Hatchery reborn

Substantial investments at Riverence Hatchery in Washington state aim to boost the potential of North American fish farming sector with premium egg supply

BY TOM WALKER

Riverence Hatchery in Washington state is putting the final touches to a state-of-the-art egg production facility, aiding their quest to grow and support the salmonid farming industry in the United States.

“We have two main goals,” explains west coast salmon industry veteran Jason Mann. “We are looking

to increase fish production and enable farmers across North America.”

Mann describes the North American trout and salmon industry as ‘flat lined.’ “The annual U.S. trout production is between 20-25,000 metric tonnes,” says Mann. That’s similar to U.S. salmon production he notes.

“But when you look at the amount of seafood that is imported, we can be a larger part of that market.”

Aquaculture production is growing in other countries he points out, but not in the U.S.

continued on page 8

RAS research targets ‘friendly’

bacteria

European team aims for more sustainable management of microbiota

BY COLIN LEY

Looking after and promoting friendly bacteria in RAS systems, rather than killing the good with the bad, could have beneficial impacts on fish health and production profitability, according to the early findings of a three-year research project run by scientists in Norway, Denmark and Germany.

Starting in 2015, the project team’s aim was to examine how much the fostering of an elevated microbial community in both RAS and flow-through systems might benefit the species being farmed. This addressed the common challenge, especially in RAS systems, that incidents of fish loss owing to unfavourable conditions and disease outbreaks may be linked to the activities of so-called “opportunistic bacteria.”

Scalable Scampi

Land-based rearing project for New Zealand Scampi shows potential for commercial viability

BY BEN NORMAND

It’s no secret that New Zealand’s primary sector is driven by exports, and the New Zealand Scampi (Metanephrops Challengeri) fishery is no exception. There are reliable reports of single scampi selling for $20/fish, or $300/kg, overseas. While the fishery is well managed and healthy now, any fisher can tell you that unstable international prices caused by the inherent unreliability of wild catch is bad for business in the long term. A sustainable, reliable source of scampi is thus desirable to those seafood companies that target New Zealand scampi.

One company pursuing this goal is Waikawa Fishery Company Limited. A self-described, “sustainable Maori seafood company,” it has been working with the Cawthron Institute in Nelson, New Zealand, to develop a proven, cost-effective and scalable way to rear New Zealand scampi on land.

REARING PROGRESS

Readers may remember that we published a short article (Hatchery International, Nov/Dec 2016) covering the launch of the project. Author Quentin Dodd led with a description of one of the earliest big breakthroughs of the project: the first birthday of Camilla, the first New Zealand scampi larvae to be reared in a laboratory successfully. Prior to this discovery, the closest science had come was to hatch one larvae in 1976. The larvae died soon after initial description.

continued on page 10

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

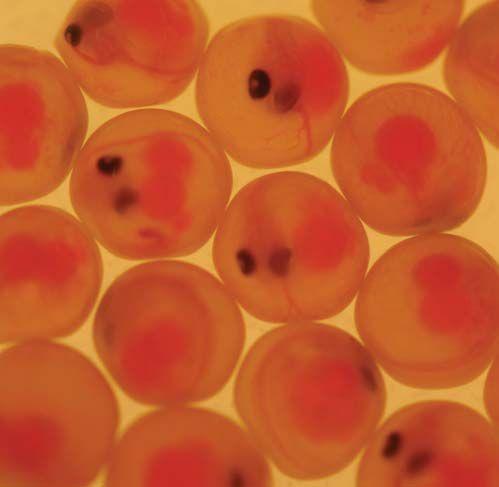

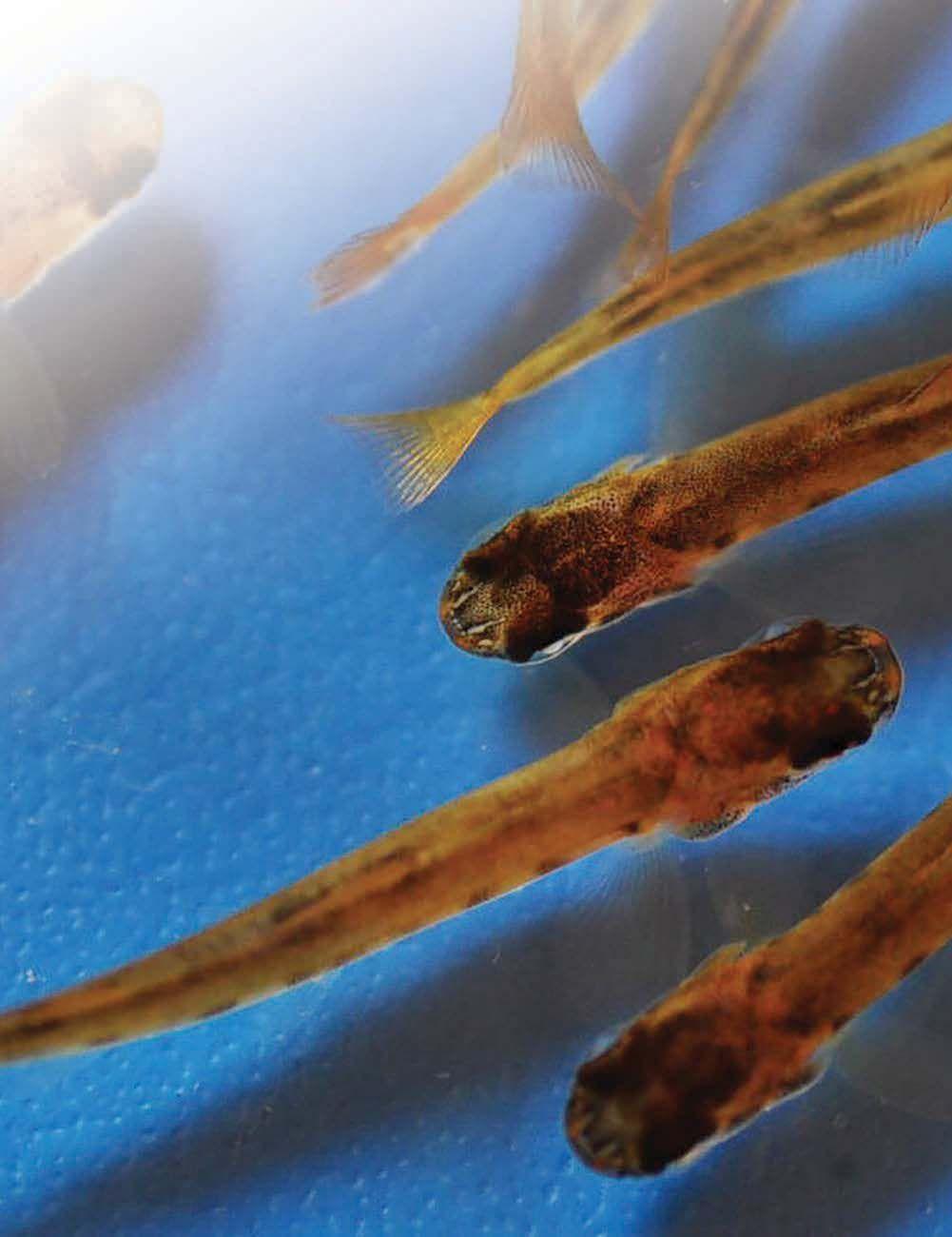

A New Zealand scampi larvae. Kevin Heasman and his team have hatched over 1500 this year so far (Photo: Kevin Heasman).

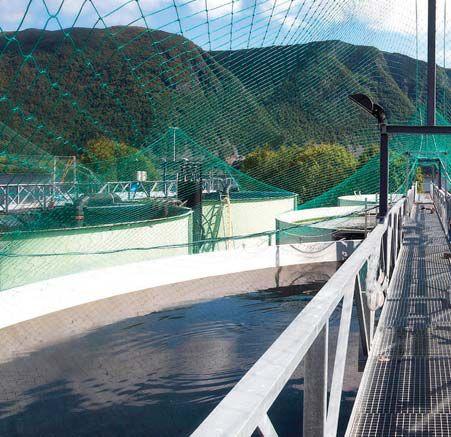

Aerial view of Riverence Hatchery. Parent company Spring Salmon bought the Washington-based Aquaseed hatchery in 2014. They renamed it Riverence, and are just completing a major renovation that will see investments total in the millions. Key to the facility are four 40’x140 hatch houses, with concrete floors and stainless steel tanks.

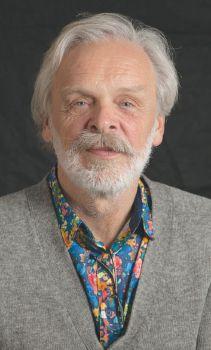

Professor Olav Vadstein of NTNU, Norwegian University of Science and Technology.

(Photo: Sharon Minkoff)

Disease and poor health are some of the main constraints for sustainable aquaculture.

MSD Animal Health develops environmentally responsible products to maximize fish survival, growth and production efficiency for the major farmed fish species: salmon, tilapia, trout and other marine species.

Every day, in every corner of the world, progressive fish farmers turn to MSD Animal

Health. They ask about our full range of products for managing the most serious diseases in aquaculture. Even more, they come to us for integrated health solutions to help them become more profitable, competitive and sustainable.

For more details please contact your local MSD Animal Health representative or contact us at aqua@merck.com or visit us at www.aqua.merck-animal-health.com. Copyright © 2016 Intervet International B.V., also known as MSD Animal Health. All rights reserved. This document contains information on veterinary products based on international registration dossiers and may refer to products that are either not available in your country or are marketed under a different trade name. In addition, the approved indications as well as safety and efficacy data for a specific product may be different depending on local regulations and approvals. For more information, read the product labeling that applies to your country or contact your local MSD Animal Health representative.

VOLUME 19, ISSUE 4 | JULY/AUGUST 2018

Editor Peter Chettleburgh, peter@capamara.com

Science Editor David Scarratt, scarratt@ns.sympatico.ca

Regular Contributors Quentin Dodd, Diogo Thomaz, John Nickum, John Mosig, Erich Luening, Philip Nickerson, Matt Jones, Ruby Gonzalez

Advertising Manager Jeremy Thain, jthain@annexbusinessmedia.com Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Circulation Manager Barbara Adelt badelt@annexbusinessmedia.com, Tel: 416-442-5600 ext. 3546

Design & Production Svetlana Avrutin savrutin@annexbusinessmedia.com

Group Publisher Scott Jamieson, sjamieson@annexbusinessmedia.com

President & CEO – Mike Fredericks

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

A subscription to Hatchery International (six issues) is $36.00 within Canada, $36.00US within North America and $46.50US outside North America. To subscribe visit our website at www.hatcheryinternational.com

Subscriptions Angie Potal, apotal@annexbusinessmedia.com Tel: 416-410-5113 • Fax: 416-510-6875 or 416-442-2191

Printed in Canada. Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO:

Hatchery International. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

ISSN 1922-4117

NEXT AD DEADLINE

The advertising deadline for the Sept/Oct issue is July 5th Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexweb.com

NEXT EDITORIAL DEADLINE

The editorial deadline for the Sept/Oct issue is July 10th. Contact the Editor, Mari-Len De Guzman at 1-289-259-1408 for details. E-mail to mdeguzman@annexbusinessmedia.com. Material should be submitted electronically after prior arrangement with the editor.

NEWS BRIEFS

New land-based farm planned for South Africa

The Danish construction company Graakjaer has inked a contract with South Africa’s Cape Nordic Corp (CNC) to construct a land-based operation and buildings for rearing sea trout.

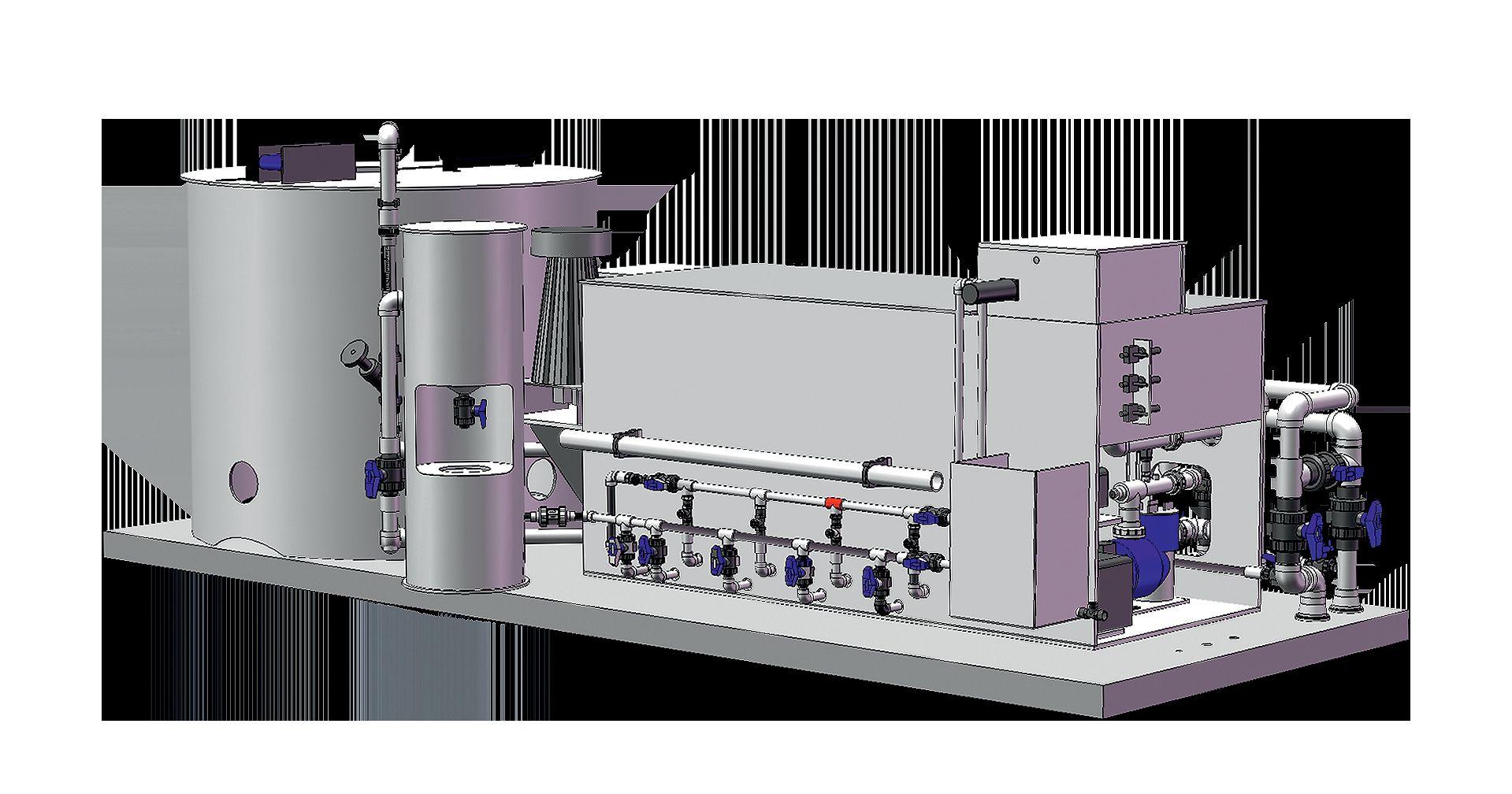

The site (pictured) is not far from Cape Town and is projected to produce around 1,800 metric tonnes of sea trout a year, with Graakjaer to provide design, processing equipment, supervision, project management, fish-farm support, and training for CNC.

A report from the region says harvest weight is projected to be 5.2kgs, and expansion is already being considered in the plans, with that eventually extending to Atlantic salmon.

Graakjaer Aqua director Morten Malle is quoted as saying the contract is a milestone for the company, and includes a water-recirculating aquaculture system (RAS) for what Malle called “a major fish-farming facility for CNC”.

Vandals hit NZ hatchery – again

Yet another 200 salmon had to be disposed of at a hatchery near New Zealand’s South-Island city of Dunedin after vandals broke in and shut down the same aeration equipment they had targeted in January.

According to information from the hatchery, salmon valued at $20,000 died in the new incident at Sawyer's Bay Hatchery.

The facility hit the headlines in January after intruders turned off aerators, forcing the non-profit trust to dispose of some $30,000 worth of salmon weighing between 6 and 9kgs.

Dunedin Community Salmon Trust chairman Steve Bennett was cited as saying 45 breeding males died in the latest break-in. The facility normally releases hundreds of thousands of salmon smolts into Dunedin's Leith River each year.

Grant awarded to Aussie hatchery

One of Australia’s oldest fish hatcheries, in the Ballarat area of Victoria, is to receive a grant of almost $64,000 from the state government to buy and install a water-cooling and filtration tower.

The money for the Ballarat Fish Hatchery – established in 1870 – will enable the not-for-profit to improve water quality and better manage temperatures, ensuring improved conditions for trout raised at the site. A report on the grant, says the state money is being matched with $33,495 from the hatchery and some $32,000 worth of in-kind labour for the project.

Photo shows area where the CNC fish farm is to be constructed.

Lapu-lapu successfully bred in Taiwan

and Eggs

• Expertise in live haul fish, fingerlings and eggs • Temperature Controlled/Insulated Containers

Fish-breeding experts in Taiwan have broken new ground with the first successful breeding in captivity of one of Asia’s premium fish: the large-mouth grouper, known in the Philippines as lapu-lapu, but most commonly referred to in China as garupa. Grouper used to be abundant in the Philippines but has become rare owing to high demand, degradation of habitat (coral reefs), and rising water temperatures.

The milestone was accomplished at Pingtung Agricultural Biotechnology Park (PABP), in southern Taiwan’s Pingtung County. The 233-hectare park performs research in areas ranging from aquaculture to environmental systems and is described by Director General Dr. Susan Chang as “the one and only science park [in Taiwan] dedicated to agricultural biotechnology”.

Kenyan institute begins hatchery construction

•

in

• Temperature Controlled/Insulated Containers

• Extra careful handling of your live animals

The Kenya Marine and Fisheries Institute (KEMFRI) is in the process of constructing a modern fish hatchery to meet increasing demands. The hatchery will be situated at the Nyanza and Western Region Fisheries Research Centre and will increase fingerling production at the facility from 200,000 to 1 million per month.

“The hatchery will ensure that production and supply of fish increases in Nyanza and other regions,” KEMFRI Regional Assistant Director Paul Orina told Hivisasa.com.

Orina predicted that with an increased interest in open water cages and other methods of fish farming, increased access to fingerlings could see aquaculture production in the area increase by 20%. He added that phasing out the current production methods such as raising fingerlings in ponds and static water tanks in the open would help address concerns over climate change and food insecurity.

Javans Omondi, a farmer from the area, said that the new hatchery should be a benefit for the industry as fingerling production is a significant expense.

Uzbekistan aids domestic aquaculture with new hatcheries

Uzbekistan’s President Shavkat Mirziyoyev is implementing a comprehensive program to develop the domestic aquaculture industry, emphasizing the need for more stocking material.

At least five new hatcheries will be built in the country by 2023, while almost all existing facilities in the industry must be modernized, Mirziyoyev said.

The first hatchery will be built as a joint venture between a group of Russian investors and an Uzbekistan company and it will be capable of producing 10 million fish fry per year.

The goal is to build five new hatcheries by 2022.

There are also two hatcheries that will be launched in 2019 through investments from certain unnamed Vietnamese companies. These facilities will be based in the Jizzakh Region and Xorazm Region, and produce 10 million and two million fry per year, respectively.

Another hatchery should be launched by a Hungarian company in the Samarqand Region, producing around 10 million fry per year.

There is no any information about the fifth hatchery. The program said, however, that all five planned hatcheries should produce 35 million fry per year.

There are also no details on what fish species each hatchery will be working with, though the program stipulates that Uzbekistan primarily will be boosting the domestic production of sturgeon, trout and salmon.

- Vladislav Vorotnikov

Scottish sturgeon hatchery and farm gets the green light

T he Fynest Caviar Co. can now proceed with finalizing plans to build a closed containment RAS on Loch Fyne in Cairndow, Scotland after the concept received the go-ahead from Argyll and Bute council’s planning committee.

According to a report from the region, the Edinburgh-based company hopes to have Scottish caviar on the market by Christmas 2020. The report also noted that the US$5million project aims to hire up to seven fulltime employees.

The company confirmed that it will produce Osteria caviar and ultimately, as much as 50mt of sturgeon meat a year from Russian and Siberian sturgeon. (Initially the meat produced will be 5mt.)

The hatchery-based production farm is the brainchild of London property developer and caviar and seafood lover, Trevor Knight, one of three directors in the company.

Knight said that the unit is being designed to fit in with a housing development to be constructed by the Ardkinglas estate for employees on the property.

Plans call for two main buildings, each a single story high, constructed in farmyard style. One building will be used for hatchery and nursery facilities while the other will be used for processing, personnel administration and other services. Thee low-level tanks will be installed outside the buildings. Pending further approval, construction is not expected to begin until later this year.

— Quentin Dodd

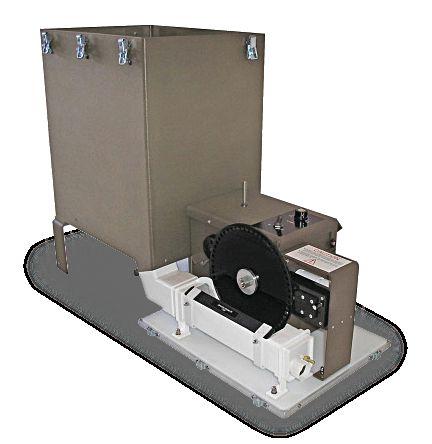

Increased Survival Rate with Significantly Reduced Water Consumption

The all-new HydroHatch Incubation System from MariSource gives hatcheries increased efficiency. With recirculation, germicidal UV filter and a titanium heat exchanger, the HydroHatch delivers increased survival rate and significantly reduces water consumption.

Features and Benefits:

65 gallon sediment and recirculation tank

Requires only 150 gallons to completely fill the unit and reservoir

High-quality, long-life quartz germicidal UV filter

Complete isolation of eggs

Easily able to increase the dissolved oxygen content of the water

230 volt 30 amp control panel

Insulated titanium heat exchanger

Precise temperature control

Comes standard with four 8-stack incubators

Additional four 8-stack incubator option available

The new HydroHatch Incubation System is ideal for Salmon, Trout, Steelhead, Perch, Channel Cat Fish, Walleye, Eels, Shrimp and Muscles.

President Shavkat Mirziyoyev has ordered construction of new hatcheries in Uzbekizstan.

START-UP

Fledgling crayfish farm set to scale up in BC SHOESTRING

Asturia Aquaculture has perfected breeding, spawning and grow-out on a small scale with ambitions to expand into commercial production.

BY TOM WALKER

ancouver Island on the west coast of Canada is a long way from the Balkans, but a European expert is looking to replicate the success he had there by raising freshwater crayfish in British Columbia.

Zeljko Djuric has been working with the local indigenous species, Signal crayfish (Pasifastacus leniusculus) for some 20 years. His company, Asturia Aquaculture Inc., has perfected breeding, spawning, juvenile and growout techniques on a small scale, but is ready to expand to commercial production.

“We were able to produce between 10 and 15 tonnes (2030,000lb) annually at our Balkan facility,” recalls Djuric. “I am confident we could do that here on Vancouver Island as well.”

Djuric began with wild-caught broodstock. Although the Signal crayfish has a range across the U.S. Pacific Northwest and into the Canadian province of British Columbia, it has remained until now, a recreational fishery only.

His current outdoor facility is gravity-fed from an extensive aquifer just north of Duncan, B.C. The water, which does not require pre-filtration, flows through a series of ponds, and is piped through the hatchery and discharged into a wetland. Watercress grows throughout the wetland and while it helps to filter the water, it is also part of the crayfish diet and is sold to restaurants in nearby Victoria

Healthy fish. Your goal. Our committment.

FORTE micro® the first ever reduced dose salmonid vaccine for North America. Multiple disease protection in a new smaller 0.05ml dose.

®

A poor mans, hatchery. Six foot round tanks hold the "compost" that Djuric cultures to support water chemistry and provide feed, including duck weed, plant trimmings and biofloc. Broodstock lives in Capilano troughs along with juveniles.

A berried female Signal crayfish.

and Vancouver year-round.

Broodstock are spawned and held in lidded trays in standard Capilano aquaculture troughs. The troughs hold broodstock and juveniles together, each at a different depth to enable them to access different nutrients in the water column. Grow-out is in meter-cubed pens suspended in the ponds.

“We can have up to 1000 crayfish in each cubic meter pen,” says Djuric, adding that if the chemistry and feed is correctly balanced, the crayfish do not live up to their cannibalistic reputation. “When they are happy they don’t eat each other,” he explains.

Six-foot round tanks hold what Djuric describes as “compost,” a culture of duckweed and plant waste, including watercress trimmings, that forms a biofloc supporting the water chemistry and providing a supplemental source of feed.

“We are using all-natural feed,” says Djuric. “They are basically scavengers and we are using mostly plant material.”

One of the intake ponds is used to culture duckweed (Spirodela polyrrhiza), an invasive species on Vancouver Island, but a key feed ingredient for the crayfish.

Djuric adds the company is developing diets with Fisheries and Oceans Canada researchers. “We are working

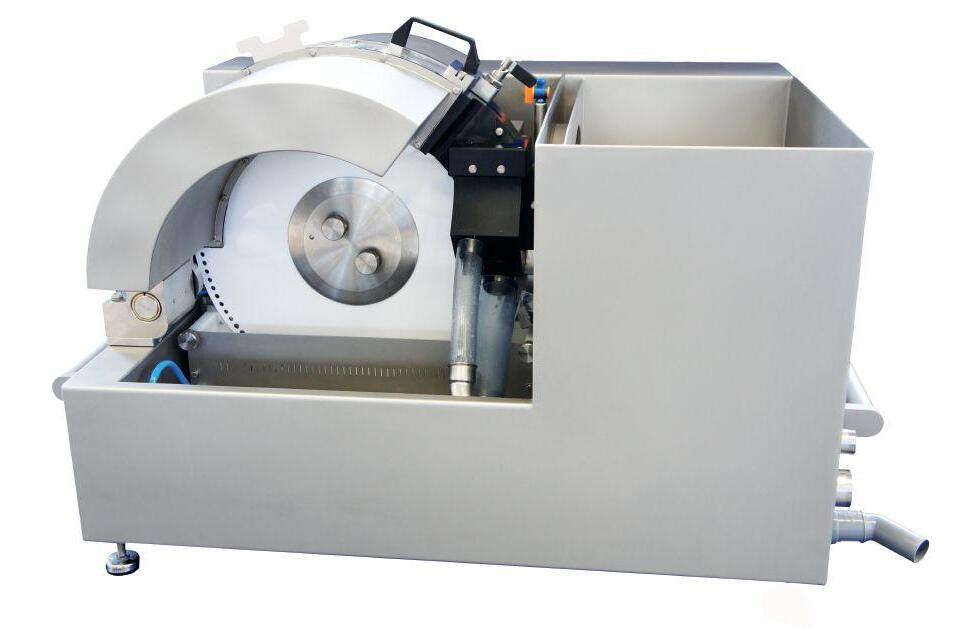

Salmonids eggs sorters

with a multi-trophic system,” says Djuric. The waste from the crayfish can fertilize the duckweed, which the crayfish eat, and some of the waste supports the watercress. “Depending on water temperatures, we are looking at two years to grow-out, post hatch,” he says.

Djuric’s Asturia Aquaculture has entered into a partnership with the local Malahat First Nation. They have constructed a grow-out site at a former cement quarry and expect to be in commercial production by June, with the capacity starting at 1000 lb. per week with plans to increase production to 2000 lb. per week. They have a target price of $20 per lb. wholesale.

Plastic trays house crayfish broodstock and are placed in the Capilano troughs. They live together with juveniles, both at different depths to take advantage of different nutrients in the water column.

Watercress does triple duty in the hatchery. It helps feed the crayfish; is an important plant in the wet land that filters the discharge water; and is sold year-round to restaurants.

US hatchery focuses investments on quality production

BLOWERS FOR RAS

Degas Towers • Sand Filters

• Fractionators • Pumps

• Bio Filters

• Ozone Systems

• Instrumentation & controls

• Heating & Cooling

•

• Blowers and more!

Rotron Regenerative Blowers offer a reliable solution for moving large amounts of air at low to medium pressures throughout your RAS operation.

Made in the USA and distributed globally to the aquaculture market by Sivat Services, these blowers include:

• Options for multiple electrical configurations and for extreme duty special coatings.

• Large line of accessories: intake filters, inlet/outlet mufflers, sound attenuation cabinets, pressure regulators, moisture separators and VFD’s

Invest in the best equipment for your RAS facility.

With 29 years of experience in the industry, starting with salmon producer Cermaq in 1987 and culminating with his retirement from EWOS feeds, Mann is now director of fish nutrition at Evaqua Farms, Riverence’s sister production company that farms trout in Idaho’s Magic Valley.

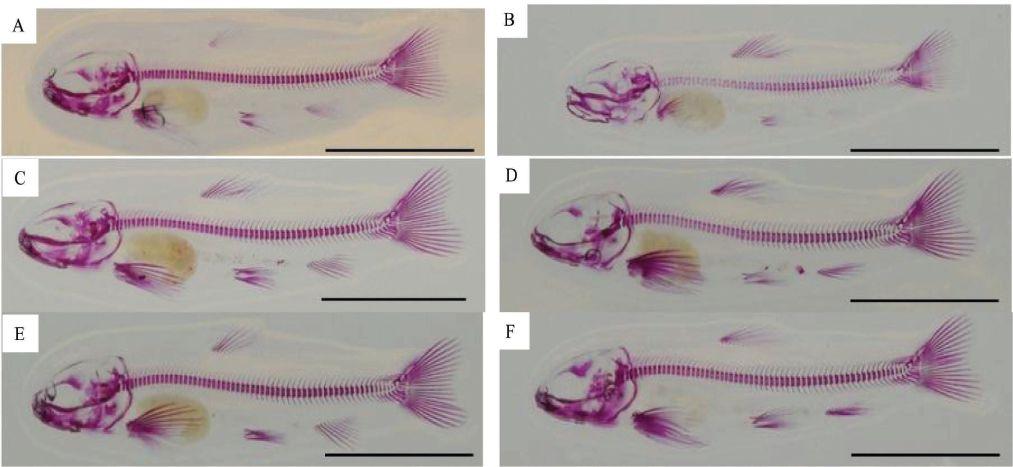

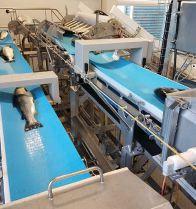

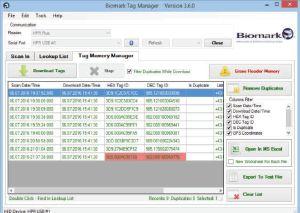

Parent company Spring Salmon bought the Washington-based Aquaseed hatchery in 2014. They renamed it Riverence, and are just completing a major renovation that will see investments total in the millions. Key to the facility are four 40’x140 hatch houses, with concrete floors and stainless steel tanks.

Fresh Water Institute’s Dr. Steve Summerfelt has consulted on the construction. “This is a more traditional RAS hatchery,” says Mann. “It’s not too elaborate or over the top. Our strength is in the attention to detail.”

QUALITY OVER QUANTITY

Being a high-volume producer is not the company’s objective Mann points out. “While major producers can look at 600 million eggs, a year, we will be much smaller than that, our capacity should be somewhere around 100 million when we are in full production and solely for the U.S. and Canadian markets.”

Current breeding objectives include increasing the percentage survival of eggs, and improving growth rates and resistance to disease. Mann says producers need consistent, premium eggs if they are to grow their business.

“Not enough energy has been put into this area,” Mann says. “When you look at livestock for instance, they are way ahead in using genetics and breeding.”

Premium eggs start with careful broodstock care Mann points out. “We feed premium broodstock diets a full year prior to spawning. Not everyone does that because it is expensive,” he says. “We want the egg yolks to be loaded with essential nutrients so that the first feed effectively is what we have fed the mother. The alvins will get a healthy start.”

“The level of Omega3s, the DHA and EPA are critical for proper egg development,” says Mann. “We work closely with local feed suppliers and custom specify diets for the various stages of growth.”

Careful egg handling right through to the end customer keeps the quality high. “We have temperature sensors in all of our egg shipping containers,” says Mann.

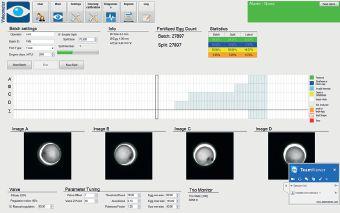

A new state-of-the-art egg picker uses machine vision to separate out the good red eggs, the suspected weak eggs (pin eyes) and the dead eggs, which are white. “We hear from our customers that when they open their deliveries they see red.”

CUSTOMER SERVICE

Special delivery packaging is just one of the customer service practices that Riverence is aiming to be noted for, explains Gabe Watkins, director of communications.

“Our goal is to support an expansion in the industry,” says Watkins. “We can do that in a number of ways.”

It starts with listening to customers. “We want to improve certain traits important to farmers,” Mann points out. “Whether it is colour, flesh marbling fat, growth rates or disease resistance.”

Becoming its own customer helps, too. In January 2017, Spring Salmon

Second generation employee Jeff Hudson holds a healthy Donaldson strain steelhead that is growing its way into the hatchery program. Adult broodstock are in the 2 kg range.

These aluminum tanks are for commercial egg incubation. Each has individual water temperature controls that help hatchery staff modify egg development times.

purchased Idaho-based trout producer Seapac’s seven farms and inventory (the second largest trout producer in the U.S.) and renamed it Evaqua Farms.

“Now we are able to follow our product right from broodstock to the table,” notes Mann. “It really helps us understand how our eggs are performing in both RAS and raceway conditions.”

Riverence is also testing eggs in lake situations with a British Columbia producer and one in Saskatchewan. They also have some in Lake Titicaca, at over 12,000 feet of elevation, Mann points out. “It is known for having low oxygen events so it’s an ideal place to test our stock for low oxygen tolerance.”

Research is an ongoing part of the program both in-house and with the University of Idaho, Fisheries and Oceans

Canada and University of Victoria. “We make all of our knowledge open source so that we can share data,” Watkins points out.

“Producers in other industries support each other by sharing knowledge and expertise, they don’t compete with each other.”

Mann is just one of the industry veterans on the Riverence team.

“Supporting the customer with fish nutritional expertise, fish health, water chemistry, we offer all of that along with the egg supply,” says Watkins.

“We think data transfer back and forth with farmers will be very important in helping make their particular species do well in their local conditions,” adds Mann. “It’s a partnership approach, we want to see success.

U.S. production will increase if we have a premium product that is growing well. That will support expansion.”

One-stop shop for salmonids

Riverence has a focus on North American indigenous species that perform in fresh water, Jason Mann explains. They produce trout, coho and Atlantic salmon eggs, with significant pedigrees.

The trout are Donaldson steelhead, a product of University of Washington professor Dr. Lauren Donaldson’s breeding program that began over 60 years ago. Riverence is broadening the trout line by introducing some native Idaho stock. “Idaho waters produce approximately 70% of the trout in the US,” Mann notes. “We wanted to add some strains that are indigenous to that water.”

The coho are the Washington-based Domsea strain, named after one of the earliest salmon farms in the U.S. The company began working with coho in 1969, and developed the Domsea line starting in 1977. Riverence acquired the Domsea line when they purchased the Rochester, Washington-based company Aquaseed.

The Atlantics are the Cascade strain, originally from Quebec’s Gaspe region and brought to the west coast and used by the National Marine Fisheries Service and private sector farms. These Atlantics have been developed for freshwater performance, having spent time at the Fresh Water Institute, but like all of Riverence’s stock, are salt-water-proven as well.

To meet growing interest, the company is developing a Golden trout line, (again based on North American stock) which is currently being held at the research station in Idaho. Photo period manipulation will support multiple delivery dates through the year and feminization and triploiding will be part of their egg programs.

Teaming up for continuity

Riverence announced an affiliation with the Danish company Troutex in September, 2017.

“They are a family-run company. We found that they shared our values,” says Riverence director of communications Gabe Watkins. “They have excellent genetics and excellent practices. They are very good at raising trout eggs. We found a lot of continuity with what we are doing.”

Diversification is really important for the industry, Watkins points out. “We want to be sure that in the event of any problems, the industry doesn’t experience a slow down.”

Troutex produces eggs in multiple locations, Watkins adds. “So the idea of having a backstop to support American producers in case there is an issue, is very important as a long-term strategy.

These are commercial broodstock tanks; the larger are 30 ft. and the smaller 20 ft, partial recirculating. The tower in between holds filter system. Light-proof covers help staff with photo-period manipulation.

We build the highest quality rearing troughs available to hatcheries:

• Smooth inner gelcoat, USDA approved and fish friendly

• Strong, deflection resistant trough design

• Drawings available for all trough sizes

• Custom built rearing troughs available at any size

Track

View our gallery of completed rearing troughs for customers at www.reiffman.com

Eliminate

Call us today with your trough specs! Toll Free 1-800-835-1081 or 509-525-1081

Visit us at www.aquanetix.co.uk Contact us: info@aquanetix.co.uk

David Reiff at david@reiffman.com

FISH TRANSPORT TANKS

We build the highest quality Fish Transports available:

• Smooth inner gelcoat, USDA approved and fish friendly

• Strong, 3/16" aluminum interior and 3/16" fiberglass exterior.

• Removable bulkhead fittings; threaded or bolt-on available

• Large hatch openings for easy access

• All SS hardware for long life, including SS toggle clamps

View our gallery of completed fish transport tanks at www.reiffman.com

Call us today with your requirements! Toll Free 1-800-835-1081 or 509-525-1081

David Reiff at david@reiffman.com

continued from cover

Scalable Scampi

The progression from the 1976 discovery to Cawthron’s successful ‘Camilla’s first birthday’ event represents a huge leap in the development of successful production. This pace has continued since. Currently, Kevin Heasman, the Cawthron aquaculture scientist in charge of the development and operation of the scampi rearing facility, has approximately 50 brood females and has hatched approximately 1500 larvae since the beginning of 2018. Broods are wild-sourced and come to the facility from Waikawa Fishery Company regularly via a purpose-built tank - first on-board the vessel, then by truck. To say that the project has developed is an understatement. It has flourished.

This success has, however, come at the expense of a few serious issues. “At the moment, we’re dealing with the very basics,” Heasman says. Fortunately, he is part of a team of dedicated scientists who can make educated assumptions about the solutions required for a burgeoning new species sector, and back those assumptions with solid research.

PROBLEM SOLVING

The first great challenge is, of course, the rearing environment. New Zealand scampi are found all around New Zealand, typically at depths of 200 to 500m, but sometimes as deep as 800m. It’s quite a challenge to determine how to replicate the aquatic conditions of such a generally un-explored area of our planet to a sufficient degree that the specimens remain healthy and continue to grow. While Heasman and his team knew there would be roadblocks, sometimes they would “just hit a wall,” and then find out why afterwards.

A notable development was the use of red light in their hatchery, which sought to avoid over-stimulating the scampi’s sensitive eyes, while offering the staff enough light to work in. This has resulted in a productive working environment for both culturist and specimen.

Another significant challenge has been diet. “Feeding them is one thing, but their dietary requirements are another…we can keep them alive, but how do you keep them healthy?” says Heasman.

It isn’t quite as easy as feeding them shrimp feed and hoping for the best. This is, then, another area where an educated assumption based on the scampi’s natural environment is implemented and practices are altered based on research. For example, they know that calcium is more biologically available at depth. They do not, however, know the correct amount or vector for the New Zealand scampi, so they work from one assumption and move to the next as required.

Once this is sorted, they have a multitude of other possible vitamins, minerals, fat and protein requirements to determine. Heasman is confident, however, in their ability to discover the answers to these dietary questions over time.

There is also the problem of uncooperative specimens. Soon after her birthday, Camilla, the most famous larvae to date, was meant to be the star attraction for an important

Kevin Heasman, aquaculture scientist at the Cawthron Institute, oversees the New Zealand Scampi Hatchery (Photo: Cawthron Institute).

PIT TAGS & SCANNERS

incoming tour. Heasman was proudly showing off the hatchery, when they suddenly noticed that Camilla appeared to have died, with her legs up and remaining perfectly still. Shortly before the onset of panic, however, he managed to rouse her from her rest and relay to the tour that she was simply behaving like an ordinary burrowing creature.

THE END GOAL

According to Heasman, the ideal outcome of this project is to recreate the success of the research-to-industry transition that was executed in the case of the SpatNZ. The genesis of SpatNZ lies in research carried out by the Cawthron Institute, and it has manifested in a commercial Greenshell mussel hatchery that will soon supply around a third of New Zealand’s Greenshell mussel spat. This hatchery is run by a business-government partnership.

The SpatNZ model is unique in that it allows Cawthron and the hatchery to continue working together, each advancing their own, symbiotic objectives. Heasman believes that this would be an ideal arrangement for the future of the New Zealand scampi project, particularly because, just as rearing them is an unprecedented challenge, so too will be the scaling up of the technology. In the words of Heasman, “there will be unforeseen challenges.”

If current success is any indication, farming Scampi will soon not be a matter of if, but when….

More information on the current state of the project can be found at www.cawthron.org.nz. More information on future developments of the project will be found in future issues of Hatchery International.

NEWS

IHN leads to cull at Canadian hatchery

Almost half of the juvenile chum salmon at the Canadian Department of Fisheries and Oceans’ (DFO) Kitimat Hatchery had to be destroyed when Infectious Haematopoietic Necrosis (IHN) was discovered.

Late last March the outbreak was detected in a tank containing 879,000 chum fry. On the recommendation of a DFO veterinarian and a biologist, through the CFIA and Salmon Enhancement Program, the call was made to destroy the fry to prevent the virus from spreading. Hatchery manager Markus Feldhoff said it was one of the worst days of his 27-year-career in enhancement.

There were no signs of the virus in the other tank containing roughly 883,000 fry allowing for their release early in April.

When asked about the possible cause of the outbreak, Feldhoff acknowledged that the hatchery probably wouldn’t be able to determine exactly how the virus got into the operation. The flow-through hatchery has two sources of water from the Kitimat River in addition to five wells.

“The Kitimat River has a run of sockeye salmon and they’re known carriers of IHN,” he said, adding that IHN is a naturally-occurring virus among wild salmon stocks along the entire North American coast from Alaska to California.

Feldhoff confirmed that this was the third outbreak of IHN at the hatchery, which also produces chinook, coho and steelhead trout for the area. The two previous incidents occurred in 1993 and 1997, also affecting chum.

- Quentin Dodd

Fertilized New Zealand scampi eggs. These eggs are collected from wild-caught females and hatched at Cawthron (Photo: Kevin Heasman).

Alaska fish board denies hatchery petition

The six-member Alaska Board of Fisheries recently declined to consider an emergency petition submitted by the Kenai River Sportfishing Association to intervene in a permit modification for the Prince William Sound Aquaculture Corporation which would have increased its pink salmon egg take by some 20 million this season.

Members of the board agreed that concerns about the large number of fish coming out of the hatcheries is an emerging issue, but they could not agree on whether or not the numbers were high enough to constitute an emergency at this point.

The not-for-profit aquaculture associations’ hatcheries in various parts of the state raise various species of Pacific salmon for release into the ocean. When the fish return they are harvested in cost-recovery commercial fisheries that fund the hatcheries for producing the next generation of fish.

In recent years though, the hatchery program has

come under criticism amid concerns regarding oceancarrying capacity and interaction with wild stocks.

The organizations involved in the petition claimed that the expansion of Prince William Sound hatchery operations would threaten wild stocks in both that area and in Lower Cook Inlet. The organizations noted that in a sampling study of pink salmon returning to streams in the lower inlet a significant number were strays from Prince William Sound hatcheries.

The petition asked the board to put the agency’s more recent permit for the hatcheries “on hold” until sufficient “consideration” can be given to the impact of hatchery fish on wild salmon stocks.

However, the Alaska Department of Fish and Game, replied that the petition did not meet the board standards for an emergency. Which in turn led to the petition not going forward and being put over until the board’s next regular meeting in September.

- Quentin Dodd

New Russian hatchery would end import dependence

Russian authorities plan to decrease import dependence on trout fingerlings and fish eggs by building a state-of-the-art hatchery in the Republic of Karelia.

The new hatchery has yet to be named, but it will be designed to produce 10 million trout fingerlings and 15 million fish eggs per year. It is hoped that the hatchery will meet the current Russian demand in these products by at least 80%, driving further growth

in the industry. The project will cost is Rub1 billion ($17 million).

Karelia is producing 75% of the farmed trout in Russia, importing six million trout fingerlings and about 18 to 20 million fish eggs per year from the U.S., Europe and South Africa, said Igor Pepelyaev, chairman of the fish department of the regional Agricultural Ministry.

By 2025 it is forecasted that Karelia will increase

the production of trout by nearly 30%. To some extent this goal will be achieved through the planned new hatchery slated to be built by 2020 and reach the designed production performance several years after.

The hatchery will be state-owned and operated by the regional authorities. Construction is expected to begin in the coming months, as soon as the project passes a government expert review.

- Vladislav Vorotnikov

Lobster decline the impetus for genetic profiling in Oman

News from Muscat in Oman indicates that there has been a serious decline in the number of spiny lobsters being landed. In the 1980s the annual catch from the waters around Oman was around 2000mt but in 2016 the catch weighed in at only 450mt.

The major commercial species in Oman is the scalloped spiny lobster (Panulirus homarus), so the decline prompted researchers at Sultan Qaboos University to begin the task of genetically profiling lobsters and the area’s populations of them. The researchers have discovered that the coast’s populations can be divided genetically into two segments. They have started working on a breeding program to restore the two Omani populations in the Arabian Sea coast between Ras Al-Hadd and Dalkut.

Oman is the largest seafood supplier in the Gulf, generating revenue of OMR240 million (US$624 million). The government of the Sultanate, has identified fisheries as a key sector for contributing to the country’s gross domestic product (GDP) in its ninth Five-Year National Development plan (2016 to 2020).

In support of that and future fisheries and aquaculture development in Oman, the Ministry of Agriculture and Fisheries Wealth (MoAFW) conducted an extensive survey of potential production locations, developed a comprehensive guide to better management practices for Oman fisheries and aquaculture, and developed a national strategic plan for the 3,200-km coastline, to protect the 900 species of finfish and shellfish, including crustaceans.

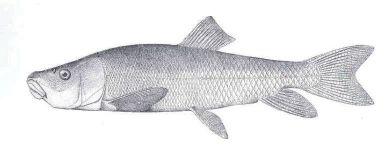

Saving the shortnose sucker

Asmall number of Lost River and shortnose sucker fish were released along the shores of Oregon’s Upper Klamath Lake several weeks ago.

The fish were the first of growing numbers destined to be raised in captivity and then released into the lake, thanks to the efforts of the US Fish and Wildlife Service.

Alan Mikkelsen, senior advisor to Secretary of the Interior Ryan Zinke, was on hand to give a symbolic helping hand to USFWS personnel, letting the fish go into the wild and answer media questions about the program.

Mikkelsen said the fish were the first cohort of what the federal government expects to be many more releases in ensuing years, in a bid to stabilize then increase the population of suckers in the lake.

Mikkelsen acknowledged that initial releases won’t likely address concerns of the Klamath Tribes. The tribes said that while they appreciated the effort, they felt strongly it needed to be done on a much larger scale to be effective.

Mikkelsen noted that the first release is just to give scientists an idea of how the fish will do and what kind of numbers can be expected to survive.

He indicated that the plan was to release double the numbers the following year and then double that again a year later.

The Bureau of Reclamation approved a budget of $300,000 a year for the project, to help it with two fish biologists, a biological technician and a contract aquaculture expert. Captured while in their larval stage in the Williamson River two years ago, the fish spent the last 18 months at the privately-owned Gone Fishing aquaculture operation not far from Klamath Falls.

The assisted rearing approach differs from a traditional hatchery program because larvae are collected from the wild rather than collecting and rearing the eggs by artificially breading adults in captivity. The traditional hatchery approach is more costly and can cause undesired results, such as reduced genetic diversity and high early life mortality.

The agency had projected that the Lost River sucker could go extinct within the next 30 to 50 years, with the shortnose left with as few as 15 years, based on current trends and mortality rates and data.

- Quentin Dodd

AUSTRALIAN RAS

Up Front, Down Under

MainStream Aquaculture has been at the forefront of aquaculture development for nearly two decades. The company’s new 1,000 tonne RAS 30 minutes from downtown Melbourne is an amalgamation of those years of experience in producing barramundi for the retail and food service sectors.

BY JOHN MOSIG

The first thing that strikes you when you enter the building is its space and quietness. As chief scientist Dr Paul Harrison explained, “Land based aquaculture has come a long way, particularly in the last decade. Our facilities are designed with the operator firmly in mind. The fish still come first, but ergonomics and automation come a very close second.” Reflecting the strong commercial element upon which MainStream has been built, Harrison pointed out that the plant has been designed to produce and sell high quality fish. From the picture window boardroom, buyers can look over the uncluttered and spotlessly clean production area, watch their fish pumped up to the grading area and slide down their respective chutes into the chilled packing room. The fish are iced and on their way to market inside an hour of being harvested. The barramundi breeding program the company has been implementing over the last 12 years has also been a contributing factor to the production efficiency. The Wyndham farm will take two million fry a year from the hatchery, which has capacity to produce 100m fry, most of which are exported.

SAVING ENERGY

Power costs have been addressed at every opportunity. A move to utilising a new technology of medium head oxygenators has resulted in significant energy savings. This has proved particularly timely as power costs have escalated dramatically in Australia over the last couple of years. Harrison estimates that targeted efficiency

AQUATIC

• EPA registered broad spectrum disinfectant and virucide*

• Maximum 10 minute contact time

• For use in cleaning and disinfecting environmental surfaces associated with aquaculture

Mainstream Aquaculture: the view from the board room. (Photo by John Mosig)

High efficiency vertical turbine pumps deliver water to the RAS (Mainstream photo)

Oxygen contact equipment and controls in the basement section (Mainstream photo).

The design is focused on enabling a single operator to move fish from and to anywhere in the plant without having to net or handle them. Apart from the saving on labour, stress on the fish is minimized.

design over the past decade has cut about 50% off the power cost per m3 of water. On top of this, he cites an economy of scale realised with the larger format systems, with the net result being improved energy bills.

The artesian aquifer over which the farm sits delivers hatchery-quality water at 29ºC with a carbonate hardness of 320ppm. No pH buffering or heating is required.

The grow-out system is a mix of proven industry equipment and unique design. The facility is on four levels: the basement with oxygenation, fish handling and control equipment; the working ground floor; the sorting mezzanine; and the dedicated processing and sales room.

Eight 600m3 tanks and the filtration system sit on the ground floor and extend into the basement. A floating bead bio-filter uses a polystyrene media for nitrifying bacteria. The filtration plant and vertical turbine pumps are situated at the far end of the insulated shed. The water passes through 60μm drum filters (Hydrotech), biofilter and degassing chamber and is then lifted once to return to the tanks via the Oxyflow oxygen contactors. A sidestream system sends water through a foam fractionator (RK2) with ozone.

from the 3800m2 roof then filtered and used for building washdown. During excess rain periods the water is automatically transferred to the header tank as part of a storm-water management plan. In the background is the slurry ice machine and cool-room for finished product, and liquid oxygen vessel supplying oxygen to the plant.

WORK OF ART

The basement section is a work of art. Whilst functionally complex, it is extremely well set out giving the sense of simplicity and is amazingly quiet. In this section the low head O2 chambers (from FOX aquaculture) and associated oxygen control (Oxyguard Pacific) operate to maintain optimal levels of oxygen in the tanks (90-100% saturation). In addition, the automated feed system (AKVA) is routed seamlessly to each tank, and a fish pumping system in which the pump remains in a fixed position is accessed. All equipment connects to a customised PLC with SCADA interface enabling a single technician to operate the plant including the activities of feeding and harvesting.

AUTOMATED HARVESTING

Harvesting is fully automated. The 600m3 tanks can be completely drained, with fish and water pumped to the fish handling equipment on the mezzanine level. Water can then be recovered through a network of fish handling pipes. Harrison said that the design here focused on enabling a single operator to move fish from and to anywhere in the plant without having to net or handle the fish. Apart from the saving on labour, stress on the fish is minimized. No feeding is lost, and consequently, there is no interruption to the production cycle. Fish are harvested and sold at 6001000g and 3-4kg. The grading floor is designed to allow the fish to be either returned to the tanks for further growth, sent to purging tanks, or sent to the chilling and processing room if they’re going to market.

WORLDWIDE REACH

MainStream has established itself as a leading supplier of barramundi table-fish, and a leader in aquaculture technology. The company’s reach is worldwide with its fingerlings now being sold in 23 countries; in addition to its own domestic sales of high quality, high value table-fish. Harrison said that, “Persevering with land-based farming in the pioneering days of the technology has provided us with valuable, albeit hard won, learning experience. The expertise we have gained has placed us at the forefront of the sector at a time when being able to control growing conditions could ensure success or failure of an aquaculture venture. The technology has a clear application for juvenile supply into large format farming operations such as pond farms and sea cages. For highly productive species like barramundi, the technology is now commercially viable for table fish production.

Globally Trusted UV Experience in Aquaculture > 400 installations

- > 825 million gallons per day treated (3.12 million m3/day)

- Designs for control of multiple pathogens

Lifetime Disinfection Performance Guarantee

- Aquafine Genuine parts program provides this peace of mind

- Economic low pressure lamp technology

- Duplex steel configurations with corrosion warranty for seawater

Long-term Industry Commitment

- Collaboratively advancing UV research in Aquaculture aquafineuv.com

Dr. Paul Harrison doing a test feed on the fish.

(Photo by John Mosig)

Despite the production intensity it is quiet and serene in the tank space. Company boardroom in the background overlooks the operation.

(Photo by John Mosig)

Rainwater is harvested

(Photo by John Mosig)

Change of plan for Alaska hatchery

According to recent reports from Alaska, two net-pens operated by the Cooke Inlet Aquaculture Association (CIAA) will not be located in the main part of Tutka Bay as previously planned.

The CIAA decided to pull the plug on its contentious plan to grow the young pink salmon fry in the outer bay and instead moved its pens back into a lagoon near the head of the bay.

A statement from the non-profit, which operates three salmon hatcheries in the Cook Inlet region, announced the reversal a few weeks ago in reply to ongoing concerns about the location of its net pens in the bay.

It said that the CIAA’s board of directors would review the operation for the future, “to determine a coordinated strategy for going forward with net pen placement in future years.”

The net pens are expected to remain part of the CIAA’s operations at Tutka Bay Lagoon Hatchery, which raises pink salmon on the south side of Kachemak Bay near Homer.

Each spring, the pink salmon fry raised in the hatchery go into the pens for some weeks, to be fed there until released into the open ocean.

The association had requested permission from the state’s Department of Natural Resources and the Department of Fish and Game to

move its pens out into open water near the head of the bay. That permit was granted in January last year and quickly triggered protest from park users and local charter boat operators.

Tutka Bay is a popular recreation spot in Kachemak Bay State Park, with tour boats passing through and lodges along its shores. At a public meeting about the net pens in May 2017, water taxi operators and park users testified against the move for aesthetic reasons. Commercial fishermen testified in favor of the move for the long-term increase in available pink salmon for harvest and stability of the hatchery organization.

- Quentin Dodd

New hatchery seeks to revive Siberian sturgeon in Kazakhstan

LLP Kuzmitch, a privately-owned company in Eastern Kazakhstan, plans to start producing sturgeon fingerlings in a bid to restore populations of this species in the region.

Siberian sturgeon was widespread in local rivers during Soviet times, but construction of numerous hydropower plants coupled with largescale poaching led to its disappearance in the early 1990s.

Vladislav Gritsenkov, general director of LLP Kuzmitch, said his company has launched a fish farm where it plans to produce from 20 to 30 tonnes of sturgeon per year. As part of that project, the company plans to build a hatchery where it would produce stocking material for its own needs – plus some surplus to be released to the Kurchum River and the Bukhtarma River.

The company wants to restock the Bukhtarminskoye water reservoir with the Siberian sturgeon. For this purpose, LLP Kuzmitch will be releasing fingerlings in the rivers flowing into the reservoir. It is not clear, however, how much time it would take to see the first results.

- Vladislav Vorotnikov

RAS research targets ‘friendly’ bacteria NEWS

Often, RAS operators seek to prevent such impacts by reducing bacteria in their systems through the use of UV or ozone disinfection. The project theme, in contrast, was that a better approach in some situations might be to find out which bacteria were present and identify those worth keeping and promoting.

“It’s not just the number of bacteria that is most important but what type are present and how they can be managed,” project coordinator Professor Olav Vadstein of NTNU Norwegian University of Science and Technology told Hatchery International

“Our challenge therefore has been to manage the microbiota we’ve found in such a way that we can promote the ‘friendly’ bacteria, while also encouraging beneficial interaction with the host and generally achieving a broader perspective on what is happening in RAS systems.

“Many existing systems are perfectly well managed, based largely on the use of UV or ozone disinfection. However, maybe placing too much emphasis on reducing bacteria numbers isn’t the best solution. It’s not a completely wrong approach, but it’s not focusing on the main issue, which we believe should be to create a better microbiota community.”

Prof Vadstein also said that farmers who put their disinfection process in the wrong place within a RAS system may actually create a bigger microbial problem in the longer term.

“As part of our work, we found that using UV disinfection just in front of the tank resulted in reduced survival rates in lobster larvae,” he said. “In such circumstances, the treatment which was used led to a reduction of bacteria numbers in the short term but created a microbial bloom in the rearing tanks.”

SIGNIFICANT GAINS

Managing the microbial community according to its good and not-so-good components appears to be a better way forward, with the benefits of this approach being potentially at their most significant in the hatchery sector, said Vadstein.

Project findings also indicate the potential for enhanced microbiota management having a beneficial contribution to make toward the reduction of antibiotic usage in hatcheries. Certainly, non-antibiotic systems, based on promoted ‘friendly’ bacteria, appear to perform as well as antibiotic-use systems where the bacteria type is less well managed.

“We are only now starting to draw our final conclusions, but the indications are encouraging,” said Prof Vadstein, who is working with research partners in Hochschule für Technik und Wirtschaft, Germany, and the Technical University of Denmark (DTU Aqua).

“A clear change of attitude or strategy toward microbial problems in RAS systems certainly appears possible, potentially making production easier to manage and considerably more sustainable than it is at present.”

Successful spat production of rock oyster in Ecuador

Astudy in Ecuador was able to demonstrate that hatchery production of rock oyster (Striostrea prismatica) spat is feasible, providing a basis for its large-scale propagation.

Suitable production conditions have resulted in inducing the reproduction of rock oyster with positive key indicators.

Fertilization rate was close to 100 percent and competent larvae survival rate was 27 percent. The production of juveniles considered as spat was deemed substantial in less than a two-month post-fertilization time.

“This result demonstrates that the description of the early lifecycle of Striostrea prismatica in this study was performed under suitable production conditions,” said Lodeiros et al.

The optimization of culture was confirmed when, after embryonic development, the complete formation of larvae with embryonic shell was obtained at 20 hours, which was two to four shorter than what was recorded in a previous study, they said.

Time was also reduced to obtain the competent larvae. From the 32 to 35 days of earlier studies, they were able to achieve this in 21 to 22 days.

“Spat production of the Rock Oyster Striostrea prismatica” was published in the Journal of Shellfish Research. It investigated the early lifecycle of S prismatica, including its embryogenesis, larval development, metamorphosis and settlement, and postlarval growth, describing some techniques to obtain large-scale spat production

Adult rock oyster were collected during a period of high reproductive activity in the shallow waters of Ayangue, Santa Elena Province, Ecuador, and conditioned for gonad maturation and spawning.

Fertilization, embryogenic and larval development were performed under laboratory conditions, then settlement of pediveliger larvae and nursing of postlarvae were performed using downwelling methods to produce spat.

Spawning induction was performed following the protocol described in a previous study with some modifications, cleaned, desiccated for 60 minutes, and exposed to thermal stimulus and spawned in trays. Rock oyster is one of the most abundant species in the rocky coastal ecosystems of Ecuador and other subtropical eastern Pacific countries. Production by culture is recommended because the natural banks are over-exploited or depleted.

Studies and efforts to induce the large-scale reproduction of this species have been done before but this is the first one that has proven the feasibility.

Talking about the previous efforts, the authors said, “These studies were developed under sub-optimal conditions, since the larval development did not reach the postlarval stage and spat, or the spat produced were scarce.”

RAS research unit at NTNU (Photo: Julie Gloppe Solem)

- Ruby Gonzalez

Photo: Paso Pacifico

RESEARCH

Green tea good for Asian sea bass fingerlings

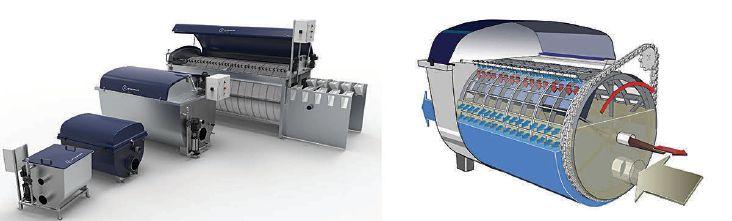

THE BEST IN RAS FILTRATION

Researchers from Egypt and Saudi Arabia found that applications of green tea were beneficial to the growth performance of Asian sea bass fingerlings.

PR AQUA ROTOFILTER DRUM FILTER

Call our aquaculture experts today with your questions, to place an order or to schedule service.

In an experiment, the researchers used green tea powder as a dietary inclusion. “The results clearly showed significant improvement of growth performance in all fish fed with green tea as dietary additive when compared to a control,” noted the researchers.

“Overall results from the treatments revealed that the dietary inclusion in low levels of green tea as a feed additive has relatively improved the growth performance, feed utilization and general health without any adverse effects on the biochemical profile of Asian sea bass (Lates calcarifer),”cited Al-Ngada RS of the King Faisal University in Saudi Arabia.

The authors noted that the World Health Organization encourages the used of herbs as an alternative to minimize use of chemicals and that there has been an increased interest in the immune-

stimulating function of medicinal herbs in aquaculture.

Despite the great potential, they noted that very few studies have evaluated green tea’s potential for use in aquaculture. “To the best of our knowledge, hardly any have been published yet about the usage of green tea as a dietary additive on the growth performance of Asian sea bass fingerlings,” they said.

Results revealed that the group fed with a diet containing low green tea powder exhibits a significant higher final body weight and daily weight gain as compared with control and 20 g/kg-1 diet.

There was no significant difference noticed in the survival rate among the treated fish groups.

Better daily feed intake was observed in the fish in the control group.

The food conversion ratio did not vary much among the treated fish.

The research was published in the Journal of Aquaculture Research and Development.

-Ruby

Gonzalez

Good deal turns costly for Alaskan hatchery

t was in April last year when Alaska’s Northern Southeast Regional Aquaculture Association (NSRAA) acquired the Gunnuk Creek Hatchery. The association submitted the only bid (US$ 400,000) for the facility, which had been closed in 2014 with a debt to the state of about US$22 million. However, NSRAA general manager Steve Reifenstuhl explains that in hindsight the purchase was not the bargain it might have seemed.

NSRAA, a private non-profit, operating hatcheries from Petersburg to Haines,has had to undertake substantial work to get the operation up and running and ready for spawning this coming fall.

Just over a million dollars has already been spent on outside renovations and Reifenstuhl expects that an additional few hundred thousand will be needed to renovate the inside of the main hatchery and install a new water-treatment and recirculating system.

The unit will be fitted with RAS because Gunnuk Creek doesn’t have sufficient water for a single-pass hatchery. While most hatcheries in Alaska are designed to have enough “head” on the water to drive it through the egg-bearing incubation units, Gunnuk doesn’t have this.

NSRAA plans to have salmon eggs at the hatchery from nearby Hidden Falls Hatchery by October.

— Quentin Dodd

Salmon fry lost in Whitehorse hatchery fire

McIntyre Creek Salmon Incubation Facility looking at rebuilding and recovery

Earlier this year an electrical error led to a fire which burned down the primary incubation building at McIntyre Creek Salmon Incubation Facility in Whitehorse, Canada. Sadly, at the time of the fire the building contained more than 30,000 salmon fry which were to be used in restoration projects for two aboriginal bands in the area.

At the time of the fire heat tape was being used to thaw frozen water pipes and the electrical error occurred at a time when the site wasn’t being monitored. The incubation building contained 16,000 chum salmon fry from the Vuntut Gwitchin First Nation to be used in the Fishing Branch River and between 25,000 and 30,000 chinook salmon fry which were to be used in the Ta’an Kwäch'än Council’s Fox Creek Salmon Restoration Project. The timing was particularly unfortunate as the fry were due to be moved to incubation tanks outside the building shortly afterwards.

The hatchery is managed by Yukon College, and spokesperson Michael Vernon says that the facility will be rebuilt but the exact timeline is still being worked out.

“We’re working with several partners on that,” says Vernon. “There’s the Department of Fisheries and Oceans, there’s another hatchery in town, the Whitehorse Rapids Fishladder, as well as the First Nations. Right now we’re focused on the recovery operations and the decommissioning of that building – pulling apart the debris in a safe manner, and in a way that doesn’t compromise the health of the creek.”

Along with lower numbers of adult returns for several years, and fewer eggs being naturally deposited, the loss will also reduce opportunities for training youth and staff in tagging in preparation for the fry release this season.

TREATMENTS

ANESTHETICS

The building itself was valued at around $30,000 and hiring contractors for the cleanup was estimated to cost around $17,000. In the meantime, the Ta’an Kwäch'än Council have indicated that their citizens are willing to volunteer to help with the cleanup and the rebuilding effort. However, it has yet to be determined whether the facility will be rebuilt exactly as it was or whether they will take the opportunity to upgrade the facility.

Along with the building itself, over 30,000 salmon fry were lost in the fire.

Most of the structures at the hatchery remain standing but the primary incubation building (left) was completely burned down.

The Ta’an Kwäch'än Council has also received an offer from Yukon Energy for the use of fry from their Whitehorse Rapids Hatchery.

- Matt Jones

Turning pits into profits

A Canadian fish farm’s

journey to

convert idle peat ponds into a viable bass-rearing enterprise

BY RON HILL

ith its frigid winters and abundant cold lakes and streams Canada’s finfish industry is dominated by the culture of trout and salmon. However, in the heart of central Ontario lies the small town of Zephyr, where a small company is

rearing non-traditional species in a nontraditional way.

Zephyr Peat Land Harvesting sells soil products specializing in peat and peat blends. Peat is harvested by excavating the surface peat deposits from old marshlands. These excavations create pits that, because of the excessive ground water, turn into ponds.

Custom Holding Systems

• Designed to maximize space and energy efficiency and minimize maintenance

• Preassembled, skid-mounted Life Support System with multiple options

• Full system monitoring available

• Salt water and fresh water versions available to suit any species e.g. crab, lobster, geoduck, tilapia and more

www.AquaticEnterprises.com

Finding himself with an ever-increasing number of ponds, in 2013 owner Bruce Blacktopp launched Zephyr Fish Farm.

PLETHORA OF PONDS

After harvesting peat for 27 years there are currently 70 ponds, with 10 to 12 more added each year. All ponds are 12-feet deep and are now purpose-built with fish farming in mind. Ledges are built into the walls of the ponds to help facilitate netting operations. Breeding ponds are built with plateaus to act as spawning areas for bass.

Because they come from peat marshes, the ponds are filled with ground water which infiltrates through the soil into the ponds and not from a stream, well, lake or traditional water source. There is no flow or water exchange and no aeration.

Species selection and operations at Zephyr fish farm are geared to take advantage of this unique and potentially problematic design. Traditional species to the region, like trout, would not perform well in the stagnant ponds. A warmer water species, specifically large mouth bass which can tolerate much lower dissolved oxygen levels and much higher water temperatures were identified as the species to be cultured in this setup.

Densities in the ponds must be kept low to avoid oxygen issues but the large number of ponds allow for a large standing biomass. Some ponds are designated for baitfish growth – fathead minnows and golden shiners – which are reared and added as forage for production fish. All fish are transferred from the pond the oldfashion way: Staff use seines, traps and fyke nets to collect fish for transport.

LARGE MOUTH BASS

Large Mouth Bass was identified as the most marketable species that could be cultured under Zephyr Fish Farm’s unique operating circumstances and is the focus of the operation. Market size fish

(550-750g) are sold live to fish markets in nearby large urban centres. Large Mouth Bass are desirable in Asian communities in the greater Toronto area, which are traditionally supplied by fish hauled from the central and southern United States. Bass are allowed to spawn naturally in the ponds. They are nest builders, and in the spring the male will build and guard a solitary nest on any firm substrate in the shallows. A few weeks after hatch the fry begin to school. They are collected and put into specialized grow-out ponds or transferred to the hatchery. Ponds are fertilized ahead of time to provide food for the young fry. Fry that are moved to the hatchery are pellet trained.

“Pellet training is pretty easy for us and the bass take to it easily now. Once they are pellet trained here in the hatchery we can transfer them out to one of the grow-out ponds, where they can forage and have their diet supplemented with pellets,” said Zephyr Fish Farm manager Russ Enslow.

“We move juveniles through the hatchery, get them graded on feed, then get them back out in the ponds.”

As this happens some fish are kept in the hatchery for longer periods. Hatchery water temperatures and feeding allow the bass kept in the hatchery to grow faster than the same cohort in the ponds. This causes production lots to be staggered to

Photos by Russ Enslow and Ron Hill

Grow-out raceway for large mouth bass.

Early rearing area.

allow for more frequent harvesting of bass throughout the year.

The recirculating hatchery has small circular tanks for pellet training and accelerated growth, and a raceway used for large mouth bass grow-out. The hatchery is fed by the 40-acre Joseph’s Lake, created by the original peat excavation in the 1980s. The lake isn’t used for commercial rearing but the water is used to supply the hatchery and pump water into ponds.

Because they are kept at low density and pellet trained, Zephyr’s bass have diminished cannibalistic tendencies. Supplied with adequate forage fish and supplemented with pellets, the bass survive well in the ponds. Nothing is added to the ponds in winter and the fish overwinter without feed or supplement.

Fish are moved from the ponds back into the hatchery raceway for final grow-out. Market size is 550-750g, depending on the time of year. Like many places doing large mouth bass grow-out, Zephyr is facing challenges when their size reaches 400 grams in the tanks and raceway. Grow-out tends to slow and fish performance falls.

“Finding the right diet has been a challenge at this stage, as has been filtration,” Enslow says. “There are a lot of diets out there but very few formulated for large mouth bass. We have switched commercial diets several times and are trying to find the one that performs best for us.”

The nature of the water in the lake with its high organic loads has been the biggest early challenge to overcome. By diversifying the diet and increasing filtration capacity, Zephyr is looking to streamline their bassgrowing process in the next several years.

WALLEYE AND PERCH

Zephyr also maintains walleye and perch stocks, which are mainly sold as fingerlings for pond stocking. One hundred and fifty pellet-trained walleye brood are spawned each year. Eggs are incubated in bell jars and fry are added to fertilized ponds. To collect the brood, water from the main lake is pumped into a pond for several days. The spawning walleye congregate around the flowing water after a few days and can be netted. Yellow perch are maintained in several ponds and sold for pond stocking. Because of their prolific nature, they are allowed to spawn naturally in the ponds. Both species are collected and pellet trained in the hatchery once the fry reach the appropriate size.

“Right now, our focus is large mouth bass because there is a market for it. If the market was there we could easily supply pellet-trained walleye or perch fingerlings for growout and gear more towards the demand,” says Enslow.

ZEPHYR EXPANSION

Fish operations started at Zephyr in 2014. It has been four years of refining practices, of trial and error, and of deciding what species perform the best. In 2017, Zephyr started its hatchery expansion project to increase filtration, water treatment and increase large mouth bass grow-out capacity.

The addition of two new drum filters and an expanded biofilter will allow Zephyr to increase bass grow-out capacity and speed. Large holding tanks are being added to the new building for staging market size fish.

With the fish ponds readily stocked and bass available for grow-out, bringing the expansion online should push Ontario’s only bass producer to maintain a steady supply of Canadian-raised bass for the Canadian market.

Pond potential

Peat forms over centuries as partially decayed vegetation builds up faster than it decomposes. This mass of partially decayed vegetation is peat and it is unique to peatlands and certain wetlands. The peat is harvested by draining the land and excavating the peat. Ontario peat is desired for mushroom culture as well as by greenhouses and nurseries. Carex peat, which Zephyr harvests, has a neutral pH, which doesn’t affect the ponds as many types of peat would.

When he bought Zephyr Peat Land Harvesting in 1991, Bruce Blacktopp quickly realized that along with a successful peat business, he now owned a significant amount of ponds. In 2011, Blacktopp started Zephyr Fish Farm and purchased a small Ontario hatchery giving him the tanks, equipment and building that allowed for operations to commence.

Fishfarm aerial.

Bass fingerlings for grading.

Bass spawning on plateau created in pond. Seining pond for large mouth bass.

Incubator for walleye

Recirculation aquaculture systems are becoming increasingly popular for a range of fish species, including salmon.

Built upon 27 years of continuous operation and learning, Skretting Aquaculture Research Centre (ARC) Lerang Research Station in Norway has significantly increased its research capacity over the past year with the addition of advanced recirculation aquaculture systems (RAS) – the first of their kind.

The independent RAS units primarily focus on the process of recirculation –examining and optimising the whole system while taking into consideration inputs and outputs. The new facility has 12 tanks with 12 independent RAS units which can be interconnected before the start of the trial to ensure equal biofilter performance. This set up enables us to test the effect of different diets on RAS performance.

Partnering with the new systems is Skretting’s dedicated feed range for RAS – RecircReady. These diets utilise specialsed feed components to increase water stability and particle size distribution of faeces, thereby improving filtration efficiency and fish welfare.

RecircReady is available for hatchery and land-based production systems.

For more information, please contact your local Skretting representative www.skretting.com

Benefits of RecircReady feeds:

• Facilitates biofilter operation by reduced load of organic material

• Reduces phosphorus and nitrogen accumulation-discharge

• Reduces turbidity/particulate matter

AUTOMATIC FEEDER

PROTEIN SKIMMER

BIOFILTER

DRUM FILTER

FISH

Our hands-on experience allows us to offer practical solutions to your situation, big or small. We have years of experience in retrofit and new construction and understand your needs.

Contact us today to learn more!

-

option to reduce energy costs. DC INTERNATIONAL 75 De Vaudreuil, Boucherville, Quebec Canada J4B 1K7 - Ph: +1 (450) 449-6400 www.dc-inter.com dctank@dc-inter.com

WANT HEALTHIER FISH?

New Jersey hatchery sets record

New Jersey’s Hackettstown State Fish Hatchery set a record in 2017, stocking over five million fish, topping the previous record of almost four million from 2014.

Fish stocked at the hatchery include walleye (2.3 million), golden shiners (655,000), channel catfish (598,174) and muskellunge (343,311) among others. Hatchery Superintendent Craig Lemon says that while favorable weather conditions did play a role, he is quick to credit the hard work and ingenuity of the crew who work at the hatchery.

“The crew has matured,” says Lemon. “I’ve been here 30 years; the rest of the crew are young guys who’ve been here three to five years. Everybody has interests and ideas about how to do things differently.”

Lemon says that the 200 acre facility is over 100 years old and has about 65 earth ponds – structures which were old and breaking down. In addition to repairing and reworking some of the pond bottoms, the crew also looked at other approaches to their work.

“We started using the ponds twice instead of just once,” says Lemon. “A lot of our production starts in April and we harvest a lot of ponds in June and typically they would stay empty after that but we started refilling ponds in June and our growing season goes probably till November.”

Aerial view of the hatchery site.

Vindication for Michigan trout hatchery

Grayling Fish Hatchery owner and operator Dan Vogler confirmed recently that state regulators have (again) approved the expansion of his hatchery situated on the banks of the Au Sable River in Michigan. Vogler started leasing the former state-operated hatchery in 2012 and two years later obtained a state permit for an expansion planned for 2016. Opposition to the project created a delay, but a modified permit will enable Vogler to proceed.

This means that he can now work towards boosting output of rainbow trout from his Harrietta Hills Trout Farm from 70,000 to 300,000 lbs a year.

The Michigan Department of Environmental Quality (DEQ) modified the earlier (2014) version of the permit. Director Heidi Grether said in a statement that the agency carried out “a careful, thorough and comprehensive review of the case.” She also noted that a state administrative judge supported Grayling in a legal battle with opponents to the expansion.

Regular testing of the hatchery water for whirling disease (WD), testing sediment downstream for the disease, installation of areas in the raceways where fish waste will settle and be vacuumed out, and testing for ammonia and dissolved oxygen will provide additional protection to the streams and are now required under terms of the permit.