AND

THE

AND

THE

Viessman is one of the most prefered and trusted brands in hydronic heating solutions in Canada for 40 years. Whether your project is a new home, commercial residence, or retrofit we offer heating solutions supported with digital tools to provide peace of mind at your fingertips:

• Program, remotely monitor & control your boiler using ViCare App

• Free expert advice when you request a heating system consultation online

• Extended 5 year parts and labour warranty for residential gas-fired condensing boilers up to 300 MBH input*

PLUMBING

IOT TECHNOLOGY AND MID-MARKET COMMERCIAL PROPERTIES

Adding value to mid-size buildings by introducing connectivity, visibility and remote controls to domestic water systems.

By Adam Bartman and Avishai Moscovich

20

PLUMBING

MATERIAL KNOWLEDGE

Identifying how differences in plastic piping materials impacts service decisions and procedures.

By Jonathan Simon

28

HVAC

ADDRESSING TEMPORARY CONSTRUCTION HEAT

There’s got to be a better way to build homes in cold weather and protect furnace systems.

By Ian McTeer

36

HYDRONICS

COMFORT VS. THERMODYNAMICS

Exploring new energy-efficient technologies and promoting the superior comfort of hydronic systems

By John Siegenthaler

40 SNOW MELT

CLEARING THE WAY

Understanding the options for snowmelt systems and the best application for your clients.

By Mike Miller

44

BOILERS

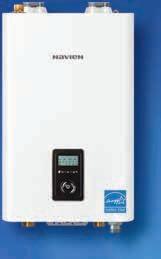

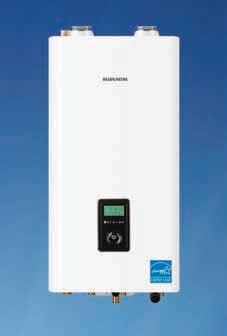

COMBI OR NON-COMBI: WHEN AND WHERE?

Webinar review: Insights and ideas from industry experts on when the combination boiler makes sense in today's marketplace.

By Doug Picklyk

54

SOLAR THERMAL LARGE-SCALE SOLAR THERMAL SYSTEMS

A review of how far we’ve come and lessons that can be applied to smaller systems.

By Robert Waters

58

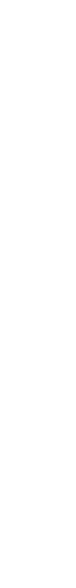

REFRIGERATION THE POWER OF THE HORSE

Reminiscing and understanding the dynamic relationship of horsepower in refrigeration.

By Dave Demma

The Gen-Eye Hot-Spot® pipe locator makes locating easy. Its total field antenna array and on-screen icons lead you right to your target, without the long learning curve.

Whether you’re an experienced pro or a first time user, you can quickly locate inspection cameras, sondes, active power lines and utility lines with pinpoint accuracy.

The Hot Spot is the industry’s most rugged locator. It’s dust and dirt proof, water resistant and never too “delicate” to get the job done.

Call the Drain Brains ® at 800-245-6200, or visit www.drainbrain.com/hotspot

IT JUST SO HAPPENS MY NEXT DOOR NEIGHBOUR HAS DECIDED TO REFINISH THE BASEMENT OF HIS 90-YEAR-OLD TORONTO HOME. He's opening it up to make a large playroom his two young boys, three and five. A silver lining to me working from home during this pandemic, is it has allowed me a front-row seat to the progress of his renovation and to gain some insights into his decision making when it came to his home's mechanical system.

As part of the reno, he’s replaced an old cast-iron boiler that had been heating the main part of the two-storey brick house for decades. (He put an addition on the back about five years ago, and heats that section with a gas-fired forced-air furnace).

The new boiler he selected is a combination boiler, for both heating and domestic hot water. His contractor helped with the decision. He’s relocating the new wall-hung ‘combi’ boiler closer to the new furnace, and it’s taking up a fraction of the space of the old unit and hot water tank together, making the playroom, heated with radiant in-floor heating, that much larger.

For him, going with the combi boiler made sense and so far everything is working out fine. (As of this writing, the old concrete floor was removed, infloor piping has been laid down and the new concrete floor poured and set).

As a happy coincidence, in this issue of the magazine we are introducing the first in a new series we’re calling 30 Mechanical Minutes, and our kick-off presentation is on the topic of combination boilers, when and where they make sense in today’s market.

Our regular contributor Steve Goldie, along with hydronics industry expert Mathew Pottins, joined me online (socially distanced via the Internet) in early September, and together they discussed the merits and challenges with combi boilers (read more beginning on page 44).

This new 30 Mechanical Minutes series will run throughout 2021 and will touch on subjects in plumbing, heating/cooling and refrigeration with voices from our contributors and others in the industry.

Each session runs live online, and you’re invited to join in, listen and ask questions. Each 30-minute session will also be recorded and hosted on our website, so if you can’t join us live you can catch up later on your own time.

This pandemic has forced us all to make changes, from how we school our children, meet up with friends and run simple errands, to how we work and continue learning. We really hope our new 30 Mechanical Minutes will provide a great break in the day for you, keep you in touch with your industry and teach you a thing or two.

Keep on the look-out for the next online session. I hope you’ll join us on this journey. <>

– Doug Picklyk, Editor

HPAC MAGAZINE

111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

TEL: 416.442.5600 FAX: 416.510.5140 www.hpacmag.com

EDITOR

ASSOCIATE PUBLISHER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

COO

Doug Picklyk (416) 510-5218

DPicklyk@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 442-5600 ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2020 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Of cer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its af liates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

Rendering of the Fieldhouse development.

Canadian developer of low-rise and condominium housing communities, The Daniels Corp., has announced the launch of its Field House EcoUrban Towns development, in Toronto. The townhome community is placing a focus on energy efficiency and low carbon emissions.

Now under construction, the project features 24, three-storey townhomes, ranging in size from just over 1,319 sq. ft. to just over 1,700 sq. ft. with prices starting at $1.1 million.

Once constructed and occupied, the townhomes are projected to use 52% less energy, emit 89% fewer greenhouse gases and reduce energy costs by 11% when compared to Daniels’ traditional townhouses.

According to Adam Molson, director of project implementation at Daniels, each unit will have ducted forced air heating and cooling via in-suite air handling units. And every unit has its own individual heat pump with dedicated compressor (which is located in the underground parking garage, rather than outside).

And for domestic hot water: “Each unit has an electric hot water tank with a conventional heating element (not heat pump). To increase the efficiency and hot water performance we have tied each hot water tank to a dedicated drain water heat recovery unit connected to the shower drains,” says Molson.

Featured elements include:

Electric high-efficiency heat pumps–

providing 300 to 360% efficiency.

PowerPipe drain water heat recovery–recovering energy from warm shower water to preheat water coming into the water heater and reducing energy consumption (40-gallon electric hot water tank)

Reversomatic energy recovery ventilators (ERVs)–set to reduce energy consumption and utility costs through the recovery of energy from exhaust air.

High performance building envelopes providing insulated walls to help reduce energy consumption and utility costs.

Low flow faucets and single flush low consumption toilets

“Smart Meter” technology and efficient appliances–including a heat pump dryer which uses approximately half the energy of alternative options.

The EcoUrban townhomes efficiency will also be supported by 18% of the development’s energy needs being supplied by the Bifacial solar panels integrated into the solar trellis above its rooftop terraces. eldhousetowns.com

NSF International, the global public health organization that facilitates standards development, and tests and certifies products, has published changes to NSF/ANSI/CAN 61, the drinking water product standard required in Canada and the U.S., to further restrict the amount of lead that can leach from plumbing products.

The new pass/fail criteria for certification to the standard will require the maximum amount of lead leaching to be

With the physical in-person CIPHEX West 2020 trade show being moved to 2021 in Vancouver, the Canadian Institute of Plumbing and Heating (CIPH) will be presenting a virtual trade show throughout the month of November, CIPHEX VIRTUAL.

The purpose of the virtual exhibition is to provide a showcase for products and 21 exhibiting companies will also present educational webinars throughout the four weeks of the event.

While exhibitor virtual booths will be accessible 24/7 for four weeks, there will also be three “live” days covering four-hour periods where visitors and exhibitors can live chat, video chat or email “live”. The three live Thursday sessions are: November 5, 10 a.m. – 2 p.m.; November 12, 5 p.m. – 9 p.m.; and November 19, 8 a.m. – 12 (noon, all eastern times). Registration for attendees is free, but there will be a $10 charge for webinars. ciph.com

reduced from 5 micrograms (µg) to 1 µg for plumbing endpoint devices such as faucets, and from 3 µg to 0.5 µg for other plumbing components such as connector hoses and small shut-off valves.

In-line mechanical devices and other product categories under NSF/ANSI/ CAN 61 are not subject to the new requirements.

Under the new standard, certification of applicable products to the lead leaching criteria is optional for the next three years to allow time to comply. On Jan. 1, 2024, all products will be required to meet the new requirements.

Revisions to the standard were approved by the Council of Public Health Consultants and ratified by the American National Standards Institute (ANSI) and the Standards Council of Canada (SCC). nsf.org

Peter Norman

The Canadian Institute of Plumbing and Heating (CIPH) and the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) are once again joining forces to present a complimentary economic forecast webinar featuring Peter Norman, chief economist at Altus Group.

The webinar, to be held on Wednesday, November 25 at 1:30 pm (eastern time), is entitled “What a Year It’s Been: What a Year Ahead!”, and it will cover many familiar economic touch points including:

The economy, housing market and construction sector: 2020 pre- and post-COVID and what could possibly lie ahead?

Outlook for residential and commercial and construction through 2021.

Outlook for renovation spending with implications on plumbing and heating dollars.

Residential construction: Will the pandemic change what and where homebuyers will buy?

Commercial sector: Expect newbuilds to shift to CAPEX as changes in workplace needs dominate.

Findings from Altus Economics research including results from the Altus Home Buyer Intentions Index.

Government sector investments: will infrastructure investment be part of a COVID economic recovery plan?

This update webinar follows Norman’s presentation from May 13th when he predicted the Canadian economy was likely headed for three straight quarters of decline before bouncing back in 2021.

Norman also acknowledged at that time that this is “not a regular recession” and he anticipated that some segments of the market would rebound quickly.

Registration is required for the November webinar. ciph.com hrai.ca

Organizers of the ISH show, the largest international trade show for the plumbing and HVAC industries that was originally planned for March 22-26, 2021 in Frankfurt, Germany will now become an entirely virtual event.

The range of digital features on offer will include exhibitor presentations (products, information, videos, personal contacts, chat functions and one-to-one video calls), along with live streams and on-demand broadcasts of the supporting program.

All of the material will be available 24/7 throughout the event, worldwide and in every time zone. ish.messefrankfurt.com

As of press time, the management team of the AHR Expo sent out a notice that the originally-planned AHR 2021 show dates of January 25-27 in Chicago have been officially postponed.

Results from a recent AHR Expo survey to gauge industry interest in moving the 2021 show from January to March revealed that the proposed date change was preferred by nearly 80% of exhibitor and attendee participants.

That led to the decision to possibly still host a live event March 15-17 in Chicago.

A final decision regarding the in-person hosting of the 2021 AHR Expo is anticipated by mid-October.

AHRExpo.com

Continued on p12

Adrian Steel’s Grip Lock and Drop Down Ladder Racks are designed with ergonomics and user safety in mind. Whether you’re upfitting a single van or an entire fleet, Adrian Steel has just what you need. Increased efficiency starts now.

Due to ongoing uncertainties because of the COVID-19 pandemic, The Buildings Show, which was scheduled to run in Toronto from December 2 -4, and BUILDEX Alberta, set for Calgary November 4-5, are being combined into a single national digital platform that is being called Buildings Week.

Running from November 30 through December 4, Buildings Week will be a virtual event comprised of exhibits and conference sessions associated with The Buildings Show | Construct Canada, PM Expo, HomeBuilder & Renovator Expo, World of Concrete Toronto Pavilion and BUILDEX Alberta.

Online registration for the virtual event will be free for industry trade professionals. There will be an early bird deadline for discounted educational programming which is set to expire Friday, November 13. thebuildingsshow.com

The Yukon government announced its Good Energy rebates for heat pumps, whereby homeowners can receive rebates covering 40% of project costs, up to a maximum of $8,000 for a new air or ground source heat pump.

In addition to its expanded rebate, the Government of Yukon is seeking participants for a heat pump pilot project. In partnership with electrical utilities, the project will support the installation of 25 heat pumps for both commercial and residential buildings that already have certain heating systems installed.

The pilot project seeks to understand how heat pump technology and existing heating systems interact to optimize performance for homes and the electrical grid. The Government of Yukon will cover installation costs of up to 40% up to a maximum of $10,000. yukon.ca

The Ontario Refrigeration and Air Conditioning Contractors Association (ORAC) is hosting a virtual two-day Women’s Day event in entitled: Women Empowering Women in HVAC/R.

Taking place Wednesday, October 21 and Thursday, October 22, each day begins at 9:00 a.m. and ends before 1:00 p.m. (eastern time).

A ‘digital ticket’ costs $24.99 and provides access to the event featuring speaker sessions, contests, and giveaways along with networking opportunities. The ticket also includes access to a post-event recording.

Early registration is encouraged. orac.ca

Roto-Rooter Services, the plumbing and drain cleaning company with over 400 franchise territories serving approximately 91% of the U.S. and 40% of the Canadian population, has announced that Robert Goldschmidt has been named president, succeeding Rick Arquilla, who is retiring after 21 years in the position.

Goldschmidt has been a member of the executive team at Cincinnati-based Roto-Rooter for 28 years. Arquilla will stay on until his retirement at the end of 2020. During his time at the helm, RotoRooter’s annual sales grew from US$280 million to US$700 million while operating profit grew from US$38 million to US$150 million. rotorooter.com

The Residential Construction Council of Ontario (RESCON) has launched a campaign to bring employers, unions and government together to combat and address racism in the industry.

RESCON kicked-off a Construction Against Racism Everywhere (CARE) campaign, using hashtag #RESCONCare. Stickers are being distributed to construction employers and the broader industry for workers to post on their hard hats and around construction sites.

RESCON and its board of directors are also spearheading the formation of a coalition of employers, unions and subtrades from all sectors of the industry. rescon.com

Adding value to mid-size buildings by introducing connectivity, visibility and remote controls to domestic water systems. BY ADAM BARTMAN AND AVISHAI MOSCOVICH P.ENG.

In every commercial or multi-unit residential building there are three primary mechanical systems: HVAC, fire protection and plumbing. In terms of monitoring, controls and real-time performance data of these three systems, plumbing has been mostly ignored. HVAC systems are largely controlled by a centralized system (often referred as a building automation system – BAS). The fire protection system is connected to the local fire departments via the building fire-panel. When it comes to domestic water, we haven't really seen a widely scaled platform in which one can connect and control different aspects of the plumbing system.

If you plot all building asset types on a spectrum, on one side we have singlefamily residential homes and on the other end we have Class A office towers.

In the past five years, with the advancements in Internet of Things (IoT) technologies, the single-family residential market has been well served by the likes of Amazon, Google and Apple with their smart home products and services. On the other end of the spectrum, the Class A office towers typically have both the budget and the expertise to apply a building automation system control and monitoring capabilities. When you look at the middle of the spectrum, which we call the mid-market, you will find a large underserved community. The mid-market includes a variety of asset types

such as new multi-family condos, smallmedium office buildings, schools, big box retail buildings, industrial buildings and strip malls. The commonality among all of these mid-market buildings, from a controls and monitoring perspective, is that they have no visibility or connectivity as it relates to domestic plumbing systems.

“Overall, there is lack of visibility and feedback information on the performance of domestic plumbing systems”

Before we delve into how you can advance design standards of plumbing systems, let’s take a look at common plumbing challenges in a commercial building. For example, we're seeing buildings that are five to eight years post construction already experiencing pinholes, frequent pressure reducing valve (PRV) failures causing water hammer and temperature imbalance in suites where no one is aware these fixtures require annual service. We see shutoff valves that seize within a couple years because no one has exercised them since the building was commissioned. If we look at the type of fixtures in a

domestic plumbing system, these are manually-operated shutoff valves, manually read meters as well as manually read, non-calibrated gauges and thermometers.

Overall, there is lack of visibility and feedback information on the performance of the domestic plumbing systems and it often causes havoc in buildings.

We can qualify the typical water related challenges a mid-market building faces and areas where connected systems can improve them into three categories:

1. improving day-to-day operations— for example, simplify the process to shutdown risers for maintenance work,

2. conserving water in areas where water rates are getting more expensive and the operational expenses on water is increasing without an apparent reason,

3. managing risk from water escape and floods.

It is important to understand the right timing to implement IoT technology into a building. There are certain opportunities in which adding connected technology to the plumbing system makes sense and provides significant value with rapid payback.

Three opportunities for when to consider adding IoT to a plumbing system:

Continued on p16

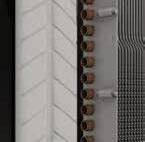

Introducing GrohSafe™ 3.0 valves, designed to accommodate every situation with:

• One simplified pressure balance platform

• Simple, easy installation

• Enhanced features

With its compact body, flat back and multiple connections options, it offers unmatched versatility on the job. Discover more at grohe.ca

ADDITIONAL CONNECTIONS

1. when designing a new building you have a lot of flexibility in the design elements and can apply a wide scale of new technology. With open walls and ceilings, it is easy to install and wire connected sensors and fixtures. Furthermore, very often, the labor is neutral. It's just a matter of installing an actuated valve in lieu of a manual valve, for example.

2. if you are looking to solve a specific need, for example if a building is experiencing pinholes on the recirculating header far earlier than it should, resulting in frequent water escape, leaks and floods, that is an opportune time to add connectivity to the plumbing system.

3. commercial properties have capital improvement plans which includes plumbing system upgrades. For example, replacing all of the riser valves, where it makes sense to consider installing actuated valves as the labour is already accounted for in the budget.

IoT technology is changing the game. Early connected solutions for the midmarket were limited due to cost or technical capabilities, and consumer products are often not scalable for larger buildings. For example, residential systems can connect to a home’s

¾-in. water supply pipe and communicate water usage and shutoff the main line in case of an emergency. When you need to connect 2-in. and 3-in. butterfly valves with a few pressure sensors to one platform, the consumer products come up short with limited capabilities.

On the other hand, a commercial BAS has all the technical capabilities but is very expensive. A BAS is often more associated with the HVAC system, not the domestic plumbing system, and particularly for a mid-market building, it is cost prohibitive.

An ideal IoT based water management solution for the mid-market should meet a few basic aspects and be low cost. It should be scalable with an ability to easily expand an installation from a small to a very large application, and it should be able to connect to a variety of sensors. Also, in order to understand system performance data its needs to read actual system conditions such as temperature, pressure and velocity to make informed decisions. Lastly, it needs to be easily retrofitted into existing buildings, non-invasive and easily installed by a plumber or service provider rather than a specialized technician.

As discussed, typical mid-market buildings don’t have access to a BAS or any type of visibility to their water systems.

In the following sections we take a look at the flow of water as it enters a typical two-zone multi-unit residential building and identify where current IoT technologies can be added to advance the plumbing designs and provide owners and operators with connectivity to their domestic water systems.

In the basement mechanical room we typically find a revenue grade water meter allowing the local water utility company to calculate consumption and bill the property. Immediately followed by a code-required backflow prevention device, and often a strainer or a filtration system to remove fine particles from the water supply. The next system inline is a boosting pump package that supplies the cold water to the building at a particular pressure.

Using IoT technology we can add visibility into the system performance by applying sensory fixtures to the existing layout without any changes to the system layout.

Connecting the existing water meter to the cloud to record water usage and flow rate data allows the building operators to see real-time conditions remotely. By adding real-time pressure sensors across the water filtration system, users can understand when the system is due

for media replacement. Adding an actuated valve following the backflow prevention device allows for easy remote water shut-off in case of emergency. Lastly, providing a connectivity platform for new booster pumps, which are typically equipped with VFD motors and sophisticated operation logic, but they may lack the connectivity option to alert the operator in case of a problem.

As we move along the domestic distribution system, water is pressurized into a high pressure system, then stepped down in the zones mechanical rooms through an arrangement that includes pressure reducing valves (PRV), circulator pump, and heat exchanger to a low-pressure delivery system to individual suites.

For example, with each zone is a group of 10 floors, we will have hot- and cold-water supply high pressure stepped down through a PRV from 200 psi to an adequate deliverable low-pressure side of 70 psi. Furthermore, on the low-pressure side we control the zone hot water conditions with a recirculating pump, a heat exchanger and a balancing valve to collect all of the hot water and put it back into the hot water supply.

Typically, this complex arrangement is left to operate with no connectivity or visibility on the system or fixture performance, however with current IoT technology there is actually a lot of value to be created for the operators and owners.

Actuated valves on the hot, cold and recirculating lines allow the operator to remotely shut down and contain a single zone in case of an emergency instead of shutting down water to the entire building. And according to AWWA every valve should be exercised on a regular basis, but it is never done. Connected valves, which are not modulating on a regular basis like in HVAC system, can be exer-

cised autonomously to ensure they operate when needed.

A pressure reducing valve is a complex fixture, requires annual service to replace the diaphragm and springs. When annual service is not maintained, a failed PRV can cause havoc by allowing high pressure delivery into suites. Delivery of high 200 psi pressure in a low pressure rated pipe increases the risk for ruptures, water hammers and temperature imbalance to tenants. By replacing the manual pressure gauges with a real-time connected pressure sensor, we can now understand the operation of a PRV and most importantly, send an alert to the operator in case a PRV fail and the outlet pressure increases above the design threshold.

The third IoT technology to apply would be on the domestic hot water recirculation within a zone. Traditionally, during building commissioning a circuit balancing valve is installed and set to allow design velocity in the recirculation line. Often, within a couple of years you will find that balancing valve has been moved, is not in the proper set position and there is no indication on the flow or water velocity in the system.

At the same time, the circulator pump is constantly running without any feedback on hot water demand. These unmonitored operation conditions, where

pressure, temperature and velocity often exceed manufacturer optimal working recommendations, lead to early failure of copper and PEX piping systems. With current IoT technology, by installing a connected flow meter, temperature and pressure sensors in lieu of the manual gauges, operators can maintain the recirculation flow rate at an optimal position and extend pipe life. Furthermore, cloud connected IoT applications can save energy by adding night setback sequences at low demand periods via throttling down the hot water recirculation flow to a minimum.

Next, let’s look at the hot and cold-water risers of the domestic plumbing system. The hot water risers will end at a recirculation header with a circuit balancing valve. Day-to-day operations in a multi-unit residential building often involve pluming service in suites. When a plumber shows up on site and needs to shut down water it is a cumbersome and disturbing process to shut down water for the whole building.

Applying affordable and low-cost IoT technology by replacing the traditional manual riser valves with a connected valve has a few benefits such as automated circuit balancing and riser shutdown in case of service calls.

As mentioned above, autonomous valve exercising ensures valves operate. In multi-unit residential buildings, toilets that malfunction and pass water often go undetected and become the main cause of water waste. Most residents are either not aware of the water passing or don’t complain about it. This makes the water bill a variable, uncontrollable cost. Looking at a bulk water bill does not provide specific enough information on water use and does not identify water waste. IoT technology, specifically real-time cold-water riser monitoring can provide real-time data and identify water waste.

Domestic hot water storage tanks often located in the boiler room will supply the hot water to suites via mixing valves. Traditionally, both storage tanks and

mixing valves are manually set and lack any type of real-time feedback on temperature settings. Now, more than ever, in a post-COVID-19 environment, there is a need for real time monitoring of hot water temperatures to prevent Legionella and other bacteria in potable water. Adding connected temperature sensors to mixing valves and actuated valves on the hot water recirculation line allows real-time water management in mid-market buildings. In addition, cloud platforms can easily be utilized to incorporate all aspects of compliance with ASHRAE Standard 188-2018 managing the risk of Legionellosis in building domestic water systems, including testing, monitoring, control and administration.

In summary, the vast mid-market segment of commercial and residential prop-

erties is in need of advanced plumbing systems to deal with older infrastructure. With control and monitoring of plumbing systems long being ignored, there is much value to add to by capturing realtime data with simple, and affordable, IoT cloud-enabled technology. <>

Adam Bartman is a second-generation Red Seal Endorsed plumber from Toronto. Combining his plumbing experience and passion for technology, he co-founded reed (www.reedwater.io) to bring plumbing systems online to help landlords and service providers manage water at commercial properties. Avishai Moscovich P.Eng. LEED AP is CMO at reed. He is an engineering graduate of Ryerson University and holds an Executive MBA from Kellogg School of Management at Northwestern University.

Plumbing is an unpredictable business, but the quality of the pumps you install shouldn’t be. Generations of plumbers have trusted our hard-working, reliable pumps to get the job done right the first time. Make a Big Impact on your next job with Little Giant.

Identifying how differences in plastic piping materials impacts service decisions and procedures.

BY JONATHAN SIMON

Many service plumbers today cut their teeth on copper piping. But they are seeing less and less of it in the field with plastic piping having become commonplace in new construction over recent decades. Rather than working on one material most of the time, today’s service plumbers may encounter copper piping in the morning, CPVC in the afternoon and PEX at the end of the day.

While the goal is the same regardless of the material—resolve existing issues and ensure the reliability of the system—these materials have distinct differences that impact how they perform in certain conditions, as well as how they are serviced. Keeping up with piping material changes can be a challenge and makes continuing education and training more important than ever.

To identify specific areas of opportunity for proactive education, our company (a supplier of CPVC pipe and fittings) tested service plumbers’ knowledge of the two main plastic plumbing materials in use today—CPVC and PEX—through an online quiz. The results uncovered some misconceptions about plastic piping materials in three key areas: cutting, fittings and diagnosing problems. Before we get into those, it’s useful to review the characteristics of the two materials.

In plastic piping, the chemical composition of the pipe can dictate how it performs in certain conditions. A good example of this is polybutylene, a plastic piping material used in new construction throughout North America in the 1980s.

Polybutylene proved unsuitable for residential water systems because of an inherent chemical incompatibility with chlorine. The material suffered from widespread chlorine-induced leaks and failures before it was removed from the market.

PEX is from the same polyolefin family of polymers as polybutene but is manufactured using a polyethylene base with cross-links between the polymer chains. PEX manufacturers also use chlorine inhibitors to mitigate incompatibility issues between the material and water treatment additives. Still, the material can be susceptible to chlorine degradation, particularly in aggressive water conditions. PEX is also softer and more flexible than either copper or CPVC and uses a different style of fitting than either of those two materials.

CPVC is a Chlorinated Polyvinyl Chloride. As a chlorinated material, CPVC is immune to the chlorine-related

problems that can exist in copper and PEX. CPVC is somewhat flexible when new, simplifying installation, and becomes more rigid as it ages. Rated to handle 100 psi at 180F/82C, it can be used in some applications that aren’t recommended for PEX, such as temperature and pressure relief lines, condensate drains and hot chlorinated water.

The biggest mistake plumbers make today when servicing CPVC is in the tools they use when cutting CPVC in service. Because of this mistaken tool selection, they also underestimate CPVC’s potential service life.

Cutting: One of the most basic and important steps in working with any material is making a clean cut. Yet roughly half of the plumbers that took our quiz chose the wrong tool for cutting in-service CPVC. Because CPVC becomes more rigid as it ages, it re -

quires a different tool when cutting new versus aged CPVC.

For new CPVC ratchet-style cutters can be used. Aged CPVC should be cut with a c-style tubing cutter, or alternately a wheel cutter or a fine-tooth saw. CPVC should never be cut with non-ratcheting pipe shears used for flexible hose and tubing.

Note, this aging process does not compromise the integrity of the pipe. The pressure-bearing capability of CPVC actually increases with age. But the pipe becomes too rigid to cut cleanly with ratchet style cutters and cstyle cutters are recommended.

Fittings: CPVC uses a solvent weld process in which the pipe slides into the fitting, maintaining full flow through the pipe. Most plumbers are familiar with this process and understand a dauber one-half the size of the pipe diameter is best for applying an even coating of solvent cement. However, many still believe repairs that require solvent cement will take hours to cure. That isn’t the case. Solvent cements specially formulated for repair can cut curing times from the several hours typical in new construction to as little as 15 minutes on cold water lines.

Identifying Failures: Pipe failures can often indicate problems that simply replacing the failed pipe won’t address. If you come across a CPVC pipe that has ballooned it is likely temperature or pressure related, and it’s worth investigating. CPVC has excellent pressure and temperature ratings, so the pipe would not be expected to fail under normal conditions. One thing to look for is a malfunctioning boiler or water heater that is overheating the water to above 200F/93C. This is not only a problem for the pipes; It could be dangerous to residents of the home.

Another issue identified in the quiz involved plumber education on the material integrity of aged CPVC. When asked whether aged or “brittle” CPVC

needed to be replaced, a majority of plumbers said yes. This perception is probably due to problems they’ve encountered when using the wrong tools for service. In fact, older CPVC has excellent pressure-bearing capability and is stronger than new CPVC. Also, remember CPVC is immune to chlorine degradation that can occur in copper and PEX. Provided it was installed correctly, aged CPVC pipe can continue to perform for many years when the correct tools are used in service.

“An online quiz uncovered some misconceptions about plastic piping materials in three key areas: cutting, fittings and diagnosing problems.”

While PEX doesn’t become more rigid with age compared to CPVC, choosing the right tool for cutting remains an issue. Plumbers would also benefit from a better understanding of the effect of PEX fittings on flow rates and how to recognize signs of chlorine degradation.

Cutting: As with CPVC, a surprisingly high percentage of plumbers selected the wrong tool to cut PEX. PEX piping can be cut with ratchet cutters or scissors-style shears, but many plumbers suggested they could use c-style tubing cutters for this material. Because PEX is a soft plastic, most c-style tubing cutters will not effectively cut into PEX tubing.

Fittings: The quiz also uncovered a lack of understanding about the impact of PEX fittings on flow. Roughly half of plumbers believe ASTM F1960 expansion PEX fittings provide full flow performance. This isn’t possible be -

cause with PEX the pipe fits around the outside of the fitting, reducing the internal diameter of the pipe—even in expansion PEX systems.

Depending on the fitting used, this can reduce the internal diameter of a ½-in. pipe from 21% to 35%, which can have a noticeable impact on flow rates. Using PEX to replace a copper or CPVC system with full flow fittings can result in unwanted pressure drop or require the use of upsized pipe to maintain system performance.

Identifying Failures: A high percentage of service plumbers who took the quiz misidentified a PEX chlorine-related failure as a failure caused by UV light. These two issues can be related in that UV light can consume the chlorine-inhibiting antioxidants added to protect the pipe from chlorine, but it doesn’t actually cause the failure. If you simply replace a failed pipe thinking the problem was UV light exposure, you could be ignoring broader water incompatibility issues within the system and end up coming back later to replace the pipe you put in.

Plumbers are sometimes reluctant to spend time on training because they would rather be serving customers. But the results from our online quiz highlight the importance of proactive training to stay up to date on newer materials. Training that delivers essential information in a concise, understandable and accessible way can actually save time by enabling plumbers to work more efficiently and effectively. <>

Jonathan Simon is the North American residential plumbing manager for Lubrizol Advanced Materials Inc., the parent company for FlowGuard Gold Pipe and Fittings. To help plumbers access training and education on servicing CPVC, FlowGuard Gold has created an online information hub speci cally for service plumbers at FlowguardGold. com/ServiceSuccess.

From heating controls to mixing valves, Resideo offers a full range of Honeywell Home hydronic product solutions. Find Hydronic Zoning Panels, Pro Press Zone Valves, T6 Pro Hydronic thermostats and more — all in one location.

Our reputation is based on providing you with products to provide homeowners with solutions. Our products have proven to be must-stock standards, engineered for accuracy, safety and reliability — and easy installation.

Moen’s M-CORE is a valve system that simplifies installation with an integrated mounting bracket that secures the valve directly to a brace. It offers a quicker temperature limit stop adjustment process, and the integrated test plug allows installers to flush and test the system without having to remove or install the cartridge. M-CORE mixing and transfer valves also are available in several inlet and outlet plumbing options. moen.ca

Goulds Water Technology has launched the GSD submersible sewage pump built to handle residential sewage systems, water transfer, heavy duty sump and dewatering applications. The pump features a cast iron design and mechanical seal for protection against sand and abrasive materials. It comes with a built-in anti-siphon hole for easier pump installation and prevents air locking. The GSD Series is available in an automatic or manual, 115 volts, 0.5 HP, single phase pump with 2-in. discharge. goulds.com

Bradley Corp has expanded its line of Express lavatory decks with two new designs: the GLX series (pictured) and TLX series. The GLX features a linear design with extra space to place belongings, while the TLX offers a streamlined trough design. The full suite of Express lavatory decks meet the demands of commercial restrooms and are made of Bradley’s smooth and non-porous Terreon solid surface material. www.bradleycorp.com

Webstone has enhanced its line of PEX E-X-P E2 tankless water heater (TWH) service valves. For applications where a higher flow rate is needed, new 1-in. hot and cold valve kits are now available. These compact, space-saving service valve TWH kits are available with a choice of either a standard brass or a lead-free pressure relief valve. www.webstonevalves.com/EXP

Cherne, a part of the Oatey family, has launched its residential plumbing smoke blower for fast and easy leak detection. Featuring a 5-ft. heavy-duty hose that fits a 4-in. cleanout tee, the blower is lightweight and corrosion-resistant. It can be used indoors and its 122-cc, 3.5-HP, 4-stroke Honda engine provides more than 700 CFM, making it fast, easy and safe. oatey.com

the complete line of Building Information Modeling (BIM) objects, for the

Available in all relevant BIM file formats. With easy navigation, these high quality, highly accurate and fully functional models allow for system testing and validation, and can be downloaded to your desktop or directly into your design model. Either way, our BIM files are quick, easy family downloads that meet all applicable standards... and your expectations.

IPEX has the tools you need to design with confidence. Visit us for the complete library of available AquaRise® BIM files. 1-866-473-9462 | ipexaquarise.com

T&S Brass and Bronze Works is offering hygiene-boosting solutions for all kinds of facilities, including an update to its antimicrobial-coated faucet handles. The antimicrobial coating (available as an option on freshly redesigned wrist-action, four-arm and lever handles) provides a barrier against microorganisms like bacteria, molds, mildew and fungi. The antimicrobial coating on T&S faucet handles is a clear finish that is fingerprint-resistant and lasts the life of the product. www.TSBrass.com

Native Trails’ Trough 3019 sinks are now offered in a 30-in. size option (previously only available in 48-in. and 36-in.). The smaller artisan-made trough sinks, constructed from natural jute fiber and cement, are suitable for powder rooms and narrow single vanities. Like all of the brand’s NativeStone products, Trough 3019 is available in pearl, ash, slate, and earth finishes. www.nativetrailshome.com

NIBCO has additional configurations of its lead-free 585HP (high performance) bronze ball valves with reversible handles, laser-welded construction, triple-sealed stem, operating pressure up to 1,000 CWP and 150 SWP, and operating temperature up to 250F. New configurations include thread x press end connections for sizes ½-in. to 2-in. and hose cap and chain for sizes ½-in. and ¾-in. for solder, press, and threaded end connections. nibco.com/585HP

HeatLink has expanded its F1960 PEX-a potable water expansion system to include large dimension sizes. 1-¼-in., 1-½-in., and 2-in. high performance polymer (HPP) fittings, no lead (Eco) brass fittings, and PEX-a expansion rings are now available. Suited for high flow water distribution applications, such as mains and risers, PEX-a Expansion Rings use the strong shape memory of PEX-a to form a watertight seal. www.heatlink.com

Bélanger, the Canadian manufacturer of faucets and plumbing supplies, has presented its latest nature-inspired collection, Nobua, part of its H2flo Luxx series which draws on the company’s 50-plus years of experience. Drawing from the beauty of nature, the luxury bathroom sink faucets, bathtub faucets and fillers, kitchen faucets and thermostatic shower kits are available in stainless steel and matt black. www.belangerh2o.com

See how quick installation can be

4x faster than a traditional couplin

Innovative one bolt design

Easy push on design

• Hold Open Clip keeps the Coupling primed for Installers out of the box

There’s got to be a better way to build homes in cold weather and protect furnace systems.

BY IAN McTEER

The headline of an online article dated July 18, 2019 immediately captured my attention: “Why your new home may come with a dirty, used furnace” by Laura Osman of CBC news, Ottawa. Accompanying the article were several photographs of an unhappy homeowner in Morrisburg, Ont. pointing to his furnace and saying, “I opened up the front of the furnace and it just looked like a bag of flour exploded in there.”

Osman continues to explain that the practice of using furnaces meant for comfort conditioning is legal during the

construction process, and that some manufacturers say they are not receiving complaints therefore all must be well. Warranty records documenting premature failures would tell a different story; however, that vault of closely held manufacturer information will not be made public anytime soon.

I remember the days when large-scale house construction went into winter hibernation. Many in the HVAC trades were laid off in December and spent the winter doing whatever else they could. I delivered furniture at one time.

Builders deserve a great deal of credit for harnessing technologies that allowed house construction to continue through the winter providing yearround employment for those of us in the residential heating industry. Superplasticizers and self-consolidating concrete combined with other warming techniques meant basements could be poured into the winter months. Builders take precautions to prevent fresh pours from freezing so that compressive strength is not compromised.

Once the concrete pour had set-up enough, carpenters started framing. Typically, propane-fired salamanders were employed to keep the foundation

warm during the framing process. Installation of the roof sheathing meant the sheet metal rough-in including a B-vent chimney could start, followed closely thereafter by the basement duct and furnace.

Then the rush was on, get the furnace gas-piped and wired so that it could be used to keep the structure warm, even if all the windows and doors had yet to be installed. Sometimes the basement floor, yet to be poured, required the furnace to be suspended 4-in. above the gravel using plumber’s metal strapping allowing the concreting job to be done later.

And, sometimes, the furnace was fired-up without ducting, the blower door was removed allowing heated air to simply flow out the top, that was before door interlock switches became a requirement.

The old draft hood equipped furnaces of yesteryear with their cold rolled steel heat exchangers, pilot lights, ribbon burners and belt-driven fans seemed almost indestructible back then. Starting one of the old blisters in a basement at 20F required

some finesse, as the chimney would be so cold the flue products would start spilling into the basement until the B-vent warmed up. Condensation would also occur inside the heat exchanger; you could hear the water boiling in there. The bimetal fan control took ages to warm up enough to start the fan, then the return air was so cold the fan would cycle off seconds later. Salamanders, when used, put some heat into the building making the furnace start-up less traumatic.

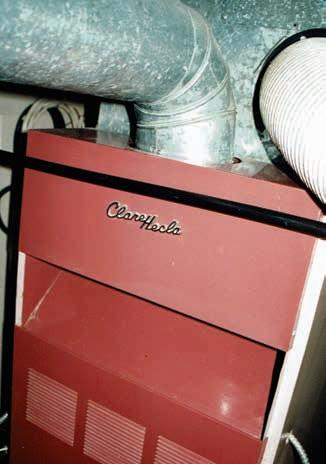

Some great Canadian-made furnaces such as the Clare Hecla (later Clare Brothers or simply Clare) model pictured to the left (not to mention, marques like McClary, Anthes, Grimbsy, Smart’s, Olsen, Conroy, Findlay, Goodcheer and others) all had their day in houses under construction at one time or another.

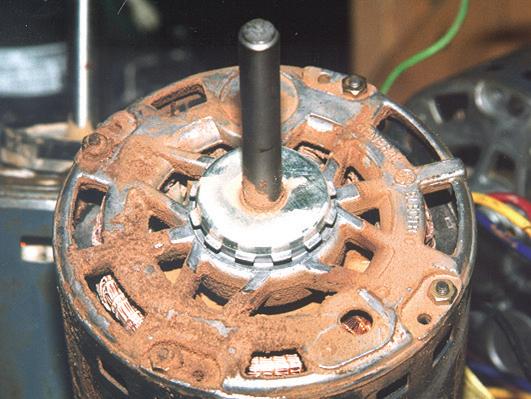

After surviving seemingly relentless clouds of drywall dust whilst heating the house under construction, unevenly loaded blower wheels would start shaking the furnace like an unbalanced washing machine causing consumer complaints.

Only one way to fix this problem: remove the blower, disassemble and clean the blower wheel with water, as no amount of brushing could remove drywall dust once centrifugally packed onto the blades.

Today’s furnaces use direct drive centrifugal blowers, the motor is secured into the assembly using a belly band or resilient mount, both styles then bolted to the blower housing. An out-of-balance wheel will stress the mounts to the point of failure or even cause the blower wheel to collapse.

I accept the argument such failures can happen at any time during the life of a furnace or air handling unit mostly caused by lack of proper maintenance. Yet, it is still the end users right to start off with a clean machine to abuse, or not, down the road.

An air handling unit (AHU), such as a gas furnace, cannot function properly or deliver its advertised benefits with a filthy or damaged blower wheel. Arguably, it is one of the most important AHU maintenance items, yet the entire blower as-

sembly is too often exceptionally difficult to access for cleaning.

Since no one has ever developed a tool meant for cleaning centrifugal wheels in place, it is still necessary to pull the blower for disassembly and cleaning. Modern gas furnaces have slide-out blowers, decidedly an improvement over the securely bolted blowers of yesterday, however, now the service tech is faced with disconnecting things like the control board platform, condensate tubing and thermostat wiring.

Other components, not necessarily affected by dust and dirt, nevertheless suffer from the rigors of construction heat. A heavily loaded blower wheel may cause the unit to overheat thus continually cycling the limit control causing it to fail-open thereby generating a no heat service call.

Limits are safeties (not operating controls) and typically do not reset after cycling repeatedly. Gas valves and hot surface igniters will have some advertised reliability vanish, stolen by useless cycling in a dusty, damp basement. Apart from blower wheels, the

on p30

most common premature failures related to temporary construction heat are blower motors, draft inducers, burners, and flame rods.

Low temperature rise creates unacceptable amounts of condensate especially in the primary heat exchanger. Furnace manufacturers want a minimum return air temperature maintained, typically 55F or 13C. New construction invariably records return temperatures considerably lower promoting excess condensation in all the wrong places.

Ultimately, acidic condensate becomes further contaminated with chlorides and fluorides contained in paint, varnishes, cleaning compounds, stains and curing concrete potentially leading to rapid deterioration of the heat exchangers. Aluminized steel, thus exposed to corrosive elements, cannot be expected to stand the test of time.

It’s not as if consumer complaints fall on deaf ears. Industry regulators and manufacturers have developed a standard for temporary heating that is typically included in the “Safety Section” of gas furnace installation instructions. As part of the ANSI Z21.47/CSA 2.3 standard, temporary heating is allowed if:

• Furnace and vent system are complete and installed per manufacturers instruction

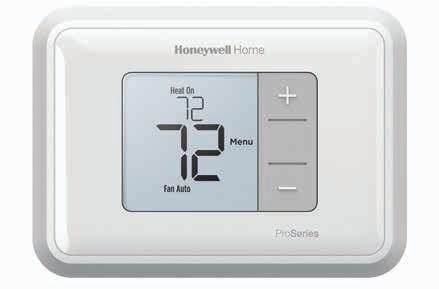

• Furnace is controlled by a room temperature thermostat

• Furnace return air duct must be complete and sealed to the furnace

• Furnace input rate and temperature rise must be verified as per the rating plate

• Furnace combustion air must come 100% from outdoors

• Furnace return air temperature range is between 55°F (12.7°C) and 80°F (26.6°C)

• Furnace must be supplied with an external, field supplied air filter.

• Furnace, duct work, and components must be cleaned upon substantial completion of the construction process. Furnace operation must be in accordance with manufacturer’s instructions.

While having a well-articulated standard providing rules for temporary heating helps both builders and HVAC contractors to provide excellent products to the public, unfortunately not all appear to be using the guidelines properly as noted in the recent CBC article. Obviously, the new homeowner’s furnace had been used for temporary heat but had not been cleaned properly, if at all. Drywall dust is so insidious, cleaning a fin-tube secondary heat exchanger while lying on ones back inside the empty blower compartment is something I doubt gets done very often after construction ends.

When drywall sanding hits high gear, cleaning/changing the furnace air filter would be a daily requirement, yet, con -

“Furnace air filters were never meant for construction applications.”

ventional 1-in. air filters are useless against drywall dust. A MERV 11 filter would load up quickly eventually blocking airflow. Furnace air filters were never meant for construction applications. Efficient filtration would require frequent intervention by some person to change loaded filters thus maintaining airflow.

Having worked in basements with a roaring propane salamander sounding a like jet airplane on afterburner, I can understand why the trades hate them. Somehow, the temperature of the building must be raised by other means before the furnace is started to prevent premature failures. It really means that a furnace meant for human comfort conditioning should not be started until the construction phase is substantially completed, a point in the process often called “carpet phase.” By then, drywalling should be completed and with construction dirt and debris cleaned out of the ductwork, the furnace is ready to start its life.

I am a classic liberal at heart, I do not believe the heavy hand of governments must regulate every function of our lives. Best practices need not carry prescriptive regulation if the group is willing to acknowledge certain instructions must be followed beforehand. Yet, best practices have been ignored too often when it comes to protecting a new homeowner’s investment.

Damaged parts, such as those I have included in this article, required a service call—a new homeowner had no heat. The homeowner had to wait at home for the service technician, possibly missing work, a major inconvenience.

Poor performance caused by filthy heat exchangers or blower components also require a service call, sometimes by an inexperienced technician and, frustratingly enough, the issue is not always resolved to the homeowner’s satisfaction leading to more service calls.

Since a high efficiency furnace is meant to save energy, how much does the collective energy budget of a given house balloon when an abused furnace component fails? Another motor must be manufactured, delivered to a store, carried to a jobsite in a vehicle, all this extra inefficiency must be added onto that house. Energy is energy, does it matter if the fur-

Gas burners and flame rods readily corrode in the face of contaminated combustion air. Burner cross lighters become blocked with rust or debris creating either rough starts or ignition lockouts. Flame rods do require yearly maintenance but should not corrode so badly once the construction chemicals are largely gone from the structure.

Here is a much better way to provide temporary construction heat, a portable heater.

nace is using it or the service truck burning through a tank of gasoline while the furnace is down?

One commentator to the CBC article wrote, “crying over nothing, a couple of weeks max out of 15 years. You ain’t gonna notice.” Well, dear reader, you can tell that to any of the homeowners unduly affected by no heat or poor performance from brand-new heating systems.

The article also noted that the Canadian Standards Association (CSA) has been in talks with industry groups with the goal of developing better standards and common guidelines, but nothing is expected from these discussions until 2021.

Our industry does not need any more media reports about unhappy customers. In the meantime, I would simply suggest that the best practice to prevent damage and premature failures of brand-new heating equipment is this: Don’t use it for temporary heat. <>

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a eld rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

Resideo adds to its Honeywell Home non-programmable thermostat offering with the new E1 Pro and T3 Pro thermostats. The E1 offers a large display and is available in a 1H/1C model. The T3 (pictured) has a larger footprint and the same wiring plate and comes in 1H/1C and 2H/1C heat pump models. Both are part of Resideo’s private label program for contractors to place their information on the thermostat face. resideo.com

FLIR Systems TG165-X MSX thermal camera is an all-in-one diagnostics tool with a spot temperature gun and thermal imager. The camera identifies hot spots that indicate electrical or mechanical failures, and cold spots that indicate water or air leaks. Built around a thermal 80 × 60 camera sensor with 4,800 pixels, a new laser-projected bullseye target aids in pinpointing areas of concern. www.flir.com/tg165-x

The SALUS ST920WF SOLO Wi-Fi thermostat connects to 2.4GHz Wi-Fi networks and can be controlled from a phone, tablet or Alexa and Google Home devices. It has a large LCD display with touch keys and five powered relay outputs to accommodate HVAC and hydronic systems: 2 H/2 C for conventional HVAC or hydronic systems and 3 H/2 C for heat pump applications. salusinc.com

Venstar’s new programmable Wi-Fi Explorer Mini Fan Coil digital thermostats are available in residential (T2100) and commercial (T2150) models, The compact units are 3.2 x 3.2 in. and less than an inch deep. Both models feature a large display, compatibility with Venstar’s wireless temperature sensor, setpoint limiting and/or total keypad lockout, two- or four-pipe configurable and the commercial model includes override capability and preoccupancy fan purge. www.venstar.com

SpeedClean’s CoilJet flexible wand with LED light allows HVAC/R professionals to clean coils in small spaces with little to no light. It works with the company’s CoilJet coil cleaning system, and well suited for mini split systems, air handler coils, PTAC coils, refrigeration units and hard-to-reach coils. The wand attaches using a quick-connect adapter and its 12-in. flexible design can bend or curve to reach tight spots. www.speedclean.com

AJ Manufacturing has two new options to its Criti-Clean Ultra HEPA filtration units in order to more effectively combat airborne viruses, as well as bacteria, mold and other pathogens. The new built-in modules include ultraviolet-C (UV-C) radiation and needlepoint bipolar ionization. The fan-powered laminar flow HEPA filter diffuser provides a steady stream of purified air into a room and is available as a traditional ceiling-mounted unit, and a portable model on wheels. ajmfg.com

Hydronic professionals need to explore new energy-ef cient technologies and promote the superior comfort of hydronic systems.

BY JOHN SIEGENTHALER

For decades, the basic approach to designing space heating systems has been: 1) Determine the “design” heating load of the building, (e.g., how many Btu/hr the building requires to maintain interior comfort during the coldest outside temperature); 2) Select a heat source capable of creating at least this many Btu/hr of heat output; 3) Design a distribution system that can divide up the heat output from the heat source and send the required rate of heat loss to each space within the building.

From the standpoint of thermodynamics, a building can be considered as a “control volume” — a simple hypothetical box that has heat flowing into and out of it. If the rate of heat input happens to equal the rate of heat loss, the temperature inside the control volume remains constant. This is called thermodynamic equilibrium. Any combination of building materials, dimensions, heating hardware, etc. that balances heat input with heat loss could attain a thermodynamic equilibrium.

Achieving and maintaining thermodynamic equilibrium within a conditioned space does not imply comfort. Even a room that maintains a stable 20C at the thermostat could have drastically different interior surface temperatures, strong drafts, a high degree of floor to ceiling temperature stratification, and millions of suspended dust particles in the air.

Still, if the space maintains a 20C air temperature at the thermostat some occupants might think the heating system’s performance is acceptable.

There are quantifiable characteristics associated with human thermal comfort. They include operative temperature, mean radiant temperature, radiant asymmetry, air temperature stratification, air velocity, relative humidity and others.

Unfortunately, most of these parameters are neither calculated as part of the system design, nor measured during com -

missioning. Instead, the sole proxy for human thermal comfort during the heating season is being able to establish and maintain an air temperature in the range of 20C at the thermostat.

I call this attitude toward comfort “Btus in a box.” For many it doesn’t seem to matter how the Btus go into the “box” (e.g., living space) as long as the inflow rate equals the outflow rate.

This attitude is applied to a wide spectrum of building types and architectural paradigms. Perhaps it’s not surprising to see it in utilitarian buildings such as business rental properties, hotels or fast food. The intended function of these buildings—generating revenue—treats human thermal comfort with minimal regard. Design to satisfy the thermostat, end of story.

In modern North American culture, energy efficiency is often touted as having high value, something we all should aspire to. Fair enough. But achieving energy efficiency at the expense of comfort will, in the long run, fail as a business strategy.

The desire for comfort is autonomic. We all continually seek it. The lack of comfort has physical and physcological consequences. It determines, in part, our productivity, our attitude and our physical health. The need for comfort is not something we can escape, trivialize or appease by saving money on inferior heating systems.

Space heating products that promote energy efficiency sometimes make claims of “comfort,” but seldom offer quantifiable justification.

Consider, for example, a ductless airto-air heat pump. Under standard AHRI rating conditions these heat pumps operate with impressive coefficients of performance. However, ductless air-toair heat pumps used in cold climates require periodic defrosting of their outdoor evaporator coil. During this pro -

“As the world moves steadily away from using fossil fuels, electrically operated heat pumps are sure to gain market share as heat sources.”

cess heat from the occupied space is sent back outside to melt frost off the coil. This causes noticeably cool air to be blown into occupied spaces.

Although the cycle may only last a few minutes, it’s unpleasant to anyone in the path of that air stream, especially on a cold winter night. Defrost can occur several times each day. How do repeated blasts of cool air into occupied spaces equate to comfort?

Even air-to-water heat pumps supplying hydronic distribution systems have to perform defrost cycles. The difference is that the required heat comes from a buffer tank, or perhaps a high thermal mass heated slab, rather than room air. The occupants will have no perception of when a defrost cycle occurs. Comfort will not be compromised.

Some advocates of ductless heat pumps also suggest that only two or three interior “high wall” cassettes are needed. The caveat is that interior doors should remain open to allow warm air to disperse throughout the house. If this constraint can’t be met, some suggest setting up small electric space heaters to keep the air temperature acceptable in rooms with closed doors. To me, that’s a major compromise in how the building can be used.

As the world moves steadily away from using fossil fuels, electrically operated heat pumps are sure to gain market share as heat sources. This presents a major opportunity for the North American hydronics industry.

To capitalize on this trend hydronic professionals must leverage the high efficiency of air-to-water or water-towater heat pumps with the superior

comfort of low temperature hydronic distribution systems.

Those that do will likely receive support from “allies” they may not have anticipated. Most electric utilities actively promote heat pumps. So do many governmental energy agencies, often with generous financial incentives.

Advocates for renewable energy and a low carbon future generally recognize that electricity—increasingly produced from large scale renewable sources—is the “fuel” of the future. Builders and architects specializing in low energy or net-zero buildings generally promote the use of heat pumps.

What you bring to the table is the track record of superior comfort afforded by low temperature hydronic systems. It’s up to you to tell this story to customers, architects, builders, politicians and anyone else who will listen. They all know that efficiency is important. Few of them understand the consequences associated with stark differences in comfort between forcedair and hydronic distribution systems.

If you plan to be in the hydronics business in the coming years, you need to know how to combine heat pumps with hydronics. I’ll do my best to bring you continuing information on this winning combination. <>

John Siegenthaler, P.E., is a mechanical engineer and a licensed professional engineer. He has more than 35 years experience in designing modern hydronic heating systems. His latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

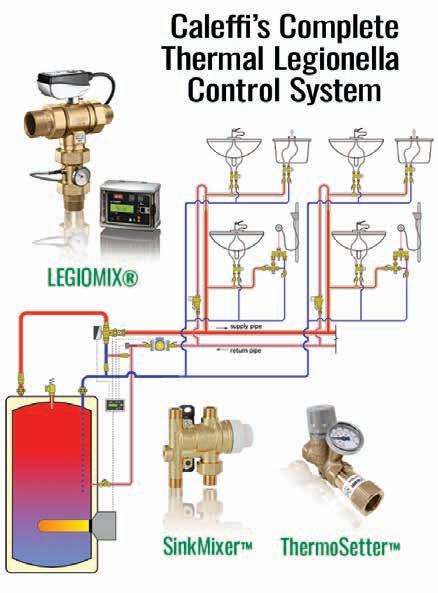

Caleffi North America is the only company that offers digital temperature mixing, thermal balancing, and scald-protection valves that are designed to work together for a total system solution in providing safe DHW in commercial buildings.

The Caleffi 6000 Series LEGIOMIX® valve has the market’s highest rated flow capacity and is available in ¾" through 3” sizes to meet the domestic hot water requirements for any project big or small. In addition to highly accurate mixed water temperature control, the LEGIOMIX has integral calendar-based automatic thermal disinfection programs which can be enabled to control Legionella bacteria. The LEGIOMIX can stand alone or connect to a building automation system with Modbus or BACnet network communication with data logging capabilities.

The 116 Series ThermoSetter™ balancing valves provide state-of-the-art temperature-based balancing for the secondary piping circuits that serve fixture groups throughout the building. The valve’s temperature setting is adjustable to provide “set it and forget it” fool-proof balancing control. Models are available with a special “bypass” cartridge that opens the valve to increase flow during a thermal disinfection cycle, for those projects that are implementing Legionella control. The 116 Series valves have been used in conjunction with the LEGIOMIX valve family around the globe for over 15 years; together they have a solid history of performance and reliability.

The 5212 SinkMIxer™ scald protection valve provides final temperature control at each point-of-use to protect people from elevated water temperatures. The convenient 4-port design minimizes connection points and the potential for leakage and the high quality mounting bracket provides a clean installation and easy serviceability.

These innovative, high performance valves are precision engineered and manufactured in Italy using low lead dezincification resistant (DZR) brass and modern composite materials for maximum scale resistance and durability. They meet all applicable standards for the USA and Canada including ASSE 1017, ASSE 1070 and plumbing codes IPC, IRC, UPC and NPC.

The complete system thermal control package is part of Caleffi’s continuing commitment to excellence in technical innovation. Call today to learn more! 414-238-2360

BY MIKE MILLER

The demand for snow and ice melting (SIM) systems continues to increase as property owners realize the convenience and safety benefits the systems provide. These hydronic systems are designed to remove snow and ice by circulating a heat transfer fluid through tubing installed in or below an outdoor surface (concrete, asphalt, or interlocking stone). Increasingly snowmelt applications are offering added peace of mind for property owners of every kind, especially commercial businesses, multi-unit residential properties and institutional buildings where they can reduce liability issues and improve access to facilities, which is even more relevant with our aging population where mobility issues can be a challenge.

Traditional snow-clearing methods (shovels, snowblowers and ploughs) over a long winter can result in unpredictable maintenance costs for property owners and the use of chemicals can damage hard surfaces. Hydronic SIM systems will pay for themselves over time, and setting them up correctly will only enhance that payback.

Designing an effective snow-melting system takes into consideration several factors, including Btu/sq.ft./hour load requirements, snowfall rates, snow density, snow temperature, outside temperature, wind speed, tubing size and tubing spacing. All these factors help a professional system designer and installer create a system that will be the most efficient and ef-

fective for the project.

When it comes to controlling the system, there are several options to choose from, including automatic, semi-automatic and manual controls.

A fully automatic system uses a sensor placed in the ground to detect when snowfall begins. The sensor sends a signal to the heat source to activate the warm liquid flow through the radiant tubing. Once the snowfall stops and the sensor is dry and clear of snow and ice, it sends a signal to stop the water flow and shut down the system. This energy-efficient method is typically the most economical, as it runs only when needed.

The location of the snow/ice detector is very critical. It should be located in an area where it would be most likely to detect snow accumulation. The detector usually adds to the initial component cost, but it helps run the system economically. Compared to a manual or semi-automatic system, the automatic sensor addition often pays for itself within months.

A semi-automatic control requires a manual intervention to start the system, but also includes a timer that will operate for a pre-set amount of time and then shut the system off. Setting

the right amount of time is the key and often hard to predict.

A manual control is simply that—the system turns on and off with the flip of a switch. While this is the most cost-effective option to install, it generally costs more to operate, as the human interface requirement typically doesn’t align with that of perfect timing to start or stop a system. Operationally, it could quickly become very expensive to operate if disabled too late or worse yet, forgotten about until the fuel bill is in the mail.

If turned off too early, it could pose a safety threat as any water from the just melted snow could reform into ice if not completely removed. When enabled too late, the slab’s pick-up time will increase, as will the running time. This system definitely requires an attentive user.

Another option for controlling a snow-melt surface is to idle the system at a pre-set temperature (typically 22°F to 28°F) to ensure it can ramp up quickly in the event of snowfall. This option is often useful in critical areas that must remain snow- and ice-free, such as walkways or entryways to buildings to keep them safe. The idle option can be used with either automatic or semi-automatic controls.

It works exceptionally well. I can’t believe how much hot water it makes.”

The warranty is great. That’s a big sales feature…especially when I tell customers I can give them a little extra.”

One thing about the boiler - I was able to hang it myself – that’s huge.”

DISCOVER WHY MORE CONTRACTORS TRUST TRIANGLE TUBE’S INSTINCT FIRE TUBE BOILER AND THE . VISIT OUR WEBSITE FOR TESTIMONIAL VIDEOS.

Any of these systems should run off a slab sensor embedded in the slab for accurate surface temperature control. Setting the right surface temperature for a melting event may change how the system performs.

For example, higher melting slab surface temperatures help clear off snow from a surface more quickly, but they are more expensive to operate as the temperature difference of slab surface temperature compared to ambient outdoor temperature is greater and therefore the load is greater.

Lower melting surface temperatures clear off snow at a slower rate, but the load of the system is decreased as the temperature difference between slab surface and outdoor air is lower. Melting surface temperatures that I personally use for snow melting systems are typically 36F residentially and 38F commercially.

You can also operate zoned snow melting systems with multiple automatic snow/ice detectors. Zoned snow melting systems accommodate higher priority and lower priority zones, as well as different slab surfaces.

Snow melting systems should never run without a system controller that was developed and designed specifically for that purpose. The reason for this is that most controls today come with very intense algorithms to make snow melting as efficient as possible.

The system should have outdoor temperature guided capability that can override the system from entering snow melting mode if it is too warm outside and mother nature could melt the snow for free, or if the outdoor conditions are so extreme that a given heat source would not have enough capacity to get the job done.

Depending on surface covering, some snow melting systems may need to control the rate of slab surface temperature rise to avoid damage to a slab caused by tensile stresses from a cold start.

Just like a radiant floor heating application, these systems circulate a warm water/glycol mixture through tubing. Embedded hydronic SIM systems can be used in any exterior area, including stairs, sidewalks, driveways, parking lots, parking ramps, loading docks, building entrances, wheelchair access ramps, and even helipads on building tops. Almost any area that accumulates snow or ice can benefit from a snow-melting system. Higher-end residential properties most often suit fully-automatic systems or a combination of fully-automatic and semi-automatic. The combination system is often used where there is a higher traffic area or zone, such as driveway and sidewalk that uses an automatic snow/ice detector, and a separate zone for a patio or deck, or around pools and hot tubs, that would only run if in use. In this case, there would be two zones, one with an automatic snow/ice detector and one with just a slab sensor and some sort of push-button device.