has one two-storey and one single-storey barn.

Paul and Peter Luyk wanted to make spreading straw easier. With the help of a fabricator, they developed a unique implement that saves them time, reduces dust and saves on fuel.

Now, the same task barely takes a few hours.

The “straw spreader” developed by TS Fabrication Inc. and the Luyks resembles a miniature manure spreader. In fact, the implement is actually based on the design of a European manure spreader model.

All components on the spreader are hydraulically driven off an external engine. A large bale of chopped straw can be placed in the spreader and is then pushed with a hydra-push system toward two upright beaters that are on a slight pitch, so that the straw doesn’t bunch when exiting the spreader.

Paul says it only takes minutes to spread one bale – a couple of minutes to load the bale into the spreader, and just over one minute to spread. The straw is spread quite evenly.

The depth of the straw depends on how fast the tractor pulls the spreader and how fast the bale is pushed through the spreader. Very little dust results and it quickly dissipates. By the time the tractor enters the barn with a new bale, the dust from the previous bale is gone.

Two-storey barns don’t present a problem for the Luyks. They use a Zoom Boom with a forklift attachment to lift the spreader, tractor and straw bales into the second storey of a barn.

So far, the Luyks are the only poultry producers enjoying the benefits of the spreader. TS Fabrication Inc. is working with Cambridge, Ontario based iCan Equipment Inc. to build future machines.

Ican engineer Nick Szabo says the Luyks are “amazed” at the fuel they save. “It’s an added bonus,” he says

Before using the straw spreader he says it used to take 60 gallons of fuel per barn floor. Now, the Luyks only use 2-3 gallons of fuel. “They no longer have to use two 100 horsepower tractors, costing 40 dollars an hour to run, in order to do the same job,” says Szabo.

The Luyks use a small 31 hp Ventrac tractor to pull the spreader. Peter says the spreader was designed for use with a tractor as small as 25 hp.

Szabo says the best thing about the spreader is that “it was developed by farmers. They knew what they wanted

A GREAT IDEA

THE SPREADER FEATURES TWO UPRIGHT BEATERS SLIGHTLY PITCHED TO PREVENT CLUMPING. A BALE OF STRAW CAN BE LOADED INTO THE SPREADER IN MINUTES, AND ONCE IN THE BARN, THE SPREADING TAKES ONE MINUTE. A ZOOM BOOM IS USED TO LIFT THE SPREADER, TRACTOR, AND BALES TO THE TOP OF A TWO-STOREY BARN.

and needed to make their job easier, and we worked with them to build it.”

Additional photos of the straw spreader can be viewed at www.canadianpoultrymag.com.

For more information on the straw spreader, contact Nick Szabo, tel: 519-212-2030 e-mail: nickszabo@icanequipment.com. ■

Genetics Celebrating Genetic Progress

Bringing affordable chicken to consumers through advancements in genetics was the focus of a unique gathering in Alberta

BY KRISTY NUDDS

The first – and most likely the only – birthday party for chickens was held in late November at the Alberta Chicken Producers Poultry Technology Centre at the University of Alberta.

It was a 50th birthday party, celebrating the genetic progress that has been accomplished by researchers in Canada. It acknowledged the individuals who worked at the Central Experimental Farm in Ottawa for their contributions in making today’s chicken more economical and available in many more ways to consumers. Also highlighted was how their contributions are helping current researchers continue the poultry community’s understanding and improvement of production performance.

The idea for the party was hatched by Dr. Frank Robinson, Dr. Val Carney, Dr. Martin Zuidhof, Dr. Doug Korver, Nick Wolanski, and Dr. Rob Renema, all current researchers affiliated with the University of Alberta’s Poultry Research Centre (PRC), those who are furthering the genetic progress that began half a century ago.

The party also served to increase awareness of the preservation of poultry’s past and to educate students.

Dr. Frank Robinson welcomed guests

to the party and to what he and his colleagues believe is “one of the strongest communities of poultry science research, teaching and community service in Canada and beyond.”

“By your attendence today, you are helping to expand our community, our knowledge base and our pride in learning,” he said.

Honoured guests included: Dr. Robb Gowe, a former head of the poultry genetics research group at the Central Experimental Farm and later a director of the Animal Research Institute; Dr. Ed Merritt, the chief scientist behind the development of the Ottawa Meat Control Strain: Dr. Allan Grunder, former poultry genetics team leader at the Animal Research Institute; Dr. Roy Crawford, a

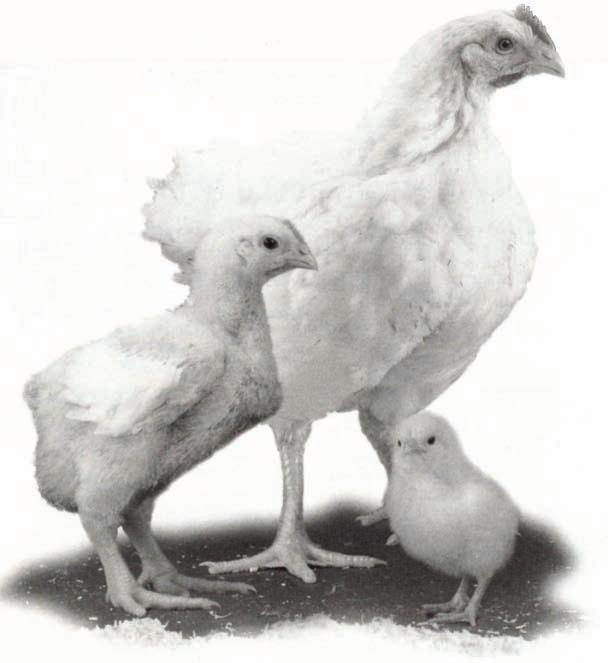

50-YEAR DIFFERENCE

It now takes only 9 g of feed to produce 1 g of breast meat – 50 years ago it took 28 g. The photo above shows the stark difference in the amount of feed required to produce the same amount of breast meat.

professor emeritus at the University of Saskatchewan, responsible for researching several qualitative genes of economic importance and responsible for preserving genetic lines of commercial poultry in an unselected state; Dr. Donald McQueen Shaver, founder of Shaver Poultry Breeding Farms Ltd., instrumental in the commercialization of technological

Faster. MovingForward...

Got Lubing? For information on our cutting-edge poultry products please contact your local Lubing Distributor.

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Specht-Canada Inc.

Stony Plain,Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Innovative products, modern manufacturing, high-tech engineering and customer service are at the heart of our company.

The product design process begins in our engineering department with 3-D modeling where samples are produced for testing with our very own Rapid Prototyping Machine.

We inventory, manufacture and assemble the majority of our products in our 52,500 square ft. facility. In order to keep up with demand a 35,000 square ft. expansion is planned for 2008 to house our 8 injection molding machines and extrusion line.

Lubing is definitely Moving Forward... Faster.

advances and licensing of laying hen and broilers for distribution in over 90 countries; and Dr. Jim Chambers, the last member of the poultry breeding team in Ottawa who contributed to the development of control stocks.

Each of these invited guests told attendees of their past research, the challenges they faced and provided a unique insight into the evolution of poultry genetic selection.

Dr. Merritt said that when he first went to the Experimental Farm in the early 1950s was to go to a poultry club meeting and discuss poultry husbandry and the different breeds, such as Rhode Island Reds. “That’s about as far as we got in this poultry club,” he said. “It just shows you how far back we were in those days.”

He spoke of the development of the original poultry meat control strain developed by him and Dr. Gowe, which was

Bio-Security

THE DISINFECTION MAT

Disinfects your boots and shoes with just one step. An intelligent and economical way to prevent the spread of disease in your greenhouse or storage facility. Place the Disinfection Mat at entrance, pour up to 2.65 gallons (12 L) of disinfectant* into the mat and step onto it before entering the building.

*We recommend VIRKON at 1% or other good disinfectant. Send for full information.

Telephone: 1-800-461-4299 Fax: (519) 442-7191

Email: sales@thestgeorgeco.com www.thestgeorgeco.com

Genetics

created by combining four meat strains (first by two-way crosses and then fourway crosses) and random breeding this population. The control strain was maintained using a restricted pedigree system. This strain was originally known as the Ottawa Control meat strain, and is now known as strain K.

This strain has served as an invaluable tool for subsequent researchers to determine the effects that modern meat selection programs have had on traits such as growth, conformation, body fat, and composition. A random sample of the original strain was sent to the United States Department of Agriculture (USDA) Regional Research Station in Athens, Georgia and was known there as the Athens-Canadian Randombred Control.

Comparative performance was then be established with the Ottawa Control.

Using this strain as a benchmark was discussed by Dr. Jim Chambers, who conducted much of his early genetic research at the Control station in the 1970s and 1980s. He said that the purpose of having control strains was “to test the progress of selection and to act as a germplasm resource.” He used the control strain extensively for comparative physiology work.

Chambers did much work on selecting for bodyweight (BW) and improved feed efficiency (FE), eventually developing a second Ottawa Control strain in 1978. In his earlier research days abdominal thickness was used as a measure but now to decrease the metabolic problems associated with growth he suggested that measuring organs would perhaps be a more useful approach.

Dr. Gowe was recognized by all of the former researchers as being “instrumental” in the establishment of control lines. The use of control strains was developed at Cornell and as a graduate student there he said he became “fascinated with the genetics research that was being done” both at Cornell and in Edinburgh.

Gowe said that control strains are “essential” and performing selection studies without these strains, in his opinion, “won’t work.” He said that an accurate

measure of progress on traits of interest cannot be obtained without the ability to separate out environmental factors.

He also stressed the importance of preserving genetic stock and used an analogy of corn breeding to drive home the point. “We have to be careful that we don’t diminish gene pools,” he said.

Dr. Grunder said the “lines of chickens were all ready for me” when he joined the Control station and grew to appreciate the importance of such strains as he continued his career. He spoke of his research with green muscle disease and how he was able to use both of the Ottawa Control strains to determine that the disease was related to increased bodyweights and that selection against the disease should be part of breeding programs.

Dr. Shaver, who began his career in poultry breeding at the age of 12, said that in the early years of purchasing stock and mating offspring that “we were crossbreeding and didn’t know it.”

After returning from the Second World War, he began convincing breeders to let him have stock, forming what eventually became Shaver Poultry Breeding Farms Ltd. He said that everyone in the room should pay “homage” to Dr. Gowe for his insight into using controls and preserving genetic lines. Shaver himself has been a great promoter of conserving stock and preserving germplasm (genetic material) to maintain biodiversity and variability for future breeding programs.

He has donated germplasm and stock to the University of Alberta and Dr. Robinson applauded him for his continued efforts.

Dr. Crawford has also donated stock to the U of A and is himself a conservationist of poultry stock. He was pleased to see some of his mentors in the room and noted that many “master’s and doctorates have resulted from the use of old stocks. It has paid off scientifically.”

At the University of Saskatchewan he used such stocks as teaching materials and found pure lines to be “a terrific source of mutations.” He has also worked extensively with grassroots (hobbyist)

Continued on page 46

NEW PRODUCTS

Windbuster™ Pilot Ignition System

Space-Ray’s new unique patented Windbuster™ Pilot Ignition System enhances flame stability and provides dependable ignition on radiant gas brooders for virtually trouble-free operation, even at wind speeds of up to 11.2 km/hour in tunnel-ventilated and other types of poultry houses. It features a push-on-style thermocouple and control arm that drops down to provide easy access to the main burner orifice.

Standard on all single-jet and radiant gas brooders used in poultry houses, the Windbuster™ Pilot Ignition system keeps the pilot light operating to increase the system’s reliability and keep the birds warm without interruption.

A New Tool to Fight Against Air Sacculitis in Broiler Chickens

The recent approval of NUFLOR® (florfenicol) 2.3% Concentrate Solution for broiler chickens brings Canadian poultry producers a new tool for the treatment and control of air sacculitis associated with E. coli. NUFLOR® Concentrate Solution is an effective way to control air sacculitis caused by bacteria when promptly administered in broiler chickens’ drinking water as soon as disease attributed to E. coli is diagnosed.

Monitor Feed Storage Temperature and Humidity

Dickson’s Wireless Wizard, the world’s first fully reliable wireless data logger, is now available to poultry breeders monitoring feed storage temperature and/or humidity, in a 30-day no obligation trial offer. Dickson’s Wireless Wizard data loggers can be monitored in real time from a desktop PC or other computer workstation and totally eliminate the delays for data downloading and cumbersome cabling of other temperature and humidity data logger technology.

Features include real-time alarms of out-of-range conditions right at users’ workstations; up to nine-day data backup storage with failsafe Dickson Data-Keep; easyto-use software that manages all loggers from one desktop; graphical display of real-time temperature and humidity data; and much more.

CUSTOMER SATISFACTION ACROSS CANADA

...“The strength and durability of the system told me that this was going to last more years than I had left in the business. ...As we got into the reality of using the system,I knew we had made the right decision.”

Al Dyck,Harman Poultry Farm,Prince Albert SK

...“My Hellmann Cage System is awesome.An excellent system to work with on a daily basis.”

Doug Pauls,Highplain Farms,Niverville MB

...“With the Hellmann Cages I am getting results I cannot believe.Uniformity in the mid 90’s...Feed conversion also improved dramatically (5.9 kilos/bird). The Hellmann troughs keep the feed in the troughs and not on the floor.”

Gerard Hoftyzer,Londesboro,ON

...“With 94% uniformity,excellent feed conversion,very good air quality;all accomplished with minimal labour inputs;I am extremely pleased with my decision to purchase Hellmann Pullet Cages.”

Paul Overmars,St.Andrews,Nova Scotia

Tel: (519) 453-3913 • Fax: (519) 453-3996

Maritimes

Contact: Herb Jansen

Phone: (902) 680-1267

Fax: (530) 430-2020

e-mail: janse17@attglobal.net

Manitoba, Saskatchewan & British Columbia

Contact: Greg Olson

Phone: (306) 260-8081 or (306) 492-2266

Fax: (306) 492-2265

e-mail: gaolson@sasktel.net

Eastern Ontario & Quebec

Contact: Stephane Chouinard

Phone: (450) 266-9604

Fax: (450) 263-2638

e-mail: stef@greenfarmline.com

Alberta

Contact: South Country Livestock, Klaus Santrau

Phone: (403) 329-0155 or (403) 308-2091

Fax: (403) 320-1808

e-mail: klaus@southcountrylivestock.com

Western & Central Ontario

Contact: Newtech Ag., Jack Lepelaars

Phone: 1-866-767-2986 or (519) 348-8483

Fax: (519) 348-9271

e-mail: jack@newtechag.com

U.S.A.

Contact: Jim Currie

Phone: (519) 868-1882 or (519) 453-3913

Fax: (519) 453-3996

e-mail: hellmannpoultry@bellnet.ca

PIC Update Poultry Epidemiologist Joins PPT

BY TIM NELSON, EXECUTIVE DIRECTOR, AND KIMBERLY SHEPPARD, RESEARCH CO-ORDINATOR

PIC is pleased to announce that Dr. Michele Guerin from the University of Guelph has been appointed as an epidemiologist with the Department of Population Medicine at the University.

This joint industry/university position is being substantially funded by a number of Poultry industry organizations (see below) through their contributions to the Poultry Program Team (PPT).

“We’ve been waiting some time to fill this position with the right person, and we now have a very good candidate” said PIC Chairman Ed McKinlay.

“Michele will add significant value to the PPT by providing an additional skillset and depth to the team” he said. “For the broader industry, that is continually facing disease challenges on any number of fronts, it is comforting to know that we finally have a poultry epidemiologist at the University of Guelph.”

It is anticipated that with her professional background, attitude, strong academic credentials, formidable research discipline and comparative youth Michele will stimulate keen interest in students who we hope, will then pursue careers in poultry science, thus building the poultry industry presence at the university in the years to come.

Michele has a longstanding relationship with the University of Guelph. She received her D.V.M. degree from the Ontario Veterinary College (OVC) in 1993 and is licensed to practise veterinary medicine in Ontario. Following

graduation, she worked in small animal and emergency practices in southern Ontario. After working in private practice for eight years her interests in zoonotic diseases, food safety and public health led her to pursue graduate studies in veterinary epidemiology. She completed an M.Sc. (2003) and a PhD (2007) in epidemiology at the Department of Population Medicine at OVC.

Her graduate work on gastrointestinal illness in humans related to the consumption of contaminated foods of animal origin is absolutely pertinent to the food safety issues we currently face as an industry.

For her M.Sc. thesis Michele investigated the link between temporal clusters of Salmonella serovars in animals and

The Poultry Program Team has a new member, epidemiologist Dr. Michele Guerin. Her skills will help the team, co-ordinated by the Poultry industry Council (PIC), face disease challenges in poultry and food safety issues.

humans, with the goal of preventing outbreaks of salmonellosis in the human population through the timely detection of temporal clusters in animal groups.

Michele’s PhD thesis focused on reducing the burden of foodborne illness associated with poultry consumption by identifying risk factors for the colonization of broiler flocks with Campylobacter

PIC WELCOMES DR. GUERIN

PIC Update

and determining where intervention efforts should be targeted.

The relevance of her research to date, focussing on the public health aspects of poultry production, is of great importance to our industry, not only for the protection of the public from foodborne pathogens, but also to secure consumer confidence to ensure the marketability of poultry products.

We welcome Michele into the industry and look forward to working with her into the foreseeable future.

RESEARCH RESULTS

PIC Project 216: Optimizing or manipulating broiler growth

Dr. Steve Leeson, University of Guelph

Genetic potential for broiler growth continues to increase yearly. Broiler birds are growing faster and reaching market weight earlier today than ever before. As a result, they are being switched to finisher diets earlier as well. By 2010, 1.75-kg pullets could easily reach market weight by 28 days of age –meaning the switch to a finisher diet could occur as early as 24 days.

This is of concern for a couple of reasons. Firstly, finisher diets are devoid of some nutrients that are necessary for optimal growth at such a young age. Nutritional requirements and feeding/ management practices must keep up with a changing bird. To date there has been no work published on finisher diets for 1.75-kg pullets. Secondly, younger birds have less developed bone and cartilage. At only 28 days of age, it is likely that this very immature bird will be more difficult to process mechanically due to bone and cartilage breakage.

Clearly, management options that delay market age need to be investigated. Dr. Steve Leeson (University of Guelph) has been investigating these issues by looking at the nutritional effects of diets varying in metabolizable energy, Lysine levels, and texture.

His findings? It’s all about texture! To read more, visit www.poultryindustrycouncil.ca and click on “Research Results.”

THE PIC CONGRATULATES THESE ORGANIZATIONS ON THEIR FORESIGHT AND THANKS THEM FOR THEIR GENEROSITY IN PROVIDING THE FUNDS NECESSARY TO BRING THE EPIDEMIOLOGIST APPOINTMENT TO FRUITION.

DR. STEVE LEESON HAS BEEN INVESTIGATING THE NUTRITIONAL EFFECTS OF DIETS VARYING IN METABOLIZABLE ENERGY, LYSINE LEVELS, AND TEXTURE IN BROILER BREEDERS.

Vaccine-based control of Avian Influenza (AI) in commercial poultry is considered, at best, only partially effective due to natural reservoirs of the virus in wild waterfowl and rapid random mutations of field strains. One possible control strategy is to stop the virus in infected cells from copying itself by using a molecule that interferes with this process. This is called RNA interference (RNAi) and its discoverers were awarded the Nobel Prize in 2006.

This strategy has been extensively developed as an anti-viral drug in humans, and a similar approach would be extremely valuable for inhibiting viral replication and studying gene function in poultry.

Dr. Serguei Golovan, together with his M.Sc. student Arusyak Abrahamyan and collaborators Drs. Eva Nagy and Shayan Sharif, have been conducting experiments to determine whether RNAi works with chicken cells and could be used for stopping AI virus replication by designing and testing RNAi molecules.

His findings? The designed molecules had different impacts on different types of cells. The RNAi molecule was able to decrease infective levels of AI virus in one type of cell up to 106 fold compared to cells in which the molecule was not used. To read more, visit www.poultryindustrycouncil.ca and click on “Research Results.”

PIC Project 187, New method to inhibit avian influenza virus replication

Dr. Serguei Golovan, University of Guelph

A NEW APPROACH TO RESEARCH REPORTING IN 2008

You’ve just read the first “PIC Update” in Canadian Poultry magazine!

Canadian Poultry magazine is working with the Poultry Industry Council to bring you research- and education-related articles each month in the magazine.

This means PIC can get research updates, factsheet information, technical bulletins, newsletter items and other important research and education news out to you on a more timely and regular basis.

We’re thrilled at the opportunity to work with Canadian Poultry to broaden our reach and we hope that you’ll find the “PIC Pages” interesting, informative, reader-friendly and above all stimulating.

Because we’re limited in space we won’t be able to reproduce all of our

PIC Update

information in full. But don’t panic, there are five additional ways to get the complete picture by contacting PIC:

• by phone at 519-837-0284

• by fax at 519-837-3584

• by e-mail at pic@poultryindustrycouncil.ca or

• by WWW: simply visit our website at www.poultryindustrycouncil.ca and just download the information you’re seeking. To make it really easy, each month we’ll present the link to the full copies of the articles featured in Canadian Poultry on the front page of our website.

• by Joining PIC: You can always be the first in line for new information and updates simply by joining PIC. As an individual or corporate member the information will automatically be sent out to you as soon as we have it in hand. ■

meller Cage Systems ®

S EGG G ELEVATOR

The egg elevator with variable speed egg belts has no transfer wheels. The egg cup is designed to ensure that eggs from any tier always enter an empty basket. The egg elevator can be equipped for overhead cross conveying or below the floor, or with a table in front of each row.

Eggs are gently lifted from the belt in the egg basket

Eggsaredischarged fromtheeggbasket viatherotarywheel to the cross conveyor

Withitsuniqueand compactdesign,the MellerEggElevator, can be adapted to all situations and barn layouts

Epidemiology

Paradigm Shift Industry changes present disease challenges

by Jim Knisley

People in the poultry industry can be forgiven for believing that things have changed in recent years and not for the better, Jean-Pierre Vaillancourt, of the University of Montreal, said at the Poultry Industry Council’s annual poultry health conference in Kitchener.

Vaillancourt said the avian influenza outbreak in British Columbia and the recent reminder in Saskatchewan lend credence to the idea. But changes and challenges are nothing new, he said. Some seem recurrent and some seem to be emerging.

New changes and challenges may seem particularly frequent in the poultry industry, but the poultry industry, as we know it, is young and its expansion over the past 40 years has been phenomenal.

“But keep in mind that since 1978 the poultry world has seen the emergence or re-emergence of at least one new disease or new variant of a known disease per year,” he said.

NOT A FAD

Dr. Jean-Pierre Vaillancourt says that before we look at the possible role of new production systems in the emergence of disease epidemics, it is important to review what effect the increase in regional density of commercial poultry farms has on infectious conditions in poultry.

The disease breaks are occurring when there are more restrictions on veterinary drugs and when the public is increasingly concerned about the safety of the food supply, he said.

Some vocal and politically active people are questioning the morality of commercial poultry production. In response, new production systems are being proposed. These include: organic, antibiotic free, indoor and free range.

“This is not likely to be just a fad,” he said.

The changes are motivated by shifts in people’s attitudes towards well-being, their own and the animals’. They are also having consequences.

“In France, standard broiler production of whole birds is expected to decline by as much as 10 per cent per year,” he said.

Two types of production will replace this. One type will be

labelled certified, which will be similar to classic production but the growers will have to show how the birds were raised and will include the capacity to trace the birds back to the farm. The other type will be organic, which will grow by 15-to-20 per cent per year.

The new production systems will create challenges, but Vaillancourt said it is important to understand the challenges that are already out there.

Vaillancourt said the poultry populations in parts of the U.S. are at “insane levels.” “Production diseases are more than likely the result of an increased infection pressure at the farm and the regional levels,” he said.

Greater regional farm densities have contributed to increasing the number of pathogens on any given production site and can affect poultry performance and, at times, “they may even become a lethal combination.”

At the same time large grocery chains and large fast food chains are in a position to dictate to producers not only what products they want, but also how these products will be produced.

For example, the Quebec restaurant chain Rotisseries StHubert wants, within a few years, to be able to offer antibiotic-free chicken to its customers. St-Hubert needs 110,000 whole chickens per week and thousands of kilograms of other poultry products, he said.

“So, marginal production systems are now emerging because of opportunities that far exceed the small niche markets they used to hold,” he said.

The challenge, he said, will be to manage growth of the new production systems.

“Indeed, the emergence of organic farming, antibiotic-free production, and other production models may also contribute to

TURKEY CORYZA (BORDETELLOSIS)

MYELOID LEUKOSIS

ORNITHOBACTERIUM RHINOTRACHEALE INF

BIG LIVER AND SPLEEN DISEASE

AVIAN NEPHRITIS CELLULITIS

VARIANT INF BURSAL DISEASE

HIGHLY VIRULENT INF BURSAL DISEASE

TURKEY RHINOTRACHEITIS

CRYPTOSPORIDIOSIS

SPIKING MORTALITY-HYPOGLYCEMIA

AVIAN INFLUENZA

VERY VIRULENT MAREK’S DISEASE

VARIANT INFECTIOUS BRONCHITIS PULMONARY HYPERTENSION SYNDROME

VARIANT MG AND MS INFECTIONS

SALMONELLA ENTERITIDIS PHAGE TYPE 4

ANGARA (HYDROPERICARDIUM) DISEASE

EQUINE ENCEPHALITIS VIRUS IN TURKEYS

RUNTING STUNTING SYNDROME

STUNTING SYNDROME IN TURKEYS CHICKEN INFECTIOUS ANEMIA

POULT ENTERITIS MORTALITY SYNDROME

TRANSMISSIBLE VIRAL PROVENTRICULITIS MULTICENTRIC HISTIOCYTOSIS

HEPATITIS-SPLENOMEGALY SYNDROME

DERMAL SQUAMOUS CELL CARCINOMA TURKEY OSTEOMYELITIS COMPLEX

SOME EMERGING AND RE-EMERGING DISEASES. MANY OF THOSE LISTED HAVE BEEN SUCCESSFULLY MANAGED BY DRUGS AND VACCINES BUT THE GROWTH OF THE INDUSTRY HAS RESULTED IN SOME BECOMING “PRODUCTION DISEASES.”

changes in the epidemiology of some diseases. If changes occur, they will be in terms of incidence and risk factors associated with their spread,” he said.

But it would be wrong to assume this will always lead to more disease problems. Meanwhile it must be recognized that pathogens aren’t necessarily confined to a single species.

“When we look at emerging production systems we tend to just think poultry, but we can share bugs,” he said.

For example, a novel H2N3 has been isolated from pigs in the U.S.

“This is not a typo,” he said. “You are probably aware of H3N2 in pigs and its ability to affect turkey breeder flocks. H2N3 is much different,” he said. H2N3 has an avian origin and is similar to an H2N3 found in mallards and other waterfowl.

“The concern here is not only that we have an avian connection to this virus, but its H receptor binding is very similar to the H of the H2N2 influenza virus associated with the 1957 human pandemic.”

This H2N3 causes two to five per cent mortality in pigs and tests on rodents have shown it can spread to other mammalian species.

To date there have been no human cases reported but the Centre for Disease Control is monitoring the situation.

The appearance of new diseases and the re-emergence of old diseases combined with new production systems, increased livestock density and increased consumer activism and public attention, argues for greater diligence.

Because diseases can be regional and studies in the Netherlands and Italy have shown that greater regional density increases disease risk, Vaillancourt said, “management of infectious disease risk must include a regional approach in terms of disease prevention

as well as disease containment.”

But improvements in regional biosecurity must be paralleled by improved communications. “The stigma attached to having an infectious disease is real and often leads to people to keep this information from others,” he said.

“But silence has been shown to be even more costly. . . . Pointing fingers has never been an effective disease control strategy,” he said.

Compensation is a hot topic in Canada, he noted. Changing production systems will tend to keep it on the front burner, he said. In other countries compensation levels take into account the level of biosecurity employed on the farm.

For example, in Australia the higher the biosecurity standards the higher the government compensation if a disease is found on the farm.

In the U.S., there is a program for surveillance of low pathogenic avian influenza. Producers in the program receive a substantially higher payout if the flock is depopulated. The program also includes payments for lost production.

The bottom line is the industry needs more surveillance and enhanced communication particularly in areas with high density. This is particularly true for emerging production systems.

“An increase in such production systems could have a significant impact on the epidemiology of poultry diseases,” he says. “However, this impact could be transient and eventually not significant as professional producers involved in these productions adapt to the reality of going from being a marginal production to a more mainstream one. But this will require a high degree of vigilance on their part regarding infectious diseases coupled with a willingness to work with neighbouring producers.” ■

Health

Gut Health Update

Coccidiosis control trends in Europe

by Jim Knisley

Coccidiosis is like an iceberg. The clinical 10 per cent you see is bad and makes it easy to forget that there is another 90 per cent (subclinical) down there somewhere.

But producers forget about the subclinical 90 per cent at their own economic peril, Maja Marien, technical manager of poultry in Europe and the Middle East for Alpharma, told veterinarians, government and industry officials and producers in Kitchener in October.

NECROTIC ENTERITIS

Marien said that subclinical disease damages birds’ enteric epithelial cells resulting in the reduction of nutrient absorption and less performance. Coccidia replicate by moving into the intestinal cells. The next generation of coccidian burst the cells’ walls to free themselves and in the process do extensive damage to the gut. Even a small number of parasites can damage the bird, affect how it performs and result in economic losses.

Subclinical coccidiosis damages birds’ enteric epithelial cells, resulting in the reduction of nutrient absorption and less performance.

Subclinical coccidiosis is also a predisposing factor for Clostridium perfringens.

Damage to the poultry industry in the United Kingdom in 1995 was estimated at 38.6 million pounds Sterling. It is estimated that 46 per cent of these costs came from reduced weight gain and 34 per cent from poor feed conversion.

“It’s a problem, an economic problem most of all,” she said.

Tools to deal with coccidiosis include vaccines, herbal products and anticoccidial drugs.

In the EU vaccines are a limited option. There are currently no vaccines registered in EU for turkeys. For chickens there are live attenuated or live unattenuated vaccines. Live

unattenuated vaccines are not registered in the EU and other vaccines are not frequently used in broilers in the EU.

A couple of problems are the price and the perception there are more bacterial enteritis problems compared with anticox, she said.

Another possible problem is that the species is in the field but not in the vaccine, e.g., E. mitis.

Herbal products are being touted by some as an alternative to traditional treatments. The anticoccidial sensitivity test (AST) evaluated five herbal products with claimed anticoccidial activity, she said.

“None of the herbal products proved to be efficacious,” she said.

However, Alpharma keeps testing and screening.

Anticoccidial drugs fall into two broad classes: chemicals and ionophores. They are effective but work differently and there are issues such as increased resistance.

“After some time of use the efficacy of anticoccidials decreases,” she said.

Cross-resistance is also a concern with ionophores.

“If resistance to one product arises other similar products will also work less efficiently,” she said.

Chemicals all have very different targets to kill parasite and there is no occurrence of cross-resistance.

Ionophores, however, have a common mode of action and cross-resistance can be a problem.

However, there are big differences between ionophores of different classes and the implications for cross-resistance.

The way to prevent the development of resistance or crossresistance is the use of a rotation program. This involves changing the anticoccidial drug to one of another class after a

few cycles. This can be in shuttle or a full program, she said.

Rotation allows the restoration of anticoccidial efficacy and limits the buildup of resistance.

RESTING PERIODS

“After using an ionophore, do not use it (or any other ionophore from the same class) again for at least six months,” she said.

Limit use of a particular chemical to once a year – so if used three months in full, give nine months’ rest.

OPTIMAL DURATION OF PROGRAMS IN TURKEYS

Ionophore and chemicals: use for up to six months and then give six months of rest.

The reason is that immunity plays a more important role in turkeys, she said.

Vaccines can also play a role in the rotation as they result in a faster restoration of sensitivity to the other treatments.

AST tests in broilers have shown that using a higher dosage can result in better coccidiosis control and will often pay off with improved bird performance that more than offsets the additional treatment costs.

Alpharma does lesion scoring during necropsy sessions in the EU to get an idea of coccidiosis control. The company also

scores “bacterial enteritis / dysbacteriosis,” she said.

“Bacterial enteritis (BE) is one of the main health problems in EU poultry production,” she said.

Treatments for BE are standard practice in the EU, she said.

A lot of factors are involved in BE including diet and management, but there is also a close relationship with (sub)clinical coccidiosis as a predisposing factor.

The clinical signs of bacterial enteritis include: wet litter; diarrhea; stable instead of increasing feed intake and an increased water/feed ratio.

Necropsy shows: fragile, thin, transparent gut; dilated blood vessels; excessive fluids in small intestine; ballooning of intestinal wall; undigested feed.

Necrotic enteritis is rather rare in the EU compared with BE and has the same contributing factors as BE but mortality can range from five to 50 per cent, but is usually 10 per cent, she said.

Tools for prevention and treatment of bacterial enteritis/necrotic enteritis include therapeutic antibiotics such as amoxicillin, linomycin and tylosin. Such treatments are standard in European production, she said.

As an NE treatment, it is hard to beat amoxicillin, she said. It is very rapid and very efficient.

Alternatives such as Alphaflor can help. Tests show lowered mortality and lower percentage of NE positive birds. But there is no antimicrobial action.

DR. MAJA MARIEN OF ALPHARMA CHATS WITH DR. LLOYD WEBER, CONFERENCE ATTENDEE, ABOUT COCCIDIOSIS TRENDS.

In Europe there are no growth promoters allowed.

Meanwhile, however, it is estimated that 50 per cent of flocks in the EU are treated at least once for bacterial enteritis.

As a consequence, you can’t underestimate (subclinical) coccidiosis as an instigator of bacterial enteritis.

Maintaining anticoccidial efficacy is very important in the prevention of other conditions especially in European conditions, where there is no fall back on 3-Nitro, growth promoters.

It is believed that many European producers use light doses to cut the cost of the treatments, but the cost to bird performance may be high. It is important that appropriate dosages be used as light dosages can result in the rapid development of resistance, more subclinical coccidiosis,

Four Golden Rules of anticoccidial programs are:

• Do not use the same anticoccidial for too long;

• Give the product a sufficiently long rest period after each period of use;

• Rotate between products of different classes;

• Use a chemical cleanup once a year, which will achieve a very good reduction in infection pressure.

The optimal duration of programs in broilers is to use an ionophore up to six months, a chemical for three months in a full program or a chemical treatment for 4.5 months in a shuttle program, she said.

more damage to the gut, less bird performance and increased economic loss.

In the same vein, rotation is essential in order to avoid resistance and reduced sensitivity.

Cleanup by using chemicals could boost performance, especially when the coccidiosis challenge is heavy.

Producers should use all the tools avail-

able for the future control of bacterial enteritis and coccidiosis. These include ionophores, chemicals, vaccines, therapeutics, and alternatives if they are shown to be effective.

They must also remember that they are not only dealing with the 10 per cent of the problem they can see, but the 90 per cent they can’t. ■

Disease Preparation Pays Off

When AI was found on a Saskatchewan breeder operation, the industry was ready

BY JIM KNISLEY AND KRISTY NUDDS

It was the most unlikely of situations in one of the most unlikely of places.

When Jim Glenn, owner of Pedigree Poultry, went to his broiler-breeder farm near Silton, Sask., 40 kilometres north of Regina on Sept. 23, he found a situation everyone dreads. The birds were very sick.

Tenille Knezacek, Saskatchewan’s poultry extension scientist, was called in. When she suspected that the birds could be infected with avian influenza (AI) she notified provincial veterinarian Dr. Bob Goodhope, who felt the situation was high-risk and notified the Canadian Food Inspection Agency (CFIA).

The CFIA collected tissue and blood from the birds and sent them to the National Centre for Foreign Animal Disease (NCFAD) and the Prairie Diagnostics Lab. Initial lab tests concluded that it was avian influenza, although it took another day to determine by PCR testing that the virus was not an H5 type. These initial results showed also showed a negative result for H7 but more sophisticated testing confirmed that it was the highly pathogenic form of H7N3.

Dr. Sandra Stephens, veterinary program officer, Saskatoon District Office, CFIA, says that early notification of a suspected disease problem is crucial. She

COMMUNICATION IS KEY

Chicken

Saskatchewan said having a game plan in place really helped the industry during the recent AI incident.

praised Glenn for his quick notification. “Some farmers may think that maybe it’s not so bad, and wait to call someone in,” she says.

She says the evidence shows that the disease broke in a spiker barn. Roosters were moved at the same time into layer barns, where the disease affected the largest number of birds. “The industry needs to be aware that spiker roosters are a

risk component,” she says.

Pedigree Poultry was immediately quarantined, control measures were put in place and quarantine zones were established. The birds were destroyed by CO2 gassing on Sept. 29th and depopulation of the barns took place over the next few days.

Although composting of infected carcasses is “useful” Stephens says due to

Clinton Monchuk of the

Farmers of

lack of floor space in the layer barns composting would be difficult, so the birds were buried in a deep pit in the claybased soil on the farm property. To prevent disease spread, the carcasses were left in the barn for several days to “decrease the viral load” and wetted down to prevent feathers and dust

Disease

becoming airborne, says Stephens.

Fortunately, says Stephens, the infected farm was isolated from other farms. Several backyard flocks are located within three kilometres and the closest commercial operation is nearly 10 kilometres away. Stephens says the incident is a good reminder to industry that “AI can

happen anywhere. Biosecurity is a 365 day a year process.”

Following protocol, the CFIA canvassed farms within one and three kilometres to assess whether poultry was present, later moving out to a 10-kilometre zone. Questionnaires to determine potential risk factors were completed.

Blood from the birds on this farm was sampled for evidence of the virus or seroconversion. One of the backyard flocks was quarantined due to its close proximity (within one kilometre) but this was only a precautionary measure, says Stephens.

The CFIA also did a 21-day trace-back for all inputs, visitors and exports on and off the farm. Stephens says that luckily Pedigree Poultry was the only poultry client of the feed company used and that the hatchery truck, which picks up eggs twice a week, hadn’t been to the farm in a couple of days. She noted that both the feed company and the hatchery practised biosecurity measures.

Stephens says it’s hard to determine how the virus entered the barn. Biosecurity was practised on the part of Glenn. The water source, ozone-treated well water, was tested but determined to be negative for AI. Stephens says that “it’s important to look at the water source as a possible source of contamination. One day of the water system not working is enough.”

The infected farm is located near Regina Beach, a known migratory flyway for waterfowl. It’s likely that wild birds are the source but “we may never know what the source of the virus is,” says Stephens.

INDUSTRY PREPAREDNESS

Two years of hard work and preparation paid great dividends in keeping the disease isolated to one farm. The Saskatchewan poultry industry was ready for AI.

After the same strain of AI crippled the British Columbia poultry industry in 2003, Saskatchewan, like other provinces, has been working to ensure that emergency plans were developed, refined and that all producers knew what to do.

“It was really helpful to have a game

Continued on page 42

Who We Are and What We Do

Chicken Farmers of Canada (CFC) is a national organization, funded completely through farmer levies paid according to the amount of chicken marketed. We were established in 1978 under the Farm Products Agencies Act. CFC operates within a regulatory environment pursuant to the Federal-Provincial Agreement for Chicken signed by federal and provincial governments and the provincial chicken boards in July 2001.

CFC and its stakeholders work together on behalf of Canada’s chicken industry, from farmer to consumer. Ours has long been a Canadian success story, known for its responsiveness and leadership within an evolving supply management system. Strong leadership and proactive strategies will always play an integral role in our ongoing success.

À notre sujet

Les Producteurs de poulet du Canada (PPC) sont une organisation nationale entièrement financée par les prélèvements perçus auprès des producteurs selon le volume de poulet qu’ils commercialisent. L’organisation a été créée en 1978, en vertu de la Loi sur les offices des produits agricoles. Les activités des PPC se déroulent dans l’environnement réglementaire prévu par l’Accord fédéral-provincial sur le poulet signé en juillet 2001 par les gouvernements fédéral et provinciaux et les offices provinciaux de commercialisation du poulet.

Les PPC et les intervenants travaillent en collaboration au nom de tous les secteurs de l’industrie canadienne du poulet, des producteurs jusqu’aux détaillants. Cette industrie, connue pour sa réactivité et son leadership dans un système de gestion de l’offre en constante évolution, est depuis longtemps un exemple à suivre au Canada. Un leadership fort et des stratégies proactives continueront d’assurer la réussite permanente des PPC.

Published by Chicken Farmers of Canada / Publié par Les Producteurs de poulet du Canada

Welfare Animal Welfare Issues and Initiatives

Consumer pressure is changing welfare practices worldwide

BY TREENA HEIN

How poultry welfare is currently defined, measured and monitored here in Canada and around the world were just some of the topics addressed at the National Farm Animal Care Council Conference held in Ottawa in September.

Among the speakers was Dr. John Webster, who studies the quantification of animal welfare (AW) at University of Bristol, in England. He believes AW quality assurance programs must include easy-to-observe objective measurements, ongoing monitoring and addressing of problems – and involve financial reward for the farmer.

Gord Speksnijder, executive director of the Canadian Poultry Research Council (CPRC), says “The issue of a financial reward to the producer who meets various standards of improved animal welfare practice is one that certainly deserves further examination. Animal welfare is a societal issue and as such goes beyond the responsibility of individual producers and their families.”

Crystal Mackay, executive director of the Ontario Farm Animal Council and also a conference presenter, says “Webster has outlined all the components of a parallel program many people know very well that was actually pioneered here in Ontario – the Environmental Farm Plan. I believe all

Dr. John Webster told NFACC attendees he believes animal welfare quality assurance programs must include easy-toobserve objective measurements, ongoing monitoring and addressing of problems – and involve financial reward for the farmer.

of those components make for a very solid program that shows definite and concrete improvements for the environment that can easily be transposed to animal care programs.” Mackay adds “These programs are in the early phases

for animal care for a few species already, but are lacking the financial incentives to improve to date. Improvements can still be made with education and evaluation, but large-scale changes will require some financial assistance.”

WELFARE CHALLENGES

Complete solutions for Cage Systems or Poultry Production.

Big Dutchman is uniquely qualified with 70 years of experience, products and services that have set the standard for efficiency, productivity and reliability.

In a world of sameness, Big Dutchman continues to create innovative ways to increase productivity. And that makes all the difference in the world.

Get Big Dutchman working for you, contact a Big Dutchman representative today.

Makingaworldofdifferenceoneclientatatime. +16163925981•e-mailbigd@bigdutchmanusa.com www.bigdutchman.com

Welfare

FACTORS AFFECTING POULTRY WELFARE – U.K. RESEARCH

In a recent study of 25 free range laying hen units in England, Webster and his colleagues measured “attitude” (arousal, noise, flight distance and response to a novel object), activity (feather pecking, aggression and use of range), physical welfare (mortality, body condition and egg quality). The study states that “Each farm was visited on four occasions by one of five trained observers. Further information relating to husbandry, health and productivity was gathered from a structured interview with the farmers.” Estimated losses (deaths and culls) in the study birds averaged about seven per cent and only a very small number were observed with signs of ill health, limb lesions or red mite infestation.

Webster and his team found a low correlation between pecking and feather loss “which implies that most of the feather pecking was of a non-aggressive, non-injurious nature.” They also concluded body condition, feather pecking and feather loss were all unaffected by the extent of beak trimming.

The team also found bird housing features or design had no significant effects on mortality. “There were however,” the team states “consistent differences in attitude, behaviour and performance attributable to floor type and the presence or absence of perches. Measures of attitude, behaviour and performance suggested that the welfare of the hens was inferior when housed on plastic floors with no perches.”

Dr. Christine Nicol, Webster’s colleague at the University of Bristol, studies laying hen housing systems, including free-range systems (large and small, organic and non-organic), indoor barn and furnished cages. She examines measures welfare in terms of physical health, non-invasive physiological indicators of stress (e.g., faecal corticosterone levels), unnatural behaviours, and post-mortem measures such as skeletal health at the end of lay.

Some of Nicol’s studies are funded through a project called LayWel, supported by the European Research Programme

Welfare

(www.laywel.eu), which focuses on the welfare implications of changing laying hen production systems. In Laywel WorkPackage 7, Nicol’s team found that “with the exception of conventional battery cages, all systems have the potential to provide satisfactory welfare for laying hens. Conventional cages do not allow hens to fulfil behaviour priorities, preferences and needs for nesting, perching, foraging and dustbathing in particular. The severe spatial restriction also leads to disuse osteoporosis.”

They concluded that “these disadvantages outweigh the advantages of reduced parasitism, good hygiene and simpler management. The advantages can be matched by other systems that also enable a much fuller expression of normal behaviour.” They conclude this because “every individual hen is affected for the duration of the laying period by behavioural restriction. Most other advantages and disadvantages are much less certain and seldom affect all individuals to a similar degree.”

Nicol adds that “In more recent work we are tending to find that welfare is better in free-range than in indoor barn systems. Physical health is generally better in furnished cages, but free-range allows more behavioural freedom.”

In terms of actual monitoring poultry welfare standards on U.K. farms, Webster says 95 per cent of free range egg production is monitored by the Royal Society for the Prevention of Cruelty to Animals’ “Freedom Food Scheme.” He says, “Thus, the Free Range premium is conditional on compliance with Freedom Food standards as monitored by their inspectors and verified by us (University of Bristol).” In terms of broilers, Webster says, “Top-value supermarkets (Waitrose, Marks & Spencers) now market, I think exclusively, their own lines of slow-growing strains of broilers (fewer leg problems) and have their own welfare monitoring schemes.”

Mackay says “I believe Canadian poultry farmers and industry partners are well aware of the major factors in poultry welfare. Some components of welfare

Welfare

have been quantified, such as lameness, and marked improvements in genetics are being made. Other components are much more difficult to measure and more research is definitely needed.”

Speksnijder, however, does not believe all of the issues in poultry welfare have been adequately identified and described. He says “Objective measures of bird welfare are lacking,” which would form the basis for “programs and guidelines for farmer self-assessment” and “[monitoring] of improvements regarding problems identified.” He adds “Perhaps just as important as identifying individual factors is examining the interaction among factors that effect bird welfare. Their interaction may be such that the end result is significantly more serious than the sum of the individual factors.”

In June 2006 the CPRC and Agriculture and Agri-Food Canada (AAFC) hosted a workshop entitled Poultry Welfare Research in Canada. Speksnijder says, “Participants representing academe, industry and government met to review Canada’s current capacity for poultry welfare research, and to decide where future efforts should be directed.” Priority areas identified as requiring more research were: Methods of euthanasia and depopulation; transportation; beak trimming; relationship between productivity and bird welfare; effect of housing environment; aggression in male broiler breeders; feed restriction in broiler breeders; studies

on pain, fear, frustration and emotional states; and the economic impact of improving poultry welfare. Issues requiring priority attention were “getting research into practice” and “co-ordination of effort across Canada.” Research projects based on these topics are being funded by CPRC, AAFC and the Natural Sciences and Engineering Research Council in addition to other sources, with a funding total of $2.2 million. The expected project completion dates range from March 2009 to December 2010.

Speksnijder says conference participants recognized that the lack of national co-ordinated effort and collaboration could be remedied by having “a dedicated poultry welfare and behaviour specialist [who] could champion this effort and create a ‘virtual centre’ or cluster of poultry welfare research in Canada.” The University of Guelph was named by a selection committee with international representation as the institution most appropriate to host the cluster.

FUTURE ACTION

With regards to what poultry welfare research remains to be done in general, Webster says, “At present, I would suggest that the priorities are for genetic research to identify layer strains less prone to feather pecking and broiler strains less prone to leg problems.” Nicol agrees. “There needs to be a massive shift towards breeding stronger, healthier birds,” she says. “Many of the problems we see are because birds have been bred for maximum production to the detriment of their skeletal health. Selection could also reduce some behavioural problems noted in non-cage systems such as feather pecking.”

In terms of worldwide regulatory change, Webster believes "the market moves so much faster than the regulations." For example, “The European Commission will require small changes in cage design to improve minimal standards for laying hens from 2012. This is 47 years after the publication of the Brambell Report that first formally acknowledged the welfare problems of caged hens and called for changes. Meanwhile, between 1995 and 2005, U.K. consumption of free-range eggs increased from below five per cent to over fifty per cent.”

Webster thinks most U.K. welfare assurance schemes are currently having little significant effect on welfare quality – considered by farmers to be simply “annual chores” – because “most are still based on box-ticking of elements of provision and give little attention to direct measurements of welfare.” He also credits a lack of real impact on the fact that “current systems do not identify, prioritise and review action plans for improved welfare” and “do not reward farmers for taking action.”

He suggests that to get the best progress and results, welfare programs should move slowly, involve farmer self-assessment, independent objective monitoring of outcomes with a concentration on major issues, an action plan for improvement which include rewards for farmers, and a reassessment afterwards to see if the improvement goals have been met.

The biggest factor in speeding up the process of having these

Welfare

things in place, according to Webster, is increased public demand for them. “It would be nice to think that this could be achieved simply by drawing attention to food produced to higher welfare standards” by such things as awards given out by the RSPCA. “In fact,” he notes, “public opinion is much more likely to be affected by aversion to perceived cruel (e.g. battery cages) or unfair practices.”

Nicol sees the 2012 EU ban on battery cages as the biggest factor that will affect industry action, but also points to “a good working relationship” that exists between scientists and industry in the U.K. as having an effect.

Speksnijder says that in Canada “a broad highway of communication between the industry and consumers must be developed. The issue of ‘Two Solitudes’ must be overcome.”

Crystal Mackay says, “I definitely do not think poultry welfare concerns have been adequately described to consumers. They are definitely confused about what to believe. Most consumers get their information from the media. Special interest groups promote simplistic messages based on ‘free everything.’ At OFAC we’re working on this with resources like our Virtual Farm Tours on www.farmissues.com and information in the ‘Real Dirt on Farming’ booklet which explains farm animal housing isn’t that simple.”

Mackay stresses that “the best way to communicate with anyone who isn’t familiar with farming about poultry welfare is to start with explaining how important it is and how much you care. Typically farmers and industry people get into too much technical information and ‘how’ we do things, and we forget to explain ‘why.’ At OFAC, we approach explaining animal care with the honest answers to ‘here’s how and why it’s done, not everything is perfect or simple, and here’s what is being done to work on problems for the future.’”

Mackay considers the growing number of consumers who care enough to ask or look up information on finding out more about how birds are raised “our big opportunity” and “also our biggest challenge.” ■

Seeusat Booth#4950,atthe InternationalPoultry&FeedExpo; January23-25,2008,GeorgiaWorld CongressCenter,Atlanta,GAU.S.A.

Energy On-farm Wind Power

Bayview Poultry Farms installs wind turbines to reduce energy consumption and produce environmentally friendly eggs

BY DAN WOOLLEY

Glen Jennings of Masstown, N.S., can justifiably consider himself a poultry industry pioneer.