By Seyitan Moritiwon

BY JEAN KO DIN

It is a truth universally known that the world is getting warmer and harsher. I read in the news the other day that Canada is experiencing above-normal temperatures across the country that could lead to harsher wildfires and potential drought conditions. As I’m writing this at the end of May, about 17,000 Manitobans had to evacuate their homes within the hour because of a rampant wildfire that gained momentum. We have not yet officially entered our summer months in Canada (June, July, and August) as I write this, but we are already experiencing the beginnings of what might be another record-breaking heatwave.

An analysis from World Weather Attribution, Climate Central, and the Red Cross says that four billion people, or about half the world’s population, experienced at least one extra month of extreme heat because of human-caused climate change from May 2024 to May 2025.

A new report by the World Meteorological Organization says that there is an 80 per cent chance that global temperatures will break at least one annual heat record in the next five years, raising the risk of extreme droughts, floods, and forest fires.

This is not fun news to report and despite what many people might think, journalists do not enjoy bringing bad news to our audiences. But, it is important news that we can’t shy away from.

Climate change is a story we continue to tell in these pages and how it affects the everyday work that you do. Although the effects are dependent on the region of the world that you reside in, unfortunately, the effects of warmer-than-normal temperatures are so universal that I’m sure every hatchery has its own story of how warmer water is affecting their animals.

Recirculating aquaculture systems technology seems to be the main answer to many of these challenges. It allows for a fully controlled environment that can ensure optimal water quality and biosecurity

for the seed or the fingerlings that are being raised in the facility. However, the animals will often have to go back to the elements at some point. Whether they leave the hatchery to help enhance the wild populations at local lakes and rivers, or they leave the hatchery to be raised for harvest in growout net pens, they will become subject to the warmer and harsher conditions.

Because of this, extensive research is taking place to understand how hatchery professionals can grow more robust fish – through genetic selection, through feed and nutrition, through vaccination, and through monitoring as many parameters as is feasible. There are certainly many tools in the aquaculture toolbox to be able to give our animals the best chance to thrive. But the question remains if this will be sustainable in the long-term.

As climate conditions progress exponentially, the pain points that we experience today will expand. The challenge that is ahead for the industry is whether innovation and scalability will keep pace with the demand for these solutions.

I think for the sake of long-term sustainability, the challenge for solution providers is not in the diversity of tools that you can provide (although this is important). Rather, it is the practicality and the versatility of these new innovations that will help hatcheries keep up. What use is the next gamechanger for the industry, if only a few, well-off facilities, can afford to adopt it? The more effective solutions are the one that are creative and simple and accessible to all types of hatchery applications.

Perhaps, this is the point of this issue’s theme on fish grading, handling, and transport. In this issue, we present some really interesting ideas that have caught our eye in this particular field. I hope it inspires a solution for your own day-to-day work. That will always be the goal for our stories here.

As I always like to say, my email inbox is open at jkodin@annexbusinessmedia.com. I hope to hear from you.| HI

VOLUME 26, ISSUE 4 | JULY/AUGUST 2025

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon smoritiwon@annexbusinessmedia.com

Contributors Mari-Len De Guzman, Chris Good, Nicole Kirchhoff, Greg Lehr, Magida Tabbara

Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Coordinator Catherine Giles cgiles@annexbusinessmedia.com

Media Designer Alison Keba akeba@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher Anne Beswick abeswick@annexbusinessmedia.com 416-410-5248

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Subscription rates (six issues) Canada: $37.74+Tax

Within North America: $48.96 CAD

Outside North America: $63.24 CAD

To subscribe visit our website at www.hatcheryinternational.com

Printed in Canada ISSN 1922-4117

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Hatchery International are copyright ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the May/June issue is March 11. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our advertising department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the May/June issue is March 14. Contact Jean Ko Din at jkodin@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

A Norwegian study has shown that higher levels of Omega-3 EPA & DHA in Atlantic salmon diets improve survival, feed performance and quality.

Veramaris, a producer of Omega-3 fatty acids, collaborated with Manolin, an aquaculture data management company, to provide proof of the dietary EPA & DHA benefits for aquaculture.

“Our approach, inspired by medical data science, delivers more precise insights,” said Tony Chen, CEO of Manolin. “Rather than comparing fish by generations, we analyzed populations, allowing us to detect patterns across similar farm conditions with much greater confidence.”

The analysis uses real-world data to compare health and harvest metrics. The study processed a decade of data from 166 farms, 430 million fish and nine Norway production zones, building on the findings of a previously published scientific research.

EPA & DHA levels in Atlantic salmon diets positively impacted fish health and feed efficiency. Mortality rates were 8 per cent lower, and the Economic Feed

Conversion Ratio (eFCR) decreased by 13 per cent, while flesh quality also improved in populations fed diets rich in EPA & DHA.

Improvements in predictability also increased by up to 50 per cent, which means greater control over outcomes and more reliable business.

“Raising salmon on diets rich in EPA & DHA checks all the boxes: better survival, feed efficiency, quality, and less waste overall,” said Yann Le Gal, global business development manager at Veramaris. “This ensures the health of the animals and improves the sustainability of aquaculture as a reliable food system.”

The California Department of Fish and Wildlife (CDFW) is upgrading 21 fish hatcheries to boost the state’s

salmon and trout populations.

The upgrade will also protect state-operated hatcheries from the impacts of climate change, as they have been experiencing reduced cold-water availability, increased disease outbreaks, and emergency fish evacuations due to extreme weather and wildfire threats.

These issues have strained hatchery operations and threaten CDFW’s ability to meet its fish production goals.

“Our salmon populations are not only an important part of our state’s biodiversity, but a rich component of our history and heritage. We have a responsibility to prepare for the future and protect the ecosystems and people whose well-being are connected to the continued success of these important species,” said California Gov. Gavin Newsom.

The “Climate-Induced Hatcheries Upgrade Project” was first funded with US$15 million in emergency drought funding in 2021. CDFW has been working with hatchery and hydrology consultants to identify concerns about water quality and quantity, fish rearing and water supply infrastructure and operational inefficiencies at the hatcheries.

The consultants developed individual reports for each hatchery with recommendations and changes to address the issues and provide reliable operations for the next 40 or more years.

Key findings and proposed upgrades include:

• Resilient infrastructure: Replacement of aging plumbing and valving systems to prevent costly emergency repairs and ensure reliable operations into the future. Many state-operated hatcheries are more than 80 years old.

• Enhanced water management and treatment: Implementation of partial recirculating aquaculture systems, water treatment, and temperature management systems to reduce water demand and improve efficiency, while reducing pathogens that can cause disease.

• Energy and sustainability innovations: Integration of advanced control systems and passive energy generation to minimize water use, operational costs and environmental impacts.

• Climate-driven design: Infrastructure upgrades tailored to withstand more extreme climate events projected over the next 20 to 40 years, ensuring production remains sustainable.

“As climate disruption continues to reshape California’s landscape, CDFW is committed to innovative action to support our state’s fisheries and the communities that depend on them,” said CDFW director Charlton H. Bonham.

“The Climate-Induced Hatcheries Upgrade Project is a roadmap to ensure that our state-operated hatcheries can meet the challenges of the future while promoting ecological health and economic vitality.”

The University of British Columbia (UBC) has released the “first-ever open-source” global map of fishmeal and fish oil (FMFO) factories.

The institution’s study sheds light on where these ingredients are being produced and who controls the industry’s footprint.

Published in Science Advances, the open-source data shows a total of 506 areas, in 63 countries, with Peru, Mauritania, and Chile hosting the highest numbers.

“Production of fishmeal is a major issue in aquaculture. Understanding where FMFO production occurs is essential for addressing its environmental, social, and economic impacts,” said lead author Lauren Shea. “Knowing that, along with what species are being used and how it affects local

Capacity

environments and economies, can support the development of more transparent and responsible aquaculture practices.”

The study estimates that more than 400 companies operate these factories, with many concentrated in sensitive regions already facing fishery stress. About 40 per cent of FMFO continues are made from whole wild-caught fish.

The study’s authors say this

makes the industry both vital and controversial. While it supports aquaculture, essential for meeting global seafood demand as wild fish stocks decline, it’s reliant on wild-caught, small-pelagic fish, which are food sources in regions like West Africa and Southeast Asia.

“Dependence on the global FMFO trade could undermine food security while fuelling unsustainable fishing practices,” said Rashid Sumaila, professor at UBC’s Insti-

tute for the Oceans and Fisheries and the School of Public Policy and Global Affairs. “This is not just an environmental issue—it’s about justice and equity.”

Using satellite imagery, national databases, and industry certifications, the researchers verified factory locations and raw material use. They cross-referenced company websites, government lists, and open-source certification data.

They found Peru hosts 125 FMFO factories—the highest in the world—while Mauritania ranks second with 42, many of which have been linked to reduced local fish availability and rising prices. Countries with few factories, like Norway and Denmark, often have disproportionately high production, thanks to better technologies and economies of scale.

The researchers say that the database is a starting point. Regular updates and deeper dives into fac-

tory-level environmental and social impacts are essential next steps, noting that countries like China, a major FMFO player, are opaque due to language barriers, lack of public reporting, and minimal online presence from producers.

“With more transparent data, governments and organizations can better regulate FMFO sourcing, track environmental impacts, and support alternatives—like plantbased feeds or novel proteins— that reduce pressure on wild fish stocks,” said Shea. “By-products can be a sustainable solution when managed properly. Improved data could further enable traceability, helping ensure that seafood products are sourced responsibly throughout the supply chain.”

The Food and Agriculture Organi-

zation (FAO) of the United Nations has published a joint certified course with Nofima on “Aquaculture breeding and genetics.”

The course is for government and private sector resource managers, policy makers and aquaculture hatchery managers. It could also be a supplement to undergraduate programmes in aquaculture.

It aims to raise awareness about the importance of the effective management of aquatic genetic

resources used in aquaculture. It highlights the roles of FAO and its member nations in aquatic genetic resources management.

Participants will learn the importance and value of aquatic genetic resources in the context of sustainable aquaculture, the value and importance of biodiversity and aquaculture selection programmes.

“This is a perfect example of excellent collaboration among a number of partner institutions,” said Ingrid Olesen, senior scientist at Nofima, in a LinkedIn post.

Other course authors include Aslam Muhammad Luqman, Bjarne Gjerde, Solomon Antwi Boison, Celeste Jacq from Nofima, Daniela Lucente and Graham Mair from the FAO.

Participants will get a digital badge when they pass a final exam after completing the course and achieving a grade of at least 75 per cent.

BY GREG LEHR, WYOMING GAME & FISH DEPT.

The success of Wyoming’s helicopter stocking operations is dependent on months of careful planning and coordination.

Each year, Wyoming Game & Fish Department stocks approximately 100,000 fish (three to four inches) into roughly 80 high alpine lakes. Fish are typically stocked the last week of July each year. At this time, waters are predominately ice-free, water temperatures have warmed up, weather patterns have stabilized, there is little to no precipitation and minimal winds.

Flights typically begin in the morning at first light where the cool mountain air can help provide lift the helicopter needs to reach the high elevation lakes.

The Spawning Crew Coordinator is responsible for the planning, coordination and the on the ground operations of the helicopter stocking procedures. High alpine/wilderness lakes are typically stocked in a two-year rotation. The number of staging locations vary depending on even (ex. 2024) and odd (ex. 2025) year rotations.

The number of specific flights at each staging location typically vary from one to seven. The coordinator works with hatchery personnel from five hatcheries to assist with the weeklong stocking operation. Hatchery personnel are responsible for transporting fish to each staging location and they perform night checks if is necessary for fish overnighted.

The majority of the species of fish reared for helicopter stocking are scheduled to be released at approximately 80 fish (3.2 inches) per pound. Fish stocked at this size survive very well, grow fast, and have high rates returning to anglers. Stocking smaller fish also aid in keeping weight limits low allowing for the helicopter to safely lift.

The Wyoming Game & Fish stocks high alpine lakes with golden trout, Eagle Lake rainbow trout, Bear, Colorado, Snake and Yellowstone River Cutthroat, along with brook trout, lake trout and hybrid tiger trout and splake. Typically, fish used for helicopter stocking are reared at hatcheries with colder water sources to keep growth restricted for stocking.

The Wyoming Game & Fish uses multiple distribution units during helicopter stocking to get the fish to different staging locations across the state. These include: one-ton pickups with a 300-gallon tank, ton-and-half trucks with a 650-gallon tank, and multi-tank distribution trailers.

The trailers include a “triple trailer” that has three individual tanks and a “quad trailer” that has four individual tanks. These two trailer distributions units have improved the Department’s efficiency with the ability to separately transport three to four different species.

Prior to being loaded onto a distribution unit and stocked, fish are taken off feed a minimum of three days prior. The fasting ensures feed has left the fish’s digestive system prior to being loaded onto the distribution unit. This keeps the best water quality for transportation and if any fish may be required to be overnighted on a truck or trailer.

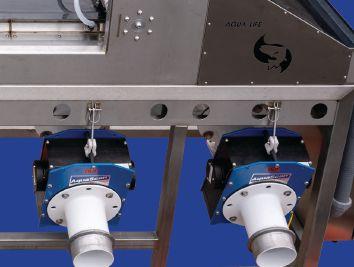

Tanks are filled with cold water at temperatures between 44-50 F to minimize stress while fish are on the truck or trailer. If water

temperatures begin to rise ice is added to keep temperatures in this optimal range. The distribution units are equipped with in-situ oxygen monitoring systems allowing personnel to monitor real time oxygen levels and water temperatures readings in all the tanks.

From the hatchery, fish are loaded from these tanks onto a specified tank location on the distribution units. If more than one species are loaded into a 300 or 650 distribution units, they can be separated by using mesh or aluminum live cars but this is typically done

loading fish into separate tanks on the multitank trailer units.

All distribution units are equipped with point four oxygen micro bubble diffusers and fresh-flo aerators. Aerators have the flexibility to operate off the truck’s power, back-up generators and utility power via a battery charger. This flexibility allows aerators to run from the start to the finish of the operation. The aerators help remove carbon dioxide, excess oxygen, and prevent a film layer from developing in the tank.

The helicopter stocking tank, is referred to as “the helicopter bucket” consists of eight 8-by3-inch aluminum cylinder tanks. This design allows for the potential to stock fish into up to eight waters with different species of fish.

In most instances, there are multiple tanks that are being stocked in a single lake. On average, three to six different lakes are stocked per flight. Each cylinder has a secure, leak-proof latched door at the bottom and top of the tank. Each cylinder is equipped with a point four micro bubble diffuser for adding oxygen and is capable of holding up to six gallons of water.

When loading fish into the helicopter bucket, typically one gallon of water is added to each cylinder and then flow meters are opened to supply oxygen to the point four micro bubble diffusers. Personnel then add two gallons of water to a five-gallon plastic bucket. Fish are then netted out of the distribution unit and placed into the plastic bucket until the predetermined number of fish has been added. The plastic bucket with the fish is then carefully poured into the cylinders.

After all cylinders are properly loaded with fish, ice is added to slow the metabolism of the fish, lower stress, and more closely match water temperatures of the colder alpine lakes. The maximum density index inside one of the eight cylinders can be as high as 6.0 however

the fish are only in cylinders on the helicopter bucket for a short time averaging 20-30 minutes but never more than an hour.

Flights are carefully planned, stocking waters in close proximity with each other to reduce total flight time. Flight plans are designed, for the most part, for the pilot to stock waters at the lowest elevation first as this reduction in weight helps the helicopter with necessary lift as it gains elevation for lakes at significantly higher elevation.

The doors on the bottom of each cylinder are wired to a toggle switch control panel inside the cockpit of the helicopter. Toggle switches are pre-labelled before each flight so the pilot can double check which tank(s) go to which water(s).

At the time of stocking, the helicopter

slows down to approximately 10-30 mph as it approaches the water. The pilot positions the helicopter bucket about 10-20 feet above the water before engaging the toggle switch(es). The falling water helps breaks up the surface tension just before the fish hit the water. The initial shock of impact adrenalizes the fish and they swim off to the depths of their new environment. Fish are stocked into the most pristine Wyoming high alpine wilderness waters.

Through these efforts, Wyoming Game & Fish has established one of the most successful helicopter stocking programs in the country, creating numerous premier and adventurous fishing opportunities in some of the most remote areas in the continental United States. | HI

Unique transport solution helps migrating salmon overcome rock barriers.

By Mari-Len De Guzman

When a massive rockslide ripped through a remote section of British Columbia’s Fraser River in 2019, it sent millions of migrating salmon into crisis. The debris created an impassable wall, cutting off critical spawning routes for one of Canada’s most iconic fish species.

With time running out and the stakes rising for endangered salmon populations, an inter-governmental collaboration turned to an unlikely high-tech saviour: a flexible, mist-filled pneumatic tube system fondly dubbed, the “salmon cannon.”

What followed was a series of bold initiatives to save millions of migrating fish and the adoption of a technology that is now reshaping how governments and hatcheries think about fish passage and fish handling.

The salmon cannon – commercially called PassagePortal – safely transported the Fraser Rivers’ migrating salmon through a pneumatic

tube, past the rockslide area to a point upriver where they continue on their epic journey to their spawning grounds – all without the need for human handling.

Unlike traditional methods that require high exertion from fish — such as (fish) ladders — the PassagePortal gets them to the top in about 20 seconds, explains Vincent Bryan III, founder and CEO of Whooshh Innovations, which developed and commercialised the PassagePortal.

“They just keep going… they end up way further upriver, much faster, simply because they’re not going through this recovery time,” Bryan says.

Whooshh Innovations have been in business since 2008, starting out in the fish processing business. Processing fish year-round provided an opportunity to learn more about the fish and its lifecycle. The

ultimate goal, says Bryan, was to move live fish in natural systems. Over the years, Whooshh’s work extended to aquaculture and then to hatcheries involved with stocking and enhancements.

“The Passage Portal itself is a modular product that is a combination of a number of the technologies that we developed along the way,” explains Bryan. “It’s capable of being either floating or on land, and getting selected fish over any dam regardless of height.”

The modular design of the PassagePortal allows users to use a specific system or a combination of them, depending on the particular purpose. The product uses a low-pressure system that moves fish through a misted, flexible tube.

The system mimics a natural underwater environment, he adds. “There’s no friction at all or very little,” he says. As the fish pass through the PassagePortal system, the tubes are misted with water for easier passage and to allow the fish to exchange oxygen.

“We’re using low pressure… enough to propel the fish at about 25 feet per second,” Bryan explains. “To the fish, it feels like they’re in 30 inches of water.”

The fish are also propelled into the water head-first, making it less stressful and reduces potential injuries to the fish. As the fish get closer to the exit of the tube, the system slows them down before they re-enter the river.

“And because of the nature of the PassagePortal system, they’re swimming in head-first. So unlike when you do a trap-and-haul,

where you’re dumping the fish out and they’re coming out backwards, there’s a risk there that you catch the gill plate and you tear the gills.”

In fact, a 2016 study by Norwegian research firm, SINTEF, evaluated the condition and welfare of salmon broodstock transported through the Whooshh system and found the system itself “did not impose an additional stress load” on the fish.

“We were not able to identify particular issues where fish welfare was clearly compromised,” the study indicated.

The Whooshh platform also includes a proprietary imaging tool called FishlRecognition, an AI-enabled imaging and computational processing system that can identify, measure and sort fish in real time using high-definition cameras, LED lights and AI algorithms. The system is designed to facilitate fish passage monitoring and management, as well as provide accurate and reliable data for fisheries research and conservation.

“We actually take 18 images of every fish in less than half a second,” Bryan says. “We’re looking at the size and the girth. We can determine whether there’s an injury. We know the species and if the fish is tagged, we can also know that particular individual. And within the next fraction of a second, make a sorting decision that happens automatically with the fish.”

The Big Bar rockslide crisis on the Fraser River in 2019 offered a

Specialists in corrosion-resistant, reliable and stable propeller pumps, with high uptime and low energy consumption- for a healthy and sustainable aquaculture.

real-world, high-stakes test for the PassagePortal technology.

During the migration season immediately following the rockslide, only about 600,000 out of the nearly five million sockeye salmon expected to spawn on the Fraser River actually made it to their spawning grounds. Faced with what federal scientists warned then as a potential extinction of certain salmon populations, the federal, provincial and First Nations governments collaboratively worked on multi-pronged solutions that included creating nature-like fish passages, blasting away rock debris to clear the river channel, and other mitigating measures.

By May 2020, Whooshh Innovations was working with Fisheries and Oceans Canada and the Yinka Dene Alliance, a coalition of six First Nations affected by the landslide to work out a solution in time for the coming spring Chinook migration. It was a twophased approach that involved an initial two migrator tube system for early Chinook passage, followed by a six-migrator tube system that allowed the passage of any size salmonid.

“The one up [on the] Fraser River initially was 500 feet. And then they extended it to 800 feet to try to get the fish further around the corner,” Bryan recounts.

The Whooshh system was able to transport thousands of fish over the landslide barriers in under 40 seconds without any physical human contact. In addition, the company deployed its FishlRecognition system at Big Bar, which allowed authorities to collect near real-time data of every single fish that went through the PassagePortal.

While the PassagePortal system is making headlines in wild rivers, it’s also transforming daily operations at hatcheries like the Washougal Hatchery in Washington State.

Located along the Washougal River in Southwest Washington, the hatchery produces 2.5 million yearling coho salmon annually for release into the Klickitat River. It also rears and releases an additional 108,000 yearling coho and 1.2 million fall Chinook sub-yearlings directly into the Washougal River, and transfers 280,000 yearling coho to Ringold Springs Hatchery to support broader program goals. The facility includes 24 raceways, a 400-foot rearing pond, and is staffed by five full-time, year-round employees – four of whom live on-site.

As part of its fall Chinook broodstock collection efforts, WDFW uses the Whooshh fish transport system at an off-site trap located about seven miles downstream from the hatchery. The trap is active daily from August through October and includes a temporary weir to intercept hatchery-origin fall Chinook before they reach natural-origin

spawning areas.

“The primary challenge we faced was the physical distance and elevation between the fish trap and the nearest accessible point for our tanker trucks – over 100 feet and up a steep bank,” says Greg Haldy, fish hatchery specialist at WDFW. “This terrain made it impossible to bring trucks directly to the trap site.”

Before installing the Whooshh system, the hatchery relied on an off-road forklift and a modified tote to move broodstock.

“This method was inefficient, limited the number of fish that could be transported at one time, and posed risks to both fish health and staff safety,” Haldy explains.

The adoption of the Whooshh system marked a major operational shift. The pneumatic tube system now moves fish from the trap, up the steep embankment, and into tanker trucks without the need for forklifts or heavy lifting – reducing physical strain on staff and minimizing handling stress on the fish.

“Since installing the Whooshh system, we have been able to move large numbers of fish more quickly and safely, reducing handling stress on the broodstock and improving working conditions for staff,” says Haldy. “While there was a learning curve – especially given that the technology was relatively new and untested on live fish when it was first implemented – our staff adapted well.”

Bryan says Whooshh is continually designing systems that improve welfare and survival of fish in the wild. Its most recent innovation, called Night Flight, is designed to address predation risks during juvenile fish release.

“When releasing the fish back into the

rivers, rather than just doing it directly during the daytime, the fish get released into a Night Flight, which is like a holding pen,” explains Bryan. “It then automatically opens up at night.”

According to Bryan, studies have shown predation is very high in the first hours after fish release. “And so, if you give the fish a chance to acclimate, and then also the cover of night, it eliminates the bird predation as well as the fish predation.”

Preliminary trials show dramatic results. “We are seeing 40-plus per cent improvement in survival of the out-migrating juveniles when released this way.”

The idea or prototype came from Ross Glover, a fish biologist in Scotland, says Bryan.

“It was so simple, also so crudely built, but the results he was getting were so good,” he recalls. “We approached him and reached an agreement with him to develop it and turn it into a commercial product.”

Launched on Earth Day 2024, Night Flight is now drawing strong interest from hatcheries and conservation groups. “I think it will be a fairly common thing,” Bryan adds. “We think this should get out there and everybody should be using it.”

With its image-based sorting system already streamlining fish movement, Whooshh is now looking ahead to new AI applications, including gender sorting and phenotyping of fish.

“One of the more frequently asked questions is, ‘Can we sort the fish male versus female?’” Bryan says. “That’s possible; we’re not offering that yet but the technology is there.”

He also sees value in using data analytics to improve fish management.

“There is real value in AI in the analytics portion of it… that’s where there’ll be an explosion of things that happen going forward.”

Meanwhile, Whooshh is continuing to serve hatcheries, tribal organizations and government agencies across North America and Europe. “The tribes and First Nations are always good customers for us,” Bryan notes. “They seem to be more eager to look for better solutions.” | HI

Celebrating Wolf Creek National Fish Hatchery’s legacy for raising trout By Seyitan Moritiwon

Every time a local fisherman reels in a rainbow trout from the waters in Kentucky, they’re reaping the benefits of the essential operation of Wolf Creek National Fish Hatchery.

For 50 years, the Wolf Creek National Fish Hatchery (NFH) has raised and stocked millions of fish for local ecosystems to thrive.

It was first created to mitigate the impact of U.S. Army Corps of Engineers water projects on fish populations. It was constructed from funds by the Department of Interior and Related Agencies Appropriation Act for 1968, and the facility was authorized under the 1934 Fish and Wildlife Coordination Act.

Although Wolf Creek NFH was established in 1975, it began its distribution program with fingerling rainbow trout stockings in 1976. The catchable rainbow trout program started in 1977 when the first lot of fingerlings reached a suitable size. Today, the hatchery raises mostly rainbow trout, several brown trout and brook trout.

The hatchery gets its rainbow trout eggs from other federal hatcheries: Erwin NFH in Tennessee, Ennis NFH in Montana, White Sulphur Springs in West Virginia, and Saratoga National Fish Hatchery in Wyoming.

Most of the fish are stocked into federal mitigation waters in Kentucky. James Gray, project leader at Wolf Creek NFH, said if the facility releases fish into state-managed waters, the Kentucky Dept. of Fish and Wildlife Resources reimburses it for those. A total of 125 different waters in the state are stocked with trout from this facility.

The hatchery used to stock about a million fish per year, and in recent years has started stocking 750,000 fish, weighing about 275,000 lbs., after the public said they’d rather have bigger fish than more fish. Just a small number of fish are stocked at four inches, six inches, eight inches, 12 inches and 15 inches.

Cumberland River,” said Gray, who has been at the facility for 31 years.

Most fish at this hatchery are stocked at nine or 10 inches and takes about 16-18 months to get a trout from egg to that size.

Wolf Creek hatchery uses a flowthrough system in its operation. It has 64 raceways and 20 smaller indoor tanks where it hatches the eggs and raises small fish. The hatchery is on Lake Cumberland, on the Cumberland River. There’s a pipe that comes from the lake, goes through the dam and then comes down to the hatchery.

“All of our water is gravity-fed from the lake, and we utilize it essentially one time… We don’t recirculate any water. It may go through more than one raceway. It may go through three or four raceways, but essentially, the water flows through the hatchery one time and then empties back out into the

While it hasn’t gone through any big renovations, over the years, it has gone through some technological changes, improving its water, oxygen, and degassing systems.

This hatchery has had an eventful fifty years raising fish. In 2006, an 8,700-square-foot environmental education centre was opened to the public, featuring a classroom and a theatre. Workshops on topics ranging from mushrooms to fly fishing draw around 100,000 visitors each year.

In the same year, three RV sites for volunteers with 50/30A electric, water, sewer, propane, phone, and internet were constructed. This provided the means to build a resident volunteer program. Two additional sites were built in 2007.

For 20 years, Wolf Creek NFH has raised different threatened and endangered species, like freshwater mussels, small-bodied fishes, darters and topminnows, and chubs. The hatchery aalso supplies fish to university students for research projects.

For 37 years, the hatchery also hosts a kids’ fishing event called Catch A Rainbow Kids Fishing Derby where children can catch fish and win prizes. The hatchery also hosts an event for kids with special needs in the area.

“And that’s always a really rewarding event, ‘cause a lot of those kids kind of get overlooked a lot of times. And so we try to help them catch a fish,” Gray said.

The hatchery also organizes a wounded warrior fishing activity for veterans who have suffered injuries related to their service, a fishing derby for seniors in the community, especially those in nursing homes.

At its Outdoor Eco Adventure event, fourthgrade students from the local school district are given mini-lessons on different subjects by partners from federal and state agencies.

“Some of ‘em may talk about water quality and some air quality and some about the

soil, and some might talk about recycling. And then we have some talk about fish and wildlife and firefighting,” Gray said.

He said this brings a lot of positive feedback from the school system.

“They really like that because a lot of kids, you can keep their attention for 15 or 20 minutes, and they’ll really listen to you and focus. And so they get 10 different lessons on 10 different subjects, and they soak it all in pretty well,” he added.

Running this hatchery takes a budget of US$1.3 million yearly. This money comes from a variety of sources, including the US Fish and Wildlife Service, the Corps engineers, and the Kentucky Dept. of Fish and Wildlife Resources.

“We really can’t speak to what our budget levels will look like in the future. Of course, our budgets are allocated by Congress, and so we are just in a period of reorganization,” said Lanier Clegg, public affairs specialist at the U.S. Fish and Wildlife Service.

Gray said that with the changes the U.S.

federal government is going through right now, the hatchery has lost a couple of staff members due to early retirements.

“Obviously, when you lose staff, that impacts what you can do… and we’ve been really fortunate over the last few years, we’ve been pretty well staffed and had adequate budgets,” Gray said. “There’s also a hiring freeze... So the tricky part is we’re not able to replace those people right now. So that’s the one thing, but that’s not just us, that’s across the whole government.”

This hatchery boasts a robust volunteer program with more than 12,000 hours of volunteer service yearly. From high school students to college students who need an internship, these volunteers can keep the hatchery afloat.

Gray remains hopeful. He doesn’t see a lot changing in the next decade. “Just hopefully we could maintain our staffing levels that we are at now and the budgets to support that, or programs that we have in place,” he concluded. | HI

BY MAGIDA TABBARA

Tabbara is a PhD candidate in Aquaculture at Auburn University with an emphasis on aquatic animal nutrition. She has over five years of experience in aquatic nutrition, feed formulations and feed manufacture, in addition to experience in scientific writing, technical writing, and journalism.

Fish grading and sorting is a common practice in the industry. Hatchery managers employ a variety of ways to sort the fish to ensure uniformity.

With good aquaculture practices, fish grading based on size helps improve fish growth and maintenance of high survival. However, despite it seeming like the norm, there’s more to grading fish than simply size sorting.

Fish within the same population and age group can have varied growth dynamics.

The animals’ growth disparity can be due to multiple factors, the primary two of which being caused by either the broodstock’s genetics or a combination of biotic and/or abiotic conditions around them. Curiously, a number of fish species display a number of social behaviours that form crucial biotic conditions influencing their feeding and therefore, their growth.

One of the most fascinating aspect of fish behaviour is social interactions and hierarchies. Many fish species structuralize their social interactions, developing hierarchies where a dominant fish controls a bunch of subordinates.

Such hierarchies can be established based on breeding status, size or level of aggression, which the latter two can be related to one another.

The biggest fish tends to declare itself the most dominant or the “alpha”, forcing others to be subordinates to spare their lives, which in a lot of cases leads to their mortality anyway. The dominant fish can intimidate the subordinates in many ways. It can prevent the small ones from accessing feed by simply reaching the feed source or the provided feed pellets first. The big fish can also attack the smaller fish and chase them around, in addition to forcing them to gather in one spot within the tank.

Such stressful situations increase the amount of energy the fish spends and increase the rate at which any feed in the stomach is digested. Additionally, the level

of cortisol in the body of those small fish skyrockets as a result of the fish being in a fight-or-flight mode.

Cortisol is considered the main stress hormone measured in the body. This hormone’s elevation alters the mechanism that regulates appetite in the brain, which can suppress appetite and cause feeding cessation. Those stressful situations all result in weight loss, growth impediment, and further size disparity among the fish population.

With the development of modern and organized fish culture techniques, farmers started sorting the fish to minimize the level of stress they encounter in the culture environment.

Disrupting fish social hierarchies seems like the best solution to unify fish growth under culture conditions.

Routinely, fish are passed through sorting equipment (graders, seines, etc.) to ensure fish of similar size stay together. Such practice helps reduce the stress caused by having one or multiple big “bullies” in the tank, reversing the effect of stress on cortisol levels, and allowing fish appetite to fluctuate based on satiation and hunger.

Grading fish also allows fish to obtain equal shares of feed. With the absence of bigger fish bullying the smaller ones, all fish within the same tank will more or less receive similar quantities of feed, which in turn allows them to grow similarly as they are exposed to similar conditions.

Additionally, fish can utilize the energy obtained from the consumed feed into developing and growing rather than allocating it into fleeing a stressful location or situation.

Moreover, in case of culturing cannibalistic fish such as walleye, cobia, or largemouth bass, frequent size sorting minimizes the risk of cannibalism, especially in the first couple of months after their hatching. When and how much to grade those fish greatly depends on their growth rates, which is something that can become a given after years of culturing the same species in a hatchery.

Despite these attractive incentives, there are important things to consider when grading fish. Disrupting fish hierarchies is not simple. A lot of factors need to be considered before proceeding with fish sorting.

Such factors include fish species and their sensitivity to handling. Crappies, shads, and even some ornamental fishes can be extremely sensitive to handling, which makes fish grading do more harm than good.

Other factors include the age of the fish and its stage of development. Larvae are the most susceptible to handling stress, whereas juveniles are considered even stronger than adults.

Another important factor to take into consideration when grading fish is water quality. High water temperatures, low levels of dissolved oxygen, or high levels of ammonia or nitrite in tandem with handling fish

can exacerbate their stress, which can lead to disease outbreaks and high mortalities. Last but not least, fish grading introduces unfamiliar fish of similar size to one another. In aggressive fish species, that can aggravate fights and increase their frequency, negating the actual reason behind grading.

Feed for thought

Fish grading by size is a useful practice that benefits fish farmers tremendously.

A lot of fish are sold by grade or size of the individual, and having the fish sorted regularly facilitates harvest and selling. Additionally, grading the fish helps with turnover

fish hierarchies is not simple. A lot of factors need to be considered before proceeding with fish sorting.

and profit, as issues of survival and growth are relatively resolved. However, there are many factors that must be accounted for when grading or handling fish.

Factors such as age, species, aggression, water quality, and disease spread are some to name a few that can interfere with grading and potentially even sabotaging the whole process. Size-based segregation can definitely be useful, you just have to do it the right way! | HI

References

Benhaïm, D., Péan, S., Brisset, B., Leguay, D., Bégout, M. L., & Chatain, B. (2011). Effect of size grading on sea bass (Dicentrarchus labrax) juvenile self-feeding behaviour, social structure and cultureperformance. Aquatic Living Resources, 24(4), 391-402.

Kelly, A. M., & Heikes, D. (2013). Sorting and grading warmwater fish.

ZeinEddine, R., Tabbara, M., & Saoud, I. P. (2024). Dietary cholesterol and aggression in Nile tilapia Oreochromis niloticus. Applied Research, 3(3), e202300084.

BY CHRIS GOOD DVM, PHD, FRESHWATER INSTITUTE

In intensive rainbow trout culture, side-swimmers – fish that swim in a coordinated manner, but with orientation altered so that they appear to be swimming on their sides (Figure 1) – are a relatively common observation.

Side-swimming behaviour can be exhibited by other farmed salmonid species, such as Atlantic salmon, but in the author’s experience rainbow trout appear to be particularly affected, although the prevalence of side-swimming within a population can vary considerably between cohorts and/or rearing conditions.

Despite the unusual swimming orientation, side-swimmers superficially appear to consume feed well and demonstrate reasonable growth performance compared to normally-swimming fish.

Although side-swimming can often be observed in recirculating aquaculture systems (RAS) utilizing circular tanks, side-swimmers can also be noted in flow-through raceways, freshwater net-pens, and other culture systems.

Despite the pervasiveness, side-swimming remains an under-studied behavior that could have performance and welfare implications that are relevant for farmers. Some commonly held beliefs regarding the causes of side-swimming include swim bladder malformation or dysfunction, excessive visceral fat accumulation, and, when raised in circular tanks, prolonged exposure to unidirectional circular water flows.

Beyond possible fish performance impacts, public perception should also be considered, as side-swimmers are inherently

conspicuous to non-aquaculturists visiting farms, and observing such behavior can potentially lead to the impression that “something’s wrong” with farmed fish in general.

Rainbow trout have been raised for many years at The Conservation Fund’s Freshwater Institute (Shepherdstown, WV), and on occasion we have had the opportunity to investigate side-swimming either in association with various culture environment

conditions or as a direct comparison between side-swimming and normally-swimming fish.

One early study (Davidson et al., 2011) focused on rainbow trout health and performance in RAS operated at either high or low water exchange rates, and among other things it was noted that side-swimming was significantly more prevalent in low-exchange RAS; further water quality assessments revealed a potential association between side-swimming and accumulating nitrate nitrogen

(NO3-N) and/or dissolved potassium.

These observations led to a more controlled follow-up study (Davidson et al., 2014) assessing rainbow trout under high (mean 91 mg/L) versus low (mean 30 mg/L) NO 3 -N conditions in replicated experimental-scale RAS. Results from this study demonstrated that NO 3 -N concentrations in the range of 80-100 mg/L were indeed associated with significantly higher side-swimming prevalence. The first dedicated

investigation to compare the anatomy and physiology of side-swimming and normally-swimming rainbow trout was carried out soon afterwards (Good et al., 2014), wherein physical measurements and representative samples of affected and unaffected fish were purposively collected and then assessed by separate personnel blinded to the collected individuals’ swimming status.

Results of this study were illuminating. Although not obvious visually, physical measurement data indicated that various performance metrics were impacted, with side-swimmers demonstrating statistically lower weight and fillet yield.

Further results suggested that swimming exertion was higher in side-swimming fish, with high blood pCO 2 and lower blood pH. Interestingly, although swim bladder malformation was significantly associated with side-swimming, it appeared that this pathology was not a prerequisite in affected fish, since a portion of the sampled side-swimmers demonstrated normally positioned and inflated swim bladders.

The Freshwater Institute’s Institutional Animal Care and Use Committee (IACUC) decided to conduct an additional investigation to assess the welfare implications of side-swimming, specifically to answer: Is the welfare of side-swimmers compromised, and should these fish be humanely culled during a given experiment?

A similar assessment to the Good et al. (2014) study was carried out, such that 20 side-swimming and 20 normally-swimming rainbow trout from the same cohort were selected and evaluated by blinded personnel.

Numerous outcomes were assessed, with an emphasis on

those related to fish welfare; namely, condition factor (K), plasma cortisol (a major steroid hormone associated with long-term stress) and fin condition (dorsal, pectoral, pelvic, ventral, and caudal fins were subjectively scored on a scale of 0-3, representing no, mild, moderate, or severe damage, respectively).

Data collected included fish length, weight, visceral weight, and qualitative swim bladder assessment (normal vs. abnormal position, inflation, and morphology). Regarding swim bladder assessment, results were similar to the previous experiment: although abnormal swim bladders were highly associated with side-swimming, this was not a necessary finding in affected fish, given that some side-swimmers possessed apparently normal swim bladders.

Fish length and weight data indicated that overall condition factor was not significantly different between side-swimmers and normally-swimming fish; likewise, no significant differences were noted in visceral weight relative to overall body weight, i.e. viscerosomatic indices.

Plasma cortisol was not significantly different between swimming types; however, variation in the data (i.e., standard errors of the means) was high, indicating that a larger sample size in future assessments would be helpful in confirming or refuting the present findings.

Finally, among the fins assessed, dorsal fin damage was significantly higher in side-swimmers compared to normal swimmers; however, normally-swimming fish demonstrated a significantly higher degree of pelvic fin damage.

In conclusion, overall results did not indicate that the welfare of rainbow trout affected by side-swimming was meaningfully compromised, although as noted plasma cortisol assessment in the future would

benefit from a higher sample size in order to confirm the findings of this study.

Regarding the results of fin condition assessments, fin erosion/damage in general is a common and largely unavoidable occurrence in intensive rainbow trout culture, and in our experience rainbow trout tend to focus on pelvic fins when engaging in agonistic fin-nipping behavior in circular tanks.

The observation that side-swimming fish had better pelvic fins, yet poorer dorsal fins, suggests that normal fin-nipping is occurring in the population, but, due to the abnormal orientation of those individuals swimming on their sides, the dorsal fin may be targeted by more aggressive fish following the typical angle of approach, leaving the pelvic

fins relatively protected from nipping. This possibility could be confirmed in future studies using video footage to better assess fin-nipping behaviour. | HI

Davidson, J., Good, C., Welsh, C., Summerfelt, S.T. (2011). Increased deformities and unusual swimming in rainbow trout Oncorhynchus mykiss raised in low-exchange water recirculation aquaculture systems. Aquacultural Engineering 45, 109-117.

Davidson, J., Good, C., Welsh, C., Summerfelt, S. (2014). Comparing the potential chronic effects of high nitrate nitrogen (80-100 mg/L) vs. low nitrate nitrogen (20-40 mg/L) on the health, performance, and welfare of juvenile rainbow trout Oncorhynchus mykiss within water recirculating aquaculture systems. Aquacultural Engineering 59, 30-40.

Good, C., Davidson, J., Kinman, C., Kenney, P.B., Bæverfjord, G., Summerfelt, S. (2014). Observations on side-swimming rainbow trout Oncorhynchus mykiss in water recirculation aquaculture systems. Journal of Aquatic Animal Health 26, 219-224.

Bioled Photoperiod, an aquaculture photoperiod systems company, has signed an agreement to supply its products and services to Riyadh-based environmental consultancy Firm, Tilad Group.

This partnership will make Bioled’s equipment and services available for current and future projects in Saudi Arabia and the broader GCC region, supporting sustainable aquaculture.

Bioled manages the correct functioning of the photoperiod system in all stages of the productive cycle.

“This milestone allows us to bring our technology to a dynamic and fast-growing market. Saudi Arabia is spearheading major aquaculture initiatives, and we are confident we will be a strategic partner in boosting both productivity and sustainability for local

producers,” said Cristina Navarro, general manager of Bioled.

“We recognize the quality and impact of Bioled’s solutions and believe they will deliver significant value to our clients. This alliance reinforces our commitment to advancing cutting-edge technologies in Saudi Arabia’s aquaculture industry,” added Franco Cerda, head of aquaculture at Tilad Group.

BioMar’s Costa Rica receives ASC Feed Certification

BioMar’s Costa Rica production facility has achieved ASC Feed Certification to support responsible aquaculture practices.

The ASC Feed Standard establishes comprehensive criteria for responsible aquaculture feed production. It covers social and labour rights, health and safety, environmental management, and sustainable sourcing of raw materials.

BioMar’s Costa Rica facility pro-

duces feed for shrimp, tilapia, and other marine species, supplying farmers across North and Central America and the Caribbean. The company said this certification is a milestone in its ongoing commitment to sustainability.

“Obtaining ASC Feed Certification shows our dedication to driving positive change in the aquaculture industry. With this certification, we will be able to provide access to ASC-compliant feed in the region and support our customers’ efforts to meet the growing demand for sustainable seafood in global markets,” said Jorge Vargas, BioMar Costa Rica’s managing director.

“It’s fantastic to see BioMar achieve yet another milestone with their feed mill in Costa Rica attaining ASC Feed Certification - the first in the country. This certification ensures farmers now have access to feed that meets the rigorous environmental and social requirements in the ASC Feed Standard, reinforcing transparency and accountability throughout the supply chain to drive aquaculture further towards sustainability,” said Aisla Jones, feed engagement and UK markets manager at ASC.

Biotech company, MiAlgae, has submitted plans for a new production facility in Grangemouth, Scotland.

MiAlgae repurposes whisky industry by-products to grow microalgae as a sustainable, cost-effective alternative to fish-derived Omega-3s.

The new facility will enable the company to address the increasing demands from aquaculture and pet food markets, which are seeking

sustainable and ethical sources of marine Omega-3s.

The company said the new site will be modular, expanding as demand grows with new facilities planned close to feedstock sources locally and abroad.

“Grangemouth has incredible potential for us as we look to the next stage of our growth. This location offers an ideal position to support our scaling efforts and meet the increasing demand for our “biotech for good” solutions, with the creation of green jobs across engineering, production, and research and development. We are confident that this new facility will help build a greener future and bring high-quality, sustainable jobs to the local community,” said Douglas Martin, founder and managing director of MiAlgae.

The first phase of the site is expected to create over 100 green jobs once operational. The planned expansion will allow MiAlgae to continue to offer retraining opportunities for workers transitioning from the oil and gas industry.

MiAlgae has been working closely with partners, including manufacturer CalaChem, throughout the planning application process. The company looks forward to the potential for collaboration with the Scottish Government to support the green transition in the region.

“MiAlgae is at exactly the right stage of growth to contribute to the success of Project Willow. We are proven at scale, there is market demand for our product, and we’re championing biotechnology in Scotland. We’re looking forward to working closely with local stakeholders and the Scottish Government to make this vision a reality,” Martin added.

MiAlgae, a producer of Omega-3s, has appointed Simon Durrant as its chief financial officer (CFO).

Durrant joins the company at a time when plans are underway to launch an industrial-scale production facility in Scotland later in the year. He brings over a decade of financial experience in high-growth and sustainability-focused businesses. He is a chartered accountant with a BA in economics from the University of Cambridge. His background includes strategic consultancy, accountancy, and early-stage investment. Durrant was an investment director at the University of Edinburgh’s Old College Capital (OCC).

“Simon’s strategic mindset and deep financial expertise will be invaluable as we scale our operations, expand internationally, and reinforce our role as a global leader in sustainable biotechnology,” said Douglas Martin, CEO of MiAlgae.

“MiAlgae’s vision for sustainability and what the team has already achieved is inspiring. It’s rare to find a solution that is so compelling from both an environmental and economic perspective, so I couldn’t resist the opportunity to join at such a critical and exciting stage of the journey. I look forward to overseeing the finance function and supporting the business as we drive growth,” added Durrant, CFO of MiAlgae.

Innovafeed featured in Avoided Emissions Platform for cutting CO₂ in agri-food

Innovafeed, an insect-based protein producer, has been recognized for concrete low-carbon solutions in the launch of the Avoided Emissions Platform (AEP)

The AEP is a global initiative that sets a framework for measuring avoided emissions, also known as Scope 4. It establishes a transparent, rigorous, and harmonized methodology to measure avoided emissions across 65 sectors, like energy, agriculture, real estate, and food systems.

It was led by Quantis, Robeco, Mirova, Edmond de Rothschild AM, and I Care by BearingPoint, and supported by over 30 partners. Innovafeed was listed among the solution

categories featured in this independent database, built upon Life Cycle Assessment (LCA) data.

“Insects are a forward-looking, measurable, and high-impact solution for transforming our agri-food system. Through our circular model, we upcycle agricultural by-products into sustainable ingredients, significantly reducing CO₂ emissions,” said Clément Ray, CEO and co-founder of Innovafeed.

Innovafeed says its contribution to the AEP

> Premium quality, disease-free eyed eggs available all year round

> Rainbow trout all female (diploid or triploid) and other salmonids We help you to grow great fish

is the result of many years of work with Quantis, an environmental consultancy specialized in LCA.

“Environmental impact must be assessed using common, robust methodologies. The AEP embodies this collective ambition: by standardizing the measurement of avoided emissions, it strengthens the credibility of climate solutions— like Innovafeed’s—and helps channel financial flows toward the most virtuous companies,” said Pierre Collet, Quantis global footprint lead.

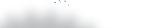

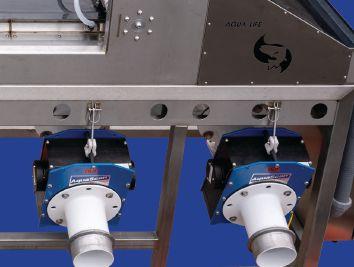

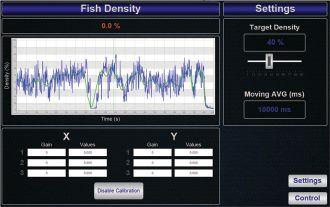

Customized for your fish farm, hatchery or

Customized for your fish

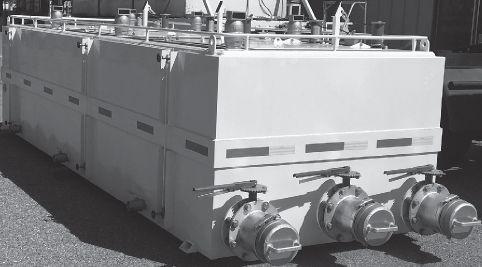

Our Commercial LSS Packages are custom engineered to meet your specific needs.

Customized for your fish farm, hatchery or research operation! Our Commercial LSS Packages are custom engineered to meet your specific needs.

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Marine and Freshwater

• Marine and Freshwater

• Mechanical filtration

• Marine and Freshwater

• De-gassing towers

• De-gassing towers

• De-gassing towers

• Wide variety of flow rates

• Mechanical filtration

• Mechanical filtration

• Chemical filtration

• Chemical filtration

• Wide variety of flow rates

• De-gassing towers

• Wide variety of flow rates

• Flow control valves

• Flow control valves

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• Ultraviolet disinfection

• Flow control valves

• Wide variety of flow rates

• Protein skimmers

• Protein skimmers

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• NEMA enclosed controls

• NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers

• Protein skimmers

• Flow control valves

• Variable frequency-drive pumps

• Variable frequency-drive pumps

• Ultraviolet disinfection • NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers

• Protein skimmers

• Temperature management

• Variable frequency-drive pumps

• Temperature management

• Temperature management

• Variable frequency-drive pumps

All our systems are pre-plumbed and fully water tested prior to shipping. Call

• Temperature management

All our systems are pre-plumbed and fully water tested prior to shipping. Call us today at

www.AquaticEnterprises.com

BY NICOLE KIRCHHOFF

Nicole Kirchhoff is the owner of Live Advantage Bait LLC (www.liveadvantagebait.com), a wholesaler of warmwater marine fish, fingerlings, and eggs for bait fish and food fish growout, research, and restoration located in Florida, USA. Kirchhoff has a PhD in Aquatic Animal Health and was Hatchery International’s Top 10 Under 40 in 2022.

In recent years, aquaculture facilities have seen a rise in fire-related disasters that have left farms gutted, animals lost, and businesses irreparably damaged.

Despite the highly technical nature of hatcheries and recirculating aquaculture systems (RAS), many farms remain vulnerable to fire – a threat that is often underestimated in water-centric operations. Fires can start in unexpected places: faulty wiring, overheated pumps, or unattended equipment rooms. When prevention measures are overlooked, the results can be catastrophic.

There are too many examples of recent deviating fires in aquaculture. In 2024, Nebraska Vegetable and Protein in Nebraska City, a pioneering aquaponics farm, was reduced to ashes due to an electrical fire. The blaze destroyed nearly US$2 million worth of infrastructure, crops, and fish, including an entire generation of salmon.

Similarly, 5-D Tropical, a family-owned tropical fish farm in Plant City, Fla., suffered a devastating fire in 2022 that destroyed one of their largest metal buildings.

In Canada, Ferme Piscicole des Bobines, one of Quebec’s largest rainbow trout producers, was engulfed in flames in March 2025 with firefighters battling for hours to save surrounding infrastructure.

These events underscore how even experienced operators can find themselves one spark away from disaster.

Why are fish farms at risk? Fish farms, particularly those using RAS and hatchery systems, rely heavily on electrical components and oxygen delivery systems, both of which are fire risks if not properly maintained.

Many farms are also located in rural areas where emergency response times can be delayed. Metal-clad buildings and high humidity environments can create the illusion of fire resistance, but ironically, these structures often lack adequate smoke detection, fire-rated barriers, or suppression systems.

Additionally, the reliance on chemicals such as sanitizers, fuels, ozone, and supplemental oxygen further increases the risk. With equipment constantly running to maintain water temperature, oxygen saturation, sanitation, and biofiltration, one

malfunction can trigger a chain reaction. Aquaculture professionals can take several proactive steps to reduce fire risk:

1. Electrical audits : Schedule annual inspections by certified electricians to check for overloaded circuits, frayed wires, and outdated panels. Pay particular attention to any plugs or circuits that are regularly tripping or you can see scorch marks.

2. Emergency shutoffs : Clearly label and maintain emergency shutoff switches for pumps, oxygen generators, and heating systems.

3. Fire suppression system s: Have readily accessible and labelled fire extinguishers throughout the farm. Install automatic extinguishing systems, such as water mist or CO2 systems, especially in equipment and chemical storage rooms.

4. Fire breaks and access roads: Keep vegetation mowed around facilities and maintain access routes for emergency vehicles.

5. Routine equipment maintenance: Establish logs and protocols for pump lubrication, motor checks, and cleaning intake systems.

6. Employee training : Run biannual fire drills and train staff in the location and use of extinguishers and emergency response.

7. Monitoring technology: Integrate thermal cameras and smoke detectors into control systems for early detection.

8. Get to know your local fire fighters. Introduce yourself to your local fire station. If possible, invite the staff for a tour of your facility, this way in a disaster they are familiar with your layout and safety protocols.

A key recommendation is to develop a Farm Fire Safety Plan and review it annually. This should include contact information for local fire services, maps of access points, locations of flammable materials, and evacuation protocols.

While individual farm action is critical, regional strategies play an equally important role. One major concern in fire-prone states like Florida is the buildup of combustible vegetation surrounding agricultural and rural lands. Prescribed burning – controlled application of fire to reduce brush and undergrowth – is a proven land management tool that decreases the risk of uncontrolled wildfires.

Florida Sen. Ben Albritton’s “Rural Renaissance” package includes significant investment in prescribed fire management, particularly to safeguard farms, timberlands, and rural communities. It aims to expand funding for prescribed burn programs, train and certify more burn managers, create buffer zones around agricultural assets, and promote cross-agency coordination for wildfire response.

By embracing this kind of forward-thinking policy, rural communities can reduce the severity of wildfires, which often spread unchecked through unmanaged landscapes. Fish farms benefit directly when the land around them is responsibly burned and maintained. Not only does this decrease the likelihood of wildfires encroaching on hatchery infrastructure, but it also opens up funding and technical assistance for private farm owners willing to participate in regional fire mitigation strategies.

It’s time to stop thinking of fire safety as a secondary concern in aquaculture. Just because water is the dominant medium doesn’t mean fire isn’t a deadly threat. From electrical fires in pump rooms to wildfires sparked in nearby forests, the risks are real and growing as climate change exacerbates drought and heat waves.

Aquaculture professionals must take stock of their vulnerabilities and invest in fire resilience now. Collaborating with local fire departments, participating in state-sponsored fire mitigation programs, and educating staff could mean the difference between a minor incident and a total loss. | HI

758-8208

info@jetco-usa.com jetco-usa.com

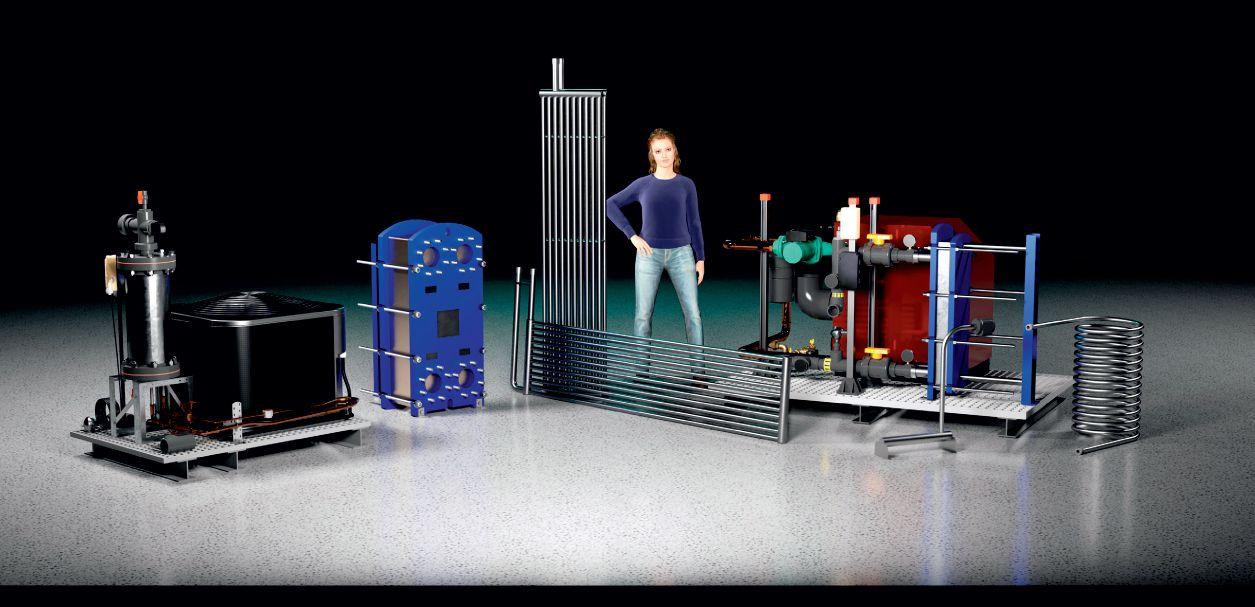

With decades of experience, we proudly serve the aquaculture industry by manufacturing high-capacity live haul fish transport tanks known for their durability, reliability, and customization. Built from all marine-grade aluminum or stainless steel, our tanks feature double-wall, all-welded construction with 1½”–2” insulation and are available in standard or fully custom designs to meet your specific transport needs.

We offer a wide range of models, including pickup, flatbed, and chassis-mounted options. Tanks can be configured with multi-compartments, custom or standard dump gates (including a two-stage pneumatic valve), folding walkways, and latching hatches for safe and efficient fish loading and unloading. Each tank includes a 2” integrated drain, external serviceable knife valve, and sight gauges to ensure accurate and complete drainage and optimal loading.

Our tanks are designed with user safety and convenience in mind, incorporating features such as anti-slip tape for secure footing, splash-proof hatches, screened vents, and leak-tight toggle latches. For ease of handling and storage, they include lifting eyes and optional forklift tubes.

We stand 100% behind every product we build and are committed to your complete satisfaction. Our team is always available to answer questions, provide consultation, and resolve any issues quickly. Most components we use are industry-standard, ensuring easy servicing and widespread availability through major suppliers.

With standard or fully custom solutions, complete design services, and proven oxygen management and monitoring systems. We continue to support the aquaculture industry with transport tanks that protect fish health, improve operations, and deliver long-term value.