LESSONS LEARNED

INDUSTRY EXPERTS

SHARE CAREER EXPERIENCES

The new StormCell® series of battery backup pumps from Liberty feature advanced professional-grade chargers, energy e icient pumps for longer run times, and optional NightEye® wireless technology for remote monitoring through your smart device.

• Available in both standard and wireless connected models

• Professional-grade chargers (10 amp and high-output 25 amp)

• Single and dual battery systems

• Energy e icient DC pump (manufactured in the U.S. by Liberty) * Model 442-25A, StormCell® Group

CON TENTS

FEATURES

12 COVER STORY

HVAC

IN WHICH I GO ccASHP!

Our intrepid HVAC writer chronicles his own journey towards cold climate air source heat pump acceptance and installation. By Ian McTeer

18

HYDRONICS

THERMAL ACCUMULATORS

How to set up buffer tanks in systems supplied by heat pumps. By John

Siegenthaler

22

HYDRONICS

OPTIMAL TUBING DEPTH IN A SLAB

In this episode of 30 Mechanical Minutes John Siegenthaler talks about achieving the ideal tubing depth for in-slab heating.

By Logan Caswell

24

HYDRONICS

WORDS OF WISDOM

Sharing reflections on the valuable role mentors have played in one man’s career.

By Robert Bean

CON TENTS

26

HYDRONICS

NEW ADVENTURES

Recalling early advice and the helping hands that guided a newcomer to Canada along his path in the Canadian hydronics industry.

By Mike Miller

32

HYDRONICS

ONE CONTROL TO RULE THEM ALL

How I got here and what I’ve learned about this industry.

By Curtis Bennett

37

SHOW PREVIEW

THE AHR EXPO RETURNS TO LAS VEGAS

The international HVAC/R community will gather again for North America’s largest trade show and conference and AHR Innovation Awards announced.

By Logan Caswell

34

PLUMBING GRAVITY IS FREE

The greatest lessons learned on the job come from making mistakes in the first place.

By Steve Goldie

38

REFRIGERATION

THE BEAUTY OF LESSONS LEARNED

Taking a few trips down memory lane to share some learned experiences.

By Dave Demma

40

SHOW REVIEW CIPHEX WEST 2021

The Canadian plumbing and heating industry gathered together in Vancouver for the industry’s first trade show event since the pandemic.

By Doug Picklyk

HELLY HANSEN IS WORN AND TRUSTED BY PROFESSIONALS ON OCEANS, MOUNTAINS AND WORKSITES AROUND THE WORLD.

CONTINUOUS LEARNING

AS I WRITE THIS COLUMN, BRITISH COLUMBIA IS STILL RECOVERING FROM MASSIVE RAIN STORMS THAT HAVE LED TO flooding, mudslides, washed out roads and rail tracks. The rainfall disrupted people’s lives, delivered further setbacks to existing supply chain issues, and came only five months after the same region experienced extreme heat and drought. Unfortunately, these once in a lifetime weather events have that uncomfortable feeling of becoming annual occurrences in areas all across the country.

It’s these climate realities that are sparking change in government policy, and that was on display at the recent CIPHEX West trade show that took place in Vancouver, November 3 and 4. As the first major industry gathering of its kind since the pandemic, the crowds were eager to explore and re-connect with the community, but contractors in Vancouver were also interested in learning more about the new city building by-law that goes into effect January 1, 2022. Any new buildings, three stories or less, can no longer be heated with fossil fuels. And pending a ruling from city council, as of July 1, 2022, contractors will require a certification for heat pump installations.

The talk about the electrification of the heating and cooling industry is beginning to become reality, and this only reinforces the constant need for contractors to be learning and upskilling to stay ahead of the curve.

When it comes to the modern HVAC/R and plumbing industry, continuous learning is valuable and especially with today’s new digital technologies. Classroom lessons from manufacturers and institutes, either online or in person, are more important than ever.

For newcomers to the industry, after time in the classroom, apprenticeship programs with hours of on-site hands-on learning and doing is where the rubber really meets the road. And for anyone who thinks their learning is done once their ticket is punched. Think again.

Being part of the skilled trades industry means being on a continuous learning curve, and for those trades people and technicians who decide that business ownership is where they want to be, or maybe moving to the manufacturer or distribution side of the business is where their career path is headed, just understand that the journey will always include learning from your own mistakes and hopefully from mentors who have already paved the way for you.

In this issue of HPAC I’ve asked some of our regular contributors to share the most valuable lessons they’ve learned along their journeys so far. For most of them the it has been the people they’ve met along the way and the life-long friendships they have forged that stand out as enduring memories.

So policy changes may force new ways of working, but it’s the strength of the community that pulls together and helps each other along that keeps the HVAC/R and plumbing industries so rewarding.

As 2021 comes to an end, the team at HPAC magazine wishes everyone a peaceful holiday season and a prosperous New Year. And keep on the lookout for our 30 Mechanical Minutes webcasts in 2022, our presence at trade shows (CMPX and MEET), and another Modern Hydronics Summit in September, all opportunities to learn and keep ahead of the curve.

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER MEDIA DESIGNER

ACCOUNT COORDINATOR

PUBLISHER

COO

Doug Picklyk (416) 510-5218

DPicklyk@hpacmag.com

Logan Caswell (416) 728-6209

LCaswell@hpacmag.com

David Skene (416) 510-6884

DSkene@hpacmag.com

Emily Sun

esun@annexbusinessmedia.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Peter Leonard (416) 510-6847

PLeonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2021 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

INDUSTRY NEWS

RIGHT TIME GROUP OF COMPANIES ACQUIRES SASKATOON’S FURNACEGUYS

The Right Time Group of Companies continues to grow with the recent acquisition of furnaceguys Home Heating & Cooling. Founded in 2008, furnaceguys provides residential heating, cooling, air quality, and hot water services to homeowners in the city of Saskatoon and the surrounding area.

Furnaceguys marks the tenth acquisition completed by Right Time and the first Saskatchewan-based addition for the growing group.

Right Time has been developing a national brand through acquisitions of existing residential HVAC replacement contractors. Founded in 2014 and headquartered in St. Catharines, Ont., Right Time was previously owned by Canadian private equity firm Clairvest Group, and was subsequently acquired San Francisco-based Gryphon Investors in December 2020.

right-time.ca

ONTARIO INCREASES INVESTMENT TO ATTRACT YOUNG PEOPLE TO SKILLED TRADES

On November 24th Ontario announced an additional $90 million investment over three-years to promote the skilled trades to young people. The spending responds to the Apprenticeship Youth Advisors report, which includes several recommendations to help solve the shortage of skilled workers in the province.

As part of the announcement, the government is also investing an additional $2.9 million, for a total of $20 million annually, to expand the Ontario Youth Apprenticeship Program (OYAP).

The OYAP now has 63 recruiters across more than 800 schools so students can learn about the trades at a younger age. By 2025, Ontario hopes as many as one in five jobs in Ontario will be in the

REPORT HIGHLIGHTS REASONS FOR BUILDING GREEN

The 2021 World Green Building Trends report, published by the Dodge Construction network, reveals that green building continues to remain a global priority, including strong interest in Canada, despite rising concerns like the COVID-19 pandemic,.

Industry professionals surveyed source both social and financial reasons for increasing their green building efforts with top reasons including lowering operating costs, lowering carbon emissions, reducing energy and water consumption, market demand, building healthier buildings, living up to internal corporate commitments and that it’s the “right thing to do.”

Respondents stated they have shifted their focus on strategies to specifically address reducing energy consumption and the carbon footprint of building projects with creating net-zero/net-positive buildings as the top priority. Doing so reflects the recognition that only by making the built environment carbon-neutral can the goal to minimize the impacts of climate change be achieved.

Additionally, the report shows how the pandemic has had an impact on the green building sector with survey respondents noting that messaging about increasing filtered air exchange in buildings directly influenced their choice of HVAC system.

In the report respondents in Canada selected the following as the top types of green building projects they will design and construct over the next three-years:

• Existing Buildings/Retrofits 54%

• New Institutional Construction 40%

• New Commercial Construction 33%

Other findings of the report include:

Most respondents (82%) are at least aware of the concept of embodied carbon – emissions from manufacture, transportation, installation, maintenance and disposal of building materials – with contractors and owners as less familiar with embodied carbon than architects and engineers.

The vast majority (79%) of those building green use at least one metric to track green building performance, an increase of five points since 2018.

About half of respondents engage in green renovation/retrofit projects, with most investors engaged in this work. construction.com

skilled trades, with the average age of people entering the trades being 29.

At the same time, a third of tradespeople are nearing retirement, meaning the province is projected to face a shortfall of 100,000 construction workers over the decade.

To encourage employers to take on more apprentices, the province’s investments in pre-apprenticeship training will increase to over $77 million annually,

starting in 2022-2023. The achievement incentive will also focus on hiring apprentices from underrepresented groups, including women, BIPOC, newcomers and people with disabilities. These initiatives bring the government’s total investment in the province’s Skilled Trades Strategy to approximately $1.5 billion between 2020 and 2024. ontario.ca

ALUMINUM DESIGN RESISTANT TO CORROSION INTRODUCING ADRIAN

FLEXIBLE CONFIGURATION FOR A WIDE RANGE OF CARGO

OPTIONAL PLASTISOL UPRIGHTS TO PROTECT YOUR LADDERS

REAR ROLLER ASSIST FOR EASIER LOADING AND UNLOADING

TALLER UPRIGHTS FOR INCREASED STACKABILITY

ADD-ON RATCHET STRAPS TO QUICKLY AND SAFELY SECURE YOUR CARGO

MAJOR WASTEWATER ENERGY PROJECT TO HEAT TORONTO HOSPITAL

The Canada Infrastructure Bank (CIB) has invested in what it’s calling the world’s largest raw wastewater energy transfer project, located at Toronto Western Hospital.

Renewable energy company Noventa worked with the hospital and Enbridge Gas to develop the $42.9 million project which will provide approximately 90% of the hospital’s heating and cooling requirements.

The retrofit project will use the Huber ThermWin System and Noventa design to transfer thermal energy to and from wastewater flowing in the mid-Toronto interceptor sewer to provide low-carbon heating and cooling to the hospital.

As a result, the hospital’s natural gas use and water consumption will be significantly reduced. Over the next 30 years, the hospital will see a cumulative reduction in greenhouse gas emissions of more than 250,000 tonnes. noventaenergy.com cib-bic.ca

TORONTO CONSIDERING NET ZERO BY 2040

Toronto Mayor John Tory has announced a new Net Zero strategy to reduce greenhouse gas (GHG) emissions in Toronto to net zero by 2040 – 10 years earlier than initially proposed.

The strategy would also look to achieve a 45% reduction in GHG levels by 2025, on the way to a 65% reduction by 2030.

If adopted, Toronto will be one of only three big cities in North America with a net zero by 2040 target. The report is being studied and could be approved by December 15.

The existing TransformTO Net Zero Strategy provides a roadmap to achieve reductions in GHG emissions from 1990 levels. Approval of the new Net Zero strategy would trigger accelerated actions to drive down emissions.

Two of the key areas being looked include:

• Accelerate a rapid and significant reduction in natural gas use.

• Establish performance targets for existing buildings across Toronto.

Toronto is currently on track to achieve its 2020 GHG emissions reduction target of 30% from 1990 levels. Communitywide emissions have decreased by 38% since 1990, despite a significant growth in population.

The primary sources of GHG emissions in Toronto are

homes and buildings (57%), mainly from burning natural gas to heat space and water. City programs, policies and strategies already in place to reduce emissions include:

• The Net Zero Existing Buildings Strategy to reduce the use of fossil fuels in all existing residential, commercial and institutional buildings within the next 30 years. The strategy will see the city implement voluntary performance measures and targets initially, intending to begin the transition to mandatory requirements in 2025.

• The Net Zero Carbon Plan to reduce emissions from more than 2,500 city-owned buildings (approximately 9.5 million sq. m.) by at least 80% by 2040.

• An updated Toronto Green Standard (TGS) (Version 4) which continues to raise the bar to all while eliminating the use of natural gas in new buildings.

• The Green Will Initiative, which sees the city partner with large building portfolio owners across Toronto to accelerate emissions reductions from buildings.

• The BetterHomesTO and the Home Energy Loan Programs, provide resources and support for homeowners, including low-interest loans for home energy retrofits. toronto.ca

GRAND OPENING

ASHRAE has officially opened its new global headquarters building, a $20 million renovation project and a fully net-zeroenergy (NZE) operation.

“The completion of this project is an important milestone for ASHRAE as a professional society and for the built environment worldwide,” said 2021-22 ASHRAE resident Mick Schwedler.”

The 66,700 sq. ft. building sits on 11 acres of land near Atlanta, Georgia. Although ASHRAE has occupied the building for more than a year, the installation of a photovoltaic (PV) solar array system was completed in October 2021, marking the beginning of the building’s operation at fully net-zero-energy performance. The PV system is a combination of three sub-arrays totalling 332kW, mounted on the rooftop and in an unused section of the parking lot.

The building operates six water source-heat pumps, a robust building automation system and demand control ventilation (DCV) to be used for high occupancy spaces in the meeting and learning centre. ashrae.org

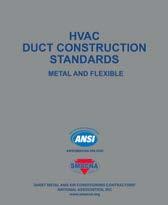

NEW EDITION OF THE HVAC DUCT CONSTRUCTION STANDARDS

The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) has released the fourth edition of its HVAC Duct Construction Standards – Metal and Flexible, updating the standard to represent the latest in sheet metal duct fabrication and installation requirements.

The updated 416-page standard was revised to provide contractors with the information they need to apply effective and efficient solutions to their projects.

Highlights of the update include:

• Added information on spray and aerosolized duct sealants

• Added tables for spiral flat oval duct for positive and negative pressure applications

• Added options for internal supports for spiral flat oval duct

• Updated liner requirements to include non-fiberglass liner types

• Added information for lined round duct and spiral fittings

• Added details for hangers to better illustrate where hangers are required

• Updated requirements for flex duct hanger spacing and hanger width.

The publication is available in book or PDF format via SMACNA’s online bookstore. smacna.org

NEW RESIDENTIAL FUEL OIL HEATING BANNED IN QUEBEC AS OF DEC. 31

– By Luc Boily

On November 17, the Quebec government announced that installing oil-fired heating appliances in new residential construction will be prohibited in the province as of December 31, 2021.

In addition, in two years following that deadline (as of December 31, 2023), installing an oil furnace or replacing one with a fossil fuel furnace in existing residential buildings will also be prohibited.

As part of its 2030 Plan for a Green Economy (PGE 2030), the government believes these news measures will contribute to achieving the target of reducing greenhouse gas (GHG) emissions from heating buildings in Quebec by 50% by 2030.

Financial assistance may be available to homeowners who are required to convert to renewable energy through the Chauffez vert Program. An amount of $134.5 million for this program is part of the 2021-2026 implementation plan of the PGE 2030. According to the government release, nearly 200,000 Quebec households still own an oil-fired heater.

“Residential oil heating systems generate the highest carbon rate in addition to other atmospheric pollutants that adversely affect air quality,” said Benoit Charette, Minister of Environment and Fight Against Climate Change, in a release. environnement.gouv.qc.ca

DATA SHOWS MOST COMMUNITIES ABOVE PROVINCIAL AVERAGES FOR RADON GAS

A new report by Take Action on Radon (TAOR) reveals that the majority of communities that have taken part in their 100 Radon Test Kit Challenge program are finding dangerous levels of radon are more common than Health Canada's national estimate. The program provides 100 test kits to each municipality willing to participate, so far 43 communities have taken part in the program.

Radon, the odourless, colourless, radioactive soil gas that is formed as uranium breaks down over time, is unstable and releases alpha particles, a type of radiation that is particularly damaging to lung tissues. Radon is a problem across Canada as uranium is present in the soils and rocks of all regions. It poses a problem indoors as it enters buildings from the surrounding soil through the foundation. Over time, radon gas levels can build up and exceed recommended guidelines.

In 2012, Health Canada released a report summarizing a Cross-Canada Survey of Radon Concentration in Homes. This work determined provincial averages ranged from 4 to 25%, and the estimated national average was 7%. According to TAOR's findings, of 43 communities tested, 39 are at or above Health Canada's national estimate. takeactiononradon.ca

21_2440_HPAC_DEC_CN Mod: October 26, 2021 8:48 AM Print: 10/28/21 2:16:59 PM page 1 v7

IN WHICH I GO ccASHP!

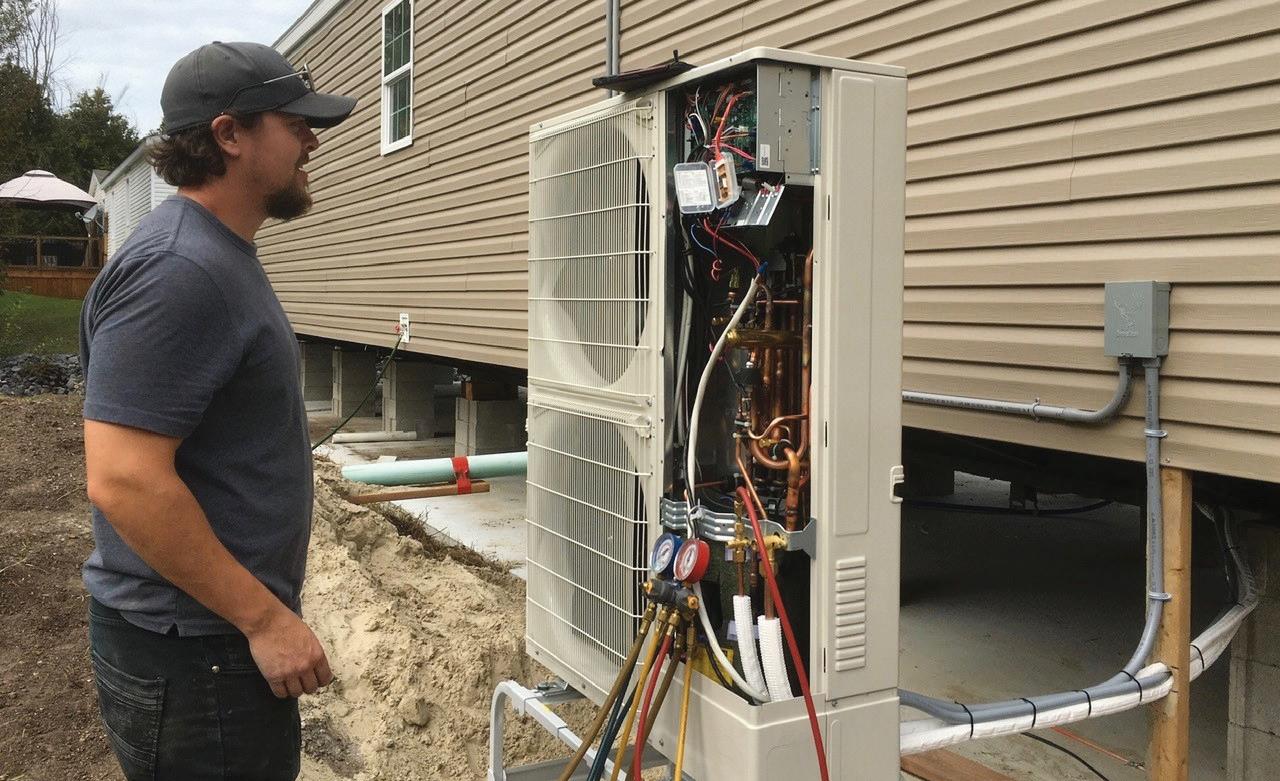

Our intrepid HVAC writer chronicles his own journey towards air source heat pump acceptance and installation. BY IAN McTEER

Ihave written extensively about heat pumps, both air source and ground source, over the years. The ability of heat pumps to output several times more useful heating watts compared to wattage consumed has held my attention for decades. However, some units do it better than others.

I examined air source heat pumps used in residential applications going back to the late 1970’s. These early units were never meant for cold climates, having inadequate defrost controls, ridiculously high balance points, compressor protection was limited to nonexistent, and they were too often installed in combination with secondrate air handling systems.

By the late 1980’s, demand defrost,

more robust compressors and increased awareness of appropriate air handling system design allowed air source heat pumps (ASHP) to improve their share of the residential market, especially in moderate climates as defined by AHRI Climate Region IV (2,000 to 2,500 heating load hours) down to Climate Region I with less than 1,000 heating load hours.

Most Canadian applications are best described by AHRI Climate Region V (greater than 3,000 heating load hours). ASHPs imported to Canada continue to be tested and rated for Climate Region IV. Thus, an ASHP with a Region IV Heating Season Performance Factor (HSPF) of 9.0 would have to be derated by 15% for

Region V, the 9.0 HSPF unit becomes a 7.8 unit in most of Canada.

Even so, later model ASHP’s continued to be plagued by defrost problems that contribute to less efficient energy utilization by returning heat meticulously squeezed from frigid outdoor air back outside to defrost an iced-up outdoor coil. Additionally, during defrost, furnace heat would be utilized to temper air being delivered by a system now in cooling mode.

Properly installed and commissioned with a focus on shielding the outdoor unit from prevailing winds, defrost periods could be shortened dramatically, often to less than five minutes. Some control boards would allow several defrost periods of up to 15 minutes to ac -

cumulate before signaling a fault code that might not be intercepted until the next maintenance call.

Faulty defrosting, whether installation related or by mechanical fault, cause ASHP’s to gobble energy. Systems trying for defrost a third time after two consecutive 15 minute defrost periods should shut down, bring on backup heat, and signal the homeowner to call for service, so I say.

Figure 1 illustrates the extent of a frozen outdoor coil. Perhaps winddriven snow overwhelmed the unit’s ability to defrost itself, maybe the defrost control board failed, or a coil sensor failed. Whatever the cause, it’s going to be a frosty no heat call for this HVAC technician.

It’s worth noting that ground source heat pumps have no need to defrost themselves as the entire outdoor component is buried below the ground out of the way of raging winds, freezing rain, and knee-deep snowfalls.

Despite my reservations about plopping a refrigeration coil outside in freezing cold weather with a potentially wonky defrosting system, I’m now on board with the latest technology used with cold climate air source heat pumps (ccASHP).

In my own situation, costs related to the equipment and installation of a ground source heat pump are still beyond my budget; had I been able to rent the ground component from a third party as once proposed by a large utility, I think I’d be doing ground source today. But when it came time to move into a smaller house, we decided to avoid the condominium route and settled instead to purchase a mobile (or manufactured) house and have it installed on a concrete pad. I’m now located in a spacious senior’s mobile park in eastern Ontario not too far from the Quebec border.

So why would I choose a ccASHP when I’m aware of potentially suffering from one or more of their long-standing shortcomings? Just like anything else,

major technological improvements, such as more robust inverter-driven compressors utilizing dense vapour injection, combined with microelectronic controls better managing defrost cycles, give me the confidence that a properly installed, expertly commissioned and well maintained ccASHP will give me the comfort and efficiency I’m looking for.

THE HOMEOWNER/CONTRACTOR RELATIONSHIP

This time I’m the homeowner, and I’m the one in the driver’s seat, right? After all, I have the gold, therefore I make the rules. That might be the way some

homeowners perceive relationships with various contractors ought to be, after all, it wasn’t that many years ago when some homes had “tradesman’s entrances” usually around back so the folks inside wouldn’t have to see the scruffy blue-collar workers whilst sipping their tea.

Times have changed so dramatically that yesterday’s notion of simply looking around for the best deal is not the prime driver of the buying decision. “What should I buy?” and “Who should do the work?” were the top-of-mind questions for me.

No one wants to pay any more than Continued on p14

Figure 1: Frozen air source heat pump.

necessary; hence, getting a “proper deal” is more like it.

HVAC equipment sophistication combined with the knowledge and technical expertise needed to design, install, commission, and maintain one’s longterm investment in efficient HVAC products means homeowners need to do some homework.

For the first time in my life, I’ve had to shop around for several contractors needed to service my manufactured house. Searching ads on the Internet and those posted in the local newspaper, I still took the time to gather references from my community. I’m happy to say that the local contractors I hired have performed as expected. But I’m still waiting for other work to be done as everyone is incredibly busy and some materials are scarce.

My focus on contractor reliability and professionalism means that I’m not necessarily brand focused. I know every brand has suffered from “issues,” some more than others, however, it’s how the problems were dealt with that counts. I selected the Mitsubishi H2i Hyperheat ccASHP combined with a matching indoor air handler installed

counterflow with 8 kW of supplemental backup electric heat.

I had the luxury of selecting an HVAC contractor having decades of experience with both air source and ground source heat pumps including Mitsubishi products. ATEL Air headquartered in Williamsburg, Ont. serves my area of eastern Ontario. My relationship with ATEL Air began when the owner, Jimmie Thom, decided to take on the Trane gas furnace and air conditioner product line in the early 2000’s. I became a technical asset for ATEL and provided installation and service training along with telephone support for ATEL technicians over the years.

Admittedly, homeowners looking for a quality HVAC experience must rely on their research and testimonials to make the buying decision. I had a much easier time of it this go around.

OUT WITH THE OLD

The “old” in this case was a single stage downflow high efficiency gas furnace provided by the home manufacturer, and it was in rather rough shape after the bumpy trip to Ontario from Nappanee, Indiana.

“I'm happy to say that the local contractors I hired have performed as expected.”

The installation involved a considerable amount of electrical wiring, both high voltage and control voltage. ATEL Air is also an electrical contractor well versed in tricky wiring jobs. The 200amp electrical panel, mounted upside down and completely encased in the stud wall with drywall all around, required some careful treatment (see Figure 2). Minor cuts into the drywall exposed a new route for the heavier wiring running to the air handler and outdoor unit.

The new indoor air handler fit neatly into its closet application (Figure 3). I’m not thrilled by the “free delivery” return air system (Figure 4) as designed by the mobile house manufacturer, but there’s no option for return ducting in such close quarters and it seems to work well enough through the extralarge grilles fitted to the utility room doors, so I’ll put that objection aside, at least for now.

I could conceivably run a duct through the utility area and pick-up

Continued on p16

Figure 2. Tricky electrical wiring accomplished.

Figure 3. The new indoor air handler fit neatly into its closet.

Figure 4. The return air system seems to work well enough.

Maestro Wi-Fi App available

some return air near the ceiling in the dining room area if necessary. Let’s wait and see if I do that!

My brand new Ecobee smart thermostat delivered my September Energy Report; already. The system operated in cooling mode just 15 hours; turns out my average setting of 23.5C saved me 16% in operating costs had I chosen a lower cooling set point of 22C.

Now for the best part, I’m in the bottom 50% of energy users compared to other Ecobee thermostat users. Obviously, I’m too sexy for my heat pump.

FUTURE OF RESIDENTIAL HVAC?

With the current concern about carbon pollution and climate change, governments continue to look for ways to reduce CO 2 emissions, meaning natural gas, propane, fuel oil and wood-burning heating appliances have fallen into disfavour amongst the regulatory set. Yet, switching many more households over to electric heat pump systems must also coincide with significant improvements to the North American electrical grid, including massive new sources of power generation.

Mark Jacobsen, co-founder of a

Stanford University civil engineering team known as The Solutions Project, thinks Canada can meet 58% of its power generation needs using wind turbines alone by 2030. As I write, the Independent Electricity System Operator of Ontario (IESO) is reporting the province-wide hourly load at 12,905 MW with nuclear plants providing 68% of the demand, wind at 15%.

With only nine years to go, I doubt we’ll see renewables take the lead in power generation by 2030.

I asked Greg Millard, service man -

ager at ATEL Air, if his customers (existing and new) are asking for quotes on ground source or air source heat pumps. His reply: “Yes, especially in areas where oil or LP (liquid propane) are the only alternatives.”

At the same time, he is not currently discouraging fossil fuels, “but we do educate the customer about the alternatives, especially when LP and oil are the other options.”

Millard tells me his customers still want tried and true gas furnaces and air conditioners as they continue to be perceived as the most affordable option when it comes down to costs related to installation, operation and maintenance.

With current supply chain issues, the very near future could be of the greatest concern to residential HVAC contractors. There may well be plenty of work in hand, however, Jimmie Thom, president of ATEL Air told me, “We spend a lot of time verifying equipment is available and expected shipping dates for sold jobs.”

Thom is concerned that some gas furnaces are in short supply, or out of stock, going into the heating season, and major replacement parts such as heat exchangers have longer lead times, weeks instead of days as in the

This high-efficiency gas furnace was removed to make way for a new cold climate air source heat pump.

Surface area, one of the secrets of higher efficiency everything, translates into a giant indoor coil obscuring the view of installer/ technician Matt Dillabough as he prepares it for service in a downflow application.

Technician Brad Jagert monitors the start-up process.

past. Millard said they’ve had to do some “brand hopping when needed and using a wider range of suppliers for material—basically buy it when and where it is available.”

To date, my ccASHP has been performing brilliantly. I’m using the thermostat’s automatic mode in which the cooling setpoint at 23.5C allows for some cooling and dehumidification on sultry autumn days. Heating setpoint at 21C allows the equipment to take the chill off early in the day as winter gets set to arrive any time now. Will modern cold climate and ground source heat pumps eventually rule the day? I think so. <>

Ian McTeer is an HVAC consultant with 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

Measures: CO, CO2, differential temperature, differential pressure

Calculates: O2, CO/CO2 ratio, Losses, Efficiency

High Altitude Compensation

Wireless Airflow Measurement*

Over-range protection pump

Wireless temperature probes* for flow and return boiler and radiator temps.

KANE 599 - ECM Tester

ECM Measurement

3 Phase Rotation Testing

Low Z / Low Pass Filter Auto Volts / Amps Selection

KANE-TCAM - Thermal Imaging

Simple, affordable point & shoot technology with high quality thermal imaging.

Ideal for heating, ventilation, refrigeration engineers and automotive & maintenance technicians.

Large LCD colour display

4 surface measurement modes to improve speed & ease of finding problems.

Surface temperature range - 20C to 300C

Sophistication—not your grandmother’s idea of a heat pump—these are views inside the outdoor unit.

Wiring running through conduit including a field fabricated support for the line set as it will eventually pass through skirting on the house, yet to be installed.

THERMAL ACCUMULATORS

How to use buffer tanks in systems supplied by heat pumps. BY JOHN SIEGENTHALER

Whenever a hydronic system is divided into several zones it’s worth considering a buffer tank between the heat source and the distribution system. This is especially true when the heat source is a single speed “on/off” device rather than a modulating device.

One example is a 4-ton geothermal heat pump supplying several individually controlled panel radiators. Each radiator represents what I would call a “micro-zone.” The output of such a zone is likely less than 10%, perhaps even less than 5% of the heating capacity of the heat source. If you connect several such zones directly to a heat source, even one that can modulate down to say 20% of rated capacity, you’re likely to experience short cycling. This same reasoning holds true for an air-to-water heat pump.

SIZING A BUFFER TANK

The size of a buffer tank is based on two parameters the designer chooses:

1. What is the minimum run time of the heat source that avoids the designer’s definition of “short cycle?”

2. And what is the allowable temperature change of the buffer tank during the minimum on-cycle time?

Once these two decisions are made, the math is easy. The minimum tank size can be determined by Formula 1.

source’s “on cycle” (minutes)

Qheat source = heat output rate of the heat source (Btu/h)

qload = rate of heat extraction from the tank (can be zero) (Btu/h)

∆T = temperature rise of the tank from when the heat source is turned on to when it is turned off (F)

where:

V = required volume of the buffer tank (gallons)

t = desired duration of the heat

Here’s an example. Assume that a designer wants a hydronic heat pump with a rated output of 48,000 Btu/h to operate with a minimum on-cycle of 10 minutes while supplying heat to a towel warmer radiator releasing heat at 2,000 Btu/h. The heat pump responds to the buffer tank temperature. It turns on when the buffer tank temperature drops to 100F, and off when the tank reaches 120F. What is the necessary buffer tank volume to accomplish this?

Just put the numbers into the formula and grab a calculator:

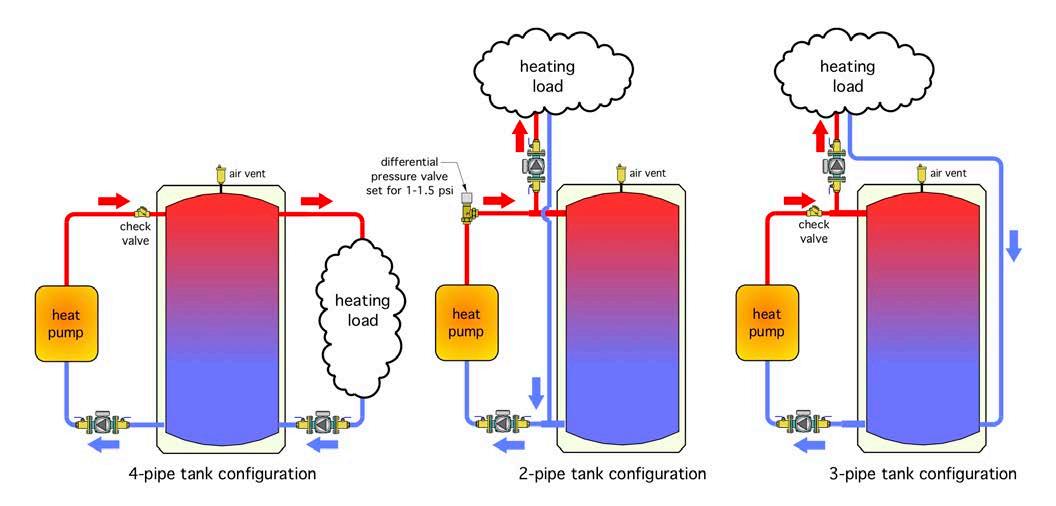

Figure 1. Two-, three- and four-pipe buffer tank configurations.

t(Q heat source – qload) 10 (48,000 – 2000)

V = = 46 gallons =

500(∆T) 500 (120 – 100)

Larger buffer tanks can provide longer heat source on-cycles. They can also allow a narrower temperature change over a specific on-cycle. It’s easy to evaluate the trade-offs between on-cycle length and tank temperature swing using Formula 1. Large buffer tanks obviously cost more, take up more room, and usually have higher standby heat loss.

MAKING CONNECTIONS

There are several ways to pipe buffer tanks. They are called “four-pipe”, “three-pipe” and “two-pipe” configurations. Figure 1 (below left) shows all three.

The four-pipe layout is the “classic” piping configuration for buffer tanks in hydronic systems. The heat source adds heat on one side, while the load removes heat from the other side. This piping configuration allows excellent hydraulic separation between the heat source circulator and the load circulator(s).

Until a few years ago I assumed that this was the only piping configuration for a buffer tank in a hydronic system. However, more research into how thermal storage tanks are piped in European systems using pellet boilers was an eye-opening experience for me. Read on and you’ll see what I learned.

One constraint of a four-pipe configuration is all heat from the heat source must pass through the tank on its way to the load. This isn’t a problem when the buffer tank temperature is being maintained. However, this arrangement definitely retards heat transfer from the heat source to the load if the tank is allowed to cool down substantially.

If you install a four-pipe buffer tank be sure to install a check valve on the heat source side of the system to prevent reverse thermosiphoning from the heated tank back through the heat pump circuit when the heat pump is off. If allowed to occur, reverse thermosiphoning can drain a substantial amount of heat from the tank over a period of several hours when the heat pump is off.

The two-pipe configuration, which I came across in some European piping schematics, places the load between the buffer tank and the heat source. This allows the possibility of passing heat directly from the heat source to the load when both are operating at the same time. That’s very desirable when recovering the building from a setback condition. If the load flow rate is lower than the flow rate through the heat source, the difference between these flow rates moves through the buffer tank.

One limitation of the two-pipe configuration is that a differential pressure valve, motorized ball valve, or other device that creates a forward opening resistance of 1 to 1.5 psi needs to be installed in the heat source piping to prevent flow that’s returning from the load from passing through the heat source when it’s off.

It’s also necessary to keep the tees that connect to the supply and return piping to the load as close as possible to the tank to allow for good hydraulic separation.

Here’s another lesson learned regarding two-pipe buffer tanks: They should only be used when the heat source is turned on and off based on buffer tank temperature.

If the heat source flow rate and load flow rate are about the same, there will be very little flow through the tank. This could lead to the heat source shutting off based on satisfying the space heating, without adding much heat to the tank. In this scenario the tank is not “engaged” in the energy flow streams.

However, when the heat source is controlled directly from tank temperature it will continue to run even after the space heating thermostat is satisfied, banking heat that’s immediately ready to go to the next zone requesting it.

MEETING IN THE MIDDLE

What do you get when you “average” a four-pipe buffer with a two-pipe buffer? Answer: A three-pipe buffer.

This configuration has become my preferred arrangement when the heat source is a heat pump. It provides the directto-load possibility on the supply side while also forcing return flow through the lower portion of the tank, and thus ensuring that the tank’s thermal mass is engaged.

Don’t expect much temperature stratification in a buffer tank connected to a hydronic heat pump. The reason is the relatively high flow rate from the heat pump. Most heat pumps have recommended flow rates of 3 gpm per ton (12,000 Btu/h) of capacity. With water as the working fluid that results in a delta-T of only about 8F.

A typical 4-ton heat pump operating at these conditions would turn over an 80 gallon buffer in less than seven minutes. Those flow rates, especially if introduced vertically into the tank, will create lots of internal mixing. Whenever possible, pipe the tank so that heated water from the heat source enters the tank horizontally rather than vertically.

It’s worth mentioning that I didn’t always appreciate the benefits of a three-pipe buffer tank, and this concept came from an engineering professor colleague several years ago.

He and I were both working on ways to improve the performance of a system supplied by a pellet boiler. We had inadvertently stumbled across the omission of one of the design details that I mentioned above (e.g., installing a differential pressure valve to prevent flow returning from the load from passing the boiler when it was off).

We also both understood some of the limitations of a fourpipe buffer tank configuration (e.g., time required to warm a large tank before the supply water temperature to the load was up to where it needed to be). My colleague suggested that a compromise between the two configurations might be worth considering.

Continued on p20

< HYDRONICS

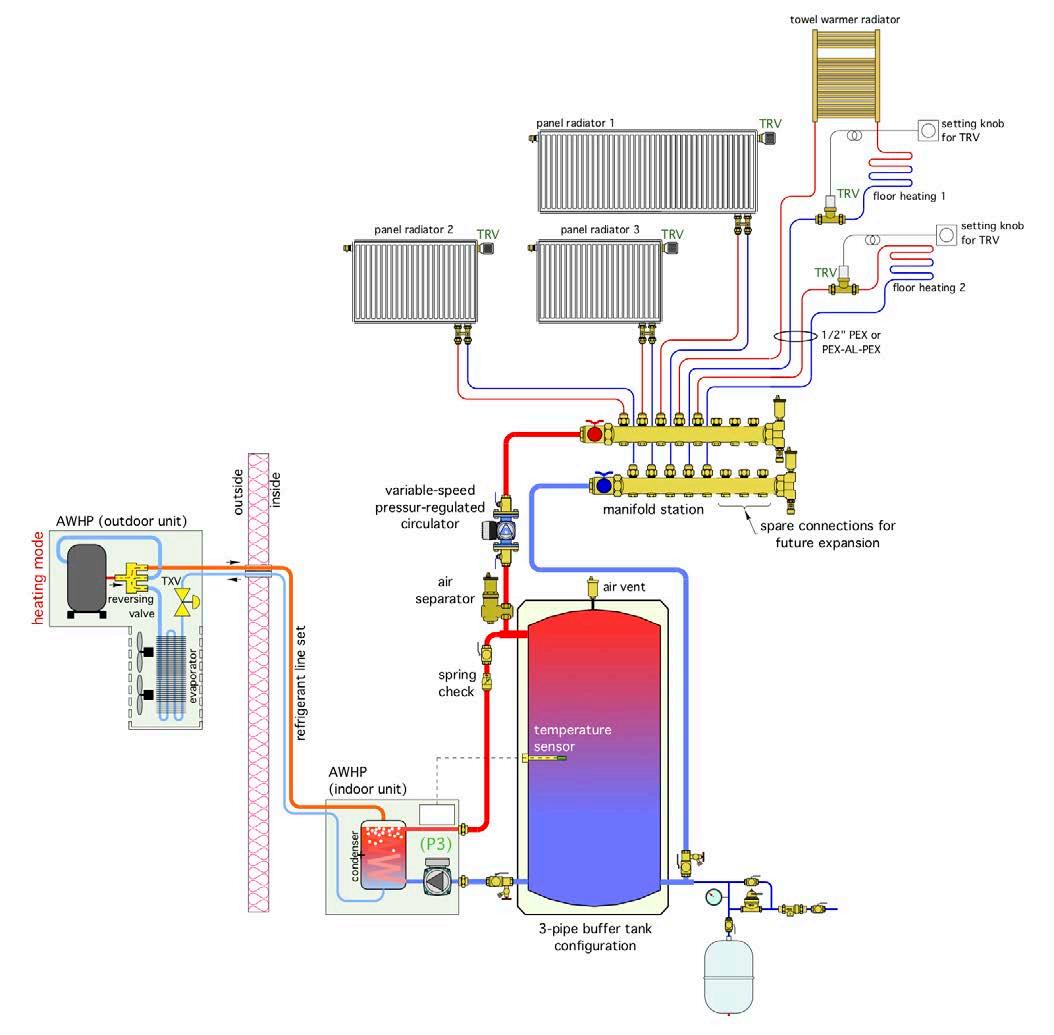

PUTTING THE PIECES TOGETHER

Figure 2 shows a simple template: an air-to-water heat pump, a three-pipe tank and a highly-zoned distribution. The heat pump supplies a combination of low temp. panel radiators and radiant floor circuits. The panel rad and the floor circuits have been designed to operate at the same supply water temperature. This eliminates the need for mixing valves. Simpler and less expensive is always preferred when possible. That’s one of the biggest lessons I’ve

learned over 40 years in this industry.

The flow and heat output of each circuit is regulated by a non-electric thermostatic valve. A variable-speed pressureregulated circulator automatically adjusts speed based on these valves.

The heat pump is turned on an off to maintain the water temperature at the middle of the buffer tank between 100F/38C and 110F/43C. In addition to buffering the heat pump against short cycling, the tank provides hydraulic separation between the heat pump’s

internal circulator and the variable speed distribution circulator.

This system leverages modern concepts that combine for high energy efficiency, reliability, and comfort. Perhaps you can use it on a future project. <>

John Siegenthaler, is a licensed professional engineer. HIs latest book is Heating with Renewable Energy (for more information visit www.hydronicpros.com).

Figure 2. An air-to-water heat pump with a three-pipe buffer tank and highly zoned distribution system.

OPTIMAL TUBING DEPTH IN A SLAB

John Siegenthaler details why tubing placement matters in a radiant-heated concrete slab.

BY LOGAN CASWELL

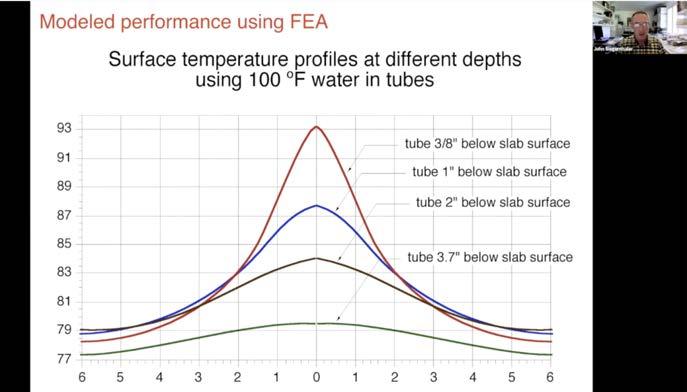

The latest instalment of HPAC Magazine’s 30 Mechanical Minutes, the free webinar series, focused on the importance of piping depth in hydronic heating of concrete slabs. HPAC editor, Doug Picklyk, was joined by John Siegenthaler, who explained how tubing depth effects heat transfer. This episode was sponsored by Arctic Heat Pumps.

Installing a hydronic heating system in a concrete slab requires planning, precision, and a lot of knowledge-based skill. Siegenthaler explained that much of the thermal performance of the final concrete is determined by how deep the tubing is laid in the slab. “The more concrete that you have over the top of the tubing, the more resistance there is,” he says.

His research shows the optimal position for the pipe is in the centre of the slab, but Siegenthaler has witnessed instances when the tubing ended up at the bottom of a four-inch or even a sixinch slab.

“Don’t let somebody tell you it doesn’t make a difference where the tube is in the slab. It does make a difference, and it’s especially relevant today as we move towards heat pumps and high-performance condensing boilers as the hydronic heat sources.”

He suggests the best way to ensure that tubes attached to a welded wire fabric end up in the middle of the slab is to have one of the masons dedicated to lifting the wire mesh and tubing at

Siegenthaler showing the surface temperature and thermal spread on slabs based on different depths of the tubing.

the leading edge during the pour. Noting the obvious, he insists that it’s important to get things right the first time, because once the concrete is laid there is no turning back.

FINITE ELEMENT ANALYSIS

Siegenthaler arrived at his conclusions regarding optimal depth for tubing following the results of computer simulations of different scenarios using Finite Element Analysis (FEA). The FEA models the thermal performance of the concrete slabs using equations and ultimately gives a picture of what’s going on thermally inside the slabs with the tubing at various locations.

He showed simulations using a fourinch slab with a 3/8-in. hardwood floor finish on top. Other constants in the modelling were 100F water temperature, 70F room temperature and oneinch polystyrene insulation under the slab. He notes that different floor finishes would give different thermal re -

sults depending on their lateral heat dispersion qualities.

The mathematical results generated by the FEA program illustrated isotherms radiating from the pipe in contour lines which transferred heat in a lateral direction over the floor above. Siegenthaler concluded the deeper into the slab the tube is located, the better the lateral heat dispersion. However, if the tube was placed at the bottom the result is a good lateral heat dispersion but a much lower surface temperature on the floor.

Can the water temperature be adjusted to get a higher thermal floor temperature reading? Yes, but going to a higher water temperature with a modern heat source such as a heat pump is going to penalize the performance of that heat pump, explains Siegenthaler.

Using an example of a typical 1980’s house with a design load which required the floor to deliver about 30 Btu/h per square foot, Siegenthaler

said it would require approximately 120F water if the tube was in the centre of the slab. Moving the tube to the bottom would mean increasing the water temperature to 134F.

In the past, that 14F difference could have been accomplished by turning up the mixing controllers, and it would not have had much effect on the overall efficiency. However, it’s not the case today where such an increase in water temperature would have a significant effect on efficiency.

“It’s an important difference, especially if you’re working with modern lowtemperature heat sources like air-to-water heat pumps, geothermal heat pumps or modulating condensing boilers,” says Siegenthaler.

Compare that to a modern efficient house with a design load of 15 Btu/h per square foot. With the tube located in the middle of the slab the optimum water temperature would be 95F com -

pared to 102F if the tube was at the bottom of the slab.

Even this seemingly small 7F increase would still impose a penalty on the coefficient of performance curves on heat pumps.

“You’ll see that definitely does impose a penalty, and remember that’s a lifelong penalty,” said Siegenthaler.

KNOBBY FOAM PANELS

Knobby foam panels are a product that have been around in the European market since the 1980s and are widely used where they put the panels over an existing structural slab and pour a thin layer of screed concrete over the top.

The product allows the thin layer to cure and micro-fissures will occur and relieve the tensile stress without causing arbitrary cracking in the finish and avoid having to perform saw cuts. The panels ensure the tubing will stay in place, but Siegenthaler would like more

data from manufacturers on the relationship between the water temperature versus heat output based on varying thicknesses of slabs poured over the product. Because the tubing is in contact with the foam and not entirely encased in concrete alone, as a designer he questions how that effects the overall thermal performance.

Siegenthaler wrapped up the segment with this advice: “If you’re designing hydronic systems today and you’re building around modern heat sources and low water temperatures, I would highly encourage you to get that tubing up off the bottom of the slab ... It’s going to enhance the performance of that heat source for the entire life of the system ... It’s not something that should be trivialized. It’s not something that should be ignored.”

Visit hpacmag.com/tech-pulse to view the entire webinar as well as past editions of 30 Mechanical Minutes. <>

WORDS OF WISDOM

Sharing reflections on the valuable role mentors have played in one man’s career. BY ROBERT BEAN

Icould (and should) write a book on my career path, it’s been a heck of ride and leaves me speechless when I think about how lucky I was to have so many special people in my life. Following are a few of the remarkable ones that molded my madness.

ENTREPRENEURSHIP: BEING UNEMPLOYABLE OPENS THE WORLD TO YOUR OWN EMPLOYMENT

The best conversation my dad had with me in my early teens went like this: “Son, I love you, and because of that I’m letting you know now that you have the personality of someone who is unemployable— not many people have that gift, but you do.” Clearly a compassionate man.

I was raised to believe that it’s good to challenge the status quo (just not at home), blaze new territory and call out BS when it needs to be called out.

I was also coached to: “Dedicate yourself to your passion, and let your work ethic and results speak for themselves.”

As young boys my brothers and I cleaned ducks for 50-cents a bird during hunting seasons, and we also did everything we could from mowing lawns to painting fences and delivering papers. And I always had side jobs building custom decks for people that had influence. By the time I was 41 I had five businesses under my belt and played at will in my sixth business from 2001 to my retirement.

Being unemployable is not a curse,

it’s a blessing—embrace it and you’ll never work a day in your life.

My dad passed away in 2020 and with him went a library of knowledge that few possess. We spread his and my brother’s ashes this past summer in the Pacific Ocean at one of our favorite fishing spots with my dad’s fishing guide piloting the boat. I thought a lot about that ceremony the following week as I hiked along the West Coast Trail in view of the places we fished…miss you dad.

BUSINESS: DO BUSINESS WITH THOSE WHO HAVE AS MUCH TO LOSE AS YOU

I’ll never forget the advice my late wife gave me following the acquisition of De Jaegher Sales. I had just turned 30 and was making my first sales call into Red Deer, Alberta.

My very first visits were to the nationwide wholesalers who proceeded to instruct me not to sell to Gerry Halford at Triangle Supply, and that if I did they would not support our company.

Needless to say, I was shocked but kept my cool. I then went directly to Triangle Supply and discovered that Gerry and I had a lot in common. We both secured our business lines of credit with the bank by using our homes as security, which meant our spouses had to sign away their dowry rights— meaning if the bank took our homes to clear up debt then our wives had no claim against the equity.

Returning home, I shared the story

with Karen and asked for her counsel. Her words: “I believe in you so much that I am willing to risk my share of the equity in our home, and Gerry’s wife believes in him so much that she did the same. You both have more to lose than the managers at the big wholesalers. Do business with Gerry and you’ll never regret it.”

True story, and Gerry and his righthand-man Barry Cunningham and the team they built went on to become a great corporate citizen for Red Deer and gave back 10-fold to the plumbing and HVAC industry in Canada than what was returned by the individuals who threatened to not do business with us.

Hats off to you Gerry and Barry – love you and miss you. Karen, you win the best advisor award. I miss you and look forward to seeing you again someday.

ENGINEERING: ARCHITECTURAL SYSTEMS SHOULD REFLECT HUMAN SYSTEMS

When we sold De Jaegher Sales to Danfoss in 2000 I had to figure out what to do with my life. Having graduated from NAIT’s Building Construction Engineering Technology program, I learned to love high performance architecture and designing radiant-based HVAC systems.

At the time I had obtained the highest level within ASET as a registered

engineering technologist in building construction (RET), but that alone would not allow me to practice independently so I wrote the APEGA exams to obtain the Professional Licensee Engineering (P.L. Eng.) designation for mechanical engineering. Once I had my license to practice and stamp drawings I embarked on growing Indoor Climate Consultants Inc. and growing my website www.healthyheating.com.

It was during that time that I really started to listen to the professors in our ASHRAE committees who were focused on human factor design—that is the physical, physiology and psychology of people living and working within the built environment.

Dr. David Scheatzle, Professor Emeritus at Arizona State University, College of Architecture and Environmental Design, was gracious enough to lend us web-based graphics that he and his students developed on thermal comfort.

The graphics had nothing, zero, not a thing to do with HVAC systems, rather they demonstrated the thermal sensory systems of the human body.

Scheatzle and his team did the early work on residential radiant cooling, which to this day continues to influence my design philosophies. During the same period, I discovered the work of Dr. Andrew Marsh who would later sell his SQU1 company to Autodesk.

Marsh understood how to graphically represent, in a nontechnical way, what people felt inside spaces and how to represent that according to the definitions within ASHRAE Standard 55 and ISO 7730.

He let us use his thermal comfort tool which ultimately drove thousands of visitors to our website, and which we continue to use today to educate the public and design practitioners on human factor design.

The lessons I learned from these and other professors was mechanical solutions should always be the last resort to solving indoor environmental quality problems and that energy use was the consequence of bad architecture.

This philosophy drove the Indoor Climate Consultants Inc. motto: “Design for People, Good Buildings Follow.”

Blame Scheatzle and Marsh for pushing me to think about client complaints from a perspective that has nothing to do with load calculations, sizing and selecting equipment.

It was the best thing that ever happened to my practice and allowed me to earn clients from all over the world. Thank you gents!

TRADES: NOTHING HAPPENS UNTIL WHAT YOU PUT ON PAPER GETS ASSEMBLED IN THE FIELD

Most don’t know this, but out of high

school I started working for a geotechnical engineering company as a lab grunt and then I later moved into the carpentry trade.

I have thousands of hours on the tools in framing and cribbing. Alan Wanagot (a Lithuanian framer) and Manfred Claussen (a German cribber) fed my work ethic and kept me in physical shape. I miss those days!

They also taught me this: everything you put together must be plumb, parallel, perpendicular, straight, square and level.

I was also taught to sacrifice fast for better—it prevents shortcuts and jobs that look like someone dropped a bowl of spaghetti on the site.

Those working in the trades know what it means to have “the eye”: the eye of perfection.

These assembly habits served me well when producing engineered drawings. I still get compliments to this day on the drawings we produced over the years. But most important of all was the ability to express our expectations from the trades. The work we saw from our fabrication shop, and the work I inspected in my engineering practice was going to get “the eye”, and if it wasn’t up to snuff it wasn’t up to our standard.

Alan and Manfred, wherever you are, bless you for not firing me when I screwed up and for imparting upon me the meaning of “excellence in the trades.”

So many others…so much knowledge…I share these lessons from my heroes to you. <>

Robert Bean is director of healthyheating.com, and founder of Indoor Climate Consultants Inc.

He is a retired engineering technology professional (ASET and APEGA) who specialized in the design of indoor environments and high-performance building systems. He is also a co-host of the Edifice Complex podcast: edificecomplexpodcast.com.

NEW ADVENTURES

Recalling early advice and the helping hands that guided a newcomer to Canada along his path in the Canadian hydronics industry. BY

MIKE MILLER

Preparing for this very personal writing assignment, I have to admit that I spent a lot of time reminiscing about many milestones in my now 30 years in this wonderful industry. The ask was to provide some history of my experience and some valuable lifelong lessons that I have learned along the way. Before I get into some of those details, I want to start by recognizing that I cannot possibly fit into one small article all the individuals who have provided invaluable support, mentorship and guidance to me over these years. That task would literally require a book! Perhaps, someday I’ll find the time to write all that, but I’m not too sure who in the world would take the time out of their busy lives to read it.

THE BEGINNING

I was raised in small village in Southwest Germany, a beautiful and picturesque area on the outskirts of the Black Forest within an hour of the Austrian, Swiss and French borders. Like many young kids back then, I was a big fan of North American movies, cars, and the huge countryside and wilderness that can be found here. It was always my dream to immigrate to North America. My family was in support of anything I set out to do, but it was my grandparents who offered the very first advice and guidance that proved to be the beginning of my future. They insisted, before I do anything, that I learn a ‘proper trade’.

Because once that was under my belt I would always have something to fall back on in life, should any other future endeavor not provide me with the opportunities I had hoped. This would eventually become all I’ll ever do!

Back in those days, three of my best school friends applied for an apprenticeship with a company just across the street from my house. This company specialized in heating, ventilation and air conditioning systems, plumbing and wood and gas-fired fireplaces. It was really because of my friends that I chose to sign up with this company as well. Had it not been for them, only God knows what I could have become?

Forward another five years, with my apprenticeship completed I set out to immigrate to Canada. What often takes several months or even years to be processed, if even approved, luckily took me only about five months and I was cleared to move across the pond.

Happening faster than I had prepared for, I ended up facing departure day without having mastered the English language. While we all learned English in school, it wasn’t anywhere near good enough to engage into any real conversations. My thought was that I’d be picking up the language easily enough once I was here? Boy, you folks speak fast over here!

JOB SEARCH

Upon my arrival in Canada, I found it difficult with my broken English to navi -

gate my job search for the first week or two, but I hit the road every morning visiting every heating shop in the lower mainland of British Columbia. Virtually all early attempts ended with no luck. Fortunately, I ended up finding a company in the Yellow Pages I thought would be a great target for me to hit, a German company name, German owner and they specialized in “European Heat Systems.” Surely I’d be able to communicate better with them?

My initial call with the owner went well. He did speak my language, and we had a good chat. Problem was, he was a small family-run business with just him, his son and a helper. He didn’t need anybody and wished me well. Continuing to look elsewhere without luck, I took a chance and kept going back to that same business daily to see if anything had changed. Luck was on my side. On the third day I called the helper failed to show up that morning

and the owner desperately needed someone.

After hitting it off with the son, I was given the opportunity to come back the following days. At first it was quite a struggle to do my job in different units of measure. Coming from millimeters, centimeters and kW/hrs to inches, feet and Btu/h and so on, took a bit of an adjustment. None the less, I had the most excellent experience during my earliest days in Canada.

If you know the area, you’ll be able to appreciate the view we had of the Vancouver skyline working at the Royal Canadian Yacht Club in Stanley Park installing hydronic heating systems in the biggest of yachts, powered by diesel-fueled boilers and capturing of waste heat off the boat’s engines. My lesson there was: “Persistency can pay off, if not overdone. Patience was the key.”

After a good few months with them, learning the differences between European and North American installations and some English, I wanted to explore more of B.C., so I left to move up north into the Cariboo. Not many heating jobs available there, and I left the industry for about a year before eventually moving to Red Deer, Alberta on my very first Canadian credit card.

RETURN TO HYDRONICS

It was in Red Deer that I ran into the two individuals who really gave me another chance to return to my industry. Those folks were Gerry Halford and Barry Cunningham. They saw something in me that not even I knew at that time, and they gave me an opportunity to work in the hydronic heating department of their supply company. On my very first day, Barry gave me an IBR booklet that teaches you how to go through a building heat loss.

He gave me that and a blueprint then sent me home to do a full analysis of a project. Even then, we had plenty of stellar software solutions that would have accomplished this same task in minutes. Not thinking much of it, I com -

pleted the challenge over the weekend and proudly turned it in on Monday.

Of course, I had to ask why he wouldn’t just let me use the much easier software? His reasoning was something I have taken with me for the rest of my career. Software is there to help make your life easier, but it doesn’t replace having the knowledge of how this science comes together. In Barry’s words: “When you use the software, you still need to know how it actually works in order to capture any potential for errors during the input of the data.”

Barry and Gerry are life-long mentors and folks I will forever respect for all they taught me, but also for the opportunities they gave me to learn more about this business beyond what I already knew from the installation side of things.

CONTROLS

I was sent to several training and tradeshow events, one of which was my very first tekmar Controls training session in Calgary. In came this (then) young fellow by the name of Greg Leupin. He spent a full two days teaching the class on hydronic systems and control solutions.

Being completely honest here, the material was WAY over my head. I struggled with the terminology and even some of the reasoning he explained. But, it turned out that Greg stayed at the same hotel as me, and I luckily ran into him that evening in the restaurant. When I approached him and told him of my struggles, Greg took the time out of his evening to explain things in even more detail. If it wasn’t for his generosity of time, it would have taken me much longer for the logic to fall into place. He helped me get up and running that evening and later became a long-time friend and mentor that I could call upon when I needed help.

ASSOCIATION, ASSOCIATIONS

Barry also allowed me to attend the Foothills Conference, a conference

Continued on p30

< HYDRONICS

that was hosted by the Alberta Hydronics Advisory Committee (AHAC), a group of like-minded individuals that formed this association to help share industry knowledge and help develop young techs.

Later, the group also became very influential in the early phases of what is known today as the CSA B214 Hydronics Installations Code. Through this group I met several others who first became mentors and educators and later friends. The list is long, but to name a few it includes: Dave Hughes, Gary Alexander, Roy Collver, Bill Benson (RIP) and Robert Bean.

What all of these guys shared is an unimaginable amount of knowledge and passion for this industry. And best yet, their willingness to sit down with literally anybody who wanted to listen to what they had to share.

I would spend hours, days and weeks going and listening to them every time they had something to say. Over the course of time I was able to pick up some of this knowledge that helped me along my career and again, they all became lifelong friends.

They also introduced me to internationally renowned industry greats such as John Siegenthaler and Dan Holohan, again two more individuals who go out of their way to mentor

Custom Built Retrofit Fan Coil Systems for Apartments & Condos

Saving you and your customers time and unnecessary cost

Installation of our high quality, custom-sized systems virtually eliminates all drywall, painting and finishing work while delivering, highly efficient, whisper quite comfort!

OUR PRODUCTS ARE:

• Canadian made

• Carry up to 5 year warranties

• Available in both vertical and horizontal configurations

INNER-COOL SYSTEMS

Contact us at 905-766-1513 and visit us online at inner-coolsystems.ca to check out our range of customizable options and our engineering excellence!

“Before you do anything else in life, learn a proper trade.” - Grandparents

and share their knowledge with anybody who will listen.

All of these fine individuals I will forever hold dear in my heart and will forever be grateful for because without them and the time they dedicated to me, an unknown young immigrant, I never would have been able to grow my own knowledge and see beyond my field of experience at that time.

I admire the relentless passion they shared and their continued dedication to commit to the betterment of this industry, often with their own time and dime, by volunteering efforts in several industry associations. They also taught me that if you feel that the industry needs to change or pursue new opportunities the best way to make something happen is to get involved.

Having now been in this industry for as long as I have, from installations to wholesale distribution and now for over two decades on the manufacturing side, I have followed their lead and guidance and have been involved in all major industry associations.

My parting words of advice to any young up-and-coming individual is this: This is the very greatest of industries filled with individuals who share unmatched dedication, passion and knowledge. You can make an absolutely rewarding career in this field.

Most hydronics folks I’ve met in my time are incredible and humble humans that are very approachable and willing to share anything they know. They believe that together we will always be stronger and more successful than any one of us can be alone.

Go approach any of them, it’s worth your time.

If you have some time to spare, get involved in local associations. Most will welcome you with open arms. We know there is much work that has yet to be done and not enough time or people to get it all accomplished. Fresh minds bring fresh ideas, and these are invaluable assets to any association, or business for that matter. <>

Mike Miller is vice president of sales, Canada with Taco Comfort Solutions and a past chair of the Canadian Hydronics Council (CHC). He can be reached at hydronicsmike@tacocomfort.com.

INNER-COOL

ONE CONTROL TO RULE THEM ALL

How I got here and what I’ve learned about this industry.

BY CURTIS BENNETT

Ilove The Lord of the Rings. My family and I do what we call a “Lord-a-thon” each year in December. We get together as we watch each movie until they are all done, all six of them, including the The Hobbit, of course. If you’re not familiar with the J.R.R. Tolkien series, the basic premise behind the movies is there is one Ring to rule them all.

This reminds me of the time Tom Hermann and I were sitting on the plane heading from Calgary to the CMPX Show in Toronto for the first time. I had just finished our initial prototype of the CPU1000, a boiler controller. It was only a raw circuit board and would only “run” hooked up to my computer. Tom and I stared down at it while on the plane, and we talked about how this one control was going to take over the industry—one control to rule them all. We loved it. I had worked on it for almost two years by this point, and it was my baby.

INTRODUCTION

My hydronics industry origin story goes like this: Tom Hermann, the “H” in HBX controls, called me up out of the blue while I was working in a different industry. He found my name through the grapevine somehow.

I was a skateboarding backwardshat-wearing kid, as Tom would say back then. He needed some help with a pump exercising board. This led to a couple other small projects before evolving into to a business partnership and the formation of HBX Controls in 2002. After all what kind of a name is “H” controls.

Tom, a mechanical engineer with

years of history in the hydronics field, saw something in me back then that has now worked out for a very long time. HBX Controls has been a thriving company for almost 20 years now, and I am proud to be part owner in it.

WHAT IS HYDRONICS?

When I first started out in the HVAC industry, I thought, “What the heck is hydronics?” I had never even heard of it (one reason we need to get the word out there more, but that is a whole other topic for another day).

I had been working with electronics and designing for a while, but I was enamoured with the idea of starting a new adventure. I would sit in Tom’s office for hours going over design possibilities and other controls. All we would do was talk controls and hydronics.

I knew that I would need to know everything there is to know about hydronics in order to build the best controls possible. We were going to take on a

very entrenched industry, and change, no matter what industry, is never an easy road. So I would have to say that Tom has been my number one influence in this industry, hands down.

INTRODUCTIONS

It was after I started to get to know the industry a little better that we were finally ready to launch our first product at the Foothills Conference in Edmonton. I had never even done a tradeshow before, and I was so excited. And on top of everything, I was asked to do a presentation on P.I.D. [Proportional Integral Derivative control], one of my favorite topics. I was very nervous, and I did not to want to screw up in front of all these people.

At the time I did not know a lot of people in our industry from outside of Alberta, but I did know of one—John Siegenthaler. Everyone in this business knows John, and he was at my presentation, which made me even more nervous. As far as I could tell the seminar went

Drawing inspiration from Lord of the Rings: one ring to rule them all.

well, at least I didn’t throw up from nerves. The next year I happened to bump into John at the massive ISH trade show over in Germany. I did not expect what happened next.

He struck up a conversation with me, and we chatted for about half-an-hour. We talked about a lot of things, like the industry in general, where things might be going, and how he loved solar technology. My main take-away was that John treated me like an equal, something I did not expect being so new in the industry. Since then, John and I still chat at trade shows and sometimes throw around control ideas, which I enjoy a lot.

KNOWLEDGE SHARING

The “physiological effects of radiant heating” was something I first learned about while sitting at a seminar led by Robert Bean. It was one of the most important aspects of hydronic heating I had ever heard.

Robert is a genius at putting these aspects of hydronics and radiant heating into perspective. I did not really know Robert at this point, but with him also being from Calgary we would bump into each other a lot.

Like John, Robert treated me like an equal right from the start. This seemed to be a trend in the industry—something I have found did not end with John and Robert.

Robert would also, when we would see each other, make time to chat about not only our industry but business and other things as well. I got to know Robert over the years well enough to even go out for dinner and pick his brain about certain things that I think we both share a passion for.

Both John and Robert have a genuine love for the HVAC industry and hydronics, and well for that matter so do I.

Something I think we all share, is we all want to see this segment of the in -

dustry grow into something that becomes a household name. Radiant heating, hydronics, physiological effects, should all be words that everyone knows.

The approach that John and Robert take in teaching and lifting the industry is great. They have helped me see that this industry is big enough to touch a lot of people, but it’s also small enough that we can all become much more than acquaintances. <>

Curtis Bennett C.E.T is the product development manager at HBX Control Systems in Calgary. He formed HBX with Tom Hermann in 2002. Its controls are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs found in residential, commercial and industrial design applications.

MECHANICAL SUPPLY NEWS

MANUFACTURERS • DISTRIBUTORS • WHOLESALERS

HAPPY RETIREMENT

Viessmann Canada held a celebration at the company’s Waterloo, Ont. headquarters on November 22nd for outgoing president Harald Prell (HP) who is retiring after 41 years with the company.

Prell first joined Viessmann in 1980 as an assistant general manager. He was promoted to general manager of North American operations in 1986, and in 1990 he established Viessmann US in Warwick, Rhode Island. He was later appointed president of Viessmann Canada in 2010.

DURAVENT ACQUIRES HART AND COOLEY

DuraVent has acquired Michigan-based Hart and Cooley, bringing together two HVAC industry venting pioneers.

Operating since 1901, Hart and Cooley’s product portfolio includes residential and commercial products including grilles, registers, diffusers, commercial and residential venting and chimney systems, and air filtration products and systems. The company owns facilities throughout Canada, the U.S. and Mexico.

DuraVent, venting and chimney specialists, also owns Security Chimneys in Montreal.

“Our immediate objective is to build one unified company, with one team, focused on world-class manufacturing and distribution,” said DuraVent president and CEO Simon Davis in announcing the deal. duraventfiltration.com

CIPH ESTABLISHES WOMEN OF DISTINCTION AWARD

The Canadian Institute of Plumbing and Heating (CIPH) Board has approved a new award to recognize women in CIPH with outstanding leadership. At the request of the CIPH Women’s Network the award was approved by the Board and will be named the CIPH Women of Distinction Award.

To be considered, nominees must demonstrate commitment to mentoring, developing and promoting women in the plumbing and heating industry through their leadership. The award is based on the following criteria: a minimum of 12 years in the plumbing and heating industry (with a CIPH member company); minimum four years of service on any CIPH committee or council; and a maximum of two women per year can receive the Award.