SMARTFLOW

HIGH LEVEL EFFICIENCY & ACCURACY

SMARTFLOW CONNECTS ALL VAKI SMART PUMPS, GRADERS AND COUNTERS FOR FULL OVERVIEW AND CONTROL OF THE FISH HANDLING SYSTEM.

Hatcheries take steps to mitigate wildfire impact on fish, facilities and personnel

By Mari-Len De Guzman

16 How to have a stressfree transport

Exploring the latest research on mitigating stress during fish transport

By Ruby Gonzalez

18 Dangerous drives

Major truck accident outlines challenges of rural fry transport

By Matt Jones

20 Quality over quantity

Best practices for fish vaccination in hatcheries

By Seyitan Moritiwon

TunaTech investigates photo sensor technology to aid in rapid pathogen detection.

By Dr. Christopher Bridges

Smarter Sensors

Industry-leading

Seamless Integration

Modbus communication integrates directly to

Compensation

VOLUME 25, ISSUE4 | JULY/AUGUST 2024

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon smoritiwon@annexbusinessmedia.com

Contributors Bob Atwiine, Christopher Bridges, Mari-Len De Guzman, Ruby Gonzalez, Matt Jones, Nicole Kirchhoff, Magida Tabbara

Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com +1-416-606-6964

Account Coordinator Catherine Giles cgiles@annexbusinessmedia.com

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher Anne Beswick abeswick@annexbusinessmedia.com 416-410-5248

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media. The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.74+Tax

Within North America: $48.96 CAD

Outside North America: $63.24 CAD

To subscribe visit our website at www.hatcheryinternational.com

PRINTED IN CANADA ISSN 1922-4117

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Hatchery International are copyright ©2024 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the Sept/Oct issue is July 12. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our advertising department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the Sept/Oct issue is July 17. Contact Jean Ko Din at jkodin@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

Handled with care

We’ve encountered a few stories lately about incidents where restocking hatcheries experienced unusual mortalities.

There was one story in Washington where one million salmon fry died when heavy rains clogged the screen of an intake water pipe with leaves and other floating debris. The water quality in the tank deteriorated very quickly, killing half of the two million young Chinook in that tank. The alarm that should’ve triggered staff on this issue was also not functional because the electrical breaker shortcircuited.

At the Douglas County Fish Hatchery in Oregon, a young man was recently arrested for pouring bleach into a tank and killing about 18,000 juvenile salmon. The story gets stranger when the charges evolved into poaching, after law enforcement connected the same man for killing fish in one of four tanks at the Gardiner, Reedsport and Winchester Bay Salmon Trout Enhancement Program hatchery nearby. The young man now faces multiple charges that are before the courts, including fines for illegal take of Chinook salmon. The maximum charge for a single salmon is US$750. The courts have the authority to multiply that amount by the number of fish taken, which could amount to over US$13 million.

And then, there is another incident in the State of Oregon that we covered in the pages of this issue. A fish transport truck had overturned onto the shoulder of a rural highway, dumping the juvenile fish in its tanks onto the road. About a quarter of the 100,000 Chinook smolts died along the bank of the creek, but the majority made it into Lookingglass Creek, 100 miles from its original destination of Imnaha River. The good news is that the driver survived the accident with minor injuries. These incidents were so unexpected but in hindsight, they were also all unavoidable. In observing the reactions from our readers to these stories, I understood how much love and care the hatchery industry truly has for the animals that they raise. These

BY JEAN KO DIN

fish are not just a production target on a speadsheet. Every day, hatchery workers dedicate their time and energy to ensure that those fish are healthy and happy. To see all that hard work and care result in incidents like these must be heartbreaking.

With that new insight in mind, I took special care in curating the stories we have for this issue. Our theme, as you can guess by now, is fish handling. We gather experts from all over our network to talk about all the different factors that come into play when handling the fish. This is a delicate stage in hatchery work because stress levels can make or break the success of that production cycle. Mortality risk is high during vaccination, grading, and trasport.

In more extreme cases, our cover story tells a unique situation where fish handling best practices are truly put to the test in an emergency wildfire situation. As climate change becomes more intense, regions that are at risk for wildfire events need to be prepared to act at a moment’s notice. Our writer, Mari-Len De Guzman, talked to experienced professionals from North America that share the lessons they’ve learned so that your hatchery team can be prepared if the wind ends up blowing in the direction of your own facility.

As always, we hope the pages of our publication continue to be useful and informative to your daily work. The goal is to continue identifying ongoing industry problems and sharing new ideas to solve them. We have recurring content through Hatchery Hack, Feed for Thought, and even our Hatchery 101 webinar series, where we can compile tons of resources.

Many of us on the editorial team have spent many years (decades for some!) actively listening to the industry and keeping track on the latest trends and topics that you might be interested in. But the most valuable ally we have in curating these stories is you, dear reader. I’d love to hear your ideas at jkodin@annexbusinessmedia.com.

Southern California steelhead trout added to endangered species list

The California Fish and Game Commission has listed Southern California steelhead trout as endangered under the California Endangered Species Act (CESA).

California Trout, or CalTrout, is an organization that helps restore and sustain vibrance and abundance in California’s freshwater ecosystems. The organization applauded CESA in a recent press release for emphasizing the urgency of the situation.

Listing Southern steelhead as endangered under California’s Endangered Species Act will strengthen federal protections for these fish, promote actions to protect them including removing obsolete dams, improving habitat, securing instream flow, and restoring watersheds and benefit human communities by improving aging infrastructure to reduce the risk of flooding and increase public safety.

CalTrout said Southern steelhead are indicators of watershed health and

river ecosystem integrity. Historically, tens of thousands of these fish swam in Southern California rivers and streams but in recent times, it is rare to see a few. Their numbers have dipped due to impacts from habitat loss, fragmentation, and urbanization.

“We look forward to working with our partners to implement the state’s conservation plan for these iconic fish, including continuing our work in the South Coast region on behalf of Southern steelhead,” the press release stated.

‘Exciting

milestone’: Hatchery mussels reintroduced in San Antonio River

For the first time, hatchery-produced freshwater mussels have been reintroduced into the wild in Texas, according to the U.S. Fish & Wildlife Service (USFWS).

The San Antonio River Authority and the USFWS released the mussels raised by Inks Dam National Fish Hatchery into the Mission Reach of the San Antonio River just south of downtown San Antonio.

“This is an exciting milestone that’s been a few years in the making,” said Amy Lueders, the service’s southwest regional director. “Freshwater mussels are really

The group is working on removing fish passage barriers and expediting the removal of obsolete dams on the Ventura River (Matilija Dam), Malibu Creek (Rindge Dam), Trabuco Creek, the Santa Margarita River. They plan to remove non-native aquatic species that threaten prime steelhead habitat, secure instream flow by reducing surface water diversions and groundwater pumping and increasing the use of recycled water; and restore watersheds.

challenging to propagate. They take a lot of work and innovation, and certainly, there was a lot of innovation and persistence from both the Inks Dam National Fish Hatchery and the biologists at the San Antonio River Authority.”

The freshwater mussel propagation program at Inks Dam represents a relatively new facet of this mission and has evolved rapidly since its initiation in 2017.

Other organizations involved with the historic release include Utah State University, The Meadows Center for Water and the Environment, the Texas Parks and Wildlife Department and the U.S. Army Corps of Engineers.

PHOTO: KATHY KAFKA/GETTY IMAGES

Senior aquatic biologist, Austin Davis, releases a freshwater mussel into the San Antonio River.

PHOTO: AUBRY BUZEK/USFWS

Philippines continues to develop mackerel tuna broodstock

The Philippines’ bid to create a tuna farming industry is propped up by continually developing a broodstock inventory. The program is spearheaded by the Southeast Asian Fisheries Development Center Aquaculture Department (SEAFDEC/AQD) and funded by the Government of Japan.

Juvenile mackerel tuna (Euthynnus affinis), locally known as kawakawa and tulingan, are caught from the wild and brought to a facility. Since the program commenced in 2020, they have succeeded in growing the fish from 100 grams to about 2,000 grams in captivity.

One-hundred-gram female juvenile hit maturity in about eight months. At 2,000 grams, on the eleventh month, fish reached maturity and started spawning eggs. Fertilization of eggs did not go through.

Male fish became spawning-capable at 1,612 grams on the seventh month.

The latest batch of juveniles was delivered in March 2024. It was composed of 17 juveniles caught from an otoshi-ami, a big-scale fish trap.

With “meticulous planning and execution during transportation,” SEAFDEC/AQD said the newly caught fish had an almost 95 per cent survival rate upon arrival at the facility.

“The kawakawa juveniles will be kept in our hatchery, where we hope they reach maturity and lay eggs. It will be another breakthrough for us if the eggs hatch into the first captive-bred tuna in the Philippines,” SEAFDEC/AQD Chief Dan Baliao said in a press statement.

Currently 25 new kawakawa are being reared at SEAFDEC/AQD, with two mature kawakawa collected as juveniles last year. These are being closely monitored for their possible spawning of viable eggs.

The project, which also includes roundfin scad Decapterus macrosoma, is studying reproductive biology, feeding habits and migration.

Project proponent and SEAFDEC researcher, Irene Legaspi and her team are developing appropriate capture and transport techniques for the acquisition of fish stocks, developing techniques in broodstock management; and monitoring and documenting occurrence of diseases in broodstock.

- Ruby Gonzalez

PHOTO: ACIB LAMAWURAN/GETTY IMAGES

Online training hub releases grass carp welfare course for Chinese farmers

FAI Academy, a multi-disciplinary training hub, has announced the release of its online “grass carp welfare indicators” course in Chinese.

With China being the largest grass carp producer globally, the launch of this course provides a resource to educate aquaculture farmers on the benefits of improving grass carp welfare in the country.

“More than 5.8 million tonnes of grass carp are produced every year, and the majority of these within China,” said FAI’s aquaculture program manager, Sara Barrento. “FAI’s primary goal is to uncover welfare science, synthesize this knowledge and then put it in the hands of farmers. This is exactly what we’re doing with the launch of the Grass Carp Welfare Indicators course in Chinese.

The FAI said in a press release that the course is based on the latest scientific research and is hosted on the FAI Academy website. It is also available in English, Portuguese, and Spanish.

“FAI has been at the forefront of driving aquatic welfare globally since 2018 and our experience shows farmers have the greatest influence on the welfare of animals in their care. That’s why our new course aims to make welfare accessible to the people that impact the fish and production processes the most – farmers, aquaculture technicians and vets,” said Barrento.

Zimbabwe’s ambitious fingerling distribution scheme hits 4 million Zimbabwe’s Presidential Community Fisheries Scheme, which was launched this year, reported that it has been able to distribute 4,357,500 million fingerlings.

This growth initiative is part of the president’s initiative to increase production to 55,000 metric tonnes by 2025 aims to improve food security, foster fish farming, and improve the livelihoods of at least 16,000 households in rural communities, according

The course also outlines how farmers can identify welfare issues and implement improved welfare practices into daily working routines.

“We’re committed to supporting the aquaculture sector in China and this manual

to the Lands, Agriculture, Fisheries, Water and Rural Development ministry. The country’s fish production currently stands at 33,000 metric tonnes annually, almost half of the 60,000 metric tonnes of annual demand.

Among the beneficiaries of this multimillion scheme are schools, village business units and youth groups with a total of 1,200 dams already certified for stocking.

So far, 24 dams, 852 fish ponds, and cages have been stocked with fingerlings as the country eyes a potential US$1 billion in revenue from its aquaculture sector. The government hopes this will boost the country’s economy which is currently shattered by

is another publication we want to share. By providing a comprehensive, scientific overview of grass carp, the Grass Carp Aquaculture Manual is intended to help disseminate more knowledge and best-practice guidelines among farmers,” said Barrento.

several Western economic sanctions.

Against this background, the southern African country has already attracted US$500,000 in funding from the Food and Agriculture Organization of the United Nations (FAO) for technical support aimed at accelerating its fish breeding and production.

This will potentially help the country to produce 166 million fingerlings per season, a big increase from the current nine million.

The country’s rural population accounts for 68 per cent of its annual fish consumption in both volume and value, while the urban community accounts for 32 per cent of its annual expenditure on fish consumption. Fish consumption per capita is about 1.2-3 kilograms.

Fish farming in Zimbabwe is dominated by the culture of Oreochromis niloticus followed by Oncorhynchus mykiss. Over 90 per cent of the cultured fish is Oreochromis niloticu, which comes from Lake Kariba.

- Bob Atwiine

Zimbabwe President E.D Mnangagwa launches the Fish4Schools Programme at Murambinda B. Secondary School Business Unit (Buhera District) under the Presidential Community Fisheries Scheme

PHOTO: ZIMBABWE DEPARTMENT OF FISHERIES AND AQUATIC RESOURCES

Putting welfare science and knowledge into the hands of Chinese farmers.

PHOTO: FAI ACADEMY

Nano-curcumin mitigates effects of stress in European sea bass fingerlings

Nano-curcumin has been found to mitigate effects of stress in European sea bass fingerlings. Stress affect growth indices, feed utilization and survival rates.

The study conducted in Saudi Arabia established that a dietary nano-curcumin dosage of 70 or 60 mg per kg may be more effective in promoting the growth, feed efficiency, haemato-biochemical parameters, and antioxidant status in European seabass fingerlings.

Curcumin is naturally occurring compound in turmeric roots.

Nano-curcumin facilitates nutrient assimilation, leading to improved growth. Because the specific surface area of compounds can increase, it becomes more bioavailable and easier for fish to utilize. Improvement in the secretion of digestive enzymes, assists in efficient digestion and absorption of food. It can provide energy sources to promote body weight and overall health.

Due to its size, nanoparticles can increase solubility, availability and efficacy in phytochemicals.

One of the benefits of nano-phytochemicals such as nano-curcumin is improving the host’s health by stimulating the defensive system, and supporting the immune system, as expressed by the survival rates in fish farming.

The study included a challenge test with V. parahaemolyticus. Groups in experimental diets with the recommended dosage had 75 and 60 survivals rates compared to the control’s 30 per cent.

The bacterium is one of the most pathogenic bacteria affecting the aquaculture industry.

“Phytochemicals are used in fish farming to reduce stress and combat diseases during intensification. Recently, nanotechnology has represented a paradigm shift in the aquatic feed industry to improve the solubility, availability, and efficacy of phytochemicals,” cited authors Samyah D. Jastaniah et al. in the study, “The effects of nano-curcumin on growth performance, feed utilization, blood biochemistry, disease resistance, and gene expression in European seabass (Dicentrarchus labrax) fingerlings.” It was published on Aquaculture Reports

Environment created by intensive farming spawns stressors.

“In order to meet the increasing demand for aquaculture products, fish farmers are adopting more intensive methods to enhance fish productivity and health. However, these intensive aquaculture systems can introduce various stressors that negatively impact the well-being and welfare of farmed fish,” they said.

- Ruby Gonzalez

Innovation Beyond Measure

Results Beyond Expectation

• 100% Titanium Heat Exchangers

• Hot & Cold Water Loop Systems

• Available with Tube Sheet, Helical Coil, or Plate

• Compact Designs

• Easy Installation

• Salt & Fresh Water Safe Chiller & Heat Pump Packages

Transparency and traceability as key biosecurity tools

Biosecurity Asia Forum discusses the urgency of disease management

By Ruby Gonzalez

Biosecurity can make or break a hatchery operation.

“It increases productivity in terms of survival, growth and FCR (feed conversion ratio). It reduces usage of expensive medicines and chemicals. Production costs are lessened because there no occurrence of mass mortalities. Lastly, it hampers the emergence of antimicrobial resistance,” explained Dr. Leobert de la Peña, head of the Research Division, Aquaculture Department of the Southeast Asian Fisheries Development Center (SEAFDEC/AQD).

The Biosecurity Asia Forum conference took place in Manila on May 23. It was held at the sidelines of Aquaculture Philippines 2024, a co-host of Livestock Philippines 2024. Speakers from Singapore, Thailand and the Philippines to discuss the urgency of mitigating disease introduction and transmission to farms.

Massive economic losses are commonly traced to the unchecked spread of deadly pathogens, making biosecurity an imperative in preventing, controlling and eradicating risks to life and health in an aquaculture environment.

Holistic approach

A biosecurity plan must require a holistic approach. At the same time, it needs to be grounded. “Measures should be justifiable. It should be scientifically sound. It should be practical and not impede with routine farming practices. It should be economically viable and find a balance between benefit and cost of the biosecurity measures,” he said. With focus on shrimps, a premium Philippine product, he said designing a biosecurity program entails monitoring health status, identification of listed pathogens and defining risks.

Pathogens that need to be “screened out of the system” should have potential economic impact on animal survival and performance. External biosecurity excludes pathogens from incoming water, wild crustaceans, visitors and fresh feed, among others. The

recommended mitigation measure for this is to use SPF and PCR analysis in shrimp for stocking and broodstock. Crab fences and pesticides could be used to keep away wild crustaceans. De la Peña emphasized that he doesn’t recommend the use of pesticides.

The goal of internal biosecurity is the containment of pathogens. It necessitates incorporating risk mitigation in standard operating procedures (SOP). Zoning and compartmentalization, for instance, increase the control and maintenance of pathogen-free areas. Visual monitoring could be made easy by providing color-coded uniforms. It allows an at-a-glance method to check if everyone is in their allocated areas.

Microscopic, bacterial and PCR tests for rearing water animals are recommended during fry selection. For stocking, he said that fry bags must be disinfected and rinsed with freshwater upon arrival. Acclimation and stocking follow. Bacterial and PCR tests must be conducted once a week.

Porous borders

“The objective is to recover production within the shortest time and with the minimal cost,” he stressed. “The efficiency will depend on the speed of the initial response to an emergency.” With this, clinical signs are warning and should always be investigated.

“Biosecurity is only as good as the methods

Exhibitors at Biosecurity Asia Forum 2024 wooed the market with innovative products.

Dr. Celia Lavilla-Pitogo, FeedMix Specialist Inc.

Dr. Leobert de la Peña, SEAFDEC/AQD

PHOTOS: RUBY GONZALEZ

employed,” emphasized Lavilla-Pitogo during the next session.

The porous borders of aquaculture make biosecurity a much tougher job compared to, say, swine and poultry, which were also forum topics.

On top of the 500 species of animals and plants in culture, the fluid environment facilitates transfer of pathogens. “There are different habitats – freshwater, brackish water, marine. There are different food habits, different production systems,” she said

Movement of live aquatic animals across international borders are a cause of serious concern because of the transboundary aquatic animal diseases (TAADs), which has potential for rapid spread. “Health certification for all stages of live aquatic animals should be provided before movement to new locations/ environments,” said Lavilla-Pitogo.

Biosecurity strategies at international and national levels need to be established.

Among the actions to be considered at the international level are transparency in disease information, especially on emerging diseases, adoption of standards in testing, and coordination for pathogen introduction

other than trade.

At the national level, stakeholders need to be aware of what pathogens are already present, she said, reiterating what de la Peña said earlier. They have to know the enemy and how to prevent and control it, she stressed. Action and prevention have to be implemented within the context of knowing what diseases to keep out, what species to prioritize, and if the stakeholders can do and afford it.

Top five

The Philippines’ top five aquaculture commodities are shrimp, milkfish, tilapia, shellfish and seaweed.

Biosecurity issues vary. Shrimp relies heavily on imported broodstock. Milkfish relies heavily on imported fry with questionable biosecurity protocols. Tilapia, meanwhile, has been traded heavily without biosecurity considerations.

Among these, only shrimp have been benefitting from effective biosecurity protocols. And this boils down to economics. It is a premium-priced product that is in high demand in domestic and global markets.

“Shrimp hatcheries have benefited from technological advances in water preparation, disinfection, sterilization. The technology is mature,” said Lavilla-Pitogo.

Milkfish fry production is not enough to supply demand, making it dependent on imported fry, mostly from Indonesia, where direct stocking in pond nurseries is practiced This is a major biosecurity threat.

Tilapia hatcheries stand to benefit from artificial incubation methods. Know-how could be free; there are many how-to’s on YouTube, Lavilla-Pitogo said, “Lack of biosecurity in the hatcheries might spawn another epizootic like Tilapia Lake Virus (TiLV).” She also underlined the need to adopt technological innovations in the hatchery sector to promote biosecurity in the value chain.

Seaweed plantings that are resistant to biofouling are needed.

Biosecurity risks come from the complete value chain.

“The complexity of aquaculture needs a holistic method to health management. The value chain approach will help the industry weld together available strategies in biosecurity and identify gaps,” said Lavilla-Pitogo.

Smarter,

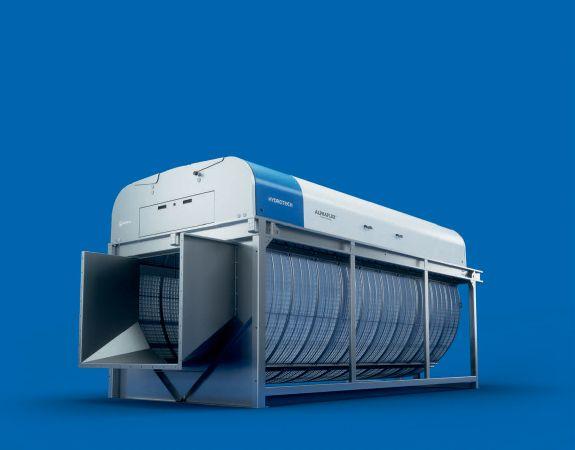

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

In the line of fire

Hatcheries take steps to mitigate wildfire impact on fish, facilities and personnel

By Mari-Len De Guzman

Every year, at the end of the spring season, when temperatures begin to rise and the rains become scarce, Peter Griffiths and his team at Creative Salmon’s Sea Spring Hatchery in Chemainus, B.C. begin to keep a close watch on potential wildfires.

Surrounded by lush forest vegetation on the east side of Vancouver Island, Sea Spring produces organic Chinook smolt. From egg to smolt, the fish spend up to 12 months at the hatchery until they are big enough to be transported to Creative Salmon’s ocean pens, where they are grown to market size.

“We haven’t had any immediate danger here (at the hatchery), but we have been on watch for forest fires because there’s been a couple of incidents over the years where, you know, it was off up in the valley, the

headwaters to the Chemainus River, and (we were) starting to get nervous,” says Griffiths, the hatchery manager for Sea Spring.

Mitigating measures

As part of its wildfire preparedness initiative, the hatchery undertakes several basic measures to mitigate the impacts of potential forest fires, such as using metal roofing instead of asphalt shingles for fire-proofing, and keeping the perimeter of the facility clear of dead trees or any dry vegetation that can serve as fuel for wildfires.

Removing this combustible debris also includes clearing areas near the oxygen storage tanks, and keeping any grass around or near the oxygen well-trimmed, Griffiths says.

He says mitigating the imminent threat of a wildfire with the basic measures is only part of overall preparedness. The

ancillary factors, such as the infrastructure that supports the facility and any hatchery equipment that can potentially become fuel for a raging fire, are also a big concern during wildfire season.

“Hydro (power) is a big one,” he explains. “Because even if (the fire is) not bearing down on your facility… all it has to do is rip through the utilities or sections (of it), and then you’re going to be relying on your generator power.”

Making sure generators are constantly maintained, tested, and properly running, is also a key part of wildfire preparedness. Land-based hatcheries rely on 24-hour power to ensure all equipment support fish life - oxygen, water quality, filtration - are in good working order and will continue to work through power outages.

Ensuring that generators are able to support

Some critical infrastructure and fish were lost during an unprecedented wildfire in September 2020. ODFW hatchery staff and their families evacuated the area with no reported injuries.

PHOTOS: OREGON DEPARTMENT OF FISH AND WILDLIFE

the facility in case of power failure also requires managing sufficient fuel supply to run the generators, Griffiths adds, and that involves coordinating with suppliers.

The most recent lesson for this was the wildfires that devastated the island of Maui in Hawaii in 2023. More than a week after the wildfire ravaged through the town of Lahaina, power is still yet to be fully restored in some of the affected areas. Communication networks also proved unstable days after the fire.

“As we saw in Maui, the power lines and poles were destroyed for huge sections. So it’s not an overnight (fix)… depending on how badly the infrastructure is affected. So making sure that you’ve got plenty of fuel and make sure you have a plan to get refueled for potentially some time,” says Griffiths.

Oxygen storage tanks and distribution lines that go into the facility need to be consistently checked for leaks, as well. “You don’t want oxygen leaking if there is potential for spark and fire, right? Because it will vigorously accelerate the combustion,” the hatchery manager explains.

Public hatcheries

Hatcheries across Canada’s west coast region have been facing a number of natural challenges, including wildfires, drought and flooding in recent years, prompting Fisheries and Oceans Canada (DFO) to undertake efforts to better understand and mitigate the effects of these extreme phenomena on salmon hatcheries,

These risk mitigation measures include commissioning fire risk assessments and taking advice from wildfire safety experts; investing in hoses, sprinklers, and other fire suppression equipment; clearing combustible material, such as underbrush, from site perimeters; and using fire-resistant roofing and building materials during maintenance or replacement work.

Low precipitation and extreme drought are a perfect recipe for a wildfire, making it easier for lightning strikes and strong winds to start a potentially wide-spreading fire. This is also part of the DFO’s risk assessment initiatives.

“Hatcheries rely on the steady flow of cool, fresh water to operate and produce healthy fish,” Rainer says. “DFO is identifying hatcheries that may be affected by low water flow or high water temperature, and

exploring short and long-term water supply improvements.” These include improving water intakes, increasing groundwater supplies and deploying efficiency measures such as using partial water recirculation or aeration.

At enhancement hatcheries, backup power and water supplies are also being reviewed to ensure that water and power continue to work during emergency or evacuation scenarios, the DFO spokesperson adds.

The Chilliwack River Hatchery, located in B.C.’s Fraser Valley, for example, is experiencing lower-than-normal flow and warmer water temperatures in the Chilliwack River, which feeds the hatchery. Long periods of low precipitation have also contributed to dry vegetation around the forest that surrounds the hatchery, increasing the risk for wildfire.

Hatchery managers at Chilliwack River Hatchery have taken specific steps to address this risk, according

according to Michelle Rainer, DFO communications advisor.

to Rainer, including measures to increase the flow of river water into the hatchery and mechanism to stop it from spilling back into the river; keeping the hatchery perimeter free of dry vegetation and dead trees; and installing a sprinkler system on the roof of the hatchery. The health and welfare of personnel are also taken into account by adjusting work hours during dry and hot seasons to avoid working during the hottest parts of the day, Rainer says.

Pacific wildfires

Wildfires are not unique to Canada, as its neighbour to the south face the same risks, particularly in the Pacific Northwest Region. Enhancement hatcheries in the U.S. are under the purview of the U.S. Fish and Wildlife Service (USFWS).

Every year, the government’s wildland fire program includes the application of prescribed fire as well as mechanical and chemical fuel treatments to agency-managed lands, Laury Marshall, assistant chief with USFWS’s public affairs department, tells Hatchery International.

“These treatments are integral components of wildfire management strategies aimed at mitigating the risk and severity of wildfires. Prescribed fires serve to reduce fuel loads, restore habitat, control invasive species, and decrease the likelihood of catastrophic wildfires,” Marshall says.

These measures are aimed at proactive wildfire risk reduction. She explains, mechanical treatments involve physically altering vegetation through thinning or removal, creating defensible space around structures, like fish hatcheries and other USFWS structures, and enhancing firefighting access. Chemical treatments target specific vegetation, controlling invasive species, and reducing overall flammability.

The September 2020 wildfires in Oregon severely affected hatcheries around the state, resulting in the death of nearly half a million fish and the early release of about 1.2 million chinook, steelhead and trout into the rivers,

Oregon DFW staff had to work quickly to evacuate the Rock Creek Hatchery during the September 2020 wildfires. About 700 remaining adult spring Chinook and summer steelhead were moved to Cole Rivers Hatchery with the intent to spawn and collect enough eggs to meet Rock Creek’s production goals. PHOTOS: MATT HILL/OREGON DEPARTMENT OF FISH AND WILDLIFE

As climate change continues, incidents of wildfires are expected to increase in size and intensity.

the Oregon Public Broadcasting reported at the time.

“One of the most valuable lessons learned from these events is the importance of having clear evacuation plans lined out for staff, as well as contingency plans for the fish and wildlife on station.

“Those could include plans to transport fish to other facilities or releasing them early. Close communication and coordination between hatchery staff and fire incident command is a big part of that planning,” Marshall notes.

Other risk management strategies have also been employed to high-risk hatcheries, including those that have been repeatedly affected by wildfires. They include developing fire response plans in collaboration with several fire management experts and agencies, reducing combustible materials or fuels near critical infrastructure, and creating contingency plans for fish evacuation in the event of an emergency.

Bigger fires, bigger threat

Although wildfires are a natural part of the forest lifecycle, Mother Nature’s way of cleaning and revitalizing the natural ecosystem, they can also be caused by human activity. As climate change continues to bring about extreme weather events, such as drought and record-level high temperatures, incidents of wildfires – whether man-made or through natural causes – are expected to continue to increase in size and intensity.

“Due to climate change, some of our facilities that have not dealt with wildfire historically are now being impacted. One area in particular that has seen anomalous wildfire activity is the Pacific Northwest, particularly the Olympic Peninsula and Columbia Gorge. National fish hatcheries in both areas have had to evacuate due to wildfires in each of the last four years,” Marshall says.

These extreme events and the resulting devastation are causing not just government but also private hatcheries, especially those situated in remote locations near forest and vegetation, to rethink their risk mitigation strategies to include wildfire-specific planning.

“It’s something that we should be thinking about,” Griffiths says, adding that risk mitigation strategies should include measures to

safeguard not just the fish and the facilities, but personnel as well.

“You have to also always keep in mind human safety… you don’t want to put your employees at risk by trying to save the facility and putting their own lives at risk. I think (wildfire emergency planning) is something that we have to talk about as a company.”

US government funding for wildfire-related mitigation strategies have also increased in response to the growing threat of wildfires,

according to Marshall. This increased funding is focused on multiple levels of mitigation efforts aimed at “reducing the risk of wildfires, protecting communities and safeguarding critical infrastructure and natural resources.”

While regions and individual hatcheries have allocated more staff time and resources internally to wildfire risk abatement activities, those activities have not received specific funding, Marshall adds.

How to have a stress-free transport

Exploring the latest research on mitigating stress during fish transport

By Ruby Gonzalez

Baskets of tilapia newly harvested from the earthen ponds were transferred to a holding tank. While this was happening, blocks of ice were likewise being thrown into the water.

Basing this protocol from handed down information, the farm owner said cooling the water was good for the animal as it minimized stress during transportation, resulting with quality products at the delivery point.

There is, however, more science involved than icing the water.

A study in China said while lowering temperature before transport could mitigate stress, a drastic change could lead to abnormal behaviour that increases stress levels. The proper way is facilitating a steady, gradual drop in temperature.

“A uniform cooling from 1 C per hour to 20, 15, 10, and 5 C had no significant effect on the tail-beat frequency of largemouth bass,” cited authors Fukun Gui et al. in “Temperature and dissolved oxygen lead to behavior and respiration changes in juvenile largemouth bass (Micropterus salmoides),” published on Fishes journal. Within

this range, they identified 15 C as suitable for the animal because it facilitates normal respiratory metabolism.

Tail-beat frequency

Experiments were conducted on the cooling methods on animal’s tail-beat frequency with focus on acute cooling and uniform cooling during transport.

A visual reference, tail-beat frequency is used as a metric reflecting the object’s physiological status and response to environmental change. Experiments showed marked increases in tail-beat frequency when temperature quickly dropped to increments of five between 20 and 5 C.

“Thus, the tail-beat frequency can be used as an evaluation index to regulate cooling rates and mitigate adverse temperature effects when assessing the impact of cooling on largemouth bass,” they explained. Aside from increased tail-beat frequency, the abrupt changes in temperature triggered abnormal behaviour such as surfacing, increased frequency and amplitude of gill movement, and abnormal swimming. This was explained as the animal’s “attempt to augment oxygen intake and adapt to a hypoxic environment during transport.”

Several factors heighten levels of fish stress in transport such as handling, density, oxygen and ammonia. Measuring cortisol levels provide dependable data on stress levels.

Stages of stress

Stages of fish response to stress have been discussed in a study in Italy.

In the primary stage, the fish responds by mobilizing energy reserves, addressing the increased metabolic demands arising from the stressful situation.

The secondary stage is manifested by the effects produced by hormones once they reach their target tissues through the bloodstream.

“If the stress response continues for an extended period, a tertiary response, or the so-called chronic stress response, takes place. This response involves comprehensive changes at the organism level, including reduced growth rates and reproductive capacities, behavioural modifications, and immunosuppression,” Martina Bortolleti et al. cited.

“Ultimately, the chronic stress response may even lead to the animal’s death.”

Their study, “Influence of Transportation on Stress Response and Cellular Oxidative Stress Markers in Juvenile Meagre (Argyrosomus regius)”, published on Animals, did welfare evaluation, including measuring cortisol levels in muscle and assessing the potential cellular localization of oxidative stress markets in various organs and tissues. Stress response was assessed during a 24-hour commercial transport in Italy.

Significant increases in cortisol levels were recorded from housing to transport and in subsequent samplings during different phases of transport. There was no significant decrease in cortisol levels during

transportation. A non-significant upward trend was recorded until the travel ended.

“The observed stress response appeared to be primarily associated with loading stress and the transport process itself, underscoring the significance of implementing appropriate operational protocols to preserve fish welfare.

Nevertheless, the overall unaltered distribution of oxidative stress markers between control and transported fish suggests that the experienced stress might have been relatively mild.”

Using muscle, instead of blood, for cortisol evaluation in assessing post-mortem stress is an “excellent tool”, they said, particularly when blood sampling is not feasible.

Load density

Stress response to the environmental factors in transportation can be further exacerbated by confined spaces. With rising costs, loading up cargo vehicles to the max is seen as saving on costs. China is no different in this approach. This has been observed with yellow catfish, among other high-demand species.

Ironically, losses could be incurred in the process of this cost-saving approach. A study in China explained density increase decreases oxygen content in the water, increases the transport stress and alters fish hormone levels. These all lead to lower survival rate after transport.

QUICK,

FISH SORTING SIZE REALLY DOES MATTER

EASY-TO-USE GRADER

“Our results revealed that overly high density is a stressor that causes damage to juvenile yellow catfish. Therefore, this study provides a scientific basis for the preservation and transport of juvenile yellow catfish,” cited authors Chai Ban et al. in a 2024 study published on Aquaculture Reports

Results showed liver oxidative stress index of the fish was affected after eight hours of transport. The degree of fish tissue damage increased with transport duration.

They recommended a transport time of eight to 24 hours for yellow fish catfish larvae. For prolonged transport, they do not recommend a density of 500 kg/m3. A transport time of <20 hours is recommended for densities of 333 kg/m3 or 250 kg/m 3 . Transport time of < 24 hours is suggested for densities of 200 kg/m3 and 167 kg/m3

Authors said while their data can provide some guidance in transportation, parameters in large-scale transportation may change. The study methodology involved a transport simulation, with small numbers of transporting water bodies and fish used for experiments.

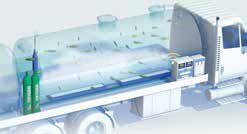

Dangerous drives

By Matt Jones

During a routine transport, a fish tanker truck was overturned while transporting over 100,000 Chinook salmon smolts. The fish were heading from the Lookingglass Hatchery in Oregon to the Imnaha River when the accident occurred. The majority of the smolts – some 77,000 – made it into the Lookingglass Creek, which is a tributary of the Grande Ronde River, while the remaining 25,529 smolts died either in the tanker itself or along the bank of the creek.

Oregon Department of Fish and Wildlife (ODFW) East Region Hatchery Coordinator Andrew Gibbs notes that while there’s nothing to indicate that this was the result of any negligence on the part of the driver, and no citations were issued by

Despite the dramatic look of these photos, the driver of this tanker carrying Chinook salmon smolts received only minor injuries.

Truck drivers transporting fish across Oregon’s rural regions sometimes face hazardous challenges en route.

PHOTOS:

law enforcement, the accident on March 29 does underscore the difficulties in transporting fish in rural areas.

“You drive a truck that weighs almost 80,000 pounds on dirt roads and curvy, single-lane roads, it’s fair easy to have a mishap,” says Gibbs. “When they stock fish all over the place, they’re not driving on regular fourlane highways that are straight and flat. It’s hazardous driving for commercial vehicles.”

Given the fact that it is unfeasible to pave all dirt roads in such areas, and that such tankers are the most efficient way to move smolt, there seems to be little further that can be done. But Gibbs notes that the ODFW do have procedures in place to limit such incidents. And they do seem to work – Gibbs has been in his current position nearly 15 years and he hasn’t encountered any incidents even close to this magnitude in that time. In fact, Gibbs says that the ODFW generally exceed the minimum standards enforced on them by the federal government.

“We try to avoid driving in inclement weather,” says Gibbs. “A lot of times, getting fish stock doesn’t have to be that day. It’s not like we’re hauling freight for a commercial trucking company with deadlines to meet. If we have a snowstorm or something coming in, we might hold off and wait a day so we can have better roads.”

The reality is that the sites where fish are going are often in remote areas that require driving over secondary roads – there’s little that can be done to change that. But in that context, Gibbs is very heartened by their safety record. And even if there aren’t areas where their procedures could be improved, it’s a good opportunity to review them anyway.

“We drive thousands of miles a year stocking fish on less than ideal roads a lot of times,” says Gibbs. “A single incident over

that time period is a pretty decent safety record. We’ve now had one pretty big one that makes you stop and pause and think about it – what we’re doing and how we’re training our drivers – but overall, I think we do a pretty good job.”

Gibbs lives about 35 minutes from where the incident occurred and rushed over as soon as he was notified.

“When I saw the truck, I was in shock that the driver was basically unscathed,” says Gibbs. “The cab was pretty smashed in.”

“Accidents can happen, but I’m hoping it’ll create a culture of safety mindedness,” says ODFW coordinator, Andrew Gibbs.

ODFW have an extensive driver training program and Gibbs describes the driver in the incident as one of their most experienced. While he’s seen nothing to indicate that the incident resulted from some negligence, he hopes that this crash will serve as an example of why safety precautions are so important.

“Accidents can happen, but I’m hoping it’ll create a culture of safety mindedness when you’re operating the vehicles,” says Gibbs. “Things can happen quickly and we got that reminder that things can happen quickly.”

The fact that the driver in this case was so experienced should also serve as a warning to other drivers.

“You could be the best driver in the world, but things happen so quickly out there,” says Gibbs. “It’s easy enough. Probably not many people who have been driving just a regular car haven’t had some sort of a small accident

LONG-LASTING AQUACULTURE PUMPS

at some point in their time driving. It’s the risk you take.”

The good news is that while the smolt that ended up in the creek did not make it to their intended destination, they are common in the Lookinglass Creek. The crash occurred a mile downstream from the hatchery where the fish were raised in the same water. There is a stocking program in the Lookingglass Creek for Chinook salmon already, it just received a total of 327,000 smolt for the year instead of the usual 250,000. The Inhana River will receive roughly 20 per cent fewer smolt compared to their usual goals.

“I don’t think it’ll be too much of a problem to get broodstock here in two years when they come back,” says Gibbs on potential long-term impacts on Inhana stocking. “The majority of our fish come back after two years in the saltwater. The Inhana program is one of our most successful programs for returning adult fish. We’re pretty far inland, about 650 river miles, so we don’t have a high survival to begin with, but the Inaha program is one of our better ones. We need to get about 280 adult fish to meet the broodstock goal, to continue the program at full production, which shouldn’t be a problem. Typically, Inaha returns are, in a good year, 3,000 or 4,000, in lean years, about 1,000 or so.”

Overall, for Gibbs, the incident appears to mostly result in a sigh of relief.

“I think the take-home message is that the driver wasn’t injured beyond some bumps and bruises and most of the fish made it into an area that we’ll be able to get our hands on them later to use for broodstock,” says Gibbs. “Of all the ways this could have gone when having an accident, this was probably the best outcome, without having a driver injury or a fatality or 100,000 fish on the ground. I guess I’m a glass half-full kind of guy but that’s how I look at it.”

Quality over quantity

Best practices for fish vaccination in hatcheries

By Seyitan Moritiwon

Vaccinating fish protects the aquaculture industry, according to Foster Scott, owner and chief veterinarian of Veterinary Aquatic Solutions Inc.

Vaccinations help prevent diseases by exposing fish to weakened or inactive pathogens, allowing their immune system to develop immunity without getting sick. It also reduces antibiotic use which prevents the possibility of antibiotic residues in food.

With better fish health, production also improves “as healthier fish grow faster and more efficiently, with fewer fish lost to disease,” Scott added.

Types of vaccines

Some of the typical diseases that are vaccinated against in Atlantic salmon and trout species are furunculosis, vibriosis, winter sore, bacterial kidney disease, infectious haematopoietic necrosis (IHN), lactococcus and infectious salmon anaemia (ISA).

Michael Ness, aquaculture technical support and account manager at Pharmaq, said the ideal time to vaccinate salmon via injection is when the fish is 25-30 grams. There are also immersion vaccines, in which the fish is immersed in the vaccine so it gets absorbed into their skin and gills.

“Usually, an immersion vaccine is given when the fish is very young and it carries them through to the time that they’re injection-vaccinated. And then the injection of vaccination will be administered and carry the fish through until harvest,” said Ness.

Autogenous vaccines are custom vaccines produced from pathogens isolated directly from an infected farm. They can get to market faster than a commercial vaccine, while commercial vaccines are mass-produced and widely distributed. It can take a few years to get to the market these licensed products but they’re useful for many pathogens which show little mutation or genetic shift over time. Ness said there’s a time in place for both types of vaccines.

“Today’s aquaculture industry faces several pathogens which can escape the effects of vaccination. Although it can be more costly and time-consuming, the development of

autogenous vaccines with health professionals and vaccine companies is an important tool for fighting bacterial pathogens on farms,” Scott said.

Best practices

Ness said a newer farmer may not understand how to administer a vaccine or its associated costs. Hence, the need for best practices in fish vaccination.

1. Veterinarian oversight. It’s important to have a fish veterinarian assess the health of the fish population before vaccination. If fish populations are stressed, have health issues, or have recently been handled, it’s best to leave them alone until they recover because vaccination is a very stressful time for the fish.

“Aquaculture veterinarians also play a crucial role in identifying, isolating, and creating autogenous vaccines for pathogens affecting fish at a farm-level,” Scott said.

2. Adequate anesthesia. If the fish are either over-anesthetized or under-anesthetized before vaccination, it can lead to many problems during vaccination.

“You can imagine a fish that’s wiggling or moving as it’s being vaccinated, that’s going to cause issues. It’s going to be stressful for the fish,” Ness said. The wiggling could cause tearing and bleeding around the injection site and if the fish is over-anesthetized, it can cause death.

3. Ensuring the proper site. The use of machines in vaccination has shown more accuracy versus hand vaccination. Machines precisely calculate the length and weight of the fish and the correct site of injection based on how long the fish is.

For the NFT machines that are used in British Columbia, most of the machines administer two vaccines into the intraperitoneal (IP) cavity, while administering an intramuscular (IM) vaccine, Naess said.

“Having a machine that can get through that tank faster ensures the fish are overall just happier. It means they can starve the fish for a shorter period of time,” Ness said.

4. Quality control. There are two different types of checks for effective vaccination: a non-lethal and a lethal check. The non-lethal

is a visual assessment where the farmer picks up the fish quickly after vaccination and assesses where the point of injection is. There is usually a bubble on the skin of the fish if the vaccine doesn’t make it inside the fish. There may also be bleeding externally. But Ness advises to sacrifice a few fish once or twice a day to ensure they’re getting correctly vaccinated.

“Euthanize them, and open them up, and ensure that the oil vaccine is where it needs to be inside the fish. There’s just no other way to really fully understand that besides sacrificing the fish,” Ness said.

Vaccinating RAS fish?

Disease can spread rapidly in RAS systems but Ness admits it is less likely if there is a strong biosecurity and water disinfection setup and protocols.

“Why not add a little bit of extra insurance with with with an efficacious vaccine?... I think that investors will not look unfavourably on that extra level of insurance that a vaccine will provide,” said Ness.

Side effects

While oil vaccines are efficacious, there can also be side effects on salmon – if the proper injection point isn’t adhered to or the vaccine doesn’t make it in the IP cavity – such as adhesions and melanization which stay with the fish till the point of harvest.

“A black mark in the fillet will cause economic losses for a salmon farmer because it doesn’t look as good,” Ness said.

He said Pharmaq has worked on lowering the side effects by reducing dosage and improving the oil adjuvants. Nonetheless, “the benefits far outweigh the negative consequences associated side effects.”

Better fish health can lead to better production outcomes. PHOTO: MICHAEL NESS, PHARMAQ

Advantages of NFT Vaccination Machines

Vaccines reduce diseases and contribute to a sustainable, profitable growth in fish farming. They reduce the need for antibiotics and chemicals, thereby limiting the pressure on the environment. Overall fish health, fish welfare and higher survival rates make vaccination a standard for most aquaculture producers. With a push to modern fish cultivation, the industry is witnessing significant changes as facilities move towards utilizing more automated equipment. Intra peritoneal and intra muscular vaccination by hand has been in use for decades, while this still effective in small numbers, it is inefficient to scale up to large production hatcheries, requires several stages of handling the fish and can be prone to human error in needle placement and dosage. With the use of the semi automatic NFT fish vaccination machines all these concerns are removed, additionally more fish can be vaccinated with fewer operators. This has proven critical in the last several years of difficult labour markets in Canada and the US.

PHARMAQ Fishteq has been at the forefront of providing vaccination solutions to aquaculture facilities for nearly two decades. The core product of our offerings is the compact and robust NFT vaccination and sorting machine. Our story started in Norway around 2005 with a focus on salmon vaccination, we have experienced substantial growth since then are present on several continents, including North America, South America, Europe, and the Asia pacific region. PHARMAQ Fishteq currently have approx. 116 machines in the market.

FUERSTE VACCINATION SERVICES

Fuerste Vaccination Services, is the exclusive North American distributor of NFT machines. FVS has been based since 2011 in the aquaculture hub of Campbell River, British Columbia, Canada. Partnering with Fuerste Vaccination Services shows our dedication to providing quality services, as they bring two decades of industry expertise to the table. FVS provides sale, setup, repair and maintenance and operation of the NFT machines depending on the market and needs of each facility. Currently there are 11 NFT machines in North America vaccinating salmon and trout.

Joint Support

The NFT machine has been on the market since

Canada/US: Fuerste Vaccination Services: Blair Billard

Mail: bbillard@fuerstevaccinations.com

2005 and has benefitted from continuous upgrades based on our customers’ needs and available technology. We offer a highly robust machine and provide our technicians with invaluable insights across various species and markets. Joint support between both FVS and Fishteq ensures a customer focused support system with full coverage of all time zones in North America. FVS maintains a supply of parts in their Campbell River warehouse, minimizing downtime, shipping and saving production loss. Knowledgeable and well-trained personnel is one of our highest priorities. FVS can seamlessly address any challenges that may arise during equipment installation, operation, or maintenance.

Seamless operation:

After sedation, the fish are transferred to the vaccination table and operators gently place the fish into the machine’s designated fish pockets. Once inside, the machines take charge, photographing each fish and allowing the computer and camera equipped with Fish Vision to identify and determine the optimal injection points. The machines handle fish in the sizes from 120 mm to 250 mm (20-150 grams). Once vaccinated the fish are graded automatically into 3 different size ranges which are pre-set by the operators and can be sent to three different receiving tanks.

Each model has different components to deliver different quantities and combinations of vaccines.

Website: NFT 20 & 30 | fuerstevaccination (fuerstevaccinations.com)

• NFT 20: Delivers one vaccine intraperitoneally, meaning that the vaccination is delivered directly in the body cavity of the fish.

• NFT 25: Delivers two vaccine formulations intraperitoneally through one needle.

• NFT 30: Delivers one or two vaccine formulations intraperitoneally and delivers one DNA vaccine intramuscularly.

• Full capacity for two machines is 18 000 vaccinated fish per hour

• NFT machines can vaccinate Salmon, Trout, White fish, Arctic Char, Sea Bass, Cod, Yellow Tail and Tilapia.

The efficiencies of multiple, simultaneous injections with the NFT Machines means the fish are out of water for less time compared to hand vaccination, and actual handling is kept to a minimum. The fish recover from the anesthetic quicker, are less stressed and typically begin feeding again within hours.

The NFT machine requires fewer operators than traditional hand vaccination and requires less training for the average operator, significantly lowering running costs and increases flexibility of vaccination planning for the production team. Its design prioritizes easy access for cleaning, ensuring optimal hygiene standards and biosecurity measures.

Contact us today to explore more about our NFT vaccination machines and to inquire about pricing.

International: PHARMAQ Fishteq: Hanne Andersen

Phone: +47 48164344

Mail: hanne.andersen@zoetis.com

Website: FISHTEQ (pharmaq.com)

Magida Tabbara

Effective and protective

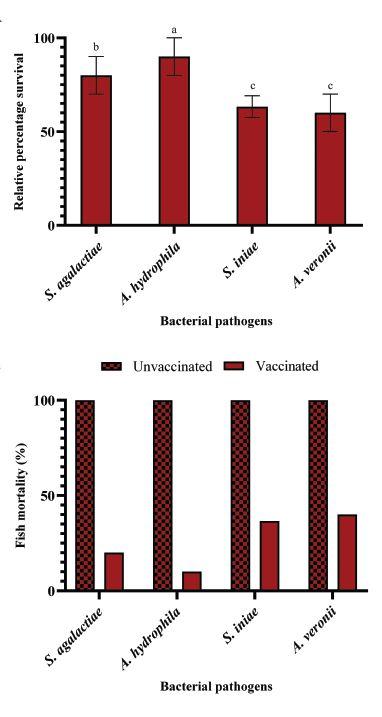

Oral bivalent vaccine enhances red hybrid tilapia immunity

In tilapia farming, disease outbreaks can cause severe economic losses. Tilapia are susceptible to a lot of microbial diseases, but the main ones encountered on farms are streptococcosis and motile aeromonad septicemia, also known as MAS.

Streptococcosis is a warmwater bacterial infection caused by Streptococcus agalactiae or Streptococcus iniae . High stocking densities and a little deterioration in water quality can onset a streptococcosis outbreak, and the infected fish start developing signs prior to perishing. Fish infected with either bacteria have their eyeballs protrude and their orbits bleed, in addition to hemorrhaging, and accumulation of blood and fluids in the peritoneal cavity.

As for MAS, it’s also a warmwater bacterial infection, but its major culprits are Aeromonas hydrophila and Aeromonas veronii. Infection with Aeromonas is mainly triggered by a stressor, which is prevalent in high-density culture environments.

Both diseases usually coincide on farms, where the causative bacteria co-infect the fish and lead to mass mortalities. The traditional solution for such outbreaks is to use antibiotics. However, with the great number of problems associated with antibiotic use, the shift towards safer solutions is imperative.

The idea

Oral vaccination is an easy application that can be administered to all fish of all sizes, without worrying about stressing the animals nor requiring a lot of labor. However, the method still needs some optimization, as research suggest that microbial antigens in the vaccine tend to degrade as they pass in the digestive tract.

A Malaysian group of scientists evaluated the efficacy of an oral vaccine developed to provide dual protection against streptococcosis and MAS in red hybrid tilapia. The results of the study provide further evidence that oral, feed-based vaccines can protect against co-infection and improve the immune response of the fish.

The approach

The Malaysian group chose red hybrid tilapia as a target organism, as it constitutes more than 95% of the Malaysian tilapia production [2]. Their research started by culturing S.

agalactiae and, A. hydrophila, into tryptic soy media, followed by inactivation with 0.5% formalin. The inactivated bacteria were pelletized by centrifugation, then emulsified with 10% palm oil and supplemented with sterile 1× phosphate buffer saline until reaching a volume of one litre. This mixture was added to one kg of commercial tilapia feed powder and pelletized.

The control feed used in the experiment was prepared similarly, but the mixture consisted of palm oil and phosphate buffer saline only. Vaccine safety was assessed for 14 days prior to the beginning of the experiment.

A group of fish were offered the vaccine-based feed and observed for any behavioral changes and clinical signs. After the vaccine-based feed was deemed safe, 102 red hybrid tilapia were divided into two groups and cultured for 16 weeks to evaluate the possible effect of the vaccine-based feed on fish growth.

During this time, the fish were offered commercial tilapia feed twice a day. At stocking, and in the second and sixth week of the trial, the fish were offered control feed or vaccine-based feed for three consecutive days.

During the entire vaccination duration, samples were collected from six fish per treatment on a weekly basis to allow for immunological analyses. Blood was collected and centrifuged to allow for serum lysozyme activity assessment and bacterial antibody titer evaluation by ELISA. Additionally, gut lavage and skin mucus samples were collected to evaluate IgM antibody titer of the four bacteria used in the vaccine.

At termination, fish performance was evaluated in terms of final biomass, weight gain, specific growth rate, and feed conversion ratio. The growth assessment was followed by a 10-week vaccination trial, during which 900 fish with average weight of 13 g were divided into six identical tanks.

The fish were offered vaccine-based feed or control feed at stocking for three days, then two booster doses were offered at the second and sixth week, for three days each time. On the tenth week, fish were challenged with S. agalactiae, S. iniae, A. hydrophila, and A. veronii by intraperitoneal injections. Mortalities were necropsied as soon as discovered, and swabs from the brain, eye, spleen, kidney, liver, and skin lesions were cultured on blood agar and used for PCR confirmation.

Figure 1. Results of the disease challenge. (A) Relative percentage survival of vaccinated fish challenged with Streptococcus spp. and Aeromonas spp. Bars represent means among replicates, and error bars represent the standard deviation from the mean. Various superscripts indicate significant differences (p≤0.05). (B) Mortality of the fish (%), vaccinated and unvaccinated, challenged with Streptococcus spp. and Aeromonas spp.

PHOTO: MOHD ALI ET AL.

Additionally, brain, kidney, liver, and spleen of fresh dead fish were examined for histological alterations. The challenge was concluded after 14 days, during which mortality and relative percentage of survival were recorded.

The outcome

No statistical differences in performance were noted among fish offered control and vaccine-based fish. However, the fish offered the vaccine-based feed had a bigger final biomass and better specific growth rate than the fish offered the control feed (final biomass of 22.73+/-1.83 and 20.73+/-0.97 g,

and specific growth rate of 1.68+/-0.35 and 1.59+/-0.49%, respectively). Similarly, fish offered the vaccine-based feed had a better FCR (1.82+/-0.10) than fish offered the control feed (1.97+/-0.07).

However, differences were clear among vaccinated and unvaccinated fish as soon as 12 hours post-challenge. Vaccinated fish started dying 48 hours post-infection, and the administration of the oral vaccine seemed to significantly decrease the mortality of the fish (Figure 1).

The interesting part resides in the histological alterations of the fish’s organs post-infection. After Streptococcus spp. infection, both vaccinated and unvaccinated fish showed similar signs of hemorrhaging, infiltration of mononuclear cells, and congestion in the brain.

The only difference was observed in the spleen of the vaccinated fish, where the congestion of blood vessels, the cytoplasmic vacuolations of some cells, and the aggregation of melano-macrophages were less severe than in unvaccinated fish. Similarly, fish infected with Aeromonas spp. but vaccinated against it exhibited milder congestion of the liver and spleen compared

to their non-vaccinated counterparts.

Additionally, fish offered the feed-based vaccine exhibited a better immune response than unvaccinated fish, both innate and adaptive. Overall, the lysozyme activity observed in the serum, gut lavage, and skin mucus was constantly higher than that in the tissues of non-vaccinated fish.

In parallel, vaccinated fish produced significantly higher levels of IgM antibody against all four bacteria used in the disease challenge, compared to the unvaccinated fish. The antibody levels increased as early as one week post-vaccination, and remained elevated throughout the entire study period.

In a nutshell, the oral bivalent vaccine comprised of formalin-killed Streptococcus agalactiae and Aeromonas hydrophila exhibits an effective immune-protective function against streptococcosis and MAS.

Despite the oral vaccine not providing full protection against the aforementioned bacteria, a partial cross protection against S. iniae and A. veronii was observed. The data collected from the present work encourage the use of oral vaccines. The benefits reside in enhancing both the innate and adaptive immunity of the fish for up to four months.

Booster doses can be easily administered at any timepoint without concern about stressing the fish or increasing labour.

Suggested readings

Full scientific article citation: Mohd Ali, N. S., Saad, M. Z., Azmai, M. N. A., Salleh, A., Zulperi, Z. M., Manchanayake, T., ... & Md Yasin, I. S. (2023). Immunogenicity and efficacy of a feed-based bivalent vaccine against streptococcosis and motile aeromonad septicemia in red hybrid tilapia (Oreochromis sp.). Animals, 13(8), 1346. https://doi. org/10.3390/ani13081346

[1] Du, Y., Hu, X., Miao, L., & Chen, J. (2022). Current status and development prospects of aquatic vaccines. Frontiers in immunology, 13, 1040336. https://doi.org/10.3389/ fimmu.2022.1040336

[2] Mohamad, S. N., Noordin, W. N. M., Ismail, N. F., & Hamzah, A. Z. H. A. R. (2021). Red hybrid tilapia (Oreochromis spp.) broodstock development programme in Malaysia: Status, challenges and prospects for future development. Asian Fisheries Science, 34, 73-81. https://doi.org/10.33997/j.afs.2021.34.1.008

Photo-ready biosecurity

TunaTech’s research investigates new photo sensor technology to aid in rapid pathogen detection

By Dr. Christopher Bridges, TunaTech GmbH

Despite impressive industrial growth, Atlantic salmon aqua culture faces significant challenges of disease control by pathogens, which can affect its sustainability.

In small/large production facilities, stressful conditions such as high stocking densities, heavy use of formulated feeds, unchecked antibiotic, and other pharmaceutical use, can cause tremendous environmental and economic impact. To ensure food security, production must be associated with appropriate disease management to assure maximum sustainability, consumer protec tion, animal welfare, and profitability.

Within the hatchery systems, non-infectious diseases may weak en the immune system of individual fish, and infectious diseases can rapidly spread throughout the facilities by the pathogens released from an infected fish by mucus, feces, or urine.

Most of these pathogens are waterborne infections and are either contagious viral diseases like infectious pancreatic necrosis (IPN), pancreas disease (PD), infectious salmon anemia (ISA), cardiomyopathy syndrome (CMS); or bacterial origin infections like Furunculosis (by Aeromonas salmonicida), Bacterial Kidney Disease (by Renibacterium salmoninarum) or Vibriosis (by Vibrio anguillarum and Vibrio salmonicida).

Detection of a pathogen at an early stage is critical for: a) treatment, or b) isolation and removal of diseased fish. Failing to detect a pathogen early may result in the complete loss of production with extreme financial consequences for the hatchery. At the same time, many of these pathogens are notifiable diseases for the veterinary authorities and therefore require rapid action to contain or isolate any outbreak.

Due to the current regime change from flowthrough systems hatcheries to recirculating aquaculture systems (RAS), the need for a rapid monitoring system has become more urgent.

Collaboration

The European Union Horizon 2020 funded a Fast Track to Innovation (FTI) research and innovation project called PHOTO-SENS. This initiative has enabled a pathogen detection solution based on a photonic integrated chip (PIC) technology originally designed and used for telecommunication and satellite applications.

This technology has been adapted to engineer a highly scalable, robust, label-free, and inexpensive biosensor for the aquaculture industry. It relies on novel biochemical recognition approaches for maximizing the specific binding of pathogen biomarkers on an asymmetric Mach-Zehnder Interferometry (aMZI) based photonic chip array, with smart multiplexing capability and size miniaturization.

The consortium of Dutch, Swiss and German companies providing specialized surface chemistry expertise (Surfix, Netherlands), microfluidics infrastructure (CSEM, Switzerland), large-scale semiconductor integration technology (PHIX, Netherlands),

system integration (LRE, Germany), and aquaculture biomarker discovery (TunaTech, Germany) has been able to deliver a miniaturized photonics-based biosensor, that is amenable to species-specific biomarker detection and cost-efficient large-scale production.

This has resulted in a miniaturized, ultra-sensitive and reliable point-of-care device with a disposable microfluidic cartridge, for analysis of eDNA samples taken from flowthrough, recirculating aquaculture systems or floating cages as found within a hatchery or aquaculture facility.

The presence of pathogens in an aquaculture tank or in cage water can be detected and measured via environmental DNA (eDNA) analysis, which is an effective and non-invasive method of determining the presence of pathogenic bacteria, viruses, and fungi in salmon aquaculture facilities.

This hatchery user-friendly process involves sampling, tank or cage water (≤1L) using a vacuum/peristaltic pump through a treated cellulose nitrate filter. The used filter is then folded and placed into an accompanying vial filled with molecular-grade ethanol or special buffer solution for the preservation of the captured DNA. eDNA sample processing and measurement can be done either in-house or by a certified laboratory and includes a simple DNA extraction protocol, injecting the extract into the microfluidic cartridge and inserting this into a stand-alone instrument.

How it works

The PHOTO-SENS approach involves novel material selective surface modification of the sensor with bioreceptors which can recognise and capture pathogen-specific DNA which results in a phase shift in the optical signal output. The DNA binding signal is then compared with a control channel without these bioreceptors.

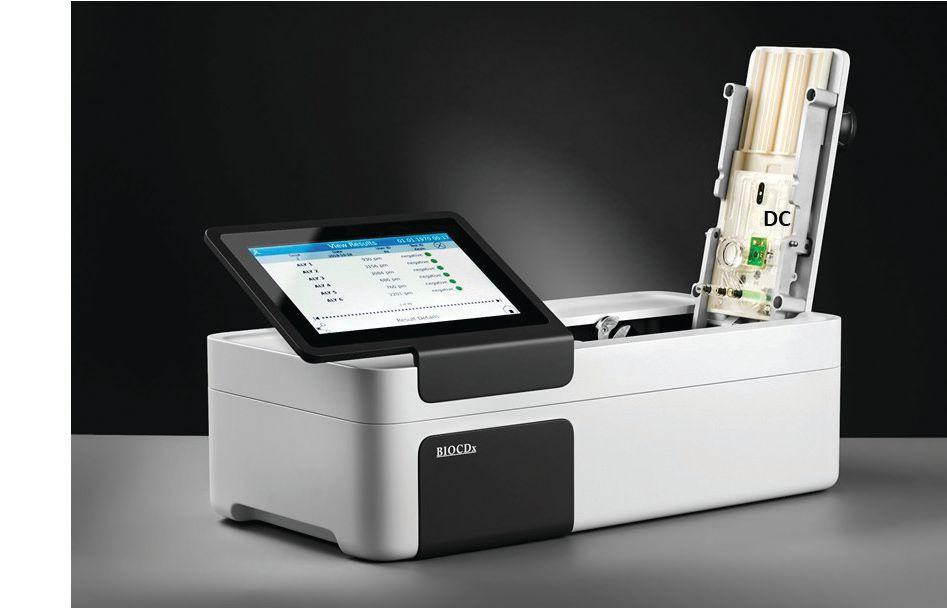

The new PHOTO-SENS desktop module with a disposable cartridge will be similar to the prototype BIOCDx laboratory module as shown.

The photonic biochip is equipped with six dual biosensor spiral elements (baseline control and test), such that multiple pathogen biomarkers can be detected at the same time. The chip is then incorporated into a disposable microfluidic cartridge with an injection port, which contains reagent blisters and is inserted into the desktop stand-alone actuation system.

Already specific assay probes have been designed for Vagococcus salmoninarum (Birkenbach, 2022) which is a causative agent of Vagococcosis, and the bacterial pathogen, Yersinia ruckeri (Kanwal, 2022), the causative agent of enteric redmouth disease. Aeromonas salmonicida has also been successfully assayed.

The benchtop readout system that provides actuation of the light source and fluid mechanics etc. is based on the demonstrator module developed in the previous EU-BIOCDx project, which used the same photonic technology but is aimed at the medical diagnostics industry. Chips and car-tridges have been produced for testing in a prototype desktop instrument and the first PHOTO-SENS prototype systems are

now being validated.

The new PHOTO-SENS desktop module is similar to the prototype BIOCDx laboratory module as shown above.

This development will enable hatcheries to constantly monitor their facilities for the presence of harmful pathogens and make rapid management decisions in terms of treatment and prevention of the spread of diseases. With disease outbreaks, detection and diagnosis needs to be carried out within a short timeframe without the need for the shipment of samples and lengthy waiting times for laboratory diagnostics.

The PHOTO-SENS module is designed for ease-of-use in the field, and it is hoped to begin field testing within the salmon farming industry including hatcheries and farms developing field protocols and establishing threshold levels of detection of various pathogens and management strategies.

Three key innovative factors can be highlighted:

1. Rapid detection of fish disease in water from flow-through systems, RAS or

8 Tests in 1 Shot!

grow-out cages.

2. Multiple sensors for different bacteria and viruses on a single microchip capable of detecting double stranded eDNA.

3. Disposable cartridge system allows high throughput for welfare surveillance.

The main vision is to provide a cost-effective, rapid monitoring for risk assessment and remediation. The system will be available for in-house laboratories at individual hatcheries and farms or through outsourcing of routine monitoring through a central laboratory. The advantages of having rapid results on-site are evident when dealing with remediation and risk avoidance. The equipment is destined to work on a traffic light system (red, amber, and green) for the health status of the system or give quantitative data to enable risk assessments to be made when providing advice for management purposes.