16

FURNACES

TOP FIVE NEW RESIDENTIAL GAS FURNACE TESTS

We owe it to our customers and to the environment to be sure that newly installed gas appliances will operate at peak efficiency.

By Ian McTeer

24

HVAC/R HVAC/R SYSTEM TROUBLESHOOTING

Taking a logical and systematic approach to determining the final cause of equipment failure, and then taking it a step further to determine the actual root cause.

By Dave Demma

28

HVAC/R

THERMOSTATIC EXPANSION VALVE TROUBLESHOOTING

Take a system-wide approach when searching for root cause problems with AC and heat pump systems.

By Jeffrey Staub

31

THE AGILITY OF IoT

Smart technology developed by PCL Construction in partnership with Microsoft is bringing sensors and smart software to jobsites and delivering immediate benefits.

By Megan Hoegler

34

PLUMBING

NEVER TAKE DRAINAGE FOR GRANTED

Using the right tools will ease the clearing of blocked drains, and you never know what you’ll find.

By Steve Goldie

40

HYDRONICS

VARIABLE SPEED “SHUTTLE” PUMPS FOR BOILER PROTECTION

Introducing a thermal clutch to protect a boiler from sustained flue gas condensation. By John Siegenthaler

46

BOILERS

GOING HYBRID FOR HEATING EFFICIENCIES

Combining a non-condensing with a high efficiency condensing boiler to get the best of both technologies in commercial heating applications. By

John Miller

52

PROMPT PAYMENT AND A PROPER INVOICE

What all parties to a construction project need to know going forward in Ontario.

By Catherine DiMarco

56

GUIDE TO REFRIGERANT REGULATION AND POLICY

The HVAC/R industry is working to make sure the transition to low global warming potential (GWP) refrigerants goes as smoothly as possible.

By John Sheff and Dean Groff

the lead out’: Canadawide investigation into lead levels in drinking water prompts reactions

The new StormCell® series of battery backup pumps from Liberty feature advanced professional-grade chargers, energy e icient pumps for longer run times, and optional NightEye® wireless technology for remote monitoring through your smart device.

• Available in both standard and wireless connected models

• Professional-grade chargers (10 amp and high-output 25 amp)

• Single and dual battery systems

• Energy efficient DC pump (manufactured in the U.S. by Liberty)

* Model 442-25A, StormCell® Group

MY FIRST MEMORY OF INTERACTING WITH A BUILDING’S MECHANICAL HEATING SYSTEM IS taking off my socks and placing my near-frozen toes over the warm air stream coming from a floor register. The burning sensation would bring tears to my eyes, but it was the price I had to pay after playing shinny on the schoolyard rink in my running shoes in the middle of a Saskatchewan winter.

Growing up we had gas-fired forced-air furnaces. It’s all I knew. Since moving east, and now living in Toronto, I’m intimately familiar with hydronic heating in homes, and more recently I’ve become acquainted with an air-source heat pump.

It’s been fascinating to learn about this technology through personal experience, and now with my exposure to the entire heating, plumbing, air conditioning and refrigeration industry as the editor of HPAC magazine I am looking forward to learning much, much, more—both residential and commercial.

I was struck by a line in Dave Demma’s article in this issue (p. 24), where he likens the role of an AC/refrigeration technician to that of a doctor. It made me think of many parallels between the role of mechanical professionals and those in the medical field.

Although HVAC and plumbing experts are more familiar with house calls, both groups are experienced at diagnosing a problem and in most cases recommending and hopefully providing a cure.

When it comes to system design, mechanical engineers might be compared with medical specialists who carry out research and clinical trials, putting theory into practice with the goal of ultimately leading to better outcomes. It takes years of school and experience to become an expert in these fields.

On the ground, the apprentice, like the medical resident, needs the classroom and in-field training to become competent. And then with experience the best rise up to become the journeymen technicians and the foremost surgeons of their craft. This is where the best in theory meets the hands-on reality, and ultimately the work gets done. Often times teamwork is required, but solutions are found and healthy buildings and people are the end result.

I look forward to learning about and sharing the latest industry news, advice and discoveries with you, our readers. And I’m still searching for a painless solution for thawing frozen toes. <>

– Doug Picklyk, Editor

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

COO

PRESIDENT & CEO

0017-9418 (Print) ISSN 2371-8536 (Online)

Contents

Doug Picklyk (416) 510-5218

DPicklyk@hpacmag.com

Megan Hoegler (416) 510-5201

MHoegler@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Vince Naccarato (416) 510-5118 VNaccarato@hpacmag.com

Emily Sun esun@annexweb.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 442-5600 ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847

PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbusinessmedia.com

Scott Jamieson sjamieson@annexbusinessmedia.com

Mike Fredericks

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $43.00 (plus tax) CDN; Outside Canada per year: $84.50 US; Elsewhere: 1 year $92.50; Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Navien designs and manufactures all the key components and uses advanced robotics to assure manufacturing integrity

Discover the new standard for compact high efficiency commercial boilers by visiting navieninc.com/series/nfb-c

• Advanced stainless steel fire tube heat exchanger • 7" Touch screen and smart controls

• 97.5% Thermal efficiency

• Common venting and cascading capability

• Top and bottom piping connections

High levels of lead have been found in pipes across the country. It’s there, but how do cities get it out? BY MEGAN HOEGLER

A year-long investigation conducted by several universities and media organizations across the country has revealed higher than acceptable lead levels in many communities.

According to the Toronto Star, one of 10 media outlets involved in the Tainted Water investigation, 33 per cent of tests revealed lead levels that exceed Health Canada’s guideline of 5 parts per billion.

The culprit? Lead pipes, which were standard in homes throughout the 20th century. From the early 1900s to as recent as the 1980s, lead was used as a primary construction material for water pipes.

“A big part of the problem is aging infrastructure,” says Ralph Suppa, president of the Canadian Institute of Plumbing and Heating (CIPH). “Water comes into contact with lead through the service lines, and most of them are on people’s properties. So you need the owners’ cooperation to replace them.”

According to the investigation produced by the Institute for Investigative Journalism, cities including Montreal, Gatineau, Saskatoon, Regina, Moose Jaw and Prince Rupert recorded lead levels comparable to or higher than those of the infamous Flint, Michigan crisis.

“Lead can be found in water service pipes in homes built before the mid-1950s,” notes William Fernandes, the director of Water Treatment and Supply for Toronto Water. “Lead can also be found in leaded-brass faucets and valves. As these corrode and break down, lead can enter drinking water.”

In cities like Regina and Saskatoon, the municipalities have provided homeowners with instructions to determine if their pipes are made of lead.

When it comes to the cost of replacing the service pipes, the City of Saskatoon has a 60/40 split payment policy—the city will pay 60 per cent of the cost while the homeowner pays 40 per cent. The city also offers interest-free repayment plans of up to five years.

Montreal, where 58 per cent of the water tested was above 5 ppb, has a more drastic plan of getting the lead out. In October, Montreal’s mayor, Valérie Plante, said that the city is drafting a by-law requiring homeowners to replace lead ser-

vice pipes, or it will send contractors to remove lead pipes from affected homes and send owners the bill.

In 2008, nearly half of the water testing from pipes in Toronto homes showed lead levels that exceeded national safety guidelines. Shortly after, the city began adding orthophosphates to the water to reduce corrosion in pipes. Today, less than 2 per cent of the samples taken exceeded the guidelines.

“The phosphate forms a protective coating inside all pipes and household plumbing fixtures, which helps reduce the potential for lead to enter tap water,” explains Fernandes.

While phosphate reduces lead levels and protects against corrosion, it doesn’t eliminate the problem entirely. The only way to do that is to remove the pipes.

“It’s a big job,” says Suppa. “You’ve got to shut off the water line, dig, remove and replace the pipes. Sometimes you have to tear up streets and front lawns to do it.”

“The cost of replacing a service water line will vary from a congested older neighbourhood where it’s maybe 2 metres in length, to a subdivision in the suburbs that could be around 10 metres,” says Suppa. “The labour involved would be a small excavator plus operator or even a rubber tire backhoe and one worker to do the piping in the trench. After a day to install, there would likely be some restoration for a paved driveway or sod for any lawn damage.”

Suppa believes the media attention given to the lead water issue is enough to get the ball rolling on these large replacement projects.

“Now that there’s been some media attention, homeowners are keen to get this done. You can even look at it as a direct opportunity for plumbing professionals.” <>

Enwave Energy Corporation is working with Brookfield Properties to incorporate additional efficiency to the heating and cooling operations of the third and final tower of Bay Adelaide Centre in Toronto, a 32-storey high rise set for completion by 2022.

The two existing Bay Adelaide Centre towers, located in the heart of Toronto’s financial district, are currently connected to Enwave’s deep lake water cooling (DLWC) system—a district energy system that draws renewable cold water from Lake Ontario to cool downtown buildings.

For the new 820,000 sq. ft. North tower, Enwave will build and operate within the Bay Adelaide Centre complex, a hot water plant that generates heat from both natural gas and electrically powered heat pumps. A supplemental heat pump will also capture residual heat from the DLWC system and reuse it to heat the building.

According to Enwave, the solution is a lower-carbon highly-efficient process that will significantly reduce greenhouse gas (GHG) emissions, and the new tower will be one of the most thermally sustainable buildings in Toronto.

ASHRAE announced the incorporation of the Indoor Environmental Quality Global Alliance (IEQ-GA) as a legal entity at the 40th AIVC conference in Ghent, Belgium on October 15. The IEQ-GA aims to promote and advocate for acceptable indoor environmental quality (thermal environment, indoor air quality, lighting and acoustics) for building occupants while ensuring the knowledge from IEQ research is implemented in practice.

“We are inspired by the forward-thinking approach IEQ-GA has in the building industry,” said 2019-20 ASHRAE President Darryl K. Boyce, P.Eng. “It is critically important that we advocate for the wellbeing of the people who occupy our buildings. Through the collaborative efforts and resources of IEA-GA’s member organizations, we will continue to provide safe buildings for generations to come.”

The creation of the IEQ-GA was the result of a presidential initiative of Bill Bahnfleth (the 2013 to 2014 ASHRAE Presidential Member and the current IEQ-GA Vice President), based on the report of a presidential ad hoc committee chaired by Bjarne Olesen, 2017-18 ASHRAE Presidential Member and current ASHRAE IEQ-GA Alternate Director.

The committee was tasked with exploring ways in which industry groups could work together to address all aspects of indoor environmental quality and health.

A memorandum of understanding was established between the Air & Waste Management Association (A&WMA), the Indoor Air Quality Association (IAQA), AIHA, AIVC, REHVA and ASHRAE to form IEQ-GA. AiCARR and ISHRAE later became members of the alliance.

“An important attribute of IEQ-GA is that it is a non-industrial alliance among societies representing all members that promote IEQ,” said Olesen. “The intent of IEQ-GA is to work with all partners of the value chain for indoor environmental quality including building research, comfort and health research, building design and installation, commissioning, operation and occupant behavior. Furthermore IEQ-GA will work with industry organizations to help their members to provide products and services that promote IEQ.”

The IEQ-GA is currently seeking new members from all the involved sectors and disciplines to join forces. Sectors include architects, consulting engineers, environmental professionals, industrial/ occupational hygienists and health specialists, among others.

The organizers of CIPHEX West 2020, Western Canada’s plumbing, hydronics, heating, ventilation, air conditioning, refrigeration and water treatment trade show being held November 4-5, 2020 in Vancouver, have announced over 30 per cent of the exhibit space has already been reserved and sales are now opened up to CIPH members and non-members.

For 2020, CIPHEX West is moving to the Coliseum at the Pacific National Exhibition in Vancouver, a new location that offers free parking for all attendees.

The list of confirmed exhibitors for next year’s event is updated and published on the show’s website. ciphexwest.ca

Efficiency Canada, a Carleton-University-based advocacy organization, has launched the first Provincial Energy Efficiency Scorecard.

“Imagine thinking of all that energy waste from our homes, businesses and industry as a ‘resource’, just like natural gas, oil or wind turbines,” Corey Diamond, executive director of Efficiency Canada, said in a release. “Now imagine harvesting that ‘resource’ in every community across Canada, creating jobs and meeting our climate change commitments. At a time when much of the country is at odds on our energy future, boosting energy efficiency is surely something all Canadians can agree on.”

The provincial scorecard—similar to the state scorecard released annually by the American Council for an Energy Efficient Economy (ACEEE)—measures policy progress on energy efficiency programs, enabling policies, buildings, transportation and industry.

“British Columbia received the top score because of policies like the Energy Step Code that create a clear pathway towards net-zero energy-ready buildings, natural gas efficiency targets and support for vehicle electrification. Québec scores second, and is the national transportation leader,” explains Dr. Brendan Haley, the study’s lead author and Efficiency Canada's policy director.

“In every province, we found both strengths and areas for improvement. We also identified policy gaps across all provinces that should be priorities for federal action—including catalyzing finance, building code implementation and compliance, transforming heating markets and training for efficiency jobs,” added Haley.

The International Energy Agency (IEA) estimates that 40 per cent of global Paris Agreement GHG reduction commitments can be met with energy efficiency measures, such as better insulation, smart home heating and cooling technologies, LED lighting and high-efficiency appliances.

An earlier report by Efficiency Canada estimated that 118,000 annual jobs would be created between now and 2030

by implementing the energy saving policies found in the PanCanadian Framework on Clean Growth and Climate Change. www.scorecard.efficiencycanada.org

ASHRAE has released updated editions of its standards for ventilation system design and acceptable indoor air quality (IAQ), Standard 62.1 and 62.2.

The ANSI/ASHRAE Standard 62.1-2019, Ventilation for Acceptable Indoor Air Quality, specifies minimum ventilation rates and other measures for new and existing buildings that are intended to provide IAQ that is acceptable to human occupants and that minimizes adverse health effects. Some changes to Standard 62.1 include new tables of ventilation rates per unit area for checking building ventilation calculations, a simplified version of the Ventilation Rate Procedure, Modified Natural Ventilation Procedure calculation methodology as well as a revised scope to specifically identify occupancies not previously covered.

The updated Standard 62.2 adds a compliance path that gives credit for particle filtration, distinguishing between balanced and unbalanced ventilation system interactions with natural infiltration, requiring compartmentalization limits for new multifamily dwellings, and allowing for single-point envelope leakage test results to be used when calculating infiltration credit. www.ashrae.org/bookstore

ASHRAE and the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) have signed a new Memorandum of Understanding (MoU), formalizing the relationship between the two organizations.

The agreement outlines how ASHRAE and NIST will work cooperatively to improve HVAC technologies and their applications. They will focus on improving building performance and cost effectiveness, through increases in energy and water efficiency and storage technologies as well as improving the interoperability of building systems and building integration with the electric grid.

Additional focus areas include supporting innovation and standards development, strengthening the resiliency of the built environment and bolstering cybersecurity of HVAC infrastructure. www.ashrae.org

Continued on p14

By Megan Hoegler

High upfront costs have traditionally led developers to shy away from geothermal technology to heat and cool residential developments. But advancements in technology and a demand for sustainable building methods is recalibrating this way of thinking.

“Technology is advancing,” said Adel Esayed, dean of the Centre for Construction and Engineering Technologies at Toronto’s George Brown College. “As a result, customers want to see that reflected in their homes.”

Birchcliff Urban Towns, a new townhouse development in Toronto’s east end, exemplifies that mindset change. The Core Development Group project includes 52 townhouse units in a U-shaped two-storey building that’s tied together through a central courtyard. A geothermal system supplied by a thirdparty energy provider will heat and cool the development, which is currently under construction at Kingston Road and Birchcliff Avenue.

“There’s been a big shift towards sustainability, so developers are starting to say ‘Hey, this is something we can use as a marketing tool,’” said Lane Theriault, president of Subterra Renewables, the Toronto-based green energy supplier working on the Birchcliff Development. “I can think of 100 or so buildings in the Golden Horseshoe that use geothermal and were built in the last 10 years.”

Subterra will install, own, and operate the geothermal system that will be heating and cooling the development, and the townhouse owners will pay a fixed monthly utility fee.

“Sizing, design and installation of geothermal requires pro expertise for the most efficient system,” says Esayed. “It’s still relatively new, so there are fewer installers and less competition.”

The Birchcliff Development will be free of natural gas as well as rooftop heating and cooling units, notes Theriault.

Construction began in June 2019. The current completion timeline is set for the end of 2020. subterrarenewables.com

NEXT Supply held a “Shoot to Win” contest at the Modern Hydronics Summit held in Toronto on September 19th, with a top prize of two tickets to a Raptors away game, including airfare and accommodations.

The winner, Codey from Genesys Plumbing in the GTA, traveled to Chicago with his young son Michael for the October 26th match-up between the NBA Champion Toronto Raptors and the Chicago Bulls. The Raptors won by a score of 108 to 84. Congratulations to both Codey and the Raptors. www. nextsupply.ca

The Joyce Centre for Partnership & Innovation (JCPI) at Mohawk College has received its Zero Carbon Building (ZCB) Performance certification from the Canadian Green Building Council (CaGBC). The Hamilton, ON building is first to achieve both ZCB Design and Performance certifications.

The JCPI was the second project in Canada and the first institutional building to earn a ZCB Design certification through the CaGBC program.

Earlier this year, HRAI held a symposium that addressed the transition to a low carbon society at the Joyce Centre, which included a tour of the facility.

The Joyce Centre is powered by a photovoltaic (PV) system that produces 500kWp AC, enough carbon-free energy to power the entire building. The building envelope also consists of triple-pane glazing and insulated pre-cast sandwich panels, helping to minimize thermal energy demand intensity (TEDI) while maximizing heating, cooling and natural light. A variable refrigerant flow (VRF) geoexchange heat pump system provides space heating and cooling.

Introduced two years ago, the ZCB Standard was designed to guide the industry in building to zero carbon and help Canada meet its international emissions targets by 2030. Since its launch, over 20 projects (including 10 certifications) are now registered under the ZCB Standard. www.cagbc.org

The annual survey shows many HVAC professionals are feeling optimistic about the business going into 2020.

The Annual Economic Outlook Survey compiled by the ASHRAE Journal and the AHR Expo has revealed a positive and optimistic outlook for the HVAC industry in 2020, while regulatory and potential political changes could have an impact on the North American market in the year ahead.

The survey was distributed to 1,418 past and prospective expo attendees and industry manufacturers to gauge the market. The complete 2020 report includes input on trends, issues and opportunities as outlined by representatives from industry associations regarding their respective areas of expertise. The survey acts as a precursor to the AHR Expo, happening in Orlando, February 3-5, 2020.

Survey respondents were also asked to write in potential opportunities, threats and challenges to be considered for the near future. Opportunities for growth identified by respondents include automation and self-diagnostic controls and continued growth in the IoT/IIoT space.

Areas of concern included rising tariffs and the need to recruit and retain a strong, skilled workforce. Additionally, changing energy efficiency regulations and R22 refrigerant phase-out remain high on respondent radars.

Potential impacts to the industry on the horizon, be they negative or positive, included the upcoming 2020 U.S. presidential election, which could affect both U.S. and Canadian markets, along with the growth of big-box retailers, SEER regulations, digitalization and the viability of new technologies on the market.

Overall, 79 per cent of survey respondents predicted good or excellent sales prospects in 2020. In terms of sales growth between 2018 and 2019, 34 per cent reported an increase of 10 per cent or more, while 70 per cent indicated sales growth of at least 10 per cent.

While there continues to be shifts in the market, the industry remains in a positive economic position. For example, heading in to 2019 the ‘retrofit and renovation’ segment was ranked as having the highest business growth potential. This year, it fell to second place, falling behind maintenance and replacement jobs.

Respondents also report expected growth in nearly all areas of the industry, the highest potential being within light commercial (72 per cent), hospital/health (67 per cent) and resi-

dential markets (64 per cent). Other top areas of predicted growth included data and telecom centres, heavy commercial, schools, office buildings, restaurants and hospitality.

According to both exhibitors and attendees, the most important consideration for consumers when making purchasing decisions is reliability. For the second year in a row both energy efficiency and indoor air quality were the next most important considerations according to exhibitors. Attendees, however, placed initial costs second followed by comfort considerations.

Looking forward, ASHRAE states there needs to be a greater emphasis placed on operability during the design, construction and turnover of buildings with an emphasis on the indoor environmental quality [IEQ] without wasting energy. The society sees an ongoing challenge within the industry is helping building owners and operators set concrete and measurable goals. One recommended solution is ensuring the design reflects the capabilities of the people operating the building, and that building operations representatives be included all the way through the design process, not only at the end.

“As an industry, we can dramatically change how buildings impact the people who occupy them by working together to provide the innovation required to create sustainable built environments around the globe,” said ASHRAE’s president, Darryl K. Boyce, in the official report. “ASHRAE is creating networks and establishing new strategic partnerships to expand on opportunities for engagement, not only within the HVAC/R industry, but across many industry sectors with stakes in [IEQ], operational performance and sustainability.” <> www.ahrexpo.com

“We

owe

it

to our customers and to the environment to be sure that newly installed gas appliances will operate at peak efficiency.”

BY IAN McTEER

Climate activists have made it clear that installing new natural gas and propane fired residential heating equipment, including cook stoves, fireplaces and water heaters, will become a thing of the past before long. Already several municipalities in North America have placed bans on future installations of residential gas utilities while also declaring climate emergencies related to excessive carbon emissions from burning fossil fuels.

Once North America’s electrical generation capacity and distribution grid have been restructured to accommodate all the power that will eventually be needed, all-electric HVAC/R will be our future. However, according to statistics from the Air Conditioning,

Heating & Refrigeration Institute (AHRI), year to date shipments (as of August 2019) of residential gas furnaces increased 5.9 per cent over the same period in 2018. U.S. factories shipped 2.29 million units, up from 2.16 million in August 2018. Even oil furnace shipments are up 14.9 per cent with 21,949 units moved into distribution since August 2018.

Gas furnaces are, arguably, one of the lowest-cost heating options for many homeowners in the replacement market and in new construction. Single zone systems can be made efficient and comfortable when proper design, installation and commissioning techniques have been utilized. We owe it to our customers and to the environment

to be sure that newly installed gas appliances will operate at peak efficiency. There are five critical tests that should be taken at start-up to verify any given unit is operating in accordance with the manufacturer’s installation instructions and industry standards. Let’s look at them one by one:

1. Gas pressure/Meter clock

2. Line & Low voltage

3. Flame signal

4. Temperature rise

5. Vent system pressure

There are three gas pressure tests that should be performed at system start-up or whenever combustion-related service problems occur. According to code, CAN/ CSA B149.1 – 15, paragraph 6.3.2, “a piping or tubing system supplied at pressures up to and including 14 in w.c. shall be designed to prevent the loss in pressure between the appliance and either the termination of the utility installation or the last-stage regulator from exceeding the maximum allowable pressure drop specified in Table 6.1.”

Table 6.1 says that for natural gas or propane installations using a piping or tubing system with a supply pressure 7 in w.c. to 14 in w.c., the maximum allowable pressure drop is 1 in w.c. This is the standard pressure rating for residential gas pressure regulators. Gas utilities typically set-up the gas pressure regulator to provide a minimum of 7 in w.c. Propane sup -

“Start-up data belongs to the heating system, not the contractor nor the homeowner.”

plier’s set up the second stage regulator to provide fuel at 11 in w.c. and must not drop more than 1 in w.c. To test for allowable pressure drop, do the Static and Working pressure tests:

a) Gas line Static Pressure test:

– Turn off the gas supply to the furnace.

– Install a pressure tap into the line side of the gas valve. Some valves have raised pressure taps that simply require loosening of the tap set screw one quarter turn. A gas resistant hose is then placed over the tap and connected to a manometer.

– Once the manometer is con-

nected, turn on the appliance gas supply. Do not start the appliance.

– Read the manometer: Let’s say the manometer reads 10.54 in w.c. on an LP system start-up. This is the Static Pressure with no gas appliances in operation.

b) Working Pressure Test

– Start the furnace; use a test mode if available on two-stage or modulating units.

– When the unit fires, note the new gas pressure and looking at the above example, it must not be less than 9.54 in w.c.

– Allow a two-stage unit or modulating furnace to achieve 100 per cent input. Again, the final stage must not result in a pressure drop. greater than 1 in w.c.

Static and Working pressure test proves the adequacy of gas supply pressure and will allow the furnace to operate according to the manufacturer’s Continued on p18

specifications. The static test will also detect excessive line pressure caused by a faulty utility pressure regulator. Too much pressure will likely damage the gas valve but it could also cause a potentially dangerous delayed ignition rough start.

c)

Contrary to popular belief, manufacturers do not set up the final manifold pressure on most residential gas furnaces. Often the pressure is set to allow test firing on the assembly line, typically something over 3 in w.c. for natural gas furnaces. Final pressure setting must be done on the job and 3.5 in w.c. is not always the required pressure. Some units require natural gas at 4.0 or 4.5 in. w.c. in the manifold. Two stage units typically fire natural gas at 1.4 to 1.7 in w.c. on first stage. Be sure to follow the manufacturers manifold gas pressure set-up instructions carefully. Record the static, working and manifold pressures for posterity. Be sure to clock the gas meter for evidence the unit is consuming the correct quantity of fuel.

Electronic controls are voltage dependent, improper voltage elicits devilish responses from circuit boards, sensors and related controls. Residential gas furnace manufacturers typically specify a nominal voltage ranging from 110 VAC to 120 VAC. Voltage fluctuations affecting proper appliance operation do occur for several reasons such as undersized branch circuit wiring or voltage transients. At start-up, just like gas pressure, static and working pressure tests take a voltage reading at the circuit board Line Hot and Line Neutral spade terminals. If your manufacturer publishes a nominal line voltage input of 120 VAC, the measured voltage at rest could be allowed to fluctuate as much as +/- 10 per cent.

Remembering that both low voltage and excessively high voltage will cause anything from erratic operation to very expensive damage, the measured voltage should be reasonably close to the manufacturer’s published nominal value. Take a second—or working—voltage reading once the fan motor has started. Ideally, there should be almost zero voltage-drop. Be sure to check for voltage across the Line Neutral terminal and chassis ground. Control boards needing a properly made earth-ground

for a zero-volt reference could lock-out or cause erratic operation if there’s more than 2 volts on ground. Some voltage issues are related to the homeowner’s electrical supply and will require a certified electrician or a utility representative to investigate voltage spikes, transients and grounding issues.

Gas furnace manufacturers also publish branch circuit wire sizes that should be used in order to provide a safe path for electrical current to be Continued on p20

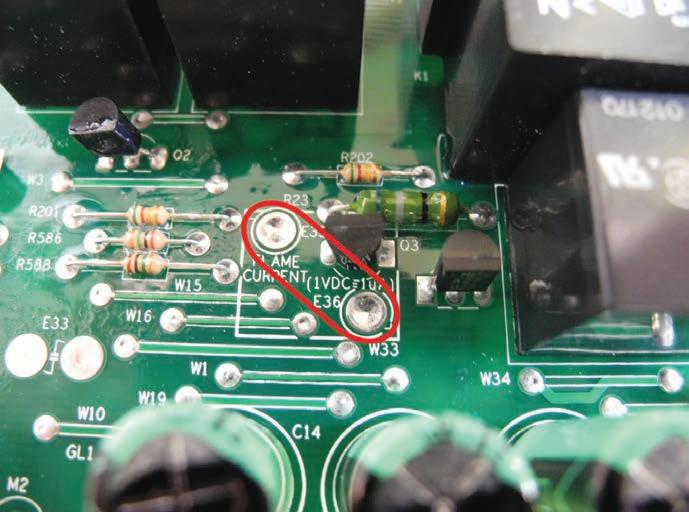

the coveted 2020 AHR Innovation Award in the IAQ category with PLP-LED!

Fresh-Aire UV is the leading award-winning North American provider of advanced HVAC Indoor Air Quality products. With a million installations world-wide, FreshAire UV offers engineered systems designed for residential, commercial, healthcare & agricultural applications. For more information visit

www.FreshAireUV.com800-741-1195 , call or email aaron@FreshAireUV.com.

- Airstream & evaporator coil disinfection

- Destroys mould, bacteria, viruses, odours & VOCs

- Lifetime EverCarbon Matrix™ w/ anti-microbial coating

- Advanced UVC quartz lamp w/ 3 year lamp life

- LED-smart notification

- Moulded translucent polycarbonate housing

- UL2998 validated for zero-ozone emissions

- Auto-sensing 18-32VAC & 110-277VAC models

- Lifetime system warranty. 3 year UVC lamp warranty

- Maintains a clean mini-split system

- Destroys mould & bio-film

- Improves indoor air quality

- UV LED spectrum is safe for eyes & plastics

- 40" Self-adhesive LED strip is easily trimmed to length

- 120-277VAC power supply

- Replaceable 50,000 hour+ LED strip

- 5 year warranty on all parts

After at least 10 minutes of operation, the vent system will start to fill with water. Accumulated water must be able to flow back toward the furnace and out through the drain.

Your manufacturer may require that the drain trap be filled prior to checking the gas manifold pressure.

consumed by the appliance during op eration. Larger input gas furnaces such as 100K and 120K Btu/hr models with blowers capable of handling up to 5 tons of cooling require heavier wire and larger circuit breakers. The old blister being removed might have been rated for service with 14-gauge wire on a 15amp circuit breaker. Connecting the new appliance using the existing wire and breaker could cause excessive voltage-drop and might even be dangerous. The manufacturers table below requires 12 gauge wire be used with the two largest models.

Condensate drain line must be freeflowing: no restrictions allowed!

Improperly installed vent systems happen far too often.

Water accumulating in an improperly sloped vent will eventually trip a pressure switch creating a no heat situation. This failure happened in January, more than a month after initial installation.

Check with your manufacturer, know how much deep negative pressure is required to close each pressure switch throughout their model line. The first stage pressure switch pictured above closes at -0.97” wc. After the unit fires, pressure will increase (move toward zero) but must not rise beyond the rated pressure for any given pressure switch. Printed on this label is the operating pressure -0.88” wc. This switch has a +/- range of 0.04” wc. During operation a tech might measure anywhere from -0.84” to -0.92” and still be within normal operating range. If the vent system pressure is within range, then the venting system is properly sized and sloped. Condensate will freely run to the floor drain or condensate pump.

Finally, measure the transformer’s low voltage output, static and working. If the voltage reading is ever less than 20 VAC or more than 30 VAC across “R” to “C”, expect erratic operation.

Typical manufacturer data of a dual pressure switch set-up providing a part number along with opening and closing pressures for each switch. The operating pressure will be printed on the label of each switch.

Table: 12-gauge wire required for large model

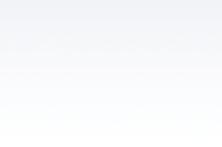

One of the most overlooked causes of erratic gas furnace operation has to be ignition lock-outs caused by a poor flame signal. This can happen for a variety of reasons: damaged or misaligned flame rod (maybe the appliance was damaged during shipment or installation), voltage problems, gas pressure problems, pinched wiring and so on. Admittedly, in days of yore, checking the flame signal wasn’t always easy. Fortunately, newer controls have solder pads incorporated onto the board so that simply touching the leads of an

Continued on p22

accurate voltmeter set on the DC scale to the pads will indicate the flame signal during operation (see image p.18).

Thus, 1 volt DC = 1 µA. A newly installed gas furnace should be producing a flame signal somewhere in the region of 2.5µA to 3.0µA. Some control boards will report-out a low-sense flame signal at 1.25µA by flashing a blink code on the control board’s diagnostic LED. Be sure to record the Day 1 flame signal for future reference.

Properly ducted forced warm air furnaces will provide decades of reliable service provided they run not too hot, not too cold, but just right. Once done with gas pressure tests and a meter clock has verified fuel input, allow the unit to run for at least 10 minutes before taking a temperature rise. Air temperature should be measured in the trunk ductwork and out of the line of sight of the heat exchanger to prevent radiant

heat from skewing the numbers.

Return air entering temperature is taken at the entrance to the blower compartment. Use a Type K thermocouple or equivalent probe designed for measuring air temperatures. The probe, pictured above, is ideal for residential ducts being long enough to get a good representative air temperature sample using a mini traverse.

All gas furnaces must operate within the manufacturer’s specified temperature rise range. Manufacturers provide charts indicating the correct range for any given model, or the charts may indicate a more precise temperature rise at the rated air flow level. For example, in the chart above, this manufacturer provides a rise range for a given model. I have removed all the model numbers, but suffice to say there are seven models of two-stage gas furnaces covered.

Another manufacturer provides two charts. The first chart (below) lists airflow versus external static pressure. I

30-60 17-33 20-50 11-28

35-65 19-36 35-65 19-36

40-70 22-39 35-65 19-36

35-65 19-36 35-65 19-36

have removed the model numbers and shown data for the two smallest units: The chart indicates the 60K Btu/hr unit comes with the blower speed factory set on the medium high speed and the blower will deliver 1065 cfm of air against 0.50 in w.c. of external static pressure. The second chart (next page) indicates the exact temperature rise that should be measured if the furnace is moving at least 1000 cfm of air. Thus, at 1000 cfm of air the temperature rise should be 53F. Since the blower’s factory setting should be delivering at least 1000 cfm, a temperature rise measurement of 60F, for example, would be unacceptable and likely indicates a serious distribution system problem. If this happens, that problem must be identified and repaired before leaving the homeowners alone with their new furnace.

After gas pressure testing is complete,

Cubic

MODEL

tee a manometer into the vent system pressure switch tubing. When re-starting the unit for the temperature rise test, take note of how much negative pressure the draft inducer can create. This number should be compared to the manufacturer’s minimum requirement for continuation of the combustion cycle. Typically, with a properly installed vent system containing a minimal amount of moisture, the deep negative should be significantly below the required closing pressure. After the temperature rise test and the limit control function has been verified (allow at

least 10 minutes of 100 per cent input operation), restart the unit and take note of the new deep negative closing pressure. It’s likely to be higher (closer to zero) but still lower than the manufacturer’s requirement. This test will verify vent system sizing (pipe size, length and elbow count) and that moisture is draining adequately. See the sidebar (page 20) for more information about checking vent pressure.

Data collected from these five tests plus any other operational details should be documented in an easily accessible method that becomes part of

the installation. Start-up data belongs to the heating system, not the contractor nor the homeowner.

Start-up information forms a vital part of any unit’s operational history and will be of great benefit to technicians during future service calls. A lifetime’s worth of service history will eventually provide the criteria necessary in making equipment replacement or repair decisions. <>

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

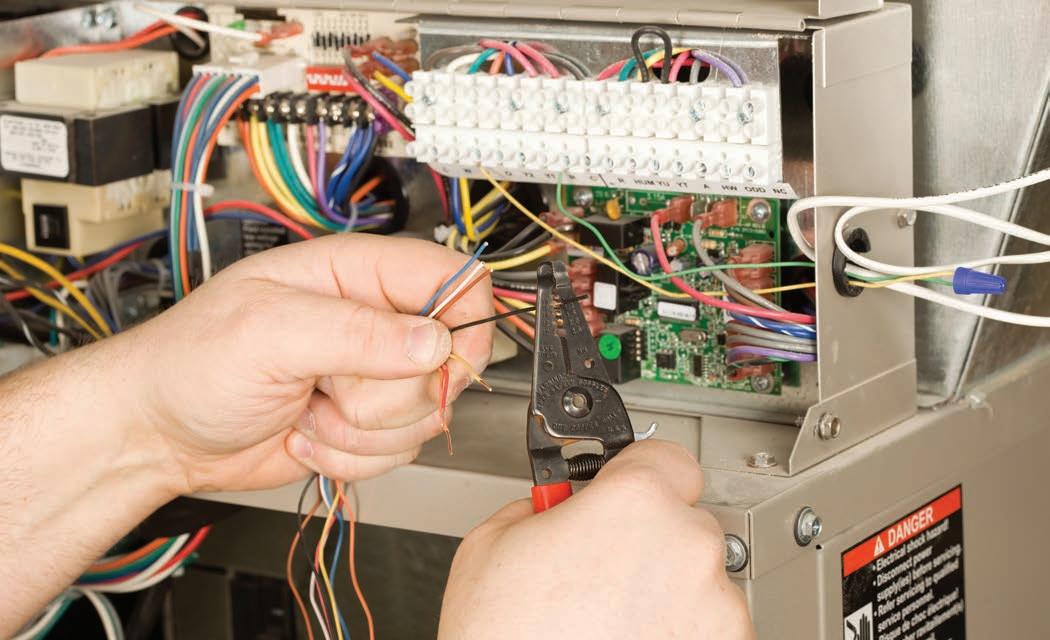

Take a logical and systematic approach to determining the final cause of equipment failure, and then take it a step further to determine the actual root cause. BY DAVE DEMMA

Ihave written on this topic in the past and have likened the role of an air conditioning/refrigeration technician to that of a doctor. With that comparison, the competent technician will have gone through an internship/residency (apprenticeship) period, which may last upwards of five years. During this period, through a combination of classroom and on-thejob learning, the apprentice technician will have acquired the necessary knowledge and field experience to become a competent journeyman technician.

Which brings us to the topic of troubleshooting—a skill that all good technicians should possess. First, the basic definition of troubleshooting: a logical and systematic approach to determining the final cause of equipment failure, and then taking it a step further to determine the actual root cause of equipment failure.

Here are the steps:

1. A failed product or process on a machine or system generates a service call.

2. The technician arrives at the jobsite.

3. A logical and systematic approach is employed to locate the source of the problem. This means resisting the temptation to immediately push the reset buttons on safety switches (controls, starter overloads, etc.) without first determining the cause for the trip.

4. The realization that if a safety switch is tripped, this is only a symptom of another issue.

5. While there might be several potential causes for a given failure, a process of elimination will result in pinpointing the exact cause.

6. Once the true cause has been determined it must then be further determined whether it was the actual cause of failure or just the final cause of failure.

Troubleshooting includes the in-depth analysis of the ultimate equipment failure and identifying the root cause of the failure.

Here’s a typical situation: a customer notices a loss of cooling capacity and a service call is placed. It’s not until a technician arrives that a cause for loss of cooling capacity can be determined. In this case, it’s obvious that the actual cause of failure was that an oil failure control tripped. This resulted in the compressor shutting down and the loss of cooling capacity.

Now, this is where the technician can either simply reset the tripped control and chalk it up as a “nuisance” trip, or spend a little time to determine the real cause of the trip. The

less than average technician, or perhaps even average technician, will take the easy road. The expert troubleshooter will spend the time necessary to find the root cause of the failure and then correct whatever that condition is.

Let's analyze what really caused this oil failure control to trip. The compressor ran out of oil resulting in low oil pressure. The oil failure control properly sensed this and as a “safety” control (a control whose function it is to protect the compressor from damage) it locked out compressor operation. But how did the compressor run out of oil?

The suction filter-drier was plugged up and the resulting reduction in suction vapor velocity inhibited the oil from returning to the compressor. But what caused the suction filter to plug up?

Well, an analysis of the removed suction filter reveals that it was plugged with decomposed oil.

What causes oil to decompose? Heat.

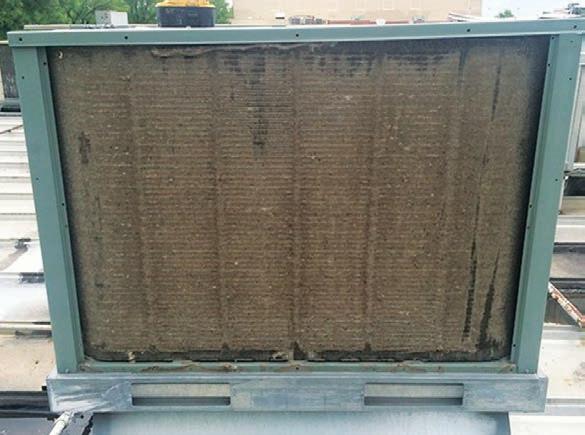

What causes the level of heat in a system necessary for the oil to decompose? Let’s go up to the roof and look at the remote condenser.

Now we’re getting somewhere.

So, the logical and systematic approach to this problem found that the compressor was inoperative due to the oil failure control trip.

Further inspection noted that the compressor crankcase was nearly empty, which caused the low oil pressure condition that resulted in the oil failure control trip.

After the control was reset, the technician checked the operating pressures, including oil pressure, suction pressure, crankcase pressure, discharge pressure, and the pressure upstream of the suction filter-drier. This revealed there was a 12 psi pressure drop across the filter-drier, which is a symptom of another problem—a restricted suction filter-drier.

Removing the filter-drier for inspection revealed the source of the contamination: decomposed oil. Mineral oil will start to decompose at 350F. Oil decomposition occurs in several

stages: initially forming a varnish (thicker and darkened oil); the next stage is a sludge (thicker than varnish and even darker); the final stage is a carbonaceous powder (solid contaminant). It was this final stage of decomposition which plugged the suction filter-drier.

Now if the suction filter-drier was plugged up it would be a good assumption to expect that the liquid filter-drier would be partially plugged as well. Both filter-driers were replaced, and the system was then restarted.

This corrects the condition that resulted in poor oil return to the compressor but does nothing to correct the condition that caused the oil decomposition. So the expert troubleshooter has more to do.

The next step was to determine the cause for the discharge temperature to be in excess of 350F. This led the technician to inspect the condenser, where he found a severely fouled condenser surface. After a thorough cleaning, the discharge pressure (and corresponding discharge temperature) were reduced to normal levels, eliminating the condition which caused the oil decomposition. The dirty condenser was the result of a lack of maintenance.

So, the real root cause here was a lack of maintenance, which resulted in a dirty condenser and ultimately in oil decomposition. The decomposed oil plugged the suction filter-drier, which resulted in high suction line pressure drop and reduced suction vapor velocity, which resulted in insufficient oil return to the compressor, which resulted in low oil level in the compressor crankcase, which resulted in low compressor oil pressure, which finally resulted in the compressor oil failure control trip.

Whew…

Now, this is only one of hundreds (if not thousands) of possible system failures that a piece of equipment might suffer. Some failures are complex (as in the example cited above), while some examples can be quite simple—a loose pipe

Continued on p26

clamp which caused the pipe to rub against the strut the pipe is attached to and wearing a hole in the pipe. The hole allowed refrigerant to leak out of the system, which resulted in a loss of cooling capacity. This doesn’t require a lot of analysis to get to the root cause. Repair the leak, tighten the clamp, and inspect other clamps to make sure this condition isn’t repeated. Once again, a lack of maintenance.

Or consider a failed motor. Perhaps the motor had reached the end of its useful life and the bearings finally seized. Or perhaps it could be the result of an overzealous in-house maintenance tech who overgreased the bearings.

“Without a complete and thorough analysis … it’s likely the system will experience a repeat failure in the future.”

Excessive grease volume (overgreasing) in a bearing cavity results in the rotating bearing elements beginning to churn the grease, pushing it out of the way. This results in energy loss and rising temperatures, which then leads to rapid oxidation (chemical degradation) of the grease and an accelerated rate of oil bleed (a separation of the oil from the thickener).

The heat that has been generated over time combined with the oil bleed will result in the grease thickener decomposing into a hard, crusty build-up that can impair proper bearing lubrication and even block new grease from reaching the core of the bearing. The end result is an accelerated wear of the bearing’s rolling elements and then ultimately a component failure.

The technician wouldn’t know the actual cause without inspecting the bearings. Now, if this is a smaller motor, it might not warrant the time to disassemble the motor and inspect the bear-

ings. But if this were an expensive 100 HP motor, it would absolutely be worth the time to inspect the bearings.

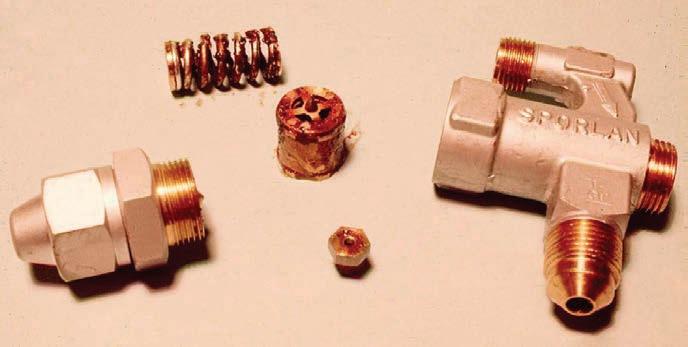

When troubleshooting reveals a component failure, typically that component is replaced. For example, an evaporator is underfeeding, resulting in an inability to maintain proper space temperature.

The technician checks the superheat at the outlet of the evaporator, and finds the superheat is 25F. Attempting to adjust the TEV does not reduce the superheat at the evaporator outlet. So, the decision is made to replace the TEV.

The system is pumped down, the TEV removed/replaced. The system liquid filter-drier is also replaced (good practice anytime the system is opened up). The system is then evacuated and restarted. The space temperature drops to the set-point, and a check of the superheat at the evaporator outlet reveals that it’s now at 8F. Perfect superheat for a medium temperature refrigeration application.

Once again, this is where the average technician will take the easy route, complete the service ticket, get a signature from the customer and then leave the site. The expert troubleshooter will not be satisfied until the cause of the TEV failure has been determined. An “autopsy” is performed on the TEV, including a disassembly to inspect the internal components so a

failure analysis can be made.

Once again, decomposed oil is the cause. This time it has plugged up the TEV port and restricted free movement of the pin carrier assembly. This failure can also be attributed to excessive discharge temperature, which was caused by a dirty condenser. And once again, a lack of maintenance.

Again, there are hundreds (if not thousands) of possible causes for system failures. The important point here is that without a complete and thorough analysis enabling the technician to get to the root cause of failure it’s likely the system will experience a repeat failure in the future.

It’s only through a complete and thorough troubleshooting of the equipment, a logical and systematic approach to determining the final cause of equipment failure, and then taking it a step further to determine the actual root cause of equipment failure, that the technician can be assured that the true cause of failure has been properly solved. <>

Dave Demma holds a degree in refrigeration engineering and worked as a journeyman refrigeration technician before moving into the manufacturing sector where he regularly trains contractor and engineering groups. He can be reached at ddemma@uri.com.

Often misdiagnosed, take a system-wide approach when searching for root cause problems with AC and heat pump systems. BY JEFFREY STAUB

Thermostatic expansion valves (TXVs) are often misdiagnosed as the root problem in poorly performing air conditioning and heat pump systems. The truth is that two-thirds of TXVs returned show no signs of failure. For this reason, we recommend taking a system-wide approach when troubleshooting. Eliminate all other components as a source of a system’s performance issues before investigating the TXV as the culprit.

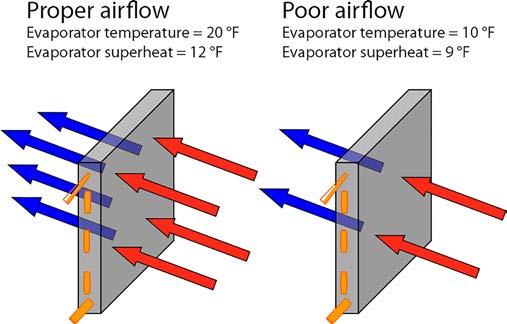

Low airflow is one sign that the cooling system is not functioning properly, and it has nothing to do with the TXV.

Figure 1 shows two identical evaporators being fed by a TXV with the evaporator on the left getting adequate airflow while the one on the right has inadequate airflow (note the superheat values and evaporator temperatures). Low airflow

can be caused by a dirty or clogged air filter or a malfunctioning fan or blower motor, so be sure to investigate those components as the source of insufficient airflow.

As seen in the table in Figure 2, a low refrigerant charge will result in a higher superheat and a lower subcooling and lower evaporator pressure. The biggest difference between low air-

Evaporator temperature = 20 ºF

Evaporator superheat = 12 ºF

Condenser subcooling = 12 ºF

Evaporator temperature = 5 ºF

Evaporator superheat = 28 ºF

Condenser subcooling = 2 ºF

flow and low charge is the level of superheat and subcooling. In a poor refrigerant charge scenario, the load is still there, but there is not enough refrigerant to absorb the heat. If signs point to the refrigerant charge being low, charge the system while following proper field procedures or original equipment manufacturer’s (OEM’s) recommendation.

An obstruction in the liquid line, such as a clogged filter drier or smashed or crimped liquid line tubing, can produce flash gas (see Figure 3), even though there is a proper refrigerant charge. Make sure to check upstream for blockages if there is flash gas at the TXV inlet. Check subcooling at both the condenser outlet and the TXV inlet prior to adding any refrigerant. A dirty or clogged filter drier is a potential culprit, especially since they are most often installed upstream from TXVs.

Ensure that the valve has been correctly installed: inadequately brazed fittings or mounted bulbs will negatively affect the TXV’s ability to operate. Inspect the valve, looking for physical signs of damage, such as dents in the power element, kinks in the tubing or signs of overheating like discoloration.

If the bulb mounting is loose, it will cause the TXV to overfeed, possibly flooding the compressor. Since 50 per cent of the heat absorbed by the bulb can come from the bulb strap, always use an OEM-recommended bulb strap (as shown in Figure 4). The sensing bulb should be securely mounted on the evaporator outlet downstream from the refrigerant header, in a position on the pipe least affected by liquid refrigerant and oil, and mounted before the equalizer tube.

Overfeeding or underfeeding can also

occur if the sensing bulb is not adequately insulated. The bulb should only be sensing the temperature of the evaporator outlet pipe; if it senses ambient temperatures, it will respond according to incorrect conditions. Insulation tape or foam should be liberally applied to shield the sensing bulb from ambient temperatures.

If these issues cannot be corrected by any other way, adjust the valve’s superheat. Note: adjusting the superheat should only be done after all other corrective measures have been taken. When adjusting the superheat (as seen in Figure 5 ), verify the rate of change per turn of the superheat spindle for the specific TXV (for example, on Danfoss TR 6 valves, one turn clockwise equals a one degree Fahrenheit increase). Be sure to note what changes are made to the superheat as it may be

Continued on p30

necessary to return the valve back to the original setting. Adjust the superheat one or two degrees at a time and give the system 10 to 15 minutes to rebalance. Once the valve is feeding, monitor the superheat as the system goes through a pulldown. Whenever possible, compare the superheat to information provided by the equipment manufacturer.

“If, after all other variables have been eliminated and the superheat has been adjusted, the TXV is still not functioning properly, replace it with a new correctly-sized valve.”

A plugged TXV will underfeed the evaporator and produce symptoms that include the evaporator operating under a vacuum or very low pressure. A plugged valve will not respond to a superheat decrease or will suddenly open up if superheat is adjusted downwards. Some TXVs have an inlet strainer. If the valve has a removable one, it may be removed and cleaned.

As a reference, use the following checklist to troubleshoot TXVs in the field:

Z Is the airflow low?

Z Is the refrigerant charge or subcooling low?

Z Are there any upstream obstructions?

Z Is the sensing bulb mounted properly?

Z Is the sensing insulated adequately?

Z Are there any signs of valve blockage?

Z Does the sensing bulb respond to heat by opening the valve?

Z Is the superheat correctly set?

Z Is the valve mounted correctly?

Z Is the valve sized according to OEM recommendations?

Another potential cause for underfeeding is a lost bulb charge. Since the bulb pressure is responsible for driving the valve open, if the pressure is reduced or lost, the evaporator and spring pressures will drive the valve closed. A quick way to check for this is to warm the sensing bulb. Simply hold it in your hand for a minute or two (as seen in Figure 6). If the bulb charge is fine and the valve is not stuck or seized, it should respond by opening.

A final potential cause for underfeeding is a valve that is too small, which will significantly hinder performance. Check the valve’s rated capacity (highlighted in Figure 7 ) against the OEM’s recommendations. The valve capacity should be equal to or greater than the OEM’s capacity rating.

If, after all other variables have been eliminated and the superheat has been adjusted, the TXV is still not functioning properly, replace it with a new correctly-sized valve. When removing the failed valve it is important to cut it out rather than sweating it out, as sweating may damage the valve and the manufacturer will not be able to determine the source of the malfunction when it is returned.

We recommend changing the filter drier every time the system is opened as insurance against future problems. <>

Jeffrey Staub is director, regional applications Americas –Danfoss. He can be reached at JeffStaub@danfoss.com.

Smart technology developed by PCL Construction and Microsoft is simplifying tradespeople and developers’ jobs through crisis prevention and cost-savings. BY

MEGAN HOEGLER

It all started with Siri.

Since Danish web developers created the voice-activated smart technology in 2010, the concept has only advanced and spawned similar applications such as Google Home and Nest.

While Amazon has managed to make Alexa a household name, the concept of smart technology in building is a new, and not fully understood, concept.

In 2017, the PCL Construction company partnered with Microsoft to develop Job Site Insights (JSI), a smart technology platform that provides contractors with job site sensors. Over two years, the partnership has worked on over 700 projects with staffs of over 10,000 tradespeople.

Despite the rapid deployment, defining smart building to potential clients can be a challenge.

“A lot of owners and clients come to us asking for a smart building,” says Chris Palmer, senior manager of advanced technology services for PCL’s business technology team. “We say ‘Great, we’ll build you one. What would you like?’ and they say, ‘I don’t know.’”

According to Palmer, this is because the buzz word ‘smart technology’ can mean many things to many different industries. For HVAC professionals and building owners, a smart building may integrate technology that monitors the temperature and humidity of a space or provides flood water detection services.

“If you look at food industries, they have regulation checks on refrigerators,” explains Julie Morin, director of IoT Solutions for Microsoft’s Canadian marketplace. “That’s a great opportunity be -

ABOVE: PCL Construction is incorporating IoT sensors in conjunction with its Job Site Insights platform to improve efficiencies on the job site.

cause there aren’t a lot of turnkey solutions on the market for customers to take advantage of. Being able to monitor temperature and get text alerts is super important to those customers.”

The Job Site Insights platform has been integrated into major residential high-rise developments, such as the SKY Residences of ICE District in Edmonton and 16 York in Toronto. Through the use of the smart technology, SKY Residences experienced a 46 per cent reduction in natural gas usage for 35 heaters over a six month-long winter season. They also had zero freeze/thaw leak incidents as a result of frozen pipes, which amounted to a $104,000 savings in rework avoidance and elimination of warranty and insur-

ance claims as a result of avoiding water-related damages.

At 16 York, JSI was able to detect a failed pump room valve coupling, allowing the damage to be managed and minimized right away and saving the development the cost of future insurance claims.

While solutions like JSI can be expensive to install, Palmer says the future savings make it worth the investment.

“The metrics and cost-savings being generated are helping us to drive adoption,” said Palmer. “Clients, like a lot of us, know the concept of smart technology. They’ve been exposed to it in their personal lives through Nest or Ring or Google Home, so extending that into a commercial space building isn’t a giant leap.”

Emerson has added system supervisor to its line of supervisory controls for large facilities. The system allows the user to control refrigerant, HVAC and lighting. Optimized for ProAct, the system collects and analyzes data, which is then cloud-processed through ProAct software, apps and services into insights about current conditions, developing trends, performance history and operational metrics. www.emerson.com

The VS 1000 RTe and VS 3000 RTe ERVs from Ventacity Systems meet Passive House Standards and are designed for humid climates. VS 3000 RTe offers an 85 per cent heat transfer efficiency and 65 per cent latent energy transfer efficiency. VS 1000 RTe offer an 82 per cent sensible heat transfer efficiency and 70 per cent latent energy transfer efficiency. www.ventacity.com

From Regal Beloit, the Genteq Evergreen VS product line of variablespeed replacement motors are electronically commutated motor (ECM) retrofits for use in residential and light commercial HVAC systems. Evergreen VS motors are pre-programmed, dual-voltage, dual-rotation motors. The Evergreen VS line is designed to replace constant airflow (variable-speed) ECM indoor blower motors. www.ECMMadeEasy.com

The Honeywell T10 Pro smart thermostat features wireless RedLink sensors with a range up to 200 feet, which monitor temperature, humidity and motion. Smart room sensors signal to the thermostat when a room becomes occupied. The thermostat can be connected to up to 20 sensors. It features a full-colour touch display, allowing for on-device set up and Wi-Fi connection. www.resideo.com

The BGH96 Series condensing furnace from Bosch Thermotechnology Corp. offers a twostage gas valve that switches between highand low-fire settings. The furnace can be integrated with the company’s Inverter Ducted Split (IDS) heat pump outdoor unit and cased coils for a dual fuel heating and cooling system. The unit features a three-way multipoise design and low-profile cabinet, as well as multi-speed ECM motors. All units come standard with a natural gas-to-LP conversion kit. www.bosch.ca

The Unico System M1218 air handler is now a separate module, making the small unit more adaptable for installation in tight spaces. The unit consists of various modules that are easily latched together and can be arranged in vertical-up-flow, vertical-counter-flow and horizontal-flow configurations. They can be combined as heating-only, cooling-only, or heating and cooling. www.unicosystem.com

The zero clearance grease duct from Durvent is intended for new and renovation restaurant construction. The double-wall stainless steel round duct ships pre-insulated with three inches of AES wool insulation and feature self-centering flue extension. www.duraventgreaseduct.com

The Ruskin BTR-250 heavy-duty isolation damper is suited for system containment or decontamination applications found in laboratories, medical facilities, clean rooms and federal buildings. It’s designed to provide bubble-tight airflow leakage performance in systems with up to 10 in. wg pressure and is available in sizes ranging from 4 to 36 in. diameter (I.D.) and includes a flanged channel frame for ease of installation. www.ruskin.com

Danfoss has added new 8.5- and 11-ton variable-speed compressors with intermediate discharge valves to its VZH range. The VZH inverter scroll compressors feature permanent magnet motors, and are designed for data centre close controls and rooftop units. www.danfoss.com

The YORK Sun Choice 15- to 27.5-ton rooftop units exceed DOE 2018 guidelines by up to 25 per cent and surpass future DOE 2023 part-load standards by almost 10 per cent. A lightweight design and direct replacement footprint allows ease of installation for retrofit applications. IntelliSpeed, an optional four stage fan control, provides improved occupant comfort and lower operating costs. Single-side access to all serviceable items provide ease of service. www.york.com

From Fujitsu General America, the Halcyon circular flow ceiling cassette system a DC twin rotary compressor, DC fan motor and optimal refrigerant cycle control. The circular airflow design uses 360-degree louvers. The new units work with wired or wireless controls (2- or 3-wire controls), and the company’s Human Sensor Kit which detects occupancy. Five sizes are available, from 18,000 to 48,000 Btu/h. Black or white grilles are available. www.fujitsugeneral.com

The Radon VAC from Tjernlund Products, Inc. consists of a plug-in fan, exterior hood and installer-purchased PVC pipe. It evacuates through the basement side wall of a property and features a sealed, galvanized fan housing and a PSC low watt motor. The product’s variable aspiration control hood is designed to dilute the radon gas with fresh outdoor air as it exits the hood and propel it away from the structure. www.tjernlund.com

The Fresh-Aire UV Purity whole house system includes a MERV 11 filter, germicidal UV-C light, and photocatalytic media. Purity, designed to purify air, can be attached to a central air system (furnace or air handler). The line includes five models. www.freshaireuv.com

The electricSchwank electric infrared heater series from Schwank range from 500 W to 6000 W. Designed for indoor and outdoor use, the models feature on/off and variable controls for single bulb heaters and two-stage control for dual bulb heaters. The series comes standard in stainless steel with custom finishes available in black, white, beige and mineral bronze. www.schwankgroup.com

Using the right tools will ease the clearing of blocked drains, and you never know what you’ll find.

BY STEVE GOLDIE

We humans are a fickle and funny bunch at the best of times. We often take for granted some of the simplest and most amazing things in life, and we get preoccupied or obsessed with irrelevant and meaningless nonsense.

The internet makes overnight celebrities of anyone who can prank, punk or tweet any and all varieties of inane foolishness. If you can surprise, shock or humiliate people, all the while catching it on camera, you might just be the next YouTube millionaire. Meanwhile, the nurses, tradespeople and everyday working class heroes that keep the lights on, the food growing and the water flowing, toil away in relative anonymity.

It is a part of human nature, and I am just as guilty as the next person. Too often we don’t notice how good we have things until something goes wrong. Most people don’t notice or pay attention to their hot water tank until it stops working,

and not being able to start the day with a hot shower can make for some unhappy customers. Few things however can ruin your day faster than a blocked drain, be it the kitchen sink, the bathtub or the main sewer line.

Yes drainage systems definitely fit the bill of things we take for granted. As long as they are working properly nobody thinks of them at all, and as soon as they stop doing their job they demand immediate and undivided attention.

I’ve cleared my fair share of clogged drains over the years. If I have learned anything, it is always be prepared to be surprised. The moment you think you have seen everything, someone will try to flush something down the toilet you never could have imagined. My closet auger still has a kink in it from when it once pulled an entire pair of blue jeans out of a toilet.

I would estimate that 75 per cent of clogged drains are caused not by misplaced pants but by the same recurring

cast of culprits: hair in bath/shower and bathroom basins; fat, grease and coffee grinds in kitchen sinks; and overly abundant paper products in toilets.

The vast majority of these blockages are cleared in a matter of minutes if you employ the right tools and strategies. Drain clearing equipment comes in a multitude of sizes and styles specific to differing sizes of drain.

Closet and urinal augers are designed to go through and clear the integral traps of toilets and urinals. Small handheld snakes, either manual or power operated, are ideal for clearing lavatory and kitchen sink drains. They typically have around 25 feet of cable between ¼-in. and ⅜-in. diameter.

Smaller snake cables typically have a fixed bulb style end. I prefer the slightly larger cable with replaceable heads which allow an assortment of styles depending on the nature of the blockage. This also allows for the use of a “drop head” end which assists in ensuring the snake goes down the drain rather than turning upwards into the vent which can be a very frustrating problem when it occurs.

Whenever I got called out to clear a drain I knew that if I wasn’t in and out in minutes, I’d have to be prepared to be there for the long-haul. That’s how it always seemed to go.

If a toilet doesn’t clear on the first or second attempt with the auger, it probably meant I was going to have to remove the toilet and put the auger through it in reverse. This would inevitably displace some foreign object, a toy car, a bottle of nail polish, a pen, or maybe even grandpa’s lost dentures.

I’m sure I have cleared hundreds of toilets over the years, and the only time I could not get one clear was in my own home. I removed the fixture and took it to yard, augered it in both directions but to no avail. After hours of frustration, sweat and swearing, I finally conceded

defeat and decided to install a new toilet. I had to know what was in the old one though, so I broke it open to find a ceramic gift my daughter had made for me in kindergarten. It was a bit larger than a golf ball and with a conical shape, a perfect size and shape to get tightly wedged into the toilet’s trapway.

I’m sure that is exactly what my twoyear-old son was thinking when he

dropped it into the toilet. I have no proof, but he has received the blame all these years.

As disruptive and upsetting as a clogged kitchen sink or backed up toilet can be, they pale in comparison to the mayhem that can occur when a main sewer line gets blocked and backed up. Few things are as upsetting as a basement full of raw sewage.

“When the four-inch main sewage line gets blocked it is time to bring out the big guns.”

When the four-inch main sewage line gets blocked it is time to bring out the big guns.

Most manufacturing company literature claims that even the ½-in. and ⅝-in. cables are good for four-inch drains, I however would never use anything smaller than a ¾-in. cable, and even at that if I encountered the slightest resistance I would go with the 1.25in. cables and the rodding machine.

The smaller cables can easily twist up inside a four-inch drain and that is no fun and can be very difficult to extract once it occurs. Better to avoid this altogether by using the bigger tool.

The rodding machines are heavier

and use 10-foot long chain reinforced cables that are fed in one at a time. It is not as convenient as the much longer self-feeding cables of the drum style rooter machines, but in my experience, when you are working on four-inch drains it is the way to go. This is particularly true if you are dealing with roots, which is often the case in main drain blockages.

In a perfect world the sun would always shine and showers would always run hot, children would keep their toy cars and kindergarten craft projects out of the toilet, and grandpas would keep their false teeth in their mouths. Until that perfect blissful world arrives however the opportunity to make a good living clearing drains will always be with us.

Your local wholesaler will be happy to ensure you have the right tools for the job, at least until your internet celebrity career takes off. <>

Steve Goldie learned his trade from his father while working as a plumber in the family business. After 21 years in the field, he joined the wholesale side of the business in 2002. His expertise is frequently called on to troubleshoot systems and advise contractors. He can be reached at sgoldie@nextsupply.ca.

From blue jeans and kids' toys to false teeth and electronics, drain cleaning can uncover many hidden treasures. If you’ve had an unbelievable find that you’d like to share, let us hear about it. Tell us what you’ve found and send an image if you have it — #DrainDiscoveries: Email: editor@hpacmag.com

Twitter: @hpacmag

Facebook: @HPACmag

Instagram: hpacmagazine

LinkedIn: HPAC Magazine

EZ Gear Sensor Faucets deliver reliability, precision, and efficiency to your commercial restroom. Thanks to the dual action of the ceramic disc cartridge and motor gear-driven operation, they outperform and outlast solenoid operated faucets. They intuitively sense the user without delay, too much force, or wasting water. Gear up for the next generation of sensor faucets with EZ Gear Technology.

You can expect up to 20 plus years of trouble-free performance.

Bradley’s WashBar with Undermount Basin system includes the company’s WashBar technology with a selection of cast-formed undermount basins made of either Evero natural quartz (8 colour options) or Terreon solid surface (5 colours), a one-gallon foam or liquid soap container and an optional access panel. The WashBar is a single piece of chrome-plated metal that combines soap, water and dryer. LED lighting on the fixture helps to visually orient the user through the process. www.bradleycorp.com

American Standard’s Greenbrook high efficiency urinal joins the brand’s one pint flush collection. An inverted back wall is designed to prevent splash while optimized surface contours and a water flushing spreader ensure a thorough rinse. The system uses up to 87 per cent less water than other standard gallon per flush urinals. www.americanstandard.com

Milwaukee’s cordless sewer sectional solution, the M18 FUEL Sewer Sectional Machine, is capable of clearing blockages of 2-in. up to 8-in. sewer lateral lines. At maximum capacity it is capable of clearing roots up to 200 ft. out. Automatic feed and retract features eliminate the need to manually pull back heavy cable. Compatible with the M18 line, it uses the REDLITHIUM battery pack. Other features ⅞-in. and 1 ¼-in. cable capacity and cable spin speed of 700 rpm. www.milwaukeetool.ca