› 10 Instrument Panel Configurations from Basic Mechanical to Integrated Glass

› Air Conditioning*

› New Cockpit 4K Video Camera* Enables Training Flight Reviews

› Derated Power Provides Increased Performance Margins at Higher Altitudes

› 2400-Hour Time Between Overhaul

Cover Story

– The frontier of electric aviation pg12

12 The Electric Frontier

Joby Aviation's Head of Product, Eric Allison, describes the push toward air taxi commercialization

16 A Different Perspective of CFIT

Ken Pothier looks at how helicopter pilots and operators can move beyond the limits of Transport Canada definitions

19 2021 MRO Directory

Detailing some of the leading Maintenance, Repair and Overhaul facilities across North America

October 2021 Volume 42: Issue 4

4 Editorial Helicopter demand set to soar over next decade

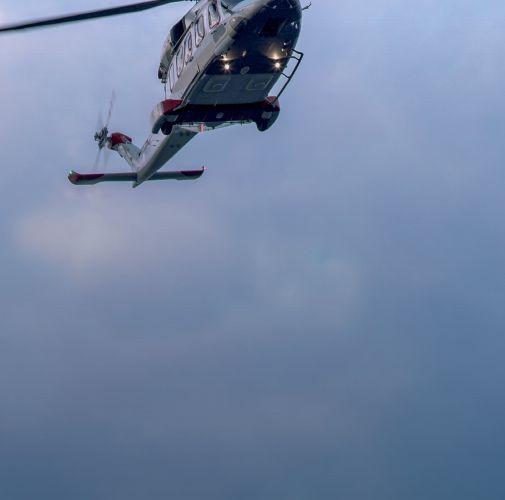

6 On the Fly STARS recieves five bladed Airbus H145

10Facing the Fire

417 Squadron shares a BC wildfire rescue

26Eyes in the Skies

Ottawa International’s pioneering drone program

COVER

Joby Aviation in July 2021 completed a test flight of more than 150 miles with its full-size protoype. (Photo: Joby Aviation)

417 Squadron provides SAR during wildfires in British Columbia pg 10

– Ken Pothier

JON ROBINSON, editor

The global helicopter market is expected to reach US$69.2 billion by 2028, according to an August 2021 report called Helicopter Market Size, Share & COVID-19 Impact Analysis by research group Fortune Business Insights, which notes the market stood at US$50.42 billion in 2020. Pointing to flat growth in 2020 at 2.0 per cent, Fortune Business Insights estimates the global helicopter market will grow from US$52.56 billion in 2021 to the US$69.20 billion mark in 2028 with a CAGR of 4.1 per cent in the forecast period.

It is difficult to fully predict how the pandemic is changing demand for the global helicopter industry, but, even as several legacy operators decided to shutter their companies over the past two years, the next few years bring potential for growth. A rising tide, however, is unlikely to lift all boats. Even as the helicopter industry illustrated how its services are essential through sectors like EMS and fighting wildfires, the potential for lasting inflation and the range of tapering policies being set into motion around the globe will impact how economies emerge from the easing of pandemic supports by governments.

It is critical for businesses of all shapes and sizes to consider how inflation might impact their most important investments for growth into the future, particularly for Canadians who might purchase aircraft in U.S. dollars. In an early October article for Bloomberg, John Authers put the situation into context with a report called Inflation

damaging in the future, along with pessimism that it’s bound to become endemic.”

Authers explains inflationary pressure is broadening as businesses wrestle with higher prices. In early October, energy prices were rising around the world. What began as a European supply issue for natural gas, quickly turned toward petroleum with the cost of a barrel of oil reaching above US$80 and seemingly heading toward US$90. Some economists were predicting the return of US$120 per barrel, which on pricing alone would certainly impact sectors like helicopter tourism.

Even as cash flow was a significant issue for many aviation operators, both fixed- and rotary-wing throughout the pandemic, several helicopter operators have taken advantage of the low interest rates over the past several months to prepare for the future, which will include the need for more flexible and fuel-efficient aircraft. At the start of September, the General Aviation Manufacturers Association (GAMA) released its report of general aviation aircraft shipments and billings through the second quarter of 2021. Piston, turboprop, business jet and helicopter deliveries increased across all segments during the first six months of 2021 as compared to the same period of 2020.

Turbine helicopter deliveries through the second quarter saw an increase of 33%, with 258 units.

Clarity Doesn’t Mean the News Is Good, followed by the even clearer subhead Disappointing labour data, spiking commodities prices and supply-chain headaches are scarier than Covid-19 for markets these days. “Absent the arrival of a truly terrifying new variant that is lethal and also impervious to all the vaccines we have at present, it looks as though we have reached the point where the market is no longer that concerned about the pandemic’s medical progression,” writes Authers. “There is general optimism that it needn’t be as horrifically

According to GAMA, turbine helicopter deliveries through the second quarter of 2021, when compared to the same period in 2020, saw an increase of 33 per cent, with 258 units; and piston helicopter deliveries saw an increase of 31.7 per cent, with 83 units. “Efforts to address ongoing supply chain issues, strengthen our workforce and enhance environmental sustainability will continue to be at the forefront as interest and demand for aircraft remains robust,” said GAMA CEO Pete Bunce, speaking to how key operational issues are becoming more intertwined. This was certainly the focus of Airbus’ first summit focused on “Pioneering Sustainable Aerospace” in mid-September.

More than ever, fuel and operational efficiency will be two critical factors for how helicopter manufacturers meet end-user requirements. As Fortune Business Insights notes, based on weight, the medium-weight segment is expected to show significant growth owing to the improved fuel efficiency and maneuverability of such machines compared to heavy-weight machines worldwide. | H

YXX short term or long term hangar storage available.

Airside is an intentionally renovated multi-purpose hangar at the Abbotsford International Airport.

With multiple spaces and a white modern finish, its the perfect venue for product launches, business events, meetings and gatherings.

• 5,000 sqft hangar

• full AV system

• in-house catering

• tables + chairs

• 24 person meeting room

STARS Air Ambulance, an Airbus operator for more than 35 years, becomes the first customer in North America to operate the new five-bladed H145. The HEMS organization took delivery of this new helicopter in Fort Erie, Ontario, at the headquarters of Airbus Helicopters Canada. This North American-first marks the receipt of STARS’ sixth H145 within the company’s fleet renewal plan and the first five-bladed version to join

its fleet. All remaining deliveries will consist of the new fivebladed H145 model and STARS has confirmed it will retrofit its initial five aircraft.

STARS is described as a physician-driven, non-profit helicopter air ambulance organization, transporting patients in need across Western Canada. In 2018, STARS published its fleet renewal plan for a total of nine H145 helicopters, the first of which was delivered in 2019. STARS

recently increased its total order to 10 H145 helicopters. The new five-bladed rotor system of the H145 increases the platform’s useful load by 330 pounds (150 kg), simplifies maintenance operations, and improves ride comfort for both

passengers and crew. Powered by two Safran Arriel 2E engines, the H145 is equipped with full authority digital engine control (FADEC) and Airbus’ Helionix digital avionics suite, designed to increase safety and reduce pilot workload.

Bell Textron Inc. released new data on the build and testing for the Bell 360 Invictus competitive prototype. The company explains its Bell 360 program is rapidly progressing through manufacturing, assembly, components testing and systems integration work for the U.S. Army’s Future Attack Reconnaissance Aircraft (FARA) program. The program team has completed multiple design and risk reviews with the Army and is on schedule for all program requirements. Bell describes the 360 Invictus as a low-risk, high-speed platform leveraging proven technology and reliable designs, being designed to deliver soldiers transformational operational capabilities at an affordable cost. Since beginning the build in late-2020, Bell explains it has made significant progress on the 360 Invictus fuselage, main rotor blades, gearbox assembly, cases and other

high-value components. By implementing a design-as-built methodology that digitally connects the entire program throughout its lifecycle, Bell explains it has increased the ability to collaborate in real-time with program partners and the Army.

Along with assembling the 360 Invictus, high-value components such as the main rotor gearbox, driveshafts and couplings are being tested at Bell’s Drive Systems Test Lab (DSTL). The DSTL is used to carry out risk-reduction efforts, explains Bell, that ensure the program has accurate and verified data to qualify components in advance of flight test. A new FARAspecific Systems Integration Lab (SIL) is also operational at Bell. This facility allows Bell to integrate flight-critical components, software, and mission systems for testing, verification, and validation of functionality before they take flight on an actual aircraft.

United Rotorcraft, a division of Air Methods Corporation, awarded Sikorsky, a Lockheed Martin company, a contract for five S-70 Black Hawk helicopters. The order will enable United Rotorcraft, as the only company authorized by Sikorsky to modify Black Hawk aircraft to the Firehawk configuration, to deliver these new production aircraft for aerial firefighting. Sikorsky will produce the five S-70 Black Hawk aircraft at Lockheed Martin’s PZL Mielec manufacturing line in Poland. Deliveries to United Rotorcraft’s 55,000-square-foot completions facility in Colorado are expected between early 2022 and mid-2023. The first aircraft received will be configured as a Firehawk helicopter for the State of Colorado, which announced its contract with United Rotorcraft on August 16.

An S-70 Firehawk helicopter operated by CAL FIRE can transport firefighters, drop water on wildfires from its 1,000-gallon (3,785 liter) belly tank, and perform hoist rescues. (Photo: Sikorsky, CAL FIRE)

To modify a Black Hawk to the Firehawk configuration, United Rotorcraft installs and integrates a 1,000-gallon (3,785-litre) external water tank system to the aircraft’s belly. Sikorsky explains fingertip controls allow pilots to drop the precise amount of water with high accuracy and refill the tank via a retractable snorkel in 60 seconds or less, while hovering 10 feet over a water source. United Rotorcraft works hand in hand with public agencies to further customize the aircraft, as needed, from communications and navigation systems, to cabin interiors, transforming the Firehawk into what Sikorsky describes as a true multi-mission aircraft, with the ability to transport up to 12 firefighters, provide medical care on board, or perform search and rescue operations.

Airbus Helicopters in September started flight testing an Engine Back-up System (EBS) onboard Flightlab, in partnership with French Civil Aviation Authority DGAC. The project opens the way toward a hybridized propulsion system for light helicopters, explains Airbus, while delivering con-

crete flight safety improvements in the short term. The campaign’s main target is to enhance flight safety of singleengine operations by providing emergency electrical power in case of a turbine failure.

To test EBS, Flightlab was equipped with a 100 Kw electric motor connected to the

main gearbox, which can provide electrical power for 30 seconds in the event of engine failure. By giving the pilot extra time to react and maintain rotor speed, the engine back-up system contributes to a safer and smoother autorotation maneuver to the ground. The current flight tests include the simulation of engine failure in different flight conditions, including takeoff and landing procedures, and corresponding limitations.

Airbus explains the flight campaign also aims to demonstrate a performance increase, thanks to the prompt electric power input. The potential benefit in terms of Maximum TakeOff Weight is to compensate for the mass of the EBS system itself, explains Airbus, and to provide helicopter operators with additional payload. Because the EBS flight campaign also looks at ways of easing the possible introduction of this Airbus techno-brick onto future production aircraft, the various components of the system have been designed with serial production in mind.

HELICOPTERS MAGAZINE

Reader Service

Print and digital subscription inquiries or changes, please contact Serina Dingeldein, Audience Development Manager

Tel: (416) 510-5124

Fax: (416) 510-6875

sdingeldein@annexbusinessmedia.com

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

www.helicoptersmagazine.com

EDITOR JON ROBINSON jrobinson@annexbusinessmedia.com

MEDIA DESIGNER ALISON KEBA

CONTRIBUTING WRITERS

DAVID CARR, FRED JONES, KRISTA KEALEY, KENDRA KINCADE, CARROLL MCCORMICK, KEN POTHIER

NATIONAL ADVERTISING MANAGER MENA MIU mmiu@annexbusinessmedia.com 416-510-6749

ACCOUNT COORDINATOR BARB VOWLES bvowles@annexbusinessmedia.com 416-510-5103

GROUP PUBLISHER, VP SALES MARTIN MCANULTY mmcanulty@annexbusinessmedia.com

COO SCOTT JAMIESON sjamieson@annexbusinessmedia.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO ANNEX BUSINESS MEDIA, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

subscribe@helicoptersmagazine.com

Published four times a year by

Annex Business Media

Printed in Canada ISSN 0227-3161

SUBSCRIPTION RATES

Canada - 1 year $31.50

USA - 1 year $74.00 CDN funds Foreign - 1 year $82.00 CDN funds plus applicable taxes

www.helicoptersmagzine.com/subscribe

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2384

Occasionally, Helicopters magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Helicopters Magazine is an associate member of the following Canadian aviation associations:

Archer Aviation Inc., an eVTOL developer, announced it will work with REEF to develop plans for urban takeoff and landing sites. REEF transforms urban spaces into neighbourhood centres that connect people to locally curated goods, services and experiences. Its network of more than 4,800 parking garages is a multi-million parking space system that covers 70 per cent of North America’s urban population, yet is largely underutilized given the changing nature of urban living in recent years.

Archer and REEF will work together to allow Archer’s aircraft to access largely dormant rooftop sites across some of the most densely populated and heavily congested urban city locations in the U.S., including the company’s two key launch markets of Los Angeles and Miami. REEF’s network lends itself to Archer’s plans for developing vertiports in dense urban areas. With proximity to high-traffic city hubs, Archer is looking to establish operations in locations that will benefit most from access to the company’s planned urban air

mobility network. Using Prime Radiant, the company’s proprietary data science technology, Archer will determine optimal landing sites within REEF’s existing network. The goal is to identify sites that already have the space needed for takeoff, landing and charging, so minimal construction is required for operations to launch.

Leonardo, the owner of Kopter since April 2020, in September participated in the 25th anniversary celebration of the Hunterverein at Mollis airfield. Leonardo showcased an AW189 super medium helicopter from its training academy, as both static and flight displays. The AW189 is the largest type in the AW family, reaching a gross weight of up to 8.6 tonnes, combining payload and range.

Along the AW189, Leonardo exhibited the AW09, the new generation single-engine helicopter currently under development at the Kopter facilities in Switzerland. In addition to developing the AW09, Kopter will contribute to the study and development of innovative technologies, explains Leonardo, through projects focusing on noise optimization and hybrid/ electric propulsion.

Alterra Mountain Company closed the purchase of Purcell Heli-Skiing in British Columbia. The business and ski tenure will be incorporated into the company’s premier mountain experience, CMH Heli-Skiing & Summer Adventures, adding nearly half a million acres to the already largest heli-skiing operation in North America. Purcell Heli-Skiing was established in 1974 by Rudi Gertsch, a former CMH guide, and has been a family business for nearly 50 years. The operation includes a 13-acre lot with a day lodge and heliport, and a tenure license for 495,000 acres of glaciers, high alpine bowls, and subalpine forest in Golden, BC, adjacent to CMH’s current Bobbie Burns tenure.

Current Purcell trips include one, two and three-day packag-

acres of wide-open glaciers, high alpine bowls, and

es for up to six people with two guides, excluding lodging and transportation. All confirmed bookings will be honoured and managed by CMH, and any available spaces will be incorporated into CMH’s current product offerings. CMH President & COO Rob Rohn will oversee the transition and all operations. | H

KENDRA KINCADE

Provincial and territorial authorities are the first to respond when a major natural disaster occurs in Canada. If they need help, they can ask the Canadian Armed Forces to come to the rescue. When the Canadian Armed Forces (CAF) respond to such a crisis, it is known as Operation LENTUS. But what happens when the CAF is responding to a natural disaster, such as a massive and powerful wildfire, and they themselves need rescuing? Whose job is that? They call in the search and rescue helicopter.

I sat down with Capt Andrew Johnson from the 417 Combat Support Squadron in Cold Lake, Alberta, to talk about his latest Op LENTUS experience with the fires out in British Columbia this past summer.

The 417 Squadron was called to British Columbia to assist provincial wildfire services and military personnel with airborne medical evacuation, and search and rescue, for the people fighting the fires. While deployed, they were also able to conduct daily training missions in the local area to expand their proficiency within mountain terrain, a valuable asset coming from Cold Lake, Alberta. The crews appreciate quite days with no calls, which means nobody is in trouble. As the sun was setting one evening, the crew of Capt Andrew Johnson, Capt Matt Rowe, Sailor First Class Andrew Clevland, and Corporal Andre-Luc Dube (439 Sqn Bagotville, Quebec) arrived back at their hotel, ready to call it a night, when suddenly the phone rang. They need to go back – people are trapped in the fire and need evacuation immediately.

Back at the base, the crew climbs into its red and yellow Griffon

417 Squadron shares a rescue from British Columbia wildfires

the fire, they set out with fierce determination – and perhaps a little excitement – that they were going to perform a rescue. This mission is what they spend hours and hours training for. They were ready.

The crew navigated their way through the dark night, engulfed in smoke and flames rising as high as 200 feet in the air. Their NVGs allowed them to make out shapes, just enough to keep them going on the mission. Finally, they see movement. They can see homes through the flames. Capt Johnson is flying and finds an area large enough to land the helicopter. “It was absolute mayhem,” he explains. “Trucks with lights on driving around like crazy with water tanks in the back, embers falling down on the helicopter, smoke and flames absolutely everywhere. Fire 100 yards from the houses. There were six to seven people surrounded by fire trying to save their land.”

Sailor First Class Cleveland jumps form the helicopter and runs over to talk to the men and let them know help has arrived. They would be rescued. Capt Johnson waits in the helicopter to be ready to lift the full load up and out of the flames. But he is surprised to receive a radio call back from Sailor First Class Cleveland announcing the men won’t leave.

“While we were flying through the smoke, we were just thinking the whole time that we were going to save these people,” Capt Johnson explains. “We were so excited to find them and land – we are there to save them. It was a real eye-opener... They just didn’t want to go.

“We called for orders and were told to do all we could and then get to safety. We made sure there was nobody willing to be rescued and, after doing everything we could to get the men out, we had to leave,” he continues. “We flew around the area searching for anyone else who may have been out there and wanted to get out, but we couldn’t find anyone.” A little defeated, they returned home.

Their NVGs allowed them to make out shapes, just enough to keep them going on this mission.

helicopter (which to me is akin to the horse that a knight and shining armour would ride), don their Night Vision Goggles (NVGs), and bring up the advanced software on their iPads that will help them navigate through the black, smoke-filled sky. “The iPad with Foreflight worked incredible with the hazard advisement on there,” Capt Johnson explains. “The technology we fly with now is incredible. I don’t think we could have done it without it.”

Armed with the small bit of information they were given, which amounted to a grid of latitudes and longitudes where they suspected the call came from, and that there were approximately six people caught in

’’

When I asked if they ever found out what happened to the men they had tried to rescue, Capt Johnson replies, “The best advice I received was that I would do myself a favour if I don’t look into it.”

I asked Capt Johnson if he considered himself to be brave, flying through terrifying conditions, putting his life at risk to save others. “In Cold Lake, we train for these situations. During the operation, we were ready. We train for it. We felt confident. We were talking through the entire operation keeping an eye on the deteriorating weather, talking about our location, talking about the minimums.” Then with a gentle smile on his face, showing the passion for his work, Capt Johnson says, “It’s probably one the spiciest things that I have ever done – the most exciting for sure.” | H

The Bose A20 Aviation Headset offers the right combination of noise reduction, clear communication and comfort. Available with a coiled cable ideal for helicopters, the A20 features Bluetooth® streaming for audio and communication*, auto-on*, auto-off, side swappable mic and FAA TSO and EASA E/TSO-C139 certification, making it the choice of pilots the world over. Hear the A20 difference today. Finance with Bose Pay powered by Klarna and start a 60-day test flight at Bose.com/A20.

Left: Joby Aviation expects its aircraft to start commercial service in 2024, transporting a pilot and four passengers at speeds of up to 200 mph.

Below: Propellers of the six forwardtilting rotor fans have been through more than 25 iterations with Joby focused on the critical issue of environmental acoustics for Urban Air Mobility. (Photos: Joby Aviation)

BY JON ROBINSON

Joby Aviation on July 27, at its Electric Flight Base near Big Sur, completed a 154.6-mile test flight of its full-size – four revenue-earning seats plus one pilot – prototype aircraft on a single charge. After Chief Test Pilot Justin Paines spent one hour and 17 minutes in the air, making 11 laps of a predefined circuit, the California company’s founder and CEO, JoeBen Bevirt, noted the flight’s significance based on what many believed to be impossible with today’s battery technology. He described it as a first step toward making convenient, emissions-free air travel between places like San Francisco and Lake Tahoe (156 straightline miles), Houston and Austin (146 miles), or Los Angeles and San Diego (111 miles) an everyday reality.

Joby’s prototype aircraft uses commercially available lithium-ion batteries, adapted for

aerospace use. The July 27 flight speaks to the efficiency and design of Joby’s prototype, which has quietly been in the making for more than a decade (now with more than 1,000 test flights completed). With the aircraft’s recent public unveiling in the rugged landscape of the Santa Lucia Mountains, Joby now looks best positioned to lead the highly anticipated transportation revolution of all-electric air taxi services. With a FAA Type Certification goal set for 2023, Joby expects its aircraft to start commercial passenger service in 2024.

In December 2020, Joby, even if it was already well-known within the aviation sector, made its advanced commercialization ambitions clear by reaching an agreement to buy Uber’s Elevate operation, which since 2016 had laid out much of the groundwork for an aerial ride-share market. In August 2021, Joby then became the first U.S.-based eVTOL company listed on the NYSE, through a Special Purpose

Acquisition Company merger (SPAC) with Reinvent Technology Partners, led by LinkedIn Co-founder Reid Hoffman. The SPAC transaction, according to Reinvent, valued Joby at a US$4.5 billion, with proceeds raised, plus cash on the balance sheet as of March 31, 2021 equaling approximately US$1.6 billion. The proceeds are expected to fund Joby through its initial commercial operations.

The addition of Uber Elevate integrates Joby’s pioneering aircraft development with a go-to-market product infrastructure, in terms of determining how an all-electric aerial ridesharing service can be rolled out to consumers. Beyond the aerostructures and propulsion intrigue of amazing ever more eVTOL aircraft, there are many infrastructure and operational pieces to fit together for true success.

Much of this needed platform vision falls on the shoulders of Eric Allison, Head of Product for Joby and one of the eVTOL sector’s

As a leading global engine and component maintenance provider, TAEAerospace has the knowledge and expertise to turn your next event around quickly.

As a TAE Aerospace customer, y you haave e acccceess s to the highest quality maintenaannce, incclud u in ing overhaul, repair or exchange e of f engine e fuel control, fuel metering units, po p w wer turbbin i e governors and star ter geeneratoors.

We are an Honeywell A Authorizzed d Warrra r nt n y and Repair Station (AWWAR A S) for the:

• Honeywell LT S101

• Pratt & Whitney Cana n da a P T66A A an a d P T6T

• Rolls-Royce M250/33000

We are also a CASA, FAA annd EASA Par t 145 approved reepair ir stati t on o .

To find out more about why y ou o r cu custommeerrs rely on TAE Aerospace, e viisiit our we w bsitte for your local sales represeentative or email sales@taeaerospace.com

pioneering explorers, who has known Bevirt since before 2010.

Allison joined Joby in January 2021 after becoming the lead of Uber Elevate in March 2018. Prior to joining Elevate, he spent more than eight years with Zee.Aero, including three years as CEO, directing the company’s engineering operation in its aim to develop an autonomous eVTOL called Cora. (Zee.areo ultimately became Wisk, which is now backed by Boeing.) At Uber Elevate, however, Allison focused on customer-facing strategies, instead of aircraft development, which is now serving Joby’s complete vision.

“Joby is building a vertically integrated business,” says Allison. “We envision providing trips for people and we’re also designing and manufacturing the aircraft. We’re going to operate them, as well.” He continues to explain how Joby’s strategy focuses on how a consumer will interact with this new type of transportation – “It is what I think about every day.”

At the start of 2021, Joby began to release specifications and images of its six-bladed, fullsize prototype, being developed with tilting fans to reach top speeds of up to 200 mph. In addition to innovative aircraft design, distrib-

uted electric propulsion allows for redundancy for safety and propeller flexibility (realized through dozens of iterations) for strong noise abatement. Joby’s resulting prototype can currently takeoff and hover with a decibel measurement – at around 55 decibels – about one thousand times less than that a helicopter (90 decibels) and avoid the high-pitch whine associated with drones. Flight of the Joby prototype, with its forward-titling rotors, is even quieter than its hover – key to success in the Urban Air Mobility market.

“Electric propulsion technologies enable new degrees of freedom in designing aircraft. One of those new degrees of freedom is distributing propulsion across the aircraft in a way that’s not possible with traditional technologies,” explains Allison. “Distributed electric propulsion [opens] up new types and new forms of aircraft, new concepts, that you can then apply to new types of missions.”

Allison emphasizes Joby has been working on determining its best form of distributed electric propulsion aircraft since being founded in 2009, refining the optimization of the technology and overall shape the aircraft, and is now “leaning into” its commercialization.

“The mission we are going after is relatively short range, call it five to 150 miles, because we have a pretty flexible aircraft that can efficiently serve a relatively wide range of trip links, but in an urban or semi-urban environment,” says Allison. This is where Joby’s new aircraft design is supported by Uber Elevate’s own historic software development to connect aerial ride sharing with ground transportation to revolutionize how people move around in urban environments.

The Elevate team put this concept to the test in 2019 with the launch of Uber Copter, described as the world’s first seamless multimodal mobility product. With a single push of a button, Uber Copter in the background built an entire trip itinerary, allowing people in New York City to be picked up by an Uber driver, taken to a heliport for a helicopter ride across the East River, and then picked up by another car to reach their final destination.

“Fundamentally, the vision that we’ve laid out is one of an end-to-end experience. We will have both our own entry points [with] a Joby app, that will enable you to request the trip, and through our partner Uber we will be able to provide first- and last-mile transportation with a car; and then we will be able to get you to the optimal skyport, match you into the next available flight or the best available flight to get you to your final destination with significant time savings on the overall trip. That’s the North Star vision of what we’re building.”

For Allison, this North Star is the culmination of years of propulsion research and development, which began with building large radio-controlled model airplanes as an undergrad. Then at Stanford, where in 2000 he began specializing in Aeronautics and Astronautics, Allison worked with a professor on tethered micro air vehicles (quadrotors). Allison’s Ph.D. thesis was on Ultrasonic Propulsion, a system to wirelessly propel a capsule around a patient’s stomach to do remote endoscopy. Captivated by flying machines since he was a child, Allison is now just months away from helping to commercialize a new future for aviation.

“We’re working on a Type Certification of the aircraft and that’s a very critical gate that we must get through. In parallel, we’re working on building up our skilled production capability that will then go along with our production certificate,” says Allison. “We have already filed for our initial Part 135 Certificate that will be the foundation of our operation, and we are building up the software platform… Those are the three pillars of what we are building over the next few years as we mature the technology, finish the Type Certification process and bring the vehicle into service.” | H

For helicopter engine accessories exchange...

When winds are near zero, mirror-like glassy water can create a situation where a pilot does not notice an unintended shallow descent that could result in contacting the water.

(Photo: Adobe Stock)

BY KEN POTHIER

Transport Canada defines CFIT as: “An occurrence in which an aircraft, under the control of the crew, is flown into terrain, water or an obstacle with no prior awareness on the part of the crew of the impending disaster.” From my perspective, rules and regulations exist to protect us.

It does not always feel that way, but that’s why they exist. When situations or concepts are not properly defined, or are lacking in definition, it is impossible to develop rules and regulations that meet our needs. I know this from my three years as the Terminology Manager for the Department of National Defence.

I believe one of the reasons that CFIT accidents occur, and will continue to occur, is because we have limited ourselves to the definitions that follow; and we have failed to properly define another set of conditions that could be used to develop additional rules and regulations or, at the very least, modify existing rules and regulations.

Transport Canada defines Visual Flight Rules (VFR) as: “The rules that govern the procedures for conducting flight under visual conditions.” And Instrument Flight Rules (IFR) as: “A set of rules governing the conduct of flight under instrument meteorological conditions (IMC).” VFR Met Conditions (VMC) as: “Meteorological conditions equal to or greater than the minima specified in Division VI of Subpart 2 of Part VI, expressed in terms of visibility and distance from cloud.” IFR Met Conditions (IMC) as: “Meteorological conditions less than the minima specified in Division VI of Subpart 2 of Part VI for visual meteorological conditions, expressed in terms of visibility and distance from cloud.” Instrument Flight Conditions (IFC) as: “Restricted meteorological conditions in which control of an aircraft in flight (other than a balloon) is required to be maintained solely by reference to aircraft flight instruments.”

During my time in the military, I flew in an organization that operated a fleet of helicopters that was not certified for military IFR flight

because of its rudimentary instrument package. All pilots flying this helicopter were required by regulations to maintain an instrument rating on the helicopter, but could not fly it in certain conditions.

The way this organization made sure of the safety for the crews flying this helicopter was to ensure IFR flying skills were maintained by providing annual IFR refresher training sessions in advanced flight simulators, and by defining “Visual Flight Conditions and Instrument Flight Conditions” and using these definitions in its Rules and Regulations.

Visual Flight Conditions (VFC) were defined as: “Flight conditions that do not require the use of any flight instrument to maintain safe attitude, altitude and airspeed.” Instrument Flight Conditions (IFC) were defined as: “Flight conditions that require the use of any flight instrument to maintain safe attitude, altitude and airspeed.”

Transport Canada’s limitation of its definition of IFC to conditions associated with meteorological conditions is too restrictive and counterproductive to the development of more effective, all-encompassing rules and regulations. Many CFIT accidents occur when pilots inadvertently fly aircraft into the ground due to them being in (by my definition) Instrument Flight Conditions, but not realizing it.

The main issue is that these pilots cannot adequately see the ground due to low light conditions or low contrast conditions. It has nothing to do with meteorological conditions. I’ll use two examples to make my point. Both are military accidents with fully trained, instrument-rated flight crews and I use these because I am very familiar with them.

On July 7, 1988, a CH136 KIOWA Helicopter (military version of a Bell 206 Jet Ranger) was flying over a large lake near Nakusp, BC. Onboard was the pilot and one passenger. Weather that day was CAVOK. Winds were near zero resulting in a glassy water (mirror like) situation. We will never know exactly what happened, but what can be surmized is that the pilot was flying at low altitude (200 to 300 feet AGL) and failed to notice an unintended shallow descent that eventu-

ally resulted in the helicopter contacting the water and flipping over. Both occupants perished in the crash. The pilot was a friend. Was the flight in IMC – No. Could this flight have been conducted under VFR – Yes. Was the flight in IFC. By my definition – Yes. So why did the pilot not maintain a safe altitude? Why did he not recognize the dangerous flight condition he was flying in?

On October 10, 1991, a CH135 Twin Huey helicopter (military version of a Bell 212) was flying northbound near the town of Burk’s Falls, ON. Onboard were the pilot, first officer and flight engineer. The pilot directed that the flight be conducted at low altitude to avoid strong headwinds aloft. The flight was flown just before sunset over hilly terrain. As the flight progressed, a light rain shower was encountered. With the sun still very visible off to the left and all three occupants looking outside, a slight turn to the left was initiated. Unnoticed was a shallow descent that was unintended. Moments later, the helicopter flew into trees at the top of a hill. There was one fatality in the crash.

I was personally involved in investigating this crash. Was the flight in IMC – No. Could this flight have been conducted under VFR – Yes. Was this flight in IFC – by my definition, Yes. So why didn’t at least one member of the crew realize the dangerous flight conditions they had encountered and directed a transition to instruments? Both Controlled Flight into Terrain accidents could have been prevented if:

• The crews had properly identified the flight conditions in which they were flying and had verbalized this to the others;

• The crews had flown with reference to their flight instruments; and

to share the workload. In your case, the transition to relying solely on instruments must happen earlier than if there are two of you to split the task of maintaining VFR while flying like you are in IFC. Trying to use VMC and IMC to direct or control safe flight operations is too restrictive and does not consider low light or low contrast ground conditions. What is IMC in one class of airspace is VMC in another, so we cannot use these terms to define safe flight conditions. We need other terms to define these conditions.

I realize why my suggestion that any flight can be conducted without reference to any flight instrument will generate debate and this is a good thing. I am sure that my simplistic suggestion of defining conditions for safe visual flight conditions will be contested and again this is a good thing. I am not proposing changing the requirement for VFR, however, pilots need to be educated to identify IFC and be capable of operating in certain types of IFC. Maintaining basic instrument flying skills could be a life saver.

We have learned why flight conditions that require reference to instruments can happen in conditions that have no weather associated and crews must be trained to identify these and react accordingly. We need to be alert for these subtle changes that require deliberate actions.

My objective in writing this article is to generate discussion and to potentially improve your chances of surviving a phenomenon that has claimed many lives and will continue to claim lives in the future unless changes are affected. I also want to improve flight safety as it pertains to CFIT. | H

• The crews had taken proper precautions to avoid colliding with the ground/water.

If you fly single pilot then you do not have a second crew member

Ken Pothier is an Airline Transport Rated pilot for both airplanes and helicopters and a former check pilot of the RCAF.

ADVANCED COMPOSITE STRUCTURES INC.

43 Muir Road, Winnipeg, MB, R2X 2X7

Tel: 204-982-6565

Fax: 204-982-6555

Website: acs-composites.com

Email: sales@acs-composites.com

Personnel: James Anning, President; Bruce Anning, VP of Technical Operations; Slobodan Oravec, GM

AEROBRIGHAM

351 Airport Road, Bldg. 500, Decatur, TX, 76234

Tel: 940-626-4849

Website: www.aerobrigham.com

Email: david@aerobrigham.com

Personnel: David Brigham, President; Danny Brigham, Vice President; Stacy Keith, Quality Director; John Rivera, Avionics

Manager; Lewis Mallet, Maintenance Manager; Jason Wagner, Integrator

AIRWORK (NZ) LTD.

487 Airfield Road, PO Box 72-516, Papakura, Aukland, NZ, 2244

Tel: +64 9 295 2111

Website: www.airworkgroup.com

Email: sales@airworkgroup.com

BELL

3255 Bell Flight Blvd., Fort Worth, TX, 76118

Tel: 800-359-2355

Website: bellflight.com

Email: marketing@bellflight.com

CHARTRIGHT AIR GROUP

2450 Derry Road East, Hangar 3, Mississauga, ON, L5S 1B2

Tel: 905-671-4674

Toll Free: 800-595-9395

Website: www.chartright.com

Email: mro@chartright.com

CUSTOM HELICOPTERS LTD.

706 South Gate Road, Saint Andrews, MB, R1A 3P8

Tel: 204-338-7953

Fax: 204-663-5037

Toll Free: 800-782-0780

Website: www.customheli.com

Email: info@customheli.com

Personnel: Jed Hansen; President & CEO; Jude Berard; Director of Maintenance

EAGLE COPTERS LTD.

823 McTavish Road NE, Calgary AB, T2E 7G9

Tel: 403-250-7370

Website: www.eaglecopters.com

Email: sales@eaglecopters.com

Since 1988 Advanced Composite Structures (ACS) has been a world leader in Rotor Blade and Composite Structure repairs. ACS' success can be attributed to a comprehensive and ongoing research and development program resulting in new and enhanced repair procedures. ACS strives to provide customers with "Sound-SolidSolutions" and focuses on fixing problems, not symptoms. ACS provides repairs on components like helicopter rotor blades, cowlings, fairings, door and floor panels, radomes, ailerons, elevators, rudders, flaps, flight controls, engine nacelles, landing gear doors and interior panels.

AeroBrigham is a full-service maintenance and customizing facility focusing on rotorcraft and medium fixed-wing aircraft. We are located at Decatur Texas airport in a 15,000 square foot facility. We are an approved vendor for Bell, AirBus, MD, Sikorski and Air Tractor. We are also a registered DOD contracting agency, CAGE code 7SJY4. Located just west of the Dallas/Fort Worth Metroplex, AeroBrigham is conveniently located in close proximity to both Bell Helicopter and Airbus Helicopters.

Airwork is an innovative, industry-leading helicopter engineering, sales and leasing company providing in-house expertise, world-class technology and certifications within the global aviation market. Airwork is an approved service centre for Airbus, Honeywell and Breeze Eastern, with workshops for turbine and dynamic component overhaul, repairs and inspections, non-destructive testing, avionics, design and manufacturing, as well as parts supply, sales and leasing. Specific expertise includes: AS350/355 MRO capabilities; Airbus approved dynamic component overhaul, repair and inspection; SD1/SD2 conversion ST; Honeywell service centre for LTS101 engines; and Honeywell-approved LTS101 engine test cell.

For more than 80 years, Bell has been reimagining the experience of flight and where it can take us. Bell was the first to break the sound barrier and to certify a commercial helicopter. Today, Bell is defining the future of on-demand mobility. As a wholly owned subsidiary of Textron Inc., Bell has strategic locations around the globe. With nearly one quarter of its workforce having served, Bell has a passion for helping the military achieve their missions. Its breakthrough innovations deliver exceptional experiences to Bell customers with efficiency, reliably and safety at the forefront.

Chartright is a Transport Canada Approved Maintenance Organization (AMO #196-92) with an approved FAA Supplement. Chartright has maintenance facilities in Toronto and Kitchener; and is capable of performing maintenance on a wide array of fixed- and rotary-wing aircraft offering a range of services from line maintenance servicing to large inspections, avionics and structures. Chartright is an authorized Leonardo Helicopters Service Centre.

Custom Helicopters is a first-rate Maintenance, Repair and Overhaul facility located in Winnipeg, Manitoba. Custom Helicopters' services include: aircraft modifications and refurbishing; sheet metal work and structural repairs; component overhauls and repairs (transmissions, tail rotor gearboxes, freewheel units, rotor heads).

Eagle Copters is a one-stop-shop for Helicopter Maintenance. With many service offerings including but not limited to; Overhauls, new and used part sales, helicopter sales and leasing, and airframe upgrades. Since 1975, Eagle has successfully transitioned from a small family business to a global team of experts with a network of affiliates in North America, South America and Australia, with capabilities spanning multiple OEM platforms.

FLYRITE ACCESORY OVERHAULS LTD.

101 - 9615 56th Avenue NW, Edmonton, AB, T6E 0B2

Tel: 780-439-6020

Fax: 780-439-6106

Toll Free: 888-439-6020

Website: www.flyrite.ca

Email: flyrite@incentre.net

Contact: Peter Jenkins

GASTOPS LTD 1011 Polytek Street, Ottawa, ON, K1J 9J3

Tel: 613-744-3530

Fax: 613-744-8846

Website: www.gastops.com

GPMS

40 Ridge Road, Cornwall, VT, 05753-9702

Tel: 888-293-4466

Website: www.gpms-vt.com

Email: info@gpms-vt.com

Personnel: Dr. Eric Bechhoefer, CEO

HELIPRODUCTS INDUSTRIES LTD.

350 - 18799 Airport Way, Pitt Meadows BC, V3Y 2B4

Tel: 604-465-5008

Fax: 604-608-9222

Website: www.heliproducts.com

Email: info@heliproducts.com

Personnel: James Rose, General Manager; Ben Bobic, Director of Sales; Katell Nixon, Customer Support Manager

HELITRADES INC.

18 Terry Fox Drive, Vankleek Hill, ON, K0B1R0 Tel: 613-678-3027

Website: www.helitradesinc.com

Email: gerry@helitradesinc.com

HELIWELDERS CANADA LTD.

Building 47, Unit #1, 21330 56th Avenue, Langley Airport, Langley BC, V2Y 0E5

Tel: 604-530-5225

Fax: 604-530-5226

Website: www.heliwelders.com

Email: eric@heliwelders.com

Personnel: Eric Hicks, Executive V.P., Sales & Marketing

Flyrite specializes in starter generator overhauls, repairs and modifications. Flyrite works with its customers professionally and personally to help them achieve their goals of reliability and economy. Centrally located in Edmonton, Alberta, since 1997. AMO 90-97.

Gastops is the world’s leading provider of intelligent condition monitoring solutions used in aerospace, defence, energy, and industrial applications to optimize the availability, performance and safety of critical assets. It Gastops offers peace of mind to its customers with innovative online monitoring sensors, at-line analysis, complex modeling and simulation, world-class laboratory testing, engineering, design, and MRO services that predict performance to enable proactive operating decisions. Gastops has been providing powerful insights into the condition of critical equipment since 1979.

GPMS offers a next generation, predictive Health and Usage Monitoring System (HUMS) designed to give rotorcraft operators the power to “Know it before it matters.” Its flagship Foresight solution provides Machine Condition Monitoring, Rotor Track and Balance, and Helicopter Flight Data Monitoring in one powerful system. Fully predictive, Foresight offers insights needed to optimize maintenance, safety and operations. GPMS has reduce kit weight and service cost to put the advantages of HUMS within reach of every operator, making all helicopters smarter and more connected.

Heliproducts is a full-service MRO provider offering industry-leading helicopter maintenance, modification and inspection services. Heliproducts has state-of-the-art paint and refinishing capabilities in addition to component repair, avionics, engine, sheet metal and composite repair support. Heliproducts is a Safran approved CDC, available for any engine related support, along with spares and a full-time engine maintenance shop. Heliproducts holds Transport Canada, FAA and EASA approvals.

With three locations across Canada, Helitrades has been proving quality workmanship and outstanding customer service to the aviation industry for more than 40 years. The Helitrades Vankleek Hill, ON, facility is a Bell approved Customer Service Facility for Structural Repair, Field Maintenance and Dynamic Component repair/overhaul. Both of the Helitrades locations in Ontario are Authorized Service Centers for Robinson Helicopters. Helitrades is also a Woodward HRT approved Licensed Repair Facility in North America for the hydraulic component repair/ overhaul.

Heliwelders is a Transport Canada, FAA, & EASA regulatory approved facility. In addition, it is a fully authorized Airbus D-Level maintenance facility. Heliwelders carries out maintenance, structural repairs, composite repair, avionics, and paint for Airbus, Sikorsky and Bell aircraft. Heliwelders specializes in major inspections and structural repairs to Airbus AS350/H125, AS355, EC130/H130, Bell 205, 206, 212, 412, and 407, Sikorsky S61 and S92 helicopters. This includes full Interior refurbishments and in-house paint capabilities. Heliwelders is also an OEM approved Safran Certified Maintenance Center (CMC) for Arriel & Arrius Level 1&2 engine support. Its wholly owned subsidiary, Nampa Valley Helicopters, located in Meridian, Idaho, is a fully authorized Airbus D-Level AS350/H125, AS355, and EC130/ H130 Dynamic Component overhaul facility. Nampa carries a large inventory of rental and exchange Airbus Dynamic Components to support the global helicopter markets, including Canada.

IMP AEROSPACE & DEFENCE

693 Barnes Road, Enfield, NS, B2T IK3

Tel: 902-873-2250

Fax: 902-873-2249

Website: www.impaad.com

Email: info@impaad.com

Personnel: Jason Kenny, jason.kenny@ impaad.com; Rick Renard, rick.renard@ impaad.com

NAMPA VALLEY HELICOPTERS INC.

1870 West Franklin Road, Meridian, ID, 83642

Tel: 208-362-0851

Fax: 208-362-9726

Website: www.nvhelicopters.com

Email: chris@nvhelicopters.com

Personnel: Chris Rekemeyer, Manager, Support & Services; Eric Hicks, E.V.P., Sales & Marketing

ROTORCRAFT SUPPORT INC.

67 D Street, Fillmore, CA, 93015

Tel: 818-997-7667

Fax: 818-997-1513

Website: www.rotorcraftsupport.com

Email: sales@rotorcraftsupport.com

Personnel: Phillip Difiore, President & Director of Maintenance; Jeffrey Teubner, Vice President Quality & Technical Operations; Veronica lozano, Sales Representative; Chris Cancelosi, Sales Representative; Keys Miller, Business Development

SELECT HELICOPTER SERVICES LTD.

105-151 Commercial Drive, Kelowna BC, V1X 7W2

Tel: 250-765-3317

Website: selecthelicopter.com

Email: info@selecthelicopter.com

Personnel: Marty Luksts, General Manager / PRM; Dana Washington, Quality Assurance Manager; Dell Luksts, Production Manager; Jeff Havard, Stores Manager

STANDARDAERO

33 Allen Dyne Road, Winnipeg, MB, R3H 1A1

Tel: 204-318-7544

Website: www.standardaero.com

Email: helicopters@standardaero.com

Personnel: Brian Hughes, Vice President of Sales and Marketing

A global leader in military, missionized and commercial aircraft IMP Aerospace is one of Canada's largest aerospace and defence organizations, as well as a Platinum member of Canada’s Best Managed Companies. Solving complex issues facing your fleet, IMP Aerospace has earned its distinction as a trusted partner around the world; providing world-leading capabilities within engineering solution, maintenance, product manufacturing, integration and training. Specifically illustrated by its CSH SAR In Service Support (ISS) Program, IMP Aerospace services as the prime contractor to Canada's fleet of Cormorant Search and Rescue CH-149 helicopters, providing all aspects of support to this critical fleet. With over 2,400 engineering and technical support staff at operations across Canada, IMP Aerospace focuses on delivering solutions across the space, air, land and sea sectors.

Nampa Valley Helicopters (NVH) is a wholly owned subsidiary of Heliwelders Canada. NVH is a fully authorized Airbus D-Level MRO facility, specializing in the repair and overhaul of the Airbus AS350/H125, AS355 and EC130/ H130 Series Dynamic Components. NVH also carries a large inventory of rental and exchange components to support its global customers. NVH provides Servo Exchanges. Heliwelders Canada is also a Safran Approved Arriel, and Arrius Certified Maintenance Center. NVH certifications include FAA, and EASA regulatory approvals.

Rotorcraft Support is a full-service MRO provider located in Fillmore, California. Founded in 1986, Rotorcraft Support has built a reputation for excellence, reliability and safety. It is an FAA and EASA Certified Part 145 Repair Station, an authorized service centre and a parts distributor for OEMs including; Airbus, Bell, Enstrom, Leonardo, MD Helicopters, Robinson, Safran Helicopter Engines, Scott's Bell 47, and Sikorsky. Services include: maintenance, repairs, avionics installations, OEM parts, aftermarket equipment, upgrades, refurbishment and completion, component overhaul and exchanges, structural repair, non-destructive testing, aircraft shipping and DAR import and export. RSI Heliport CN67, Frequency 123.075. Certifications: FAA: YT2R331L, EASA 145.5629

Select Helicopter specializes in the overhaul and maintenance of hydraulic components and cargo hooks. Support provided for components installed on Bell 204, 205, 206, 206L, 212, 214, 407, 412, 427, UH-1 and Airbus H125 (AS350), AS355; and cargo hooks manufactured by Onboard Systems, Dart Aerospace, Cargo Aids and Mechanical Specialties. As a Transport Canada AMO and EASA Part-145 Repair Station, Select provides support to a global customer base, focusing on lasting quality and value.

Founded in 1911, StandardAero has become one of the world aerospace industry’s largest independent MRO providers. Through the synergistic merger of businesses with complementary specialties, that have exponentially increased its capabilities and customer commitment, StandardAero offers extensive MRO services and custom solutions for business aviation, commercial aviation, military, and industrial power customers. Nearly 6,600 professional, administrative and technical employees work in 55+ facilities worldwide, with additional strategically located regional service and support centres, as well as mobile service teams all across the globe. The StandardAero Helicopters Business Unit holds major OEM licenses for Airbus, General Electric, Pratt & Whitney Canada, Rolls-Royce, Safran and Sikorsky. Its capabilities include helicopter engine and airframe maintenance, repair and overhaul, engine component repair, dynamic component repair, engineering services, STC development, interior completions and paint applications.

VIH AEROSPACE INC.

1962 Canso Road, North Saanich, BC, V8L 5V5

Tel: 250-656-3987

Fax: 250-655-6861

Website: www.vihaerospace.com

Email: vih@vih.com

Personnel: Arne Arneson, General Manager; Ian Teschke, Director of Maintenance; Brian Thistle, Director, Business Development, Sales & Marketing; Marc Leduc, MRO Sales Manager

USA BORESCOPES

2061 Bearden Road, Clarksville, TN, 37043

Tel: 931-362-3304

Fax: USA BORESCOPES

Toll Free: 931-362-3304

Website: usaborescopes.com

Email: bill@usaborescopes.com

Personnel: Mike Costello

VIH Aerospace offers top quality, value-enhanced helicopter maintenance, manufacturing, repair and overhaul (MMRO) services; including STC development and integrations, delivered effectively and professionally to meet or exceed Original Equipment Manufacturer (OEM) specifications. VIH Aerospace is a Bell approved Customer Service Facility (CSF).

USA Borescopes is a global supplier of world class remote visual inspection equipment. It offers a wide selection of borescopes and videoscope systems that are designed for today'ss aviation, rotorcraft and aerospace professionals.In addition, USA Borescopes can perform borescope repairs on any make or model borescope with free repair estimates. All work is guaranteed to meet OEM standards.

arly on the morning of March 15, 2021 a privately operated drone took an unauthorized 11-minute flight just north of the airfield at Ottawa International Airport (YOW). The same drone flew 24 flights during March, including flights close to the Civic Hospital Air Ambulance Helipad, the CHEO Helipad and Parliament Hill. “We know what type of drone it was, its unique ID number, its flight time, flight path and its maximum altitude,” says Michael Beaudette, YOW’s VP of Security, Emergency Management and Customer Transportation. “It should not have been flying in any of those locations and in doing so, was in violation of Transport Canada regulations.” Beaudette is leading a pioneering drone detection pilot program at YOW in partnership with InDro Robotics, QinetiQ and NAV Canada. The results to date have been eye-opening.

The issue of drones operating near airports gained international attention in late 2018, when they were spotted flying near Gatwick Airport in the UK. The airport ended up suspending more than 1,000 flights impacting 140,000 travellers. That incident led to the formation of a Blue Ribbon Task Force, which included YOW’s President and CEO Mark Laroche, with a report released by the task force in October 2019.

There are now two types of technology being demonstrated in YOW’s drone detection pilot program: radio frequency (RF) detection and micro Doppler radar. RF drone detection is provided by InDro Robotics and Remote Sensing. InDro installed an RF receiver station on the roof of the passenger terminal building that can detect drones operating on 2.4 and

“In March of this year, the InDro system detected 1,626 flights within the 15-kilometre zone, including 64 flights that occurred at night,” reports Beaudette. “The totals were up significantly over January, as the weather got warmer and people decided to take their drones out for a fly.”

The second technology being demonstrated as part of the program is a micro Doppler radar solution called Obsidian from QinetiQ. Obsidian uses millimetric wave radar – 9-12 ghz – to detect the movement of the small spinning propellers on a drone flying anywhere within two kilometres of the airport.

Precisely what actions should be taken when a drone is detected flying where it shouldn’t is also part of the program. “As part of this project, we’ve been conducting tabletop exercises with our partners at NAV Canada, Transport Canada, airlines, emergency services and law enforcement,” says Beaudette. “Developing appropriate response protocols and responsibilities ultimately has to be part of the solution.”

NAV Canada, which owns and operates Canada’s civil air navigation system welcomes the collaboration. “Drone use across Canada continues to expand at a significant pace and NAV Canada is taking a proactive approach to ensure the safety of our skies for both traditional aviation and new entrants. We welcome collaboration with partners like the Ottawa International Airport as our industry continues to push forward on drone safety initiatives,” says Alan Chapman, Director of RPAS Traffic Management at NAV Canada.

Our system interrogates each device to gain more information to pin down GPS point X, Y and Z.

5.8 ghz within a 15-kilometre radius.

“Our system interrogates each device to gain more information to pin down GPS point X, Y and Z – Z being important, as we want to know how high the device is flying,” explains Philip Reece, CEO of InDro Robotics. “We can also determine the make and size of the device, which helps determine what kind of threat it may pose. For example, a small, slow moving drone that’s far away is less of a threat than a large drone on an airport flight path.” The InDro system includes a user interface that provides real-time and consolidated historical reports, including drone ID numbers in most cases.

For their part, pilots are justifiably wary of drones and welcome the detection demonstration pilot program at YOW. “There is no equipment onboard any aircraft, fixed or rotor, that is capable of detecting a drone in flight,” says Greg Hulme, Chief Pilot, Rotor Wing, with Ornge Air Ambulance. “The consequences of a mid-air collision with a drone range anywhere from damage to our aircraft, injury to our crew, injury to persons or property on the ground. In a catastrophic collision it is not unreasonable to assume that there could be a loss of crew, patient and aircraft.”

YOW’s Mark Laroche says the purpose of the program is neither to shame drone operators nor scare the public. “The vast majority of drone operators aren’t out there trying to disrupt aviation nor threaten aircraft,” explains Laroche. “But we need to know where they are and, if they do pose a threat, be ready to take the appropriate action that we as an airport can take to ensure safety.” The ground-breaking program will continue at YOW through to the end of 2021. | H

Krista Kealey is the Vice President of Communications and Public Affairs with the Ottawa International Airport Authority.

All major energy stakeholders are implementing ambitious sustainability plans to manage the energy transition with Green House Gas emission reduction playing a huge role.

Leonardo’s AWFamily product portfolio – AW169, AW139 and AW189 – while providing the advantage of a common design philosophy, embeds sustainability to the benefit of the global climate policy. Carbon emissions are minimised versus payload available and the aircraft feature up to 70% recycled materials.

Inspired by the vision, curiosity and creativity of the great master inventor –Leonardo is designing the technology of tomorrow.

Times may be challenging, but you can rely on our dedicated team to ensure every one of the countless individuals who depend on us, can rise to that challenge. Because the best air support deserves the best ground support. Our dedication, expertise and determination have contributed to over 100 million hours in the air. And it’s this commitment to teamwork, that makes the team work.

Partnerships. We make it fl y.