Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Grove Shims™ has the per fect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for per fect alignment. No guesswork or realigning. Our shims save you time and money Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com

Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

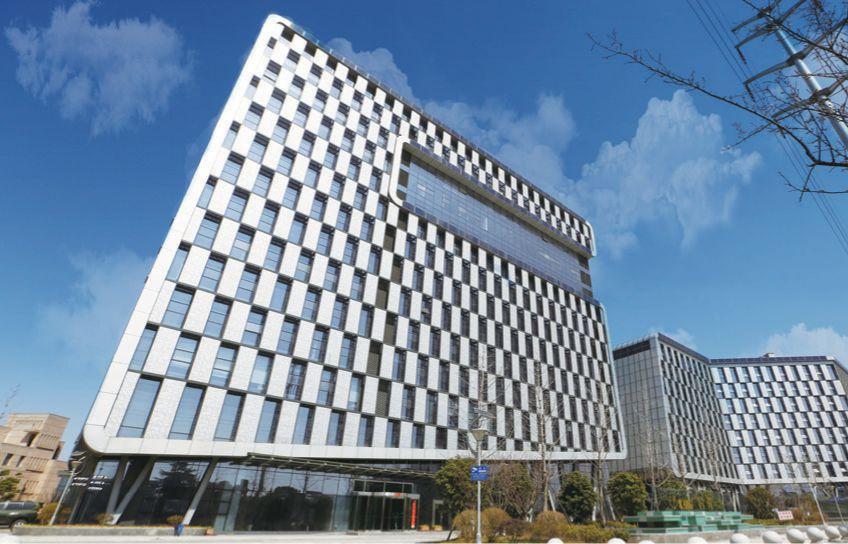

Digital twinning technology could be the new future of building management. It opens up new avenues for improving efficiencies of glass installed in buildings.

18 Untangling the terms

Latest updates to CCDC’s standard contract form in 2020 is good news for glaziers. 22 Together at Top Glass

Education, networking and more awaiting attendees at the second and improved online version of Top Glass this year. 26

A preview of what to expect at Top Glass Conference and Exhibits 2021

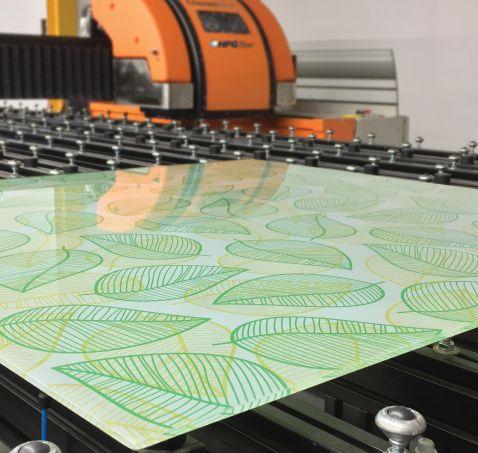

We pick the brain of Andrew Dolphin, general manager of glass operations at BV Glazing and president of the Ontario Glass and Metal Association, about some of the issues facing glass fabricators these days. Dolphin is looking with some concern at the city of Toronto’s proposals to require bird friendly patterns on surface #1 of all new windows. He thinks a float glass plant in southern Ontario would be nice, but not necessarily a game changer.

There are two modes of thinking and each is equally important in our work.

Been reading an excellent book called The Master and His Emissary by Iain McGilchrist. It’s all about the differences between the right and left hemispheres of the brain. As I read it, I keep thinking of ways this information applies to the business world.

Most of us know that the left side of the brain controls the right side of our bodies and vice versa. But the differences in what the hemispheres do goes much deeper than that. The left side is where all our focused attention happens. It’s the side that looks at things, identifies them, makes decisions and plans action. The right side of our brain is where the brain does all its “background” work. It’s probably what Freud was talking about when he described the subconscious. It’s actually more aware of our environment than the left side as this is where all the information from our senses is collected, filtered and prioritized for importance. Thus the title of the book: the right brain is the master who knows about everything going on and comes up with the innovative strategies, the left side is his emissary who acts on his memos but thinks he’s in control of everything.

• Great glazing

• Northern facades

What on earth does any of this have to do with your business? Well, one way is in how we think about marketing. A lot of people expect advertising to work like a lever: you put out ad X and the phone rings Y times. When that doesn’t happen, they become frustrated and conclude advertising doesn’t work.

That’s left-brain thinking. Direct-response advertising is a thing and does work, but it has to be executed properly and represents only one of several advertising strategies. Another kind engages the right-brains of its audience: branding. This sort of advertising inserts your company into your market’s environment, making its message and character part of the background your prospects live with every day. Once this is accomplished, when decision time comes for your clients, they are much more likely to direct their left-brains’ attention to your company.

One of the reasons for this is that your right-brain is better at noticing new things and thinking new thoughts. Remember, it’s where information is collected and assimilated; your left-brain is engaged in actually rejecting irrelevant information, narrowing your attention and sorting through the data to extract the useful and actionable bits. The left-brain deals with what you already know and actively prefers to focus on that information, resisting the distracting addition of potentially irrelevant detail.

So when employees resist change in your organization, they are letting their left-brains run the show. This is perhaps an inevitable result in the parts of your organization where problem-solving is important and people who are good at problem-solving are employed – that’s what the left-brain does. But an organization also needs out-of-the-box thinking, acceptance of novel ideas and broad awareness of the business conditions both internal and external. So in business, there needs to be a master who considers all factors and contemplates all possibilities as well as emissaries who attack problems and drive specific tasks.

In short, in business, we need to think with our whole brains! •

April 2021

Volume 33 • Number 2

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquires or changes, please contact Shawn Arul, Audience Development Manager

Tel: 416.510.5181

Fax: 416.510.6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE EDITOR | Sukanya RAY GHOSH srayghosh@annexbusinessmedia.com 647.203.7031

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

NATIONAL ACCOUNT MANAGER | Amanda McCRACKEN AMcCracken@annexbusinessmedia.com 519.429.5234

ACCOUNT COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Alison KEBA

VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $85.00 (in CDN dollars)

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

Acid-etch it. Backpaint it. Frit it. Digitally print on it.

Starphire Ultra-Clear® glass: THE ULTIMATE BLANK SLATE

Xinyi Canada has announced the withdrawal of its proposal to build a $400

expressing its disappointment at the col-nouncement followed Stratford council -

statement cites “misinformation and falsehoods spread by small opposition

the grounds the plant would use too much followed opposition by small but vocal are putting their hands up to say theynue and 400 jobs the Xinyi project would The Independent to start working with its local Member of Provincial Parliament and Sarnia/Lampsupport for inviting a proposal from Xinyi

in part to prevent “unfounded attacks on looks forward to bringing the project

land a deal to build its plant in southern

Bwewill have held our Annual Technical Conference and program included “Fenestration: A technical accessibility perof ABE Factors; “Designing with structural laminated glassson of Kuraray America; the Code Talkers acoustics panel; “Process to certify to Passive Petit of Passive House Canada; “Decontaminating glass surfaces by Mike Hammond of Vitro Architectural Glass; and “How to uncover the truth about ERP before you buy by Andy Pratico

The FenBC Annual General Meeting was held at the remember when compulsory current government wanting totion here in BC? Right now there are no details on what are conducting very preliminary surveys to see what the FenBC

AVFQ held its virtual Anand workshops covered several

Bergeron is continuing as the chairperson of the board of -

ment between the AVFQ and the Fenestration and Glazing -

of mutual synergies that will enable the two organizations to support their respective agreement was formalized on proud of this new partnership offered a new service to its members: an Action or Conaimed at preventing psychological and/or sexual harassment innancial support of CNESST (the

we have developed various tools that can be used within and reserved only for employees of member companies ofbec has been in effect since June comply with it no later than module to help AVFQ members

Quebec has adopted a bill that

activities have been on -

erations as soon as it is safe to do so and have more updates

AGMCA turns the spotworking for his dad on weekgraduating with a diploma in-

on our negotiation team during the 2019 collective bargaining

Tvalue to our members since our bread-and-butter live

a series of educational white

Makimoto (TAGG) will address

a while joined Aralco in the to the Niagara Region and Peninsula Glass in 2001 when

business has grown from a base of seven employees to a level

Tim and Nancy decided to relocate Peninsula Glass to a larger

both a commercial and residenits commercial work is curtain division handles anything from broken windows to shower

an interest in the Service and Commercial Agreement negotiations with the union and be-

Tim provides the board with the Hamilton Niagara region on our provincial steering commit-

The year 2020 has been very has been especially challengevents are geared towards charging any dues in 2021 to companies that had paid their

not be holding our spring golf

hopeful that circumstances have improved to the point that we will be able to pull off our fall golf tournament that is booked

release of multiple vaccines there is light at the end of the tunnel and we plan to resume events next year as soon as it

person next year and resume our role as the networking

microphone on the GlassTalk

TA coalition of construction sector associations have allied to urge the federal and provincial governments to deliver on

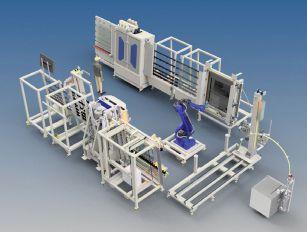

Ivone North America for information on new glass fabrication machin-

ing Engineering Companies and the National Trade Contractors

omy but all levels of government must deliver on infrastructure

“Despite billions of dollars of existing infrastructure commit--

time is now to deliver on billions of dollars of investments so we

Ton a proposal to enhance health and safety training stan-

such as automated lines with robotic glass handling; developments that Bovone and Salem have worked together for years to expand in the

Fabrication Supplies – offering all glass fabrication tooling and supplies and leading technical service and support including repair and periodicplies and deep knowledge and expertise from our technical service

worker in the province comes home safe to their loved

of our loyal customer base while expanding our market share of

proposed changes are designed to make compliance easier for businesses by bringing all health and safety regulatory

Uexecutive order instructing federal procurement bureaucrats to close loopholes allowing waivers of domestic supply

to oversee procurement and ensure the various Buy America

sures in comments to Door and Window Market response to Glass Canada

It is common for a country’s government to encourage government purchases of products made within the country to help bolster the domestic economy and jobs. Many of these regulations or guiding governmental principles have been place for some time. In fact, the United States’ Buy American Act dates back to

1933. The latest executive order signed Jan. 25 by U.S. president Joe Biden, continues the federal government’s focus on encouraging government purchases of products made in the U.S. The new order establishes a Made in America director who will oversee the order and applicable Made in America laws as federal agencies procure and purchase products. As part of the effort, a website will be established to allow the public to view waivers proposed or granted to the order. That website has not yet been activated. The prior Trump administration also encouraged the purchase of products made in America when it, too, encouraged the federal government’s purchase of products manufactured domestically.

The U.S. and Canada remain strong trading partners with each other, bolstered by the new United States-Mexico-Canada trade agreement that went into effect in July of 2020. In a free market economy, much of that trade between manufacturers importing or exporting products is with individual companies, rather than government entities in different countries. Therefore, the focus of the latest Buy American executive order, which centres on federal government purchases of products made in the U.S., is not likely

and American companies.

The Fenestration and Glazing Industry Alliance has announced the appointment

than 20 years of industry experience in both residential and commercial window

“Amy has experience as a Technical Committee and board member at the Fen-

service and interpersonal skills and her intense interest in the technical performance standard

The National Glass Association has announced the publication of a new Glass Technical Paper titled provides information on delayed forced entry security glazing options for windows and doors installed in

“This GTP was written as

that will be of great help in narrowing the product choices based on the

agreements will develop mutual synergies that will allow both organizations to best support

provincial associations and and FGIA agreed to collaborate by sharing information and offering

“Provincial associations are already tracking provincial developments closely so it would be

The paper outlines the types of security glazing available based on the level of penetration resistance of active standards in use related to educational facilities for glass-only testing as well as glazing system

Primer to Design Safe School Projects in Case of Terrorist Attacks and School Shootings

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows. He can be reached at David. Heska@wsp.com.

It’s been quite the year. Twelve months ago our worlds got rocked. Life is not the same, whether that’s in the manufacturing plant, the job site or the office. So, I thought in this column I would reflect back and look forward. At the upcoming Top Glass conference, Gary Watson from Diamond Schmitt will tackle the same topic in a session called “Reflections and Projections: How the Last Year Changed Our Industry” so I hope I’m not repeating a lot of what he will say.

My prediction is that life will return to a new normal in 2022 but many of the health and safety measures we’ve added over the past year will remain. Why wouldn’t we keep encouraging staff to wash their hands regularly? If we can save hours of commuting time, why wouldn’t many professionals keep working primarily from home? Here are five other predictions.

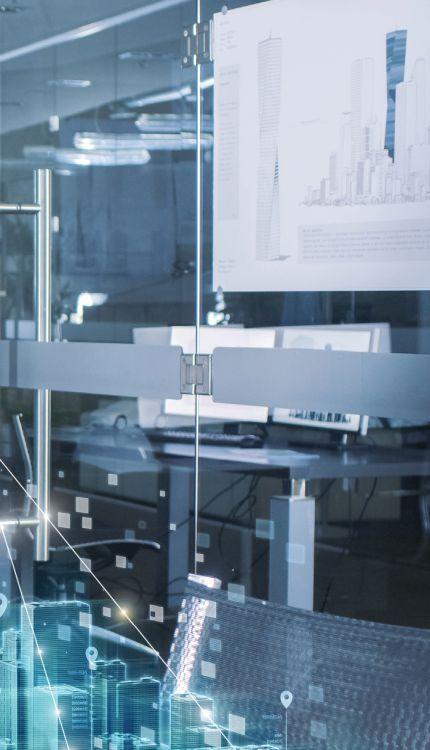

1. When downtown offices start reoccupying there will be an increased use of interior glass.

2. The large open office concept days are behind us.

3. Incentives will need to be provided to staff who have settled into working from home to attract them back.

4. Architects will see a greater demand for collaborative, flexible meeting room space within offices.

5. Co-working office spaces in smaller communities will increase in demand with employees only needing to head into “the big city” a couple days a week.

I would like to remind us all that buildings annually account for approximately 40 percent of global energy use in their construction and operation.

Another Top Glass session I’m looking forward to is on new technology in glass lamination with Mark Jacobson. I anticipate that the decision tree he will share will be a valuable tool for each of us as we sell and select the appropriate interlayer. Whether that’s providing UV filtration, acoustic dampening, impact resistance or post-breakage retention, the use of laminate glass is increasing and so should our knowledge of the product.

Finally my WSP colleague Will Nash will be discussing low-carbon building materials at Top Glass. Our clients have heard us talk about embodied energy for at least 10 years now. The industry and government jurisdictions have caught up and begun asking designers to provide life-cycle analyses for the products they specify. It is important for everyone to understand the difference between initial embodied energy, recurrent embodied energy and operating energy. Initial embodied energy is used to manufacture, transport and assemble the materials to construct a building. Recurrent embodied energy is the energy consumed in the maintenance, replacement and retrofit processes of a facility. Finally, operating energy is the gas and electricity used to heat, cool and light.

I will leave it to Mr. Nash to explain some of the recent trends but I would like to close reminding us all that buildings annually account for approximately for 40 percent of global energy use in their construction and operation. This percentage has been slightly declining over the past decade, but much more can and should be done. It’s time for us to seriously consider what part we can play in making a difference for our kids and grandkids. •

Switchable Smartglass is made in Canada. An innovative technology elegantly turns opaque glass to transparent by simply pressing a button.

Our Smartfilm – if the glass is already installed – is well suited for both retrofits and new spaces. The versatile technology can be used on doors, windows, glass partition walls, offices, cubicles, washrooms, showers, hospitals, facades etc.

The system can be activated via remote control, wall switch, or smartphone app and can also be put on a timer, while regulating the degree of transparency. Natural light is a key part of interior design; so is privacy. Smartglass/Smartfilm is easy to maintain, dust-free, allergen-free and unlike curtains and blinds, definitely not a space guzzler.

Smartglasscan Inc. offers the best of both worlds. The result is a smarter and healthier workspace with privacy as the key, all at the flip of a switch.

by ANDREW SNOOK

When it comes to the construction and maintenance of buildings – and the glass installed and serviced in them – architects, engineers and glaziers are always looking for the latest and greatest techniques and technologies to help improve efficiencies on their projects. One of those technologies that has been garnering a lot of interest in recent years in the world of building construction and maintenance is digital twins.

Digital twins are the latest evolution in the digital modelling of buildings, offering users and manufacturers a look in real-time at how their buildings or products are performing. A digital twin is a virtual copy of any physical object that has the ability to offer critical information to the end user as to how that object is performing.

“Think of it like an iWatch, which could be compared to a digital twin of you,” explains Jay Polding, industry account manager for Architecture, Engineering and Construction SolidCAD. “It’s taking various measurements that can be accessed in real time. The data can be tracked over a period of months or years. From a single source, a medical professional can observe key measurements, things like heart or oxygen level. Buildings, though, are much bigger and harder to see than just one person. That is the promise of the digital twin for buildings. The idea of being able to make good decisions based upon the building’s live performance data and digital 3D model.”

Building and facility managers have been reliant on software to track the performance of mechanical equipment like HVAC units and boilers for some time now, to help optimize things like energy efficiency and predictive maintenance. Digital twins bring this one step further, offering performance data in real-time of key parts of buildings with the help of sensors – windows included.

“A scenario of this may be placing temperature, moisture or movement sensors on the outside and inside of a wall system. Not only do you have a 3D digital model, but you have live information that can be monitored over time,” Polding says. “A person could open the digital twin, click on a specific sensor and get a live readout of the data. A next step may be to integrate data from those sensors into your overall building systems like HVAC, lighting, and maintenance.”

Polding says digital twins will have a growing role in building management because of its potential to help manage the energy a building is using and how efficient each aspect of that building is, such as the glass installed or the mechanical and electrical systems. Building maintenance is also an area where the digital twin can give important information of when work has been done and what work needs to be done. This is vital considering the steep price tags that come with managing almost any building.

“Energy and health codes are becoming more challenging to the curtainwall industry. Being able to prove how a building performs in a real-world application is important to meet those challenges” he says.

Polding says that much of the data building managers are currently receiving from existing monitoring systems would be integrated into a digital twin. A digital twin, however, takes it a step further. People are visual. In the current environment, the performance data of a building

is on various dashboards, equipment readouts and reports. The collection and aggregation of this data is complex and different in almost every building type. By providing current data in the context of a digital 3D model operators and contractors who enter the building to provide service are equipped to quicky and efficiently do their job.

“One of the biggest expenses on a curtain wall is the glass. It is very hard to make changes if it shows up to the site and doesn’t fit.” Polding says. “This is why physical prototyping is common for large and complex pieces of glass.” Two key aspects of a digital twin are already playing a crucial part in the prototyping of glass and systems. This is by using Building Information Modeling (BIM) as well as Reality Capture which includes

laser, lidar and other technologies.

“One example I have seen in the industry is building envelope replacement on older, poured concrete buildings. The concrete slabs often vary in thickness and level. Being older buildings, slabs may not have been poured perfectly and have shifted over time,” he says. Scanning and modeling existing conditions is an investment that keeps on paying returns throughout the life of the project.

“Manufacturing and installation should be based on reality, not somebody’s 40-year-old drawings or various on-site sketches and measurements,” he says.

From the manufacturing standpoint, Polding sees an opportunity to integrate the use of sensors, shading technology and opening systems into a system which are digital twin-ready. Roof systems are also

an area where data like air flow, weight and moisture level could add value to a digital twin. When installing, communication is key to address the various unforeseen challenges.

Digital twin technology is gaining traction as the pieces start fitting together. These pieces include BIM, Reality Capture, Common Data Environments like Autodesk Construction Cloud and internet-of-things connectivity sensors and software.

Autodesk announced at Autodesk University Virtual 2020 the future availability of Autodesk Tandem. Autodesk Tandem brings project data together from its many sources, formats and phases, to create a data-rich digital hub that tracks asset data from design through operations – a digital twin. There are other vendors developing for the digital twin market, too.

U.K. construction software provider, Asite, sees a key role for digital twinning in building retrofits. In its Smart Retrofits report, it lays out five ways the technology could help achieve energyefficiency goals when upgrading older buildings for higher performance. The first is by creating twins to collect data through sensors and identify where existing buildings are wasting energy, perhaps by heating rooms cooled by poorly performing fenestration.

Next is tracking and predicting. A digital twin model can can store data on the expected lifecycle of building components, compare it to collected use data, and update maintenance schedules, part orders and replacement alerts to streamline planning for when and where retrofits should happen. The report claims better maintenance activities can achieve 20 percent energy savings annually.

Another way twinning can help is by monitoring and modelling human activity in the building. The use of a building often changes over its life span.

Occupancy loads may go up or down. Different areas may get more or less use than they did when the building was originally opened. Even more radical changes in use can happen, such as migration from commercial or industrial space to retail or even residential. The times of day when the building is occupied can change. Any of these changes can have measurable effects on energy use and demand different approaches to future retrofits. Digital twinning can help owners understand these relationships. Perhaps an area that once required substantial daylighting is no longer used during the day, making shading devices or tinted glass feasible. Maybe a room that once had office workers in it is now used for storage and doesn’t need operable windows any more.

Twinning can deliver broader sustainability in the built environment by predicting what waste will be generated by retrofit activities, allowing retrofitters to plan for recycling and reuse of the replaced materials. Many digital twin models for different buildings could be set up to share information, allowing for coordination of retrofit activities where new materials are bought in bulk and work scheduled across multiple sites. Asite also sees benefit in model owners sharing information to increase knowledge aof common sources of inefficiency.

Finally, Asite points to the potential benefit of future-proofing buildings by incorporating better resilience and longer life-spans through retrofitting. As our understanding increases of the impact of a building’s use and environment over time, including changes in climate impacts, its retrofits can be better planned to address the current needs and anticipate the needs of the future.

As clients are faced with more stringent health and energy codes, building a digital twin makes more sense. A fully realized digital twin may only be a few years away as the building blocks are forming quickly. This will present opportunities and challenges to the glass industry. The envelopes of the future will likely be connected to the building in a more meaningful way with embedded technology which plugs into the digital twin. •

by Marg Webb is FGIA’s glass products and Canadian

industry affairs director.

AVFQ, the Quebec glazing and fenestration association, and the Fenestration and Glazing Industry Alliance have announced an official collaboration agreement aimed at enabling both organizations to further enhance support of their respective members. The resulting synergistic arrangement, formalized Dec. 17, 2020, promises to enhance the reach and visibility of both organizations, while ensuring efficiencies in monitoring codes and regulatory affairs in Canada. This is especially true for the Canadian fenestration and glass industry, which is comprised of many small and medium-sized companies.

AVFQ and FGIA agreed to share information and offer reciprocal benefits and services to members in the areas of meeting attendance, education, advocacy, technical standards, research and product certification, thereby strengthening the industry.

In general, the collaboration maximizes both organizations’ financial and staff resources, reduces or eliminates duplications and maximizes efficiencies for the members of each. It now offers AVFQ members discounted rates to attend FGIA conferences held in Canada as well as virtual conferences. FGIA members may also attend AVFQ’s Annual Conference at the member discounted rate. Additionally, a task group is being created to explore the possibility for AVFQ to use FGIA education content such as FenestrationMasters and the IG Fabricator workshop and adapt it to its audience as needed. AVFQ will also be invited to support FGIA research projects focused on constantly improving the quality of industry products.

From the AVFQ point of view, the arrangement is particularly expected to enhance involve-

FGIA and AVFQ will work to coordinate public comments, thereby providing great value to both memberships and strengthening industry collaboration and consensus.

ment in national Canadian codes and regulatory work, making AVFQ members aware of the latest developments outside of the province of Quebec while providing information to FGIA regarding relevant developments within Quebec. Both organizations will work to coordinate public comments, thereby providing great value to both memberships and strengthening industry collaboration and consensus.

With the latest edition of the National Building Code of Canada, including Section 9.36 of the NBCC (residential energy code) and the National Energy Code for Buildings slated for publication by year-end, the Commission on Building and Fire Codes is shifting attention to issues for the next code cycle. All standing committees are now developing their work activities for the upcoming code cycle. As an example of some issues specifically meaningful to our industry that are currently in play for the next cycle, the arrangement should help establish clarity and resolve apparent conflicts between directives on whole-building air tightness, as recently issued by the CCBFC and the Standing Committee on Energy Efficiency for inclusion in 9.36 (the residential energy code).

The SC-EE has developed a list of unintended consequences relating to the current proposed code changes. A small working group has been created at the Standing Committee on Housing and Small Buildings to review how these consequences may impact the remainder of Part 9 of the NBCC. Also of concern is Proposed Code Form 1541, which would reduce the allowable fenestration and door to wall ratio. The industry coalition informally established earlier in 2020 were successful at maintaining the current FDWR but this is slated for the next code cycle (2025).

The 2020 cycle resulted in more stringent U-values for our products and it is expected that this trend will continue especially in light of the Market Transformation Initiative looking at Net Zero houses by 2030.

I would emphasize that it is critical for our associations to be there from the beginning of the next code cycle to ensure that our voice is heard. Going forward, I am confident the FGIA-AVFQ collaboration will enhance the effectiveness of all these activities and will be critical to our industry position.•

by TREENA HEIN

At the core of every contract negotiation is one question: who bears the risk? The final agreement represents an allocation of risk between the parties involved.

So it’s good news for glaziers that updates were made in 2020 to the Canadian Construction Document Committee’s standard contract form. The CCDC contract is just a template, of course, that no one is required to use. But it’s been a widely accepted standard for major construc-

tion contracts in Canada for many years now. The first template was created about 25 years ago, and the second version, CCDC2, was released in 2008. Chances are, your customers’ contracts with the project owner are based on it. The changes made last year were intended to allow more certainty for contractors on a number of fronts, but as is the case when any framework is updated, all parties need to pay close attention to new contracts going forward to ensure the terms are understood and met. Let’s dive into what glazing contractors need to know.

In the new template, “substantial performance” is separated from a new term, “ready-for-takeover.” This major change means there are now two main milestones in finishing construction projects instead of one. “Usually, all parties are paid 90 percent of their invoices during the project and the rest is holdback dispersed at the end of the job,” explains lawyer and construction law expert, Glenn Ackerley from WeirFoulds. “The conditions for achieving substantial performance and ready-for-takeover were intertwined and complicated, which led to delays in holdback payment for main contractors and subcontractors such as glaziers. This will make it faster.”

Statutory holdback remains tied to the substantial performance milestone as laid out in provincial lien legislation, which is the point in the contract where the building has achieved a prescribed financial completion level, even with some incomplete work or deficiencies remaining to be addressed. Once substantial performance has been reached, the statutory holdback lien notification period and payment terms take effect. “The other parallel track, if you will, to project completion is ‘ready-for-takeover,’ which means the building is officially the owner’s,” Ackerley explains. “Things like building warranties and insurance policies kick in. Ready-for-takeover will usually be at a later date than the point of substantial performance, a later date than perhaps you have been used to.”

According to mondaq.com, ready-for-takeover is achieved when conditions such as these are met: achieving substantial performance; issuing of an occupancy permit; final cleaning and waste removal; delivery of operations and maintenance documents to the owner; and completion and submission of as-built drawings

However, Michael Assal, president of Taplen Commercial Construction in Ottawa and a Canadian Construction Association representative on the CCDC board, notes that in a phased

ABOVE: These people are acknowledging a contract agreement with an ancient ritual known as a “handshake.”

handover, parts of the building may be taken over by the client after achieving occupancy well ahead of substantial performance. The new template contemplates the possibility of an owner taking early occupancy of a building after substantial performance is achieved but before readyfor-takeover conditions are met, if the owner wants to accept responsibility for any remaining work and start the clock on warranties.

Another major change to the CCDC-2 Contract was made to minimize the use of supplementary conditions, which in many contracts add dozens of extra pages. This is an area that often impacts subtrades, since the conditions are more specific and can address individual elements of the building. The effect sometimes was to “bury” conditions in the contract that could substantially affect acceptance of work after completion.

The new contract form is designed to work together with the CCDC’s new Division 01 – General Requirements template to list all the required terms and conditions of the contractor’s work, providing clarity and helping reduce risks for contractors. “Up to this point, terms and conditions would have typically been placed in various places in the contract,” says Ackerley. “Now, some of the commonlyused ones have been taken and standardized to some extent to make them fairer, and grouped together. However, I caution contractors that they will need to read the entire contract much more carefully, to determine what exactly is expected and don’t assume all conditions are grouped in this section.” Ackerley also warns that even though this change has been made in an attempt to simplify and reduce conditions, some owners may place as many or more supplementary terms and conditions as they did the past. Assal notes that this is because some owners and their consultants or legal counsel have been reluctant to accept that the Division 01- General Requirements are part of the contract as they are quite technical, but with the updated official CCDC bundle, this will hopefully change.

Terms relating to the right of early occupancy, for example, have sometimes been very numerous, unclear and even arbitrary in contracts in the past, and this

was potentially a source of friction and dispute. To help with this, the new template attempts to standardize reasonable conditions for early occupancy.

With the recent roll out of the CCDC-2, there will be a need for further clarification and modifications in other complimentary CCDC contract templates for all related contracts, such as contractorsubcontractor, client-consultant and client-architect contracts. “When the main contract template is updated, it’s the start of a new cycle to make sure all other documents are consistent with it,” explains Canadian Construction Documents Committee secretary, Eric Lee.

“CCA has a working group that is close to finalizing the new CCA 1 Stipulated Price Subcontract,” he adds, “and it could be released this year. Other comments received from CCA members are being carefully examined.” The CCA working group tasked to update CCA 1 consists of representatives from different sectors and CCA members who had submitted comments on the working drafts. In the interim, the current CCA-1 2008 version will still work with the new CCDC-2. Glass Canada will follow developments closely to keep readers informed.

Glazing contractors frequently complain that financial and legal risk in projects is passed down to them through the terms of contracts they feel forced to accept in a competitive environment. It may surprise them to know contractors feel much the same way about the terms they see from project owners. In his keynote speech at Buildings Week in late 2020, Geoff Smith of EllisDon complained about the decline of an ethic of mutual cooperation and seeking the common benefit in favour of short-term financial gains and an impersonal, transactional approach. The goal of the CCDC and the recent changes is, in part, to make responsibilities more clear, allocate risks more evenly and create a framework for agreement that leaves less room for dispute down the road.

Contractors, subcontractors and project owners are probably not going to be holding hands and singing Kumbaya any time soon, but the updated CCDC looks to be a step in the right direction. •

The CCDC includes two construction owner representatives from each of the representatives from four national orga-

notes that other than the owner rep-

Current Owner Representatives:

Integrated Solutions

Construction Canada

Association of Consulting Engineering Companies-Canada (ACEC) Representatives:

Canada

Canadian Construction Association (CCA) Representatives:

Construction G2

Construction

McDonald

(CSC) Representatives:

Services

CBCL Consulting Engineers

Royal Architectural Institute of Canada (RAIC) Representatives:

Association

Document Advisor

How many of you perform a thorough checklist examination of your fall protection harness and how often? I’ve seen several scenarios when it comes to workers using and doing harness checks. Some workers purchase their own. There are standard roof kits available that are pretty reasonably priced but personalizing can get pricy depending on what you’re looking for. Some workers depend on the company to provide the harness, which can mean you get what’s available.

Harnesses can survive the trauma of a fall or run over without being visually apparent, another reason to do detailed checks. If you suspect or have been told that your harness has experienced a trauma you can remove it from service due to “loss of faith”. It’s critical to perform a thorough inspection. A ‘quick look’ inspection is not sufficient for the user’s safety because any small imperfection can lead to a malfunction. Those working at heights well know it’s not the time to discover a problem once you’re up there. With that in mind let’s go over the requirements for inspection.

The checklist is broken down into material sections, let’s go through it.

Common webbing fabrics include nylon and polyester. Materials used for hazardous conditions like welding and arc flash exposure contain fire retardants and some type grounding material. These straps secure every single part of the harness as well as your body. Any visual or odorous variations, even the smallest can cause a malfunction.

D-Rings, buckles, adjusters and snap hooks: This hardware secures the functionality of your harness. Check for damage that distorts or defaces as well as any marks on any part of the ware.

user’s safety because any small imperfection can lead to a malfunction.

Make sure springs aren’t sticking or jamming.

Stitching: The condition of the stitching on any part of the harness should always be in flawless condition to support you in a fall and for fall restraint. There should be front and backstitching, both in perfect condition without frays and missing or loose stitches.

Lanyards and lifelines: The CSA standards for personal energy absorbers and lanyards were effective February 1, 2020. The most important updates are in the instructions for use. The updated standard includes new information on the selection, use and lifespan of fall protection gear, especially energy-absorbing lanyards and horizontal lifelines. Manufacturers are now required to include a table, chart or graphic in equipment manuals illustrating the use of energy absorbers based on the user’s weight and free-fall distance; this illustration will specify the complete range of weights and distances permitted for the device. Along with all the checks mentioned in this article ensure there is CSA information and check spring tensions for retention and indicator activation.

Labels and markings: Labels and markings are records of the harness CSA testing to meet standards for safety and/or performance. Ensure the labels are securely held in place, that you can read the CSA markings and labels, and the manufacturer’s in service date is present; the date the harness was made available for use which also date stamps how old the harness is.

Harness capacity over 310 pounds is available however not CSA Rated.

Suspension trauma is also known as harness hang syndrome. It occurs when the body is held upright without any movement. “If the person is strapped into a harness or tied to an upright object” it will eventually cause fainting. The harness straps will stop the blood in the back leg veins and block blood from going to the heart. This will eventually diminish oxygen to the brain which is what causes the fainting. It is critical to have a rescue plan for suspension trauma; it can be fatal in 10 minutes and cause death in 15 to 40 minutes.

Working at heights without being properly trained and being comfortable doing so, can lead to serious injury and even death. It is critical for workers to report their work refusal to their supervisor and contact their local OHS authority to report any reprisals due to work refusal.

Be Safe. Be Well.•

SENTRYGLAS® is a part of the Kuraray interlayer portfolio which also includes Trosifol® Sound Control, bringing outstanding acoustic performance to your project.

by SUKANYA RAY GHOSH

Top Glass Conference and Exhibits is on schedule and coming to everyone’s screens on April 21 with industry-specific content for the commercial glazing industry. As with every year, glazing contractors, curtainwall manufacturers, storefront fabricators, architects and building engineers will come together for a day of education, networking and review of the latest technology during the day-long event.

Hosted by Glass Canada magazine, Top Glass is a great place to:

• Earn continuing education credits

• Network with industry professionals

• Browse the latest technology

Everyone had different expectations from the year 2020. It was a year that held so many possibilities before it arrived. But, things do not often go as planned. 2020 will primarily be remembered as the year that an unwelcome guest in our lives, COVID-19, wreaked havoc on the world. However, with the bad came a lot of good. As humans, we evolved, adjusted, innovated, learned to live life anew and kept moving forward.

In 2020, Glass Canada hosted the first ever virtual version of the Top Glass Conference. The industry came together to make the event successful even though it took place right in the middle of the devastating pandemic. The beginning of this year brought the renewed hope of meeting in-person again. However, even though vaccines are out, COVID-19 continues to be a major part of our lives.

This year, therefore, Glass Canada will be hosting the second virtual edition of the event and ninth edition overall since its inception. Canada’s premier gathering for the architectural glass industry is online, different but has a lot to offer.

Each year, the show welcomes stakeholders of the commercial glazing industry for an intense round of education sessions and to find the friends they need to make their businesses succeed. A big part of every event is the logistics involved in getting

everyone together in one venue. Therefore, in the past, the attendees of the event have typically come in from the GTA. Since the show will be held online this year, Top Glass will be welcoming attendees from coast-to-coast using the show’s virtual platform, Pheedloop.

The virtual trade show will be bringing the latest advancements in technology for the commercial glazing industry from top suppliers. All attendees will have the opportunity to roam the virtual halls of the “show floor” to network with friends, peers and suppliers. As with every Top Glass edition, education remains a top priority. Hosted by industry experts, this year’s four hour-long sessions can help attendees qualify towards continuing education credits.

EVENT DATE: April 21

TIME: 11:00 am EST

TO REGISTER: Follow link on the glasscanadamag.com homepage

Session: Year Changed our Industry.

Time: 11:30 am to 12:30 pm

There is no doubt the pandemic has impacted us all in different ways. Many businesses are failing and the jobless rate increases, yet the Ontario construction industry remains vibrant. In his keynote presentation, Gary Watson of Diamond Schmitt Architects will offer an exploration that compares our construction activity with the global scene, evaluates changes to the way we work and reflects on these impacts on architectural practice.

With a background in manufacturing and design, Gary’s passions coincide in architecture. Since joining Diamond Schmitt Architects in 2000, he has worked on a number of awardwinning projects with experience in many building sectors, including large-scale academic buildings, athletic facilities, theaters, hospitals, offices and residential. Prior to his time at Diamond Schmitt, he accumulated a broad range of experiences in art, engineering and manufacturing positions, including General Motors Advanced Engineering Group, furniture manufacturing, sand-casting, mural paintings and Toronto’s Pearson Airport. Gary loves learning, technology and creation. These passions resulted in a well-rounded knowledge in the In-person networking taking place at Top Glass’s 2019 edition. Networking breaks between sessions will give attendees the chance to have key conversations virtually this year.

Gary Watson, senior associate at Diamond Schmitt Architects

An education session goes on in full swing during the 2019 event. There will be no compromises in education at the 2021 event with the added advantage of coast-to-coast participation.

11:00 am to 11:30 am Trade show and networking

11:30 am to 12:30 pm

12:30 pm to 12:45 pm Trade show and networking

12:45 pm to 01:45 pm

Go deep on new technology in glass lamination

01:45 pm to 02:15 pm Trade show and networking

02:15 pm to 03:15 pm

Embody this: Low-carbon building materials for improved life cycle calculations

03:15 pm to 03:30 pm Trade show and networking

03:30 pm to 04:30 pm

The View from the Top: A look at the latest developments in swing stage technology and safety

practice of architecture. Gary is an office leader in digital design and building technologies. All aspects of the project from early design to resolving complex constructability issues attract his interest and excitement.

Session: Go deep on new technology in glass lamination

Time: 12:45 pm to 01:45 pm

In this accredited AIA presentation, Kuraray’ Mark Jacobson will introduce attendees to the important concepts around laminated glass and its applications in architecture.

Laminated glass has been used in a variety of architectural applications, ranging from office buildings and schools to institutional and high security buildings. A variety of clear and tinted interlayers are available, providing post-breakage glass retention, UV filtration, acoustic dampening and impact resistance.

This course presents the history and development of laminated glass from its inception as an automotive product to more advanced structural glass applications. In addition to the course material, an additional aspect of the presentation will be a “how to” segment on selecting the appropriate interlayer for a particular application.

This will include going through a decision tree based on the application to come up with the best choice of interlayer.

Mark Jacobson, market manager for Kuraray America’s North American division

Mark Jacobson is the market manager in North America for Trosifol interlayers. He has been involved in the laminated glass industry for over 10 years in architectural and photovoltaic applications. Mark provides training for architects, designers, engineers, and contractors on laminated glass and is a member of CSI. He worked for DuPont for over 35 years prior to his five years with Kuraray and graduated from Purdue University with a Bachelor’s degree in chemical engineering.

Session:

calculations

Time: 02:15 pm to 03:15 pm

In the architectural glass industry, the fight to prevent climate change has mostly revolved around making more energy-efficient building envelopes to reduce the amount of power needed to heat, cool and ventilate buildings. But what about the energy used to obtain, fabricate and transport the products used to make those envelopes?

Climate-conscious jurisdictions such as California are asking designers to provide lifecycle analyses for the products they specify. In response, manufacturers are starting to track the carbon emissions their processes

produce and market “low-carbon” versions. There are also lower carbon alternatives to many common products and materials, even if those features don’t appear on the label. In this presentation, Will Nash of WSP explains the drive for life cycle analyses and environmental product declarations and assesses the growing field of low-carbon options for architectural glazing.

Session: The View from the Top:

A look at the latest developments in swing stage technology and safety

Time: 03:30 pm to 04:30 pm

Rik Vandelinde is a project manager for Winsafe and sits on committees developing standards for the safe design and use of swing stages and other suspended access equipment. So, who better to update us on the latest regulations and technology that our workers depend on every day?

Join Rik to discover how to stay safe at heights, how to avoid swing access design pitfalls and how to make your projects run smoother and faster with exciting advances in access equipment.

There will be plenty of opportunities throughout the day at this years’ show for everyone to gather and chat virtually. No matter how good an education program is or how many vendors are exhibiting, the real opportunity at a trade event is in the chance to meet someone new and hear what they have to say. While building in-person connections is still not a possibility, there is no need to miss out on forging new relationships and strengthening old ones. The Pheedloop platform will allow everyone to “walk” the show floor with the added bonus of not tiring themselves out! •

High-Performance Windows at Johnson & Wales University’s John J. Bowen Center for Science and Innovation Visit obe.com/weseeabreakthrough to see how our team of technical experts partnered with the glazing contractor to take this project from vision to reality. Let’s solve your next project, together.

erdmanautomation.com

Erdman also has a concept that utilizes two application stations and

box with the concept of the Erd-

• Maximum social distancing

• Maximum safety and ergonomics

available

• Grid application adds roughly 20 seconds per unit

canadianpremiumsand.com

CPS is developing its wholly owned low iron silica sand deposit in Manitoba to supply manufacturing and coatpercent renewable electricity from the grid and the advanced available

aims to set a new standard for low-carbon footprint to produce -

materials and responsibly produced Canadian energy creates a -

Strong and clear kuraray.us.com

The SentryGlas interlayer from the Trosifol times stronger and up to 100 times stiffer than

SentryGlas ionoplast interlayer retains its clarity interlayer is less vulnerable to moisture exposure

carbon-negative products based on a life-cycle carbon assessment as they save or avoid more non-renewable energy consumption and associated emissions after installation of end use products

in residential homes and commercial buildings is a key component of emissions reduction strategies as outlined by the federal department of Environment and Climate Change Canada in

glass to manufacture solar panels is expected to accelerate in the coming years resulting from global electricity grid de-carboniza-

use of SentryGlas ionoplast interlayer has now expanded considerably as structural engineers developed for hurricane applications could also

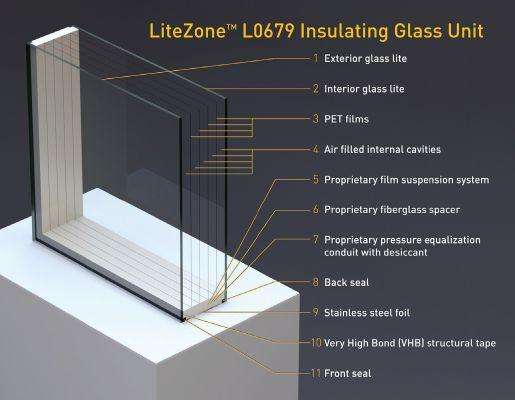

LiteZone insulating glass units achieve overall insulating values up thicker insulating glass units to achieve remarkable perforair pressure between the inside and outside of the glass unit to

no concern with deteriorating insulating values or failure due

Edge seal stress due to changing temperatures is minimal because viewing areas and can be installed without a window frame in -

Trusted for 5 decades by glaziers, Powr-Grip vacuum lifters and hand cups are engineered and manufactured to the highest standard for safe, efficient handling of glass and other materials. Don’t settle for less — get a Powr-Grip!

To see more or share your Powr-Grip photos with us, go to @woodspowrgrip

ments are then sent to production where

even control the degree of transparency that friendly technology reducing energy costs

obe.com

has announced that it will be offering a selection of its storefront systems to customers in

engineers and manufactures fully integrated all-glass and aluminum entrance doors

aluminum extrusion and glass -

teams of engineers and project managers have industry experience in all applications including

such as the Series 3000 thermal Multiplane have been designed

3000 Thermal Multiplane offers improved thermal performance

The Series 3000 Thermal Multiplane provides more options

structural silicone glazing and a front set installation option utilizing continuous head and

Thermal Multiplane has available glazing adapters and gasket

one-fourth of an inch to one

following are the features and

two inches by four and a half inches

set or multi set glazing

anchoring of sill member

head anchor clip

• SSG glazing with patented funnel bridge option for Front Set

• Continuous head and sill assembly option for Front Set

• Screw spline and shear block assembly

options complete

corners

• High sidelite base

• Thermally broken members with polyurethane thermal breaks

• Accommodates projected and casement vents exceed the latest SB 10

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company in Metro Vancouver. richp@constructioncreative.com

Warning: This article may be triggering for some readers. Please read on at your own discretion.

If you are a hunter or target shooter, you are well aware that we are in the middle of the worst ammunition shortage in modern history. If you are fortunate enough to find your preferred brand, caliber and weight in stock, be prepared to pay the price. It almost takes the fun out of going to the range.

There are several different factors at play. Demand was already high pre-COVID due to a number of political issues however buying intensified once the virus reached the shores of North America. Ammo maker Hornady saw their biggest sales month ever in March 2020. Bill Boorman, owner of New Westminster, BC’s Boorman Archery, also shared that March 2020 was his 50-year-old archery company’s largest month ever.

It is the toilet paper effect. As with hand sanitizer, Lysol wipes and tissue, once people started panic-buying, the price for ammunition started skyrocketing. Ammunition is a consumable. In order to use a firearm, you need to consume cartridges. Otherwise it just sits there. From all accounts, most of the demand is from thrifty recreational shooters who recognized where prices were going at the beginning of all of this and bought bulk.

All of a sudden there was a large, sustained surge in demand and then the shutdowns hit. Manufacturing ammo is arguably non-essential and production facilities around the world experienced varying degrees of shutdowns. Not only are the basic components needed to manufac-

By all means, products are available. However, the challenge is getting them from where they are to where you need them in a timely manner.

ture ammunition still in short supply, major suppliers are having troubles finding the basics like packing tape and boxes.

Before I moved into marketing, I studied transportation logistics at the BC Institute of Technology. It wasn’t my passion but I learned a great detail about the supply chain. The term supply chain has never been so apparent than now. When a link breaks, things fall apart.

We might not be able to travel to the States anymore but it turns out that Americans are experiencing the same issue with paying people not to work that we are. So even if the big manufacturers can hire and retain labour, they are only as strong as the weakest link in their supply chain.

Ammunition is a textbook supply chain case study, however, obviously, it’s not just ammo feeling pressure. Furniture, auto parts, athletic equipment and a lot more are having longer than normal lead times.

I’ve heard the price of a container from Asia to Vancouver has tripled over the last year or so. Online sales have overwhelmed the postal services and couriers. There still aren’t enough drivers for trucking companies. It takes longer and has become harder and more expensive to source product, any product, and move it from Point A to Point B.

Perhaps panic buying might be a stretch to draw as a parallel, however the same factors are contributing to reports of extended lead times across the glass industry. By all accounts, product is available. However, the challenge is getting it from where it is to where you need it in a timely manner.

Which is a great segue to the now-paused Xinyi Canada Glass float glass facility in Stratford, Ont. It’s a complicated issue. On one hand, it’s a $400 million investment injected into the region while the federal debt is over $1 trillion and Ontario is grappling with its own colossal deficit. On the other hand, it’s ton of local jobs, new technology, additional capacity and more choice for locally, sourced, Canadian-produced products. Hmm, maybe it’s not that complicated after all. But the project has turned hyperpolitical and faces significant hurdles. The Kens and Karens have spoken.

While the price of ammo and other products have double and tripled, evidently the latest round of glass price increases have stuck. At least that is encouraging. Hopefully it’s sustainable. This is not a great time to start competing on price.•

Introducing Acuity™ low-iron glass — which is 60 percent less green than ordinary clear glass . The new Solarban® Acuity™ series by Vitro Architectural Glass provides the truly clear look you want with the outstanding performance of the full range of Solarban® solar control low-e coatings.

Upgrading a low-e coated clear insulating glass unit to Solarban ® Acuity™ glass will typically increase the total installed curtainwall cost by only $1–2 per square foot.