Japan’s quest to conquer bluefin farming

Despite researchers successfully closing the loop, full-cycle tuna farming remains a challenging feat

BY BONNIE WAYCOTT

Pacific bluefin tuna (Thunnus orientalis) have long been held in high regard, sought after for sushi and sashimi, and worth billions of dollars. But this fondness for the species has triggered a crisis: overfishing has drastically reduced numbers in the wild, so much so that bluefin is now on the Red List of Threatened Species by the International Union for Conservation of Nature.

With wild bluefin populations continuing to tumble, Japan has taken the lead in trying to bolster supply. In 2002, Kinki University (or Kindai, a blend of the district name Kinki and Daigaku, meaning university) became the first in the world to successfully raise bluefin in cap-

tivity. Since then, a number of Japanese seafood firms have followed suit.

One such firm is Maruha Nichiro. Headquartered in Tokyo, the listed company has been on a decades-long search for the answers to farming bluefin. Research began in 1987 but work was discontinued in 1997 after no significant progress was made. In 2006, however, the company decided to try again and, with the help of six universities, successfully reared bluefin in captivity for the first time in 2010. Five years later, its first commercial shipment of farmed bluefin was delivered to Japan’s private business sector.

Global pandemic takes its toll on hatcheries

BY MATT JONES

The COVID-19 pandemic has caused significant impacts to almost every aspect of modern life and business, and the fish culture sector is no exception. Business has been impacted at every level, including the operations of hatcheries. Hatchery International spoke with representatives for the industry from around the world about the impacts of the pandemic-related orders for citizens to remain at home and for non-essential businesses to close.

EUROPE

Exploring anaerobic digestion for waste management in RAS

Recirculating Aquaculture Systems (RAS) have become increasingly popular for land-based intensive aquaculture production due to their biological security, year-round operation, control of the culture environment, and reduced water usage. Development of new RAS facilities near local markets may also lead to improved food security, especially considering the aftermath of the COVID-19 pandemic.

Closed-loop RAS also allows for efficient solid waste capture and collection. However, the intensive nature of the process also results in the production of a concentrated waste stream, with waste treatment and disposal leading to additional costs for farmers. Farmers may also have to bear disposal costs of offal or other byproducts from harvesting and fillet processing. In addition, fish mortalities, which can range from 6.6 to 9.5 percent for salmonid strains (Davidson et al., 2016), also create disposal challenges. The utilization of waste as a valuable resource can be an effective way to increase the sustainability of aquaculture facilities and promote a circular economy.

continued on page 14 continued on page 25

The biggest impact on the industry worldwide has been the closures of restaurants, hotels and catering services. Javier Ojeda, interim general secretary for the Federation of European Aquaculture Producers (FEAP), says that over 35 percent of farmed fish in Europe cannot be sold currently. Retail sales may be slightly increased, but nowhere near enough to offset the loss of the other markets. As a result, the industry is experiencing a liquidity problem due to lost revenues. And, with stocks in the water, farm production cycles have been disrupted as the pens and tanks are not empty in time to put in new juveniles. Ojeda identifies two significant impacts on hatcheries.

continued on page 10

Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

MARINE SPECIES COVID-19

BY ABHINAV CHOUDHURY AND CHRISTINE LEPINE

Photo: Maruha Nichiro

Photo: tumsasedgars / iStock / Getty Images Plus/Getty Images

Photo: Vladimir Zapletin / iStock / Getty Images Plus/Getty Images

VITALIS

NEW

Vitalis PRIMA

Maximum vitality for offspring

Introducing Vitalis PRIMA, the most comprehensive marine fish broodstock diet. Based on international research collaboration and in-depth explorations with hatchery professionals, Skretting has developed a new standard in broodstock nutrition.

A total of 5 highly specific upgrades have been added to the previous market leading Vitalis CAL specification to address modern broodstock management challenges. For more information, please contact your local feed consultant.

BY MARI-LEN DE GUZMAN

Hatcheries starting to feel the heat

Editor Mari-Len De Guzman, mdeguzman@annexbusinessmedia.com

Associate Editor Jean Ko Din, jkodin@annexbusinessmedia.com

Regular Contributors Lynn Fantom, Ruby Gonzalez, Ron Hill, Matt Jones, Liza Mayer, John Mosig, Bonnie Waycott

Advertising Manager Jeremy Thain, jthain@annexbusinessmedia.com Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com • Tel: 416-510-5180 Fax: 416-510-6875 or 416-442-2191

Production Svetlana Avrutin, savrutin@annexbusinessmedia.com

Group Publisher Todd Humber, thumber@annexbusinessmedia.com

COO Scott Jamieson, sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media.

The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

A subscription to Hatchery International (six issues) is $37.00 within Canada, $48.00 CAD within North America and $62.00 CAD outside North America. To subscribe visit our website at www.hatcheryinternational.com

Circulation Costumer Service

Email: ugrzyb@annexbusinessmedia.com

Tel: 416 510 5180 • Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1

Printed in Canada. Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com

Tel: 800-668-2374

ISSN 1922-4117

Next Ad Deadline

The advertising deadline for the September/October issue is July 15th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the September/October is July 15th.

Contact Mari-Len De Guzman at mdeguzman@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

Afew weeks into the COVID-19 pandemic, our team at Hatchery International and our sister publications Aquaculture North America and RAStech magazine, wanted to hear from our readers about how this global health crisis has affected their business and their operations.

So many news stories have come out about the economic consequences of COVID-19 and many of them tell a dire story across major industries, as businesses remain close or operate under limited capacity, and hundreds of thousands of workers laid off and small businesses lose their livelihoods.

How has COVID-19 affected hatcheries, many of which are dependent on the business viability of fish and shellfish farms? How have social distancing and de-risking measures affected stocking and enhancement programs? What are the most pressing challenges hatcheries are facing as this global pandemic continues?

We posed these questions to our readers in a short survey we sent out a few weeks ago. The responses reflect a growing concern among the sector that if the current situation lingers, the long-term consequences can be devastating.

One shellfish hatchery in Washington state, which rely on farmers’ seed orders for their business told us that sales have been “very low” since the pandemic began. They are hopeful that funding relief from the government will help them weather this challenge.

But the concern is real that, “by the time relief funding is available, our hatcheries would have had to close and seed will be wasted.”

The concerns are not just economic, however. Not-forprofit stock enhancement agencies are worried that labour challenges due to physical distancing measures and health

risk concerns will significantly impact enhancement activities. As with commercial hatcheries, financial challenges are also worrisome.

“We are partially funded by municipalities in our county, who are all in spending freezes already,” said a respondent from a not-for-profit shellfish organization on the U.S. east coast. “If more than 20 percent of our member towns drop out, it will cause financial stress for the organization. If a loss of members were to continue more than one fiscal year we could go under. Our seed is used for local wild stock enhancement, which is just as important now, as local people may need to harvest shellfish to reduce their food bills.”

Indications point to a prolonged pandemic that is having a ripple effect downstream to hatcheries and egg producers. It is likely that COVID-19 is going to stick around for at least a couple more seasons – or until a suitable vaccine becomes available. It has already fundamentally changed not just our way of life but the way businesses and organizations operate to stay afloat.

Now more than ever, the industry must be united in finding ways to help each other get through this crisis. We are all in this together.

In speaking with some hatcheries and fish farmers, it is evident some are doing well and have not suffered the same losses as others. Sharing best practices on how to navigate this pandemic through industry associations or social media groups will be meaningful and helpful.

This is the time to come together as an industry to get us through this crisis.

Have you got a story tip or a hatchery operation with a great story to tell? Send me an email at mdeguzman@annexbusinessmedia.com.

Editor’s Note: Due to evolving developments surrounding Covid-19, aquaculture events have been undergoing scheduling changes. To avoid providing inaccurate information, as the situation remains fluid, we will not be running the Events Calendar this issue. Please check our website, www.hatcheryinternational.com for up-to-date information.

BioMar teams up with shrimp hatchery in Vietnam

Global aqua feed company BioMar Group has joined forces with one of Vietnam’s leading shrimp hatchery company Viet-UC Seafood Corp. The two firms have signed a memorandum of understanding wherein Denmark-based BioMar will become part owner and operational lead in the feed factory owned by Viet-UC.

“We believe that a feed partnership with Viet-UC in Vietnam will bring important synergies to the feed business as well as the hatchery and grow-out business of Viet-UC,” Carlos Diaz, CEO of BioMar Group, said in a press release. “Both companies have a common focus on sustainability, food safety, traceability, quality and performance, which we believe will be strong drivers to strengthen and develop both companies as well as the aquaculture industry in Vietnam.”

Viet-UC is one of the leading shrimp hatcheries in the world. The Vietnamese company aims to build an integrated seafood group.

BioMar Group is a global supplier of aquaculture feeds. The company wants to extend its footprint in the Asian market.

BioMar is already a significant shrimp feed producer

COLLABORATION

Team effort saves 400,000 Rainbow trout lives

Some 400,000 Rainbow trout were saved from potential destruction thanks to a collaborative effort among some public and private organizations in Washington state.

Cooke Aquaculture Pacific, Northwest Fisheries Enhancement (NWFE), Tacoma Power and the Washington Department of Fish and Wildlife (WDFW) came together last April in an effort to find a home for the group of Rainbow trout juveniles from Cooke’s Skatter Creek Hatchery in Rochester, Washington, after a permitting process has been delayed. When NWFE chairman Larry Pryor learned that Cooke was about to destroy the hatchery fish after being unable to find a place to divert them to, he reached out to several groups across the U.S. Northwest that might have a need for Rainbow trout stock. Eventually, he found Tacoma Power which could accommodate the fish in Riff Lake. After receiving the necessary approvals and permits from Cooke and the WDFW, the fish were safely transported from Skatter Creek Hatchery and successfully placed in Riff Lake.

Cooke Aquaculture Pacific’s freshwater production manager Doug Simms, along with other staff from the Skatter Creek Hatchey, delivered the fish and oversaw the stocking at Rick Lake.

"This turned into other opportunities now and Cooke Aquaculture Pacific will be growing more Rainbows for NWFE stocking and planting needs throughout the Northwest for other recreational fishermen,” said Pryor. He thanked the people who made this life-saving feat possible, including Jim Parsons, general manager at Cooke Aquaculture Pacific, who has since become an advisory member and "a strong resource" to the NWFE.

Salmon ova from Iceland arrive in China amid COVID-19

Even as travel restrictions continue across the globe due to the COVID-19 global pandemic, some 400,000 salmon eggs have safely crossed the Atlantic for delivery to Chinese farms.

Iceland-based StofnFiskur HF, a Benchmark Genetics company, announced the safe arrival of the salmon ova last April, marking the second delivery of eggs to

“It

“We are very pleased that the logistics so far have gone well,” says Robert Rúnarsson, global sales manager of Benchmark Genetics. “It is a challenge to plan airline shipments these days due to the Corona crisis. Cancellations and changes of flights are made on short notice. Fortunately, there are still daily connections between Iceland and Europe that makes it possible to get our products further exported to the global market,” he said.

StofnFiskur is the largest supplier of ova to the growing land-based aquaculture industry, and is the only foreign company that can deliver eggs to Chile.

“The aquaculture companies that run full-cycle landbased production also require deliveries every single month of the year, and we are proud to be able to fulfil their needs,” said Rúnarsson.

BioMar CEO Carlos Diaz

The salmon eggs from StofnFiskur’s Iceland facility reached Beijing within 24 hours, before being distributed to three salmon production facilities. (Photo: StofnFiskur)

The city of St. John’s in Newfoundland and Labrador looks forward to welcoming the global aquaculture community in the fall of 2021

Global aquaculture event postponed to 2021

What would have been the largest aquaculture conference in Canadian history has been postponed to 2021 because of the COVID-19 pandemic.

Instead of this fall, World Aquaculture Society (WAS) North America and Aquaculture Canada will be held Sept. 26-29, 2021 at the St John’s Convention Centre in Newfoundland and Labrador.

“Interest was enormous leading up to COVID-19 but due to the uncertainty of air travel we decided that we would postpone it,” Mark Lane, executive director of Newfoundland & Labrador Aquaculture Industry Association (NAIA), said.

“It was a hard decision but we think it was a responsible decision to ensure maximum participation from colleagues around the world,” he said.

NAIA is co-organizing this edition of WAS North America with the World Aquaculture Society and the Aquaculture Association of Canada. The event is the culmination of many years of effort among the three organizations to have a joint meeting in Canada.

“We feel confident that in 2021 the event will be even larger than we anticipated. PreCOVID our trade show was basically sold out – 120 sold out of 130 booths. More than 500 participants have already registered and a number of people are on board for sponsorship,” said Lane.

– Liza Mayer

Recirculation System Design, Supply and Construction.

• Commercial Farms, Hatcheries, Aquaponics, Research Labs, Public Aquariums, Live Holding Systems – we do it all!

• Representing leading RAS equipment manufacturers.

Report: Hatchery salmon account for 18% of Alaskan salmon harvest

Some 50 million hatchery salmon were caught by Alaskan fishermen in 2019, according to the annual salmon enhancement report by the Alaska Department of Fish and Game (ADFG).

Valued at $118 million, they represent 18 percent of the state’s total salmon harvest. The report was primarily for the benefit of the state legislature to evaluate the success of enhancement efforts, but the same data is used by hatchery operators and local ADFG staff to develop management plans.

ADFG section chief Flip Pryor said the numbers for hatchery salmon are subject to all the same conditions and influences as returning wild salmon.

“When natural returns do well, so do our enhancement efforts and vice-versa,” Pryor said. “In 2019, the natural and our enhanced runs were both modest compared to other years.”

Thirty-nine million hatchery salmon were caught in 2018 and while 2019 saw an increase, it fell well short of the 79 million hatchery salmon that were forecasted in the 2018 report. Pryor said there is much speculation as to the potential causes, but nothing definitive that would cause authorities to consider making changes to the system.

Thor Eppler “bucking” a chum salmon to extract male gametes on an egg slide at the Neets Bay Hatchery. Chum salmon returned to Alaska’s Southeast sector at only 7 percent of what was forecast, but there is little firm data to indicate why or if the numbers will be part of a long-term trend.

“It’s assumed that you just have high predation years, where the release coincides with something – whales, cod, Pollack – something they run into and have a high mortality very early out of the hatchery,” Pryor said. “That’s assumed to be what’s going on. These things can be localized.”

In Alaska’s Southern Southeast sector, chum salmon returned at only 7 percent of what was forecasted and pink salmon in the Prince William Sound area only returned at 1.6 percent. Pryor said the Prince William Sound pink salmon and Southeast chum are the largest contributors to Alaska’s fisheries. In fact, those fish in those sectors were primar-

ily responsible for a significant increase in egg take numbers in recent years, which have mostly been consistent since 1995 but have reached their highest ever numbers in the past three years. Pryor attributed this to increases in hatchery permitted capacity that were approved years ago and are starting to produce adult returns.

Pryor also noted that Alaska has experienced warm and dry conditions that affected holding and migratory behavior of salmon, which could have made an impact – although the impact of weather and drought was only mentioned in relation to the Southeast region in the report itself.

Due to the complexity of the information being dealt with – the number of species, release areas, other aquatic species that could influence returns, environmental impacts – the firm numbers for hatchery salmon returns could be impacted by a variety of factors.

“We don’t do anything if [numbers fluctuate] one year or even two years,” said Pryor. “It has to be several years in a row where you’re seeing the same thing and figuring out from the sampling data that, okay, we thought maybe 10 percent of them will be caught in this fishery while 20 percent of them are actually being caught in this fishery.”

Hatchery salmon catches were roughly 11 million higher than the previous year but still fell well short of the numbers that had been forecasted.

All photos by Flip Pryor

– Matt Jones

Dutch study investigates cost of microalgae production in hatcheries

The cost of microalgae production in aquaculture hatcheries could be minimized and production volume maximized by optimizing temperature and light conditions, according to a new study from the Netherlands.

Adding more artificial light could reduce cost by a third in small-scale systems and scaling microalgae production facilities from 25 square meters to 1,500 square meters could lead to a 92-percent cost reduction, the study found.

“I would like hatcheries to realize the true cost of microalgae production in their current form and show how it can be improved,” author Pieter Oostlander, a PhD candidate at the Wageningen University and Research (WUR), told Hatchery International. The study was part of his PhD thesis and the Robust Algae for Aquaculture (RAAQUA) project.

The RAAQUA project was a collaboration between the HZ University of Applied Sciences, Vlissingen, the Netherlands, and the Department of Bioprocess Engineering of WUR and done in collaboration with the Dutch aquaculture industry.

The cost of maintaining a microalgae production facility has been estimated to account for an average of 30 percent and up to 60 percent of the total budget of aquaculture hatcheries and nurseries.

Many hatcheries in the Netherlands maintain in-house, small-scale microalgae production facilities for production of live feed. Microalgae are usually grown in non-automated bubble-column systems at unknown production costs.

“If we can work together towards more optimized production systems in terms of cost, the aquaculture products from hatcheries could become more affordable/economically feasible competitors of fisheries, etc. More/new land-based aquaculture products could potentially become an interesting business case, ultimately resulting in a more sustainable industry,” Oostlander says.

The study compared commercially available reactors commonly used in aquaculture, observed tubular photobioreactors and bubble-columns in two placement possibilities, and used artificial light in an indoor facility and utilized sunlight in a greenhouse under Dutch climate conditions.

The final results of the project were presented to the Dutch aquaculture industry.

The scale of a microalgae production facility has a very large impact on the cost. Biomass yield on light showed the largest effect on cost when not considering a different scale of the production process. Process parameters such as temperature control should be aimed at optimizing biomass yield on light rather than other forms of cost reduction.

“It takes time to change a production system or adapt an existing system towards a more cost-efficient strategy for microalgae production,” he says. “Based on the large difference in cost price between the optimized scenarios and current practices, it is worth it to consider changing towards more cost-efficient production.”

To counter biases on laboratory experiments or computer models/calculations in “completely changing” a production protocol, they established a research facility using pilot scale tubular photobioreactor as part of the project at the HZ University of Applied Sciences. Research was conducted at larger scale representing true production scale in hatcheries.

– Ruby Gonzalez

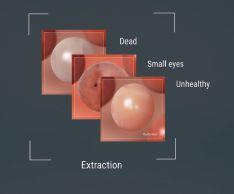

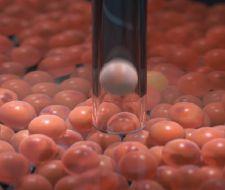

• Unviable egg elimination

• High accuracy in counting

• Size sorting

Pieter Oostlander, PhD candidate at the Wageningen University and Research, and his team focused on cost price calculation of microalgae production in aquaculture based on real-world production data and computer models. (Photo: HZ University of Applied Sciences)

Philippines begins culture of new mudworm species to feed crab, shrimp broodstock

he Southeast Asia Fisheries Development Center (SEAFDEC) in the Philippines has started culturing the newly identified mudworm species, Marphysa iloiloensis, which has the potential of being an outstanding supplemental natural food for crab and shrimp broodstock.

TThe development of a reliable culture technique for aquaculture use is important to lessen dependence on wild stocks and produce a disease-free and sustainable supply, said Mary Anne Mandario, associate researcher at SEAFDEC and part of the group behind the identification of the species in September 2019.

Named after the province of Iloilo, where it was discovered, the mudworm species, is a natural food for shrimps and crabs. “They naturally inhabit the mangrove mudflats, where mangrove crab breeders and juvenile shrimps feed on them. Since they are a natural part of the diet of shrimps and crabs in the wild, they may have strong acceptability and digestibility traits compared to other natural food,” Mandario says.

The mudworm contains 60 to 70 percent crude protein and 10 to 14 percent crude fat. Polychaetes, in general, are used as maturation diet to improve the reproductive performance of crustacean broodstock. Improved reproductive performance means higher fecundity, fertilization and hatching rates which correspond to a higher production of healthy crablets and shrimp post-larvae.

In 2019, SEAFDEC produced 5 kilograms of the mudworm, which is enough for one-time feeding of about 1,390 shrimp (Penaeus monodon) broodstock. The entire volume was supplied to the shrimp and crab hatcheries of SEAFDEC Aquaculture Department (AQD).

“This is important to be able to establish a feeding protocol of M. iloiloensis to shrimp and crab breeders,” she explains.

This production came from a 14-sqm culture area. A bigger area is needed to scale to commercial production and meet the demands of crustacean hatcheries. She likewise stresses, “Continuous refinement of culture protocol should be done to further improve the production in the grow-out.”

Mussel, squid, and sandworm are commonly used as supplemental diet for shrimp and crab broodstock. Since mussel and squid are also human food, aquaculture requirements compete with human consumption. Sandworm, which is commonly cultured and sold worldwide, dies after spawning. The mudworm is capable of reproducing throughout its lifetime.

Its larvae and juveniles can be used as feed for juvenile fish and for ornamental fishes. Alive, the mudworm can be used as bioremediators of organically-enriched fish pond sediments and coastal harbors.

– Ruby Gonzalez

“Lots of people that live here remember the days when there was a giant school of salmon and steelhead and everybody was fishing. That’s certainly not the case now. So these projects undertaken by A Rocha and their hatchery have the community very interested.”

British Columbia council backs hatchery grant application

In an April meeting held via phone, the District of Houston’s council agreed to act as a financing conduit for a grant application on behalf of environmental stewardship organization A Rocha. The organization has applied to Farm Credit Canada’s Agrispirit program for $25,000 which would be used to fund a solar power energy system for their hatchery on Buck Creek in BC. The solar panels would help offset the energy costs of a larger project the group is working on.

“We’re building a nature center addition to the present fish hatchery building that’s going to be an environmental education center for school groups and tourists and day camps,” says A Rocha Project Coordinator Cindy Verbeek. “Solar power is a way of making us more sustainable so we can reduce our operations costs into the future.”

Not including the solar panels, A Rocha is roughly $35,000 short of a $200,000 fundraising campaign for the nature center. Verbeek says the end goal is to have the solar panels offset at least 50 percent of the hatchery and nature center’s energy usage.

The hatchery released 800 coho fry in the spring of 2019 and have begun their fourth year raising salmon. Verbeek says that A Rocha hopes the nature center will provide a new funding stream to support the organization’s long term goal of habitat restoration.

Involving the local municipality is FCC’s way of keeping grant applicants honest – the funding would be provided to the district, which would then administer the funds to the applicant.

“The river that we are located on is considered one of the most endangered rivers in the broader watershed,” says Councillor Jonathan Van Barneveld. “Lots of people that live here remember the days when there was a giant school of salmon and steelhead and everybody was fishing. That’s certainly not the case now. So these projects undertaken by A Rocha and their hatchery have the community very interested.”

Mary Anne Mandario, associate researcher at SEAFDEC in the Philippines, holds newly identified mudworm species, M. Iloiloensis.

Being a natural part of the diet of shrimp and crab in the wild, M. Iloiloensis may have strong acceptability and digestibility traits compared to other natural food.

– Matt Jones

Students learn about salmon rearing at A Rocha’s hatchery on Buck Creek in British Columbia. A Rocha is currently fundraising to build a nature center which would provide many more educational opportunities.

Photos: Courtesy of Mary Anne Mandario

Nanobubble trumps diffuser aerator in Indonesia shrimp study

Using nanobubble generator in the production of whiteleg shrimp (Penaeus vannamei) in indoor raceway ponds resulted in high survival and growth rates, according to a new study.

“The results revealed that nanobubble has managed to maintain dissolved oxygen (DO) at the optimal range and affected the shrimp growth,” said authors Asri Ifani Rahmawati, et al. in the study, “Enhancement of Penaeus vannamei shrimp growth using nanobubble in indoor raceway pond,” which was conducted in East Java, Indonesia.

Fifty-meter ponds were stocked with 34,000 juvenile whiteleg shrimp at a stocking density of 680 per cubic meter. Results on day 81 showed that the nanobubble treatment yielded better survival rate, feed conversion ratio, total harvest and productivity. The total virus-bacteria also decreased, and total harvest and productivity were almost a hundred percent higher. The results were compared to another treatment using diffuser aerator.

The study investigated the effects of using a nanobubble generator on the growth environment. With whiteleg shrimp farming steadily growing in Indonesia, the authors stressed the need for “the best practices in technology and management of water quality” and acknowledged the major role of DO in improving water quality.

TABLE: Nanobubble vs. diffuser aerator in indoor shrimp raceway pond

Nanobubble generator produces nano-sized bubbles to increase DO levels throughout the ponds. The machine that was used combined the gas-liquid flow with honeycomb structures for highefficiency nanobubble generation. This nanobubble generator could maintain DO under optimal conditions during cultivation days. With this and its other “unique characteristics, nanobbuble has managed to improve DO levels in the ponds.”

There is a positive correlation between shrimp biomass and oxygen consumption rate. “The enhancement of growth proved that the energy absorbed by shrimp in a nanobubble pond is higher because of the oxygen levels available in the pond,” they say. The study was published in Aquaculture and Fisheries.

–

Ruby Gonzalez

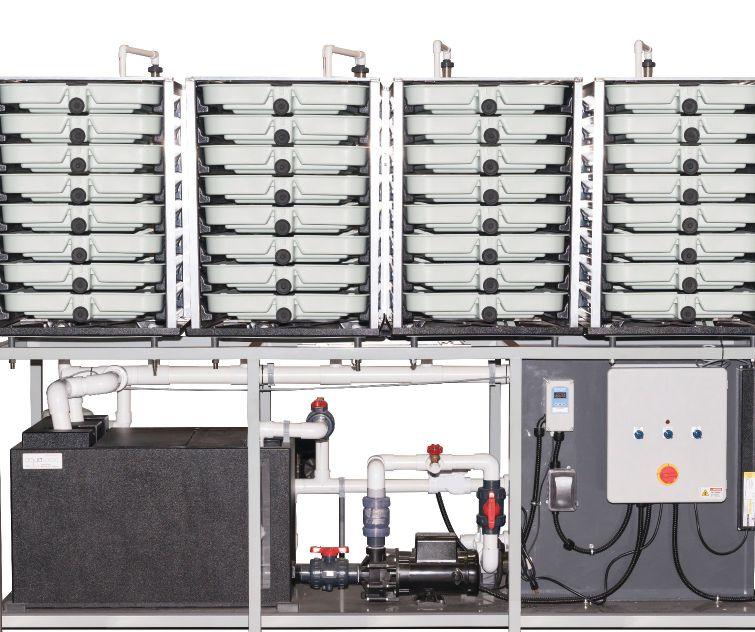

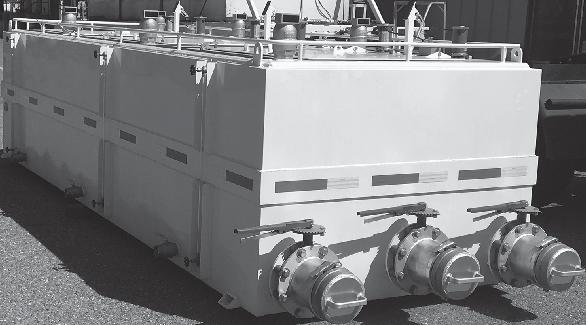

Increased Survival Rate with Significantly Reduced Water Consumption

The all-new HydroHatch Incubation System from MariSource gives hatcheries increased efficiency. With recirculation, germicidal UV filter and a titanium heat exchanger, the HydroHatch delivers increased survival rate and significantly reduces water consumption.

Features and Benefits:

65 gallon sediment and recirculation tank

Requires only 150 gallons to completely fill the unit and reservoir

High-quality, long-life quartz germicidal UV filter

Complete isolation of eggs

Easily able to increase the dissolved oxygen content of the water

230 volt 30 amp control panel

Insulated titanium heat exchanger

Precise temperature control

Comes standard with four 8-stack incubators

Additional four 8-stack incubator option available

The new HydroHatch Incubation System is ideal for Salmon, Trout, Steelhead, Perch, Channel Cat Fish, Walleye, Eels, Shrimp and Muscles.

Figures based on tables in “Enhancement of Penaeus vannamei shrimp growth using nanobubble in indoor raceway pond” by Rahmati et al.

COVID-19 COVER

Global pandemic takes its toll on hatcheries

Mark Ely of Limestone Springs Fish Preserve says recreational stocking is down by roughly 50 percent and processing for the food market is down by around 20 percent, but on-site fishing is actually up by 40 percent as it’s one of the few outdoor activities still accessible to Pennsylvanians.

“First, clients of the hatcheries are short on liquidity and at the same time, they are not able to take in the juveniles that they had programmed to receive and buy,” says Ojeda. “The problem of the ongoing part of the industry is moving down the value chain over to hatcheries. Hatcheries are beginning to experience liquidity problems, but many are facing the non-possibility of sending their juveniles over to the farms. There is a month, month-and-a-half delay on the impact of the COVID crisis on hatcheries, but it’s arriving and what they have to do is stop production.”

Hatcheries and other aquaculture businesses continue to operate as essential businesses – food is still required and fish are already in the waters. Conducting hatchery operations while observing social distancing measures has presented a logistical challenge as work shifts and procedures must be altered. But there are other challenges that are out of the hands of the hatchery operators.

“There has been a high risk in the normal management of farms, because the delivery of liquid oxygen or of feed has been at risk in certain moments because of cross-border complications between neighbouring countries or just inside each country,” says Ojeda. “Hatcheries are very, very dependent on the availability of gasses like liquid oxygen or CO2.”

Ojeda says FEAP has been lucky that there haven’t been any cases where transportation issues have caused problems for hatchery operators in their membership, but the risk was there and companies had to look at developing contingency plans in case their deliveries were delayed.

NORTH AMERICA

Katie Harris, president and general manager of Mt. Lassen Trout and Steelhead in California, says that the order for residents of the state to stay at home halted every market that their farm and hatchery serves.

Jerry Weigel, fish production and development section supervisor with the North Dakota Game and Fish Department, theorizes that hatcheries may have an easier time adjusting to pandemic circumstances since strict biosecurity measures are standard in the industry.

Javier Ojeda, interim general secretary for the Federation of European Aquaculture Producers, says the impacts of the COVID-19 pandemic and related business closures hit fish farms first and hatcheries about a month or a month and a half later.

“As of right now, we have no sales for the foreseeable future and this is traditionally our busiest time,” says Harris. “I pray this ends quickly but I am not optimistic given the conditions here in California. My goal is to try to stay in business with as few layoffs as possible.”

Operators are concerned about the impacts that long-term, stay-at-home orders will have. For hatcheries that support recreational fishing efforts, winter and spring leading into the summer are crucial times of year and Harris, who also serves as president of the U.S. Trout Farmers Association, is worried about the impacts.

“How long these quarantines last and when stocking can resume or begin will probably dictate the fate of many farms,” says Harris.

Pennsylvania’s Limestone Springs Fishing Preserve has three segments to its rainbow trout business, says owner Mark Ely: recreational stocking, the food market and on-site fishing. Each aspect of that business has been affected by the pandemic. Much like in Europe, sales to restaurants have vanished entirely and are not offset by minor increases to sales in grocery stores.

“And our stocking side is way off,” says Ely. “In Pennsylvania, we’re very big on the recreational stocking business for trout. But all the municipalities who buy for rodeos in their county or in their borough, they basically all cancelled. Some of the bigger clubs that get hundreds of people out cancelled, so that side has really taken a hit and that’s our bread-andbutter right now. That pays the payroll in December, what we’re making now. It’s tough.”

On-site fishing is actually up, however, as fishing remains one of the few outdoor activities that Pennsylvanians can still enjoy. But Ely notes that they have had to change some of their operating protocols, including disinfecting everything possible and ensuring that customers maintain proper social distancing.

Jerry Weigel, fish production and development section supervisor with the North Dakota Game and Fish Department, says the state is fortunate as they are likely the last state in the lower 48 to be shipping fish. As of press time, they were starting spawning operations for Northern Pike and had yet to take any eggs.

“The lateness of our activities is hopefully helping us get past some of these very critical weeks right now,” says Weigel. “And then on the hatchery end, of course, we have all our salmonids and trout on hand and that’s all essential services – it’s almost business as usual up there, not much of a change at all.”

State hatcheries have also incorporated new safety protocols, keeping workers far apart from each other whenever possible. In cases where social distancing is not possible, masks and even clear acrylic shields are employed. Weigel theorizes that hatcheries and aquaculture companies may be better suited to adjust to the circumstances of the pandemic since strict bio-security measures are already a fact of life in the industry.

“We fully disinfect our transport units and everything before we leave the state, that’s been a standard protocol,” says Weigel. “A lot of the things that we’re seeing now that we’re doing as humans that seem so foreign have been standard protocol in the fish world for a long time.”

One of the biggest concerns for Weigel was that interstate travel restrictions would prevent the department from trading walleye for trout with their counterparts in the Wyoming Game and Fish Department. However, restrictions were lifted just before press time and Weigel had already made two trips to Wyoming.

ASIA

The first large-scale impacts of COVID-19 were felt in Asia, before they were reported in North America or Europe. Numbers released by China, for example, show a peak of nearly 20,000 new cases in February that dropped to single digits in the following months. As such, Asia is in many ways ahead of other markets and there is a sense that normalcy is slowly beginning to return.

“Most farms and hatcheries are already open,” says Dr. Huang Jie, director general of the Network of Aquaculture Centres in Asia-Pacific. “In the early times, there were huge losses for this market. In China, there is a big market for aquatic animals, but during that time it just stopped. So they lost a lot. But I think recently, the price is going up.”

Huang says many in the sector believe there will be a “golden period” in the market as things return to normal and as citizens, desperate for a return to pre-pandemic life, will be eating out at restaurants more than before.

Operators in Asia and around the world should be wary of rushing to get things back to normal, however. Shortly after Huang spoke with Hatchery International, new cases in China returned to double-digits for the first time in weeks. And in Singapore, which had been lauded as a model in pandemic response earlier in the year, a second wave of the virus saw confirmed cases jump from 266 to over 5,900 in a country with a population of 5.7 million.

Air stone choices and maintenance

BY RON HILL

The importance of diffusers and air stones to hatcheries cannot be overstated. If there is anything at a farm that needs to be of high quality, it is oxygen diffusers and air stones. Diffusers and air stones are delivering oxygen where and when it is needed most –there cannot be failures. They are inefficient by nature – contact time is limited to the time it takes for the bubbles to reach the surface and much oxygen is lost into the atmosphere – but are extremely effective in providing oxygen where it is needed.

CHOOSING THE RIGHT OXYGEN DIFFUSER

There are many types of diffusers and stones available; choose the right one for your farm and your application. Diffusers are generally plastic, or metal bodied with large ceramic stones inset. Oxygen is pushed through the ceramic stone creating a fine misty sheet of microbubbles. Microbubbles are desirable for their good surface-to-volume ratio, which allow excellent gas exchange with the water.

Diffusers need to be matched to their control flow meters and line oxygen pressure. Not all flow meters will work with ceramic diffusers and diffusers can have different maximum pressure ratings so make sure to match the diffuser to your system. Many plastic body diffusers exist, but they are not created equal. Some plastic body diffusers can be difficult –although the plastic body is tough they are often susceptible to flipping over and weights may need to be added. Extendable plastic track locks are susceptible to sections or end pieces twisting off in the tank.

The barbed hose fitting can be either perpendicular to the diffuser (it sticks straight up) or level with the stone (it comes out the end). Models with the hose fitting coming out the top prevent the stone from easily flipping over while descending and gives you the assurance the diffuser is still upright even if you can’t see it in the water. Select the style that works for the application; brass adaptors can be added to models with level fittings. It can be extremely frustrating to get a diffuser to flip over and sit properly on the bottom, especially with smaller stones.

CHOOSING THE RIGHT AIR STONE

Air stones are coarser than diffusers, deliver much larger bubbles and can deliver a much larger volume of gas. Air stones are much cheaper than diffusers but are much less efficient at adding oxygen to water. Air stones are often used for agitation as well as providing for fish metabolism; air is used instead of oxygen to provide agitation.

Like diffusers, there are many different stones out there. Choose stones with a larger pore size if the objective is agitation for a biofilter, etc. If the objective is to provide oxygen to fish, choose stones with a smaller pore size.

Many stones are notoriously brittle and are often found broken during shipping. Regular use is often very hard on the barbed hose fittings, which are usually made of plastic and tend to break off. Ask your supplier for the sturdiest models as they will likely be able to tell you which one their customers are happy with.

MAINTENANCE

Keeping diffusers in top condition is a key component in oxygen and facility management. Multiple spare diffusers should be on hand for easy replacement. How diffusers are used and stored will determine how much maintenance they need. If the diffusers are left in the tank not running, they need to be inspected regularly and purged. As the diffuser sits unused in

produce a fine sheet of micro-bubbles which effectively oxygenate the

the bottom of the tank, water infiltrates the pores of the diffuser and works its way up the line. When the stone is turned on, water must be purged out of the diffuser by air pressure in the line before the diffuser can emit oxygen. Purging can cause delays in starting up the oxygen stone as the water is slowly pushed out – it is much more difficult to push water through the diffuser than it is oxygen.

Diffusers can also become clogged from the minerals or the organics in the water and should be brushed regularly. Stones that are not permanently submerged should be hung so they drip dry and should require less service. Ensure that diffusers are not allowed to freeze in cold weather unless they are dried and drained, even small amounts of water can cause cracks in the pores when it turns to ice.

Cracked or chipped diffusers emitting irregular bubble patterns should be removed and replaced immediately. Cracked stones should never be used again, amateur repair jobs can have disastrous consequences as stones can explode in spectacular fashion.

All stones should be serviced and sanded yearly. Each should be cut off the hose, the fitting inspected, set to dry and lightly sanded with 60 grit sandpaper. Sand lightly, only enough to clean out the tops of the pores. Inspect clogged or old diffusers – they may be serviced and re-used providing they are not cracked. Diffusers can be lightly acid washed with muriatic acid solution to remove stubborn mineral deposits or fouling that can clog the diffuser.

Whatever oxygen delivery device you choose, ensure it is tested and inspected regularly and find problems before you start using the oxygen.

Air stones come in many sizes, provide large bubbles and are usually made of silica or aluminum oxide.

Diffusers with an upright barbed fitting can be easier to keep upright.

Diffusers

water.

MainStream Aquaculture bares multiple expansion plans

Australian barramundi producer targets global growth

BY JOHN MOSIG

Afamily aquaculture company started in 2001 as a 50-tonne a year barramundi producer has become a global leader in the sector. Already producing about 2,000 tonnes of Lates calcarifer and 40 million fry per year, MainStream Aquaculture has embarked on an exciting expansion program that will consolidate its position as an industry leader.

Hatchery International caught up with MainStream’s managing director, Boris Musa, at the company’s Wyndham headquarters, on the outskirts of Melbourne, Victoria in Australia. He was upbeat as to the future of the company and industry.

“We ship barramundi seed stock to 25 countries, as well as being the major supplier to Australian growers. Our table fish products, marketed under the Infinity Blue Spring and Salt Water brands, command an increasing price premium. Despite exceptional volume growth, demand remains strong,” Musa says.

With 70 percent of the seafood consumed in Australia imported, mostly from Asia, it would suggest there’s much room for the expansion of the local aquaculture industry.

Furthermore, a recent collaborative study – “Fish to 2030: Prospects for Fisheries and Aquaculture” – by the World Bank, Food and Agriculture Organisation of the United Nations and International Food Policy Research Institute stated that by the end of the decade, 62 percent of food fish will be farmed.

“Diversification in farm location and production methodology provides broad coverage in the market from plate size to filleting size fish. In particular with smaller fish – that demonstrate a shorter shelf life than the larger fish – close proximity to key markets affords MainStream a massive advantage over more remote farms,” Musa says.

SELECTIVE BREEDING

While advances in nutritional understanding, automated systems and fine-tuned husbandry practices have all played

their role, one of the key elements of MainStream’s success has been its selective breeding program. The company now have almost 1,000 broodstock covering dozens of families from which to work with and are up to seven generations of improved genotype. MainStream’s Wyndham hatchery has eight breeding tanks and can produce 70 million commercialgrade fry annually, not to mention the two research and development hatcheries in Queensland.

“To put that in perspective, global production of barramundi is about 100,000 tonnes. If called upon, MainStream could supply the global barramundi industry’s stocking needs twice over,” Musa explains.

“As an enterprise, we’ve never devoted more funds to R&D than we’re presently committing. We’ve mapped the barramundi genome and developed multiple arrays from which to identify favourable traits, thus enabling us to accelerate productivity gains.”

Into 35-day old silver barramundi fingerlings ready to be moved in to the nursery

60-day old juvenile barramundi in MainStream’s nursery

From its Townville facility, MainStream has worked closely with James Cook University (JCU) for well over a decade and has achieved an average five percent growth improvement annually. “With the genetic potential of the species, we expect to continue at that rate for many years to come.”

Growth is just one of the four attribute targets they have set out to improve. “Apart from growth through both increased appetite and enhanced feed conversion efficiency, we’ve improved fillet yield, disease resistance, and behavior (less aggression),” Musa says. “In all four areas we have made significant gains; gains that translate into economic value.”

CURRENT DEVELOPMENTS

MainStream currently has three major projects underway. The first, with a 2021 completion timeline, will more than double the size of the grow-out section of the Queensland operation - from 46 x 0.75-hectare ponds to almost 100. It will also see the establishment of a state-of-the-art RAS nursery. The nursery will enable the company to maximize the growth of the juvenile fish under 24/7 optimal conditions and, by stocking 200-gram fingerlings in the ponds, reduce mortalities materially. Musa puts a conservative production estimate of 3,000 tons for the expanded farms. Secondly, the company is carrying out a $1.24-million feasibility study at Morwell in Victoria’s Latrobe Valley. The region is an industrial and coal-fired power hub and is planning for an emission-neutral future. MainStream, in partnership with Australian Paper Mills (APM) and the Latrobe Valley Authority (LVA) is developing a plan that will be part of that future.

“We’ve established that the plan is technically feasible. The most exciting aspect is that the water, which meets our stringent quality requirements, is heated, and available in immense volumes,” says Musa. “Our first-stage target is 3,500 tons of fillet-sized fish (4kg), mainly for the Melbourne and Sydney markets.”

The LVA has provided $800,000 in funding towards the feasibility study, which is expected to be finalised by mid2020. The facility would support up to 500 Victorian jobs in the construction phase and around 190 ongoing work placements in the Latrobe Valley.

LVA CEO, Karen Cain, is positive at the project launch. She says the coming together of the two operations – as dissimilar as they may seem at first glance – demonstrates how important the union is, not only for the people of the Gippsland region, but to the economy of the whole state.

Surveys carried out indicate the local community welcomes a food producing and processing industry of this scale as a stepping stone towards a sustainable food producing region, providing employment and encourage further investment in the region.

The third project, a U.S. expansion, is in its infancy. “What we see is not dissimilar to the situation we confront here in Australia: sophisticated customers valuing a

quality, sustainably produced and safe source of seafood,” Musa explains. “Furthermore, local production from the wild and farmed fisheries is insufficient to service local demand. America’s biggest import item after oil and gas is seafood. We’re currently selling Australian barramundi into the market to get a better understanding of the pricing architecture and market opportunity.”

He explains that MainStream’s business model is to site farms in proximity to key markets. “The Arizona location for expansion provides access to 100 million consumers in the surrounding states. We are managing a 500-ton pilot project with the capacity to scale up. There is great infrastructure and an abundance of warm, high-quality saline bore water, which is perfect for barramundi. We’re growing fish there and

they’re doing remarkably well.”

MainStream’s long-term genetic improvement program and fingerling supply has supported the expansion of the barramundi sector in Australia, North America, the Middle East and South East Asia. “We’re proud of the fact that we have underpinned the development of large barramundi industries in some of the countries where we ship fingerlings.”

“In other places, we’re helping with a transition from shrimp, which are more susceptible to catastrophic crop losses, and from lower value tilapia. Barramundi performs as well as the tilapia on farms but achieves a higher price for finished product for growers.”

Boris Musa may be contacted at b.musa@mainaqua.com.au

Hatchery manager, Alpa Pansuriya, monitoring the progress of a batch of Barramundi larvae

MainStream Aquaculture founder and chief scientist Dr. Paul Harrison monitoring the progress of MainStream's golden barramundi broodstock pool

Japan’s quest to conquer bluefin farming MARINE SPECIES COVER

EARLY STAGE

Maruha Nichiro’s bluefin hatchery was established from another facility that was built in 1990 to rear sea bream and tiger puffer. Two fish farms in Amami Oshima, an island in Kagoshima Prefecture, southern Japan, were chosen for egg-to-harvest trials because of their expertise in raising young sea bream and their locations, which made it possible for staff to collect bluefin eggs from the wild.

“For the first few years, we spent a lot of time learning everything there was to know about the biology of young tuna,” says Yuji Kamimura, manager of the larval section, Shinokawa Branch, Amami Yougyo Inc.

“One of the reasons why our research came to a standstill was because young tuna don’t eat an artificial diet like other fish, and could not be observed in their natural habitat. We had a lot of trial-anderror experiments.”

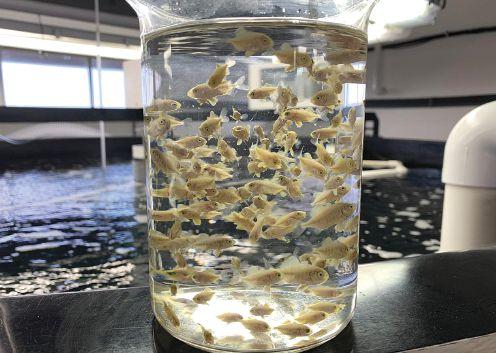

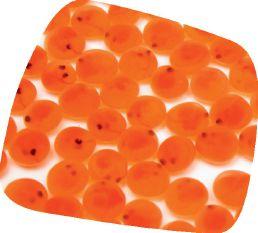

Today, bluefin broodstock in the Amami Oshima farms are kept in-house. The fish lay eggs in the summer months between May and August. Fertilized eggs are gathered from the surface of the water (one female lays several million eggs, each about one millimeter in diameter) and put into large tanks for incubation.

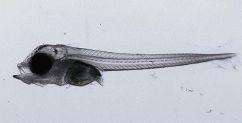

Once the eggs have hatched into larvae, they’re around 2.5mm in length. They are then reared in tanks until they reach six to

seven centimeters long. During this time, they are given DNA-enriched rotifer two times a day, morning and afternoon, from three days after hatching until around 10 days.

“One of the biggest challenges during the larval stage is VNN, or Viral Nervous Necrosis,” says Kamimura. “Once the eggs have been collected, we disinfect their outer layer using ozone bleach water, by immersing the eggs in it, just once, for around three to five minutes.”

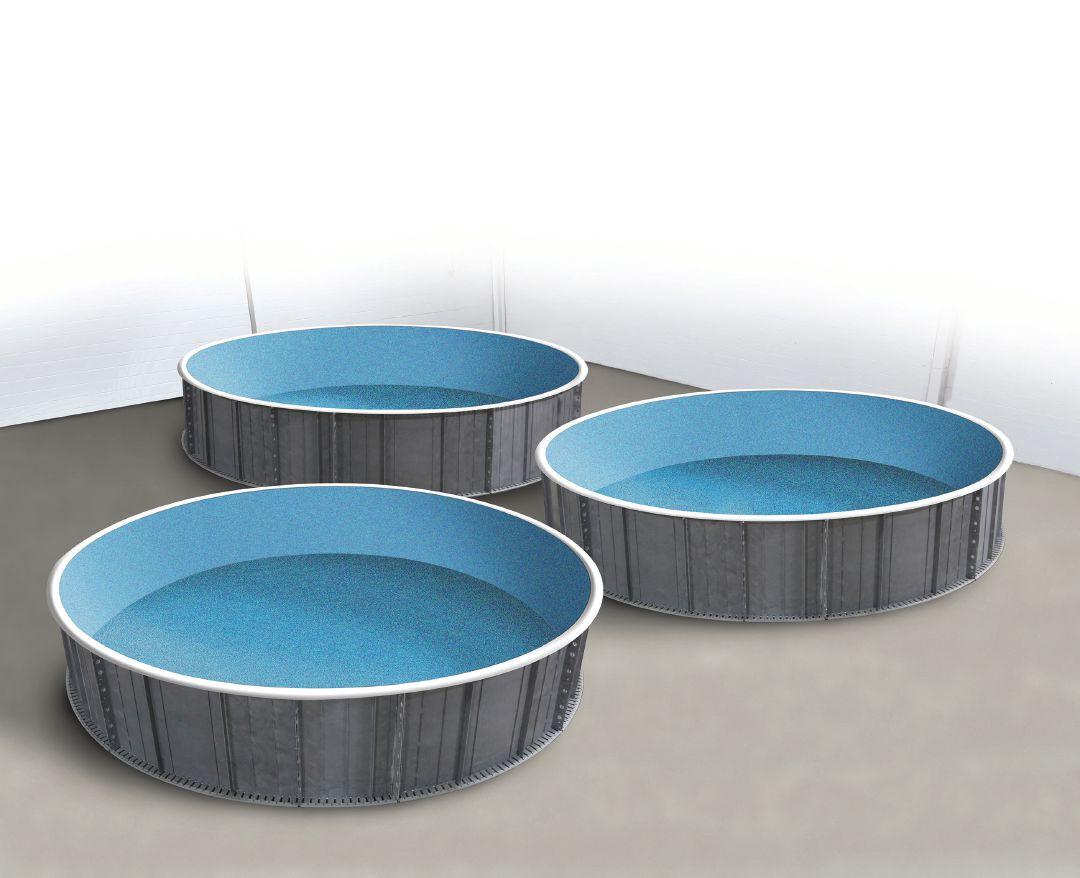

The hatchery has three rearing tanks for the larvae. Each is about 80 tons, and one tank can hold approximately 800,000 larvae. Seawater for rearing is collected from the coast in front of the hatchery and put into a drum filter where it’s cleaned through sand filtration and disinfected with UV. A series of chillers is used to maintain the right water temperature of around 26°C (78.8°F).

The larvae are given a diet of striped beakfish from seven days after hatching

until around 25 days. Minced fish and compound feed are offered from Day 20 after hatching and onwards. After 28 days, they reach a total length of five to six centimeters and are moved offshore to ocean net pens. There, they are farmed for about three and a half years until they’re ready to be shipped to market.

Since 1958, Faivre has been developing and manufacturing high quality equipments for the aquaculture industry

SURVIVAL CHALLENGES

Closed-cycle aquaculture may sound promising, but handling bluefin in farms is notoriously difficult, especially in the hatchery and early growth stages. As well as being extremely sensitive to stimuli like light, temperature and noise, spawning

to

is unpredictable and the larvae are fragile. At Maruha Nichiro, hatchery staff work closely to monitor and adjust lights above the rearing tanks and the current of the water to prevent mortality among the larvae.

“The main cause of death in the early stages of larval rearing is surface tension-related death, and death at the bottom of the tank by sinking,” said Kamimura. “This occurs at night, presumably because the density of the larval body is higher than the density of seawater, and larvae swim less during the night. Adjusting water flow can affect the survival and feeding of larvae, but we still need a more viable solution.”

There are also feed sustainability challenges due to the vast amount of feed that bluefin require. According to Takahisa Ookado, assistant manager of the fresh fish sales section in the aquaculture operation department, in addition to live feed, the majority of Maruha Nichiro’s feed is natural fish and residua from mackerel canneries.

Work is currently underway to allow the farm to shift to fishmeal alternatives like plant proteins, as well as moist pellets and extruded pellets.

“From a sustainability viewpoint, much more work is required to come up with fishmeal alternatives for farmed bluefin. We are conducting further research into alternatives that will still provide good taste and flesh quality for consumers. We are also actively working to improve the food we feed to juveniles,” Ookado says.

SUSTAINABLE GOALS

Maruha Nichiro’s goal is to increase its output so that by 2021, it would be selling 78,000 bluefin, of which 15,000 will come from closed cycle aquaculture.

“We’re aiming to increase the ratio of closed cycle fish that we ship to 19 percent by 2021,” says Hiroyuki Metoki of Maruha Nichiro’s investor relations and public

Commercial Filtration Systems

•

•

•

•

relations department. “As our technology improves and we become more experienced, we would like this figure to reach 100 percent. After all, a zero percent usage of wild juveniles means zero pressure on wild bluefin stocks.”

In the meantime, Maruha Nichiro is in the initial consultation phase of getting certification with the Aquaculture Stewardship Council (ASC). The company sees bluefin farming as a key business unit, and is looking forward to addressing the challenges left in its quest to bring the farmed species to the world market.

“When we look at recent global warming and environmental changes, such as regime shifts, it may well become impossible to procure bluefin from the wild,” says Ookado. “In Japan, bluefin numbers have been decreasing considerably, for example in areas such as the Tsugaru Strait in the northeast. A huge factor behind this is the extremely low number of species that bluefin eat, such as saury and squid. In this sense, the closed cycle concept is a necessity, but addressing the various challenges it brings will take some time.”

Metoki believes that wild bluefin populations could recover, but says that more solutions are needed in terms of feed efficiency, advanced nutrition and even selective breeding.

“Our technology could be duplicated and scaled up,” he says. “But we need to implement various measures from different angles to improve it – for example in feed – because this is not sufficient. To address this, Maruha Nichiro has set up an alliance with several academic experts from fields such as nutrition, digestion, immunity, ophthalmology, DNA analysis and genetics.”

“One thing yet to be tried from now on is selective breeding,” he continues. “It’s a common method that has been implemented in the cultivation of various species but nobody has ever succeeded with bluefin. This could be a possibility for us one day but we still have a lot to learn.”

•

•

•

•

•

•

•

•

All photos to Maruha Nichiro

Day 20

Day 25

Yuji Kamimura

(Left) Due

overfishing, the highly sought-after and highvalue Pacific bluefin tuna has been placed on the list of threatened species. (Top) Maruha Nichiro’s bluefin farm is located in Amami Oshima. (Bottom) Bluefin juvenile lifecycle in days.

MARINE SPECIES

Seeding the future of oyster farming

Hoopers Island Oyster says things are looking up for this shellfish sector

BY LYNN FANTOM

I

n an environment eager for good news, the announcement of a strong spring spawn and “really healthy larvae moving through the hatchery” at Hoopers Island Oyster Co. lifted spirits along the U.S. Eastern Seaboard after a year when persistent rainfall and low salinity had doused them.

Much of the new seed now being reared at Hoopers Island’s nursery will be grown out on the company’s leases in the Chesapeake Bay.

Over the years, this Maryland-based business has morphed into one dedicated to helping the overall oyster industry thrive – supplying seed and equipment, along with generous doses of advice. The hatchery, which began full-time operation in 2017, already accounts for 15 to 20 percent of company sales.

“Our goals as a commercial hatchery obviously are to produce as much as we can to support not only our own business, but provide infrastructure for other aquaculture farmers up and down the mid-Atlantic,” says hatchery manager Natalie Ruark.

This spring’s spawn has been “a good start,” she says.

OFF TO A GOOD START

Such success seems to be occurring at other hatcheries in the Chesapeake region, Ruark says, which is also good news. To meet the growing needs of both farmers and restoration efforts is a challenge.

“It’s a lot of demand with only a few producers. After a bad year, it really makes up for us to have a good one,” says Ruark. “It’s a night and day difference,” she adds.

At the same point a year ago, salinity was in the single digits, hovering at six to seven parts per thousand (ppt). This spring it shot up to 17 ppt and, even after rainy days, is holding in the 14 to 15 ppt range.

In addition, Ruark notes, the quality of the ambient water has improved. Hoopers Island’s hatchery is located in the remote community of Crocheron (population: 21). Even though there is minimal agricultural runoff and a tiny population, the heavy rainfall last year still produced “suboptimal” water quality.

For the Hoopers Island hatchery, work began in earnest in early February with the conditioning of broodstock and algae propagation. About eight weeks later, in a white building with turquoise trim, technician Allison Fitzhugh

was ready with her scalpel to extract gametes from ripe, shucked oysters and to start mixing eggs from diploid females and sperm from tetraploid males in seawater. The process resulted in fertilization, cell division, and then hungry larvae swimming freely in 1,500-gallon tanks. This procedure will be repeated every week until September. “We produce as much as we can for the time that we have,” says Ruark.

In 14 to 18 days, the larvae are ready to move to the

Natalie Ruark, hatchery manager at Hoopers Island Oyster Co.

Hoopers Island’s hatchery and nursery are located in the tiny community of Crocheron, Maryland. Photo: Hoopers Island Oyster Co.

All photos: Hoopers Island Oyster Co.

At grow-out, the oysters are regularly pulled, cleaned and graded.

Larvae are fed up to eight times a day.

nursery and set on crushed oyster shell in an upweller. In three to five days, they become seed.

SEED SPECS

Hoopers Island sells seed in seven sizes, from one to 12 millimeters. “Typically, we see a lot of our customers start out with a mid- to larger-size seed, in the six to 12-millimeter range,” notes Ruark.

That is because the equipment to handle that size seed costs less, and new growers want to get to market sooner. Start-up expenses are, of course, a key consideration for “oysterpreneurs,” as Hoopers Island calls them.

There has been a dramatic increase in these new farms in the US, according to the USDA. For example, between 2013 and 2018, the number grew 123 percent in Virginia and 313 percent in North Carolina, both states Hoopers Island serves.

But as growers become established and diversify their operations, they opt to invest less money in seed and more labour into their product.

“We’ll see those customers over the years make decisions that will allow them to handle seeds that are one and two millimeters because it’s more cost effective for them,” she says.

The hatchery’s primary focus is triploid production.

“That circles back to our goal of providing infrastructure to aquaculture operations. Some 90 percent of the customers we service would prefer a triploid product.” To spawn those triploid larvae, Hoopers Island relies upon the storied tetraploid lineages of the Virginia Institute for Marine Sciences (VIMS).

DISEASE RESISTANCE

All of the Eastern oyster (Crassostrea Virginica) seed that Hoopers Island sells originates from broodstock selectively bred at VIMS. That is a mark of distinction.

“By developing disease-resistant triploid oysters, the VIMS team literally saved the oyster industry of the Chesapeake and really the entire East Coast. With broodstock lines resistant to MSX and Dermo, they made modern oyster aquaculture possible,” says Chip Terry, co-founder and chief executive of Oyster Tracker, farm management software now used by over 40 growers around the world.

Currently, Hoopers Island offers two strains for purchase: DBY-H and LOLA (yes, they are pronounced as girls’ names). “These strains have been painstakingly cared for and created,” says Ruark, echoing Terry’s comments about VIMS.

Which seed does she recommend? As a hatchery manager who has a background in both biology and environmental sciences, she says she will first ask customers: What type of environment are you growing in? High or low salinity? What is the prevalence of pathogens present on your lease?

“Those kinds of things all factor into the performance of your seed along with the strain that the hatchery produces,” she says.

With pathology testing also conducted by VIMS, Hoopers Island is able to transport and sell seed across state lines to New Jersey, Delaware, Virginia, and North Carolina, as well as in its home state of Maryland.

EQUIPMENT

Although Hoopers Island started as an oyster farming operation, its success in manufacturing its own aquaculture equipment attracted the attention of other growers. Today, equipment sales represent the largest portion of the company’s business.

Equipment is designed with practicality, efficiency, and durability in mind, says Ruark. Its upwellers are a good example of how Hoopers attempts to offer its customers flexibility, too. The tank itself is fixed, but the silos that house the seed can be customized with mesh appropriate for a range of seed sizes.

“A tank comes with a set of 12 silos. A lot of time we find customers like to tailor four silos for setting, four for oneand two-millimeter seed, and four for something larger –all in just one unit.”

Hoopers Island has staked out a position in the growing U.S. oyster industry that goes well beyond its own farming operations. It hopes to revolutionize the business “from seed to shuck.”

A REFRESHER ON TRIPLOIDS

Triploidy (having three sets of chromosomes) has transformed oyster farming just as it did agriculture, with larger kiwis and blueberries and seedless varieties of watermelons and grapes. (Before triploidy, even bananas had seeds.)

The absence of seeds reflects the fact that triploids are infertile. What this means for oysters is that during the summer months – when consumers want to sit outside, sipping rosé and slurping oysters – triploids do not breed. They stay plump and firm.

Their wild diploid cousins, however, reproduce in warmer weather. After they release the content of their gonads, which constitute up to 40 percent of their mass, they become watery and thin. Some researchers say this affects consumers’ perception of flavour as well. From the standpoint of the oyster farmer, this genetic variation enhances marketability in the lucrative halfshell market. Triploids grow faster because they’re not putting all of that energy into reproduction and, in doing so, help growers avoid disease.

Faster growth means meatier oysters.

– Lynn Fantom

MARINE SPECIES

Kampachi juveniles thrive in RAS

Mexico’s The King Kampachi sets its sight on selective breeding

BY LIZA MAYER

Hatchery manager Mauricio Moreno remembers 2018 as a breakthrough year for The Kampachi Company, an offshore farm in La Paz, Baja California Sur, in Mexico. It broke ground on a pilot hatchery that year and within months made its first delivery of kampachi (Seriola rivoliana) to market. Before the year closed, the company received a fund injection of $5 million from impact investor Sustainable Ocean Fund.

The Kampachi Company of Mexico is an offshoot of Hawaii-based Kona Blue Water Farms, co-founded in 2001 by marine biologists Neil Anthony Sims and Dr. Dale Sarver. Following Kona Blue’s sale in 2011, Sims and fellow Kona Blue executive Michael Bullock founded the R&D company Kampachi Farms, now called Ocean Era. The two business ventures were instrumental in developing kampachi as a new aquaculture species between 2004 and 2009.

The Mexican state of Baja California Sur was deemed an ideal site to farm and scale up production of kampachi. The species is native in the Gulf of Mexico and “the weather and temperatures are really good for having the best growth rate,” says Moreno.

Jorge Schmidt joined the Mexican venture as CEO in 2016, “bringing in a fresh perspective, financing, and economic and legal expertise,” according to the company.

Describing himself on his LinkedIn profile as a “former litigator and U.S. Army special operations veteran,” Schmidt wrote that he came across the “stalled project” and “quickly arranged for the financing needed to launch The Kampachi Company’s commercial-scale production.”

RAS IS KEY

The funding from Sustainable Ocean Fund helped the company start the land-based hatchery and later install a recirculating aquaculture system (RAS), after the hatchery team struggled with juvenile production issues.

While RAS has long been used in the farmed salmon industry to raise smolts, the technology was revolutionary for The Kampachi Company because it enabled it to raise kampachi larvae year-round. Before it had RAS, larvae perished before they reach juvenile stage when temperatures went up in the summer. This prompted Moreno and his team to stop rearing larvae during the hot months and instead use the hiatus to sanitize the hatchery and prepare it for the next season. With RAS, the team is able to raise juveniles up to 20 grams, by which time they are big and

strong enough to withstand the warmer offshore waters.

“Water temperature could reach 30°C or more in the summer. At these temperatures everything changes in a hatchery: water quality, live feeds, and of course a high stress period that were an impediment to reaching an acceptable producation of juveniles for production plans,” says Moreno.

Roughly a year later, Moreno stood before the audience at Aquaculture America 2020 in Hawaii, announcing that he and his team delivered to the company’s offshore net pens in September 2019 the first batch of more than 100,000 juveniles raised in RAS.

“This milestone opened a new window for production in the toughest season of the year, giving us new opportunities to satisfy a high-value fish market in Mexico and in the world,” he says.

All photos: The Kampachi Company

Larvae culture assistant technician spreading the first microdiets for weaning

Kampachi juveniles during weaning phase at 22 to 25 days old, weighing about 300 mg each

Offshore farm site located four miles from the coast, in water over 230 ft deep, in the Gulf of California

But the path wasn’t as straightforward as it seems, the hatchery manager notes. The breakthrough came only after solving several bottleneck issues: broodstock management to obtain high-quality juveniles year-round without hormones; egg incubation crashes; post-hatch sinking larvae; and first feeding mortalities, to name a few.

He attributes the success in navigating those challenges to the team’s shared understanding of what they were trying to achieve. “It is important that all the technical team members really understand what we are trying to give to the larvae. Then it’s easier to have more control on the system and in the rearing techniques because in the RAS system small details make a big difference.”

Moreno acknowledges there are still many issues to contend with. He doesn’t mind though, because he thrives in solving problems. In Spain, he worked with other species, such as Sparus aurata, Dicentrarchus labrax, and argyrosomus regius, which weren’t as challenging to grow, he says.

“With other species everything goes smoothly. But with Seriola rivoliana everyday is a new challenge. Making adjustments, making decisions are the norm.”

The constant adjustments are due to the fast growth of the fish, known locally as “pez fuerte” or “strong fish.” It could grow from larvae to 500 grams – which the company calls “kampachitos” – in five months; and to 2.5 kilograms in 10 to 12 months.

“Because they grow so fast, they have ever-changing requirements. They change the water quality so fast so it’s really a challenge to get them to thrive and develop, and not just make them survive. Being there to understand what’s happening and give them the best things they need to thrive, and for us to have a reasonable number to take offshore is always our goal,” Moreno says.

NEXT STEPS

Moreno also notes there is a lot to be learned about the nutritional requirements of kampachi. There are now several ‘Seriola’ formulations, which are of “fair enough quality” but still have room for improvement, he says.

Sims is actively working on developing fish feed for Seriola rivoliana. Ocean Era is collaborating with fish physiologist Dr. Rick Barrows and with the organizers of the F3 FishFree Challenge to develop transformative feed formulations that rely less on forage fish.

MARKET PROSPECTS

The Kampachi Company introduced King Kampachi to the U.S. market at Seafood Expo North America (SENA)

in Boston in March 2019. But like virtually every business, it saw its main market dissipate with the closure of restaurants because of COVID-19. The company has since kept production going with “the lowest effort” to maintain profitability. Harvests are now processed and frozen. “We have to find that market for frozen fish,” Moreno says.

“The COVID situation changed everything,” he adds. However, he is optimistic that the company has growth prospects in the local market. “Our CEO is looking really closely at the local market, which could be a main market for us, not just fancy restaurants but also households. We are finding that the Mexican market looks really accepting of really good final product.”

Gerätebau GmbH

An der Sauerlandkaserne 1

D-57368 Lennestadt (Oedingen)

Telefon: 0049 2725-22021-0

E-Mail: info@linn.eu · www.linn.eu

Other bottleneck issues in farming kampachi that still need to be addressed include skin fluke (Neobenedenia girellae), considered the biggest challenge in farming the species. At Aquaculture America 2019, company co-founder Neil Anthony Sims said the three- to five-millimeter ectoparasite is itself not a problem for the fish; instead, it is the infection from wounds that develop when the parasiteafflicted fish tries to scratch the itchiness away by flashing against the tank or net.

“The disease impact is a factor that will always be present in any animal production industry,” says Moreno. “What we face is the learning curve about any disease that could be ‘new’ to this species and how to manage it. For now the parasites are the most concerning health issue, and we’ve been able to develop a monitoring and treatment protocol with good results.”

The company also hopes to develop a selective breeding program that will allow it to have the best spawns, consistently.

“The quality of the eggs is very variable, meaning all the quality parameters that we measure in this industry, such as percentage of viability, size, fecundity, color, all those things are not consistent.

“Before COVID-19 we were on the track to start doing this with local genetic research institutes. We will need to retake [this initiative] ASAP when the world comes back from the COVID situation.”

Innovation Beyond Measure

• Salt &

• Available with Tube Sheet, Helical Coil, or

• Hot & Cold Water Loop Systems

• Compact Designs

• Easy Installation

• Incubator Rack Systems

• Gas Boilers

Market-size kampachi. The farm received Aquaculture Stewardship Council certification in 2019

The future is frozen Technology ensures continuity of high-quality genetics

BY MARI-LEN DE GUZMAN

What do bovine and fish have in common? They both come fresh or frozen.

Advancements in cryopreservation technology have made it possible to produce generations of genetically superior animals from the same sire and long after that father had left this world. This technique has taken off in the cattle industry over the last 50 years and has gradually been adopted in commercial aquaculture, particularly in salmonids. Two major players provide cryopreservation equipment and services to the aquaculture sector: Cryogenetics, headquartered in Norway and with offices in the U.S, Canada and Chile, and IMV Technologies based in France. Both companies provide the equipment and technology for cryopreserving milt, as well as the training and knowledge transfer to allow farms to do their own cryopreservation process

in-house, if they so choose. In addition, Cryogenetics also offers storage service for frozen milt for facilities who do not have the space to store them on site.

Most of the applications for cryopreservation in fish culture is in salmonids, although the technology is essentially feasible for other aquatic species for a variety of purposes.