Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Bass Installations is gaining recognition for its great work on high-profile projects in the Greater Toronto Area and beyond. Here’s the story of Steve Callender and the home-grown glass installation company he built.

Go ahead, interact

The Glass Canada Facebook page is a great place to catch up on the latest news, with items from our website re-posted there along with bonus content such as photos from industry events. See something that sparks a thought? Go ahead and post a comment. It’s free!

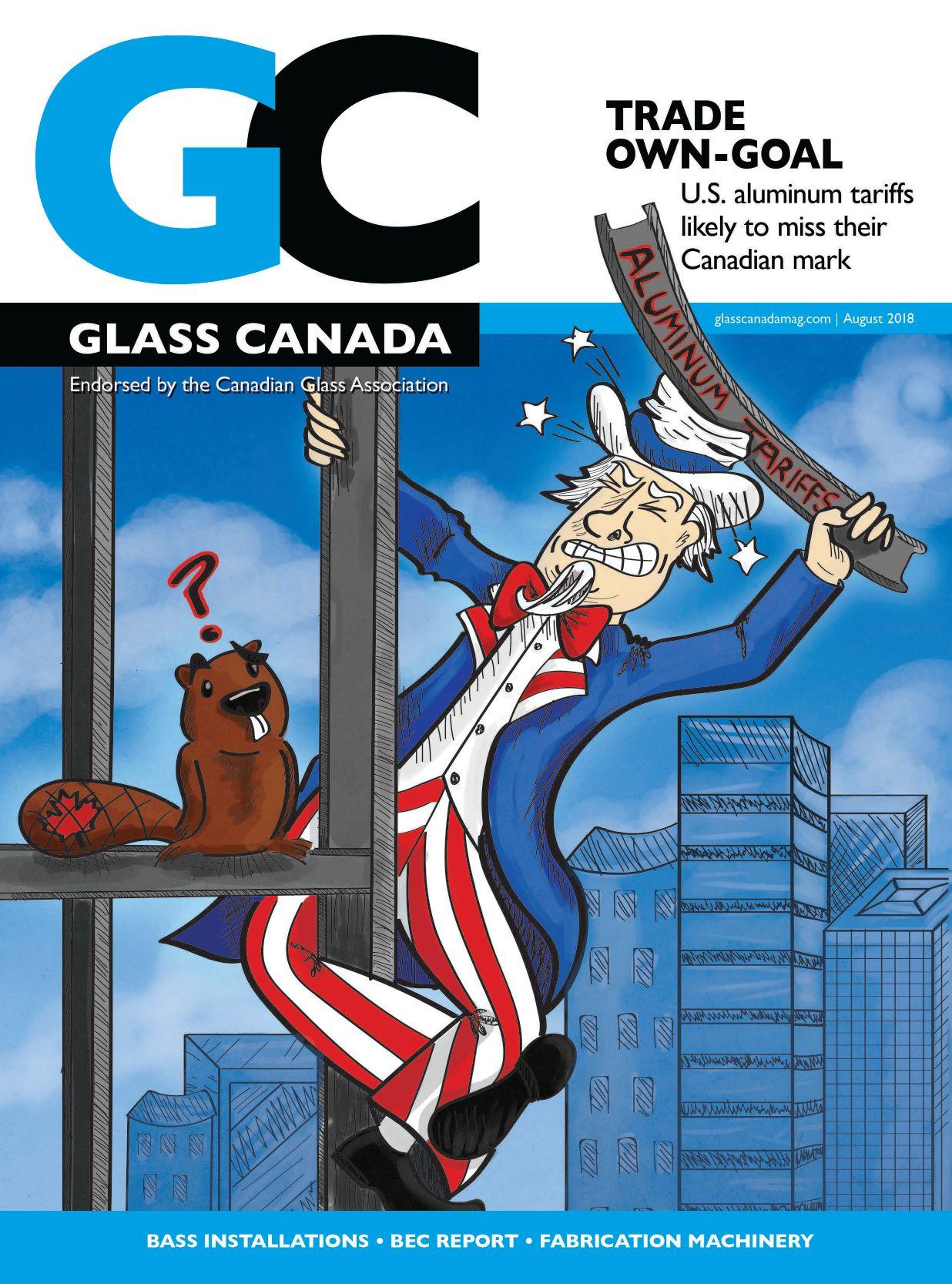

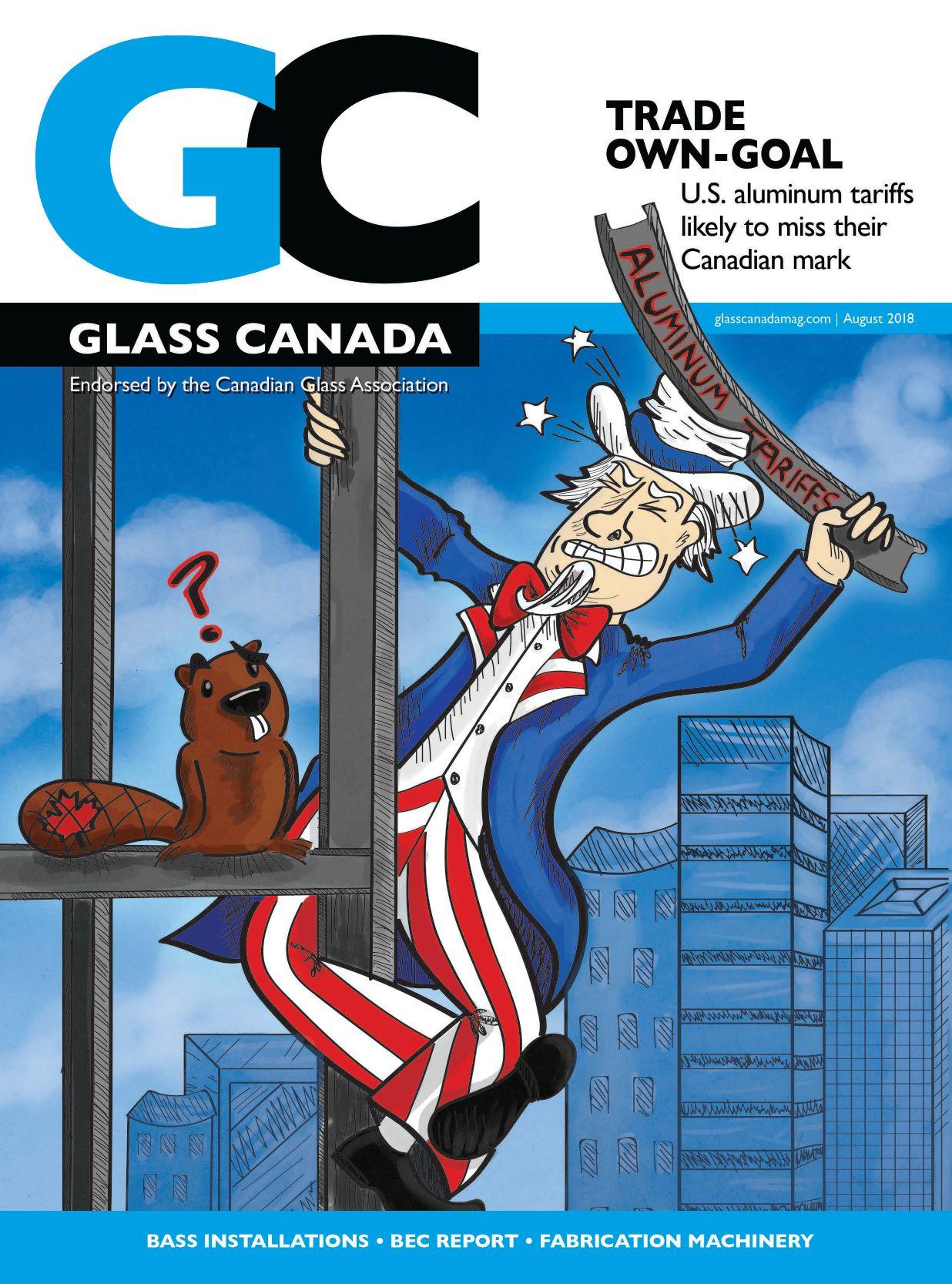

8 An own-goal on trade

Aluminum tariffs designed to protect domestic manufacturers will likely have the opposite result on both sides of the border.

24 The end of the beginning Optimism returned to the Building Envelope Conference this spring.

28 Fabrication machinery showcase

Our review of the latest in glass manufacturing technology

Global trends revealed GPD’s organizing chair gives his overview of the industry from the vantage point of a major international event.

David Heska

Frank Fulton

An economic own-goal

EDITORIAL

U.S. tariffs on aluminum are likely to hurt them more than us.

Our cover looks a bit different than usual this month. Don’t worry, we aren’t turning into a political magazine. But I suppose it’s an example of how politics has infected everything in this age of Trump that the best approach to our big topic looks like a political cartoon. The U.S. tariffs on Canadian steel and aluminum have been greeted with head-scratching and condemnation by just about all responsible economic commentators. It’s been well established for a very long time that trade protectionism accomplishes the exact opposite of what protectionists claim. People worried about business and job losses in a particular sector often convince politicians that allowing that sector to be exposed to competition from abroad will damage the economy. The proposed solution is either trade barriers like those imposed by the U.S., or subsidies for the affected companies like those extended to Chinese curtainwall manufacturers a decade ago. But the lesson of history is that these measures almost always inflict more damage than benefit on the broader economy.

NEXT ISSUE

• Imagic Glass

• Nanoglass

• Curtainwall

Trade barriers attract a retaliatory response, as we saw last week in Ottawa’s imposition of tariffs on American aluminum windows and doors. That raises the price on those products and, let’s face it, makes it more likely that you as a Canadian supplier will also raise prices or at least not make efforts to go lower. I hear you saying, “Higher prices? Yes, please!” But if I’m a politician, I’m supposed to be looking at the whole picture. Higher prices on products mean consumers have to spend more for the same items, bringing standards of living down (at least until wages catch up – which erases the benefits to companies of the higher prices). Optional spending will be curtailed, leading to recession, which hurts everyone. Then there’s all the people who made a living importing, selling and servicing the foreign products that are now blocked or too expensive. Flip through this magazine and count the number of advertisements placed by American companies. If they ever decided to abandon the Canadian market, would you give me a job?

As outlined in our cover story by Treena Hein, the impact to Canadian glass fabricators of the aluminum tariffs is likely to be slight, since sourcing extrusions from Canadian sources is always a possibility. The greater impact will be to American fabricators and exporters of manufactured systems, who will see their costs rise. It’s unclear at this time if they will make any attempt to pass those costs along. but either way they end up impacted financially or in terms of reduced competitiveness. Trump doesn’t seem to understand that even the tremendous power of the White House doesn’t enable him to move the Canadian aluminum mines where the bulk of North America’s supply comes from. Of greater concern are the retaliatory tariffs on aluminum windows and doors that our government has imposed, which will certainly impact prices on contractors used to sourcing those products in the U.S. Perhaps it’s time to look for a domestic supplier?

In this World Cup soccer season, it sure looks like the U.S. has scored an own goal with these tariffs. Maybe they just aren’t that good at the game.•

GLASS CANADA

August 2018

Volume 30 • Number 4

Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Curtis MARTIN

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

Testing anisotropy

Louis Moreau, head of technology and innovation at Agnora, along with Rick Wright, director of technical services at Oldcastle BuildingEnvelope (and ASTM C14 and C14.08 chair), has assembled an international group of stakeholders to develop a new ASTM standard test method for anisotropy measurement in glass. The initial kick-off meeting took place at Apple’s former headquarters, One Infinity Loop.

“As a manufacturer and supplier of monolithic, laminated and insulating glass panels to the high-end retail markets, we produce larger panels that must use heattreated components, ionoplast interlayers and multi-layer assemblies,” said Moreau. “This invariably produces optical phenomena that are observable but deemed ‘inevitable’ physical properties inherent to glass fabrication. We want to offer high-quality products and believe that we can improve those aspects.”

As task group chair, Moreau has over 25 years of experience in the glass industry and brings an eclectic mix of international experience from float manufacturing, highperformance vacuum coatings, large building glazing and high-end glass fabrication. In 2016, Louis and the Agnora team partnered

with McMaster University to study four optical phenomena: haze, anisotropy, clarity, and interference fringes. The results of the study were presented at the 2017 Glass Performance Days conference in Tampere, Finland, sparking dialog with several key stakeholders to start addressing anisotropy measurement.

“We are continuing our very interesting journey that will lead to quantifying phenomena that are deemed inevitable but, in our opinion, can be improved,” adds Moreau. “In the long term, measuring anisotropy will lead to esthetic improvements of large and complex glass panels.”

In the spirit of cooperation, the overall goal for Moreau was to create a forum to address the complexity of this phenomenon and to foster creative interactions. The ASTM kick-off meeting included Apple, Agnora, Oldcastle BuildingEnvelope, Skanska UK, HCU Hamburg, Munich University of Applied Sciences, Saint-Gobain Glass, SoftSolution, Viprotron, LiteSentry, Arcon Flachglas-Veredlung, Friedmann and Kirchner, McMaster University, Glasstech, Glaston America, Sedak, Permasteelisa, Standard Bent Glass, EOC, Corning, NSG, Kuraray, LBNL, Trulite and Eastman Chemical.

COMING EVENTS

August 23

PGAA Golf Lacombe, Alta. pgaa.ca

August 24

AVFQ Golf

Bromont, Que. avfq.ca

September 12 - 14

GlassBuild America Las Vegas, Nev. glassbuildamerica.com

September 13 - 14

RCI Canadian Building Envelope Symposium Mississauga, Ont. rci-online.org

September 20

OGMA Fall Golf Woodbridge, Ont. ogma.ca

October 15 - 18

AAMA National Fall Conference Tucson, Ariz. aamanet.org

October 24

FenBC Industry Conference

Surrey, B.C. fen-bc.org

December 3 - 5

WinDoor Quebec City windoorshow.ca

2019

April 17

Top Glass Mississauga, Ont. topglasscanada.com

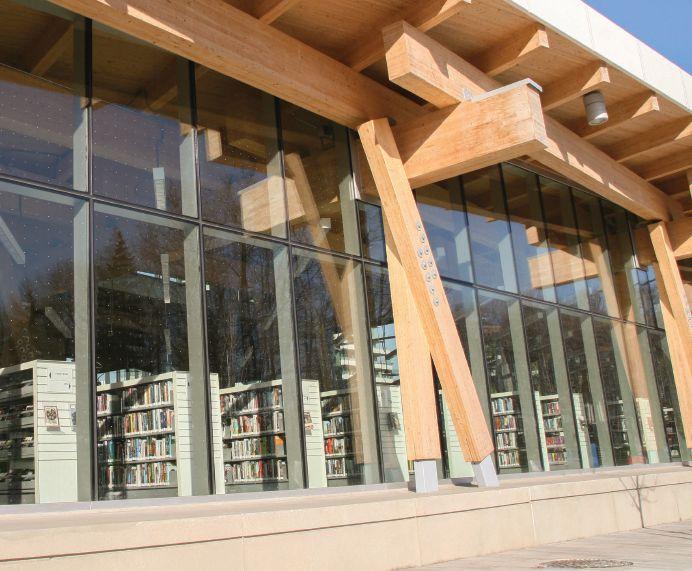

Photo courtesy Morrison Hershfield

CGA Newsletter

Canadian Glass Association

National activities of the Canadian Glass Association are on hiatus pending discussions of a new direction for the association. To help chart a course forward, please contact David Langton at dlangton@compglass.com.

Fenestration Association of B.C.

October 24 is the date for the FenBC Industry Conference at Sheraton Guildford in Surrey, B.C. We are working on our agenda at this time. Please visit our website at fen-bc.org to get updated information. If you are interested in sponsoring or being an exhibitor, check out the link on our website.

FenBC’s Annual Golf Tournament was May 17 at Northview Golf Course. Thank you to our sponsors: Cardinal IG (Top Tier sponsor), PFG Glass (Air Cannon Sponsor), Cascade Aquatech (Beat-the-Pro Sponsor) and Vetrotech Saint Gobain (Trivia Sponsor) for your support.

Congratulations to the winning foursome consisting of Chris Boswell and Ryan Knodel from Oldcastle, Tony Scigliano from Coniston and Blake Ashforth from Glastech Contractors. This team also won the trivia contest sponsored by Vetrotech Saint Gobain. The Cascade Aquatech Beat-thePro hole was won by the K&W Glass innovations foursome. The winner of the PFG Glasssponsored air cannon long drive hole was Ryan Dennett of Greenlite Glass. The big winner of the day with the Cardinal

Canadian Glass Association

3759 York Durham Line, Stouffville, Ont. L4A 7X4

Tel: 250.258.0578

canadianglassassociation.com

IG-sponsored set of golf clubs was Chris Lambert of Kawneer. It was a great sunny day (not like last year’s monsoon!) and we all had fun.

Here in B.C. all the FenBC members are pretty busy so the association does not have much planned over the summer. Our Education Committee is working on educational webinars for the fall. The FenBC Technical Committee is working on the October conference and the Glazing Systems Specification Manual (GSSM) in collaboration with Morrison Hersfield. The Marketing Committee is working on ways to increase our profile here in western Canada and looking at our websites to make any necessary changes.

Prompt Payment B.C. is working hard here to get prompt payment provincial legislation that ensures participants in the construction chain receive timely payment for goods delivered and services rendered so that no individual or group of service providers carry an unfair burden of the construction risk and costs. The group is working to ensure legislation that removes unnecessary impediments to delayed payment is put in place. You can find out more at promptpaymentbc.ca.

Here at FenBC we wish you all a safe and happy summer!

Architectural Glass and Metal Contractors Association

The AGMCA and its industry partners predict that over the next 10 years we will lose 20 per cent of our journeyperson labour force to retirement. This compounds

the skilled labour shortage in our province.

The need to attract and retain new apprentices has never been greater. While trying to attract new candidates, we face stiff competition from other industries, other trades and indeed other companies within our own trade.

The AGMCA and its member employers are partners at the skills training centre located at 130 Toro Road in Toronto. The centre is run by the Finishing Trades Institute (FTI). Here, new apprentices are trained in the latest glazing techniques, using the latest technology. Through its Glazier Apprenticeship Committee, the AGMCA oversees the training and monitors the progress of the apprentices. Employers need to view apprentices as an asset, not a liability. They are the lifeblood of our industry.

There are grants and/or tax credits available to all employers of current apprentices. Visit the FTI website at ftiontario.com for all the associated links or contact us at info@agmca.ca for further details.

Ontario Glass and Metal Association

TONY MENECOLA: The Ontario Glass and Metal Association presented its Lifetime Achievement award to Tony Menecola, president of Applewood Glass and Mirror, at its spring golf tournament on May 31 in Milton, Ont. Menecola is president of the Architectural Glass and Metal Contractors Association and the award was presented by that organization’s executive

director, and long-time friend of Menecola, Noel Marsella. Marsella noted Menecola’s life-long involvement in the industry. Raised by his father, Lorenzo, a steel window manufacturer who immigrated to Toronto in the 1950s, Menecola started assisting his father when he was 12 and went into business with him in 1979. FISHING DERBY: Things aren’t looking good for our annual fishing derby this summer due to circumstances beyond our control. We don’t have a date confirmed but if we can pull it off it will take place in August and flyers will be sent out well in advance.

FALL GOLF: Mark your calendar for Thursday, Sept. 20, make your plans, arrange your group and be at the Country Club in Woodbridge. Keep your eyes out for notices as the date approaches.

CONSTRUCTION LIEN AMENDMENT ACT:

One component of the act came into effect on July 1 introducing new performance and labour and material payment bond wordings for all publicly funded work in the province. It is mandated that all public projects in excess of $500,000 are to be bonded (50 per cent performance bonds and 50 per cent labour and material payment bonds). New bond wordings will be provided in support of public contracts. A member bulletin on the topic will be sent to OGMA members in the next while.

AODA’s NEXT HURDLE: In case you missed it, companies had until the end of 2017 to put a new set of accessibility policies and procedures into place. To find out your legal obligations, go to ontario. ca/page/accessibility-laws.

Trade own-goal

own-goal

Experts agree U.S. tariffs will accomplish little.

by TREENA HEIN

It’s impossible to name a bigger economic story in Canada right now than the tariff war that’s been started by U.S. president, Donald Trump. In mid-2018, he followed through on plans to charge Canadian firms tariffs of 25 per cent on steel and 10 per cent on aluminum that crosses the border. Trump says he imposed the tariffs because he believes his country is being treated unfairly in various ways relating to trade, and because he believes the tariffs will help protect American jobs and boost the U.S. economy. He’s also listed national security concerns over relying on foreign metal materials for shipbuilding and so on.

Experts put the estimated impact to the Canadian economy at over $3 billion USD a year. On July 1, Prime Minister Trudeau instigated dollar-for-dollar counter-tariffs on many types of U.S. goods entering the Canadian market.

Riyaz Dattu notes that although they are quite new, the U.S. tariffs have already caused much economic confusion. “There is also confusion about the effect of this situation on NAFTA,” notes the partner at Osler, Hoskin and Harcourt law firm (five offices in Canada and one in New York) who specializes in international trade and investment law. “The U.S. is using these tariffs against Canada as a means to provide leverage for the U.S. to gain more friendly terms under NAFTA and it’s put the negotiations process into disarray.” Dattu says it’s hard to tell how long this will continue, as the U.S. has indicated that as long as Canada doesn’t agree to some points in the NAFTA negotiations (for example, Canada doesn’t want a sunset clause which would entail a review every five years, and wants to keep Chapter 19 dispute resolution by an international panel), the tariffs will continue. “It could be as long as next year,” he says.

Similarly, Michael McCaig (senior vice president and general manager at Alumicor) believes these tariffs are here to stay until at least the end of 2018. Alumicor manufactures curtainwall, storefront and windows at facilities across Canada. Its parent company is American and while Alumicor does export a few specialty products into the U.S. market, it’s a small portion of its total sales. “President Trump has already publicly linked any revisiting of the tariffs to NAFTA negotiations and has indicated there would be no deal until after the interim U.S. elections in November,” he explains. “I think it is difficult for anyone to say how long the tariffs will be in place because Washington has associated so many different reasons for implementing and keeping the tariffs in place.”

The impact of the steel and aluminum tariffs on glass industry firms who buy their systems from U.S. suppliers is, first and foremost, increased prices, according to Andreas Schotter, associate professor at the Ivey Business School of Western University in London, Ont. “There are higher prices, but construction must still go on,” he reports. “American manufacturers have already jacked up their prices, and construction becomes more expensive and substitutes will be used in the window and door industry where possible, like wood or vinyl. Projects may be delayed due to the uncertainty.” Schotter adds that in commercial construction, for contracts that have already been signed, the main contractor will get squeezed due to the higher prices of materials and they will consequently likely squeeze contractors farther down. Residential contractors are in a better position, he notes, as there’s a smaller dollar impact and project lead times are much shorter and therefore much fewer contracts are affected.

Competition Glass in Kelowna, B.C., purchases aluminum products from the U.S., but owner David Langton (who is also president of the Canadian Glass Association) says he had not, as of the last week of June, received any price increase notices.

Prices and consequences

Before the tariffs came into effect, the price of raw aluminum in Canada had already increased since January to the tune of nearly 25 per cent. McCaig says there are several political and economic reasons for the increase, including the U.S.-announced sanctions impacting Russia’s largest aluminum company. This created concerns over physical supply that caused prices to spike in April. There have also been supply shortages due to operational issues at several aluminum producers, he says. Additionally, U.S.sourced aluminum extrusions have gone up more than Canadian aluminum extrusions due to the weakening of the Canadian dollar over the past few months.

“We expect that aluminum price itself will go up a few more percentage points, but the market has been anticipating this action for several months and we believe the bulk of the increase has already been built into the midwest transaction premium,” notes McCaig. “Aluminum imported into Canada now faces an additional 10 per cent tariff so imported aluminum from the U.S.A. will be subject to this tariff. Fortunately, Canada has a robust domestic aluminum industry, so sourcing from Canada will mitigate the counter-tariffs announced by Canada effective July 1 on U.S.- imported aluminum.”

Dattu notes that price increases have caused some Canadian firms to change their source of supply from U.S. to Canada and other countries – and Alumicor is one of them. McCaig confirms that his team is actively investigating sourcing activities. “We are planning to move a significant volume of orders from U.S. companies to Canadian companies,” he reports, “solely based on the potential financial impact of continuing to buy from the U.S.”

Leverage going forward

Canada outcompetes all other nations in supplying steel and aluminum to the U.S.A. Canada exports almost all (almost 90 per cent) of our steel to the U.S., and we export about 85 per cent of the aluminum we produce, which makes up about two thirds of America’s aluminum imports.

In Dattu’s view, Canada therefore does have some leverage with the aluminum we sell across the border, and McCaig agrees. “Canada exports about five times the amount of aluminum to the U.S. as

It’s hard to understand what the U.S. hopes to achieve with its aluminum tariffs when big fabricators like Alumicor can simply source their extrusions in Canada and move domestic production here. Send your thank-you notes to 1600 Pennsylvania Ave., Washington D.C.

it imports from the U.S.,” McCaig notes. “The U.S. does not have the capacity to support its aluminum requirements and relies on countries like Canada to meet its demand. There is no way to quickly ramp up U.S. aluminum manufacturing and Canada has very cost-effective capacity.” McCaig therefore believes the situation will be resolved in the near future, given that it makes sound economic sense for both countries.

He believes that given the significant impact this has on our companies, industry and the economy as a whole, he would obviously like to see the tariffs on both sides eliminated altogether. “The value of the tariffs, both as a percentage and dollar value, is so significant that some experts are saying both Canada and the U.S. could be pushed into financial turmoil, especially if things escalate further,” he observes. “Tariffs between the two countries will only result in higher prices for citizens of both countries.” McCaig expects that once the political climate shifts after the November 2018 mid-term elections and the NAFTA negotiations are over the majority of these tariffs will be eliminated. “However, given the uncertainty associated with the current U.S. administration,” he notes, “the outcome and timing of any resolution is

very difficult to predict.”

Schotter expresses worry that the tariff situation will not be remedied through the actions taken by the World Trade Organization. “I’m concerned the WTO has no teeth,” he says. “It has made strong statements, but Trump doesn’t care. I think the right path is to lobby hard behind the scenes with U.S. interests that do not want these tariffs. And that’s being done. We should not retaliate as we are way too small and dependent on the U.S. in terms of trade.” McCaig points out another concern related to the retaliation: there are presently no U.S. tariffs on Canadian aluminum windows and doors being sold into the U.S. market, but U.S. windows and doors are included in the retaliatory Canadian tariffs. He wonders if the U.S. will take action to even up that score.

For his part, Langton believes “this may be a summer storm. But when major U.S. firms announce they are moving their production facilities offshore, it seems to me that the process is somewhat misguided. The proof will be in the pudding, won’t it? I’m sure as the summer progresses, NAFTA and other agreements will either ‘blow up’ or proceed. Hopefully cooler heads will prevail on all of this.” •

BRINGING URBAN INNOVATIONS TO LIFE.

Creating multifamily façade solutions that residents love. An airy, well-lit and energy-efficient apartment becomes a home when it’s filled with the people and things we love. Providing high-performing solutions that positively impact loved ones in their favorite space makes for happier living. High-performance multifamily façades for high performers.

kawneer.com

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David.Heska@wsp.com

Pull back the curtain

Every summer thousands of curtainwall projects are constructed across Canada. Regardless of the type of system installed, whether it’s stick or unitized, there can be some common issues that arise during and after construction.

First let’s briefly define the two major types of curtainwall systems.

Stick-built systems are installed and assembled together on a floor-by-floor, piece-by-piece basis (these pieces are the “sticks”). The benefits to this type of system are that it can be low-cost and more flexible in creating building shapes. Unfortunately, installation can be very labour-intensive and the quality of on-site workmanship is typically lower than factory-controlled workmanship. Unitized systems are pre-fabricated in modules and delivered to site in panels. Panels are typically one storey tall and connect like puzzle pieces. Because of this, unitized systems are constructed faster with a higher quality due to factory manufacturing, but the shipping costs increase.

Now let’s turn our attention to a few common issues, namely: torque, condensation, fire and IGU failure.

In curtainwall with pressure-plate glazing, one important element all parties involved need to know is the required torque pressures. Some specifications call for torque pressures as low as 20 inchpounds. Others state “increase torque to 50 to 60 inch-pounds after all four sides have been secured.” Contractors recognize that over-torquing dramatically increases the likelihood of glass breakage and so they tend to err of the side of caution, however, if the torque pressure is not achieved water ingress may occur. Specifiers and designers must be clear and provide acceptable torque ranges. An on-site

Specifiers and designers must be clear and provide acceptable torque ranges.

THE ENGINEER

review should be completed to ensure that these design parameters are being met.

Another common deficiency is condensation on the interior surfaces of curtainwall elements. I’ve been involved on a few projects where the building owner has asked us to review “moisture problems” after only six months of occupancy. Typical issues causing condensation on interior surfaces are poor detailing, inadequate HVAC design and thermal bridging that has not been considered. As our industry moves forward, it is critical that design professionals and contractors work collaboratively to reduce these occurrences. Education is also important so that words and drawings on a page can be translated into facades that can actually be built in the real world.

An increased awareness of fire safety is also leading to more attention to proper smoke-sealing between the floor slab edge and the back of the curtainwall assemblies. Compartmentalization of areas from one another is important to slow down the passage of fire between floors. Typical details show fire-rated assemblies that have been approved to Canadian standards are required to provide confidence that the materials will remain in place during a fire event. Often, there is a need for clarity around site-specific conditions where the “typical” detail does not apply.

Finally, an issue that is becoming more popular as our building stock gets older is IGU replacement in curtainwall. Around the 25-year mark, some of the seals on insulating glass units begin to fail and building owners are faced with a decision to either reactively replace fogged units (sometimes at a rate of 10 to 20 IGUs per year) or proactively upgrade their curtainwall system. The payback for 100 per cent IGU replacement can be compelling in most cases due to substantial savings resulting from advanced IGU technology today (i.e. better solar heat gain coefficients and overall U-values).

So if you’re visiting downtown Vancouver, Calgary, Toronto or Montreal this summer, take a look up at some of the curtainwall buildings and ask yourself, “What could have been done by the engineer or the contractor or the manufacturer to make this a better building”? •

Capture clarity.

Fit the bill—and the build—with new Acuity Low-Iron Glass. Elevate aesthetics for a modest investment, without sacrificing performance. New Acuity Glass by Vitro Architectural Glass (formerly PPG Glass) is an affordable low-iron solution available with Solarban® solar control low-e coatings, offering vivid views with no green cast. Where conventional clear glass was once a given, pure clarity is now within reach.

Request samples and learn more at vitroglazings.com/acuity

Low-Iron Glass

UNDERtheGLASS | BY JACK KOHANE

Need more Bass

A small shop lands high-profile projects.

The massive rings on the Eaton Centre’s TEC bridge are installed and Bass workers prepare to install the interior glass. The bridge was partially built on James St. just west of the Eaton Centre and moved into place on July 8, replacing the old bridge between the Eaton Centre and the Bay, over Queen Street.

BASS INSTALLATION AT A GLANCE

Look up, up, up at Toronto’s gleaming glass towers and there’s a lot of the Bass Installation team’s handiwork on display. From the lustrous curtainwall and windows of the lofty 72-floor First Canadian Place (BMO Tower), to the 51-storey Bay and Adelaide Centre office skyscraper; and from the luxurious, 68-floor Shangri-La Hotel/Condo spire, to the prestigious Adelaide Hotel (formerly Trump International Hotel and Tower), Bass boasts some of the city’s tallest and architecturally complex structures within its prodigious projects portfolio. The Mississauga-based glass installation specialist is a top go-to firm when major builders seek the installation of curtainwall, windows, entrances, skylights and revolving doors.

“We believe we can do it all,” says Stephen Callender, president of Bass Installation. “While our experience has been primarily working in the industrial-commercial-institutional (ICI) market, we are pushing the boundaries to respond for the need of quality unionized installation practices in the high-rise residential market. We are a company that is constantly

striving for continuous improvements. We push ourselves to better our installation practices, to improve our safety procedures and to increase our use of technologies.”

In recognition of its accomplishments, Bass was recently awarded the 2018 OGMA (Ontario Glass and Metal Association) Award of Excellence for the University of UTSC (Toronto Scarborough Campus) Environmental Science and Chemistry Building project at the Top Glass conference. “Working with topnotch customers like SotaWall (headquartered in Brampton, Ont., and one of North America’s leading curtainwall suppliers) on unique projects such as the UTSC project is one of the key ingredients to the success of a project,” notes Callender. Bass also earned the 2010 Award for Excellence in Safety Leadership for its work on the Trump International Hotel and Tower project. Callender’s team managed over 20 suspended stages on that monumental structure and it was part of a safety blitz conducted by the Ministry of Labour that year. “It’s a great source of pride for us to win these awards. It’s a testimonial to our

Location: Mississauga

Founded: Oct. 2004

President: Stephen Callender

Employees: 30-150 (dependent on projects of various sizes and scope)

Serves: Mainly GTA Focus: Commercial

excellent safety performance delivered on such prestigious projects that make bold statements in glass.”

Being bold is something Callender and his crew know something about. It wasn’t easy building Bass, subject to the ebb and flow of the unpredictable construction cycle.

Arriving in Toronto from his native Barbados in 1979, Callender started his first job working at a window factory in Scarborough in east-end Toronto. With no prior experience in the glass business, Callender worked his way up in the company by sheer hard work and a savvy knack for using the tools of the trade. Those basic tools have evolved into sophisticated machinery that gets installations done quickly and efficiently at

heights of hundreds of metres. Today’s sky-high job sites means Bass’s installation crews rely on an innovative tool kit, primarily DeWalt and Hilti brand power tools, including drills, screw guns, power saws and Wood’s Pow’r suction grips. Installation equipment covers the range of swing stages and Spider Cranes (supplied by Suspended Stages, Scafom Canada and Up and Down Lifting Solutions).

In the early 1980s, he joined the Ironworkers Union (Local 721) and continued working for a variety of companies while completing his apprenticeship. By late 1980s, he became a general foreman for Antamex International (today part of Oldcastle Glass) and ran various key projects in Toronto, including 250 Yonge Street (the Eaton Centre).

Then the recession of 1992 hit. “Like many others in the construction industry, I was laid-off and out of work,” Callender recalls. But he refused to be idle for long. He partnered with a colleague to start their first curtainwall installation company, G+S Associates, where they acquired some small curtainwall, window and revolving door projects throughout the Greater Toronto Area. By 2003, the company changed its name to Bass Installation and the following year Callender became the company’s sole owner. He continued to procure projects such as the William Osler Centre in Brampton, as well as the Canada Life Building and the Bay/Adelaide Centre in Toronto. His entrepreneurially minded daughter, Natasha Callender-Wilson, who graduated the Humber College accounting program in 2007, joined Bass as a business partner and is today its vice-president of business operations and health and safety.

Working from the basement of their family home, Stephen Callender would price jobs by night and manage a growing number of projects by day. Natasha handled the bookkeeping, payroll and health and safety functions while finishing her business degree at York University. In 2010, Bass went into expansion mode, acquiring office and warehouse space in an industrial park area of Mississauga. It continues to acquire additional administrative and operational space as the number of clients and project increase.

“Our reputation precedes us among the GTA’s top high-rise builders,” nods Natasha. “We don’t need to advertise what we do, we’ve grown organically as more and more business comes to us. There’s

been occasions when we’ve been involved in multiple big projects for blue-chip clients all at one time.” It’s a formidable feat of multi-tasking that the Bass team relishes.

Callender adds that the company’s key asset is its people. “Our installation crews

have working with us, we would not be able to do this alone.” Many of the Bass crew members have been with the firm for many years which, Callender believes, enables the company to maintain quality and consistency in its work. “Behind our installation crews is our ever-growing operations

We don’t need to advertise what we do. We’ve grown organically.” – Steve Callender

are professionally skilled tradespeople of the glaziers and ironworkers unions,” he notes. Bass encourages its employees to participate in training and educational opportunities so that they too can aim at continually improving their knowledge and skills. “Without the qualified, knowledgeable and skilled individuals that we

team, which supports the crews in the field to help get the job done right and on time.”

Recalling some of the heftiest installation challenges he’s encountered, Callender points to the Adelaide Hotel project as a particularly thorny example. With a top dome height of 827 feet, making it the fourth-tallest structure

in Toronto and all of Canada, the site was a tight one to move people and machinery around when the heavy granite frames (some weighing 3,600 pounds) arrived on site. “We needed specialized equipment to manoeuvre the humungous frames in place. We then set up floor cranes and created our own engineered monorail system for easier and efficient installation methods.”

First Canada Place (BMO), located in the heart of Toronto’s financial district, with its brilliant white fritted exterior wall and laminated fritted glass and bronze glass corner panels, proved an engineering test for the Bass. “We were

Steve started from the basics to build Bass Installations and now the future looks bright with his business-savvy daughter, Natasha at his side.

working on a very ridgid schedule,” remarks Callender. “The unique installation method was different than anything we had ever done before. We installed the panels from the top down and while the building was still occupied.” The three-tiered platform was mapped into quadrants that consisted of the lower platform where the old marble was removed, the middle platform used for the tie-ins on to the building structure and the top platform where Bass installed the new fritted white glass. “The end product gives the building a clean and contemporary look,” he opines.

In achieving such spectacular results, Callender is quick to credit his skilled workforce. The Bass field personnel are all unionized and, he claims, are usually easier to attract. “If we have a job they want to work on, they usually come to us. Skills and knowledge can be taught to most individuals, but the key

is the right fit for our company.”

Ensuring safety remains at the forefront of the Bass mission. According to Natasha, the company’s safety program is above the industry standard and lays out the ground rules as to how things are done. “Our safety culture is one of the things we believe sets us apart from other companies, because safety is at the cornerstone of every type of project we do.”

Now the brass at Bass are building on their experience in the ICI market to push the boundaries in the high-rise residential market, including such soaring current projects such as the 789 residential suites of One Bloor East (balcony and point-supported glass wall), YC (Yonge and College) Condo with 633 residential units, and 11 Wellesley (740 suites).

“The reward is looking back at all the projects we’ve worked on over the years and looking ahead to the ones we are planning to do,” smiles Callender. “We’ve installed curtainwall and revolving doors on some of the highest profile projects in the city of Toronto. There’s no stopping Bass now.” •

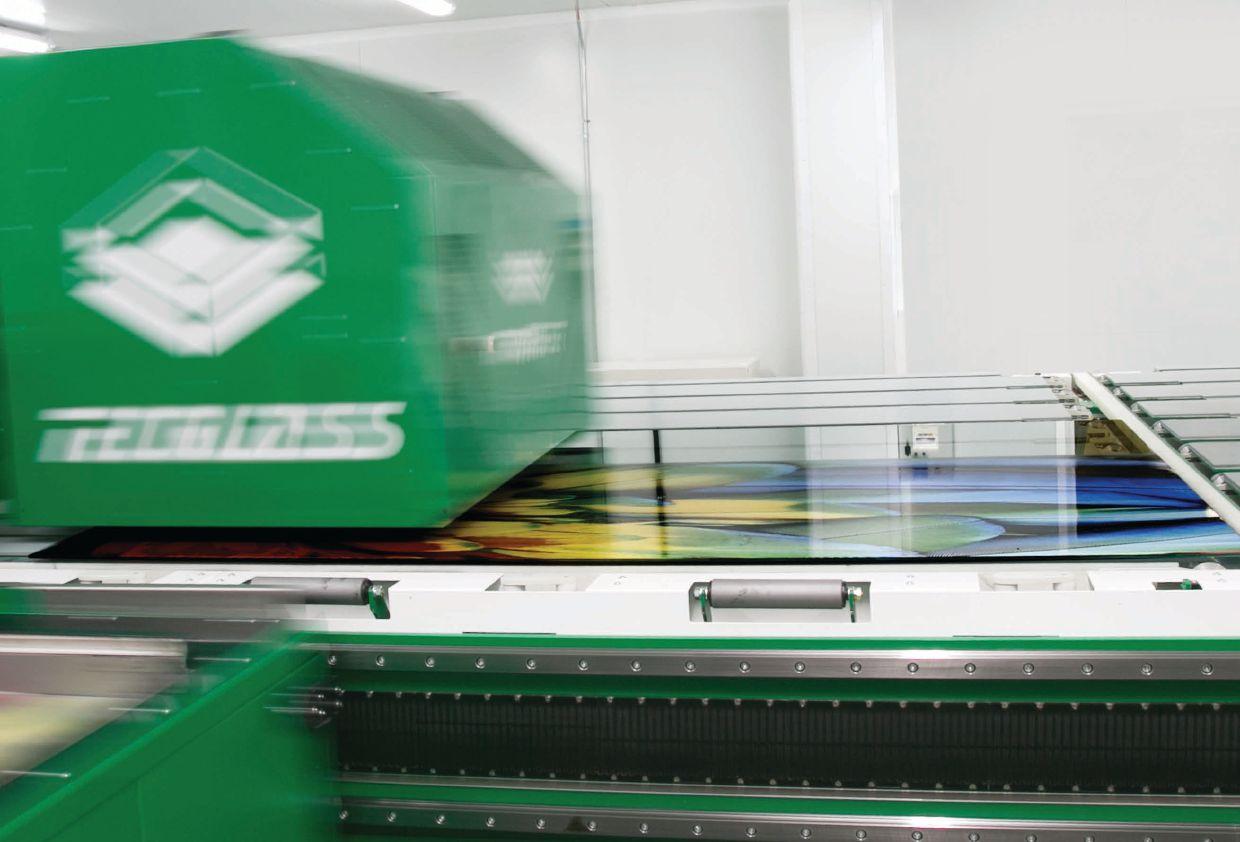

PRINTED DESIGNS

IN SIZES UP TO 110" X 200"

Global trends revealed at GPD Knowledge

grows when knowledge is shared.

It’s a time of real advancement in the technology of glazed building facades. Thanks to innovations in computer and materials science, our projects can be bigger, higher-performing and more beautiful than ever before

Glass Performance Days (GPD) is a leading glass industry conference taking place each year in Tampere, Finland. The philosophy of GPD is summed up with a quotation from the Indian poet, Bhartrihar: knowledge grows when knowledge is shared. The purpose of the event is to develop the whole glass supply chain globally.

At the 25th anniversary GPD event, experts in the field held 180 presentations on new technologies, trends and innovations. The following is a summary of more than 10,000 PowerPoint slides, boiled down to the most interesting and most important topics.

Worldwide glass market trends

The glass industry has experienced significant changes over the past 25 years. New players have entered the market and production has grown. Twenty-five years ago there were 150 float lines, now

there are more than 500. Just a quarter of a century ago Europe, the United States and Japan produced 60 per cent of all the glass in the world. Now their share has dropped to below 20 per cent.

The rise of eastern Asia, especially China, is reflected in the market in many ways. In Asia, demand and manufacturing are both on the rise. More than half of all float lines and production capacity are located in China and there are more than 7,000 Chinese glass patents nowadays – a significant growth from the slightly more than 300 patents there were 25 years ago.

The production capacity of float lines and the life cycle of furnaces have increased. There have been technical developments in efficient energy use, melting technology and various coating technologies. The thin glass developed for cellular phones and tablets is used more and more in architecture, interior design and the automotive industry.

ABOVE: The Market Hall in Rotterdam, Netherlands, features the largest suspended cable facade in Europe. The building combines residential living with an open shopping area in the middle.

Photo credit: Mick Eekhout

As glass becomes a better barrier between the environments inside and outside the building, it paradoxically acts as a better gateway between the two. Huge, unbroken vistas to the outside no longer mean sky-high heating and cooling bills thanks to innovations such as low-E coatings, smart glass, triple glazing and heated glass.

Fabrication processes have also improved significantly in 25 years. The size of safety glass and insulating glass elements has increased considerably and the new coatings raise energy efficiency to a whole new level. Energy balance is given special attention today. Glass can be bent into more complex shapes and different coatings give it new features and possibilities. Process automation has increased and improved production efficiency. Better quality control, on the other hand, has reduced the number of complaints and errors in the various stages of the fabrication process.

The total demand for flat glass in 2016 was 73 million tons, or 9.2 billion square metres (calculated on three-millimeter glass) dominated by China (51 per cent of global demand). The growth in demand is very fast in China because of the current construction boom. There are also a great number of buildings with single-glazed windows about to be renovated in China and in Central Europe as well. In Europe, triple glazing is becoming a new standard. In energy-efficient moder n construction, all this means an increased use of coated insulating glass elements.

The development of new technologies and products has remained mostly in Europe and in the U.S. Automotive and automotive glass industries are also focusing on Asia, but in this area, too, R&D and design is often carried out in Europe.

Glass is used above all for architectural purposes (facades, interiors and refurbishment). Building glass accounts for about 80 per cent of total flat glass demand. The automotive industry uses 10 per cent of total glass demand and the remaining 10 per cent go to different special applications, such as fast-growing solar glass applications.

It is worth noting the growing amount

of buildings 200 metres tall or taller. The construction of high-rise buildings has increased rapidly as a result of sharp rises in urbanization and land plot prices. Climate consciousness also favours high buildings as close construction reduces carbon dioxide emissions from traffic. In 2017, there were already over 1,300 buildings in the world that rise over 200 metres.

Industry 4.0 a nd the internet of things

Industr y 4.0 is a concept of a fourth industrial revolution first coined in Germany. IoT (Internet of Things, the industrial internet) is changing production and operating methods significantly. Automation and digitalization bring productivity to a new level in efficiency, flexibility, quality and time-to-market.

Glaston and other players have developed the collecting and processing of big data as it opens up a whole new kind of potential. For example, the properties of every single piece of glass can be traced over the decades. In buildings, databases used for building materials will track their properties and recyclability to greatly improve security of supply.

Worldwide glass design

trends

No matter if it is a city-centre skyscraper or a small town house on the design board, the natural surroundings and nearby buildings are carefully taken into consideration by the architect. How the building fits into its environment; the angle of the sun; where the wind comes from; the effect of the local climate on the energy consumption of the building...all these and more are now part of how architects approach their projects.

One of the biggest trends is total transparency, where glass is the most natural choice. Transparent glass connects the building with its surroundings, nature and people. On the other hand, it separates and protects against natural forces. In advanced glass technology, the transparency of the glass can be dynamically adjusted, which offers new opportunities for glass interior decoration and for managing energy flows in the facade of a building.

Large, uniform glass surfaces are nowadays energy-efficient and able to keep heat either indoors or outdoors, whichever is required. In tall buildings, facades can be converted into attractions. For example, in Hong Kong, skyscrapers are used as platforms on which computer-controlled

Photo credit:

Cesar Rubio

LEDs illuminate impressive animated images. In the future this will be utilized in many ways in entertainment and communication. A glass-bottomed bridge over a canyon is a major attraction and a sure “Wow!” effect, at the same time offering safe passage to the other side of the canyon.

Fondation Louis Vuitton in Paris, designed by Frank Gehry, is an excellent example of the diversity of glass in construction. The trend is to use unconventional, softer or more organic forms in the buildings. This has raised the demand for bent glass. As bending technologies have also developed, the multifunctional use of glass can add shape, spectacle and distinctiveness to any building.

Daylighting

There is a lot of research data on the effects of daylight. For example, it improves work performance and learning achievements and makes patients recover faster. Daylight utilization is therefore justified in the design of buildings by wellbeing, profitability and sustainability.

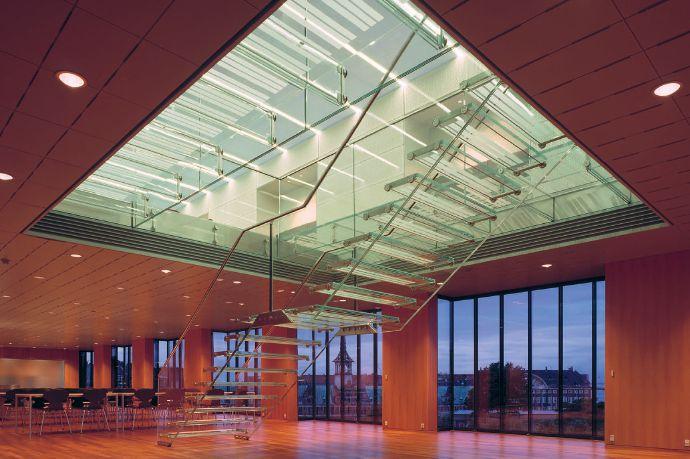

By using glass, daylight can be brought into the building and reflected further in the interior. Transparent structures in the interior can allow light to pass deeper into the building and be re-directed with reflecting surfaces.

To get the best of daylight and energy balance, we can add movable sunshades, switchable glazings, solar panels and – the latest development – transparent solar panels that are integrated into windows. There are already a lot of ways to utilize daylight for the comfort and wellbeing of inhabitants as well as for the energy production in the building while creating things that please the eye.

Even in energy-conscious European markets, the advantages of ample daylighting are outweighing concerns over window/wall ratios.

Worldwide automotive design trends

The development of glass technology will bring new trends to the automotive industry, especially to commercial vehicles. Glass is an important part of a vehicle’s the load-bearing structure. Glass sizes and shapes become more challenging for manufacturers, but at the same time they bring new experiences and applications to vehicle users. Commercial and passenger vehicle displays improve when display data can be projected on a windshield or shown on an in-built transparent display. The driver no longer has to take his or her eyes off the road or work area as the required information is displayed on the windshield.

In addition to safety, the automotive industry emphasizes energy efficiency. The need for cooling or heating can be reduced by using coated glass or smart glass to help regulate the vehicle’s interior temperature.

New technologies

Thin glass is already in use in mobile phones and tablets and it is coming into the construction and the automotive industries. Ultra-thin glass (0.01 to 0.3 millimetres) is so thin it can be rolled. There are already successful cases of the first roll-to-roll coated glasses, although they are still too narrow for architectural use.

Thin glass applications will be greatly diversified as manufacturing, coating and lamination technologies are improving. It will soon be possible to produce the wider sizes required by architecture and coating technologies will allow many new properties for mass-produced glass. There will be things like furniture laminated with ultra-thin glass or wallpaper made of it. And they will be durable and easy to clean in the same way as cell phones and tablets already are.

In architectural use, structural features can be added to glass in many ways, most typically by laminating tempered glasses with special films, by bonding a honeycomb structure inside insulating glass or by laminating a wire into a glass beam. Good design and glass bending will offer additional features. 3D printing has also taken its first steps in the glass industry, but so far it has had few applications.

Igloos made of electrically heated glass

Electrically heated glass has brought some good financial results to developers, for example, in the accommodation industry. Accommodation customers are willing to pay for unique experiences such as staying in a transparent igloo under the starry sky in the glow of the Northern Lights. There is no draft in the proximity of electrically heated glass to spoil the customers’ experience. Finnglass, one of the pioneers in the field, has been developing electrically heated glass for 20 years now and it would be suitable for many applications in modern construction. A heated glass wall is more expensive than traditional glazing but it generates substantial savings in energy consumption and increases available floor space. The inner surface of electrically heated glass is warmed one or two degrees above the room temperature, hence the cold wall effect and convection are prevented. The energy consumption is only 20-40 watts per square. Radiators or fans are not required, so the interior space is free for other uses.

Photo credit: Stig Mikkelsen

December 3-5, 2018

Quebec City Convention Centre Quebec City, QC

Register Online Today: windoorshow.ca

3 au 5 décembre 2018

Centre des congrès de Québec Ville de Québec, QC

Inscrivez-vous en ligne aujourd’hui : www.windoorshow.ca/?lang=fr

Don’t miss the opportunity for:

• Education

• Newest technology

• Networking

For more information on exhibiting at WinDoor contact Danielle Labrie - dlabrie@annexbusinessmedia.com

Ne manquez pas cette chance :

• Formations

• Technologies les plus récentes

• Réseautage

Pour en savoir plus sur les expositions pendant WinDoor, communiquez avec Danielle Labrie - dlabrie@annexbusinessmedia.com

Proudly presented by / fièrement présenté par Use Promo Code GLASS2018 to attend the show for free!

Utilisez le code promotionnel GLASS2018 pour obtenir votre billet gratuit!

This brings significant benefits to space use and increases the building’s area. Electrically heated glass can also be used in glass ceilings to melt snow and ice and to prevent condensation.

Worldwide glass energy trends

Buildings account for 44 per cent of total energy consumption in EU countries (industrial buildings: seven per cent; domestic and tertiary buildings: 37 per cent). Switching to more energy-efficient windows would allow significant savings as windows are estimated to be responsible for 24 per cent of heating needs in the EU and for nine per cent of cooling needs.

The impact of buildings on energy consumption is enormous: they use 60 per cent of all electricity produced and account for more than one-third of greenhouse gas emissions.

It is not just about how windows keep the heat inside (reducing the need for heating) or outside (the need for cooling decreases). An intelligent facade can convert sunshine into energy. Integrated solar panels are also becoming popular in Finland and the Nordic countries. Transparent solar panels are integrated into windows and the user does not notice the difference compared to a traditional window. With regard to solar collectors, new ideas on how to produce warm air and hot water or to apply them to cooling the building are already in use.

In today’s digital printing processes a resolution up to 1,400 dots per inch is achieved and it is possible to decorate large surfaces, like different views on the outside and inside walls of a building. At

the same time, the energy balance of the building can be improved with ceramic ink that absorbs excess energy.

The building of the future produces at least part of the energy it uses and automatically balances its energy streams. Its windows can regulate the amount of heat and light passing through them and also use infrared and ultraviolet components of light to produce electricity. Smart glass and media facade technologies are being developed, so interesting news is on the horizon.

Structural glass applications

Tim Macfarlane was on of the first to start developing the use of glass as a structural material in buildings in the ‘70s and ‘80s. This has given rise to the idea of total transparency, where wind and structural loads can be borne with glass structures to create new types of buildings. Of course, this has put demands on glass machine manufacturers and glass processors for new products and equipment for handling and transferring large and heavy glass panels.

Cold bent glass has been used in buildings for over 10 years and, because the experiences are good, the use has increased and diversified. In cold bending the insulating glass element made of tempered flat glass is mechanically bent in the shape of the building frame when installed. However, the sharpest bends are always made by thermal bending. The latest and most demanding process is lamination bending, which is carried out in connection with the autoclave process. This method requires a lot of experience and know-how, but it will

New capabilities in laminates and glass bending are enabling greater creativity than ever in structural glass elements such as bridges and stairs.

diversify the possibilities in glass construction.

The latest addition is the introduction of transparent structural silicones. They enable design of even more transparent structures and applications.

Worldwide glass quality trends

Tempered glass sizes have grown considerably over the last couple of decades; today the largest glasses are 3.3 by 20 metres. Growth in glass sizes and new coatings create particularly strict demands for the tempering and lamination processes, so quality control and the various measurement methods are important.

Product development in Glaston and Viprotron has focused, among other things, on the development of anisotropy and/or roller wave distortion measurement methods. This enables better quality to be achieved to suit the most demanding applications. Sparklike has developed a method for measuring the argon gas content of insulating glass elements through the glass. This can be done either on the production line, after production at the factory or on the construction site. It ensures that elements not meeting the agreed values are not used in buildings. Measuring in these projects is always cheaper than replacing faulty elements after construction work.

About the author

Jorma Vitkala is the founder of the Glass Performance Days Conference (GPD) and has been chairing the organizing committee since the beginning. He is the first recipient of the “The Jorma Vitkala Award of Merit” awarded by the international glass industry by Dow Corning and Kuraray. At the same occasion, Vitkala received several recognitions: the special awards of the HKFA (Hong Kong Facade Association) and the KAFA (Korean Architect Façade Association), a USGlass plaque and a honourary membership in the Glass Association of North America. The Finnish Flat Glass Association has nominated Vitkala Glass Builder of the Year 2013 and he received the Tampere Congress Award in 2001. •

EVENT

THE END OF THE BEGINNING

by RICH PORAYKO

The Building Envelope Conference returned to Caesars Palace in Las Vegas this past March with numbers not seen since before the Great Recession. Over 500 attendees converged on the three-day conference known as the industry’s premier building envelope event to make connections and discuss challenges and trends in the glass and glazing industry.

Without a doubt, the topic on everyone’s mind was tariffs, with a lot of folks north and south of the border who say they are very nervous. Although many of the leading indicators are positive, there is also some real worry that a downturn in the U.S. economy has already started. Residential permits are off in some areas and the unprecedented political uncertainty weighs heavy on many.

This year’s State of the Industry was an excellent panel discussion on challenges, trends and market perspectives that resonated with the audience and could have gone on much longer than the allotted 75 minutes.

The session was moderated by Jeff Haber of W&W Glass. Haber opened the session by saying what everyone was thinking: “Congratulations, because it seems like over the last five years the industry has practically doubled after coming back from the recession. Everyone is feeling optimistic and things are going well. The question to everyone is, are we at the end of the beginning or the beginning of the end of the current cycle?”

Haber told the audience that the Architectural Billings Index is positive and growth is projected at the three-to-five per cent level for 2018 and 2019, slightly higher or lower depending on the geographical location and market. “Many contractors across the spectrum are inundated with requests for proposals right now,” said Haber. “Traditionally, when we think this many years into the building cycle, we’d be at the end of the road but it’s becoming increasingly clear that is really not the case. Regardless of the politics, the current administration has juiced the economy, at least in the short term, which should be a benefit to most of us.”

Haber pondered if the possibility of new infrastructure spending including P3s will give a further boost to the building industry or if rising material costs, wage inflation and lack of skilled labour will put a damper on future growth. “Significant price increases were passed along from the glass industry. Everyone has heard that new tariffs have been implemented by the U.S. government on aluminum and steel. It’s going to be a very interesting process over the next few weeks and months to find

BEC

attendees

wonder how long the good times can roll.

out what happens to the cost of materials.”

The panel unanimously agreed that personnel continues to be a challenge with Benson Industries’ Jeff Heymann telling attendees that he sees a lot of people applying to Benson with CAD skills but no idea how to draw. “And the learning curve to being able to think and understand what we’re actually doing takes a lot of years.”

Heymann highlighted that creative tension within a project

ABOVE: Tom Jackson of SteelEncounters shared his strategies for attracting and retaining employees in today’s difficult labour market. He told the audience 95 per cent of employees will say company culture is more important than pay.

team is important. “All parties need to start off with a clear expectation of what we are doing. We’ve been adamant recently that, at the first kickoff meeting, we define goals, benchmarks, expectations and milestones and we deputize someone to be the sheriff in the room. You have to have a sheriff. There is conflict. There is tension. We are all trying to pull towards the same thing, which is to get a product delivered. A building –on time and on budget. Sometimes we need to be mindful of that and all parties sometimes need to be reminded of that again. Creating the right environment is a really great start. Just like any company culture. The project has to have its own culture. If it is a truly collaborative culture, it should work well.”

Joe Conover of Clark Construction agreed that healthy tension is a good thing, “To me, the key is to manage that tension and to turn something that is potentially a danger into a positive.”

Skidmore, Owings and Merrill LLP’s Keith Boswell provided the architect’s perspective. “We need to create the design. We need to develop the design.

We need to document the design. And then we need to shepherd the design as others get involved. In the beginning, we are the lead singers. We are Gladys Knight and everyone else is the Pips. As it moves into construction, if we have done our job right, we are now the backup singers.”

“Our role as a facade contractor is taking what the architect has drawn and actually realizing it with metal, fasteners, silicone, glass,” said Heymann. “We also have to be mindful of supply chain as we explore new materials and finishes. We try to bring it all together. We probably don’t bring in our suppliers into a design-assist situation enough. Lately, the supply chain has become a lot more complex. We’re procuring globally. We should probably engage the glass manufacturers and fabricators more than we do.”

Heymann shared that Benson Industries is constantly going out, looking at suppliers and evaluating them before making a big award. “If we work with people over again, we have a certain confidence level but if we haven’t

worked with you, we want to understand what you can and cannot do. We don’t want you biting off more than you can chew. You have to understand that we are unitizing glass and if we don’t have glass on time, we have to ship a panel out with a piece of plywood and it costs a lot of money to glaze that in the field. All of these things become very important for us.”

“Setting a huge piece of glass on the Apple Store is complicated,” Heymann explained. “Setting a huge piece of glass on top of the Sales Force Tower in San Francisco is really complicated. You’re 1,000 feet in the air trying to do it.”

According to Heymann, the schedule is the most important thing. “As we see more glass coming in from offshore, some of it is fantastic stuff but it adds a level of complexity. You’ve got international shipping and initial lead times. And then what happens when there is a breakdown in the supply chain?

Crystal balls are dangerous tools. But for now it looks like the biggest challenge in the North American glass industry will be managing growth. •

by MARGARET WEBB

A new level of certainty

Earlier this year the Insulating Glass Manufacturers Alliance decided to pursue additional accreditation for the Insulating Glass Manufacturers Association of Canada certification program and has selected ANSI, the American National Standards Institute, as the third-party accreditation body that will issue the accreditation. ANSI participates in the International Accreditation Forum MLA (Multilateral Recognition Arrangement) with the SCC (Standards Council of Canada). ANSI will perform annual assessments of the IGMAC certification process to ensure it meets stringent international requirements under ISO 17065:2012.

The IGMAC Certification Program design, development and administration has been included under IGMA IS0 9001 accreditation since 2002. The IGMA board of directors decided to pursue ANSI accreditation to ISO 17065 as the most relevant standard for third-party certification accreditation.

The IGMAC certification program is recognized by Natural Resources Canada for IG certification for the Canadian Energy Star program and the National Fenestration Rating Council (NFRC).

In addition to ANSI’s assessments, Administrative Management Systems (AMS) will operate as the certification body for the IGMAC program. Using AMS as the certifier will add another layer of assurance to the program and will help ensure conformance to accreditation requirements. AMS is an ANSI-accredited certification body that manages multiple product certification programs, including the Insulating Glass Certification Council (IGCC) certification program.

Accreditation is expected to be granted in the fourth quarter of this year. What does this mean for IGMAC manufacturer participants?

IGMAC accreditation by ANSI is expected in the fourth quarter of this year.

IGMA

Manufacturer participants in the IGMAC program will notice little change to the certification process. IGMA will remain the program administrator and will still coordinate certification activities and conduct product reviews. One change you will notice once accreditation is gained is that the IGMAC certificates will bear the AMS and ANSI logos – an indication of the value-added oversight from both organizations.

The requirements placed on participant manufacturers’ products will remain unchanged as a result of this accreditation. Product testing will still be conducted by participant-selected, IGMACapproved testing laboratories to the same IGMAC-recognized test methods and standards. Certified product will still be inspected by IGMAC-approved inspection agencies as well.

To realize the benefits of this new arrangement, manufacturer participants will need to re-execute an updated license agreement with IGMA and AMS. The changes to the license agreement will serve to strengthen and improve the language used over the previous version. It is anticipated that the new agreement will be sent out to manufacturer participants in the third quarter of this year.

Announced earlier this year, the IGMAC Certification Program database is now automated using specially designed software. This transference of the data has now been completed and we expect that early in 2019 the Customer Information Portal (CIP) will be launched. The CIP will be the communication venue between IGMA and program participants. Each designated program participant contact will be able to access their data, audit reports, notices and certificates via the portal. This will further streamline the certification process and provide added value to the program participants.

An announcement will be publicized once ANSI accreditation has been accomplished and a second announcement will be issued for the launch of the Customer Information Portal.

For more on the benefits of ANSI accreditation, visit ansi.org. For more information on AMS, visit amscert.com. You can find an explanation of how the IAF MLA works at iaf.nu. If you have any questions regarding the IGMAC Certification Program, please contact our office or visit igmaonline.net.•

FABRICATIONMACHINERY

Built strong

biesse.com

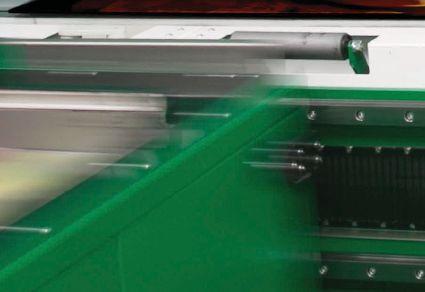

The Busetti F Series double edger, designed and built with years of experience, offers a more robust chassis.

The solid frame construction of the machine helps absorb vibration and promotes longer spindle life.The F Series also features a unique alignment system using two drive belts to transport the glass through the grinding and polishing process with great precision to ensure the highest quality edge polish. Additionally, the unique design of the working area and electro-spindle (along with a special drop-down deck) prevents water penetration into the drive mechanism, ensuring the long life of these components.The high level of automation and the PC-based control represent a functional and easy-to-use solution for companies that need to reach higher levels of productivity.

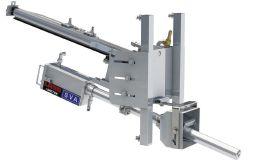

Automatic retraction

landinst.com

Non-contact temperature measurement specialist Ametek Land, working in partnership with furnace-monitoring-system manufacturer SVA Industrie Fernseh, has developed a new housing and pneumatic auto-retraction system for Ametek Land’s NIR-B (Near Infrared Borescope) Glass thermal imaging solution for glass furnace applications. This development means that Ametek Land’s award-winning NIR-B Glass thermal imager is further protected against damage from overheating within a glass production environment, especially in cases of air purge, water cooling or power failure. The pneumatic auto-retract system consists of an innovative and rapid-response retraction mechanism that instantaneously retracts the instrument from the furnace wall in the event of a failure. The system will retract from a number of failures such as air purge, water cooling, mains power and, if there is an over-temperature condition detected, at the borescope tip. The system is fully pneumatic and has no exposed electrical components operating within the extremely high-temperature environment of the glass melt tank. The system’s IP66- rated control box can be positioned up to 20 metres away and houses an uninterruptable power supply that automatically retracts the NIR-B Glass in the event of a power failure. Within the harsh process environment of the glass furnace, an integrated air purge ensures that the thermal imager maintains a clean lens at all times. With a high-performance water-cooling system built in as standard, the overall system has a low air flow requirement, even in the highest temperature furnaces. NIR-B Glass, which was launched in 2016, enables glass producers to receive continuous real-time temperature data, combined with a crystal-clear thermal video image. This means operators can clearly “see” cold spots from air leaks coming through structural refractory, so that cracks or collapses are easily detected. This, combined with the ability to visualize flames, allows the plant to optimize the flame pattern and burn efficiency. The ability to overlay thermal profiles across the crown and along the melt allows for accurate batch line control, production throughput optimization and batch transit time recording. Designed specifically for the glass-melt furnace working environment, the NIR-B Glass is designed to withstand the high ambient temperatures. With over 324,000 temperature measurement points in the field of view, the NIR-B Glass also can monitor the drift in crown roof thermocouples.

Advanced software features allow multiple visual or output alarm controls to be set as specified by the plant. Critical areas, like port arches, can be continuously monitored for overheating, with automated alarms set for over-temperature conditions. This can be vital in extending the lifespan of the melt tank refractory and in providing greater asset protection through more accurate, remote infrared temperature measurement and live thermal imaging.

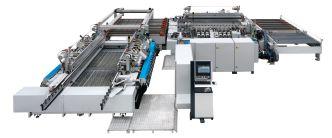

Big glass processing

bystronic-glass.com

Bystronic has introduced system solutions for insulating glass with Thermo Plastic Spacer from its original inventor. The B’Vario TPS and B’Jumbo TPS from Bystronic glass are individual insulating glass manufacturing production solutions, providing unique versatility. They only differ in the available working heights. The B’Vario TPS is available at a minimum height of 1.6 meters while the B’Jumbo TPS is a large dimensioned line of up to 3.3 meters. Both can be additionally equipped with the finisher feature for the esthetic smoothing of the TPS bevel joint.

Bystronic glass is the inventor of the TPS IG manufacturing process with several million installed TPS IG units worldwide. The production is greatly simplified thanks to the direct application onto the glass by a machine called TPS’applicator. The width of the spacer can be changed as desired during operation without any time loss. This way of production eliminates the need to stock different spacer profiles and connectors. The finisher is an optional machine that can make the patented bevel joint of TPS invisible. With the standard, proven solution, the gas-tight bevel joint does not require any thermal-mechanical reworking. With the optional use of the finisher, the customer can additionally smooth the bevel joint leading to an upgraded aesthetical result. The overall result is customers now have the possibility to make the patented TPS bevel joint nearly invisible. The size, shape and thickness of TPS remain unchanged and processing of shaped formats is possible.

Bowed glass no problem

forelspa.com

Forel’s jumbo glass line promises exceptional performance and features in terms of weight , thicknesses and non-planarity of the processed glass sheets, aligned or stepped. The Forel line can process some of the largest sizes of IG glass requested by today’s market. The line is able to adapt itself to glass sheets that are not perfectly flat – by as much as centimetres –with a focus on size, accuracy and the types of processes carried out. The line consists of a loading area, coating removal, a washing machine, inspection and frame mounting, a 180-degree glass-turning section, an assembling press with gas filling (argon and krypton) and an automatic sealer. The line will process single glass sheets up to 40 millimetres thick

and insulating glass up to 100 millimetres thick. This requires a load

metre. Structural stepped units with a vertical offset up to 250 millimetres and leading horizontal offset up to 1,000 millimetres are possible. The line can process bowed glass up to 2.5 millimetres per linear metre (15 millimetres over a six-metre glass length). The

stepped unit assembler can put the smaller glass in the front and a dedicated glass unloading section is included.

Lower cycle times

lisec.com

LiSec set itself the target of developing the most

brand-new high-performance machine in the new

LiSec design with the name

automatically and quickly thanks to the state-of-the-art motive power engineering. With linear motive power engineering and the integrated measuring system, the new SprintCut ensures maximum cutting speed and outstanding dynamics. The maximum acceleration is approximately 16 metres per second per second and the maximum speed is 310 metres per minute. The linear drive has few moving parts, which means the mechanical wear is lower resulting in longer maintenance intervals and low downtime costs. Beside the especially high acceleration, this motive power engineering allows an excellent positioning accuracy of the cutting head with a maximum offset of 0.1 millimetres. Due to the intelligent control, the maximum speed is reached as quickly as possible. Through careful constructive improvements, LiSec has been able

machine operating company. The operation of the cutting table is made easier by a higher degree of automation and new electronic controls. The cutting pressure control, grinding pressure control, monitoring of the consumption of cutting oil and cutting wheel wear are all automated, and as a preventive measure the -

ing unplanned downtimes. LiSec estimates customers with highly automated production lines in multiple-shift operations can

Complete solutions for glass production

cmsna.com

CMS North America brings more than 30 years’ experience and innovation to the glass machining market. It offers complete solutions for high-speed glass production with a full line of state-of-the-art CNC glass processing machines and a staff of highly skilled professionals who help deliver superior CNC systems consultation, installation and service. CMS emphasizes a no-limitations approach to each project and works to develop the ideal solution for each machining challenge.

RESOURCEDIRECTORY

by FRANK FULTON

Fair workplace legislation disaster

For those of you fortunate enough to live outside of Ontario, you may have heard that we’ve recently had a change of provincial government. Voters were so enamoured with the job done by the previous ruling Liberal party that they did not elect enough candidates to even maintain official party status.

Maybe this happened because people became just a little bit concerned that the Ontario government debt had ballooned to almost $350 billion with no end of deficit spending in sight, hadn’t forgotten the $1.9 billion blown on starting construction and then scrapping two electric generating plants, or didn’t believe that the cap-and-trade carbon tax introduced in the province last year would be anything more than a cash grab to fund further frivolous politically motivated causes. Or maybe people and particularly businesses didn’t care all that much for the “Fair Workplaces, Better Jobs Act, 2017” that set the highest minimum wage in the country.

I have to tell you that deciding how to vote in this election was no easy task. Two parties promised voters freebies galore paid for by just a little extra tax on the rich. The Conservatives, led by the Trump-inspired brother of our former drug addicted, drunkard, national embarrassment mayor of Toronto, had no clear platform except for a vague promise to reduce wasteful spending. He won with a landslide majority