PRODUCT SHOWCASE BLOWER DOOR TESTING OFFERS OPPORTUNITY FOR CONTRACTORS WHY USE REMOTE DIAGNOSTICS? WHAT TO DO WITH LIQUID CONDENSATE MECHANICAL SYSTEMS FIND A PLACE IN 3D PRINTED STRUCTURES

PRODUCT SHOWCASE BLOWER DOOR TESTING OFFERS OPPORTUNITY FOR CONTRACTORS WHY USE REMOTE DIAGNOSTICS? WHAT TO DO WITH LIQUID CONDENSATE MECHANICAL SYSTEMS FIND A PLACE IN 3D PRINTED STRUCTURES

The T10 Pro Smart Thermostat with RedLINK™ Room Sensor extends the thermostat’s reach into the rooms that matter – like bedrooms and living spaces. Homeowners can prioritize different rooms at different times of day, or, they can allow each sensor’s motion-detection technology to shift priority automatically as they move around the house. It’s a smart, simple way to help your customers feel right at home.

Visit ForwardThinking.HoneywellHome.com/TSeries to learn more.

BOILERS

DEALING WITH THE PRODUCTS OF COMBUSTION PART II

Handling liquid condensate must be done properly to avoid damage to the building, problems with appliance operation and angry customers.

By Robert Waters

22

HEATING THE OLDEST TECHNOLOGY

Super insulation combined with zoned radiant heating has the potential to push fossil fuel heating into obsolescence.

By Ian McTeer

30

HVAC/R

BENEFITS AND ADVANTAGES OF THERMOSTATIC EXPANSION VALVES

By Jeffrey Staub

32

TECHNOLOGY

WITHIN REACH

Mechanical systems find a place in 3D printed structures.

By Jillian Morgan

34

CIRCULATORS

HYDRAULIC DIETING

Think about reducing head loss to reduce the kilowatt•hours of electrical energy required to operate the system

By John Siegenthaler

World class sports facility presents unique IAQ and air distribution issues.

By Ralph Kittler

48 TESTING

SEALING BUILDING ENVELOPES

Blower door testing offers opportunity for contractors.

By Jillian Morgan

50

HVAC

AN UNTAPPED ENERGY SAVINGS OPPORTUNITY

The return on investment from re-staging with an active sensing system can be as low as 12 months.

By Steven Graves

60

MANAGEMENT

THEY REALLY HATE US

New prompt payment rules may help mend relationship between gcs, subtrades.

By David Kennedy

66

DIAGNOSTICS

REMOTE TECHNOLOGIES OFFER A WIN-WIN FOR CUSTOMERS AND CONTRACTORS

Remote A/C diagnostics and monitoring systems belong in every technician’s truck.

By George Tsintzouras

68

BIRD’S EYE VIEW

The costly consequences of falls at heights demand a culture shift.

By Jillian Morgan

76

CONTROLS

ENHANCING FACILITY SAFETY WITH INTEGRATED HVAC CONTROLS

HVAC systems are a critical part of an overall connected safety strategy.

By Michael Hugh

I WAS GOING TO CALL THIS COLUMN “NOT THE FINAL CHAPTER” but then I realized that it is the name of a movie centred on resident evil and final strikes, hardly the makings of a graceful farewell.

After writing over 100 Upfronts, this will be my last. I am moving on to other things, including spending time with my family and friends, and undertaking new challenges.

I knew this was going to be a good run from the moment I was elevated to business class on my way to British Columbia for an industry event. It was just weeks into the job and I was traveling with the publisher. I told the flight attendant I couldn’t leave my boss in economy. Fortunately she said they could certainly accommodate him.

After take off, comfortably seated with a beverage in hand the publisher said, “You know that three month probationary thing Kerry? It’s gone.”

So, thank you Air Canada and a nod to that publisher for giving me the opportunity to work in this industry. To everyone who helped me get over the learning curve I am most appreciative. To our readers, thank you for continuing to look to HPAC for industry leading content.

Apropos this is the heating issue – I send warm wishes to HPAC’s readers, advertisers, and especially the wonderful team I have had the privilege of working with.

DOUG PICKLYK has over 20 years of experience in the trade publishing industry, most recently serving as the editor of Canadian Consulting Engineer magazine, the publication for professional engineers in private practice working in the built environment. He’s looking forward to attending industry events and engaging face-toface with the HPAC community in the months and years ahead. Doug can be reached at 416.510.5218 or by e-mail dpicklyk@hpacmag.com.

MEGAN HOEGLER joins HPAC as the associate editor. She holds a Bachelor of Journalism from Ryerson University and has worked as a freelance journalist for The National Post and Toronto Life. Megan lives in Toronto, ON. She can be reached at 416.510.5201 or by e-mail MHoegler@hpacmag.com.

EDITOR

INCOMING EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

COO

PRESIDENT & CEO

Kerry Turner

Doug Picklyk (416) 510-5218

DPicklyk@hpacmag.com

Megan Hoegler (416) 510-5201

MHoegler@hpacmag.com

David Skene (416) 510-6884

DSkene@hpacmag.com

Vince Naccarato (416) 510-5118

VNaccarato@hpacmag.com

Emily Sun

esun@annexweb.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 442-5600 ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbusinessmedia.com

Scott Jamieson sjamieson@annexbusinessmedia.com

Mike Fredericks

their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2019 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $43.00 (plus tax) CDN; Outside Canada per year: $84.50 US; Elsewhere: 1 year $92.50; Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Introducing Navien NFB-C fire tube commercial boilers

Navien designs and manufactures all the key components and uses advanced robotics to assure manufacturing integrity

Discover the new standard for compact high efficiency commercial boilers by contacting your local Navien agent.

• Advanced stainless steel fire tube heat exchanger

• 7" Touch screen and smart controls

• 97.5% Thermal efficiency

• Common venting and cascading capability

• Top and bottom piping connections

BY MEGAN HOEGLER

In the world of refrigeration and air conditioning, it never cools down, the competition just heats up.

At least this is the case for Zach Walsh from Cambridge, Nova Scotia, who was awarded a Medallion of Excellence in refrigeration and air conditioning at the WorldSkills competition held in Kazan, Russia.

The four-day international competition took place from August 22-27, 2019 and had Walsh competing against some of the best students and apprentices from around the world.

“Some of these guys had been training for three plus years, just for this event,” said Walsh, 22. He was selected to compete for Team Canada after his performance in the WorldSkills Selection Event held in conjunction with the Skills Canada National Competition that took place in Halifax May 26-29, 2019.

Walsh was one of 32 members of the WorldSkills Team Canada that competed that week. Prior to the selection event, Walsh won a gold medal at the Nova Scotia Skills competition in 2016, 2017, and 2018, and won a national gold medal in his skill in 2017 (Winnipeg) and 2018 (Edmonton).

SAVE THE DATE FOR THE 26TH SKILLS CANADA NATIONAL COMPETITION

May 28 – 29, 2020

Skills Canada BC will host the Skills Canada 2020 National competition in Vancouver, May 27 to 30, 2020, at the Vancouver Convention Centre.

• Opening ceremonies: May 27

• Competition dates: May 28, 29

• Closing ceremonies: May 30

www.skillscompetencescanada.com

“Being on Team Canada was an amazing and formative experience that I’ll never forget. I’m so grateful for all of the support I’ve received over the years and this week in particular, from family, friends, teachers, colleagues, industry partners and Skills Canada. This medal of excellence is truly an honour to receive,” said Walsh. “I’m proud and honoured to have been able to represent my industry and Canada.”

To prepare for this high-level competition, Walsh spent the several months leading up to the event practicing and training as much as he could. By day, he trained on the job with his employer, Acadia Refrigeration & AC in Kentville, NS and in the shop at Nova Scotia Community College in Dartmouth.

Walsh also practiced as often as he could in his spare time. “I wanted to improve my efficiency and time since I knew that was going to be a big part of the competition,” he said.

“We are thrilled to have brilliant skilled youth like Zach represent our province on the world stage. Zach is one of the most focused and determined competitors we’ve ever had,” said Courtney Gouthro, executive director of Skills Canada –Nova Scotia. “We couldn’t be more proud of him.”

Now back to work with Acadia Refrigeration and AC, Walsh wants to get his Red Seal in Refrigeration and Air Conditioning.

Walsh, who originally planned on becoming a mechanical engineer, is happy he opted for a hands-on career instead.

“I knew I couldn’t be behind a desk all day, I wanted something hands on,” he says. “In this job, there’s always more to learn and you’re doing something different every day.”

To young people considering a career in the trades, Walsh says ‘go for it.’

“You’ll never be bored.”

https://worldskills.org/

A muscular mid-size machine with more power, the Sewerooter T-4 quickly punches through tough clogs in 3" and 4" lines. A larger 9/16" Flexicore® cable does a better job of transferring the torque than traditional 1/2" cables do.

It gets down the line easier and clears clogs faster. And the portable workhorse is easier to handle in tight spaces, on stairs, and loading into your truck.

Get the whoosh faster—the sound of success. To learn more, call the Drain Brains at 800-245-6200, or visit www.drainbrain.com/T4

The Canadian Commission on Building and Fire Codes invites interested parties to take part in a final opportunity for public review of the proposed changes to the 2015 editions of the National Building Code, the National Fire Code, the National Plumbing Code and the National Energy Code for Buildings. The review runs on the Codes Canada webpage from October 22

to December 23, 2019. Once the public review period begins, more information will be available online, including explanations about the proposed changes and instructions on how to submit comments.

The purpose of the public review is to provide users of the model codes and stakeholders with a detailed look at the changes being considered and to seek comments as to whether proposed changes should proceed as proposed, or be edited, revised or withdrawn. The responsible standing committee will consider each comment in its recommendations on the proposed changes. The final changes are subject to approval by the Canadian Commission on Building and Fire Codes and will be published by the National Research Council of Canada in the 2020 editions of the Codes Canada publications.

On July 17, the Government of Quebec published proposed revisions to its halocarbon regulations in the Quebec Gazette.

The proposed regulation changes will prohibit, effective January 1, 2021, the sale, manufacture, installation and distribution of air conditioning and refrigeration equipment operating with HFCs with a high global warming potential, with the exception of domestic appliances, chiller-type appliances and transport refrigeration appliances. The complete ban on the installation of HFC-based appliances will be applied to certain industries, including food stores and large supermarkets, which may use technologies that use natural refrigerants.

Introduced by Minister of the Environment and Climate Change Benoit Charette, the proposed amendments are intended to reduce the equivalent of nearly 6.6 million tonnes of CO2 emissions between 2021 and 2035. The proposed regulatory amendment was subject to a consultation period which ended August 31, 2019.

The draft regulation also proposes to review the qualifications of persons who carry out operations on devices containing halocarbons. It also specifies the standards related to their recovery, the actions to be taken in the event of a leak, as well as the recovery and treatment of used halocarbons.

Under the proposed regulations, the new prohibitions will apply to new facilities and end-of-life devices only, which would allow the industry “a gradual and orderly withdrawal of the affected products.” The Minister’s announcement also stated that the “government is hopeful that the modernization of equipment will be done quickly enough, as several companies have already demonstrated the profitability of halocarbon-free systems.”

www.publicationsduquebec.gouv.qc.ca/dynamicSearch/telecharge. php?type=1&file=104033.pdf

Contact Codes Canada by e-mail codes@nrc-cnrc.gc.ca or telephone: 613.993.9960.

https://nrc.canada.ca/en/certifications-evaluations-standards/codescanada?utm_source=Openfield& utm_medium=email&utm_campaign= B2726658

Mr. Rooter Plumbing , a Neighborly company, recently held its annual conference in San Antonio, TX where franchisees nominated and awarded top performers.

Franchisee of the year, the company’s highest honour, went to Mike and Vesna Kolakovic – Mr. Rooter Plumbing of Mississauga. The award is presented by each company to the franchisee who has consistently grown through proper training and management of their organization and has had a consistently high level of sales.

“We applaud these individuals and their teams for building a great organization that homeowners can depend on and look forward to their continued success and strong leadership for years to come,” said Doyle James, president of Mr. Rooter Plumbing.

www.neighborlybrands.com

Continued on p12

Philip Rizcallah, director, research and development, construction at the National Research Council of Canada is the nineteenth recipient of the Joseph K. Seidner Award.

The presentation took place at the annual Canadian Advisory Council on Plumbing meeting in Ottawa, ON, on August 13th, 2019.

The Canadian Advisory Council on Plumbing provides a forum for industry, regulators, and product certification organizations to share new concepts and ideas, to discuss policy and programs, and to review innovations and new technologies that affect plumbing standards, as well as the certification and testing of plumbing products.

The award is in recognition of Rizcallah’s contributions to Canadian plumbing codes and standards. Rizcallah began his career 30 years ago when he worked as a fire protection engineer for the federal government in Ontario and Atlantic under what was then Human Resources Development Canada. www.ciph.com

Honeywell and 7-Eleven Inc. have announced the adoption of Honeywell Solstice N40 (R-448A) refrigerant as 7-Eleven’s standard for remote condensers supporting its refrigeration cases installed across Canada and the United States.

7-Eleven also selected Honeywell’s lower global warming potential (GWP) alternative for retail refrigeration in Japan last year, becoming the first leading retail chain in the country to adopt the refrigerant.

The convenience retailer set measurable corporate social responsibility (CSR) goals in 2016 to reduce its environmental footprint. The company’s CSR mission has three focus areas – planet, products and people. Using 2015 as a baseline, 7-Eleven committed to continuing to reduce its carbon footprint and increase community engagement in the U.S. and Canada by concentrating on energy, packaging and philanthropy.

It aims to reduce its energy footprint in stores by 20 per cent by 2027. www.honeywell.com

The Honourable Amarjeet Sohi, Minister of Natural Resources Canada recently announced the launch of a new Energy Manager Program. The program accepted project proposals until September 30, 2019. There may be a second application period later in the year if funding remains available.

The Energy Manager Program will help identify and adopt energy efficiency solutions by offering funding to hire energy managers and undergo energy assessments for industrial, commercial and institutional facilities, and fleets.

The Program is available to small- and medium-sized enterprises, municipalities, universities, colleges, schools, hospitals, and non-profit organizations in Ontario, Saskatchewan, Manitoba, or New Brunswick, and are located in one of these provinces — provinces where the federal carbon pricing backstop applies.

The proposed project end date must be no later than March 31, 2021. For more information, e-mail nrcan.emppge.rncan@canada.ca.

HRAI recently announced the addition of a staff position focused on the needs of members in the Province of Ontario. This newly created position of Government Relations Specialist has been filled by Dorothy McCabe.

McCabe is an experienced government relations and notfor-profit professional whose past roles include Chief of Staff for the Mayor and Council of the City of Kitchener, Manager of Stakeholder Relations for the Hon. John Milloy (who held various Ministerial roles with the Ontario government) and most recently as Director of Community and Organizational Development for KidsAbility.

She is reporting to HRAI Vice President of Government and Stakeholder Relations Martin Luymes. The creation of this role focused on government policies, programs and regulations in the Province of Ontario will allow HRAI to dedicate more time and existing staff resources to regulatory matters in other provinces. www.hrai.ca

Trades apprentices and the trades education system in British Columbia are receiving more support through expanded services and regional outreach.

Effective September, the Industry Training Authority (ITA) brought the total number of Apprenticeship Advisors to 20 across the province, with new advisors in the Prince George, Terrace/Kitimat, Abbotsford/Mission, Chilliwack, and Vancouver/Richmond regions.

These advisors will help build knowledge and awareness of the BC apprenticeship system and provide guidance to apprentices and employer sponsors on processes and policies relating to the apprenticeship journey.

The addition was made possible through funding from the Ministry of Advanced Education, Skills and Training.

Through an understanding of their specific regions, the advisors are expected to build relationships with local industry members and apprenticeship sponsors and identify opportunities to remove barriers and boost success rates of apprenticeships.

ITA has also created a new region – North Vancouver Island – which is being staffed by existing advisor Shannon Hanson, who previously supported North Vancouver and the Sea-toSky region. The Sea-to-Sky region is now being staffed by existing advisor Chris Klar.

Training providers such as colleges are expected to benefit from increased Apprenticeship Advisors who will help current trades students navigate the apprenticeship system as well as assist experienced workers (challengers) in their journey to achieving credit for knowledge and skills they already possess.

“ITA’s continued support enables the apprentices in our trades program to be successful in their career path,” said Randy Kelley, Director, Applied and Technical Studies, University of the Fraser Valley. “We’re looking forward to working with the new Apprenticeship Advisors to further the work we’re doing to elevate trades education in the region by increasing awareness of the skilled trades, improving access through innovative program delivery, and guiding students during their apprenticeship journey.”

There are over 70,000 job openings expected for skilled trades professionals throughout the province in the next decade.

The Industry Training Authority (ITA) leads and coordinates British Columbia’s skilled trades system. ITA works with apprentices, employers, industry, labour, training providers and government to fund training, issue credentials, support apprenticeships, set program standards and increase opportunities in the trades. www.itabc.ca

Victor, an ESAB brand, has launched its 2019 “Rulers of the Flame” student contest. It is open to students who are residents of the Canada (excluding Quebec) or the U.S., in cutting, welding and related programs at secondary, post-secondary, technical and vocational schools. Victor will award more than $50,000 in equipment and cash prizes. Entries will be accepted from now until December 2, 2019. Winners will be announced on December 14.

Three winners will be selected in each of the contest’s two categories – individual essay and team fabrication project. Individuals will win $250 and a Victor Medalist 350 Outfit by submitting a 500-word essay that best supports the contest theme. Teams will submit a metal fabrication project that incorporates an oxy-fuel equipment process (cutting, heating, welding or brazing) as one or more of the fabrication steps and must incorporate the Rulers of the Flame logo (obtain the logo, rules and details).

Each member of a winning team receives $250 as well as a Victor Medalist 350 Outfit, while the school associated with the winning team receives a cutting and welding package.

The student contest coincides with Victor’s “Rulers of the Flame” social media campaign, which encourages anyone who wants to share their best work with Victor gas equipment to use #rulersoftheflame for recognition on Victor’s social channels. Or, projects may be submitted online for the chance to win a Victor Performer EDGE 2.0 Outfit. Eligible entries will be entered for monthly drawings. www.info.esabna.com/rulers-contest

Natural Resources Canada offers an easy-to-use site showing incentives by province. Select a province to see what financial incentives or programs are available. This grouping of incentives related to energy efficiency from provincial/territorial governments, major Canadian municipalities and major electric and gas utilities is updated regularly. It is a useful resource for contractors who want to stay on top of what products the government is incentivizing and what money is available to their customers. www.nrcan.gc.ca/energy-efficiency/energy-efficiencyhomes/financial-incentive-province/4947

Continued on p14

On May 2, 2019, amendments (Ontario Regulation 88/19) to the Building Code regulation (O. Reg. 332/12) were filed. O. Reg. 88/19 further aligns Ontario’s Building Code with the 2015 National Construction Codes and is based on proposals the Ministry consulted on in 2016 and 2017.

The Building Code Compendium published by Publications Ontario has been updated to reflect changes to the Building Code that have come into effect as a result of Ontario Regulation 88/19, and that will come into effect on January 1, 2020 and January 1, 2022.

Electronic updated pages for the Building Code Compendium are available for free download at www.publications.gov. on.ca/510167_U.

Building Code Compendium active subscribers will receive their amendment binder inserts from Publications Ontario. Binder inserts for non-subscribers will also be available for purchase. For more information, please visit Publications Ontario at www.publications.gov.on.ca.

ASHRAE has launched a webpage dedicated to refrigeration technology and its application.

The webpage features standards, design guides and ASHRAE courses. ASHRAE endorsed conferences and events covering refrigeration and refrigerants, refrigerant designations, interviews with members in the field of refrigeration, research and news on refrigeration-related topics are also included. www.ashrae.org/refrigeration

Standata has released an information sheet G-01-17(Rev1) Gas Fired Appliances Used for Heating Buildings Under Construction. The bulletin was developed by Municipal Affairs Alberta and industry representatives to inform stakeholders of the requirements to ensure the installation and operation of gas heating appliances comply with the manufacturer’s certified installation instructions and the CSA B149.1 Natural gas and propane installation code. https://open.alberta.ca/dataset/0cb3696b-4af3-46fcbeea-4c3128485ab8/resource/a1a21008-8c2f-413db407-aebd4fdc6fe4/download/g-01-17rev1-gasfiredappliancesusedforheatingbuildingunderconstruction.pdf

The state-of-the-art

Maison de RadioCanada building in Montreal is set to be completed by the end of 2019.

Johnson Controls is working with Broccolini Construction and Broccolini Investments, through its subsidiary, La Société en Commandite La Nouvelle Maison, to create a new, high-tech Maison de Radio-Canada building in Montreal that will house the Canadian Broadcasting Corporation (CBC)/Radio-Canada. Through a long-term lease, the new building will help meet the CBC/Radio-Canada’s needs in today’s digital and media environment.

The 418,000 square foot headquarters is expected to improve collaboration, innovation, productivity and safety through new critical equipment, systems and infrastructure. It will also meet strict environmental and sustainable development standards, boasting green spaces and rooftops, along with water and energy management.

In addition to providing many technologies and solutions for the building, Johnson Controls will provide lifecycle services to the CBC/Radio-Canada for a guaranteed fixed cost to La Société en Commandite La Nouvelle Maison for the next 30 years.

Construction is set to be completed by late this year, with a move-in date of early 2020.

When move-in is completed Groupe Mach Inc. will begin work on the revitalization of the old Radio-Canada site located at the foot of the Jacques-Cartier Bridge.

The revitalization of the block currently occupied by RadioCanada calls for mixed-use development, including social and community housing, affordable housing, and green spaces. The Groupe Mach proposal also favours reconnecting certain streets to promote greater integration with the rest of the neighbourhood. The Radio-Canada tower will be preserved under the plan, but converted for new use.

Photos of archeological inventory work done on the site of the new Maison de Radio-Canada, including the walls of a former Dominion Metal Works furnace, are available online. http://newmrc.radio-canada.ca/2017/06/08/imagesfrom-the-archeological-inventory-work-on-the-site-of-thefuture-maison-de-radio-canada/

The number of unfilled jobs in Canada’s construction sector outpaced all other industries and the national average in the first four quarter of 2019, according to a recent report by the Canadian Federation of Independent Businesses.

Coast to coast, 435,000 private sector jobs sat vacant during the first four months of the year, up 0.1 percentage points from the previous quarter. Across all sectors, the national vacancy rate reached 3.3 per cent — well below that of the construction sector, which topped out at 4.9 per cent.

“The national vacancy rate has been steadily climbing for the past two years and it reached another record high last quarter,” said Ted Mallett, CFIB’s vice-president and chief economist. “The rate of growth is slowing compared to this time last year, but employers in Quebec, BC and Ontario are having a harder and harder time finding workers, especially in the smallest businesses.”

The Help Wanted report, released June 12, paints yet another unfavourable picture of the tightening labour market in construction.

In January, research organization BuildForce Canada forecast the industry would need to enlist more than 300,000 workers over the next decade to combat lagging recruitment and the impending retirement of some 261,000 workers.

The Canadian Apprenticeship Forum’s 2019 labour report expects some 67,000 journeypersons will be required over the next five years to keep workforce certification levels afloat for key trades in the majority of Canadian provinces.

To meet that demand, Canada’s 10 largest Red Seal trades — excluding Quebec and the territories — will need to attract 167,793 apprentices.

From 2019 to 2023, more than 4,000 journeyperson plumbers and 2,718 journeyperson steamfitters will need to be recruited. The organization determined the industry would therefore need to attract 9,602 plumber apprentices and 4,872 steamfitter apprentices.

Though employment growth for the skilled trades is poised to slow, decreasing demand for construction electricians and plumbers, new recruits will be needed to offset an aging workforce and accelerating retirement rates, CAF-FCA found.

The organized pointed to a decline in new apprentices since 2014, fewer youth entering the trades and the potential erosion of training capacity as other key challenges in the years ahead.

CAF-FCA expects 164,100 apprentices to register in the top 10 Red Seal trades over the next five years. That figure is down nine per cent compared to the previous five years. Across all trades, the demand for skilled workers is strongest in Ontario, British Columbia and Alberta. <> www.cfib-fcei.ca www.caf-fca.org

Dealing with liquid condensate must be done properly to avoid damage to the building, problems with appliance operation, and angry customers. BY

ROBERT WATERS

In Part I of “Dealing with the products of combustion” in HPAC August 2019 we looked at the options and challenges when dealing with flue gas from a condensing appliance. This issue we continue looking at this topic with a focus on the other product of combustion from a condensing appliance that must be dealt with: liquid flue gas condensate.

Contractors who install gas-fired condensing boilers know that dealing with condensate is often a big challenge, especially when retrofitting new modern condensing appliances into old buildings that may have limited access to drainage and old drainage pipes.

Dealing with liquid condensate must be done properly to avoid damage to the building, problems with appliance operation and angry customers. Let’s

start with a little chemistry lesson.

The combustion process is simply a chemical reaction that combines natural gas (CH4) and oxygen (O2) and ignites them inside a condensing boiler. The resulting chemical reaction produces a flame and large amounts of sensible and latent energy. The sensible energy is released directly to the combustion chamber from the heat of the burner flame. The latent energy is locked up in the water vapour (H2O) of the flue gases. In any chemical reaction such as combustion, the elements that go in are the same as those that come out. They are however arranged differently. Going into the combustion process are four oxygen molecules, four hydrogen molecules and one carbon molecule. Coming out in the flue gases are exactly the same molecules,

Condensing boiler operating modes

just rearranged into carbon dioxide (CO2) and water (H2O). You arel probably having high school flashbacks by now so enough chemistry!

Condensing boilers achieve higher efficiencies than standard boilers by capturing a large portion of the energy contained in that high temperature water vapor. By condensing the water vapour inside the boiler’s heat exchanger, we can release the latent energy and make use of it before it escapes up the chimney. The condensing process is maximized by passing the hot flue gases through the heat exchanger where the cooler return water flows back into the boiler.

Since over 10 per cent of the energy contained in the natural gas is in the form of latent energy, the result is that a condensing boiler can achieve efficiencies upwards of 98 per cent. The exact efficiency will vary, and is dependent on what water temperature the boiler is being operated at. Flue gas starts to condense when the boiler return water temperature drops below the

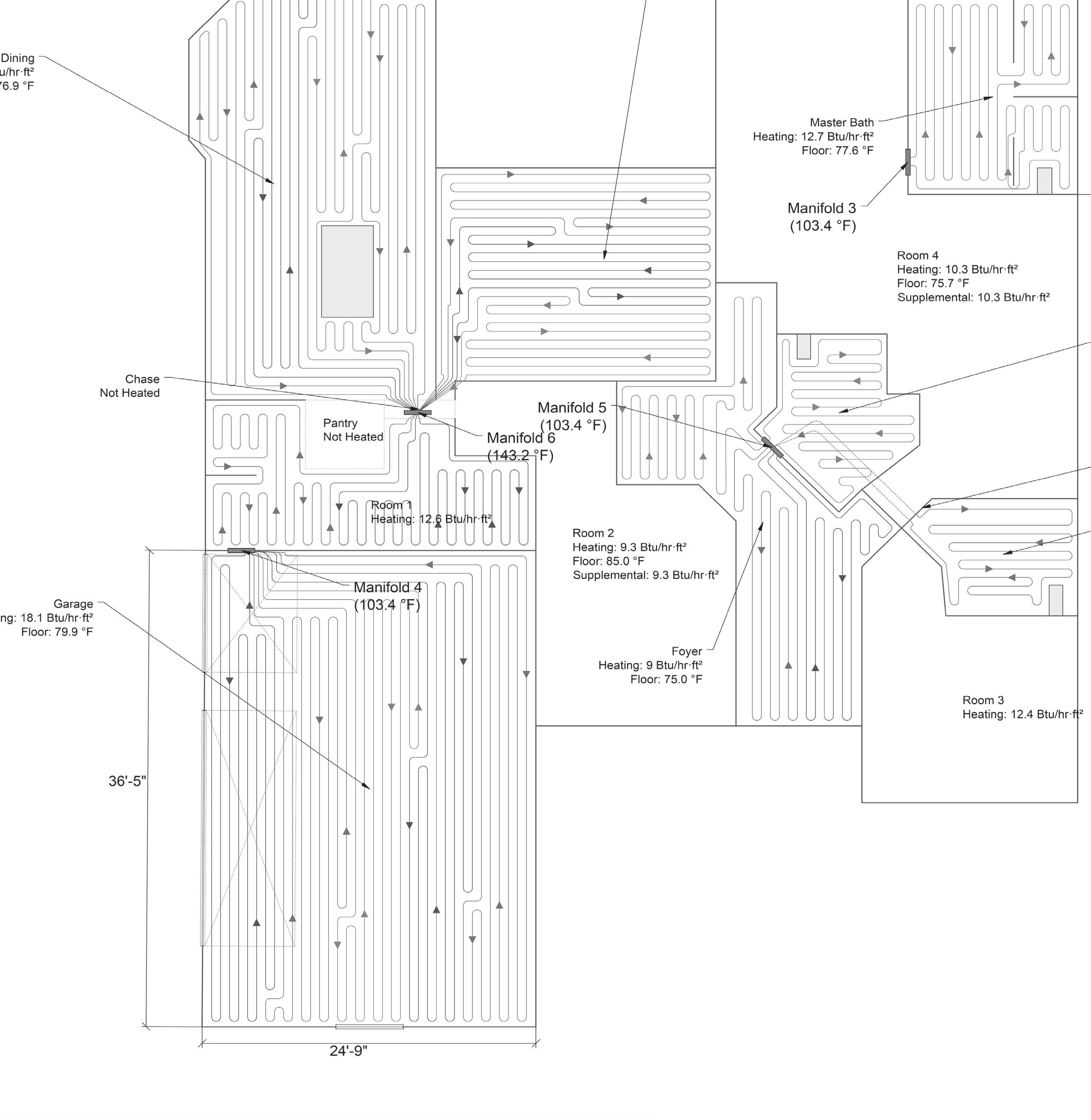

dew point of 55C/130F. The lower the return water temperature, the more condensation, the higher the efficiency. That is why condensing boilers work so well with low temperature, high mass radiant floor heating systems.

When a condensing boiler is working optimally the result is a much lower flue gas temperature, and lots of condensed water. Both must be disposed of, and last month we looked at the issues of low temperature flue gas disposal. Here we will take a closer look at how to deal with disposing of the liquid flue gas condensate.

Let’s start by looking at some facts about flue gas condensate. First, there is potentially a lot of it to deal with. A rule of thumb is that when the boiler is operating in fully condensing mode, approximately 3.8 liter/1 usg per hour of condensate is produced for every 100,000 Btus of input. Of course, the amount will vary with boiler operating temperature, and will stop completely if the boiler is operated at high water temperatures. Second, flue gas condensate is basically distilled water, but it is very acidic. It contains concentrations of nitric, sulfuric, and hydrochloric acids and will have a pH value in the range of 3.8 to 4.5. This acidic water can cause serious damage to piping systems, sewage systems, septic systems and other items it may come in contact with, especially metals such as copper, steel and cast-iron.

Condensing boilers incorporate a condensate drainage line connected directly to the bottom of the heat exchanger. To keep flue gases from also exiting out this line, an internal P-trap will be installed in this drainage line. After passing through the P-trap the condensate will drain away by gravity from the boiler, either directly into a floor drain in the mechanical room, or into a condensate removal pump to be pumped to a different location.

A malfunctioning condensate disposal system can cause serious problems that can result in a no-heat call or water damage to the building. When the condensate is not able to flow away freely from the boiler, it will back up and flood the combustion chamber. This will eventually block the flow of flue gas or rise to the level of the flame sensor, and will result in a burner lockout. Now you will get a no-heat call from an unhappy customer.

Most appliance P-traps are designed to be easily disassembled for cleaning, and this must be done on a regular basis. The P-trap will tend to accumulate debris, so regular maintenance is the first and probably the most important step in keeping the condensate drainage system functioning properly. Ideally a floor drain is located close to the appliance allowing for easy gravity drainage of the condensate water. Floor drains are not always available however, and are not always close to where they

are needed. Running a drain pipe a long distance across the floor or through the wall into the basement shower is not always going to be popular with the customer.

Condensate removal pumps offer the best solution when a floor drain is not readily available, as they work well in tight spaces and allow the condensate to be pumped vertically or horizontally to wherever a convenient drain is found. Take the time to fully discuss all of the condensate disposal options with the customer, so they are fully on board with whatever path you decide is best.

Regardless of where the condensate goes, care must be taken to avoid the corrosive effects that condensate can have on metals. Older buildings with cast iron sewer drain pipes and cast iron drain covers must be protected from the acidic condensate as damaging corrosion will occur rapidly.

Condensate neutralizers are available to increase the pH of the condensed water to acceptable levels, which effectively neutralizes the acid in the condensate before it goes down the drain.

In some jurisdictions neutralizers are mandatory – check with your local building department. Neutralizers work by running the flue gas condensate through a bed of alkaline limestone chips or pellets. Over time the limestone media dissolves and must be refilled.

Condensate neutralizers must be serviced on a regular basis to keep them functioning properly. The best way to check if the neutraliser is working properly is to test the treated condensate with a pH meter. If not serviced, they will stop providing protection from acidic condensate, and can get plugged or fouled up over time. Ensure that the customer is aware of the service requirements of the neutralizer.

With both floor drains and condensate pumps, problems occur when the liquid cannot drain properly from the boiler. Under sizing the condensate line from the boiler to the drain can be one reason that this occurs. When sizing these lines, some contractors underestimate the amount of condensate liquid that comes from a condensing boiler. A ½ in. line may be fine for an AC unit, but a minimum of ¾ in. pipe size is usually recommended for a heating boiler. Condensate lines are typically PVC or PEX pipe.

Lack of flow can also result when there is no atmospheric vent in the condensate line. With no vent, a double trap can be created in the line which will eliminate the natural gravity siphoning. It is important to always provide an air gap between the drainage pipe and condensate disposal system.

A trick some contractors use is to install a tee in the line from the appliance with one side open to the air to keep the condensate line vented and flowing properly. With floor drains, problems can occur when the line is pushed too far down into the drain. There must always be an air space between the end of the pipe and the water level in the drain,

“Regardless of where the condensate goes, care must be taken to avoid the corrosive effects that condensate can have on metals.”

so if a pipe is stuffed too far into the drain the liquid will not flow properly and will back up into the boiler.

This can also happen when using a condensate pump, as the condensate line from the appliance must not be stuffed too far into the reservoir of the pump. Condensate liquid will also back up into the appliance if this happens. For both floor drains and condensate pumps a good practice is to be able to see the liquid drip from the pipe end into the drain or reservoir.

Dealing with the products of combustion from high efficiency equipment must be done very carefully to avoid building and appliance damage and nuisance breakdowns. Contractors have the responsibility to closely examine the unique requirements of each project, and provide the best long term solution for the customer.

Take the time to discuss the condensate drainage options with the customer and make sure they are aware of the service requirements. When quick or inexpensive solutions are used, problems often occur that result in expensive equipment and building repairs for the owner. Everyone should strive to make sure this does not happen by doing it right the first time. <>

Robert Waters is president of Solar Water Services Inc., which provides training, education and support services to the hydronic industry. He has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com.

95% AFUE, Wall Mounted, Modulating Condensing Boiler with “THINK Intelligence Within”.

Combustion

The THINK combustion management system continuously monitors the gas and air mix and adapts its output to e ciently suit requirements.

You don’t step into the 2019 Ford Super Duty, you step up to it. An absolute beast of a truck, it’s designed to challenge the laws of physics. No matter how tough your task, this truck has your name on it. Depend on the 2019 Super Duty to get the job done, and then some.

It starts with a 6.7-litre Power Stroke V8 diesel engine offering 450 horsepower and 935 lb.-ft. of torque. Super Duty allows you to outwork and outsmart the competition thanks to its mighty capability plus a suite of intelligent features.

ENOUGH MUSCLE TO MOVE MOUNTAINS

You’ll get a maximum gooseneck towing of 35,000 lbs. and a conventional towing maximum capacity of 21,000 lbs. So if you’re looking to tow big, call on none other than the beast that is the Super Duty.

TONS OF TORQUE FOR TONNES OF HAULING

In addition to the 935 lb.-ft. of torque, this truck also comes with a massive 7640-lb. maximum payload rating. When the Super Duty went to a military grade‡ aluminum alloy bed and body paired with a high strength steel frame, the net weight saving‡‡ went into its frame, leaf springs, trailer hitch, rear axles and transfer case, while also coming out up to 24 times stiffer than the outgoing model. This truck doesn’t buckle to even the heaviest payloads.

AVAILABLE CLASS-EXCLUSIVE TRAILER REVERSE GUIDANCE SYSTEM†

The Ford Super Duty is the only heavy-duty truck in its class to offer an available Trailer Reverse Guidance System† to increase its sightlines. Visibility is enhanced via cameras in the side view mirrors and visual guides in the centre dash screen, giving you a clear rear view of where the trailer is going. And with a customer-placed rear trailer camera that seamlessly integrates into the centre stack screen, it turns reversing a trailer from an exercise in futility into an exercise in precision. THE 2019 SUPER DUTY. WORKS AS HARD AS YOU DO, AND THEN SOME.

Super insulation combined with zoned radiant heating has the potential to push fossil fuel heating into obsolescence. BY

IAN MCTEER

Imagine a benighted king travelling back to his drafty castle after a long day of abusing his serfs and annoying the local nobles. It is a cold winter’s day sometime after chimneys became popular but before the advent of central heating.

Servants pile three-foot long logs onto an already roaring blaze. The monarch reclines in front of the crackling source of welcome warmth. How lucky for him that the high-backed chair parked in front of the fire protects his back from the frigid combustion air racing to help feed the fire. As the smoke rises up the newfangled chimney, it takes much of the heat with it. Yet, our monarch gradually overheats in his wingback chair demanding the servants move him farther away from the fire. He had no understanding of why a fire some distance away made him so uncomfortable.

The campfire effect, well known to campers, means whatever side one faces toward the fire gets warm while the other side remains uncomfortably cold. While many people still burn wood

for heat, more efficient stoves and furnaces have replaced the roaring open fireplace. For others, sitting in front of a fire is more of a recreational pursuit.

Incredibly, heat produced in a fireplace is transmitted through space to a body without directly affecting the surrounding air. Thermal radiation is defined as, “the transmission of heat through space by wave motion: the passage of heat from one object to another without warming the space between.”

Consider the largest “fireplace” burning some 93 million miles away: the sun. With a diameter of 864,340 miles (1,380,000 kilometers) and a core temperature of nearly 4,000,000 degrees Kelvin, the sun has been burning for over 4.6 billion years. Every second, nuclear reactions fuse 4 x 1038 protons into helium-4; four million tons of mass are converted into pure energy via E = mc2.

Over its lifetime, about 0.03 per cent of the sun’s mass has been converted to energy, that is approximately the

mass of the planet Saturn. Fortunately for us, there’s plenty more mass left to convert into energy.

The sun’s surface, known as the photosphere, is composed of hot ionized gases around 6000C generating vast amount of energy. Visible light and infrared radiation emmitted from the photosphere reaches earth in the form of electromagentic waves travelling at the speed of light. The solar spectrum consists of several wavelenth regions distributing energy approximately:

Visible: 54 per cent

Infrared: 43 per cent

Ultraviolet: 3 per cent

Scientists have estimated an average of 58 Btu/hr (17 W) per square foot of solar energy incident on the land mass of the United States is many hundreds of times as great as the annual consumption of energy.

Atoms and molecules in any mass above absolute zero (-460F) have some energy causing motion that creates heat energy.

Heat, for our purposes, is something transferred between two or more objects. When heat transfer between objects ceases, heating ceases. It is the transfer of heat we crave to understand and to promote more efficiently. We understand that heat transfers in three different ways:

1. Conduction: explains how heat moves through solids. The kinetic theory of heat suggests that heat enegy creates increased molecular action. As a substance absorbs heat, the heated, higher energy molecules bump into their neighbours setting them off into violent motion. Thus, heat is conducted from one substance to another.

2. Convection: heated molecules move from one place to another carrying heat with them instead of colliding with neighbouring molecules.

3. Radiation: heat energy transferred by electromagnetic waves. Radiant energy must first be absorbed by a material mass before it can be converted into sensible heat.

The human body is a fascinating example of heat transfer to and from the environment:

This infrared thermometer defaults to a near blackbody emissivity: ξ = 0.95. Emissivity measures how well a material emits infrared energy.

Shiny, very reflective surfaces are not conducive to accuracy. As an example, I placed some flat black tape on the RA ductwork. Notice the temperature variation between the black surface and the shiny surface with ξ = 0.95. This type of thermometer cannot accurately measure spot sizes less than 0.7 in. (1.8cm) in diameter. The farther the distance from the target, the larger the spot size must be. Note that this thermometer cannot be used to accurately measure the temperature of the air inside the duct. Use a thermocouple probe meant for air temperature.

Infrared camera captured the radiant heat from my body reflected to the camera from the shiny RA duct over a distance of 30 inches (76mm).

Example of using an infrared camera set at ξ = 0.95, (distance = 4 ft., 1.2m) on shiny ductwork in cooling mode. I painted a flat back spot onto the duct. Note wildly different temperature readings between the black spot and the shiny duct just off to the side of the black surface. Again, use a thermocouple probe when measuring air temperature inside the duct.

Shading of the outdoor unit does not necessarily improve cooling efficiency due to the incredible volume of air constantly passing through the outdoor coil. However, homeowners too often restrict airflow by planting trees and shrubbery closely. There should be a four-foot (1.2m) clear space around the outdoor unit. Lilac (bottom) and other shrubs must be maintained yearly to prevent overgrowth onto the unit. In heat pump applications, an evergreen shrub or tree such as this blue spruce will help to protect the outdoor unit from strong winds during the winter.

It should be noted radiation is not confined to very hot surfaces as all substances radiate heat energy. Hot surfaces will radiate large amounts of energy while cooler surfaces will radiate smaller amounts.

Glass has the peculiar property of transmitting heat energy from the sun directly into a building; however, once the radiant is converted to sensible by the buildings furnishings, occupants or other objects, the low energy heat energy radiation from these objects is blocked by the glass, trapping heat in the structure. Perhaps a desirable trait for the winter, but definitely unwanted during the summer.

Thermal imaging cameras and infrared thermometers have become popular tools in the HVAC industry in the last few years. Seemingly easy to use, it is even easier to make mistakes when accuracy is required unless the user has been trained in basic thermography. An infrared camera will immediately show surfaces at different temperatures but how do you distinguish between hot spots and reflections?

A thermographer needs to account for measurement details such as distance from the target, spot size and emissivity. An object with an emissivity of one absorbs all the solar electromagnetic radiation falling on it and is known as a perfect blackbody. An object that reflects 100 per cent of the electromagnetic radiation falling on it is a perfect reflector having an emmissivity of zero. Perfect blackbodies and reflectors are not typcially found in everyday HVAC applications. A flat black surface

such as a cast-iron stove has an emissitivy of 0.95, a shiny reflective surface such as tin foil registers about 0.10, meaning that only 10 per cent of the radiant energy is absorbed. (See the sidebar on p23 for more on emissivity.)

The Roman Hypocaust, developed as early as 350 BC, was a radiant system that utilized wood burning fires to produce and circulate hot air (and smoke). The hot air circulated through enclosed areas beneath the floors and then up the walls through embedded clay tiles to outlets in the roof.

Hydronic and steam systems favoured cast iron radiators placed around the interior perimeter of a building to radiate heat energy into the surroundings. If left free standing, the rads would also establish a convection current carrying heat further into the room. However, homeowners often enclosed the rads with elaborate structures meant to conceal them,

inadvertently hindering heating efficiency.

Eventually, finned-tube hydronic and electric baseboard convectors replaced radiators and convection heating became the norm.

For those who can afford underfloor radiant heating, there is no other system providing such a level of thermal comfort in my opinion. Underfloor radiant allows for multiple zones in both hydronic and electric applications. Should the radiant floor not cover the entire heat loss of the building, it is easy enough to add some baseboard convectors to help cover the load on design days. With net zero or Passivhaus tight construction and controlled ventilation building techniques becoming more desirable, even prescriptive in some building codes, radiant floor warming may be plenty enough heat for such buildings.

Like any other heating device, any radiant application must be designed, in -

stalled and commissioned according to the manufacturer’s instructions and industry practices. Tubing can be punctured; electric cables can be cut or shorted.

Manufacturers make installation as easy as possible, but a proper job continues to require trained and conscientious installers. Electric radiant may be installed under many different floor coverings with heating elements embedded in a roll-out mesh or in single cable format not unlike hydronic tubing.

Electric radiant manufacturers provide warranties but the contractor typically is on the hook to provide installation data related to the electrical characteristics of the system measured before and after the installation.

Underfloor temperature sensors may become problematic over time. Perhaps install a second one at the preferred location leaving the wiring tucked into the wall cavity behind the controller in case it is ever needed. Why chop-up the floor just for a wonky sensor?

Radiant floors work can well in many types of commercial buildings; others use gas-fired radiant tube heaters such as in the service reception areas of automobile dealerships to great effect.

Radiant panel heaters installed below the ceiling or on the walls may not have the desired effect in situations where furnishings and people are in sparse supply to absorb and reflect the radiation. Cool spots may develop that will garner complaints from the inhabitants. Better to do floor warming or baseboard convection.

At one time, industry concensus seemed to favour installing residential condensing units on the north side of a building when possible. The idea was to get the unit out of direct sunlight in the hopes that it will run more effiecienty. A study

conducted by the Florida Solar Energy Center in 2015 concluded the temperature of the air entering the condenser has the pivotal effect on efficiency, not local shading, including shade from trees or shrubbery.

My outdoor unit moves 3200 cfm, if it runs for an entire hour. A staggering 192,000 cubic feet of air will pass through the coilduring this time. No amount of shading will cool that amount

of air enough to be effective at lowering the condensing temperature.

Placing a modern cold climate heat pump (ccASHP) on the south side of the building sheltered from prevailing winds and snow drifts is more desirable. Still, a lot of radiation will be required to warm the entering air enough to make a difference in the unit’s heating efficiency.

Continued on p26

Homeowners often ask about hiding the outdoor unit with plants, shrubs and trees, which is OK but for two important considerations:

1. Vegetation must be trimmed to maintain a four-foot space to the unit. Airflow must not be impeded and falling leaves should not be allowed to enter the unit.

2. Vegetation must not impede service access – rule of thumb: something that is difficult to maintain does not get maintained.

When measuring the temperature of the air entering an outdoor condenser coil, place the thermometer probe on the shady side of the unit or otherwise shade the probe. Solar radiation will be effective in reducing accuracy.

In past articles, I have discussed how we are going to heat buildings, especially residential buildings, as efficiently as possible from now on. Should old forced warm air heating systems designed for yesterday’s furnaces be abandoned in favour of ground source heat pumps or ccASHPs; or inverter driven heat pumps utilizing small duct, high velocity air handlers?

There are many options but in the end the first cost of any system is the primary factor determining equipment selection. Electric radiant heating combined with a ductless cooling unit installed in a net zero or Passivhaus application might be attractive to the upscale set. However, for those looking at improving the bulk of Canada’s leaking old housing already radiantly heating the countryside, I would put my money on better insulation, tighter doors and windows along with a zoned ductless or small-duct high velocity system.

Remarkably, there is abundant solar radiant energy available yet it is not so easy to gather and to control. In 1976, physicist Amory Lovins, founder of the Rocky Mountain Institute, proposed a greater reliance on “soft energy paths” especially those efforts aimed at conserving energy and improving efficiency.

Had the notion of super insulation combined with zoned radiant heating, perhaps solar powered, been intensively cultivated years ago, fossil fuel heating would have become as obsolete as the cranky old king and his primitive fireplace. <>

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

Napoleon’s Oakville Series is made up of four models from 24,000 to 40,000 Btus. A robust "H" style burner provides a display of flames across the width of the firebox. Designed with ease of installation in mind, the inserts feature a clean face design, large viewing area and flush finishing faceplates in 2 ½ in. or 5 in. widths. The inserts have a Crystaline ember bed, split oak logset and Bluetooth eFire. www.napoleon.com.

From Schwank, the SchwankAir 500, 2000 and 2500 series air curtains are available in ambient, electric heated, and water heated models. The 500 series is available in a 208V, 12 Amp model or a 208V, 25 Amp model. The 2000 (pictured) and 2500 series are intended for door sizes up to 10 ft. high and 11.5 ft. high, respectively, and are available in 208V, 230V, 480V, and 600V models. www.schwankgroup.com

The DuraChimney II cap features a lowprofile design with mesh characteristics. DuraChimney II products are built to stay cool on the outside, provide a hot draft on the inside and offer a fire-safe design intended to protect the chimney and building. www.duravent.com

From Goodman Manufacturing, the GMEC96, GMSS96 and GMSS92 gas furnaces feature a 14 in. wide cabinet and 96 per cent AFUE rating. Models range from 30,000 Btu/h to 60,000 Btu/h with a 3-ton airflow. The furnace offers twostage firing and features a two-speed induced draft blower, silicon nitride ignite, self-diagnostic control board, colour-coded low V terminals and low, continuous fan speed options. www.goodmanmfg.com

Lyric fireplaces from Ortal feature Cool Wall Technology and a heat barrier screen around the unit. Available models include front-facing, three-sided, corner (left or right), peninsula, see-through and stand-alone. The fireplaces are certified for use with either natural gas or propane gas and are compatible with wood or fabric wall finishes. www.ortalheat.com

A differential pressure sensor from Sensaphone measures air pressure in two areas and indicates if there is a difference between the readings. Sensaphone offers duct-mounted and wall-mounted sensors that send data to its monitoring devices that accept a 4-20 mA signal. The duct-mounted sensor monitors positive and negative pressure from the two included duct mounts. www.sensaphone.com

From Bosch Thermotechnology, the 80 per cent AFUE gas furnace features a four-way multipoise design and cabinet height of 33 ¾ in. The unit’s control board is equipped with LED fault codes. All furnaces come standard with a natural gas-to-LP conversion kit. The design features a left- or right-hand connection for gas and electric service. The furnace comes equipped with a removable bottom closure panel for bottom return applications. www.boschheatingandcooling.com

The deep-pleated 4 1/2 in. replacement filters and MERV 13 deep-pleated carbon filter from Clean Comfort Indoor Air Essentials are designed for media air cleaners. Rated MERV 11, the filters can be used in AM11 series CleanFit and AMB11 builder’s model cabinets. The company’s 1-, 2- and 4-in. wide filters are now offered in some nominal sizes for specific applications. www.cleancomfort.com

From Modine Manufacturing Company, the Model BTP gas-fired power vented unit heater features 82 per cent thermal efficiency. It comes in seven sizes, from 150,000 to 400,000 Btu. The unit comes standard with a 409 stainless steel primary heat exchanger. www.modinehvac.com

Whispertherm thermal recovery unit from The Whalen Company uses either a two-row or three-row integral hydronic heating air coil. It features a constant torque EC motor, which offers five available motor speed settings. The unit includes internal stainless steel design with a P-trap style rubber drain line. It is intended for new construction and retrofit applications in both low-rise and high-rise buildings. Other features include a flush-mounted, floating design and multiple grille sizes. www.whalencompany.com

From Cooper&Hunter, the Dakota series ductless mini split heat pump for single zone applications can work in temperatures as low as -22F. When temperatures reach 36F, a built-in heater warms the base of the outdoor unit so condensation does not freeze. The series offers multiple fan speeds, high density silver ion filters, GoldFin anti-corrosive coating and optional Wi-Fi control. Dakota models deliver anywhere from 9,000 to 24,000 Btu/h cooling capacity and 10,900 to 24,000 Btu/h heating capacity. www.cooperandhunter.us

From Britech, the Twisto connection kit is designed for heat tracing connections. It features a 2 m. PVC-Type SJTOW connector cable. The kit offers a nominal voltage of AC 250 V, a nominal current of 20 amps and an ambient temperature range of -40C to 85C. www.britech.ca

The Monterey Plus+ home furnace from Williams Comfort Solutions offers recessed or surface-mounted installation and is available in 25,000, 35,000 and 50,000 Btu/h sizes. It features automatic temperature and safety controls, a resettable vent-limit safety switch and a side-relief opening draft hood design. Thermostat is included. www.ontor.com

Nortek Global HVAC's model E7 features a 1/2-hp. ECM fan and a control board that facilitates the 16 speeds. The control board’s seven-segmentstyle readout screen expedites troubleshooting by displaying operational modes of cooling, heating, fan circulation, dehumidification, motor fault, lockout and idle. DC relays operate reliably, quietly and reduce service troubleshooting time. Available in a 29-in. high E7EM heat-only base unit, or 60-in.-high E7EU upflow and E7ED downflow models, the latter two come with a coil box for field-installing the optional evaporator coil and accompanying filter. www.nortekhvac.com

The SRP Stealth from Superior Radiant Products is a condensing system classified as a Category IV radiant tube heater. The vented infrared heater utilizes a microchannel flue gas heat exchanger along with a single canopy over its parabolic reflectors. Model THE14N offers two-stage technology on the high fire 135,000 Btu/hr and steady operation on the low fire 85,000 Btu/hr. www.superiorradiant.com

BY JEFFREY STAUB

Thermostatic expansion valves (TXVs) are one of the most common type of adjustable orifice throttling device in air conditioning and refrigeration systems worldwide. But how do TXVs compare to other throttling devices? Fixed orifice devices such as capillary tubes or pistons are cheaper and electronic expansion valves (EEVs) offer greater superheat control across a large load range, so why are TXVs popular?

EEVs are top-of-the-line throttling devices. EEVs can be programmed to work with the other components in the system. While EEVs can outperform TXVs, the gains often do not justify the much higher cost. A standard TXV can increase efficiency versus a fixed orifice device by about 30 per cent for only a small increase in cost.

One reason for the greater expense is that EEVs need additional components to work properly, including a controller and sensors. While TXVs have been engineered to be selfcontained, EEVs are best seen as part of a greater whole, operating according to data the sensors collect and the commands the controller and its underlying software sends out. And while a TXV can be a drop-in replacement for a piston or capillary tube, the same cannot be said for an EEV.

Systems that require exact precision, such as those with variable-speed compressor technology, where the load, ambient conditions, and compressor mass flow go through high rates of change, will benefit from having an EEV and complimentary components.

Fixed orifice devices are ideal throttling devices if conditions never change. If the load on the system is constant and the ambient temperature remains steady, then a simple capillary tube or piston would be preferable to an adjustable orifice device such as a TXV. However, outside of a laboratory, static conditions are simply not realistic.

Seasonal temperature changes have a profound effect on system performance, as does increasing the heat load inside. For example, summer brings warmer weather, which increases the condensing pressure of the refrigerant in the air conditioner. Since the throttling device acts as a type of dam within the system, a fixed orifice device will not open more when the load increases to allow more refrigerant through, which increases the superheat on the compressor.

Additionally, once the load decreases (perhaps at night), the back pressure drops, which significantly increases the risk of liquid refrigerant making it to the compressor, damaging it. A TXV will modulate open or closed based on changing conditions and will adjust to maintain a constant superheat. This in turn ensures that efficiency is optimized and the compressor is protected against damage from liquid refrigerant.

Another important factor is reliability. The power element is the most common part of a TXV to fail, so having one that is made from high-quality materials will extend the life of the valve. Laser-welded, stainless steel power elements offer the longest life possible.

Another common point of failure is the sensing bulb capillary tube. Once again, stainless steel offers flexibility and durability not available with other metals. Stainless steel sensing bulb coils can be bent and flexed over and over without fear of cracking.

Finally, TXVs are often used to upgrade a system from a fixed orifice device, so a TXV that is easy to install is most ideal. Retrofitting a fixed orifice device system with a TXV is easy, especially when the valve comes packed with the most common fittings to attach to the evaporator distributor, making upgrades hassle-free. <>

Jeffrey Staub is director, Regional Applications Americas — Danfoss. He can be reached at JeffStaub@danfoss.com.

3D printing has gained traction in the construction industry.

Mechanical systems find a place in 3D printed structures. BY JILLIAN MORGAN

Ateam of researchers at the University of Waterloo in Ontario are steadily working to develop a 3D printing system that will pump out concrete to form homes and buildings.

Far from the first of its kind, the technology will use a robotic printing arm to deposit concrete based on a digital model of the structure.

Led by mechanical and mechatronics engineering professor Amir Khajepour, the researchers are developing the technology for Canadian company AMIDA 3D with plans to unveil a prototype in the summer of 2020.

“I’ve been in connection with [AMIDA 3D] for the past year or so and it has a large program with them in developing technologies both from the robotic aspects and also on the material aspects,” Khajepour says.

Bora Bulajic, president of AMIDA 3D, says 3D printing technology has made serious strides in recent years.

“Already, the applications being used in the world today are tremendous. We believe it’s unstoppable,” he says.

Increasingly, 3D printing has gained traction in the construction industry as a way to quickly and cost-effectively construct homes and buildings.

“The benefits we see are that, first of all, it’s green construction. It has a lower carbon footprint by far compared to existing methods. It’s more cost efficient, so you’ll be able to do more for less,” Bulajic says. “The fact that we can be so mobile is huge because the cost of distance is a big addition to the price of the building or infrastructure project.”

3D printing is poised to disrupt the construction industry, though Bulajic says mechanical contractors are not likely to encounter any serious changes on the job.

“When we’re looking at all the other elements that have to go in, like wiring and plumbing and HVAC, it’s all going to be in there, of course,” he says. “The only thing that’s going to be radically different, in my opinion, is that there’s going to be a very interactive process… but you’ll need all the people, you’ll need all the technicians and tradespeople… It’s not disruptive in terms of replacing people.”

These structures still require the same electrical and mechanical components, Khajepour says. His team is currently researching different methods of installing those systems.

“Some of the questions [are] how to run water or electrical or heating in the walls through the process of this automated printing,” he adds. One solution, according to Khajepour, is to leave space in the design of the structure for electrical or wall pipes to be inserted and covered.

“For the air, the situation might be a little bit difficult because the current approach is to run the ducts mostly through the walls from one floor to the other floor,” he says. “This can also be done in the 3D printing meaning that when you design it you have to leave a larger, open space that the ducts could go through.”

Still, he says the industry will not need to reinvent the wheel.

“It’s just a different way of looking at these new houses,”

he says. “It’s not that we need to completely develop new things or new wires or new pipes for these new buildings.”

3D printed homes and buildings require developers to think about the design and installation of mechanical systems ahead of time – since, unlike other building materials such as wood, concrete is less flexible.

“There’s no way after its built [to] start making holes in the wall,” Khajepour says. “You have to think in advance…. [Currently,] for houses, we don’t need to think in advance about where to run the cables or the heating or the cooling. It’s very easy to add them after the shell of the house is done. For 3D printing, you have to incorporate that into the design.”

While the research team works through those questions, Khajepour says there is one stumbling block.

“We still don’t have any standards or guidelines for this,” he says. “We have to have the standards and the way to add it to the CAD model of the house. So when you print it you have all those conduits, whether it’s the heating, plumbing or electricity.”

Though the technology offers benefits to the construction industry, it could be a while before homes are built with 3D printers.

“3D printing is gaining momentum… How long will it take to become a mainstream construction approach for houses? That’s a question mark,” Khajepour says. “It takes time. We are at the very starting point of this new technology. It’s happening but it takes time, same as autonomous driving… Where it goes and how long will it take? That’s obviously a big, million-dollar question. But it’s happening.”

The structural design of a 3D printed home, such as the roof and the cost of materials, are a few challenges he expects along the way.

“I don’t think that it’s going to replace existing construction practice,” Khajepour says. “One thing that we have to remember is we have to be a little bit more pragmatic and realistic on these 3D printed houses. It’s not something that you click and then at the end you move in.”

Still, for Bulajic, the technology offers opportunity for the construction industry.

“We believe that the market for something like this is really large because it can address so many different things,” he says. “It can used for infrastructure projects, it can used for the emergency rapidly deployed structures; storage, military applications… livestock enclosures, housing – We believe that this is something that is definitely going to have an impact going forward.” <>

BY

JOHN SIEGENTHALER

When designing hydronic circuits most of us focus on what is necessary for that circuit to absorb thermal energy at a heat source, carry it along like a conveyor belt, and release that energy at one or more heat emitters. After all, that’s the principal objective of any hydronic heating system –regulating thermal energy transfer from source to load.

But thermal energy is not the only energy being processed in hydronic systems. Electrical energy is being converted into mechanical energy. The latter is referred to as “head” in the hydronics industry. Circulators convert electrical energy into head energy.

The efficiency of that conversion can vary over a wide range, from single digits to upwards of 60 per cent. Small wet rotor circulators operating near either end of their pump curve have very low electrical to head energy conversion efficiency. Larger, circulator with more efficient multi-horsepower motors, and applied so that they operate near the middle of their pump curve, represent the higher end of the efficiency range.

Head energy is eventually dissipated into heat due to friction between fluid molecules, as well as friction between the fluid and surfaces it flows across.

Every hydronic heating professional understands that there’s

a cost associated with operating a circulator. Every kilowatt•hour of electrical energy “fed” to the circulator comes at a price. In some areas it is only a few cents. In other locations, such as remote locations where diesel fuel is trucked in to power generators, it is over half a dollar per kilowatt•hour. Ouch!

It is not hard to understand that reducing head loss in hydronic systems reduces the kilowatt•hours of electrical energy required to operate them. But do we really think about this enough as we design?

Imagine a closed hydronic circuit constructed of type M copper tubing and having an equivalent length of 200 feet. Assume this circuit needs to convey a flow rate of six gpm along a round trip between a mechanical room and the coil of an air handler. What tube size would you normally select for this circuit?

The usual sizing criteria for copper tubing in smaller hydronic systems is to keep the flow velocity no higher than four feet per second. That flow velocity corresponds to a flow rate of 6.4 gpm in ¾ in. type M copper tubing, so, ¾ in. is likely the common size selected to handle this flow requirement. My guess is that many of you didn’t have to consult a flow velocity versus flow rate chart in order to select a ¾ in. tube for this flow rate. You just knew from previous experience that a ½ in. tube was too small and a 1 in. tube was “overkill” for six gpm, so you picked the size in between.

Let work in a few simple calculations to see if that was a good choice.

Assuming the 200 ft. x ¾ in. copper tube circuit was carrying water at an average temperature of 120F it would have the circuit head loss curve shown in Figure 1

You can make a circuit head loss curve like this by graphing head loss versus flow rate values that can be looked up in many design references. The data in these references is usually listed as feet of head loss per 100 feet of pipe. Since our assumed circuit has an equivalent length of 200 feet, we can just double the head loss values, plot the points on the graph, and draw a smooth curve through them.

Figure 2 shows the same head loss curve along with the pump curve of a typical small wet rotor “zone” circulator. The point where these two curves cross is called the operating point. It’s where the head energy supplied to the water by the

Figure 2 Head loss curve with pump curve of a typical small wet rotor “zone” circulator

circulator exactly matches the head energy being dissipated from the water by friction. If you draw a line straight down from the operating point you can find the flow rate the system will operate at. In this case it's about 5.9 gpm. Since this flow rate is very close to the target flow rate of 6 gpm, this circulator would be an acceptable selection.

Figure 3 shows the same curves as Figure 2, but adds another curve, shown in green, representing the “wire-to-water efficiency” of the circulator, that is the efficiency at which the circulator converts electrical energy into head energy). The efficiency values are shown as decimal percentages on the graph’s right vertical axis.

At the operating point of 5.9 gpm, the circulator has a wireto-water efficiency of 19.5 per cent. That value is not very impressive, but it also not far below the peak wire-to-water efficiency of this circulator, which is about 22 per cent.

The owner of a hydronic system does not pay, at least directly, for head energy. They pay for the electrical energy needed to operate the circulator that imparts head energy to the water. You can estimate that cost by considering the power demand of the circulator, and the total on-time of the circulator.

The electrical power input to a circulator can be estimated using Formula 1:

Formula 1:

head loss of 3/4" x 200' circuit pump curve for circulator wire-to-water efficiency of circulator

rate (gpm) head loss (piping) (ft of head ) head added (circulator ) (ft of head)

Figure 3 Curve, shown in green, representing the “wire-to-water efficiency”

f = flow rate in circuit (gpm)

H = head loss of circuit while operating at flow rate (f) (feet of head)

D = density of fluid circulating in system (lb/ft 3) n = wire-to-water efficiency of circulator operating at flow (f) and head (H) (decimal %)

For the operating point shown in Figure 3 the estimated electrical input to the circulator would be estimated at: w e = 0.003017 () ×

The annual operating cost of any device the requires a specific power input, and operates for a known number of hours can be easily calculated using Formula 2. Formula 2: w e = 0.003017 () × f × H × D n w e = 0.003017 () × f × H × D n = 0.003017 () × 5.9 × 11.9 × 0.195 C annual

Where:

w e = 0.003017 () × f × H × D n = 0.003017 () ×

Cannual = annual operating cost ($/yr)