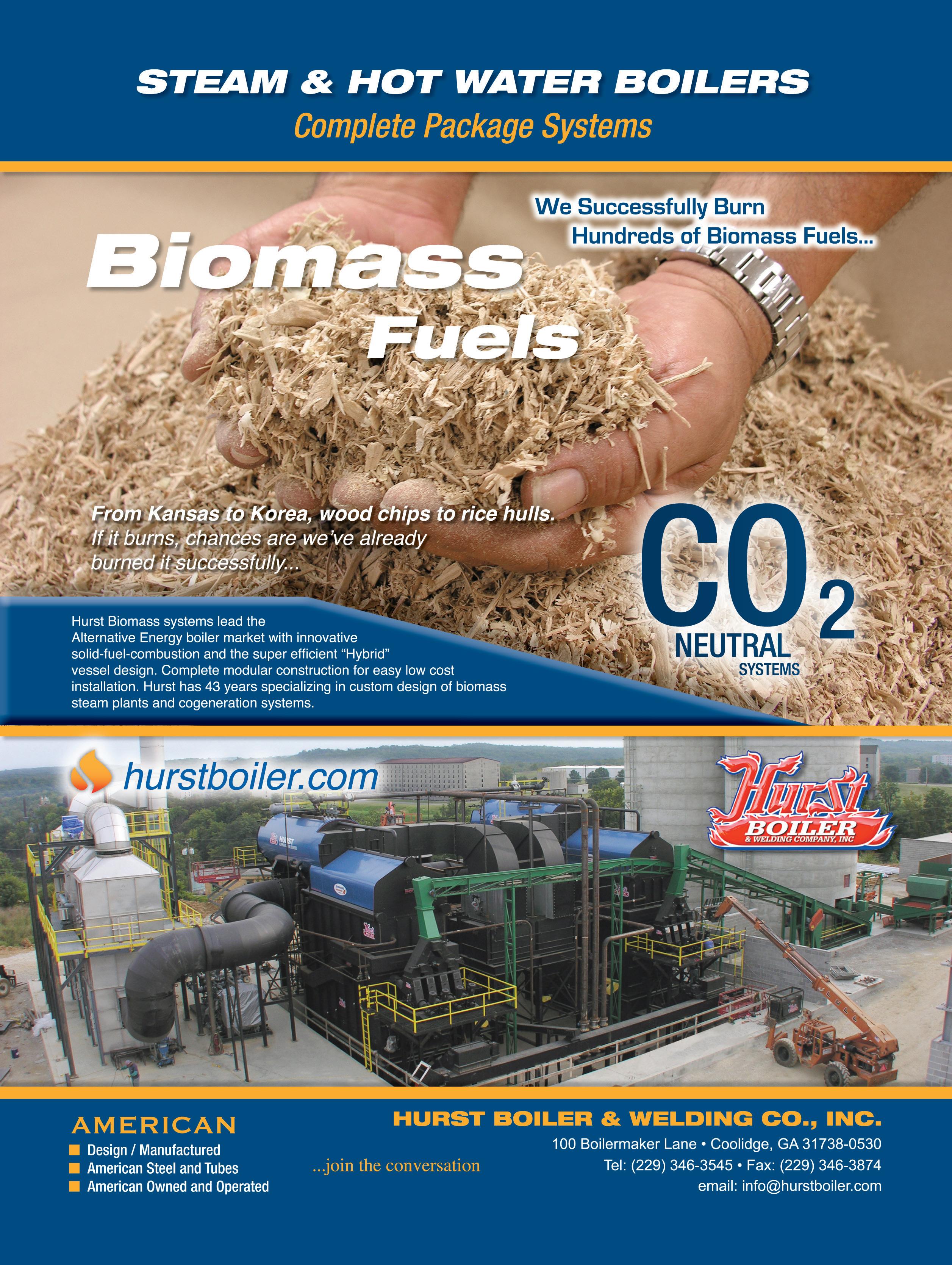

The mountain pine beetle has taken a toll on western trees. Will bioenergy companies get to the dead wood before nature takes its course?

North American biomass operations are beginning to adopt some innovative slash handling and transport solutions.

Fraser Papers’ Plaster Rock, New Brunswick, sawmill is more than 100 years old and now has a new lease on life, thanks in part to a project that will reduce its energy costs.

Professional engineer Arie Verloop describes how biomass combustion problems can be traced to issues with time, temperature, and turbulence.

Delegates to the Canadian Renewable Fuels Association’s sixth annual summit were reminded that they need to know their input costs, variables, risks, and competitors.

“Combustion

problems can be eliminated, and relative trouble-free combustion can be achieved, by upgrading in three major areas.”

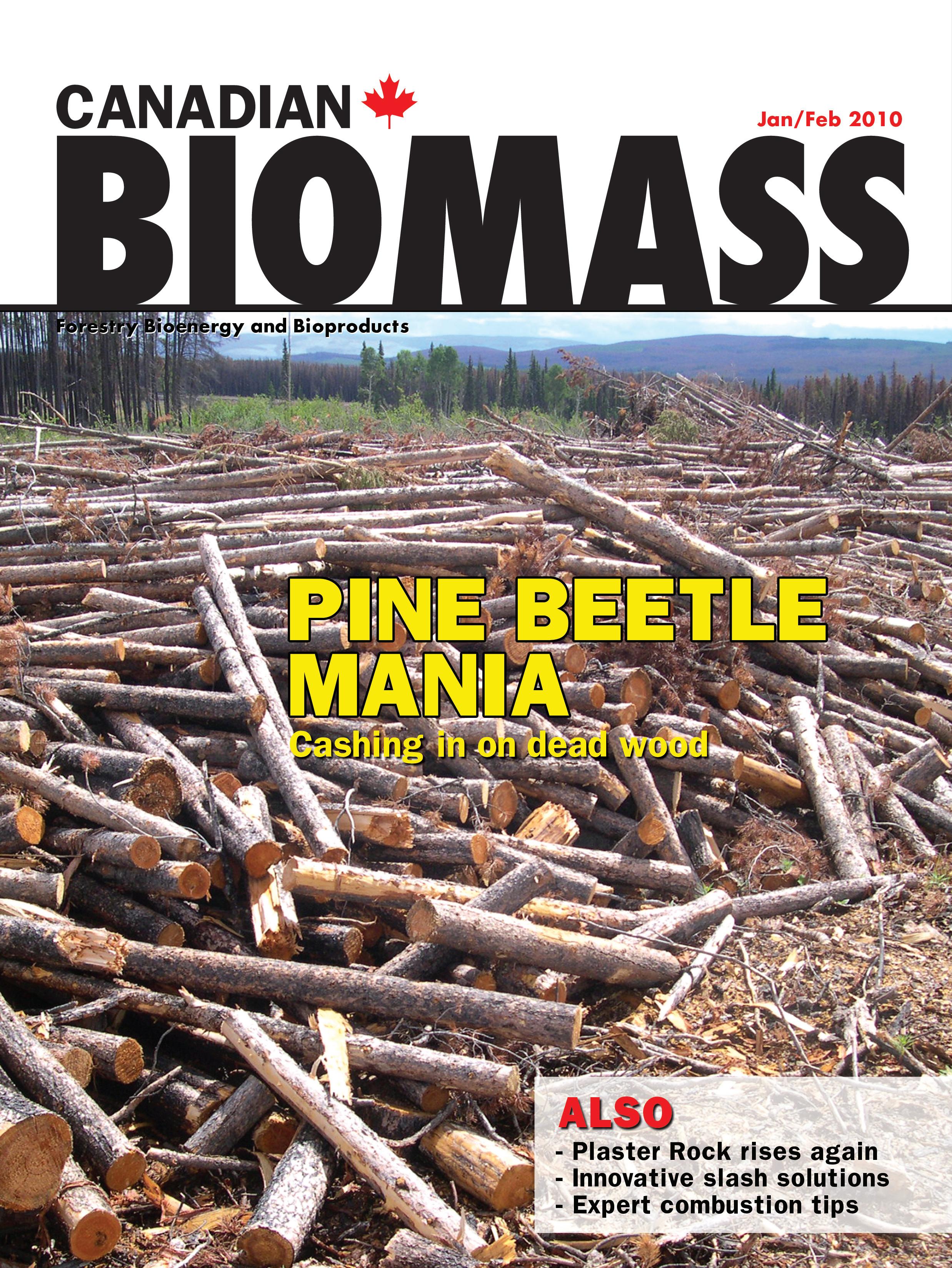

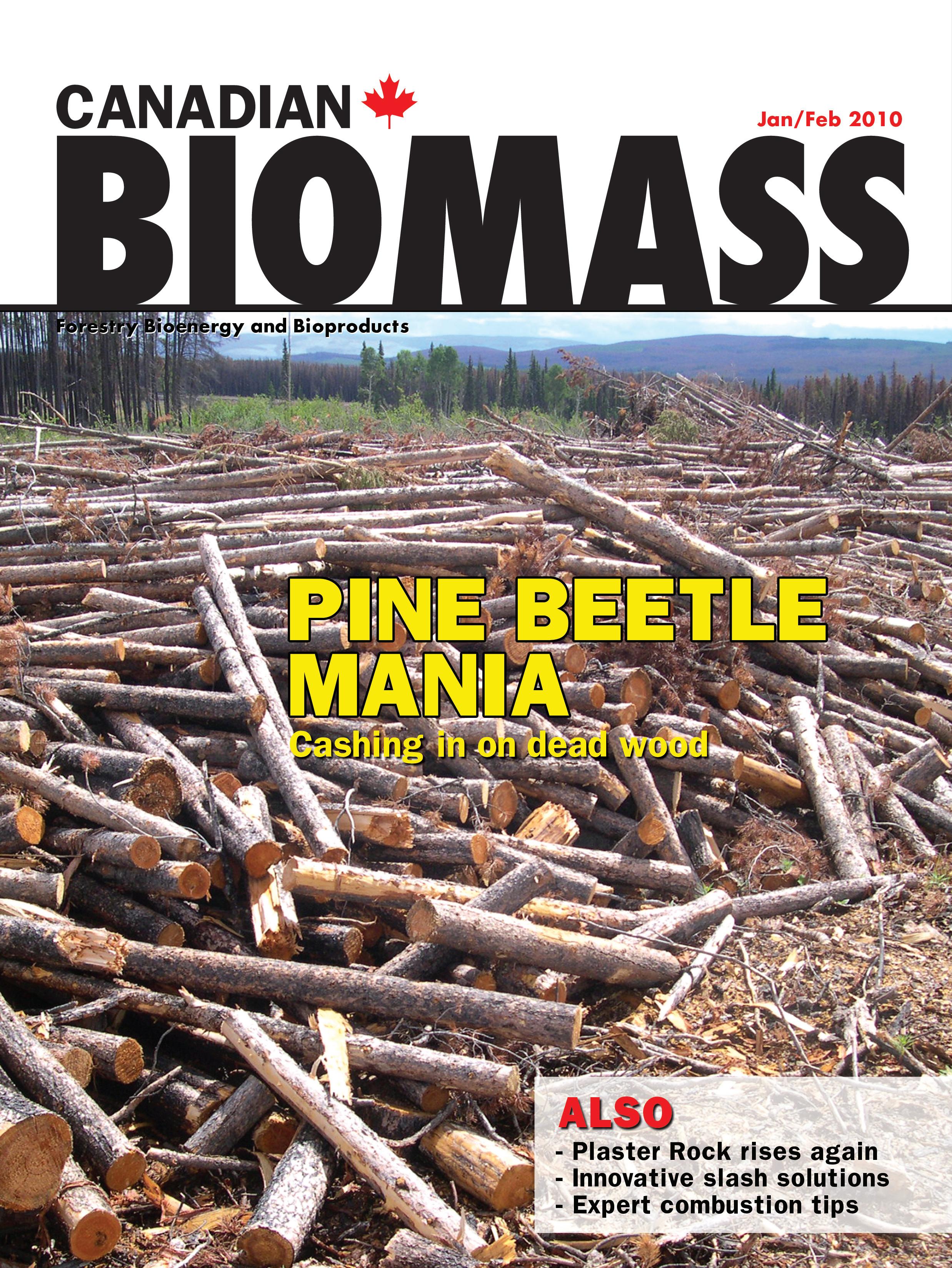

Roadside residues await pick-up after sawlogs were recovered from a mountain pine beetle salvage harvest near Quesnel, British Columbia.

Story on page 8.

Photo: Jack MacDonald/ FPInnovations

There are plenty of renewable energy projects on the books; some of them even make sense.

on’t get me wrong – I love forest biomass. It’s a great Canadian asset that is currently underutilized. It’s a renewable energy option in a country that will soon need all available options. It’s home grown, building our communities and filling our wallets. For the right entrepreneur with the right idea, opportunities abound. Still, from time to time a dose of reality helps keep us humble, forces us to do our homework, and helps separate bad ideas from golden opportunities.

Just such a dose was applied to delegates at the Canadian Renewable Fuels Association’s Growing Beyond Oil Summit held in Vancouver last December. Don Roberts of CIBC World Markets addressed bioenergy from an investor’s perspective, and the view was enlightening. Don’s basic message was simple – people are reluctant to invest in something with a lot of unknowns. While biomass has a lot of positives right now, certainty isn’t among them. Key variables include the price of fossil fuels, the price of carbon, the cost of feedstock, public policy, and conversion technologies. “At present, all five of these variables are in a state of flux, and investors hate uncertainty,” is how Don summed it up for a suddenly quiet audience.

gies – either wood pellets or direct-fired biomass combustion. Both routes use proven, relatively simple technology. There will be movement on the biofuel and biorefinery front, especially among pulp and paper players, but that approach is best left to those with deeper pockets, larger asset ledgers, or subsidies.

Feedstock cost and availability is also something that those in forest biomass have a better handle on than others looking at the sector. We have the skills, the relationships, and the complementary businesses to help get biomass where it needs to be at reasonable costs. The key is to make the right products from the right fibre in the right place.

Even public policy is in our hands to the extent we wish it to be. Maintain sustainable operations and prove it, develop professional public communications efforts, and do a little skilled lobbying work, and public policy will go your way more often than not. As a bonus, we bypass both the food vs. fuel and indirect land-use change issues plaguing agricultural biomass. Similarly, create viable domestic markets to help diversify the revenue stream from your pellets, and investors will breathe easier.

Volume 8

Editor/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Associate Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Contributors - Colleen Cross, Reg Renner, Mark Ryan, Evelyne Thiffault, Bill Tice

Market Production Manager

Josée Crevier (514) 457-2211 ext 21 jcrevier@forestcommunications.com

National Sales Managers Tim Tolton - ttolton@forestcommunications.com 514-237-6614

Guy Fortin - gfortin@forestcommunications.com 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8 Ph: (514) 457-2211 Fax: (514) 457-2558

Western Sales Manager Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Kelli Kramer

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0318-4277

Circulation

e-mail: cnixon@annexweb.com Tel: (514) 457-2211 Fax: (514) 457-2558 Mail: 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8

Subscription Rates: Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $6.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

From time to time, we at Canadian Biomass make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

Existing and proposed forestry biomass projects have no control over the price of fossil fuels or the value put on carbon, but they can certainly consider the other three when crafting their business models to be as attractive as possible to investors, partners, or possible employees. For instance, most forest biomass businesses currently rely on solid biomass conversion technolo-

So before you visit your banker with the next best biomass project, carefully consider Don’s five variables and do your best to minimize the uncertainty surrounding each. In the meantime, read our new column on project funding on page 13. •

Scott Jamieson, Editor sjamieson@annexweb.com

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.com

Roddickton-Bide Arm, NL –The government of Canada is providing $1.18 million to assist Northern Peninsula Forest Resource Association Inc of Newfoundland in developing an inventoried wood lot in support of a new wood pellet facility located in the town of Roddickton-Bide Arm. The funding for the project comes from the Community Adjustment Fund.

“This initiative represents a strategic investment in a project that will assist the development of a new wood pelletizing plant which is expected to start production in the fall of 2010 and which brings important value-added capacity to the regional forest

industries sector,” says Senator Fabian Manning on behalf of the Honourable Peter MacKay, minister responsible for Newfoundland and Labrador.

The project is of importance to some 20 local business operations that employ about 150 people in the forest industry. Business and community leaders in the Roddickton-Bide Arm area have identified this project as a strategic opportunity to support the creation of additional employment in the region. The inventory of wood fibre will serve as feedstock for the local wood pelletizing facility, which will produce pellets for both the domestic and international markets.

Montreal – Hydro-Québec has accepted eight bids for a total of 60.7 MW in response to its April 14, 2009, call to purchase power generated by biomass cogeneration in Quebec. Electricity deliveries are scheduled for December 1, 2012. The average price of the winning bids is 11.2 cents/kWh, including 0.4 cents/ kWh for transmission costs.

The projects call for capital expenditures of about $180 million, plus another $39 million for transmission infrastructure.

production of these installations. The terms of the contracts could range from 15 to 25 years.

Biomass Ad Final:Layout 1 1/4/10 12:26 PM Page 1

According to the original call for tenders, the biomass used within the new cogeneration installations has to correspond to a minimum of 75% of the combustible used for the electricity

Hydro-Québec Distribution is working with the project proponents to finalize the contracts, which will then be submitted to the Régie de l’énergie for approval. The proponents are responsible for obtaining all necessary permits prior to the start of construction. Three companies were selected to provide 20 MW of power generated from landfill methane. One company will provide 7.8 MW from two biodigesters. The remaining 32.9 MW will be provided by three companies using residual forest biomass.

Beltran Technologies, Inc. 1133 East 35th St., Brooklyn, NY 11210 USA 718.338.3311 • Fax: 718.253.9028 info@beltrantechnologies.com www.beltrantechnologies.com

Beltran’s advanced technology converts carbon-based waste into profitable bioenergy, biofuels and co-products your company can use now!

• Biomass feedstock-flexible system can use low-value agricultural, animal, industrial, wood or municipal wastes.

• Produces clean-burning, multi-use synthesis gas, combined heat & power (CHP), biofuels, hydrogen, marketable chemicals.

• Advanced gasification reactor, wet electrostatic precipitator and engine-generator are closely integrated for optimum efficiency.

• Scalable, adaptable solution for harvesting safe, renewable energy, reducing pollution and CO2, and turning costly waste into sustainable profit.

Ask for our free TECH REPORT, From Waste to Watts.

Williams Lake, BC – Pioneer Biomass, a new subsidiary of the Pioneer Group, will soon be operational with funding support from the Government of Canada’s Community Adjustment Fund and the Northern Development Initiative Trust’s Capital Investment and Training Rebate program. The Pioneer Group is a familyowned business that includes log homes, land development, logging, trucking, and

forest management. Pioneer Biomass will use two custom-built horizontal grinders to produce wood fibre that will be sold for pellet production and hog fuel biomass for cogeneration plants in the Cariboo region of British Columbia. Emphasis will be placed on using mountain pine beetle logging waste.

The federal government’s Community Adjustment Fund is providing $1.15

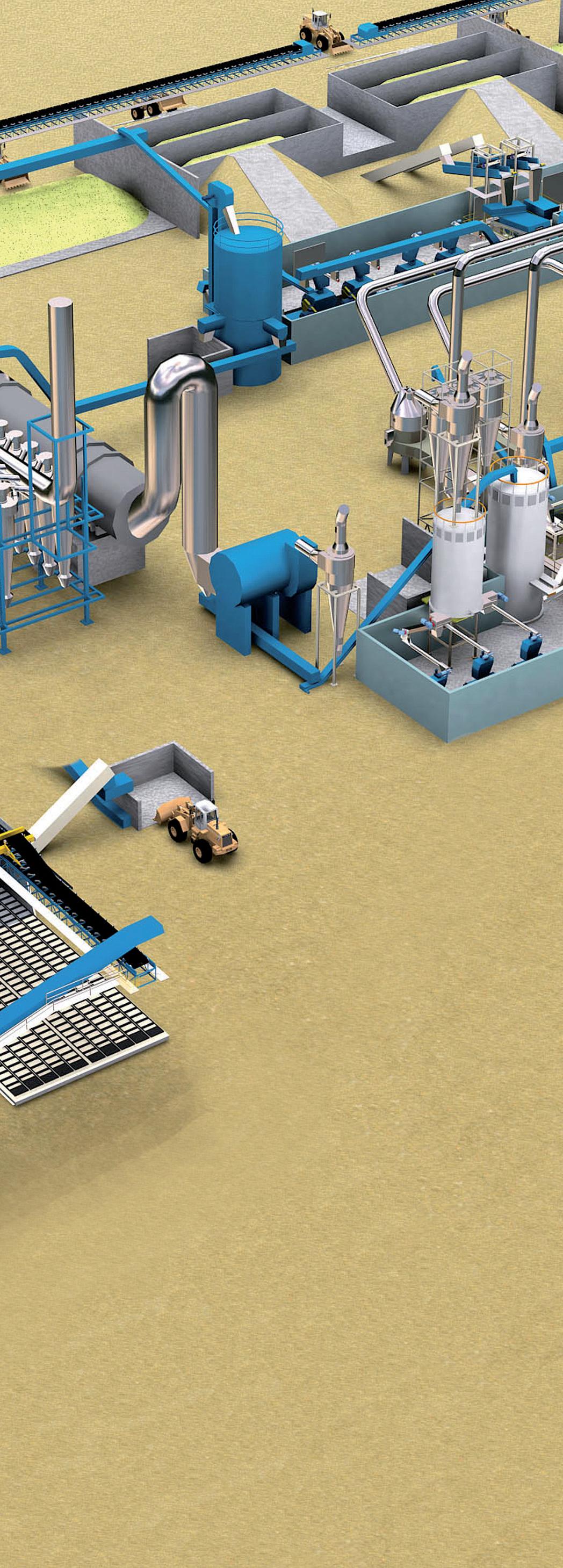

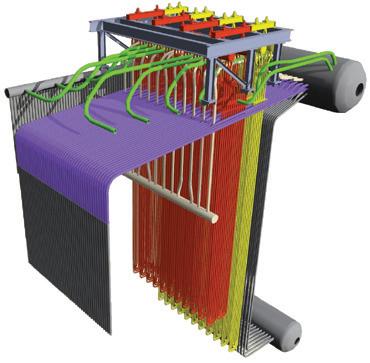

Quality pellets, guaranteed. For perfect pellets the entire production system must work together flawlessly. Buhler enables total process control by providing a complete process design package and key equipment for drying, grinding, pelleting, cooling, bagging and loading. This, combined with Buhler ’s integrated automation system, unrivaled after sales support and training provides a seamless solution, guaranteed.

million towards the project. In addition, the Northern Development Initiative Trust has approved funding under the Capital Investment and Training Rebate program to support the creation of 24 jobs associated with the start-up. “This funding plays an important role in out ability to move forward ith this project,” says Marcel Therrien, director of Pioneer Biomass. Pioneer Biomass plans to begin operations in early 2010.

Cottles Island Lumber Company has invested in a pellet plant and is now supplying premium wood pellets to stores throughout Atlantic Canada. It is a family-owned business located 1 km south of Summerford, Newfoundland. It also offers various residential and commercial wood-pellet heating appliances.

Edmonton-based Dansons is partnering with Sundance Forest Industries to make wood pellets from wood residue at Sundance’s mill in Edson, Alberta, located 200 km west of Edmonton. Initial production is estimated at 15,000 tonnes/year of pellets, with capacity increasing eventually to about 160,000 tonnes/year.

The Burns Lake Lakes District News reports that Tahtsa Timber has signed a 12-year, 2.5-million cubic-metres biomass purchase agreement with the Burns Lake Community Forest to supply a proposed pellet plant.

Terrace, British Columbia, the location of a proposed wood pool, is being considered for development by various bioenergy companies. GV Energy of Calgary, Alberta, is considering the Skeena Industrial Development Park as the site of a new biorefinery to produce dimethyl ether from woody biomass. In addition, General Biofuels, an international company, is considering the region for a pellet plant that could start production in 2011.

Waterdown, ON – Sustainable Development Technology Canada (SDTC) has awarded a project led by SunOpta BioProcess Inc up to $5.5 million in funding for the construction of a pilot plant. The plant will demonstrate an integrated process to produce both food-grade xylitol (a sugar substitute) and fuel-grade cellulosic ethanol. Using wood chips as feedstock, SunOpta’s technology is projected to decrease process water consumption by up to 75% compared to producing corn ethanol, but with the life-cycle carbon benefits of cellulosic ethanol. The proposed project involves the construction of a demonstration plant capable of producing up to 620 tonnes of xylitol and two million litres of cellulosic ethanol per year. According to SunOpta BioProcess president Murray Burke, the integrated biorefinery technology will produce xylitol, liquid biofuels from cellulose, and bioenergy from lignin. The SDTC funding for the project will be leveraged with funding from members of its consortium, including Xylitol Canada and Emerald Forest Sugars Inc.

Atlanta, GA – Raven Biofuels International Corporation has established a partner Canadian corporation, Raven Biofuels Ltd (RBL). RBL will develop production technologies for biofuels and renewable chemicals in conjunction with the forestry sector and will pursue Canadian opportunities in bioenergy and clean technology.

The first proposed project is the Tk’emlups Biorefinery Project, to be located in Kamloops, British Columbia. It will operate through a joint venture with the Kamloops Indian Band (KIB). The goals for this project in early 2010 are to: complete a preliminary engineering study, conclude a feedstock study, hire key personnel, finalize site agreements, initiate permitting, perform initial feedstock testing, formalize initial feedstock supply agreements, sign initial off-take agreements for biorefinery products, and secure additional funding.

The proposed Tk’emlups Biorefinery will require a continuous fibre supply of 500 dry tons/day to produce its initial output of 11 million gallons/year of fuel grade ethanol, chemicals, and lignin. It is planned that KIB will be the primary fibre supplier for the biorefinery. The biorefinery design will be scalable to increase output once capacity is reached.

Sandwell Engineering has been hired to review and assess the technology and process for dilute acid hydrolysis of wood to produce chemicals and ethanol. Sandwell will assess the applicability of this process to mountain pine beetle-killed lodgepole pine and will review the application of the equipment to a production plant. It is also considering new design applications whereby a biorefinery could be integrated into a kraft pulp mill. Further lab testing or pilot plant runs will be required to confirm design criteria parameters for commercial development of the refinery.

Mountain pine beetle-killed wood is ready for the taking, but can bioenergy companies get to it before nature takes its course?

By Treena Hein

BritishColumbia is abuzz with bioenergy. Of the 68 municipalities, 103 First Nations, and numerous rural settlements in the region of the mountain pine beetle (MPB) epidemic, not many are ignoring the possibilities of turning “beetle wood” into pellets, direct heat, and/or electricity – and at the same time, into profit, jobs, and hope.

The 2008 update of the Mountain Pine Beetle Action Plan, released in 2002 by the BC Ministry of Forests and Range (BCMFR), estimates that since the late 1990s, MPB has killed over 620 million cubic metres of lodgepole pine. The affected area covers more than 130,000 square kilometres, about four times the size of Vancouver Island. By 2015, the pest is expected to have killed 76% of the pine volume in the interior of British Columbia and will have continued its march eastward.

There will be 400- to 500-million hectares of MPB-destroyed trees in British Columbia available for harvest in the next 20 to 30 years, assuming there’s no major fire or blow-down, says Don Gosnell, BCMFR manager of bioenergy initiatives. But an abundance of dead trees doesn’t necessarily spell success for bioenergy projects, in his opinion. “The markets will determine whether the wood comes out or not, for whatever reason,” Gosnell says. The beetle wood is declining in quality, and trees are breaking off halfway up, he notes, leaving a difficult and dangerous situation for those who want to come in and clean up.

“Advanced regeneration is occurring in a lot of places,” Gosnell adds, “and the gov-

ernment won’t let anyone come in because they’d damage that undergrowth. Some stands are too remote or on terrain that is unharvestable.” He says that, currently, there are tenure opportunities of lowerquality stands of dead pine offered by the province, and that the “reasonably healthy” pulp sector is using some of that.

“To get investment for a bioenergy project,” Gosnell explains, “you have to secure supply and prove you can truck it to your plant with logistics that make sense.” Traditionally, that has taken the form of residue from sawmills, many of which have shut down in recent years. For these reasons, most bioenergy projects that aim to use MPB-killed wood do not use it exclusively as raw material.

Securing fibre supply continues to be a challenge for the developing biomass energy sector, agrees Tony Sauder, forest feedstocks program leader for FPInnovations, which has its head office in Pointe-Claire, Quebec.

“For areas of the BC interior where the MPB has had a presence,” he says, “the long-term availability of roadside harvest residues will decrease over the next five to ten years and will be replaced by accumulations at satellite merchandising yards and the harvesting of dead, standing timber to allow reforestation to proceed. This means the general price for feedstocks will increase significantly, as users must cover more transportation costs and more development costs.”

There is a silver lining, however, in that the trees can still wait some time for harvest.

Dr. Kathy Lewis, University of Northern British Columbia, samples mountain pine beetle-killed trees to determine the shelf life of affected trees.

because the entire trunk is in contact with the ground, says Lewis. Moist soil can lead to rapid fall-down because it helps keep the wood moist and ripe for decay fungi, but drier sites can also provide high fall-down rates because they support enhanced carpenter ant activity.

“The limiting factor for [usable] lifespan is the fall-down rate of the trees,” says Dr. Kathy Lewis, professor of ecosystem science and management at the University of Northern British Columbia (UNBC) in Prince George. Lewis’ research shows that standing MPB-killed trees up to six months dead possess greenwood characteristics. Between two and eight years after death, the wood shows “stable properties,” and most trees are still standing. Starting around the eight-year mark, however, they begin to fall in large numbers because of rot and woodborer infestations at the base. Once a tree falls, rapid deterioration ensues

The mountain pine beetle epidemic has decimated forests in central British Columbia and continues to spread.

Another silver lining can be found in the fact that companies are ready, willing, and able to dive into bioenergy. “The existing forest industry has long experience with handling wood fibre from the forest and is well positioned to work with energy companies to supply biomass for new processes,” says Sauder. “The existing Canadian pulp industry [also] has infrastructure for generating electricity from biomass.” For example, Canfor Pulp Limited Partnership has cogeneration plants at its three BC pulp mills. Electricity generation at its Prince George and Intercontinental mills is being expanded incrementally, and opportunities for further expansion are being investigated at the Northwood facility.

At Pinnacle Pellet Prince George, most of the feedstock is beetle wood. “Generally up until about a year ago,” says chief operations officer Leroy Reitsma, “we exclusively used mill byproduct fibre. However, since the economic downturn, mill production has decreased while at the same time, the degradation of MPB-killed trees has increased significantly, so we’re moving into the forest and cleaning up the materials left behind, which are not merchantable for lumber production.”

There is definitely enough fibre out there, in Reitsma’s opinion, if you’re smart about it. “The key principle we’ve always

adhered to is to work with sawmills that are leaders in the industry,” he says. “For example, we’ve worked together with Canadian Forest Products (Canfor) and the Moricetown Native Band in Houston, British Columbia, to benefit everyone in building a pellet plant as partners beside the Canfor sawmill in 2006. The sawmill has realized an increased revenue stream from its byproducts, and the partnership receives steady access to raw materials.”

Abbotsford-based Biomass Secure Power is another company using a partner strategy. It has an agreement with Lower Nicola Indian Band to begin construction in early 2010 on a 12-MW biomass cogeneration and pellet plant in Merritt. President and CEO Jim Carroll says that the plant will use only beetle wood sourced from local mill residue and specifically cut under tender.

More Versatility. More Opportunity. Normally, high-quality chips and mulch are produced on separate machines, but with the Morbark® Quick Switch, you can produce both products and virtually double your market opportunities with a single Morbark ® grinder. The best horizontal grinders on the market are now the most versatile with the introduction of the Morbark ® Quick Switch Grinder-to-Chipper Conversion Kit.

Horizontal Grinder-to-Chipper Conversion Kit. Turn grinder downtime into profit by modifying the hammermill of your Morbark® horizontal grinder in the field – without special tools or heavy equipment. Make the switch and produce high-quality biomass fuel chips in only a few hours!

Go to Morbark.com/QuickSwitch to see a video demonstration or call 800-831-0042 for more information.

Another strategic alliance – this one between Western Biomass Power Corporation of Prince George and the Tsilhqot’in National Government – will submit a Phase II proposal to BC Hydro’s Bioenergy Call for Power. If accepted, a $260-million, 60MW generating plant (with some heat also produced) using mostly beetle wood will be built in the Cariboo Chilcotin region.

Western Biomass’ manager of business development, Jeff Paquin, says, “The Tsilhqot’in National Government recently bought an idle sawmill that shut down about a year ago, which employed mostly First Nations people, and Western Biomass bought the land next to it. This project, if accepted, will mean that the sawmill’s financial viability will greatly improve and thereby sustain traditional sawmill jobs while creating new bioenergy employment.” The cost of forest management planning, harvesting, and reforestation will be shared between the two operations, and both partners will share electricity profits. Western Biomass is also submitting a proposal for a 30-MW plant with Gitxan First Nations in the Hazelton area.

The BC government instituted the Bioenergy Call for Power as part of its efforts to become electrically self-sufficient by 2016. Phase I, conducted in 2008, resulted in four electricity purchase agreements from projects headed by Canfor Pulp and PG Interior Waste to Energy in Prince George, Domtar Pulp and Paper Products in Kamloops, and

The Northern Development Initiative Trust, an independent regional economic development corporation, continues to distribute funding on behalf of the British Columbia and Canadian governments for many new bioenergy initiatives that involve the use of mountain pine beetle (MPB)-killed wood. These include the following.

Del-Tech Manufacturing has received support to develop a biomass cogeneration plant at the Baldy Hughes Therapeutic Community addictions centre near Prince George. Del-Tech has also received a $5.5-million loan towards the construction of a $15-million thermal oil biomass heating plant to be leased to Canfor’s Mackenzie sawmill for dry kiln operation. Del-Tech and Nechako Mechanical are receiving assistance to develop new wood pellet-fired boiler systems that can compete with low-emission European models.

Various partners in and around Fort St. James have received funds to commission a marketing plan to further develop bioenergy opportunities as part of the development of a worldclass bioenergy industry cluster in that community.

Pinnacle Pellet Meadowbank has received a loan to install a biomass decontamination and preparation system. This will enable the use of additional processed fibre directly from logging operations and reduce debris-related costs.

Pioneer Biomass is receiving a loan of about $1 million to expand its business into the recovery of wood waste that would normally be burned on logging sites. The company plans to operate two custom-built horizontal grinders and the support equipment to produce and deliver material to Capital Power and Pinnacle Pellet.

Northwest Wood Preservers is receiving a $2-million loan towards constructing a $5.5-million pellet plant at the Vanderhoof Specialty Wood Products value-added finger joint lumber plant in Vanderhoof, near Prince George. The pellet plant will use all residual waste from the fingerjoint plant, which in turn primarily uses lumber trim ends from MPB-killed trees.

All-Wood Fibre, a biomass chipping company that now offers a range of biomass procurement and processing services, has received expansion money to source fibre and purchase its first grinder.

Cariboo Waste Products in Quesnel, a newly formed division of Clan Logging, has received rebates to support an expansion to manufacture wood chips for use in pulp, pellet, and bioenergy plants.

In November 2009, the BC Bioenergy Network (BCBN), a provincially funded organization supporting the growing bioenergy sector, announced a strategic agreement with the First Nations Energy and Mining Council and the First Nations Forestry Council to further the development and commercialization of bioenergy technologies. In October 2009, BCBN announced a similar strategic agreement with Terasen Gas and distributed $52,500 to Initiatives Prince George to support the Northern Bioenergy Partnership, an industry-led collaboration that will establish the region as a bioenergy leader.

Our customers want complete pellet production plants from a single source –We have the expertise to deliver turnkey process equipment.

Günter Natus – Sales Director

Your benefit from an experienced and wellknown reliable supplier of complete wood production plants:

- Complete pellet plants including engineering from one source - Main equipment from Dieffenbacher Group

- Turnkey plants with performance guarantee

- Fast start-up and reliable production

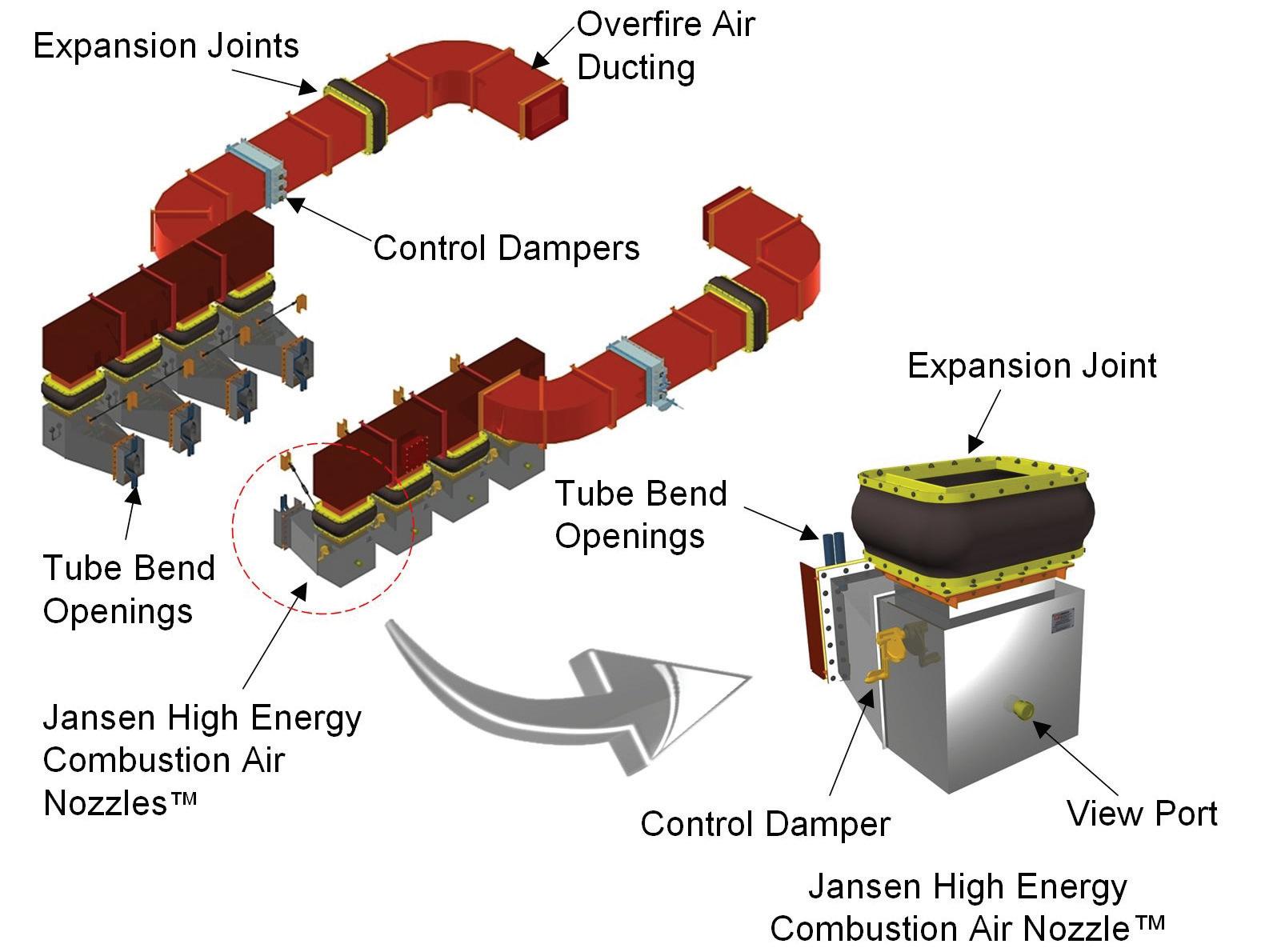

Since 1976, Jansen Combustion and Boiler Technologies, Inc. (JANSEN) has provided customized engineered solutions to owners/ operators of boilers in the Forest Products and Waste-to-Energy Industries. Our mission is to improve the operating performance (fuel burning capacity and economy, efficiency, and emissions performance) of existing boilers that burn difficult fuels such as biomass, chemical spent liquors, municipal solid waste (MSW), refuse derived fuel (RDF) and tire derived fuel (TDF).

JANSEN has conducted engineering performance evaluations of over 300 boilers, worldwide, and has provided combustion system and/or superheater upgrades of over 80 biomass, chemical recovery, MSW, and RDF boilers.

JANSEN has the capability and experience to function as your one-source solution to boiler retrofit projects. With the ability to define, engineer, contract and manage design-construct projects, we offer EngineerProcure-Construct (EPC) capabilities.

A synopsis of our broad range of services:

> Full service engineering design for steam, power, and combustion systems

> Biomass, MSW, RDF, TDF, fossil fuel, and chemical recovery boiler performance evaluations

> Effective overfire air (OFA) delivery system upgrades on biomass and other waste-fueled boilers

> Replacement or upgraded superheater design and supply

> Boiler circulation analyses

> Computational Fluid Dynamics (CFD) modeling

> Feasibility studies and cost/benefits analyses

> Emissions reduction (CO, NOx, PM, SO2, TRS, VOC)

> Operations support and training

Zellstoff Celgar Limited Partnership (Mercer International) in Castlegar. Building on Phase I, Phase II is calling for both larger-scale and community-level proposals that involve sources such as underused forest-based biomass and wood waste sourced from new forest tenure.

Here is a roundup of other projects, some well established and some new. Capital Power (formerly EPCOR), based in Edmonton, Alberta, runs the largest biomass electricity plant in North America. Built in 1993 in Williams Lake, it produces 68 MW from both mill residuals and logging waste.

A wood gasification system with 15-million-BTU output will be operational at UNBC by the end of 2010. It will deliver high-temperature hot water to the existing water heating system. In addition, UNBC has selected Nexterra Systems to supply and install a turnkey biomass gasification system that will displace up to 85% of the natural gas currently used to heat campus buildings. It will also serve as an anchor for the new Northern Bioenergy Innovation Centre. Construction began in June 2009 and will be complete by mid-2010. Nexterra has also installed biomass gasification systems at the Kruger tissue mill in New Westminster and at the Tolco plywood mill near Kamloops, and has other projects on the go.

The city of Quesnel, through its Community and Economic Development Corporation (QCEDC), is gathering funding with its partners for an innovative cogeneration project with an anticipated completion date of mid2012. “The system would likely be a first in North America,” says QCEDC executive director Jim Savage. The heat

from the existing local sawmill wood burner (used to heat kilns) will be recovered to produce up to 2 MW of electricity – about half Quesnel’s current residential consumption. A projected 5.5 MW of waste heat will be used to heat large community buildings.

At its demonstration plant in McBride, Alterna Biocarbon of Prince George is using Van Aardt process pyrolysis-based technology to transform biomass feedstock into a variety of carbon-based energy products.

FPInnovations (Feric Division) has completed a number of studies to evaluate systems for grinding MPB-killed wood. For example, they’ve analyzed the use of a track-mounted horizontal grinder to comminute roadside residues in the BC southern interior for Domtar’s pulp mill at Kamloops.

Pacific Bioenergy’s pellet plant in Prince George is using a significant amount of beetle wood from logging slash and sawmill residuals.

Western Biomass’s Paquin believes bioenergy’s future in British Columbia is very bright in terms of the new research, training, employment, and investment it is creating. “In other words,” he says, “there is a silver lining to the MPB infestation, and the opportunity is resulting in the full and complete use of wood fibre, with long-term forest management plans being developed by industry and First Nations alike.” •

By Reg Renner

s the Vancouver 2010 Winter Olympics approach, our thoughts turn towards the athletes and all the hard work and sacrifices that have gone into making their respective Olympic teams. They started with a dream that might have begun when they were six years old. It doesn’t matter how or when the dream started. It only matters that after tremendous sacrifice and hard work, they are now on the edge of fulfilling their dream of competing in the Winter Olympics.

In this upcoming six-part series on financing your bioenergy project, I will focus on a 10-point checklist that will help you expand your project idea into an operational business. I will discuss feedstock security, the marketplace, equipment selection, business plans, and how to build your credit strength. The analogy of “training for the Winter Olympics” will remain my focus, because in this marketplace, if you are not serious about your involvement and preparation, then you are not ready to move your project from dream to reality.

After joining Atticus Financial Group in 2004, I was quickly introduced to the concept of equipment financing and how that might apply to the greenhouse industry. A month into my new career, a local greenhouse grower toured me through his biomass boiler room and then pointed out that he had used an equipment lease to finance his multi-million-dollar boiler system. The door opened and my dream started – helping others use equipment financing to fulfil their dreams to enter the growing bioenergy marketplace. The real challenge is how we move your dream from a vision to the reality of a successful business.

As an example, if you are interested in joining the Canadian Bobsleigh team, the team website (www.bobsleigh.ca) lists the attributes required to participate: explosive

power and strength, speed, self-motivation and hard work, and being a team player. In more than five years of financing projects for the horticultural and bioenergy industry, I recognize that these requirements are also needed for individual and corporate business success. Do you have the courage and determination that is required to plan and practise to make your dream a reality? Are you a serious corporate athlete or just playing in a recreational league for the fun of it?

Many visionary people across North America have the dream of building a pellet mill in their neighbourhood and some even have the feedstock secured, but very few are willing and able to push off and ride the equivalent bobsleigh through the twists and turns of an Olympic course. The reality is that no one would jump into a bobsleigh without having done their research and trained with an experienced crew. No doubt there is risk and reward in this sport, as there is in any business endeavour. So my goal in this series is to help you identify those risks and encourage you to strive for the reward and fulfillment of your dream.

not make his country’s Summer Olympics team, but still held onto his powerful dream of competing in the Olympics. Fortuitously, he stumbled upon a former bobsleigh coach who was hiding out in Jamaica, trying to forget his own dream that had gone off the tracks. The point of this story is that someone with a dream and a strong desire to succeed can be successful beyond even their own imagination.

You will need a team of adventurous supporters and encouragers, along with

In following the analogy of the bobsleigh team, if you haven’t already seen the Disney movie Cool Runnings, then you should check out the movie trailer (go to www.youtube.com and type “Cool Runnings movie trailer”). This hilarious movie not only proves the point that you need a sense of humour to be successful, but it shows that you also need a vision and a strong desire if you are to succeed. This true story is based on a Jamaican track athlete who did

immense perseverance, for there will be adversity, possibly moments of heartbreak, and maybe even some crashes along the way. As a bioenergy visionary, you will need to share your dream with others and start preparing for your own Olympic Games of financing and then building your bioenergy project. In my next article, I will expand on building your team and how to finance your dream based on that timeless question from Cool Runnings:

“Are you feeling Olympic today?” •

Reg Renner of Atticus Financial in Vancouver, BC, finances equipment ranging from biomass boilers to densification equipment. With 38 years of greenhouse/horticultural experience, he also recently helped secure carbon offset credits for four BC greenhouse clients. Email: rrenner@ atticusfinancial.com.

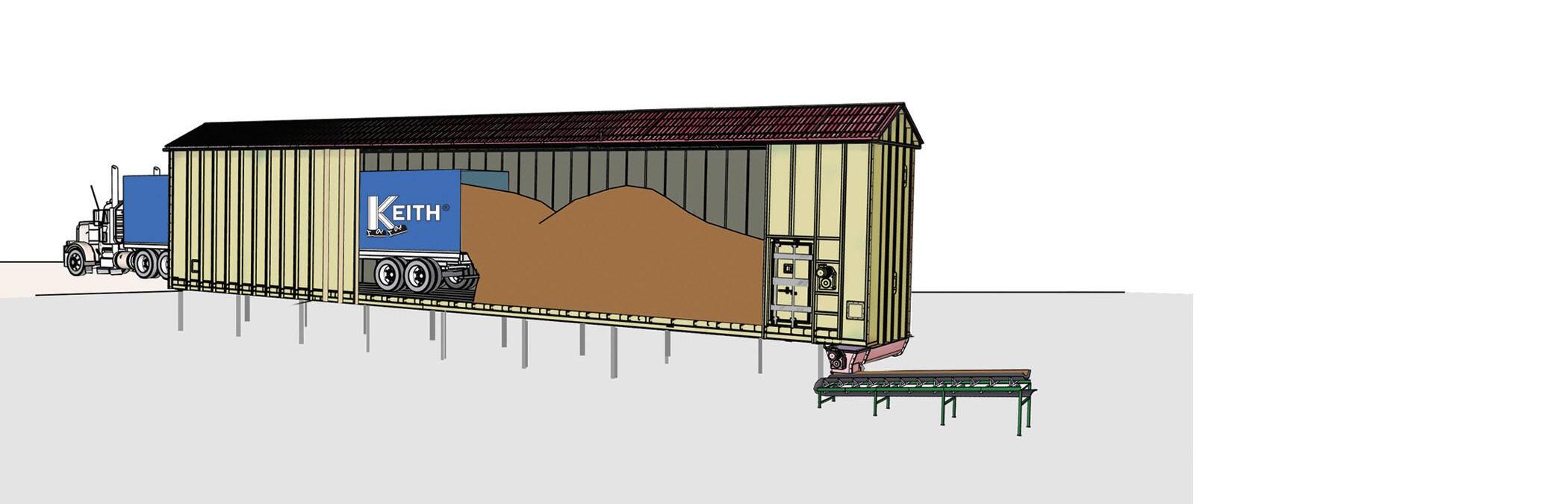

North American biomass operations are beginning to adopt some unique slash handling and transport solutions.

By Heather Hager

orFoperations that get biomass straight from the forest, the first step in the supply chain is deciding how to collect and transport the leftover slash from logging or thinning. Efficient slash handling can be difficult because the material varies in shape and size and lacks density. In an effort to make slash recovery cost effective while maintaining a clean, high-quality product, three machines are going where none have gone before: into the forest.

The Bruks 805 forwarder-mounted mobile chipper, the John Deere 1490D Energy Wood Harvester, and the Ponsse Brush Transport System all have one thing in common: they densify slash while collecting it. Each, however, uses a different strategy to accomplish this.

Bruks’ strategy is to bring the chipper to the slash, rather than dragging the slash to a roadside chipper or grinder, says Blase Grady, vice-president of mobile chipping North America for Bruks Rockwood. A

drum chipper, with 450-hp diesel engine, mounts directly on any brand of forwarder and blows chips into a self-contained chip bin. Once the bin is full, the forwarder moves to the roadside and dumps into a waiting chip van or roll-off container.

The chipper handles slash, tops, limbs, and whole logs up to 20 inches in diameter. The self-dumping chip bin holds about 7.3 bone-dry tonnes and rises up to 14 feet for dumping into transportation containers. The chipper is fuel efficient and has a high peak production rate for its size, says Grady.

“It fits in well in thinning and cut-tolength (CTL) operations,” says Grady. “Once the logging operation leaves, the equipment can come back in and move about the area where they’ve done the logging to collect and chip all the slash that’s left.”

“The efficiency and cost savings of a onepiece operation is key,” he adds. “Logging operations can leave the slash in windrowed piles to dry, and when they go back to chip, send one operator and one machine.” Other benefits are clean chips (if the slash is clean) and the ability to go where chip vans cannot.

Grady says that most biomass harvesting in Scandinavia is done using this type of machine. “We have been making them for 30 years. We probably have 150 operating in Europe right now,” he says. The forwarder-mounted chipper is relatively new in North America, with one currently working in Nova Scotia. Three more are being manufactured in Sweden for use in Colorado, California, and Oregon. In the Canadian context, the mobile chipper is well suited to smaller cut blocks, where bringing in a large chipper/grinder crew is not economical.

John Deere’s strategy is to densify slash by tying it into compact bundles, a strategy tried by several other Scandinavian suppliers over the years. Its 1490D Energy Wood Harvester, also known as a slash bundler, is mounted on a forwarder. “A grapple on the forwarder picks up slash and puts it into a feed chute. The feed chute pulls it in, compresses it, and then wraps the compressed slash with baling twine,” explains Mike Schmidt, manager of forestry renewables for John Deere Forestry. The process is continuous, like making sausage. As the compressed slash leaves the machine, bundles are cut to desired length and fall to the ground.

Finished bundles are 24 to 30 inches in diameter. “Two 10-foot bundles gives you about 1 ton (0.9 tonnes) of green material at 50% moisture content,” says Schmidt. Most operations produce 20 to 40 bundles/hour, depending on operating conditions. He adds, “We’ve put entire invasive western juniper trees with 24-inch butts through the

The John Deere 1490D Energy Wood Harvester compresses slash by up to 80% of its loose volume.

machine without delimbing them, so you can put very large pieces through if you need to.”

“In clear-cuts, if you know before you log a site that you’re going to be bundling that slash, then the machines that process the timber can orient the slash so that a bundler can come through and pick it up out of windrows. That eliminates most of the site prep work for replanting,” explains Schmidt. In thinning and CTL operations, the slash bundler can move within the remaining stand. A trailer-mounted model is under development for whole-tree operations, in which processing occurs at roadside. For a logger interested in producing biomass, says Schmidt, this will eliminate both the expense of an additional forwarder and the need to maintain chipping or grinding equipment.

Bundles are transported using standard logging equipment. “There are a lot of log-

The Ponsse BTS compresses slash and can also handle roundwood.

ging roads, especially in the western United States, where you cannot get chip vans on the road. But if you can get a log truck into the site, you can bring these bundles out,” explains Schmidt. In addition, the bundles can be piled and left to dry or stored until use without worrying about spontaneous combustion or degradation.

The slash bundler is manufactured in Finland and has been available in Europe since 2002, with about 75 units operating in 16 European Union countries. It has recently entered the North American market, with working units in Michigan, Texas, Washington, and Maine. Typically, it requires a large biomass combustion plant with a large grinder as end user to handle the bundles.

The newest strategy in slash handling is Ponsse’s Brush Transport System (BTS). It comprises forwarder-mounted curved bunk arms that move up and down, compressing slash as it is piled onto the forwarder. The original model has bunk arms at fixed locations on the forwarder. A newer model has bunk arms that can be moved closer to the front or back of the forwarder, depending on the distribution of slash in the load space, says Stacy Wagler, technical support and product development for Ponsse North America. The compression bunks can attach to any type of forwarder, provided that it has at least 15- to 16-tonne capacity. “If you put

the bunks on too small of a machine, you will have trouble because you will overload the machine,” says Wagler.

By compressing the slash, the BTS can double or triple the slash-carrying capacity of a standard forwarder, depending on the tree species. “We’ve done some comparison with a standard 16-tonne forwarder that would only get between four and six tonnes with the load maxed right out. With these bunks, we’re getting between 12 and 15 tonnes per load,” explains Wagler. He says the BTS particularly increases efficiency for hardwood slash. “Because there’s so much air in the crowns, they need to be broken and crushed down in the load space to make it efficient.” Increasing the load capacity results in less travelling and fewer loads required than with a standard forwarder. This means less fuel consumption and greater efficiency.

The BTS was developed for and introduced in North America in 2007 and is not currently available elsewhere. One unit is working in British Columbia, and there are several in the U.S. Great Lakes area. Generally, this option requires considerably less capital investment for loggers just getting into the biomass business, but assumes some form of roadside grinding or chipping.

These machines are designed to increase the mobility and efficiency of gathering slash in the field to make forest biomass collection an economical venture. Which option is best for the user will depend on his/her specific operational conditions, as well as the final purpose and end user of the biomass. •

A more than 100-year-old sawmill in Atlantic Canada has a new lease on life thanks in part to a project that will see its energy costs plummet.

By Bill Tice

Abrand new biomass powered energy system is helping a long-standing sawmill in western New Brunswick secure its future. Employees at the Plaster Rock dimension lumber mill, which is owned by Fraser Papers and located in the small town of Plaster Rock, fired up the new equipment in mid-November of 2009.

At a cost of about $10.5 million, the energy system accounted for the biggest portion of an almost $18-million investment Fraser Papers made in the facility. But it hasn’t been an easy ride for the company. The upgrade project had been approved in the fall of 2008; the last log was processed on February 13, 2009, prior to the upgrade work starting. But everything came to a screeching halt four months later in June 2009, when Fraser Papers went into creditor protection. It would be an additional five months before the mill would produce another stick of lumber.

“When we went into creditor protection, we had already gutted most of the

sawmill, we had started work on the energy project, and really nothing was operational except for the planer mill,” explains Paul McKinley, general manager of lumbermill operations for Fraser Papers. “At that point, there was no turning back if we wanted to run again. We had to finish the work in progress.”

The mill site and the project sat idle for approximately two months while Fraser Papers negotiated a repayable loan from the Province of New Brunswick. Securing the government financing was enough to get things rolling again; however, the markets were not so kind. Lumber prices and demand were still low, meaning that even if they could start up earlier, producing lumber would probably be a money-losing proposition.

“With the lumber markets the way they were, it worked in our favour to take our time with the project,” explains McKinley. “The good news is, that allowed us to complete this project carefully and safely, employ many of our own previously laid-off employees to do the installation labour, finish the project without incurring overtime costs, and re-open when we thought the timing was right.”

Once the work resumed, a team of 25 to 30 people, including the mill’s entire main-

tenance team, some operators, and a few helpers, started erecting the boiler and other components in the energy system and began work on other parts of the project, which included two new dry kilns that are heated by the energy system, and upgrades in the sawmill production process. On November 16, 2009 the sawmill officially started up again. By the time the planer mill was re-started in early December, about 140 people were back at work. Two shifts are now running, employing about 175 people.

“These have been very tenuous times for us,” McKinley adds. “With the support of our employees, the New Brunswick

government, our owners, and our suppliers, we have been able to put some of our difficulties behind us and move on.”

Now that they are up and running again, the cost savings alone from the new biomass powered energy system, when compared to the facility’s old oil burning energy plant, will help the mill be more competitive. Prior to the 2009 shutdown, the Plaster Rock mill consumed 5.5 million litres of oil annually when running at full capacity, most of that going to run a pair of approximately 10-year-old oil-fired package boilers that biomass project co-ordinator Ron Beaulieu explains came preassembled on a skid and required only a hook-up for steam and water, and of course, oil.

“We were using the oil-fired boilers for two-thirds of our energy, and we also used four old Dutch oven biomass boilers that date back 60 to 80 years for the balance of our heat,” adds Beaulieu, who is the manager of energy projects for Fraser Papers and splits his time between sawmill and pulp and paper operations across the company. “We were using bunker C oil, which is one of the lowest priced oils on the market, but when prices peaked at around $150 a barrel, our oil costs would have been about $3.5 million when calculated on an annual basis at full capacity.”

Beaulieu estimates that with the annual fuel costs of running the new energy system at just $500,000 per year based on today’s cost of biomass, the mill will see a payback on the $10.5-million investment in about three years. “The financial benefits were of course one of the main driving factors behind the project, but the environmental benefits were also important to us,” he says. “Our emissions were controlled in the past, but with the new energy system in place, our greenhouse gas emissions have been substantially reduced and we are carbon neutral.”

Biomass power isn’t new to Fraser Papers. As Beaulieu explains, the Plaster Rock mill has been somewhat dependent on biomass boilers for years, and at the Edmundston pulp mill, the company installed a cogeneration plant in 1996 that includes a 600,000-pound/hour biomass boiler and a 46-MW steam turbine. “Here at Plaster Rock, we didn’t install a turbine at this time, but we have left the space and designed the boiler such that we can install a 7.5-MW turbine at a later date,” Beaulieu says. “The timing just wasn’t right for us

right now, but we are looking at it for down the road. If it goes ahead, we could sell excess power to the grid.”

After a careful vendor selection process that included proposals and bids from five com-

panies, Fraser Papers went with London, Ontario-based KMW as the main supplier for the Plaster Rock project. “Our timing was good,” Beaulieu says. “We started the submission process right at the beginning of the recession, and companies were starting to feel the pressure, so there were some

• DEAL DEBARKERS

Low maintenance

Highest fiber recovery

• ROTARY SCREENS

Reliable performance

Easy maintenance access

• SLANT DISC CHIPPERS

Mini chips for better drying, less milling

High quality chips from residuals or round wood

• WOOD ROOM PACKAGES

Systems available include log decks and conveyors, as well as debarking, chipping and screening

good deals out there.”

Initially, Beaulieu says they thought about trying to fit all of the new equipment into the mill’s existing boiler building, but they ended up using that space for a fuel bin and leaving enough floor space in the building for the turbine to be added later. A new building was erected to house the KMWspecified Cleaver Brooks 80,000-pound/ hour steam generator (boiler). The energy system runs on mill waste, which is primarily bark from the sawmill’s Cambio and Nicholson debarkers. “Our sawmill will process 18,000 to 19,000 logs/day, and 10 to 12% of each log is bark,” Beaulieu explains. “That gives us about twice as much bark as we actually need for the energy system, so we will send our excess to the Edmundston mill. We don’t need to buy any biomass on the open market or use any biomass from logging operations, so we are essentially selfsufficient in this area.”

The energy process starts in the fuel bin, which can hold up to 350 green tonnes of bark. From the fuel bin, the bark feeds into the KMW combustor, which is an improved Scandinavian design with moveable step grates. The combustor step grates feature three zones, with the first zone designed to condition or dry the fuel, the second to gasify the fuel, and the third to burn leftover carbons. Very limited undergrate air is used, with the bulk of combustion air introduced directly above the gasification zone. Glycol is used to cool down the grates. This heated glycol is then circulated through floor-embedded tubing in the fuel bins to preheat

the biomass before combustion, making the entire process more efficient.

The flue gases from the combustion process, which enter the Cleaver Brooks boiler at 1600°F, heat the water to generate steam before exiting the boiler at 500°F. An economizer that was specified by KMW and supplied by Eco Inc from Tulsa, Oklahoma, preheats the boiler feedwater and further reduces the flue gas temperatures to 250°F. The flue gas then goes through a multi-clone dust collector to remove particulate matter before exiting through the stack to the atmosphere.

The steam generated by the process is sent to a pressure reducing station that takes the steam from 100 pounds per square inch (PSI) to 40 PSI, and this is used to heat the mill’s two new MEC kilns, the older existing kilns, and the log conditioning ponds, and also provides heat for the mill buildings. The pressure reducing station and 1,200 feet of steam line that runs from the energy system to the kilns were designed and installed by Design Build Mechanical from Bathurst, New Brunswick.

KMW specified and supplied several safety measures in the energy system, including temperature sensing equipment and a water spray system at the point where fuel is pushed into the combustor. This is to prevent a fire from burning back into the fuel supply equipment. They also supplied a flue gas recirculation fan to ensure that the maximum temperature of the combustor is not exceeded.

“This is a highly efficient system, and there are some fairly significant environmental benefits,” Beaulieu adds. “Because of our gasification system, we don’t need an electrostatic precipitator to control environmental emissions, which reduces our costs and means the system only produces about 1.5% ash from the biomass combustion.”

Although the new energy system won’t solve all of the mill’s financial woes, it is certainly a big part of the plan aimed at putting this facility back on track to being profitable. It’s also seen as a long-term investment that is helping the employees, suppliers, customers, and supporters of this historical sawmill look forward to the future with a new sense of optimism. •

For more on the sawmill upgrade at Plaster Rock, see the Jan/Feb 2010 issue of Canadian Wood Products or visit www.canadianwoodproducts.ca.

By Arie Verloop

boiler owners and operators are showing increased interest in evaluating the combustion performance of their equipment to improve its efficiency. The driving forces behind this interest are: (1) the rising cost of fossil fuels and the need to generate steam from cheaper sources; (2) stricter environmental regulations to reduce air pollutant emissions, requiring cleaner biomass combustion; (3) the general desire to operate equipment more efficiently and minimize wasted heat; and (4) the increasing demand for using renewable fuels to reduce carbon dioxide output from fossil fuels.

Biomass fuels should be differentiated from the broader category of renewable fuels. Some people define renewable fuel as any non-fossil fuel, including municipal solid waste and tire-derived fuel. However, my definition of biomass fuels only includes various types of waste wood (bark, hogged fuel, sawdust, wood clippings, chips, pellets, construction and demolition wood) and agricultural wastes from harvesting and processing (shells, husks, pits). Black and red spent liquors that are burned in chemical recovery boilers in the pulp industry can be counted as biomass fuel because their fuel value derives from lignin and hemicellulose that are dissolved from wood chips during the pulping process. Waste sludge from water treatment plants, which consists of organic material, is also regarded as biomass fuel, although its high moisture content prevents combustion in the absence of other fuels.

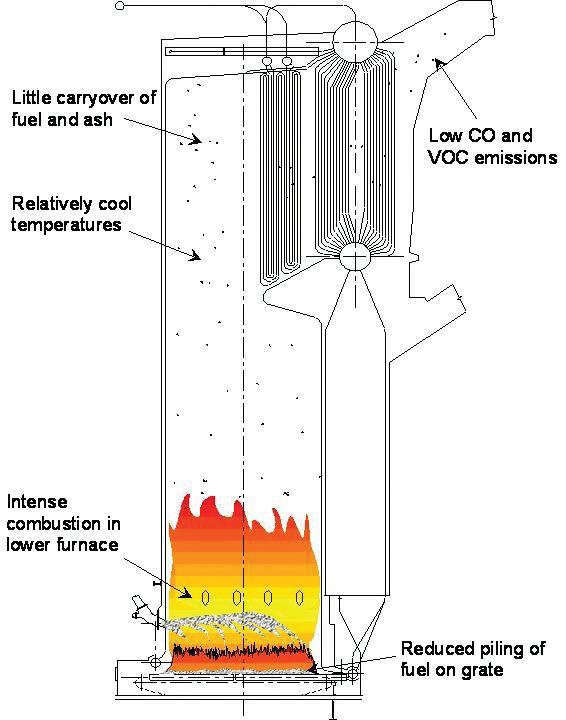

Biomass boilers come in a variety of sizes. The larger boilers burning biomass fuels (alone or co-fired with fossil fuel) are conventional units with a steaming range of about 20 tons/hour to over 250 tons/hour, producing high-pressure steam at elevated temperature for electrical power generation and/or cogeneration of process steam. The two most common technologies for biomass combustion are stoker grates and fluidized beds, with stoker technology far more prevalent in North America. Industries using these biomass boilers include pulp and paper and other forest products, as well as independent power producers. In recent years, utilities have begun to look more into converting their fossil fuel-fired boilers to burn biomass. Here, I focus on the combustion of solid biomass on a stoker grate.

Most biomass fuels have a relatively high moisture content, typically 30 to 55%, but possibly in excess of 60%. The fuel value stems from the carbon and hydrogen content. Combustion con-

sists of reactions between fuel components and oxygen from air and fuel, releasing heat and light. The “Three T’s” must be met for the proper burning of any fuel: Time, Temperature, and Turbulence. Sufficient reaction and retention time is needed to complete the oxidation/combustion reactions, sufficient heat must be present to start and sustain combustion, and adequate mixing of fuel components and combustion air is necessary.

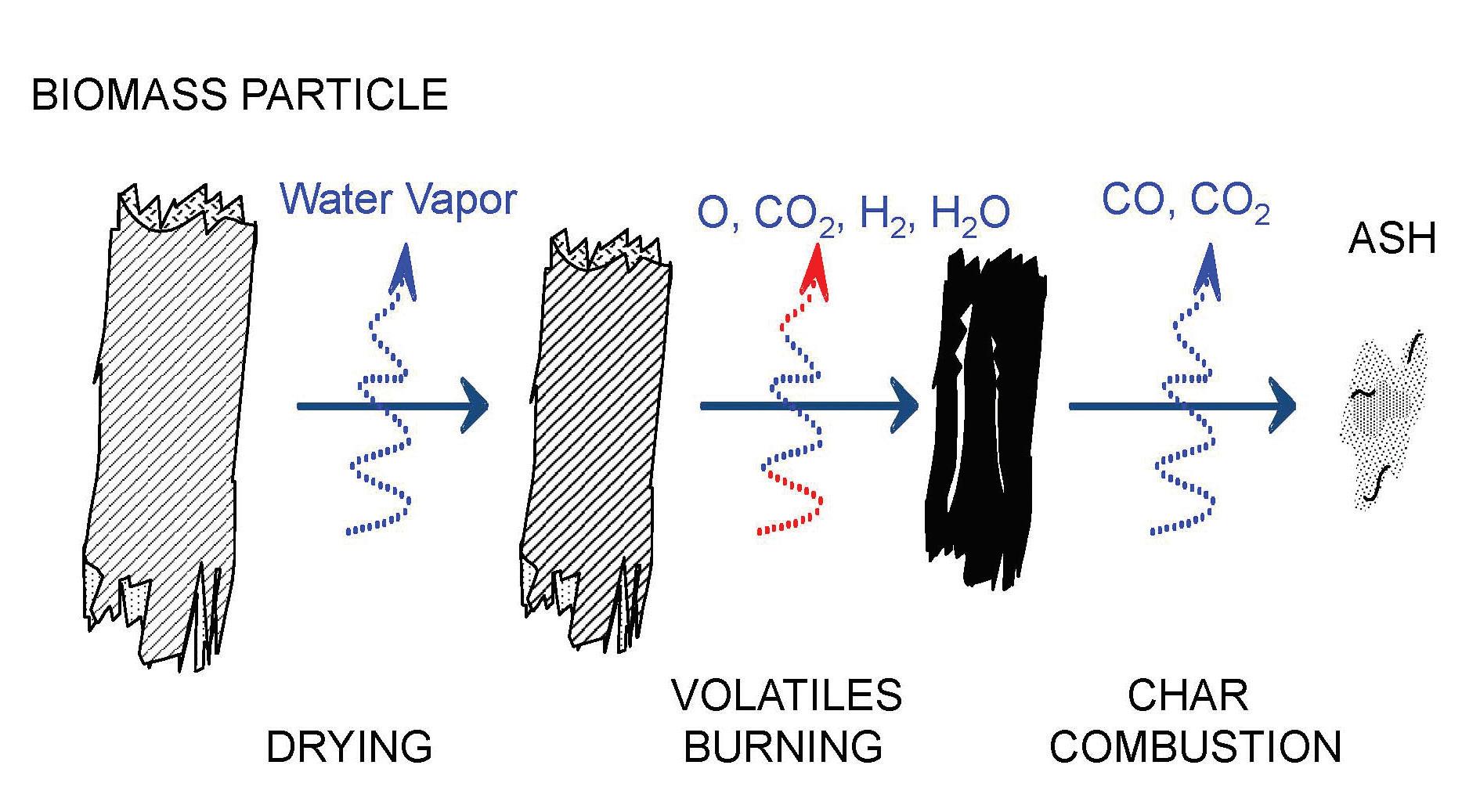

Biomass combustion occurs in three stages: drying, volatiles release and burning, and char combustion (Fig. 1). The drying stage requires heat to evaporate water, with the rate of drying depending on particle size and temperature. Next, pyrolysis gases (carbon monoxide, hydrogen, carbon dioxide, water, and volatile organic compounds) are released, and oxygen is needed for volatiles combustion. By weight, biomass contains about 70% volatiles and 30% fixed carbon. Finally, char combustion requires oxygen,

releases heat, reduces particle size, and leaves residual ash. Combustion problems can be deduced from not meeting all of the Three T’s and can occur in any of the combustion stages.

In pursuit of continuous and reliable operation, the owner/operator typically has the following goals in mind for the boiler:

• Attain uninterrupted and stable operation;

• Meet regulatory limitations for emissions of air pollutants such as carbon monoxide, volatile organic compounds, nitrogen oxides (NOx), and particulate matter;

• Optimize fuel economy, often by displacing fossil fuels with less expensive biomass;

• Maximize thermal efficiency and heat recovery.

Meeting these goals simultaneously is often more difficult to achieve for biomass fuels than traditional fossil fuels. Specific operational goals and priorities will vary from boiler to boiler and may change over time. However, factors affecting fuel costs and emissions performance will always have a high priority.

In attempting to meet operational and economic goals, the owner/ operator may face challenges because of combustion problems. These problems are evidenced by one or more symptoms (Fig. 2):

• Fuel piling on the grate and unburned fuel coming off the grate;

• Frequent furnace puffing caused by unbalanced mixing of air and combustible gases;

• Elevated levels of ash carryover and high unburned carbon content in the fly ash, including sparks and embers. This may lead to accelerated erosion of pressure parts, ducting, induced draft (ID) fan, etc. It can cause fires in the boiler’s downstream equipment;

• Delayed combustion and high gas temperatures in the upper furnace. This may lead to overheating of superheater tubing and high gas temperatures exiting the boiler, sometimes limiting the ID fan capacity;

• High excess air or oxygen in flue gas resulting in a loss of thermal efficiency;

• Increased stack concentrations of air pollutants.

The resulting net effect of these combustion problems is a reduction in the biomass burning rate and, depending on steam demand from the boiler, an increased need for fossil fuel co-firing.

After identifying the symptoms, the task at hand is to troubleshoot the boiler’s operational performance and determine the root causes of combustion problems. A boiler engineering evaluation characterizes the unit, diagnoses the problem, establishes the unit’s strengths and limitations, and determines the appropriate measures needed to overcome the limitations and meet the goals of the owner/operator. Key steps in the evaluation are:

• Collecting operational data and information to characterize the design and operation of the unit;

• Analyzing combustion to quantify material and heat flows and establish thermal efficiency and fuel economy;

• Computational fluid dynamics modelling to simulate combustion process parameters and heat transfer characteristics;

• Analyzing steam/water circulation to resolve potential problems;

• Defining conceptual modifications to remedy the combustion problems and limitations;

• Quantifying potential benefits of upgrading the boiler’s combustion system;

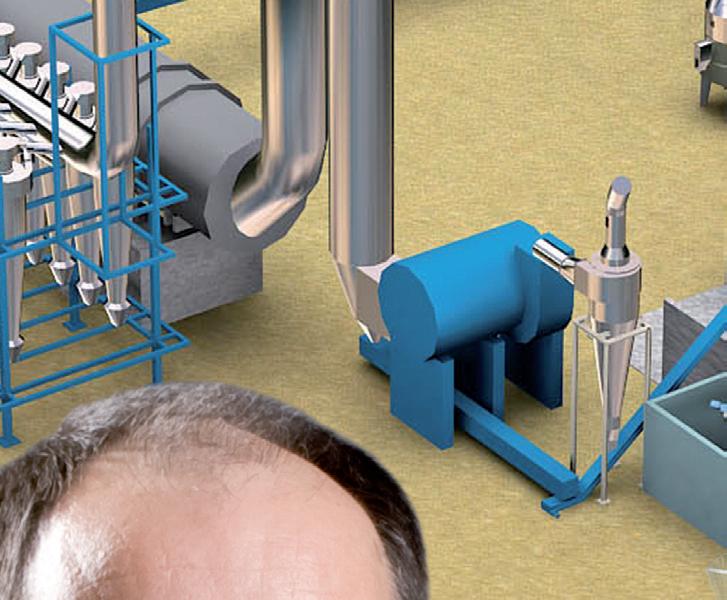

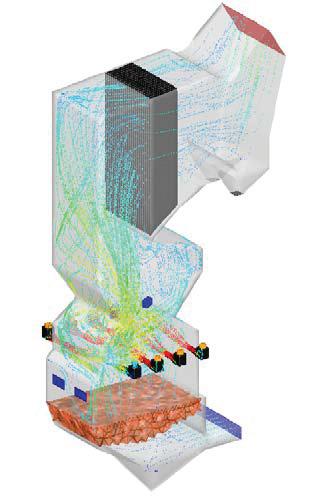

Computational fluid dynamics modelling analyzes key combustion performance factors and quantifies the operational benefits expected from system upgrades and modifications.

• Analyzing heat transfer to identify opportunities to improve efficiency and/or steam parameters.

The outcome of an engineering evaluation is a clear understanding and path forward to remedy the combustion problems.

To meet the Three T’s, the root cause(s) of combustion problems usually are related to inadequacies in the fuel and air delivery (aside from limitations in fuel supply and assuming the biomass is delivered at proper particle size and distribution and acceptable moisture content). The design and operational performance of (1) the fuel distributors, (2) the stoker grate, and (3) combustion air delivery parameters are three areas that have a significant effect on a boiler’s biomass combustion capacity and performance. A further breakdown of these factors shows:

Fuel Distributors:

• Number and width of the fuel spouts

• Fuel delivery method: mechanical or air swept

• Degree of flexibility to control fuel trajectory onto the grate

Stoker Grate:

• Type of grate (pinhole, travelling, vibrating, reciprocating)

• Dimensions of the grate

• Air distribution under the grate

• Mechanical repair condition

Combustion Air Delivery:

• Quantity, temperature, and pressure of undergrate air (UGA) and overfire air (OFA)

• Flexibility to control UGA to different grate areas

• Number, size, and location of OFA ports/nozzles

• Ratio of OFA to total air flow and control flexibility.

Effective fuel and air delivery hardware and proper operational parameters provide for these desirable combustion conditions:

• Even and balanced distribution of fuel on the grate with flexibility to control fuel trajectory;

• Limited UGA quantities to minimize lift-off of fine fuel particles from the grate;

• Preheated combustion air, particularly when burning fuels with high moisture content;

• Effective OFA supply, with high individual air jet momentum, leading to proper mixing of air with combustible gases coming off the grate.

Combustion problems can be eliminated, and relative troublefree combustion can be achieved, by upgrading some or all of the hardware components or operational parameters in the three major areas listed above (e.g., Fig. 3). For example, since the late 1990s, Jansen Combustion and Boiler Technologies has completed combustion system upgrades on 50 solid biomass-fired boilers. These units were manufactured by a variety of original equipment manufacturers, with installation dates ranging from the mid-1950s to early 1990s. Upgraded units have experienced the following benefits:

• Increased biomass burning capacity, typically by 5 to 40%, depending on boiler size and particular goals;

• Improved ability to handle biomass/mixed wood and sludge with a wide range of moisture content;

• Reduced or eliminated need for fossil fuel co-firing;

• Improved thermal efficiency by reducing excess air, flue gas temperatures in the stack, and unburned carbon in the ash;

• Reduced carryover of fly ash and other inert material to minimize the abrasive effects of erosion on pressure parts, ducting, and ID fan;

• Reduced stack emissions of carbon monoxide, NOx, and particulate matter, with an average reduction of 41% for carbon monoxide and 6% for NOx. •

Arie Verloop is vice president of technology and client relations for Jansen Combustion and Boiler Technologies Inc. He is a licensed professional engineer, specializing in chemical recovery and biomass boiler processes. Since joining Jansen in 1980, he has conducted and developed engineering evaluation projects for more than 150 biomass boilers and has led many boiler operations training seminars and workshops. Since its inception in 1976, Jansen has conducted performance evaluations of over 300 industrial biomass boilers worldwide. This article was written with contributions from Jansen’s process engineering and mechanical design groups. www.jansenboiler.com

OBuying biomass by the tonne means that users could be paying for excess water, not heat.

By Mark Ryans

ne of the hidden enemies of an efficient supply chain is a simple compound: water. Because of the importance of this subject, I will take a couple of columns to cover the topic properly.

Water occurs primarily within the biomass itself, but in winter, it can also show up as snow and ice clinging to tops and branches or on top of uncovered storage piles of comminuted residues. Moisture content is the single most important quality criterion for forest-origin biomass, yet we rarely manage it. To put it frankly, moisture content is not managed because we either don’t recognize its importance throughout the supply chain or we don’t want to be bothered measuring it. Although attitudes are changing, harvest residues are often taken for granted and not treated as a product from the forest.

The most common scenario today is for feedstock payments to be made on a green tonne basis at the mill gate, thus inciting the supplier to deliver the material as moist as possible to maximize payload. This results in paying for excess water, with a negative energy effect and a less efficient bioenergy system than it should be. On larger-scale operations, delivered biomass is often stored uncovered for months, leading to increases in moisture content or losses in dry matter.

Before addressing the management of residues for the control of moisture, I will introduce why moisture content is important, or more precisely, why low moisture content should be an objective of any biomass supply chain. Because most of the biomass used today is for burning, whether it is for the generation of heat, CHP, or simple (and inefficient) electrical power, we need to understand that water must be “burned off” before the energy value of wood is realized. Another emerging use of

forest feedstocks is for pellets. Additional energy for drying needs to be applied to the feedstock to reduce the moisture so that the final product from the dies is less than 10% moisture. The wetter the material, the more heat that is wasted.

Biomass burners are not all built the same, but they have more-or-less similar burning efficiency curves (Fig. 1). The burning efficiency, expressed as the available heat per unit weight at a given moisture content decreases from a maximum of about 80% at 0% moisture to 40% at 70% moisture content. For example, burning fresh residues at 50% moisture content would result in a burning efficiency of 61%. The heat curve drops slowly until about 30% moisture content, rapidly between 35 and 50%, and then dramatically above 55%.

There is also a common misunderstanding that different types of woody biomass differ in energy content. When expressed on a weight, rather than volume basis, the energy value does not vary greatly between species or parts of a tree and only varies by about 10%, from just less than 19 to 20.5 megajoules/kilogram.

In a simple analogy, you wouldn’t use wet firewood in a wood-burning stove if you want sufficient heat from it. You wouldn’t pay for green firewood the same as you would for dry firewood, and if you do buy it (at a lower price) you would season it before using it the next winter.

Small- and medium-scale boilers require more homogeneous feedstocks with

lower moisture content, so there is ongoing attention to feedstock quality. Large modern boilers such as those used in Nordic countries can handle various feedstocks at almost any moisture content, but that does not mean that excessively wet biomass is acceptable. European mill managers recognize the value of low moisture content and pay for biomass on a megawatt-hour (MWh) basis. I am also amazed at how field practitioners in those countries know

the “volume” of a roadside pile of harvest residues or stumps in MWh content. They don’t talk about green tonnes. Deliveries are usually monitored for moisture content using systematic sampling, or volume and weight conversions are used when shipments from known providers are relatively stable. Under all approaches, payments for harvest residues are based on energy content, not green weight.

In my next column, I will show an example of the cost implications of delivering wet biomass and discuss some approaches to manage the moisture content of biomass. •

Mark Ryans is with FPInnovations’ Feric division and can be reached at mark.ryans@fpinnovations.ca.

CRFA delegates were reminded that, like any other business, bioenergy enterprises need to know their input costs, variables, risks, and competitors.

By Scott Jamieson

thereare more variables than constants in bioenergy today, and anyone looking for long-term success had best deal with that fact. This was the main take-home message for the more than 300 attendees at the sixth annual Canadian Renewable Fuels Summit held in early December 2009 in Vancouver.

Of course there was also plenty of good news, mostly involving the industry’s continued growth despite a struggling economy. Speakers celebrated how far the biofuels sector has come, how much it brings to regional and mostly rural economies, and the technological advances in conversion technology that will improve profitability and reduce the carbon footprint even further. Several speakers even looked to the forest sector as the next best fibre source for expanding ethanol production to meet rising global demand. Still, for those considering an investment in biomass in Canada, there was plenty else to ponder over the two days.

Canadian Renewable Fuels Association (CRFA) president Gordon Quaiattini opened with a national status report on ethanol and biodiesel. He told delegates that the sector is delivering the renewable fuels and greenhouse gas (GHG) reduction that Canadians and our policy-makers expect, performance that he went on to measure in several ways.

Survey says: Quaiattini unveiled a brand new Praxicus Public Strategies public opinion poll showing that Canadians are overwhelmingly supportive of the sector. Findings include:

• 89% of Canadians believe we should move towards a low-carbon economy, with renewable fuels replacing at least some fossil fuels;

• 84% recognize that renewable fuels boost economic activity and employment in rural communities;

• 82% feel that a plan to tackle climate change should include renewable fuels to lower GHGs;

• 85% see the sector as a source of value-added production and hightech employment.

Clearly public support for biomass is the industry’s to maintain or lose.

Building communities: The CRFA also revealed an impact study quantifying the economic effects of producing biofuels in Canada. Given that the overwhelming majority of gasoline used in Canada is imported, the contrast is stark. The Doyletech study of the Integrated Grain Processors Cooperative

CIBC World Markets’ Don Roberts has been studying the possible role of biomass and biofuels in the forest sector for the past year, and cautions that with so many variables up in the air, investors will be leery. “Investors don’t like uncertainty, and there is a lot of uncertainty here.”

ethanol plant in Aylmer, Ontario, found that just building this plant resulted in a net job creation of 1,152 person years, saw direct investment in the region of $276 million, and increased tax revenues and reduced government costs of $7.8 million (municipal), $44.2 million (provincial), and $70 million (federal). Ongoing, the plant brings 55 person years of employment each year, $53.7 million in local spending, and a combined net benefit of $11 million per year at all levels of government.

Reducing GHGs: The environmental effects of any renewable energy source should always be measured versus its alternatives. In the case of biofuels, that alternative right now is petroleum-based gasoline. Putting geopolitical effects aside, a recent Cheminfo Services Inc study found that the current mix of ethanol reduced GHGs by 62% compared to traditional fossil fuels.

If this was the good news, several of the next speakers brought delegates back down to earth. Bob Dinneen, president of the U.S.-based Renewable Fuels Association (RFA), recounted some of the ongoing public relations battles his industry faces south of the border. Much more so than our smaller biofuels sector here, RFA members have been battered by attacks on their public image, attacks that Dinneen says are in part sponsored by competitors in the fossil fuel sector and are driven by the sector’s own success. At over 50 billion litres and 8% of the nation’s fuel supply, biofuels are big enough in the United States to draw the ire of big oil.

Dinneen spoke mostly about two campaigns: the well-known food vs. fuel debate, and the more recent, and possibly

even more threatening, indirect land-use change (ILUC) issue. Dinneen says that the food vs. fuel debate is a red herring that the U.S. sector is starting to make headway countering. However, he cautions Canadian producers that this issue will emerge in Canada as the sector’s production levels grow and competitors start to see biofuels as a threat, rather than a complementary supply source. Bring on another spike in oil prices, watch food prices increase as a result, and look out when politicians and oil public relations hacks look for culprits.

Still, it is the ILUC issue that keeps Dinneen awake at night. The premise behind ILUC is that any land used to grow biofuel crops in Canada or the United States automatically demands that a similar area of land be deforested elsewhere in the world and planted to replace the grain diverted to biofuels. As a result, the carbon footprint of North American biofuels must now include this vague global link. The real world economy is more complex than this. The overly simplified ILUC calculation makes for some very dangerous and counterproductive assumptions, Dinneen concludes.

Forest-based biomass and bioenergy are in many ways exempt from these issues. As long as forest-based biomass is grown and extracted as part of a sustainable forestry operation, and the land remains forested over time, forest biomass holds some public relations and market-

ing advantages over agriculture-based fuels. Still, it is just as likely that both renewable fuel sources will be tarred by the same brush in the public mind. Dinneen urges Canadians to get out in front of these issues and to keep the debate at the local or national level when it comes to comparing GHG emissions.

“If you do that, the total environmental impact of renewable fuels is already 40 to 60% lower than gasoline and will get better as we improve our systems and conversion technologies. But if you include vague concepts like ILUC on a global scale, our impact advantage vanishes.”

The reality is that regardless of what we do in Canada, the world is demanding and producing more biofuel. In fact, Tammy Klein of the Global Biofuels Centre counted at least 30 countries that will be implementing biofuel use targets in 2010. Most of these are developing countries, and the drivers are economic as much as environmental, but the end result is the same. As these countries consume and produce greater volumes of biofuels, and as Europe and the United States adopt regulations and incentives that favour the carbon footprint of some types of biofuels over others (i.e., sugar cane ethanol over corn-based), the global import and export flows will start to change. Klein even sees the United States becoming an ethanol exporter as fuels deemed less desirable on the domestic market find markets elsewhere.

MARCH 11-12, 2010 • Biomass Conversion to Heat & Electricity Workshop Normal, IL 309-268-8160 http://go.illinois.edu/biomassworkshop

APRIL 20-22, 2010 • SmallWood 2010: Bridges, Business & Biomass Hot Springs, AK 608-231-1361 ext. 208 or conferences@forestprod.org www.forestprod.org/smallwood2010

MAY 3-7, 2010 • European Biomass Conference & Exhibition Lyon, France www.conference-biomass.com

MAY 4-6, 2010 • International Biomass Conference & Expo Minneapolis, MN 701-746-8385 www.biomassconference.com

MAY 12-13, 2010 • Northern Alberta Forestry & Construction Show: Energy, the Environment & Innovation Grande Prairie, AB 780-532-3279 www.evergreenpark.ca

MAY 25-27, 2010 • World Bioenergy 2010 Jönköping, Sweden www.elmia.se/en/worldbioenergy

If all this policy uncertainty makes you nervous, you’re not alone. Don Roberts of CIBC World Markets looked at the bioenergy sector from a forestry and investor perspective and said that such issues make investors look twice. Sustainability issues like ILUC, soil quality, and forest sustainability are key to attracting financial backers, he agrees, but there is more. In all, Roberts lists five variables that shape bioenergy economics: the price of fossil fuels, the price of carbon, the conversion technology, feedstock cost (as high as 80% of variable costs), and public policy.

“Right now, all five of these variables are in a state of flux, and investors don’t like uncertainty, so you have a problem,” Roberts told delegates. “Oil prices are high, but not so with natural gas. Carbon prices are all over the map. There is a lot going on in conversion technology – I’ve tracked nine pathways for forestry alone - but there are also a lot of snake oil salesmen. Biomass prices are volatile, which is not good, and assessing delivered costs over the long-term is complex.” In short, if you have any hope of attracting larger sums for biomass and bio-