SMART BUILDINGS COLLABORATIVE APPROACH TO CONSTRUCTION

SMART BUILDINGS COLLABORATIVE APPROACH TO CONSTRUCTION

OPTIMIZING CLIENT COMFORT THIS SUMMER MAINTENANCE CALLS

SPRING START-UPS IN A COVID WORLD 2021 SERVICE VEHICLE REPORT EFFICIENCY, POWER AND CONVENIENCE

12

WHAT ABOUT COOLING?

Every hydronics professional should be ready with an answer to this longstanding question.

By John Siegenthaler

18

HVAC COOL CUSTOMERS

Follow these steps to maintain the optimal performance of your residential clients’ cooling equipment.

By Ian McTeer

24

HVAC

SPRING START-UPS IN A COVID WORLD

The third episode of 30 Mechanical Minutes features a discussion on HVAC maintenance calls in 2021 with HPAC’s Ian McTeer and Gary McCreadie from HVAC Know It All.

By Doug Picklyk

27

AN OUNCE OF PREVENTION

The enduring value of maintenance programs for the refrigeration cycle. By Dave Demma

38

SMART BUILDINGS: AT THE INFLECTION POINT

Market segment offers general contractors and subtrades opportunities for growth and a new, collaborative approach.

By David Kennedy

6

8 NEWS

Net Zero community coming to the Ottawa area will include a district energy

30

HEAT PUMPS

BUILDING A CASE FOR HEAT PUMPS IN COMMERCIAL HEATING

Recent compressor technology innovations are driving sustainability benefits for heat pumps in largescale operations.

By Drew Turner

50

PLUMBING

62

44

DIGITIZING HEALTHCARE DELIVERY

The new Cortellucci Vaughan Hospital provides a case study in collaboration and smart construction.

By Doug Picklyk

56

SERVICE VEHICLE REPORT E-VOLUTION

Despite more talk about electric vehicles, for now service truck and van updates in 2021 focus more on fuel efficiency and convenience features.

By Jil McIntosh

PERSPECTIVES ON PIPING

Tracing back to the history of the trade, piping materials have evolved and while many materials still stand the test of time progress has led to a broader range of residential solutions.

By Steve Goldie

A revolutionary water heating system design and application approach that features greater BTU input for quick reaction, an optimized storage buffer for extra power when needed, the bene t of high water turnover, and exclusive duplex stainless steel AquaPLEX® construction for unmatched performance and longevity. Learn more about PVI’s Dynamic Water Heaters at pvi.com.

OptiSize® will help you select an optimally-sized water heater for your next project

IN WHAT COULD BE SEEN AS A WIN FOR THE ENTIRE PLUMBING AND HVAC INDUSTRY, on April 19th the federal government unveiled its first budget in over two years and included programs that address skilled trade employment and investments in energy efficienct technology. With COVID-19 cases rising nationwide, the Feds acknowledge the country needs to overcome the pandemic first and then focus on rebuilding stronger and smarter.

On the employment front, the budget includes $470 million over three years to establish a new Apprenticeship Service. The Service would help 55,000 first year apprentices in construction and manufacturing Red Seal trades connect with small and medium-sized employers.

Employers would be eligible to receive up to $5,000 for all first-year apprenticeship opportunities to pay for upfront costs, doubled to $10,000 for employers who hire people from underrepresented groups.

The government will also spend $960 million over three years towards a new Sectoral Workforce Solutions Program to fund training in areas where employers are looking for skilled workers.

In addition, Budget 2021 will provide $4.4 billion to the Canada Mortgage and Housing Corp. to help homeowners complete deep home retrofits through interest-free loans of up to $40,000.

In conversations I’ve had with the owners of small HVAC service outfits, any incentives that help drive home-owner investment in new high-efficiency equipment is a good thing, and enlarging the pool of workers in the trades is always number one or two on the list of wants.

Two other victories I’d like to shine a light on are the winners of this magazine’s first ever Sweet Heat contest. Launched in early December last year, the installation contest called on hydronic contractors from across Canada to share photos of recent projects and explain the challenges and creative solutions they used. With 31 entries received, the contest was divided into two categories: commercial and residential.

The final judging was performed by HPAC writers and hydronics industry experts John Siegenthaler and Robert Bean.

The winners and first-runners-up were announced during the final session of the 2021 Modern Hydronics Summit, held online March 30 and 31.

Congratulations to Riverdale Plumbing in Toronto for taking first place in the residential category for a large house project in Toronto, and to the runner-up, Denrite Mechanical of Sturgeon County, Alta.

Grand Mechanical Solutions of Brantford, Ont. was the runner-up in the commercial category, and the winner was Rambow Mechanical of Kelowna, B.C. for a residence building at the University of British Columbia Okanagan campus. Profiles of these two winners and more insight into their winning projects will appear in the next issue of Modern Hydronics, found within the August 2021 issue of HPAC.

These winning entries are prime examples of building better and smarter. With the aid of new federal financial incentives and a growing workforce, we anticipate an even greater range of contest entries in years to come. <>

Doug Picklyk, Editor

Reader Service

Print and digital subscription inquiries or changes, please contact

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE

PUBLISHER

ASSOCIATE EDITOR

MEDIA DESIGNER

ACCOUNT COORDINATOR PUBLISHER COO

Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

David Skene (416) 510-6884 dskene@hpacmag.com

Logan Caswell (416) 728-6209 lcaswell@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Peter Leonard (416) 510-6847 pleonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2021 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

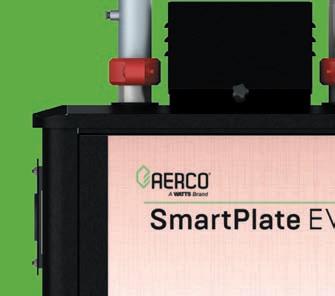

Introducing SmartPlate EV. With its ultracompact 24" x 32" footprint, vertical piping connections and capacities up to 4500 MBH and 300 PSIG, the SmartPlate EV indirect water heater gives you greater design flexibility for standard and high-pressure systems. It also easily integrates with AERCO’s Benchmark boilers and smart Edge Controllers for a powerful combination system. Join the EVolution. SmartPlate EV. 24 x 32

Rendering of the Zibi community

The federal government together with the Federation of Canadian Municipalities (FCM) has announced a $23 million investment towards the construction of the new district energy (DE) system for Ottawa-Gatineau’s carbon-neutral 34acre Zibi waterfront development.

The National Capital Region’s first net-zero community, the Zibi Community Utility (ZCU) DE system (an equal partnership between Hydro Ottawa and Zibi) will leverage locally-generated hydroelectricity, river-coupled cooling from the Ottawa River and waste industrial heat from the local Kruger Products industrial plant.

All buildings at Zibi will be interconnected through a hydronic loop that will deliver heating and cooling energy generated at the central plant, to be located in the lower level of a 15-storey residential building. The design is based on low temperature (+/-40C) heating water temperatures.

The fully-operational DE system is scheduled to be completed this year, with the entire Zibi community build out slated for 2032. zibi.ca/zcu

The federal government stepped-up its clean-energy initiatives during its spring budget with the announcement of interest-free loans to help Canadians with energy efficient home improvements.

The new funding will build on the 1-million free energy audits and up to

The 2021 Modern Hydronics Summit, held online March 30 and 31, filled two afternoons and attracted 871 attendees with hydronics enthusiasts logging in from across the country.

In total there were nine educational sessions, including keynote addresses from John Siegenthaler on reducing water temperature in existing hydronic systems. Other session topics included: air-to-water heat pumps, snow and ice melt solutions, buffer tanks, energy metering and more. During each scheduled session attendees engaged with speakers via public text chat, and the overall feedback on the event was very positive. John Siegenthaler noted: “Kudos to HPAC for pulling this virtual conference off so well. Wish we had something like this for hydronics in the U.S.”

In addition, winners and first-runners-up of the first ever Sweet Heat installation contest were announced at the Summit. Launched late last year, the contest called on hydronic contractors in Canada to share recent installation photos and explain the challenges and creative solutions used. With 31 entries received, the contest was divided into two categories—commercial and residential. The final judging for the contest was performed by Siegenthaler and Robert Bean.

In the commercial category the runner up was Grand Mechanical Solutions of Brantford, Ont., and the winner was Rambow Mechanical of Kelowna, B.C. For the residential category, runner up was Denrite Mechanical of Sturgeon County, Alta., and the winner was Riverdale Plumbing of Toronto. The two winning entries will be featured in the Fall edition of Modern Hydronics, included within the August issue of HPAC magazine.

700,000 grants valued up to $5,000, announced in the 2020 Fall Economic Statement.

Budget 2021 proposes to provide $4.4 billion on a cash basis ($778.7 million on an accrual basis over five years, starting in 2021-22, with $414.1 million in future years), to the Canada Mortgage and Housing Corporation (CMHC).

The interest-free loans worth up to $40,000 will help homeowners and landlords undertake retrofits identified through an authorized EnerGuide energy assessment. In combination with grants announced in last Fall’s Economic Statement, the loans will help eligible participants make more costly retrofits.

Also included is a dedicated stream of funding to support low-income homeowners and rental properties serving low-income renters.

The program is expected to be available by summer 2021. More than 200,000 households can take advantage of this opportunity.

Recommendations include:

• Replacing oil furnaces or low-efficiency systems with a high efficiency furnace, air source heat pump, or geothermal heat pump.

• Installing a high-efficiency water heater or on-site renewable energy like solar panels. canada.ca

Continued on p10

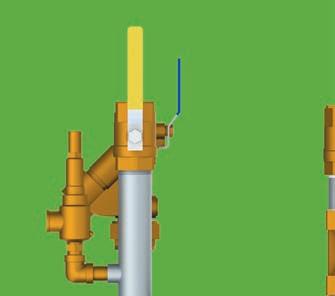

Advanced technologies and innovative designs are fused with industry-leading manufacturing expertise in Lync’s complete, cost-effective water technology solutions. Our expertly engineered, fully integrated and assembled systems minimize planning, design and installation time while maximizing your return on investment. Learn more at lyncbywatts.com.

Fully designed and assembled solutions from one source

Commercial Heat Pumps, Water Heating Solutions, Water Quality Solutions

The ASHRAE Epidemic Task Force updated its statement on the airborne transmission of COVID-19 in buildings: “Airborne transmission of SARS-CoV-2 is significant and should be controlled. Changes to building operations, including the operation of heating, ventilating, and air-conditioning systems, can reduce airborne exposures.”

The statement replaces an April 2020 statement which indicated airborne transmission was “sufficiently likely,” and airborne precautions should be taken. At that time, both the World Health Organization (WHO) and the Centers for Diseases Control (CDC) contended that the virus transmission was by droplet and fomite modes, not airborne. Both organizations have since acknowledged the risk of airborne transmission indoors.

“This may seem like a small step, but we feel it is important to leave no doubt about our position, given the muted support for ventilation and filtration as important tools in the effort to stop the pandemic, from some organizations that should be leading more strongly,” said ASHRAE Epidemic Task Force Chair William P. Bahnfleth. ashrae.org/COVID-19

BOREHOLES COMPLETED FOR ONTARIO’S LARGEST GEOTHERMAL CONDO TOWER

According to Camrost Felcorp Inc., the developer of the Exchange District mixed-use community in downtown Mississauga, the drilling of 186 geothermal boreholes which will provide the en -

The U.S.-based Air Conditioning, Heating and Refrigeration Institute (AHRI) has released a report that examines fire safety issues related to mildly-flammable A2L refrigerants.

The study, undertaken in cooperation with UL and the Firefighter Safety Research Institute (FSRI), compared A2L (lower flammability) with A1 (no flame-spread) refrigerants in real-world situations.

The project included five fire scenarios designed by fire service professionals. In summary the refrigerant reactions delivered similar results in most scenarios. Both A1 and A2L refrigerants generated hydrogen fluoride (HF) gas in quantities considered hazardous without PPE, and in most scenarios there was not a significant relative difference in HF gas generation between the A1 and A2L refrigerants used in the investigation.

For a complete look at the study including refrigerants used visit ahri.org.

ergy source for two towers in the development has been completed. The development will include condominium towers, a rental residence and hotel.

The project will bring geothermal energy to the rental tower, as well as the planned boutique hotel structure, and 650 suites in the 66-storey EX3 condo tower, the tallest residential development in the province to feature a geothermal-based solution.

The developer is partnering with Diverso Energy, a geothermal energy service provider, on the heating and cooling solution, and also announced a partnership with Mitsubishi Electric to use the company’s water-source variable refrigerant flow (VRF) system in the development.

theexchangedistrict.com

Right Time Group of Companies, a residential HVAC contractor group founded in 2014 and headquartered in St. Catharines, Ont., has acquired Atlas Service Company Inc. based in Oakville, Ont. and owned by CEO Roger Grochmal since 1986.

AtlasCare is the fifth acquisition completed by Right Time Group, and the first since the Group itself was acquired by

San Francisco-based private equity firm Gryphon Investors in December 2020. Right Time is intent on developing a national footprint through acquisitions or partnerships with residential HVAC replacement contractors.

“Right Time is very pleased to welcome AtlasCare to the Right Time family. We have long been impressed by the business that Roger Grochmal and his son, Michael Grochmal, have built at AtlasCare and are excited about this partnership,” said Right Time CEO Jeremy Hetherington in a company release.

“AtlasCare has a long history and a strong culture, and when it came to entrusting that legacy to a buyer, Right Time was the natural choice,” said Roger Grochmal in the release.

Right Time now operates out of 12 Canadian locations across Ontario, Manitoba, and B.C. right-time.ca <>

914 registrations and an astounding 871 actual attendees - with all 10 provinces represented – it was truly a national event!

9 sessions (6 concurrent) averaging 260 attendees. Total number of session visits was 2598. Within the sessions there was a total of 614 “chats” between the attendees and speakers!

27 exhibitors took a chance on this new virtual event and they were rewarded with an average of 99 visits per booth adding up to 2673 total booth visits in just 8 hours!

The Summit concluded with the announcement of the two winners of HPAC’s inaugural Sweet Heat Competition. Check out the winners and learn more about their installations in the August issue of HPAC!

Thank you to our sponsors and exhibitors!

You should be ready with an answer to this long-standing question. BY JOHN SIEGENTHALER

The versatility of modern hydronics technology allows designers to create systems that are specifically designed to the needs and constraints of almost any building. While best known for space heating, most modern hydronic systems for residential buildings also include provisions for heating domestic water.

Still, for decades, one of the shortcomings of smaller hydronic systems has been the inability to cool buildings. This missing link has undoubtedly swayed prospective clients away from hydronic systems, defaulting to ducted forced air because it provides both heating and cooling. Many of those decisions were made without factoring in the differences in comfort between these competing distribution systems.

The inability of smaller hydronic systems to provide cooling is changing as the future of energy supply moves away from fossil fuels and toward electricity.

This transformation is taking place in the two largest global markets for hydronics: Asia and Europe. In Germany, a bastion of hydronics technology, incentives aimed at reducing fossil fuel usage have allowed electrically-powered heat pump sales to overtake boiler sales in each of the last three years. And in China, air-to-water heat pump sales now exceed two million units per year.

For decades the trends in hydronic heating in these markets, especially Europe, have influenced market trends in North America. Examples include PEX tubing, condensing boilers, panel radiators and high efficiency circulators. If history is an indicator, the North American hydronics market is likely to see a major

increase in the projects opting for heat pumps rather than fossil fuel boilers.

This transformation will bring the ability to provide chilled water cooling, and that’s a “big deal” in my opinion. It now allows hydronic heating pros to offer clients who increasingly look for cooling in new building construction, a solution that’s not a completely separate system, or one installed by a different contractor.

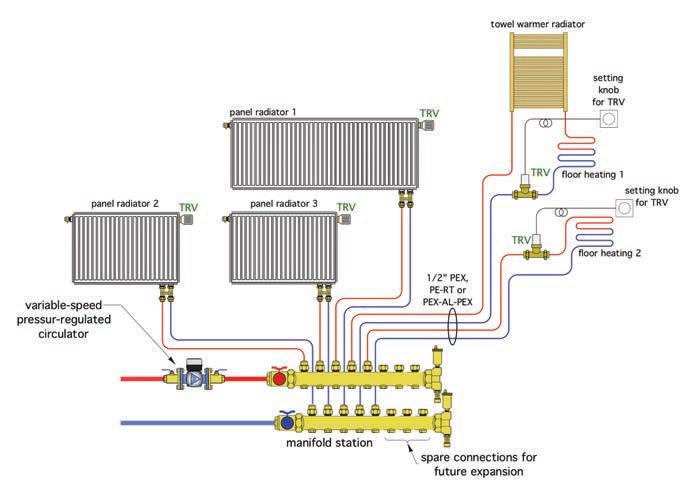

One approach that I like to promote is multiple heating zones in combination with single zone cooling. The heating distribution system could use the same type of heat emitter in all zones, or it could use a combination of emitters.

An example would be radiant floor, wall or ceiling heating in some areas combined with panel radiators in other areas. Ideally, all heat emitters would be sized for the same supply water temper-

ature. This keeps the system simple by eliminating the need for mixing.

Figure 1 shows a combination of heat emitters, all served by homerun circuits of ½-in. PEX, PE-RT or PEX-AL-PEX tubing from a common manifold station.

Flow to the manifold station is handled by a variable speed pressure-regulated circulator set for constant differential pressure. Each emitter is equipped with a non-electric thermostatic radiator valve. That valve is built into the panel radiators. The only thing needed to make each panel radiator into an independently controlled zone is to screw a thermostatic operator onto that valve.

The other two circuits show a combination of radiant panels and a towel warmer. Flow through these circuits is controlled by an external thermostatic valve equipped with a remote adjustment dial. That dial is typically mounted to a wall at normal thermostat height.

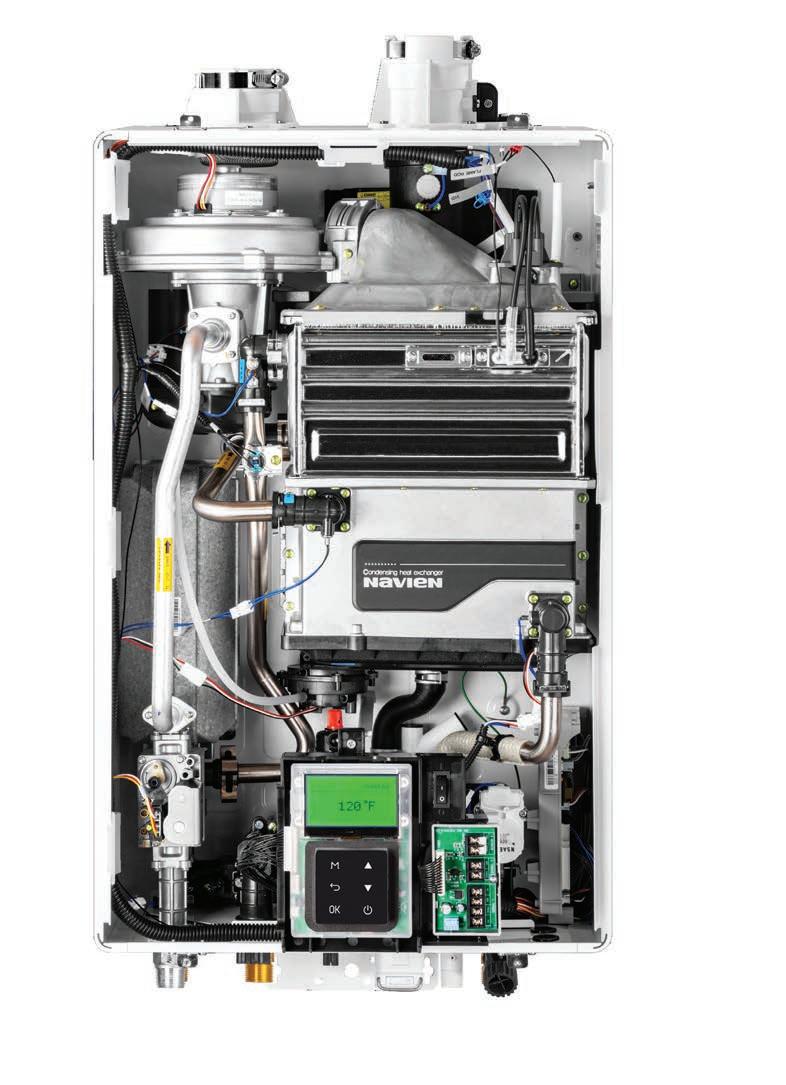

Durable dual stainless steel heat exchangers 2'' PVC up to 75 feet and 1/2'' gas up to 24 feet

Optional NaviCirc TM - easy to install with no recirc return loop needed

Continued from p12

This combination of thermostatic valves provides five independently controlled heating zones. As these valves open, close, or modulate flow, the variable speed circulator senses the “attempt” to change differential pressure, and immediately adjusts motor speed to cancel out that attempt. This allows the flow in each homerun circuit to remain stable regardless of what zones are active.

The manifold station is shown with extra connections. This allows future emitters to be added with relative ease. It’s a relatively inexpensive up-sell that most clients would accept and see as professional forethought on your part.

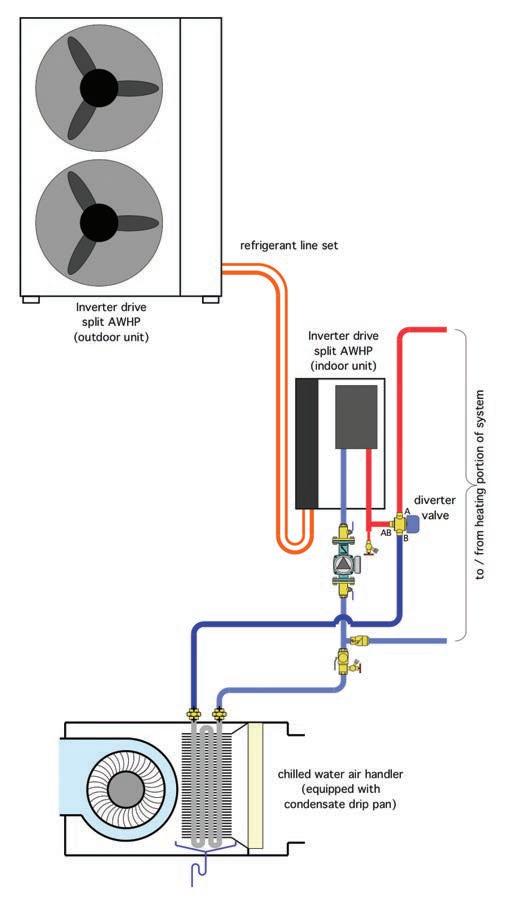

Now, Figure 2 shows a low ambient air-to-water heat pump as the sole source of heating (and cooling) energy.

The heat pump is equipped with a variable speed inverter drive compressor. This allows it to modulate both heat output and cooling capacity down to about 40% of peak rating. The compressor speed changes based on maintaining user-specified leaving water temperatures for heating mode and cooling mode operation.

In most systems this allows the heat pump to supply an air handler sized to the building’s cooling load without use of a buffer tank—provided the air handler’s capacity is not smaller than the minimum cooling capacity of the heat pump, and there is only one zone of cooling.

Since the heat pump is a “split system” there’s no need to protect the outdoor unit from freezing, and thus the system can operate with water rather than an antifreeze solution.

The diverter valve directs flow leaving the heat pump to the heating or cooling portion of the system. It should be configured with its normally-closed port, which is usually designated as “A,” supplying the heating portion of the system, leaving the normally open port, which is usually designated as “B,” to supply the cooling mode.

The “A” port should only open when the heat pump is operating in heating mode. This allows the diverter valve to prevent reverse thermosiphoning through what could otherwise be an unblocked piping path between the upper and lower portions of a buffer tank (to be discussed later). It eliminates the need for a check valve to prevent reverse thermosiphoning.

The air handler would supply a ducted distribution system. Since this portion of the overall system is for cooling, the ideal arrangement would put the outlet registers in the ceiling or high on the walls. This allows the cooled air to mix with room air without creating drafts.

In cold climates it’s best to install the air handler in conditioned space. This eliminates the possibility of freezing water in the air handler’s coil during winter. It also reduces the potential for energy-wasting convective air flow through the air handler

and ducting due to temperature stratification in the building.

If the air handler has to be mounted in unconditioned space some means of freeze protection is required. The possibilities include draining the coil during winter, using antifreeze in the system, building an insulated “dog house” enclosure around the air handler, or installing heat tracing cable and hoping that no long duration power outages occur.

I’m not a fan of any of these if they can be avoided.

Even small, residential air handlers can generate several gallons of condensate when operating on a humid day. Be sure to pipe up a condensate drain.

The final subsystem is a reverse indirect tank that provides buffering for the space heating zones, which typically have heat transfer requirements much smaller than the minimum

Continued on p16

Solstice - SIM

Inverter Monobloc

SIM-036 (3 ton)

Heating Capacity Range: 13,200 - 38,700 Btu/h*

Cooling Capacity Range: 1 - 3 tons*

COPs: up to 5.01*

*Using AHRI 550/590 Test Criteria

SIM-060 (5 ton)

Heating Capacity Range: 25,400 - 70,600 Btu/h*

Cooling Capacity Range: 1.5 - 5 tons*

COPs: up to 4.67*

*Using AHRI 550/590 Test Criteria

Standard Features

• Reliable Mitsubishi Inverter Compressor

• User Friendly Touch Screen Control

• Monobloc Design (No On-Site Refrigerant Charging)

• Low Ambient Cooling

• Freeze Protection

• Low Amp Draw with Ultra Quiet Operation

Solstice - Extreme Low Ambient Heat Pump

LAHP-48 (4 ton)

Heating Capacity: 64,500 Btu/h*

Cooling Capacity: 40,000 Btu/h*

COPs: up to 3.18*

*Using AHRI 550/590 Test Criteria

Standard Features

• Reliable EVI Copeland Compressor

• Simple Piping and Pumping with Easy Zoning

• Modulating Fans for Higher Efficiencies

• Monobloc Design (No On-Site Refrigerant Charging)

• Low Ambient Freeze Protection

Solstice - SIS Inverter Split System

SIS-060A4 (5 ton)

Heating Capacity Range: 20,500 - 71,500 Btu/h*

Cooling Capacity Range: 2.5 - 5.2 tons*

COPs: up to 3.09*

*Using AHRI 550/590 Test Criteria

Standard Features

• Reliable Panasonic EVI Inverter Compressor

• Simple Indoor Piping Similar to Wall Hung Boilers

• Designed for High Performance in all Temperature Ranges

• Extreme Low Ambient Heating Performance to -20°F

• SIS System Includes both Indoor and Outdoor Units

• Split Design Provides the Flexibility to Eliminate the Use of Glycol in the Hydronic Loop

heating capacity of the heat pump. (Figure 3.) The tank piping is configured around one currently available reverse indirect. It’s a “two-pipe” configuration, which allows for “direct-to-load” heat transfer at times when the heat pump is running at the same time there is a space heating load.

One shortcoming of a two-pipe tank configuration is that a portion of the flow returning from the space heating load can pass through the heat source when it is not operating. This reduces heat transfer from the tank to the load. It also increases extraneous heat loss to the mechanical room, and lowers the mixed water temperature supplied to the space heating load.

The latter occurs due to the two flow streams, one passing through the tank

and the other through the heat source, recombining upstream of the space heating circulator.

This can be prevented by ensuring that the “A” port of the diverter valve is only open when the heat pump is in heating mode.

During heating mode operation the temperature of the buffer tank is monitored by a setpoint controller. When the sensor at the midpoint of the tank drops to some minimum value the heat pump is turned on. This happens regardless of any demand for space heating.

The goal is to keep the water in the tank’s shell warm enough to provide on-demand domestic water heating whenever there’s a draw at a fixture.

Once turned on, the heat pump continues to operate until the tank sensor reaches some upper limit. That limit should be several degrees lower than the safety high limit setting programmed into the heat pump’s internal controller. This is where a tradeoff needs to be made. The lower the temperature at which the buffer tank is maintained, the higher the heat pump’s coefficient of performance (COP). However, for tank temperatures below about 115F, the domestic water will only be “preheated” rather than fully heated.

Preheated domestic water will require a temperature boost prior to use. That boost could come from an electric on-demand tankless heater or multiple smaller-capacity electric heaters located close to each fixture group.

It’s also possible to base the buffer tank temperature on outdoor reset control. The warmer the outdoor temperature the lower the buffer tank temperature. This keeps the water in the tank just hot enough to provide the building’s heating load, but a greater temperature boost is required for domestic water leaving the tank.

The “optimal” temperature control for the tank must factor in the energy used for both space heating and domestic hot water, the COP of the heat pump operating over a range of both water temperature and outdoor temperatures, and the cost of electricity used for direct resistance heating.

Based on simulations I developed it appears the best seasonal heat pump COPs are achieved when the buffer tank temperature is based on outdoor reset, with the “top off” energy to bring DHW to its final delivery temperature provided by electric resistance heat.

During cooling mode the heat pump monitors its leaving water temperature, and adjusts compressor speed to maintain a suitable setpoint, typically in the range of 45 to 50F.

To ensure DHW availability, the system would give priority to maintaining the temperature in the reverse indirect tank. When the tank needs heating, the heat pump temporarily switches from chilled water to heating mode.

The air handler blower can be kept on, as the time required to boost the temperature of the buffer tank during warm weather should be minimal because the heat pump is operating at high heating capacity. When the tank reaches its upper temperature the heat pump switches back to cooling.

Most heat pumps have a built-in time delay on compressor operation when switching modes, or when a signal attempts to restart the compressor right after it was turned off. This allows the

large differential pressure present across the compressor to dissipate prior to an attempted start.

I encourage you to “read up” on air-towater heat pumps. Their ability to provide cooling as well as heating and DHW is a viable and cost-effective solution to a question that’s been asked by many prospective clients desiring hydronic heating: “But what do I do about cooling?” Informed hydronic pros are now ready with an answer. <>

John Siegenthaler, P.E., is a licensed professional engineer and has more than 40 years experience in designing modern hydronic heating systems. His latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

Follow these steps to maintain the optimal performance of your residential clients’ cooling equipment. BY IAN

McTEER

As another cooling season begins, I’m thinking back to the late 1980’s when I worked for an HVAC contracting firm as an installer and service technician. The company expected me to identify and sell new systems whenever appropriate. I did manage to sell several new cooling systems despite my limited sales skills, but more often potential customers dismissed my central cooling arguments as nothing more than an unnecessary expense: “It’s only hot for a few days, so we’ll use a fan and keep the windows open,” was a typical objection.

Times have changed. More than 30 years later, it is hard to find a house without central cooling in southern Ontario and many other locations across Canada. Canadian summers, although short, are often ridiculously hot and humid. If

you look at a chart of cooling load hours as published in ACCA Manual J, Torontonians endure a mere 700 cooling load hours compared to Miami, with over 7,700 cooling load hours.

Interestingly, Miami’s summer outside design dry bulb temperature is only 2F higher than Toronto’s (89F compared to 87F) and only a 5F higher wet bulb temperature (77F versus 72F). But therein lies a big problem for HVAC service technicians: early season start-up often means attempting to verify proper cooling system operation when the cooling unit may be completely unloaded.

While residential cooling systems installed in Miami run under load almost 90% of the time, identical equipment installed in Toronto may run in cooling mode less than 10% of the time.

Therefore, given the brevity of our

cooling season combined with unsuitable weather conditions often prevalent at start-up, technicians may have to rely on service history, accumulated data and minimum environmental conditions to be sure a given unit will cool effectively and efficiently all summer.

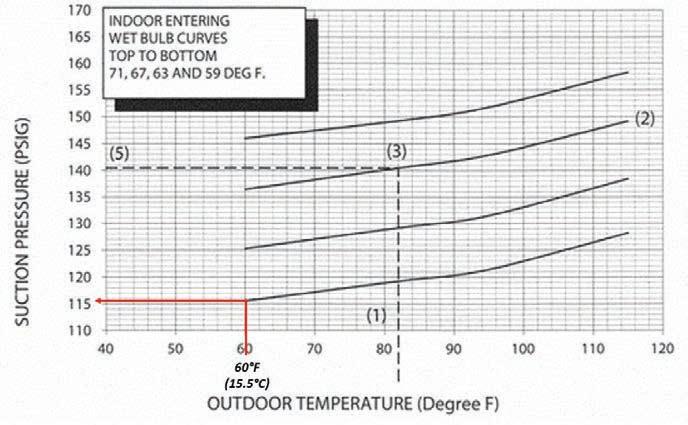

Figure 1 (below) is a manufacturer’s chart indicating 60F dry bulb outdoor air temperature entering the condenser and 59F wet bulb air entering the evaporator are the min. operating conditions.

On a chilly spring day, the refrigeration system may not respond as expected (in this case 116 psig suction pressure) indicating the system may not be ready for a July heatwave. Without sufficient load on the evaporator, too many technicians are liable to alter the refrigerant charge or to replace system components thought to be problematic when the real issue is simply no load.

Soon service vans will be loaded with replacement filters, refrigerant, coil cleaner and replacement parts such as run capacitors, contactors and motors.

Residential HVAC service departments will have a baseload of equipment service histories and commissioning data related to their own installations. Technicians should familiarize themselves with all collected data including any notes from previous service calls before venturing forth.

Amid the enormous variety of installed equipment in the field, technicians must understand the individual manufacturer’s instructions for determining proper performance especially under minimal load conditions.

Contractors selling maintenance plans as a component part of a new installation have the best opportunity to ready an HVAC system for the rigors ahead. Many a service contractor will altruistically adopt orphaned equipment often consisting of a sub-par in -

system deficiencies like poor heat distribution that may or may not fit the spring tune-up protocols of clean, inspect and test.

If cleaning a blocked evaporator coil has little effect on improving air flow to the master bedroom, then another service call should be scheduled to investigate that common problem.

After the customer interview, check for a communicating or smart thermostat controlling the system. Look for stored faults or alert codes especially reoccurring faults such as flame failure, open limits and communication errors. How were past issues resolved and why have one or more reoccurred?

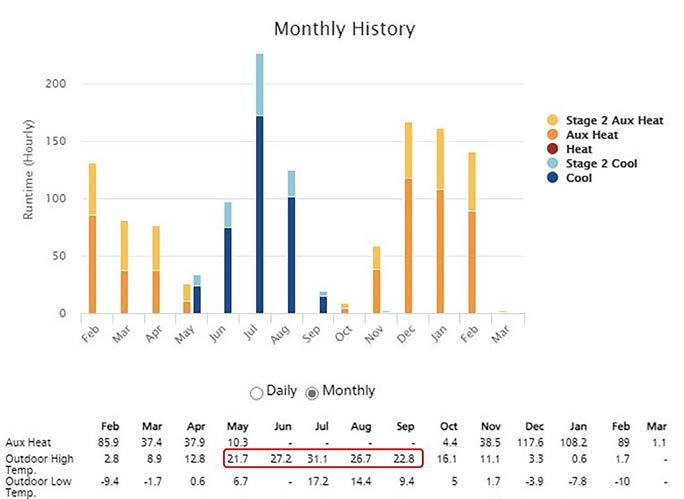

Such faults provide clues as to what maintenance is required. See if the thermostat has a monthly record of operating hours; plenty of clues to be found there. In Figure 2, a graphical display of my HVAC needs is presented for the year 2019. In my case, during the summer I keep the room at 75F (24C) although the system will operate in dehumidification mode when the RH exceeds 55%.

Notice that I used a total of 34 hours of cooling capacity (mostly first stage) in the month of May, while the heat and humidity of July caused the system to run a total of 227 hours, just 54.4 hours in second stage. To my point, the system ran a total of 504 hours in 2019, or roughly 6% of the time.

stallation combined with little or no maintenance creating an entirely different start-up experience for a consumer not used to HVAC repair bills.

A residential start-up routine should have several moving parts: a conference with the end-user, a visual inspection of the entire system, cleaning

components and replacing consumable items, then testing and data collection.

Data collected from an end-user interview consists of asking questions related to unusual occurrences such as different noises, problems during the heating season, odours or water leaks. The homeowner might reveal severe

Disconnect power to the air handler then visually inspect the unit looking for signs of refrigerant leaks, water leaks, loose wiring, blower wheel condition, and evaporator coil cleanliness. Be sure DIP switches, interface settings, and motor wiring taps are set-up correctly to coincide with outdoor unit capacity or the AHRI certified rating.

During the air handler inspection, the test of any maintenance contract might come to the bare coverage as

Continued on p20

the time and materials needed to thoroughly clean an evaporator coil, blower wheel, secondary heat exchanger, drain assembly and to verify settings could easily run into several hours, not normally part of the contract.

Depending on the manufacturer, there might be numerous settings to verify when servicing an orphaned unit with no service history (see Figure 3, previous page). As the images in Figure 4a and 4b show, (also previous page) evaporator coils must be inspected and cleaned where possible.

The condensate drainage system must be ready to handle condensate (Figure 5, above). Some drains are too small or use non-standard components. Blow out the drain lines, clean condensate pumps and test operation. Always inspect the blower wheel in conventional air handlers and mini

splits (Figure 6, below). The indoor head may have to be removed for cleaning, or the coil may be cleaned in place if the blower wheel is clean. Be sure to clean or supply a new air filter.

Some indoor tune-ups could turn into overhaul or system replacement situations. Apprise the customer and leave a quote for additional services.

Once the myriad of vital components has been inspected, settings verified and necessary cleaning completed, reapply power. Observe the furnace control board for any flashing fault codes. Older boards will not remember faults: check for codes before deenergizing.

Some units have a user interface containing stored faults, recover and analyze data concerning faults. Check for voltage at the control board Line H and Line N connections as well as low voltage transformer output.

Put the indoor unit into operation in a test mode (if available) or “fan on” mode listening for anything unusual. Verify voltage at the board and test the fan motor amperage. Be sure to record this data.

With all power sources disconnected from the outdoor unit, begin inspection of key components including the outdoor coil, refrigerant line set, signs of refrigerant leaks, electrical connections, condenser fan motor and blade, and cabinet integrity. Clean outdoor units of rodent nests and bug intrusions. Consider offering a contactor upgrade such as Emerson’s Sure Switch (Figure 7, next page) featuring totally enclosed contacts providing brownout and short cycle protection.

Visually inspect components such as capacitors and look for copper tube rubs, pinched wires and high voltage connections If the compressor has a starting capacitor, inspect all electrical connections and capacitor integrity. If any starting components must be replaced, use only manufacturer approved components.

All electrical connections, low and

high voltage, indoor and out must be inspected for damage, overheating, and tight connection. Low voltage spade connections are often overlooked. Remember to check inside the outdoor disconnect box for debris, corrosion and loose connections, critter infestations, etc.

Once the clean and check is complete, restore power and start the system to operate at 100% capacity, use thermostat test mode if so equipped. Allow the system to operate for a minimum of 15 minutes at the appropriate test load parameters before taking system data.

The following information is the minimum requirement to establish a yearover-year performance history:

• Temperature of the air entering the indoor coil: dry bulb and wet bulb.

• Temperature of the air leaving the indoor coil: dry bulb and wet bulb.

• Temperature of the air entering the outdoor coil: dry bulb.

• Suction Pressure.

• Suction Line Temperature.

• Head Pressure.

• Liquid Line Temperature.

• Discharge Line Temperature.

• No Load Volts.

• Full Load Volts.

• Full Load Amps.

• Lock Rotor Amps.

• Crankcase Heater operation, if equipped.

Note: premium units, typically featuring inverter drive compressors, have on-board or other methods of displaying much of the above data; it should be downloaded and archived.

Using this collected performance data, a technician can make objective judgements as to the system’s capabilities during the cooling season ahead.

So far, I have not mentioned airflow, the most important parameter of all.

When analyzing entering and leaving wet bulb data, total Btu/h of the system can be determined to a reasonable degree of accuracy provided the actual system airflow is known—guessing or pluggingin nominal values is not allowed! Do a temperature rise test, or measure air pressure drop across the air filter or evaporator coil provided the numbers obtained coincide with the chart provided by the device manufacturer. Once an accurate measure of airflow has been recorded, use the following formula to determine system Btu/h: for this example, a cooling unit with a nominal AHRI rated cooling capacity 23,850 Btu/h is being evaluated (Figure 8).

Btu/h

Suppose an entering wet bulb is 56F and the leaving wet bulb is 45F. Use a psychometric chart to convert 56F Wb to 23.85 Btu/pound of air and 45F Wb to 17.69 Btu/pound. Airflow is measured at exactly 800 cfm. How does this measured value compare with the manufacturer’s chart for system performance at a given outdoor temperature? Is the value close enough?

Assuming, at seasonal start-up, the collected values mirror a manufacturer’s performance data chart and industry standards, this information should be recorded on a copy of the job ticket and left with the equipment; the HVAC system also owns this data, in my view. Whether a residential service call entails simple maintenance, or an unfortunate breakdown, or leads to a potential system replacement opportunity, having reliable performance data included in the service history eliminates vexatious guesswork and assumptions leading to faster, more accurate customer service. <>

Ian McTeer is an HVAC consultant with 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

Introducing the Infinite Comfort Series. Now, offer your customers ultra-efficient, multi-position air handling units from Fujitsu General.

• Revolutionary side discharge outdoor condensing units are highly efficient and save space allowing for multiple installation options

• Quiet operation - indoor as low as 25dBA and outdoor as low as 53dBA

• Units range in size from 24,000 to 48,000 BTU/H

• Adaptive fan motor speed control assures optimum comfort

• Longer line length - 160ʹ (24k & 30k BTU/H) and 230ʹ (36k & 48k BTU/H)

• Excellent energy ratings (19 SEER and >10 HSPF) equal big utility rebates For more information, please visit www.FujitsuGeneral.com

The third episode of 30 Mechanical Minutes features a discussion on HVAC maintenance calls in 2021 with HPAC ’s Ian McTeer and Gary McCreadie from HVAC Know It All.

On Wednesday, April 7th HPAC Magazine hosted its third free 30 Mechanical Minutes educational webinar, this edition focusing on HVAC maintenance calls for the upcoming cooling season.

Entitled, ‘Spring Start-ups in a COVID World,’ the live webinar session was sponsored by Navac. Hosted by HPAC editor, Doug Picklyk, the webinar featured regular HPAC contributor Ian McTeer and Gary McCreadie from HVAC Know It All.

The discussion opened with a focus on best practices when kicking off a Springtime HVAC maintenance call in 2021. “Having never experienced being in the service industry under such conditions as COVID-19, I can understand it must be very challenging for technicians in the field,” acknowledged McTeer. “I always thought the very first thing the technician needs to do is to talk to the homeowner find out how the system's been working—were there funny noises, unusual odours or failures during the heating season? Because some heating issues can lead to cooling problems. One of the oldest rules of thumb: if you can’t heat a building you’ll never cool it.”

He also says that new smart thermostats should be your next stop. “Go into

Ian McTeer shared images of data collection examples possible with new smart thermostats and connected appliances

the information section and see if you can find anything on cycle rates, alerts, or any type of codes that haven been generated. Make note of those and essentially you’re off and running.”

While many A/C service technicians often want to start with the outdoor units, McTeer believes that’s a mistake, because any measurements you get outside could be skewed if the indoor system is not working properly. So he says, “Go find the air handler first.”

McCreadie addressed the Spring maintenance call from a commercial technician’s perspective. “Customer communication is number one as far as I'm concerned, because the customer knows their equipment, not always the best, but they know when odd things are happening.”

He starts a maintenance call with his senses, looking at filters, coils, fan blades and contactors. “I always like to start without any tools in my hand, just

having a visual of the unit.”

Next comes verifying power, making sure the line voltage into the machine is correct and making sure that control voltage is correct. “Then you need to know if the blower is working, because without proper airflow the A/C side of things is not is not going to work properly.”

The talk then moved to the topic of the pandemic, indoor air quality, and how technicians can address these issues with homeowners and facility managers.

“In my estimation, the main job of the filter is to help to keep the equipment clean,” says McTeer. He’s heard people urging MERV 13 filtration, but in his opinion that is too restrictive for the average residential HVAC system.

“I think a good solution for a homeowner who insists on better filtration would be to go with a bypass HEPA system,” said McTeer. He also mentioned

HPAC Magazine’s HVAC specialist, Ian McTeer, is an HVAC consultant and retired field service representative with over 35 years of experience in the industry. He was a field rep for Trane Canada and is a refrigeration mechanic and Class 1 Gas technician. He resides in eastern Ontario.

Gary McCreadie is a Toronto-area licensed refrigeration and gas technician and an online sensation with a very active social media presence—bringing both education and entertainment to the HVAC industry. Starting on Facebook, McCreadie now has a massive following on all social media channels (Twitter, Instagram, Facebook, YouTube) as the HVAC Know it All. He also has his own website, App and a regular podcast. hvacknowitall.com

other solutions such as bipolar ionization devices and UV-C lights, but there are concerns with the effectiveness of all these options.

“I haven’t had any customers reach out and ask about air

purification devices,” says McCreadie. “They are very polarizing in the industry at the moment, and as Ian was mentioning, there’s some industry people that that are looking down upon them at the moment.

“The three main factors of indoor air quality are humidity, ventilation and filtration, and if you can deal with all three things you could probably get away with having good air quality in your home or building.”

He agrees that MERV 13 isn’t something you can just install and walk away. “You need to take a baseline and see if there are any changes to the system.” He described a recent job in a server room where he did a baseline with a MERV 8, then put the MERV 13 in and did some readings. “There was a bit of an air loss but not enough that I was scared to let it stay in the system. We’ll go back in two to three months when it’s loaded to take another reading. If it can’t survive the resistance of that filter then we’re going to have to think about doing something else—stepping up the airflow or going back to the MERV 8.”

As for indoor air quality ventilation, McCreadie noticed a “big difference” in his own home’s air quality with an HRV running. “I think more commercial buildings should start implementing HRV/ERVs as well, because I think it’ll really help with air quality.”

Continued on p26

For McCreadie, items like pulleys (or sheaves) and bearings on a blower system can often get overlooked on a maintenance call. “If the pulleys start to wear the belts are going to start to sit deeper and become worn faster.” He also checks the shafts of blower wheels and motors, moving them back and forth and making sure there’s no play, because if the fan doesn’t run nothing else works properly

For McTeer, it’s the technicians who service all makes and models that have a tougher time and are more likely to miss things. “I think what often gets overlooked is technicians take some data, but they don’t necessarily compare it with the manufacturer’s data for expected performance under the conditions that they’ve measured on that particular day. And the other thing that gets

missed is that data just doesn’t get recorded or left behind so other technicians can use it in the future.”

“If the pulleys start to wear, the belts are going to start to sit deeper and become worn faster.”

A lot of the buildings McCreadie takes care of have building automation systems, and he finds the trend logs include very valuable information. “I’ve used these trend logs to actually troubleshoot an issue and then go to the machine and just verify that my diagnosis was correct.”

And on the residential side, more ap -

pliances have the ability to communicate data, and some newer units have pressure transducers in them now so you don't even need to hook up gauges anymore, you can just read a DC voltage off a control board, notes McTeer. “I really like that stuff, but I think most of the appliances in the market are not there yet.”

McTeer and McCreadie also answered listener questions on filters for ductless mini splits, crank case heater alternatives, duct cleaning and preparing a compressor to move it.

To view the entire recorded webinar visit hpacmag.com/tech-pulse. <>

You’re in an unpredictable business, but the quality of the pumps you install shouldn’t be. Generations of plumbers and HVAC professionals have trusted our hard-working, reliable pumps to get the job done right the first time. Make a Big Impact on your next job with Little Giant.

“You can pay me a little bit today … or you can pay me a lot more later on.”

As funny as that statement might sound, this was a common phrase amongst the technicians I worked with, and it was representative of that faction of equipment owners who never wanted to invest in a preventative maintenance program.

I would liken that sentiment to the owner of an expensive car who refuses to have his/her car serviced on a regular basis. Sure, if the car isn’t abused, you might cheat the odds and go for a few years without a serious breakdown. But mechanical parts and devices all share a common fate—they wear, and they will fail at some point in time. That point comes sooner with a lack of maintenance.

In most climates the typical air conditioning system will be idle for some portion of the year. This is not to suggest an idle system will be subject to some type of failure before the weather warms up, but performing a spring equipment check will ensure that when the heat arrives, the system is working properly.

There are several items that should be included in the typical preventative maintenance checklist:

• Extra resistance in electrical connections or points of contact can lead to excessive voltage drop, which can cause voltage drop, overheated wiring/melted insulation, occasional

fires, and ultimately motor failures. All electrical connections should be checked for tightness, and motor contactor contacts should be inspected to verify that they’re not excessively burned/pitted. If so, the contactor should be replaced.

• Motors outfitted with sealed bearings do not require field lubrication. Motors not utilizing sealed bearings should be lubricated periodically, in accordance with the manufacturer’s recommendations.

• Technicians cannot assume that homeowners, or building owners, are replacing air filters on a regular basis. These should be checked, and replaced if necessary.

• Check thermostat setting and calibration.

• Inspect condensate drain, and drain pan. Verify that drain is clear, that drain pan is clean, and treat with algaecide.

• Inspect ducting for air leaks, and repair as necessary.

• Start system, check operating pressures, compressor amperage, condenser and evaporator fan motor amperage.

In addition to the above-mentioned checks, there are two additional checks which can have a huge impact on system efficiency, performance, system energy consumption and equipment longevity.

As has been stressed in this column over the years, the purpose of the vapour-compression refrigeration cycle is to transfer heat from the refrigerated (or conditioned) space to the refrigerant, and eventually to some location outside of the refrigerated (conditioned) space. The two heat transfer surfaces which facilitate that process are:

1. Evaporator, which allows the heat content of the air in the space to be transferred to the saturated refrigerant flowing through the evaporator tubes, and

2. Condenser, which allows the heat absorbed in the space (plus the heat added during the compression process) to be rejected outside the space.

It goes without saying that the proper selection of equipment and components is essential to provide the design temperature in the refrigerated (conditioned) space. It should also go without saying that the two heat transfer surfaces need to operate at peak efficiency to maintain the design temperature in the refrigerated (conditioned) space.

The number one killer of evaporator and condenser capacity and efficiency

is dirt, debris or anything else that would inhibit airflow through the fin-tube construction of both the evaporator and condenser.

A study by the U.S. EPA (Environmental Protection Agency) some years ago found that a relatively small film of dirt (0.042-in. thick) on a heat transfer surface resulted in a 21% loss in heat transfer efficiency.

This condition has to be one of the easiest to detect. All it requires is visual inspection. Cleaning a heat transfer surface is relatively easy as well. A brush to remove the larger film, chemicals that aid in the cleaning process, CO2 to blow the debris out of the fins, or for larger outdoor condensers a garden hose.

Now, if this is one of those equipment owners that doesn’t want to pay for the maintenance, here are the potential issues:

Dirty Evaporator:

• The dirt and debris blocks the air flow path, which results in a reduction in air flow through the fin-tube bundle. Since the ability to transfer heat from the air to the refrigerant flowing through the evaporator tubes is proportional to air flow, the air flow reduction results in a reduction in heat transfer. The evaporator is no longer capable of removing the heat necessary to maintain the desired temperature in the space. The equipment will undoubtedly operate for longer periods of time, resulting in higher power consumption (and higher electric bills). If the equipment has greater capacity than the design load, the space temperature will likely still be maintained. If the equipment is marginally sized to begin with, it’s doubtful the space temperature will be maintained at the desired level.

• The thermostatic expansion valve (TEV) will vary the refrigerant mass flow entering the evaporator in response to the superheat condition at the outlet of the evaporator. TEVs have the ability to throttle down during lower load conditions, but there is a limit to how far they can throttle down and still maintain a superheated condition at the evaporator outlet. If the air restriction is severe enough, causing a severe reduction in load, the TEV could reach a point where it’s incapable of maintaining a superheated condition at the evaporator outlet. This can result in some amount of liquid refrigerant flowing to the compressor inlet, causing damage to the compressor.

• As mentioned above, the reduced load condition will cause the TEV to throttle closed in an effort to maintain the superheat setpoint. This results in a reduced refrigerant mass flow. If the evaporator is located below the compressor, a minimum refrigerant suction vapour velocity is required to bring the oil back to the compressor. As the TEV

throttles closed, the reduction in mass flow will result in a lower suction vapor velocity. At some point, the velocity may reduce to the point where the oil is no longer able to return to the compressor. Smaller condensing units with hermetic or scroll compressors are not equipped with a safety switch that will turn the compressor off during a low oil level condition. Again, there is potential for compressor damage/failure.

• A similar reduction in air flow through the condenser fin-tube

bundle reduces the condenser capacity. The result is a system that operates at an elevated condensing pressure. This increases the compression ratio, which reduces compressor capacity. Viewing the Btu capacity of a Copeland M/N 2DA3075E-TFD at varying condensing temperatures illustrates this:

40F SST and 90F SCT 120,000 Btu

40F SST and 100F SCT 113,000 Btu

40F SST and 110F SCT 104,000 Btu

40F SST and 120F SCT 97,000 Btu

40F SST and 130F SCT 90,000 Btu

• Elevated operating temperature from reduced compressor capacity will affect the oils’ ability to properly lubricate. Between 310F-330F mineral oil will lose the lubrication film between piston rings and the piston cylinder, resulting in ring wear. In addition, the higher compression ratio exerts a greater force on the piston wrist pin bearing and connecting rod bearings. Extended periods of operation under this condition will reduce compressor life.

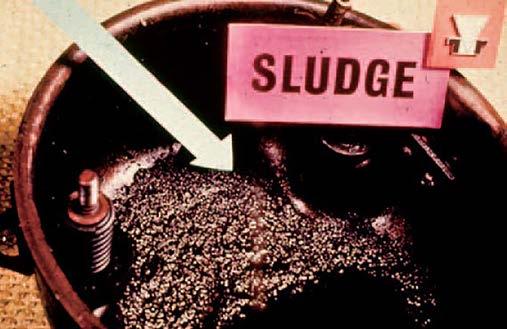

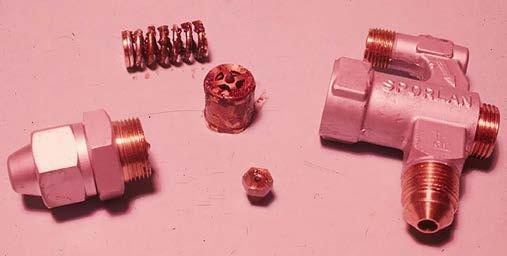

• Compressor oils will begin decomposing at elevated temperatures (350F for mineral oil, and 400F for POE). As the temperatures for mineral oil and POE rise above their respective decomposition thresholds, the oil will begin to polymerize; a process which results in the oil molecules combining into larger and larger molecules. The oil is first transformed into a dark thick oil, then a sludge, and finally a solid powder. Not only does this reduce the lubricating ability of the oil, it also has the potential to plug up strainers, filterdriers, smaller orifices in control valves, lubrication ports in the compressor, all with destructive and costly results.

Now, the next time your customer tells you that they just can’t afford to have you perform any preventative maintenance on their equipment, you can

confidently rehearse why he/she absolutely cannot afford to forego maintaining their equipment. But, in the event that your powers of persuasion are insufficient to change their mind, remem -

ber the phrase: “You can pay me a little bit today, or you can pay me a lot more later on,” with the added caveat, “But please remember that I tried to warn you.” <>

Dave Demma holds a degree in refrigeration engineering and worked as a journeyman refrigeration technician before moving into the manufacturing sector where he regularly trains contractor and engineering groups. He can be reached at ddemma@uri.com.

Recent compressor technology innovations are driving sustainability benefits for heat pumps in large-scale operations.

BY DREW TURNER

Many organizations are working to identify ways to reduce their dependence on carbonrich fossil fuels. Their goal: to reduce their emissions of the greenhouse gases implicated in climate change, while, hopefully, also decreasing their energy costs and bolstering their organizational reputation.

For many organizations, heat production is their largest application of energy, space heating for buildings being among the largest components of that output, so efforts to reduce carbon emissions has recently led organizations to consider replacing fossil-fuel fired furnaces and boilers with electricdriven options.

Electric heat pumps most commonly consist of equipment based upon constant speed positive displacement screw compressor technology, and while efficient, often offer an ROI payback period that is somewhat longer than many organizations require to justify investment. Further, the more efficient heat pump technologies, based on operating temperature limitations, have previously required changing out demand-side equipment to enable operation at significantly lower heating temperatures.

There is a new compressor technology emerging specifically geared for heat pump applications that enables gains in efficiency while eliminating many of the limitations. These oil-free magnetic bearing centrifugal compressors are currently involved in test projects and modeling suggests that when

used in electric heat pump applications can provide up to 40% greater energy efficiency compared to constant speed positive displacement screw compressor-based heat pumps. When compared to variable speed positive displacement screw compressors—a more efficient heat pump technology— modeling suggests that a 10-15% reduction in energy costs can be realized.

These comparative improvements can increase over time because oilfree, magnetic bearing centrifugal compressors maintain performance over the long term, whereas positive displacement screw compressor-based heat pumps can degrade as much as 10% in the first five years and 20% within the first 10, driven by a combination of the mechanical degradation of the sealing process as well as oil-driven heat transfer degradation.

In short, this is an innovation that will be of interest to heat pump designers,

manufacturers, energy management consultants, and any commercial or industrial facility interested in decreasing its carbon footprint, increasing energy efficiency and reducing heating costs.

And oil-free magnetic bearing centrifugal compressors are not an unknown technology. They borrow foundational elements from well-proven technology in air-conditioning / chilling / cooling applications.

The heart of most electric temperature conditioning equipment—both heating and cooling—is the compressor.

Several types of compressors are used in HVAC applications, all fitting in the categories of either positive displacement or dynamic (centrifugal or axial) technology. In positive displacement versions energy is used to generate pressure and the refrigerant is squeezed to add energy to it. In the centrifugal/dynamic versions, refrigerant is thrown, increasing kinetic energy. The latter is frequently more efficient, driven by the inherent advantages of dynamic compression and the aerodynamic design optimized to the targeted temperatures.

Further, due in part to the kinetic forces in a centrifugal/dynamic compressor, it is possible to move a higher volume of low-pressure refrigerants. These as a rule have lower global warming potential (GWP), while at the same time they also have a limited flammability risk.

One choice to be made in designing a compressor is whether to specify oil-lubricated or oil-free bearings. As suggested, in oil-bearing versions some amount of oil will leak into other areas of the system over time. This oil becomes held up in the heat exchangers, from which it has to be returned to the compressors. Inevitably, and more frequently today with heat exchanger tube enhancements, some of this oil becomes entrained in the enhancements and degrades tube heat transfer performance, resulting in a drain on capacity and energy efficiency.

Additionally, with screw compressors there is mechanical degradation of the compression sealing process that occurs due to the metal-to-metal contact, which can erode the clearances, allowing high-to-low pressure leakage and creating further capacity and efficiency degradation.

Heat pump designs mainly follow one of three setups: air-toair, air-to-water, and water-to-water. Air-to-air and air-to-water heat pumps extract heat from ambient air, because they extract heat from what can be very low temperature ambient air they may offer lower efficiency and capacity.

A water-to-water heat pump would generate greater benefits as operating temperature limitations at the lowest ambient conditions are no longer a concern. The setup logistics of a water-to-water heat pump, however, can be more ambitious and require a larger upfront investment.

Operating water-to-water heat pumps at a central location and piping the thermal energy to a series of buildings in a “district heating” model could provide the greatest immediate benefits. While district heating is more common today on university, hospital, and corporate campuses where related buildings are in close proximity, the use of this technology— with its high efficiency and scalability—can be considered the “holy grail” for all those who truly desire to minimize their carbon footprint and energy usage.

Operators seeking to reduce their carbon footprint and lower operating costs are looking at their heating strategies. The advent of new generation compressors in electric heat pumps may be a game changer. As these compressors continue to generate results in commercial demonstrations, the time is ripe for early adapters to consider the possibilities. <>

This article was adapted from the white paper, “The growing role of electric heat pump technology in reducing emissions, minimizing carbon footprint, and decreasing energy costs in commercial heating applications”. Drew Turner is the global marketing manager – oil-free solutions with Danfoss. He can be reached at drew.turner@danfoss.com.

Daikin Industries has added a new vertical configuration to its PreciseLine air handlers, which are designed to improve indoor air quality. The new vertical configuration gives engineers and contractors additional flexibility. Systems can be equipped with MERV 13 filters, capturing particles as small as 0.3 to 1 micron. Direct-drive fan technology eliminates the possibility of rubber particles from entering the airstream. www.daikinapplied.com/products/air-handlers/preciseline

The Danfoss Universal TR6 Expansion Valve Kit, designed for aftermarket use, comes packaged with everything needed for installation. The valve adapts to 90% of HVAC systems. The kit is available in seven models that cover OEM air conditioner and heat pump designs, from 1.5 to six tons in systems that employ either R-22 or R-410A. With two kits available, service technicians will be prepared for nearly any job that requires a TXV.

www.danfoss.com/tr6

Fujitsu General America has released singlephase J-IV and J-IVs Airstage VRF heat pump systems offering heating capacity at an outdoor ambient temperature of -15F. The J-IVs offers efficiency levels up to 19.7 SEER, while the J-IV offers up to 19.8. New enhancements include the ability to reduce electrical circuit breaker sizes, base pan heaters, and durable metal fan guards. fujitsugeneral.com

YORK Sun Premier commercial HVAC rooftop units are now available in 25-80 tons capacity with faster installation and simplified start-up. The units feature start-up wizards, a 5.5-in. OLED display and numeric keypad that can be upgraded to a full-colour touchscreen. A RTU Toolkit app provides access to unit-specific information and technical support by scanning the unit’s QR code. Options include various airflow path configurations, IEQ options such as UV lights, and modulating options. Remote monitoring allows technicians to interface with units without getting out of the truck. www.york.com/sunpremier

Green Link Engineering’s MetalHead is strong and durable support system for pipes and other rooftop equipment. The aluminum extrusion design with a triangular base, topped with a built-in strut channel can connect with standard strut hardware can be used for securing large pieces of mechanical equipment. MetalHead is engineered with 100 mil aluminum sidewalls with a hard-anodized surface, allowing the base to withstand a 10,000-lb. vertical compression over a 47 sq. in. footprint.

greenlinkengineering.com

Automated Logic released its latest OptiFlex BACnet building controllers for the WebCTRL building automation system (BAS). Both models include Ethernet, serial, and USB ports for easy network connectivity. The controllers Include on-board input/output (I/O) points for HVAC equipment such as rooftop units, fan coil units, chilled beams, exhaust fans, unit vents, air curtains and variable air volume (VAV) boxes.

www.automatedlogic.com

• Industry Best Domestic Hot Water Delivery from a Combi Floor Boiler:

First minute delivery of 6+ gpm at a 70˚ rise Continuous delivery of 5.2 gpm at a 70˚ rise

• Industry Only Smart Heating Technology. The FT Series combi boiler with smart technology will supply abundant space heating while simultaneously supplying endless domestic hot water.

• FAST Hot Water Delivery. Combi boiler features a unique, integrated domestic hot water mini-indirect tank that contains up to one gallon of stored hot water for immediate response.

• Easy Installation. Built-in low loss header, front and side access panels, flexible venting options, top connections and fits into tight spaces.

• Ultra-High 95% AFUE Efficiency. The FT Series’ modulates with a 10:1 turndown for additional savings.

NAVAC is now offering a smart refrigerant charger that features a digital manifold gauge and a precision wireless electronic scale. The digital manifold gauge features pressure and temperature displays as well as calculated super-heat and sub-cooling data. Features such as a brushless DC-driven vacuum pump and wireless temperature probes round out the NRC62D’s multifaceted capabilities. navacglobal.com

EVAPCO added new resources for engineers, specifiers and facility managers, as the company’s Building Information Modelling (BIM) files now allow for greater planning in the life cycle of buildings. The new 3D models include a full spectrum of products from evaporative to dry cooling towers, closed-circuit coolers and evaporative condensers. EVAPCO’s files include platforms, ladders, super-low sound fans, connection locations, airflow clearance requirements, and an easier toggle format. www.evapco.com/resources

Westinghouse has added a new single zone 36,000 Btu/h wall mounted model to its line of mini-split heat pump systems. Like the other models in its line-up, the 36,000 Btu/h model includes a variety of features typical in high-end models, including a base pan heater, wireless remote control, front LED display and five indoor fan speeds. www.WestinghouseAC-USA.com

Baltimore Aircoil Company introduced the HXV Hybrid Cooler for evaporative and dry cooling applications. The unit delivers cooling while maximizing water savings. Maintenance access to the cold water basin, prime surface coil, and the fan drive system, and operators can inspect the spray distribution system while the unit is in operation. Also includes uninterrupted operation with multiple fans, optional redundant pumps and a variety of operating modes. Dry coil provides natural plume abatement when running wet. www.baltimoreaircoil.com

Mestek Boiler Group introduced an inverter driven air-towater heat pump for commercial applications. Sold under the RBI and Advanced Thermal Hydronic brands, the new heat pump delivers both heating and cooling capacities. Benefits include low ambient performance (-20F), user friendly touch-screen controls, inverter compressors and C-fin heat exchangers and built-in redundancy. www.mestek.com

Two larger refrigerant branch units are now available from Fujitsu to simplify installations and expand the heat recovery capability of VR-II series Airstage VRF systems. The new units manage simultaneous heating and cooling in heat recovery systems and can serve between eight and 12 zones. The units offer flexible piping options, and their compact size means they can be accommodated in a variety of floor plans, elevations and design changes. They require no drain pan. fujitsugeneral.com

Market segment offers general contractors and subtrades opportunities for growth and a new, collaborative approach. BY DAVID

It is still relatively early days for Canada’s smart building market. Most projects continue to take the conventional route, employing HVAC, electrical, lighting, security and other such systems in their separate silos. But early adopters have begun to look at buildings not as a jumble of interdependent systems, but as the system as a whole, capable of integrating subsystems to improve energy use, guide automation and optimize the wide array of connected components.

Smart building discussions have been ongoing in the construction industry for at least 20 years, according to Sam Boyajian, vice-president of integrated building technology at Modern Niagara. For 15 of those 20, however, it was little more than talk, with owners not typically ready to take the plunge, he said during a panel discussion with three industry experts hosted by On-

KENNEDY

Site, HPAC and Electrical Business magazines this March.

“Now,” he says, “I would argue that the owners and the developers have sort of leapfrogged the engineering community, and now they’re starting to pull the rest of us along because now they’re demanding it.”

“We’re at a bit of an inflection point,” Boyajian adds.

In Canada, governments building hospitals have been among the first movers, partly because smart building systems offer the most discernible benefits to larger facilities.

Certain forward-looking private owners are also beginning to embrace smart buildings, Colin Flock, vice-president of operations for EllisDon’s facilities services division, says. More are expected to follow as early adopters quantify the energy savings and other benefits offered by their smart buildings.

“In the next 10 years, it’ll just be a different landscape, Flock says.

Erica Brabon, the director of energy and sustainability for the facility services division at Black & McDonald also expects adoption in the building market to move quickly, though what will be considered “smart” a decade from now will be a moving target, she says.

“Smart building initially was the connectivity, the energy efficiency and being able to trend and capture all this data,” Brabon says. “But now, over the past year, expectations have changed. We might want to track occupancy patterns, we might want to track indoor air quality, people might want assurances that the air changes per hour in their space have been achieved.”

The opportunities for contractors are considerable, though they will need to be comfortable with quickly evolving technology and a moving set of goal posts.

Technology adoption in construction, particularly of cloud-based software, has gone through step change between 2020 and 2021, largely due to the pandemic. While many GCs and subs are already using sophisticated tools for overseeing their projects, those behind the curve will likely need to catch up to enter the smart building market.

“If you’re not using them already, I would say that that could create a lag in the types of projects that you’re working on,” Brabon says, adding that Black & McDonald gets a major boost from employing technologies that bridge the construction and operations phases.

“It’s a huge benefit to us playing both of those roles… to be able to take advantage of some of the technologies or cloud-based tools that are used during construction, to make for a very easy hand-off into operations, to better understand what the facility use requirements are, how we can change that and update that over time,” she says.

“The software’s out there, and the partnerships are out there... It’s more of a cultural thing in the contracting community. My only piece of advice is don’t double down on the status quo. This is happening, and that’s just the way it’s going to be.”

– Sam Boyajian, Modern Niagara

Among other examples, Brabon points to photo tagging, which takes much of the manual work out of progress updates, as a key piece of technology that is streamlining work on-site and simplifying integration when subsystems of smart buildings are forced together.

Boyajian does not see the technology curve as being overly steep for contractors, but says the slow-to-change mentality of some in construction can put up barriers.