Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Grove Shims™ has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Updating older buildings to meet today’s standards can pose a number of unique issues including incompatibility of materials and added strain on the existing façade.

16 Best foot forward

Think about the specific needs of women when choosing PPE for your workforce.

7 Canada’s Glass Associations

Ryan Spurgeon, the young president of one of Canada’s iconic architectural glass fabricators, Antamex, joins Glass Talk to share his experiences through a period of whirlwind change for the company. Spurgeon talks about the struggles of the early days, ownership by Oldcastle and the new era of indpendence and restructuring.

We need to decide if this industry thing really works for us.

Readers of this magazine will remember the Xinyi debacle, chronicled by Frank Fulton, in which a proposal to build a float glass plant near Guelph, Ont., was torpedoed by a vocal group of environmental activists advancing evidence-free concerns about groundwater use, among other objections. Now, the good folk of Guelph have risen up again in opposition to another industrial development proposal, this time for a plant to manufacture refrigerators and freezers. A process, by the way, that is already taking place in nearby Georgetown.

The complaints seem familiar, even though the industry and process are completely different. Groundwater is being brought up again, even though the new plant doesn’t draw any for its production process. The opposition groups are raising the spectre of fuel spills from trucks and foam from firefighting efforts in the event the plant has a fire. Given this concern, it’s hard to see what development could possibly meet their approval.

Well, actually there is one. Some of the objectors mentioned the need to preserve farmland. Funny, I thought fires and spills happened on farms, too. Not to mention the introduction of tanks full of pesticides and fertilizer. But let’s leave that aside to address the question of why apparently any industrial development can no longer go forward in Ontario.

• Facade integration

• Material handling

There have always been people who don’t like factories and cities. They place great emphasis on their concerns for the health, social and economic consequences of damaging the environment, and also raise moral questions about destroying ecosystems and potentially entire species. I’m not here to litigate the environmental debate; suffice to say I’m sympathetic to each side on certain points. But it seems indisputable that, for better or worse, modern society depends on some level of industrial activity in order to function. These proposals for development keep coming before city councils and they are backed by large companies and financial institutions comprising thousands of people. I don’t know what the polling numbers show in Guelph, but I bet there is at least some support for a new plant with all the investment and jobs it would bring. Obviously, Guelph councillors have to follow the mandate of their constituents. But is that mandate really reflected in the loud groups who appear at these planning meetings?

Making decisions can be scary, but I think Guelph councillors and their fellows across the province and the country need to make one on this larger issue. If proposals come before them that meet all the regulatory burdens (of which there are many), yet can still be killed simply through the vocal opposition of a possibly non-representative group, then government simply loses the ability to do anything, for good or ill. There will always be opposition to anything from some quarter. Municipal governments should take a clear position on whether they support industrial development in their precincts or not, and communicate it openly. If they do, they should face down opposition when proposals meet the standards set out for them. If they don’t, they should say so, and companies can stop wasting their time. •

October 2021

Volume 33 • Number 5

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquiries or changes, please contact Shawn Arul, Audience Development Manager

Tel: 416.510.5181

Fax: 416.510.6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE EDITOR | Alex MACKENZIE amackenzie@annexbusinessmedia.com 416.510.6809

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

BRAND SALES MANAGER | Nav MATHARU nmatharu@annexbusinessmedia.com 226.931.5095

ACCOUNT COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Curtis MARTIN VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $85.00 (in CDN dollars)

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

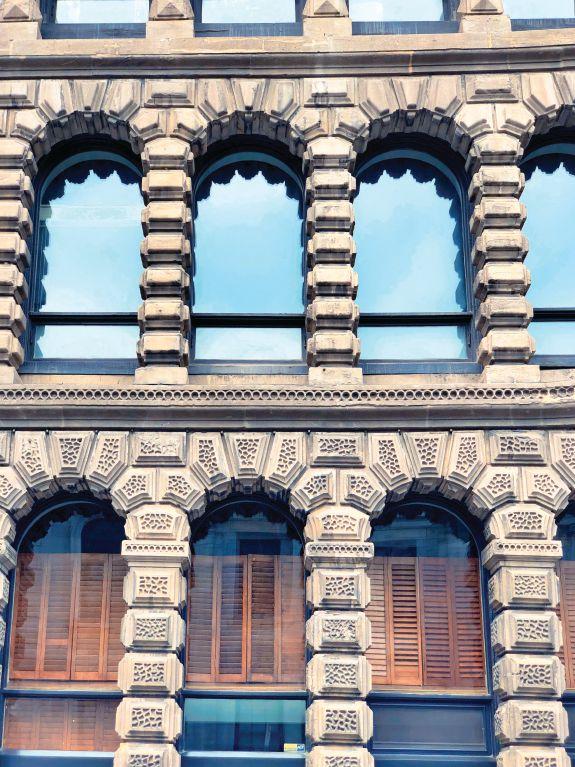

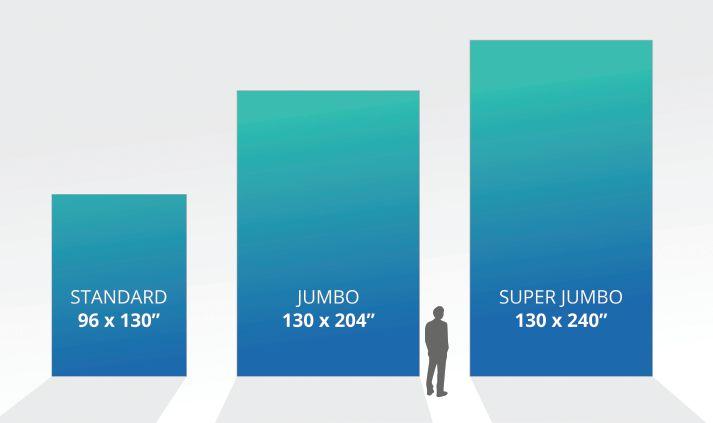

Guardian Glass has announced the company is now producing 130-by-240-inch, or “super jumbo,” SunGuard coatings on clear or Guardian UltraClear float glass at its Carleton, Mi., facility. Guardian is responding to demand from architects who are pushing design boundaries with buildings that maximize views and natural light for occupants in interesting, forward-thinking facades while also reaching energy performance codes and standards.

“Super jumbo helps our fabrication customers improve yields on many common commercial sizes and produce oversize insulating glass units that aren’t possible with standard jumbo coated glass,” says Chris Dolan, commercial segment and technical services director for Guardian Glass North America.

Independent Guardian Select fabricator Press Glass is capitalizing on this advantage. Press Glass brought its longstanding expertise in super jumbo – its Polish facility fabricates glass up to 275 inches – to North America last year. Its Ridgeway, Va., factory was built to accommodate 130-by-240-inch glass. The fabricator has some of the largest glass sizes available in North America.

“Our customers want larger glass, whether it’s commercial or residential,” explains Piotr Styk, senior estimator and project manager at Press Glass. “Everyone is calling for expansive views, and the bigger the better. When we were deciding on equipment to purchase for our new facility, we

researched the maximum glass size available in North America. Guardian offered the largest size at 240 inches, so we made sure to equip our facility with machines that could handle that size. At Press Glass, we strive to exceed quality standards. Every order is a custom order, so it’s essential that we work together effectively. Our communication with Guardian works very well. It’s a very effective partnership.”

That partnership has delivered on projects that range from Press Glass’ Ridgeway facility, which boasts 231-by-115-inch triple insulating glass units that include Guardian SunGuard SNX 51/23 coated glass and SunGuard SuperNeutral 68 coated glass, to the under-construction Terminal 5 at Chicago O’Hare International Airport, which uses Guardian SunGuard SNX 62/27 coating on UltraClear low-iron glass in a large variety of sizes.

“Even in circumstances where we’re not using super jumbo as the standard size, it helps us maximize yield and minimize waste because the cutting optimization is better,” explains Spencer Green, area sales representative for Press Glass.

Guardian Glass super jumbo glass is available with multiple high-performance Guardian SunGuard coatings on clear and UltraClear low-iron substrates, at 6-, 8-, 10and 12-millimeter thickness. These coatings allow architects and designers greater flexibility to specify coated glass that meets their performance and aesthetic goals.

Business Media is proud to announce Alex Mackenzie has joined Glass Canada. Alex takes on the role of associate editor as Sukanya Ray Ghosh steps into her new role as editor for Manufacturing Automation and Pulp & Paper Canada

Alex graduated from Northern Michigan University in 2011 with a BS in psychology and subsequently earned their MA in English in 2017 from Southern New Hampshire University. They bring with them diverse editorial knowledge and experience in the B2B publication sector having worked as associate editor for Allured Business Media’s Perfumer & Flavorist magazine from 2019 to 2021.

One of Alex’s primary focuses in this role is to revitalize Glass Canada’s social media presence across all platforms.

The Association de vitrerie et fenestration du Québec (AVFQ) has collaborated with Transition Énergie Québec (TEQ) as part of the reevaluation of the Novoclimat program. This program encourages the construction of new homes with high energy performance, according to specific construction requirements. It targets houses, small residential buildings and large residential buildings with four to 10 floors. For the part of the program dedicated to large buildings, the discussions with TEQ were fruitful for both consumers and industry players. Thanks to the representations and arguments brought forward by the AVFQ, the program will be more open and accessible. In fact, more types of windows will be able to qualify and thus increase the use of energy-efficient products at a reasonable cost.

After two years of absence, the Omnium AVFQ was back on Sept. 9 at the magnificent Le Blainvillier Golf Course near Montreal. Our 288 golfers were enthusiastic to meet up as well as the many sponsors. In compliance with the sanitary rules in force at that time, 350 people gathered at the end of the day to network and share their fun facts.

Under the theme “The future is now,” the AVFQ’s annual conference will feature more than a dozen workshops and conferences. It is also time to book Feb. 10 and 11 at the magnificent Château Frontenac in Quebec. The program and registration are available at avfq. ca. The Prix Lumières Gala will be back to reward the most beautiful projects in the industry. It will also be an opportu-

nity to launch the AVFQ’s 60th anniversary celebrations.

In order to support and properly inform its members, the AVFQ is organizing two forums this fall: one on the tricky problem of the lack of labour and the other on digital transformation. These forums will make it possible to know the different possibilities and to discuss the respective experiences.

From time to time, the AGMCA uses this space to highlight its volunteer directors or its member companies.

This month, we salute AGMCA president, Tony Menecola of Applewood Glass.

Tony was first introduced to the business by his father, Lorenzo, and spent summers and weekends from the age of 12 helping his dad out in the shop.

Upon completing his education, Tony joined his dad full time. Together they turned out a lot of work from a small shop on Wolfedale Road. Twice, they had to add approximately 8,000 square feet to keep up with their commitments.

Through continued hard work and determination, Applewood became successful, building a customer base that was anxious to do more work with Tony, given his emphasis on quality and his conscientious attention to detail. Tony takes his commitments seriously, and by the ‘90s, he had developed a niche within the market: fabricating and installing unitized curtainwall for small and mid-size buildings. Previously this was

the exclusive domain of large curtainwall specialists.

From that humble beginning in 1979 on Wolfedale Road, Applewood has come a long way. Today, Applewood’s shop on Southfield Road is a stateof-the-art facility, with over 50,000 square feet of efficiency and a staff of over 50 people. Applewood has completed several signature projects, including the BMW dealership at the foot of the Don Valley and the Aviva building at 407 and Warden.

In addition to running Applewood Glass, Tony’s commitment to our industry is well documented. He was a long-time director of the OGMA, has been a director of AGMCA for almost 30 years and is our current president. He is the chair on our Glazier Apprentice committee, overseeing the training of our glass and metal technicians. He also sits on our local apprentice committee that monitors the progress of the apprentices and ensures they complete their training. Tony is also a valuable member of our negotiating committee, representing the concerns and issues that affect all of our unionized glazing contractors. Tony can be reached at a.menecola@ applewoodglass.com.

I t is with great sadness that we bring you the news of the passing of one of our industry’s most virtuous and respected gentlemen. Al Jones left us just a week before his 93rd birthday. Al was one of the

good guys and was well liked by everyone who had the pleasure of meeting him. He had a great sense of humour, was always joking, always friendly, and seldom ran out of something to say.

Al was athletic his entire life, was a better-than-average golfer and enjoyed playing at the Toronto Ladies Golf Club. Even though the men’s locker room was in the basement next to the furnace, Al said he liked the company at his course of choice. As a younger man, Al was quite the baseball player and it was at one of his games at Christie Pits that he met his wife, Barbara.

Al began his career as a draughtsman at Pilkington Glass on Mercer Street in the late 1940s, where he quickly worked his way up the ladder to land an outside sales position, calling on glass shops and architects. His technical background helped him to excel at his job. He moved on for a short stint at Scarborough Glass before joining Fred Fulton to grow the sales at Sealite Glass Ltd. in the early 1960s. They become good friends while both working at Pilks.

Al made a big move in 1971 when he bought Jessup Glass and eventually changed the name to Parkway Glass and Mirror Ltd. when he moved the company up to Denison Avenue in 1975. Al’s son Steven was a key member of the company until winding things down in 2018.

Al selflessly gave back to our industry by becoming a director of the Architectural Glass and Metal Contractors Association in 1980. In 1989, he assumed the role of Treasurer, a position he held with pride and integrity until his retirement from the board in 2019.

Vitro Architectural Glass (formerly PPG Glass) announced that it has reached an agreement with LandGlass and VIG Technologies to sell their tempered vacuum insulating glass (VIG) products in North America.

“LandGlass and their LandVac brand uses the world’s best VIG technology, so their products are a natural fit in Vitro’s already expansive and trusted product portfolio,” said Martin Bracamonte, vicepresident of marketing and innovation for Vitro Architectural Glass. “For Vitro customers, designers and other channel partners, this agreement will unlock an entirely new paradigm of highperformance glass possibilities.”

Vitro will begin offering tempered VIG units in North America beginning in late fall 2021. The company also plans to install LandVac equipment and begin manufacturing VIG units in its North American facilities as the market for VIG products develops. The new 8.3-millimeter tempered VIG units consist of two fully tempered lites of glass separated by a non-leaded metal seal and a vacuum space. The inclusion

of fully tempered glass enables the LandVac VIG unit to be used globally across indoor and outdoor temperature extremes, which can cause failures in non-tempered VIG units. VIG units deliver an R-value of 14, which is closer to the R-value of a traditional wall than glass. Improved R-values in cladding materials are increasingly in demand as building owners and developers face imperatives to minimize their environmental impact, from new stringent energy code updates to Net Zero energy goals.

“Building envelope materials with extraordinary R-values, such as VIG products, have the ability to significantly reduce demand for artificial heating and cooling,” added Bracamonte. “That energy use reduction results in commensurate reductions in greenhouse gases. Vitro is proud to provide this new product platform as yet another way to maximize the environmental value of our products.”

VIG units can be used alone as a replacement for monolithic glass or as a substitute for the interior lite in a

HHH Equipment Resources, a division of Salem Fabrication Technologies Group, has announced the launch of a new, exclusive line of glass edging equipment.

Using over 125 years of glass industry experience, HHH developed Kodiak, a line of glass edging equipment that is designed to specifically meet the needs of the North American market and its fabricators. The Kodiak machines feature heavy-duty spindles and frame construction that are designed for continuous use and ideal for oversized glass. All machines are UL/CE certified, come with a comprehensive warranty and will be serviced in the United States by HHH’s team of 23 technicians.

“After many years serving the industry, we began to recognize gaps in the market for North American fabricators. Our fabricators need equipment that is reliable, offers competitive speeds and is serviced here in the United States. We’re proud to be the first in the glass industry to offer a brand of edging equipment that is exclusively designed for and serviced in the U.S.,” says HHH equipment resources president, Mike Synon.

The complete Kodiak line will include glass edging, polishing, beveling and mitering equipment. All Kodiak equipment was built to offer exceptional edge quality, competitive production speeds and proven track design. The Kodiak line launches with two machines: the Kodiak 10 flat polishing machine and the Kodiak 10-45 glass polishing and mitering machine. Three additional machines are expected to follow in late 2021.

traditional one-inch insulating glass unit where it forms a secondary airspace and creates a hybrid IGU that significantly improves the unit’s thermal efficiency, delivers better noise abatement and eliminates condensation. The VIG units will be available with Solarban 60 solar control, low-E coatings by Vitro Glass. When a VIG unit is used as the interior lite in a hybrid IGU, the exterior lite will be available with the full range of Solarban coatings and Vitro Glass substrates. VIG units will be available exclusively through the Vitro certified network of glass fabricators and window manufacturers. In January Vitro Launched Solarban R77 glass, followed in March by Solarvolt building-integrated photovoltaic glass modules, the product of Vitro’s acquisition of Solarnova, a Germany-based manufacturer of BIPV technology.

Bracamonte concluded, “This is just the beginning of a new generation of sustainable, environmentally and technologically focused products emerging from Vitro’s intense innovation culture.”

Ubiquitous Energy, a transparent solar energy technology provider, and Antamex Industries of Concord, Ont., have agreed to form a partnership to bring transparent solar glazing to the commercial glazing market. This partnership advances Ubiquitous Energy’s go-to-market strategy to bring its UE Power window products to market with Antamex, who is a widely recognized, and reputable design-engineer-manufactureinstall unitized curtainwall facade supplier.

“Antamex has a rich history of offering and delivering reputable, customized and high-quality unitized glazing solutions to our global customers. We are excited to be working with the Ubiquitous Energy team to bring a new type of solar energy generating glazing to the market,” said Antamex president, Ryan Spurgeon.

Greg Hildebrand, Exp technical director of building science, passed away Aug. 23 after a battle with cancer. Exp posted the following tribute: “During his storied career, Greg took on many different roles, including that of researcher, educator, practitioner and mentor. Greg showed great leadership, not only within Exp, but to the greater engineering community through his many contributions to industry associations, memberships and committees. He was recognized by his peers on several occasions, including the Ontario

Building Envelope Council’s, Anthony A. Woods Award (The Beckie) and the Canadian Standards Association’s Award of Merit. Greg also cochaired the CSA A440 Series Technical Committee, that sets the performance requirements for fenestration assemblies, and more. His work can be seen throughout Canada, but also internationally, as he was part of the iconic Bahá’í Temple of South America in Santiago, Chile; the Dubai Bank, UAE; the National Veterans Memorial and Museum in Columbus, among others. “

The Canadian Federation of Independent Businesses has made a new resource document available to members to assist them in developing a policy regarding COVID vaccination for staff. The template is not intended to provide a framework for mandating vaccines for customers or staff, and the CFIB explicitly recommends against doing so in its release. The CFIB announcement follows:

Our members are frequently contacting our business advisors about vaccination in their workplaces.We are pleased to share our new vaccination policy template that we developed in collaboration with lawyers from Sherrard Kuzz. It’s a detailed resource to help you discuss vaccination issues with your staff – without spending thousands on professional counselling.As vaccination is a complex topic, this policy can help you have this conversation sensitively and implement the right health and safety protocols for your business. It doesn’t mandate vaccination for your employees, but rather outlines your expectations as well as the employee’s rights.As a rule, CFIB does not comment or advocate on medical issues. However, considering the many legal issues involved (health and safety, human rights, privacy and employment and labour relations), we felt it important to give you this tool to mitigate risks to your business and avoid fines, lawsuits and/or forced closures. CFIB recommends that you use caution in considering any policy that would require employees or customers to be vaccinated.As governments themselves are reluctant to mandate vaccines in settings like hospitals, a small business could face an expensive human rights or privacy-related lawsuit if it were to implement one. You can find the policy template in our members-exclusive resource library that houses a variety of templates and documents every business owner should have, including:

• *New*Vaccination Policy

• Drug and Alcohol Policy

• Employee Handbook

• Social Media Policy

• Anti-Harassment and Anti-Bullying Policies

Drawing from 15 years with Alumicor, Maxime Allain now serves as the company’s director of client development and as project coordinator for the eastern region. Allain works closely with both the company’s customer services and sales teams, while supporting clients and architects with aluminum-framed building envelope products for largescale projects in Quebec and the Maritimes. In his combined role, Allain reports to Mario Savoie, vice president of sales for Alumicor’s eastern region. He began his career at Alumicor as a junior door/frame fabricator after earning his diploma of professional studies in installation and manufacturing of glass products from Le Chantier Training Centre. Continuing to develop his skills and knowledge, Allain earned a certificate in management from the University of Montreal-HEC Montreal. His team leadership and determination led him to new opportunities in estimating, customer services, project coordination and eventually, internal sales supervisor.

Based in Montreal and fluent in French, Allain is a member of Devis de construction Canada, also known as Construction Specifications Canada and has completed the Principles of Construction Documentation course.

by KATHY KRAFKA

FGIA U.S. Technical Operations Director

With how to achieve net-zero energy and how to reduce greenhouse gas emissions among the hot topics of the day, it’s no wonder there are sometimes similarities in conversations about building codes and standards in Canada and the United States. Similarities crop up in those conversations as those involved with developing or influencing codes and standards seek to strike the often delicate balance of achieving greater energy savings, or reducing greenhouse gas emissions, while providing reasonable paybacks that will help justify to building and property owners and managers the cost of making energy-saving or lowered embodied-carbon improvements. Whether it’s referencing ASHRAE 90.1 in commercial code language, considering how to drive greater electrification of buildings or offer options for on-site renewable energy sources, it’s a time of significant change in building codes and standards in both Canada and the United States.

When fenestration and glazing industry representatives are part of the conversation on energy-saving improvements, they’re also seeking to ensure that buildings maintain that allimportant daylighting factor that’s essential to human performance. This is done by not reducing the fenestration and door to wall ratio, as it is called in Canada, or the window-to-wall ratio, as it’s often referenced in the United States.

The movement to make buildings more energy-efficient in the United States has been fueled by a

More than 26,000 Canadian buildings have already used the Energy Star Portfolio Manager to measure and track energy use.

flurry of U.S. president Joe Biden’s executive orders that have thrust climate change into virtually every aspect of U.S. government action and consideration. With the U.S. federal government’s White House Council on Environmental Quality announcing plans to develop building performance standards for federal buildings, that’s fueling the potential market for energy-saving fenestration, since the U.S. federal government is one of America’s largest property managers. President Biden’s goal is to modernize and upgrade America’s residential and commercial buildings to be affordable, resilient, accessible, energy efficient and electrified.

With the United States now considering how much more stringent the criteria for U-factors and solar heat gain coefficients should be for the proposed Energy Star 7.0 specification for windows, doors, and skylights now in play, other changes to the U.S. Energy Star programs for buildings are likely also on the way. While the U.S. Environmental Protection Agency, which administers the Energy Star program, says the new 7.0 specifications won’t go into effect any sooner than Jan. 1, 2023, it remains clear that there’s already a movement underway to make buildings more energy efficient in Canada and the U.S.

Natural Resources Canada and the U.S. EPA have already signed a new Cooperative Research and Development Agreement. The agreement recommits the two government agencies to continued collaboration on EPA’s Energy Star Portfolio Manager, a free online tool that compiles energy, water, waste and emissions measurements and tracking for commercial, institutional and multifamily buildings. The EPA and NRCan started their commercial building efficiency collaboration in 2011 by enhancing Portfolio Manager with Canadian-specific content including metrics and data. The latest agreement includes new one-to-100 Energy Star scores for the most common types of buildings in Canada, plus it adds the ability to make greenhouse gas comparisons and includes updated Canadian metrics and French content.

More than 26,000 Canadian buildings have already used the Energy Star Portfolio Manager to measure and track energy use. That’s equivalent to about one-third of the commercial space

by ANDREW SNOOK

Countries around the world are constantly looking for new ways to reduce their carbon footprints to decrease the speed of global warming. As part of this global effort, Canada and 120 other countries have committed to reaching the goal of net-zero carbon emissions by 2050. One of the keys to successfully meeting these targets will be reducing the carbon emissions produced by existing and new buildings.

This means national goals and standards for building energy efficiency will only continue to increase.

“I do think it poses new challenges, but it also poses new opportunities. The industry is constantly changing and we’re constantly improving and trying to get better,” says David Heska, director for southwestern Ontario building sciences at WSP Global. “Yes, this is a bigger step forward, but it’s not like we haven’t seen change in the past.”

Heska says façade designers and glazing installers have had to re-vamp and adjust as standards and building energy

targets have changed over the years, and they can do it again.

From a new building design perspective, Heska says the new energy efficiency goals will stress more consideration being placed on looking at every aspect of the building envelope as being connected.

“The building envelope and mechanical system is connect-

ed,” he says. “It is much more common now to have the building envelope renewed at the same time you’re considering what type of heating and boilers and HVAC systems you need inside your building. If you’re going to do both, do them together. Don’t think you’re just going to tackle the building façade and not touch the mechanical systems at all because if you make

Updating older buildings to meet today’s standards can pose a number of unique issues including incompatibility of materials and added strain on the existing façade.

your façade way tighter you increase the R-value from R2 or R3, which is most glass buildings, to R5 or even up to R10, then the amount of heating and cooling you need changes drastically. You have to consider them both in line.”

For glazing contractors, Heska believes the new goals will mean a shift in focus on air tightness.

“All of the details – where the connections of the roof ties into the top of the walls, where the penetrations occur, where there are thermal breaks at balcony slabs or other locations, the amount of air barrier detailing – a spotlight is going to be shined on that in the next five to 10 years,” he says. “This will result in glazers not just having to be glass installers but also thinking about the air and vapour barrier. All of their caulking and sealant detailing is critical to installing this curtainwall or window wall glass system.”

Ted Redlarski, owner of Noram, says the technologies are available to counter any challenges related to meeting energy targets for existing and new buildings. The question is whether a building owner is willing to pay for those solutions.

“No question the technology is there, but it’s expensive. Therefore, few clients are willing to buy. Some lose money on it because the benefits aren’t compensating the costs fast enough,” he says. “As technology gets invested into further, it will get cheaper. Right now, most of the novelties are expensive for the average investor in any market. The rich companies or governments that spend on PR are going to those novelties, but there’s not a high enough return for the average investor.”

Will there be significant differences in older building structures that make it harder to integrate today’s windows and curtainwall? Well, it depends.

“Some buildings are easier to integrate than others,” Heska says. “Some buildings we are able to reuse and salvage some of the framing elements in place, if it was designed to be able to take larger structural loads. In other cases, we’ve installed a secondary outer skin – left the first façade and glazing system in place and just re-skinned over top of it and almost abandoned the one in the wall below.”

He says that re-skinning over the existing framing can prevent having to demolish an entire section of a building.

“It’s helped with some of the façade renewal because, if you don’t have to rip everything off, then you can just get rid of those glazing components and vision glass areas once you get there,” Heska says. “Contractors and building owners and occupants like it if it can be done in one day because it’s fast.”

George Torok, principal, façade specialist, at Morrison Hershfield, says the challenges with existing buildings will be wide-ranging depending on the kinds of buildings someone is looking at upgrading.

“Are you considering replacing isolated elements? For instance, if you have an older building with individual punched windows. Or are you thinking about replacing and tearing off exterior skin and starting again? There’s a huge difference there, because if you’re replacing individual elements, then there’s only so far you can go,” he says. “There’s also a certain rationality there that, typically, windows are the weak point thermally in a building envelope. So, it doesn’t make a lot of sense to take a window to the point where it’s better than the rest of the surrounding building envelope. Then you’re just transferring

problems from one element to another.”

When it comes to different-sized window openings, Heska says staying up to date on codes and standards is vital.

“We design professionals need to be on our toes and staying up to the current best practices related to the various changes that are occurring to the Ontario Building Code and other guidance,” he says.

This is true for safety as well as energy efficiency.

“The industry building inspectors, as well as some architects, haven’t considered all of the factors they need to when designing large window openings,” Heska says. “Especially in higher levels of buildings because the wind loads that those glass elements and glazing elements need to take are higher. They also need to withstand any sort of impact load.”

While not a common issue, some glazers have experienced issues with their current adhesives being incompatible with some of the older adhesives.

One of Torok’s colleagues, many years ago, experienced this issue while working on a building that was built with structural silicone-glazed insulating glass units. Constructed in the 1970s, the early days of structural silicone glazing, the units had reached the end of their useful life and needed to be replaced. But when Torok’s colleague tried to replace them, he found the new adhesive wouldn’t bond with the original adhesive.

“The problem they found was in trying to find new structural silicone sealant that would adhere to the old sealant. Generally, you try to remove as much of the old sealant as you can, but you don’t want to damage the surface of the existing frame. So, there will always be some residue on the metal surface,” Torok explains. “They could not find a new silicone to bond to the old silicone, so they had to add very thin strips of metal on to the existing frame and mechanically bond that to the frame, which provided the new surface.”

Beyond that more sophisticated example, Torok says other issues with older sealants can occur.

“Older sealants, if they go back long enough, might be linseed-oil-putty-based,” he says. “It might be very difficult to remove them because they’re extremely hard and removing them could cause damage to the underlying material.”

That said, there are pre-construction reviews that glazers need to go through for a structural silicone glazing project, and one of those is adhesion testing.

“You want to make sure the sealant will stick to the substrate. Adhesion quality can change depending on the finish material like the paint. You might need to use a primer with a particular sealant. A primer-sealant combination might not work, and then you might have to change,” Torok says.

Older structures can sometimes present a challenge with not being able to handle the weight of today’s façades.

“If you’re looking at really old systems that are single-glazed, and you’re simply adding another layer of glass in it, making it double-glazed, that’s an extra three pounds per square foot for a 6-millimeter-thick glass. So, it does add load,” Torok says. “If

you need to have a more robust system of glazing, then the existing framing may no longer support it. Existing anchors may not be good enough, so you may have to tear the whole system out and re-engineer the anchors.”

Heska says he has not worked on any catastrophic failures related to structures not handling the weight of today’s façades, but he has heard of projects failing.

“There is a project I’m aware of where the façade loading was too large and, as a result, some of the existing structure began to crack,” he says. “Those are one-offs and not common. A designer cannot just assume that the original building can just take this new load. Calculations and analysis need to be undertaken to determine if the new façade works.”

include exterior ventilation,” Torok says. “But how do you integrate that with the mechanical systems of a building? That’s a big question.”

In existing residential buildings, one of the bigger issues is window-mounted air conditioners.

“I’ve been in buildings where people have taken hammers and hacksaws to aluminum windows to fit their air conditioners,” Torok says. “It makes far more sense to buy a new air conditioner that’s smaller that fits better into the opening. But, you own it already, and you have to go out and buy [the new unit]. So, you need an incentive to get rid of the old unit.”

Torok watched a presentation years ago by Toronto Community Housing where they were trying to solve

“The insulation of new façade systems has higher insulating values than the Toronto Green Standard is calling for, and that standard is resulting in a greater focus on where the weakest points have been.”

Although it is possible for an older structure to encounter weight restrictions, Redlarski says it’s unlikely to occur.

“This is applied engineering that can always be solved with different costs, I don’t foresee a problem,” he says. “Typically, the new façades are lighter than the old ones, and the old structures, they would stand the test of time.”

Redlarski says that the real issue is justifying costs to building owners.

“Some owners still withhold going ahead for updating buildings to standards that are leading edge because they cannot increase rents to offset this.” he says.

In the old days, people relied on opening their windows to get fresh air but, for decades, people have relied much more on mechanical systems. But with a desire to include more exterior ventilation to help meet future emissions targets, many challenges lie ahead.

“With the people thinking ahead to those aspirational goals – the 2030 and 2050 challenges – there is a desire to

the challenge of retrofitting their older buildings where residents were using a variety of older air conditioners causing the building’s energy costs to soar. To help solve this issue, residents were offered floor-based air conditioners that have a simple duct system that is placed into the window openings. This solution significantly reduced issues related to air leakage, water leakage and trouble accessing exterior walls for maintenance.

“It saved them operating costs. It was actually cheaper to give everyone a new air conditioner,” Torok says.

The insulation of new façade systems has higher insulating values that the Toronto Green Standard (for example) is calling for, and that standard (and similar ones) is resulting in a greater focus on where the weakest points have been, which are the thermal breaks and transitions, Heska says.

“With all of those thermal breaks and insulation challenges, there are typical details and best practices that can be

followed,” he says. “Designers now have the ability to determine, if you were to construct it using this certain drawing and details, then you’re going to achieve an R-value of five. Where, if you made this slight improvement, you can get an R-value of eight. We can do that when we’re designing, but we also need to have the installers in line and understand why these changes have been made. If we just design it, and it doesn’t get constructed that way, it’s kind of a waste of time.”

Heritage buildings can sometimes present additional challenges since there is typically a strong desire to maintain the original look of the building as much as possible.

“In can be difficult,” Torok says. “For instance, if you have an existing building with steel framed windows, steel can be very high strength. So it can be very narrow, and it provides potentially a very light appearance to the glazing. If you’re bound to keep that, it’s difficult to achieve that in any material other than steel. It is possible to get thermally broken steel-framed windows that look very similar to traditional, non-broken, steelframed windows. But that’s expensive to deal with and the thermal performance is not that great. So, then it becomes a question of looking at other aspects. Are the frames still in good shape? Are there other elements surrounding the windows that might need repair that would justify a replacement?”

Heska says there are certain buildings that can’t be brought up to the current standards for air tightness and thermal insulation, because if glazers and designers were to do that, it would cause other issues to the heritage elements of the buildings.

“There has to be some discussion between the owner of the building, the engineer-designer, and the local jurisdiction looking at imposing the efficiencies of buildings, because there’s a bit of trade-off between the two in some cases. Most of the people that I’ve talked to on the owner’s side, and the enforcement side with inspectors, understand they don’t want the nicest building in downtown Toronto that are heritage to all of a sudden have components falling off the outside face because they’ve insulated the inside too much.” •

ManufacturingJobsite.ca is Canada’s premier online job portal for the growing manufacturing sector. A laser focus on the right people across the country’s largest manufacturing media audience means you get the right applicants the first time. No more massive piles of unqualified applicants, just professional employers reaching qualified professionals.

Powered by the top manufacturing media brands in Canada, the reach to over 500,000 industry professionals on ManufacturingJobsite.ca is amplified by:

Website advertising to 185,000 qualified monthly site visitors

A comprehensive and magnifying reach across multiple associated job boards

Email promotion and job alerts to 131,000 industry emails using Canada’s largest CASL-compliant direct access to manufacturing professionals

Social media promotion to all brand networks on Facebook, Instagram, Twitter and LinkedIn

In order to meet this high demand and elevate women in the industry, safety must remain a high priority for businesses looking to fill the gaps.

The current state of the economy shows an immediate need for workers following the COVID-19 pandemic, especially when it comes to the manufacturing and construction industries. But the bleaker picture is the state of these industries over the course of the next decade and the lack of skilled workers when it comes to filling the demand for the growing number of projects.

According to the government of Canada, between 2019 and 2028, about 700,000 skilled trades workers are expected to retire. Meeting the demand for anticipated projects will require the recruiting and training of thousands of additional skilled workers.

That being said, there is optimism around meeting these needs, as provinces and the government of Canada along with non-profit groups work together to encourage younger generations and untapped demographics to join the trades. One of the demographics that is essential to reach is women. However, there are still systemic barriers that need to be addressed in order to successfully encourage women to pursue careers in the trades.

In order to meet this high demand and elevate women in the industry, safety must remain a high priority for businesses looking to fill the gaps. This means women need the right protective

ABOVE: Proper PPE for women ensures jobsite safety and makes it conducive for them to work in the trades.

equipment for the job ¬– and more importantly the right fit for the task at hand. For too long, women in the trades have needed to find workarounds for PPE designed largely for men. Gear and equipment such as boots, coveralls, goggles, gloves, respirators and even tools are mandatory for the jobsite. Despite this, many women may feel frustrated – and potentially unsafe – when using ill-fitting equipment. Keeping every employee on the jobsite safe is non-negotiable and can often be achieved by ensuring proper fit when it comes to PPE.

Although Canada has experienced a small rise in the number of women joining the skilled trades, there is certainly room for improvement. In 2018, Statistics Canada reported that women accounted for roughly 47 percent of the national workforce. Of that, just 12 percent were in construction, and only an estimated four percent working in on-site jobs with the remainder holding off-site roles.

While there is a national movement to recruit all Canadians into the skilled trades, there are also programs that specifically focus on elevating women into these fields. In 2018, the government announced several programs to encourage women to join the trade movement including an Apprenticeship Incentive Grant for Women, a Women in Construction Fund and a new pre-apprenticeship program. These efforts hope to play a part in securing thousands of jobs for women in the workforce.

Further, this past May, parliament members secured nearly $900,000 in funding to the College of Carpenters and Allied Trades for a project housed under the Union Training and Innovation Program. This funding is part of the Government of Canada’s $62 million investment over five years to help develop a highly qualified skilled trades workforce and prepare Canadians to fill available jobs as the economy restarts. As part of the program, the College plans to implement online learning as a means of supporting a more diverse and highly skilled carpentry workforce.

On top of the national efforts, provinces and territories are taking it upon themselves to incentivize untapped demographics to take up the trades. One example is the Ontario government investing $47 million over the course of the next year to hire more apprentices, improve the quality of training and help them complete their training and certification through the new Achievement Incentive Program and the expanded Apprenticeship Capital Grant.

In terms of initiatives specifically focused

Innovation and advancement of materials in recent years have contributed to improved fit and functionality of

on safety, the Builders Code is a pilot program in British Columbia whose main goal is to ensure the province’s construction employers adopt and champion human resource policies guaranteeing the equal and fair treatment of women. The initiative is focused on the retention of tradeswomen through improved policies and practices from employers. Research has demonstrated that equal and fair treatment of all employees and a feeling of inclusivity is essential for creating a safe and productive workplace.

According to the Canadian Centre for Occupational Health and Safety, PPE is the last line of defense for a worker when it is not possible to eliminate a potential workplace hazard. However, if personal protective equipment does not fit properly, it is unable to be effective. Men and women are built differently (that is, size, height, shape and so on), so why should women be expected to wear men’s workwear on a jobsite?

CCOHS states: “All workers have a right to a safe workplace. PPE designed for the dimensions of an average male worker means that female workers may be forced to rely on gear that is too large or disproportionate. From headwear to footwear, ill-fitting PPE can cause safety hazards, reduced dexterity from oversized gloves, hard hats that fall off, baggy coveralls catching on equipment and trips and falls because footwear or shoe covers are too large.”

With this in mind, a 2016 study of female

construction workers in the American Journal of Industrial Medicine found a majority of women reported fit problems with many types of PPE including gloves, harnesses, safety vests and work boots. The general complaint was that the equipment was too large to be worn effectively.

At the end of the day, addressing women’s safety needs on the jobsite creates a more inclusive and appealing working environment for them in the trades. When it comes to PPE, safety starts from the ground up. Proper footwear helps reduce the chances of slips, trips and falls along with crush and impact injuries on the jobsite. Additionally, the type of footwear can have a significant impact on comfort and all-day performance. Selecting the right work boot or shoe with the correct fit and appropriate features for the specific trade, task or environment can play a large part in making the days feel shorter and the job that much easier, not to mention safer.

Fit matters. In fact, it’s critical. Women in the market for safety boots or shoes should seek out brands that design and fit their products for the specific biomechanics of a woman’s foot and a women’s-specific fit will help to lay the foundation for a better performing work boot. Other fit and safety features include an unobtrusive-fitting

safety toe cap to give feet room to move, breathe and bend and a heel cup that makes wearers feel like their foot sinks back into the footwear as they lace the boot up, keeping the foot well-connected with a secure fit. These elements contribute to keeping the foot secure, comfortable and stable. Stability is crucial when it comes to safety on the job. Being able to trust each step can have a significant impact when it comes to preventing accidents.

Beyond fit, it’s essential to choose a safety footwear that satisfies the proper industry standards. This may include safety toe caps, electric shock resistant rating and metatarsal guards, among other requirements. In Canada, all CSAcertified safety footwear must include a puncture-resistant midsole plate for underfoot protection. In today’s market, some of the most important changes to the safety footwear has involved the innovation and advancement of materials to improve fit and functionality. For example, thanks to material improvements, puncture-resistant plates can now be flexible, non-metallic woven textiles, helping to reduce weight, improve flexibility and the ease of walking through metal detectors without sacrificing safety.

Other material advancements have bridged the gap between trades and trends.

New materials such as non-marring, hightensile-strength fabrics bring an athleticinspired breathability and functionality to the safety market. This has led to the ability to create sportier, more sneaker-like silhouettes. Comfort materials and advanced compounds further add the cushion, support and energy return needed for long days on hard surfaces.

As a safety footwear manufacturer, we also have some insights on what to look for when selecting women’s safety boots and some best practices when shopping for safety footwear.

When it comes to finding the best fit for footwear, workers should try on shoes towards the end of the day when feet tend to be more swollen and at their largest. This allows for a better fit from start to finish of the work day and ensures that the shoe will accommodate any swelling without causing harmful restriction of the bloodflow to the feet. Both feet should be measured when shoe shopping as most feet are not the same size. Workers should also bring a pair of socks they would typically wear with their boots. Socks should provide cushioning and ideally be made of a moisture-wicking material like Merino wool, which offers natural antimicrobial keeping feet stink-free and dry. A smart sock choice can also prevent foot problems like fungal infections or blisters, which form from moisture being trapped in the sock.

Now is the time for manufacturers and purchasing managers to invest in recruiting women to the skilled trades. That starts with creating a safe space for women to work –including proper-fitting PPE. By providing women with the safety equipment fit for them to tackle any job, we can better outfit the future of the trade industry in Canada. It is up to each business and work crew to set the bar for women’s PPE high and ensure that all employees feel safe and empowered to take on any task at hand.

Robin Skillings is the senior global marketing director for Keen Utility. In her tenure at Keen Utility she has spearheaded the “Tradeswomen Tested” program, enlisting some of today’s leading female tradeswomen to test and advise in the development of future women’sspecific safety products for the brand.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows. He can be reached at David. Heska@wsp.com.

Like most of you, I haven’t been on a plane in the past two years. But let’s take a few moments to imagine it’s 2013 and our 16-person airplane is about to touch down on the dirt airstrip in South Sudan. When we arrive at our accommodation, we are immediately greeted by a crowd of Sudanese men and women and are invited to the community dinner that evening. The first weeks are spent adjusting to the heat, the language, the culture and our new workplace.

I’ve reflected back a few times this summer to my time in Africa. I still get emails and text messages from some of my former colleagues, and as my company explored what a “return to the workplace” would look like, I caught myself comparing cultures. The collective culture I experienced overseas is quite different from the individualist culture here at home. Enjoying a dinner feast with the community was, and still is, a regular occurrence there. However, currently, in most parts of Canada, a community dinner is off-limits and would be avoided by many. I raise the topic of collectivism and individualism not to say that one is right and one is wrong, but to point out a few ways our culture impacts our work and our current reality.

French philosopher Alexis de Tocqueville described individualism as “a moderate selfishness that disposes humans to be concerned only with their own circle of family and friends.” A pandemic, lockdowns, and layoffs have subtlety nudged many of us further away from collectivism and towards individualism. After all, isn’t it only natural to put ourselves first? Shouldn’t

Communicating clear expectations to all employees has never been more important.

we make sure our oxygen mask is on before we help those around us?

On the individualism scale it may not surprise you to find out that, in one ranking, the United States is the country with the highest score. Australia, the U.K. and Canada are not far behind. At the other end of the spectrum, countries like China, Nigeria and Pakistan have high collectivism scores. Research is being conducted, but we shouldn’t be surprised when we hear or read news that various countries have responded differently to government lockdown policies. Each country has a unique culture, so of course, our responses are going to be different.

What does any of this have to do with the current state of our Canadian glass industry? If we start with the understanding that culture is the backbone of successful companies and organizations then we realize throughout the past year many of us have had to reimagine what our company culture looks like. Is the office open or closed? Are masks or vaccines mandatory or not? What rules need to be followed in the lunchroom or at the company barbeque? Communicating clear expectations to all employees has never been more important. Similarly, leaders need to be even more willing to revisit these expectations as new information and feedback is provided.

Anthropologist Philip Bock has said: “Culture is what makes you a stranger when you’re away from home.” It’s what made me long to sit down and watch Hockey Night in Canada while living on the banks of the Nile River, and culture is what makes employees long to continue working at a place they can contribute, belong and succeed. •

by JAMES HONG

To begin this article, I’d like to address the recent change in this column’s title. Initially, when I was asked what I’d like for the column title, I took a light-hearted approach and tried to infuse some humour for such a serious topic as safety by using a familiar phrasing for both title and pen name. Given what’s transpired in the last year, including current tensions, I’ve decided to change the title from ‘What Went Wong’ to include my actual name ‘What Went Hong.’ Thank you for your readership and keeping the safety of all in the forefront of your intentions.

COVID-19 mask wearing is required when keeping six feet apart is not possible. Having said that, I consider that rule to be inconsistent with the reality of the construction work environment and the nature of construction teams. Our people are far too busy focussing on doing a professional and safe job to be spending energy on this rule. The solution: keep your mask on.

I am passing along a company wide email I composed not so long ago:

It’s been a difficult year for everyone. Exhaustion and frustration are natural reactions to the pandemic. Due to recent findings that job site workers are either removing their masks or wearing them incorrectly, we need to firm up our commitment to keeping everyone safe.

Masks are mandatory at all times while on the job site, even when working alone. COVID-19 is airborne and spreads through breathing from the mouth and nose, as well as other airway access. Removing or wearing a mask incorrectly has the potential to contaminate the air around you. Let’s not forget that people can be carriers without any symptoms.

Please be diligent. We’re almost out of this, now is not the time to relax. Keep yourselves, your families and your co-workers safe.

We do not have control over who might enter the job site every second of the day, especially when working alone. Visitors and other unexpected persons could enter the jobsite and be infected, or you could be infected from their unprotected breath. Crowded jobsites pose an extra severe threat for exposure when mask protocols are not followed.

All job sites have mandated requirements for mask posters on site, instructing how to wear a mask properly. The daily safety meetings are to happen at start of shift and for every shift during the job. This update should include mask-wearing information.

Daily toolbox safety mask topics:

• State the reason for the meeting.

• Remind people that masks are mandatory at all times on the job site.

• Use the poster to instruct how to wear a mask properly.

• Instruct to always cover the nose and how to do so when wearing a mask.

• If people need some air, they are to go outside and take their mask off while following distancing protocols.

Please be diligent. We’re almost out of this, now is not the time to relax. Keep yourselves, your families and your co-workers safe. No one wants to be the mask police; unfortunately, it falls to us to keep a close eye out to protect ourselves and those around us. When you see someone without a mask, or not wearing a mask properly, it cannot wait until break time or one hour or even one minute, it must be corrected on the spot and must be reported in your daily log.

The sentiments I’ve expressed in the above email are heartfelt and, if I may say so, applicable to everyone no matter their working circumstances. We need to remind ourselves that COVID-19 mask-wearing is essential PPE, just as important as a fall protection harness or hard hat. Be safe. Be well. •

Anybus Wireless Bolt Controller Area Network (CAN) has provided thousands of industrial applications with wireless ethernet access. With a rugged and unique form factor for bolt-on-machine mounting, it is designed for the most demanding industrial applications. Use cases vary from warehouse installations and automated guided vehicles to manufacturing. HMS has now launched the Anybus Wireless Bolt CAN, featuring CAN-based communication to the host equipment. The new Anybus Wireless Bolt for CAN enables CAN-based, heavy-duty machinery and applications to transfer CAN data over a robust wireless link. Wireless communication is established either over a fast wi-fi connection or a reliable Bluetooth link. The CAN data is transported over a TCP/IP link which enables other standard

Ericsson has extended its Cloud RAN (Radio Access Network) offering to include support for 5G mid-band and Massive MIMO deployments. With mid-band spectrum, communications service providers can capitalize on their 5G spectral assets to roll out services quickly and efficiently, while delivering a more responsive experience to mobile broadband users.

These latest enhancements to Ericsson’s portfolio were developed in close collaboration with customers such as Verizon. They will enable service providers to seamlessly evolve towards cloud-native technologies and open network architectures and meet the demand for more deployment flexibility. Service providers will also be able to ex-

wi-fi infrastructure to also connect to the wireless link if desired. A typical use case is wireless access to CAN data from an industrial vehicle, such as a bulk material transport truck. For example, with the Anybus Wireless Bolt CAN, J1939 CAN data is easily communicated to a handheld tablet which gives the operator full control and

visibility of the ongoing bulk material filling process. Anybus Wireless Bolt CAN is fully transparent when it comes to transporting CAN data, meaning that it works with any CAN-based protocol, including CANopen. This opens the possibility to create mobile automation islands in any manufacturing process – the Anybus Wireless Bolt CAN will bridge the CANopen line wirelessly. In addition to the new Anybus Wireless Bolt CAN, the Wireless Bolt product family includes other versions which can connect to the host equipment using serial and industrial ethernet connectivity. On the wireless side of the Wireless Bolt, the wi-fi and Bluetooth options were recently complemented with a version that supports the new LTE standards NB-IoT and CAT-M1, targeting IoT applications.

tend Ericsson Cloud RAN reach with seven million 5G-ready Ericsson Radio System radios already in the field globally.

Since the introduction of Ericsson Cloud RAN at the end of last year, Ericsson has the capability to introduce a virtualized RAN solution across all deployment scenarios including existing footprints - also known as bluefield deployments. Bluefield deployments enable service providers to deploy Cloud RAN into their networks and capitalize on the full interworking between the two network architectures. This is driven by Ericsson Cloud Link, which enables value-add network technologies such as Ericsson Spectrum Sharing, Uplink Booster and Carrier Aggregation to operate across platforms.

A high-performing mid-band 5G deployment requires 150 times more compute power than 4G, in half the time. With the addition of hardware accelerators to deliver part of this needed compute power, cloud infrastructure becomes a feasible option for mid-band deployments. To meet the high-performance standards in 5G and beyond, Ericsson and Intel are pioneering the Cloud RAN space together.

Ericsson Cloud RAN creates more options for communications service providers and delivers a truly cloud-agnostic

platform, supported by its long-term strategic partner, Intel. The portfolio will leverage Intel’s compute across multiple product generations of Intel Xeon Scalable processors and accelerator technology, to enable high-density capacity solutions. This enables both companies to deliver the type of performance seen in the most demanding RAN environments in the world.

The emergence of virtualized and distributed computing architectures, together with disaggregation of hardware and software, has reinforced the value of open innovation ecosystems. Ericsson Cloud RAN is designed to be cloud-agnostic with supplementary cloud integration services to facilitate the onboarding to the service provider’s cloud infrastructure of choice.

To deliver that value and building on the foundation laid with Intel, Ericsson is also working with ecosystem partners, including industry-leading IT infrastructure vendors such as Hewlett Packard Enterprise (HPE). This collaboration brings additional flexibility to Cloud RAN deployments, as Ericsson customers will now also have an option to select HPE workloadoptimized edge compute based on HPE ProLiant servers and any cloud platform to deploy their Cloud RAN networks.

hpe.com

HPE Edgeline Converged Edge Systems converge operational technology (OT) –such as data acquisition, control systems and industrial networks – with enterpriseclass IT in a single, rugged system suited for harsh edge environments to enable innovative new abilities at the edge. Unleash the edge’s full potential by running enterprise-class applications unmodified at the edge – not just pared-down edge versions. Run identical workloads in the data centre, cloud or edge – whether containers, virtual machines, databases, softwaredefined storage or something else. Actuate and control things at the edge through a single integrated platform that combines OT systems with enterprise-class IT. You can connect OT systems over interfaces such as direct-wired I/O and industrial protocols that don’t exist in the traditional ethernet-based IT environment. Overcome harsh edge environments with a rugged form factor that is designed for severe, space-constrained and dusty environments to withstand shock, vibration and extreme temperatures ranges. Converge OT systems already out at the edge with enterprise-class IT systems traditionally found in the datacentre to improve insights for greater business efficiency. Optimise operations by actuating the equipment that drives the industrial edge. Improve uptime and system administrator efficiency with new first-of-a-kind edge-optimised management that provides iLO-based familiarity and simplicity. iLO Amplifier Pack (Integrated Lights-Out) is an at-scale inventory and update management tool which enables customers with large Gen8, Gen9 and Gen10 Hewlett Packard Enterprise server deployments to get rapid up-to-date inventory and automate firmware and driver updates. It also assists in manual and automated recovery of systems with corrupt firmware.

Azure Defender for IoT offers agentless, network-layer security that is rapidly deployed, works with diverse industrial equipment, and interoperates with Azure Sentinel and other SOC tools. Deploy on-premises or in Azureconnected environments. Use passive, agentless network monitoring to gain a complete inventory of all IoT/OT assets, with zero impact on the IoT/OT network. Analyze diverse industrial protocols to identify device details including manufacturer, type, serial number, firmware level, and IP or Media Access Control (MAC) address. Visualize the entire IoT/OT network topology, see device communication paths, and quickly identify the root cause of operational issues such as misconfigured devices. Proactively address vulnerabilities in the IoT/OT environment. Identify risks such as unpatched devices, open ports, unauthorized applications and unauthorized connections. Detect changes to device configurations, programmable logic controller (PLC) code and firmware. Prioritize fixes based on risk scoring and automated threat modeling, which identifies the most likely attack paths to compromise crown jewel assets. Monitor for anomalous or unauthorized activity using IoT/OT-aware behavioral analytics and threat intelligence. Strengthen IoT/OT zero trust by instantly detecting unauthorized or compromised devices. Rapidly triage real-time alerts, investigate historical traffic, and hunt for threats. Catch modern threats like zero-day malware and living-off-the-land tactics missed by static indicators of compromise (IOCs). Explore full-fidelity packet captures (PCAPs) for deeper analysis.

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

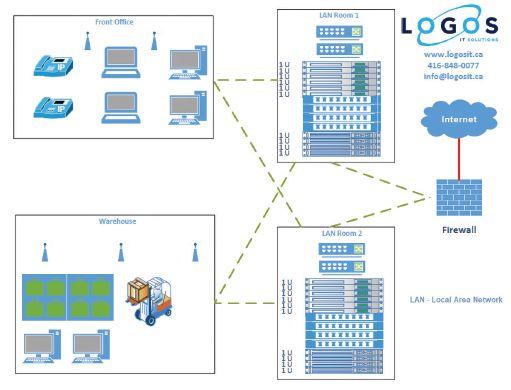

Warehouse Wi-Fi is critical for any operation, as so much of today’s modern warehouses rely on technology. Security is by far the most crucial component to consider when setting up a network. Regardless of the size of the warehouse, when introducing a new network, or expanding an existing one, it is important to ensure that everything connected to the Internet has the ap -

•

propriate security protocols in place to keep a company’s data safe. But, security is not the only factor to consider when setting up a network; safety must be considered in tandem with how the business intends to use the network. An effective network is highly secure without resulting in lost productivity. A system with multiple layers of security may keep a business safe, but it may also slow production if every user has to login multiple times to access a single piece of data. A properly designed network is segregated, allowing for multiple access points depending on who needs to access the data, and how often. Each sub-network still readily talks to the others to maximize data protection. How a network is segregated comes down to what each business needs. A good network engineer will analyze your requirements and custom design a network to them. From there, hardware will be purchased to fulfil that solution. Be wary of a network solution that comes from hardware being sold to you before a custom solution is designed — it’s a sign that the network engineer is creating a plan based on what they want to sell rather than what your facility may actually need.

Tempered up to 96 x 144

Custom Laminated up to 86 x 144

Bent Tempered Laminated to 66 x 96

wago.com

The PFC200 XTR Controller for extreme environments and Ex areas: Engineering, controlling and visualizing where other controllers fail. With the PFC200 XTR Controller, WAGO offers a rugged device that excels in extreme environments. Requiring no additional protective equipment, the controller defies temperature fluctuations of minus-40 to plus-70 C, has extreme resistance to impulse voltage up to five kilovolts, is immune to interference and vibration-proof up to five gravities. Thanks to the eRuntime environment based on Codesys V3 and the real-time-capable Linux operating system, this PLC is the efficient control system for your automation tasks. This includes locations that demand more than a typical automation system can provide.

Fujitsu.com

Fujitsu Components America has released a family of mesh network and multi-sensor units featuring built-in Wirepas Massive network connectivity. Based on the Nordic nRF52832 and an embedded FWM7BLZ20W Fujitsu Wirepas wireless module, the new FWM8BLZ08-x series endurance line consists of:

• FWM8BLZ08A Mesh Anchor unit for location/asset tracking reference point

• FWM8BLZ08T Mesh Tag unit with an acceleration sensor for location/asset tracking

• FWM8BLZ08Y Mesh sensor unit with embedded temperature, humidity, barometric pressure, illuminance, sound level, and acceleration sensors

• FWM8BLZ08C Mesh CO2 sensor unit also includes onboard temperature, humidity, barometric pressure, illuminance, sound level, and acceleration sensors

The CO2 sensor unit is powered by USB-C while all the other units have the option to be powered by four AA batteries or USB-C. Each is IP-65 rated against water and dust.The batterypowered anchor unit provides up to a five-year battery life. Utilizing the Fujitsu Mesh Anchors, Mesh Tags and Mesh Sensors, the Wirepas Positioning Engine (WPE) provides location awareness of stationary items and moving assets.

The units’ contemporary housing measures a compact 74.2-by-74.2-by-28 millimetres.They are FCC/ISED, CE and Radio Act Japan certified and have an operating temperature range of minus-20 to plus-60 C (with the CO2 sensor version starting from minus-10 C). CONTACT US TODAY!

t: (905) 669-6963

tf: (800) 361-4012

e: rimac@metalcurving.com

t: (905) 669-6963 tf: (800) 361-4012 e: rimac@metalcurving.com

by RICH PORAYKO

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company. richp@ constructioncreativecom

I’m fine. We’re fine. Everything is fine. It’s a mess. On top of the abnormal headaches, our industry lost some really good people recently and we have a dead-heat, snap election! Between the election, Delta variant, vaccine passports and the fall of Afghanistan, a lot of people are even more on edge, and the tinfoil hat crowd has crawled out of the woodwork.

No, Karen, the vaccine will not track you. Your smartphone and tablet already do that. Email marketing has been tracking you for years though. Marketing emails contain invisible pixels that report info back to the sender on who is and who is not opening, what they are clicking, when they are doing it and what device they are doing it on. This happens when the emails are opened and the images are downloaded, usually automatically. It’s one of the many reasons why email marketing is one of the most effective forms of marketing.

This will all be changing when Apple’s IOS 15 drops this fall with its “Mail Privacy Protection.” Mail Privacy Protection is going to affect your company’s email marketing, no matter which platform you are using. Read on and take some time to get familiar with what is and is not changing as well as some simple tips moving forward.

Announced in June 2021, Apple’s Mail Privacy Protection will give users of Apple’s Mail app for iPhone, iPad, Mac computers and Apple Watch the option if and when they want to open marketing emails. It is expected that most Apple users will opt in. Apple Mail will then start preloading images including the tracking pixel regardless of whether the recipient actually opened the email or not. This will allow users to mask information such as where and when they open

Mail Privacy Protection is going to have a significant impact on e-commerce and more sophisticated companies with larger marketing budgets.

an email, what device was used and other online activities linked to that device.

According to Litmus, Apple Mail is one of the most popular email clients in use today, accounting for 52 percent of all emails opened in 2021. Essentially, that means pixels and open rates will no longer be reliable as a performance metric. That’s a game-changer.

Since the data on who is and is not opening emails will no longer be reliable, auto-sending to non-openers will not be possible. That is a well-used, time-trusted marketing tool that is no longer available in the toolkit.

On the bright side, there are certain advantages to the glass industry lagging behind the adoption of technology. With B2C accounts, we see over 90 percent of recipients on mobile devices. With the glass industry, we only see around 20 to 25 percent of email recipients and website visitors using mobile devices for work. I estimate that Mail Privacy Protection will likely affect about 15 to 20 percent of my glass industry subscribers.

Some data will be limited. Email list segmentation, automation and A/B subject line testing will change or cease to exist. These will be a non-issue for most glass companies as these are techniques that are not typically called for by our trade.

Mail Privacy Protection is going to have a significant impact on e-commerce and more sophisticated companies with larger marketing budgets. For most glass companies that use email marketing, the stakeholders need to be aware that this change is coming and it’s going to permanently skew their open rates. For the most part, everything else can be worked around if you are simply looking to send a newsletter or promo every month.