Increase your power for resuscitation

The LUCAS® chest compression system helps emergency care teams around the world do what they do best — save lives. Increase your resuscitation power now.

Improve CPR quality

• Deliver Guidelines-consistent, high-quality chest compressions at recommended rate and depth while allowing for chest recoil1

• Allow fewer interruptions compared to manual CPR, leading to higher compression ratios2,3 and increased blood flow to the brain4,5

Enhance efficiencies

• Calm the scene and reduce stress by eliminating the need to manage a compression rotation schedule

• Utilize data integration capabilities to enhance post-event analysis and quality improvement efforts

Keep your team safe

• Avoid awkward and potentially dangerous situations when performing CPR during patient movement

• Potential to reduce CPR-related injuries to the CPR provider

7

seconds

median interruption when transitioning from manual to LUCAS device compressions during routine BLS/ALS use6

increased blood flow to the brain vs. manual CPR7

+60% higher coronary perfusion pressure vs. manual CPR 8

139%

1. Panchal AR, Bartos JA, Cabañas JG, Donnino NW et al. Part 3: Adult Basic and Advanced Life Support: 2020 American Heart Association Guidelines for Cardiopulmonary Resuscitation and Emergency Cardiovascular Care. Circulation. 2020;142(suppl 2):S80-S381

2. Olasveengen TM, Wik L, Steen PA. Quality of cardiopulmonary resuscitation before and during transport in out-of-hospital cardiac arrest. Resuscitation. 2008; 76(2):185-90.

3. Maule Y. The aid of mechanical CPR: better compressions, but more importantly – more compressions…(translated from French language; Assistance Cardiaque Externe; Masser mieux, mais surtout masser plus…). Urgence Pratique. 2011;106:47-48.

4. Carmona Jimenez F, Padro PP, Garcia AS, et al., Cerebral flow improvement during CPR with LUCAS, measured by Doppler. Resuscitation. 2011; 82S1:30,AP090. [This study is also published in a longer version, in Spanish language with English abstract, in Emergencias. 2012;24:47-49]

5. Rubertsson S, Karlsten R. Increased cortical cerebral blood flow with LUCAS; a new device for mechanical chest compressions compared to standard external compressions during experimental cardiopulmonary resuscitation. Resuscitation. 2015;65(3):357-63.

6. Axelsson C, Karlsson T, Axelsson AB, et al. Mechanical active compression-decompression cardiopulmonary resuscitation (ACDCPR) versus manual CPR according to pressure of end tidal carbon dioxide (PETCO2) during CPOR in out-of-hospital cardiac arrest 9OHCA). Resuscitation. 2009;80(10):1099-103.

7. Levy M, Yost D, Walker R, et al. A quality improvement initiative to optimize use of a mechanical chest compression device within a high-performance CPR approach to out-of-hospital cardiac arrest. Resuscitation. 2015;92:32-37.

8. Magliocca A, Olivari D, De Giorgio D, et al. LUCAS versus manual chest compression during ambulance transport: a hemodynamic study in a porcine model of cardiac arrest. Journal of the American Heart Association. 2018;8(1).

This document is intended solely for the use of healthcare professionals. A healthcare professional must always rely on his or her own professional clinical judgment when deciding whether to use a particular product when treating a particular patient. Stryker does not dispense medical advice and recommends that healthcare professionals be trained in the use of any particular product before using it. The information presented is intended to demonstrate Stryker’s product offerings. A healthcare professional must always refer to operating instructions for complete directions for use indications, contraindications, warnings, cautions, and potential adverse events, before using any of Stryker’s products. Stryker or its affiliated entities own, use, or have applied for the following trademarks or service

FEATURE

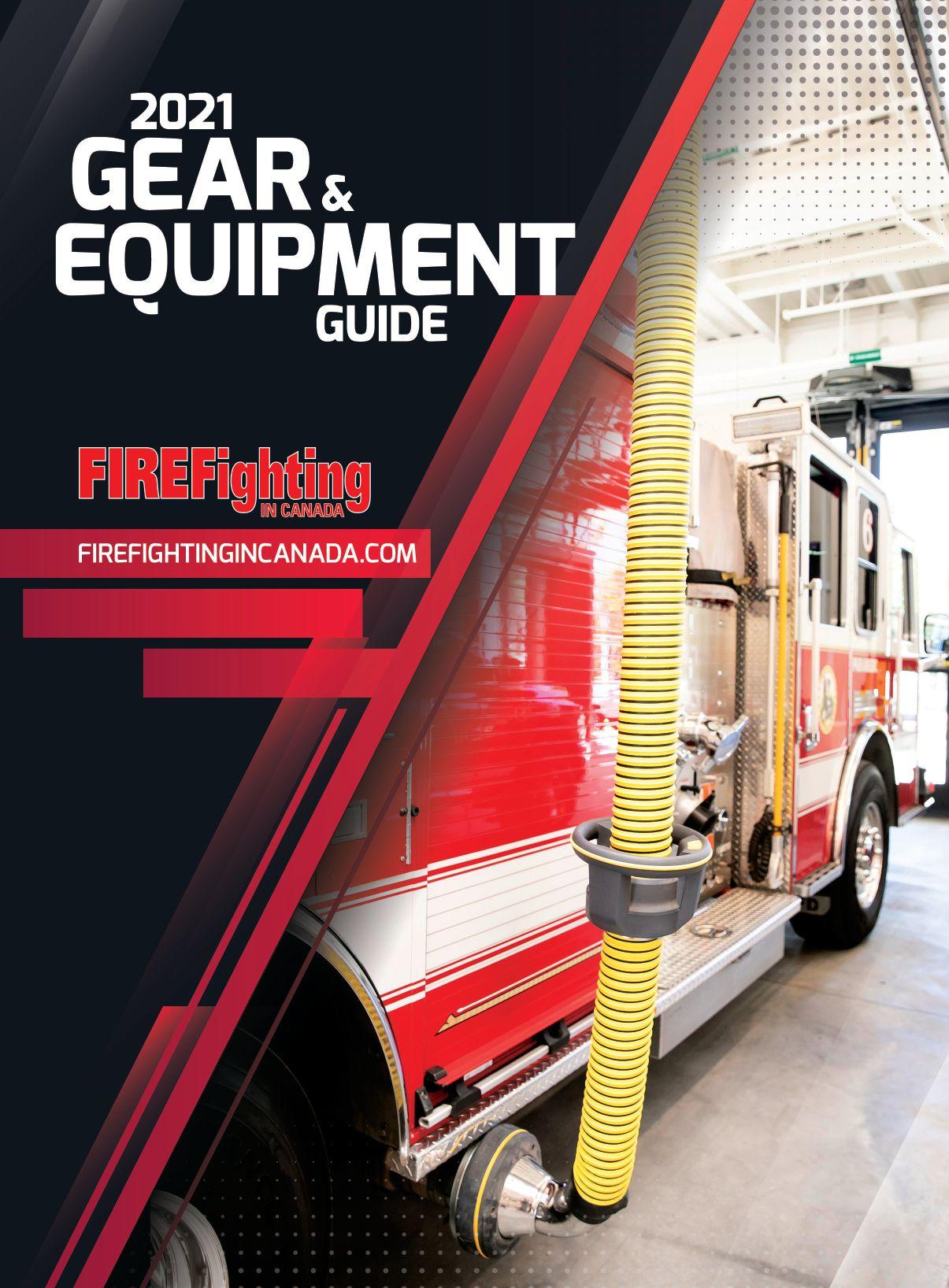

GEARING UP FOR URBAN INTERFACE FIRES

Looking at urban interface fires from a municipal fire service prospective

By Kirk Hughes

Hot and smoky days have become as common as backyard BBQs and family get togethers during the summer months. The last few years have seen a steady increase in wildfires across Canada. With higher temperatures and drought-like conditions continuing in certain provinces, municipal fire departments are being called into service to battle wildland urban interface fires as resources are stretched thin. Differing in nature than a structural fire, wildfires require both technical understanding and physical stamina to confront. Alongside that, the proper equipment and gear is a pivotal part of any firefighter’s toolbox when dealing with these specific types of fire calls.

Structural gear works for structural fires, however, it is extremely limiting and cumbersome when working on the fire lines. If a municipal fire service is going to be engaged in providing response to a wildland fire situation, it is recommended that a fire service give serious consideration to the purchase of specific gear designed for wildland use.

The first recommendation for transitioning from structural gear to wildland, is the choice of footwear. Fire boots, often rubber, clunky and lacking ankle support, don’t cut it in the bush. Wildfire boots made of leather, with a decent sole and reinforced toe (but not metal) are preferred, especially with 8” plus of ankle support. Designed to meet the perilous conditions of rugged and uneven terrain, the wildland fire boot must be sturdy enough to deal with the intense conditions expected, but mobile enough to allow a firefighter to move quickly in emergency situations. Poor footwear will tire and wear out a firefighter in rapid order, so pairing proper footwear with good socks is a smart choice. Firefighters should wear wool or merino wool socks, preferably with cushion shock material that works well with a decent insole. Proper footwear is arguably the most important feature between structural firefighting and wildland interface calls.

There are few things more tiring than fighting a grassfire when wearing full bunker gear. Designed to take the high heat conditions expected to be encountered in a building fire, structural gear is often heavy and bulky. With a reduced need for handling high temperatures, wildland gear is often flame resistant, lightweight and form adjustable to fit closer to the body. Made from Nomex or similar material, a good set of wildland coveralls include reflective trim, reinforced knees/elbows and sturdy pockets to hold radios and small hand tools. Often yellow or khaki in colour, coveralls have a high neck and often include adjustable loops for the wearing of belts or web gear. Relatively inexpensive, coveralls are the main protective gear issued to municipal departments that partake in urban interface activities. Following behind, and

sometimes more preferred than the coverall, is the combination “brush shirt and pants” often worn by wildland firefighters. Some departments have opted for this method of protective clothing due to it’s inter-changeability, ease of replacement and care. The typical brush shirt is yellow in colour with limited reflective trim, flame resistant, with a button chest and front pockets. Easier to repair and maintain than the coveralls, the brush shirt and pant combo has its pros and cons, often boiling down to individual choice of the wearer and cost for the department. Many different styles exist for protective clothing, and it is advisable that a department select gear specific to their taskings and expected use. Either way, a good set of wildland gear will save wear, tear and fatigue on more expensive structural gear and allow a firefighter to be more effective on the wildfire ground than if saddled with using impractical or ineffective gear.

Sound footwear and sturdy protective clothing are only effective when paired with decent gloves. Unlike structural gloves,

– Continued on page 6

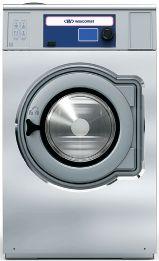

Laundry Solutions for Fire Departments

Ontario Laundry Systems is a leading provider of laundry solutions to fire departments across the province. We are uniquely qualified to provide the commercial laundry equipment you need to safely and effectively clean turnout gear and other items. Our team of experts will help you select and install the right machines to meet the requirements of your fire department.

ARE YOU PROTECTED?

Every firefighter knows that turnout gear is the most important tool they have in staying safe while on the job. PPE must be consistently and properly washed and dried in commercial laundry equipment in order to prolong the life of the gear and keep firefighters safe, healthy and ready for the next call.

Reduce the Risk

For firefighters, clean gear isn’t just a preference — it can mean the difference between life and death. Research shows that firefighters have a much higher risk of developing cancer due to exposure to toxic chemicals and particles that are generated in fires. A major way to reduce this risk is proper cleaning and care of Personal Protective Equipment (PPE).

The best method to protect firefighters and minimize the risk of toxins absorbing into the body is by properly decontaminating gear immediately after use. Having on-site laundry equipment means firefighters can quickly and easily wash and dry PPE following a fire or emergency response.

The Right Equipment

If your gear isn’t cleaned properly, the particles and chemicals left behind can diminish the safety properties the gear was designed to offer. However, too rigorous of a wash can also jeopardize the integrity of the protective materials. Commercial washer-extractors from Ontario Laundry Systems provide

advanced technology to deliver superior wash results while, at the same time, taking gentle care of garments to ensure that their protective qualities aren’t compromised.

PPE drying cabinets are designed to dry a wide range of gear that cannot or should not be placed in a traditional tumble dryer. The cabinets are ideal for drying all types of turnout gear including jackets, pants, boots, gloves, parkas and miscellaneous items.

A Trusted Partner

With over 25 years of commercial laundry experience, Ontario Laundry Systems understands the unique needs of fire departments and their gear. We have equipment specifically designed to meet those requirements. Ontario Laundry Systems proudly serves dozens of fire departments across the region.

Fast Turnaround

Equipment from Ontario Laundry Systems is designed to get firefighters’ gear back into action faster. With an easy-to-use, dependable in-house laundry

solution, you can process laundry on your schedule without wasting time sending PPE out to be cleaned. And because our machines are durably constructed with heavy-duty, computer-optimized frames and backed by a strong warranty, you won’t have to wait for time-consuming and costly repairs.

Select models feature programmable cycles designed to easily handle firehouse growth or any other changes in your operations. The programs can be adjusted with new washing instructions or requirements. You can customize individual programs for your turnout gear, truck towels, liners, gloves, and of course also have the ability to process regular wash such as uniforms, towels, bedding and station wear.

NFPA 1851 Compliance

At Ontario Laundry Systems, we’re more than just aware of fire gear cleaning guidelines and standards. Our experts understand them inside and out, and our equipment is designed for total compliance. We can help explain the latest guidelines regarding wash formulas, chemicals, best practices and more. Contact us for a free consultation.

info@ontariolaundry.com www.ontariolaundry.com

– Continued from page 3

wildland gloves are lightweight and built with dexterity in mind. Usually made of cowhide leather, they are typically unlined with a knit non-burn cuff for added wrist protection. Simple work gloves will suffice, however avoid gloves with plastic mouldings, rubber coating or meltable materials, as they will not hold up for long on the fire line when exposed to the work conditions of a wildfire. Building from the ground up, the last major piece of kit required for urban interface fire fighting is the helmet assembly. Generally, this also consist of eye protection, various neck and face veils and night lighting. Although structural helmets have been employed for wildland interface, the preference is to move towards the less burdensome weight of a wildfire helmet, that emphasises sun protection while maintaining the integrity expected if encountering falls, bumps or strikes. Coming in various colours, a wildland helmet is specifically engineered to meet the special needs of forestry firefighting. Often manufactured from heat-resistant thermoplastic, they contain rachet-style sizing suspension, a chinstrap and reflective decaling. Wide brim style helmets are preferred over the traditional “baseball” style helmets, for their rear neck protection and water deflection properties. Helmets that have the built-in shroud neck protector have become the industry standard for wildland firefighters, however for municipal departments this is an added, albeit nice, luxury. Increasingly seen on urban interface helmets are the placement of “google clips”, self-adhesive plastic hooks designed to keep a pair of googles in place atop the helmet brim. Usually inside the suspension of the helmet, a firefighter will place their face and nose protector – usually a hot shield style bandanna that covers the nose, mouth, and face. Despite not being a respirator in the typical sense, the bandana provides a low level of respiratory relief from large airborne particles, embers, and ash, which filter through a mesh fabric. Most of these mask styles are adjustable with Velcro and utilize a nose pinch bar to enhance comfort and fit. Of course, other models exist, from the N95 to the more robust rubberized/plastic single cylinder respirators, however avoiding plastic components is advisable.

The final piece of equipment that urban interface firefighters often utilize and are a good investment for any firefighter that may be assigned to wildland operations, is a set of rugged goggles. The debate between using the standard safety glasses over the goggles varies by department, and even by firefighter, but that said, there is merit in using a sealed mode, fog and scratch resistant polycarbonate lenses as the primary method of protecting the eyes – especially in heavy smoke conditions. Protecting the eyes is a priority, and a high grade set of goggles is never a poor investment.

As our society encroaches more into nature, the rapid growth of wildland-urban interface fires will continue. More fires will be caused by human interactions with nature, through accidents or intentional starts, and those fires will be harder to fight in areas where neighbourhoods and people have intermingled themselves so close to forested areas. As a municipal fire service, the risk of these wildland fires in our communities need to be addressed, prevented and planned for and the first step is ensuring that firefighters are properly equipped with the right gear to do the job safely.

Kirk Hughes is the director of protective services and the fire chief for the County of Vermilion River in Alberta. Kirk previously served in the Royal Canadian Mounted Police as well as several fire services across Ontario, Manitoba, the Northwest Territories and Alberta.

TRUE CLEAN AIR

Plymovent Life Safety Systems provide clean air at work for humanity and the planet anywhere in the world at all times. More firefighters and emergency responders are protected by the Plymovent Magnetic Grabber® than any other nozzle in the world. Its self-aligning conical design is integrated with magnets that provide a quick and easy “click and seal” connection, preventing harmful exhaust fumes from

HIGHLIGHTS

Introduced in 2009

Red Dot design award winner

Virtually 100% source capture

Available in stainless steel

contaminating the facility. The floating magnets are positioned in a pattern to ensure optimal connection and automatic disconnection at the correct moment when vehicle exits the station. Safety Taken Seriously – An integrated rubber safety shield on the Magnetic Grabber®, along with the Plymovent Safety Disconnect Handle, ensures your system, equipment and personnel are well protected.

Effortless “click and seal” connection

Ambient air cooling Nozzle functions without electricity

LONGTIME U.S. RESCUE STRUT MANUFACTURER

NOW SERVING CANADA

For more than 25 years, one name has been synonymous with stabilization and lifting in the US: Res-Q-Jack. Now, Res-Q-Jack is pleased to announce they are providing Canada with the same proven performance, reliability and user-friendly operation that comes with their rescue struts

Res-Q-Jack struts were born through first-hand experience in the emergency services field and have been continually refined to suit the needs of today’s responders through field testing and communication with departments around the world.

From hand-welds to high-end machining, Res-Q-Jack struts are built with care, inspected and tested to ensure years of reliable and effective performance in the field. Res-Q-Jack builds each rescue strut by hand in their shop from proven and predictable materials, and distributes them globally through a network of authorized dealers.

While Res-Q-Jack struts are intuitive by design, they also believe a great rescue tool is only as good as the training behind it. That’s why when your department purchases from Res-Q-Jack, they’ll provide free in-service training, at your facility, on both equipment and techniques Res-Q-Jack is excited to be a part of Canadian rescue operations, and would love to show you how their tools work.