Designed for large or small applications, Franklin Electric offers innovative drive and control options that require minimal adjustments for simple installation and operation. From providing constant pressure for residential well systems to moving mass volumes of water, trust Franklin for your residential, agricultural, commercial, and municipal water pumping system needs. Pumps, motors, and electronics – all from one reliable source.

Experience Quality. Experience Franklin.

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

Managing Editor | Laura Aiken laiken@annexweb.com (416) 522-1595

Editor | Colleen Cross ccross@annexweb.com (519) 428-3471

Sales Manager | Ed Cosman ecosman@annexweb.com (519) 429-5199, (888) 599-2228, ext 276

Account Coordinator | Barb Comer bcomer@annexweb.com (519) 429-5176, (888) 599-2228,

Media Designer | Brooke Shaw bshaw@annexweb.com

Group Publisher | Martin McAnulty mmcanulty@annexweb.com

Director of Soul/COO | Sue Fredericks

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@groundwatercanada.

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. 0383-7920

Circulation

subscribe@groundwatercanada.com Tel: 416-442-5600 ext. 3543 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada - 1 Year $42.00 (plus 5% GST - $44.10)

U.S.A. - 1 Year $60.00

Occasionally, Ground Water Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Serving the Canadian Ground Water industry for 43 years.

10 SPREADING THE GOOD AROUND

Strong customer focus works for Conrad Well Drilling of Parry Sound, Ont. 14 THE APPRENTICESHIP ROUTE

Can these programs help protect the ground water industry and secure its future? 20 WHAT CUSTOMERS WANT

Experience and education are keys to satisfaction, say educators, drillers and customers

Well owners can soon get loans to remedy dry wells in southwestern Nova Scotia

Some residents in southwestern Nova Scotia who suffered through a drought in the summer of 2016 will soon be eligible for a government loan through their municipality to improve their home’s water supply. CBC News reports.

Pilot project explores ground water banking

A pilot project involving central California agricultural water agencies will explore the feasibility of storing water supplies in shallow underground basins from which the agencies may pump water to recharge the aquifer. WestsideConnect.com reports.

www.groundwatercanada.com

by Colleen Cross

@GroundWaterMag

facebook/groundwatercanada

Are you having trouble finding a few good people? It’s no secret that many of Canada’s trades need an injection of qualified and motivated workers. The ground water industry is no different. Water-well contractors, pump installers, geotechnical and geothermal drillers, and hydrogeology firms alike all need good, committed employees with can-do attitudes.

Where is the next generation coming from? Many of you employ your children and other family members. It’s easy to see this is very much a familyfocused industry – and all the richer for it.

The next logical place to look is to the schools that feed the industry such as Fleming College’s resources drilling and blasting program in Ontario and Red Deer College’s water well driller apprenticeship program in Alberta.

It’s also becoming more and more important to look outside your circle for good candidates, for example, to make a concerted effort to hire more female and Indigenous candidates or mid-career workers who are mulling options for retraining.

Too often, Canadian water-well drilling businesses compete with oil and gas or with U.S. companies for drilling prospects. In the larger picture, they compete for talent with a host of other better-known trades and professions – among them construction, plumbing and fire fighting.

What the ground water industry does is very specialized and not widely known among the general public. That’s why it is vital to raise awareness of the essential services you provide.

That is no small task. It’s a hurdle we in trade publications share to some degree: we too provide a specialized service to customers – in our case, our readers, who require information, resources and industry connections. We are writing for the industry but we keep in mind the wider public by doing things like making our website easy to find and reaching out to related industries. It’s part of what we call branding, which is just a fancy word for making sure people know who we are, what we do and where to find us.

Water-well drillers need to do this too – and then some! You already educate well owners about their

responsibilities, about what contractors do and what cost pressures are behind the prices they set.

The time has come for ground water to get out there in the public eye. It’s important to pay competitive wages, provide great benefits packages, earn a reputation for safety, be a committed mentor and help new recruits develop their skills. But in the long run, the only way to grow your talent pool is to build the ground water brand.

Finding good staff is not only a labour but also a public relations problem to solve. And if there’s one thing well drillers excel at, it’s solving problems!

As a service business, you know your stuff. But do you know how to market yourself and your industry? There are many ways to get out there in the community. Contact high school guidance counsellors and offer to visit a classroom to talk about your work, help with a children’s festival, provide education on your website and attend job fairs in your community.

Here’s another one: Craft an effective press release – perhaps during Ground Water Awareness Week in March – that tells people what your company does, how the ground water industry is unlike any other, the differences between town and rural well systems and how they can help protect the ground water. (A template is available on our website’s Ground Water Awareness Week page.)

Go one step further and send that release to your local newspaper, radio or TV station, and community magazine. Trust me, editors love an announcement that tells a good story – a tricky job or an overly exuberant artesian well you got under control – and gets to the point.

Above all, support your provincial association, attend the events they plan for your benefit and stay informed about the national association now under development. Only with your support can these organizations amplify your voice to the public, to the government, and beyond.

NEXT ISSUE: The next issue of Ground Water Canada will focus on pumps and pump tech.

Don’t miss it!

A University of Waterloo study suggests that if a major fall flood were to occur in Canada, the financial costs of flooding in rural and urban areas would be 29 and 38 per cent lower, respectively, with wetlands in their natural state versus being lost due to development.

Leaving wetlands in their natural state could reduce the financial costs of flooding by nearly 40 per cent, according to a recent report from the University of Waterloo.

Researchers at Waterloo’s Intact Centre on Climate Adaptation, found that avoiding wetland loss could lead to substantial savings for Canadian communities that experience flooding. In compiling the report, researchers compared the financial costs of a major flood event in urban and rural areas, where wetlands were left in their natural state, versus where a computer model simulated wetlands loss.

The modelling showed that if a major fall flood were to occur, the financial costs of flooding in rural and urban areas would be 29 and 38 per cent lower, respectively, with wetlands in their natural state versus being lost due to development, the centre said in a news release.

“With the flooding events in recent history, it has become clear that the human and financial costs of these events are substantial,” said Prof. Blair Feltmate, the head of the centre and one of the report’s authors. “With the everincreasing financial burden of flooding to Canadians, it is remarkable that a practical and cost-effective means to alleviate flood risk is readily available – that is, simply leave natural wetlands natural.”

The researchers used two locations in Ontario – one rural and one urban – where flood damage costs avoided were calculated using average historic insurance claims data and provincial flood damage estimates from Ontario and Alberta. These flood damage costs estimates took into account the costs of damages to building structures and their contents.

The Ontario Ministry of Natural Resources and Forestry and Ducks Unlimited Canada funded the report.

The Ontario Ground Water Association will host its first golf tournament to raise funds for scholarship awards for graduates of Fleming College’s resources drilling and blasting program.

The OGWA’s aim is to raise funds that can be held in an interest-earning account to be dispersed each year to the recipients at its annual convention.

“It is important to recognize the academic achievements, year to year, of deserving students and welcome them into the ground water community,” said Paul Conrad of the association’s board of directors.

The event will be held at the Elmira Golf Club in Elmira, Ont., on Friday, Sept. 29. Check-in time is 12 noon followed by a shotgun start at 1 p.m. followed by a prime rib and chicken cordon bleu dinner.

Those wishing to join in this day of fun and fundraising can contact Anne Gammage through the OGWA website (www.ogwa.ca) or call 519-245-7194.

If you can’t attend, you can still help support the industry’s next generation by making a donation through the association. Funds earmarked for the scholarship will be set aside for this purpose.

On July 14, Friesen Drillers held an open house to celebrate its 125th birthday. The family business has seen many changes since C.K. Friesen sunk his first well back in 1892. Friesen Drillers is owned and operated by the fourth generation of the Friesen family with the fifth generation already out in the field.

The company’s headquarters in Steinbach, Man., opened the doors of its private museum to host customers, dignitaries, vendors and the public. Inside the company’s showroom are original 1900 Chapman Drill Rig 4, one of the first motorized rigs; its 1936 Chevrolet pickup; older

gas pumps; as well as different sizes and shapes of drill bits. A blacksmith shop representing founder C.K. Friesen’s original trade was on display, as well as ground water finding equipment.

About 20 people work at the company and it has three branches in addition to Steinbach: Andrew and Sons in Saskatchewan, Paddock Drilling in Brandon, Man., and Mel’s Wells in Ontario. Sister and brother Kim and Jason Friesen head up the business.

We congratulate Friesens on more than a century of success!

The compact CME-55LCX features a new 130 horsepower diesel engine and can crank out up to 12,100 foot-pounds of rotary torque. That’s more than any other drill in its class.

Equipped with the standard 20’ or optional 22’ mast, it’s perfect for typical everyday operations. But on jobs where overhead clearance gets tight, the CME-55LCX can quickly transform to low clearance mode. The overall set-up height when mounted on the CME-300 tracked carrier, is then reduced to 12’1”. Low clearance sheaves allow full use of the hoist lines.

That means you can take on jobs under service station canopies, bridges, or other overhead restrictions that others can’t.

The CME-55LCX is available with many options to help get the job done as efficiently as possible. It can be equipped with slide bases, auger racks, toolboxes, hydraulic rod holder/ breakout wrench systems, and more.

The optional automatic SPT hammer even has a secondary lifting system for low clearance situations.

The CME-55LCX and the CME-300 remote controlled tracked carrier make an excellent team. Since the CME-300 is designed specifically for carrying CME drill rigs, there are no compromises. It has the best center of gravity for both mobility and drilling. You won’t find a more rugged carrier in its class. And since the rubber tracks will not damage most pavement, you can also use this rig anywhere you might use a truck-mounted drill.

Give us a call and find out how the new high-torque CME-55LCX low clearance drill can give you more power and more versatility for more production.

A group of seven cyclists rode 1,100 kilometres through the Rocky Mountains, their only access to water being the fresh water sources they found on their route.

The fundraising challenge was run by Calgary charity Wheels for Wells. The seven cyclists rode from Vancouver to Calgary in late July with the goal of raising awareness and funds for a World Vision Canada water project in Somalia.

“In Canada we are lucky, we have access to an abundance of water. The number 1 point of this ride is to create awareness of global communities that do not. We wanted to do something disruptive that will cause people to think about water and have the critical conversations about global water issues,” ride director David Custer said in a news release. By drinking only from the streams and rivers they find along the way, Custer said he and the

team wanted to start the conversation by showing how easy it is to access clean water here in Canada.

Wheels for Wells was founded five years ago by Alex Weber, now 15, who said, “My dream is for all the world to have clean water. It is not an unrealistic dream.”

The team had a few setbacks such as a shortage of water, minor crash and mechanical difficulties, said Jennifer Miller, communications co-ordinator for World Vision. You can follow their ride through their facebook page at https://www.facebook.com/ wheelsforwellsproject/.

This year’s tour raised $16,792 and Wheels for Wells through other activities has raised more than $30,000 this year, Miller said. It has raised more than $180,000 in the last five years to support water programs in Kenya, Somalia, Sudan and Mauritania.

Ken Fyfe of Fyfe Well Drilling in Qualicum Beach, B.C., has worn many hats during some 43 years as a water-well driller. Fyfe shared with Ground Water Canada photos of his recently restored steam drill rig made by Keystone Company in Beaver Falls, Penn.

He bought the Keystone cable tool, or churn drill, from the Swanson family on a creek off Dease Lake near the B.C.-Yukon Territory border in 2015, which he says was a major stop for miners travelling to the gold rush in Cassiar. The rig was buried deep in the brush and the family helped him retrieve it. He hauled it home by trailer and the rest is, literally, history. It took him and his team two years to restore the machine.

Fyfe is a trained steam engineer who also has worked as a welder, machinist, logger and inventor – as showcased on the company’s website – seems uniquely qualified to lead the restoration.

“It was a pretty straightforward job,” he says, with help from friends Les Stevens, Mike Hobson and Russ McCoy. “These guys played a big part in the restoration of that machine. The engine for the machine had been removed years before and I tracked it down to a place called Jade City100 miles further north. Norm and Shirley Vickery still had it. I was able to talk them out of it as they liked the idea of the restoration of the drill rig.”

Fyfe showed off the bright red beauty to the Industrial Heritage Society in Port Alberni, of which he is a member. He believes it is the only operating steam drill in Canada but says it is entirely possible there are others out there “in someone’s boneyard.” He encourages other collectors to come forward and share their stories.

The steam drill was designed for sampling, the same

technology used in mining. “A lot of youngsters have never had a chance to see something like this,” he says. “With old technology, it’s all turned inside out. You can see everything.”

Fyfe says readers who like the older technology may want to visit the Facebook page “Rotary and cable tool drill rig pictorial history” to check out vintage equipment and to share their own projects and experiences. To see before-and-after photos, visit www.groundwatercanada. com. If you have photos of vintage equipment, a restoration project or tales of the old days you’d like to share, email editor Colleen Cross at ccross@annexweb.com or call her at 519-428-3471, ext. 261.

Paul Conrad has built his business – and his life – around a simple concept: treat others the way you want to be treated and that good will come back to you. It’s a karmic perspective that influences everything he does, from the wells he drills and the service he offers, to how sees his role in the protection of ground water, and how he works with other businesses and people in his community.

by CAROLYN CAMILLERI

Paul Conrad and his grandfather, Howard Conrad, and father, Al Conrad, pose for a rare three-generation photo. It was Howard’s first time out to see the drill rig his grandson had bought.

To explain, he talks about a big storm that hit the Parry Sound area one Friday in July.

“They had to evacuate the provincial park, and the people camping must have had one heck of a scare: trees came down that crushed their trailers and tents,” Conrad says. “People around here took those people in.”

“You see it more and more of people around here, and that kind of good spreads: you help people out and it comes back to you.”

People helped Conrad when he got started in 1996. After he graduated from the blasting

and drilling program at Sir Sandford Fleming College, he drilled a few wells with Roy Lang of Lang Well Drilling in Hillsburgh, Ont.

“Roy is a very nice guy – he and his wife are both lovely people,” Conrad says.

Conrad then answered an ad for a job with Eckerson Well Drilling in Milton, N.Y.

“Eckerson had a well driller who drilled all the wells but was getting older,” he says.

That “old driller” was Ron Bank Sr. His son, Jim Eckerson Jr., looked after pumps and water treatment.

Conrad, who has been on the Ontario Ground Water Association board since 2013, says one of the things he likes about being involved with industry associations is that issues get discussed and knowledge is shared, for example, around regulations and why they are important in protecting ground water.

“We have to be good stewards, and if we’re not, we won’t have jobs. We won’t have water either,” he says, adding that it’s better for everyone if everyone does a good job.

“I may get accused of being finicky, but everything’s in order and you can definitely tell on my jobs that it was me that did it, because they almost all look the same. Sometimes it comes from the right-hand side feeding water and other times from the left, but it’s an exact same looking pump job in the end.”

That’s how his customers like it. “Customers want to know that everything’s being done correctly,” Conrad says. “Years ago, people might not have known a lot about regulations, but they’re researching it now. The internet has all the answers they want. They want to do it right.”

Conrad has had customers ask him if he will be grouting, for example. He likes to take time to explain a little of what he is doing to help them make sense of it all.

“They’re inquisitive, and they want to know about their water source. They want to know how to protect it,” he says. “But the end result for me is to give everyone a well like I would drill for myself.”

Doing that keeps Conrad very busy. He has an assistant – a woman who is newly graduated from Fleming College –but because he holds the licence he has to be at every job site.

“It was at Eckerson that I learned a great deal about water wells, pump systems and water treatment. You go to college and you do learn, but once you’re out there every day doing it, you’re retaining a lot more.”

Conrad learned the job, and he also learned about the industry. “Jim encouraged participation within the industry associations, and soon I was going to events with him and becoming

involved in their associations,” Conrad says. “I joined the National Ground Water Association and started taking examinations for certification.”

When Conrad returned to Canada several years later, he started Conrad Well Drilling, a business he runs with his family to serve the Parry Sound, Muskoka and Georgian Bay area. On March 29, 2017, they celebrated 10 years in business.

“I like to oversee every job, but I’d love to find licensed well drillers who could take over some of this. There’s enough work where I’m just running around and trying to meet people and set up jobs, looking at what’s required and ordering the materials. Then there’s the drilling and the pumps and whatever else, plus the phone calls. I get pretty busy, but I know I’m very lucky.”

Asked for tips for other drilling companies, Conrad says make sure you

Continued on page 28

Can these programs help protect the ground water industry and secure its future?

John Larson started in the well drilling industry in 1973, when he was 18 years old. Once he had his apprenticeship ticket and had worked for a while, he started Larson’s Water Well Drilling and Servicing out of Lougheed, Alta.

by CAROLYN CAMILLERI

The business celebrated 40 years on May 31. He’s held a number of positions in his community – on town council and as mayor – and was on the board of the Alberta Water Well Drilling Association for 16 years. He’s retired from all that now, but he does keep one foot firmly in the industry: teaching the apprenticeship program at Red Deer College.

Red Deer College offers a two-year well driller program. Classes generally have 12 students at a time – most of them younger guys, he says – but some older, and two or three women over the years.

“Each year, they have to have 1,800 hours of field experience to come to school, with a total to get their apprenticeship ticket of 3,600 hours in the field,” Larson says. Classroom time is 180 hours each year.

“We say that what I teach in class is probably 20 per cent of what they need to know. Eighty per cent in the field is kind of our ideal,” he says. “I teach basically the tip of the iceberg.”

But it is a valuable tip of the iceberg.

“That’s why they like having somebody that actually has been out there doing it, because

you can ask questions, and you can get some good discussions going,” Larson says. “The bigger the class, the better discussions you get.”

“I love doing it. I never thought I would end up doing something like this. This fall will be my ninth year,” he says, adding that the well driller who taught the program before him was there for 16 years.

Darcy Schmidt of Darcy’s Drilling Services, in Alberta’s Ponoka and Drayton Valley area, also started in the industry at a young age with his father. In 1978, he was in the very first apprenticeship program offered at Red Deer College.

“For me, it was invaluable. You learned from the people you went to school with, plus you had instruction, and you learned different ways to do things and not just the one standard way you’d been taught from your dad or your boss,” Schmidt says.

The program offers apprentices some attractive benefits. “One of the things they came out with here couple of years ago is you can have any kind of trade certificate in Alberta – a plumber, electrician, or water

Blistering speed. 70% less mess. Unique capabilities not found anywhere else. Picture a sonic drill in your future!

• Drill 3-5x faster using water or air, depending on conditions

• Drill, case, loop and grout in one step for geothermal projects

• Continuous core samples to 300 ft. for environmental investigations

• Various rig models and sizes available to suit your business needs

combines water level, temperature and conductivity sensors in one compact device.

• 4-electrode platinum conductivity sensor

• Autoranging 50 to 80,000 µS

• Hastelloy pressure sensor

• Ranges 5m - 200m

• Titanium ceramic PVD coating

• Memory for 27,000 sets of readings

• 8 year battery

ECO-SAFE™ Nonmetallic Thread Compound is a premium quality compound containing carbon based fibers and additives and other natural extreme pressure and anti-wear agents. These components are blended into JET-LUBE’s high temperature calcium complex base grease. The base grease offers the additional advantage of superior adhesion to wet steel surfaces, resistance to water wash-off and most drilling fluids. ECO-SAFE is especially effective for invert or high-pH drilling fluids.

ECO-SAFE carries the NSF 61 Standard certification and is approved for all down-hole applications and contact with potable water. Also, excellent for stainless steel pump connections.

• Rated: -20˚F (-29˚C) to 500˚F (260˚C)

• Excellent performance on high-chrome or nickel alloys

• Contains no metals

• NSF H2 Registered • Non-toxic

High film strength

High frictional properties

NSF 61 Standard Approved

well driller, or whatever – and there’s a program at NAIT [Northern Alberta Institute of Technology] that’s called the Trades to Degree program. You can take your trade certificate and go to NAIT and start third-year business with it,” Larson says.

That flexibility makes the program attractive to students, especially if they are concerned about job stability. Another benefit for a registered apprentice is if they are injured on the job and can no longer do that job, they can be retrained in another trade.

Larson says Alberta’s well-drilling industry is relatively small, and many of the companies are mom-and-pop operations with second, third and fourth generations.

“There are probably a couple hundred of us in Alberta, and I know most of them,” Larson says. “I think most people are doing alright as far as getting staff, and our classes have been fairly full or overfull, so that’s a good sign.”

Businesses also benefit from apprenticeship programs. Sarah WattsRynard, executive director of the Canadian Apprenticeship Forum, says the latest Canadian Apprenticeship Forum research (2011) showed that for every dollar an employer spends on hiring an apprentice, they receive an average return of $1.47. This is based on research with 1,000 skilled trades employers who actively hire and train apprentices, Watts-Rynard adds. Costs considered included wages,

benefits, administration, journeyperson oversight, materials and waste.

“We also asked about productivity measures, such as charge-out rates or time savings when a journeyperson has assistance with complex tasks,” she says. “Many employers also take advantage of tax credits and/or wage subsidies to offset the cost of training.”

“Across most of the 21 trades we studied, apprentices were generating a positive net return by the end of their second year.”

“Many employers take advantage of tax credits and/or wage subsidies to offset the cost of training.” –Sarah Watts-Rynard

Larson points to the Government of Alberta’s Trade Secrets website (http://tradesecrets.alberta.ca) for more information about benefits to businesses, but says one of the best reasons to hire an apprentice is the apprentice. Motivation to work is high and an apprentice comes with some good foundational knowledge they’ve learned in the classroom: welding, mechanics and hydraulics, as well as

drilling and different kinds of rigs. In the second year, they learn well construction and development.

“The skill level the guys have when they come out of the program – they haven’t picked up all the bad habits that people who have never gone to school can pick up,” Schmidt says. “So the drilling industry has gotten way better here since the apprenticeship program started.”

Perhaps, too, people who have been through the program and understand the benefits look to support it when they are hiring.

“Employers often say apprenticeship is a ‘no-brainer’ for their business,” Watts-Rynard says. “In many cases, they were an apprentice themselves and feel as though this is an important part of paying it forward to the next generation.”

After all, it is a source of staff that have learned the same way you have. Schmidt says one of the biggest pluses of the program is that it gives companies a broad base for hiring employees who want to have journeyman status.

Larson concurs. “It’s good to have an apprentice out on the job site, for sure. Either you’re supervised or you’re unsupervised, and once you’ve got your ticket, then you don’t have to have anybody supervising you,” he says. “Once they’re there, they usually stay –a lot of them do anyways.”

In Alberta, the competition well-

drilling companies have in attracting employees is the oil field.

“It’s always about the oil field,” Larson says. “It gets tough to compete with wages, because [workers] can go to the oil field and make $40 an hour or even $50, and we’re probably at $30, give or take. Some are maybe less than that. It’s hard to get long-term employees who want to commit.”

While the pay may be good in the oil field, the jobs aren’t always long-term.

“Some [employees] don’t think too far ahead,” Larson says. “It’s a lot better now than it used to be because, after the last crash with oil prices, I think a lot of them have figured that one out. We’ll see what happens.”

At Darcy’s Drilling, Schmidt works with three of his four children. Two of them, his son Michael Schmidt and his daughter Cara Riske, have completed the RDC Water Well Driller Program.

“My experience was really good at RDC. I got to learn quite a bit,” says Riske, who completed the program in 2011.

“John [Larson] is a really good teacher, and we got to do some handson stuff,” she says, adding that classes aren’t always in the classroom and

include going out to rigs and meeting drillers on site.

As a woman in the industry, Riske has found the experience positive.

“I love it because I grew up with it with my dad, and when we were little, he would take us out on calls,” Riske says. “And I love being outdoors.”

Although she has her ticket, she doesn’t do a lot of the drilling but instead focuses on service work.

“Most people are just amazed that a woman is coming out and able to troubleshoot and figure out what’s wrong,” she says, adding that she definitely encourages more women to get into the industry.

Watts-Rynard says there is certainly a lot of interest in a more diverse skilledtrades workforce.

“I think employers and unions are making an effort to look beyond their traditional workforce to be more inclusive, and it makes good business sense to do so,” she says. “Employees with differing experiences and

backgrounds think differently and solve problems in new ways, opening the door to new processes and innovations that might otherwise not have occurred.”

In 2015, only 13.7 per cent of newly registering apprentices were women, compared to 11 per cent in 2005.

“Most women enter trades that are female-dominated – early childhood educator and hairstylist, for example,” Watts-Rynard says. “When you look at industrial and construction trades, women generally fall below the five per cent mark.”

Other diverse groups are in similar circumstances: 8.7 per cent immigrants, 8.2 per cent visible minorities, and 6.3 per cent Indigenous.

“There has definitely been progress, and I get a strong sense the desire is there to make continued improvements, but change has been slow and there’s still a long way to go,” Watts-Rynard says.

For the view from B.C. and Ontario, see our Winter issue.

You provide high-quality wells and servicing, but are you meeting your customers’ less tangible need for information and peace of mind? We spoke with a ground water educator, established drilling companies and a satisfied would-be customer to get insight into what constitutes great customer service.

Ken Williamson, of Red Deer, Alta., has had his share of face time with well owners. Williamson, a retired farm and water specialist with Alberta Agriculture and Forestry, has helped the department conduct workshops in the province since 2006. The sessions are intended to help people better understand their wells and their responsibilities as owners under Alberta’s Water Act.

“People were asking about problems with biofouling, iron bacteria and sulphur. Around 2004, we started putting together and doing presentations. By early 2008 the formal Working Well program was launched,” he says of the joint effort among Alberta Environment and Parks, Alberta Agriculture and Forestry, the Alberta Water Well Drilling Association and Alberta Health Services.

The initiative to offer workshops had its roots in the growth of coal bed methane drilling, Williamson says. “Thousands of wells were being drilled and people were concerned about contamination of water wells and environmental effects. There were

a lot of public meetings. People didn’t understand how wells worked.”

Working Well workshops, which are offered on demand in the fall, winter and spring, are typically hosted by municipalities and advertised locally. Since the beginning of the program, Williamson says more than 6,000 well owners and potential purchasers have participated in nearly 230 workshops.

“Eighty per cent of the time, a driller can make it out to the meeting,” he says. “Drillers get good PR when they attend and they see that customers are more knowledgeable.”

When people attend a workshop they receive their drilling report. They also do an exercise called “Draw Your Well” in which they use their individual well data to come up with a picture of the well. “It can get a little crazy with so many people working through the exercise at once and trying to get answers to questions, but it is of great benefit to them,” Williamson says.

Many participants ask about biofouling and shock chlorination. “Lots of people are not comfortable doing

by COLLEEN CROSS

it themselves,” he says. “Theoretically anybody can shock-chlorinate a well, but lots of times they need to go beyond that and have a professional come in, pull the pump, clean the well and put it all back together again,” he says. “This is a value-added service the drillers can do and if you’ve got a more knowledgeable customer who knows why they might have to do that, they’ll probably be more willing to do it.”

When installing a new well, drillers could be on the hunt for old wells not properly reclaimed and unsafe well pits, Williamson says. “There could be potential here for drillers to teach people about pitless adaptors,” he says, adding that in Alberta, there is federal and provincial government funding for farmers to decommission old wells and put in adaptors.

Williamson also sees untapped potential for drillers to set up longterm service contracts with customers to have onsite inspections, use a sonic well sounder to measure water level or test water as requested beyond the free testing provided by the province.

Conductivity

Interface

Pressure

As for customer service practices, he says people really appreciate businesses returning calls in a timely manner and talking to them. The simple act of communicating can mean a lot.

Aaron Drilling in Foothills, Alta., has garnered great online testimonials that stem from strong communications.

“Thank you so much for your time and efforts in obtaining the water results on our place in a timely fashion. And thanks for explaining the results to my client,” writes J. Zaba in a testimonial featured on the company’s website.

Tyler Crawford, who co-owns the business with Chris Quinlan, fields many questions from new and would-be well owners. “A lot of people are interested in city-like pressure and quality. A lot of houses built in the country are quite spectacular. They need a lot of water during a peak demand period. . . . So they basically want to know if they will be able to shower, wash dishes and do a load of laundry at the same time . . . and not have to worry about water.”

“Something they ask about less but that I always bring up is the water

quality,” he says. “I always tell people the water quality is almost more important than the water quantity, if you had to pick one of the two.

“Chemistry is a detailed and long conversation typically with people, and

PROUDLY SERVING THE GROUNDWATER INDUSTRY SINCE 1992: Lackner McLennan Insurance has made it their business to protect other businesses, and their specialty program for the groundwater industry has been making waves.

PROGRAM DESIGNED FOR:

• Water Well Drilling Contractors

• Pump Installation Contractors

• Geo Thermal Heating Contractors

• Hydro Geologists / Geo Scientists

• Manufacturers / Suppliers

COVERAGES INCLUDE:

• Automobile & Fleet

• Property & Commercial Liability

• Environmental Impairment Liability

• Errors & Omissions (Professional) Liability

• Bonding

Directors & Officers / Employment Practices COVERAGE: A liability program designed to provide you with defense costs arising from an employee dispute or issue with one of the Ministries. (Labour, Environment, Revenue)

STEPHEN BLEIZEFFER

519.579.3330 ext. 311 sbleizeffer@lmicanada.com www.lmicanada.com

getting somebody from the city who is used to just a line coming in and having a 12-grain hard chlorine-smelling, nonstop supply coming into their house and having them understand the reality that their water is coming from the ground now and could potentially have coliform bacteria, iron content, manganese, highsodium, low-sodium. All these things are new to them so they need to be educated on the reality of the chemistry as well as the production of their well.”

Crawford and Quinlan spend a fair bit of time discussing test results with well owners. “On site we do things like take pictures on site, we draw schematics; our in-field techs are reconnaissance officers, for lack of a better term. The senior management makes the phone call to discuss the results. ”

Crawford says they do a lot of guesswork based on experience. With nearly 40 years in business experience is something the company has in spades, having changed hands from Crawford’s grandfather, Fred Hager, to Brad Myers, then back to Crawford and Quinlan.

“Experience in the water well drilling industry is the most important thing a contractor can have,” Crawford says. “If they are inexperienced, while they’re learning, that’s when they need a mentor. It’s an industry that is hugely reliant on learning from the past. My grandfather was a water well driller for his whole life. He mentored Brad, Brad mentored me, and that knowledge passed down from

11:22 AM

generation to generation is invaluable.”

Like Aaron Drilling, Stengel Pumps & Well Drilling of St. Williams, Ont., puts great focus on education and talking with customers. Carrie and Tom Stengel have run the business for 25 years.

She encourages potential customers to give them a call to learn about water quality. “Buyers want to know if they can have a productive well drilled in that area, what style of well is right for them and what costs are involved,” she says.

Stengel says great customer service means being as informative as you can be with people. “It’s about always trying to provide our existing clientele with good service, so if they call us in the middle of the night – they’re out of water or they have an emergency situation – we will be there for them,” she says, “and if we can’t, we’ll try and talk them through it.”

She says the company’s small size makes it easier to provide good service. “We reached the point where we said, ‘Do we grow?’ We just thought that for us, we could provide better service if we stayed the way we were. With just the two of us, we can have a more personal relationship with our customers.”

As part of their service, they keep warrantees on file and remind customers about maintenance milestones for their water treatment systems. They don’t charge labour to do this servicing.

While their approach may sound like good old-fashioned, customer service, they have found new technologies – namely, smartphones – help them answer questions in a timely manner. “People can take a photo and message you through Facebook or email, and show you what the problem is. People tend to email these days rather than call but often that’s good,” she says. “We can respond quickly when we’re in the field.”

Sarah Otto of Langton, Ont., was the recipient of the Stengels’ personalized service. Otto had always been on municipal water and wasn’t certain what owning a well and septic system entailed. “I think it scares away a lot of people; it’s a little intimidating,” she says. “If you get yourself into a situation where you’ve got a problematic well or septic, now all of a sudden you’re responsible for that whereas when you’re on municipal that’s not an issue.”

While looking at potential new homes last summer, Otto encountered a rural

property with a well that gave her pause. She called the Stengels to arrange a well inspection. Unable to do a site visit immediately due to a very busy, very dry season, Carrie Stengel offered her time and expertise over the phone.

Stengel suggested Otto take photos of the well, and based on those photos was able to determine the well was not professionally drilled: it did not have an airtight seal and since it was near a driveway there was a risk of contamination.

“She was happy to give me that pro

bono type of explanation,” Otto says. “It was really helpful. She potentially kept me from making a bad real estate decision.

Otto also was pleased to get a “crash course” from Stengel on the difference in soils and how they affect wells. “I got a little bit of a crash course through her, which was really nice. You don’t get that kind of customer service from just anywhere.”

“She probably spent a good hour just explaining everything and she didn’t have to do that.”

With In-Situ, you trust your water monitoring equipment and data to be accurate and reliable, every time. We’re in the field 24/7, so you don’t have to be.

in-situ.com/gwc

Rockmore International has added the ROK 550T to its T Series down-the-hole (DTH) hammer line. The tubeless Rockmore T Series DTH hammers use drill bits with industry-standard shank connections without the imbedded plastic blow tube/foot valve.

The ROK 550T is a 127 mm (5 in.) class hammer model that uses the industry-standard QL5/QL50 bit shank, but with the blow tube and foot valve removed.

With high-performance drilling characteristics rated for drilling 140 to 152 mm (5.5 to 6 in.) diameter holes, the hammer is suitable for blasthole mining and construction applications and for drilling of deep-hole water wells and geothermal systems.

The ROK 550T hammer uses Rockmore’s patented SonicFlow technology, whic helps increase airflow by simplifying and streamlining the air paths to minimize back flow and turbulence, thus delivering more energy to the piston.

www.rockmore-intl.com

Goulds Water Technology’s line of submersible turbine pumps features hydraulic coverage that delivers the pump head and capacity a system requires, while maximizing

the efficiency and extending pump life.

The company’s submersible turbine models feature a pump design that may be easily configured as a multistage assembly to provide flexibility in initial pump selection and future system modifications. They contain abrasion-resistant, thickwall, cast-iron bowls and 316SS investment cast stainlesssteel impellers to ensure a wide range of hydraulic coverage and durability.

The turbine models can be customized based on the pump’s application and the pump units are available in a wide range of metallurgies to meet the needs of different environments.

All models are NSF/ANSI 61 and 372 certified to comply with safe potable water regulations. When bundled with a motor and a drive up to 450 horsepower, the pumps are eligible for a three-year product warranty.

goulds.com/turbinepumps

Rock Monster HD back reamers from Ditch Witch are designed to help horizontal directional drilling operators improve drilling performance in hard-rock conditions.

The new back reamers are equipped with the company’s

patent-pending EdgeGuard protection to increase the life of the reamer, reduce replacement costs and keep crews profitable. This design incorporates strategic placement of tungsten carbide discs on critical areas of the bit shirttail, giving operators an advantage over hardfacing and tungsten carbide inserts, the company said in a news release.

Other innovations, including High Energy Tumbling inserts, improve cutting structure life through increased fracture toughness and wear resistance, helping to extend the usable life of the back reamers.

“Operators continue to drill in ever-challenging terrain, making the durability of their downhole tools a critical component to a successful job,” said Jeff Davis, Ditch Witch product manager for HDD tooling and drill pipe, in the release.

The back reamers include a full-coverage cutting structure to maximize weight on the bit, providing better performance in rock. They are designed with interchangeable nozzles in multiple sizes so that operators can customize fluid-flow specifications to specific drilling conditions.

They are compatible in rock applications with current Ditch Witch HDD rigs and available in five different sizes: 10 in. x 4 cutters, 12 in. x 4 cutters, 14 in. x 4 cutters, 14 in. x 5 cutters and 16 in. x 5 cutters.

www.ditchwitch.com

Heron Instruments has a water level meter to tackle every project and meet every budget. The company has

expanded and improved the quality of its water-monitoring instruments while maintaining competitive pricing, the company said in a press release.

To complement its fourfunction Dipper-T, Skinny Dipper and robust DipperTough, Heron has added a new compact Little Dipper2 and dual function Dipper-T2 and given the Water Tape2 dual-function capability.

To protect your investment, a carry case is always included. www.heroninstruments.com

The Lone Star LST1G+HDA Geotechnical Drill from Little Beaver provides engineers and soil technicians with a precise and easy-to-operate drilling solution for standard penetration tests and soil sampling in nearly any soil.

Lone Star designed the drill to address growing demand for automatic hammers that deliver improved depth control compared to manual hammers. The LST1G+HDA comes standard with a 140pound automatic safety hammer. The heavy-duty rig is mounted on a manoeuvrable, single-axle trailer that can be towed behind a small or

standard sized truck.

The LST1G+HDA is capable of drilling 152.4 mm (6 in.) boreholes down to 30.48 m (100 ft.). The drill can also be used with Little Beaver’s split spoon samplers and AWJ drilling rod for obtaining core samples or conducting geotechnical testing and environmental soil sampling.

Little Beaver offers several auger options to adapt to varying applications. Solid stem augers are available in 3 to 8 in. diameters and hollow stem augers are available in 6 and 8-inch diameters. The hollow stem augers, which can drill to 60 feet, feature a 2.75- or 3.75 in. internal diameter for collecting samples without risking contamination from surrounding soil. The LST1G+HDA’s standard configuration allows for dry auger boring with the use of a solid or hollow stem auger. The drill is also capable of mud rotary boring using an optional mud pump, swivel and bit.

A 27-horsepower Kohler EFI gas engine powers the drill, which includes a 3,000-

psi hydraulic system.

The 3,000 lb. unit is mounted on a rugged yet lightweight single-axle trailer equipped with a 2 in. hitch, levelling jacks and spare tire. For improved manoeuvrability, the company offers a specially designed frame for mounting the unit to a one-ton flatbed truck.

www.lonestardrills.com

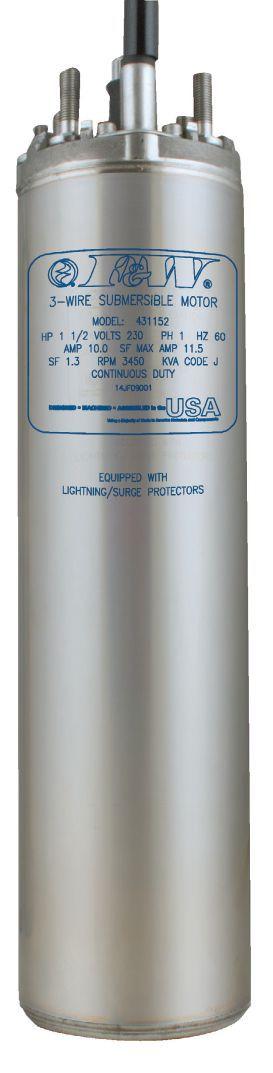

Franklin Electric wants to help water-well contractors and pump product dealers run their businesses smarter. The company’s Key Dealer Program provides a suite of services to help contractors distinguish themselves from their competition and elevate their business. These services range from peace of mind through product protection, professional development and marketability.

Specific services include a website builder, Google AdWords marketing, Facebook setup and support, directory listing, scholarship aid, and

homeowner referrals.

For example, the Google AdWords marketing service uses standard online advertising methods to promote businesses on relevant Google searches with ads developed by Franklin Electric experts to drive customers to contractors’ websites.

keydealer.franklinwater.com

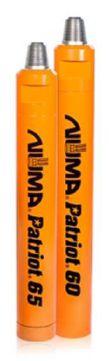

Numa, a manufacturer of DTH hammers and bit technology, has released a new generation of Patriot 60 and Patriot 65 hammers. Based upon advanced engineering and driller input, both hammers provide increased reliability, enhanced performance, and faster penetration rates than previous versions.

The Patriot 60 hammer is suited for water well, construction, oil and gas, utility, quarry, and mining drilling applications where contractors are not looking to run a heavyduty version. The hammer features a reversible case and operates at a higher pressure than the previous generation. Tests have proven the hammer has a higher BPM and drills consistently against back pressures, like water in the hole, the company said in the release. The Patriot 60 has a 139 mm (5.5 in.) outside diameter and runs QL60 shank bits capable of drilling holes 152 to 222 mm (6 to 8¾ in.) in diameter. The Patriot 65 is a heavy-duty hammer designed specifically for the quarry, mining, and construction industries where ground conditions warrant. The hammer has a thicker, reversible case. www.numahammers.com

Scientist and educator John F. Jones, who in the early 1960s was the first practising ground water specialist in Eastern Canada, passed away on Nov. 26, 2016, at the age of 82.

Jones, who held bachelor’s and master’s degrees in science and a professional engineer designation, early in his career worked with the Alberta Research Foundation as a ground water geologist on a project in the Peace River area of Alberta with mentor and boss Robert Farvolden.

In the early 1960s, he became chief the Nova Scotia Department of Mines “Groundwater Section” established to evaluate the occurrence and characteristics of the resource.

In the 1960s, the deputy minister of mines, J.P. Nowlan asked Jones to start a ground water program in Nova Scotia that would provide an overview of ground water resources and an understanding of the relationship of ground water to the province’s other water resources.

During the 1960s and 1970s, Jones introduced and taught a hydrogeology course at Dalhousie University’s

department of geology and supervised several masters theses on hydrogeology topics.

Jones became director of the Water Planning and Management branch of the Nova Scotia Department of Environment and served in that capacity until he retired. One of the many important roles played by the department was managing ground water use through water withdrawal permits for water uses greater than 23,000 litres a day.

During the latter part of his career, he was the senior policy advisor to Nova Scotia’s deputy minister of environment. “Although the word ‘sustainability’ wasn’t used as it is now, by the time John retired in 1991 the practice in Nova Scotia was to manage our ground water resources with sustainability of the resource in mind,” former student and colleague Terry W. Hennigar wrote in a tribute to Jones (see our website). “He was a visionary, and the right man for the right job at the right time!”

–Adapted from a tribute by Terry W. Hennigar, senior engineer and hydrogeologist at Water Consulting, and other of Jones’ former students and colleagues. The full tribute may be found at www.groundwatercanada.com.

Continued from page 12

size your systems right for the customer.

“You don’t want to design a system that is going fail right after your warranty ends,” he says. “I try to make a system that’s going to last 20 to 25 years.”

While Conrad gets a five-year warranty on motors and pumps, he offers his customers a 10-year warranty and sets up the system to last.

“When you size things out right for the customer, then everything’s going to run properly and everyone’s happy. If they don’t have to call you back for 20 years, when they do call, they are happy to do so.”

Conrad says one thing that has really helped him over the years is having a live person answer the phone. “My family answers the phone while I’m out drilling wells,” he says, explaining that when potential customers get an answering machine, they often hang up and call somewhere else. Having a real person answer the phone makes a difference, and if a customer’s problem needs immediate attention, Conrad’s dad can get a message to him.

“If it’s an emergency, you want to know someone’s answering that phone and that they’re trying to help,” Conrad says. “I’ve even referred jobs at this point so

that customer gets help. I believe we should be looking out for each other in this industry. I’m not going to make a customer wait two days for me when they may have no water if I know there’s someone that could fix them up right now. What do I make on it? Nothing, but that’s not what it should all be about, right?”

“Trying to use your local people and spread the work around is what it’s about.” –Paul Conrad

It is about being part of a community and supporting other businesses; for example, calling in a local business to do backhoe or excavating work or to deliver a dump truck full of stone or install a septic system.

“Trying to use your local people and spread the work around is what it’s about,” Conrad says. “Because you know what? That same guy who did our excavating may be the guy that puts a driveway in for a brand new customer or

a septic guy who does their septic and if that customer needs a well, they’re going to say, ‘Give Conrad a call.’”

He also refers out to other drillers. “We do wells, pumps, and some mild water treatment, which we don’t get into that often. There are other guys that do treatment if it gets extensive, and I usually refer. It’s good to pass work on to others. Same with the drilling. I generally stick to within an hour of here. We get calls all the time for jobs that are over an hour away, and I say, ‘You know, I could quote you, but honestly, there are other drillers in your area that are reputable and a lot closer.’ ”

He makes recommendations or directs them to the OGWA’s list of members in good standing. “I think it does a lot for my relationship with the other drillers. For the most part, everybody gets along and makes a living around here, and I don’t think there’s too much animosity between any of us,” Conrad says. “I can’t drill them all. I need to make a living, but I don’t need every job. I got my bills, and if I can pay those and save a buck at the end of the day, I’m fairly content.”

He says it’s especially important to have a good reputation in this industry. “We need to be reputable. You do a good job on a well and that person might tell two people, but if you do something that

wasn’t good on a well, they might tell 20 or 25 people.”

A solid reputation leads to word-ofmouth referrals. “Having a website’s important, but word of mouth, I believe, gets the work,” he says. “I can’t tell you how many jobs I’ve done where I’ve drilled for people, put a system in, and all of a sudden their neighbours are calling. “

Conrad says his customers particularly like that he guarantees water and offers a set price. Why he does it is a story.

When he first returned from New York and started his business, he was charging by the foot, the way he had learned at Eckerson – the way everyone he knew did it. But here, customers were asking him, “Don’t you have a set price? Don’t you have a guarantee?” As it turns out, that was the way it was done in Parry Sound.

“Lloyd Trodden, who ran Bettray Well Drilling – he passed away a few years ago – was a great guy, interesting and funny. He drilled for a long time, and I think he started this damn thing where it was a set price and water guaranteed,” Conrad says with a laugh.

But everybody conformed to it, because customers like it. “Setting the

price and guaranteeing the water puts the customer at ease, because they know that in the end they’re going to have enough water for their house, whether it’s 100 feet or 400 feet, and if they are building a home, they can budget.”

Figuring out that pricing was hard, he says, but you do get some wells that are 60 feet and not so many that are 400 feet. If hydrofracturing is needed, Conrad pays for it, though he says that is only two to 10 per cent of the wells, a figure that changes every year.

He adds that you do have to make money or there’s no sense in doing it at all. “You might feel a little depressed that you’re not making as much money that day, but it works out the next week or the week after,” he says. “I really do find, the more you know the area, it works out.”

And customers know that hydrofracturing means you didn’t make a lot on the job. “Again, it’s a good thing. They tell their neighbours,” he says. “There are certain streets where I drilled one well, say 10 years ago, and

then two years after that, I got two more on that street. Now, when I look back at one street, in particular, I’ve done 15 wells on it.”

It’s a customer-focused approach. “The customers are your business, and I think that’s something you have to think about. At the end of the day, you have your own life or your own problems, but I think it all works itself out if you just do the right thing and try to do for others what you would do for yourself. It’s like karma. It’s spreads around.”

His final thoughts are to express his gratitude. “I think it is important to recognize people, and what I want to say here is thank you to Jim Eckerson Jr. and Ron Banks Sr. for everything they taught me when I first went to New York. And my family has helped me from the beginning. They’ve been great to me, and I want to express my gratitude to my mom and dad – Al and Mary Conrad – for all their support and help.”

And that’s how some of that goodness comes back around.

by Alex Shteriev

The value of a business depends on what the market is willing to pay for it at any given time. Values depend on the industry, buyer interest and willingness to transact, and the state of the economy.

Knowing the value of a business as well as understanding what factors make it valuable can help owners focus on the right things when running a business. Even if you are not planning to sell, bringing in employees as partners or investors at any given time is only possible if they understand what the business value is at that time.

Additionally, even if you are planning to pass the business on to your children or family member, you need to have an arm’s length business valuation done.

At the current moment, the market is valuing businesses within the Water Service Industry at the following earnings before interest, tax, depreciation and amortization (otherwise known as EBITDA) multiples: revenue $0-$500,000 (1.79x); revenue of $500,000-$1,000,000 (2.69x); and revenue of $1,000,000-$1,500,000 (3.92x)

By taking an annual amount of maintainable EBITDA and multiplying it by the Enterprise Value/EBITDA multiple, one can attain a rough estimate of the business enterprise value. While this estimate of value is generally inclusive of certain balance sheet items, it does not take into account adjustments necessary for excess working capital, redundant assets and other circumstances.

Some service industry businesses have difficulty maximizing their value due to the nature of the work they do. Multiples could be negatively impacted by unpredictable workflow, fluctuating profit margins and the uncertainty of future business. Key areas of improvement that are pertinent to service businesses are growth potential, recurring revenue streams and owner reliance. Improving these areas can go a long way in increasing value and sellability.

Contractors should focus on finding a way to carve out a niche within their industry. By doing so, competition is reduced as you are not competing directly with others in the marketplace and can differentiate your services. A niche allows for the market to be defined, creating greater certainty of financial performance and growth potential, and reducing the perceived risk of the business.

Due to the nature of the work performed by service industry professionals such as waterwell contractors, it is difficult to project where the next dollar of income is coming from. Introducing a recurring revenue stream into the business model is comforting to a buyer as it allows them to see future revenues that will be realized upon a change in ownership. Creating a business that does not need to be started from scratch each month will increase the value to buyer and maximize a sale price. An example would be a well-drilling contractor taking over the maintenance and inspection needs for the well for a recurring monthly or annual fee.

The reliance on a single owner depresses the value that can be extracted from a business. If a business is dependent on a single owner, it decreases the sellability of the business. Establishing a management structure and human resource organization that is not completely dependent on the owner is important in maximizing the business’s value. Also, the ability to have a seamless transition upon the sale will increase the value and likelihood of successful sale.

Alex Shteriev specializes in the sale of small to medium-size Canadian businesses. Headquartered in Toronto, Beacon has offices throughout southern Ontario and transacts businesses across Canada.

1494 Bell Mill Road, P.O. Box 456, Tillsonburg, ON, Canada, N4G 4J1 P.O. Box 2663, Buffalo, NY, USA, 14240-2663

Phone: 519.688.0500 Toll Free: 800.387.9355 Fax: 519.688.0563 Email: wells@wellmaster.ca Online: www.wellmaster.ca

Cable Tool

Rotary

Threaded

Weld On

Sizes 2” to 36”