Norwegian company brings cool concept to live feed

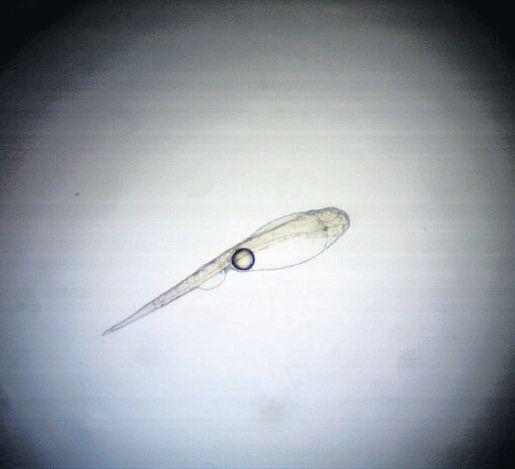

Planktonic AS utilizes cryo-preservation techniques to provide live zooplankton for marine hatcheries.

BY MATT JONES

As the arms race to develop more efficient and effective live feeds for hatchery applications continues Norway’s Planktonic AS has developed a unique approach which they say could be a game-changer for the industry.

The process includes a method for harvesting large amounts of plankton from the ocean, which is then cryopreserved. The plankton is packed in sacks of 600g, corresponding to about 30 million plankton individuals, and these are stored in thermos flasks with liquid

A size comparison between juvenile lumpfish from the same egg batch –the ones on the left were fed traditional dry starter feed, the larger ones on the right were fed live Cryo-plankton.

nitrogen. When this feed is to be used, it is thawed in seawater, and the plankton then becomes live again and therefore constitutes a natural feed for the juvenile fish.

THE RIGHT STUFF

“The right marine fatty acids in the earliest live stages are crucial in order to release the potential for growth in marine fish,” says Rune Husby, CEO of Planktonic AS. “Natural zooplankton contains these fatty acids and is such a superior feed to any other feed type out there. This is well documented in literature and publications, but

Coho to Go…

Justin Henry thinks he’s got some pretty good fish eggs for sale. Northern Divine Aquafarms produces certified organic, fertilized, female monosex, coho salmon (Oncorhynchus kisutch) eggs.

“I think we are the only company in the world doing this,” says Henry, the General Manager of Northern Divine, based in Sechelt, just north of Vancouver, British Columbia in Canada.

Formerly called Target Marine, the company began as an integrated coho aquaculture facility with hatchery and net pen-growout systems in 1986. The current owners bought the company in 1994.

THIRTY YEARS OF BREEDING

Broodstock was initially sourced over a period of three years from the Kitimat River in Northern BC and has been selectively bred for growth, disease

there has been no effective way of presenting such a feed to marine hatcheries that made industrial sense. Until now.”

Husby says that to utilize their live feed, a hatchery manager need only throw the cryopreserved nauplii into sea water and within eight hours they are ready for use.

A much simpler, less expensive and less time consuming process, Husby says, than cultivating a batch of rotifers or hatching artemia cysts or cultivating algae for feed.

continued on page 8

Canadian company produces all-female coho eggs for shipment world-wide

US researchers identify effective method of gender manipulation for southern flounder

The most effective method of gender manipulation to create all-female stocks of southern flounder (Paralichthys lethostigma) uses a combination of UV irradiation to denature genetic input from male southern flounder prior to egg activation, followed by a pressure shock.

The process was described in Manipulation of Gender in Southern Flounder to improve stock enhancement programs and or Manipulation of gender in southern flounder to improve culture, authored by Elizabeth Silvy, a student at Texas A&M University,

continued in "Better Breeding" feature on page 21

Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 80 Valleybrook Dr., Toronto, ON M3B 2S9

Graduate student Elizabeth Silvy prepares a male flounder for hormone injection.

Photos: Elizabeth Silvy

Disease and poor health are some of the main constraints for sustainable aquaculture.

MSD Animal Health develops environmentally responsible products to maximize fish survival, growth and production efficiency for the major farmed fish species: salmon, tilapia, trout and other marine species.

Every day, in every corner of the world, progressive fish farmers turn to MSD Animal

Health. They ask about our full range of products for managing the most serious diseases in aquaculture. Even more, they come to us for integrated health solutions to help them become more profitable, competitive and sustainable.

For more details please contact your local MSD Animal Health representative or contact us at aqua@merck.com or visit us at www.aqua.merck-animal-health.com.

Volume 18, Issue 5 | SEPTEMBER/OCTOBER 2017

Editor Peter Chettleburgh, peter@capamara.com

Science Editor David Scarratt, scarratt@ns.sympatico.ca

Regular Contributors Quentin Dodd, Diogo Thomaz, John Nickum, John Mosig, Erich Luening, Philip Nickerson, Matt Jones, Ruby Ganzalez

Advertising Manager Jeremy Thain, jthain@annexweb.com Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Circulation Manager Barbara Adelt, badelt@annexbizmedia.com

Design & Production James S. Lewis, james@capamara.com

Group Publisher - Scott Jamieson sjamieson@annexweb.com

COO – Ted Markle, tmarkle@annexweb.com

President & CEO – Mike Fredericks

outside North America. To subscribe visit our website at www.hatcheryinternational.com

Subscriptions Angie Potal, apotal@annexbizmedia.com

Tel: 416-510-5113 • 1-800-668-2374 (CDN) • 1-800-387-0273 (US/FGN) Fax: 416-510-6875

Printed in Canada. Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Hatchery International. CIRCULATION DEPT. 80 Valleybrook Dr., Toronto, ON M3B 2S9 ISSN 1922-4117

Next Ad Deadline

The advertising deadline for the Nov/Dec issue is Sept . 8th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexweb.com

Next Editorial Deadline

The editorial deadline for the Nov/Dec issue is Sept . 8th. Contact the Editor, Peter Chettleburgh at +1.250.478.3973 for details. E-mail to peter@capamara.com. Material should be submitted electronically with prior arrangement with the editor.

NEWS BRIEFS

ISA suspected at AquaGen brood site

According to a recent press release from AquaGen, a virulent variant of the ISA virus was detected in salmon broodstock at the company’s Merraberget sea site in western Norway.

The release from AquaGen notes that the Atlantic salmon population in question have an average weight of about 12 kg and were planned to produce eggs from September 2017. There are a total of 14,500 broodfish at the site.

“There has not been any increase in mortality,” notes AquaGen, “and the virus detection was initially reported on 6th July 2017 as part of routine surveillance and sampling carried out by the fish-health service Åkerblå. The site is located in Tingvollfjorden and the distance to the nearest neighbouring site is over 10 km.

AquaGen’s other egg producers in Hemne and Steigen have additional capacity and the company says that it will be able to meet customers’ egg requirements for the egg-season 2017/2018.

New facility to produce omega-3 fatty acids in Nebraska

New funding, jobs for Canadian research

Canada’s Department of Fisheries and Oceans has announced the establishment of eight new marine science jobs and continuation of some $8.9 million in funding for the agency’s St Andrew’s Biological Station in the eastern province of New Brunswick.

The money will also be used to “rebuild” some of the aging laboratory facilities at the station which was founded in 1908 - Canada’s oldest biological research station. The facility carries out scientific studies focused on the Bay of Fundy and the Gulf of Maine, as well as monitoring regional coastal ecosystems and the state of traditional fisheries stocks and aquaculture programs.

Evonik and Royal DSM recently announced that the companies will build a commercial-scale production facility for omega-3 fatty acids using natural marine algae in Blair, Nebraska.

DSM Nutritional Products and Evonik Nutrition & Care plan to invest up to US$ 200 million in the facility (US$ 100 million by each party over two years).

According to an announcement from the companies initial annual production capacity will meet roughly 15% of the current total annual demand for EPA and DHA by the salmon aquaculture industry.

The new facility will allow for the production of omega-3 fatty acids without using any fish oil from wild caught fish. Initial applications will be in salmon aquaculture and pet food.

View of the Merraberget sea site in the Tingvoll fjord, Norway.

St Andrew’s Biological Station.

Cargill opens new research lab in Norway

The Cargill fish-feed company recently opened a new aquaculture- research lab addition in Dirdal, Norway, dedicated to developing new diets for the fish-farming industry.

Created at a cost of $1.25 million, says the company, the new research building unit “furthers Cargill’s commitment to strengthening its aquaculture research and development capabilities.” It was built on the Cargill (formerly EWOS) Innovation Center grounds, where research has been conducted for more than 30 years.

The new lab houses 11 employees who will work to support Cargill’s pilot plant, sea site fish trials and aqua scientists.

Lampreys besiege California hatchery

After the Feather River Fish Hatchery in Oroville, California was hit by flooding earlier this year, personnel at the facility confirmed that the unit has also experienced a sudden, unexpected invasion of lampreys.

A statement from the state Department of Water Resources notes that the eellike fish have always lived in the depths of the Feather River, but recently hatchery manager Penny Crawshaw said the unit’s external fish ladder was suddenly blitzed by hundreds of the creatures, some of which got stuck to the hatchery’s public-viewing windows.

Crawshaw said nobody at the hatchery had seen any lamprey at that location in something like 25 years and the size of the invasion made them considerably more visible than they had been for decades.

The hatchery staff eventually shut off the water flow through the ladder so the fish couldn’t go up, and returned hundreds to their usual stretch of river.

None of the lamprey entered the hatchery, said Crawshaw.

UAE launches restocking program

A report from Dubai notes that the United Arab Emirates’ Ministry of Climate Change and Environment, working in collaboration with a private facility, recently released numbers of large (150gram) Qabit (rhabdosargus sarba) and black sea bream (Sha’am) fish in protected marine areas, with 30,000 of the specially cultured fish to be released in each emirate.

Minister Thani Bin Ahmad Al Zeyoudi said the initiative is aimed at increasing the stocks of local fish and developing the local fish species’ breeding program – as well as providing technical services and advice to small local fish farms.

Australian scientists breed sea urchins to test export potential

ea urchins are a favourite menu item for sushi consumers in Japan, especially on Okinawa, where collector urchins (Tripneustes gratilla) grow naturally but are now seriously over-fished.

With this in mind researchers at Australia’s Southern Cross University (SCU) in New South Wales have been breeding it at the National Marine Science Centre (NMSC) in Coffs Harbour. A recent statement from the Centre says it’s about to send some to Japan and also plans to boost the state’s aquaculture industry by exponentially increasing the numbers of urchins available for export.

Over the past decade, according to SCU program leader Associate Professor Symon Dworjanyn, personnel at the NMSC have not only closed the life cycle of the collector urchin, but have succeeded in growing “millions” of them in the laboratory. In the process, one member of the team has made an extraordinary discovery, which may well account for the high densities at which the urchins normally grow in the wild, and which could make them a candidate for culture for the export trade.

SCU marine biologist and PhD candidate Hannah Sheppard-Brennand discovered that collector sea urchins have an anti-predator defence mechanism called pedicellariae – miniscule but fairly potent venom-bearing jaws that grow between the urchins’ spines and which can be released in a small cloud to deter potential predators.

These pedicellariae release a venom that is effective in deterring fish, but which Dworjanyn said has never been any serious problem for him or his staff when spawning sea urchins in the lab.

Getting them to spawn is comparatively easy. The urchins are brought to the verge of releasing eggs and sperm by feeding to the point of excess with the common Sargassum seaweed, then they inject a small group, usually three males and three females, with potassium chloride (KCl). The urchins are normally kept at temperatures of 24-27°C, and three females can release tens of millions of eggs apiece, while the males put out 1015 (many billions) sperm. Fertilization is external.

The researchers speculate that the pedicellariae, in addition to the urchins’ short spines, could help account for the high densities at which the urchins can grow in the wild, if not over-fished.

Dworjanyn said that increasing consumer demand and reduced natural supply are creating opportunities for commercial sea urchin culture in Australia, and that the technology they have developed to produce juvenile sea urchins “is world beating in its efficiency.” He believes that, through SCU and the Centre’s research program, Australia has an excellent opportunity for growing sea urchins in high quality, warm water aquaculture sites with a clean “green” image.

The program has received financial support and assistance from the federal government, and planned a shipment of juveniles to Japan in July this year.

– Quentin Dodd

The key to your future in aquaculture is here.

Over the past decade staff and researchers at the National Marine

Centre (NMSC) in

have closed the life cycle of the collector urchin and succeeded in growing millions of them in the laboratory. It's hoped that the success will help boost the state’s aquaculture industry by exponentially increasing the number of urchins available for export. A trial shipment of juveniles to Japan was planned for this summer.

Photos: Ben Mos

Science

Coffs Harbour, New South Wales

Tripneustes gonads.

POINT OF VIEW NEWS

Multi-species marine hatchery opens in Sri Lanka

Sri Lanka’s first multi-species hatchery for marine finfish was inaugurated at Tharmapuram, in the city of Batticaloa – on the east coast of the island – last June. Designed to assist in the development of marine finfish farming that has already been started in the region, the facility will help local farmers and fish breeders meet growing local and export demands.

The Head of Cooperation for the European Union’s official delegation to Sri Lanka and the Maldives, Libuse Soukupova, said that the proper handling of a new marine finfish hatchery could bring substantial export earnings and benefits to Sri Lanka, since it’s already been shown there is a market in the European Union for a variety of marine finfish species. She mentioned in particular sea bass, grouper, milk fish, silver pomfret, sea bream, mahi mahi, cobia and snapper. She also said that encouraging the culture of such species would help minimize the exploitation of native lagoon and marine fisheries and increase income levels in fisher communities.

The Multi-Species Marine Finfish Hatchery was built by the Food and Agriculture Organization of the United Nations (FAO), in partnership with the National Aquaculture Development Authority (NAQDA), with some 142 million rupees (roughly $2.2m USD, 1.2m Euros) from the European Union. Established under the European Union Support to District Development Program (EU-SDDP), it has enough capacity to produce four million fingerlings a year for distribution to finfish farms throughout the country.

– Quentin Dodd

Early life stage research… a new opportunity for US aquaculture

BY JOHN NICKUM

The Foundation for Food and Agriculture Research (FFAR) is a nonprofit organization established by the United States’ Congress in the 2014 Farm Bill. Remarkably for these times, there was bipartisan congressional support for the organization and the activities it supports, which include aquaculture.

The FFAR announced a competitive, matching grant research program in early June (2017), designed to stimulate innovative research on farmed production of fish and shellfish. One of the focus areas identified in the announcement was research to identify best practices for early stage life cycle production of commercial fish.

Studies to identify additional species with potential for commercial production are another focus area. And studies to analyze the potential for expansion of presently cultured species into additional geographic areas will also be encouraged.

These types of research and development studies are complicated and difficult, but they are important, perhaps essential, if the United States is to become competitive in international aquaculture production.

environments are required for live feed production. Those who prefer formulated feeds argue that adding facilities and operations for these live food items increases costs and the possibilities for failure… one more chance to screw up. Conversely, developing formulated feeds and feeding systems that meet all the requirements needed by the newly hatched fish can be costly and complicated… very complicated.

THE WALLEYE CHALLENGE

My own research, many years ago, provides an example of the challenges involved with the culture of early life stage fish, especially species that have not been hatcheryreared previously.

FINANCIAL CONSTRAINTS

The financial capabilities of the aquaculture community for research and development studies are very limited, essentially non-existent; so, it is encouraging to obtain support from an organization such as FFAR.

Research focused on production of “new” species and, especially on early life stage production methods, is rarely a priority for commercial farmers, or even managers of state and federal facilities.

When current methods are considered to be satisfactory (good enough?) and produce satisfactory survival and growth of the species under production there is little, or no, incentive to investigate new methods and/or culture of additional species.

Budgets are always lean, so exploring new horizons is pretty much an unaffordable luxury for most farmers and managers. If new methods are to be developed, or production of “new” species explored, funds will have to come from government programs, or non-profit foundations.

DIFFERENCE OF OPINION

There is a long-standing argument among fish culturists concerning the preferred approach for culturing early life stage fishes. Those who prefer to maximize control of the entire process want predictable feeding regimens based on formulated feeds. The other, traditional, side of the “discussion” argues that it is unrealistic to design feeds that the young fish will eat and satisfy all of their survival and growth needs. These culturists contend that offering live food items, similar to those the fish would eat in a natural environment is more realistic.

However, the live food approach requires additional culture operations; production of an array of invertebrates and/or algae. Extra culture units and/or natural pond

My students, research associates, and I focused on developing intensive culture systems for walleyes (Sander vitreus); systems to rear them from first-feeding early life stage through to market size. Walleyes, and other fish similar to them, such as striped bass (Morone saxatilis), are especially difficult because the newly hatched fish are very small (7-8 mm), have small mouths, and very small yolk sacs. The energy and nutrient reserves in their yolk sac are extremely limited. They must begin feeding within 3 to 4 days, at the longest, or they “sink” into energy and nutrient deficits from which they cannot recover.

Adding to the problems in the case of walleyes is the fact that first-feeding larvae lack several gut enzymes; therefore, digestibility of feeds was a major issue. We designed initial feeds on formulas designed to replicate the nutrient and energy composition of walleye eggs, but with lower fat content. Feeds with full equivalent fats had the consistency of peanut butter.

Tank/trough culture of first-feeding fish requires solutions to an array of culture conditions in addition to a satisfactory feed. Water temperatures, light conditions, water movement, and aeration systems all must be controlled within narrow limits similar to those experienced by each species in its natural habitat.

In the case of walleyes, and similar carnivorous species, control of cannibalism adds to the challenges. All these challenges notwithstanding, it is technically possible to rear walleyes from hatching to market size fish (~ 4 kg) under intensive culture conditions. However, price competition from wild-caught fish captured primarily from large Canadian lakes, has prevented the development of economically feasible walleye farming.

CREATIVE FARMERS

The research support offered by FFAR will provide creative farmers, managers, and researchers with incentives to identify species with market potential, and design research plans to address the myriad challenges inherent in the culture of early life stages that suit the needs of “new” species in new geographic areas.

Given the reality that the United States currently imports almost 90% of the seafood consumed domestically, half of which comes from foreign aquaculture sources, it is vitally important for American producers to accept and meet these challenges.

Silver pomfret is one of the species under consideration for production in the new facility.

lorida red tilapia (Oreochromis sp) fry may tolerate salinity levels up to 36‰ without requiring acclimation if they come from broodstock acclimated at the same level, according to researchers from Egypt.

Tilapia broodstock and larval production under different water salinities without acclimation, published in the Journal of Aquaculture Research & Development, “highlights the importance of rearing Florida red tilapia broodstock in saltwater in order to have offspring tolerable to the marine environment.”

“While the suitability of the Florida red tilapia strain for seawater grow-out has been demonstrated by high growth rates and feed conversion efficiencies, the hatchery phase of production remains restricted to water of lower salinities. The need for low-salinity water for maintaining broodstock and fry – thus affecting the ability of farmers to obtain fingerlings –restricts the establishment of future hatcheries in low-salinity water areas,” the authors said.

The study was conducted for 32 weeks at El-Max Research Station, NIOF, in Alexandria, Egypt.

FOUR SALINITY LEVELS

TWO-PHASE STUDY

Conducted in two phases, the study began by focusing on the effects of different salinity levels on the broodstock’s growth performance and fry production.

Placement:

The research team was composed of Ghada R. Sallam, Hadir A. Aly, Mohamed A. El-Absawy, and Zeinab A El-Greisy from the National Institute of Oceanography and Fisheries (NIOF), Alexandria Branch; and Walied A Fayed from the Alexandria University.

Red tilapia fingerlings, which were raised as broodstock, were acclimated in fiberglass tanks on four salinity levels – 9‰, 18‰, 24‰, and 36‰ – and freshwater as a control treatment. After spawning, fry were collected for the second phase of the experiment. Each batch of fry from broodstock of a different salinity level was exposed to three different salinity levels, low, medium and high at 9‰, 18‰, and 36‰, respectively,

without an initial acclimatization period.

“The results implied that best growth for broodstock was observed with 36‰ and no significant difference in survival,” the authors cited.

Broodstock with 18‰ produced the highest number of fry/kg. But this indicator aside, fry from broodstock with 36‰ performed the best. It tolerated high salinity levels of 18 and 36‰ with high survival rates of 90 and 92‰, respectively, and with highest growth rate.

INCREASED PERFORMANCE

“It could be concluded from the study

of Florida red tilapia broodstock increases with increasing salinity after gradual acclimation.

“Also, when fry of Florida red tilapia from acclimated broodstock are reared in marine water they could possibly tolerate high salinity (marine environment) levels without acclimation. Therefore, the study highlights the possibility that acclimation of Florida red tilapia broodstock at high salinity levels produces seed that could tolerate the direct transfer to marine water without requiring acclimation,” they said. – by Ruby Gonzalez

cool concept

continued from cover

MAXIMIZING THE GAINS

“Less work, faster growth, improved pigmentation and reduced mortality will certainly contribute to better economics for the hatchery manager,” says Husby. “In addition, reduced microbiological activity in the fish tanks reduce the need for cleaning the tanks. The fish will experience better health and lower mortality. The immune system will benefit from the right type of feed and we have conducted studies ourselves showing that fish getting our feed better cope with stress than fish given traditional feed.”

Transporting Planktonic’s feed requires a cryocontainer to maintain the temperature. “It’s not like you can take it in a suitcase and carry it on a plane, but I think it’s quite efficient,” adds Husby.

Planktonic AS was formed initially in 2008 by Nils Egil Tokle, a PhD in marine biology, and Haavard Aakeroy, a mussel farmer and co-owner of Norway’s largest mussel producer. The company was formed initially to focus on inert feed, but in time developed the cryopreservation technique.

“They started experimenting with this in a small scale and had a little bit of a hunch as to what species that this could actually work with,” says Husby. “Due to both extreme creativity and in-depth knowledge about zooplankton biology, they could actually leap-frog a lot of stages that people otherwise would struggle with for years. When we discussed this with people from either academic circles or people from the cryopreservation business, they are struck with awe that this is actually possible with an organism in this context.”

BIGGEST CHALLENGE

The biggest challenge for the company currently is producing enough product to meet demand. They currently sell everything they produce. Expansion of their business will require proportional expansion of their operations.

“It’s about purchasing equipment,” says Husby. “It’s about making the equipment even better, and actually doing everything we do a little bit better. So, it’s all about industrializing the process and being able to produce even more tons than we do today. We have to make sure everything in all departments is working efficiently.”

To utilize the Planktonic product a hatchery manager need only throw the cryo-preserved nauplii into sea water and within eight hours they are ready for use.

Since 1958, Faivre has been developing and manufacturing high quality equipments for the aquaculture industry

An x-ray shows the Cryo-plankton inside the stomach of a sole.

COVER

Northern Divine Profile

resistance, body conformation and color for over 30 years.

“Our breeding program has remained incredibly diverse,” says Henry. “We have never had to go back and collect more stock.”

As an aquaculture species, coho have a number of advantages and when you factor the all-female component, you can literally double those advantages, Henry explains.

“Coho have a fast growth rate that really sets them apart from other salmon,” he says. “In salt water at an ambient temperature between 6 – 20°C, a 50g smolt typically reaches 3 kg in 13 months.” That rate can be increased in a controlled system with optimal rearing photoperiod and temperature, Henry adds.

It’s a great product Henry maintains. “Coho are a bright silver colored salmon,” he says. “The flesh can be a very dark red and they are leaner than Atlantics or chinooks. Chefs looking for something a bit out of the ordinary love them.”

Coho are equally at home in both salt and fresh water and are suitable for ocean or lake pens, or land-based facilities. “We have salmon farmers raising them in ocean pens, trout farmers raising them in full RAS and a variety of combinations in between,” says Henry.

THE QUEST FOR FEMALES

But it’s the coho roe, that got Northern Divine on the quest for an all-female population.

“In the olden days of salmon farming, the roe was just being thrown into the offal tote with the rest of the guts to go for rendering,” Henry recalls. “One day a customer asked if we could send him some of the roe so that he could make ikura, or salmon caviar. We did, and at the end of the season he sent us a cheque for $7,000.”

“Well, we didn’t throw out any more roe,” Henry chuckles. He says coho roe has the second highest market value to that of chum salmon, which is only sourced from the wild. Indeed he should know, Northern Divine also raises white sturgeon for caviar and flesh sales.

“We wondered if it was possible to produce an all-female population,” says Henry. “It took 10 years, but that is what we did. It’s a similar process to that used for rainbow trout and chinook but its trickier.” He says the process is proprietary, and complex, involving manipulating various environmental conditions. “But we are certified Organic,” he adds. “So that tells you something.”

MULTIPLE BENEFITS

Producing an all-female egg multiples the benefits of raising coho. With an allfemale stock, you are able to save costs. “There is no risk of precocious males that will need to be taken out of your production,” Henry says. “Because there are no males, you are able to push your smolt growth faster without worrying about the risk of jacking.”

“And if you are looking to do Ikura, with all-female fish you have double the roe.” Henry notes.

Over the years Northern Divine phased out the net pens and fresh salmon sales and moved all their broodstock holdings onto land. A full RAS system re-uses 99% of their water.

“We are in an isolated situation with excellent ground water and our landbased system allows us to be certified disease-free,” Henry points out. He says the company is certified by the Canadian Food Inspection Agency (CFIA) compartmentalization program,

that follows the guidelines of the World Organization for Animal Health (OIE). The program includes specific premise requirements to ensure that the exported eggs are consistent with international standards for aquatic animal health management.

“The compartmentalization from CFIA allows us to more easily export our eggs,” says Henry. “We are currently shipping across North America as well as Europe, Asia and South Africa and we hope to be servicing the Chilean market soon.”

Temperature and light controls allow them to have four spawn cycles with extended windows of availability. “We are able to ship eggs throughout the year,”

Customers are diverse. Salmon farmers are adding them to their sites Henry says. “Coho are resistant to ISA and to sea lice so adding coho to a location can be beneficial.” Henry acknowledges that it is a niche market, but one that pays a premium.

“The feedback we get is that the trout farmers who have tried them are sticking with them,” says Henry. “They are looking to diversify, they find that the growth is amazing and they like the benefits of the all female. That’s the opportunity we are offering our customers.”

Henry says. “Trays of 50,000 live eggs, on ice in insulated boxes, can go around the world.”

Lloyd Henry, long time aquaculture technician at Northern Divine Aquafarms, holds big female coho salmon during broodstock sort.

Overview of outside tanks at Northern Devine Aquafarms.

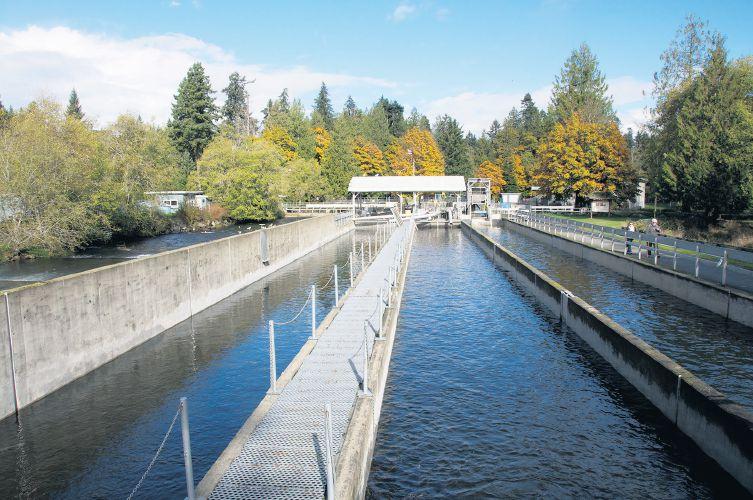

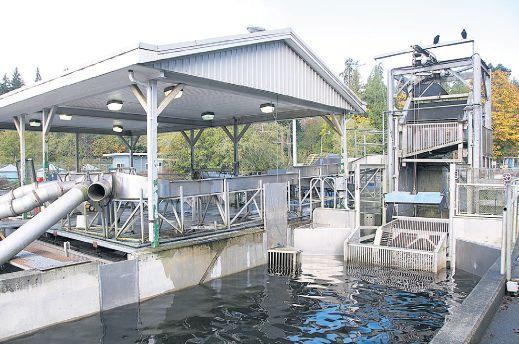

White River national hatchery back in business

early six years ago floodwaters caused by Tropical Storm Irene slammed into the US Fish and Wildlife Service’s White River National Fish Hatchery in Bethel, Vermont resulting in its closure. Now, following an extensive $2.3 million renovation and repair program, the hatchery is “back in business” with a new mission to produce eggs for landlocked salmon destined for Lake Champlain, and lake trout for Lakes Ontario and Erie.

N“contaminating” the remaining tanks. Thousands of big Atlantic-salmon broods-fish were donated to Native American groups for use in ritual ceremonies, and approaching 500,000 lake trout intended for stocking into Lake Ontario and other locations had to be destroyed.

Not all the tanks inside and outside the main hatchery building as yet have fish, but many do and the hatchery is revving up for its new work in producing and distributing eggs. In a special reopening ceremony Vermont’s US Representative, Peter Welch, referred to the hatchery as “a real symbol of resilience” as well as of respect for nature.

In August 2011 floodwaters from the White River inundated the hatchery’s outdoor holding tanks, flushing out thousands of hatchery-raised Atlantic salmon (Salmo salar) into the river and

Prior to 2011, the hatchery’s main purpose had been to raise Atlantic salmon for release into tributaries of the Connecticut River, as part of a decadeslong program to restore the native stocks of Atlantics in Connecticut, Massachusetts, Vermont and New Hampshire.

Then, according to manager Henry Bouchard, in the following year, USFWS officials decided to abandon the Connecticut River since too few adult fish had been returning to the river to reproduce, and agreed that the facility’s new role would be to maintain broodfish and raise eggs to send to other units.

U Turkish producer touts record shipment to Oman

ntil recently, Kilic's sea fish were shipped by sea, but market demand from land-locked areas in the Persian Gulf necessitated a look at alternative transport.

The fish transported to Oman were placed in boxes made of special plastic and loaded on a plane equipped with oxygen for the flight.

Serkan Ilgaz, Director of Hatcheries and Foreign Investments, reports in a company release that Turkey has become the market leader in sea bream and sea bass.

“Our hatcheries in Muğla and Aydın produce 200-250 million seed fish a year – half the seed fish production in Turkey.

We are now exporting live fish to Tunisia (where we have 30% of the market), Oman, and Saudi Arabia.” Kilic produces 50,000 tons of fish annually, of which 70% is exported.

Turkey’s Kilic Holding successfully completed its largest air shipment to date when 1.2 million live juvenile Mediterranean sea bream (worth USD $500,000) were airlifted to Oman.

Russian hatcheries to offset negative impact of new bridge

Three hatcheries from Krasnodar Krai in Russia will release 500,000 sturgeon fry per year, or 1.5 million in total, to the Kuban River and Azov Sea from 2017 to 2019, partly to help mitigate damage done by construction of the Kerch Strait Bridge.

The Kerch Strait Bridge is a road-rail bridge under construction to establish a land connection between Crimea and mainland Russia. However, according to ecologists, primarily from the Ukraine, whose government actively opposes the project, the new bridge will seriously damage the local environment, including populations of sturgeon in the Azov Sea.

estimated that total damage to the flora and fauna of the Kerch Strait from construction of the new bridge could be as high as UAH 10 billion (US$381 million). It promises to take Russia’s government to the international court over these claims.

The program itself doesn’t indicate that the Kerch Strait Bridge will actually bring harm to the local environment, suggesting instead that populations of sturgeon in the Azov-Black Sea basin should be increased because in recent decades it significantly dropped owing to large-scale poaching in the region.

The Institute of Water Problems and Melioration of the National Academy of Sciences in the Ukraine recently

For hatcheries in southern Russia the construction of the Kerch Strait Bridge will mean increased utilization. In accordance to several contracts, three hatcheries operating in the region, already release significant sturgeon fry to regional waters per year and within the new contract this figure will be increased.

– Vladislav Vorotnikov

The Kerch Strait Bridge is a road-rail bridge under construction to establish a land connection between Crimea and mainland Russia.

New aquaponics facility planned for Malawi

Students and professors from Lakeland University, Sheboyan, Wisconsin, were recently reported to be preparing to fly to Malawi, Africa to collaborate in building an unusual aquaponics facility. The project is a joint effort between business- and biology students at the college and graduate student Patrick Tembwe, who hails from Malawi. Tembwe, graduated from Lakeland in 2004 and was back on campus studying for his MBA, said he’s excited to be planning what he thinks will be the first aquaculture-and-hydroponics business in that country.

A report from Wisconsin said that the plan is to grow tomatoes, lettuce, onions, kale and other vegetables, along with chambo (Oreochromis lidole), a tilapia-like fish native to Malawi. The plants will be grown without soil, supplied with nutrients from the fish culture tanks.

And in addition to selling the produce, Tembwe intends to supply a nearby orphanage with vegetables and fish. He and four Lakeland students were reportedly learning how to operate the system, in part through a partnership with Lake Orchard Farms Aquaponics, located near Sheboygan. Tembwe has already learned to set up his own system in Africa, initially using 110-gallon (420 litre) tanks rather than the 500 gal tanks he is used to at Lake Orchard Farms.

PROFILE

Dainichi Corporation Japanese producer a veteran in sea bream sector

For 35 years a marine hatchery on Japan’s Shikoku Island has been producing red sea bream juveniles for deep-water growout in local waters.

BY BONNIE WAYCOTT

ed sea bream (Pagrus major) has been eaten in Japan for at least 5,000 years. It’s featured prominently in festive occasions because the Japanese word for the species, madai, sounds like medetai, meaning auspicious or joyous. It’s also an important species for Japan’s commercial aquaculture sector. Its fast growth rate and ability to spawn naturally in captivity makes it economically advantageous and particularly attractive.

EARLY DAYS

One company that’s been reaping the benefits of red sea bream is Dainichi Corporation on the island of Shikoku, southwest Japan. Since its establishment in 1982, it’s been specialising in deep sea farming – the rearing of red sea bream at depths of 40 to 50m, with a nearby hatchery called Yamasaki Giken Co., Ltd supplying juveniles for growout. Although Yamasaki Giken began as a machine manufacturer, its founder’s interest in the environment sent it moving in a totally new direction.

“Our founder is extremely interested in the severity of declining fish stocks,” explained Sachi Morita of Yamasaki Giken’s Research and Development division. “He decided to open a hatchery because he believed we should produce the fish we want to eat, not take from the wild.”

Yamasaki Giken sits on an area of 10,000m2 and faces Uranouchi Bay, an enclosed bay in the southern part of Shikoku. At 10.5km long, its morphological features suggest what’s known as a submergent coastline. The bay is

low and narrow with small inlets that offer protection from high waves and strong winds.

Yamasaki Giken employs 33 people divided into five departments – land operations, sea operations, research and development, sales and marketing and management.

REARING SYSTEMS

Two round tanks, each containing up to 50 fish, are used to rear broodstock, and 22 holding tanks are used for larvae and fry. Rotifers are reared in 12 holding tanks, while artemia are incubated in four and grown in four.

Selected references of landbased RAS2020™ fish farms

• Salmon – Swiss Alpine Fish, Switzerland

• Kingfish – Sashimi Royal, Denmark

• Salmon – Fredrikstad Seafoods, Norway

WATER TECHNOLOGIES

Landbased fish farming for the future

We provide turnkey standard solutions, such as RAS2020™

– aquaculture systems, for large-scale sustainable fish production.

• No underground piping

• Reduced foot print – up to 40 – 50 pct.

• Flexible production – adjustable tank size

• Tailored wastewater treatment

For further information please contact us at aquaculture@kruger.dk Meet us at Aqua Nor booth A2-601

Resourcing the world

Seawater for the tanks is drawn directly from the ocean, disinfected through ultraviolet sterilization and pumped into the holding tanks. Once purified, it’s returned to the ocean. Regular water checks are conducted in line with Japan’s Water Pollution Prevention Act and strict controls are in place for broodstock selection.

“We select our broodstock based on size and traits,” said Morita. “We tag them for identification, photograph them, and take a DNA sample. We make sure that they have a high level of genetic diversity and that inbreeding is avoided. We check that the fish are active with complete fins and scales and free from disease. This is key to sustainable production.”

BROODSTOCK AND EARLY REARING

The broodstock are put into holding tanks at the beginning of December. Water temperature and light are carefully controlled and in February and March their eggs are collected, transferred to separate tanks and divided into floating and sinking. Dead eggs that settle at the bottom are removed by siphoning, while the floating ones are transferred to rearing tanks until they hatch into larvae. Samples are also taken to check for the virus that causes Viral Nervous Necrosis (VNN) that typically affects the younger stages of fish.

After hatching, the condition and feed intake of the larvae are monitored daily. On the first day, they are minute at around 3mm and live on their yolk sac for the initial three days. By the fourth day, when their eyes and mouths become more prominent, the actual feeding begins. When they’re between 2 and 26 days old they are given rotifers, artemia at 14 to 29 days old, frozen copepods at 15 to

All photos: Yamasaki Giken Co

A hatchery technician checks quality of rotifers.

Juvenile red sea bream just prior to delivery.

Routine water quality check and monitoring.

Hatchery staff seine up juveniles for delivery to grow-out sites.

29 days and formulated feed from day 23 onwards.

“We control feeding, water temperature and dissolved oxygen using a computer, said Morita, “while an automated system rears rotifers and artemia, cleans them and distributes them to the tanks. When the larvae are around 40mm and have developed into fry capable of feeding themselves, the tanks start to become congested so they are moved to offshore cages.”

OFFSHORE OPERATIONS

The fry are reared offshore until they’re around 70mm. They are then divided according to size into small, medium, large and extra large, and separated to allow more space to move around and reduce stress. When they’re around 80mm, they’re returned to the hatchery and checked for any deformities (those that cannot be delivered are removed) before being shipped out in line with orders received from Dainichi and other growout facilities.

The fry are delivered on boats or conventional light trucks containing open tanks for shorter distances or closed tanks for larger quantities and long distances. After delivery, a Yamasaki Giken staff member checks the fry and makes sure that any information that could be required in the next stage of production is shared.

Biosecurity and disease prevention are key to a successful procedure.

DISEASE PREVENTION

“Our disease prevention measures are pretty thorough,” says Morita. “Staff must step into trays containing Glutaraldehyde before entering the tank areas. We have lost thousands of larvae to disease before, so we rigorously disinfect equipment, and if necessary, minimize frequent transfers to tanks.”

Any larvae or fry suspected of carrying disease are taken to Yamasaki Giken’s research laboratory for examination. Dissection, the isolation of bacteria and PCR diagnoses can identify any possible disease and contribute towards early detection and prevention. Those that have already been shipped can be returned if required, and feedback is provided that will be of use in the next production stage.

Morita believes that farmed fish will continue to be a key commodity.

“The demand for farmed fish is rising,” she said, “and there will be more sales, not just within Japan but also to the rest of the world. Security, safety and good product quality are vital, beginning at the hatchery stage. Our mission is to make our operations more transparent and work in line with the needs of today’s fish farmers.”

systems for fish farms for both freshwater and marine fish species

Aeration and degassing systems

Wastewater treatment plants for industrial and domestic sewage

Bioscrubbers and cooling towers

EXPO-NET Danmark A/S Georg Jensens Vej 5, DK-9800 Hjørring, Denmark Email: plast@expo-net.dk www.bio-blok.com - www.expo-net.com

The BIO-BLOK ® filter media is a Danish manufactured and patented product.

Hatchery staff inspect juvenile red sea bream prior to delivery to sea sites.

RESEARCH NOTES

Effect of diet on carp reproductive performance and quality of progeny

ish oil (FO)-based diets attained the best production performance value for common carp larvae and fry, “although not significantly,” according to an abstract entitled the Effect of the diet composition on reproductive performance of common carp breeders and development of progeny.

“Long-chain polyunsaturated fatty acids (LcPUFAs) of the ovary samples have shown significant differences between the control and fish oil (FO) group. FO and vegetable oil (VO) groups had higher eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA), but lower arachidonic acid (ARA) proportions than control groups most likely caused by the applied feeds,” noted Sándor et al of Hungary’s Research Institute for Fisheries and Aquaculture in the abstract.

Histological observations, they said, did not reveal any significant differences in vitellogenic oocytes between dietary treatments. It was explained that this was probably due to the nearly adequate simulation of natural food supply.

“Broodstock nutrition can significantly impact reproductive performance and affect the quality of progeny. The nutrient supply regarding the fatty acids, especially LcPUFAs, has special importance as they significantly could contribute to adequate nutrient reserves of the eggs,” they noted.

Groups of female breeders and males were each assigned to specific feeds in order to document the effect on the quality of gametes in common carp breeders and to the development of progeny of diets with different LA+LNA (Linoleic acid/Alpha-linolenic acid)/LcPUFA and n-3/n-6 ratios.

These had moderate fish meal and fish oil content (feed FO with low LA+LNA, high LcPUFA); plant protein and vegetable oil (feed VO with high LA+LNA, low LcPUFA); and wheat as control feed and by applying additional pelleted feed to simulate the contribution of natural food (1/3 of protein requirement was supplied in the additional complete pelleted feed).

At the end of trial, an identical number of males and females were sampled. Gonads were collected for FA measurements and eggs for histological analysis.

At three days post-hatch, the larvae were sampled to evaluate rate of deformity, weight and height. During the pre-nursing period, the fry were reared on natural feed. Fry performance production and FA composition were conducted after four weeks of rearing.

– Ruby Gonzalez

Canadian government reverses decision to cut salmon enhancement programs on west coast

anada’s Department of Fisheries and Oceans (DFO) has decided against a number of proposed cuts to its salmonid-enhancement and – support programs on the nation’s west coast.

The department is also reversing cuts to its Resource Restoration Unit, the engineers and biologists who help volunteers run community-based enhancement programs such as small hatcheries and stream restoration projects on the west coast of Canada.

One volunteer in a stream-keepers group in Hecate Strait, halfway up British Columbia’s coastline, called the reversal “a success story for community volunteers all through the province,” adding that there are an estimated 35,000 such volunteers scattered across BC. “Locally, it would have been devastating to our programs, our little hatcheries, and especially the salmon in the classroom.”

In Haida Gwaii, the Salmon in the Classroom program brings egg incubators to 15 elementary – and high school classrooms every winter and spring. A teacher in the area said elementary students learn the salmon lifecycle – from egg to

fry, smolt and finally adult salmon, while the high-school youngsters deal with such subjects as ecology and habitat, stream restoration and forestry practices.

According to DFO, the Salmon Enhancement Program (SEP) budget this year is $27 million, with most of that money going to 23 major hatcheries run by the department. The department’s review of the Salmon Enhancement Program had suggested cutting out “non-core” projects such as community-run hatcheries that apparently raised only 8% of the total salmonid-fry released in 2015.

The proposed cuts were immediately unpopular, particularly in Haida Gwaii, where local New Democratic Party Member of Parliament Nathan Cullen was quoted as saying he found them “mystifying” – particularly given the small amount of money that would be saved.

“We need kids knowing more, not less about the salmon world, so they can become the generation that does better than the previous one at protecting it,” he’s cited as saying.

–

Quentin Dodd

SHELLFISH

Photo: Devin Harvey, SeaWeb

Fish farms made in Germany

• Fish farm design: RAS and flow through

• Turn key systems

• Drumfilters

• Moved bed filters

• Fixed bed filters

• Denitrification

• Oxygenation

• UV disinfection

• Oxygen monitoring

• Farm control systems

• Feeding systems

Seed supply a challenge for North American oyster producers

The head of Taylor Shellfish in North America talks about the challenges of seed supply and sounds the alarm on the POMS virus.

BY TOM WALKER

The seed side of the shellfish farming sector is challenging, says Bill Taylor, the president of Taylor Shellfish based in Washington state, and the largest shellfish grower in North America.

“I tell people all the time that there is a reason why a mature Pacific oyster female has 100 million eggs,” says Taylor, only partly joking. “It’s because you need a lot of eggs to come up with adequate survival. They have very high mortalities in their progeny and the reason they have been able to survive is because they are very fecund.”

One of the biggest issues for Taylor Shellfish and indeed for producers across the industry, is having a consistent and reliable source

One of the biggest issues for Taylor and indeed across the industry, is having a consistent and reliable source of seed. “I would say there is probably a shortage of oyster seed and it is a perpetual problem,” adds Taylor.

He describes it as a boom and bust cycle. “Some months are great for hatcheries and some are not great. The seed you thought you had dies and so what you thought was going to be a great year all of a sudden is not so great.” There is seed available Taylor elaborates, but it doesn’t always come at the times, or in the sizes, or the quantities, that an operation wants.

“We have a facility in Hawaii, facilities in Washington state, and our secondary nurseries in Northern California,

Washington, and up in British Columbia and in every one of those sites there is a potential for losses,” he says.

“The hatchery larval level is usually where you have the most issues,” Taylor points out. “We know some basic things about larval culture at this stage of the game but I think we are a long way away from having a comprehensive idea as to everything that affects the larvae.”

“We definitely had problems with ocean acidification(OA) starting about 10 years ago,” he adds. “But that is only one component at the larval level.” He says the effects of temperature, water supply and salinity can be equally as challenging.

The unusually cold and late running winter in the Pacific Northwest this year delayed seed growth and crops by about

Bill Taylor (foreground) readily acknowledges larval-level problems related to ocean acidification, but also points to concerns regarding the effects of temperature, water supply and salinity.

of seed.

POMS and the risk of imported seed

Producers need seed but Bill Taylor is concerned about the risk of importing seed from outside the Pacific Northwest region.

“We have a high health program here in Washington, Hawaii and British Columbia so we have a pretty good idea of what our seed is like.” he explains. “Seed being brought in from other areas definitely needs to meet those standards. I am very concerned with the POMS, (Pacific Oyster Mortality Syndrome) or herpes oyster virus, because it has devastated both France and the New Zealand and Australian industries.

“Having seed bought in that is even close to a POMS area scares us a lot,” says Taylor. “We have talked to friends in Australia who have had to deal with it. They basically lose their whole crop. So it is of major concern to us. And it should be a concern for everybody in the industry. It will wipe out 99% of your younger stock.“

A lot of issues like marketing or predators are part of daily life, he comments. “They are certainly concerning, but at the end of the day nothing is static in the marine environment or in business; you are always adapting.”

“Those kinds of things I call incremental, we can deal with them, they aren’t catastrophic,” says Taylor. “But something like POMS definitely can be catastrophic.”

Taylor says he understands POMS is something hatcheries can breed resistance to fairly quickly. “But until you actually have the POMS virus, it is very difficult to know what broodstock might be resistant to it,” he points out. “Just because you have a very hardy oyster now doesn’t mean it’s resistant to POMS.”

But after three to five years without any income and trying to figure this out you can easily be out of business, warns Taylor. “Is it better to go without seed rather than to risk wiping out an industry? That is definitely our concern.”

two months Taylor says. “We’ve been farming shellfish for a long time and I don’t know that I have ever seen a year where there was this dramatic a delay of growth,” he maintains.

“We had poor results in our Quilcene hatchery here in Washington for oyster larvae and we suspect there is an algae coming in from our water source that has a toxin in it. We think that the algae is toxic to shellfish but we don’t know 100% if that is the problem.”

The key, he says, is to isolate the problem and work on it, which is what they did with OA. “Once we understood the problem (and that took us about a year and a half to realize) it took us about another year or so to come up with a solution. It’s frustrating, but you just dig in and work at it.”

“We know that OA affects the early larval stage,” he notes. “What we don’t know as much about, but are somewhat suspicious about, is that it may affect the setting stage and that early week or two post-set.

It’s harder to gather information on post-set Taylor points out. “It is a less controlled environment where we are doing the remote setting.”

In the hatchery they have sophisticated monitoring systems, but in a remote setting location where there is simply a tank, water heater and a pump they often don’t have the right equipment for monitoring.

“Again, it might be ocean acidification, but it might be a whole host of other issues that are affecting the setting.”

Taylor calls them ‘head scratchers.’ “There are some things we just don’t know the answers to and suspect it will be like that for some time.”

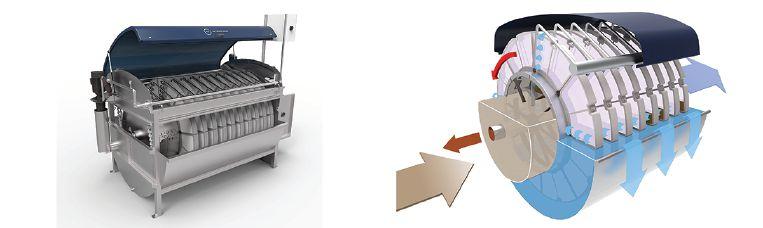

COMPLETE AUTOMATED HATCHERY FEEDING SYSTEM

Purpose-designed complete feeding system for any hatchery.

The system caters for ALL feeds, live, liquid and dry, from Algae, rotifers, Artemia to microdiets and weaning diets.

Fitted with a computerized, touch screen controller, the system is extremely flexible with feeding schedules and feed amounts (as low as 50mg per feeding event).

Taylor Shellfish has facilities in Hawaii, Washington state, and secondary nurseries in Northern California, Washington, and in British Columbia, Canada. An unusually cold and late running winter in the Pacific Northwest this year delayed seed growth and crops by about two months.

BAHAMAS

Egg variation a key to restoration of dwindling conch populations

Different genetic makeup provides quality and quantity

BY RUBY GONZALEZ

ollecting queen conch eggs from several females is a key factor to ensure variation in the offspring from an experimental hatchery in the Bahamas notes a recent study.

The hatchery was set up as part of a program to restore queen conch populations in the region. The project originated with the Hummingbird Cay Foundation (HCF) and is part of their mission. HCF conducted this study in partnership with the Florida Atlantic University and Harbor Branch Oceanographic Institute (HBOI-FAU).

“We conducted this study to determine variation between egg masses from different females. Each egg mass holds half a million eggs, meaning one egg mass could be all we need to run our hatchery. But since we found evidence of variation, we concluded that we need to gather eggs from many females to sustain a hatchery with the purpose of restoring the species,” Laura Issac told Hatchery International. Issac is a student of Biology, Environmental and Sustainability Studies at the University of Kentucky and a 2016 & 2017 summer intern at the HBOI-FAU.

AN ENDANGERED SPECIES

View of egg mass experiment set-up. Just small pieces of each egg mass are shown.

Overfishing in the ‘70s marked the beginning of the decline in conch populations. By 1992, it was listed in Appendix II of the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES).

Initial experiments investigated the viability of the new hatchery by conducting studies that observed conch egg mass hatch rates and veliger (larval) growth and development.

“Population genetics tells us if all members in a population have a similar genetic makeup – without variation in offspring – there could be a higher possibility of a population crash. For example, one disease could wipe out all the members,” she added.

Variation of veliger hatching, development, and growth from five Strombus gigas queen egg masses: for restoration of the species, was authored by Issac under the mentorship of Dr. Megan Davis. It was conducted from June 20 to July 4, 2016 in Hummingbird Cay, a private island off the southwest shore of Great Exuma, Bahamas.

Davis, an associate executive director at HBOI-FAU, was a co-founder of the world’s first queen conch farm in the Caribbean, where she was instrumental in developing commercial techniques for queen conch aquaculture.

Queen conch, take three years to reach maturity. Survival is threatened by sharks, rays, turtles, lobsters, predatory gastropods and humans.

A total of five egg masses (EM) were collected from two locations. Thirty-one to 100% of the veligers hatched out on the first night.

On day 1, EM1 had 100% hatching rate, followed by EM5 (89%), EM3 (88%), EM4 (35%) and EM2 (31%).

It was observed that throughout the five embryo development stages, EM1 and 5 and, then EM3 and 4, developed at the same rate. EM2 required an extra 24 hours to develop to stage 5, or the ready-to-hatch stage.

A study was conducted for veligers that hatched out of EM1 to determine growth and development of the veligers fed three different phytoplankton feeds.

Queen conch – “among the most desirable yields that the Caribbean can offer.”

This study determined how well veligers could be grown exclusively on natural foods found in unfiltered seawater.

The veligers were fed either Tahitian Isocrysis galbana (Tiso) with naturally occurring foods in unfiltered seawater, Chaetoceros gracillis (Cg) with the natural foods in the unfiltered seawater, or only naturally occurring foods in unfiltered seawater.

The rest of the veligers from other egg masses were fed a traditional commercial phytoplankton feed with the naturally occurring foods in unfiltered seawater.

FEEDING CHALLENGES

The four-day feeding experiment showed that veligers fed with Tiso had the fastest growth rate and had a siphonal length of about 490 µm on day 4. Those fed with Cg followed closely at about 475μm. There was significant

difference with those fed natural foods; these veligers were about 335 μm.

The highest survival rate was shown to be 97% for veligers from EM1, which were fed Cg. The lowest, 77% for veligers, from EM4 fed with Tiso and natural foods. The veligers from the other EM fed with Tiso and natural foods had significantly higher survival rates.

“Further experimentation will show if there is a better way to feed veligers in this specific hatchery setting,” Issac said.

Asked about the components of a successful conch restoration program, she said, “There are many,” and implied that the issue must be tackled through a holistic approach.

“One is education of the public and of the fishermen and hopefully getting them engaged in our efforts. Another is providing an alternative way to get conch, such as through aquaculture. Finally, this situation may even call for a fishing intervention,” she said.

There are cultural and bureaucratic challenges, among others.

“Conch fishing is a large part of the Caribbean life style. We would be asking fishermen to alter this now to ensure they still have conch later. Fishing is not regulated as heavily here as it is in the United States, so that’s another challenge,” Issac said. “Trying to place a moratorium will be difficult, and keeping poachers away may prove to be even more challenging.”

Photos: Laura Issac

Laura Issac, study author, left, and her mentor, Dr. Megan Davis, associate executive director at HBOI-FAU.

SPECIAL SECTION BETTER BREEDING

Norwegian researcher touts benefits of selective breeding

elective breeding of aquatic species has economic benefits coming from increased productivity, better utilization of natural resources, as well as improved welfare of the animals.

In The benefit of using selective breeding for aquatic species, published in the Journal of Aquaculture Research & Development, Trygve Gjedrem of the Department of Breeding and Genetics at Nofima AS, Norway, noted, “Results from selective breeding of aquatic species is very encouraging. Estimates of genetic gain per generation for key traits, like growth rate, is in the order of 13%, implying that it can be doubled in six generations. Results are also promising for other traits particularly for disease resistance. Aquaculture farmers should be stimulated to start breeding programs for major breeds.”

As an example, Gjedrem used the Atlantic salmon, which is said to be “the only aquatic species where close to 100% of the fish produced are genetically improved.” At present a four-kg Atlantic salmon takes only two years to produce, which is half the time it took in the 1970s.

The economic benefits: Production is doubled using the same infrastructure; loss due to mortality is reduced (because length of life is shortened); cost of labor per kg fish produced is markedly reduced (close to halved); and by providing such benefits, the breeding programs have revolutionized salmon production.

“If FCR is 30% improved by selection after 11 generations compared with the wild base population this means that the Norwegian salmon production today saves $0.7to 0.8 billion in feed costs because of efficient breeding programs,” he said.

For more aquatic species breeding programs to be implemented, he recommended the following actions:

Scientists and aquaculture organizations should inform farmers about the great benefit of using genetically improved stocks and further, encourage them to form cooperatives and start breeding programs.

Local governments should stimulate as well as financially support establishment of breeding programs.

The number of farmed species should be reduced/maximized because running a breeding program has a cost.

– Ruby Gonzalez

Genetics roadmap to develop more resilient farmed fish

Tilapia a focus

WorldFish will embark on new research to create more resilient fish with characteristics such as disease resistance and more effective feed utilization.

Based on a roadmap developed with world experts at a WorldFishhosted fish breeding workshop at the Roslin Institute in Edinburgh last spring, the research will use advanced techniques such as genomic selection to introduce these characteristics into its improved tilapia strains.

Since 1988, WorldFish has used selective breeding to develop and manage the fast-growing Genetically Improved Farmed Tilapia (GIFT) strain. The strain has been disseminated to at least 16 countries, mostly in the developing world, and is grown by millions of small-scale fish farmers for food, income and nutrition across the globe.

Use of genomic selection tools, which enable the selection of animals based on genetic markers, will allow WorldFish to expand its GIFT research beyond a growth-only focus and introduce selection for characteristics that are otherwise difficult to measure, such as resilience and feed efficiency. Genomic selection has enabled a steep change in the rate of genetic improvement of terrestrial livestock, and has the potential to do the same in fish.

Expansion of GIFT research is a key part of the CGIAR Research Program on fish (FISH) and supports WorldFish efforts under its sustainable aquaculture program to increase the productivity of small-scale aquaculture to meet growing global demand for fish.

John Benzie, Program Leader, Sustainable Aquaculture, WorldFish noted: “Incorporating new traits in the breeding program for GIFT will help fish farmers prepare for future challenges such as climate change and increasing evidence of disease risks. This will particularly benefit farmers in Africa and Asia, where tilapia is critical for food security yet farmers often have limited access to improved fish breeds suited to local conditions.”

Estimates of genetic gain per generation for key traits, like growth rate, is in the order of 13%, implying that it can be doubled in six generations.

Since 1988 WorldFish has used selective breeding to develop and manage the Genetically Improved Farmed Tilapia (GIFT) strain.

BETTER BREEDING

gender manipulation for southern flounder

Dr. Robert Vega of Texas Parks and Wildlife Department, and her supervisor, Dr. Todd Sink of Texas A&M AgriLife Extension Service.

“These genetically monosex female offspring can then be gender-reversed to become functional males while remaining genetic females. The sex-reversed flounder can then be spawned with normal females to create all-female populations,” Silvy told Hatchery International.

Gender determination in southern flounder is more dependent on temperature than genetics. Due to high temperatures caused by natural and manmade reasons, gender has been skewed to as high as 16 males:1 female.

Females can spawn hundreds of thousands of eggs per year, while it only takes a single male to fertilize several females over the course of a spawning season. Thus, the greatest impact of a stock enhancement program on a wild population comes from the females. “The creation of gynogentic, gender-reversed prodigy will allow stock enhancement programs to produce and stock a greater number of females,” she said.

Three methods were used to manipulate gender: induction of gynogenesis through pressure shock with later gender reversal by steroidal hormones; induction of gynogenesis through cold shock with later gender reversal by steroidal hormones; and induction of triploidy through pressure shock of normal gametes.

Induction of triploidy using pressure shock is another method to improve growth of southern flounder. Triploids still exhibit male or female characteristics, but because they have three sets of chromosomes they are sterile and do not expend a great deal of energy or nutrients on reproduction that are instead directed toward growth.

Two study controls were also used. One used normal gametes and the other irradiated sperm to ensure the UV irradiation process worked.

While studies on gender manipulation had been done before, this is the first time different methods had been used side-by-side on one species.

The benefits of the stock enhancement programs are far-reaching. “In the case of benefits to either the aquaculture producers or commercial fishermen, the end result is that consumers will benefit through increased market availability of southern flounder and potentially reduced prices,” she said.

Foodfish aquaculture was a major consideration for the studies.

The male southern flounder is slow to grow, taking several years to reach 12 to 14 inches. In culture, it may never reach the minimum market size of 1 pound, and if it does, it may require two to three years. This results in a long period of no cash flow for the producer.

“Females grow faster and achieve larger sizes, so monosex female cultures are optimal for production. Consequently, the methods we employ to create allfemale populations using gynogenetic, gender-reversed broodstock have potential to increase commercial foodfish production,” she noted.

– Ruby Gonzalez

continued from cover

Milt and eggs are mixed by gently swirling to promote fertilization.

Photos: Elizabeth Silvy

Eggs activated by irradiated sperm display arrested development.

Eggs activated by ‘ normal’ sperm’.

Larval flounder at 3 days post hatch.

High Density

Self Cleaning

Biosecure • Compact

Call us today at +1-250-889-5075 info@industrialplankton.com www.industrialplankton.com

BETTER BREEDING

The Roslin chip has been developed for two key species – the Pacific oyster (pictured) and the native European flat oyster, which is also an important species in many locations.

● O2 control with optical sensor, intelligent feeder control and many more functions

● Data, status and alarming on smartphone, tablet or PC

● Ideal for ponds, raceways and recirculation systems

SENECT GmbH & Co. KG, An 44 - No. 11, D-76829 Landau / Germany phone: +49 - 6341 - 95 95 210, email: info@senect.de

Genetic advance for oyster culture aimed at improving broodstock selection

BY COLIN LEY

Anew genetic tool, designed to enable oyster farmers to select breeding stock according to both disease resistance and yield benefits, is at an advanced stage of development at the University of Edinburgh’s Roslin Institute.

specialists in several European countries, plus Australia and Mexico.

The team at Cawthron already has extensive selective breeding experience in relation to oysters and disease resistance, dating from a crisis point in 2010 when ostreid herpes (OsHV-1) virus almost wiped out New Zealand’s Pacific oyster stocks.

Scientists at Roslin have created a genetic chip ‘loaded with tens of thousands of pieces of DNA, each of which carry a specific fragment of the oyster’s genetic code.’

MULTIPLE GOALS

Initially developed to help identify oysters with a specific resistance to the highly damaging Oyster Herpes Virus (OHV), the chip is currently being assessed for its ability to also identify oysters with desirable characteristics, such as faster growth rates.

Working now with the new Roslin chip, Cawthron’s researchers are exploring its impact on virus resistance issues and seeking to establish whether it can supplement and enhance the selective breeding programmes they have already put in place to produce resistant strains.

“We’ve already completed challenge experiments on DNA samples, looking at the genetic basis of observed natural resistance to OHV in some oysters, seeking to establish why some survive the virus while others don’t,” Roslin Institute’s Dr Ross Houston told Hatchery International “In addition, we’re examining whether there are individual genes that contribute to the observed resistance.

“The more we learn and understand about the genetics of resistance in relation to OHV, the greater the opportunity to use these genomic tools to assist in selective breeding for resistance to the disease.”

While OHV losses vary greatly from incident to incident, severe outbreaks have been known to result in mortality levels of up to 90%.

CHIP CHALLENGE EXPERIMENTS

The chip challenge experiments carried out so far have been run by the Centre for Environment Fisheries and Aquaculture Science (Cefas) in Weymouth, using oyster seed from a farm in Guernsey. Researchers at Edinburgh Genomics and at Cawthron Institute in New Zealand are also involved in the work, alongside input from

“Initially developed to identify oysters with a specific resistance to the highly damaging Oyster Herpes Virus (OHV), the chip is also being assessed for its ability to identify oysters with desirable characteristics, such as faster growth rates.”

END-USE POTENTIAL

Scientists at both Roslin and Cawthron are keen to see the chip developed to be used as widely as possible by hatcheries, not just restricted to its original virus focus. In that context, Roslin’s academic basis, alongside Cawthron’s academic plus industry R&D focus, is designed to help expand the end-use potential of development.

“Our aim is to provide the industry with a genetic test to predict which oysters, from which they are selecting breeding stock, are more likely to be resistant to OHV,” said Dr Houston. “In terms of timescale, such a test could be available for use commercially about two years from now with the combination of selective breeding and genomic technology having the potential to combat both disease issues and improve production levels.”

Roslin Chip

BETTER BREEDING

Genetic discovery a breakthrough in search for disease-resistant seaweed

esearch conducted into the genetic make-up of a resilient red alga has taken scientists a step closer to breeding disease-resistant seaweed.

Researchers at the Scottish Association for Marine Science (SAMS) in Oban, Scotland have established the genetic code for the Porphyra umbilicalis, a small, but tough intertidal species that can tolerate a range of conditions and is among the world’s most valuable commercial seaweeds.

The researchers mapped the 13,125 genes in the seaweed – a human has around 20,000 – to help discover what makes the intertidal species so resilient, as they aim to breed marketable seaweed that can withstand threats from common diseases.

They examined the red alga’s pathogen receptors –the equivalent of antibodies that recognise diseases and alert the alga to an attack – and found that the alga’s defences are unlike other plants.

The SAMS work has contributed to a research paper [Insights into the red algae and eukaryotic evolution from the genome of Porphyra umbilicalis] recently published in the American Journal Proceedings of the National Academy of Sciences (PNAS).

seaweed industry – the British botanist Kathleen Mary Drew-Baker unveiled the life cycle of this alga and paved the way for the industrialisation of seaweed in Japan – and we hope our work can play a part in developing this industry into the future.”

Porphyra umbilicalis, more commonly known as Laver, can adapt to conditions on different parts of rocky shores and is able to withstand prolonged periods of exposure to the air as well as tolerating a greater degree of wave action than most other red algae.

The development of resilient and marketable seaweed would be of great

SAMS algal pathologist Dr Yacine Badis said: “Like any living organism, algae are plagued by diseases. Understanding how they detect and defend against disease is key to unlocking the future development of resistant strains.”

“Although red algae and land-based plants are related, the typical defence mechanism found in plants was not detected in Porphyra. This means that Porphyra has original pathogen detection strategies, a finding that opens exciting avenues of research into red algal immunity and its use in modern breeding programmes.”

“UK research on Porphyra umbilicalis has previously helped to shape the global

benefit to the global aquaculture industry, which has developed at an unabated pace over the past six decades and is thought to be worth in excess of $5billion. However, farmed stocks are extremely susceptible to disease.

SAMS molecular phycologist Dr Claire Gachon said: “This work is part of our long term efforts to support the development of seaweed aquaculture worldwide through a better understanding of the diseases that plague the industry.”

The work at SAMS is part of the GlobalSeaweed project, a network of scientists advising on global seaweed policy funded by the UK’s Natural Environment Research Council (NERC).

Tissue sampling unit for streamlined genetic sample collection

PIT Tags

Pre-loaded PIT Tag System

Readers

• Tag Management Software

• Custom PIT Reading Systems

• Onsite-tagging Services, Training and Technical Workshops